Page 1

MITECH SURFACE

ROUGHNESS TESTER

MR200

User’s Manual

MITECH CO.,LTD.

www.mitech-ndt.com

Page 2

1

mvip@mitech-ndt.com

CONTENTS

1 Overview

..................................................................................................................................................................

2

1.1 Technical Parameters................................................................................................................................. 2

1.2 Functions &Features...................................................................................................................................2

1.3 Working Principle.........................................................................................................................................3

1.4 Instrument Configuration............................................................................................................................3

1.5 Working Conditions..................................................................................................................................... 4

2 Structure and Outline

..........................................................................................................................................

4

2.1 Main Body Structure................................................................................................................................... 4

2.2 Probe Structure............................................................................................................................................4

2.3 Display...........................................................................................................................................................5

2.4 Keypad Definitions...................................................................................................................................... 5

3. Operation

...............................................................................................................................................................

5

3.1 Connecting Probe........................................................................................................................................5

3.2 Power On/Off................................................................................................................................................5

3.3 Battery Charging..........................................................................................................................................6

3.4 Parameter Setting........................................................................................................................................6

3.5 Preparation Before Measurement............................................................................................................ 7

3.6 Start Measurement......................................................................................................................................8

3.7 Display Readings.........................................................................................................................................9

3.8 Save/Read Measurement Results..........................................................................................................10

3.9 Print Measurement Results..................................................................................................................... 10

3.10 Communication With PC........................................................................................................................ 11

3.11 Remote Control and Measurement......................................................................................................12

3.12 SD Card Instructions...............................................................................................................................12

4 Software Information

.........................................................................................................................................

12

5 Maintenance

.........................................................................................................................................................

12

5.1 Probe........................................................................................................................................................... 12

5.2 Main Unit.....................................................................................................................................................12

5.3 Battery......................................................................................................................................................... 12

5.4 Calibration Specimen................................................................................................................................12

5.5 Maintenance Notice.................................................................................................................................. 12

6 Troubleshooting

..................................................................................................................................................

13

7 Optional Accessories

........................................................................................................................................

13

7.1 Height Support & Probe Sheath............................................................................................................. 13

Height Support and Probe Sheath................................................................................................................ 13

7.2 Height Lifting Pillar.................................................................................................................................... 13

7.3 Standard Probe..........................................................................................................................................14

7.4 Curved Surface Probe.............................................................................................................................. 14

7.5 Deep Groove Probe.................................................................................................................................. 15

7.6 Small Hole Probe.......................................................................................................................................16

7.7 Extension Bar.............................................................................................................................................17

8 References

............................................................................................................................................................

17

8.1Terms............................................................................................................................................................ 17

8.2 Traversing Length of Filters..................................................................................................................... 17

8.3 Parameters Definitions............................................................................................................................. 18

8.4 Recommended Table of Sampling Length............................................................................................20

Appendix

..................................................................................................................................................................

21

Appendix I: Standard Code and Name Table..............................................................................................21

Appendix II: Roughness Parameters Display Range.................................................................................21

User Notes

................................................................................................................................................................

22

Page 3

2

mvip@mitech-ndt.com

1 Overview

The Portable surface roughness tester MR200 could give a fast, accurate test of the roughness, applied

on work site and mobile measurement. It is portable to carry, easy to operate, reliable to test and full

functional advantages. Adopted 2.7 inch OLED Screen, equipped with wireless communication module,

Micro-USB port, standard Bluetooth module and SD card, it can not only achieve wireless remote control

and measure but also can connect with PC, wireless Bluetooth printer and memorize more data.

1.1 Technical Parameters

Sheet1-1

Name

Content

Measurem

ent Range

Z axis(Vertical)

320μm(Ra=80μm)

X axis(Horizontal)

17.5mm

Resolution

Z axis(Vertical)

0.01μm/±20μm

0.02μm/±40μm

0.04μm/±80μm

0.08μm/±160μm

Measurem

ent Item

Parameter

Ra, Rq, Rz, Rt, Rp, Rv, RS, RSm, Rz(JIS), Ry(JIS), RSk, R3z, Rmax,

Rpc, Rmr, Rku, RΔa, RΔq, Rδc, Ry

Rk, Rpk, Rvk, Mr1, Mr2, A1, A2, V0

Standard

ISO, ANSI, DIN, JIS

Graph

Roughness profile, Bearing ratio curve, Direct profile

Filter

RC, PC-RC, Gauss, D-P

Sample Length(Lr)

0.25,0.8,2.5mm

Assessment Length(Ln)

Ln= Lr×n, n=1~5

Probe

Measure principle

Displacement Differential Inductance

Stylus

Natural diamond, 90 cone angle, 5μmTip Radius

Measured force

<4mN

Guide head

Ruby, Longitudinal radius 40mm

Traversing speed

Lr=0.25,Vt=0.15mm/s

Lr=0.8, Vt=0. 5mm/s

Lr=2.5, Vt=1mm/s

Return, Vt=1mm/s

1.2 Functions &Features

28 Measuring parameters: Ra, Rq, Rz, Rt, Rp, Rv, RS, RSm, Rz(JIS), Ry(JIS), RSk, R3z, Rmax,

RPc, Rmr, Rku, RΔa, RΔq, Rδc, Ry; Rk, Rpk, Rvk, Mr1, Mr2, A1, A2, V0;

Adopt 320μm high accuracy inductance probe;

Four filter methods of RC, PC-RC, GAUSS, D-P ;

Compatible with four standards ISO, DIN, ANSI, JIS;

Adopt 2.7 inch 128×64 dot OLED display,without back-light and dead spot. Capable of showing

all parameters, profile graph and Chinese/English menu;

Adopt the most popular DSP chip to control and process data;

Build-in storage can memorize 20 sets of complete measurement data;

External SD Card can expand mass data storage;

Build-in wireless remote control module to remote control measurement;

Build-in Bluetooth module can be connected with the Bluetooth printer to print all the

parameters and profiles;

Build-in Micro-USB port, can communicate with PC make measurement results analysis by

data processing software;

Build-in lithium-polymer rechargeable battery and charging protection circuit;

Mechatronics design, smaller and portable to carry;

Automatic shut down for power saving, each operation step has a hit message;

Full accessories, options for curve surface probe, deep groove probe, small hole probe, tiny

hole probe, tooth surface probe, small pillar, height adjust platform, extension bar, lateral transfer

rod etc.

Page 4

3

mvip@mitech-ndt.com

1.3 Working Principle

This instrument adopts needle scanning method to test the surface roughness of the work piece.

When measuring roughness of part surface, the probe is placed on the surface of the part and then

tracing the surface at constant rate. The probe acquires the surface roughness by the sharp stylus in

probe. The roughness causes displacement of probe which results in change of inductive value of

induction coils thus generate analogue signal which is in proportion to surface roughness at output end

of phase-sensitive rectifier. This signal enters data collection system after amplification and level

conversion. After that, those collected data are processed with digital filtering and parameter calculation

by ARM chip and the measuring result can be read on OLED display. The results can be printed by

Bluetooth printer.

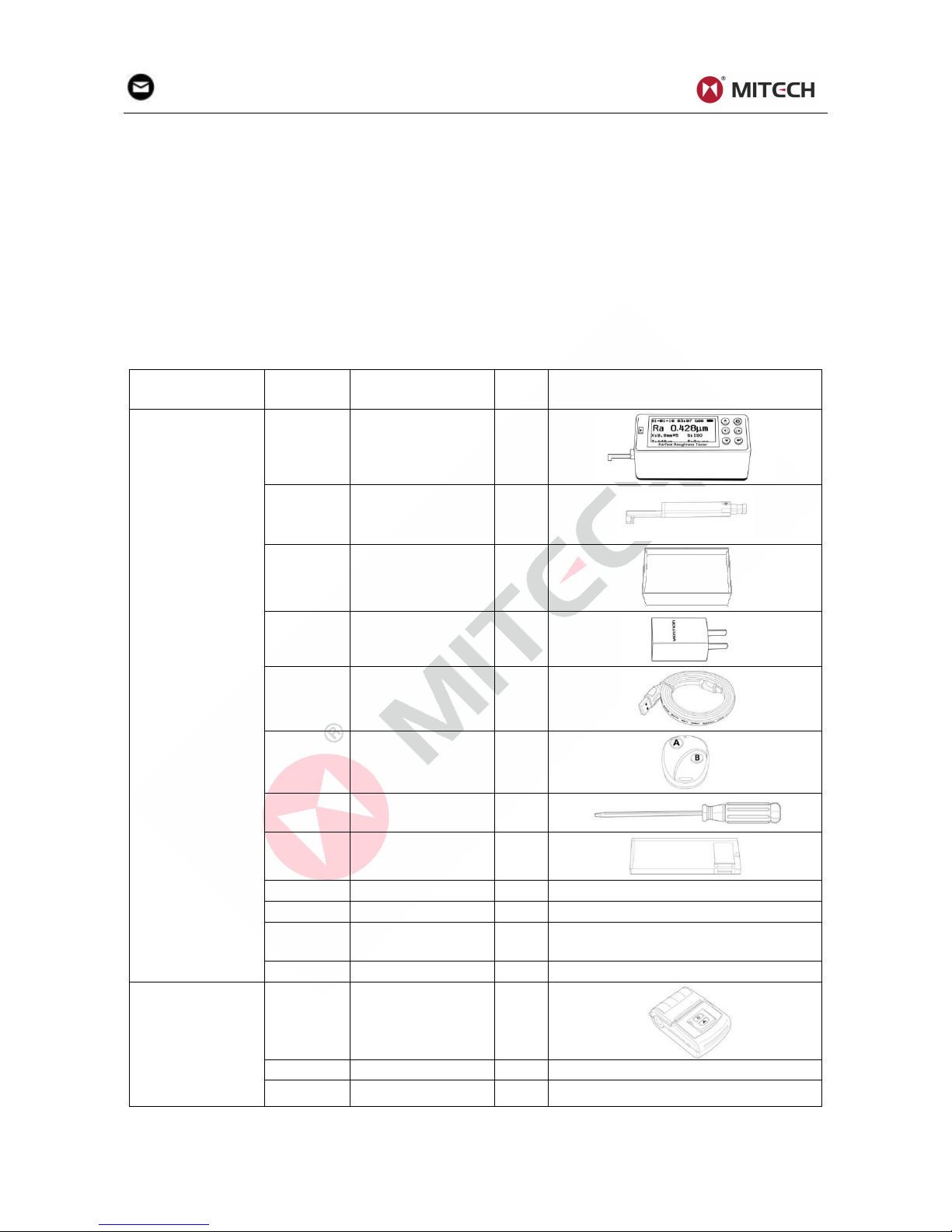

1.4 Instrument Configuration

Sheet1-2

No.

Item

QTY

Remarks

Standard

Configuration

1

M200 Main Unit

1

2

Standard Probe

1

3

Roughness

Specimen

1

4

Charger

1

5

USB Cable

1

6

Remote Control

1

7

Straight

Screwdriver

1

8

Specimen Plate

1

9

User’s Manual

1

10

Packing List

1

11

Product Certificate

1

12

Warranty Card

1

Optional

Configuration

1

Bluetooth Printer

1

2

AC Adapter

1

3

Printer Paper

1

Notes:

Please check the instrument and spare parts when getting the instrument. If anything missing

please contact the manufacturer.

Page 5

4

mvip@mitech-ndt.com

1.5 Working Conditions

Ambient temperature: -20℃~+50℃;

Storage temperature: -30℃~+70℃;

Relative humidity: ≤90%;

The surrounding environment should avoid of vibration, strong magnetic field, corrosive

medium and heavy dust.

2 Structure and Outline

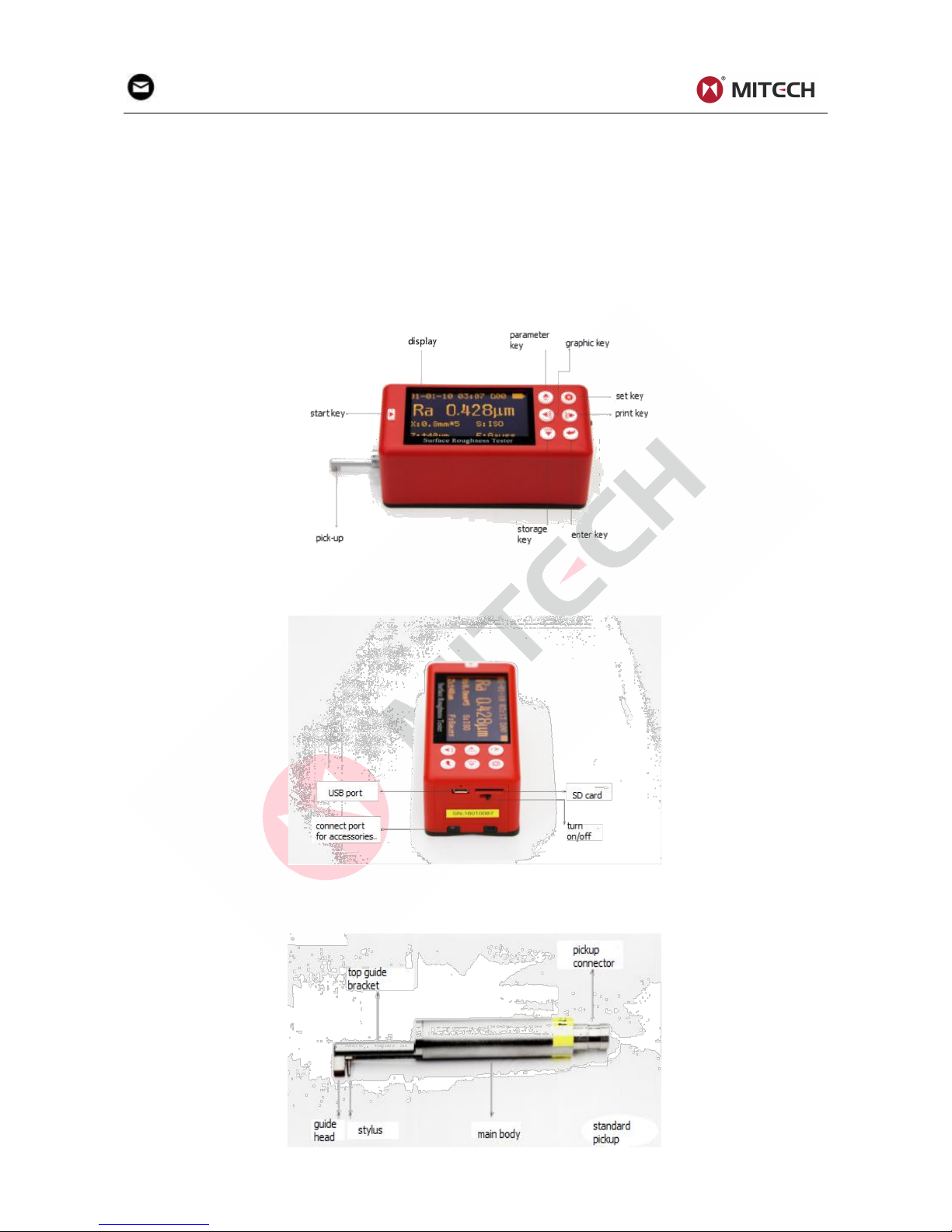

2.1 Main Body Structure

2.2 Probe Structure

Page 6

5

mvip@mitech-ndt.com

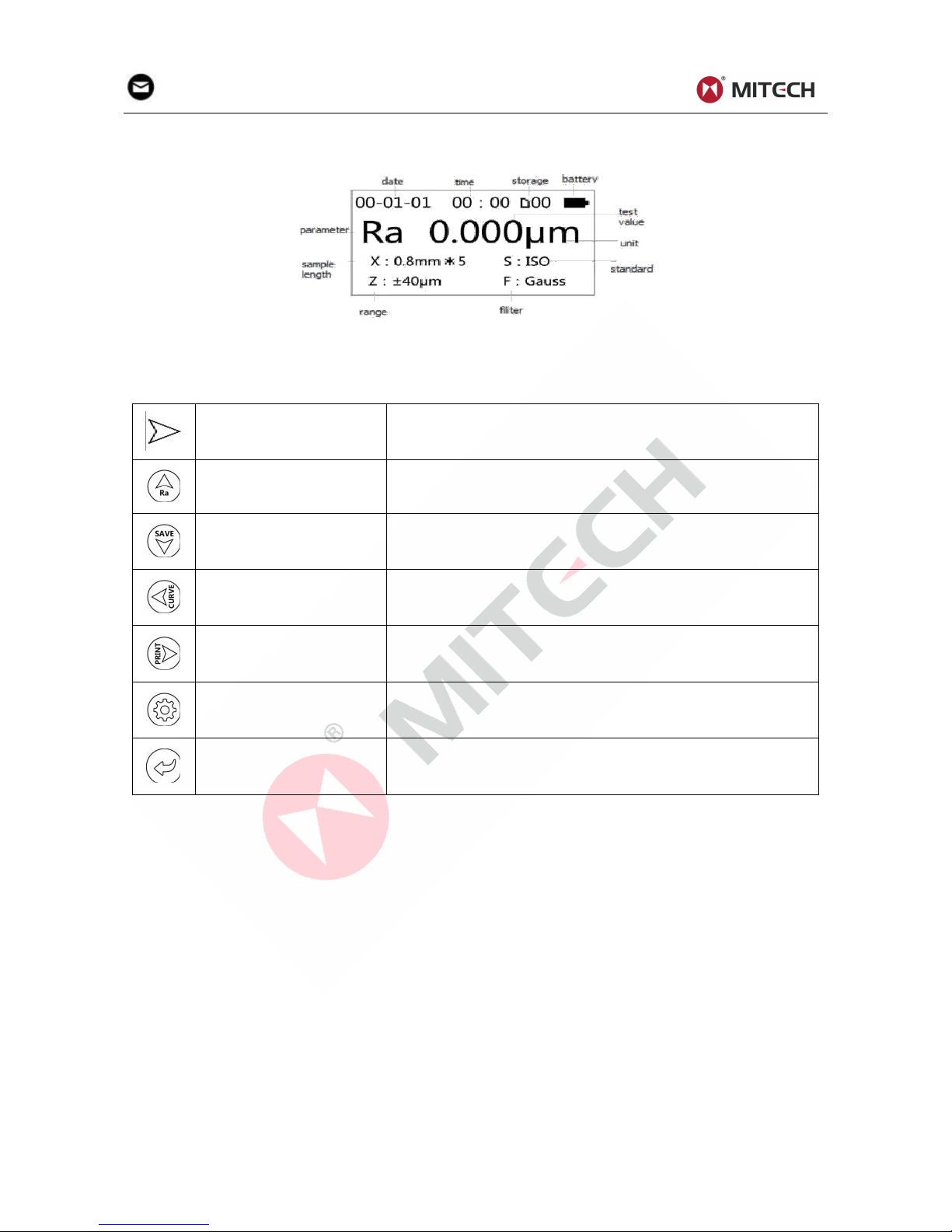

2.3 Display

2.4 Keypad Definitions

Sheet2-1

Start key

Used to start measuring.

Up arrow/Parameter key

Press this key to enter the parameter item, press the set key

to exit.

Down arrow/Storage key

Press this key to enter saving record interface.

Left arrow/Graphic key

Press this key to enter graphic item, showing curved, graphic,

bearing ratio curve and others.

Right arrow/Print key

Press this key to start Bluetooth printer for printing.

Set/Menu key

Press this key to enter setting, long press to enter main

menu.

Enter key

Press this key to show the location of the stylus, press again

to exit. In other interface, this key is used to confirm the

modify result or exit the present interface.

Notes:

In other interface, the unified regulation for up, down, left, right four arrows function keys is as

follows: up and down arrows to switch for selecting item; left and right arrows to adjust and

setting specific figures and values.

3. Operation

3.1 Connecting Probe

To ensure the stylus down, the probe is plugged into the host connection socket and pushed lightly to the

end. When pulling out, first pull out the probe from the connection socket, then take it out slowly from the

driver. The entire operation should avoid damage to the probe.

Notes:

The probe stylus is a key part of the instrument. In the plugging in and pulling out process, we

should be careful not to touch the stylus to avoid damage.

3.2 Power On/Off

The instrument switch located in the lower-left corner in panel showed as 2.1 instrument side back

figure.

Page 7

6

mvip@mitech-ndt.com

3.3 Battery Charging

When MR200 appears the low voltage tips or could not boot, it should be charging to the promptly. When

charging, put the charger into the micro-USB port, then put the charger into the socket. This instrument

adopts Li-poly battery, without memory effect, could be charged at any time. Red light indicates charging,

the green light indicates charging finished. The complete charging time is approximate 3-4 hours. It may

damage the battery for charging long time. When the instrument leaves the factory, the battery switch is

off.

3.4 Parameter Setting

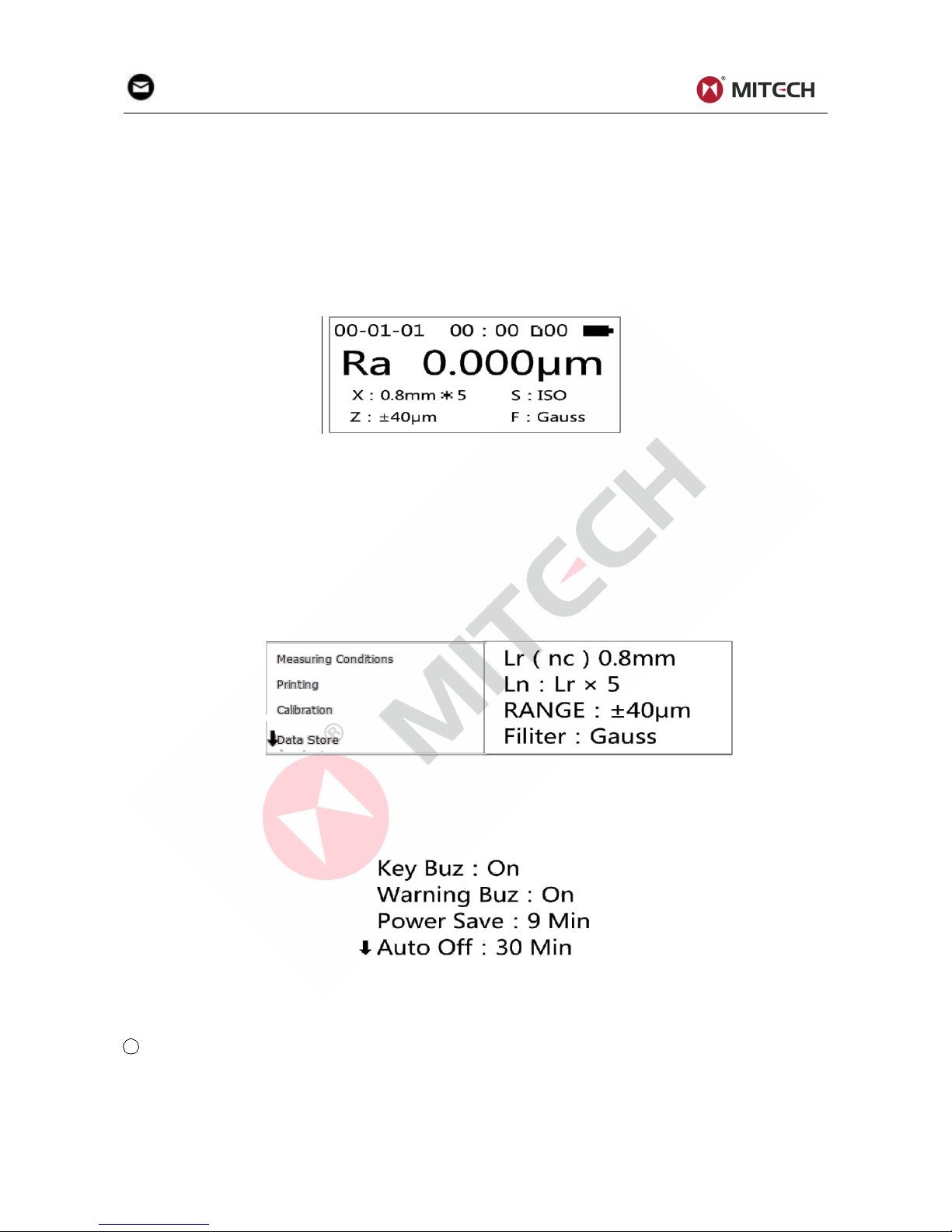

In the main interface, press "Settings button" enter the main menu

Main Interface

3.4.1Measuring Conditions Setting

Measurement conditions setting by two ways: Quick settings and Menu settings.

Quick Setting: In the main menu, press "Settings button" enter quick setup mode, follow the cursor,

modify the measurement conditions through the up, down, right and left arrows, press the "Enter button"

to confirm exit.

Menu Setting: In the main menu mode, press "Settings button" enter the menu setting mode, select

"Measurement condition setting", you can modify the "Sample length", "Evaluation length", "Range",

"Filter", "Standard", " Parameters "," C (rmr) "," C (rpc) "," Rmr (rδc) "," Unit of measurement ".

Main Menu Conditions Setting

3.4.2 System Setting

In main interface, long press setting to enter menu setting, choose system setting, enter the sub-menu.

In this menu, you can set: “Key Buz”, “Warning Buz”, “Power Save”, “Auto Off”, “Time Calibration”, “Low

Noise Test”, “Display Test”, “Remote Matching”, “Surface Type Selection”. Press enter key to exit.

3.4.3 Time Setting

Clock setting is always showed when first use, press left (right), up(down) to set the clock. When

finishing, press the enter key to exit.

If the time is wrong, adjust the clock as follows:

1 Enter the main interface

The interface is the main interface. MR200 always shows this interface before and after the measuring.

Includes the main measurement parameters and conditions of the measurement information, such as

sample length, assessment of the length, range, filter and measurement units.

Page 8

7

mvip@mitech-ndt.com

2 Enter the main menu

Under the main interface, long press Set / Menu button to enter the main menu, press the enter key to

enter the clock calibration interface (diagram below)

3 Time Calibration

In accordance with uniform provisions of arrow keys, use the up/down key to select figure to be set.

3.4.4 Unit of Measurement

Under the main interface, long press setting / Menu button to enter the main menu (such as left), use

up(down) arrow to select units of measurement, press the Enter key to enter the measurement unit

interface (see figure below), press setting to exit.

3.4.5 Setting Language

In main interface, long press set/menu key enter the main menu. Use Up (Down) arrow to select

language, press the Enter button to confirm exit.

3.5 Preparation Before Measurement

Correct and regular operation is available to obtain accurate measurements, make sure to follow the

implementation of standardized operations.

Turn on and check the battery voltage firstly, wipe the surface clear with a clean soft towel, and ensure

that sliding track of probe is perpendicular to process grain direction of the measured surface. Main unit

and probe is parallel to the work piece surface. When measuring, the instrument should stay away from

vibration, magnetic fields, wind and etc. Measurement results will not be influenced by the external

environment

Page 9

8

mvip@mitech-ndt.com

3.5.1 Stylus Position

First, check the stylus position.

When measuring in surface, usually don’t need adjust stylus position.

When using the Height Lifting Pillar to measure the work-piece surface, you need to adjust the vertical

height of the instrument to determine the pointer near zero. After the pickup is exposed to the measured

surface, the measurement can begin.

3.5.2 Calibration

If the difference between the measured value and the specimen value is greater than the scope of

equipment requirements, or user requirements are more accurate, you can use that value of the

calibration function to correct measurement results.

The calibration steps are as follows:

1 Enter the Calibration Menu

Under the main interface, long press setting / menu button to enter the main menu, press up (down)

arrow to select calibration, press the enter key to set correct values, as follows:

2 Setting Correct Values

Press upper (lower) arrow to select the required range, press the left (right) arrow to adjust settings.

According to the evaluation, revise the inaccuracy, input the corresponding range then exit. Test

several times and make a fine tuning until proper.

Notes:

The calibration value is according to the corresponding operating, each range can be calibrated

independently from each other. Calibration results are stored in the instrument's memory and

will not lose after shutdown.

3.5.3 Calibration Cautions

1 If the actual measured value exceeds ± 10% of the value of the calibration model, indication

calibration should be used in accordance with the percentage of actual bias calibration, the

calibration range should not exceed ± 20%.

2 Under normal circumstances, the instruments have been rigorously tested in the factory. The

showing error is much less than ± 10%. Frequently use calibration function is not recommended at

this time.

3 If you want to set the showing calibration value to 00, it will restore to the factory setting.

3.6 Start Measurement

1 Start

After finishing above operations, in the main unit, press start key to start measuring.

2 Measuring

Measurement after the beginning of the first interface, at this time, probe is collecting data.

Page 10

9

mvip@mitech-ndt.com

3 Digital filter sampling ends, it begins digital filter.

4 Calculating

After the filtering, all parameters are under calculating.

Notes:

If you press the power button accidentally and cause the shutdown when measuring. Then turn

on, the probe will be reset at this time, please do not have any interference until the reset is

completed.

3.7 Display Readings

After finishing measurement, the results display steps as below:

1 Check Parameters

Press the up arrow to enter all parameters interface. Press up or down arrow to check, and press

setting key to exit the main menu.

2 Graphic

Under the status of the main interface, press the left arrow to enter the graphical display interface.

Each page shows a sampling length, through the left (right) arrow to switch to other sampling length.

At this interface, press the Enter key to amplify or reduce the profile. By pressing setting/menu key

to exit the main interface. Press up (down) arrows to switch the interface to the material ratio curve.

Press set/menu key to exit graphics interface.

Page 11

10

mvip@mitech-ndt.com

3.8 Save/Read Measurement Results

1 Save Current Data

Under the status of the main interface, press down arrow to enter the save/read interface. Press up

(down) arrow to select save current data, press the enter key to enter the save interface.

Notes:

If the data storage is full, you can delete them in "Data store" menu. When deleting data, you

should be careful to avoid wrong operation. The instrument can store 20 groups of measurement

results.

2 Read History Data

If you need to check the history data, enter the menu and select data store, then choose read history

data, find the group you want, press enter to read.

3.9 Print Measurement Results

Instrument can equip with wireless Bluetooth printer, real time printing on site, also can connect it to the

PC to print

1 Match printer before printing

a. Install the matched printer and place near the MR200;

b. In the sub-menu of printer result, select "Printer Pair", press the "Enter key" to enter the Printer

Pair status and it will display "Pairing Successful” in 3 seconds. Press setting key to return the main

menu and print.

Page 12

11

mvip@mitech-ndt.com

2 Print results formats could be customized

Enter the menu setting, and enter the sub-menu of print results.

You can choose Print Ra, R... or Print R & PROF, Print Self R..or Self R..Set.

Print Set Interface

3 Start printing

Under the status of the main interface, press right-arrow to output measured parameters and profile

to the printer.

4 Print paper

3.10 Communication With PC

The instrument can be equipped with PC-advanced analysis software. The software has a database

management, graphics display, parameters display, measurement operation, print management,

document management and other functions.

Page 13

12

mvip@mitech-ndt.com

3.11 Remote Control and Measurement

This instrument provides remote control to start the measurement, in some cases, that can improve the

stability of the measurement.

Before using the remote control, pair the remote control.

In the main interface, press "Settings Button" to enter the menu setting mode, select "System settings",

press "Enter key" Into the "System settings" Sub-menu, select "Pairing the remote control", press "Enter

key" to enter remote control pairing status, display "Pairing successful" In 3 seconds, press "Set button"

to return to the "Main screen", now you can use the remote control.

3.12 SD Card Instructions

The instrument is equipped with an SD card. The users can do remote software upgrades and enjoy

convenient maintenance service. Upgrade steps are as follows:

1 Through the official public platform, download new software;

2 Copy software to the SD card (connect SD card through a converter to the USB port on the

computer) .

3 Remove the SD card into the SD card slot in the back of the instrument;

4 Enter into the main menu, select "Software information", press the enter key to enter the

upgrade interface.

5 Select the SD card upgrade, press the enter key to start the upgrade. The upgrade process

takes a few minutes. When the progress bar is full flashes to indicate the upgrade completely;

6 Power off and power on.

4 Software Information

It is the instrument model, software version number, the factory serial number and identification number.

5 Maintenance

5.1 Probe

1 After completing the measurement work, please put the probe into the box;

2 Always take care to protect the stylus of the probe;

3 Probe is a key component to pick up signal. It is both precise and sensitive and comparatively

fragile required the fine manipulation.

5.2 Main Unit

1 Remove dust to keep the surface of the host clean with soft and dry cloth;

2 It is a precision measuring instrument and should be kept gently to avoid greater vibrations in

case of causing internal damage and affecting the use.

5.3 Battery

1 Observe battery signal frequently. When there is a low voltage, please charge;

2 Charging time is about 3 to 4 hours. Do not to charge for a long time.

5.4 Calibration Specimen

1 Maintain a clean specimen surface;

2 Avoid scratches on the work area surface of the specimen.

5.5 Maintenance Notice

When the instrument shows abnormal phenomenon, such as no measurements, the liquid crystal

abnormal display, larger error, the keyboard operation failure or malfunction confusion, please refer to

Page 14

13

mvip@mitech-ndt.com

the troubleshooting index table, exclude common failure. Please do not disassemble or adjust any fixed

assembly parts, you should entrust to the company's after-sales service department for maintenance

and disposal.

Notes:

The company will only accept repair business under the standard process. If not, failure loss will

be at your own risk.

6 Troubleshooting

Sheet 6-1

Errors

Possible cause

Troubleshooting

Out range

probe or main unit isn’t parallel with

Measured surface

Change larger range and

adjust stylus position

No test data

Didn’t test after boot

Do the actual measurement

Motor dead

Transmission gear jammed

Re-measure

Run-time error

Wrong interrupts

Reboot

7 Optional Accessories

7.1 Height Support & Probe Sheath

When the measured surface of the work-piece is smaller than the bottom surface of the instrument, you

can use the optional accessory probe sheath and height support as auxiliary support to complete the

measurement (as shown below).

Height Support and Probe Sheath

Notes:

1. Length is not less than the driving stroke of the measurements, otherwise the probe may fall

out work-piece, resulting in failure;

2. Confirm measuring platform are locked;

3. Prior to measuring, adjust the height-adjustable legs to a suitable height with calipers.

7.2 Height Lifting Pillar

Height lifting pillar can help to adjust the position more accurately between the work-piece and the

instrument, make the operation more stable and reliable and expand the measuring space, so it can do

roughness measurement of a larger volume work-piece surface.

Using a height support, pay special attention to misuse of the probe close to the work-piece, to prevent

damage to the probe.

When the probe is close to the work-piece surface, the pointer position of the stylus is at the middle

position of the display. When the measured Ra value is smaller recommend measurement platform and

use the remote control to start the measurement, in order to reduce the impact of the external

environment. When using special probes, such as holes, deep grooves and curve surface probe, etc.,

you must use the column height support or other height adjustment device.

Page 15

14

mvip@mitech-ndt.com

Height Lifting Pillar

7.3 Standard Probe

The standard probe is the most frequently used probe. It can meet most of the surface roughness

measurement, such as plane, slope, conical surface, the inner hole, the groove and other. It can do

convenient hand-held measurement. Except the standard probe, other probes require the use of special

measuring platform to measure.

7.3.1 Picture and Measurement of Standard Probe

Parts Name

Measurement

7.3.2 Operation Instruction

1 Hand-held measuring

Plug the probe into the instrument, measure the surface of the work-piece directly. Setting the

correct measurement conditions, we should also pay attention to:

a. Main body of the probe maintaining the level state;

b. probe sliding direction perpendicular to the texture of work-pieces.

2 Using height lifting pillar

See 7.2 height lifting pillar

a. Plugging standard probe carefully into the instrument, install it on the column connecting part of

the pillar, check the tightening;

b. Adjust the carriage of the pillar slightly above the surface, adjust the probe slowly to the

work-piece. In the process you should be careful, especially the probe is about to touch the

work-piece;

c. Adjust the body of the probe to the level visually observe whether the stylus position is near the

center; When lifting probe, we must pay attention to the direction. Wrong or fall operation will

damage the probe.

7.3.3 Indication Calibration

1 Measure multi-scale line model;

2 Read Ra value;

3 Compare above value with the sample values.

7.3.4 Cautions

1 The probe stylus is a key part of the instrument. During the plugging in and pulling out, we

should hold the root of guide head bracket and be careful not to touch the stylus to avoid damage;

2 Finishing the measurement, it should be put into the box.

7.4 Curved Surface Probe

Surface probes are used to measure smooth cylindrical surface roughness with greater than 3mm radius.

Even larger radius spherical surfaces can be achieved the desired approximation. The larger the

curvature radius, the better the testing results.

Page 16

15

mvip@mitech-ndt.com

7.4.1 Picture and Measurement of Curved Surface Probe

Curved Surface Probe

Measurement

7.4.2 Operation Instruction

1 Plugging the probe carefully into the instrument, install it on the connecting part of the pillar;

2 Using the curved surface probe, we should try to use a shorter range, such as 0.25um

sampling length especially when the arc is small;

3 Raise the slide adjustment rack of pillar slightly above the work piece surface, fall the probe till

contact with the work-piece. In the process, you should be careful especially when the probe is

about to touch the work-piece;

4 Make the probe stylus point at the surface peak (or lowest point);

5 Adjust the body of the probe to the visual level state, observe whether the stylus position is

near the center;

6 Before measurement, move the work-piece to the right half of the measuring range, press start

key for measurement.

7.4.3 Indication Calibration

1 Use the single-scale line for calibration

2 Calibration Operation

Indication Calibration

As shown, single-scale line model is inclined at an angle, the head and the stylus can pass through the

line respectively, rather than simultaneously (in this case, the value is not a true depth). After the

measurement, observe the profile, there is a rectangular deep groove. Read single-scale line model

value by several ways:

a. Read Rt value. Sometimes the location is not good, it will lead wrong readings;

b. Using software to measure the depth value on computer;

c. Read the profile really measured depth value on the printer and divided by magnification.

7.4.4 Cautions

1 The probe stylus is a key part of the instrument. During the plugging in and pulling out, we

should be careful not to touch the stylus to avoid damage;

2 The main difference between the curved surface probe and others is the position of the head

and the stylus is paralleling, while others’ are one behind the other;

3 Surface probe cannot match multi- scale calibration model, which is due to its structure.

7.5 Deep Groove Probe

Deep grooves probe is similar with standard one. The only difference is the deeper depth. It can

measure the roughness of the most flat, slope, conical surface, the inner hole, the groove and other

surfaces. Deep groove probe cannot be used for hand-held measurement, the other probes require the

use of special measuring platform to measure.

Page 17

16

mvip@mitech-ndt.com

7.5.1 Picture and Measurement of Deep Groove Probe

Deep Groove Probe

Measurement

7.5.2 Operation Instruction

1 Plugging standard probe carefully into the instrument, install it on the connecting part of the

pillar, then check if locked tightening;

2 Raise the slide adjustment rack of pillar slightly above the work-piece, fall the probe till contact

with the work-piece. In the process, you should be careful especially when the probe is about to

touch the work-piece;

3 Adjust the body of the probe to the level state, observe whether the stylus position near the

center;

4 When lifting or falling the probe, please especially pay attention to the operation direction to

avoid mistake.

7.5.3 Indication Calibration

1 Use the multi-scale line to calibration for the deep groove probe

2 Read Ra value;

3 Compare the value with the sample value

7.5.4 Cautions

1 The probe stylus is a key part of the instrument. During the plugging in and pulling out, we

should be careful not to touch the stylus to avoid damage;

2 Finishing the measurement, it should be put into the box.

7.6 Small Hole Probe

Small hole probe is used to test the inner surface of the hole which is larger than 2.5mm diameter, other

functions are the same as the standard probe.

7.6.1 Picture and Measurement of Small Hole Probe

Small Hole Probe

Measurement

Page 18

17

mvip@mitech-ndt.com

7.6.2 Operation Instruction

1 Adjustment before measuring:

a. Plugging the probe carefully into the instrument, then check if locked the tightening;

b. Raise the slide adjustment rack of pillar slightly above the work-piece’s surface, fall the probe

till contact with the work-piece. In the process, you should be careful especially when the probe is

about to touch the work-piece; Generally, please note to adjust the body of the senor to the level

position first, then adjust slightly to the stylus position.

c. The small hole pickup is different from the standard one and deep groove one. Its head is

behind the stylus. When the stylus touches the work-piece, the stylus position will rise from lower

point.

2 Measurement:

Adjust slightly the stylus position to the center.

7.6.3 Indication Calibration

1 Use the multi-scale line to calibrate the small hole probe

2 Calibration operation:

a. Measure the multi-scale line sample;

b. Read Ra value;

c. Compare it with the sample value.

7.6.4 Cautions

1 The pickup stylus is a key part of the instrument. During the plugging in and pulling out, we

should be careful not to touch the stylus to avoid damage;

2 Finishing the measurement, it should be put into the box.

7.7 Extension Bar

Using the extension bar can increase the depth of the probe for entering the work-piece to measure

deeper parts of the work-piece. Its length is about 50mm.

8 References

The instrument calculates parameters on the filter profile and the direct profile, all calculated in line with

the GB/T3505-2000 "Geometrical Product Specification(GPS) ——Surface texture: Profile

method——Term, definitions and surface texture parameters.”

8.1Terms

Filtered profile

profile signal after primary profile is filtered to remove waviness

Direct-profile

adopt central line of Least Square Algorithm

RC

analogue 2RC filter with phase difference

PC-RC

PC-RC filter: RC filter with phase-correction

GAUSS

In accordance with GB/T18777-2002 Geometrical Product

Specification(GPS), Surface texture, Profile method, Metrological

characteristics of phase correction filter

8.2 Traversing Length of Filters

RC Filter

Page 19

18

mvip@mitech-ndt.com

● GAUSS Filter

● PCRC Filter

8.3 Parameters Definitions

8.3.1 Arithmetical Mean Deviation of Profile Ra

Ra is arithmetic mean of the absolute values of profile deviation Z(x) from mean within sampling length.

8.3.2 Root-mean-square Deviation of Profile Rq

Rq is the square root of the arithmetic mean of the squares of profile deviation Z(x) from mean within

sampling length.

8.3.3 Maximum Height of Profile Rz

Rz is the sum of height Zp of the highest profile peak from the mean line and depth Zv of the deepest

profile valley from the mean line within sampling length.

8.3.4 Total Peak-to-valley Height Rt

Zv and Rt is the sum of the height of the highest peak Zp and the depth of the deepest valley Zv over the

evaluation length.

8.3.5 Maximum height of Profile Peak Rp

Rp is the height from the highest profile peak line to mean line within sampling length.

Page 20

19

mvip@mitech-ndt.com

8.3.6 Maximum Depth of Profile Valley Rv

Rv is the depth from the deepest profile valley line to mean line within sampling length.

8.3.7 Mean Spacing of Local Peaks of Profile RS

RS is the mean spacing of adjacent local peaks of the profile within sampling length.

8.3.8 Mean Spacing of Profile elements RSm

RSm is the mean spacing between profile peaks at the mean line within sampling length.

8.3.9 Ten Point Height of Irregularities RzJIS

The sum of the mean height of the five highest profile peaks and the mean depth of the five deepest

profile valley from mean within the sampling length.

8.3.10 Maximum Height of Profile RyJIS

The same to 8.3.3 Rz。

8.3.11 Skewness of The Profile RSk

RSk is the quotient of the mean cube value of the profile deviation (Yi) and the cube of Rq within

sampling length.

8.3.12 Average Height From Peak to Valley R3z

R3z is the mean of the sum of the third profile peak height and the third profile valley depth of each

sampling length over evaluation length.

Notes: Recommend 5 sample lengths to evaluate.

Page 21

20

mvip@mitech-ndt.com

8.3.13 Rmax

The same to 8.3.4 Rt.

8.3.14 Peak count Rpc

C value is the distance of two parallel lines centered with middle line. There are two ways. One is

absolute value method. The other is relative percentage method.

8.3.15 Profile support ratio curve Rmr

8.3.16 The support length ratio of the profile Rmr(c)

8.4 Recommended Table of Sampling Length

Page 22

21

mvip@mitech-ndt.com

Appendix

Appendix I: Standard Code and Name Table

Standard Code

Standard Name

ISO 4287

International Standard

DIN 4768

German Standards

JIS B601

Japanese Industrial Standards

ANSI B46.1

American Standard

Appendix II: Roughness Parameters Display Range

Parameters

Display Range

Ra Rq

0.005μm ~ 80μm

Rz R3z Ry Rt Rp Rm

0.02μm ~ 320μm

Sk

0 ~ 100%

S Sm

1mm

tp

0 ~ 100%

Page 23

22

mvip@mitech-ndt.com

User Notes

Warranty:

The product is guaranteed for one year since purchased. Log www.mitech-ndt.com or follow our

company official public platform to register for maintenance. Please fill the blanks as required, if the

product is not registered for maintenance, it will follow the date of manufacturer.

When applying for maintenance, please visit our official website, www.mitech-ndt.com or official

accounts, submit “online reporting to repair” sheet.

In accordance with the international relevant regulations, the following are not within the scope of free

warranty,

Damage caused by man-made or improper keeping;

Self-dismantle or non-special repair shop dismantle;

Do not follow the requirement of service registration or warranty expired;

Consumable parts.

Service Promise:

MITECH users have lifelong maintenance service

Free maintenance, inspection, software upgrade and etc.

Add: Room E506, YingChuangDongLi Park, 1# of ShangDi East Road,

Haidian District, Beijing, China

Post code: 100085

Website: www.mitech-ndt.com

Email: mvip@mitech-ndt.com

Tel: 0086-10-58858658

Loading...

Loading...