Page 1

Chapter 3

Paper specifications

Page 2

Chapter 3 Contents

3-1 Introduction ...................................................................................................................................... 3-3

3-2 Power supply/motor driver board .................................................................................................. 3-4

3-2-1 Power supply circuit........................................................................................................................ 3-4

3-2-2 Motor driver circuit .......................................................................................................................... 3-5

3-3 Controller board............................................................................................................................... 3-6

3-3-1 Solenoid driver................................................................................................................................ 3-7

3- 4 Printer interface .............................................................................................................................. 3-8

3-4-1 Connector configuration.................................................................................................................. 3-8

3-4-2 Controller board CPU I/O interface................................................................................................. 3-9

3-5 Sensors........................................................................................................................................... 3-11

3-6 Error message................................................................................................................................ 3-12

3-7 Printing timing charts.................................................................................................................... 3-13

Page 3

3-1 Introduction

This chapter explains the operation of the electrical circuits in the bulk stacker. Procedures for

hardware troubleshooting are also included in this chapter. Schematic diagrams are provided in

Appendix. The schematic diagram should be referred to along with the explanation in the following

pages.

The electrical system of the bulk stacker can be functionally divided in the following two parts:

Power supply/motor driver

Controller

These two part are mounted on separate circuit-boards. Details on each part follow are explained

on the following pages.

3-3

ST-20

Page 4

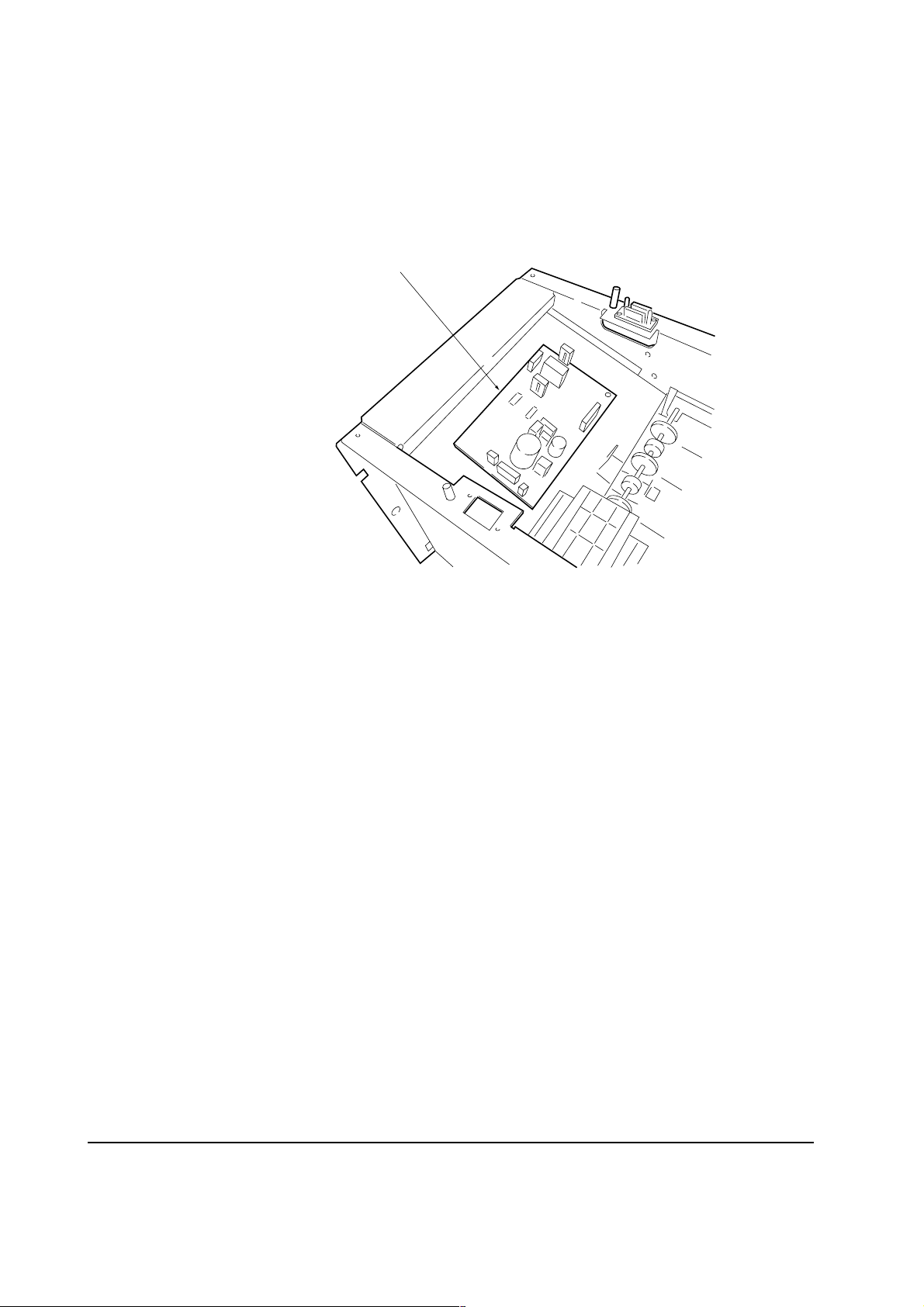

3-2 Power supply/motor driver board

See figure 3-2-1 below. The motor driver/power supply board is located on the top of the bulk

stacker, inside the top plate.

Power supply/motor driver board

Figure 3-2-1 Location of power supply/motor driver board

3-2-1 Power supply circuit

See appendix power supply/motor driver board circuit diagram.

The bulk stacker has no power switch provided as the printer's power switch simultaneously activates

the bulk stacker's power supply. When printer power turns on, the 5 V DC reaches at pin #3 of the

interface connector. It activates and closes relay RL1 on the motor driver/power supply board

which in turn connects the primary power (120 or 220 V AC) to transformer T1. The power supply

section produces both the 5 V and 24 V DC and feeds them accordingly to the respective circuits.

Regulator IC1 is provided for the 5 V DC power supply.

ST-20

3-4

Page 5

3-2-2 Motor driver circuit

See appendix power supply/motor driver circuit board diagram.

The motor driver receives commands for driving the feed motor from the controller board through

connector J1.

The feed motor is located on the top of the bulk stacker, inside the top panel. The feed motor drives

the feed roller for feeding paper arriving from the printer towards the paper tray. Power voltage for

this motor is regulated by means of resistors R11 and R14 on the power supply/motor driver board

so as to obtain a constant 16 V DC source. The feed motor turns on when the level of pin #9 of J1

(FEEDON*) becomes low.

3-5

ST-20

Page 6

3-3 Controller board

The controller board is located on the right inside of the bulk stacker as shown in figure 3-3-1

below.

Controller board

Figure 3-3-1 Location of the controller board

A 4-bit CPU (µPD75004) is used in the controller board to manage controlling the following devices,

while keeping contact with the printer using the serial communication method.

Solenoid driver

Printer interface

Sensor controller

Details on each of these devices follow.

ST-20

3-6

Page 7

3-3-1 Solenoid driver

The bulk stacker has one solenoid (Duplexer selection solenoid). Solenoid is located as shown in

Figure 3-3-2 below and changes the paper path according to the simultaneous activation of the

duplexer (DU-20/DU-21).

See figure 3-3-3, If the bulk stacker is used together with the duplexer for duplex printing, the CPU

IC1 turns the DPSON* signal low , which in turn ener gizes duplexer selection solenoid to allow the

paper to be fed into the duplexer.

Duplexer selection solenoid

Figure 3-3-2 Duplexer selection solenoid

24 V DC

CPU

IC1

37

14

Driver

IC3

15

DPSON*

Figure 3-3-3 Solenoid control signal

3-7

Duplexer

selection

solenoid

ST-20

Page 8

3- 4 Printer interface

This section provides information regarding the bulk stacker's interface to the printer.

3-4-1 Connector configuration

The bulk stacker and the printer exchange signals between each other through connector J7 which

is mounted on top the bulk stacker . The names and the functions of the signals handled by the bulk

stacker are as follows.

5 4 3 2 1

6 7 8 9 10

Bulk stacker's left side

Printer positioning pin

Figure 3-4-1 Bulk stacker connector

Table 3-4-1 Bulk stacker connector pin assignment

Pin No. Input/Output Signal Description

1 Input DSENS Duplexer’s feed path sensor (open collector) output

(24 V DC if duplexer is installed above the bulk

stacker)

2 Input SCKD Serial clock

3 Input +5 V 5 V DC power

4 Output READY Hand shake signal

5 Input SEL0 Select bit 0

6 Input SEL1 Select bit 1

7 Input SEL2 Select bit 2

8 Output SID Bulk stacker output data

9 Input SOD Bulk stacker input data

10 - GND Ground

ST-20

3-8

Page 9

Signals SEL0, SEL1, and SEL2 are used by the printer to select and deselect the bulk stacker. The

bulk stacker is selected as the paper destination when SEL0 is “1”, SEL1 is “0”, and SEL2 is “1”.

All levels are of C-MOS level. Pulled-up for input and open-circuited for output. The clocksynchronous serial interface configuration is used with the maximum synchronization clock of 200

kHz.

3-4-2 Controller board CPU I/O interface

Table 3-1 below shows signals used by the controller board CPU (µPD75004) for its I/O interface.

Table 3-4-2 Controller board CPU I/O signals

Pin Input/Output Signal Description Logic (Meaning)

12

-

SOD(SI)

Printer's communication

14

18, 19

17

25

24

22, 23

31

32

33

27-29

10, 11

13

9

40, 41

39

-

Input

Input

Input

-

Input

-

-

-

-

Output

Output

SCKD*

RCOPN*

DSENS

SOIN*

-

NSBF*

SEL0-SEL2

DIPSW1-DIPSW2

SID (SO)

READY*

FEEDON*

Communication clock

Not used

Rear cover status

Paper feeding in duplexer

Paper detection in bulk stacker's

paper inlet

Not used

Not used

Paper full in paper tray

Not used

Bulk stacker activation bits

Bulk stacker mode selection bits;

“1” for both bits (at power on)

Status to printer (communication)

Ready to send status

Not used

Feed motor status

-

Cover open

No paper

Paper detected

-

-

Paper full

-

-

-

-

-

Ready

-

On

On

38

37

34-36

6, 7

Output

Output

-

-

RDYLED*

DPSON*

-

-

READY indicator status

Path selection/duplexer

Not used

Not used

3-9

To duplexer

-

-

-

ST-20

Page 10

The following table shows port assignment for the controller board CPU (µPD75004).

Table 3-4-3 Controller board CPU pin assignment

Port bit3 bit2 bit1 bit0

Port0

Port1

Port2

Port3

Port4

Port5

Port6

Port7

Port8

SI

-

-

RDYLED*

-

-

-

-

SO

RCOPN*

NSIN*

VLOW*

FEEDON*

-

SEL2

-

SCK

SOIN*

-

-

NSBF*

SEL1

DIPSW2

-

DSENS*

READY*

DPSON*

SEL0

DIPSW1

ST-20

3-10

Page 11

3-5 Sensors

The bulk stacker has sensors provided for controlling paper transportation and detection of paper

jam. The following sensors are used:

Table 3-5-1 Controller board CPU input sensors signals

Sensor Signal Function Type of sensor Logic

Inlet sensor

Paper tray

exit sensor

Paper tray

full sensor

SOIN*

NSIN*

NSBF*

Mounted at the paper inlet of

the bulk stacker. Detects the

paper fed and occurrence of

paper jam; provides various

timings for bulk stacker

control.

Located at the paper tray exit.

Detects timing of paper exit

and occurrence of paper jam.

Detects if the paper tray

becomes full (approximately

1500 sheets).

Photo

interrupter

Photo

interrupter

Photo

interrupter

Pin #24 of CPU

IC1 turns to low

while paper is

sensed.

Pin #23 of CPU

IC1 turns to low if

paper exists.

Pin #32 of CPU

IC1 becomes low

when the paper

tray is full.

3-11

ST-20

Page 12

3-6 Error message

The printer looks after itself and shows various error codes starting with the Call Service person

message if a defect is found during operation. The error messages pertaining to use of the bulk

stacker together with the printer are as follows.

Table 3-6-1 Error codes regarding bulk stacker

Error code Meaning Suggested remedy

C4

C5

C6

For other error codes, refer to printer's Service Manual.

Defect in communication between the

bulk stacker and the printer engine.

Error during self-diagnostics of bulk

stacker.

Defect at power-up in communication

between the bulk stacker and the

printer engine.

Replace the printer’s engine

board. Replace the bulk

stacker’s controller board.

Replace the connector of bulk

stacker.

Replace the bulk stacker’s

feed motor. Replace the bulk

stacker’s power supply/motor

driver board.

Replace the printer’s engine

board. Replace the bulk

stacker’s controller board.

Replace the connector of bulk

stacker.

ST-20

3-12

Page 13

3-7 Printing timing charts

FS-3700/ST-20/A4

3-13

FS-3700 Motor

(MMOT)

FS-3700 Cassette feed

(FDCL1)

FS-3700 Registration clutch

(REGCL)

FS-3700 Registration sensor

(JAMR)

FS-3700 Fuser sensor

(JAM0)

HS-20 Motor

(MON, VLOW)

HS-20 Sensor

(HSPAP)

ST-20 Feed motor

(FEED)

ST-20 Inlet sensor

(SOIN)

ST-20 Paper tray exit sensor

(NSIN)

0 (s)

1055 (ms)

1055

24

2454

2012

2620

2243

High speed

2621

4311

5163

4117

Low speed

4697

5382

5495

6

5706

5872

5918

6754

6798

6899

810

8413

7369

7948

7500

9170

7807

7748

8532

10011

10055

9170

9194

10154

12 14

11842

11842

10760

12445

11070

11010

11800

ST-20

Page 14

ST-20

FS-3700/DU-20/ST-20/A4 (Continued to next page)

3-14

FS-3700 Motor (MMOT)

FS-3700 Cassette feed

(FDCL1)

FS-3700 Registration clutch

(REGCL)

FS-3700 Registration sensor

(JAMR)

FS-3700 Fuser sensor (JAMO)

HS-20 Motor (MON, VLOW)

HS-20 Sensor (HSPAP)

DU-20 Motor

(FEED0, FEED1, VLOW)

DU-20 Clutch (CLON)

DU-20 Stepping motor

(PA, PB, PA_, PB_)

DU-20 Entrance sensor (PISNS)

DU-20 Home sensor (PHSNS)

DU-20 Exit sensor (POSNS)

DU-20 Guide home sensor

(GHOME)

ST-20 Feed motor (FEEDON)

ST-20 DU-1/ST-20 (DPSON)

ST-20 Inlet sensor (SOIN)

ST-20 Paper tray exit sensor

(NSIN)

0 (s)

4

4500

5456

5702

4500

High speed

6068

6

6914

6082

5982

FWD.

High speed

6218

CCW

6178

6218

810

9022

9978

8626

7576

8160

Low speed

9378 17020

10432

10216

10218

10266

High speed

10488

12 14 16 18 20 22 24 26

11130

11716

12412

13437

13587

CW

13724

REV.

Low speed

15166

15218

15166

15360

16492

16268

15800

FWD.

High speed

16936

16936

16100

16498

16748

17104

16812

17850

17706

17106

16788

CCW

16788

18800

18612

18172

FWD.,REV.

18180

18180

1826416630

19660

19182

18908

19488

19532

19524

20206

19870

19992

20408

21211

20186

20374

21248

21296

21361

CW

21754

21870

22042

21816

21816

23288

22008

23398

22608

22920

22450

22750

22706

22668

23140

23460

23672

23586

23586

23438

CCW

23146

23438

23408

23750

24500

24826

23758

23758

24050

25450

25264

25834

24832

24832

24936

Page 15

FS-3700 Motor (MMOT)

FS-3700 Cassette feed

(FDCL1)

FS-3700 Registration clutch

(REGCL)

FS-3700 Registration sensor

(JAMR)

FS-3700 Fuser sensor (JAMO)

22 (s)

22920

23140

23460

24

23758

24508

25450

25264

26

26522

26312

26854

27024

26642

27900

28 30

29788

Repeat

29566

28522

30398

30108

31156

32 44 36 38

36332

36624

36330

31904

32954

34544

28310

39178

40

42 44 46 48

FS-3700/DU-20/ST-20/A4 (Continued)

43941

40768

3-15

ST-20

HS-20 Motor (MON, VLOW)

HS-20 Sensor (HSPAP)

DU-20 Motor

(FEED0, FEED1, VLOW)

DU-20 Clutch (CLON)

DU-20 Stepping motor

(PA, PB, PA_, PB_)

DU-20 Entrance sensor (PISNS)

DU-20 Home sensor (PHSNS)

DU-20 Exit sensor (POSNS)

DU-20 Guide home sensor

(GHOME)

ST-20 Feed motor (FEEDON)

ST-20 DU-1/ST-20 (DPSON)

ST-20 Inlet sensor (SOIN)

ST-20 Paper tray exit sensor

(NSIN)

22450

22042

22008

23146

22608

23586

23586

23288

23398

22706

22668

23672

23758

23758

23438

CCW

22750

23438

23408

24826

24050

25834

25562

24832

24832

24936

26164

26836

26206

26198 29386

30320

30230

30230

30082

CCW

30082

30096

30398

30398

30740

31466

31476

31476

31612

32476

32206

32846

33482

32888

32880

27944

27060

27861

CW CW

28462

28011

28658

28436

29098

28706

28462

29932

29400

29796

30042

39350

29288

34590

34688

34688

34507

34657

34870

35116

3535633700

35622

35978

36454

36454

36016

36042

36624

36624

37430

36788

37700

37700

37454

38702

38066

39926

40812

41580

41336

42264

42200

42596

47576

43560

43684

43018

Loading...

Loading...