Page 1

ST-11

SERVICE

MANUAL

Published in Jun.’00

843BF110

Page 2

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Parts names ......................................................................................................................................... 1-1-2

1-1-3 Machine cross section.......................................................................................................................... 1-1-3

1-1-4 Drive system ........................................................................................................................................ 1-1-4

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

(1) Unpacking....................................................................................................................................... 1-2-1

(2) Removing tapes and pads .............................................................................................................. 1-2-2

1-3 Maintenance Mode

1-3-1 Maintenance mode............................................................................................................................... 1-3-1

1-4 Troubleshooting

1-4-1 Paper misfeed detection ...................................................................................................................... 1-4-1

(1) Paper misfeed detection ................................................................................................................. 1-4-1

(2) Paper misfeed detection condition ................................................................................................. 1-4-1

(3) Paper misfeed ................................................................................................................................ 1-4-1

1-4-2 Self-diagnosis....................................................................................................................................... 1-4-2

(1) Self-diagnostic function .................................................................................................................. 1-4-2

(2) Self-diagnostic code ....................................................................................................................... 1-4-2

1-4-3 Electrical problem................................................................................................................................. 1-4-2

3BF

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly ......................................................................................... 1-5-1

(1) Precautions..................................................................................................................................... 1-5-1

1-5-2 Procedure for assembly and disassembly ........................................................................................... 1-5-1

(1) Adjusting the center line ................................................................................................................. 1-5-1

2-1 Mechanical construction

2-1-1 Mechanical construction....................................................................................................................... 2-1-1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

(1) PCBs, motors and clutches ............................................................................................................ 2-2-1

(2) Switches ......................................................................................................................................... 2-2-2

2-3 Operation of the PCB

2-3-1 Side deck main PCB ............................................................................................................................ 2-3-1

2-4 Appendixes

Timing chart.................................................................................................................................................... 2-4-1

Wring diagram ................................................................................................................................................ 2-4-2

1-1-1

Page 3

1-1-1 Specifications

3BF

Type .............................................. Deck type

Paper ............................................ Plain paper (64 - 80 g/m

Paper size ..................................... A4/11" × 8

1

/2"

Capacity ........................................ 4000 sheets (80 g/m

2

)

2

)

Power source ................................ Electrically connected to the copier (5 V DC, 24 V DC)

Dimensions ...................................371 (W) × 589 (D) × 685 (H)* mm

5

14

/8" (W) × 233/16" (D) × 2615/16"* (H)

*: The height includes that of casters.

Weight...........................................Approximately 36 kg/79.2 lbs

1-1

1-1-1

Page 4

1-1

3BF

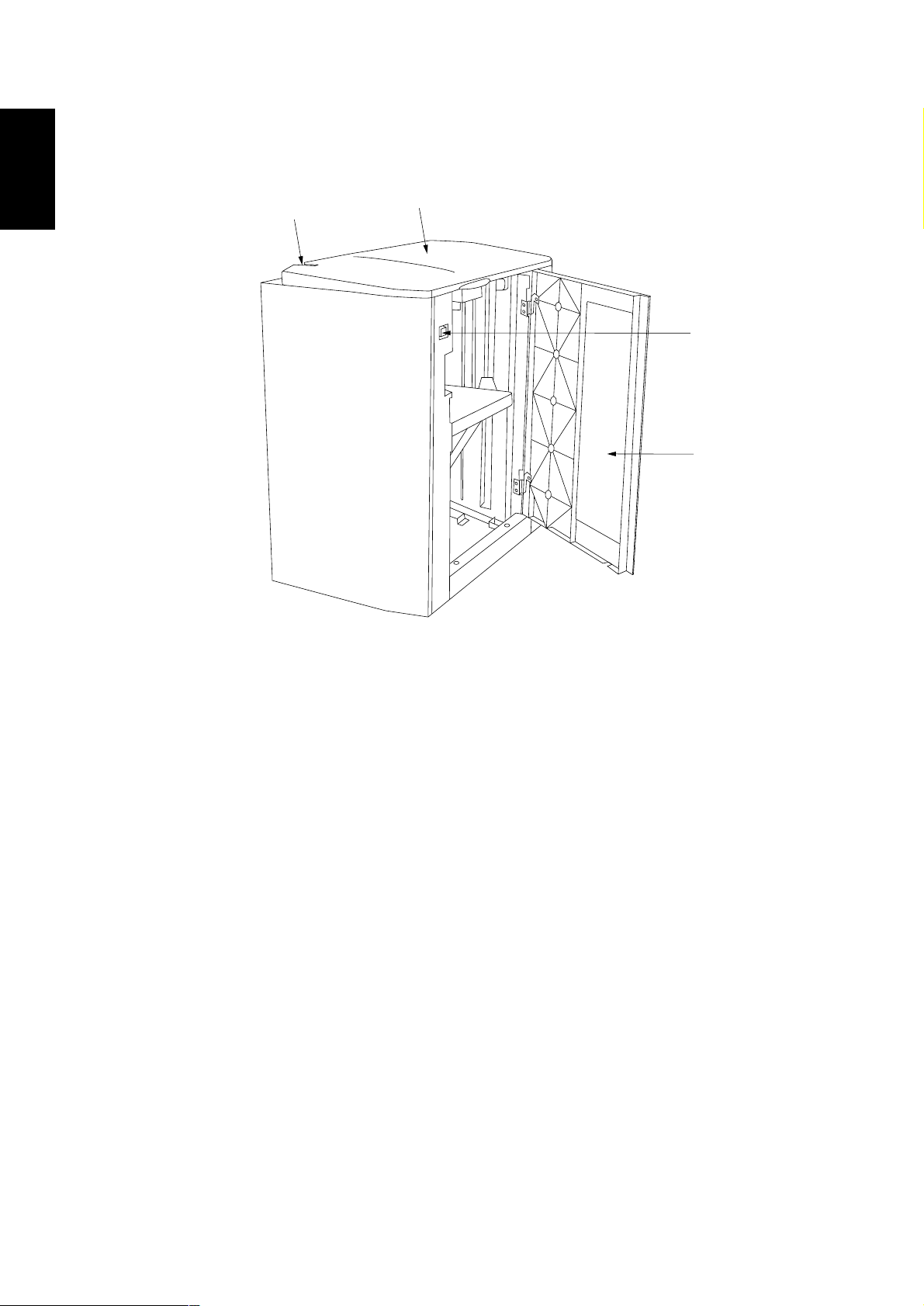

1-1-2 Parts names

4

1

3

2

Figure 1-1-1 Parts names

1 Upper cover

2 Right cover

3 Right down switch

4 Side deck release button

1-1-2

Page 5

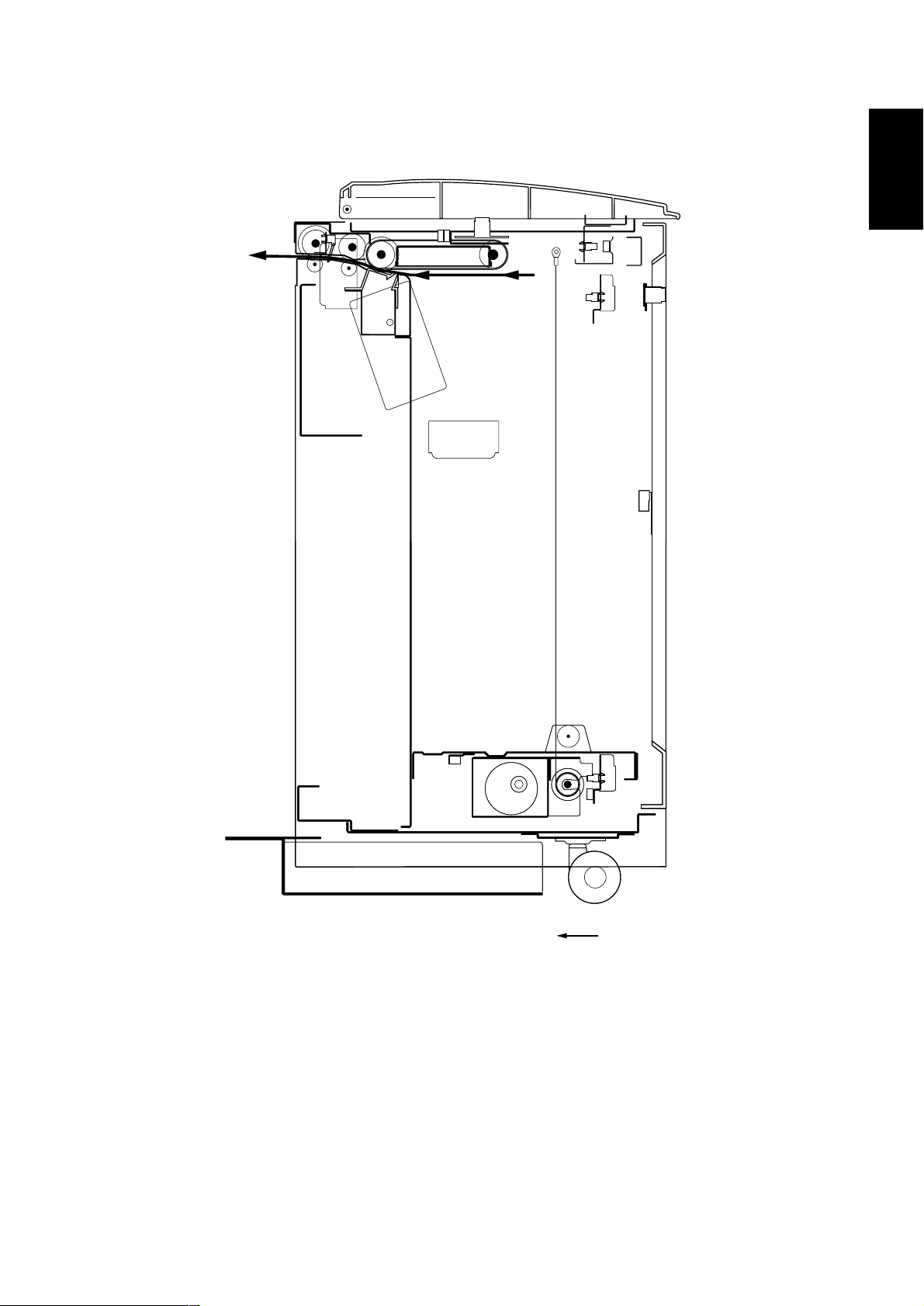

1-1-3 Machine cross section

3BF

1-1

Figure 1-1-2 Cross section

Paper path

1-1-3

Page 6

3BF

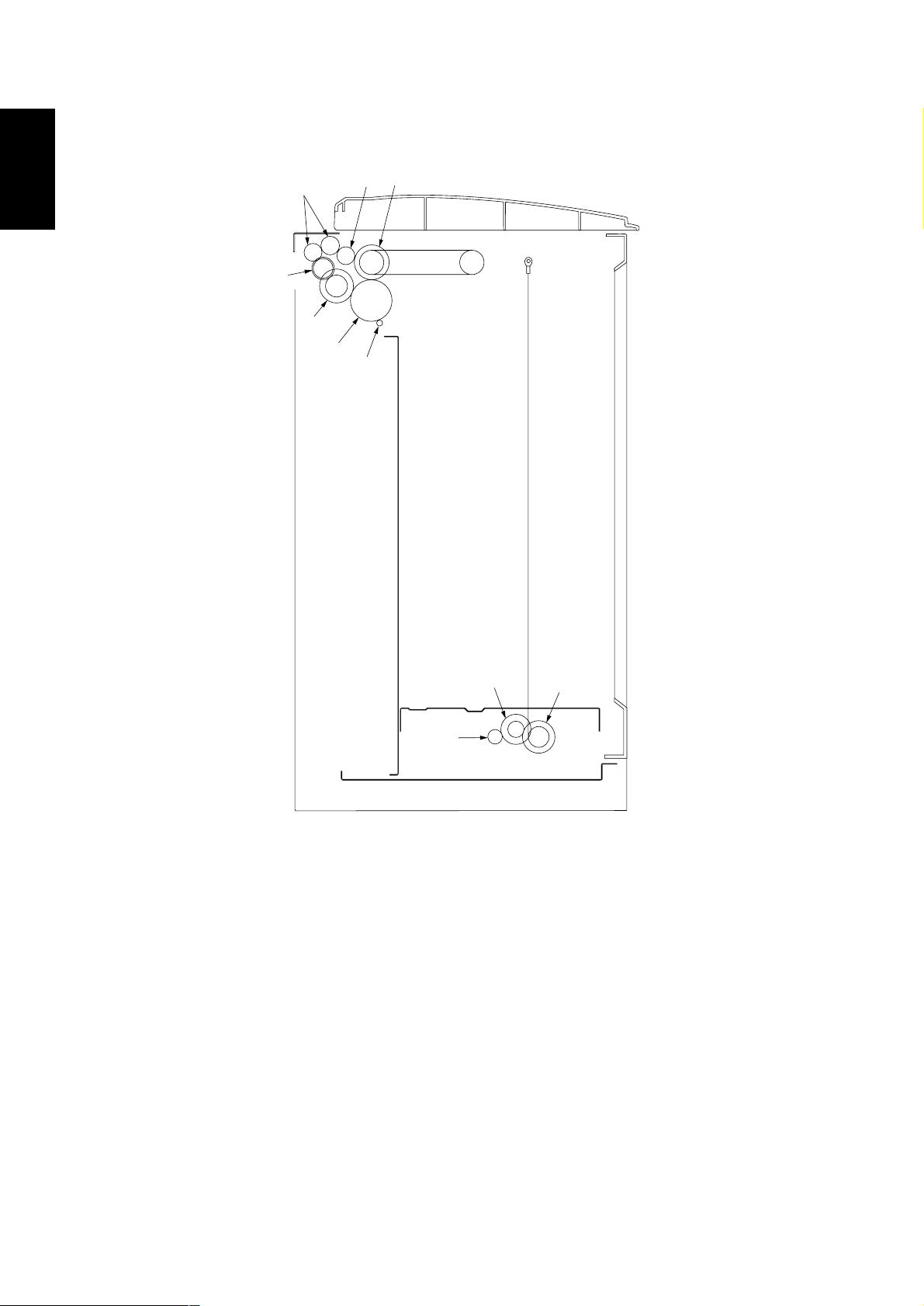

1-1-4 Drive system

1-1

4

5

3

2

6

1

7

9

8

Figure 1-2-3 Drive system

1 Paper feed motor gear

2 Feed gear 55/45

3 Duplex drive gear 24/36

4 Idle gear 20/24

5 Developing gear 20

6 Eject gear 20

7 Paper feed cluch gear

8 Lift gear 16

9 gear 31/17

0 Oil roller gear

0

1-1-4

Page 7

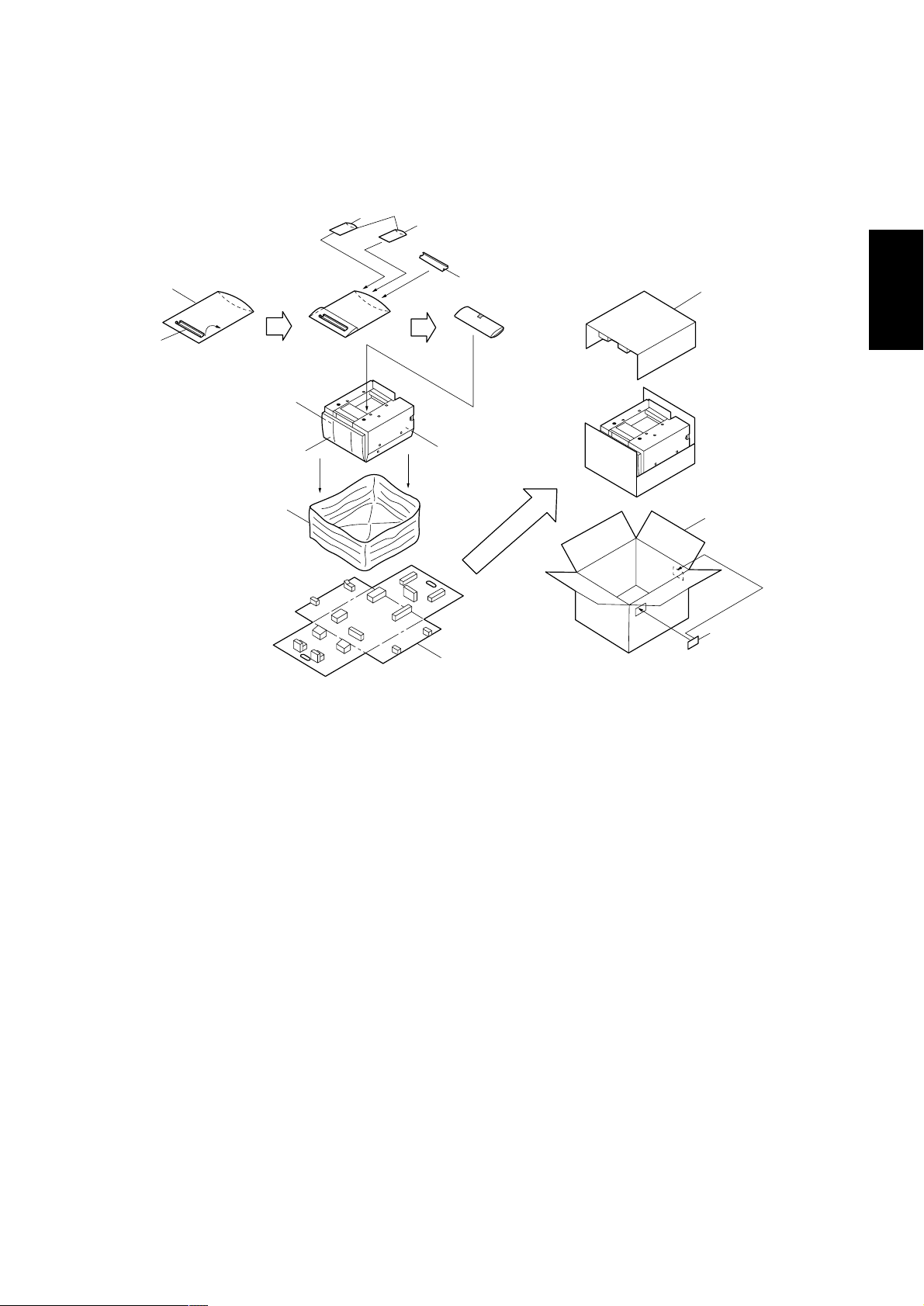

1-2-1 Unpacking

^

(1) Unpacking

3BF

2

&

!@

$

1

4

5678

3

%

0

#

1-2

*

9

Figure 1-2-1 Unpacking

1 Side deck

2 Upper merge guide

3 Lower merge guide

4 Interlock switch backstop

5 Cross-head chromate binding screw, CVM4 x 06

6 Flat-cross-head chromate screw, FHM4 x 12

7 Cross-head TP tap-tight P chromate screw, M4 x 6

8 Cross-head TP tap-tight P chromate screw, M4 x 8

9 Bottom pad

0 Top pad

! Lift spacer

@ Guide spacer

# Outer case

$ Machine cover

% Cover spacer

^ Plastic bag (70 x 110 mm)

& Air padded bag (400 x 500 mm)

* Bar code labels

1-2-1

Page 8

3BF

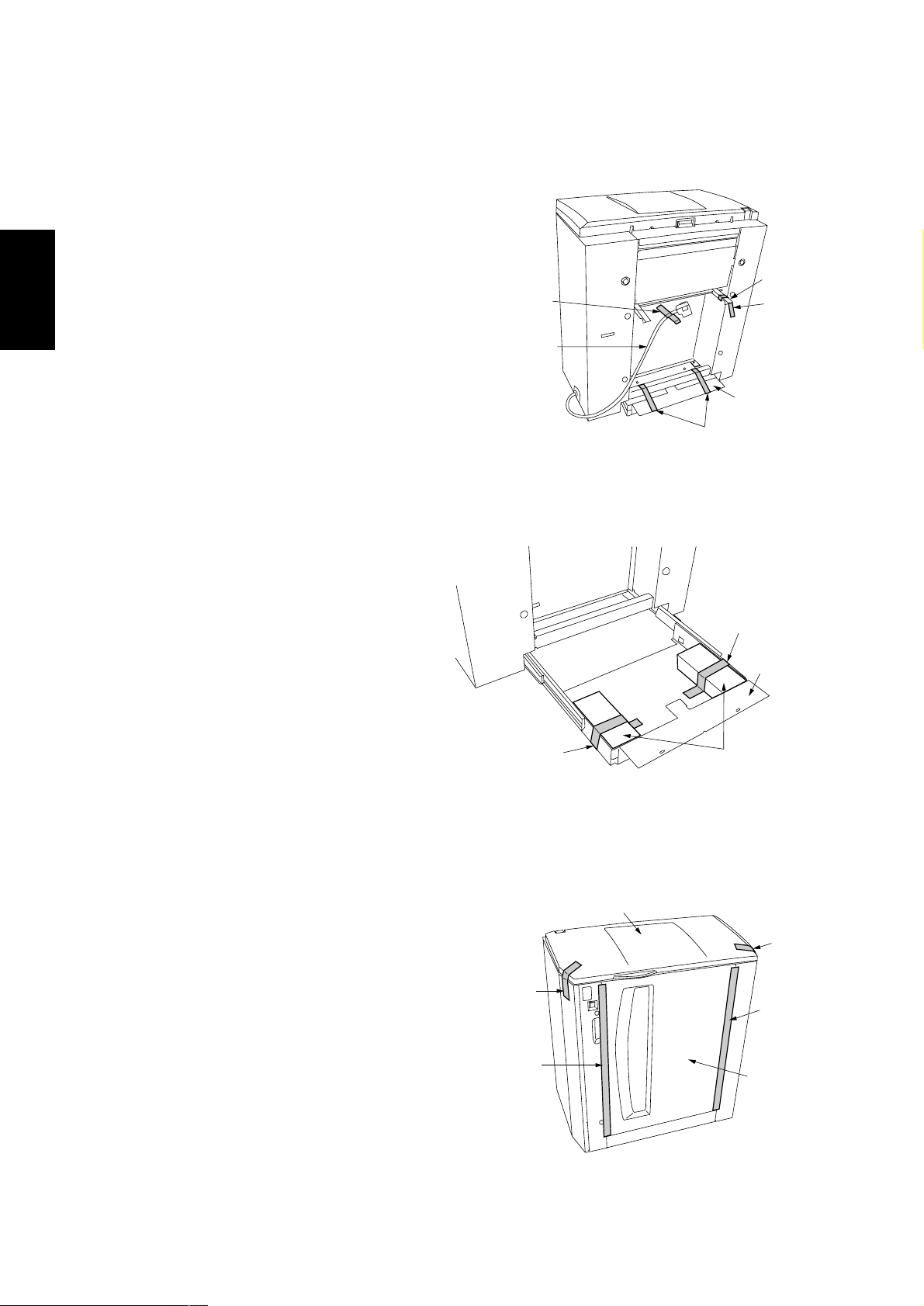

(2) Removing tapes and pads

Remove the tapes and pads as follows before machine installation.

1. Remove the tape securing the hook.

2. Remove the tape securing the signal cable.

3. Remove the two tapes securing the base

retainer.

1-2

4. Draw the base retainer out and remove the

tape securing each of the two base spacers

and then the spacers.

Tape

Signal cable

Hook

Tape

Base retainer

Tapes

Figure 1-2-2

Tape

Base retainer

5. Remove the two tapes securing each of the

upper and right covers.

Tape

Tape

Tape

Base spacers

Figure 1-2-3

Upper cover

Tape

Tape

Right cover

Figure 1-2-4

1-2-2

Page 9

6. Open the right cover and remove the tape

securing the cover spacer and then the

spacer.

7. Open the upper cover and remove the guide

spacer.

8. Remove the tape securing each of the two lift

spacers and then the spacers.

3BF

Cover spacer

Tape

1-2

Right cover

Figure 1-2-5

Guide spacer

Tape

Lift spacers

Figure 1-2-6

Tape

Upper cover

1-2-3

Page 10

1-3-1 Maintenance mode

3BF

Maintenance

item No.

U208 Setting the deck lift operation

Description

Sets the operation of the side deck lift motor for when paper in the side deck is exhausted.

Purpose

To be set according to the paper loading method.

Method

Press the start key. The screen for selecting an item is displayed.

Setting the paper loading method

1 Select the method to load paper at the screen for selecting an item.

Display

Side Feed

Upper Feed

Initial setting: Side Feed

2 Press the start key. The setting is set. The screen for selecting a maintenance item No. is displayed.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key. The screen for

selecting a maintenance item No. is displayed.

U247 Checking the operation of the side deck motors and clutches

Description

Turns on motors and clutches of the side deck.

Purpose

To check the operation of motors and clutches of the side desk devices.

Start

1 Press the start key. The screen for selecting an item is displayed.

Method

1 Press the item to be operated. The selected item is displayed in reverse and operation starts.

Display

SDECK MOT

SDECK FAN

SDECK LIFT

SDECK CVCL

LDECK FDCL

To stop the side deck lift motor, press the stop/clear key.

If this maintenance item is executed with the upper cover of the side deck open, detection of the upper

limit is not possible and thus the side deck lift motor overruns.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item

No. is displayed.

Description

Load paper through the right cover.

Load paper through the upper cover.

Motors and solenoids

Side deck drive motor (SDDM)

Separation fan motor (SFM) and Suction fan motor (IFM)

Side deck lift motor (SDLM)

Side deck paper conveying clutch (SDCCL)

Side deck paper feed clutch (SDPFCL)

Description

1-3

U337 Setting the paper size for the side deck

Description

Sets the paper size for the side deck.

This maintenance item is applied to only Japanese specification machines, so no setting is necessary.

1-3-1

Page 11

3BF

1-4-1 Paper misfeed detection

(1) Paper misfeed detection

When a paper jam occurs, the machine stops operating immediately. The copier operation section shows a jam message

and the jam location.

To remove the jammed paper, detach the side deck from the copier.

(2) Paper misfeed detection condition

• No paper feed from side deck (jam code 15)

Paper feed switch 1 (PFSW1) of the copier does not turn on within 848 ms of the side deck paper feed clutch (SDPFCL)

turning on; the clutch is then successively held off for 1 s and turned back on twice, but the switch again fails to turn on

within 848 ms.

SDPFCL Off

PFSW1

(Copier)

848 ms 848 ms

1 s 1 s

848 ms

Timing chart 1-4-1

(3) Paper misfeed

Problem Causes/check procedures Corrective measures

A paper jam in the

side deck is

indicated during

copying.

Check if the side deck

paper feed clutch

malfunctions.

Electrical problem with the

Check and repair if necessary.

Check (see page 1-4-2).

side deck paper feed

clutch.

On

Off

On

1-4

1-4-1

Page 12

1-4

3BF

1-4-2 Self-diagnosis

(1)Self-diagnostic function

When a problem is detected in the side deck, copying is disabled and the copier operation section displays a code

consisting of “C” followed by a number, indicating the nature of the problem.

After removing the problem, the self-diagnostic function can be reset by reattaching the side deck.

(2)Self diagnostic code

Code Contents

C032

Side deck communication problem

• An error code from the side deck is

detected eight times in succession.

No communication: there is no reply

after 3 retries.

Abnormal communication: a

communication error (parity or

checksum error) is detected five times

in succession.

Causes Check procedures/corrective measures

Poor contact in

the connector terminals.

Defective copier

engine PCB.

Defective copier

main PCB.

Defective side

deck main PCB.

Remarks

Check the connection of connector CN9 on

the copier main PCB and the connector

CN3 on the side deck main PCB, and the

continuity across the connector terminals.

Repair or replace if necessary.

Replace the copier engine PCB and check

for correct operation.

Replace the copier main PCB and check

for correct operation.

Replace the side deck main PCB and

check for correct operation.

1-4-3 Electrical problem

Problem Causes Check procedures/corrective measures

The side deck paper

feed clutch does not

operate.

Broken side deck paper

feed clutch coil.

Poor contact of the side

deck paper feed clutch

connector terminals.

Defective side deck main

PCB.

Check for continuity across the coil. If none, replace the side

deck paper feed clutch.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN5-A10 on the side deck main PCB goes low. If not,

replace the side deck main PCB.

1-4-2

Page 13

3BF

1-5-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the finisher power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the boards.

• Do not touch any PCB containing ICs with bare hands or any object prone to static charge.

1-5-2 Procedure for assembly and disassembly

(1) Adjusting the center line

Make the following adjustment if there is a regular error between the center lines of the original and the copy image when

paper is fed from the side deck.

Note: Before performing this adjustment, be sure to perform the center line adjustment of the copier.

Procedure

1. Run maintenance item U034 and make a test

copy.

2. Measure the discrepancy L (mm) between the

center lines of the paper and test copy.

3. Open the lower vertical conveying cover of the

copier. Loosen the two screws securing the deck

retainer and move the V-shaped groove on the

deck retainer by the measured amount L and

retighten the screws.

• If the center line is shifted to the machine front,

move the V-shaped groove of the deck retainer

toward the machine front (copy example 1).

• If the center line is shifted to the machine rear,

move the V-shaped groove of the deck retainer

toward the machine rear (copy example 2).

Screw

Screw

1-5

Figure 1-5-1

L

Copy example 1 Copy example 1

Figure 1-5-2

L

1-5-1

Page 14

3BF

2-1-1 Mechanical construction

The side deck consists of the paper lifting mechanism, which winds up paper with the wire of the side deck lift motor

(SDLM), and the paper feed and conveying mechanism, which conveys paper with the drive of the paper conveying belt,

feed roller and left feed roller.

The side deck lift motor (SDLM) raises the lift by winding up the wire engaged with the pulley. The lift is stopped at the upper

and lower limit by the control of the upper limit detection switch (ULPSW) and lower limit detection switch (LLPSW).

Paper is fed by controlling currents of air. The top sheet of the paper loaded on the lift is floated by the separation fan motor

(SFM) and then induced onto the paper conveying belt by the suction fan motor (IFM). The sheet thus attracted to the paper

conveying belt is then conveyed to the feed roller and left feed roller by the drive of the side deck drive motor (SDDM).

1

2

#

*

%

%

!

¤

‹

9

$

(

^

0

@

3

5

›

fi

^

)

&

fl

4

⁄

6

‡

·

°

‚Œ

8

7

„

2-1

1 Upper paper conveying guide

2 Lower paper conveying guide

3 Paper guide

4 Paper conveying belt retainer

5 Left side deck guide

6 Upper limit switch mount

7 Switch cover

8 Paper level detection switch

mount

9 Lower separation duct mount

0 Lower suction duct

! Upper separation duct

@ Upper suction duct

# Left feed roller

Figure 2-1-1 Side deck (1)

$ Feed roller

% Paper conveying pulley

^ Paper conveying belt pulley

& Paper conveying belt

* side deck paper feed clutch

(SDPFCL)

( side deck paper conveying

clutch (SDCCL)

) side deck drive motor (SDDM)

⁄ Suction fan motor (IFM)

¤ Separation fan motor (SFM)

‹ side deck feed switch (SDFSW)

› Upper cover safety switch

(UCSSW)

fi Upper cover open/close switch

(UCOSW)

fl Upper down switch (UDSW)

‡ Paper level detection switch

(PRDSW)

— Upper limit safety switch

(ULSSW)

· Upper limit detection switch

(ULPSW)

‚ Right cover open/close switch

(RCOSW)

ΠRight cover safety switch

(RCSSW)

„ Right down switch (RDSW)

2-1-1

Page 15

3BF

4

7

1

0

2-1

9

8

2

Figure 2-1-2 Side deck (2)

1 Lift

2 Side deck lift motor cover

3 Lower limit detection switch mount

4 Lift wire

5 Lift wire pulley

6 Wire holding plate

7 Mirror pulley

8 Side deck lift motor (SDLM)

9 Side deck paper empty switch (SDPESW)

0 Lower limit detection switch (LLPSW)

! Lower limit safety switch (LLSSW)

5

6

3

!

2-1-2

Page 16

3BF

SDPFCL

CN5-A10

SDFSW

CN6-B1

SDCCL

SFM

CN6-A1

SDMPCB

SDDM

CN6-B7

CN4-4

CN5-A12

SDLM

IFM

CN6-A2

CN6-B11

ULPSW

CN6-B6CN5-A8

LLPSW

Figure 2-1-3 Side deck block diagram

Start Key ON

50 ms

SDPFCL

SDCCL

ESW

(Copier)

SDFSW

SDDM

bc

190 ms

a

d

Timing chart 2-1-1

a: When the start key is pressed, the side deck drive motor (SDDM) turns on.

b: 50 ms after the start key is pressed, the side deck paper feed clutch (SDPFCL) turns on.

c: When the eject switch (ESW) of the copier turns off, the side deck paper feed clutch (SDPFCL) turns off.

d: 190 ms after the eject switch (ESW) of the copier turns off, the side deck drive motor (SDDM) turns off.

2-1

2-1-3

Page 17

2-2-1 Electrical parts layout

(1) PCBs, motors and clutches

3BF

5

4

6

2

7

8

1

3

Machine front Machine inside Machine rear

Figure 2-2-1 PCBs, motors and clutches

1. Side deck main PCB (SDMPCB) .................. Controls electrical components in the side deck and communications

with the copier.

2. Side deck drive motor (SDDM) ..................... Drives the paper feed and conveying mechanism in the side deck.

3. Side deck lift motor (SDLM) .......................... Drives the paper lift mechanism of the side deck.

4. Side deck paper conveying clutch

(SDCCL)........................................................ Transfers drive from the paper conveying belt.

5. Side deck paper feed clutch (SDPFCL) ........ Transfers drive from the left feed roller and feed roller.

6. Separation fan motor (SFM).......................... Separates the uppermost sheet in the side deck.

7. Suction fan motor (IFM) ................................ Attracts paper to the paper conveying belt.

8. Side deck dehumidifier heater (SDDH)......... Dehumidifies paper in the side deck.

2-2

2-2-1

Page 18

3BF

(2) Switches

1

11

12

10

8

3

6

4

13

14

9

2-2

2

Machine front Machine inside Machine rear

5

7

Figure 2-1-2 Switches

1. Side deck paper feed switch (SDFSW)......... Detects a paper misfeed.

2. Side deck paper empty switch (SDPESW) ... Detects the presence of paper in the side deck.

3. Paper level detection switch (PRDSW)......... Detects the paper level in the side deck.

4. Upper limit detection switch (ULPSW) .......... Detects the lift reaching the upper limit.

5. Lower limit detection switch (LLPSW)........... Detects the lift reaching the lower limit.

6. Upper limit safety switch (ULSSW) ............... Breaks the safety circuit when the lift overruns the upper limit.

7. Lower limit safety switch (LLSSW)................ Breaks the safety circuit when the lift overruns the lower limit.

8. Upper down switch (UDSW) ......................... For the controlling of the descending of the lift when the upper cover is

opened.

9. Right down switch (RDSW)........................... For the controlling of the descending of the lift when the right cover is

opened.

10. Side deck set switch (SDSETSW) ................ Detects the side deck attached to the copier; breaks the safety circuit

when the deck is detached from the copier.

11. Upper cover safety switch (UCSSW) ............ Breaks the safety circuit when the upper cover is opened.

12. Upper cover open/close switch (UCOSW) .... Detects whether the upper cover is open or closed.

13. Right cover safety switch (RCSSW) .............. Breaks the safety circuit when the right cover is opened.

14. Right cover open/close switch (RCOSW) ..... Detects whether the right cover is open or closed.

2-2-2

Page 19

2-3-1 Side deck main PCB

SDMPCB

5 V DC

3BF

24 V DC

Copier

24 V DC

SDSETSW

UCOSW

5 V DC

RESET

SDFSW

ULPSW

RCOSW

UDSW

LDSW

PRDSW

LLPSW

RxD/TxD

FEED WAIT

STOP REQ

24 V DC

5 V DC

Reset IC

(IC7)

24 V DC

24 V DC

24 V DC

_RESET

5 V DC

CPU

(IC3)

24 V DC

5 V DC

SDLM

driver circuit

(IC8)

SDDH

SDDM REM

SDDM CLOCK

SDDM ALARM

UCSSW

ULSSW

RCSSW

LLSSW

SFM

IFM

SDCCL

SDPFCL

SDDM

SDLM

Figure 2-3-1

The main component of the side deck main PCB (SDMPCB) is the CPU IC3. It controls the overall operation of the side deck

by receiving detection signals from switches as inputs and outputting drive signals to motors and clutches.

Communication of control signals with the copier is performed serially or through two parallel cables (FEED WAIT and STOP

REQ).

With the control signal received from the CPU IC3, the SDLM driver circuit IC8 drives the side deck lift motor (SDLM). A safety

circuit consisting of the side deck set switch (SDSETSW), upper cover safety switch (UCSSW) and right cover safety switch

(RCSSW) ensures the security by cutting 24 V DC supply for the SDLM driver circuit IC8 and drive output for the side deck

lift motor (SDLM) when the side deck is detached from the copier or when the upper or right cover is opened.

The reset IC7 monitors the 5 V DC power supply. When the power is turned on and when the supply voltage becomes low,

the reset IC7 outputs a RESET signal to the CPU IC3 to reset the system for the prevention of malfunctions.

2-3

2-3-1

Page 20

2-3

2-3-2

Figure 2-3-2

R69

R70

R67

3BF2801

R68

R65

R68

18

IC8

IC7

3BF

A1

B12

IC3

IC4

R39

L15

L12

R25

10

D2

R12

X1

C8

R36

R37

R38

D3

C9

C10

L11

TR3

R13

R14

L10

1

CN3

L9

L8

R3

+

R5

R7

D1

R8

R9

C7

R10

ZD1

C3

C4

C2

+

C6

IC1

C5

C6

L21

L26

3

L27

R71

IC2

4

L2

C11

R26

R11

C12

C14

R16

R27

R17

R28

R18

R29

R19

R30

R20

R31

R21

R32

R22

R33

R23

R34

R24

R35

C13

L7

TR1 TR2

A12

CN5

B1

R1

C1

L1

1

CN2

5

L2

L2

1

CN1

2

L3

L4

R2

R4

A1

A11

CN6

B11

TR5

R60

C16

C17

R46

R47

R48

R49

R50

R57

R51

R52

R53

R54

R55

R64

R58

R81

+

1

+

C23C22C21

C24

C25

C19

R63

1

+

IC6

C28

R82

L22

R59

C18

C20

R72

IC5

C20

R68

L18L20

L17

L19

TR4

C56

10

R42

R43

D4

R44

R45

L13

L14

L16

L15

CN4

B1

R41

R40

Page 21

Terminals (CN) Voltage Remarks

1-1 2-3, 4 24 V DC 24 V DC supply, output

1-2 2-1 0/24 V DC SDSETSW on/off, input

1-3 2-3, 4 24/0 V DC 24 V DC supply, input (via SDSETSW)

1-4 2-3, 4 24/0 V DC 24 V DC supply, input (via SDSETSW and UCOSW)

2-2 2-1 5 V DC 5 V DC supply, input

2-5, 6 2-3, 4 24 V DC 24 V DC supply, input

3-1 3-2 0/5 V DC (pulse) Serial communication signal, output (TxD)

3-3 3-4 0/5 V DC (pulse) Serial communication signal, input (RxD)

3-6 2-1 0/5 V DC STOP REQ signal, output

3-7 2-1 0/5 V DC FEED WAIT signal, input

3-8 2-1 0/5 V DC RESET signal, input

3-9 2-1 0/5 V DC (FEED REQ signal, input)

3-10 2-1 0/5 V DC (PFD FEED SW signal, output)

4-2 4-6 0/5 V DC SDDM CLOCK signal, output

4-3 4-6 0/5 V DC SDDM ALARM signal, input

4-4 4-6 0/5 V DC SDDM REM signal, output

4-5 4-6 5 V DC 5 V DC supply for SDDM, output

4-9, 10 4-7, 8 24 V DC 24 V DC supply for SDDM, output

5-A2 5-B11 0/5 V DC RDSW LED on/off, output

5-A3 5-B10 0/5 V DC UDSW LED on/off, output

5-A4 5-B11 0/5 V DC RDSW on/off, input

5-A5 5-B10 0/5 V DC UDSW on/off, input

5-A6 5-B6 5 V DC 5 V DC supply for PRDSW, output

5-A7 5-B6 0/5 V DC PRDSW on/off, input

5-A8 5-B5 0/5 V DC LPSW on/off, input

5-A9 5-B4 0/5 V DC RCOSW on/off, input

5-A10 2-3, 4 0/24 V DC SDPFCL on/off, output

5-A11 2-3, 4 0/24 V DC SDDH on/off, output

5-B2 2-3, 4 24 V DC 24 V DC supply for SDFDH, output

5-B3 2-3, 4 24 V DC 24 V DC supply for SDPFCL, output

5-B7 5-B5 5 V DC 5 V DC supply for LLPSW, output

5-B8 5-B10 5 V DC 5 V DC supply for UDSW, output

5-B9 5-B11 5 V DC 5 V DC supply for RDSW, output

5-A12 6-B11 +24/0/-24 V DC SDLM forwarding/stop/reversing, output

6-A1 2-1 0/5 V DC SFM on/off, output

6-A2 2-1 0/5 V DC IFM on/off, output

6-A3 6-A5 24 V DC 24 DC supply for SFM, output

6-A4 6-A6 24 V DC 24 DC supply for IFM, output

6-A7 2-1 5 V DC 5 V DC supply for SFM, output

6-A8 2-1 5 V DC 5 V DC supply for IFM, output

6-A9 6-A10 5 V DC 5 V DC supply for SDPESW, output

6-A11 6-A10 0/5 V DC SDPESW on/off, input

6-B1 6-B3 0/5 V DC SDFSW on/off, input

6-B2 6-B3 5 V DC 5 V DC supply for SDFSW, output

6-B5 6-B4 5 V DC 5 V DC supply for ULPSW, output

6-B6 6-B4 0/5 V DC ULPSW on/off, input

6-B7 2-3, 4 0/24 V DC SDCCL on/off, output

6-B8 2-3, 4 24 V DC 24 V DC supply for SDCCL, output

3BF

2-3

2-3-3

Page 22

Start Key ON

RCL*

FCL1*

SDPFCL

SDCCL

PFSW2*

TC REM*

ESW*

RSW*

FSW*

PFSW1*

SDFSW

PFM*

SDDM

DM*

MC REM*

CN13-A8

CN13-A6

CN5-A10

CN6-B7

CN20-A11

CN5-5

CN4-12

CN3-28

CN20-B8

CN12-5

CN6-B1

CN21-B3

CN4-4

CN18-21

CN6-3

50 ms

165 ms

Image ready

240 ms

100 ms

100 ms

300 ms

190 ms

125 ms

375 ms

40 ms

*: Copier

3BF

Timing chart

2-4

2-4-1

Page 23

8

7

6

5

4

3

2

1

Wiring diagram

A B C D E F G H IJ

8

1

Copier

2

3

4

5

6

7

8

16151413121110

9

RESET

7

PFD DET

6

RxD

5

S.G (RxD)

TxD

S.G (TxD)

2

STOP REQ

FEED WAIT

P.G

13

SDFSW

21

FEED REQ

34

4

24 V

5

24 V

6

P.G

7

5 V

8

P.G

9

RD/BK

YW/BK

WE/BK

PK

LB/BK

GN/BK

GY

PE

BE

BK

WE

RD

GN

YW

BN

OE

3-8

3-5

3-3

3-4

3-1

3-2

3-6

3-7

2-4

3-10

3-9

2-6

2-5

2-3

2-2

2-1

6-B1

6-B2

6-B3

6-B4

6-B5

6-B6

6-B7

6-B8

6-B9

6-B10

6-B11

1-1

1-3

1-2

1-4

6-A1

6-A7

6-A3

6-A5

6-A2

6-A8

6-A4

6-A6

11

SDFSW

10

5 V

9

S.G

S.G

5 V

6

ULPSW

587

SDCCL

R24 V

2134

SDLM-

24 V

SDLM DRV 24 V

SDSETSW

R24 V SIG

SFM

5 V

R24 V

P.G

IFM

5 V

R24 V

P.G

YW

OE

RD

BE

GN

OE

RD

BE

5

9

716 21384

16

A B C D E F G H IJ

GY

GN

OE

BE

YW

OE

BN

RD

GY

LB

PK

RD

RD

GN

BN

1

3

BE

2

2

OE

1

3

GN

1

8

BE

7

YW

6

3

OE

5

4

LB

4

5

RD

6

3

GN

1

2

72

PK

8

2

1

BN

3

31

2

1

2

1

2

3

321

SDFSW

ULPSW

SDCCL

ULSSW

SDSETSW

SFM

1

2

3

4

1

1

2

2

3

3

4

4

IFM

GY

RD

1

2

3

4

5

UCSSW

UCOSW

GRAY

GY

PURPLE

PE

LIGHT BLUE

ORANGE

PINK

RED

OE

RD

LB

WHITE

BLUE

BEWEPK

YELLOW

GREEN

YW

GN

BROWN

BLACK

BN

BK

Wire color

Mark

SDMPCB

6-A10

6-A11

6-A9

5-B1

5-A1

5-B4

5-A9

5-B12

5-A12

5-B8

5-A3

5-A5

5-B10

5-B9

5-A2

5-A4

5-B11

5-A10

5-B3

5-A6

5-B6

5-A7

5-B7

5-B5

5-A8

5-A11

5-B2

4-10

4-9

4-8

4-7

4-6

4-5

4-4

4-3

4-2

4-1

S.G

SDPESW

5 V

P.G YW

B12

A12

S.G

B9

RCOSW

A4

B1

SDLM+

A1

5 V

B5

LED REM

A10

UDSW

A8

S.G

B3

5 V

B4

LED REM

A11

RDSW

A9

S.G

B2

SDPFCL

A3

24 V

B10

5 V

A7

S.G

B7

PRDSW

A6

5 V

B6

S.G

B8

LLPSW

A5

SDDH

A2

24 V

B11

R24 V

R24 V

P.G

4

P.G

5

S.G

5V

6213

SDDM REM

SDDM ALM

87

SDDM CLK

9

10

BE

PK

OE

LB

12

GN

YW

GN

YW PK

GN LB

YW

GN

GN

YW

YW

GN

GN

YW

GN

YW

GN

YW

GN

YW

YW

GN

GN

YW

GY

GY

GY

GY

GY

GY

GY

GY

GY

GY

1

12

10

11

1

2

3

4

5

6

7

8

9

10

9

4

1

5

6

3

9

4

2

310

7

6

6

7

5

8

2

11

YW

OE

BN

LB

BE

OE

GN

GN

BE

BN

RD

1

13

5

9

12

2

3

11

9

5

2

12

4

10

10

4

86

77

6

8

311

10

9

8

7

6

5

4

3

2

1

YW

BE

OE

OE

BE

PK

GN

RD

1

3

21

2

BE

PK

OE

321

SDPESW

GY

PK

1

LB

2

BE

3

PK

4

OE

5

BN

PK

GY

BE

1

2

4

3

BN

LB

PK

GY

1

2

3

4

RCSSW RCOSW

SDLM

PK

1

YW

2

BN

3

BE

4

LB

5

PK

1

YW

2

3

1

2

3

4

1

2

3

4

1

2

UDSW

RDSW

SDPFCL

LLSSW

PRDSW

321 321

LLPSW

2

1

10

1

958

2

3

7

4

6

5

6

7

8

2

9

134

10

SDDH

SDDM

2-4-2

2-4

8

7

6

5

4

3

2

1

3BF

Page 24

KYOCERA MITA EUROPE B.V.

Hoeksteen 40, 2132 MS Hoofddorp,

The Netherlands

Phone: (020) 6540000

Home page: http://www.mita.nl, Email: info@mita.nl

KYOCERA MITA NEDERLAND B.V.

Gyroscoopweg 122, 1042 AZ Amsterdam,

The Netherlands

Phone: (020) 5877200

KYOCERA MITA (U.K.) LTD.

Mita House, Hamm Moor Lane,

Addlestone, Weybridge,

Surrey KT15 2SB, U.K.

Phone: (01932) 858266

KYOCERA MITA ITALIA S.P.A.

Via Marconi 8, 20041 Agrate Brianza,

Milano, Italy

Phone: (039) 65641

S.A. KYOCERA MITA BELGIUM N.V.

Hermesstraat 8A 1930 Zaventem, Belgium

Phone: (02) 7209270

KYOCERA MITA FRANCE S.A.R.L.

1 Rue Pelloutier,

77183 Croissy Beaubourg, France

Phone: (1) 60175152

KYOCERA MITA ESPAÑA S.A.

Edificio Mita, Avda. De Manacor Nº 2,

Urb. Parque Rozas, Apartado De Correos 76,

28230 Las Rozas, Madrid, Spain

Phone: 34-91-631-8392

KYOCERA MITA FINLAND OY

Kirvesmiehenkatu 4, 00810 Helsinki,

Finland

Phone: (09) 478 05200

KYOCERA MITA (SCHWEIZ) AG

Hölzliwisen Industriestrasse 28,

8604 Volketswil, Switzerland

Phone: (01) 9084949

KYOCERA MITA DEUTSCHLAND GMBH

Industriestrasse 17, D-61449 Steinbach/TS,

Germany

Phone: (06171) 7005-0

KYOCERA MITA GMBH AUSTRIA

Eduard Kittenberger Gasse 95

A-1230 Wien, Austria

Phone: (01) 86338 210

KYOCERA MITA SVENSKA AB

Siktgatan 2

162 26 Vällingby, Sweden

Phone: (08) 4719999

KYOCERA MITA DANMARK A/S

Industrivej 11, DK-4632 Bjæverskov,

Denmark

Phone: 56871100

KYOCERA MITA PORTUGAL LDA.

CASCAISTOCK-Armazem nº8,

Rua das Fisgas, Alcoitão,

2765 Estoril, Portugal

Phone: 1-4602221

KYOCERA MITA SOUTH AFRICA

(PTY) LTD.

Unit 3, "KYALAMI CRESCENT",

KYALAMI BUSINESS PARK,

1685 Midrand, South Africa

Phone: (011) 4663290

KYOCERA MITA

AMERICA, INC.

Headquarters:

225 Sand Road, P.O. Box 40008

Fairfield, New Jersey 07004-0008

U.S.A.

Phone: (973) 808-8444

KYOCERA MITA ASIA

OCEANIA SALES DIVISION

2-28, 1-chome, Tamatsukuri, Chuo-ku,

Osaka 540-8585, Japan

Phone: (06) 6764-3668

KYOCERA MITA AUSTRALIA PTY.

LTD.

P.O. Box 211,

Regents Park Estate Unit 2,

Block V 391 Park Road,

Regents Park N.S.W. 2143, Australia

Phone: 61-2-9645-5100

KYOCERA MITA NEW ZEALAND LTD.

5 Howe Street, Newton, Auckland 1,

P.O. Box 68343,

Auckland, New Zealand

Phone: (09) 377-2088

KYOCERA MITA (THAILAND) CORP.,

LTD.

9/209 Ratchada-Prachacheun Road,

Bang Sue, Bangkok 10800, Thailand

Phone: (02) 586-0333

KYOCERA MITA SINGAPORE

PTE LTD.

121 Genting Lane, 3rd. Level,

Singapore 349572

Phone: 65-7418733

KYOCERA MITA HONG KONG

LIMITED.

11/F., Mita Centre,

552-566 Castle Peak Road,

Tsuen Wan, New Territories,

Hong Kong

Phone: 852-2423-2163

KYOCERA MITA

CORPORATION

2-28, 1-chome, Tamatsukuri, Chuo-ku,

Osaka 540-8585, Japan

Phone: (06) 6764-3555

Fax: (06) 6764-3981

©2000 KYOCERA MITA CORPORATION

is a trademark of Kyocera Corporation

is a registered trademark of KYOCERA MITA CORPORATION

Printed in Holland

Loading...

Loading...