Page 1

Chapter 4

Hardware note

Page 2

Chapter 4 Contents

4-1 Introduction ...................................................................................................................................... 4-3

4-1-1 Notes on power............................................................................................................................... 4-3

4-2 Troubleshooting............................................................................................................................... 4-4

4-2-1 Analyzing basic hardware symptoms.............................................................................................. 4-4

4-2-2 Checking the 24 V DC and 5 V DC lines ........................................................................................ 4-6

(1) Checking the 24 V DC line ............................................................................................................ 4-6

(2) Checking the 5 V DC line .............................................................................................................. 4-7

4-2-3 Power supply/indicator panel problem............................................................................................ 4-8

(1) Power supply problem ................................................................................................................... 4-8

(2) Indicator panel problem ................................................................................................................. 4-8

4-2-4 Interface problem............................................................................................................................ 4-9

(1) Call service person C1 or C4......................................................................................................... 4-9

4-2-5 Mechanical problem...................................................................................................................... 4-10

4-2-6 Feed motor problem ......................................................................................................................4-11

4-2-7 Duplexer selection solenoid problem............................................................................................ 4-12

4-2-8 Sensor problem ............................................................................................................................ 4-13

(1) Inlet sensor .................................................................................................................................. 4-13

(2) Paper tray exit sensor.................................................................................................................. 4-14

(3) Paper tray full sensor................................................................................................................... 4-15

4-2-9 Location of sensors....................................................................................................................... 4-16

4-3 Paper jam problem......................................................................................................................... 4-17

4-3-1 Analyzing paper jam problem (basic)............................................................................................ 4-18

4-3-2 Analyzing paper jam problems...................................................................................................... 4-19

Page 3

4-1 Introduction

This chapter explains procedures for identifying and correcting bulk stacker problems

(troubleshooting). Most of problems concerning the bulk stacker may arise from defects in the

interface with the printer as the bulk stacker is directly controlled by the printer electronics. The

Analyzing basic hardware symptoms chapter 4, section 4-2-1 on next page allows to determine

whether the problem is caused by a defect in the interface with the printer or in the bulk stacker's

power supply.

This chapter covers the following troubleshooting procedures.

Power supply/indicator panel problem

Interface problem

Driving unit (paper transportation) problem

Sensor problem

Error massages

Paper jam

The diagram indicating the locations of the sensors is attached at the end of section 4-2.

4-1-1 Notes on power

The power supply/motor driver board includes AC circuit. To avoid electrical shock hazard, a great

care should be exercised when handling the power supply/motor driver board and other AC cablings.

Unless instructed to be plugged to the power source, the bulk stacker's power cord must be

disconnected from power.

4-3

ST-20

Page 4

4-2 Troubleshooting

When bulk stacker malfunction occurs, begin troubleshooting by going through the following

flowchart.

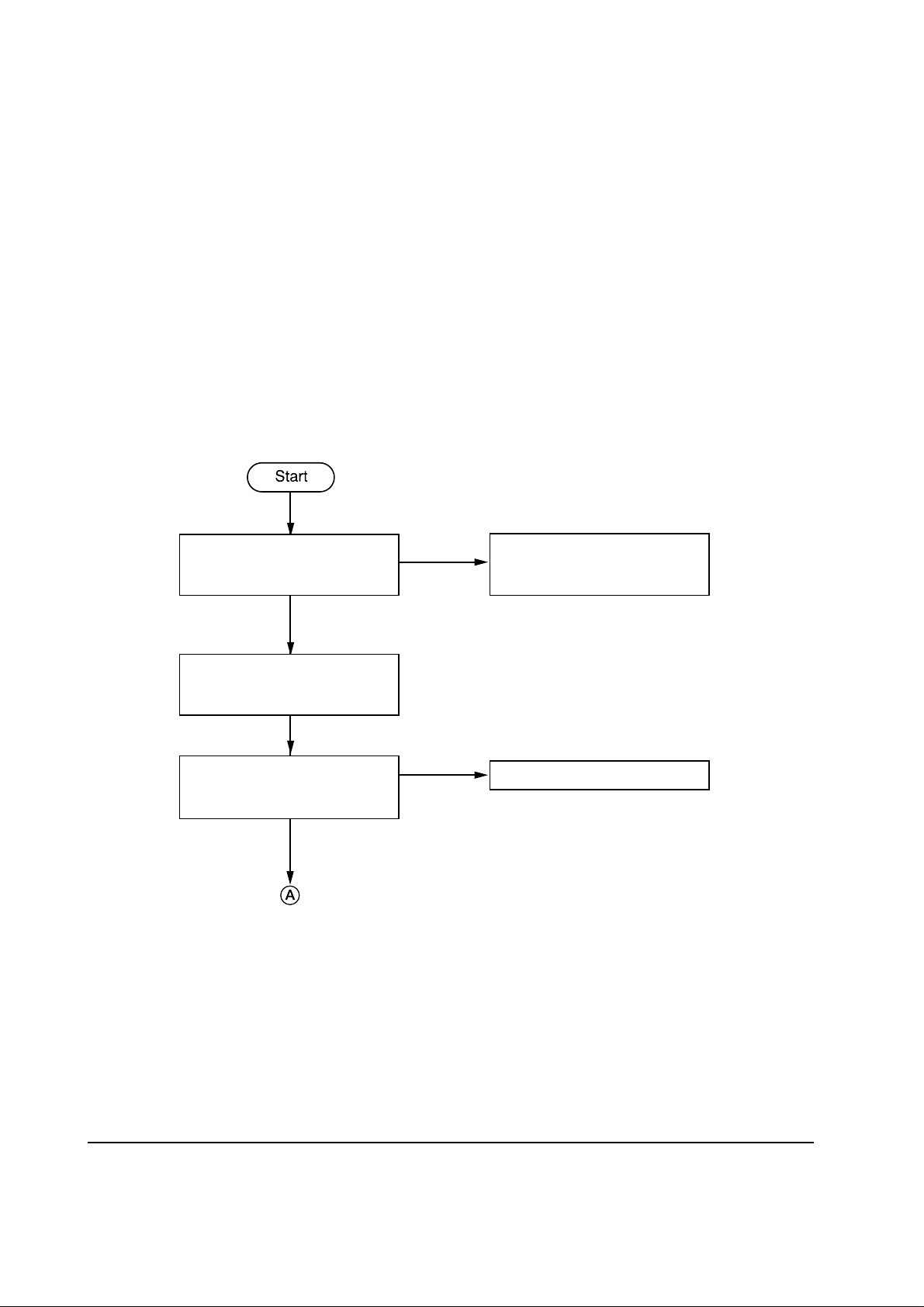

4-2-1 Analyzing basic hardware symptoms

Following this chart allows analyzing basic problems concerning the bulk stacker hardware. The

bulk stacker should be left installed to the printer in normal manner while following the flowchart.

Bulk stacker's connector (on top

of bulk stacker) mated properly

with the printer's?

Yes

Remove the right side cover of

bulk stacker. See Chapter 2;

section 2-2-3.

Is J7 (interface) of controller

board in bulk stacker connected

properly?

Yes

Continued on next page

No

No

Turn power off and try

remounting the printer on the

bulk stacker.

Connect properly.

ST-20

4-4

Page 5

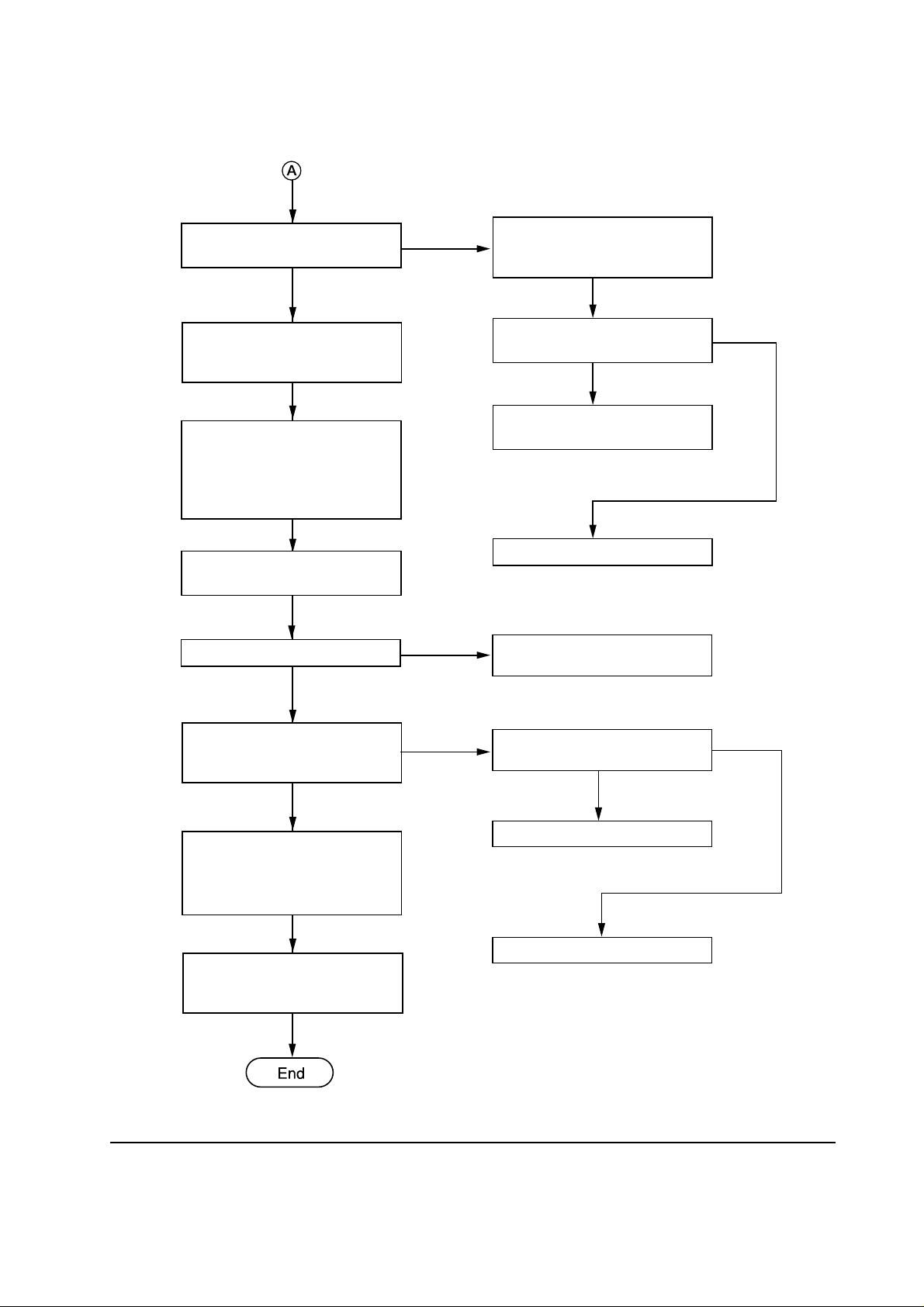

Continued

+5 V at pin 3 of J1 on controller

board?

No

Turn printer power off.

Disconnect stacker power cord

from the outlet.

Remove bulk stacker's top

cover. Remove jumper wires

TJ1 and TJ2 from controller

board, and insert them to (TJ1)

and (TJ2), respectively.

Connect bulk stacker power

cord from the outlet.

Feed motor rotates?

No

Yes

Yes

Remove the left side cover of

bulk stacker. See chapter 2;

section 2-2-2.

Yes

5 V DC at pin 3 (white) of

stacker connector?

Replace harness of bulk stacker

connector.

Replace printer engine board.

Replace power supply/motor

driver board in bulk stacker.

No

AC power across pins 1 and 3 of

J11 on bulk stacker's power

supply/motor driver board?

Yes

Check 24 V DC and 5 V DC

lines according to Checking the

24 V DC and 5 V DC lines on

next page.

Reset jumper wires (TJ1) and

(TJ2) back to TJ1 and TJ2 on

controller board, respectively.

No

AC power across pins 1 and 5 of

J12?

No

Replace AC harness.

Replace fuse F1.

4-5

Yes

ST-20

Page 6

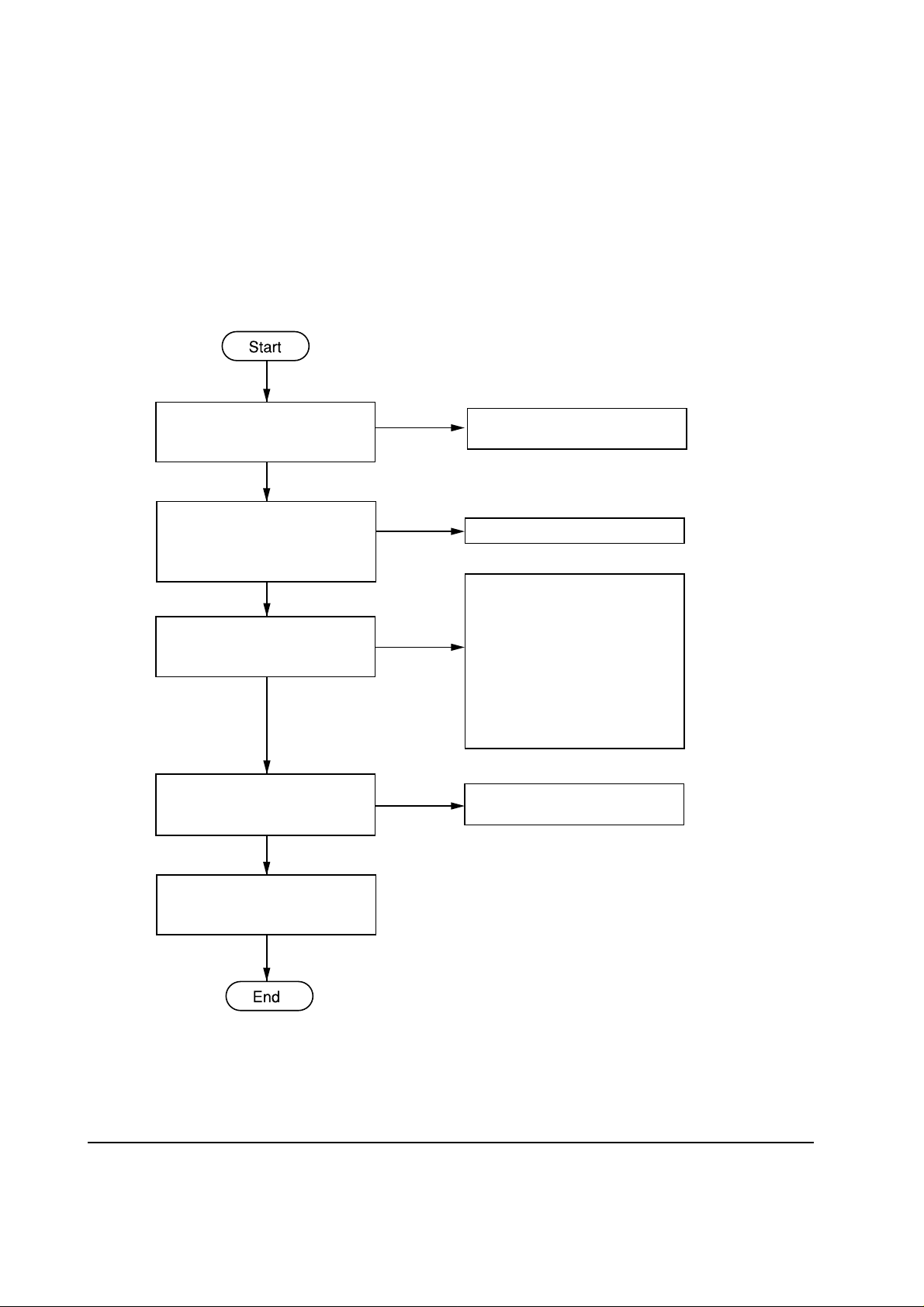

4-2-2 Checking the 24 V DC and 5 V DC lines

The following two charts allow checking whether the DC power lines are correctly routed.

(1) Checking the 24 V DC line

24 V DC at the first pin of J1

on bulk stacker's controller

board?

No

24 V DC at the first pin of J1

and J10 on bulk stacker's power

supply/motor driver board?

No

24 V DC at pin 2 of J10 on bulk

stacker's power supply/motor

driver board?

Yes

Fuse F2 on bulk stacker's power

supply/motor driver board

blown?

Yes

Yes

Yes

No

Yes

Replace stacker's contoroller

board.

Replace harness to J1.

Unplug AC power cord.

Measure resistance across pins 1

and 2 of J10. Open and close the

bulk stacker rear cover. If

resistance won't vary, replace

the interlock switch and the

harness. If resistance vary,

replace bulk stacker's power

supply/motor driver board.

Replace power supply/motor

driver board in bulk stacker.

ST-20

Replace fuse F2. If not

corrected, replace power

transformer.

4-6

Page 7

(2) Checking the 5 V DC line

5 V DC at pin 3 of J1 on bulk

stacker's controller board?

No

5 V DC at pin 3 of J1 on bulk

stacker's power supply/motor

driver board?

No

Is fuse F3 on bulk stacker's

power supply/motor driver

board blown?

Yes

Replace fuse F3. If not

corrected, replace power

transformer.

Yes

Yes

No

Replace bulk stacker's controller

board.

Replace harness to J1.

Replace power supply/motor

driver board in bulk stacker.

4-7

ST-20

Page 8

4-2-3 Power supply/indicator panel problem

(1) Power supply problem

Power supply problem can mainly caused by the following causes:

Defect in the interface with the printer

Defect in the power supply/motor driver board

Troubleshooting to these items can be executed by following section 4-2-1, Analyzing basic hardware

symptoms, previously explained.

(2) Indicator panel problem

To isolate problems regarding the bulk stacker's indicator panel, use the chart below.

5 V DC at the first pin of J2 on

bulk stacker's controller board?

Yes

Harness properly connected?

Yes

Replace indicator panel.

Yes

Does indicator panel work?

Yes

No

No

No

Power supply problem. See the

previous page.

Reconnect the harness properly.

Replace bulk stacker's controller

board.

ST-20

4-8

Page 9

4-2-4 Interface problem

Interface problems are implied by the printer's front panel message Call Service person C1 or C4.

T o act with these messages, follow section 4-2-1 Analyzing basic hardware symptoms, then use the

chart below.

(1) Call service person C1 or C4

Follow flowchart Analyzing

basic hardware symptoms,

section 4-2-1.

Chart followed successfully?

Yes

Replace bulk stacker's

contoroller board.

Yes

No

Follow chart's instructions.

4-9

ST-20

Page 10

4-2-5 Mechanical problem

The bulk stacker's main mechanical component are listed as follows:

Feed motor

Duplexer selection solenoid (for routing paper to the bulk stacker or the duplexer)

The following flowchart can be used for isolating problems with all of the above motor and solenoid.

Before making investigation on each part, follow this chart first.

Set dipswitch (DS1) segments

of 1 and 2 of DS1 on bulk

stacker's controller board to ON

(left).

Remove bulk stacker's top

panel. Remove jumper wires

TJ1 and TJ2 from power

supply/motor driver board, and

insert them to (TJ1) and (TJ2),

respectively.

Plug bulk stacker's AC power

plug to the power outlet.

Test mode initated?

No

Yes

Controller board

Dipswitch

(DS1)

Power supply/motor driver board

RL1

TJ2 TJ1

(TJ2)

(TJ1)

Nomal position

ON

2

1

Test mode position

(Motor check)

ON

2

1

Test mode position

(Sensor check)

ON

2

1

See section 4-3-2

Check feed motor.

Replace bulk stacker's power

supply/motor driver board. (To

stop bulk stacker, unplug

power).

ST-20

J12

RL1

TJ2 TJ1

(TJ2)

(TJ1)

J12

When troubleshooting is finished,

reset jumper wire (TJ1) and (TJ2)

back to TJ1 and TJ2 on the power

supply/motor driver board,

respectively.

Figure 4-2-1 Test mode settings

4-10

Page 11

4-2-6 Feed motor problem

Start

12 V DC at pin 2 of J8 of power

supply/motor driver board?

No

Are pins 7 and 9 of J1 on power

supply/motor driver board at

low?

No

Are pins 7 and 9 of J1 on

controller board at low?

No

Replace bulk stacker's controller

board.

End

Yes

Yes

Yes

Check through 24 V DC line. If

OK, replace feed motor.

Replace power supply/motor

driver board.

Replace harness to J1.

4-11

ST-20

Page 12

4-2-7 Duplexer selection solenoid problem

Duplexer selection solenoid is for switching paper to the bulk stacker or the duplexer.

24 V DC at pin 5 of J3 of

controller board?

Yes

Is pin 4 of J3 on controller

board toggling through on and

off?

Yes

Replace duplexer selection

solenoid.

No

No

Check through 24 V DC line.

Replace bulk stacker's controller

board.

ST-20

4-12

Page 13

4-2-8 Sensor problem

The bulk stacker uses sensors for detecting presence of paper (See section 4-2-9). The following

chart allows checking through these sensors when problem with sensors is encountered.

NOTE On power supply/motor driver board, move the jumper wires in sockets TJ1 and TJ2

to (TJ1) and (TJ2) [test mode position] , respectively.

(1) Inlet sensor

5 V DC at pin 10 of J5?

Yes

Manually activate the inlet

sensor actuator.

Does pin 11 of J5 turn to 0 V?

Yes

Replace bulk stacker's controller

board.

No

Check through 5 V DC line.

No

Replace inlet sensor.

4-13

ST-20

Page 14

(2) Paper tray exit sensor

5 V DC at pin 7 of J4?

Yes

Manually activate the paper tray

exit sensor actuator.

Yes

Does pin 8 of J4 turn to 0 V?

Yes

Replace bulk stacker's controller

board.

No

No

Check along 5 V DC line.

Replace paper tray exit sensor.

ST-20

4-14

Page 15

(3) Paper tray full sensor

5 V DC at first pin of J4?

Yes

Manually activate the paper tray

full sensor.

Yes

Does pin 2 of J4 turn to 0 V?

Yes

Replace bulk stacker's controller

board.

No

No

Check along 5 V DC line.

Replace paper tray full sensor.

4-15

ST-20

Page 16

4-2-9 Location of sensors

Figure 4-2-2 below shows the name and location of all sensors used in the option units.

Paper empty sensor (EF-1)

Feed sensor

(HS-20/HS-21)

Paper empty sensor

(PF-20/PF-21)

Feed sensor

(DU-20/DU-21)

Paper empty sensor

(DU-20/DU-21)

Inlet sensor

Paper tray exit sensor

Adjustment guide

home positioning

sensor (DU-20/DU-21)

Feed sensor

(DU-20/DU-21)

*For resupplied paper

Paper tray full sensor

Bulk stacker ST-20

ST-20

Figure 4-2-2 Location of sensors

4-16

Page 17

4-3 Paper jam problem

This section explains how to cope with paper jam problem that occurs in the bulk stacker. Paper

jam in the bulk stacker is indicated by flashing READY indicator on the bulk stacker front side. If

the bulk stacker and the printer seem not to recover from paper jam after jammed paper is removed,

begin troubleshooting by following the Analyzing paper jam problem (basic) flowchart on next

page.

4-17

ST-20

Page 18

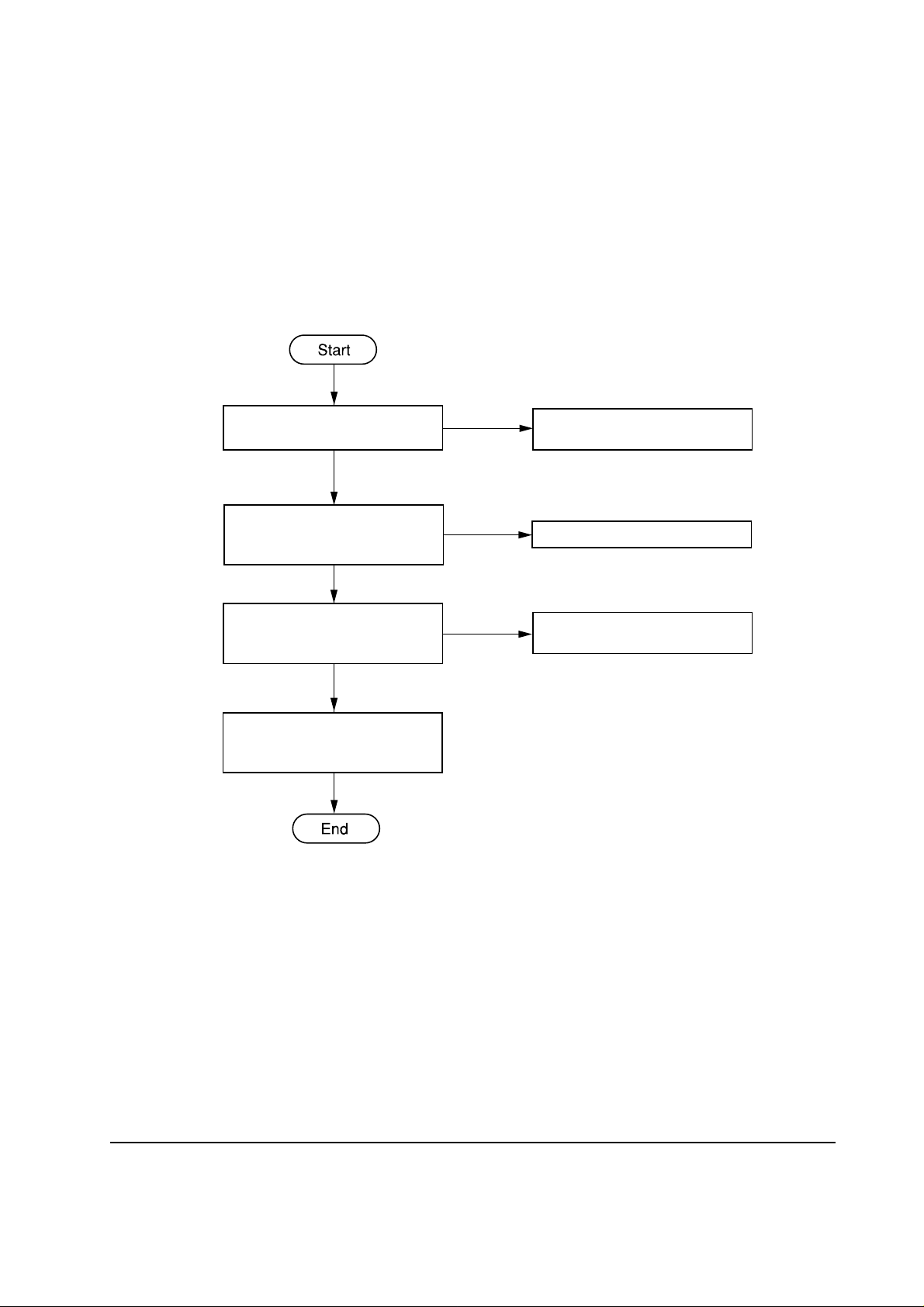

4-3-1 Analyzing paper jam problem (basic)

bulk stacker

installed as per

specifications?

Yes

Turn printer power on.

Is POWER lit?

Yes

Stacker

selectable in STACK

SELECT key?

Yes

Is READY lit?

No

Refer to stacker's

No

specifications.

Chapter 1,

section 1-5.

Check

connectors and

power supply.

No

Check electrical

troubleshooting.

No

Check electrical

troubleshooting.

ST-20

Yes

Print a status page.

Paper jam?

No

Yes

Follow analyzing

paper jam

problems flow

chart. section 43-2.

4-18

Page 19

4-3-2 Analyzing paper jam problems

Follow the flowchart below when instructed to do so while following the Analyzing paper jam

problem (basic) flowchart (section 4-3-1). This flowchart will in turn lead you to the specific

remedy as tabled in Table 4-3-1.

Duplexer

installed (above

stacker) ?

No

Paper path

adaptor mounted

on duplexer?

No

Install PA-1 paper path

adaptor.

Paper jammed

at entrance of

bulk stacker?

Yes

Yes

Yes

Paper

jammed in

duplexer?

No

Is the

correct adaptor

model used?

Yes

Go to Table 4-31, item 2.

Yes

No

Go to Table 4-31, item 1.

Change adaptor

to the correct

one.

No

ST-20

4-19

Page 20

The table below summarizes various symptoms and remedies for paper jam problems. Use this

table according to the directions obtained by following the Analyzing paper jam problems flowchart.

Table 4-1 Remedies for paper jam problems

Item CauseSymptom

Paper missed

1

to enter bulk

stacker but

entered

duplexer and

jammed.

Paper trapped

2

at the entrance

of bulk stacker.

Defective duplexer

selection solenoid.

Defective duplexer

switching flap.

Defective duplexer

selection solenoid.

Paper path adaptor is PA1 is not mounted on bulk

stacker (if paper feeder is

mounted above bulk

stacker), or paper path

Suggested remedy

Check solenoid assembly for proper

operation. Replace solenoid assembly if

necessary.

Check the flap switching lever at duplexer

bottom for proper operation. Replace the flap

switching lever if necessary.

After executing remedy , confirm bulk stacker

and duplexer work properly by running bulk

stacker in self test mode. See chapter 4,

section 4-2-5.

Obtain and install a correct PA-1.

adaptor PA-1D is

mounted on bulk stacker.

Bulk stacker's entrance

roller (or PA1-D roller)

did not revolve due to

excessive disc clutch

effect.

Loose driving belt

tension or belt not

hooked properly.

Defective feed motor.

Replace disc clutch assembly.

Hook belt properly and adjust the tension

properly.

Confirm motor and driver mechanism work

properly by running bulk stacker in self test

mode. To set test mode of bulk stacker, see

chapter 4, section 4-2-5. Replace feed motor

if necessary.

ST-20

4-20

Page 21

Item CauseSymptom Suggested remedy

Paper jammed

3

after clearing

sensor.

Defective sensor(s). See

Figure 4-2-2 for

location of sensors.

Clean sensor. Check sensor actuator for

smooth elevation.

Operate bulk stacker in sensor test mode:

Remove jumper wires from TJ1/TJ2 and insert

them into (TJ1/TJ2) on power supply/motor

driver board, and set segment 1 of dipswtch

(DS1) to ON and segment 2 of DS1 to OFF,

See figure 4-2-1. Plug bulk stacker to power.

Feed A5 paper from the bulk stacker's inlet.

Check if READY on the bulk stacker flashes

two times (once at the inlet sensor and at the

paper tray exit sensor. Replace sensor(s) if

necessary.

4-21

ST-20

Loading...

Loading...