Page 1

MITECH ULTRASONIC

FLAW DETECTOR

MFD500B

User’s Manual

MITECH CO.,LTD.

www.mitech-ndt.com

Page 2

mvip@mitech-ndt.com

1

CONTENTS

1 Introduction...........................................................................................................................................................3

1.1 Features of the Instrument...........................................................................................................................3

1.2 Specifications................................................................................................................................................. 4

1.3 Instrument Standard Configuration............................................................................................................ 5

2 Understanding the Keypad, Menu System and Display...........................................................................5

2.1 Structure Feature...........................................................................................................................................5

2.2 Screen Display...............................................................................................................................................6

2.3 Keys and Rotary Knob Features.................................................................................................................8

2.4 Menus and Functions....................................................................................................................................9

2.5 Alarm Lights.................................................................................................................................................... 9

3 Initial Start-up.......................................................................................................................................................9

3.1 Power Supply................................................................................................................................................. 9

3.2 Connecting a Probe.................................................................................................................................... 10

3.3 Starting the Instrument............................................................................................................................... 10

4.0 Operation......................................................................................................................................................... 10

4.1 Adjusting the Display Range..................................................................................................................... 10

4.2 Setting the Material Velocity...................................................................................................................... 10

4.3 Setting the Display Delay...........................................................................................................................10

4.4 Selecting the Probe Test Mode................................................................................................................. 11

4.5 Selecting a Rectification Mode..................................................................................................................11

4.6 Setting the A-Scan Reject Level............................................................................................................... 11

4.7 Setting the Gain...........................................................................................................................................12

4.8 Changing the Gain-Adjustment Increment (DB STEP).........................................................................13

4.9 Auto Gain Feature.......................................................................................................................................13

4.10 Configuring the Gates.............................................................................................................................. 13

4.11 Setting the Damping Level.......................................................................................................................14

4.12 Setting the Pulse Energy Level.............................................................................................................. 14

4.13 Setting the Pulse Width............................................................................................................................17

4.14 Adjusting the Pulse Repetition Frequency (PRF)................................................................................17

4.15 Specifying the Probe Frequency............................................................................................................ 17

4.16 Specifying the Piezo Crystal Size.......................................................................................................... 17

4.17 Setting the Probe X-Value....................................................................................................................... 17

4.18 Probe Delay Calibration...........................................................................................................................17

4.19 Setting the Angle of Incidence................................................................................................................ 17

4.20 Magnifying the Contents of a Gate........................................................................................................ 18

4.21 Freezing the A-Scan Display...................................................................................................................18

4.22 Setting the Display Grid........................................................................................................................... 18

4.23 Selecting Units...........................................................................................................................................18

Page 3

mvip@mitech-ndt.com

2

4.24 Scale Setting..............................................................................................................................................18

4.25 Fill function................................................................................................................................................. 19

4.26 Setting the Display Brightness................................................................................................................19

4.27 Setting the Display Color......................................................................................................................... 19

4.28 Setting the A-Scan Color......................................................................................................................... 19

4.29 Setting the Menu Color............................................................................................................................ 20

4.30 Key Sound..................................................................................................................................................20

4.31 Date and Time Setting..............................................................................................................................20

4.32 Display the System Information..............................................................................................................21

4.33 Resetting the Instrument..........................................................................................................................21

4.34 Connecting to a Computer.......................................................................................................................21

5 Calibration and Measurement....................................................................................................................... 21

5.1 Calibration with Straight-and Angle-Beam Probes................................................................................ 21

5.2 Calibration with Dual-Element (TR) Probes............................................................................................23

5.3 Distance Amplitude Curve......................................................................................................................... 23

5.4 Measuring with DGS/AVG..........................................................................................................................26

5.5 Curved Surface Correction........................................................................................................................28

5.6 AWS D1.1 Weld Rating Feature............................................................................................................... 28

5.7 Crack Height Measuring Feature..............................................................................................................28

5.8 Envelope Function...................................................................................................................................... 29

5.9 Peak Hold Feature...................................................................................................................................... 29

5.10 B-Scan Feature......................................................................................................................................... 30

5.11 Weld Figure Feature................................................................................................................................. 30

5.12 Coded Echo color......................................................................................................................................30

5.13 Data Storage..............................................................................................................................................32

6 Maintenance and Care..................................................................................................................................... 33

6.1 Care of the Instrument................................................................................................................................33

6.2 Care of the Batteries................................................................................................................................... 34

6.3 Maintenance.................................................................................................................................................34

6.4 Warranty........................................................................................................................................................34

6.5 Tips on Safety.............................................................................................................................................. 34

Appendix.................................................................................................................................................................35

Appendix A: Charging the Batteries................................................................................................................35

Appendix B: Menu Structure............................................................................................................................36

User's Note: ..........................................................................................................................................................36

Page 4

mvip@mitech-ndt.com

3

1 Introduction

The MFD500B is an advanced digital ultrasonic flaw detector featuring full digital TFT LCD and a host of

new features to meet challenging inspection requirements. Combined with powerful flaw detection and

measurement capabilities, extensive data storage, it is capable for transfer detailed inspection data to

the PC via its high-speed USB port.

The instrument incorporates many advanced signal processing features including a 10MHz RF

bandwidth to permit testing of thin materials, narrow band filters to improve signal to noise in high gain

applications, a spike pulse for applications required higher frequencies and a adjustable square wave

pulse to optimize penetration on thick or highly attenuating materials.

The instrument can be widely used in locating and sizing hidden cracks, voids, disbands and similar

discontinuities in welds, forgings, billets, axles, shafts, tanks, pressure vessels, turbines and structural

components.

1.1 Features of the Instrument

The instrument extends the performance and range of applications that are capable of being satisfied by

a portable instrument. The quality, portability, durability, and dependability that you have come to expect

from the popular Mitech MFD Series instruments remain.

1 Leading Technology including full English menu, master-slave, shortcut key and rotary key

design, it is easy for operation.

2 Adopted with full digital TFT LCD, clear screen brightness, capable for choosing the

background color, waveform color and menu color. Adjustable brightness freely, suitable for operating

under different environments.

3 High performance security battery module is easy to assemble and disassemble, the instrument

can work continuously more than eight hours.

Display

Hi-resolution (320×240 pixels) full digital TFT LCD with adjustable brightness, it is capable of providing

high contrast viewing of the waveform from bright, direct sunlight to complete darkness.

The hi-resolution TFT LCD display with fast 60 Hz update gives an “analog look” to the waveform

providing detailed information that is critical in many applications including nuclear power plant

inspections.

Range

Up to 6000 mm in steel; range selectable in fixed steps or continuously variable, suitable for use on large

work pieces and in high-resolution measurements.

Pulse

Pulse Energy selectable among Low (300V), Medium (500V) and High (700V)

Pulse Repetition Frequency adjustable from 10 Hz to 1 KHz in 1 Hz increments

Damping selectable among 100Ω, 200Ω and 400Ω for optimum probe performance

Test Modes including Straight, Angle, Dual and Thru-transmission

Receiver

Sampling:10 digits AD Converter at the sampling speed of 160 MHz

Rectification:Positive Halfwave, Negative Halfwave, Fullwave and RF

Analog Bandwidth: 0.5MHz to 15MHz capability with selectable frequency ranges (automatically set by

the instrument) to match probe for optimum performance.

Gain:0 dB to 110 dB adjustable in selectable steps 0.1 dB, 2 dB, 6 dB, and locked

Gates

Two fully independent gates offer a range of measurement options for signal height or distance using

peak triggering.

The echo-to-echo mode allows accurate gate positioning for signals which are extremely close together.

Gate Start: Variable over entire displayed range

Gate Width: Variable from Gate Start to end of displayed range

Gate Height: Variable from 0 to 99% Full Screen Height

Alarms: Threshold positive/negative

Page 5

mvip@mitech-ndt.com

4

Memory

Memory of 100 channel files to store calibration set-ups

Memory of 1000 wave files to store A-Scan patterns and instrument settings.

All the files can be stored, recalled and cleared.

Video Recorder

Screen scenes can be captured as movie files. About 2 minutes movie can be saved to the inside

memory. They can be re-played using the instrument or the PC software delivered with the instrument.

Video Recorder is useful in many situations, convenient for those who want to analyze the probing

activities later.

Functions

Semiautomatic two point calibration: Automated calibration of transducer zero offset and/or material

velocity

Flaw Locating:Live display Sound-path, Projection (surface distance), Depth, Amplitude,

Flaw sizing: Automatic flaw sizing using AVG/AVG or DAC, speeds reporting of defect acceptance

or rejection.

Digital Readout and Trig. Function: Thickness/Depth can be displayed in digital readout when using

a normal probe. Sound-path, Surface Distance and Depth are directly displayed when using angle

probe.

Both the DAC and the AVG method of amplitude evaluation are available.

Curved Surface Correction Feature

Crack Height Measure Function

Weld Figure Feature

Magnify Gate:spreading of the gate range over the entire screen width

Video Recording and Play

Auto-gain Function

Envelope: Simultaneous display of live A-scan at 60 Hz update rate and envelope of A-scan display

Peak Hold: Compare frozen peak waveform to live A-Scans to easily interpret test results.

A Scan Freeze:Display freeze holds waveform and sound path data

B Scan display feature

AWS D1.1 Feature

Real Time Clock

The instrument clock keeps running tracking the time.

Communication

High Speed USB2.0 Port

The DataPro software helps manage and format stored inspection data for high-speed transfer to the PC.

Data can be printed or easily copied and pasted into word processing files and spreadsheets for further

reporting needs. New features include live screen capture mode and database tracking.

Battery

Internal rechargeable Li-ion battery pack rated 7.2V at 8800 mAh

8 hours nominal operating time depending on display brightness

8-10 hours typical recharge time

Knob

Operating adjustments are easily and quickly made using the rotary knob.

1.2 Specifications

Range: 0 to 9999mm, at steel velocity

Material Velocity: 300 to 15000m/s

Display Delay: -20 to 3400 µs

Probe Delay/Zero Offset : 0 to 99.99µs

Sensitivity Leavings:>60dB (flat-bottomed deep hole 200mmФ2)

resolution :>40dB (5P14)

Noise Level: ≤ 8%

Test Modes: straight ,angle, dual element and thru-transmission

Page 6

mvip@mitech-ndt.com

5

Pulse Repetition Frequency ranges from 10 Hz to 1000 Hz

Pulse Energy: Low (300V), Medium (500V) and High (700V) spike pulse.

Damping: 100Ω, 200Ω and 400Ω

Bandwidth (amplifier bandpass ): 0.5 to 15MHz

Gate Monitors: Two independent gates controllable over entire sweep range

Rectification: Positive half wave, negative half wave, full wave, RF

System Linear Error: Horizontal: +/-0.1% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB.

Reject (suppression): 0 to 80% full screen height

Units: Inch or millimeter

Transducer Connections: BNC or LEMO

Power Requirements: AC Mains 100-240 VAC, 50-60 Hz

Overall Dimensions:263H×170W×61D mm

Relative Humidity:(20 ~ 95)% RH

Power Supply:DC 9V

Operating Temperature: -10℃ to 50℃

Storage Temperature: -30℃ to 50℃

1.3 Instrument Standard Configuration

No.

Item

Qty

Remarks

Standard

config.

1

Main unit

1

with full digital TFT LCD Display

2

Straight Beam Probe

1

4 MHz, Φ10

3

Angle Beam Probe

1

4 MHz, 8 mm×9 mm, 60°

4

Probe Cable

1

Q9-C5,or optional C9- C5

5

Battery Module

1

8.8 amp hour (MB-02)

6

Power Adapter

17Supporting pillar

1

8

Attached files

1

9

Datapro Software

1

10

USB Cable

1

11

Power Cable

1

12

ABS Case

1

Optional

config.

1

Protective Cover for Main Unit

2

Dual-crystal Straight Probe

2 Understanding the Keypad, Menu System and Display

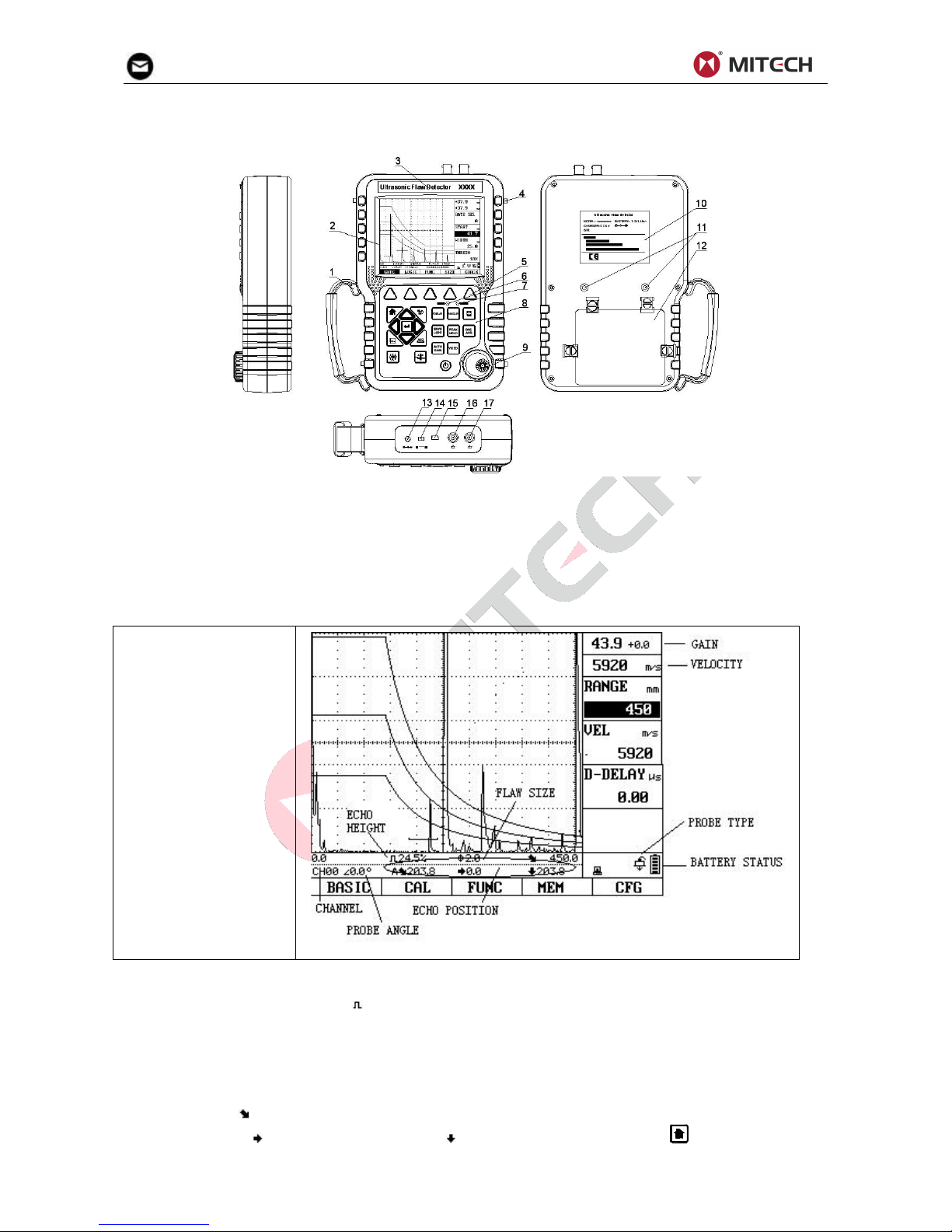

2.1 Structure Feature

The right figure gives an overview

of the instrument system.

1、The Main Unit

2、Probe (Transducer)

Page 7

mvip@mitech-ndt.com

6

The Main Unit

1.Belt 2.LCD Display 3.LOGO 4. Hooks 5. Menu Keys

6. Alarm LED 7. Power LED 8. Keypad 9. Rotary Knob

10. Product Label 11.Support Pillar Screw 12. Battery Case

13. Power adapter port 14. Battery Switch 15. USB Socket

16., Probe Cable Port (Transmit) 17. Probe Cable Port (Receive)

2.2 Screen Display

The instrument displays are designed to be easy to interpret.

The Instrument has a

digital screen for the

display of A-Scan.

The status line below

the wave display shows

values of range settings

and measured values.

On the first status line

Echo height is displayed as: 24.5%. It means that the peak echo height inside the current selected

gate is 24.5% FSH (Full Screen Height of the wave area).

Flaw size value means ERS (Equivalent Reflector Size) of the reflector signal inside the current

selected gate. It is displayed after the AVG curve is switched on. When the DAC curve is on, this

value will be displayed as the dB offset of the peak echo inside the current selected gate to the

reference DAC curve (DAC→OFFSET→SIZE REF).

The icon ‘ ’ indicates that the horizontal scale is displayed as sound path (S-PATH). It can be

changed to ‘ ’ (Projection value) or ‘ ’ (Depth) by simply pressing repeatedly.

Page 8

mvip@mitech-ndt.com

7

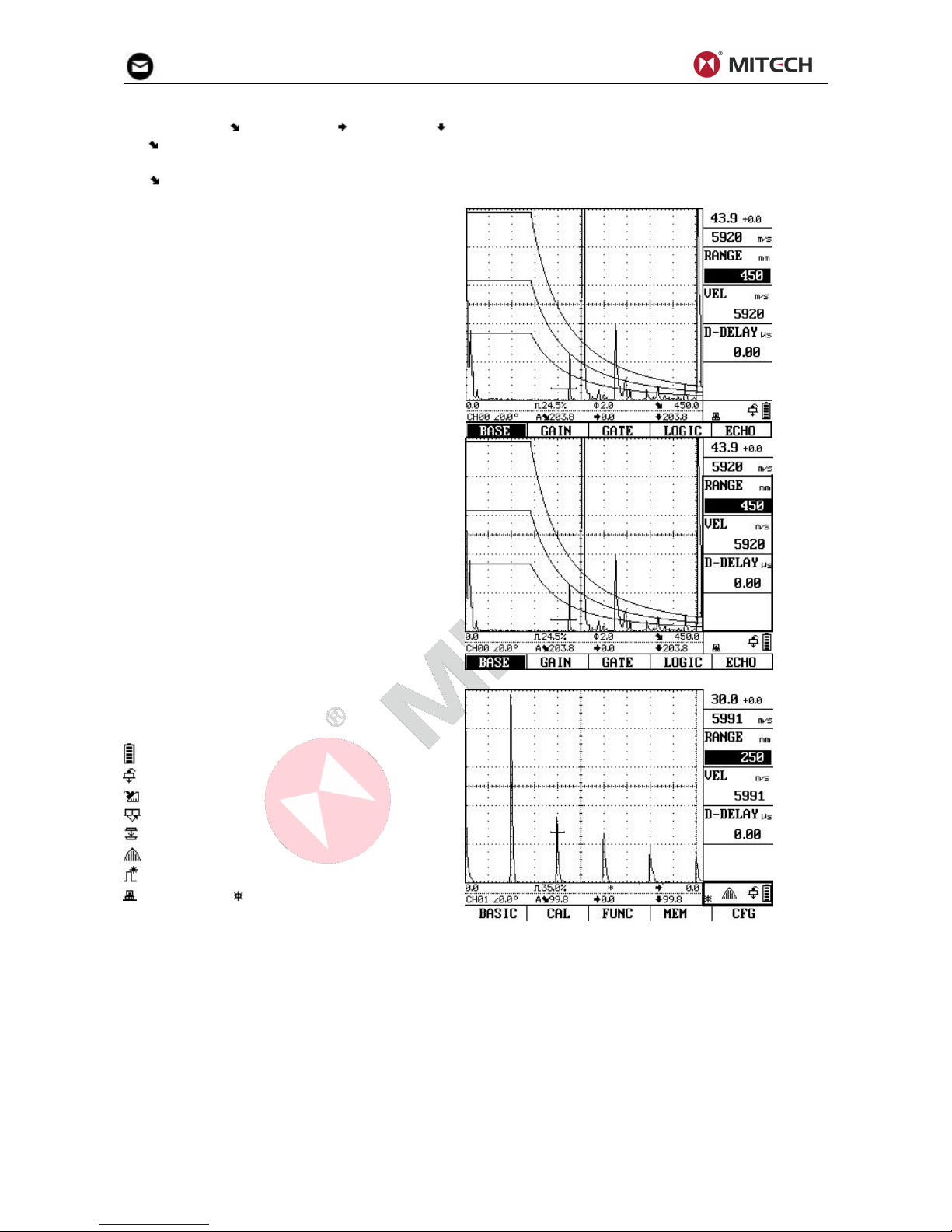

On the second status line, it shows the channel file name, the beam angle and the measured value of

the peak echo ( : Sound path. : Projection. :Depth) inside the current selected gate.

“A 61.3” means gate mode is single; current selected gate is gate A; and peak echo position: sound

path 61.3 mm.

“AB 24.0” means Echo-Echo mode of the gates; selected gate is gate A; sound path: 24.0 mm.

The names of the menus or submenus

are displayed at the bottom of the screen.

The selected menu or submenu is

highlighted.

Indicated at the right of the display, next

to the A-Scan, are the functions of the

corresponding menu.

The status area at the bottom-right corner

shows the system status. The following

status will be showed:

: Indicates the battery capacity

: Straight beam probe

: Angle beam probe

: Dual element probe

: Through-transmit mode

: Envelope function on

: Peak hold function on

: USB online; : A-Scan freezed

Page 9

mvip@mitech-ndt.com

8

The status area at the top-right corner

indicated shows the system gain and the

sound velocity.

2.3 Keys and Rotary Knob Features

To access any function:

Press one of the five menu keys (F1~F5) to select a menu. The menus across the

bottom of the display will immediately be replaced with the submenus contained in the

selected menu

Press a menu key (F1~F5) again to select the submenu containing the desired function.

Press and to move the cursor to select the desired function.

Change the value listed in the function box with the rotary knob. Some values can also

be adjusted with repeatedly pressing the knob.

Special keys such as Gain, Gate, Range, Probe Zero-Offset Calibration, Angle Calibration,

Freeze, Save Waveform, Auto-Gain, Envelop, Peak Hold and etc. are grouped together for

easy thumb control. This design allows direct access to important instrument set-up

parameters and provides easy and fast operating in difficult inspection environments

Functions of the keys:

Home key immediately returns the instrument to the main screen (full screen)

Freeze key freezes the A-Scan

Magnify key expands the gate range to full screen

For turning the instrument On/Off

Db-Step key selects the gain submenus or switch the db step

A

/

B

Gate key - Gate functions selecting gate functions and Gate A/B switch

Range key - Range function selecting

Probe-Delay key – Probe Delay calibration

Probe-Angle key selects the angle calibration functions

Save key performs a data-storage of the A-Scan pattern

G

A

I

N

A

U

T

O

Auto-Gain key starts or stops the Auto-Gain function

L

O

P

E

E

N

V

E

Envelope key turns the Envelope function on and off

The instrument is designed to

give the user quick access to all

of the instrument’s functions.

Its easy-to-use menu system

allows any function to be

accessed with no more than

three key presses.

The instrument is designed to

give the user quick access to all

of the instrument’s functions.

Its easy-to-use menu system

allows any function to be

accessed with no more than

three key presses.

Page 10

mvip@mitech-ndt.com

9

P

E

A

K

H

O

L

D

Peak-Hold key turns the Peak-Hold function on and off.

V

I

D

E

O

Video key starts or stops recording a segment of the display

D

A

C

A

V

G

DAC-AVG key selects the menus of DAC/AVG

Up Arrow key – Move the cursor up to select the desired function

Down Arrow key – Move the cursor down to the desired function

searches next echo towards left, or move the cursor to left when inputting digit numbers.

searches next echo towards right, or move the cursor to right when inputting digit numbers.

confirms or switches current selection

Rotary knob makes it convenient for handling device parameters and functions. It supports three

operations: turn clockwise, turn counter-clockwise and single press.

Turn clockwise: increase the selected parameter, or change the selection.

Turn counter-clockwise: decrease the selected parameter, or change the item selection.

Single press: changes mode between coarse and fine parameter adjustments or changes item selection.

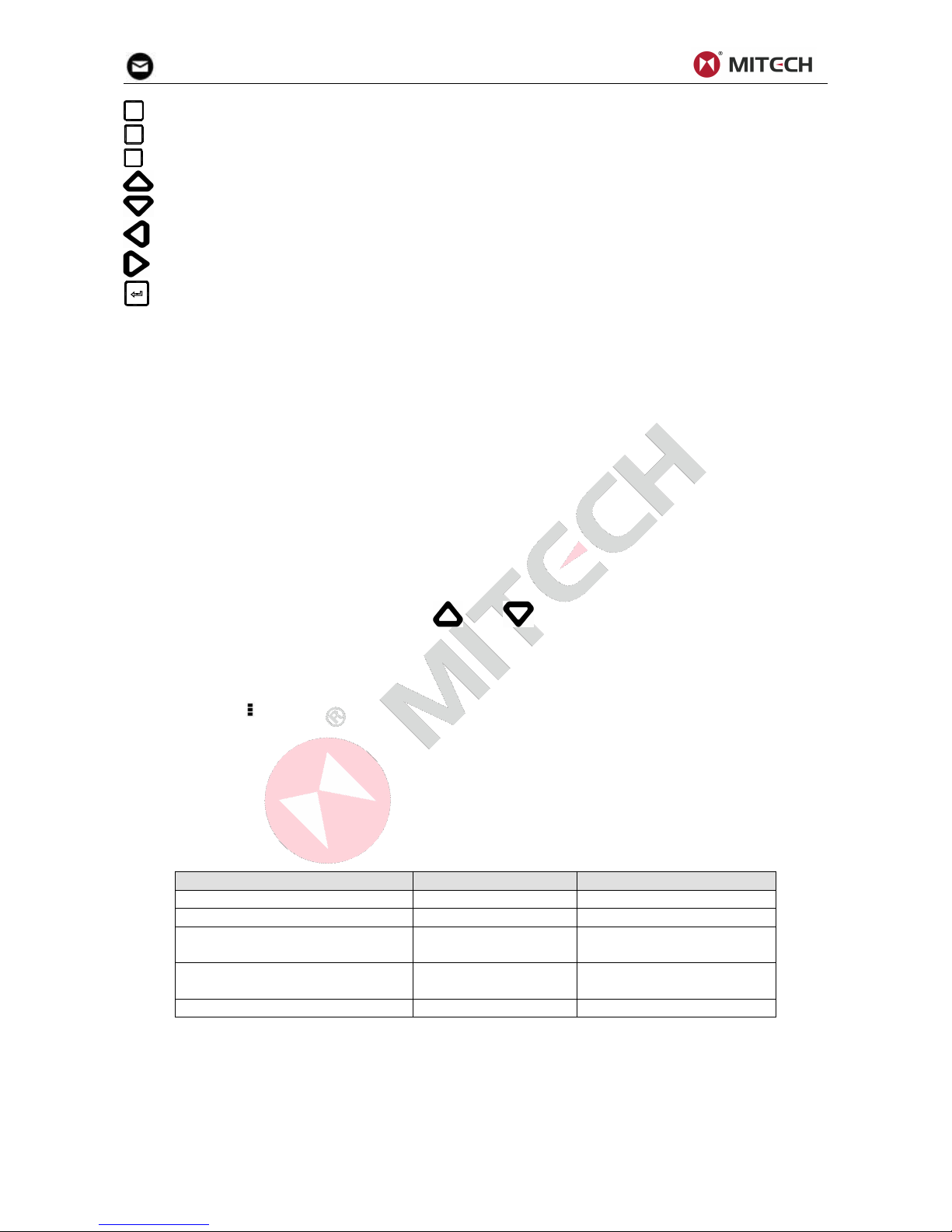

2.4 Menus and Functions

The instrument menu system consists of several menus, submenus, and functions. It allows the operator

to select and adjust various features and instrument settings.

Available menus are accessed via the Home Menu. Note that the menus visible on your particular

instrument depend on which options are installed.

Each menu contains several submenus.

Menus and submenus are selected by pressing the key below the desired item (F1 to F5).

When a submenu is selected, the functions contained in that submenu are listed in the Function Bar

down the right-hand side of the display screen.

Functions are then selected by pressing and .

Turning the Function Knob will change the value shown in the selected function’s box.

Note that some functions, like RANGE, have both coarse and fine adjustment modes. There are three

steps in the fine adjustment mode. Coarse and fine modes are selected by pressing the knob more than

once. An icon of “ ” will appear on the left of the function name when the function is in fine adjustment

mode. When the function is in coarse adjustment mode, turning the function knob will produce large

changes in the selected function’s value. When the function is in fine adjustment mode, rotating the

function knob will change the value by smaller amounts.

2.5 Alarm Lights

Two alarm lights appear at the top-right corner front of the instrument’s keypad. One alarm light is

marked as ALRM, which is assigned to the gate alarm. When a gate alarm is triggered, this light will

illuminate. The other light is marked as PWR indicating power and battery status.

Status

ALRM LED

PWR LED

Gate alarm

Red on

×

Battery charging

×

Flash red/green

Battery charge completed with

external power connected

×

Green on

External power connected

No battery installed

×

Green on

No external power

×

off

3 Initial Start-up

3.1 Power Supply

The instrument can be operated with an external power adapter or with batteries.

You can connect the instrument to the mains supply system even if it carries batteries. A discharged

battery is charged in this case, viz. parallel to the instrument operation.

Operation Using the Power Supply Unit

Page 11

mvip@mitech-ndt.com

10

Connect the instrument to the mains socket-outlet using the power supply unit. The plug receptacle is at

the top left of the instrument. Push the plug of the power supply unit into the plug receptacle until it snaps

into place with a clearly audible click. The PWR LED on the keypad of the instrument will light in green

color if the connection is properly aligned

Operation Using Batteries

Use a lithium-ion battery pack provided with the instrument for the battery operation.

The battery compartment is situated at the instrument back. The cover is fastened with 4 screws To

insert the battery pack

Loosen the four screws of the battery cover.

Lift the cover off upward.

Insert the battery into the battery compartment.

Close the battery compartment and fasten the screws.

Turn on the instrument to make sure the battery is installed correctly and firmly.

Note:

The battery switch on the top of the instrument must be set to ON when operating with the battery

pack or charging it.

When not using the instrument, set the switch to OFF to save power.

3.2 Connecting a Probe

To prepare the instrument for operation, you have to connect a probe to it. The instrument is available

with the probe connectors BNC (LEMO connectors are optional).

When connecting a probe to the instrument, it’s not only important that the probe’s physical connection

be properly made. It’s also important that the instrument is properly configured to work with the installed

probe. The Instrument will operate with one or two single-element probes or with a dual-element probe.

To install a single-element probe, connect the probe cable to either of the two ports on the front of the

instrument. When two probes or a dual-element probe is connected to the instrument, the “Receive”

probe connector should be installed in the right port and the ‘Transmit’ probe connector in the left port.

3.3 Starting the Instrument

To start the instrument, press the switch-on key . If it operates on the internal battery pack, make sure

to set the battery switch to ON position before starting.

The start display of the instrument appears; here you will also see the current software version and the

serial number of the instrument. The instrument carries out a self-check and then switches over to

stand-by mode.

The settings of all function values are the same as before switching-off of the instrument.

The instrument will shut off automatically when the battery capacity level is too low.

4 Operation

4.1 Adjusting the Display Range

The function group BASE enables you to make the basic adjustment of the display range. The display on

the screen must be adjusted for the material to be tested and for the probe used.

Calibration requires the use of calibrated standard made of the same material as the test piece. Prior to

calibrating the instrument/probe combination, the A-Scan display-screen range (the material thickness

Connect one single element

probe to either port.

Connect leads from a Dual

Element Probe to both ports.

For through-transmission,

connect two single element

probes to the transmit (left,

labeled as ) and receive

(right, labeled as ) ports.

Page 12

mvip@mitech-ndt.com

11

value represented by the full horizontal width of the screen) will normally be set to a value equal to or

slightly larger than the calibrated standard.

1 Activate the BASE submenu (located in the BASIC menu) by pressing the menu key below it.

Three functions will appear down the right side of the display screen.

2 Select the function item titled RANGE. You’ll note that RANGE has both coarse and fine

adjustment modes. Coarse and fine modes are selected by repeatedly pressing .

3 To change the range, turn the knob.

4 The display’s horizontal range will remain as set.

Range is adjustable in fixed steps or

continuously variable.

4.2 Setting the Material Velocity

Use VEL to set the sound velocity within the test object. Always ensure that the function VEL is correctly

set. The instrument calculates all range and distance indications on the basis of the value adjusted here.

Velocity range:300m/s~15000m/s

Coarse adjustment, in steps as follow

2260m/s 2730m/s 3080m/s 3230m/s

4700m/s 5920m/s 6300m/s

4.3 Setting the Display Delay

Here you can choose whether to display the adjusted range (for example 300 mm) starting from the

surface of the test object, or in a section of the test object starting at a later point. This allows you to shift

the complete screen display and consequently also the display zero. If the display should for example

start from the surface of the test object, the value in D-DELAY must be set to 0. To set the display delay

1 Activate the BASE submenu (located in the BASIC menu) by pressing the menu key below it.

Three functions will appear down the right side of the display screen.

2 Select the function item titled D-DELAY.

3 To change the display delay, turn the knob. You’ll note that the displayed echoes shift to the left

or right.

D-DELAY range: -20~3400 µs

Coarse adjustment: 12 pixel space (in µs)

Fine adjustment: 1 pixel space (in µs)

4.4 Selecting the Probe Test Mode

You can use the function PROBE to activate the pulse-receiver separation. The following modes are

available:

STRAIGHT- For single straight beam transducer operation ( will be displayed).The probe

connection sockets are connected in parallel.

ANGLE- For single angle beam transducer operation ( will be displayed)

DUAL – For the use with dual-element (TR) probes ( will be displayed); the right-hand socket is

connected with the amplifier input whereas the initial pulse is available at the left-hand socket.

THRU – Through-transmission mode for the use with two single-element probes ( will be

Page 13

mvip@mitech-ndt.com

12

displayed); the receiver is connected with right, the pulse is connected with left.

Select the probe model step:

1 Activate the PROBE submenu (located in the CAL menu) by pressing the menu key below it.

2 Select the function item titled PROBE.

3 To change the probe mode, turn the knob. Each available probe mode is represented by an icon

on screen display whenever that probe mode is indicated.

4 The probe mode will be set to the last one displayed.

4.5 Selecting a Rectification Mode

You can select the rectification mode of the echo pulses according to your application in the function

RECTIFY (BASIC→ECHO→RECTIFY).

Rectification affects the orientation of the A-Scan on the display screen. The A-Scan represents the

pulse (echo) that’s returned from the material being tested to the instrument. The series of echoes looks

like the Radio Frequency (RF) signal.

Note that the RF signal has a negative

component below the axis, and a positive

component above the axis.

RF rectification is useful when evaluating a

probe.

RF rectification is forbidden when displaying

the DAC/AVG curves.

Positive Half Rectification means that only

the upper (positive) half of the RF signal is

displayed.

Negative Half Rectification means that only

the bottom (negative) half of the RF signal is

displayed. In the figure above, note that

even though it’s the negative half of the RF

signal, it’s displayed in the same orientation

as a positive component. This is only to

simplify viewing. The signal displayed in the

view identified as Negative Rectification is

the negative component of the RF signal.

Full-Wave Rectification combines the

positive and negative rectified signals

together, and displays both of them in a

positive orientation. Full-wave rectification is

recommended for most inspections.

Use the following procedure to select a rectification mode

1 Activate the ECHO submenu (located in the BASIC menu) by pressing the menu key below it.

Page 14

mvip@mitech-ndt.com

13

Three functions will appear down the right side of the display screen.

2 Select the function item titled RECTIFY. You’ll note that there are four options:

POS- Shows the positive component of the RF signal

NEG- Shows the negative component of the RF signal but displays it in a positive orientation

FULL-Shows the positive and negative halves of the RF wave, but both are oriented in the positive

direction.

RF- Shows the echo with no rectification

3 Select the rectification method.

4.6 Setting the A-Scan Reject Level

The function REJECT allows you to suppress unwanted echo indications, for example structural noise

from your test object. To omit a portion of the A-Scan, you must define the percentage of full-screen

height you wish to omit. You may omit A-Scan up to 80% of the screen height. To set a reject percentage

1 Activate the ECHO submenu (located in the BASIC Menu) by pressing the menu key below it.

2 Select the function item titled REJECT.

3 Set the required percentage value by turning the knob.

You should handle this function with great caution, as it may of course happen that you suppress echoes

from flaws as well. Many test specifications expressly forbid using the reject function.

4.7 Setting the Gain

Instrument gain, which increases and decreases the height of a displayed A-Scan, is adjusted with the

gain functions.

The gain includes the basic gain, the

offset gain and the correction gain. The

basic gain and the correction gain are

also displayed on the top-right corner of

the screen.

The maximum of the total gain (the basic

gain plus the offset gain plus the

correction gain) is 110 dB.

The offset gain is for the purpose of flaw evaluation. The DAC/AVG curves remain unchanged when

adjusting the offset gain.

Sensitivity correction gain: Compensate for the transfer losses in the material under test. This correction

gain is necessary if test object and reference block have different surface qualities. You have to find out

the adjustment value for the compensation of transfer losses by experiments. The gain is varied

accordingly in this correction, while the curve line remains unchanged. To set the sensitivity correction

gain, select the function T-CORR and then adjust its value according to the experiment.

When DAC is active, adjusting the basic gain setting will result in an equal adjustment of the DAC curve

position. To increase the instrument gain without changing the DAC curve position, please use the

T-CORR function to compensate for varying coupling/surface conditions.

4.8 Changing the Gain-Adjustment Increment (DB STEP)

When adjusting the A-Scan Gain, each click of the adjustment knob increases or decreases the gain

level by a dB increment equal to the DB STEP. Several values can be specified for DB STEP. Available

increments include: 0.1dB, 1dB, 2dB, 6dB and 0dB. Note that setting the DB STEP to 0dB prevents

adjustment of the instrument gain and prevents any changes using the knob.

To select one of the existing DB STEP values:

1 Activate the GAIN submenu (located in the BASIC menu) by pressing the menu key below it.

2 Select the function item titled DB STEP.

Page 15

mvip@mitech-ndt.com

14

3 Change the DB STEP value by repeatedly pressing key or by turning the knob.

Note that DB STEP value can be quickly changed by repeatedly pressing the key .

4.9 Auto Gain Feature

Use the Auto Gain function to automatically set the basic gain, so as to adjust the peak echo inside the

currently selected gate to a target height.

1 Set the target echo height using the AUTO function located in the FUNC submenu.

2 Press

GAIN

AUTO

to start the Auto Gain function. “AUTO-XX%” will be shown on the screen.

3 The Auto Gain function will end when the echo height reaches the target value. Or you can stop

the function by pressing

G

A

I

N

A

U

T

O

again.

4.10 Configuring the Gates

The gates monitor the range of the test object where you expect to detect a flaw. If an echo exceeds or

falls below the gate, an alarm signal is shown via the ALRM LED. The gate chooses the echo for the

digital time-of-flight or amplitude measurement.

The instrument has two gates: gate A and B. Gate A and B are independent of one another. Setting the

position and characteristics of the A- and B-Gates is the first step to configuring the instrument for flaw

detecting or material-thickness measurement. The GATE functions controls not only the location of the A

and B-Gates, but also the alarms and other features activated when an A-Scan signal crosses a specific

gate.

A-Scan signals crossing the A or B-Gate are evaluated for the purposes of flaw detection and

material-thickness evaluation. When the signal crosses the A or B-Gate, the maximum point (peak) of

the signal (in the specific gate) is used for evaluation purposes. The measured value is indicated on the

status line.

Selecting a Gate

Selecting a gate by using the GATE SEL

function in the GATE submenu.

You can also repeatedly press

A

/

B

to

switch the selected gate between Gate A

and Gate B.

The selected gate will be shown in solid

line. The unselected gate will be shown in

dashed line.

Positioning Gates

Use the following procedures to set the vertical and horizontal position of the A and B-Gates. Remember

that gate position has the following effects on instrument performance:

A-Scan echoes on the right side of the display screen represent features that occur at a greater

depth from the test-material surface than those on the left of the display screen. Therefore, moving a

gate to the right means that the gate is evaluating a deeper portion of the test material.

A wider gate will simply span the equivalent of more test-material depth

Increasing the vertical height (called threshold) of a gate means that only reflected signals of

sufficiently large amplitude will cross the gate.

Setting a Gate’s Starting Point

You can fix the starting point of the gates A or B within the display range.

1 Activate the GATE submenu (located in the BASIC menu).

2 Select the gate to be positioned using the GATE SEL function.

3 Select the gate START function and adjust the starting point by turning the knob. Increasing and

decreasing the value of the starting point moves the gate to the right and left, respectively.

Page 16

mvip@mitech-ndt.com

15

4 The gate starting point will remain as set, even when width adjustment is made.

Coarse adjustment: half of a lattice

Fine adjustment: 1 pixel space

When the gate exceeds the display range,

as shown in right figure, the measured

value will be shown as “*” on the status

line.

You can also set the selected gate’s starting point using the Quick Search Function. Quick Search

Function is achieved by simply pressing the and . Note that the instrument will only search the

echo whose peak crosses the selected gate in this function.

Adjusting a Gate’s Width

You can determine the threshold value of the gates within the range of 0 to 99% FSH (Full Screen Height)

for triggering the LED alarm if this value is exceeded or not reached, depending on the setting of the

LOGIC function.

1 Activate the GATE submenu (located in the BASIC menu).

2 Select the gate to be positioned using the GATE SEL function.

3 Select the gate WIDTH function and adjust its value by turning the knob.

Setting a Gate’s Threshold (Vertical Position)

You can determine the threshold value of the gates within the range of 0 to 99% FSH (Full Screen Height)

for triggering the LED alarm if this value is exceeded or not reached, depending on the setting of the

LOGIC function.

1 Activate the GATE submenu (located in the BASIC menu).

2 Select the gate to be positioned using the GATE SEL function.

3 Select the THRESH function and adjust the vertical height by turning the knob. Increasing and

decreasing the value of the threshold moves the gate up and down, respectively.

Defining B-Gate Alarm Logic

This function allows you to choose the method for triggering the B-Gate alarm.

Gate alarms can be set to trigger when an A-Scan echo crosses the gate (POSITIVE logic) or when no

echo crosses the gate (NEGATIVE logic) within the displayed range.

A-Gate is locked to POSITIVE logic. And

B-Gate can be set to either POSITIVE or

NEGATIVE.

The appearance is different between the

POSITIVE gate and the NEGATIVE gate when

displayed, as is shown in right figures.

Note that the alarm and measurement function

of the gates is only active within the display

range.

Use the following procedure to specify B-Gate

logic:

Page 17

mvip@mitech-ndt.com

16

1 Activate the LOGIC submenu (located

in the BASIC menu) by pressing the menu key

below it.

2 Select the B-LOGIC function and

choose the gate-alarm triggering logic.

Turning the Audible Alarm On or Off

When a gate alarm is activated, one or more of the following will occur:

An alarm indication light on the front of the instrument will illuminate

An audible alarm (HORN) will sound

Use the following procedure to turn the horn off or on:

1 Activate the LOGIC submenu (located in the BASIC menu) by pressing the menu key below it.

2 Select the ALARM function and turn the audible alarm ON or OFF.

Setting the Gate Work Mode

Two options for the gate work mode: SINGLE and E-E.

SINGLE: measures the distance from the work piece surface to the peak echo inside the selected gate.

E-E (Echo-Echo mode): measures the distance between two peak echoes (the two peak echoes should

be selected by two gates). It is useful in thickness measuring.

Use the GATE MODE function in the LOGIC submenu to select the gate work mode.

Page 18

mvip@mitech-ndt.com

17

Gate Mode: Single

Gate Mode: E-E

4.11 Setting the Damping Level

Note: For this model, the parameter is fixed.

This function serves for matching the probe. You can use it to adjust the damping of the probe’s

oscillating circuit and to consequently change the height, width and resolution of the echo display.

1 Activate the PULSER submenu (located in the CAL menu) by pressing the menu key below it.

2 Move the cursor to the selection titled DAMPING.

3 To change the specified damping level and optimize the A-Scan signal appearance, turn the

knob. You’ll note that the following damping levels are available: 100Ω、 200Ω、400Ω.

4 The damping level will be set to the one last displayed.

4.12 Setting the Pulse Energy Level

Use the function ENERGY to set the pulse voltage. The relative energy with which the pulse fires can be

selectable set to LOW, MEDIUM or HIGH.

The setting MEDIUM is recommended for most inspections. HIGH is used for inspections in which

maximum sensitivity is import, e.g. for the detection of small flaws. Choose the setting LOW for

broadband probes or if narrow echoes are required (better lateral resolution).

To set the pulse energy

1 Activate the PULSER submenu (located in the CAL menu) by pressing the menu key below it.

2 Select the function item titled ENERGY.

3 Select the energy level by turning the knob or continuing to press the key.

4.13 Setting the Pulse Width

The function is no available in this model.

4.14 Adjusting the Pulse Repetition Frequency (PRF)

The pulse repetition frequency indicates the number of times an initial pulse is triggered per second. You

can determine whether you need the highest possible PRF value, or whether you are satisfied with a low

value.

The PRF value ranges from 10 Hz to 1000 KHz. The larger your work piece, the smaller PRF values are

needed in order to avoid phantom echoes. In the case of smaller PRF values, however, the A-Scan

update rate becomes lower, for this reason, high values are required if a work piece should be scanned

fast.

The best way to determine the suitable PRF value is by experimenting: start from the highest step and

reduce the value until there are no more phantom echoes.

To set the PRF level

1 Activate the PULSER submenu (located in the CAL menu) by pressing the menu key below it.

2 Select the function item titled PRF.

3 Change the PRF value by turning the knob.

4.15 Specifying the Probe Frequency

In this function, you can specify the probe frequency according to the frequency of your probe. The

instrument will automatically utilize a built-in filter to match the probe frequency.

1 Activate the PROBE submenu (located in the CAL menu) by pressing the menu key below it.

2 Select the function item titled FREQ.

3 To change the specified frequency, turn the knob.

4 The probe frequency will be set to the last one displayed.

4.16 Specifying the Piezo Crystal Size

Use DIAMETR function to set the Piezo Crystal Size of your probe. This value is required when

programming the AVG.

4.17 Setting the Probe X-Value

Page 19

mvip@mitech-ndt.com

18

The function X-VALUE enables you to set

the X-Value (distance between the probe’s

leading face and probe index/sound exit

point) of the probe used. This value is

required for the automatic calculation of the

reduced projection distance in angle beam

transducer operation.

Adjustment range: 0~50 mm

4.18 Probe Delay Calibration

Each probe has a delay line between the transducer element and the coupling face. This means that the

initial pulse must first pass through this delay line before the sound wave can enter the test object. You

can compensate for this influence of the delay line in the function P-DELAY.

If the value for P-DELAY is not known, read Chapter 5 in order to determine this value.

4.19 Setting the Angle of Incidence

The ANGLE function enables you to adjust the angle of incidence of your probe for the material used.

This value is required for the automatic calculation of the flaw position. The angle of incidence for the

straight-beam probe is fixed to 0°.

Adjustment range: 0°~80°.

4.20 Magnifying the Contents of a Gate

Whenever an A-Scan is active, pressing the key enlarges the displayed portion of the A-Scan

contained in the selected gate. Any of the available gates may be specified as the selected gate. The

width of the magnified gate determines the level of magnification since the display is magnified until the

gate width equals the full-screen width. The display will contain the magnified view until pressing

again.

Before Magnifying

After Magnifying

4.21 Freezing the A-Scan Display

Whenever an A-Scan is active, pressing freezes the A-Scan display. The active A-Scan will remain

as it appeared when was pressed and the display will remain frozen until is pressed again.

4.22 Setting the Display Grid

1 Activate the SYS submenu (located in the CFG menu) by pressing the menu key below it. Four

functions will appear down the right side of the display screen.

2 Select the function item titled GRID.

3 To change the grid type, Press key or turn the knob. Each grid style is shown in the

Page 20

mvip@mitech-ndt.com

19

display screen’s A-Scan window as it is selected. You’ll note that the following styles are available:

G1-Ten major horizontal and five vertical divisions, with two major horizontal and vertical divisions.

G2-Two major horizontal and vertical divisions.

G3-No on-screen grid. Only display-edge marks are visible.

G4- Ten major horizontal and five vertical divisions.

4 The grid style will be set to the last one displayed.

4.23 Selecting Units

In the function UNITS you can choose your favorite unit system between METRIC and IMPERIAL unit

systems.

1 Activate the SYS submenu (located in the CFG menu) by pressing the menu key below it.

2 Select the function item titled UNITS. You’ll note that the following options are available:

METRIC-metric unit system.

IMPERIAL-Imperial unit system

3 To change the units of measurements, Press key or by means of the knob.

4 The unit of measurement will be set to the choice last displayed.

4.24 Scale Setting

As an alternative to the measured values, the instrument enables to display a scale on the first status

line. The scale gives you an overview of the position of echoes.

The following settings are possible:

S-PATH: Display of sound path scale

P-VALUE: Display of projection distance

scale

DEPTH: Display of depth distance scale

Select the function SCALE. Then use the knob to set the required display mode.

As an alternative, you can repeatedly press to switch the scale.

4.25 Fill function

The function FILL toggles between the filled and the normal echo display mode. The filled echo display

mode improves the echo perception due to the strong contrast, especially in cases where workpieces

are scanned more quickly.

4.26 Setting the Display Brightness

Use the function BRIGHT to set the display brightness. You can choose between four brightness options:

25%, 50%, 75% and 100%.

1 Activate the LCD submenu (located in the CFG menu) by pressing the menu key below it. Four

functions will appear down the right side of the display screen.

Page 21

mvip@mitech-ndt.com

20

2 Select the function item titled BRIGHT.

3 To change the brightness level, Press key or turn the knob.

4 The display brightness will remain at the level last displayed.

Note: For the 25% option, the instrument consumes less current and consequently increases the

operating time in battery operation.

4.27 Setting the Display Color

The SYS COLOR value determines the color of the background, the gate and the DAC/AVG curves. All

color schemes are recommended for indoor operation while S0 and S3 are best suited for outdoor

operation.

1 Activate the LCD submenu (located in the CFG menu) by pressing the menu key below it. Four

functions will appear down the right side of the display screen.

2 Select the function titled SYS COLOR. There are nine preset color schemes.

3 To change the display’s color scheme, turn the knob.

4 The display color will remain at the scheme last displayed.

4.28 Setting the A-scan Color

1 Activate the LCD submenu (located in the CFG menu) by pressing the menu key below it.

2 Select the function titled WAV COLOR. There are seven A-Scan color options.

3 To change the A-Scan’s color, turn the knob.

4 The A-Scan echo will remain the color last displayed.

4.29 Setting the Menu Color

1 Activate the LCD submenu (located in the CFG menu) by pressing the menu key below it.

2 Select the function titled MNU COLOR. There are ten color options.

3 To change the menu’s color, turn the knob.

4 The menu will remain the color last displayed.

4.30 Key Sound

The key sound can be turned on/off using the KEY SOUND function located in the HORN submenu

(CFG→HORN→KEY SOUND).

4.31 Date and Time Setting

For a correct documentation you should always make sure that you are using the correct date and time

setting.

1 Activate the INFO submenu (located in the CFG menu) by pressing the menu key below it. Four

items will appear down the right side of the display screen.

2 Select the function Y-M-D. The

date is displayed in Year-Month-Day format.

Note that the first time you press the knob,

the year item is highlighted. The next time

you press the knob, the month item is

highlighted. Finally, pressing the knob will

cause the day item to be highlighted.

3 To change the year, month or days, turn the knob while the desired item is highlighted.

4 When complete, press the one more time. The current date will be set to the date

displayed.

Time is displayed in Hour-Minute format. And the time setting procedure is similar to that of the date.

Page 22

mvip@mitech-ndt.com

21

Once set, the internal clock of the instrument will maintain the current date and time.

4.32 Display the System Information

You can enter the INFO submenu to see the software version and the serial number of the instrument.

The VERSION and the S/N values are read-only. They cannot be modified by the user.

4.33 Resetting the Instrument

In case the instrument can no longer be operated, or you need to make a basic initialization (factory

setting), you can reset the instrument to original.

The instrument can be reset by the SYS RESET function. All the memory data, including the wave files,

the channel files and the video files, will be cleared during system reset. And the instrument settings will

be reset to default.

To reset the instrument

1 Activate the RESET submenu (in the MEM menu) by pressing the menu key below it.

2 Press the and key to select the SYS RESET function.

3 Press key or turn the knob to trigger the reset action. It will prompt out “Reset to

original?”. Press the menu key below YES to confirm the reset operation. Or press the menu key below

NO to cancel the reset operation.

NOTE:

The effects of resetting the instrument may not be reversed.

No key action should be performed during resetting process.

4.34 Connecting to a Computer

The instrument is equipped with a USB port at the upper left of the instrument. The PC can be connected

with the instrument via the USB port. A-Scan display, instrument settings, and videos stored in the

memory of the instrument can be transferred to the computer through the USB port. Detailed information

of the communication software and its usage refer to the DataPro software manual.

5 Calibration and Measurement

Before working with the instrument, you have to calibrate the instrument: you have to adjust the material

velocity and display range and allow for the probe delay depending on the material and dimensions of

the test object.

To ensure a safe and proper operation of the instrument, it is necessary that the operator be adequately

trained in the field of ultrasonic testing technology.

Below you will find some examples of common calibration methods for certain test tasks.

5.1 Calibration with Straight- and Angle-Beam Probes

Case A: With Known Material Velocity

Calibration process

1 Set the known material velocity in VEL function.

2 Couple the probe to the calibration block.

3 Set the required display range in RANGE. The calibration echo must be displayed on the

screen.

4 Position the gate on one of the calibration echoes until the sound path of the echo is indicated in

the measurement line.

5 After this, change the adjustment of the function P-DELAY until the correct sound path for the

selected calibration echo is indicated in the measurement line.

Example:

You are carrying out the calibration with a straight probe for the calibration range of 300 mm via the

function group BASE using the calibration block DB-P (thickness 225 mm) which is laid flat-wise.

Page 23

mvip@mitech-ndt.com

22

1 Select a new channel and clear that channel

(MEM→CHANNEL→FILE).

2 Set PROBE type to STRAIGHT.

3 Set RANGE TO 300 mm.

4 Set the known material velocity of 5920 m/s in VEL.

5 Set the gate so that it is positioned on the first

calibration echo (from 225 mm).

6 Read the sound path on the status line. If this value is

not equal to 225 mm, change the adjustment for the function

P-DELAY until it is at 225 mm.

7 Save the calibration result to current channel file.

225

This completes the calibration of the instrument to the material velocity of 5920 m/s with a calibration

range of 300 mm for the straight-beam probe used.

Case B: With Unknown Material Velocity

Use the semiautomatic calibration function of the instrument via the function group CAL for this

calibration case.

The distances between two calibration echoes must be entered. The instrument will then carry out a

plausibility check, calculate the material velocity and the probe delay, and automatically set the

parameters using the calculation result.

Calibration Process

1 Set the required display range in RANGE. The two calibration echoes selected must be

displayed on the screen. Set the range so that the second calibration echo is located on the right edge of

the screen.

2 Select the function group PDELAY(CAL→PDELAY).

3 Enter the distances of the two calibration echoes in S-REF1 and S-REF2.

4 Position one gate on the first calibration echo.

5 Position the other gate on the second calibration echo.

6 Press key when CAL is selected to trigger the calibration.

The calibration is confirmed by the message “Calibration is finished”. The instrument will now

automatically determine the sound velocity and the probe delay and set the corresponding functions

accordingly. The value of the function P-DELAY will be set to the correct value.

If the instrument is not able to carry out any valid calibration on the basis of the input values and the

echoes recorded, a corresponding error message is displayed. In that case, please check the values of

your calibration lines and repeat the process of recording the calibration echoes.

Example:

You are carrying out the calibration with a straight probe for the calibration range of 300 mm

1 Select a new channel and clear that

channel (MEM→CHANNEL→FILE).

2 Set PROBE type to STRAIGHT.

3 Enter the distances (thicknesses) of

the two calibration lines S-REF1 (225 mm) and

S-REF2 (450 mm).

4 Position one gate on the first

calibration echo.

5 Position the other gate on the second

calibration echo.

Page 24

mvip@mitech-ndt.com

23

6 Press key when CAL is selected

to carry out the calibration. The valid calibration

is briefly confirmed and carried out.

7 Save the calibration result to current

channel file.

5.2 Calibration with Dual-Element (TR) Probes

Dual-element (TR) probes are especially used for wall thickness measurement. The following

peculiarities must be taken into account when using these probes:

Echo Flank. Most dual-element (TR) probes have a roof angle (transducer elements with inclined

orientation toward the test surface). This causes mode conversions both at beam index (sound entry into

the material) and at the reflection from the backwall, which can result in very jagged echoes.

V-Path Error .Dual-element (TR) probes produce a v-shaped sound path from the pulse via the

reflection from the backwall to the receiver element. This so-called “V-path error” affects the measuring

accuracy. You should therefore choose two wall thicknesses that cover the expected thickness

measurement range for the calibration. In this way, the V-path error can be corrected to the greatest

possible extend.

Higher Material Velocity Due to the V-path error, a higher material velocity than that of the test material

is given during calibration, especially with small thicknesses. This is typical of dual-element (TR) probes

and serves for compensation of V-path error.

With small wall thicknesses, the above-described effect leads to an echo amplitude drop which has to be

especially taken into account with thicknesses less than 2 mm.

A stepped reference block having different wall thicknesses is required for calibration. The wall

thicknesses must be selected so that they cover the expected readings.

Calibration Process

We recommend to use the semiautomatic calibration function for the calibration with T/R probes.

1 Set the required test RANGE

2 Increase the probe delay until the two calibration echoes selected are displayed within the

range

3 Set the pulse and receiver functions according to the probe used and the test application.

4 Select the function group PDELAY.

5 Enter the distances of the two calibration echoes in S-REF1 and S-REF2.

6 Position one gate on the first calibration echo.

7 Position the other gate on the second calibration echo.

8 Press key when CAL is selected to trigger the calibration.

The correct calibration is confirmed by the message “Calibration is finished”. The instrument will now

automatically determine the sound velocity and the probe delay and set the corresponding functions

accordingly. The value of the function P-DELAY will be set to the correct value.

If necessary, check the calibration on one or several known calibration lines, e.g. using the stepped

reference block.

5.3 Distance Amplitude Curve

The instrument is available with Distance Amplitude Curve (DAC) function. Functions for the

distance-amplitude curve are accessed through the DAC Menu, which is located by pressing

D

A

C

A

V

G

.

Page 25

mvip@mitech-ndt.com

24

When displayed, the DAC curve visually represents a line of constant reflector peaks over a range of

material depths. A new feature of the instrument is a multiple-curve option that displays three dB offset

DAC curves simultaneously. Each curve represents constant reflector size at varying material depth.

Remember that in DAC mode, the only deviation from traditional display and operation is the

appearance of the DAC curve. All A-Scan echoes are displayed at their non-compensated height.

A DAC curve is programmed using a series of same-reflector echoes at various depths covering the

range of depths to be inspected in the test material. Because near field and beam spread vary according

to transducer size and frequency, and materials vary in attenuation and velocity, DAC must be

programmed differently for different applications. A DAC curve can be based on up to 16 data points

(material depths).These points are recorded from the DAC menu as described below.

Recording the DAC Curve

DAC Curve points are typically taken from a standard with equally sized reflectors (holes) located at

various material depths. The primary echo from each of these points (for up to a total of 16 echoes) are

recorded. When DAC is active, the instrument displays a curve that represents echo peaks for constant

reflectors at varying material depth.

Before starting to record a reference curve, the instrument must be correctly calibrated. To program the

DAC Curve:

1 Access the DAC menu by pressing

D

A

C

A

V

G

, then select the DAC submenu by pressing the menu key

below it.

2 Press and to select the PROGRAM item. Press the key or turn the knob to

Trigger the DAC program. When DAC program is triggered, “DAC” and a digit number indicating the

point index appears on the top right corner of the display.

3 Couple the probe to the first reference point and adjust the gate so that it is broken by the

primary echo. If necessary, adjust the gain so that the echo crosses the gate and the highest peak in the

gate is at approximately 80% of full-screen height. The highest peak must not be higher than 100%

full-screen height. Note that you can press or to search the next echo very quickly.

4 While the gate is lined up over the first reference echo, Press and to select the

RECORD function press the key to record the first DAC Curve point. Note that the largest echo to

cross the A-Gate will be treated as the reference echo. The gain value at which this point is recorded

becomes the “baseline” gain value.

5 Continue to record additional curve points up to a maximum of 16 points (note that at least one

DAC Curve points are required). As soon as you have recorded at least one curve reference points, your

DAC is already active.

6 When complete press and to select the FINISH and press key, then follow

the on-screen prompts to exit the DAC program.

Note that you can change the DAC curve line type between CURVE and DIRECT.

The stored DAC curve points can be edited as described in next section.

Editing DAC Curve

After reference points are recorded, their values may be manually adjusted, or some points may be

manually deleted. To edit or delete points:

1 With the DAC menu accessed, select EDIT submenu.

2 Select EDIT function. Continue to press key or turn the knob to start the EDIT process.

When DAC EDIT process is triggered, “DAC” and a digit number appear indicating the point index on the

top right corner of the display.

3 Press or to select the point to edit.

4 To adjust a point’s height-Select ADJUST function. Turn the knob clockwise or anticlockwise to

adjust the point’s echo height.

5 To delete a point – Select DELETE function. Continue to press key or turn the knob to

delete that point from the DAC records.

Page 26

mvip@mitech-ndt.com

25

6 When complete select FINISH and press key and follow the on-screen prompts to finish

the editing.

Creating DAC Offset Curves

When operating with DAC turned on, three DAC curves including RL, SL and EL are typically displayed.

The three curves can be offset from the original DAC curve (ML) by a user-inputted amount.

1 Select the function DAC-RL (or

DAC-SL, DAC-EL) located in the OFFSET

submenu.

2 Change the offset value by means of

the knob.

The offset range from -50dB to 50dB.

Specifying the DAC Reference Curve

Once the DAC curve is recorded and displayed (if not displayed, switch on by turning DAC DISP on),

echoes are automatically compared to the size reference curve, which can be specified in the SIZE REF

selection. The options include RL, SL, EL, and ML.

The dB equivalent height of the signal above or below the corresponding DAC Reference Curve

amplitude is displayed as a comparison result.

The comparison result is shown as right

figure.

Note that the result is like: RL-1.2. It means

that the peak echo height inside selected

gate is -1.2 dB offset to the DAC-RL line.

Deleting a DAC Curve

To delete a stored DAC curve

1 With the DAC menu activated, select the DEL submenu.

2 Select the DEL DAC function.

3 Press key or turn the knob. Then confirm your operation.

Turning On/Off the DAC display

Turning DAC DISP On and Off causes the DAC curves to be displayed or removed.

1 With the DAC menu activated, select the DISPLAY submenu.

2 Select the DISP DAC function.

3 Press key or turn the knob to turn On/Off the DAC display.

Note that if the DAC curve is not created, it will prompt out “No DAC curve found” and DAC DISP will be

set to OFF.

Page 27

mvip@mitech-ndt.com

26

Echo Evaluation with DAC

In order to be able to evaluate a flaw indication by means of the DAC, certain conditions must be met.

The DAC curve must already be recorded.

It only applies to the same probe that was used when recording the curve. Not even another probe

of the same type must be used.

The DAC only apply to the material corresponding to the material of the reference block.

All functions affecting the echo amplitude must be set the same way as they were when the curve

was recorded.

5.4 Measuring with DGS/AVG

Using the AVG (the same as DGS) function, you can compare the reflecting power of a natural flaw in the

test object with that of a theoretical flaw (circular disk-shaped equivalent reflector) at the same depth.

Note: You are comparing the reflecting power of a natural flaw with that of a theoretical flaw. No definite

conclusions may be drawn on the natural flaw (roughness, inclined position, etc.).

The so-called AVG diagram forms the basis for this comparison of the reflecting power. This diagram

consists of a set of curves showing the correlation of three influencing variables:

Distance between the probe and circular disk-shaped equivalent reflector

Difference in gain between various large circular disk-shaped equivalent reflectors and an infinitely

large backwall

Size of the circular disk-shaped equivalent reflector. The influencing variable always remains

constant for one curve of the set of curves.

The advantage of the AVG method lies in the fact that you can carry out reproducible evaluations of

small discontinuities. The reproducibility is most of all important, for example, whenever you aim to carry

out an acceptance test.

Apart from the influencing variables already mentioned, there are other factors determining the curve

shape: sound attenuation, transfer losses, amplitude correction value, probe and etc.

The following probe parameters affect the curve shape:

Element or crystal diameter

Frequency

Delay length

Delay velocity

You can adjust these parameters on the instrument in such a way that you can use the AVG method with

many different probes and on different materials.

Note: Before setting the AVG function, the instrument must first be calibrated because all functions

affecting the AVG evaluation mode (VEL, P-DELAY, DAMPING, ENERGY, P-WIDTH, FREQ, DIAMETER,

RECTIFY) can no longer be changed after the reference echo has been recorded.

Settings for the AVG measurement

Before using the AVG feature to evaluate reflectors in test pieces, the characteristics of the attached

probe must be specified, certain characteristics of the reference standard must be input, and a reference

echo must be stored. You must select the REF submenu (AVG→REF) and input the characteristics for

the probe you’ve connected including:

FREQ- The probe’s frequency rating

DIAMETER – The probe element’s effective diameter rating

Record the Reference Echo that Defines the AVG Curve

Prior to generating the AVG curve, a test standard with a known reflector must be used to define a

reference point. Acceptable test standards include these reference types:

BW – Backwall echo with reference defect size defined as infinity

SDH – Side Drilled Hole with a reference defect size defined as the hole’s diameter.

FBH – Flat Bottom Hole with a reference defect size equal to the hole’s facial diameter.

Follow these steps to record a reference echo:

1 Select the PARA submenu, then the REF TYPE function. This function allows you to select one

of the three reference types described above.

2 Select the REF SIZE function, and specify the size of the known standard’s reference flaw.

Page 28

mvip@mitech-ndt.com

27

3 Select the AVG submenu, then the PROGRAM function. Turn the knob to start the AVG

program. When AVG program is triggered, “AVG” appears indicating the point index on the top right

corner of the display.

4 Couple the probe to the known standard, capture the reference flaw so that its reflected echo is

displayed on the instrument’s A-Scan, and adjust selected Gate’s starting point to ensure that the

resulting echo triggers the gate.

5 Adjust the gain until the reference flaw’s A-Scan peak measures 80% of FSH (Full Screen

Height).

6 With the probe coupled to the standard, and the reference flaw’s echo captured by selected

Gate, press key to record an AVG reference echo.

7 After the AVG reference echo is recorded, its value may be manually adjusted using the

ADJUST function.

8 When complete press key after FINISH is selected and follow the on-screen prompts to

exit the AVG program.

Note that only one AVG reference echo can be stored at a time. To delete the currently stored reference

1 Access the DEL submenu

2 Select DEL AVG, and then follow the on-screen prompts.

Once a reference echo has been recorded, the AVG curves (the AVG-UL, the AVG-ML and the AVG-DL)

are automatically displayed using default settings.

Creating AVG Offset Curves