Page 1

SRDF-2

SERVICE

MANUAL

Published in Apr. ’02

843C0110

Page 2

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 3

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 4

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

Page 5

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement....................

Page 6

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

Page 7

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................................ 1-1-1

1-1-2 Parts names and their functions ............................................................................................................ 1-1-2

(1) Parts names .................................................................................................................................... 1-1-2

1-1-3 Machine cross section ........................................................................................................................... 1-1-3

1-1-4 Drive system ......................................................................................................................................... 1-1-4

(1) Drive system .................................................................................................................................... 1-1-4

1-2 Handling Precautions

1-2-1 Installation environment ........................................................................................................................ 1-2-1

1-3 Installation

1-3-1 Unpacking and installation .................................................................................................................... 1-3-1

(1) Unpacking ........................................................................................................................................ 1-3-1

1-4 Maintenance Mode

1-4-1 Maintenance mode ................................................................................................................................ 1-4-1

(1) Executing a maintenance item ........................................................................................................ 1-4-1

(2) Maintenance mode item list ............................................................................................................. 1-4-2

(3) Contents of maintenance mode items ............................................................................................. 1-4-3

3C0

1-5 Troubleshooting

1-5-1 Original misfeed detection .................................................................................................................... 1-5-1

(1) Original misfeed indication ............................................................................................................. 1-5-1

(2) Original misfeed detection conditions .............................................................................................. 1-5-1

(3) Original misfeeds ............................................................................................................................. 1-5-3

1-5-2 Image formation problems .................................................................................................................... 1-5-5

(1) There is a regular error between the centers of the original and copy image. ................................ 1-5-6

(2) There is a regular error between the leading edges of the original and copy image. ...................... 1-5-6

(3) There is a regular error between the trailing edges of the original and copy image. ....................... 1-5-6

1-5-3 Electrical problems ................................................................................................................................ 1-5-7

(1) The original feed motor does not operate. ....................................................................................... 1-5-7

(2) The original conveying motor does not operate. ............................................................................. 1-5-7

(3) The original feed solenoid does not operate. .................................................................................. 1-5-7

(4) The switchback feedshift solenoid does not operate. ...................................................................... 1-5-7

(5) The eject feedshift solenoid does not operate. ................................................................................ 1-5-7

(6) The switchback pressure solenoid does not operate. ..................................................................... 1-5-7

(7) The original feed clutch does not operate. ...................................................................................... 1-5-8

(8) A message indicating cover open is displayed when the DF is closed correctly. ............................ 1-5-8

(9) An original jams when the main switch is turned on. ....................................................................... 1-5-8

1-5-4 Mechanical problems ........................................................................................................................... 1-5-9

(1) No primary original feed. ................................................................................................................. 1-5-9

(2) No secondary original feed. ............................................................................................................. 1-5-9

(3) Originals jam. ................................................................................................................................... 1-5-9

1-6 Assembly and Disassembly

1-6-1 Precautions for assembly and disassembly ......................................................................................... 1-6-1

(1) Precautions ...................................................................................................................................... 1-6-1

(2) Running a maintenance item ........................................................................................................... 1-6-2

1-6-2 Original feed section ............................................................................................................................. 1-6-3

(1) Detaching and refitting the DF forwarding pulley and DF feed pulley ............................................. 1-6-3

(2) Detaching and refitting the DF separation pulley ............................................................................. 1-6-4

(3) Adjusting the DF magnification ........................................................................................................ 1-6-8

(4) Adjusting the DF center line ............................................................................................................ 1-6-9

(5) Adjusting the scanning start position ............................................................................................. 1-6-10

(5-1) Adjusting the DF leading edge registration ........................................................................... 1-6-10

(5-2) Adjusting the DF trailing edge registration ............................................................................ 1-6-11

(6) Adjusting the margins for scanning the original from the DF ......................................................... 1-6-12

1-1-1

Page 8

3C0

2-1 Mechanical construction

2-1-1 Original feed section ............................................................................................................................. 2-1-1

(1) Original feed timing .......................................................................................................................... 2-1-2

2-1-2 Original switchback section ................................................................................................................... 2-1-3

(1) Operation of original switchback ...................................................................................................... 2-1-4

2-1-3 Original conveying section .................................................................................................................... 2-1-5

(1) Original switchback/conveying timing .............................................................................................. 2-1-6

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ............................................................................................................................ 2-2-1

(1) PCBs ............................................................................................................................................... 2-2-1

(2) Switches and sensors ...................................................................................................................... 2-2-2

(3) Motors .............................................................................................................................................. 2-2-3

(4) Clutches and solenoids ................................................................................................................... 2-2-4

2-3 Operation of the PCBs

2-3-1 DF driver PCB ....................................................................................................................................... 2-3-1

2-4 Appendixes

Timing chart No. 1 ........................................................................................................................................... 2-4-1

Timing chart No. 2 ........................................................................................................................................... 2-4-2

Timing chart No. 3 ........................................................................................................................................... 2-4-3

Maintenance parts list...................................................................................................................................... 2-4-4

Periodic maintenance procedures ................................................................................................................... 2-4-5

Connection diagram ........................................................................................................................................ 2-4-7

Wiring diagram ................................................................................................................................................ 2-4-8

1-1-2

Page 9

1-1-1 Specifications

Type ............................................... Machine mounted type duplex sheet-through document feeder

Original feed system ...................... Automatic feed

Originals ......................................... Sheets

Original weights.............................. Single-sided original mode: 35 – 160 g/m

Double-sided original mode: 50 – 120 g/m

Original paper................................. Plain paper, thermal paper, art paper and colored paper

1

Original sizes .................................. A3 – A5R, folio/11" × 17" – 5

/2" × 81/2"

No. of originals ............................... Up to 70 sheets (A3, B4, folio, 11" × 17", 8

Up to 100 sheets (up to A4/11" × 8

Up to 30 sheets in the auto selection mode

Original processing speed.............. Original replacement: Max. 62 sheets/min (A4/11" × 81/2")

Original scanning: 167 mm/s (100%)

Power source ................................. Electrically connected to the copier (5 V DC and 24 V DC)

Dimensions .................................... 553 (W) × 478 (D) × 137 (H) mm

3

/4" (W) × 1813/16" (D) × 53/8" (H)

21

Weight ............................................Approx. 10.5 kg/23.1 lbs

2

2

1

1

/2")

/2" × 14")

3C0

1-1-1

Page 10

3C0

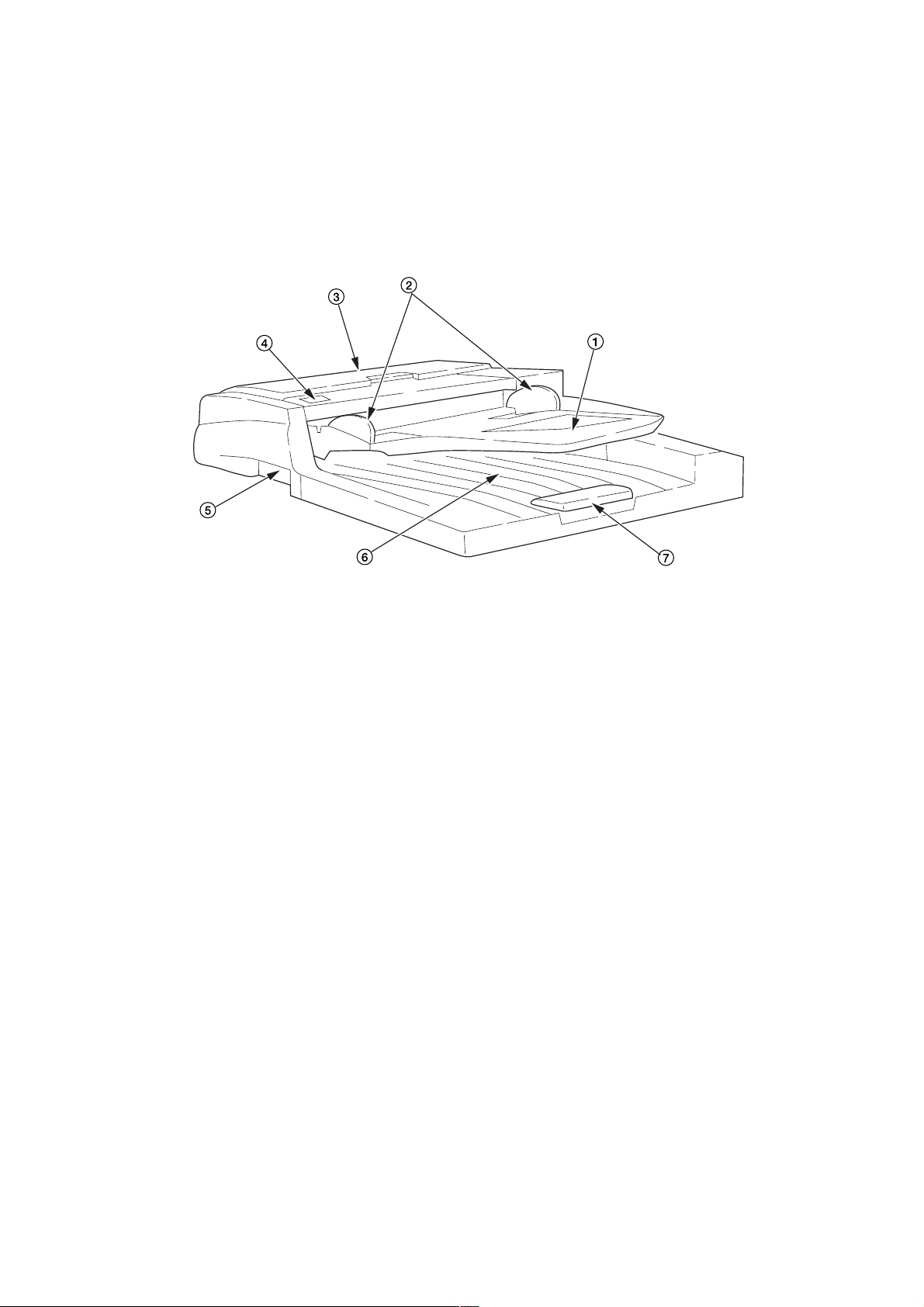

1-1-2 Parts names and their functions

(1) Parts names

Figure 1-1-1

1 Original table

2 Original insert guides

3 DF original reversing cover

4 Original set indicator

5 Original eject cover

6 DF opening/closing lever

7 Ejection extension

1-1-2

Page 11

1-1-3 Machine cross section

3C0

Paper and original path

Figure 1-1-2 Machine cross section

1 Original feed section

2 Original switchback section

3 Original conveying section

1-1-3

Page 12

3C0

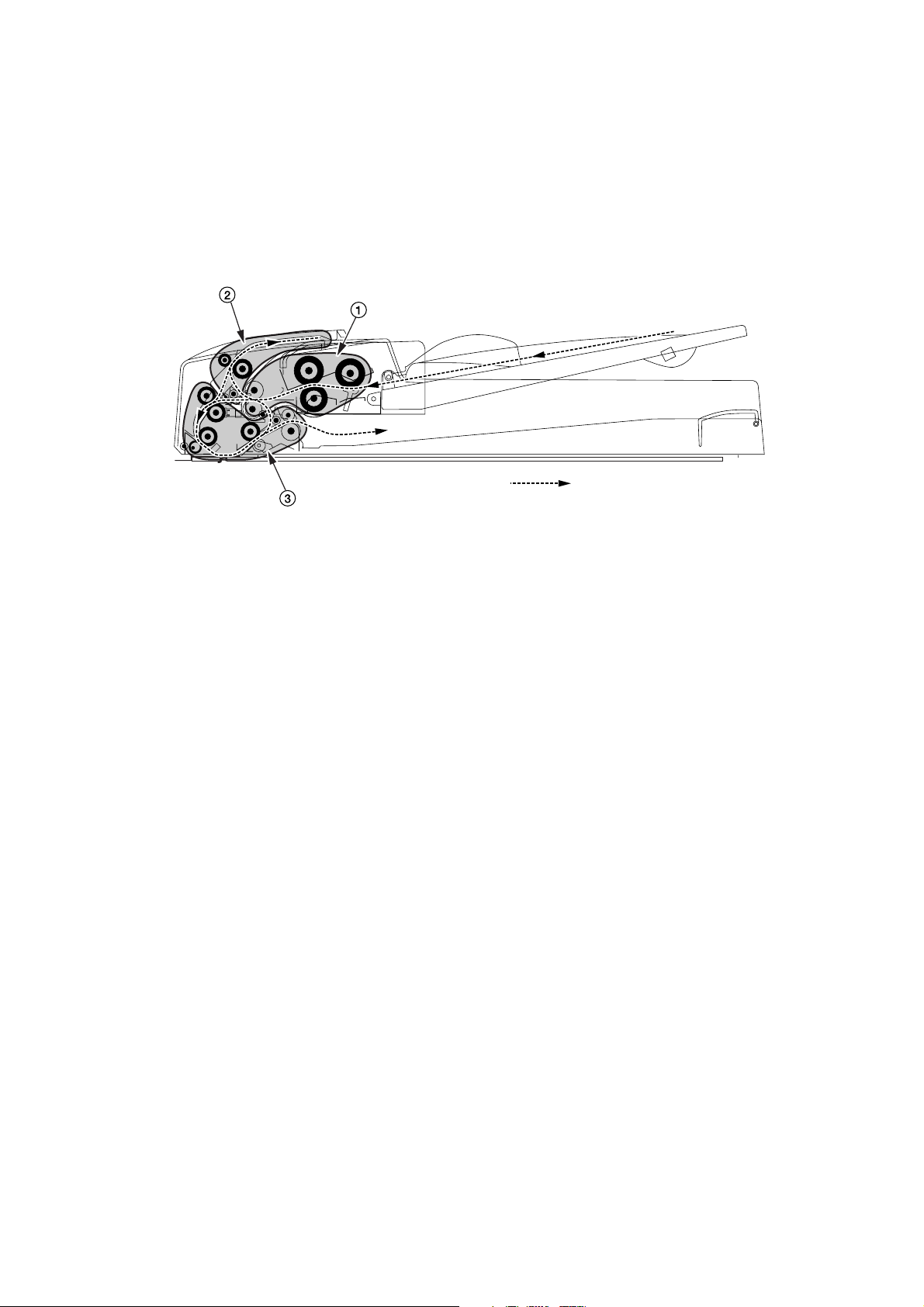

1-1-4 Drive system

(1) Drive system

6

1

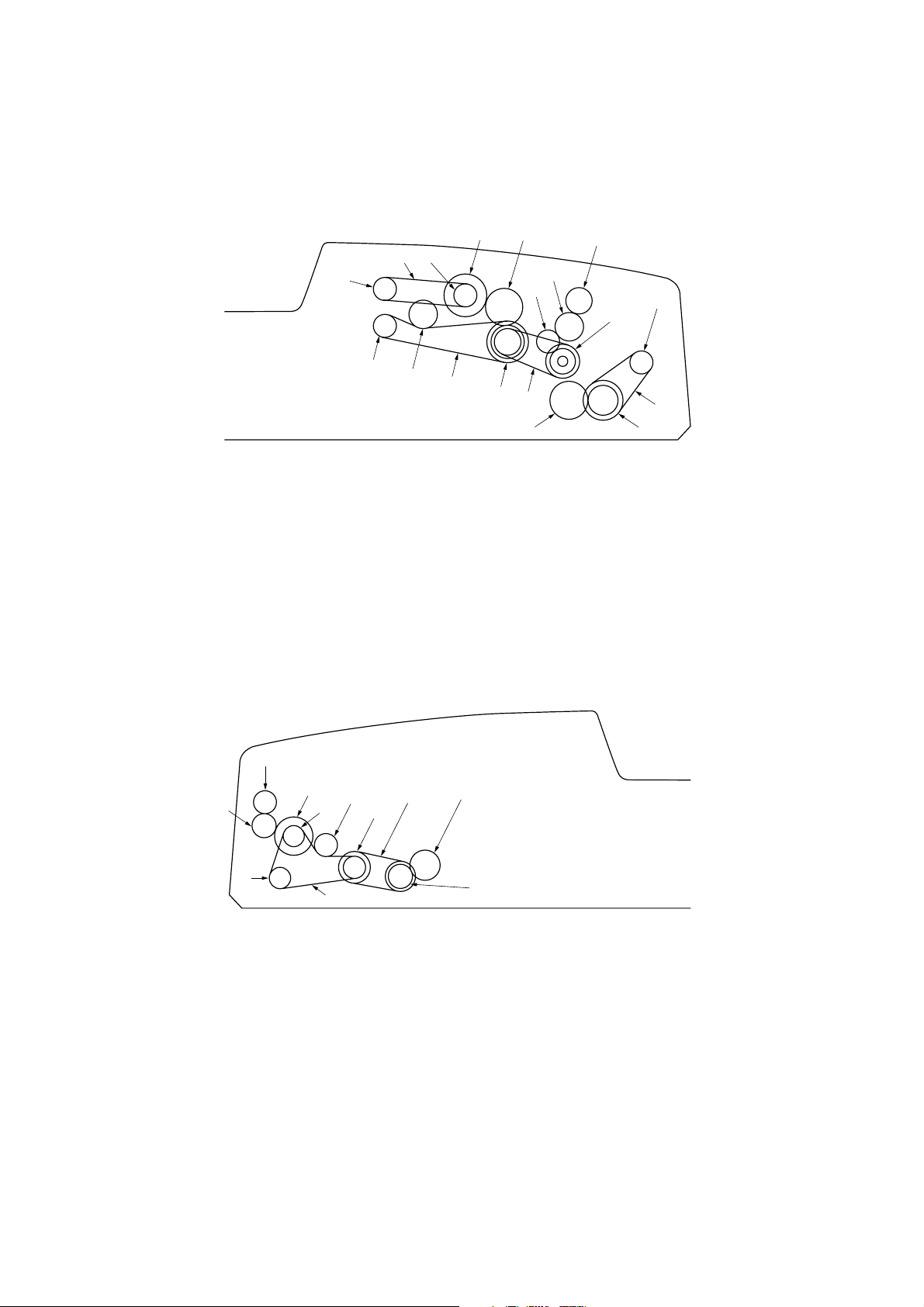

Figure 1-1-3 Drive system (inside rear of machine)

1 Original feed motor pulley

2 Pulley 35/22/22

3 Idle gear 26

4 Original feed clutch gear

5 DF original feed pulley 18

6 DF forwarding pulley 18

7 Tension pulley

8 Original feed drive belt

9 DF forwarding belt

9

7

5

43

#

@

!

0

8

2

$

&

As viewed from machine rear

0 DF registration pulley 28/18

! Idle gear 15

@ Idle gear 20

# Switch back gear 18

$ DF registration drive belt

% Gear 22/35

^ Original conveying motor pulley

& Gear 28

* Original conveying drive belt 1

^

*

%

8

7

6

5

9

0

1

4

!

Figure 1-1-4 Drive system (inside front of machine)

1 Lower original conveying pulley 25/18

2 Gear 18/25

3 Eject gear 18

4 Middle original conveying pulley 18

5 Upper original conveying pulley 18

6 JAM release gear 24

3

2

As viewed from machine front

7 Joint gear 14

8 JAM release gear 14

9 Tension pulley

0 Eject drive belt

! Conveying drive belt 2

1-1-4

Page 13

1-2-1 Installation environment

1. Installation location (Be based on the copier establishment place.)

• Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other

strong light when removing paper jams.

• Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto

the machine.

• Avoid dust and vibration.

• Choose a surface capable of supporting the weight of the machine.

• Place the machine on a level surface (maximum allowance inclination: 1° ).

• Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

• Select a room with good ventilation.

3C0

b

c

3

a: 553 mm/21

b: 478 mm/18

c: 137 mm/5

/4"

13

/16"

3

/8"

Figure 1-2-1 Installation dimensions

a

1-2-1

Page 14

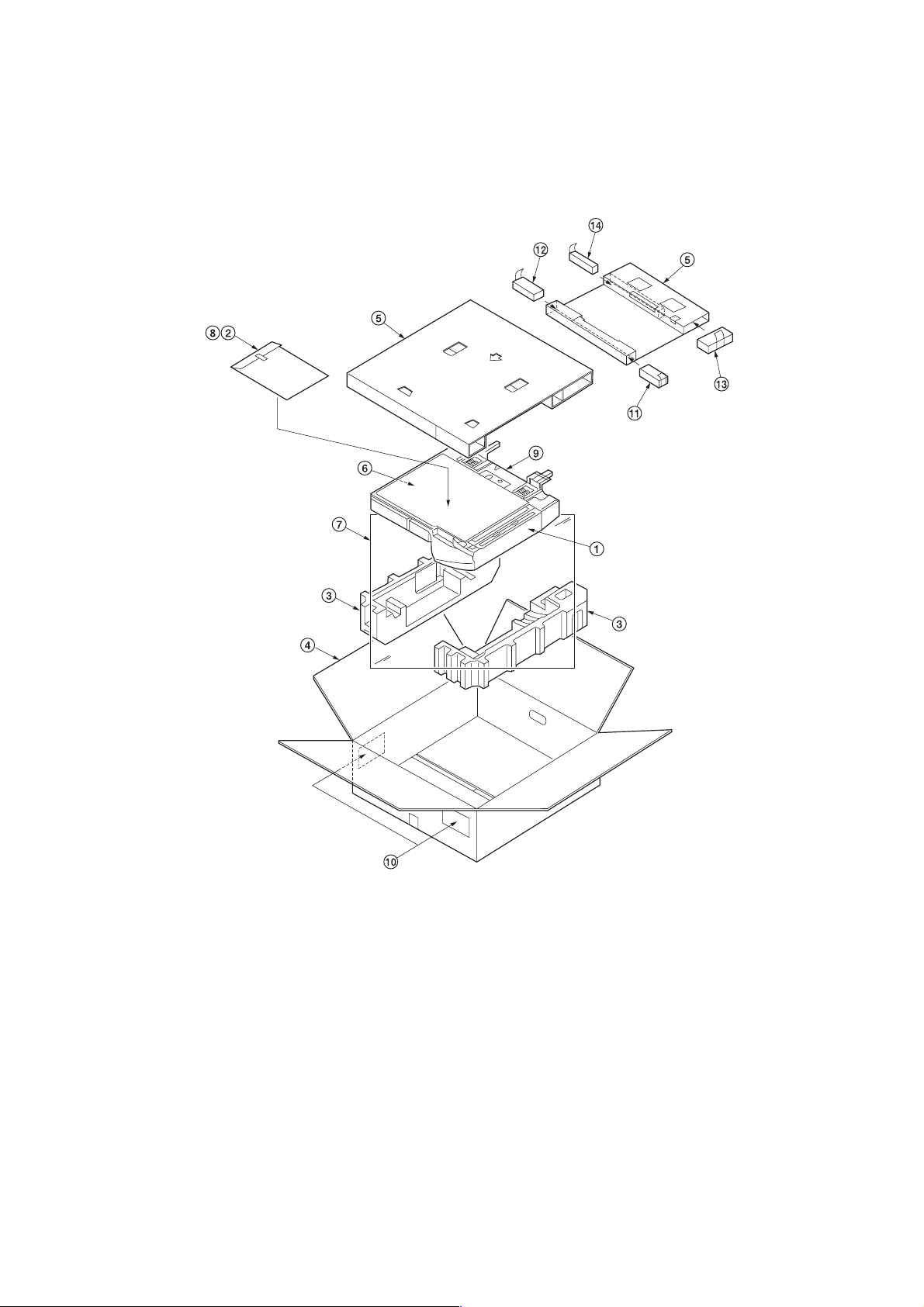

1-3-1 Unpacking and installation

(1) Unpacking

3C0

Figure 1-3-1 Unpacking

1 Document feeder

2 Installation guide

3 Bottom pad

4 Outer case

5 Upper pad

6 Eject pad

7 Plastic sheet (1300 × 1300)

8 Plastic bag

9 Plastic bag (200 × 200)

0 Bar code labels

! Front A pad

@ Front B pad

# Rear A pad

$ Rear B pad

1-3-1

Page 15

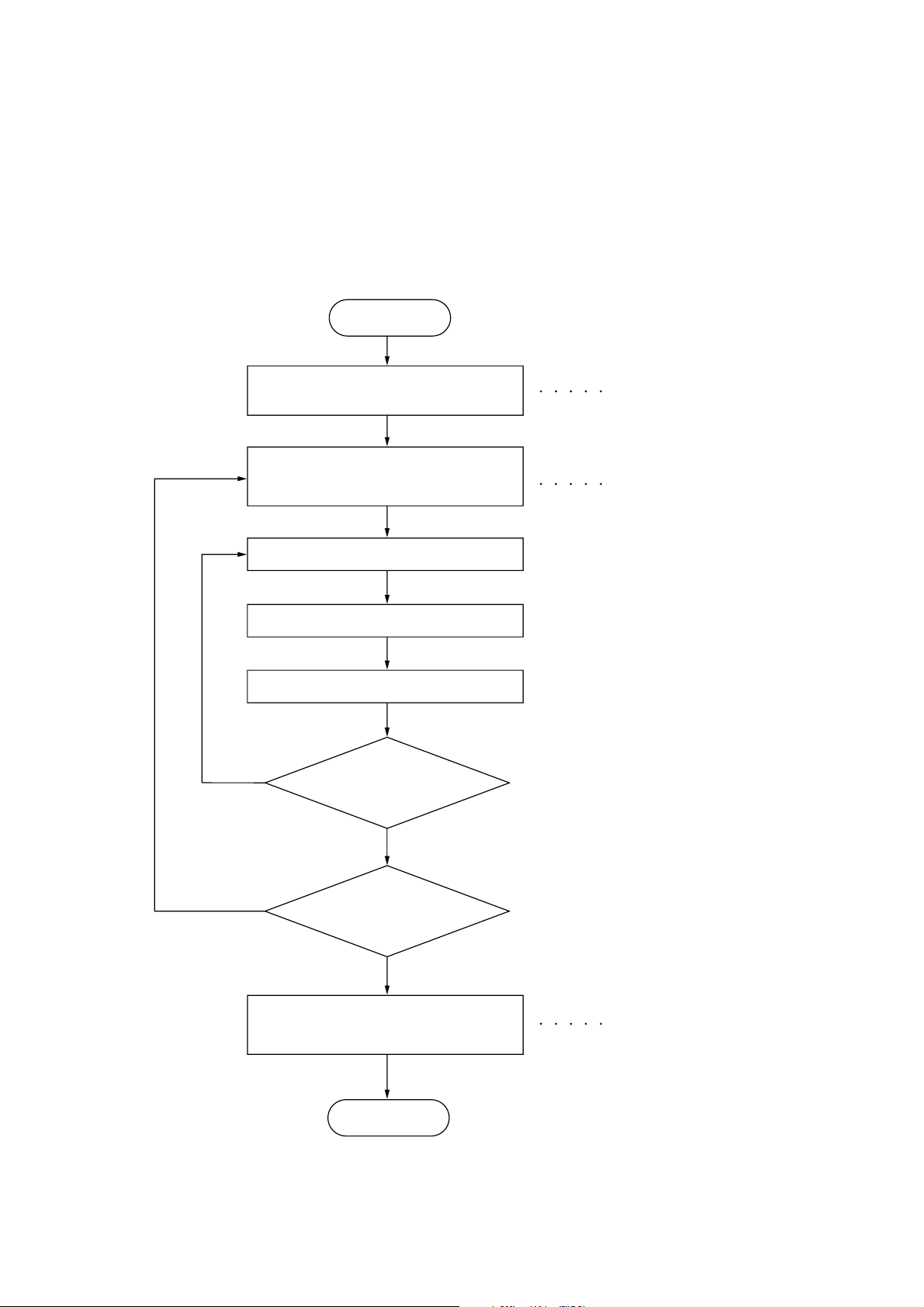

1-4-1 Maintenance mode

The copier is equipped with a maintenance function which can be used to maintain and service the machine.

(1) Executing a maintenance item

Start

3C0

Yes

Enter “10871087” using

the numeric keys.

Enter the maintenance item

number using the cursor up/down keys

or numeric keys.

Press the start key.

The selected maintenance item is run.

Press the stop/clear key.

Repeat the same

maintenance item?

Maintenance mode is entered.

The maintenance item is

selected.

Yes

No

Run another maintenance

item?

No

Enter “001” using the cursor

up/down keys or numeric keys

and press the start key.

End

Maintenance mode is exited.

1-4-1

Page 16

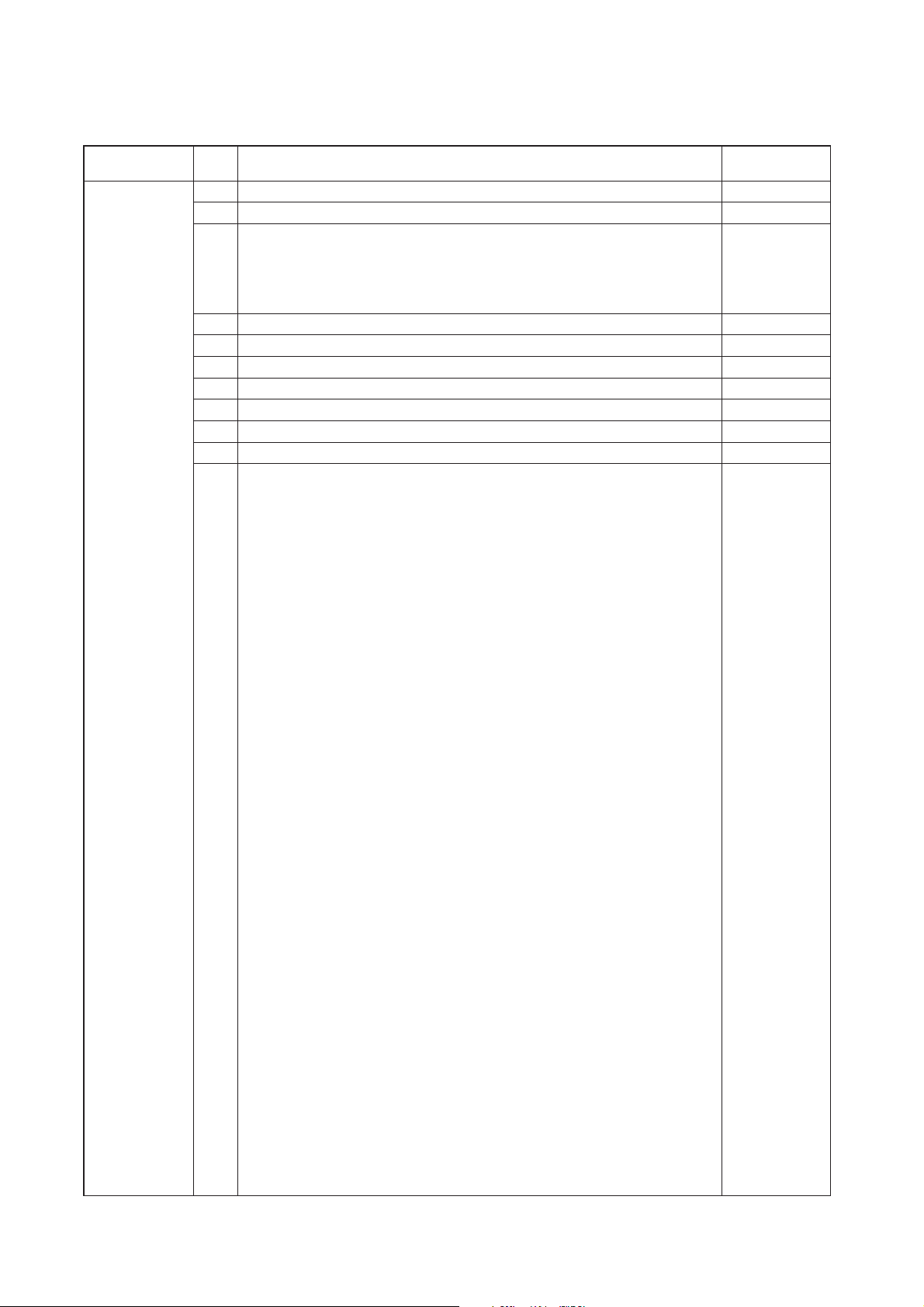

3C0

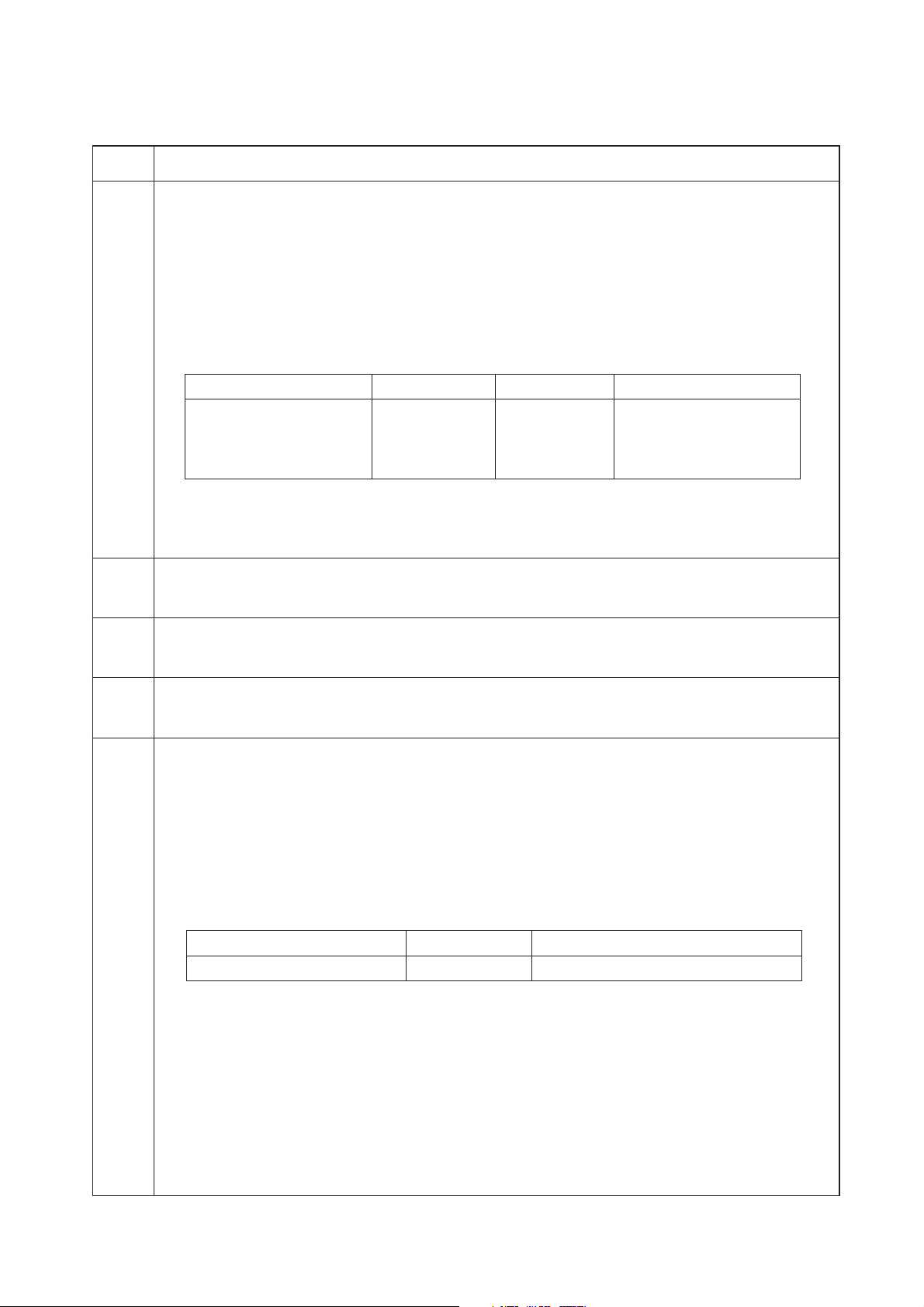

(2) Maintenance mode item list

Section

DF U068 Adjusting the scanning position for originals from the DF 0

Item

No. setting*

U070 Adjusting the DF magnification 0

U071 Adjusting the DF scanning timing

• DF leading edge registration 8 (black and

• DF trailing edge registration 0

U072 Adjusting the DF center line 0

U074 Adjusting the DF input light luminosity (black and white copiers only) 1

U203 Operating DF separately —

U243 Checking the operation of the DF motors, solenoids and clutch —

U244 Checking the DF switches —

U263 Setting the paper ejection when copying from the DF (color copiers only)

U404 Adjusting margins for scanning an original from the DF —

Maintenance item contents

Initial

white copiers)

0 (color copiers)

TRAY (NORMAL)

* Initial setting for executing maintenance item U020

1-4-2

Page 17

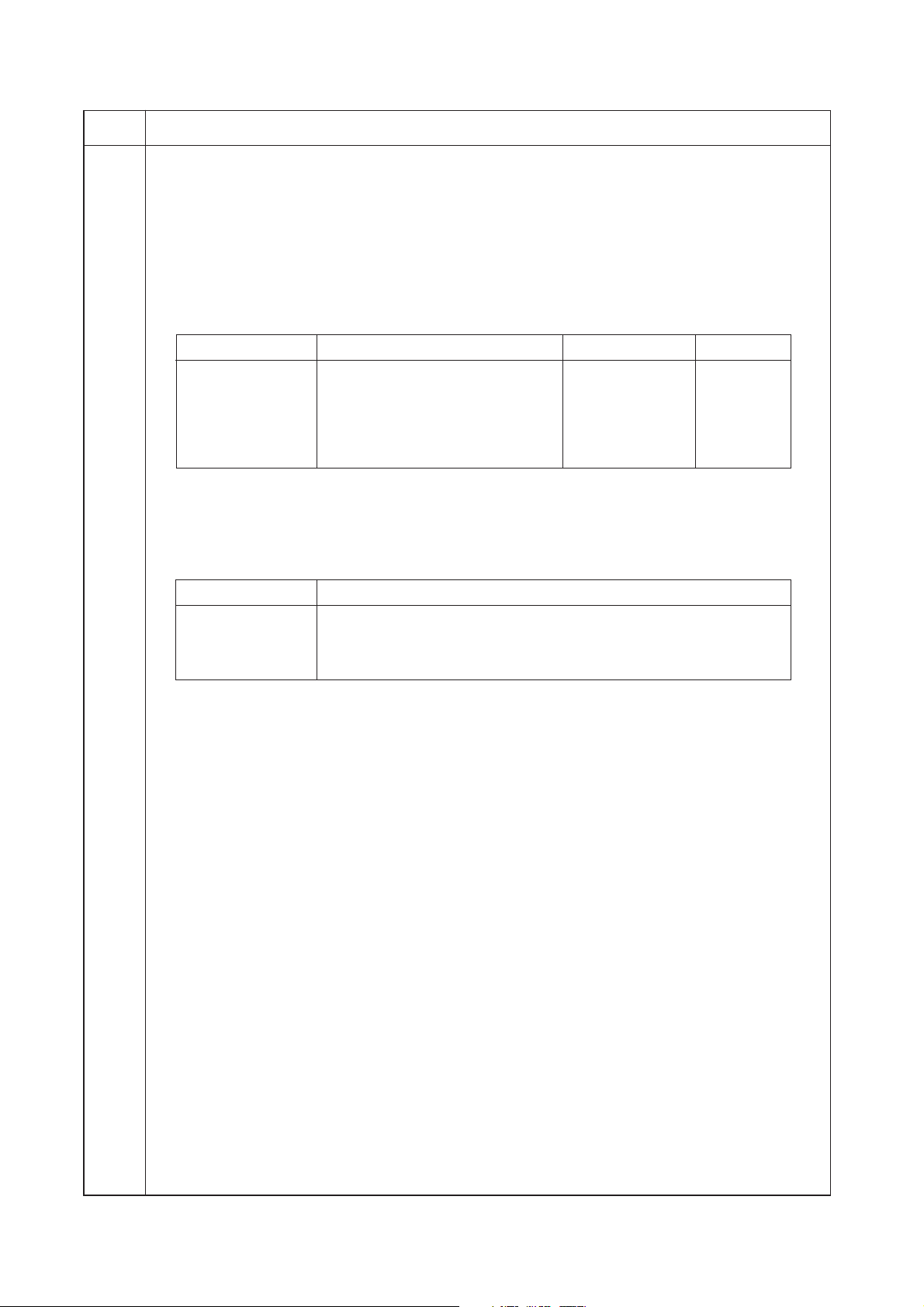

(3) Contents of maintenance mode items

3C0

Maintenance

item No.

U068 Adjusting the scanning position for originals from the DF

Description

Adjusts the position for scanning originals from the DF.

Purpose

Used when there is a regular error between the leading edges of the original and the copy image.

Method

Press the start key. The screen for executing is displayed.

Setting

1. Change the setting using the cursor up/down keys (in the case of black and white copiers).

Change the setting using the cursor left/right keys (in the case of color copiers).

Description Setting range Initial setting Change in value per step

Scanning position –2 to +3 0 0.254 mm (in the case of

–9 to +9 0 0.169 mm (in the case of

Increasing the setting moves the image backward, and decreasing it moves the image forward.

2. Press the start key. The value is set.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

U070 Adjusting the DF magnification

Adjustment

See pages 1-6-8.

U071 Adjusting the DF scanning timing

Adjustment

See page 1-6-10.

U072 Adjusting the DF center line

Adjustment

See page 1-6-9.

U074 Adjusting the DF input light luminosity (black and white copiers only)

Description

Adjusts the luminosity of the exposure lamp for scanning originals from the DF.

Purpose

Used if the exposure amount differs significantly between when scanning an original on the contact glass and

when scanning an original from the DF (installed to the black and white copiers).

Method

Press the start key. The screen for executing is displayed.

Setting

1. Change the setting using the cursor up/down keys.

Description Setting range Initial setting

DF input light luminosity 0 to 8 1

Increasing the setting makes the luminosity higher, and decreasing it makes the luminosity lower.

2. Press the start key. The value is set.

Interrupt copy mode

While this maintenance item is being performed, copying from an original can be made in interrupt copy mode.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item No. is

displayed.

Description

black and white copiers)

color copiers)

1-4-3

Page 18

3C0

Maintenance

item No.

U203 Operating DF separately

Description

Simulates the original conveying operation separately in the DF.

Purpose

To check the DF.

Method (in the case of black and white copiers)

1. Press the start key. The screen for selecting an item is displayed.

2. Place an original in the DF if running this simulation with paper.

3. Select the item to be operated. The selected item is displayed in reverse.

4. Select the magnification using the cursor up/down keys.

Display Operation Setting range Initial setting

ADF With paper, single-sided original 50 to 200 (%) 100

RADF With paper, double-sided original 50 to 200 (%) 100

ADF (NON-P) Without paper, single-sided original 50 to 200 (%) 100

RADF (NON-P) Without paper, double-sided original 50 to 200 (%) 100

5. Press the start key. The operation starts for the selected magnification.

6. To stop continuous operation, press the stop/clear key.

Method (in the case of color copiers)

1. Press the start key. The screen for selecting an item is displayed.

2. Place an original in the DF if running this simulation with paper.

3. Select the item to be operated using the cursor up/down keys. The selected item is displayed in reverse.

Display Operation

ADF With paper, single-sided original

RADF With paper, double-sided original

ADF (NON-P) Without paper, single-sided original (continuous operation)

RADF (NON-P) Without paper, double-sided original (continuous operation)

4. Press the start key. The operation starts.

5. To stop continuous operation, press the stop/clear key.

Completion

Press the stop/clear key when the operation stops. The screen for selecting a maintenance item No. is

displayed.

Description

(continuous operation)

(continuous operation)

1-4-4

Page 19

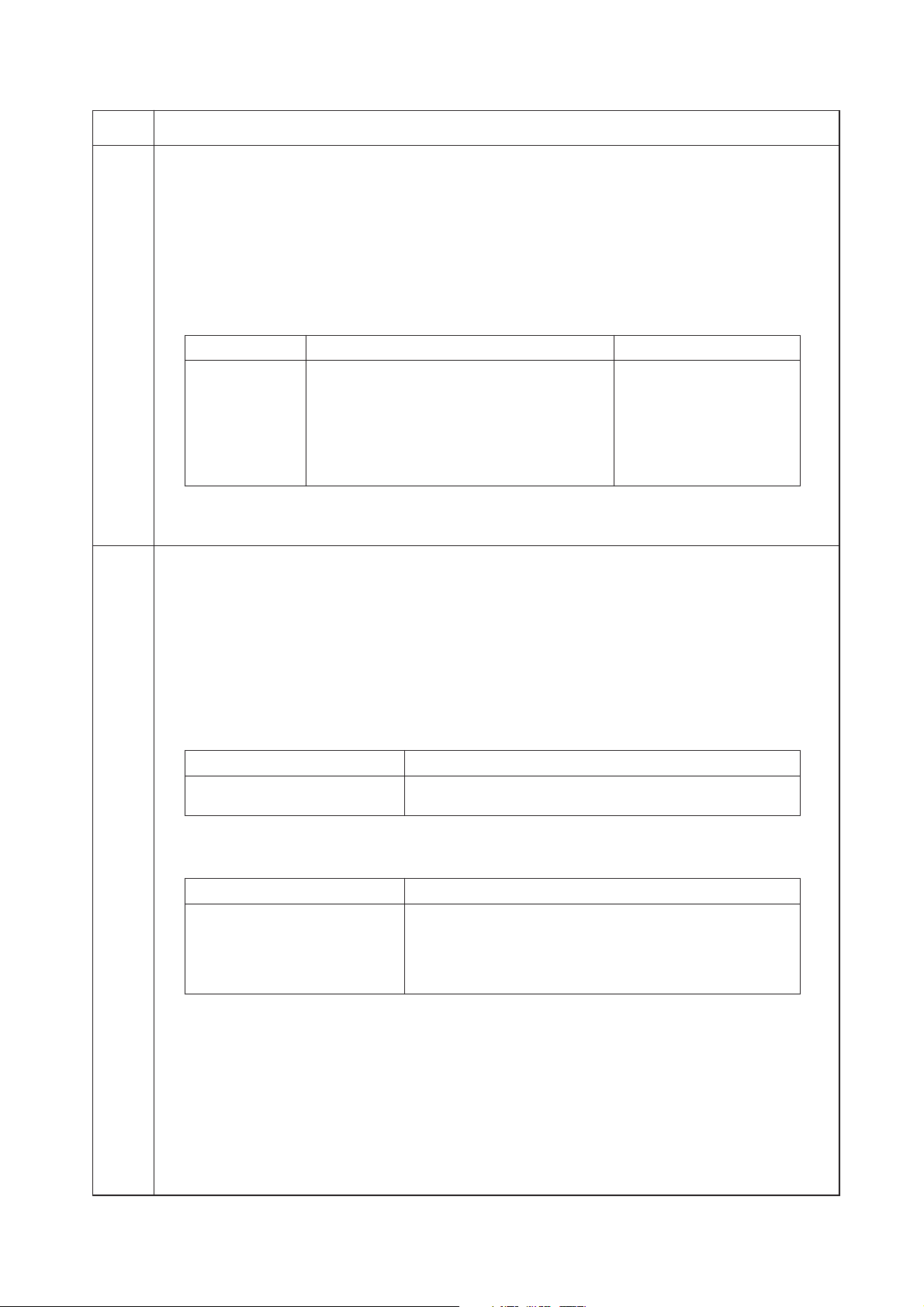

3C0

Maintenance

item No.

U243 Checking the operation of the DF motors, solenoids and clutch

Description

Turns the motors, solenoids or clutch in the DF on.

Purpose

To check the operation of the DF motors, solenoids and clutch .

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the item to be operated (in the case of black and white copiers).

Select the item to be operated using the cursor up/down keys (in the case of color copiers).

The selected item is displayed in reverse and the operation starts.

Display Motors, solenoids and clutch Operation In operation

F MOT Original feed motor (OFM) In operation

C MOT Original paper conveying motor (OCM) In operation

FD CL Original feed clutch (OFCL) On for 0.5 s

EJ SL Eject feedshift solenoid (EFSSOL) On for 0.5 s

RJ SL Switchback feedshift solenoid (SBFSSOL) On for 0.5 s

FD SL Original feed solenoid (OFSOL) On and off

RP SL Switchback pressure solenoid (SBPSOL) On and off

3. To turn each motor off, press the stop/clear key.

Completion

Press the stop/clear key when operation stops. The screen for selecting a maintenance item No. is displayed.

U244 Checking the DF switches

Description

Displays the status of the respective switches in the DF.

Purpose

To check if respective switches in the DF operate correctly.

Start

1. Press the start key. The screen for selecting an item is displayed.

2. Select the type of switches (SW or VR) to be checked (in the case of black and white copiers).

Select the type of switches (SW or VR) to be checked using the cursor up/down keys (in the case of color

copiers).

The screen for executing each item is displayed.

Display Type of switches

SW On/off switches

VR Volume switch

Description

Method for the on/off switches (SW)

1. Turn the respective switches on and off manually to check the status.

If the on-status of a switch is detected, the corresponding switch is displayed in reverse.

Display Switches

SET SW Original set switch (OSSW)

FEED SW Original feed switch (OFSW)

REV SW Original switchback switch (OSBSW)

TMG SW DF timing switch (DFTSW)

SZ A SW Original size length switch (OSLSW)

2. To return to the screen for selecting an item, press the stop/clear key.

1-4-5

Page 20

3C0

Maintenance

item No.

U244 Method for the volume switch (VR)

1. Move the original insertion guides to check the detection status of the original size width switch.

The detected original width is displayed as a numerical value with the decimals omitted.

Numerical

103.936

104.448

139.264

139.776

146.432

146.994

value

000

49.664

50.176

61.440

61.952

····························································

Description

Original width to be detected

1

/2" × 81/2"

5

A5R

B5R

Folio/A4R

B4/B5

1

8

/2" × 14"/

1

8

/2" × 11"

197.120

197.632

197.720

223.232

256

CF (11"

A3/A4

×

15")

11"

11"

11"

×

×

×

17"/

15"/

81/2"

For example, if any value between 105 and 139 is displayed when the original insertion guides are adjusted

for A4R paper, it indicates that the original width is detected correctly.

2. To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item No. is

displayed.

1-4-6

Page 21

3C0

Maintenance

item No.

U263 Setting the paper ejection when copying from the DF (color copiers only)

Description

Sets whether the copies will be ejected in the same or opposite order as the originals when copying from the

DF.

Purpose

Set according to the preference of the user when installed to the color copiers.

Method

Press the start key. The screen for selecting an item is displayed.

Setting

1. Use the cursor up/down keys to select the ejection order.

Display Setting

TRAY(NORMAL) Opposite order ejection (during side ejection)

TRAY(MEMORY) Same order ejection using memory copy (during side ejection)

ALL(MEMORY) Same order ejection using memory copy

Initial setting: TRAY(NORMAL)

2. Press the start key. The setting is set, and the screen for selecting a maintenance item No. is displayed.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key. The screen for

selecting a maintenance item No. is displayed.

U404 Adjusting margins for scanning an original from the DF

Adjustment

See page 1-6-12.

Description

1-4-7

Page 22

3C0

1-5-1 Original misfeed detection

(1) Original misfeed indication

When an original jams, the machine immediately stops operation and a message is shown on the copier operation panel. The

DF original set indicator also flashes red.

To remove the jammed original, open the DF or the DF original reversing cover.

To reset the original misfeed detection, open and close the DF or DF original reversing cover to turn DF safety switch 1 or

2 off and on.

• Misfeed in DF

Jam code 70

Jam code 71

Jam code 72

Jam code 73

Jam code 74

Jam code 75

Jam code 76

In the case of color copiers

In the case of black and

white copiers

(2) Original misfeed detection conditions

OFSW

OSBSW

DFTSW

Figure 1-5-1

1-5-1

Page 23

3C0

Section Jam code Description Conditions

Original

feed section

70

No original feed

In the primary original feed for the second original or after in

the 1 sided or 2 sided original mode, even if retry operation is

performed two times, primary original feed is not performed.

Original

conveying

section

71

72

73

An original jam in the

original feed section 1

An original jam in the

original feed section 2

An original jam in the

original conveying section

In the secondary original feed in the 1 sided original mode,

even if the specified number of pulses of the original feed

motor (OFM) passes after the original switchback switch

(OSBSW) turns on, the ON status of the DF timing switch

(DFTSW) is not detected.

In the secondary original feed in the 1 sided original mode,

even if the specified number of pulses of the original

conveying motor (OCM) passes after the DF timing switch

(DFTSW) turns on, the OFF status of the original feed switch

(OFSW) or the original switchback switch (OSBSW) is not

detected.

In the original switchback in the 2 sided original mode, even

if the specified number of pulses of the original feed motor

(OFM) passes after the original feed switch (OFSW) turns

on, the OFF status of the original feed switch (OFSW) is not

detected and the ON status of the original switchback switch

(OSBSW) is not detected.

In the secondary original feed in the 1 sided or 2 sided original mode, even if the specified number of pulses of the original conveying motor (OCM) passes after the DF timing

switch (DFTSW) turns on, the OFF status of the DF timing

switch (DFTSW) is not detected.

In the secondary original feed in the 1 sided or 2 sided original mode, before the specified number of pulses of the original conveying motor (OCM) passes after the DF timing

switch (DFTSW) turns on, the OFF status of the DF timing

switch (DFTSW) is detected.

Original

feed section

Original

switchback

section

74

75

76

An original jam remaining

after retries

An original jam in the

switchback section 1

An original jam in the

switchback section 2

In the secondary original feed in the 1 sided or 2 sided original mode, even if retry operation is performed five times,

secondary original feed is not performed.

In the original switchback in the 2 sided original mode, even

if the specified number of pulses of the original feed motor

(OFM) passes after the original switchback switch (OSBSW)

turns on, the OFF status of the original switchback switch

(OSBSW) is not detected.

In the secondary original feed in the 2 sided original mode,

even if the specified number of pulses of the original feed

motor (OFM) passes after the original conveying motor

(OCM) turns on, the ON status of the DF timing switch

(DFTSW) is not detected.

In the original switchback in the 2 sided original mode, even

if the specified number of pulses of the original feed motor

(OFM) passes after the original feed switch (OFSW) turns

on, the OFF status of the original feed switch (OFSW) is not

detected and the OFF status of the original switchback

switch (OSBSW) is detected.

While the back side of an original is being scanned in the 2

sided original mode, even if the specified number of pulses

of the original conveying motor (OCM) passes after the DF

timing switch (DFTSW) turns on, the ON status of the original

switchback switch (OSBSW) is not detected.

1-5-2

Page 24

(3) Original misfeeds

Problem Causes/check procedures Corrective measures

(1)

An original jams

when the main

switch is turned on.

A piece of paper torn from

an original is caught

around the original feed

switch.

Remove any found.

3C0

(2)

An original jams

during continuous

copying of multiple

originals.

Defective original feed

switch.

A piece of paper torn from

an original is caught

around the original

switchback switch.

Defective original

switchback switch.

A piece of paper torn from

an original is caught

around the DF timing

switch.

Defective DF timing

switch.

Defective original feed

switch.

Check if the original feed

motor or the original conveying motor malfunction.

Run maintenance item U244 and turn the original feed switch on

and off manually. Replace the original feed switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Remove any found.

Run maintenance item U244 and turn the original switchback

switch on and off manually. Replace the original switchback

switch if indication of the corresponding switch on the touch

panel is not displayed in reverse.

Remove any found.

Run maintenance item U244 and turn the DF timing switch on

and off manually. Replace the DF timing switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Run maintenance item U244 and turn the original feed switch on

and off manually. Replace the original feed switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Run maintenance item U243 and select the original feed motor/

original conveying motor on the touch panel to be turned on and

off. Check the status and remedy if necessary.

(3)

An original jams is

indicated during

copying (no original

feed).

Jam code 70

(4)

An original jams

during copying (a

jam in the original

feed/conveying section).

Jam code 71/72/73

Defective original feed

switch.

Check if the original feed

motor malfunctions.

Defective DF timing

switch.

Defective original feed

switch.

Run maintenance item U244 and turn the original feed switch on

and off manually. Replace the original feed switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Run maintenance item U243 and select the original feed motor

on the touch panel to be turned on and off. Check the status and

remedy if necessary.

Run maintenance item U244 and turn the DF timing switch on

and off manually. Replace the DF timing switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Run maintenance item U244 and turn the original feed switch on

and off manually. Replace the original feed switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

1-5-3

Page 25

3C0

Problem Causes/check procedures Corrective measures

(4)

An original jams

during copying (a

jam in the original

feed/conveying section).

Jam code 71/72/73

Defective original

switchback switch.

Check if the original feed

motor malfunctions.

Run maintenance item U244 and turn the original switchback

switch on and off manually. Replace the original switchback

switch if indication of the corresponding switch on the touch

panel is not displayed in reverse.

Run maintenance item U243 and select the original feed motor

on the touch panel to be turned on and off. Check the status and

remedy if necessary.

(5)

An original jams

during copying (a

jam in the original

switchback section).

Jam code 75/76

Check if the DF original

feed pulley or the DF

separation pulley is deformed.

Check if the DF registration roller or the DF registration pulley is deformed.

Check if the lower original

conveying roller or the

front scanning pulley is

deformed.

Check if the original conveying motor malfunctions.

Defective original

switchback switch.

Defective DF timing

switch.

Check visually and replace the deformed pulley.

Check visually and replace the deformed pulley.

Check visually and replace the deformed pulley.

Run maintenance item U243 and select the original conveying

motor on the touch panel to be turned on and off. Check the status and remedy if necessary.

Run maintenance item U244 and turn the original switchback

switch on and off manually. Replace the original switchback

switch if indication of the corresponding switch on the touch

panel is not displayed in reverse.

Run maintenance item U244 and turn the DF timing switch on

and off manually. Replace the DF timing switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

(6)

Original jams frequently.

Check if the original feed

motor malfunctions.

Check if the original conveying motor malfunctions.

An original outside the

specifications is used.

The DF forwarding pulleys,

DF original feed pulley or

DF switchback pulley is

dirty with paper powder.

The DF original feed pulley

and the DF separation pulley do not contact correctly.

Run maintenance item U243 and select the original feed motor

on the touch panel to be turned on and off. Check the status and

remedy if necessary.

Run maintenance item U243 and select the original conveying

motor on the touch panel to be turned on and off. Check the status and remedy if necessary.

Use only originals conforming to the specifications.

Clean with isopropyl alcohol.

Check and remedy.

1-5-4

Page 26

1-5-2 Image formation problems

3C0

(1) There is a regular error

between the centers of

the original and copy

image.

See page 1-5-6

(2) There is a regular error

between the leading

edges of the original

and copy image.

See page 1-5-6

(3) There is a regular error

between the trailing

edges of the original

and copy image.

See page 1-5-6

1-5-5

Page 27

3C0

(1) There is a regular

error between the

centers of the

original and copy

image.

Causes

1. Misadjusted DF center line.

(2) There is a regular

error between the

leading edges of

the original and

copy image.

Causes

1. Misadjusted DF center line.

Check procedures/corrective measures

Readjust the DF center line (see page 1-6-9).

Causes

1. Misadjusted DF original scanning start

position.

Causes

1. Misadjusted DF original scanning start

position.

(3) There is a regular

error between the

trailing edges of the

Causes

1. Misadjusted DF original scanning end

position.

original and copy

image.

Causes

1. Misadjusted DF original scanning end

position.

Check procedures/corrective measures

Readjust the DF original scanning start position (see page 1-6-10).

Check procedures/corrective measures

Readjust the DF original scanning end position (see page 1-6-11).

1-5-6

Page 28

1-5-3 Electrical problems

Problem Causes Check procedures/corrective measures

(1)

The original feed

motor does not

operate.

Defective original feed motor coil.

The connector terminals of

the original feed motor

make poor contact.

Check for continuity across the coil. If none, replace the original

feed motor.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

3C0

(2)

The original conveying motor does not

operate.

(3)

The original feed

solenoid does not

operate.

(4)

The switchback

feedshift solenoid

does not operate.

Defective DF driver PCB.

Defective original conveying motor coil.

The connector terminals of

the original conveying motor make poor contact.

Defective DF driver PCB.

Defective original feed solenoid coil.

The connector terminals of

the original feed solenoid

make poor contact.

Defective DF driver PCB.

Defective switchback

feedshift solenoid coil.

The connector terminals of

the switchback feedshift

solenoid make poor contact.

Check for continuity across the original feed motor coil and connector terminals. If good, replace the DF driver PCB.

Check for continuity across the coil. If none, replace the original

conveying motor.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check for continuity across the original conveying motor coil and

connector terminals. If good, replace the DF driver PCB.

Check for continuity across the coil. If none, replace the original

feed solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the original feed solenoid operates when CN5-B13 or

CN5-B12 on the DF driver PCB is low. If it does, replace the DF

driver PCB.

Check for continuity across the coil. If none, replace the

switchback feedshift solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

(5)

The eject feedshift

solenoid does not

operate.

(6)

The switchback

pressure solenoid

does not operate.

Defective DF driver PCB.

Defective eject feedshift

solenoid coil.

The connector terminals of

the eject feedshift solenoid

make poor contact.

Defective DF driver PCB.

Defective switchback pressure solenoid coil.

The connector terminals of

the switchback pressure

solenoid make poor contact.

Defective DF driver PCB.

Check if the switchback feedshift solenoid operates when CN5B8 on the DF driver PCB is low. If it does, replace the DF driver

PCB.

Check for continuity across the coil. If none, replace the eject

feedshift solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the eject feedshift solenoid operates when CN5-A7 on

the DF driver PCB is low. If it does, replace the DF driver PCB.

Check for continuity across the coil. If none, replace the

switchback pressure solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the switchback pressure solenoid operates when CN5A2 or CN5-A3 on the DF driver PCB is low. If it does, replace the

DF driver PCB.

1-5-7

Page 29

3C0

Problem Causes Check procedures/corrective measures

(7)

The original feed

clutch does not

operate.

Defective original feed

clutch coil.

The connector terminals of

the original feed clutch

make poor contact.

Check for continuity across the coil. If none, replace the original

feed clutch.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

(8)

A message indicating cover open is

displayed when the

DF is closed correctly.

(9)

An original jams

when the main

switch is turned on.

Defective DF driver PCB.

The connector terminals of

DF safety switch 1 make

poor contact.

Defective DF safety switch

1.

A piece of paper torn from

an original is caught

around the original feed

switch.

Defective original feed

switch.

A piece of paper torn from

an original is caught

around the original

switchback switch.

Defective original

switchback switch.

Check if the original feed clutch operates when CN5-A5 on the

DF driver PCB is low. If it does, replace the DF driver PCB.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check for continuity across the contacts of the switch. If none

when the switch is on, replace DF safety switch 1.

Remove any found.

Run maintenance item U244 and turn the original feed switch on

and off manually. Replace the original feed switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Remove any found.

Run maintenance item U244 and turn the original switchback

switch on and off manually. Replace the original switchback

switch if indication of the corresponding switch on the touch

panel is not displayed in reverse.

A piece of paper torn from

an original is caught

around the DF timing

switch.

Defective DF timing

switch.

The surface facing the DF

timing switch is soiled.

Remove any found.

Run maintenance item U244 and turn the DF timing switch on

and off manually. Replace the DF timing switch if indication of

the corresponding switch on the touch panel is not displayed in

reverse.

Check if the projection at the center of the conveying cover that

is facing the DF timing switch is soiled with paper powder. If so,

clean it.

1-5-8

Page 30

1-5-4 Mechanical problems

Problem Causes/check procedures Corrective measures

(1)

No primary original

feed.

The surfaces of the DF forwarding pulleys,

DF original feed pulley or DF separation pulley are dirty with paper powder.

3C0

Check and clean them with isopropyl alcohol if they are dirty.

(2)

No secondary original

feed.

(3)

Originals jam.

Check if the DF original feed pulley or the

DF forwarding pulley is deformed.

Electrical problem with the following clutch

or solenoid:

• Original feed solenoid

• Original feed clutch

The DF registration pulley and the DF registration roller do not contact each other correctly.

Originals outside the specifications are used.

The surfaces of the DF forwarding pulleys,

DF original feed pulley or DF separation pulley are dirty with paper powder.

The DF original feed pulley and the DF

separation pulley do not contact each other

correctly.

If so, replace (see page 1-6-3).

See pages 1-5-7 and 8.

Check visually and remedy if necessary.

Use only originals conforming to the specifications.

Check and clean them with isopropyl alcohol if they are dirty.

Check visually and remedy if necessary.

1-5-9

Page 31

1-6-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the board.

• Do not touch any PCB containing ICs with bare hands or any object prone to static charge.

• Use the following testers when measuring voltages:

Hioki 3200

Sanwa MD-180C

Sanwa YX-360TR

Beckman TECH300

Beckman DM45

Beckman 330*

Beckman 3030*

Beckman DM850*

Fluke 8060A*

Arlec DMM1050

Arlec YF1030C

* Capable of measuring RMS values.

3C0

1-6-1

Page 32

3C0

(2) Running a maintenance item

Start

Enter “10871087” using

the numeric keys.

Enter the maintenance item

number using the cursor up/down keys

The selected maintenance item is run.

Yes

Yes

or numeric keys.

Press the start key.

Press the stop/clear key.

Repeat the same

maintenance item?

No

Run another maintenance

item?

Maintenance mode is entered.

The maintenance item is

selected.

No

Enter “001” using the cursor

up/down keys or numeric keys

and press the start key.

End

Maintenance mode is exited.

1-6-2

Page 33

1-6-2 Original feed section

(1) Detaching and refitting the DF forwarding pulley and DF feed pulley

Follow the procedure below to clean or replace the DF forwarding pulley or DF feed pulley.

Procedure

1. Open the DF original reversing cover.

2. Remove the two screws holding the upper

original feed cover and then the cover.

• Detaching the DF forwarding pulley

3. Remove the stop ring at the machine front

and then remove the bushing.

4. Pull out the forwarding shaft toward the rear

side of the machine and slide the bushing.

5. Remove the DF forwarding pulley from the

forwarding shaft.

• Detaching the DF feed pulley

6. Remove the stop ring at the machine front

and then remove the bushing.

7. Remove the stop ring at the machine rear.

8. Pull out the front original feed shaft toward

the rear side of the machine and slide the

bushing.

9. Remove the DF feed pulley from the front

original feed shaft.

10. Clean or replace the DF forwarding pulley

and the DF feed pulley.

11. Refit all the removed parts.

* When refitting the DF forwarding pulley and

DF feed pulley, ensure that the notches in the

pulleys are aligned with the projections on the

one-way clutches.

Front original

feed shaft

One-way clutch

Bushing

Stop ring

3C0

DF feed pulley

DF forwarding pulley

Stop ring

Stop ring

bushing

bushing

Machine

front

DF forwarding belt

One-way clutch

Bushing

forwarding

shaft

Machine

rear

Figure 1-6-1

1-6-3

Page 34

3C0

(2) Detaching and refitting the DF separation pulley

Follow the procedure below to clean or replace the DF separation pulley.

Procedure

1. Open the DF original reversing cover.

2. Remove the DF front and rear covers.

3. Remove the two screws holding the upper

original feed cover and then the cover.

Screws

Upper original

feed cover

4. Remove the four connectors and then

remove the wires from the two wire clamps.

Figure 1-6-2

Connectors

Wire clamps

1-6-4

Connectors

Figure 1-6-3

Page 35

5. Remove the two screws holding the solenoid

bracket and then the bracket.

6. Remove the screw and then remove the feed

guide pin.

Screw

3C0

Feed guide pin

7. Remove the E-ring and then the original feed

clutch.

8. Remove the E-ring and then remove the

bushing.

Screws

E-ring

Solenoid bracket

Figure 1-6-4

E-ring

Original feed clutch

Figure 1-6-5

Bushing

1-6-5

Page 36

3C0

g

9. Open the registration guide and remove the

guide.

10. Remove the two screws holding the upper

feed guide plate and then the plate.

Registration guide

Upper original feed

guide plate

Screw

Screw

11. Remove the two screws holding the original

feed lift and then the lift.

12. Remove the screw holding the separation

guide and then the guide.

Figure 1-6-6

Screw

Separation guide

Screw

1-6-6

Screw

Ori

inal feed lift

Figure 1-6-7

Page 37

13. Remove the separation shaft from the

separation pulley arms.

14. Remove the stopper and torque limitter from

the separation shaft and then remove the DF

separation pulley.

15. Clean or replace the DF separation pulley.

16. Refit all the removed parts.

3C0

Torque limitter

DF separation

pulley

Stopper

Separation shaft

Separation pulley

arms

Figure 1-6-8

1-6-7

Page 38

3C0

(3) Adjusting the DF magnification

Adjust magnification in the auxiliary scanning direction if magnification is incorrect when the DF is used.

U053

(See the service manual

of the copier.)

U065(main scanning

direction)

(See the service manual

of the copier.)

U065(auxiliary scanning

direction)

(See the service manual

of the copier.)

U070

Caution

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

Procedure

Main scanning

direction

Start

Auxiliary

scanning

Enter maintenance mode.

Enter “070” using the numeric keys.

Press the start key.

direction

Original

Copy

example 1

Figure 1-6-9

Copy

example 2

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key to

exit maintenance mode.

End

Press the start key.

The new setting

is stored.

For copy example 1, increase

the value using the cursor up key

(cursor right key).

No

For copy example 2, decrease

the value using the cursor down key

(cursor left key).

* ( ) indicates the case of color copiers.

Setting range: –25 – +25 (in the case of

black and white copiers)

–2.5 – +2.5 (in the case of

color copiers)

Initial setting: 0

Changing the value by 1 changes

the magnification by 0.1%.

Increasing the value makes

the image longer, and decreasing it

make the image shorter.

1-6-8

Page 39

3C0

(4) Adjusting the DF center line

Perform the following adjustment if there is a regular error between the centers of the original and the copy image when

the DF is used.

U034

(See the service manual

of the copier.)

(See the service manual

U067

U072

of the copier.)

Caution

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

Procedure

Reference

Start

Enter maintenance mode.

Copy

example 2

Enter “072” using the numeric keys.

Original Copy

example 1

Figure 1-6-10

Press the start key.

Select the item to be adjusted.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key to

exit maintenance mode.

End

Press the start key.

The new setting

is stored.

For copy example 1, increase

the value using the cursor up key

(cursor right key).

No

For copy example 2, decrease

the value using the cursor down key

(cursor left key).

* ( ) indicates the case of color copiers.

Setting range: –39 – +39 (in the case of

black and white copiers)

–20 – +20 (in the case of

color copiers)

Initial setting: 0

Changing the value by 1 moves

the center line by 0.17 mm.

1-6-9

Page 40

3C0

(5) Adjusting the scanning start position

Perform the following adjustment if there is a regular error between the leading or trailing edges of the original and the

copy image.

U034

(See the service manual

of the copier.)

(See the service manual

U066

U071

of the copier.)

Caution

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

(5-1) Adjusting the DF leading edge registration

Procedure

Start

Enter maintenance mode.

Enter “071” using the numeric keys.

Original

Copy

example 1

Copy

example 2

Figure 1-6-11

Press the start key.

Select “LEAD EDGE ADJ”.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key to

exit maintenance mode.

End

Press the start key.

The new setting

is stored.

For copy example 1, increase

the value using the cursor up key

(cursor right key).

No

For copy example 2, decrease

the value using the cursor down key

(cursor left key).

* ( ) indicates the case of color copiers.

Setting range: –32 – +32

Initial setting: 8 (in the case of black and

white copiers)

Initial setting: 0 (in the case of color copiers)

Changing the value by 1 moves

the leading edge by 0.17 mm.

Increasing backward and decreasing it moves

the image forward.

1-6-10

Page 41

(5-2) Adjusting the DF trailing edge registration

Procedure

Start

Enter maintenance mode.

3C0

Enter “071” using the numeric keys.

Press the start key.

Select “TRAIL EDGE ADJ”.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Is the image correct?

Yes

Press the stop/clear key to

exit maintenance mode.

End

Original Copy

example 1

Figure 1-6-12

Press the start key.

The new setting

is stored.

For copy example 1, increase

the value using the cursor up key

(cursor right key).

No

For copy example 2, decrease

the value using the cursor down key

(cursor left key).

* ( ) indicates the case of color copiers.

Setting range: –32 – +32

initial setting: 0

Changing the value by 1 moves

the trailing edge by 0.17 mm.

Increasing backward and decreasing it moves

the image forward.

Copy

example 2

1-6-11

Page 42

3C0

(6) Adjusting the margins for scanning the original from the DF

Perform the following adjustment if margins are not correct.

(See the service manual

U402

of the copier.)

(See the service manual

U403

U404

of the copier.)

Caution

Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

Procedure

DF leading edge margin (3 ± 1.5 mm [2 ± 1.0 mm])

Ejection direction

Start

Enter maintenance mode.

(reference)

* [ ] indicates the case of

color copiers.

DF left margin

(2 ± 1.0 mm)

DF right margin

(2 ± 1.0 mm)

DF trailing edge margin

(2 ± 1.0 mm)

Figure 1-6-13

Enter “404” using the numeric keys.

Press the start key.

Select the item to be adjusted.

Press the interrupt key.

Place an original on the DF

and make a test copy.

Are the margins correct?

Yes

Yes

Proceed to another mode?

No

Press the stop/clear key to

exit maintenance mode.

A MARGIN (LEFT/mm): DF left margin

B MARGIN (TOP/mm): DF leading edge margin

C MARGIN (RIGHT/mm): DF right margin

D MARGIN (BOTTOM/mm): DF trailing edge margin

* ( ) indicates the case of color copiers.

Press the start key.

The new setting

is stored.

Change the setting.

Increasing the value using the cursor

No

up key (cursor right key) makes the

margin wider.

Decreasing the value using the

cursor down key (cursor left key)

makes the margin narrower.

* ( ) indicates the case of color

copiers.

Setting range (initial setting)

DF left margin: 0 – +10.0 (2.0 [2.0])

DF leading edge margin: 0 – +10.0 (3.0 [2.0])

DF right margin: 0 – +10.0 (2.0 [2.0])

DF trailing edge margin: 0 – +10.0 (2.0 [2.0])

Changing the value by one moves

the margin by 0.5 mm [0.1 mm] for all.

* [ ] indicates the case of color copiers.

1-6-12

End

Page 43

3C0

2-1-1 Original feed section

The original feed section consists of the parts shown in Figure. An original placed on the original table is conveyed to the

original switchback section or the original conveying section.

Figure 2-1-1 Original feed section

1 Original table

2 DF forwarding pulleys

3 DF original feed pulley

4 DF separation pulley

5 DF original feed upper guide

6 DF original feed lower guide

7 Original stopper

8 DF registration pulley

OFSW

9 DF registration roller

0 DF registration guide

! Original set switch (OSSW)

@ Original feed switch (OFSW)

# Original feed clutch (OFCL)

$ Original feed solenoid (OFSOL)

% Original feed lift

OFCL

OSSW

OFM

OFSOL

CN6-B5

CN5-B12 -

CN5-B13

CN5-A5

CN6-B2

DFDPCB

CN5-B1 -

Figure 2-1-2 Original feed section block diagram

CN5-B6

2-1-1

Page 44

3C0

(1) Original feed timing

OFSOL A

OFSOL R

Fwd. rotation

Rev. rotation

OSBSW

DFTSW

10 ms 150 ms

OFCL

OffOFM

OFSW

OCM

200 ms

298 P* 20 ms

150 ms

*Burst of OFM pulses

Timing chart 2-1-1 Original feed (in simple-sided original mode)

a The OFSOL A signal goes high for 10 ms and then turns off for 200 ms. It goes high again for 150 ms and the original

feed solenoid (OFSOL) turns on, raising the original feed lift to convey the original forward.

b 298 OFM pulses after the leading edge of the original turns the original feed switch (OFSW) on, the original feed

clutch (OFCL) and original feed motor (OFM) turn off. 20 ms later, the rotation of the motor switches to the reverse

direction and secondary original feed is performed by rotation of the DF registration roller.

c Simultaneously as the trailing edge of the original turns the original feed switch (OFSW) off, the original feed motor

(OFM) turns off.

d After ejection of the original, as the original conveying motor (OCM) turns off, the OFSOL R signal turns on for 150

ms and the original feed solenoid (OFSOL) turns off.

2-1-2

Page 45

2-1-2 Original switchback section

The original switchback section consists of the parts shown in Figure. The original from the original feed section or

original conveying section is reversed and conveyed to the original conveying section.

Figure 2-1-3 Original switchback section

1 Switchback pulley

2 Switchback roller

3 Switchback feedshift guide

4 Left switchback guide

5 Switchback guide

6 Original switchback switch (OSBSW)

7 Switchback feedshift solenoid (SBFSSOL)

8 Switchback pressure solenoid (SBPSOL)

3C0

SBPSOL SBFSSOL

OSBSW

CN5-A2 -

CN5-A3

CN6-A5

CN5-B8

DFDPCB

Figure 2-1-4 Original switchback section block diagram

2-1-3

Page 46

3C0

(1) Operation of original switchback

In the double-sided original mode, the switchback feedshift solenoid (SBFSSOL) turns on, changing the position of the

switchback feedshift guide. This switches the path of the original to the original switchback section to where the original

is fed.

The switchback feedshift solenoid (SBFSSOL) then turns off, allowing the switchback feedshift guide to return to the

original position by which the path of the original is switched back to the original conveying section. The now reversed

original is carried to the original conveying section and the switchback pressure solenoid (SBPSOL) turns off, releasing

the switchback pulley to prevent an original jam in the original switchback section.

Switchback

pulley

Switchback feedshift guide

Figure 2-1-5

2-1-4

Page 47

3C0

2-1-3 Original conveying section

The original conveying section consists of the parts shown in Figure. Synchronized with the copier scanning operation,

the original is conveyed across the slit glass and ejected when scanning is complete.

In the double-sided original mode, the eject feedshift solenoid (EFSSOL) turns on, moving the eject feedshift guide to

switch the path of the original. When the scanning of the first face (reverse face) of the original is complete, the original is

conveyed to the original switchback section again.

Figure 2-1-6 Original conveying section

1 Upper original conveying pulley

2 Upper original conveying roller

3 Lower original conveying roller

4 Front scanning pulley

5 Middle original conveying roller

6 Middle original conveying pulley

7 Eject pulley

8 Eject roller

OCM

DFTSW

9 Original conveying guide

0 Eject feedshift guide

! Upper eject guide

@ Lower eject guide

# Slit glass (copier)

$ DF timing switch (DFTSW)

% Eject feedshift solenoid

(EFSSOL)

EFSSOL

CN5-A13

CN5-A8 -

CN6-B14

DFDPCB

CN5-A7

Figure 2-1-7 Original conveying section block diagram

2-1-5

Page 48

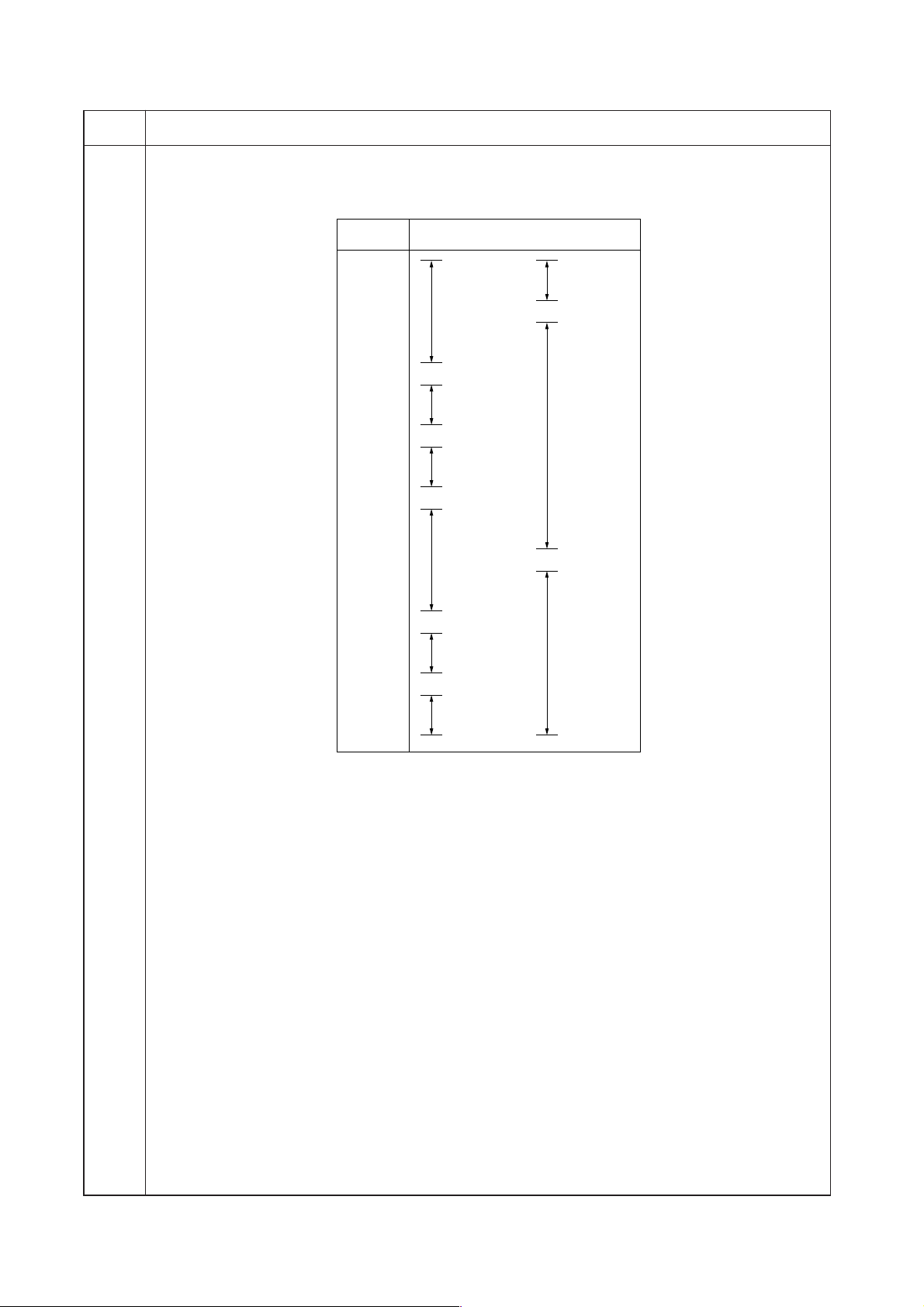

3C0

(1) Original switchback/conveying timing

Fwd. rotation

Rev. rotation

OffOFM

OFSW

SBFSSOL

SBPSOL A

SBPSOL R

OSBSW

OCM

EFSSOL

DFTSW

298 P

100 ms

*1

20 ms

*1

135 P

Scanning speed

30 ms

*2

78 P

Scanning speed

*1 Burst of OFM pulses

*2 Burst of OCM pulses

Timing chart 2-1-2 Reversing the first face of the original

a During primary original feed, when the original feed switch (OFSW) turns on, the switchback feedshift solenoid

(SBFSSOL) also turns on, changing the position of the switchback feedshift guide. This switches the path of the

original to the original switchback section.

b 298 OFM pulses plus 20 ms after the original feed switch (OFSW) turns on, the rotation of the original feed motor

(OFM) switches to the reverse direction and the original is conveyed to the switchback section by the rotation of the

switchback roller.

c Simultaneously as the original feed switch (OFSW) turns off, the switchback pressure solenoid (SBPSOL) turns on to

operate the switchback pulley.

d When the trailing edge of the original turns the original switchback switch (OSBSW) off, the switchback feedshift

solenoid (SBFSSOL) turns off, the switchback feedshift guide returns to the original position.

e 135 OFM pulses after the original switchback switch (OSBSW) turns off, the original feed motor (OFM) turns off. 100

ms later, the original feed motor (OFM) rotates forward, switching the rotational direction of the switchback roller. The

original in the original switchback section is then reversed and conveyed to the original conveying section.

f Simultaneously as the original feed motor (OFM) starts rotating forward, the original conveying motor (OCM) turns on

to convey the original onto the slit glass. The eject feedshift solenoid (EFSSOL) simultaneously turns on, changing

the position of the eject feedshift guide. This switches the path of the original to the original switchback section.

g When the original is conveyed onto the slit glass, the DF timing switch (DFTSW) turns on. 78 OCM pulses later, the

switchback pressure solenoid (SBPSOL).

h 30 ms after the switchback pressure solenoid (SBPSOL) turns off, the original feed motor (OFM) turns off.

2-1-6

Page 49

Fwd. rotation

OFM

Rev. rotation

OFSW

SBFSSOL

135 P

100 ms

*1

Scanning request signal: On

Scanning speed

*1

327 P

100 ms

3C0

SBPSOL

SBPSOL

OSBSW

OCM

EFSSOL

DFTSW

362 P

30 ms

*1

*2

78 P

Scanning speed

30 ms

2252 P*2 + 30 ms

*1 Burst of OFM pulses