Page 1

Chapter 4

Specifications

Page 2

Chapter 4 Contents

4-1 Hardware notes ................................................................................................................................ 4-3

4-4-1 Hardware configuration................................................................................................................... 4-3

4-1-2 Motor drive board............................................................................................................................ 4-4

(1) Feed motor drive circuit ...................................................................................................................... 4-4

(2) Paper empty detection/Cassette detection circuit............................................................................... 4-5

4-1-2 Connector board ............................................................................................................................. 4-6

4-2 Paper feeding system...................................................................................................................... 4-7

4-2-1 Paper control signals ...................................................................................................................... 4-8

4-2-2 Paper feeder’s cassette feeding ..................................................................................................... 4-9

4-2-3 Paper sensor ................................................................................................................................ 4-10

Page 3

4-1 Hardware notes

4-4-1 Hardware configuration

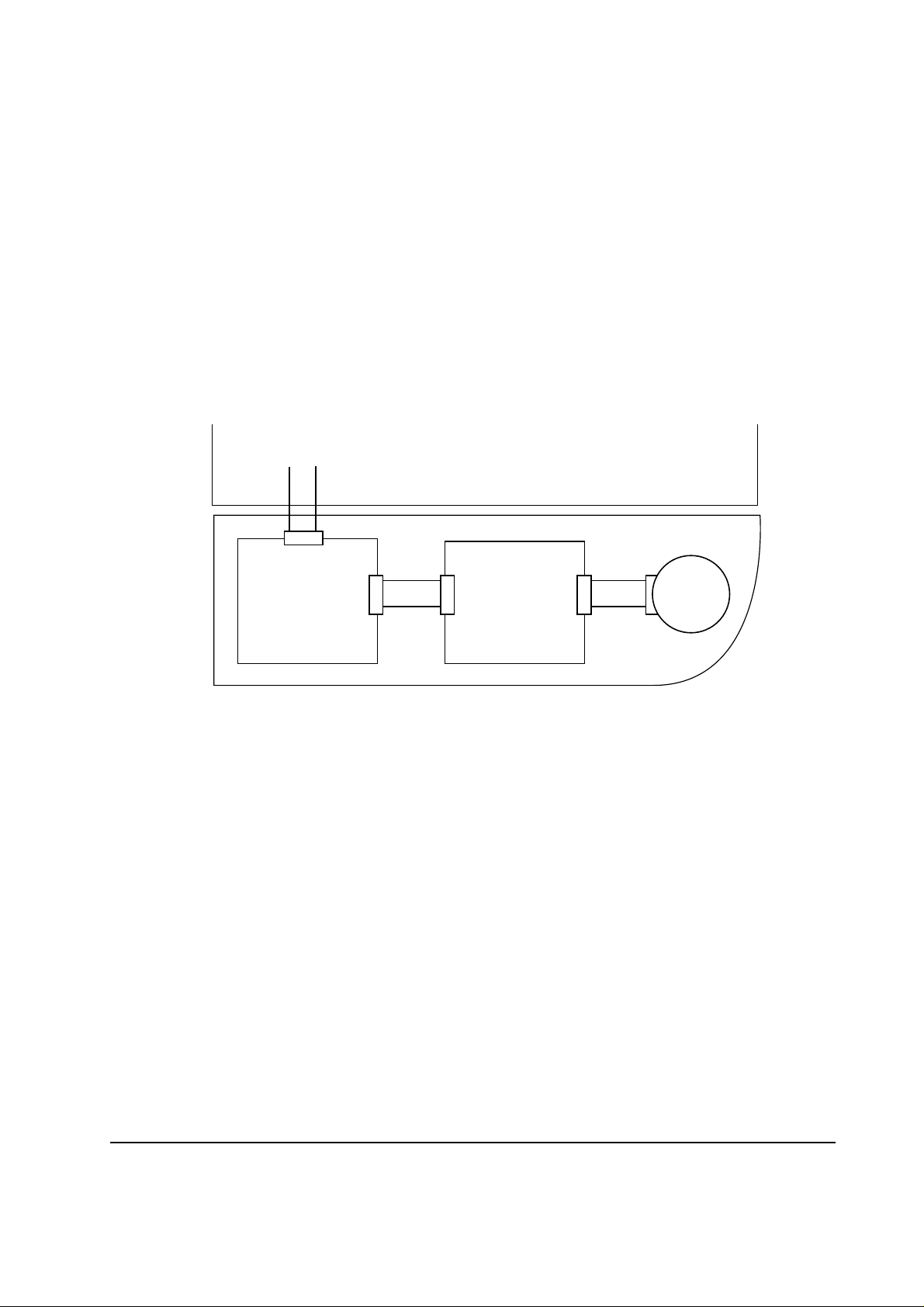

The hardware of the paper feeder PF-16 includes the connector board, motor drive board, the feed

motor, etc. The connector board is used to relay the signals between the paper feeder and the printer.

The motor drive board includes the feed motor driving circuit, paper empty detection/cassette detection circuit, etc.

Engine board

Connector board

(KP-595)

Printer

Motor drive board

Paper feeder

(KP-597)

Feed

motor

Figure 4-1-1 Hardware configuration block diagram

4-3

PF-16

Page 4

4-1-2 Motor drive board

(1) Feed motor drive circuit

The feed motor is driven by the 12 V DC supply which is obtained by down-converting the 24 V

DC supply from the printer by zener diodes DZ801 and DZ802. Two zener diodes are used in series

for compensation of the temperature response of zener diodes.

Control over the current for driving the feed motor is implemented as follows: Transistor Q803

turns on when the current flowing through resistor R805 is in excess of the predetermined value.

This in turn controls the base voltage of transistor Q801 which is connected with Q803, turning

Q801 on and disconnecting the current in the feed motor. Transistor Q801 then turns off since no

current flows through R805. Now Q801 turns on and drives the feed motor . By repetitively continuing

the above procedure, the maximum current in the feed motor is regulated and the over-current

situation is prevented.

Feed motor drive circuit

R801

R802

DZ801

DZ802

24V DC

Q801

C

Q803

E

B

C

E

R804

B

R805

Feed motor

PF-16

Figure 4-1-2 Feed motor drive circuit

4-4

Page 5

(2) Paper empty detection/Cassette detection circuit

The motor drive board mounts the sensor and switch for detection of paper emptiness and cassette

presence. Paper sensor PH801 is a photo interrupter that detects presence of paper by means of the

actuator. Cassette switch SW801 is a push switch that detects the presence of the paper cassette as

triggered by a pin.

5 V DC

Motor drive board

CPU

SENPW

PFPER*

Printer

R238

Engine board

R803R243

SW801

PH801

Actuator

Paper feeder PF-16

Pin

Paper cassette

Figure 4-1-3 Paper empty detection/Cassette detection circuit

Table 4-1-1 Paper empty detection/Cassette detection circuit signals

Signal Input/Output Function Meaning

SENPW

Input

Input Illuminates the paper sensor (LED)

only while the printer’s fan is running.

Control signal for the

paper sensor (PH801)

LED.

PFPER*

Output

H: Paper empty or no cassette

L: Paper present or cassette inserted

Detection signal for

paper cassette or paper.

4-5

PF-16

Page 6

4-1-2 Connector board

The connector board mounts connector YC701 for connecting to the printer and connector YC702

for connector to the motor drive board. The diagram below shows the arrangement of the connector

pins.

1 2 3 4 5 6

YC701 viewed at the bottom

Figure 4-1-4 Connector (YC701)

Table 4-1-2 Connector (YC701) pin assignment

Pin No. Input/Output Signal Function

1

Input

24 V DC power

-

2

Input

Feed motor drive signal

L: On (Run)

H: Off (Stop)

3

Input

Control signal for LED

L: Paper or cassette is present

illumination

4

Output

Paper empty and cassette

H: Paper is empty or the cassette is present

insertion detection signal

5

6

Output

-

Paper feeder installation

signal

GND

L: Paper feeder installed

H: Paper feeder not installed

Ground

PF-16

4-6

Page 7

4-2 Paper feeding system

The paper feeding system picks up paper from the paper feeder PF-16. Paper is fed at a precise

timing in synchronization with data processing. The paper feeding system finally delivers the printed

page to either the face-down or face-up tray as manipulated by the user . The figure below shows the

components comprising the paper feeding system and the paths through which the paper travels.

Process unit

(PU-16)

Fuser unit

Feed roller

Paper feeder PF16

Figure 4-2-1 Paper feeding system diagram

4-7

PF-16

Page 8

4-2-1 Paper control signals

The following diagram shows for sensors and rollers that guide paper during printing. The printer’s

engine controller provides these signals in conjunction with the electrophotography process that is

driven by the printer’s main logic controller system.

Printer FS-600/FS-680

Engine Controller

Face-down rollers

PFSEN

PAPER*

SENPW

PFMDR*

Exit

sensor

EXITJ*

Exit rollers

Connector board

(KP-595)

Main motor

Heat Roller

Pressure

Roller

MOTDR

Drum

Transfer

roller

Motor drive board

(KP-597)

RESIDR

Regist.

clutch

Registration

rollers

RESIT*

Regist

sensor

PAPER

Paper

sensor

Cassette

switch

Paper

sensor

FEDDR*

Feed

clutch

Feed

motor

Manual

feed tray

PF-16

Paper feeder PF-16

Figure 4-2-2 Paper control system block diagram

4-8

Page 9

4-2-2 Paper feeder’s cassette feeding

The printer’s main logic controller sends the PRINT* signal to the engine controller after it has

finished processing data. The printer’s engine controller CPU then starts the main motor (MOTDR),

polygon motor, registration rollers, and the fuser heater. The engine controller then issues the

PFMDR* signal which connects the paper feeder’s feed motor power to the feed roller. The feed

roller feeds the top sheet in the paper stack in the paper feeder’s cassette towards the registration

rollers until the paper reaches the registration sensor (RESIT*). As the engine controller sends

VSREQ* to the main logic controller, the main logic controller subsequently issues VSYNC* to

activate the registration rollers, thus starting to feed paper forwards to the drum. The paper is

advanced to the drum, to the fuser unit, triggering the exit sensor (EXITJ*), and finally delivered

either to the face-down or face-up tray as manipulated by the user.

4-9

PF-16

Page 10

4-2-3 Paper sensor

A photo penetration type sensor is used for the paper sensor. While paper is not present as shown in

1 the reflector at one end of the sensor’s actuator is normally seated in between the photo transmitter and the sensor . While the paper is present, the reflector is pushed up by the paper and the light is

interrupted as shown in 2, thus triggering the sensor.

1

2

Figure 4-2-3 Paper sensor

PF-16

4-10

Loading...

Loading...