Page 1

SERVICE

MANUAL

Published in Oct.’01

843C1110

Page 2

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 3

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 4

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

Page 5

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement....................

Page 6

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

Page 7

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Parts names ......................................................................................................................................... 1-1-2

1-1-3 Machine cross section .......................................................................................................................... 1-1-3

1-1-4 Drive system ........................................................................................................................................ 1-1-4

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

(1) Unpacking ....................................................................................................................................... 1-2-1

(2) Removing tapes and metal fittings ................................................................................................. 1-2-2

1-2-2 Installing the mailbox (option) .............................................................................................................. 1-2-5

1-3 Maintenance Mode

1-3-1 Maintenance mode ............................................................................................................................... 1-3-1

1-4 Troubleshooting

1-4-1 Paper misfeed detection ...................................................................................................................... 1-4-1

(1) Paper misfeed detection ................................................................................................................. 1-4-1

(2) Paper misfeed detection conditions ................................................................................................ 1-4-1

(3) Paper misfeeds ............................................................................................................................... 1-4-5

1-4-2 Self-diagnosis ....................................................................................................................................... 1-4-7

(1) Self-diagnostic function .................................................................................................................. 1-4-7

(2) Self-diagnostic codes ..................................................................................................................... 1-4-7

1-4-3 Electrical problems ............................................................................................................................. 1-4-10

(1) The paper conveying motor does not operate (C801). ................................................................. 1-4-10

(2) The front jogger motor does not operate (C817). ......................................................................... 1-4-10

(3) The rear jogger motor does not operate (C818). .......................................................................... 1-4-10

(4) The tray elevation motor does not operate (C814). ...................................................................... 1-4-10

(5) The front stapler motor does not operate (C821). ........................................................................ 1-4-10

(6) The rear stapler motor does not operate (C822). ......................................................................... 1-4-11

(7) The paper conveying belt clutch does not operate. ...................................................................... 1-4-11

(8) The paddle clutch does not operate. ............................................................................................ 1-4-11

(9) The punch clutch does not operate. ............................................................................................. 1-4-11

(10) The trailing edge press solenoid does not operate. ...................................................................... 1-4-11

(11) Feedshift solenoid 1 does not operate. ........................................................................................ 1-4-11

(12) Feedshift solenoid 2 does not operate. ........................................................................................ 1-4-12

(13) Paddle solenoid 1 does not operate. ............................................................................................ 1-4-12

(14) Paddle solenoid 2 does not operate. ............................................................................................ 1-4-12

(15) Paddle solenoid 3 does not operate. ............................................................................................ 1-4-12

(16) The rotating plate solenoid does not operate. .............................................................................. 1-4-12

(17) The drive switching solenoid does not operate. ........................................................................... 1-4-12

(18) The punch pattern solenoid does not operate. ............................................................................. 1-4-13

(19) The pressure switching solenoid does not operate. ..................................................................... 1-4-13

(20) Forwarding solenoid does not operate. ........................................................................................ 1-4-13

(21) Paper jams when the main switch is turned on. ........................................................................... 1-4-13

(22) “Out of staples. (Front) Add staples.” or “Out of staples. (Rear) Add staples.” is displayed

when the main switch is turned on. .............................................................................................. 1-4-14

1-4-4 Mechanical problems ......................................................................................................................... 1-4-15

(1) No paper feed. .............................................................................................................................. 1-4-15

(2) No paper ejection to the sort or non-sort trays. ............................................................................ 1-4-15

(3) Paper jams. .................................................................................................................................. 1-4-15

(4) Abnormal noise is heard. .............................................................................................................. 1-4-15

1-1-1

3C1

Page 8

3C1

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly ......................................................................................... 1-5-1

(1) Precautions ..................................................................................................................................... 1-5-1

1-5-2 Procedure for assembly and disassembly ........................................................................................... 1-5-1

(1) Detaching and refitting the static eliminator brushes ...................................................................... 1-5-1

(2) Detaching and refitting the punch unit ............................................................................................ 1-5-2

(3) Adjusting the center of the punch holes ......................................................................................... 1-5-3

(4) Adjusting paddle clutch turn-on timing ............................................................................................ 1-5-4

2-1 Mechanical construction

2-1-1 Construction of each section ................................................................................................................ 2-1-1

(1) Paper conveying section ................................................................................................................ 2-1-1

(2) Internal tray section ........................................................................................................................ 2-1-6

(3) Punch section ................................................................................................................................. 2-1-9

(4) Stapler section .............................................................................................................................. 2-1-12

(5) Non-sort tray section .................................................................................................................... 2-1-14

(6) Sort tray section ............................................................................................................................ 2-1-15

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

2-3 Operation of the PCB

2-3-1 Main PCB ............................................................................................................................................. 2-3-1

2-4 Appendixes

Timing chart No. 1 .......................................................................................................................................... 2-4-1

Timing chart No. 2 .......................................................................................................................................... 2-4-2

Timing chart No. 3 .......................................................................................................................................... 2-4-3

Timing chart No. 4 .......................................................................................................................................... 2-4-4

Wring diagram ................................................................................................................................................ 2-4-5

1-1-2

Page 9

1-1-1 Specifications

Type .............................................. Floor standing

Number of trays ............................ Sort tray: 1

Non-sort tray: 1

Tray capacity ................................. Sort tray (75 – 80 g/m

When not stapling:

1500 sheets: A3, B4 (257 mm × 364 mm), 11" × 17", 8

3000 sheets: A4, A4R, 8

When stapling 2 sheets:

300 sheets: A3, B4 (257 mm × 364 mm)

450 sheets: 11" × 17"

600 sheets: 8

700 sheets: 8

750 sheets: A4, A4R

850 sheets: 11" × 8

When stapling 3 or 4 sheets:

300 sheets: A3, B4 (257 mm × 364 mm)

400 sheets: 11" × 17"

700 sheets: A4, A4R, 8

750 sheets: 8

800 sheets: 11" × 8

When stapling 5 to 10 sheets:

500 sheets: A3, B4 (257 mm × 364 mm), 11" × 17"

800 sheets: 8

850 sheets: A4, A4R

900 sheets: 8

When stapling 11 to 20 sheets:

800 sheets: A3, B4 (257 mm × 364 mm)

950 sheets: 11" × 17"

1000 sheets: 8

1100 sheets: A4, A4R

1200 sheets: 8

When stapling 21 to 29 sheets:

1300 sheets: A3, B4 (257 mm × 364 mm)

1400 sheets: 11" × 17"

1500 sheets: 8

When stapling 21 to 49 sheets:

2700 sheets: A4R

3000 sheets: A4, 8

When stapling 30 sheets:

1500 sheets: A3, B4 (257 mm × 364 mm),11" × 17", 8

When stapling 50 sheets:

3000 sheets: A4, A4R, 8

Non-sort tray:

150 sheets: A3, B4 (257 mm × 364 mm), folio, 11" × 17", 8

250 sheets: A4, A4R, A5R, A6R, 11" × 8

Stapling limit .................................. 30 sheets: A3, B4 (257 mm × 364 mm), 11" × 17", 8

50 sheets: A4, A4R, 11" × 8

Power source ................................ Electrically connected to the copier

Dimensions ................................... 688 (W) × 598 (D) × 1055 (H) mm

1

27

/8" (W) × 239/16" (D) × 411/2" (H)

Weight ........................................... Approx. 50 kg/110 lbs

2

weight paper)

1

/2" ×11", 11" × 81/2"

1

/2" × 14"

1

/2" × 11"

1

/2"

1

1

/2" × 11"

1

/2" × 14"

1

/2" × 11", 11" × 81/2"

1

/2" × 14"

1

/2" × 11", 11" × 81/2"

1

/2" × 14"

/2" × 14"

1

/2"

1

/2" × 11", 11" × 81/2"

1

/2" × 11", 11" × 81/2"

1

/2", 81/2" × 11" [75 – 80 g/m2]

1

/2", 81/2" × 11"

1

/2" × 14"

1

/2" × 14"

1

/2" × 14"

1

/2" × 14" [75 – 80 g/m2]

3C1

1-1-1

Page 10

3C1

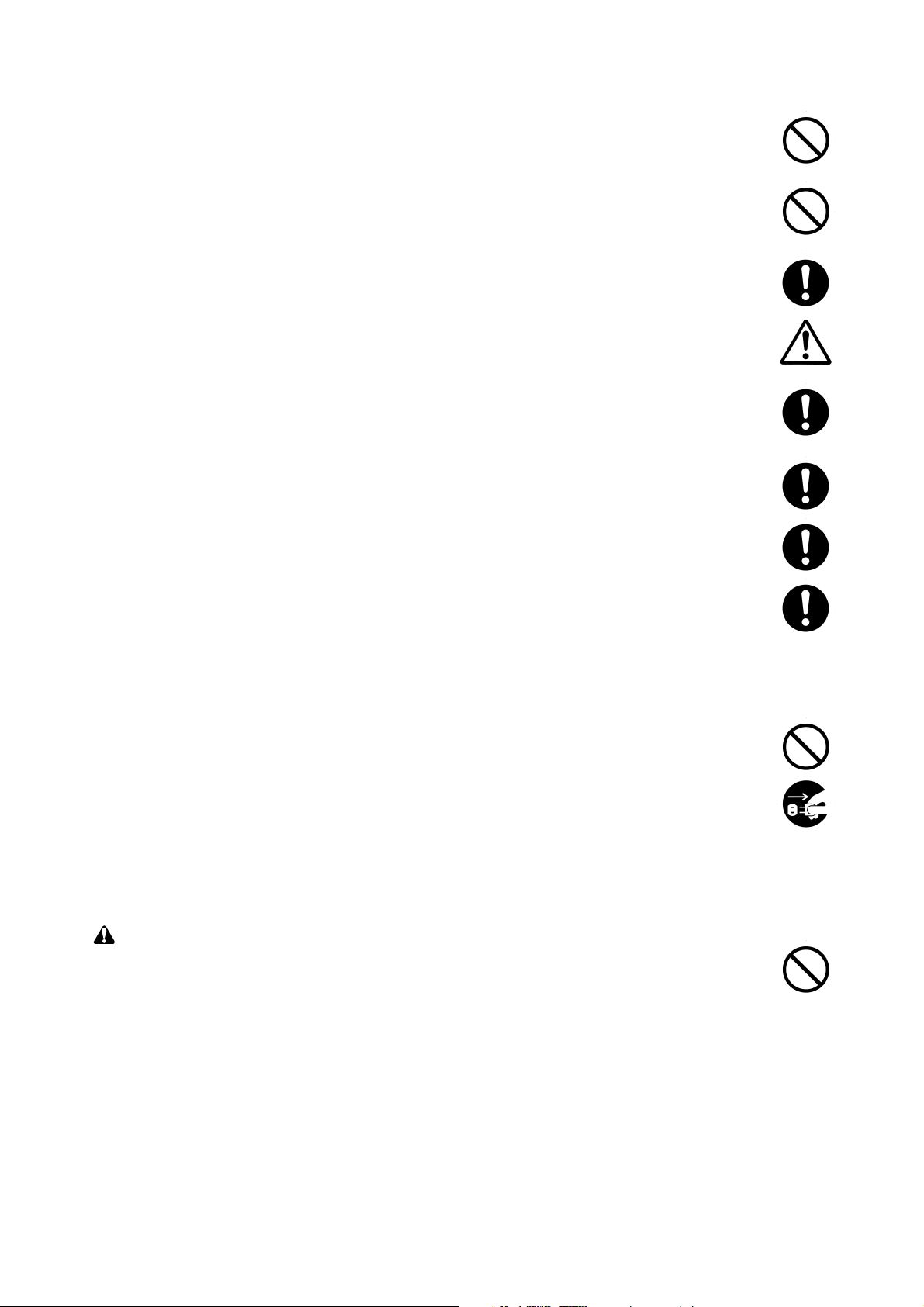

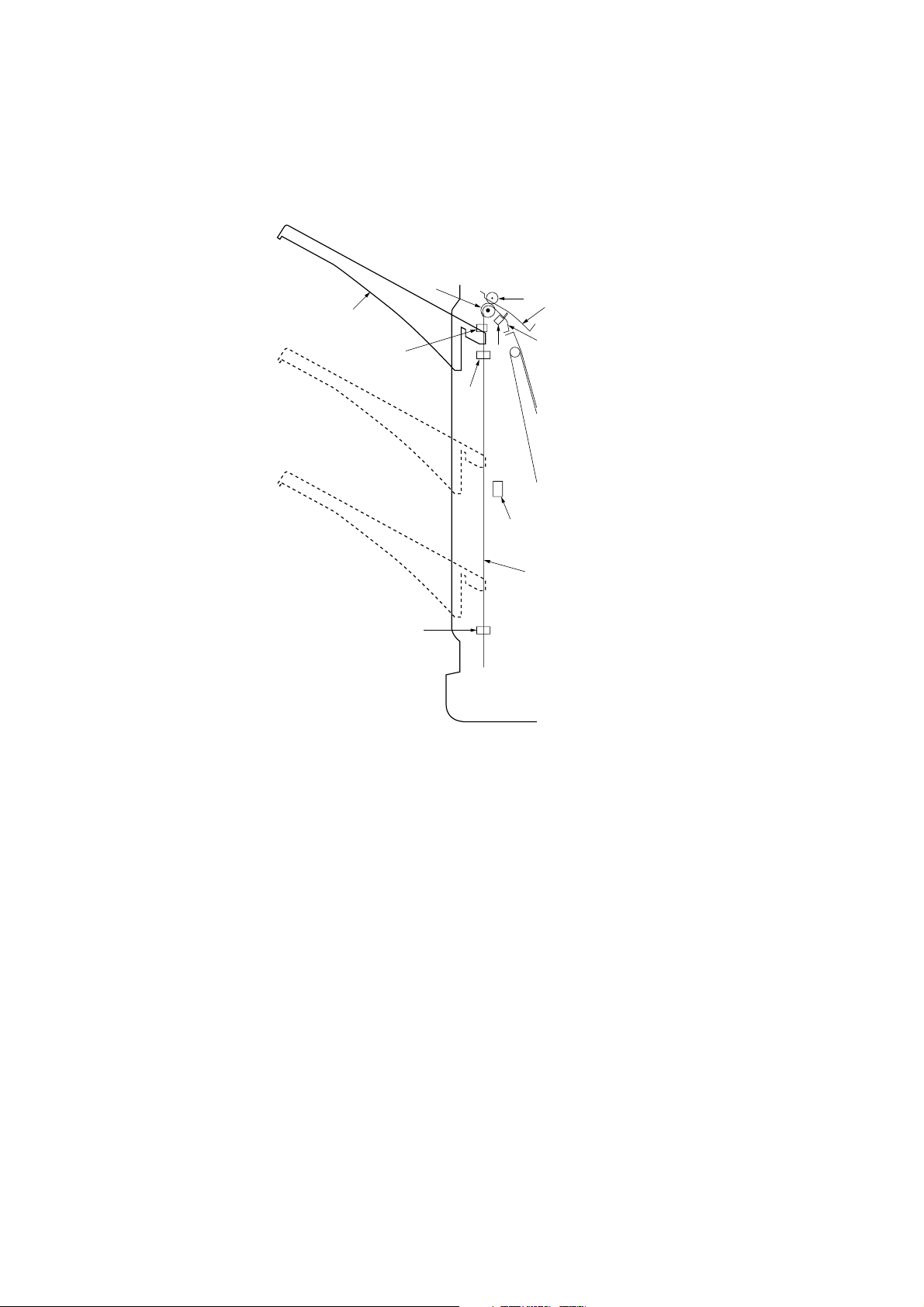

1-1-2 Parts names

1-1-2

Figure 1-1-1 Parts names

1 Sort tray

2 Non-sort tray

3 Finisher release button

4 Front cover

5 Front cover handle

6 Upper cover

7 Waste punch box

8 Waste punch box knobs

9 Internal tray

0 Internal tray handle

! Conveyor knob A

@ Conveyor guide handle A

# Conveyor guide handle B

$ Conveyor knob B

% Pressure adjustment lever

^ Stapling unit handle

& Staple holder release lever

* Staple holder

Page 11

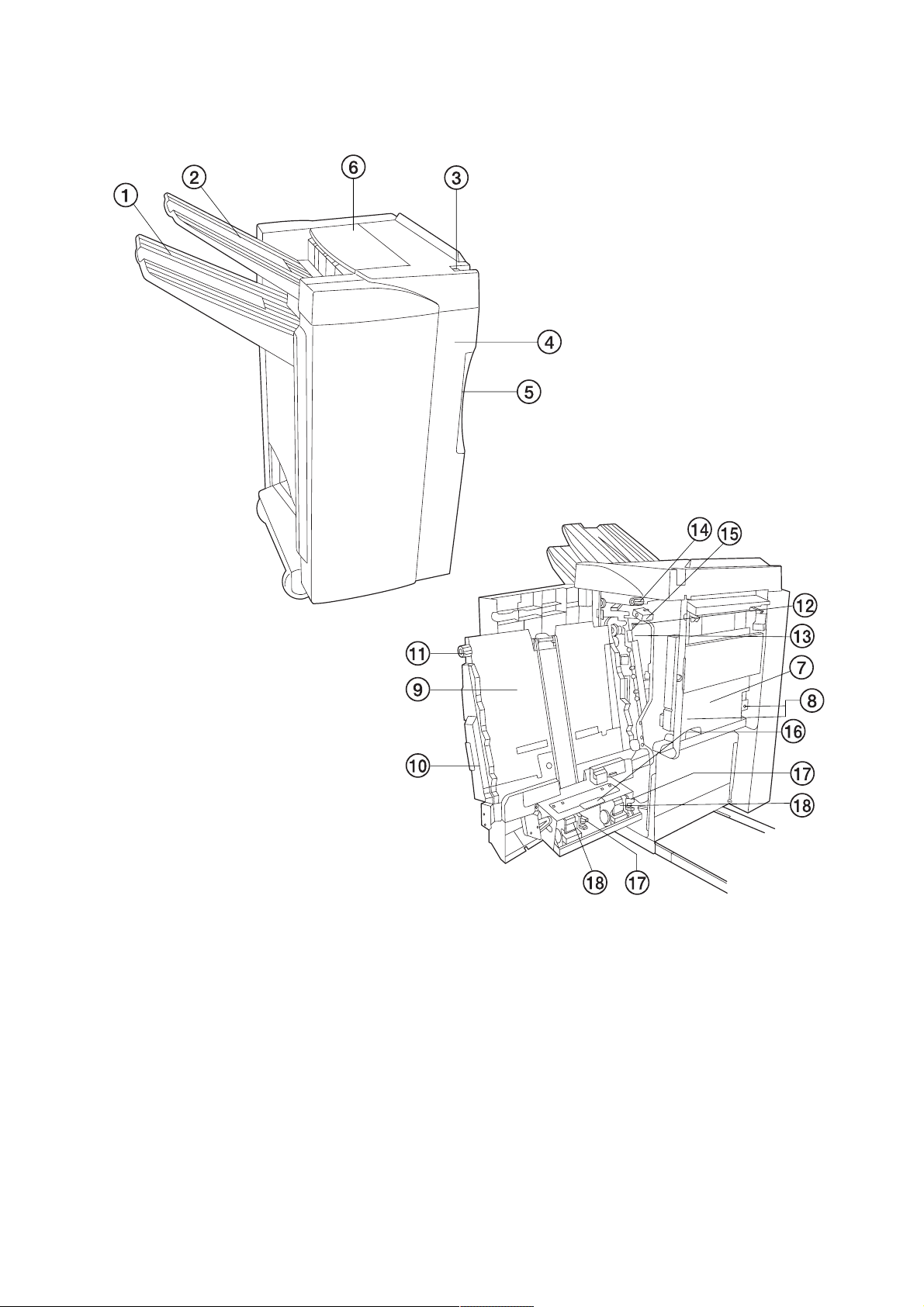

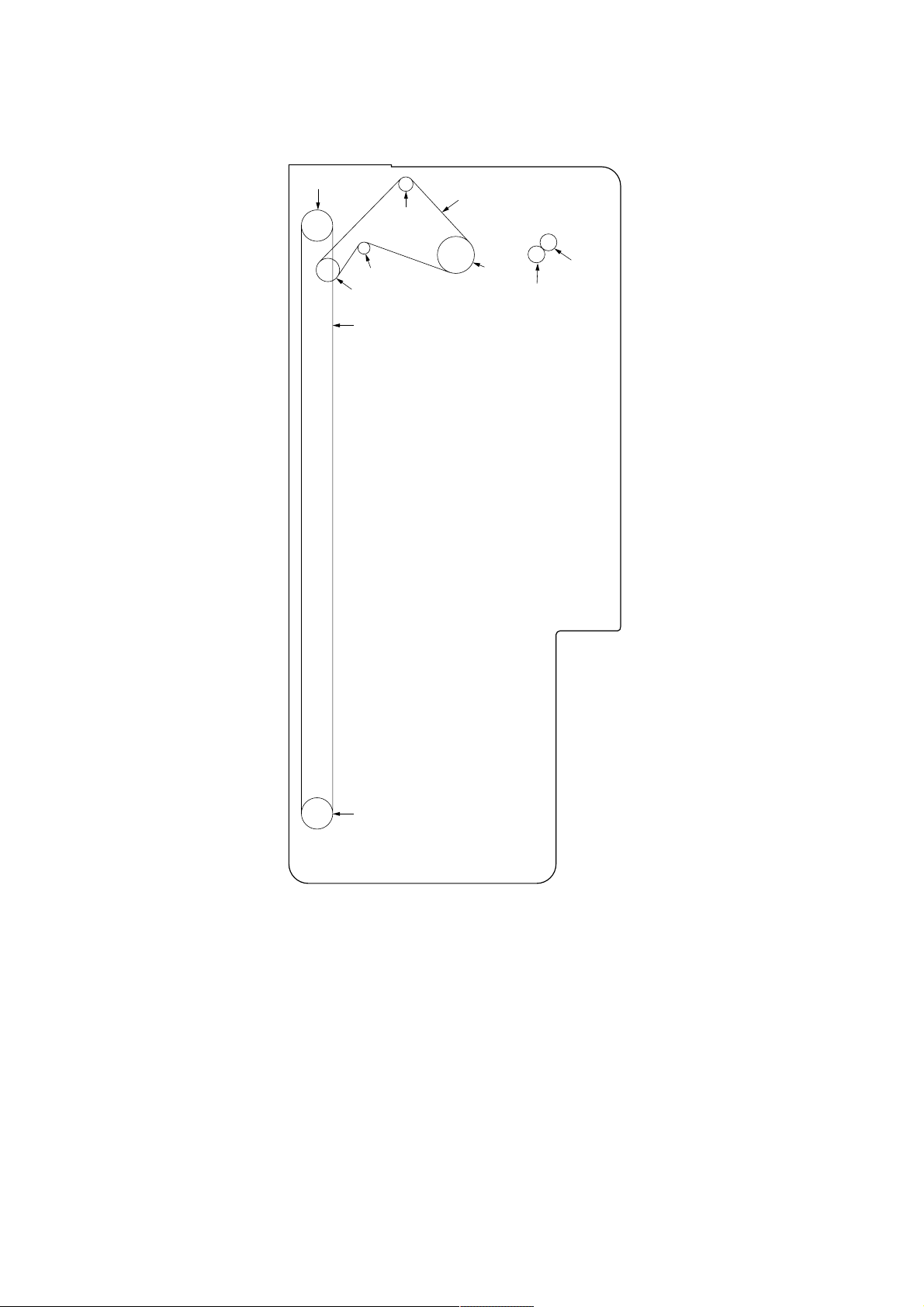

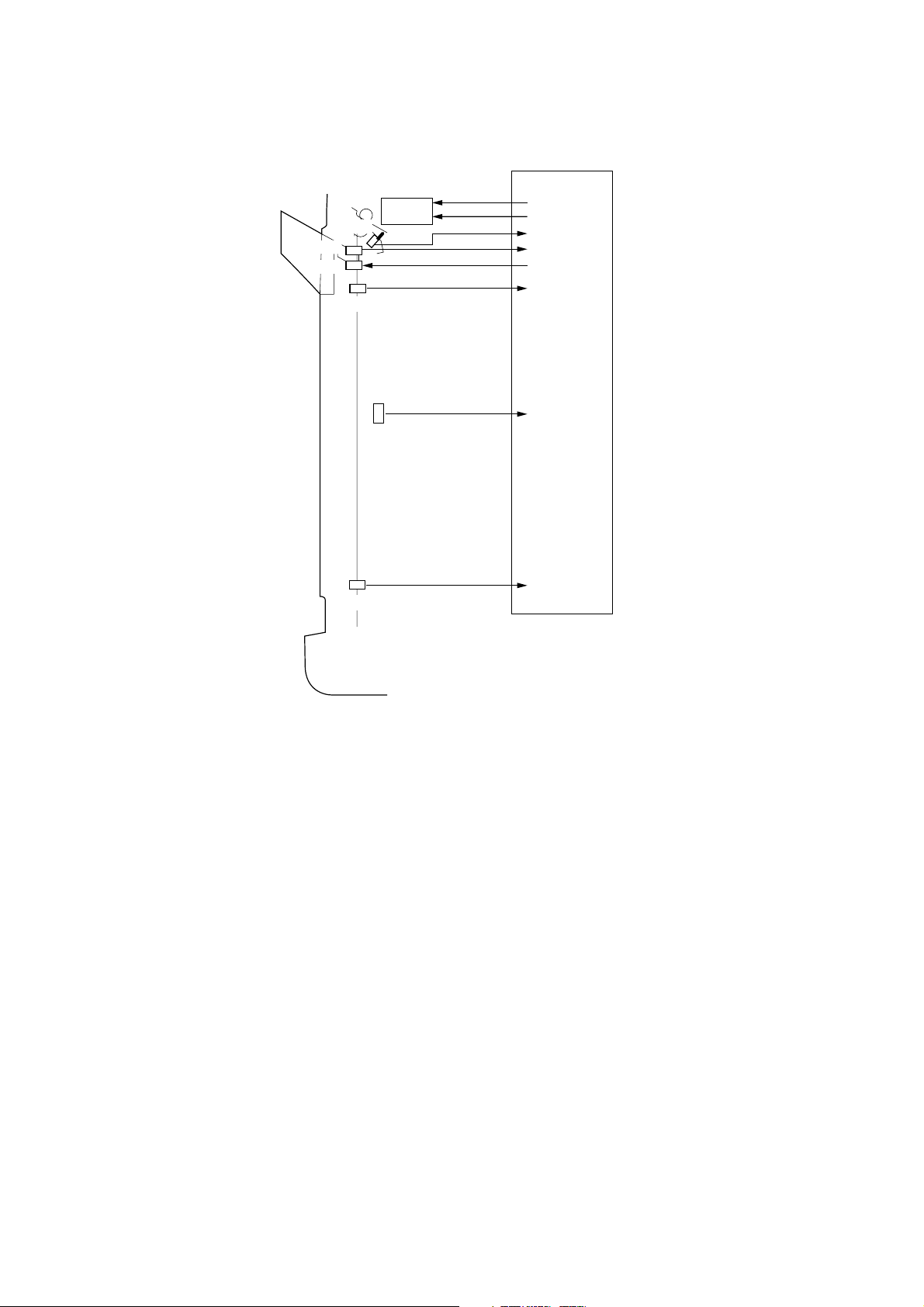

1-1-3 Machine cross section

3C1

6

5

3

1

2

4

Paper path

Figure 1-1-2 Cross section

1 Paper conveying section

2 Internal tray section

3 Punch section

4 Stapler section

5 Non-sort tray section

6 Sort tray section

1-1-3

Page 12

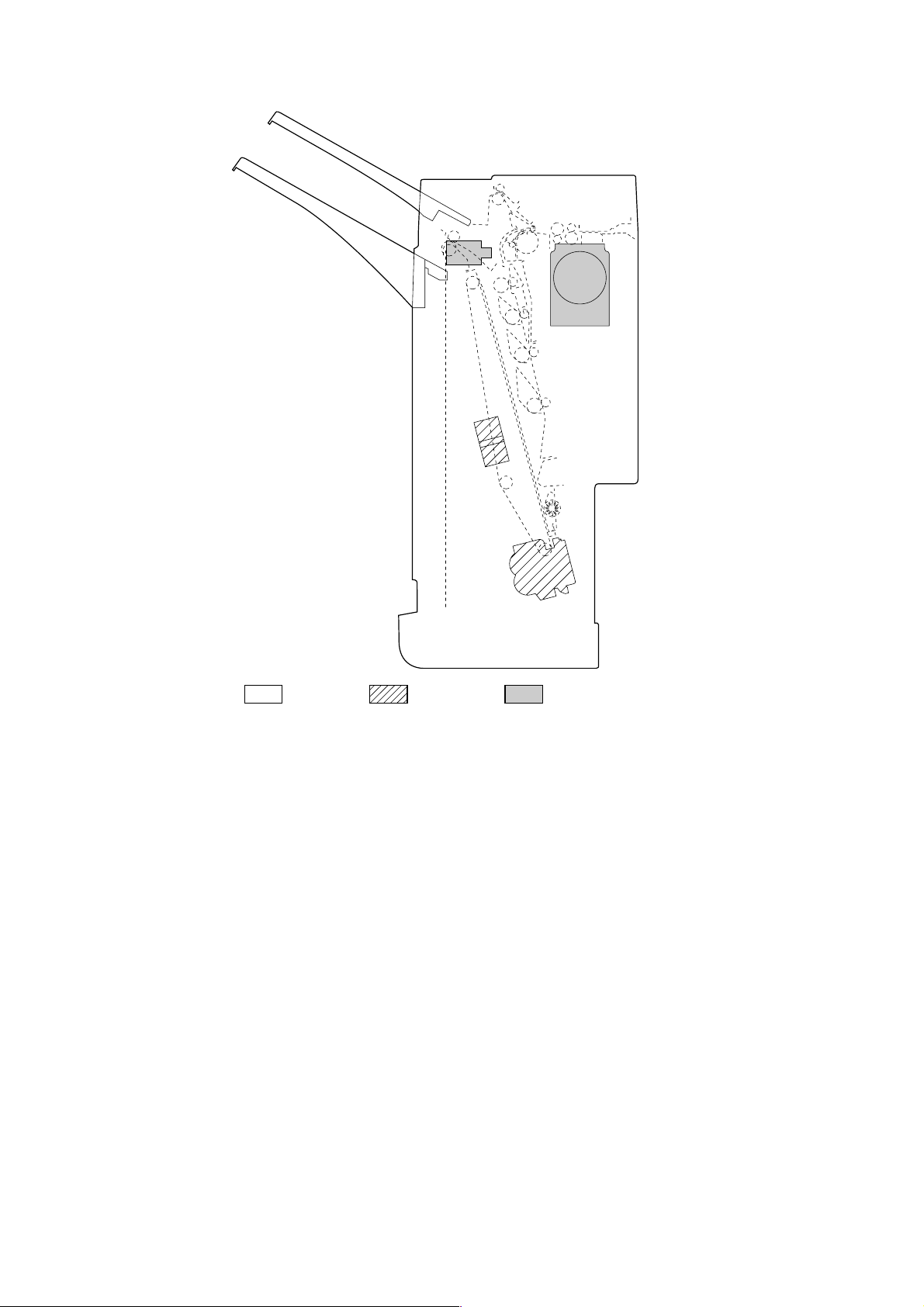

3C1

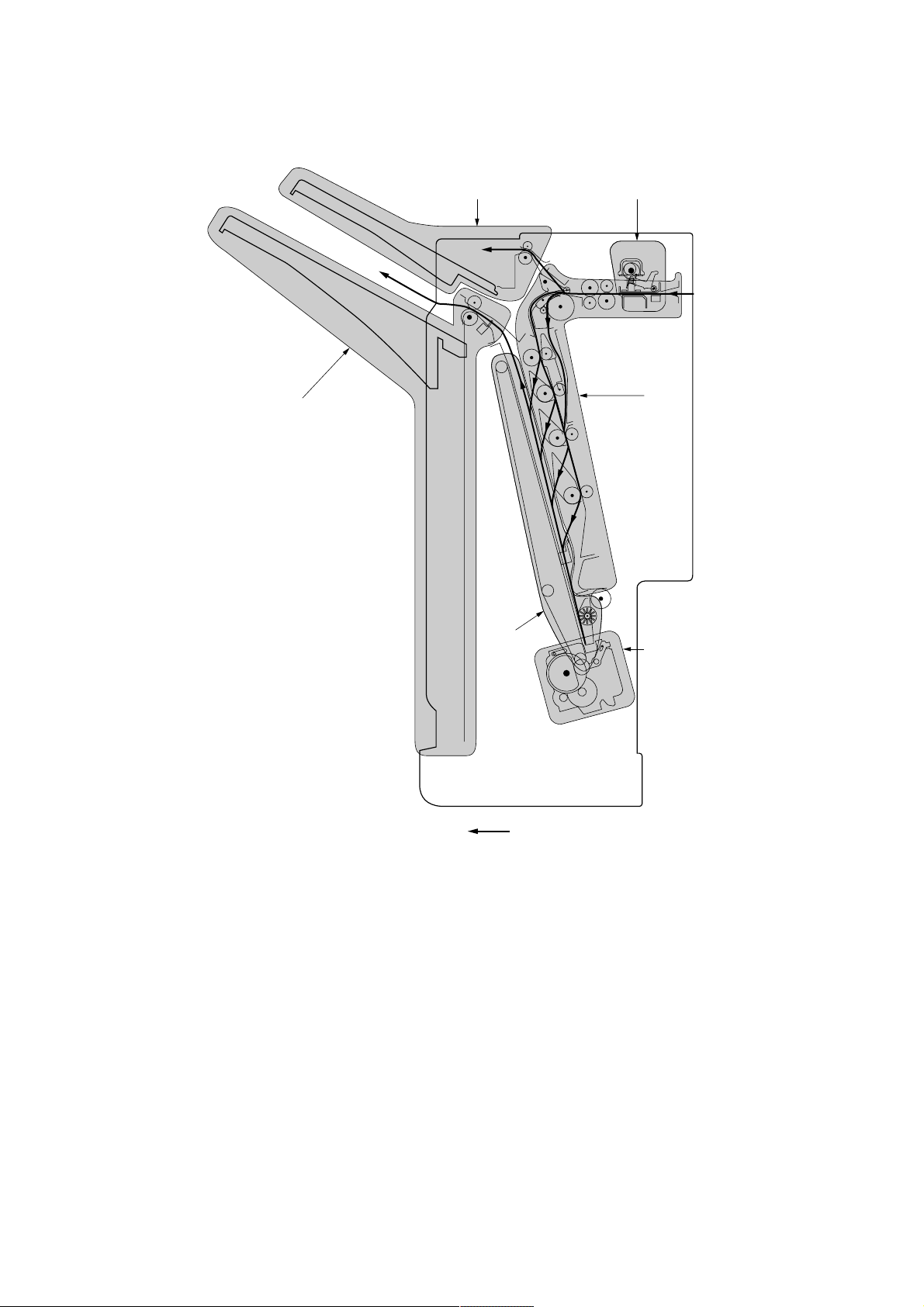

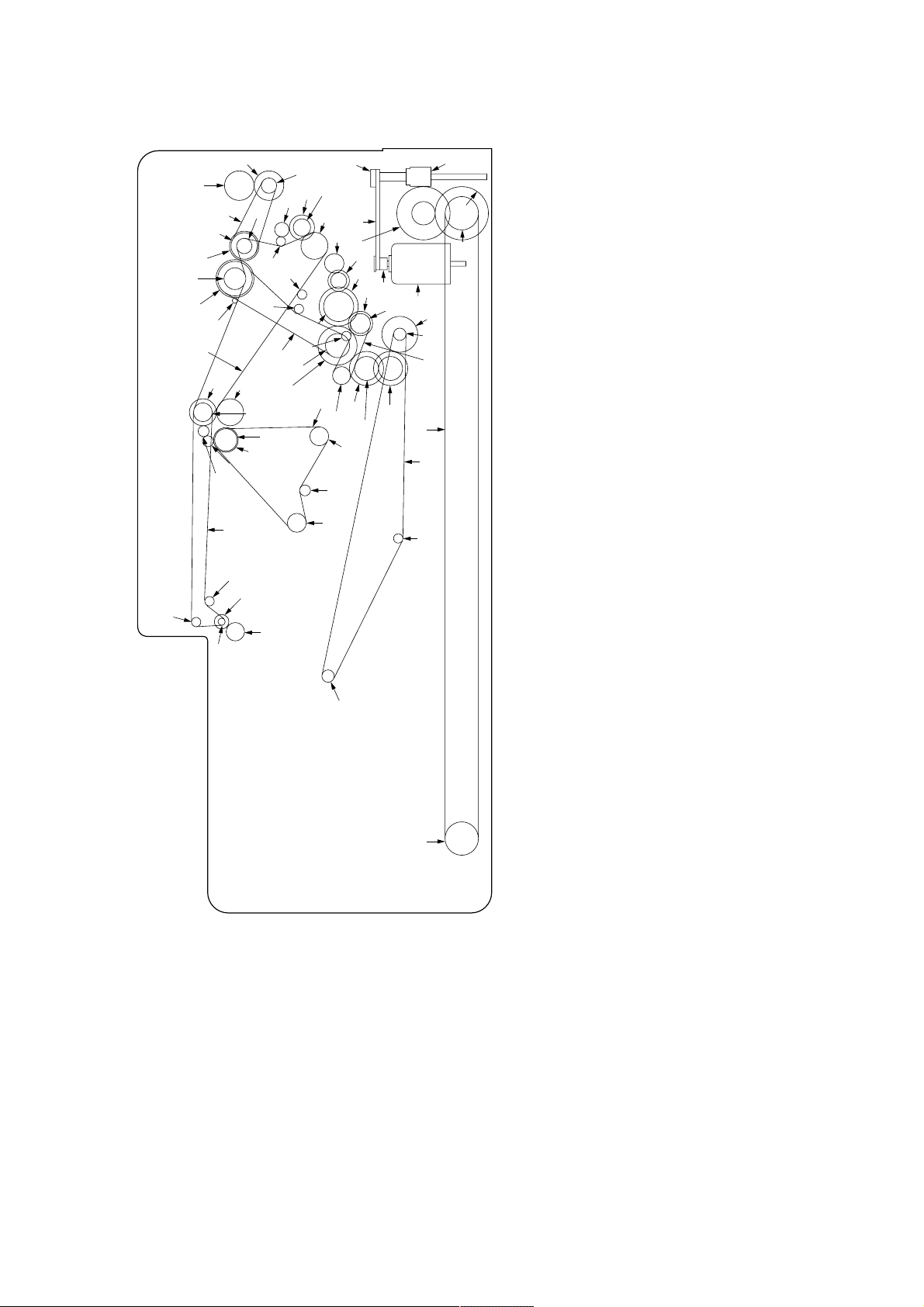

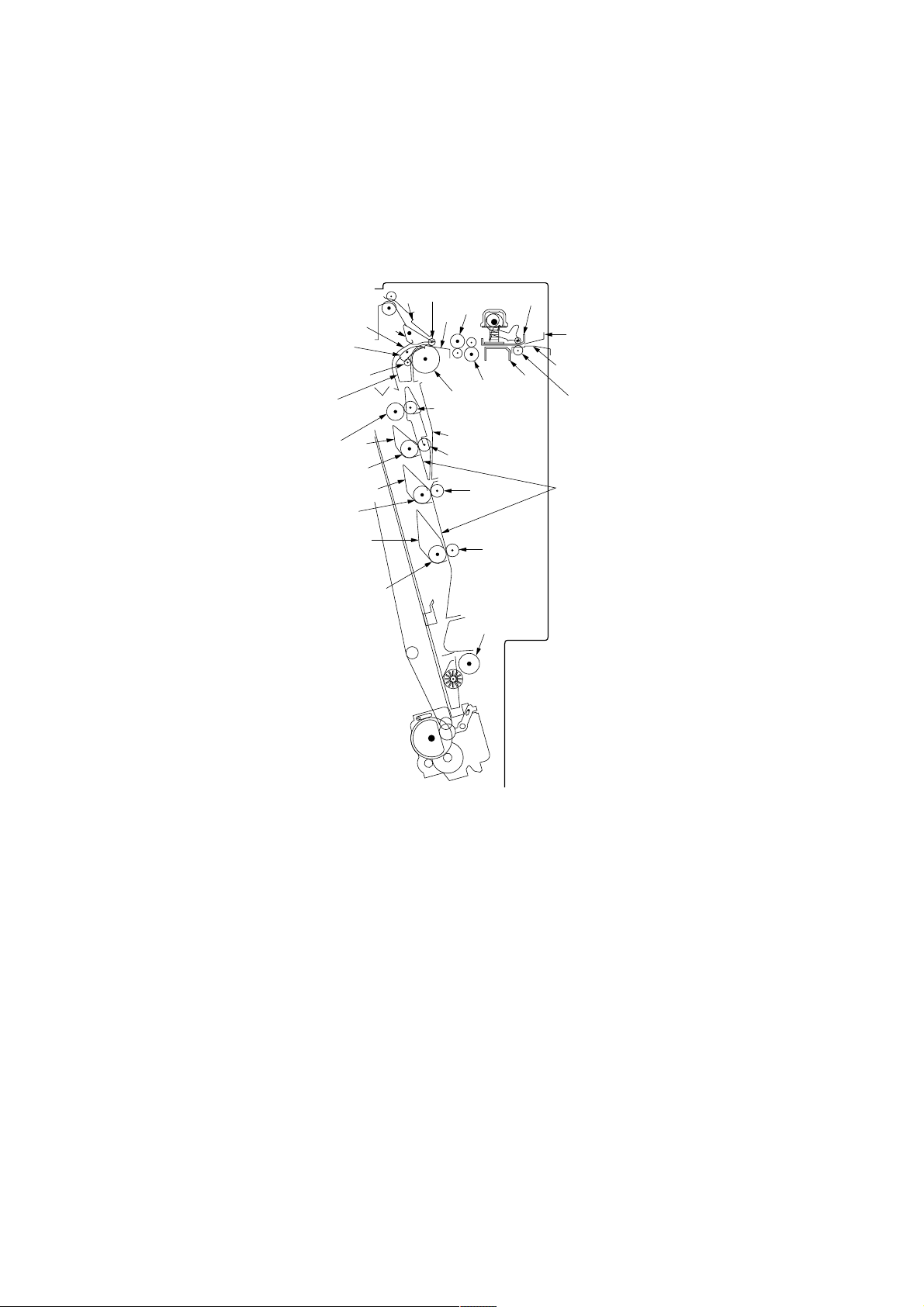

1-2-4 Drive system

7

1

5

4

6

3

2

0

9

1-1-4

8

As viewed from machine front

Figure 1-2-3 Drive system 1 (machine front)

1 Eject drive belt

2 Paper entry pulley 40

3 Tension pulley

4 Sort eject pulley 27

5 Eject pulley 20

6 Tray elevation belt

7 Pulley 20S5M

8 Pulley 20S5M

9 Gear 20

0 Gear 20

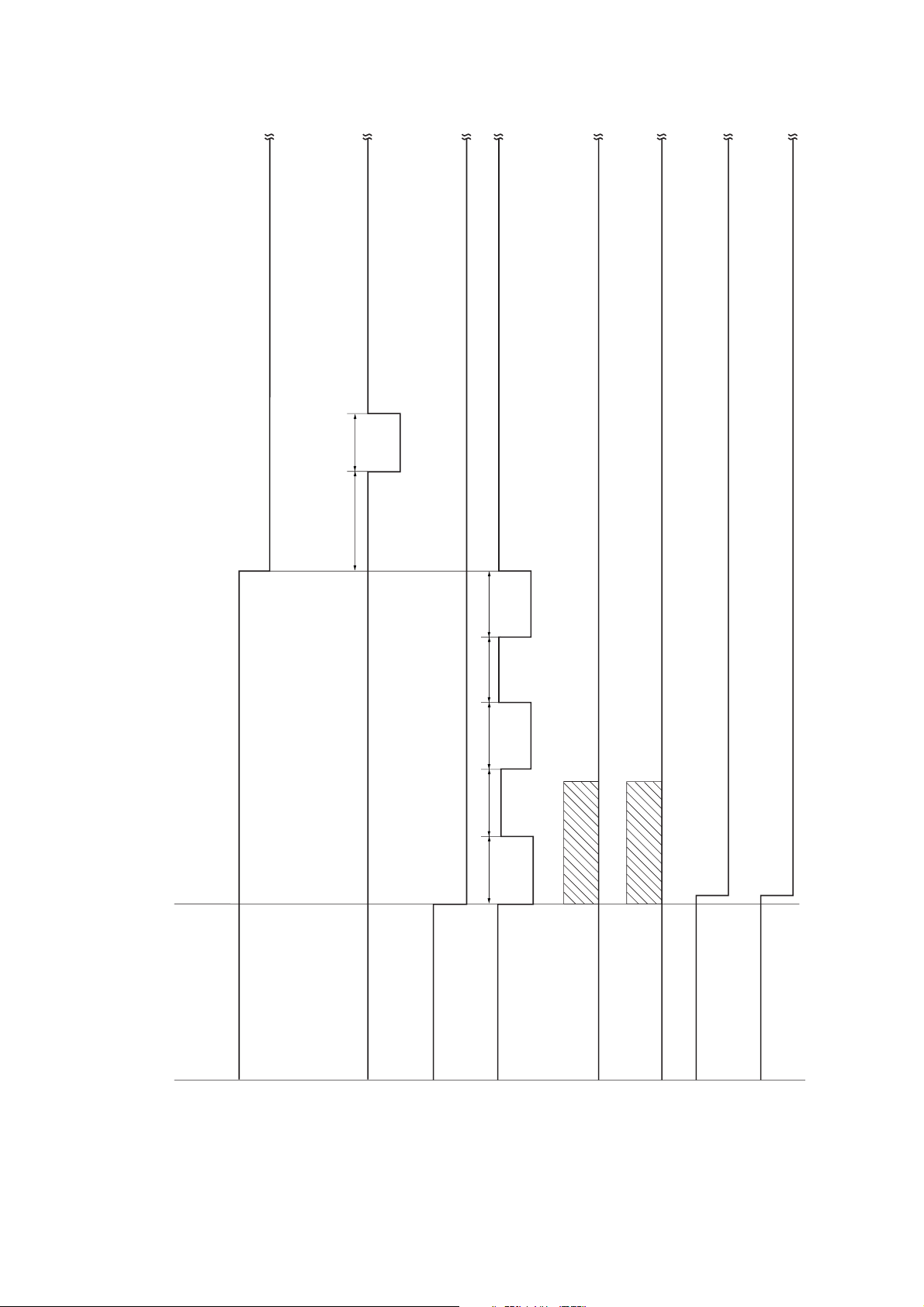

Page 13

3C1

(

)

^

&

%

$

∏

#

@

⁄

!

Í

Ï

Ó

ν

Ú

Ò

Ô

ı

˜

¯

Â

¿

˘

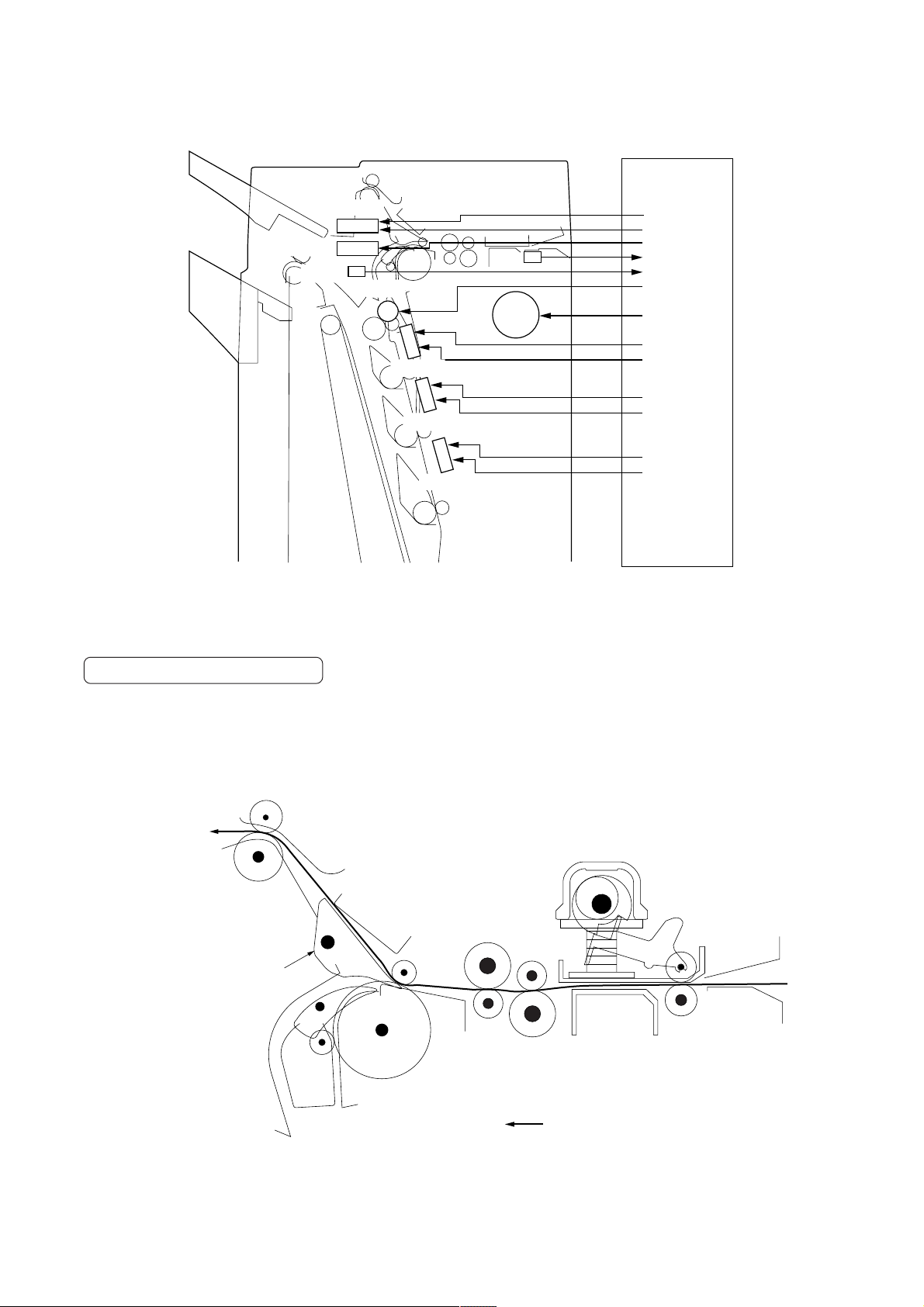

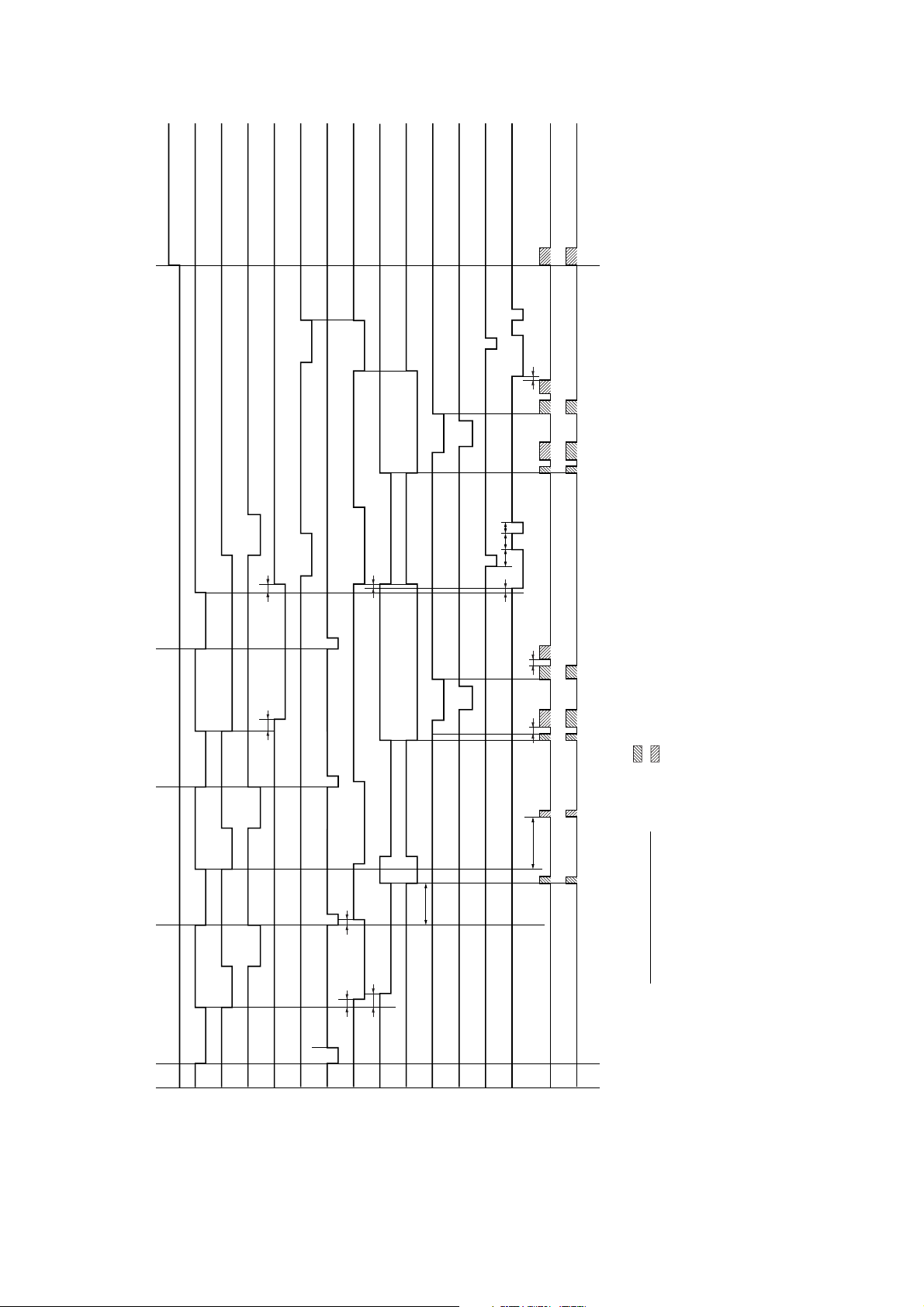

Figure 1-2-4 Drive system 2 (machine rear)

1 Tray elevation motor

2 Tray elevation motor pulley

3 Tray drive belt 22

4 Pulley 34

5 Worm gear

6 Gear 18/50

7 Gear 51

¤

∞

§

Å

£

4

3

6

*

¢

™

∏

fl

‡

2

¡

·

‹

›fi

¸

„

Œ

´

˛

Ç

◊

Ø

As viewed from machine rear

8 Pulley 20S5M

9 Tray elevation belt

0 Pulley 20S5M

! Paper conveying motor gear

@ Pulley 37/48

# Tension pulley 20

$ Gear 45

°

‰

1

9

0

¨

ˆ

ˇ

Á

‚

5

7

8

% Pulley 40

^ Pulley 30

& Punch drive belt

* Pulley 14

( Gear 29

) Punch clutch gear

⁄ Tension pulley

¤ Middle drive belt

‹ Pulley 21

› Gear 40

fi Feedshift drive gear 31

fl Paddle input gear 42

‡ Feedshift roller gear 17

— Coupling pulley 20

· Tension pulley

‚ Upper feedshift belt

ΠCoupling pulley 20

„ Gear 33

´ Gear 24SB

‰ Gear 24/33

ˇ Paper conveying belt clutch gear

Á Pulley 20S3M

¨ Paper conveying belt

ˆ Tension pulley 20S3M

Ø Middle tray idle pulley 22

” Tension pulley

Å Pulley 31

Í Feedshift drive belt

Î Coupling pulley 20

Ï Drive switching gear 27

˝ Coupling pulley 22

Ó Gear 27

Ô Sub-section interconnecting gear

Æ Sub-section interconnecting gear

Ò Feedshift gear 22

Ú Coupling pulley 20

¸ Lower feedshift belt

˛ Coupling pulley 20

Ç Tension pulley

◊ Coupling pulley 20

ı Forwarding drive belt

˜ Tension pulley

Shutter pulley

¯ Gear Z29

˘ Shutter pulley

¿ Paper conveying clutch gear

¡ Gear 23

™ Paddle idle gear 20/22

£ Clutch gear 36

¢ Gear 16

∞ Decurler gear 34

§ Decurler gear 27

1-1-5

Page 14

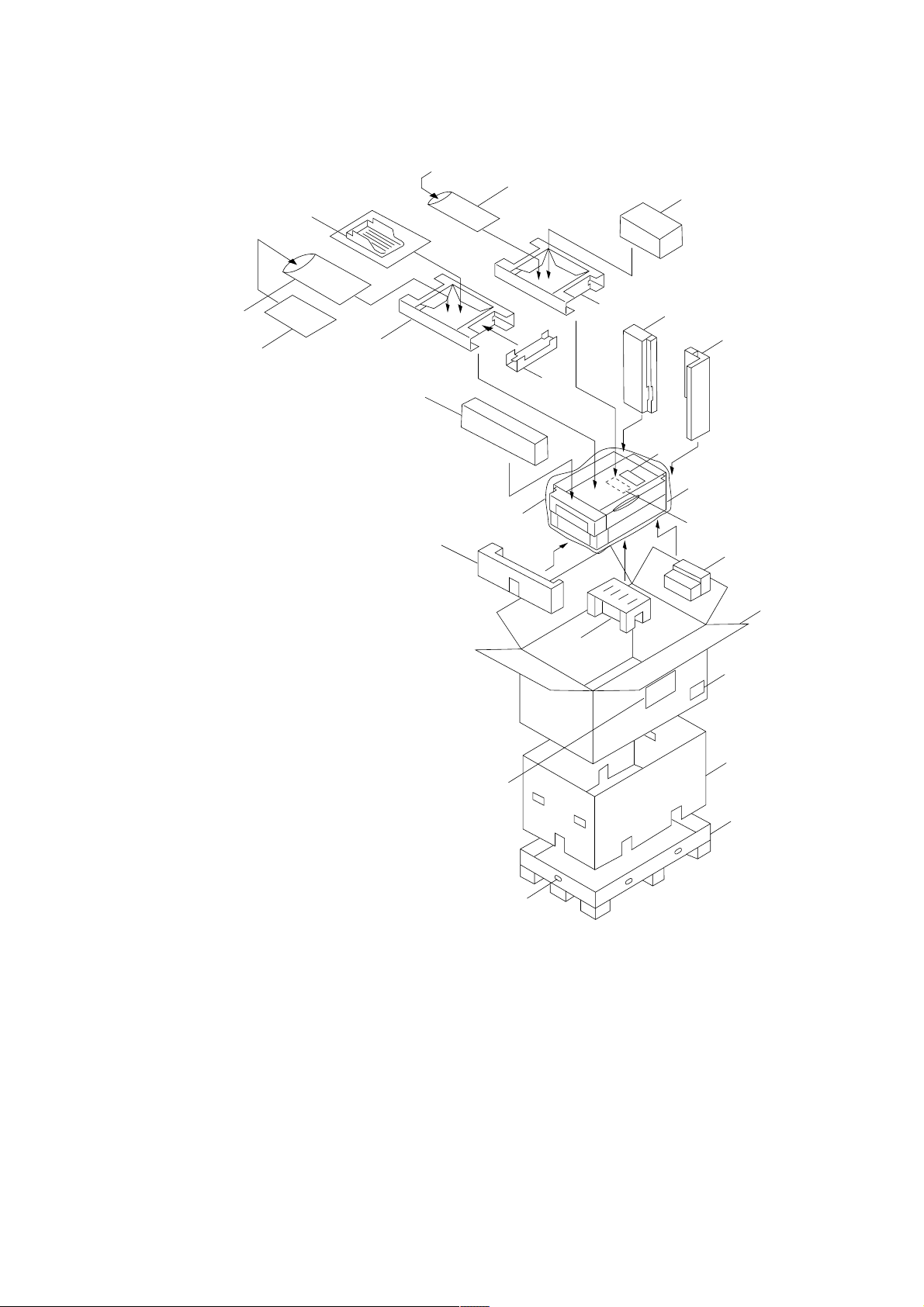

1-2-1 Unpacking

3C1

(1) Unpacking

›

‡—

2

8

$

3

#

¤

⁄

4

^)

9

fi

!

@

‹

1

&

0

5

Important: When moving the finisher, hold

the center of the sort tray mount,

otherwise the elevation belt may

become dislocated.

Figure 1-2-1 Unpacking

1 Finisher

2 Tray set assembly

3 Retainer

4 Stapler cartridges

5 Outer case

6 Inner frame

7 Bottom case

8 Upper spacer

9 Top spacer

0 Spacer (casters)

! Rear right spacer

@ Front right spacer

# Lower left spacer

$ Upper left spacer

% Middle left spacer

^ Spacer (stapler)

& Spacer (conveyor)

* Hinge joints

( Bar code labels

) Air-padded bag

%

fl

6

(

7

*

⁄ Machine cover

¤ Air-padded bag

‹ Leaflet

› Plastic bag

fi Curl eliminator set

fl Code labels

‡ Installation guide

— Installation guide

1-2-1

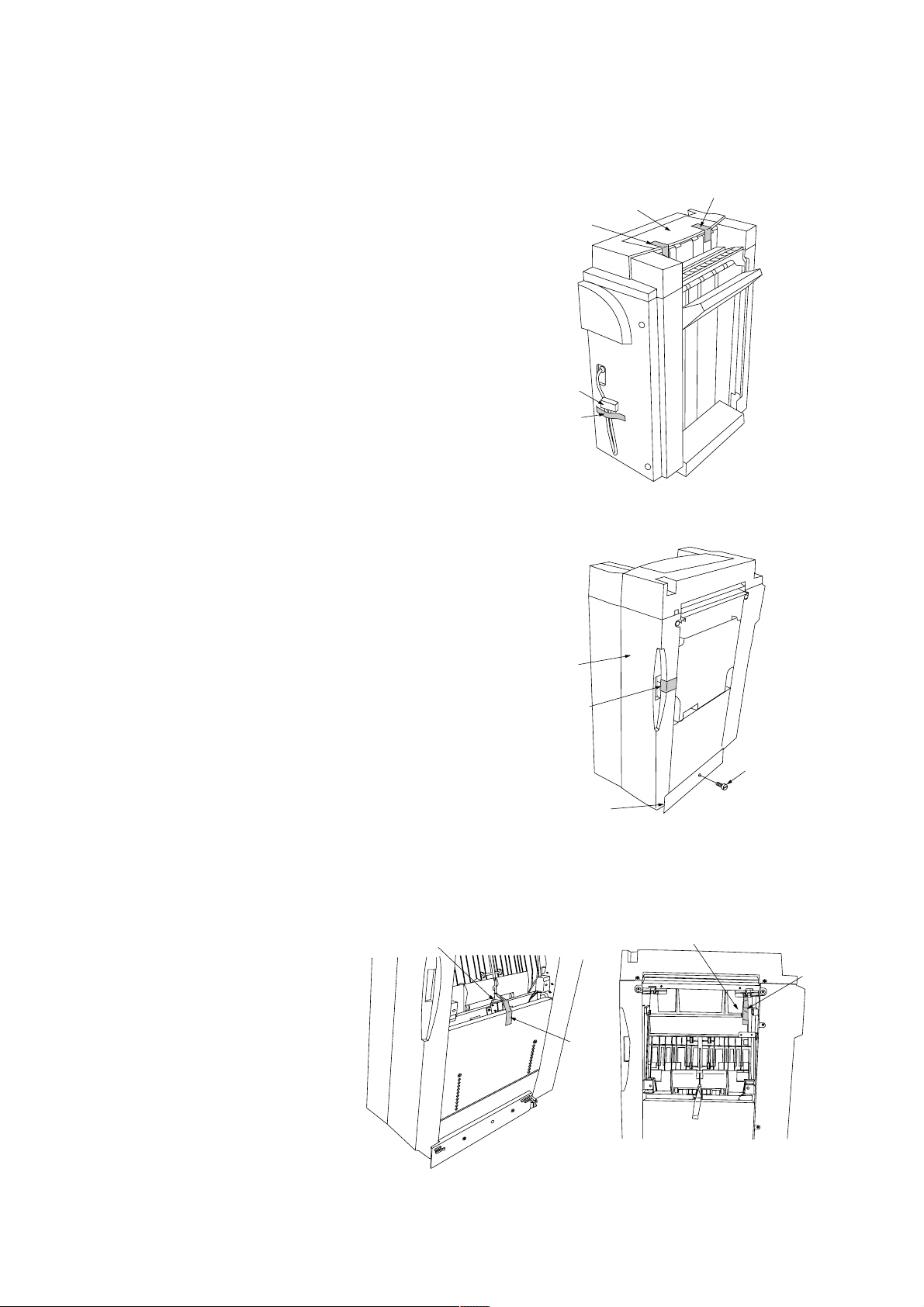

Page 15

3C1

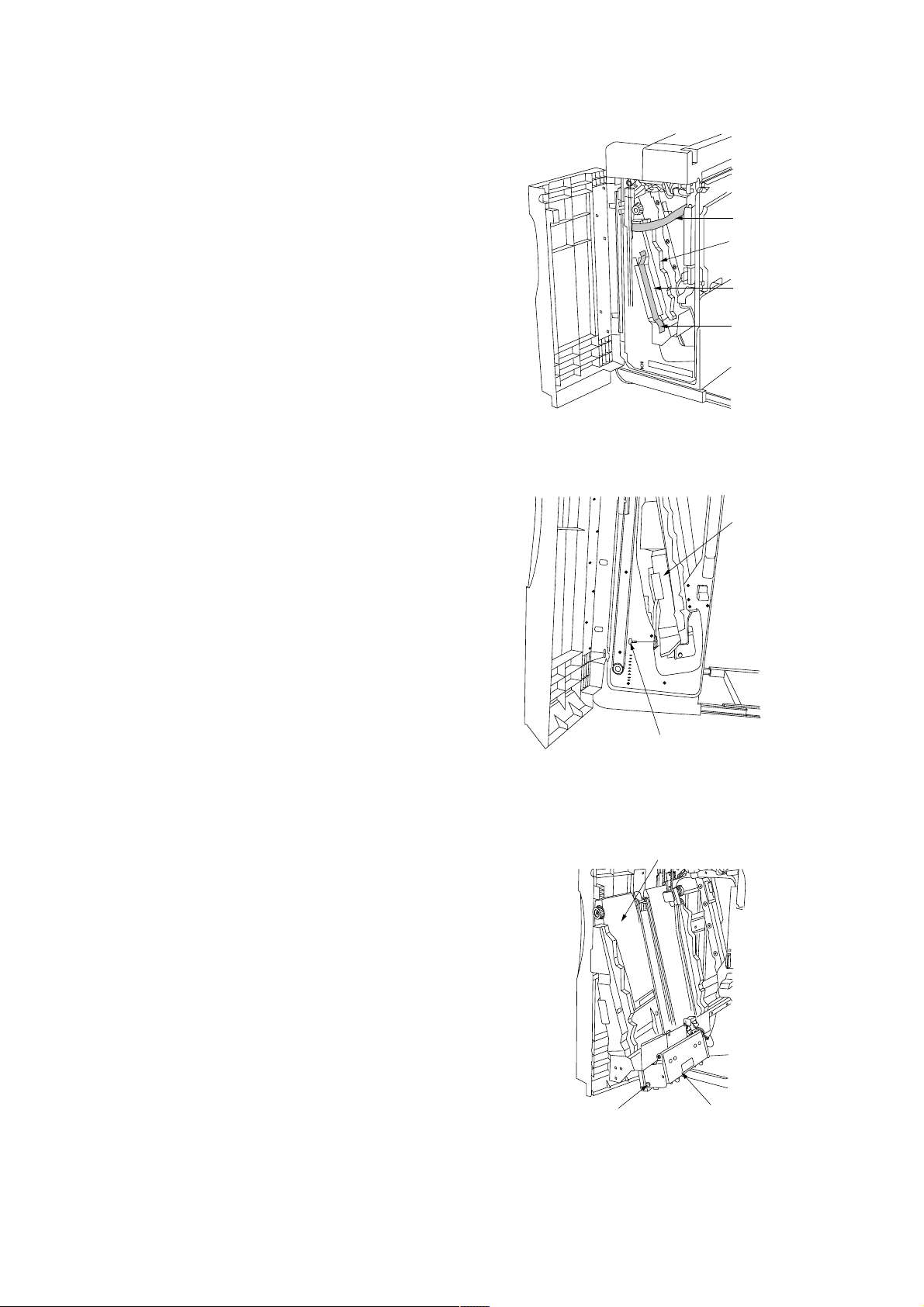

(2) Removing tapes and metal fittings

When installing the machine, be sure to remove the following tapes and metal fittings.

Procedure

1. Remove the two tapes holding the upper cover.

2. Remove the tape holding the signal cable.

3. Remove the tape holding the front cover.

4. Remove the pin holding the rail unit.

Tape

Signal cable

Tape

Upper cover

Figure 1-2-2

Tape

5. Remove the scrap hole-punch tank and then the

tapes holding the rotating plate solenoid and the

retaining path guide.

Rotating plate solenoid

Front cover

Tape

Pin

Rail unit

Figure 1-2-3

Retaining path guide

Tape

Tape

1-2-2

Figure 1-2-4

Page 16

6. Open the front cover and remove the tape

holding the internal tray.

7. Remove the tape and cushion sheet

8. Remove the tape and then the pin holding the

internal tray.

3C1

Tape

Internal tray

Cushion sheet

Tape

Figure 1-2-5

Internal tray

9. Pull the internal tray out. Remove the tape and

then the pin holding the stapler unit.

Pin

Pin

Figure 1-2-6

Internal tray

Stapler unit

Figure 1-2-7

1-2-3

Page 17

3C1

10. Remove the tape and then the cushion sheet

holding the internal tray wheel sensor.

11. Remove the tape and then the pin holding the

stapler unit.

Stapler unit

Internal tray

Cushion sheet

Tape

Pin

Figure 1-2-8

1-2-4

Page 18

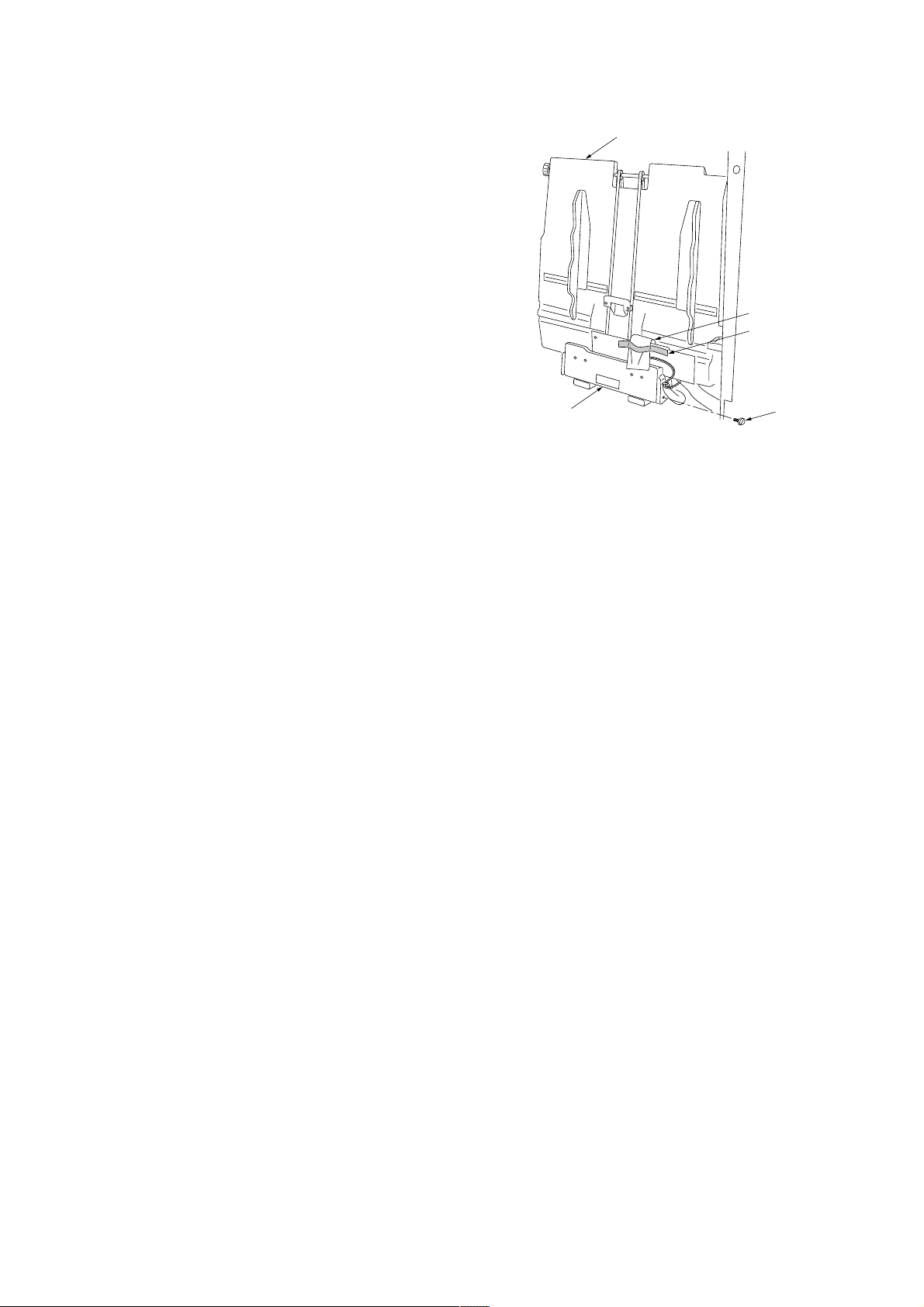

1-2-2 Installing the mailbox (option)

3C1

Procedure

1. Remove the front top cover and rear top cover at

the top of the finisher using a flat-blade

screwdriver or the like.

2. While inserting the pins located at the front and

rear of the bottom of the mailbox into the

notches located at the front and rear of the top of

the finisher, attach the mailbox to the finisher.

Notch

Rear top cober

Finisher

Front top cover

Figure 1-2-9

Mailbox

Notch

Pin

Notch

Pin

3. Secure the front and rear attachment points of

the mailbox and finisher using a TP-A chrome

screw M4 x 14 for each.

Note: Be sure to secure the front connection

portion together with the mounting plate

cover.

Pin

Notch

Pin

Finisher

Figure 1-2-10

Mailbox

TP-A chrome

screw M4 × 14

TP-A chrome

screw M4 × 14

Finisher

Mounting

plate cover

Figure 1-2-11

1-2-5

Page 19

3C1

4. Fit the seven copy eject bins to the ejection

section of the mailbox from the lowest bin to the

highest.

Note: To fit a copy eject bin, hold it at an angle as

shown in the diagram, warp it lightly by

squeezing at both ends and then insert the

pins located at the front and rear into the

round holes located at the front and rear of

the mailbox.

5. Remove the two screws located as shown in the

illustration that secure the side cover of the

mailbox, and remove the blanking seal from the

finisher.

Mailbox

Round hole

Pin

Copy eject bin

Figure 1-2-12

Mailbox

Side cover

6. Attach the main body mounting plate to the

mailbox and finisher using the two TP-A chrome

screws M3 × 10 and the + bind chrome screw

M4 × 25.

Figure 1-2-13

Main body

mounting plate

Screws

Blanking seal

Finisher

Mailbox

TP-A chrome

screws M3 × 10

+Bind chrome

screw M4 × 25

1-2-6

Finisher

Figure 1-2-14

Page 20

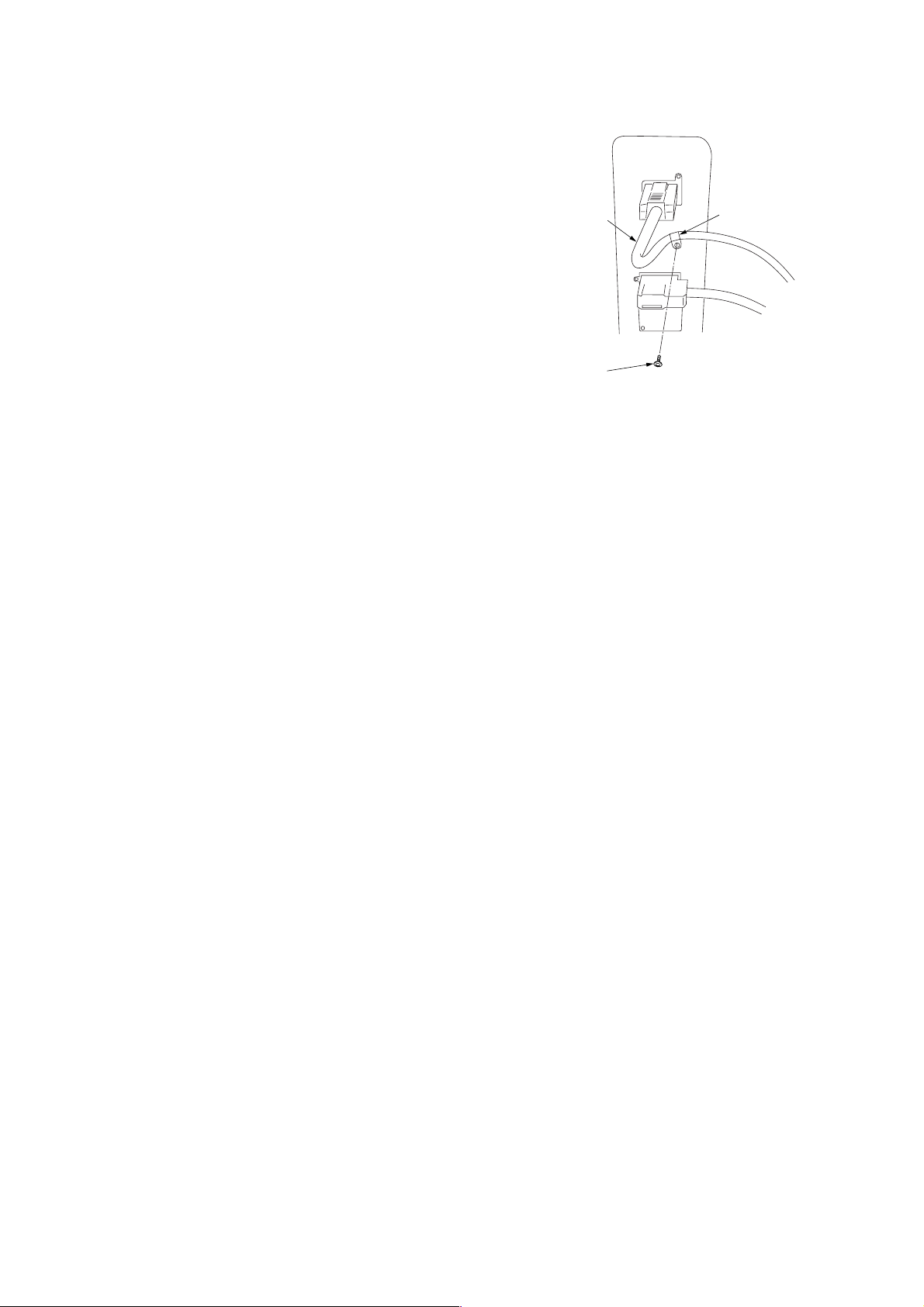

7. Connect the finisher to the copier and connect

the signal lines of the mailbox to the connector at

the rear part of the copier.

8. Only for 230V specifications

Insert the clamp, GNK-5N and shield to near the

base of the signal line of the mailbox.

Remove the screw fitted to the copier, and

secure the clamp, GNK-5N and shield to the

copier using the screw.

9. Insert the copier power plug to the outlet and

turn the copier main switch on to check the

operation.

Signal line

Screw

3C1

Clamp

Figure 1-2-15

1-2-7

Page 21

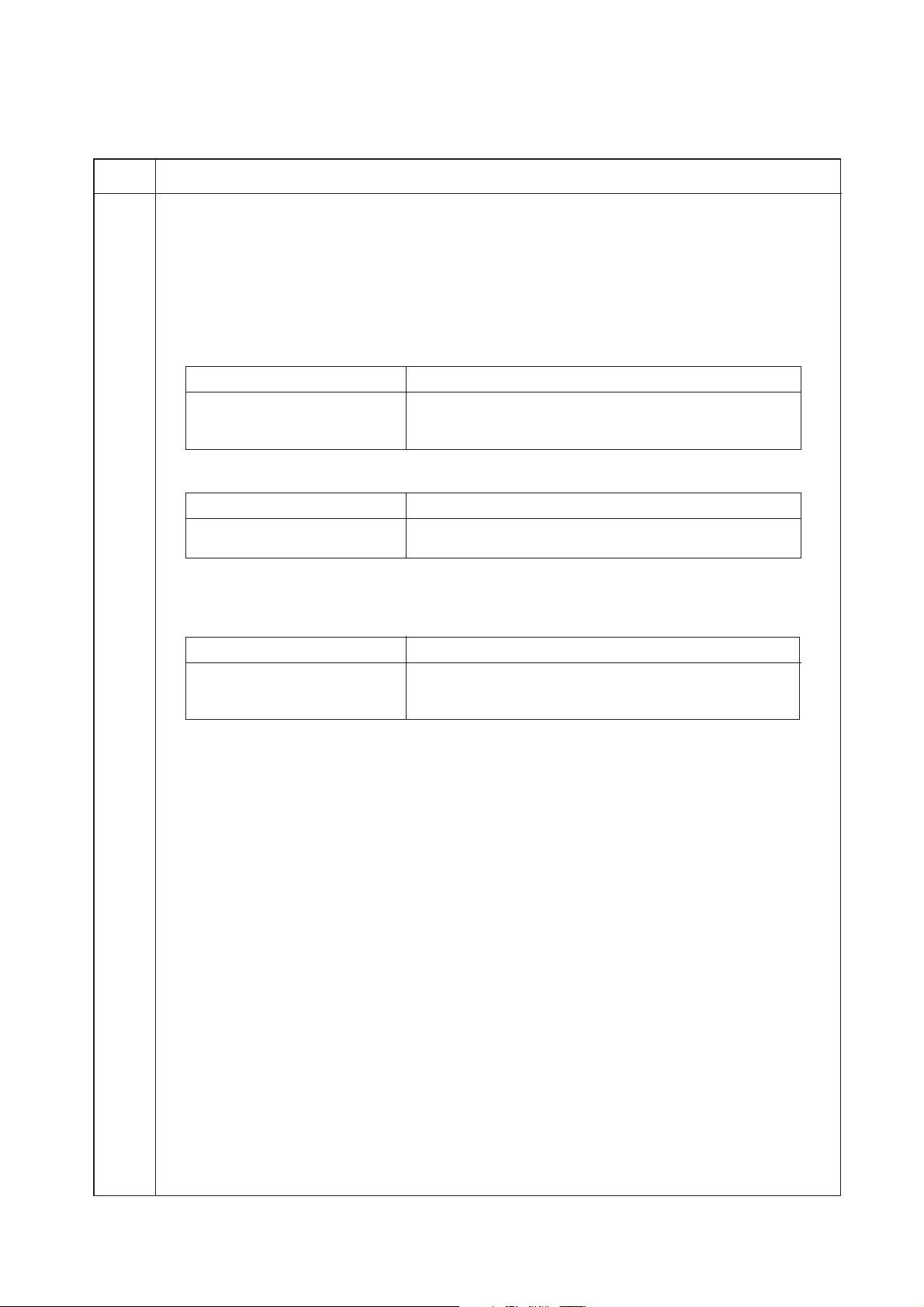

1-3-1 Maintenance mode

3C1

Maintenance

item No.

U237 Setting finisher stack quantity

Description

Sets the number of sheets of each stack on the main tray and on the intermediate tray in the optional

finisher.

Purpose

To change the setting when a stack malfunction has occurred.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the item to be set. The selected item is displayed in reverse.

Display Description

MAIN TRAY Number of sheets of stack on the main tray

MIDDLE TRAY Number of sheets of stack on the intermediate tray for sort

Setting the number of sheets of stack on the main tray

1. Change the setting using the cursor up/down keys.

Setting Description

0 1500 sheets

1 3000 sheets

Initial setting: 0

2. Press the start key. The setting is set.

Setting the number of sheets of stack on the intermediate tray for sort copying or staple copying

1. Change the setting using the cursor up/down keys.

Setting Description

0 For sort copying: 30 sheets, for staple copying: 50 sheets

1 For sort copying: 50 sheets, for staple copying: 50 sheets

2 For sort copying: 30 sheets, for staple copying: 30 sheets

Initial setting: 0

2. Press the start key. The setting is set.

Completion

Press the stop/clear key. The screen for selectiong a maintenance item No. is displayed.

Description

copying or staple copying

1-3-1

Page 22

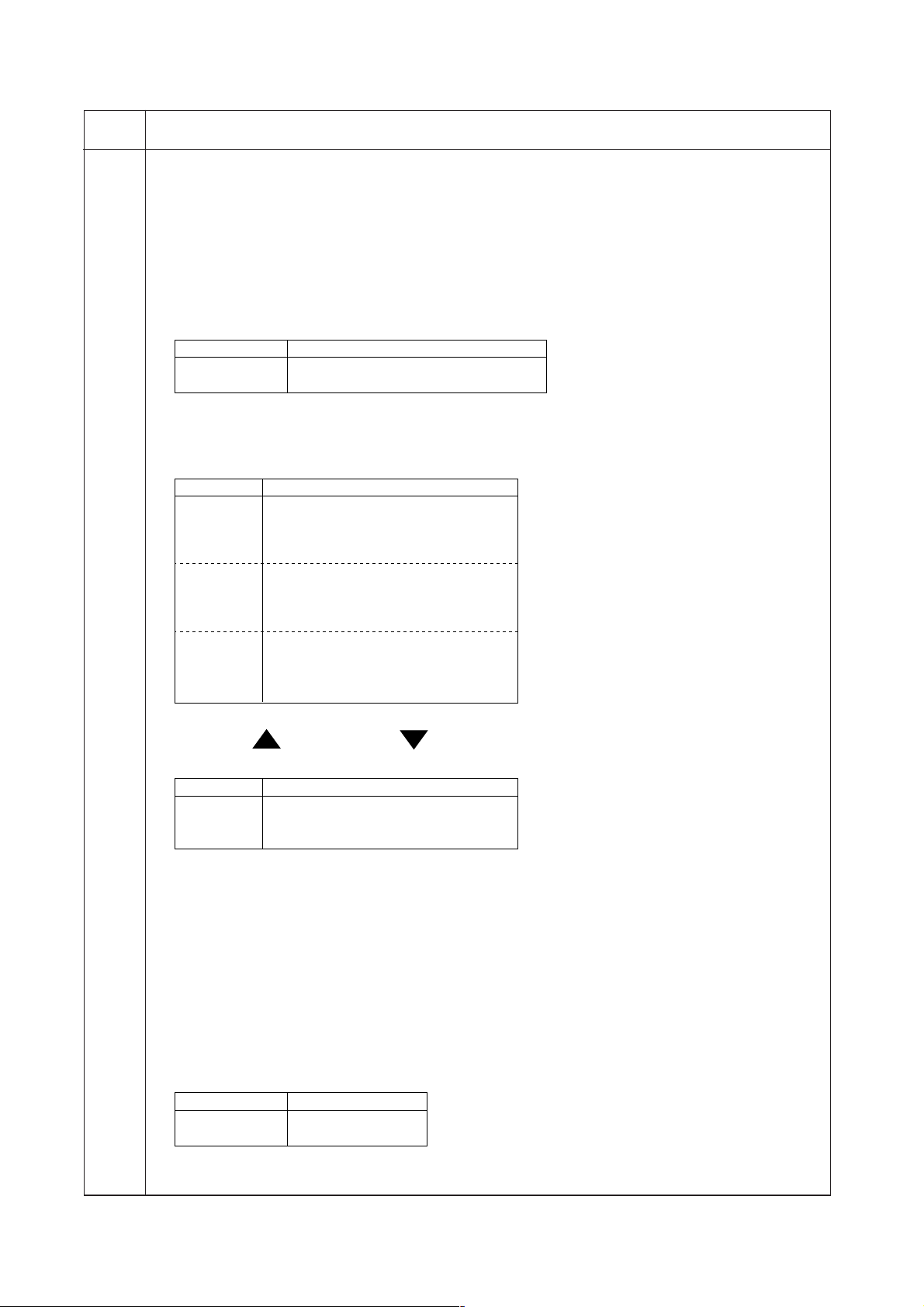

3C1

Maintenance

item No.

U240 Checking the operation of the Finisher

Description

Turns the finisher cluches or solenoids.

Purpose

To check the operation of the finisher cluches and solenoids.

Start

1 Press the start key. The screen for selecting an item is displayed.

2 Select an item. The screen for executing each item is displayed.

Display

CL, SOL TEST

JOGGER TEST

Method to check the operation of cluches and motors

1 Select the item to be operated. The selected item is displayed in reverse, and the motor or solenoid turns on

for 0.5 s.

Display Clutches and solenoids

HBCL

PYSL

PSL1

PSL2

PSL3

BSL1

BSL2

PCL

PNSL OFF

PNSL ON

PNCL

KYSL

Description

Checks operation of cluches and motors.

Checks jogging and stapling operations.

Paper conveying belt clutch (PCBCL)

Paper shift solenoid (PSSOL)

Paddle solenoid 1 (PDSOL1)

Paddle solenoid 2 (PDSOL2)

Paddle solenoid 3 (PDSOL3)

Feedshift solenoid 1 (FSSOL1)

Feedshift solenoid 2 (FSSOL2)

Paddle clutch (PDCL)

Paper shift solenoid (PSSOL) OFF

Paper shift solenoid (PSSOL) ON

Punch clutch (PCL)

Trailing edge press solenoid (TEPSOL)

Description

1-3-2

Display Clutches and solenoids

PCSL

DCSL

PGSL

2 To turn each clutch or solenoid on while the motor is driving, press the interrupt key before selecting the

clutch or solenoid.

The drive motor turns on, and the selected clutch or solenoid remains on until the selected item is pressed

again.

3 To stop the motor drive, press the interrupt key.

4 To return to the screen for selecting an item, press the stop/clear key after the motor stops.

Method to check the jogging and the stapling

1 Select the item to be operated.

2 To turn each clutch or solenoid on while the motor is driving, press the interrupt key before selecting the

clutch or solenoid.

Display

JOGGER

STAPLE

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Pressure switching solenoid (PSWSOL)

Drive switching solenoid (DSSOL)

Paper entry guide solenoid (PEGSOL)

Description

Operation of jogging

Operation of stapling

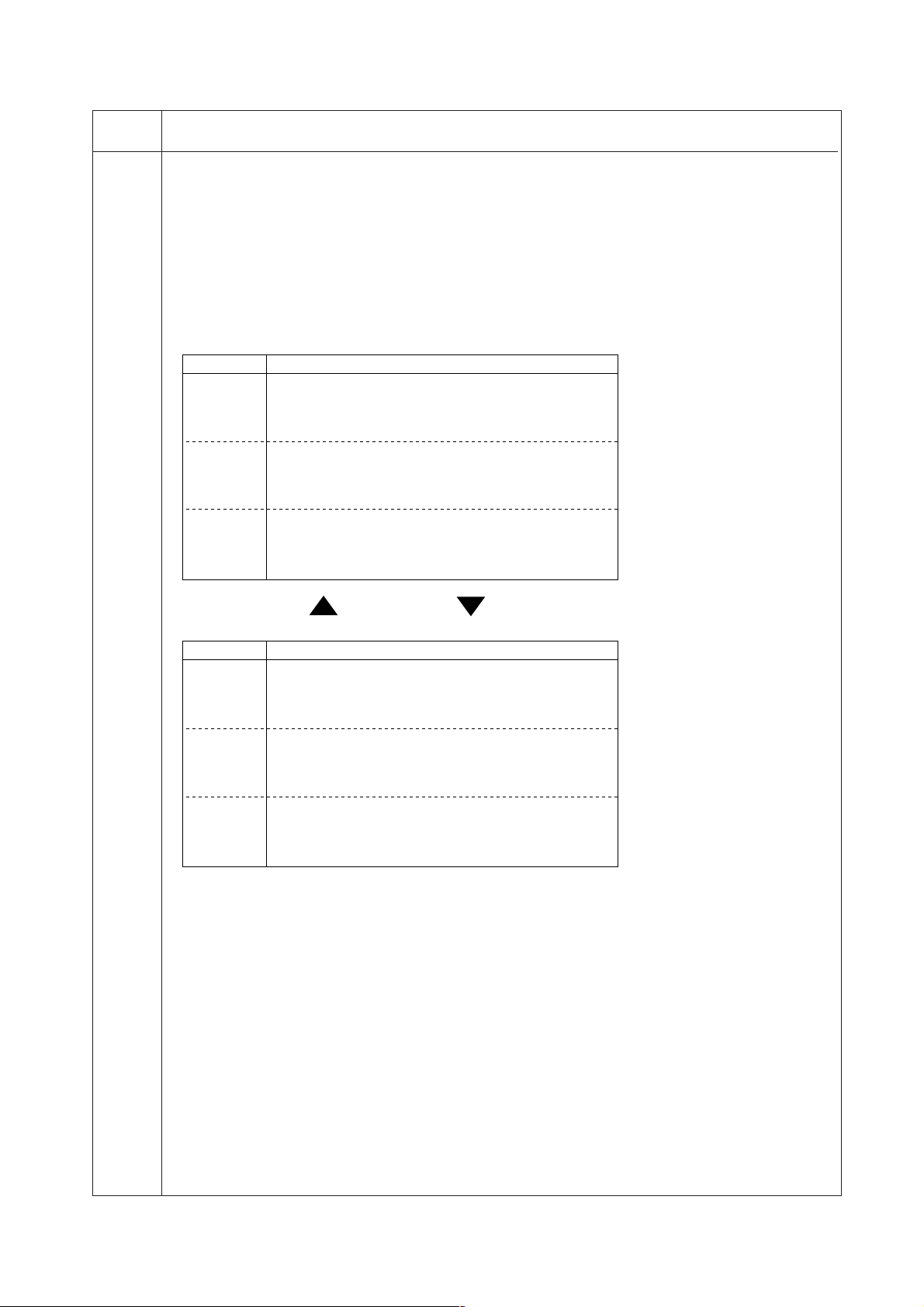

Page 23

3C1

Maintenance

item No.

U241 Checking the finisher switches

Description

Displays the status of the respective switches on the finisher.

Purpose

To check if respective switches on the finisher operate correctly.

Start

1 Press the start key.

2 Turn the respective switches on manually. The on-status of a switch is displayed in reverse.

Display

KOS

PS 3

FJHS

PS 2

DS

SS

RJHS

FSES

FSPS

RSES

RSPS

US

Swithes

Trailing edge press detection sensor (TEPDS)

Eject switch (ESW)

Front jogger home position sensor (FJHPS)

Internal tray wheel sensor (ITWS)

Front cover switch (FCSW)

Joint switch (JSW)

Rear jogger home position sensor (RJHPS)

Front stapler empty sensor (STES)

Front stapler self-priming sensor (STSPS)

Rear stapler empty sensor (STES)

Rear stapler self-priming sensor (STSPS)

Upper cover switch (UCSW)

Description

Display

FSTHS

RSTHS

FCES

RCES

SKS 1

PS 1

HBH S

SKS 2

PS 4

SKS 4

PKS

SKS 3

Completion

Press the stop/clear key when operation stops. The screen for selecting a maintenance item No. is displayed.

Swithes

Front stapler home position sensor (STHPS)

Rear stapler home position sensor (STHPS)

Front stapler cortridge sensor (STCS)

Rear stapler cartridge sensor (STCS)

Tray stock sensor A (TSSA)

Paper entry sensor (PES)

Paper conveying belt home position sensor (PCBHPS)

Tray stock sensor B (TSSB)

Tray midpoint sensor (TMS)

Tray lower limit sensor (TLLS)

Scrap hole-punch sensor (PDTS)

Tray upper limit sensor (TULS)

1-3-3

Page 24

3C1

Maintenance

item No.

Description

U330 Sets the number of copies for switching the copy eject tray in the finisher

Description

Sets the number of copies at which the copy eject tray will switch from the sub tray to the main tray.

Purpose

Selects the value according to user request.

Method

Press the start key. The screen for adjustment is displayed.

Setting

1 Use the numeric keys or Up/Down keys to adjust the preset value.

Description

Number of copies to be ejected on the sub tray

Setting range

1 to 100 (sheets)

Initial value

100

The copy eject tray is switched from the sub tray to the main tray when the number of copies ejected to the

sub tray exceeds the preset value.

2 Press the start key. The setting is set , and the screen for entering a maintenance item No. is displayed.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key. The screen for

selecting a maintenance item is displayed.

1-3-4

Page 25

3C1

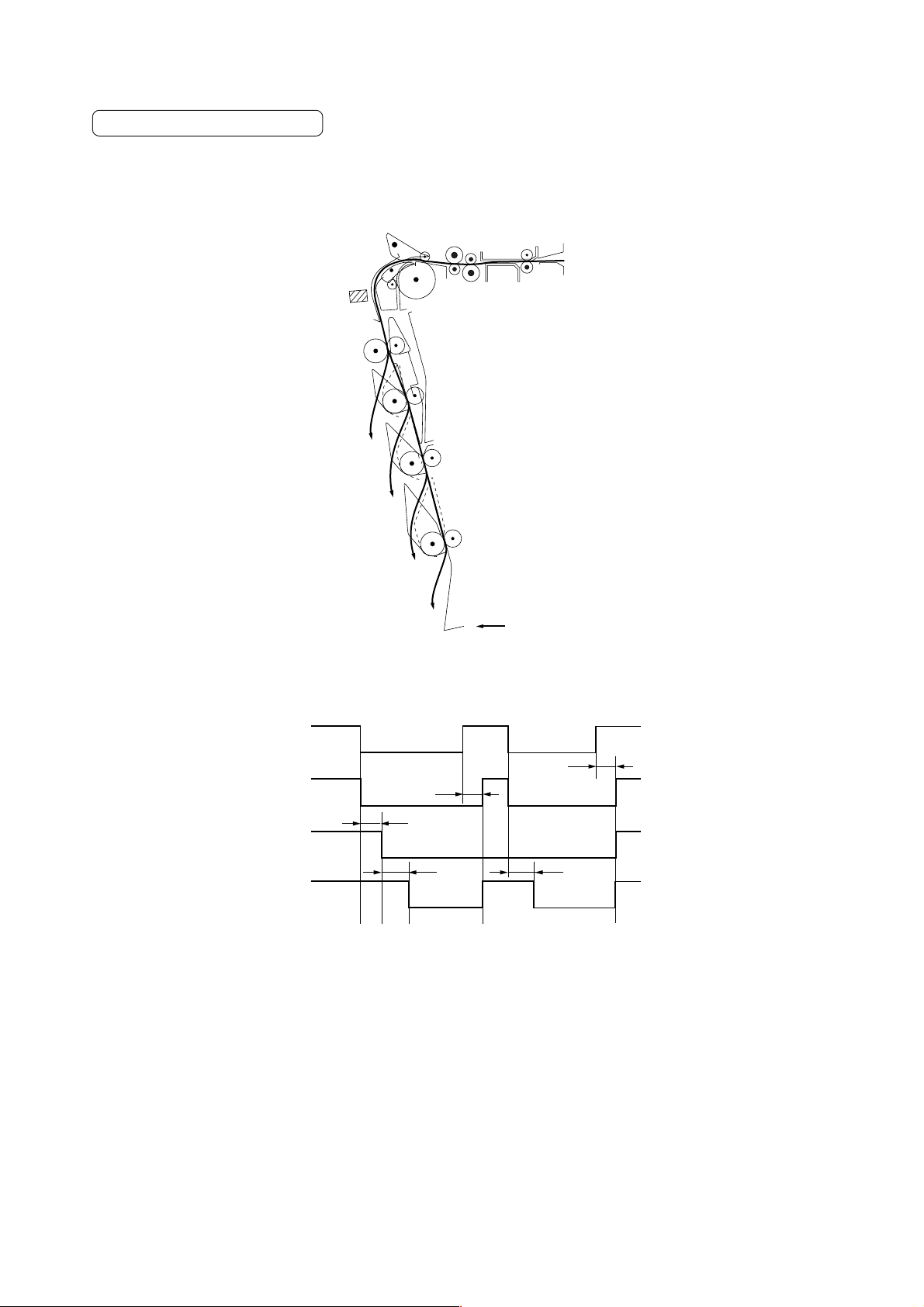

1-4-1 Paper misfeed detection

(1) Paper misfeed detection

When a paper jam occurs, the machine stops operating immediately. The copier operation section shows a jam message and

the jam location.

To remove the jammed paper, detach the finisher from the copier.

To reset the paper misfeed detection, turn the joint switch (JSW) off and on.

(2) Paper misfeed detection conditions

ESW

PCS1

PES

PCS2

ITS

ITWS

Figure 1-4-1

1-4-1

Page 26

3C1

1. Initial clogging jam (jam code 00)

• When the power is turned on, the paper entry sensor (PES), paper conveying A3 sensor (PCSA3), paper conveying A4

sensor (PCSA4), eject switch (ESW) and internal tray sensor (ITS) are on.

2. Jam in paper entry section (jam code 81)

• The paper entry sensor (PES) does not turn on within 1287 ms of paper ejection from the copier.

3. Jam in eject section of non-sort tray (jam code 82)

• The paper conveying sensor 1 (PCS1) does not turn on when 1424 ms elapses after the paper entry sensor (PES) has

turned on.

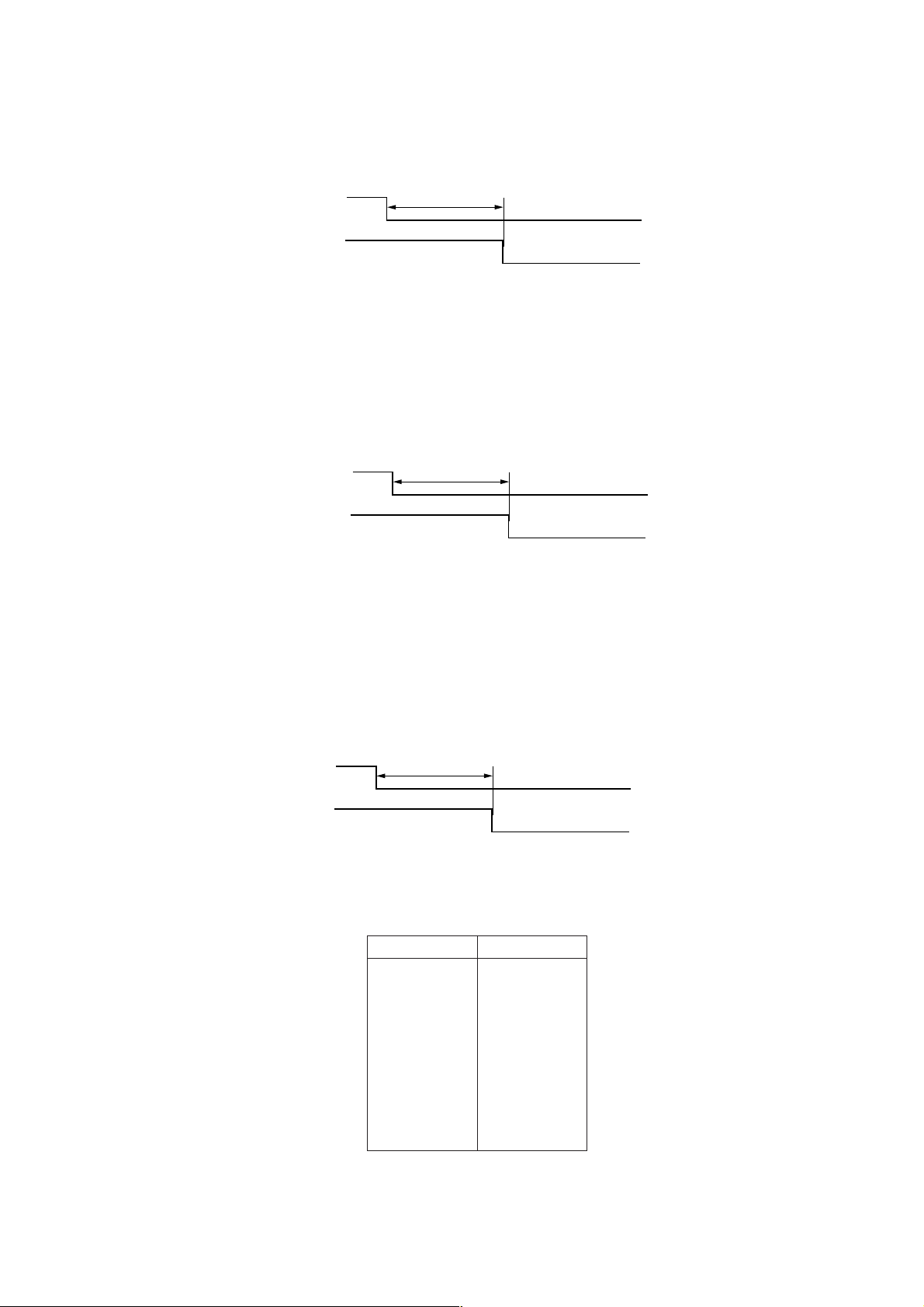

PES

PCS1

1424 ms

Off

On

Off

On

Timing chart 1-4-1

4. Jam in paper conveying section of internal tray (jam code 83)

• When large paper (A3, B4, A4R, ledger or legal) is fed, the internal tray wheel sensor (ITWS) does not turn on even if certain

time (depending on the paper size. See Table 1-4-1.) elapses after the paper conveying sensor 1 (PCS1) has turned on.

PCS1

ITWS

Specified time

Timing chart 1-4-2

Paper size Time (ms)

A3 1544

B4 1544

A4R 1488

Ledger 1544

Legal 1544

Table 1-4-1

Off

On

Off

On

1-4-2

Page 27

3C1

• When small paper (A4, B5 or letter) is fed, the paper conveying sensor 2 (PCS2) does not turn on even if 811 ms elapses

after the paper conveying sensor 1 (PCS1) has turned on.

PCS1

PCS2

811 ms

Off

On

Off

On

Timing chart 1-4-3

• When small paper (A4, B5 or letter) is fed, the internal tray wheel sensor (ITWS) does not turn on even if 833 ms elapses

after the paper conveying sensor 2 (PCS2) has turned on.

PCS2

ITWS

833 ms

Off

On

Off

On

Timing chart 1-4-4

5. Jam in eject section of sort tray (jam code 84)

• The eject switch (ESW) does not turn on within a specified time (varies depending on the paper size; see Table 1-4-2)

of the paper conveying belt clutch (PCBCL) turning on.

PCBCL

ESW

Specified time

Off

On

Off

On

Timing chart 1-4-5

Paper size Time (ms)

A3 500

B4 700

A4R 850

A4 1000

B5 1200

11" × 17" 500

81/2" × 14" 700

1

/2" × 11"R 850

8

1

11" × 8

/2" 1000

Table 1-4-2

1-4-3

Page 28

3C1

• The eject switch (ESW) does not turn off within a specified time (varies depending on the paper size; see Table 1-4-3)

of its turning on.

ESW

Specified time

Timing chart 1-4-6

Paper size Time (ms)

A3 1400

B4 1200

A4R 950

A4 700

B5 600

11" × 17" 1400

81/2" × 14" 1200

1

8

/2" × 11"R 950

1

11" × 8

/2" 700

Table 1-4-3

Off

On

1-4-4

Page 29

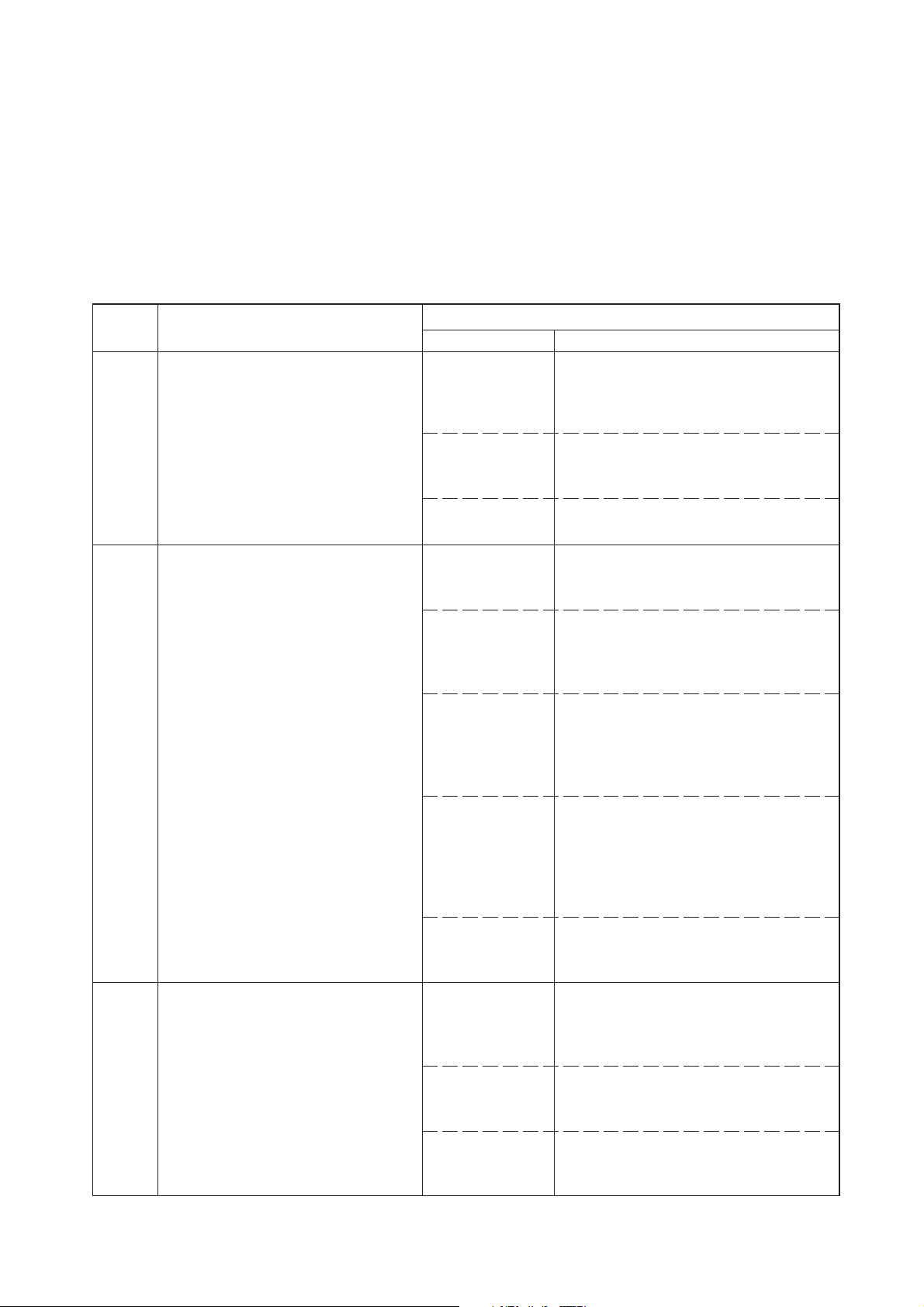

(3) Paper misfeeds

Problem Causes/check procedures Corrective measures

(1)

Paper jams when

the main switch is

turned on.

A piece of paper torn from

copy paper is caught

around the paper entry

sensor.

Check visually and remove any found.

3C1

Defective paper entry

sensor.

A piece of paper torn from

copy paper is caught

around the paper

conveying sensor 1.

Defective paper conveying

sensor 1.

A piece of paper torn from

copy paper is caught

around the paper

conveying sensor 2.

Defective paper conveying

sensor 2.

A piece of paper torn from

copy paper is caught

around the eject switch.

With 5 V DC present at CN6-1 on the main PCB, check if CN6-2

on the main PCB remains low or high when the paper entry sensor is turned on and off. If it does, replace the paper entry sensor.

Check visually and remove any found.

With 5 V DC present at CN12-16 on the main PCB, check if

CN12-14 on the main PCB remains low or high when the paper

conveying sensor 1 is turned on and off. If it does, replace the

paper conveying sensor 1.

Check visually and remove any found.

With 5 V DC present at CN12-15 on the main PCB, check if

CN12-13 on the main PCB remains low or high when the paper

conveying sensor 2 is turned on and off. If it does, replace the

paper conveying sensor 2.

Check visually and remove any found.

(2)

A paper jam is

indicated in the

paper entry section

during copying (jam

in the paper entry

section).

Defective eject switch.

A piece of paper torn from

copy paper is caught

around the internal tray

sensor.

Defective internal tray

sensor.

Extremely curled paper.

Defective paper entry

sensor.

Check if the upper or lower

paper entry guide is

deformed.

With 5 V DC present at CN6-3 on the main PCB, check if CN6-4

on the main PCB remains low or high when the eject switch is

turned on and off. If it does, replace the eject switch.

Check visually and remove any found.

With 5 V DC present at CN5-25 on the main PCB, check if

CN5-26 on the main PCB remains low or high when the internal

tray sensor is turned on and off. If it does, replace the internal

tray sensor.

Change the paper.

With 5 V DC present at CN6-1 on the main PCB, check if CN6-2

on the main PCB remains low or high when the paper entry

sensor is turned on and off. If it does, replace the paper entry

sensor.

Check and remedy.

1-4-5

Page 30

3CG

Problem Causes/check procedures Corrective measures

(3)

A paper jam is

indicated in the

paper conveying

section during

copying (jam in the

non-sort tray eject

section).

Defective paper entry sensor.

The paper conveying roller

and the upper paper conveying pulley do not make

proper contact.

With 5 V DC present at CN6-1 on the main PCB, check if CN6-2

on the main PCB remains low or high when the paper entry

sensor is turned on and off. If it does, replace the paper entry

sensor.

Check and replace if there are any problems.

(4)

A paper jam is

indicated in the

internal tray section

during copying (jam

in the internal tray

paper conveying

section).

(5)

A paper jam is

indicated in the

ejection section (jam

in the sort tray eject

section).

Check if the upper or lower

paper conveying guide is

deformed.

Defective internal tray

wheel sensor.

The feedshift rollers 1, 2, 3

and 4 and the feedshift

pulleys 1, 2, 3 and 4 do

not make proper contact.

Damaged eject switch

actuator.

Defective eject switch.

The eject roller and pulley

do not make proper

contact.

Defective paper conveying

belt.

Check and remedy.

With 5 V DC present at CN5-19 on the main PCB, check if

CN5-8 on the main PCB remains low or high when the internal

tray wheel sensor is turned on and off. If it does, replace the internal tray wheel sensor.

Replace if there are any problems.

Check and replace if there are any problems.

With 5 V DC present at CN6-3 on the main PCB, check if CN6-4

on the main PCB remains low or high when the eject switch is

turned on and off. If it does, replace the eject switch.

Check and replace if there are any problems.

Check and replace if there are any problems.

(6)

Paper jams

frequently.

The surfaces of the paper

conveying roller, or upper

and lower paper conveying

pulleys are soiled with

paper powder.

Check if the paper

conveying roller, and

upper and lower paper

conveying pulleys make

proper contact.

The surfaces of the sort

tray eject roller and pulley,

or the non-sort tray eject

roller and pulley are soiled

with paper powder.

Check if the sort tray eject

roller and pulley, and nonsort tray eject roller and

pulley make proper

contact.

Clean with isopropyl alcohol.

Remedy if necessary.

Clean with isopropyl alcohol.

Remedy if necessary.

1-4-6

Page 31

3CG

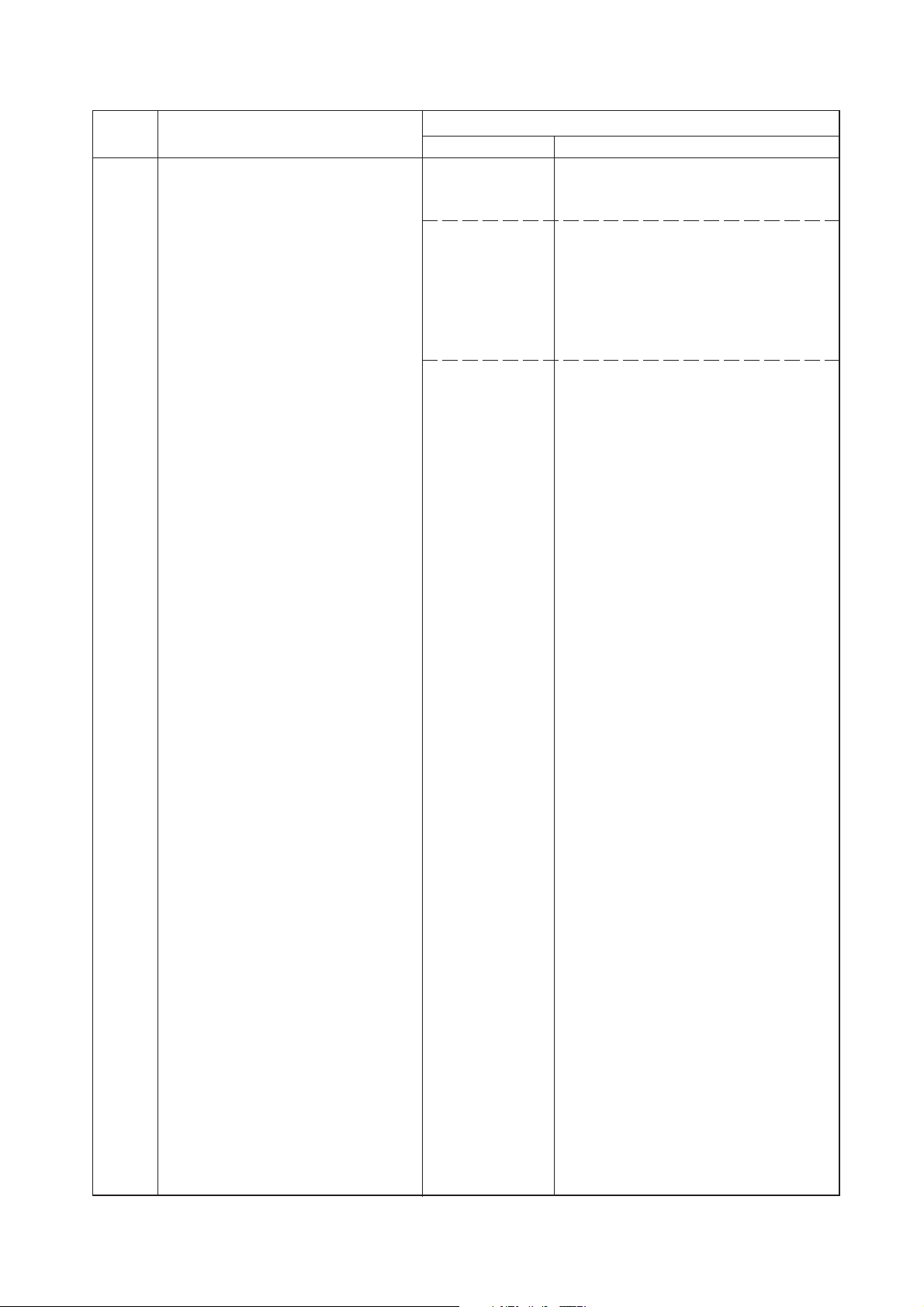

1-4-2 Self-diagnosis

(1) Self-diagnostic function

When a problem is detected in the finisher, copying is disabled and the copier operation section displays a code consisting

of “C” followed by a number between 801 and 822, indicating the nature of the problem.

After removing the problem, the self-diagnostic function can be reset by reattaching the finisher to turn the joint switch off and

on.

(2) Self diagnostic codes

Code Contents

C801

C803

Paper conveying motor problem

The paper conveying motor lockup

signal is detected for 0.5 s or longer.

Paper conveying belt problem

An on-to-off or off-to-on state change of

the paper conveying belt home position

sensor is not detected within 2 s of the

paper conveying belt clutch turning on.

Remarks

Causes Check procedures/corrective measures

The paper

conveying motor

connector makes

poor contact.

The paper

conveying motor

malfunctions.

Defective main

PCB.

The paper

conveying belt is

out of phase.

The paper

conveying belt

clutch malfunctions.

The paper

conveying belt

home position

sensor malfunctions.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

Replace the paper conveying motor and

check for correct operation.

Replace the main PCB and check for

correct operation.

Adjust the paper conveying belt so that it is

in phase and check for correct operation.

Replace the paper conveying belt clutch

and check for correct operation.

Replace the paper conveying belt home

position sensor and check for correct operation.

C814

Tray elevation motor problem

The sort tray is not detected in the

home position within 30 s of the start of

the tray elevation motor rotation.

When the elevation motor rises, the

tray upper limit sensor turns on for

more than 2 s.

The paper

conveying belt

home position

sensor connector

makes poor contact.

The internal tray

is incorrectly

inserted.

The tray elevation

motor connector

makes poor

contact.

The tray elevation

motor malfunctions.

Defective main

PCB.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

Check whether the internal tray unit or front

cover catches are damaged.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

Replace the tray elevation motor and

check for correct operation.

Replace the main PCB and check for

correct operation.

1-4-7

Page 32

3C1

Code Contents

C817

C818

Front jogger motor problem

While the front jogger is not detected in

the home position, the front jogger

home position sensor does not detect

the jogger within 1.5 s of the start of

front jogger motor clockwise rotation.

After the front jogger is detected in the

home position, the front jogger home

position sensor still detects the jogger

within 0.5 s of the start of front jogger

motor counterclockwise rotation.

Rear jogger motor problem

While the rear jogger is not detected in

the home position, the rear jogger

home position sensor does not detect

the jogger within 1.5 s of the start of

rear jogger motor clockwise rotation.

After the rear jogger is detected in the

home position, the rear jogger home

position sensor still detects the jogger

within 0.5 s of the start of rear jogger

motor counterclockwise rotation.

Remarks

Causes Check procedures/corrective measures

The front jogger

motor connector

makes poor

contact.

The front jogger

motor malfunctions.

The front jogger

motor home position sensor connector makes

poor contact.

The front jogger

motor home position sensor malfunctions.

Defective main

PCB.

The rear jogger

motor connector

makes poor

contact.

The rear jogger

motor malfunctions.

The rear jogger

motor home position sensor connector makes

poor contact.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

Replace the front jogger motor and check

for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

Replace the front jogger home position

sensor and check for correct operation.

Replace the main PCB and check for

correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

Replace the rear jogger motor and check

for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

C821

1-4-8

Front stapler problem

The front stapler home position sensor

does not change state from nondetection to detection within 0.2 s of the

start of front stapler motor

counterclockwise (forward) rotation.

During initialization, the front stapler

home position sensor does not change

state from non-detection to detection

within 0.6 s of the start of front stapler

motor clockwise (reverse) rotation.

The rear jogger

motor home position sensor malfunctions.

Defective main

PCB.

The front stapler

connector makes

poor contact.

The front stapler

malfunctions.

a) The front

stapler is blocked

with a staple.

b) The front

stapler is broken.

Defective main

PCB.

Replace the rear jogger home position sensor and check for correct operation.

Replace the main PCB and check for

correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

a) Remove the front stapler cartridge, and

check the cartridge and the stapling

section of the stapler.

b) Replace the front stapler and check for

correct operation.

Replace the main PCB and check for

correct operation.

Page 33

3C1

Code Contents

C822

Rear stapler problem

The rear stapler home position sensor

does not change state from nondetection to detection within 0.2 s of the

start of rear stapler motor

counterclockwise (forward) rotation.

During initialization, the rear stapler

home position sensor does not change

state from non-detection to detection

within 0.6 s of the start of rear stapler

motor clockwise (reverse) rotation.

Remarks

Causes Check procedures/corrective measures

The rear stapler

connector makes

poor contact.

The rear stapler

malfunctions.

a) The rear

stapler is blocked

with a staple.

b) The rear

stapler is broken.

Defective main

PCB.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, remedy or replace the cable.

a) Remove the rear stapler cartridge, and

check the cartridge and the stapling

section of the stapler.

b) Replace the rear stapler and check for

correct operation.

Replace the main PCB and check for

correct operation.

1-4-9

Page 34

3CG

1-4-3 Electrical problems

Problem Causes Check procedures/corrective measures

(1)

The paper

conveying motor

does not operate

(C801).

Poor contact of the paper

conveying motor connector terminals.

Defective paper conveying

motor.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the paper conveying motor rotates when 24 V DC is

present at CN11-1 and 5 V DC at CN8-1, and CN8-4 is held low.

If not, replace the paper conveying motor.

(2)

The front jogger

motor does not operate (C817).

(3)

The rear jogger

motor does not operate (C818).

(4)

The tray elevation

motor does not operate (C814).

Defective main PCB.

Poor contact of the front

jogger motor connector

terminals.

Defective front jogger

motor.

Defective main PCB.

Poor contact of the rear

jogger motor connector

terminals.

Defective rear jogger

motor.

Defective main PCB.

Poor contact of the tray

elevation motor connector

terminals.

Defective tray elevation

motor.

Check if 24 V DC is present at CN11-1, 5 V DC is present at

CN8-1, and CN8-4 goes low. If not, replace the main PCB.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the front jogger motor rotates when 24 V DC is present

at CN4-5 and CN4-6, and drive pulses are at CN4-1, CN4-2,

CN4-3 and CN4-4 on the main PCB. If not, replace the front jogger motor.

Check if 24 V DC is present at CN4-5 and CN4-6 on the main

PCB. If not, replace the main PCB.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the rear jogger motor rotates when 24 V DC is present

at CN4-7 and CN4-8, and drive pulses are at CN4-9, CN4-10,

CN4-11 and CN4-12 on the main PCB. If not, replace the rear

jogger motor.

Check if 24 V DC is present at CN4-7 and CN4-8 on the main

PCB. If not replace the main PCB.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the tray elevation motor rotates when 24 V DC is

present at CN9-1 and CN9-2 on the main PCB. If not, replace

the tray elevation motor.

(5)

The front stapler

motor does not operate (C821).

1-4-10

Defective main PCB.

Poor contact of the front

stapler motor connector

terminals.

Defective front stapler

motor.

Defective main PCB.

Check if 24 V DC is present at CN9-1 and CN9-2 on the main

PCB. If not, replace the main PCB.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the front stapler motor rotates when 24 V DC is present

at CN10-1 and CN10-3 on the main PCB. If not, replace the front

stapler motor.

Check if 24 V DC is present at CN10-1 and CN10-3 on the main

PCB. If not, replace the main PCB.

Page 35

Problem Causes Check procedures/corrective measures

(6)

The rear stapler

motor does not operate (C822).

Poor contact of the rear

stapler motor connector

terminals.

Defective rear stapler

motor.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if the rear stapler motor rotates when 24 V DC is present

at CN10-5 and CN10-7 on the main PCB. If not, replace the rear

stapler motor.

3C1

(7)

The paper

conveying belt

clutch does not

operate.

(8)

The paddle clutch

does not operate.

(9)

The punch clutch

does not operate.

Defective main PCB.

Broken paper conveying

belt clutch coil.

Poor contact of the paper

conveying belt clutch connector terminals.

Defective main PCB.

Broken paddle clutch coil.

Poor contact of the paddle

clutch connector terminals.

Defective main PCB.

Broken punch clutch coil.

Poor contact of the punch

clutch connector terminals.

Defective main PCB.

Check if 24 V DC is present at CN10-5 and CN10-7 on the main

PCB. If not, replace the main PCB.

Check for continuity across the coil. If none, replace the paper

conveying belt clutch.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN5-2 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace the paddle

clutch.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN7-16 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace the punch

clutch.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN7-18 on the main PCB goes low. If not, replace the

main PCB.

(10)

The trailing edge

press solenoid does

not operate.

(11)

Feedshift solenoid 1

does not operate.

Broken trailing edge press

solenoid coil.

Poor contact of the trailing

edge press solenoid

connector terminals.

Defective main PCB.

Broken feedshift solenoid

1 coil.

Poor contact of feedshift

solenoid 1 connector terminals.

Defective main PCB.

Check for continuity across the coil. If none, replace the trailing

edge press solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN12-9,10 on the main PCB goes low. If not, replace

the main PCB.

Check for continuity across the coil. If none, replace feedshift

solenoid 1.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN7-2 on the main PCB goes low. If not, replace the

main PCB.

1-4-11

Page 36

3C1

Problem Causes Check procedures/corrective measures

(12)

Feedshift solenoid 2

does not operate.

Broken feedshift solenoid

2 coil.

Poor contact of feedshift

solenoid 2 connector terminals.

Check for continuity across the coil. If none, replace feedshift

solenoid 2.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

(13)

Paddle solenoid 1

does not operate.

(14)

Paddle solenoid 2

does not operate.

(15)

Paddle solenoid 3

does not operate.

Defective main PCB.

Broken paddle solenoid 1

coil.

Poor contact of paddle solenoid 1 connector terminals.

Defective main PCB.

Broken paddle solenoid 2

coil.

Poor contact of paddle

solenoid 2 connector terminals.

Defective main PCB.

Broken paddle solenoid 3

coil.

Poor contact of the paddle

solenoid 3 connector terminals.

Check if CN7-4 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace paddle solenoid 1.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN8-12 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace paddle solenoid 2.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN8-16 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace paddle solenoid 3.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

(16)

The rotating plate

solenoid is not

activated.

(17)

The drive switching

solenoid does not

operate.

Defective main PCB.

Broken rotating plate

solenoid coil.

Poor contact of the

rotating plate solenoid

connector terminals.

Defective main PCB.

Broken drive switching solenoid coil.

Poor contact of the drive

switching solenoid

connector terminals.

Defective main PCB.

Check if CN8-20 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace the rotating

plate solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN12-2 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace the drive

switching solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN8-23 on the main PCB goes low. If not, replace the

main PCB.

1-4-12

Page 37

Problem Causes Check procedures/corrective measures

(18)

The punch pattern

solenoid does not

operate.

Broken punch pattern

solenoid coil.

Poor contact of the punch

pattern solenoid connector

terminals.

Check for continuity across the coil. If none, replace the punch

pattern solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

3C1

(19)

The pressure

switching solenoid

does not operate.

(20)

Forwarding solenoid

does not operate.

(21)

Paper jams when

the main switch is

turned on.

Defective main PCB.

Broken pressure switching

solenoid coil.

Poor contact of the pressure switching solenoid

connector terminals.

Defective main PCB.

Broken forwarding

solenoid coil.

Poor contact of the

forwarding solenoid connector terminals.

Defective main PCB.

A piece of paper torn from

copy paper is caught

around the paper entry

sensor.

Defective paper entry

sensor.

Check if CN7-8 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace the

pressure switching solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN7-14 on the main PCB goes low. If not, replace the

main PCB.

Check for continuity across the coil. If none, replace the

forwarding solenoid.

Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Check if CN12-6 on the main PCB goes low. If not, replace the

main PCB.

Check visually and remove any found.

With 5 V DC present at CN6-1 on the main PCB, check if CN6-2

on the main PCB remains low when the paper entry sensor is

turned on and off. If it does, replace the paper entry sensor.

A piece of paper torn from

copy paper is caught

around the paper

conveying sensor 1.

Defective paper

conveyingsensor 1.

A piece of paper torn from

copy paper is caught

around the paper

conveying sensor 2.

Defective paper conveying

sensor 2.

A piece of paper torn from

the copy paper is caught

around the eject switch.

Check visually and remove any found.

With 5 V DC present at CN12-16 on the main PCB, check if

CN12-14 on the main PCB remains low when the paper

conveying sensor 1 is turned on and off. If it does, replace the

paper conveying sensor 1.

Check visually and remove any found.

With 5 V DC present at CN12-15 on the main PCB, check if

CN12-13 on the main PCB remains low when the paper

conveying sensor 2 is turned on and off. If it does, replace the

paper conveying sensor 2.

Check visually and remove any found.

1-4-13

Page 38

3C1

Problem Causes Check procedures/corrective measures

(21)

Paper jams when

the main switch is

turned on.

Defective eject switch.

A piece of paper torn from

the copy paper is caught

around the internal tray

sensor.

With 5 V DC present at CN6-3 on the main PCB, check if CN6-4

on the main PCB remains low when the eject switch is turned on

and off. If it does, replace the eject switch.

Check visually and remove any found.

(22)

“Out of staples.

(Front) Add staples.”

or “Out of staples.

(Rear) Add staples.”

is displayed when

the main switch is

turned on.

Defective internal tray

sensor.

Defective front stapler

empty sensor.

Defective front stapler cartridge sensor.

Defective rear stapler

empty sensor.

Defective rear stapler cartridge sensor.

With 5 V DC present at CN5-25 on the main PCB, check if CN526 on the main PCB remains low when the internal tray sensor

is turned on and off. If it does, replace the internal tray sensor.

With 5 V DC present at CN5-23 on the main PCB, check if CN518 on the main PCB remains low or high when the front stapler

empty sensor is turned on and off. If it does, replace the front

stapler empty sensor.

With 5 V DC present at CN5-23 on the main PCB, check if CN520 on the main PCB remains low or high when the front stapler

cartridge sensor is turned on and off. If it does, replace the front

stapler cartridge sensor.

With 5 V DC present at CN5-21 on the main PCB, check if CN510 on the main PCB remains low or high when the rear stapler

empty sensor is turned on and off. If it does, replace the rear

stapler empty sensor.

With 5 V DC present at CN5-21 on the main PCB, check if CN512 on the main PCB remains low or high when the rear stapler

cartridge sensor is turned on and off. If it does, replace the rear

stapler cartridge sensor.

1-4-14

Page 39

1-4-4 Mechanical problems

Problem Causes/check procedures Corrective measures

(1)

No paper feed.

Check if the surfaces of the paper conveying

roller, or upper and lower paper conveying

pulleys are soiled with paper powder.

3C1

Clean with isopropyl alcohol, if they are

soiled.

(2)

No paper ejection to the

sort or non-sort trays.

(3)

Paper jams.

(4)

Abnormal noise is

heard.

Check if the paper conveying roller, or upper

and lower paper conveying pulleys are deformed.

Paper outside specifications is used.

Check if the surfaces of the sort tray eject

pulley and roller, or non-sort tray eject pulley

and roller are soiled with paper powder.

Check if the sort tray eject pulley and roller,

or non-sort tray eject pulley and roller are

deformed.

Check if the paper is extremely curled.

Check if the paper conveying roller, and upper and lower paper conveying pulley make

proper contact.

Check if the sort tray eject pulley and roller,

and non-sort tray eject pulley and roller

contact each other properly.

Check if rollers, pulleys and gears all

operate smoothly.

Replace any deformed or worn pulley or

roller.

Use only paper conforming to the

specifications.

Clean with isopropyl alcohol, if they are

soiled.

Replace any deformed or worn pulleys or

rollers.

Change the paper.

Remedy if there are any problems.

Remedy if there are any problems.

Apply grease to the bushings and gears.

1-4-15

Page 40

1-5-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the finisher power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the boards.

• Do not touch any PCB containing ICs with bare hands or any object prone to static charge.

1-5-2 Procedure for assembly and disassembly

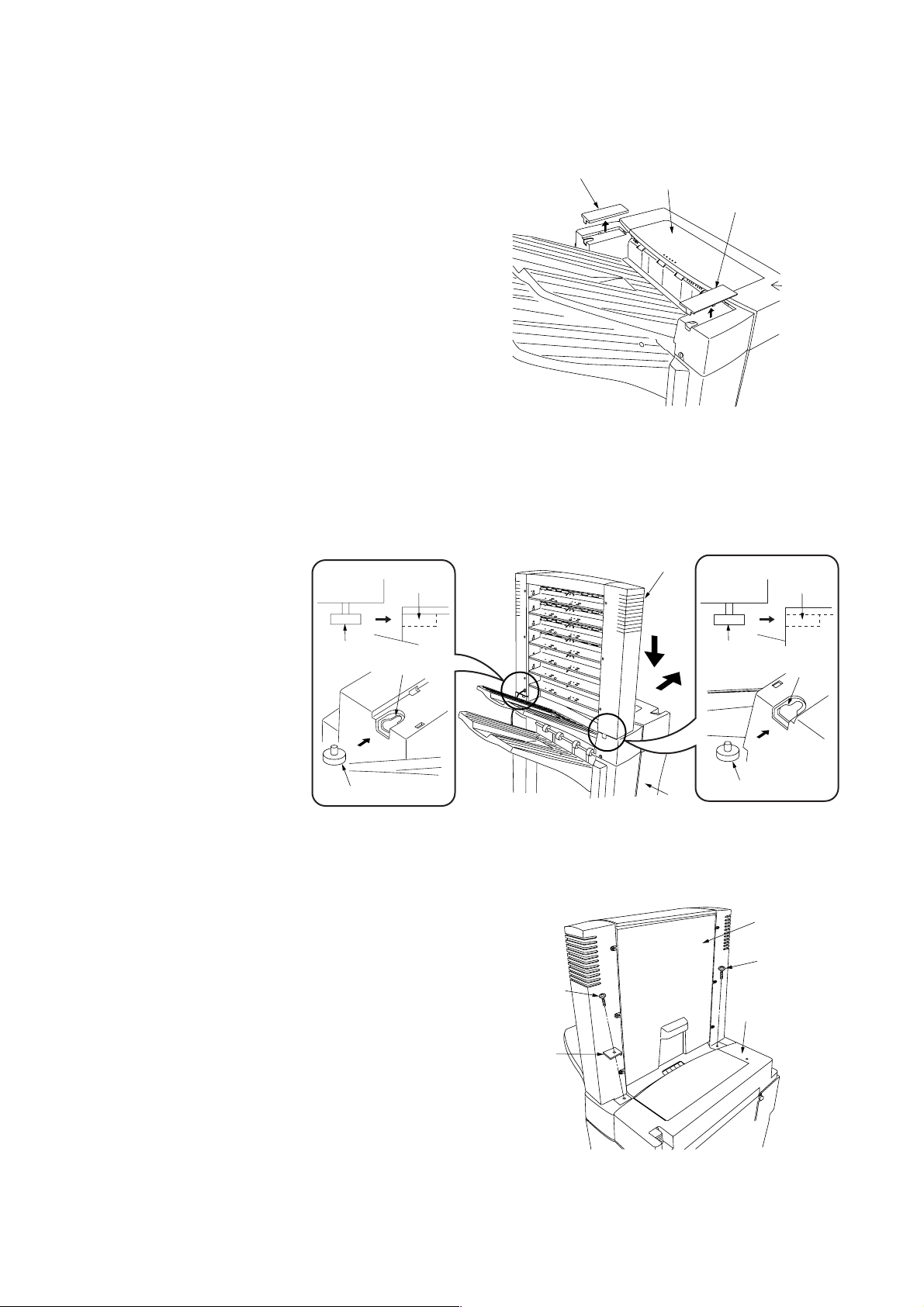

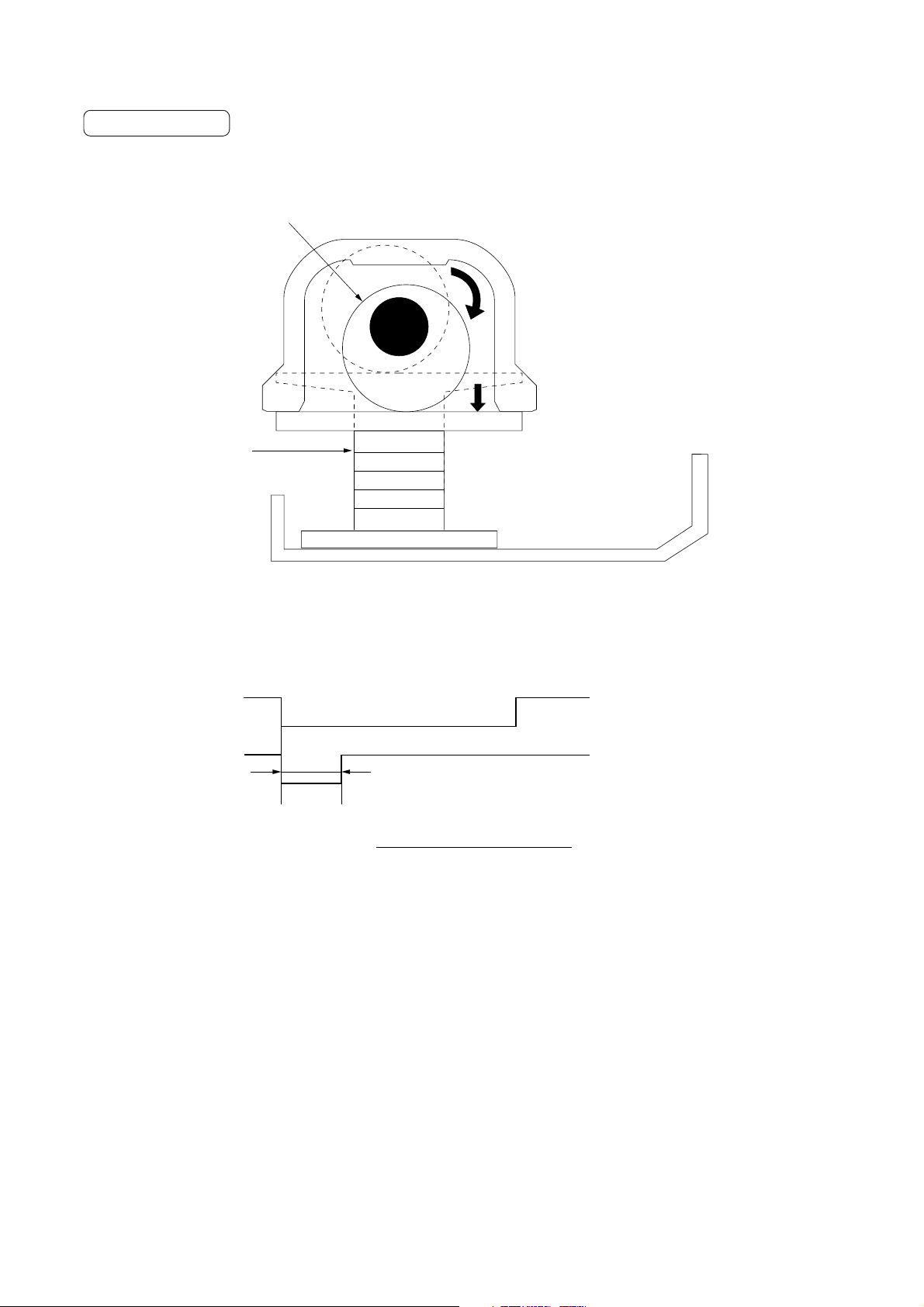

(1) Detaching and refitting the static eliminator brushes

Replace the static eliminator brushes as follows.

3C1

Non-sort tray static eliminator brush

Procedure

1. Open the upper cover.

2. Remove the non-sort tray static eliminator

brush.

3. Fit a new non-sort tray static eliminator brush

so that it makes contact with the grounding

plate.

Sort tray static eliminator brush

Procedure

1. Remove the top cover (four screws).

2. Remove the sort tray static eliminator brush.

3. Fit a new sort tray static eliminator brush.

Non-sort tray static

eliminator brush

Grounding

plate

15 ± 3 mm

4 ± 1 mm

Sort tray static

eliminator brush

Upper cover

Non-sort tray static

eliminator brush

Figure 1-5-1

Non-sort tray static

eliminator brush

0 – 1 mm

8 ± 2 mm

Sort tray static eliminator brush

Figure 1-5-2

1-5-1

Page 41

3C1

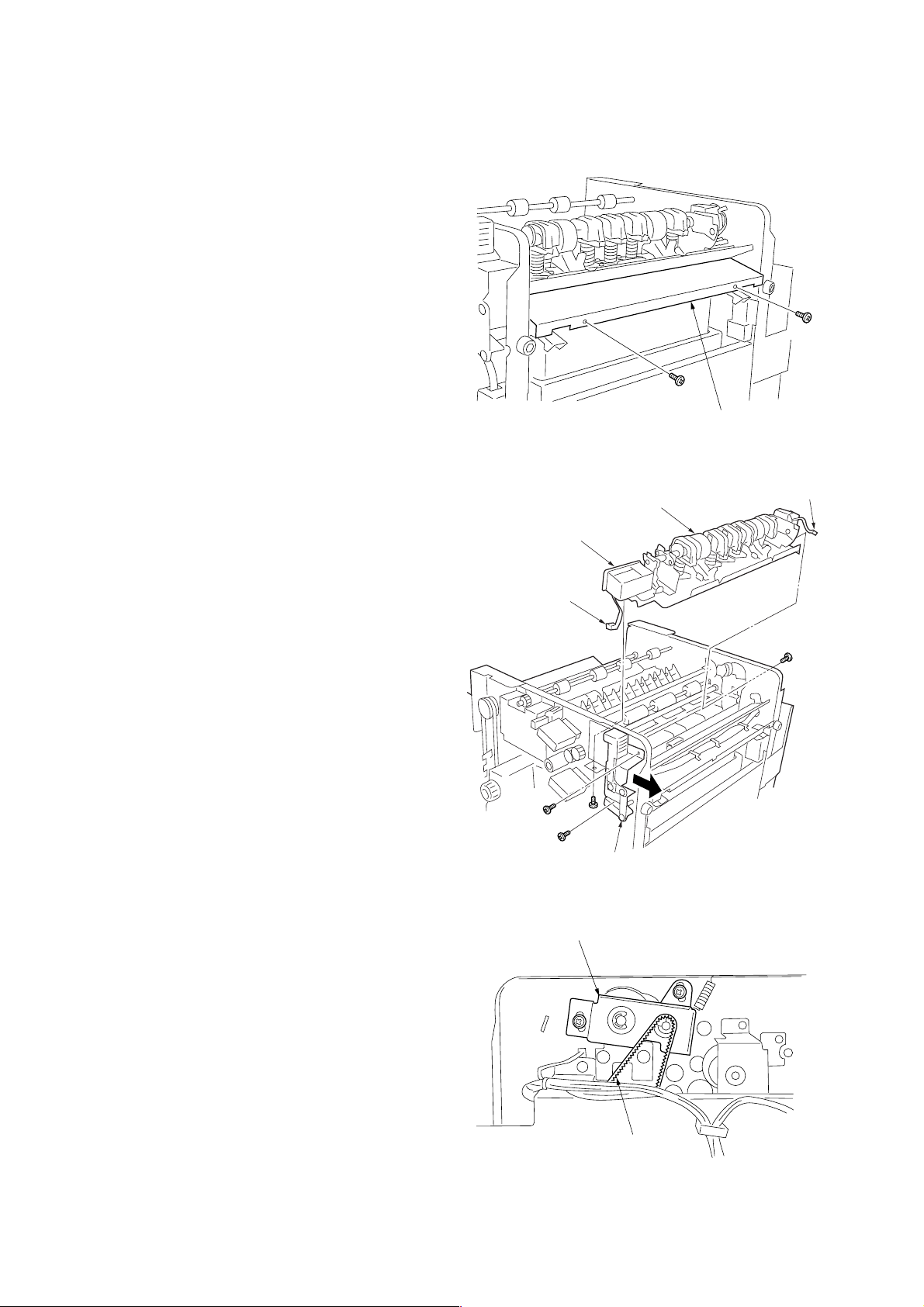

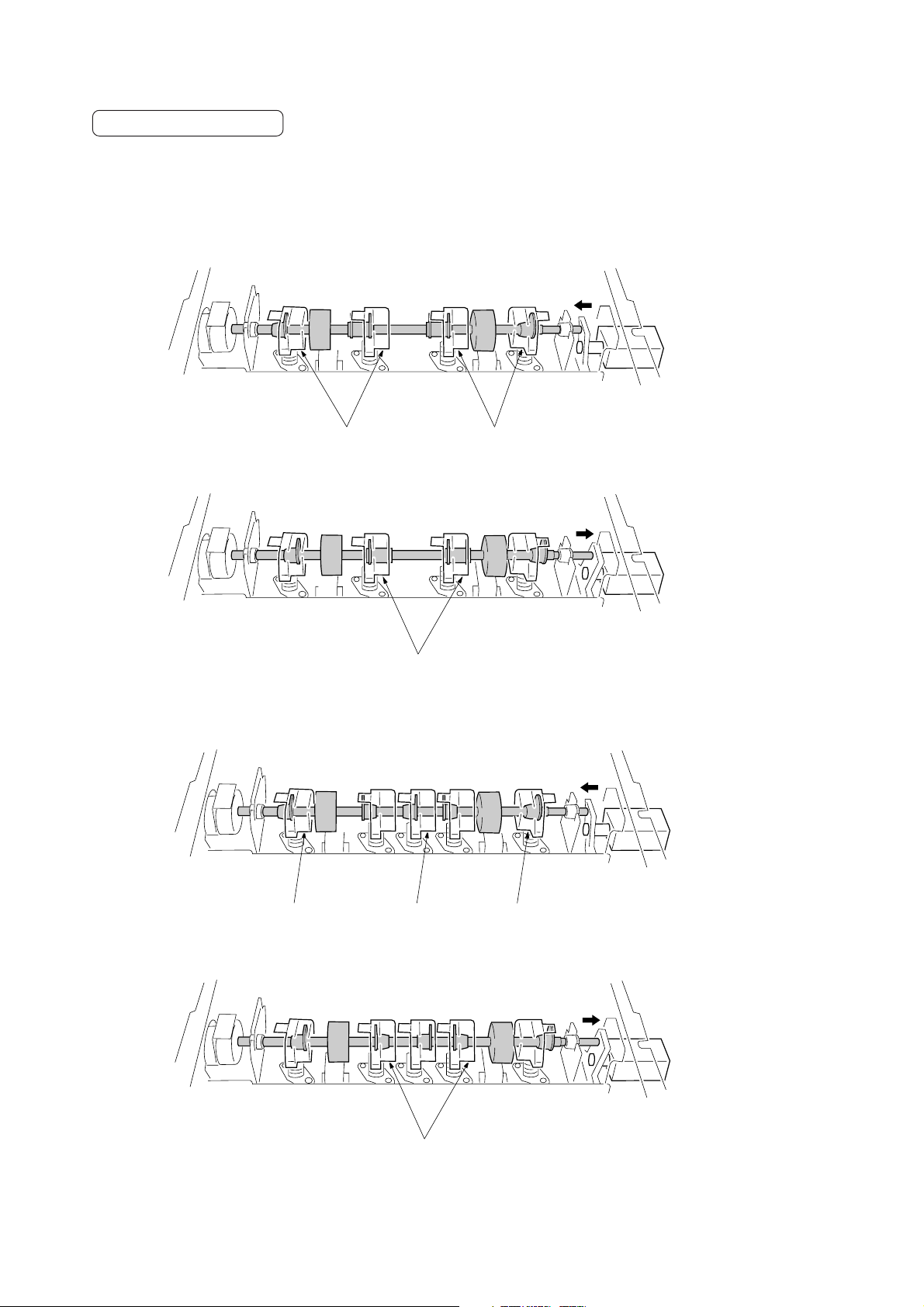

(2) Detaching and refitting the punch unit

Replace the punch unit as follows.

Procedure

1. Remove the top cover (four screws).

2. Open the front cover.

3. Remove the lower paper entry guide (two

screws).

Lower paper

entry guide

Figure 1-5-3

4. Remove the 3-pin connector of the hole-punch

pattern solenoid, and the 2-pin connector of the

punch clutch.

5. Remove the two screws holding the finisher

release button mount, and pull it in the direction

of the arrow.

6. Remove the screws holding the punch unit at

the machine front and rear (one screw each).

*At this time, turn on the punch pattern solenoid

(the axis is slid to the front side of the

machine).

7. Slide the punch unit toward the machine front

and detach it.

8. Fit a new punch unit.

*When fitting the new unit, tighten the screw at

the machine rear and then the screw at the

front.

9. Loosen the two screws of the punch drive unit,

check the tension of the tension belt, and then

tighten the screws again.

10. Refit all removed parts.

punch solenoid

3-pin connectors

Finisher release

button mount

Punch drive unit

punch unit

Figure 1-5-4

2-pin connector

1-5-2

Tension belt

Figure 1-5-5

Page 42

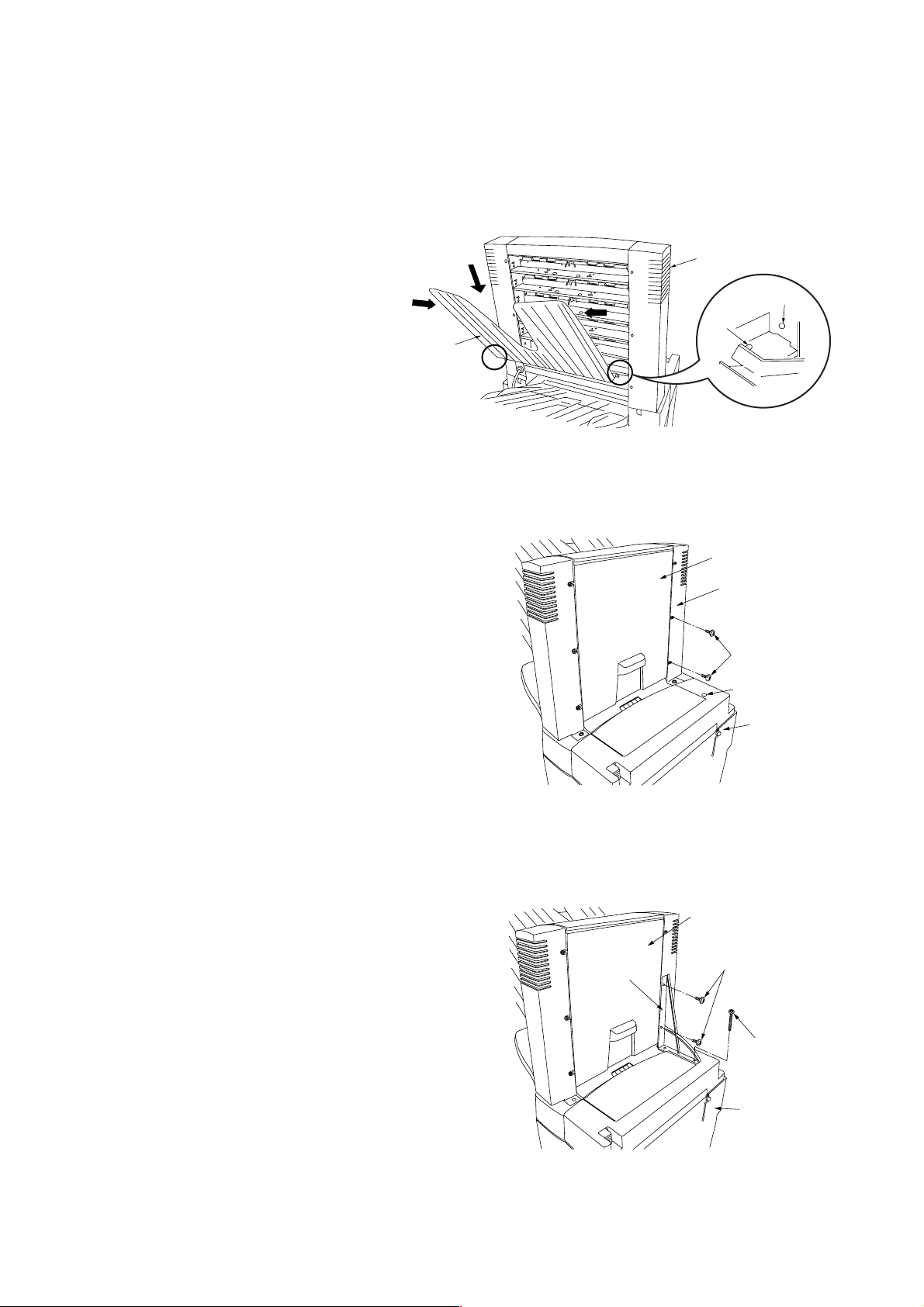

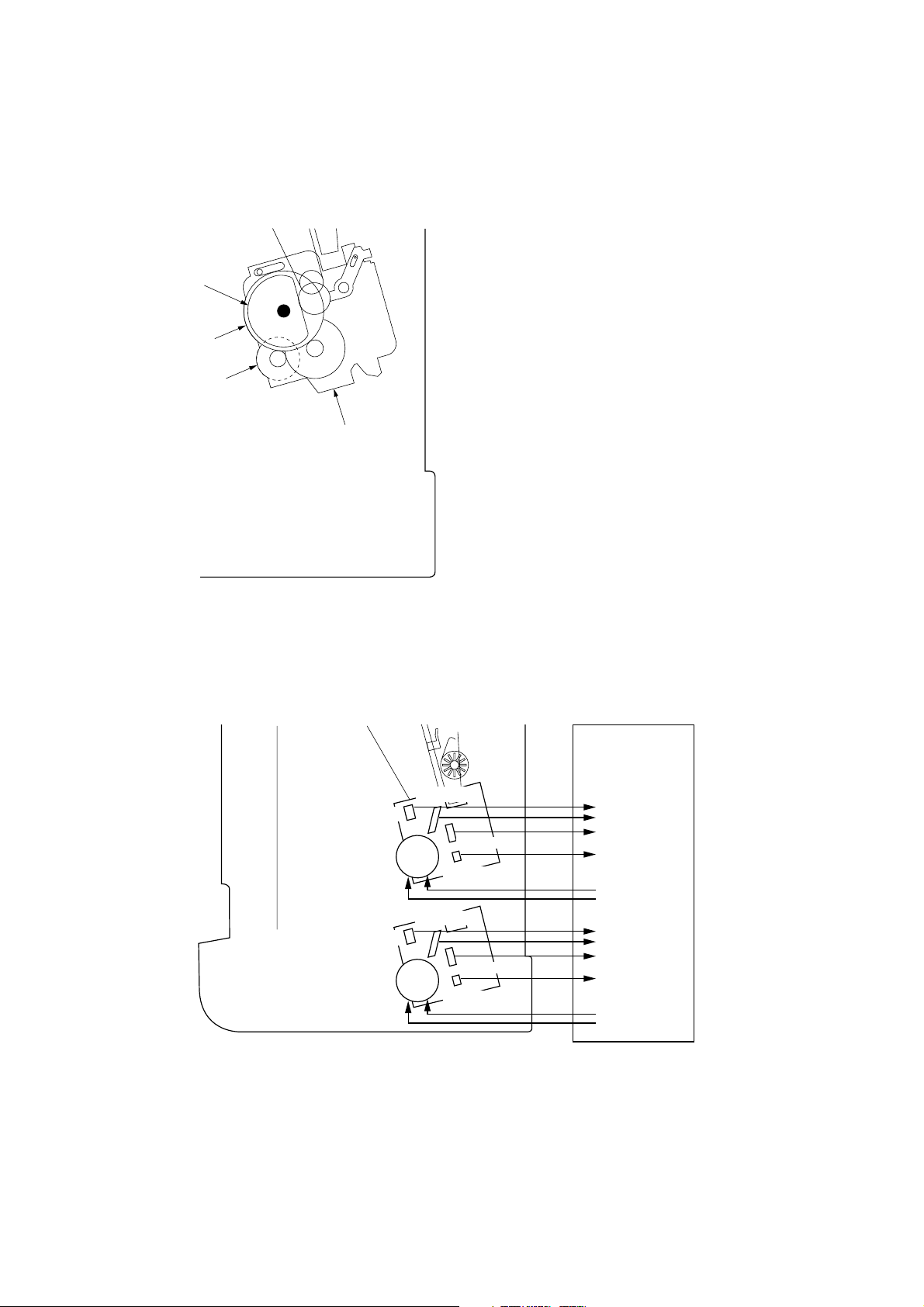

(3) Adjusting the center of the punch holes

Adjust the center of the punch holes after installing the finisher or when the center is displaced.

Procedure

1. Measure the distance (mm) of the punch hole

center displacement.

2. Loosen the four screws securing the retainer.

Shift the retainer by the measured distance

(mm), and tighten the screws.

• When the punch hole is displaced toward the

machine front (Figure 1-5-6), shift the retainer

Displacement

distance (mm)

toward the machine rear ( ).

• When the punch hole is displaced toward the

machine rear (Figure 1-5-7), shift the retainer

toward the machine front ( ).

Displacement

distance (mm)

3C1

Figure 1-5-6

Screws

Figure 1-5-7

Retainer

Screws

Figure 1-5-8

1-5-3

Page 43

3C1

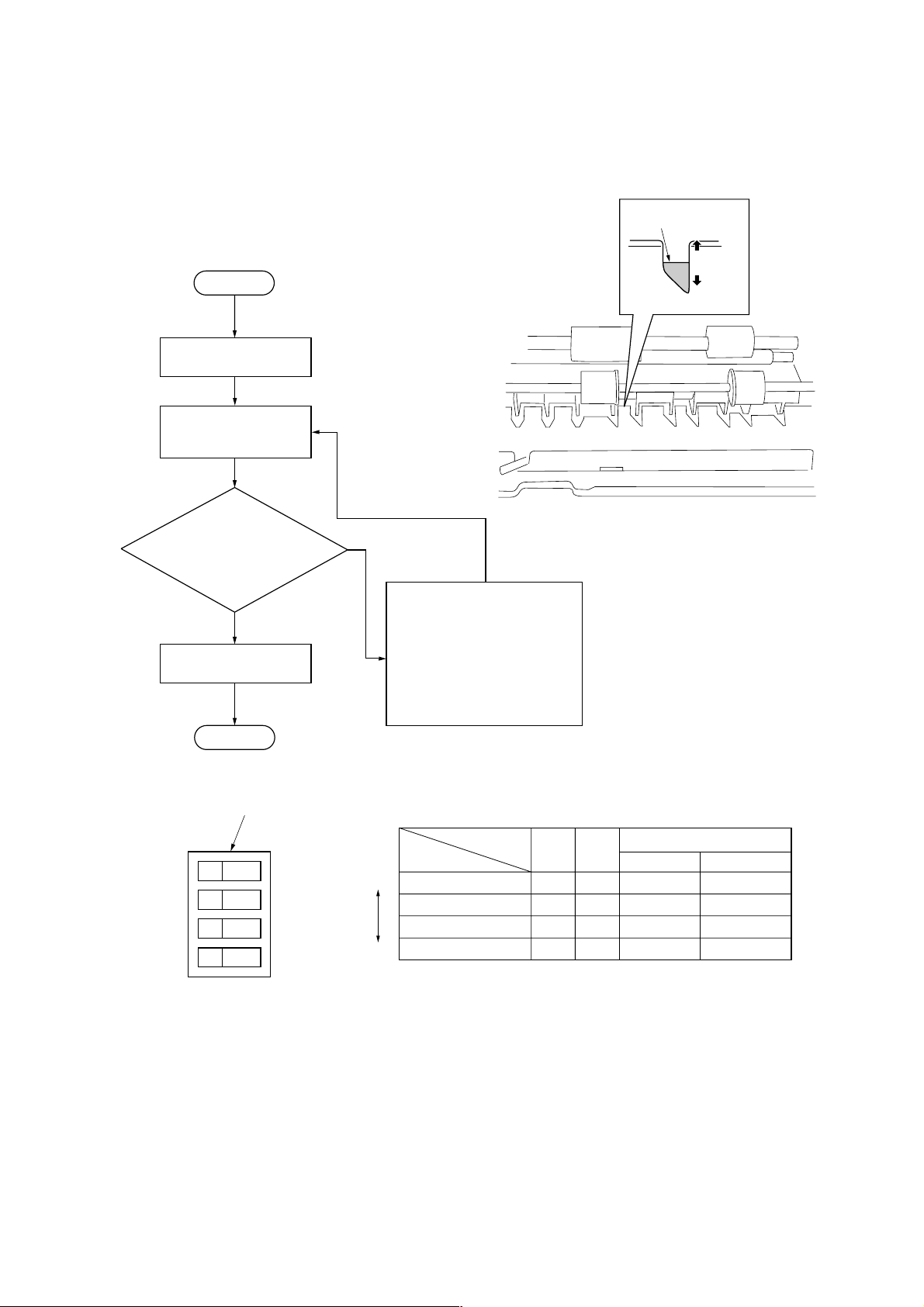

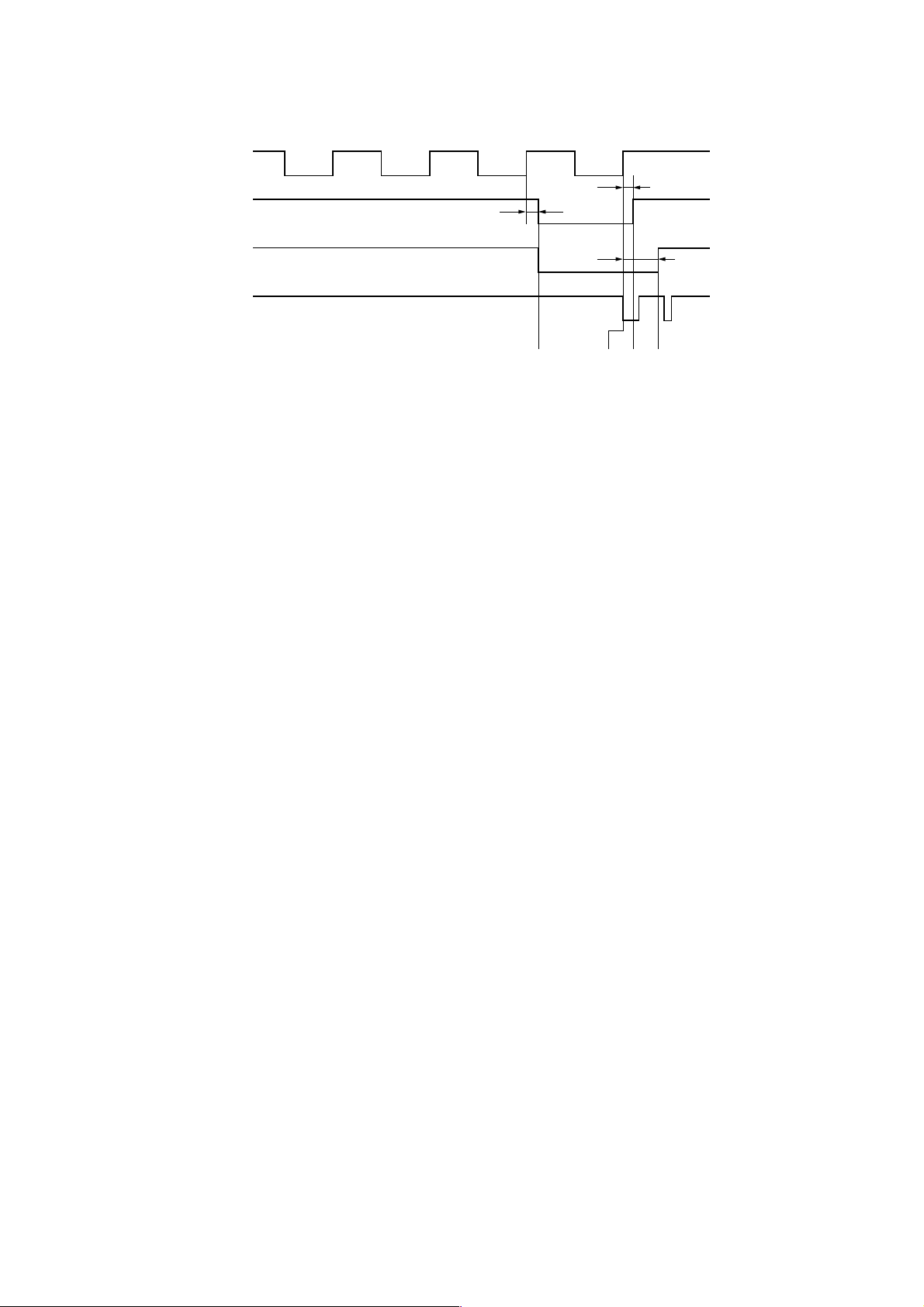

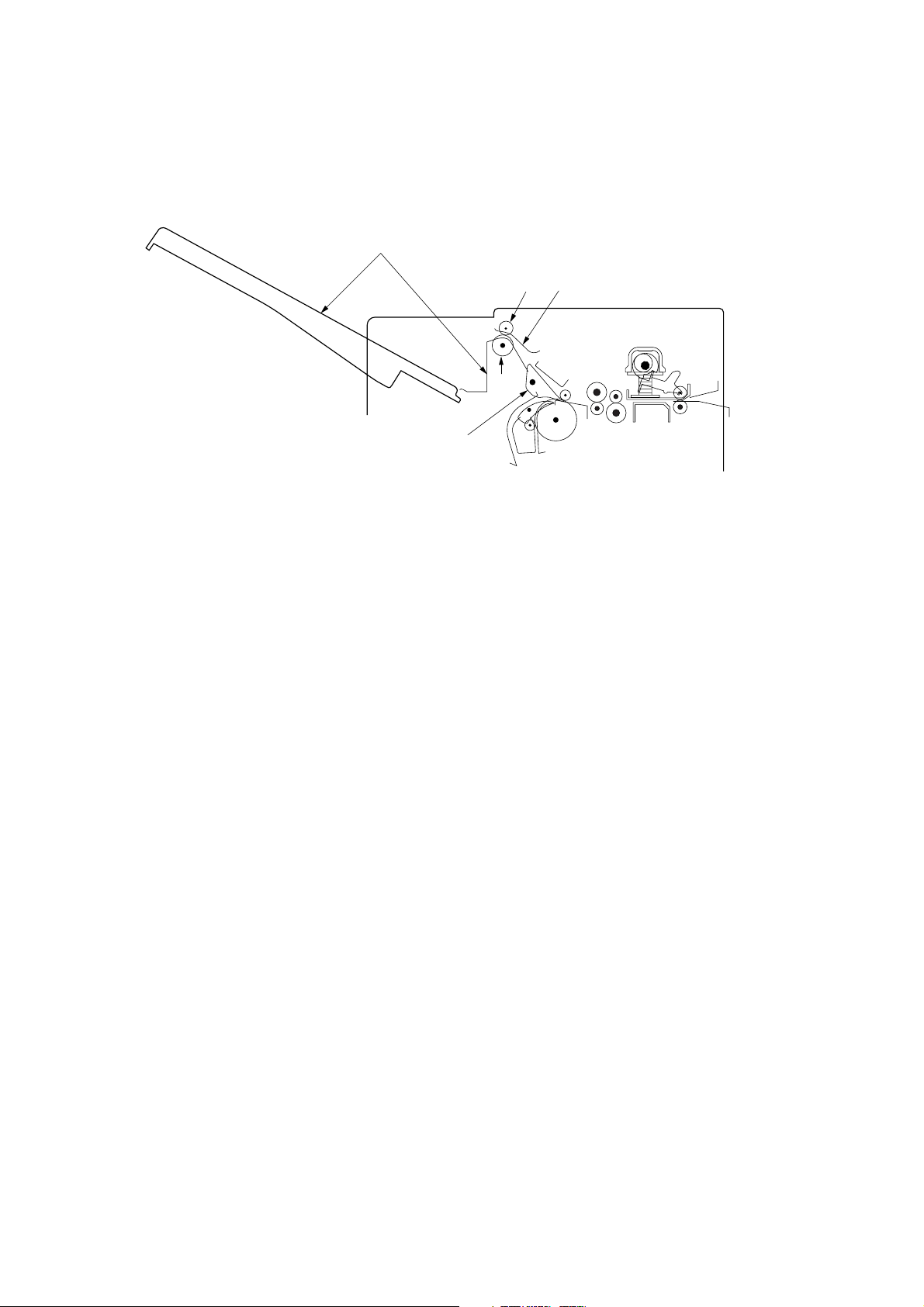

(4) Adjusting paddle clutch turn-on timing

Adjust the paddle clutch turn-on timing if, after disassembling or replacing the drive section or adjusting the belt tension, a

paper jam occurs in the paper conveying section during continuous sort copying from 2 or more originals.

Procedure

Trailing edge

of paper

Start

A

B

Remove the top and

rear covers.

Make test copies in continuous sort copy mode

using 2 or more originals.

Is the trailing

edge of the first sheet

paused in the paper conveying

section positioned within the

slots in the metal plate?

(Figure 1-5-9)

Yes

Refit the top and rear

covers.

No

Adjust the paddle clutch turn-on

timing using DIP switches 1 and

2 on the main PCB.

If the turn-on timing is set earlier,

the pausing position of the trailing

edge of the first sheet moves

toward A; if the timing is set

later, it moves toward B (Figure

1-5-9 and Figure 1-5-10).

Figure 1-5-9

End

DIP switch

ON

Figure 1-5-10

OFF

Earlier

1234

Later

Off

timing

DIP switch

A

B

C

DON

No.

12

ON ON

ON OFF

OFF OFF

OFF

Paddle clutch turn-off timing

Inch Metric

100 ms 105 ms

105 ms 110 ms

110 ms 115 ms

115 ms 120 ms

Table 1-5-1

1-5-4

Page 44

3C1

(5) Adjusting the pressure of the curl eliminator mechanism

If paper ejected from the copier is curled and a paper jam occurs, adjust the pressure of the curl eliminator mechanism to

reduce curl of paper.

Procedure

1. Remove the top cover (four screws).