Page 1

Chapter 3 HARDWARE NOTES

Page 2

Hardware Notes

Introduction

3.1 Introduction

This chapter describes an operational overview of the paper feeder. It ensures correct understanding of the behavior of both the mechanical and electrical mechanism of the paper feeder to

assist servicing.

The following basic functions of the paper feeder are discussed in the following pages.

❐ Friction-retarded roller (FRR) system

❐ Electrical parts, page 3-6

❐ IC details and pin assignments, page 3-9

❐ Feed motor driver, SLA7024M (U4), page 3-10

❐ Tray motor driver, TA8428K (U5), page 3-11

, page 3-5

3-2

PF-7E

Page 3

Hardware Notes

Overall block

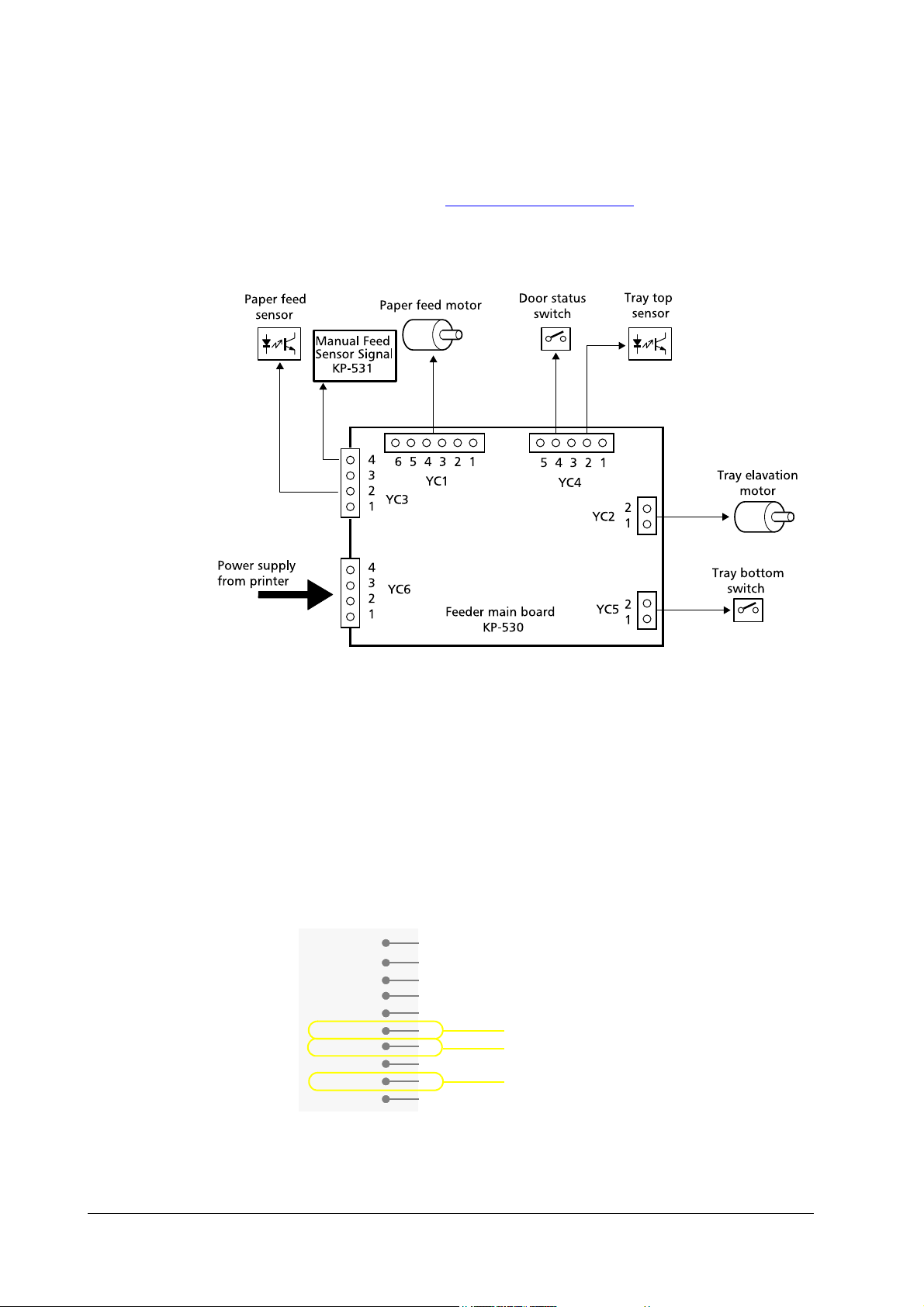

3.2 Overall block

Figure 3.1 Feeder main board

The diagram below shows the main board and the components of the paper feeder. For a fully

detailed schematic information, see Chapter 5 Schematic diagram

.

The KP-531 board provides liaison for the manual feed sensor signal as well as giving an identifying signal that the PF-7E is installed with the printer.

The printer recognizes installation of the PF-7E when pin #6 of YC782 on KP-502 [Envelope

feeder mount board] on the printer (=YC1 on KP-531 on the PF-7E) turns to L. This signal

turns to H in case an envelope feeder EF-1 is installed.

Refer to the connector pin assignment for YC-1 below. Pin #6 is grounded for the PF-7, which

left open for the EF-1, effectively allowing the printer to identify either of these option feeders.

Figure 3.2 YC-1 connector on KP-531

OP

VDD

MON*

UNIT*

OP

PF7UNIT*

PEMP*

SGND

HANDS

PGND

10

1

2

3

4

5

6

7

8

9

Identifies the PF-7 installation

Unused for the PF-7

Manual feed sensor for printer

PF-7E

3-3

Page 4

Hardware Notes

Overview of feeder operation

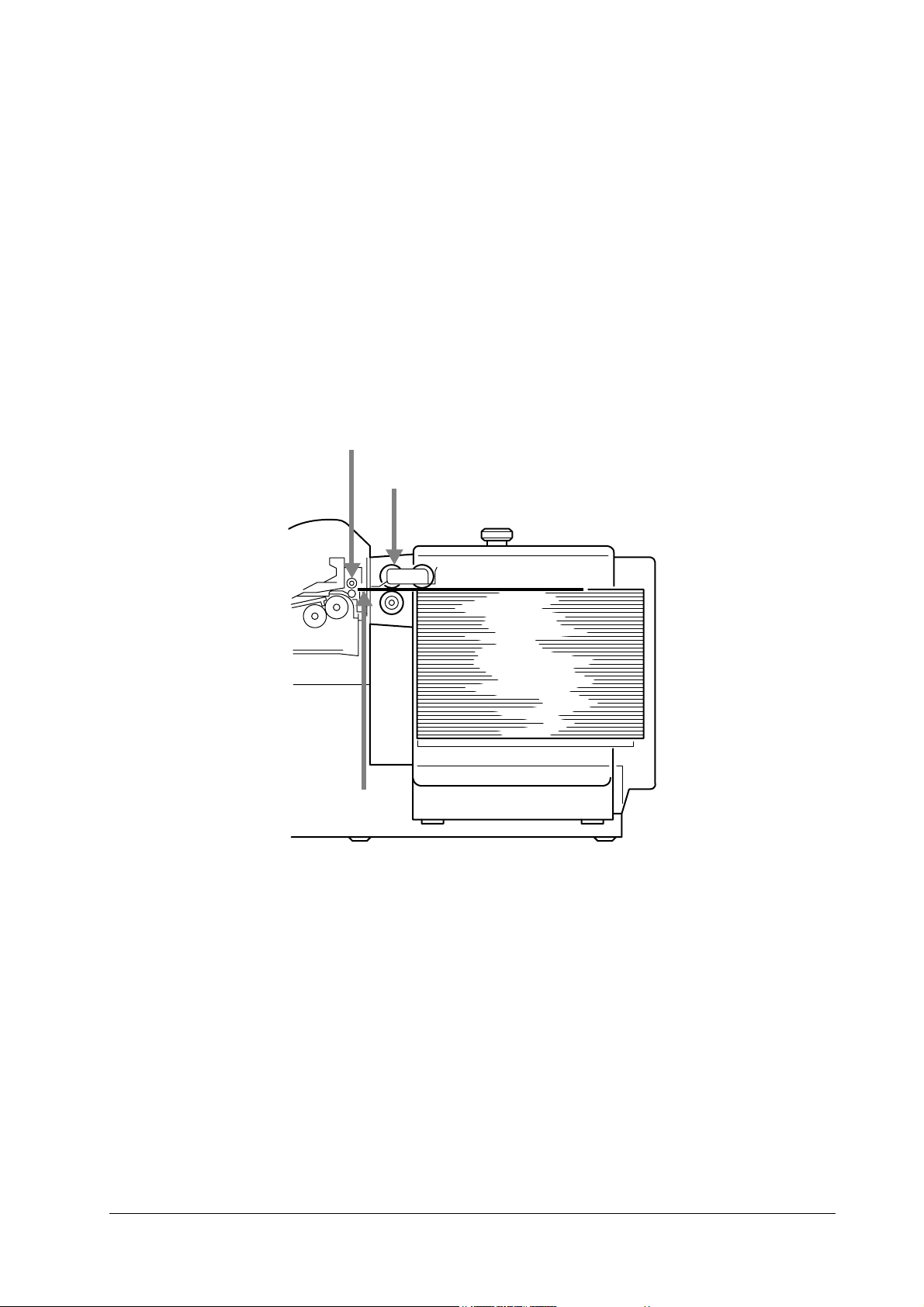

3.3 Overview of feeder operation

The PF-7E feeds paper which turns on the PF-7E’s feed sensor. If the printer’s feed sensor will

not turn on in 2 seconds since the PF-7E’s feed sensor has turned on, the PF-7E forces paper

into the printer. Unlikewise, the precedent PF-7 feeder pauses when its feed sensor has turned

on until the printer’s feed sensor turns on.

To avoid paper jam caused when several sheets of paper are fed at one time, the feeder uses the

friction-retarded roller (FRR) system for paper feed. The operating theory for this system follows this section.

Figure 3.3 Feeder interface to printer

Printer manual feed roller

Feed roller (See page 3-5.)

Subsequently-fed paper

3-4

PF-7E

Page 5

Hardware Notes

Overview of feeder operation

Friction-retarded roller (FRR) system

The paper feeder utilizes the friction-retarded rollers to ensure a reliable paper feeding free of

multiple feeding problem. This system is comprised of the paper feed roller, reverse roller, and

the torque limiter as shown in figure below.

Figure 3.4 FRR system

Feed roller

Reverse roller

Figure 3.5 Feed and reverse rollers

Oneway clutch

In this system, both the paper feed and

reverse rollers are driven clockwise at the

shaft. The reverse roller, however, has the

torque limiter (one-way clutch) at one end

which in normal paper feeding effectively

frees the reverse roller from the shaft to turn

in counterclockwise direction by means of the

friction given by the paper feed roller through

the paper.

Assuming more than one sheet of paper are

accidentally fed and pinched between these

rollers, there no longer is friction between the

rollers as the friction is subtle among the

sheets of paper. The reverse roller can then

rotate following the shaft rotation defeating

the torque limiter. The feed roller continues

feeding the top sheet towards the printer; the

reverse roller feeds the second sheet backward, thus avoiding misfeeding problem.

PF-7E

3-5

Page 6

Hardware Notes

Overview of feeder operation

Electrical parts

The feeder’s internal electronics, including the one-chip microprocessor µPD78213 is used as

CPU, serves mainly for activating and deactivating the motors to elevate the tray and feed

paper (towards the printer manual feed rollers) in cooperation with the sensors.

The function of each major component of the feeder is as follows. (All these components are

connected to the main circuit board KP-369.)

Figure 3.6 Electrical part layout

➊

Paper feed sensor

➍

Tra y upper li m i t

➏

Tray elevation

motor

➋

Feed motor

➐

Power supply

connector

➌

Feeder cover sensor

➎

Tray bottom limit

sensor

Paper feed sensor (➊)

This sensor monitors the presence of paper at the feeder output slot. It requests the feeder

CPU to forward or stop paper feed into the feeder output slot.

If paper is not found at the sensor, the sensor requests the CPU to drive the paper feed motor;

as the paper feed motor drives the top sheet of the stack forward and the leading edge of the

paper hits and passes the sensor and the leading edge of the paper reaches the printer’s registration rollers, the sensor then requests the CPU to stop revolving the motor.

3-6

PF-7E

Page 7

Hardware Notes

Overview of feeder operation

Paper feed motor (➋)

This is a stepping motor which is

activated when requested by the

paper feed sensor to feed paper

toward the feeder output slot. Feed

motor driver U4, SLA7024M, is a

constant-current chopper type

driver IC which includes power

MOSFETs for simplified driver configuration of the stepping motor. See

section 4.4. for details on this IC.

The driver output current for the

motor is adjusted and limited by

components R7, R8, R12, and C5

which determine the output current,

Io, in the following formula:

Io

R8

---------------------

R7 R8

+

×≈

C5

----------

R12

The chopping frequency, represented by the period of time during

the absence of current flow, Toff, for

the stepping motor is determined as

follows:

Toff 0.51 R5×C2×0.51 R6 C3

≈

=

××

Feeder door status sensor (➌)

This sensor reports feeder CPU as to whether the feeder door is closed or open. If the door is

open, the sensor sends COVOP signal by which the CPU begins activating the tray selection

motor so that the paper tray descends until the tray bottom sensor is energized or the door is

closed again.

Tray top position sensor (➍)

This sensor, when the top of the paper stack in the paper tray has reached the top most position, ready for feeding paper through the feeder output slot, sends feeder CPU the TRYUP signal to stop the tray elevation motor.

Tray bottom position sensor (➎)

PF-7E

This sensor, when stepped on by the paper tray as the paper tray descends, sends feeder CPU

the TRYLW signal to stop the tray elevation motor.

3-7

Page 8

Hardware Notes

Overview of feeder operation

Tray elevation motor (➏)

This is a DC-servo motor to raise or descends the paper tray. It revolves in either forward or

reverse direction in the control of motor driver U5, TA8428K, a full-bridge type DC motor

driver, in accordance with the feeder door status sensor (switch). The logic for motor revolution

is tabled as follows.

Figure 3.7 Tray motor driver

Table 3.1. Logic for tray movement

Raise L H L H

Descend H L H L

Still L L High imped.

H level is approximately 5V for inputs and 20 to 22V for outputs.

Power supply connector (➐)

A 10-pin connector is used to connect the feeder to the printer power supply. The connector

supplies +5V and +24V DC power only: No signal connection is made between feeder CPU

and the printer engine system. The connector is the same type one as used for some Kyocera

printer models and option equipment.

Figure 3.8 Connector wiring

Input Output

IN1 IN2 OUT A OUT A

Feeder main board (➑)

All electrical component are mounted on board KP-369. The feeder CPU µPD-78213C is

responsible for most functions of the paper feeder electronics. It entertains sensor output signals such as from tray elevation top/bottom sensors, paper feeding sensor, door status sensor;

3-8

PF-7E

Page 9

Hardware Notes

Overview of feeder operation

and delivers motor driving outputs for paper feeding and tray elevation motors. Figure below

shows the inputs/outputs for the CPU.

Figure 3.9 Main board layout

IC details and pin assignments

This section describes information on the major ICs used with the

paper feeder. Figure below shows ICs used with the paper feeder

(KP-369 board).

Main controller, µPD78213GC (U1)

The 78213 is a one-chip microprocessor, including ROMs and

RAMs for controlling paper feeding using motors. This IC looks

like the figure below and has the following pin assignment.

For the pin assignment, see table 3.2.

D78213 pin assignment

Table 3.2. D78213 pin assignment

Pin # Port # Signal Function

1 P64 RD

2-5 P63-60 — Unused —

6— RESET Reset —

7 — X2 — —

8 — X1 — —

9 — V

10-17 P57-50 A15-8 Address bus, H: active Output

18 P47 AD7 Address/data bus A7/D7, H: active Both

19 P46 AD6 Address/data bus A6/D6, H: active Both

D78213 pin assignment

Read timing for option units, L: Active Output

SS

— —

, below.

Input/

Output

PF-7E

3-9

Page 10

Hardware Notes

Overview of feeder operation

Table 3.2. D78213 pin assignment (Continued)

Pin # Port # Signal Function

20 P45 AD5 Address/data bus A5/D5, H: active Both

21 P44 AD4 Address/data bus A4/D4, H: active Both

22 P43 AD3 Address/data bus A3/D3, H: active Both

23 P42 AD2 Address/data bus A2/D2, H: active Both

24 — V

25 P41 AD1 Address/data bus A1/D1, H: active Both

26 P40 AD0 Address/data bus A0/D0, H: active Both

27 — ASTB — —

28-31 P20-23 — Reserved Input

32-39 P24-33 — Unused —

40 — — — —

41 — V

42 — AV

43 — AV

44 P75 COVOP Door status, H: open Input

45 P74 MFEED

46 P73 TRYUP Tray elevate signal, H: elevate Input

47 P72 TRYLW Tray lowering signal, H: lower Input

48 P71 FEED Paper feed signal, H: feed paper Input

49 AN0 ISENS Tray elevate motor encoding sensor Input

50-53 P34-36 — Unused —

54 P00 OUT1<MO> Tray elevat. motor drive signal 1 Output

55 P01 OUT2 Tray elevat. motor drive signal 1 Output

56, 57 P02, P03 — Unused —

58 P04 OUTA Feed motor drive signal, phase A Output

59 P05 OUTB Feed motor drive signal, phase B Output

60 P06 OUTC Feed motor drive signal, phase A

61 P07 OUTD Feed motor drive signal, phase B Output

62-64 P67-65 — Unused —

SS

DD

SS

REF

— —

— —

— —

— —

Printer’s manual feed sensor, L: paper present Input

Input/

Output

Output

Feed motor driver, SLA7024M (U4)

The SLA7024M, U4, is a constant-current chopper type driver IC

which includes power MOSFETs for simplified driver configuration

of the stepping motor. The PWM-type chopper circuitry has a good

high-frequency response and advanced driver efficiency. Figure below

shows a simplified internal circuitry of this IC.

3-10

PF-7E

Page 11

Hardware Notes

Overview of feeder operation

Figure 3.10 SLA7024M internal diagram

Tray motor driver, TA8428K (U5)

The TA8428K, U5, is a full-bridge driver IC for controlling the tray elevation motor. This IC provides four modes of motor operation, forwardrotating, reverse-rotating, brake, and stop. The door status switch,

when open, requests U5 to rotate the tray elevation motor in forward

direction so that the paper tray descends; while it drivers the motor in

reverse direction when the door status switch is closed. The driver stops

the motor either when the tray has reached the top or bottom most position, pressing the appropriate sensor.

PF-7E

3-11

Page 12

Hardware Notes

Overview of feeder operation

3-12

PF-7E

Loading...

Loading...