Page 1

STDF-3

Page 2

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Part names and their functions ............................................................................................................ 1-1-2

1-1-3 Machine cross section .......................................................................................................................... 1-1-3

1-1-4 Drive system ........................................................................................................................................ 1-1-4

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

1-3 Troubleshooting

1-3-1 Original misfeed detection .................................................................................................................... 1-3-1

(1) Original misfeed indication ............................................................................................................ 1-3-1

(2) Original misfeed detection condition ............................................................................................. 1-3-2

(3) Original misfeeds .......................................................................................................................... 1-3-3

(1) An original jams when the main switch is turned on. ............................................................. 1-3-3

(2) An original jams during continuous copying of multiple originals. ......................................... 1-3-3

(3) An original jams in the DF during copying (no original feed). ................................................ 1-3-3

(4) An original jams in the DF during copying (an original jam in the original feed

and conveying sections). ....................................................................................................... 1-3-3

(5) Original jams frequently. ........................................................................................................ 1-3-3

1-3-2 Image formation problems ................................................................................................................... 1-3-4

(1) There is a regular error between the centers of the original and copy image

when the DF is used. .................................................................................................................... 1-3-5

(2) There is a regular error between the leading edges of the original and copy image

when the DF is used. .................................................................................................................... 1-3-5

1-3-3 Electrical problems ............................................................................................................................... 1-3-6

(1) The original feed motor does not operate. .................................................................................... 1-3-6

(2) The original conveying motor does not operate. ........................................................................... 1-3-6

(3) The copier scans the contact glass when originals are loaded on the DF. ................................... 1-3-6

(4) An original jams when the main switch is turned on. .................................................................... 1-3-6

1-3-4 Mechanical problems ........................................................................................................................... 1-3-7

(1) No primary original feed. ............................................................................................................... 1-3-7

(2) No secondary original feed. .......................................................................................................... 1-3-7

(3) Originals jam. ................................................................................................................................ 1-3-7

3A7

1-4 Assembly and Disassembly

1-4-1 Precautions for assembly and disassembly ......................................................................................... 1-4-1

(1) Precautions ................................................................................................................................... 1-4-1

1-4-2 Procedure for assembly and disassembly ........................................................................................... 1-4-2

(1) Detaching and refitting the DF forwarding pulley and DF original feed pulley .............................. 1-4-2

(2) Detaching and refitting the DF separation pulley .......................................................................... 1-4-3

(3) Adjusting the lateral squareness of the DF ................................................................................... 1-4-4

(4) Adjusting the DF magnification ..................................................................................................... 1-4-5

(5) Adjusting the DF center line .......................................................................................................... 1-4-7

(6) Adjusting the scanning start position when the DF is used ........................................................... 1-4-9

(6-1) Adjusting the DF leading edge registration .......................................................................... 1-4-9

(6-2) Adjusting the DF trailing edge registration ......................................................................... 1-4-11

(7) Adjusting the margins for scanning the original from the DF ...................................................... 1-4-13

2-1 Mechanical construction

2-1-1 Mechanical construction ....................................................................................................................... 2-1-1

(1) Original feed mechanism .............................................................................................................. 2-1-1

(2) Original feed timing ....................................................................................................................... 2-1-3

1-1-1

2-2 Electrical Parts Layout

2-2-2 Electrical parts layout ........................................................................................................................... 2-2-1

Page 3

3A7

2-3 Operation of the PCBs

2-3-1 DF driver PCB ...................................................................................................................................... 2-3-1

2-3-2 Original size detection PCB ................................................................................................................. 2-3-4

2-4 Appendixes

Timing chart No. 1 .......................................................................................................................................... 2-4-1

Timing chart No. 2 .......................................................................................................................................... 2-4-2

Periodic maintenance procedures .................................................................................................................. 2-4-3

Wiring diagram ............................................................................................................................................... 2-4-4

1-1-2

Page 4

1-1-1 Specifications

3A7

Original feed system ...................... Automatic feed

Originals ......................................... Sheets

Original weights.............................. 35 – 160 g/m

2

Original sizes .................................. A3 – A5R, folio/11" × 17" – 51/2" × 81/2"

Number of originals ........................ Up to 70 sheets (A4 or smaller paper of 80 g/m

2

75 g/m

)

Up to 50 sheets (B4, folio or larger paper of 80 g/m

2

75 g/m

)

Up to 30 sheets in the auto selection mode

Thermal and art paper must be fed individually.

Power source ................................. Electrically connected to the copier

Machine dimensions ...................... 553 (W) × 478 (D) × 121 (H) mm

3

/4" (W) × 1813/16" (D) × 43/4" (H)

21

Weight ............................................Approx. 6.9 kg/15.18 lbs

2

, or 11" × 81/2" or smaller paper of

2

, or 81/2" × 14" or larger paper of

1-1

1-1-1

Page 5

3A7

4

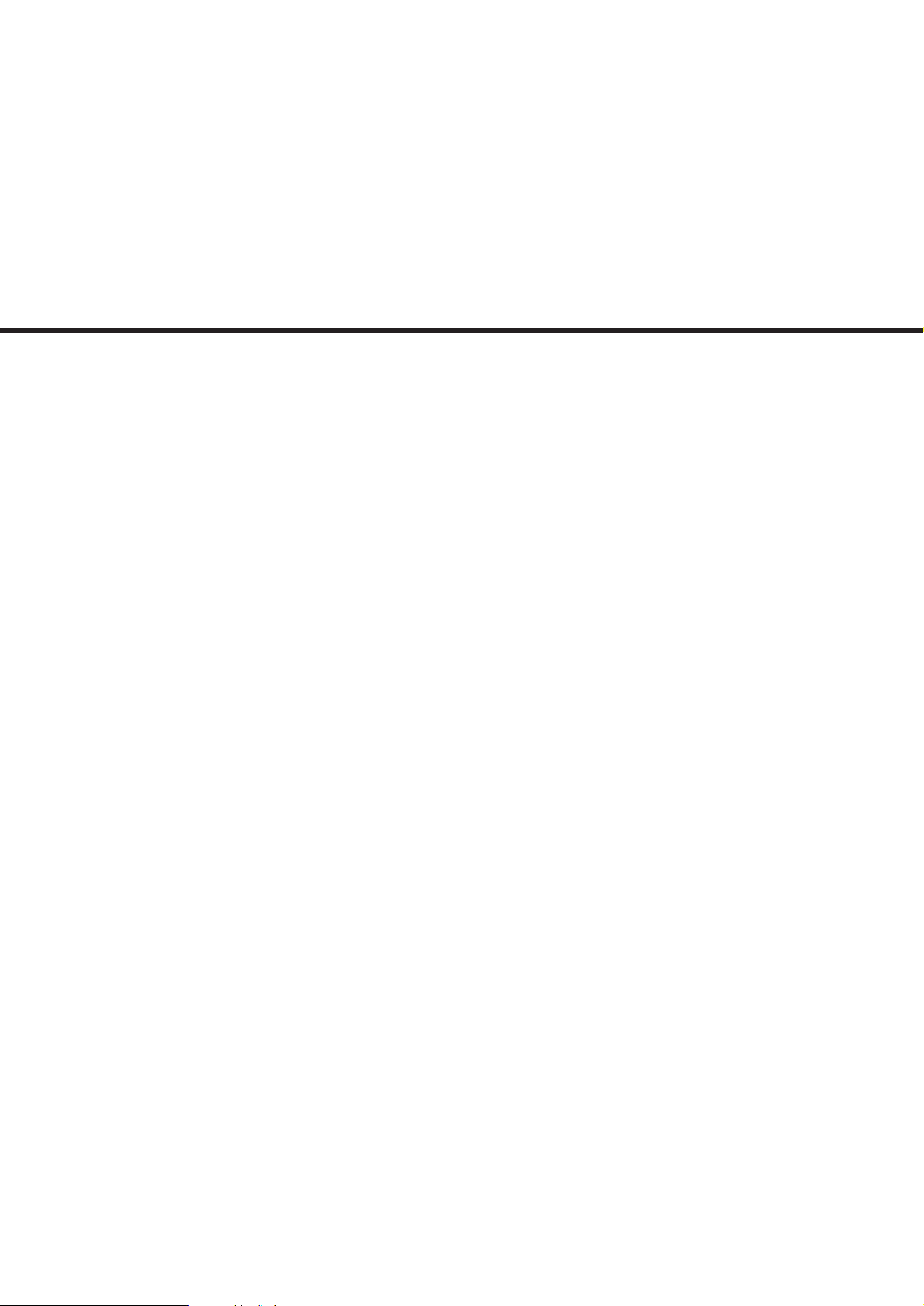

1-1-2 Part names and their functions

1-1

5

3

Figure 1-1-1

1 Original table

2 Original insertion guides

3 DF open/close handle

4 Original eject cover

5 DF original cover

2

1

1-1-2

Page 6

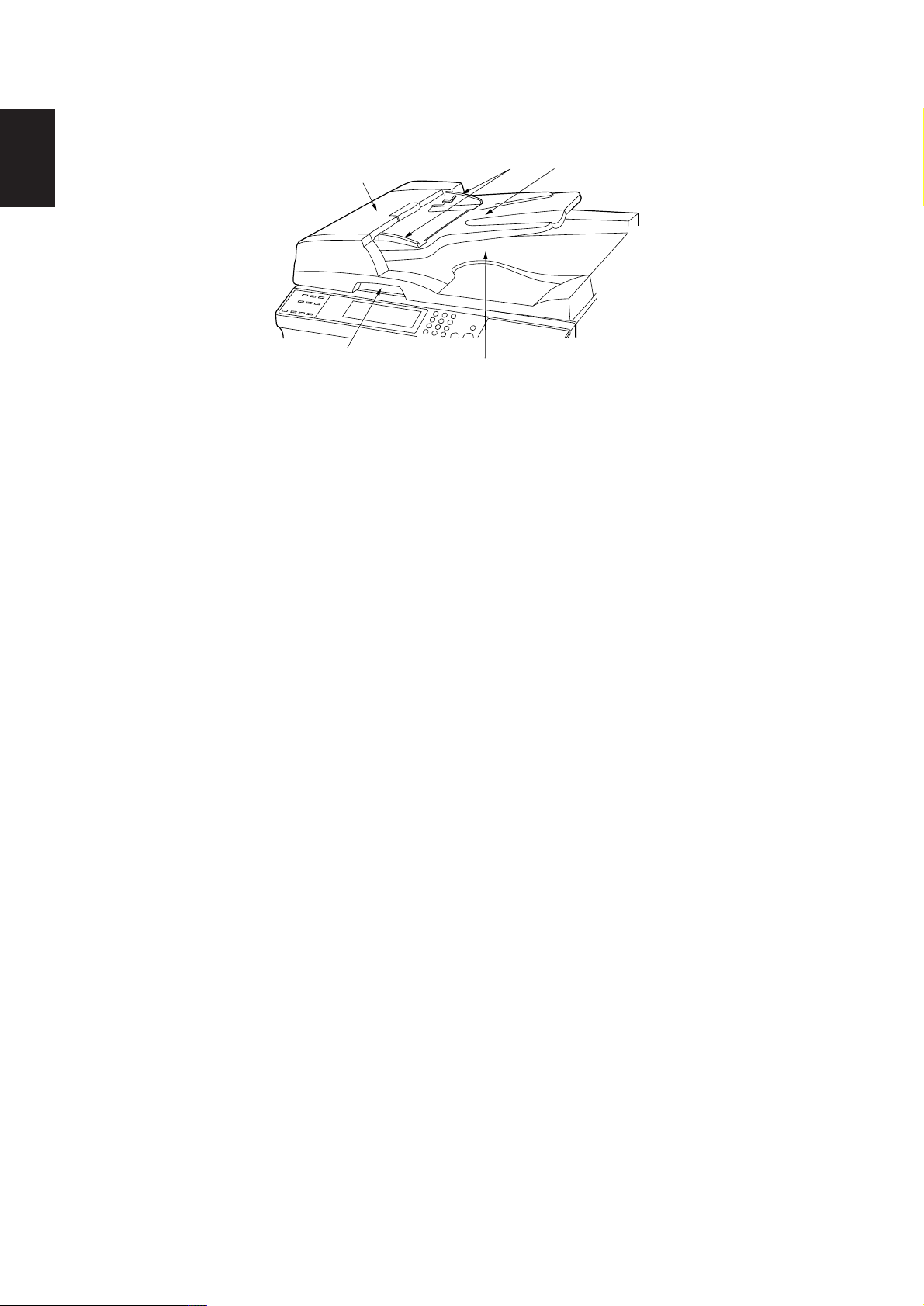

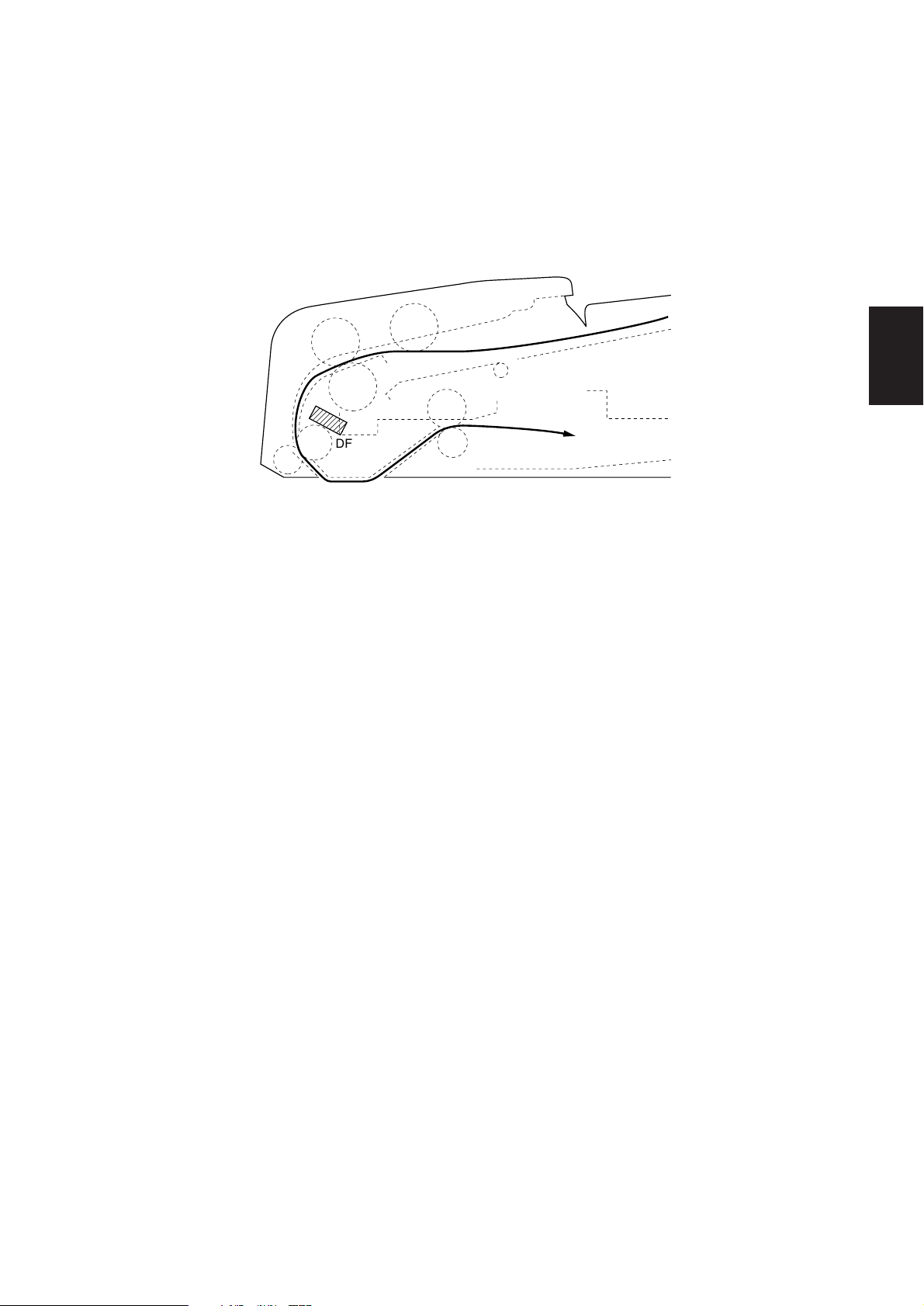

1-1-3 Machine cross section

3A7

1-1

Original path

Figure 1-1-2 Machine cross section

1-1-3

Page 7

3A7

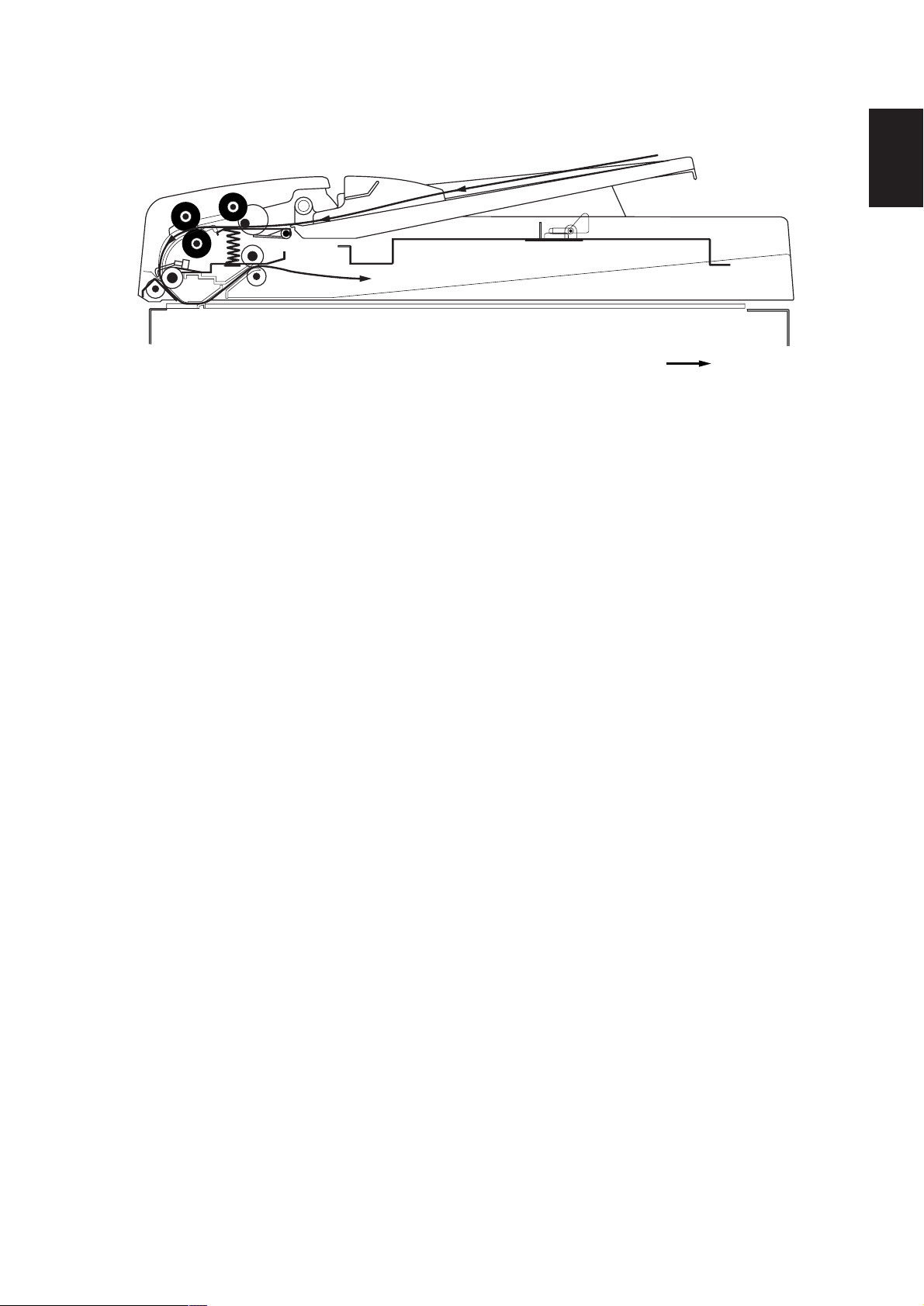

1-1-4 Drive system

1-1

@

!

5

6

7

2

0

9

4

#

$

1 Original feed motor gear

2 Gear 42/29

3 Lift gear 38

4 Idle gear 20

5 Original feed gear 30

6 Original feed pulley

7 Forwarding belt

8 Forwarding pulley 20

9 Original conveying motor gear

^

8

3

1

&

%

Figure 1-1-3

0 Idle gear Z45/B16

! Original conveying belt 92

@ Tension pulley

# Registration pulley 19

$ Original conveying pulley 24

% Original conveying belt 190

^ Tension pulley

& Original conveying pulley 24

1-1-4

Page 8

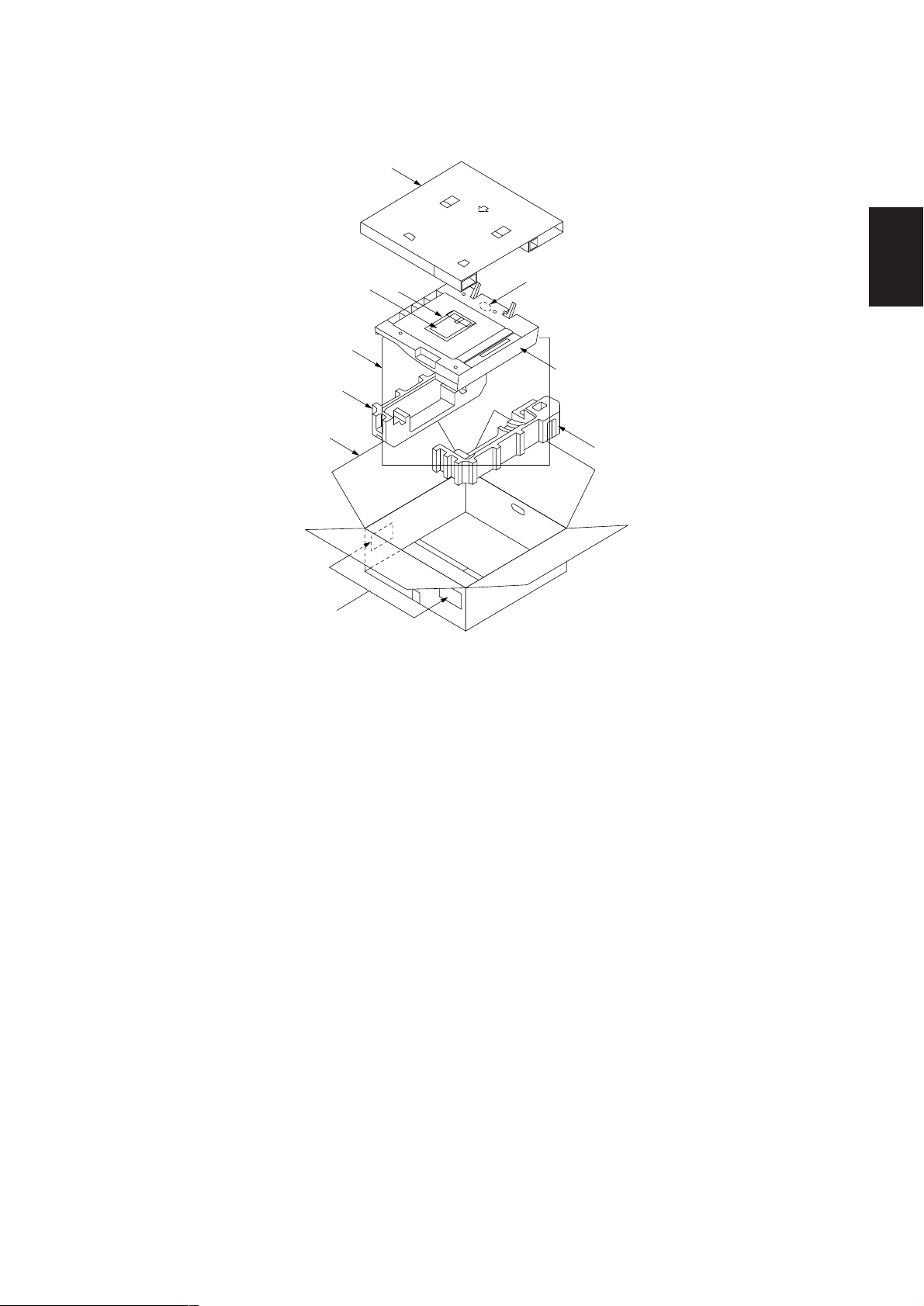

1-2-1 Unpacking

6

4

7

2

5

3

3A7

1-2

9

1

4

8

Figure 1-2-1 Unpacking

1 Sheet through DF

2 Installation manual

3 Plastic bag

4 Bottom pads

5 Upper pad

6 Outer case

7 Plastic sheet

8 Bar-code labels

9 Plastic bag

1-2-1

Page 9

3A7

1-3-1 Original misfeed detection

(1) Original misfeed indication

When an original jams, the machine immediately stops operation and the occurrence of an original jam is indicated on the

copier operation panel.

To remove the jammed original, open the DF or the DF original cover.

To reset the original misfeed detection, open and close the DF or the DF original cover to turn DF safety switch 1 or 2 off and

on.

DFTSW

Figure 1-3-1 Original misfeed detection

1-3

1-3-1

Page 10

3A7

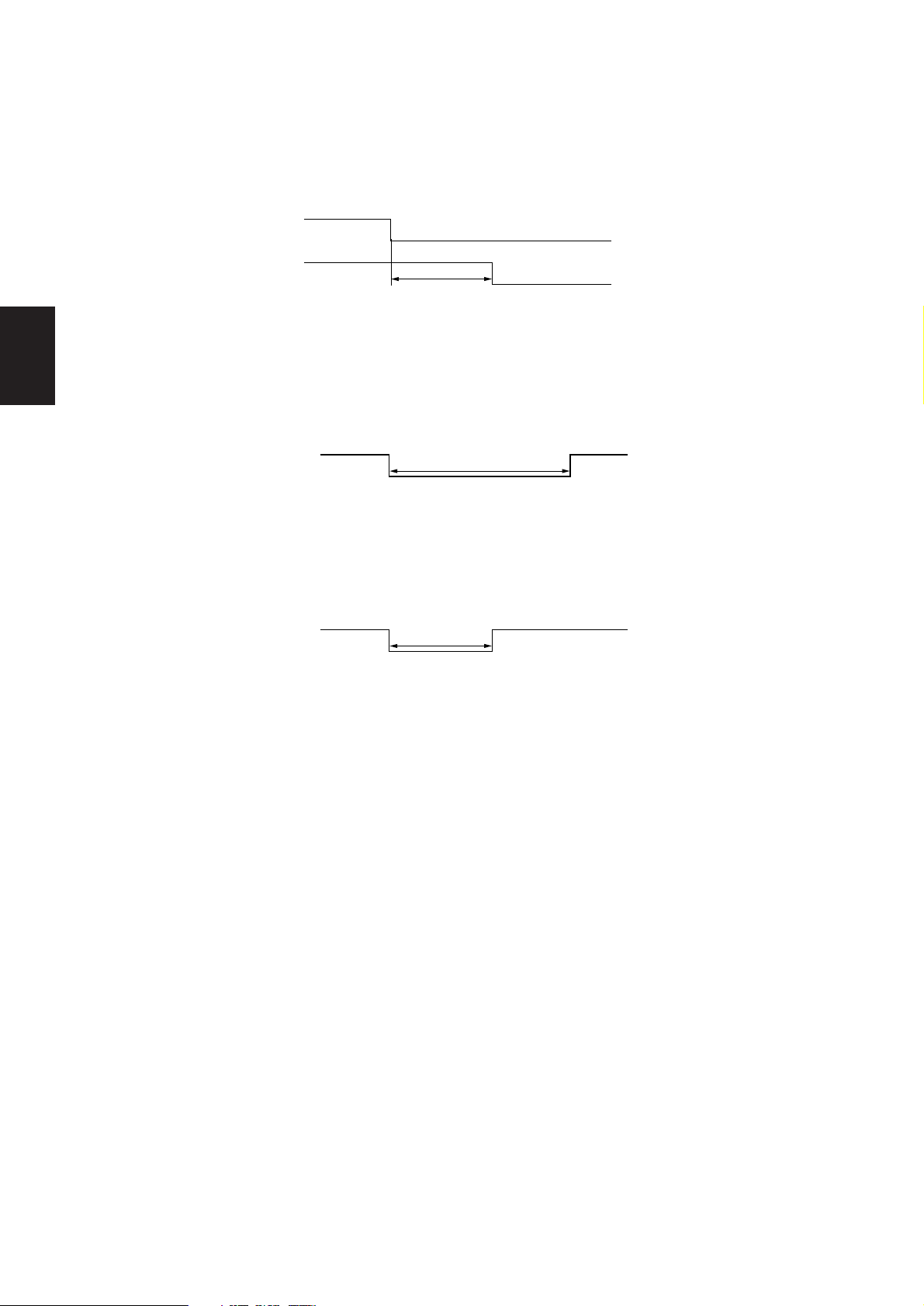

(2) Original misfeed detection condition

• No original feed (jam code 70)

During the primary feed of the second or later original, the DF timing switch (DFTSW) does not turn on within 1410 original

feed motor (OFM) pulses of the start of forward rotation of the original feed motor (OFM). After up to five retries, the DF

timing switch (DFTSW) still fails to turn on.

1-3

OFM

DFTSW

1410 P*

* Burst of OFM pulses

Off

On (Fwd.)

Off

On

Timing chart 1-3-1

• An original jam in the original feed and conveying sections (jam code 73)

During the secondary original feed, the DF timing switch (DFTSW) does not turn off within 10200 original conveying motor

(OCM) pulses of the DF timing switch (DFTSW) turning on.

DFTSW

10200 P*

* Burst of OCM pulses

Off

On

Timing chart 1-3-2

During the secondary original feed, the DF timing switch (DFTSW) turns off within 1764 original conveying motor (OCM)

pulses of the DF timing switch (DFTSW) turning on.

DFTSW

1764 P*

* Burst of OCM pulses

Off

On

Timing chart 1-3-3

1-3-2

Page 11

(3) Original misfeeds

Problem Causes Check procedures/corrective measures

(1)

An original jams

when the main

switch is turned on.

A piece of paper torn from

an original is caught around

the actuator of the original

size detection PCB.

Defective original size

detection PCB.

Remove any found.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-3 on the DF driver PCB remains low when the actuator on

the machine front side of the original size detection PCB is turned

on and off. If it does, replace the original size detection PCB.

3A7

(2)

An original jams

during continuous

copying of multiple

originals.

(3)

An original jams in

the DF during

copying (no original

feed).

A piece of paper torn from

an original is caught around

the DF timing switch.

Defective DF timing switch.

Defective original size

detection PCB.

Check if the original feed

motor or original conveying

motor is malfunctioning.

Defective DF timing switch.

Check if the original feed

motor is malfunctioning.

Check if the DF forwarding

pulley, DF original feed

pulley or DF separation

pulley is deformed.

Remove any found.

1-3

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-1 on the DF driver PCB remains low when the DF timing

switch is turned on and off. If it does, replace the DF timing

switch.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-3 on the DF driver PCB remains low when the actuator on

the machine front side of the original size detection PCB is turned

on and off. If it does, replace the original size detection PCB.

Check and remedy.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-1 on the DF driver PCB remains high when the DF timing

switch is turned on and off. If it does, replace the DF timing

switch.

Check and remedy.

Check visually and replace the pulley if deformed (see pages

1-4-2 and 3).

(4)

An original jams in

the DF during

copying (an original

jam in the original

feed and conveying

sections).

(5)

Original jams

frequently.

Defective DF timing switch.

Check if the DF forwarding

pulley, DF original feed

pulley or DF separation

pulley is deformed.

Check if the upper or lower

DF registration roller is

deformed.

An original outside the

specifications is used.

The DF forwarding pulley,

DF original feed pulley or

DF separation pulley is

soiled with paper powder.

The DF original feed pulley

and DF separation pulley

do not contact correctly.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-1 on the DF driver PCB remains high or low when the DF

timing switch is turned on and off. If it does, replace the DF timing

switch.

Check visually and replace the pulley if deformed (see pages

1-4-2 and 3).

Check visually and replace the roller if deformed.

Use only originals conforming to the specifications.

Clean with isopropyl alcohol.

Remedy.

1-3-3

Page 12

3A7

1-3-2 Image formation problems

1-3

(1) There is a regular error

between the centers of

the original and copy

image when the DF is

used.

See page 1-3-5.

(2) There is a regular error

between the leading

edges of the original

and copy image when

the DF is used.

See page 1-3-5.

1-3-4

Page 13

3A7

(1) There is a regular error

between the centers of

the original and copy

image when the DF is

used.

Causes

1. Misadjusted DF center line.

(2) There is a regular error

between the leading

edges of the original

and copy image when

the DF is used.

Causes

1. Misadjusted DF center line.

Check procedures/corrective measures

Readjust the DF center line (see page 1-4-7).

Causes

1. Misadjusted DF original scanning start position.

1-3

Causes

1. Misadjusted DF original scanning start

position.

Check procedures/corrective measures

Readjust the DF original scanning start position (see page 1-4-9).

1-3-5

Page 14

3A7

1-3-3 Electrical problems

Problem Causes Check procedures/corrective measures

(1)

The original feed

motor does not

operate.

Broken original feed motor

coil.

The connector terminals of

the original feed motor

make poor contact.

Check for continuity across the coil. If none, replace the original

feed motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

1-3

(2)

The original

conveying motor

does not operate.

(3)

The copier scans the

contact glass when

originals are loaded

on the DF.

(4)

An original jams

when the main

switch is turned on.

Defective DF driver PCB.

Broken original conveying

motor coil.

The connector terminals of

the original conveying

motor make poor contact.

Defective DF driver PCB.

The connector terminals of

DF safety switch 1 make

poor contact.

Defective DF safety

switch 1.

Defective original size

detection PCB.

A piece of paper torn from

an original is caught around

the actuator of the original

size detection PCB.

Defective original size

detection PCB.

Check for continuity across the coil and connector terminals of

the original feed motor. If present, replace the DF driver PCB.

Check for continuity across the coil. If none, replace the original

conveying motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check for continuity across the coil and connector terminals of

the original conveying motor. If present, replace the DF driver

PCB.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check for continuity across the contacts of DF safety switch 1. If

none when the switch is on, replace DF safety switch 1.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-3 on the DF driver PCB remains high when the actuator on

the machine front side of the original size detection PCB is turned

on and off. If it does, replace the original size detection PCB.

Remove any found.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-3 on the DF driver PCB remains low when the actuator on

the machine front side of the original size detection PCB is turned

on and off. If it does, replace the original size detection PCB.

1-3-6

A piece of paper torn from

an original is caught around

the DF timing switch.

Defective DF timing switch.

Remove any found.

With 5 V DC present at CN5-8 on the DF driver PCB, check if

CN5-1 on the DF driver PCB remains low when the DF timing

switch is turned on and off. If it does, replace the DF timing

switch.

Page 15

1-3-4 Mechanical problems

Problem Causes/check procedures Corrective measures

(1)

No primary original feed.

The surfaces of the DF forwarding pulley, DF

original feed pulley or DF separation pulley

are soiled with paper powder.

3A7

Check and clean them with isopropyl

alcohol if they are soiled.

(2)

No secondary original

feed.

(3)

Originals jam.

Check if the DF forwarding pulley, DF original

feed pulley or DF separation pulley is

deformed.

Electrical problem with the original feed

motor.

The upper and lower DF registration rollers

do not contact each other correctly.

Electrical problem with the original conveying

motor.

Originals outside the specifications are used.

The surfaces of the DF forwarding pulley, DF

original feed pulley or DF separation pulley

are soiled with paper powder.

The DF original feed pulley and DF

separation pulley, or the upper and lower DF

eject roller do not contact each other

correctly.

Check visually and replace the deformed

pulley (see pages 1-4-2 and 3).

See page 1-3-6.

Remedy.

1-3

See page 1-3-6.

Use only originals conforming to the

specifications.

Check and clean them with isopropyl

alcohol if they are soiled.

Remedy.

1-3-7

Page 16

1-4-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the board.

• Do not touch any PCB containing ICs with bare hands or any object prone to static charge.

• Use the following testers when measuring voltages:

Hioki 3200

Sanwa MD-180C

Sanwa YX-360TR

Beckman TECH300

Beckman DM45

Beckman 330*

Beckman 3030*

Beckman DM850*

Fluke 8060A*

Arlec DMM1050

Arlec YF1030C

* Capable of measuring RMS values.

• Prepare the following as test originals:

1. NTC (new test chart)

2. NPTC (newspaper test chart)

3A7

1-4

1-4-1

Page 17

1-4

3A7

1-4-2 Procedure for assembly and disassembly

(1) Detaching and refitting the DF forwarding pulley and DF original feed pulley

Clean or replace the DF forwarding pulley and DF original feed pulley as follows.

Procedure

1. Open the DF original cover.

2. Remove the original feed pulley guide.

Original feed

pulley guide

Figure 1-4-1

• Detaching the DF forwarding pulley

3. Remove the stop ring at the machine front.

4. Pull the forwarding shaft out and remove

the DF forwarding pulley.

• Detaching the DF original feed pulley

5. Remove the stop ring at the machine front and

remove the bushing.

6. Pull the original feed shaft toward the machine

rear and shift the rear bushing toward the

machine rear.

7. Remove the DF original feed pulley.

8. Clean or replace the DF forwarding pulley and

DF original feed pulley.

9. Refit all the removed parts.

Stop ring

Stop ring

Bushing

DF forwarding pulley

Figure 1-4-2

DF original feed pulley

Original feed shaft

Forwarding shaft

Bushing

1-4-2

Figure 1-4-3

Page 18

(2) Detaching and refitting the DF separation pulley

Clean or replace the DF separation pulley as follows.

Procedure

1. Open the DF original cover.

2. Remove the screw securing the original feed

guide and then the guide.

3A7

Original feed guide

Figure 1-4-4

3. Remove the stop ring, pull the separation shaft

out and remove the DF separation pulley.

4. Clean or replace the DF separation pulley.

5. Refit all the removed parts.

Stop ring

Figure 1-4-5

1-4

DF separation

pulley

Separation shaft

1-4-3

Page 19

3A7

(3) Adjusting the lateral squareness of the DF

Perform the following adjustment if the leading edge or trailing edge of the copy image is laterally skewed (lateral

squareness not obtained).

Caution:

Before adjusting the lateral squareness of the DF, adjust the amount of slack in the paper at the registration roller and

scanner image lateral squareness at the copier first and check the lateral squareness of the copy image by copying using

the DF. If squareness is still not obtained, perform the following adjustment.

Procedure

Start

Place an original on the DF

and make a test copy.

1-4

Is the image correct?

Yes

End

No

Remove the three screws and DF

lower front cover. See Figure 1-4-7.

Loosen the two screws and adjust the

position of the original feed unit using

the center of the scale as the reference.

See Figure 1-4-7.

¥ For copy example 1, turn the

adjustment pin and move the original

feed unit toward the machine left (b).

¥ For copy example 2, turn the

adjustment pin and move the original

feed unit toward the machine right (e).

Tighten the two screws.

Refit the DF lower front cover.

Original Copy

example 1

Figure 1-4-6

Copy

example 2

1-4-4

Adjustment pin

DF lower

front cover

Screws

Original feed unit

Figure 1-4-7

Page 20

(4) Adjusting the DF magnification

Adjust magnification in the auxiliary scanning direction if magnification is incorrect when the DF is used.

3A7

U053

U034

U403

U402 U066

U070

U065

U071

(P. 1-4-9)

U404

(P. 1-4-13)

Caution:

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

Procedure

• 20 cpm copier

Enter maintenance mode.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Start

Auxiliary

scanning

direction

Enter “070” using

the numeric keys.

Press the start key.

Press the start key.

The new setting is stored.

Main scanning

direction

Original

Figure 1-4-8

Copy

example 1

Copy

example 2

1-4

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

No

Change the setting using the

cursor left/right keys.

• For copy example 1, increase

the value to make the copy

image longer.

• For copy example 2, decrease

the value to make the copy

image shorter.

Setting range: –25 to +25

Changing the value by 1 changes

the magnification by 0.1%.

Reference: 0

1-4-5

Page 21

3A7

• 15 cpm copier

Enter maintenance mode.

Start

Enter “070” using

the numeric keys.

Press the start key.

Auxiliary

scanning

direction

Main scanning

direction

Original

Figure 1-4-9

Copy

example 1

Copy

example 2

1-4

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

No

Press the start key.

The new setting is stored.

Change the setting using the

zoom +/– keys.

• For copy example 1, increase

the value to make the copy

image longer.

• For copy example 2, decrease

the value to make the copy

image shorter.

Setting range: –25 to +25

Changing the value by 1 changes

the magnification by 0.1%.

Reference: 0

1-4-6

Page 22

3A7

(5) Adjusting the DF center line

Perform the following adjustment if there is a regular error between the centers of the original and the copy image when the

DF is used.

U034

U402

U067 U072U403

U404

(P. 1-4-13)

Caution:

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

Procedure

• 20 cpm copier

Start

Enter maintenance mode.

Enter “072” using the numeric

keys and press the start key.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

Press the start key.

Change the setting using the

cursor left/right keys.

No

• For copy example 1, increase

the value.

• For copy example 2, decrease

the value.

Setting range: –39 to +39

Changing the value by 1 moves the center line

by 0.17 mm.

Reference: 0

Reference

Original Copy

The new setting

is stored.

example 1

Figure 1-4-10

Copy

example 2

1-4

End

1-4-7

Page 23

3A7

• 15 cpm copier

1-4

Start

Enter maintenance mode.

Enter “072” using the numeric

keys and press the start key.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

Reference

Original Copy

Press the start key.

The new setting

is stored.

Change the setting using the

zoom +/– keys.

No

• For copy example 1, increase

the value.

• For copy example 2, decrease

the value.

Setting range: –39 to +39

Changing the value by 1 moves the center line

by 0.17 mm.

Reference: 0

example 1

Figure 1-4-11

Copy

example 2

End

1-4-8

Page 24

3A7

(6) Adjusting the scanning start position when the DF is used

Perform the following adjustment if there is a regular error between the leading or trailing edges of the original and the copy

image.

U034

U402

U066 U071U403

U404

(P. 1-4-13)

Caution:

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

(6-1) Adjusting the DF leading edge registration

Procedure

• 20 cpm copier

Start

Enter maintenance mode.

Enter “071” using the numeric

keys and press the start key.

Original

Copy

example 1

Copy

example 2

Figure 1-4-12

Select “LEAD EDGE ADJ”

using the cursor up/down

keys.

Press the interrupt key.

Press the start key.

The new setting is stored.

1-4

Place an original on the

DF and make a test copy.

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

No

• For copy example 1,

increase the value using

the cursor right key.

• For copy example 2,

decrease the value using

the cursor left key.

Setting range: –32 to +32

Reference: 0

Changing the value by 1 moves

the copy image by 0.19 mm.

Increasing the value moves the copy

image backward, and decreasing it

moves the image forward.

1-4-9

Page 25

3A7

• 15 cpm copier

Enter maintenance mode.

Start

1-4

Enter “071” using the numeric

keys and press the start key.

Light the copy exposure indicator

exp. 1 using the copy exposure

adjustment keys.

Press the interrupt key.

Place an original on the

DF and make a test copy.

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

No

Original

Press the start key.

The new setting is stored.

• For copy example 1,

increase the value using

the zoom + key.

• For copy example 2,

decrease the value using

the zoom – key.

Setting range: –32 to +32

Reference: 0

Changing the value by 1 moves

the copy image by 0.19 mm.

Increasing the value moves the copy

image backward, and decreasing it

moves the image forward.

Copy

example 1

Figure 1-4-13

Copy

example 2

1-4-10

Page 26

(6-2) Adjusting the DF trailing edge registration

Perform the following adjustment if the original scanning end position is not correct.

Caution:

If the copies look like copy example 2, clean the DF original scanning section.

Procedure

• 20 cpm copier

Start

Enter maintenance mode.

Enter “071” using the numeric

keys and press the start key.

Select “TRAIL EDGE ADJ”

using the cursor up/down

keys.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Press the start key.

The new setting is stored.

Original Copy

example 1

Figure 1-4-14

3A7

Copy

example 2

1-4

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

• For copy example 1,

No

increase the value using

the cursor right key.

• For copy example 2,

decrease the value using

the cursor left key.

Setting range: –32 to +32

Reference: 0

Changing the value by 1 moves

the copy image by 0.19 mm.

Increasing the value moves the trailing

edge of the copy image backward,

and decreasing it moves the trailing

edge of the image forward.

1-4-11

Page 27

3A7

• 15 cpm copier

Enter maintenance mode.

Enter “071” using the numeric

keys and press the start key.

Light the copy exposure indicator

exp. 2 using the copy exposure

adjustment keys.

Start

Original Copy

example 1

Figure 1-4-15

Copy

example 2

1-4

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

Press the start key.

The new setting is stored.

• For copy example 1,

No

increase the value using

the zoom + key.

• For copy example 2,

decrease the value using

the zoom – key.

Setting range: –32 to +32

Reference: 0

Changing the value by 1 moves

the copy image by 0.19 mm.

Increasing the value moves the trailing

edge of the copy image backward,

and decreasing it moves the trailing

edge of the image forward.

1-4-12

Page 28

(7) Adjusting the margins for scanning the original from the DF

Perform the following adjustment if margins are not correct.

3A7

U402 U404

U403

Caution:

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

Procedure

• 20 cpm copier

Start

Enter maintenance mode.

Enter “404” using the numeric keys.

Press the start key.

Adjustment items

Select the item to be adjusted

using the cursor up/down keys.

Press the interrupt key.

A MGN: DF left margin

B MGN: DF leading edge margin

C MGN: DF right margin

D MGN: DF trailing edge margin

Press the start key.

The new setting is stored.

1-4

Yes

Place an original on the DF

and make a test copy.

Are the margins correct?

Yes

Proceed to another mode?

No

Press the stop/clear key.

Exit maintenance mode.

End

No

Change the setting.

• Increasing the value using the

cursor right key makes the

margin wider.

• Decreasing the value using the

cursor left key makes the

margin narrower.

Setting range (default)

DF left margin: 0.0 to 10.0 (2)

DF leading edge margin: 0.0 to 10.0 (3)

DF right margin: 0.0 to 10.0 (2)

DF trailing edge margin: 0.0 to 10.0 (2)

Changing the value by 1 moves

the margin by 0.5 mm for all.

Ejection direction

(reference)

DF left margin

+1.5

(2.5

mm)

–2.0

DF leading edge margin (3 ± 2.5 mm)

DF right margin

+1.5

mm)

(2.5

–2.0

DF trailing edge margin

(3 ± 2.5 mm)

Figure 1-4-16

1-4-13

Page 29

3A7

• 15 cpm copier

Enter maintenance mode.

Enter “404” using the numeric keys.

Select the item to be adjusted using

the copy exposure adjustment keys.

Start

Press the start key.

Adjustment items (copy exposure indicator)

Exp. 1: DF left margin

Exp. 2: DF leading edge margin

Exp. 3: DF right margin

Exp. 4: DF trailing edge margin

1-4

Yes

Press the interrupt key.

Place an original on the DF

and make a test copy.

Are the margins correct?

Yes

Proceed to another mode?

No

Press the stop/clear key.

Exit maintenance mode.

End

No

Press the start key.

The new setting is stored.

Change the setting.

• Increasing the value using the

zoom + key makes the margin

wider.

• Decreasing the value using the

zoom – key makes the margin

narrower.

Setting range (default)

DF left margin: 0.0 to 10.0 (2)

DF leading edge margin: 0.0 to 10.0 (3)

DF right margin: 0.0 to 10.0 (2)

DF trailing edge margin: 0.0 to 10.0 (2)

Changing the value by 1 moves

the margin by 0.5 mm for all.

Ejection direction

(reference)

DF left margin

+1.5

(2.5

mm)

–2.0

DF leading edge margin (3 ± 2.5 mm)

DF right margin

+1.5

mm)

(2.5

–2.0

1-4-14

DF trailing edge margin

(3 ± 2.5 mm)

Figure 1-4-17

Page 30

3A7

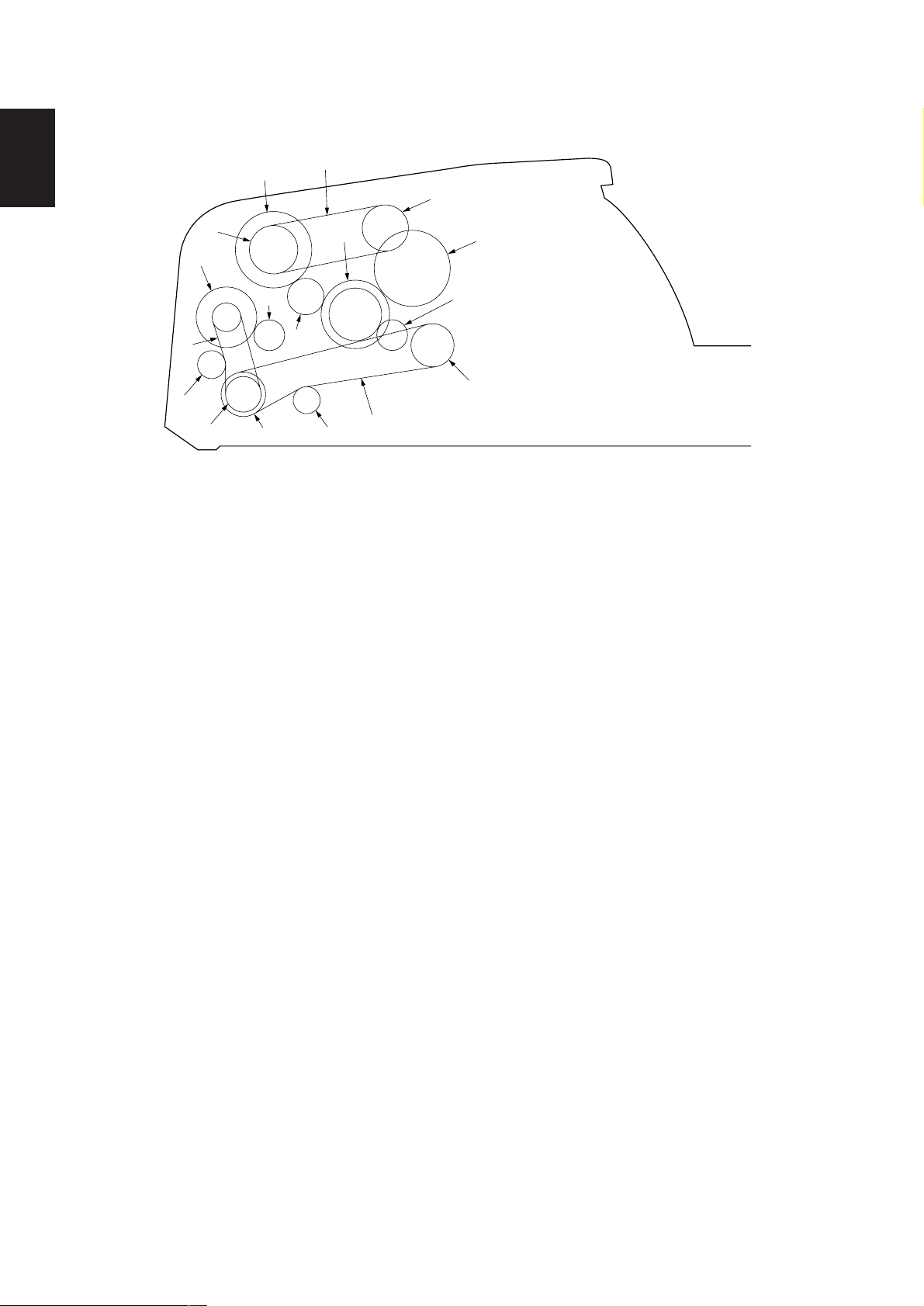

2-1-1 Mechanical construction

(1) Original feed mechanism

The DF consists of the components shown in Figure 2-1-1. It conveys the original across the DF contact glass in synchronization with the copier scanning operation.

During primary original feed, the original feed motor (OFM) turns on and the lift cam starts rotating, moving the lift guide up

until the originals make contact with the DF forwarding pulley. The DF forwarding pulley feeds the originals one by one and

the DF original feed pulley conveys the original further into the DF. During secondary original feed, the original conveying

motor (OCM) turns on and the DF upper registration roller and DF lower registration roller convey the original onto the DF

contact glass. The DF upper eject roller and DF lower eject roller then eject the original to the original eject cover.

178253

6

%

4

!

@

)^

Figure 2-1-1 Original feed mechanism

1 Original table

2 DF forwarding pulley

3 DF original feed pulley

4 DF separation pulley

5 Original feed pulley guide

6 Original feed guide

7 Lift guide

8 Lift cam

9 Lift lever

0 Lift spring

(

&

0

#

9

$

*

! DF upper registration roller

@ DF lower registration roller

# DF upper eject roller

$ DF lower eject roller

% Original conveying guide

^ Scanning guide

& Upper eject guide

* Lower eject guide

( DF timing switch (DFTSW)

) DF contact glass (copier)

2-1

2-1-1

Page 31

3A7

2-1

DFTSW

CN2-2

OCM OFM

OSDPCB

CN1-8

CN1-6

CN1-5

CN1-4

CN1-3

CN1-2

CN5-1

CN5-3

CN5-4

CN5-5

CN5-6

CN5-7

CN4A-3 –

DFDPCB

Figure 2-1-2 DF block diagram

CN4A-8

CN4B-1 –

CN4B-6

2-1-2

Page 32

(2) Original feed timing

DF start signal

DFTSW

3A7

Fwd. rotation

OFM

Rev. rotation

Fwd. rotation

OCM

Rev. rotation

300 P

192 P

1

1

192 P

3606/3329 P2*

1260/1129 P2*

450 P

1

1

2300 P

2

ABC D FE

1

Original: A4R/11" × 8

1

: Burst of OFM pulses

P

2

: Burst of OCM pulses

P

* Metric/inch

Timing chart 2-1-1

A When the DF start signal turns on, the original feed motor (OFM) starts rotating forward, driving the DF forwarding

pulley and DF paper feed pulley to start primary original feed.

B 300 OFM pulses after the leading edge of the original turns the DF timing switch (DFTSW) on, the original feed motor

(OFM) turns off to complete the primary original feed.

C The original conveying motor (OCM) starts rotating forward, driving the DF upper registration roller and DF upper

eject roller to start secondary original feed.

D 1260/1129 OCM pulses after the original conveying motor (OCM) turns on, the original feed motor (OFM) rotates

forward for 192 pulses.

E 3606/3329 OCM pulses after the original conveying motor (OCM) turns on, the original feed motor (OFM) rotates in

reverse direction for 192 pulses.

F 2300 OCM pulses after the trailing edge of the original turns the DF timing switch (DFTSW) off, the original conveying

motor (OCM) turns off to complete the secondary original feed. At the same time, the original feed motor (OFM) starts

rotating in reverse direction for 450 pulses.

/2"

2-1

2-1-3

Page 33

2-2-2 Electrical parts layout

3A7

8

6

4

2

7

Machine front Machine inside

5

1 3

Machine rear

Figure 2-2-1

1. DF driver PCB (DFDPCB) ........................... Controls electrical components.

2. DF safety switch 1 (DFSSW1) ..................... Breaks the safety circuit when the DF original cover is opened; resets

original jam detection.

3. DF safety switch 2 (DFSSW2) ..................... Breaks the safety circuit when the DF is opened; resets original jam

detection.

4. Original size detection PCB (OSDPCB) ...... Detects the presence and width of the original.

5. Original size length switch (OSLSW) ........... Detects the length of the original.

6. DF timing switch (DFTSW) .......................... Detects the original scanning timing.

7. Original feed motor (OFM) ........................... Drives the original feed section.

8. Original conveying motor (OCM) ................. Drives the original conveying section.

2-2

2-2-1

Page 34

2-3-1 DF driver PCB

Copier

DF driver PCB

IC

Motor

driver IC

Motor

driver IC

24 V DC

24 V DC

24 V DC

OCM A

OCM B

OCM A

OCM B

24 V DC

OFM A

OFM B

OFM A

OFM B

3A7

OCM

OFM

Switches

Figure 2-3-1 DF driver PCB block diagram

The DF driver PCB (DFDPCB) consists mainly of the motor driver ICs. It drives the original feed motor (OFM) and original

conveying motor (OCM) with control signals from the copier. It also relays 5 V DC supply and signals to each switch.

2-3

2-3-1

Page 35

3A7

CN5

+

CN2

C1

IC1

222

121

+

C2

IC2

121

CN6

13

L1

L2

L3

L4

L5

L6

L7

L8

B1

B8

C3

C4

A8

CN4

L9

L10

CN3

21

CN1

91

10 2

A1

+

+

Figure 2-3-2 DF driver PCB silk-screen diagram

2-3

2-3-2

Page 36

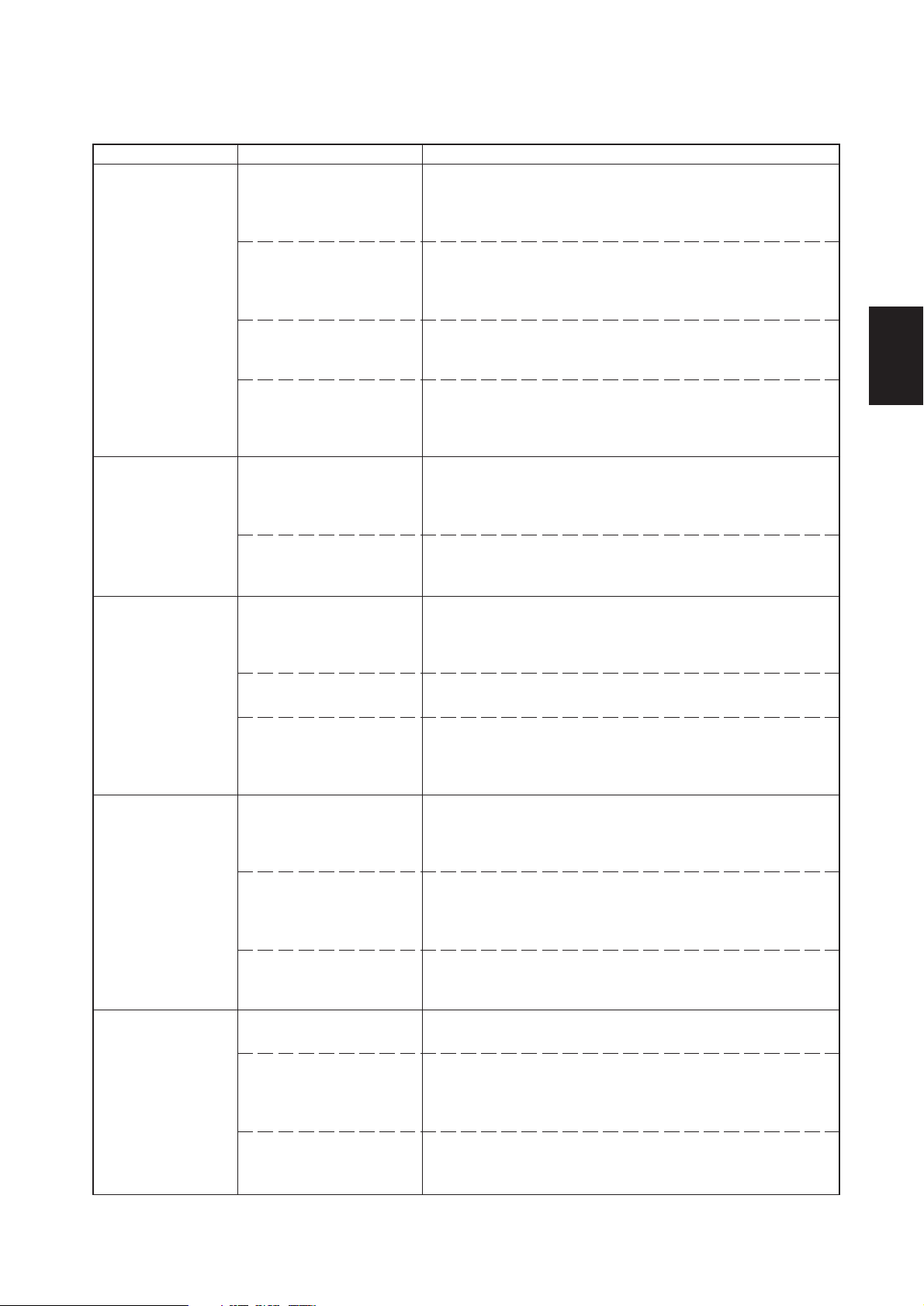

Terminals (CN) Voltage Remarks

1-1 1-3, 4 24 V DC 24 V DC supply, input

1-2 1-3, 4 24 V DC 24 V DC supply, input

1-7 1-9, 10 5 V DC 5 V DC supply, input

1-8 1-9, 10 5 V DC 5 V DC supply, input

2-1 1-3, 4 24/0 V DC DFSSW2 off/on, output

2-2 1-9, 10 5/0 V DC DFSSW1 off/on, output

2-4 1-9, 10 0/5 V DC OFM ENABLE signal, input

2-5 1-9, 10 0/5 V DC OFM energization mode signal, input (OFM RET)

2-6 1-9, 10 0/5 V DC (pulse) OFM drive clock pulse, input

2-7 1-9, 10 0/5 V DC OFM rotational direction switching signal, input

2-8 1-9, 10 0/5 V DC OCM ENABLE signal, input

2-9 1-9, 10 0/5 V DC OCM energization mode signal, input (OCM M1)

2-10 1-9, 10 0/5 V DC (pulse) OCM drive clock pulse, input

2-11 1-9, 10 0/5 V DC OCM rotational direction switching signal, input

2-12 1-9, 10 OCM current control voltage, input

2-16 1-9, 10 0/5 V DC OSLSW original size detection (length) signal, output

2-17 1-9, 10 0/5 V DC OSDPCB original size detection (width) signal, output (B)

2-18 1-9, 10 0/5 V DC OSDPCB original size detection (width) signal, output (C)

2-19 1-9, 10 0/5 V DC OSDPCB original size detection (width) signal, output (D)

2-20 1-9, 10 0/5 V DC OSDPCB original size detection (width) signal, output (E)

2-21 1-9, 10 0/5 V DC OSDPCB original present/not present detection signal, output

2-22 1-9, 10 0/5 V DC DFTSW on/off, output

3-1 3-2 24/0 V DC DFSSW2 off/on, input

4-A3 1-9, 10 24 V DC 24 V DC supply for OCM, output (A)

4-A4 1-9, 10 24 V DC 24 V DC supply for OCM, output (B)

4-A5 1-9, 10 0/24 V DC (pulse) OCM motor coil energization pulse, output (A)

4-A6 1-9, 10 0/24 V DC (pulse) OCM motor coil energization pulse, output (B)

4-A7 1-9, 10 0/24 V DC (pulse) OCM motor coil energization pulse, output (A)

4-A8 1-9, 10 0/24 V DC (pulse) OCM motor coil energization pulse, output (B)

4-B1 1-9, 10 24 V DC 24 V DC supply for OFM, output (A)

4-B2 1-9, 10 24 V DC 24 V DC supply for OFM, output (B)

4-B3 1-9, 10 0/24 V DC (pulse) OFM motor coil energization pulse, output (A)

4-B4 1-9, 10 0/24 V DC (pulse) OFM motor coil energization pulse, output (B)

4-B5 1-9, 10 0/24 V DC (pulse) OFM motor coil energization pulse, output (A)

4-B6 1-9, 10 0/24 V DC (pulse) OFM motor coil energization pulse, output (B)

5-1 5-2 0/5 V DC DFTSW on/off, input

5-3 5-2 0/5 V DC OSDPCB original present/not present detection signal, input

5-4 5-2 0/5 V DC OSDPCB original size detection (width) signal, input (B)

5-5 5-2 0/5 V DC OSDPCB original size detection (width) signal, input (C)

5-6 5-2 0/5 V DC OSDPCB original size detection (width) signal, input (D)

5-7 5-2 0/5 V DC OSDPCB original size detection (width) signal, input (E)

5-8 5-2 5 V DC 5 V DC supply for OSDPCB, output

5-10 5-9 5/0 V DC DFSSW1 off/on, input

5-11 5-9 5 V DC 5 V DC supply for DFSSW1, output

6-2 6-1 0/5 V DC OSLSW on/off, input

6-3 6-1 5 V DC 5 V DC supply for OSLSW, output

3A7

2-3

2-3-3

Page 37

3A7

2-3-2 Original size detection PCB

CN2-1 CN1-15 V 5 V

PI1

PI2

PI3

PI4

PI5

CN2-3GND

CN2-2DFTSW

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

PI1

PI2

PI3

PI4

PI5

GND

DFTSW

Figure 2-3-3 Original size detection circuit

The original size detection PCB (OSDPCB) consists of five transmission-type photointerrupters, the original set switch (PI5)

and original size width switches B to E (PI4 to PI1). It determines the presence of the original on the original table by the on/

off status of the original set switch (PI5) and the width of the original by the combination of the on/off status of original size

width switches B to E (PI4 to PI1), and then sends these detection signals to the DF driver PCB (DFDPCB).

2-3

2-3-4

Page 38

3A7

• Original size detection

Original size width switches B to E (PI4 to PI1) are arranged from the inner side to the outer side of the PCB as shown in

Figure 2-3-4. When an original is placed on the original table, the original size is determined by the turning on of the original

size width switches and the on/off status of the original size length switch (OSLSW) on the original table.

Outer side

Metric specifications

13

CN1

8

1

CN2

PI1

PI2

PI3

PI4

PI5

Inner side

Figure 2-3-4 Original size detection PCB

Table 2-3-1 Original size detection

Original size

A3 On On On On On

11" × 15" On On On On On

B4 On On On Off On

Folio On On Off Off On

A4R On On Off Off Off

B5R On Off Off Off Off

A4 On On On On Off

A5R Off Off Off Off Off

B5 On On On Off Off

Inch specifications

Original size

11" × 17" On On On On On

11" × 15" On On On On On

1

8

/2" × 14"R On On Off Off On

1

/2" × 11" On On Off Off Off

8

1

11" × 8

5

/2" OnOnOnOn Off

1

/2" × 81/2"R Off Off Off Off Off

Original size width switch Original size length switch

B (PI4) C (PI3) D (PI2) E (PI1) OSLSW

2-3

Original size width switch Original size length switch

B (PI4) C (PI3) D (PI2) E (PI1) OSLSW

2-3-5

Page 39

3A7

CN5-1DFTSW

CN4B-3,

4, 5, 6

OFM

CN4A-5,

6, 7, 8

OCM

Fwd.

rotation

Rev.

rotation

Fwd.

rotation

Rev.

rotation

DF start signal Secondary original feed start

Primary original feed end

300 P

1

450 P

1

1260/

1129 P

2

*

192 P

1

3606/3329 P

2

*

192 P

1

2300 P

2

P

1

: Burst of OFM pulses

P

2

: Burst of OCM pulses

* Metric/inch

" × 11" original

2

/

1

2-4

Timing chart No. 1 Feeding an A4R/8

2-4-1

Page 40

3A7

CN5-1DFTSW

CN4B-3,

4, 5, 6

OFM

CN4A-5,

6, 7, 8

OCM

DF start signal Secondary original feed start

Start of secondary feed

for next original

Start of primary feed

for next original

Primary original feed end

300 P

1

300 P

1

192 P

1

800 P

2

450 P

1

192 P

1

3606/3329 P

2

*3606/3329 P

2

*

2300 P

2

325 ms

192 P

1

Fwd.

rotation

Rev.

rotation

Fwd.

rotation

Rev.

rotation

1260/

1129 P

2

*

192 P

1

1260/

1129 P

2

*

P

1

: Burst of OFM pulses

P

2

: Burst of OCM pulses

* Metric/inch

2-4

" × 11" originals continuously

2

/

1

Timing c hart No. 2 Feeding two A4R/8

2-4-2

Page 41

Periodic maintenance procedures

3A7

Section

Original feed DF original feed pulley Replace Every service 1-4-2,

section and DF separation pulley 3

Section

Original DF upper registration Clean Every service Clean with alcohol or a dry cloth.

conveying roller

section

Section

Original eject DF upper eject roller Clean Every service Clean with alcohol or a dry cloth.

section

Maintenance

part/location

DF forwarding pulley Replace Every service 1-4-2

Original size detection Clean Every service Airbrush.

PCB

DF timing switch Clean Every service Airbrush.

Original feed lift friction Check and replace Every service Replace if damaged.

plate

Maintenance

part/location

DF lower registration Clean Every service Clean with alcohol or a dry cloth.

roller

Maintenance

part/location

DF lower eject roller Clean Every service Clean with alcohol or a dry cloth.

Eject section static Check and replace Every service Replace if damaged.

eliminator

Method Maintenance cycle Points and cautions Page

Method Maintenance cycle Points and cautions Page

Method Maintenance cycle Points and cautions Page

Section

Covers DF contact glass Clean Every service Clean both sides of the glass

Section

Others Original holder sheet Clean Every service Clean with alcohol or a dry cloth.

Maintenance

part/location

Covers Clean Every service Clean with alcohol or a dry cloth.

Maintenance

part/location

Scanning sheet Clean Every service Clean with alcohol or a dry cloth.

Indication plate sponge Clean Every service Clean with alcohol or a dry cloth.

Method Maintenance cycle Points and cautions Page

with alcohol or a dry cloth.

Method Maintenance cycle Points and cautions Page

2-4

2-4-3

Page 42

3A7

ABCDEFGH I J

ABCDEFGH I J

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

C17-1

C17-2

C17-3

SG

5V

OSLSW

3

2

1

(CN6)

C9

(CN2)

C17

C5-9 GY

SG

3

5V

SG

C10-4 GY

C10-3 GY

C10-2 GY

C10-1 GY

C12-6 RD

OSDPCB

C5-8 GY

C5-7 GY

C5-6 GY

C5-5 GY

C5-4 GY

C5-3 GY

C5-2 GY

C5-1 GY

C9-1 GY

C15 C14

SG

5V

DFTSW

DFTSW

PG

SET SW

OSDPCB B

OSDPCB C

OSDPCB D

OSDPCB E

5V

3

2

1

8

7

6

5

4

3

2

1

SG

3

OSLSW

C9-3 GY

C9-2 GY

OSLSW

5V

2

1

OFM BCOM

OFM ACOM

OCM BCOM

OCM ACOM

C9-12

C8-1

DFTSW

SET SW

OSDPCB D

OSDPCB B

OSLSW

DF SHORT

OCM CLK

OCM ENABLE

OFM RET

OFM ENABLE

M1

DFSSW2

24V

DFSSW2

C3-1 RD

1

C3-2 RD

P1

2

OE

YW

BE

DFTSW

OFM

OCM

BK

WE

RD

BE

YW

C4 (A-3) RD

C4 (A-4) GY

C4 (A-5) GY

C4 (A-6) GY

C4 (A-7) GY

C4 (A-8) RD

C12

1

2

3

4

5

6

OE

OCM B

OCM A

6

5

C13

OCM ACOM

OCM BCOM

OCM A

OCM B

1

2

3

4

BK

WE

RD

BE

YW

C4 (B-1) RD

C4 (B-2) GY

C4 (B-3) GY

C4 (B-4) GY

C4 (B-5) GY

C4 (B-6) GY

C10

1

2

3

4

5

6

OE

OFM B

OFM A

6

5

C11

OFM ACOM

OFM BCOM

OFM A

OFM B

1

2

3

4

DFSSW1

C5-11 GY

C5-10 GY

C18

DFSSW1

5V

2

1

P1-1 RD

P1-2 RD

DFDPCB

C14-8 GY

C14-7 GY

C14-6 GY

C14-5 GY

C14-4 GY

C14-3 GY

C14-2 GY

C14-1 GY

C18-3 GY

C18-2 GY

C18-1 GY

C10-5 GY

C10-6 RD

C12-5 GY

C12-4 GY

C12-3 GY

C12-2 GY

C12-1 GY

C1-1

C1-2

C1-3

C1-4

C1-7

C1-8

C1-9

C1-10

M1 GN

M1 GN

24V

24V

PG

PG

5V

5V

SG

SG

FG

FG

A-1

A-2

A-3

A-4

A-5

A-6

A-7

A-8

A-9

A-10

A-11

Mi2 (11P) WHITE

C6

A-12

DFTSW

A-13

OSLSW

A-14

DFSSW1

A-15

DFSSW2

A-16

A-17

DF SHORT

A-18

OSDPCB B

A-19

OSDPCB C

A-20

SET SW

A-21

OSDPCB D

A-22

OSDPCB E

A-23

11

10

9

8

7

6

5

4

3

2

1

C2-22

C2-16

C2-2

C2-1

C2-15

C2-17

C2-18

C2-21

C2-19

C2-20

Mi2 (12P) WHITE

C7

12

11

10

9

8

7

6

5

4

3

2

1

OCM M1

OCM Vref

OCM CWB

OCM CLK

OCM ENABLE

OFM CWB

OFM CLK

OFM RET

Mi2 (11P) RED

C8

C2-9

C2-12

C2-11

C2-10

C2-8

C2-7

C2-6

C2-5

11

10

9

8

7

6

5

4

3

2

1

OFM ENABLE

C2-4

B-1

B-2

B-3

B-4

B-5

B-6

B-7

B-8

B-9

B-10

B-11

C6-2 GN

C6-1 GN

C6-11

C6-10

C6-9

C6-8

C6-7

C6-6

C6-5

C6-4

C7-12

C7-4

C7-2

C7-3

C7-5

C7-6

C7-11

C7-7

C8-8

C8-7

C8-6

C8-11

C8-4

C8-3

C8-2

C7-10

C7-9

SET SW

DFSSW1

5V

OSDPCB E

OSDPCB D

OSDPCB C

OSDPCB B

PG

DFTSW

12

11

10

9

8

7

6

5

4

3

2

1

(CN5)

C5

OFM B

OFM A

OFM B

OFM A

B-1

B-2

B-3

B-4

B-5

B-6

B-7

B-8

OCM B

OCM A

OCM B

OCM A

A-8

A-7

A-6

A-5

A-4

A-3

A-2

A-1

(CN4)

C4

OSDPCB E

OSDPCB C

OCM Vref

OCM CWB

OCM M1

OFM CWB

OFM CLK

DFSSW1

DFSSW2

(CN2)

C2

(CN1)

C1

(CN3)

C3

SG

SG

5V

5V

PG

PG

24V

24V

24V

DFSSW2

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

2

1

Wire color

Black

Yellow

Blue

Red

Orange

Gray

Symbol

BK

YW

BE

RD

OE

GY

2-4

Wiring diagram

2-4-4

Loading...

Loading...