Page 1

Chapter 3

Hardware notes

Page 2

Chapter 3 Contents

3-1 Hardware notes ................................................................................................................................ 4-3

3-1-1 Hardware configuration................................................................................................................... 4-3

3-1-2 Feeder board .................................................................................................................................. 4-4

(1) Feed motor drive circuit ................................................................................................................. 4-4

(2) Pickup solenoid drive circuit .......................................................................................................... 4-6

(3) Parallel/serial converter circuit....................................................................................................... 4-7

3-1-2 Interface connector ......................................................................................................................... 4-8

PF-80/PF-81

3-2

Page 3

3-1 Hardware notes

3-1-1 Hardware configuration

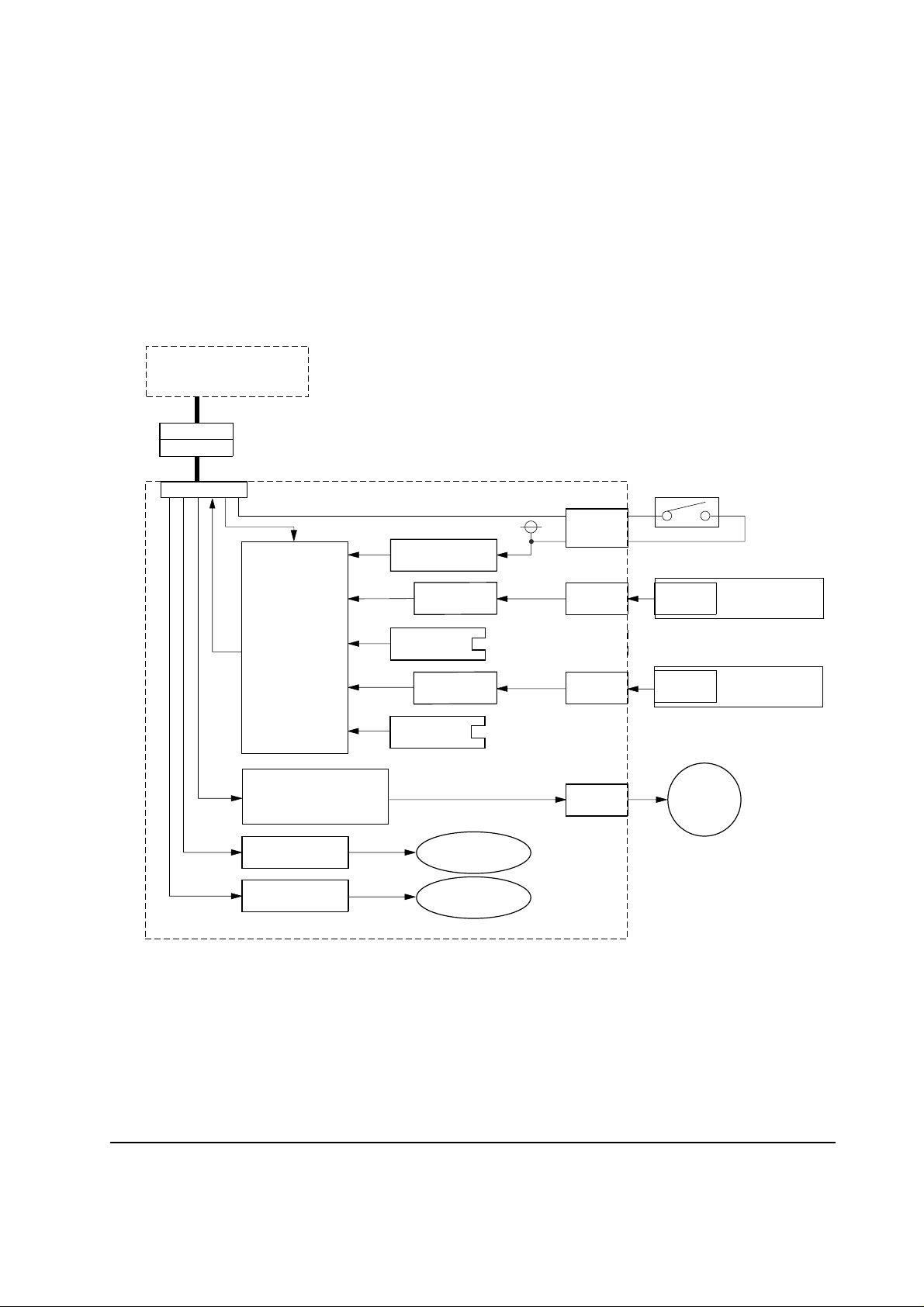

The hardware of the paper feeder PF-80/PF-81 includes the feeder board, tray sensor boards, feed

motor and the door switch. The feeder board is mounted the pickup solenoids, sensors. The feeder

board is under control of the printer main unit. See figure below.

Printer engine

DRAWER

DRAWER

Feeder board

CN901

Door switch

Parallel/serial

converter

circuit

Feed motor drive circuit

Pickup solenoid

drive circuit (A)

Pickup solenoid

drive circuit (B)

Door open

detect circuit

Tray sensor

circuit (A)

Paper empty

sensor (A)

Tray sensor

circuit (B)

Paper empty

sensor (B)

Pickup solenoid

(SOL901)

Pickup solenoid

(SOL902)

+24 V AS

CN902

CN904

CN905

CN906CN903

CN907

Feed motor

Tray sensor

board (A)

Tray sensor

board (B)

Figure 3-1-1 Hardware configuration block diagram

3-3

PF-80/PF-81

Page 4

3-1-2 Feeder board

The feeder board includes the feed motor drive circuit, pickup solenoid drive circuit, and the parallel/

serial converter circuit. The feed motor drive and pickup solenoid circuits drive the feed motor and

the pickup solenoid (SOL901, SOL902), respectively, depending on the control signals given by

the printer. The parallel/serial converter circuit converts the signals detected on the tray sensor

boards, paper empty sensors, and the door switch into the serial data signals which are delivered to

and commanded by the printer.

(1) Feed motor drive circuit

The feed motor (2-phase stepping motor) is driven by the stepping motor driver IC911. When the

OPMCTL signal is low, the current flows into the feed motor. When the signals are output as shown

below, the feed motor rotates.

OPMCTL

A

B

A

B

Figure 3-1-2 Feed motor timing chart

PF-80/PF-81

3-4

Page 5

PF-80

(Motor speed control signal)

PFMSET1

CN901

OPMCTL

Base clock (547 kHz)

Frequency divider

PFMSET1: H (534 Hz)

PFMSET1: L (267 Hz)

Phase control circuit

PF-81

PFMSET1

CN901

OPMCTL

(Clock signal)

617165

ABB

A

Stepping motor

driver

(IC911)

Phase control circuit

OUTBN

OUTB

OUTAN

OUTA

+24 V AS

11

18

1

8

Feed motor

CN905

OUTBN

OUTB

OUTAN

OUTA

+24 V AS

11

18

1

8

CN905

617165

ABBA

Stepping motor

driver

(IC911)

Figure 3-1-3 Feed motor drive circuit block diagram

3-5

Feed motor

PF-80/PF-81

Page 6

(2) Pickup solenoid drive circuit

The pickup solenoids (SOL901 and SO902) are driven by the transistors (Q901 and Q902) respectively. When the O1PCTL signal is high (Q901 turns on), the current flows into pickup solenoid

(SOL901) and the paper is fed from the middle tray . When the O2PCTL signal is high (Q902 turns

on), the current flows into pickup solenoid (SOL902) and the paper is fed from the lower tray.

OPMCTL

O1PCTL

or O2PCTL

Less than 5 s

Figure 3-1-4 Pickup solenoid drive signal timing chart

Pickup

solenoid

SOL901

Pickup

solenoid

SOL902

O1PCTL

O2PCTL

CN901

+24 V AS

Q901

+24 V AS

Q902

Figure 3-1-5 Pickup solenoid drive circuit block diagram

PF-80/PF-81

3-6

Page 7

(3) Parallel/serial converter circuit

The parallel/serial converter circuit is under control of signals OPSCLK and OPSLD. These signals

are used to convert the parallel input signals generated by the paper empty sensors and the door

switch into the serial data signal of OPRDD0 and OPRDD1 which are in turn delivered to the

printer.

+24 V

OPSCLK

OPSLD

CN901

OPSRDD0 (Serial data signal)

OPSRDD1 (Serial data signal)

Figure 3-1-6 Parallel/serial converter circuit

Parallel/serial

converter

circuit

(IC904)

(IC905)

GND

+5 V

GND

D901

5.5 V

GND

Paper

empty

switches

+24 V

CN902

Tray sensor boards

CN903/904

Door switch

3-7

PF-80/PF-81

Page 8

3-1-2 Interface connector

The interface connector is for connection of signals between the paper feeder and the printer. The

diagram below shows the arrangement of the connector pins.

7 8 9 10 11 12

1 2 3 4 5 6

Figure 3-1-7 Interface connector

Table 3-1-1 Interface connector pin assignment

Pin No. Input/Output Signal Function

10

1

2

3

4

Input

Input

Input

+5 V

GND

OPMCTL

O1PCTL

5 V DC power supply

Ground for 5 V DC

Feed motor drive signal L: On (Run), H: Off (Stop)

Pickup solenoid (SOL901) drive signal

H: On (Run), L: Off (Stop)

5

Input

O2PCTL

Pickup solenoid (SOL902) drive signal

H: On (Run), L: Off (Stop)

6

Output

OPSRDD0

Serial data signal (Middle tray status, paper empty

and paper feeder’s door open)

7

8

9

Output

Input

Input

Input

OPSRDD1

OPSCLK

OPSLD

+24 V

Serial data signal (Lower tray status, paper empty)

Clock signal for serial communication

Serial data loading signal

24 V DC power supply

11

12

PF-80/PF-81

Input

GND

Ground for 24 V DC

Feed motor speed control signal (PF-80)

L: High speed, H: Low speed

Feed motor drive clock signal (PF-81)

3-8

Loading...

Loading...