Page 1

KM-6230

Product

Technical

Information

August 2000 Preliminary Version

Page 2

In this ‘

concerning the KM-6230. We hope that this booklet provides you with useful data regarding performance and

construction of this model.

This booklet has been composed of the latest av ailable data. However, the specifications and design are

subject to change without notification.

©

Product T echnical Information Booklet

K yocera Mita Europe 2000

’ you will find specifications and rele vant technical inf ormation

Page 3

Contents

1GENERAL SPECIFICATIONS .............................................................. 4

1.1 Product Specifications.......................................................................................................4

1.1.1 Copier Specifications......................................................................................................... 4

1.1.2 Network Printer Specifications (the optional printer kit is necessary)Printing System (G)... 6

1.2 Paper Specifications .......................................................................................................... 7

1.3 Lifetime Data ..................................................................................................................... 7

2FUNCTIONS................................................................................... 7

2.1 Basic Functions................................................................................................................. 7

2.2 Copier Functions................................................................................................................ 8

3MACHINE CONSTRUCTION................................................................ 9

3.1 Scanning Section............................................................................................................... 9

3.2 Printing Section ................................................................................................................. 9

3.3 Photoconductor.................................................................................................................. 9

3.4 Charging Section ............................................................................................................... 9

3.5 Developing Section ............................................................................................................ 9

3.6 T r ansfer Section................................................................................................................. 9

3.7 Separation Section ............................................................................................................ 9

3.8 Fixing Section.................................................................................................................. 10

3.9 Charge Erasure Section ................................................................................................... 10

3.10 Cleaning Section.............................................................................................................. 10

3.11 Memory ........................................................................................................................... 10

4TECHNICAL SPECIFICATIONS .......................................................... 10

4.1 Electrical Aspects ...........................................................................................................10

4.2 Environment/Safety Aspect............................................................................................. 11

4.2.1 Work Environment ...........................................................................................................11

4.2.2 Approvals ........................................................................................................................ 11

4.2.3 By-products [Blue Angel testing method]......................................................................... 1 1

4.3 Maintenance .................................................................................................................... 11

4.4 Reliability Data................................................................................................................. 11

5PERFORMANCE............................................................................ 12

5.1 Image Quality .................................................................................................................. 12

5.1.1 Copy Image ..................................................................................................................... 12

5.1.3 Image Area...................................................................................................................... 13

5.2 Paper feed / conveying .................................................................................................... 1 4

APPENDIX 1 LIFETIME OF THE CONSUMABLE PARTS ................................. 15

PPENDIX 2 MAINTENANCE LIST KM-6230, ST-11 DF & F-4330 ........ 1 6

A

PPENDIX 3 MAINTENANCE KITS KM-6230 .......................................... 2 3

A

Page 4

Product Technical Information KM-6230

1GENERAL SPECIFICATIONS

1.1 PRODUCT SPECIFICATIONS

1.1.1 COPIER SPECIFICATIONS

Model KM-6230

Type Desktop

Function Copier

Network printer (optional),Network scanner (option)

System Stationary original (with DF), moving original (with DF) /

indirect electrostatic process

Originals Sheets, books or 3-dimensional objects up to A3

Alignment Without DF: Left rear

With DF: Centre matching

Resolution Scanning section: max. 600 x 600 dpi

Printing section: max. 600 x 600 dpi

Gradation Text mode: 2 tones/dot, 256 gradations, error diffusion

Photo mode: 2 tones/dot, 256 gradations, error diffusion

Mixed mode: 2 tones/dot, 256 gradations, no discrete gradation error

diffusion

Multiple copying Up to 999 copies

Zoom function 25 ~ 400 % (in steps of 1 %)

25 ~ 200 % (in steps of 1 %) <with DF)

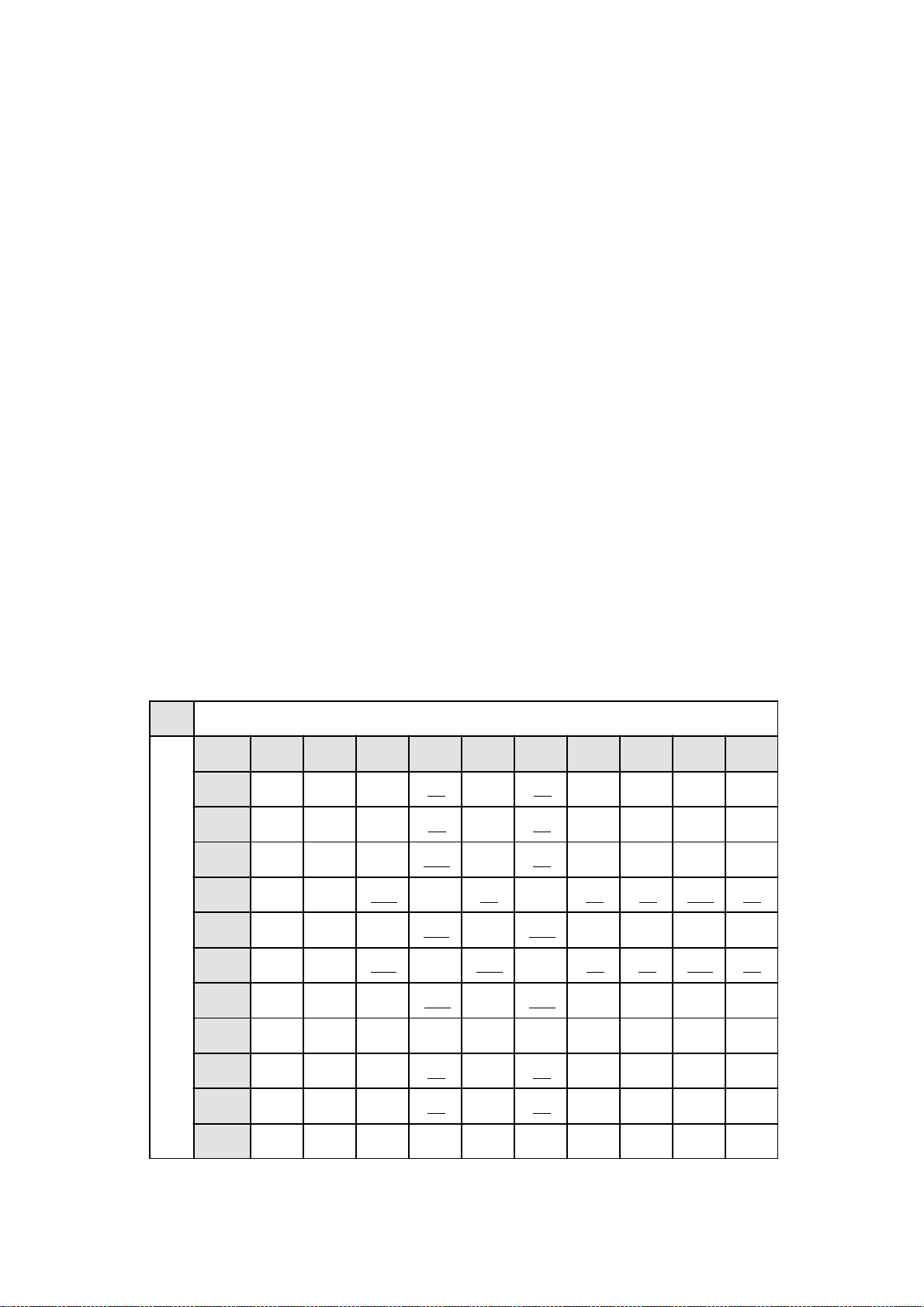

Magnification ratios (AMS) 22R9E

Magnification Ratios Table

(%)

A3 10086707061 61 50 43 70 35

B4

A4R 141 122 100 100 86 86 70 61 100 49

A4

B5R

B5 115 115 100 100 81 70 115 57

A5R

B6R

Folio

11"x1-

5"

A6R

A3 B4 A4R A4 B5R B5 A5R B6R Folio A6R

115 100 81 81 70 70 57 50 81 40

100 100 86 86 70 61 100 49

163 141 115 1 15 100 100 81 70 115 57

200 173 141 141 122 122 100 86 141 70

127 110 90 90 77 77 64 55 100 44

106 91 75 75 65 65 52 45 75 37

Magnification with the underline can be performed only in rotation copy mode

Preliminary Version August 2000 4 © Technical Department

Kyocera Mita Europe B.V.

Page 5

Product Technical Information KM-6230

First copy (A4R/100 %) Without DF: 3.6 sec. or less (manual / ??)

With DF: 6.9 sec. or less (manual)

Copy speed Single original (normal copy / using memory / paper fed from the upper drawer):

Without DF (100 %) A4: 62 copies/min.

A4R: 44 copies/min.

A3: 32 copies/min.

B5: 62 copies/min.

B5R: 50 copies/min.

B4: 38 copies/min.

With DF (100 %) A4: 62 copies/min.

(200 %) A4: 62 copies/min.

Double sided (10 sets of 5 double sided copies from 10 single sided originals)

A4 (manual): 113 sec. or less

Double sided (10 sets of 10 double sided copies from 10 double sided originals)

A4 (manual): 228 sec. or less

Paper feed system

System Standard setting: 2 drawers, front deck and 1 stack bypass front deck

Optional setting: 2 drawers, front deck1 stack bypass and 1 paper feeder

Capacity Drawer Up to 550 sheets (80 g/m²)

Optional paper feeder (ST-11): 4,000 sheets (80 g/m²)

Front deck: 3,000 sheets (80 g/m²)

Bypass: 100 sheets (80 g/m²)

Paper Front desk: A4 / 60 ~ 160 g/m²

Optional paper feeder: A4 / 80 g/m²

Bypass: A3 ~ A6R, folio, Envelope / 60 ~ 200 g/m²

Drawer: A3 ~ A5R, Folio 60 ~ 80 g/m²

Paper eject system

System Sid e tra y (standard): Face-up / face-do wn paper eject

Capacity Side tray Plain paper: 250 sheets (80 g/m²)

Special paper: Up to 250 sheets

Warm up time (20 °C/65 %RH) Normal: 360 sec. or less

Preheat mode: 90 sec. or less

Energy saver mode: 30 sec. or less

Machine sizes approx. 685 (W) x 795 (D) x 1170 (H) mm

Machine weight 200 kg

Optional equipment Paper f eeder: ST -11

Finisher: F-4330, F-4220 stitcher

Printer kit: Printing System(L)

Tandem Kit: TK-1

K ey counter

Mail Box M-2107

Preliminary Version August 2000 5 © Technical Department

Kyocera Mita Europe B.V.

Page 6

Product Technical Information KM-6230

1.1.2 NETWORK PRINTER SPECIFICATIONS (THE OPTIONAL PRINTER KIT IS NECESSARY)PRINTING SYSTEM (G)

Buffer memory 16 MB (standard), 64MB (Maximum)

Network environments Printer server: 100Base-TX, 10Base-T / TCP/IP, IPX/SPX, Ethertalk

I/F board: 100Base-TX, 10Base-T / TCP/IP

Operating systems:

Server

SERVER Windows N T 4.0

CPU

RAM

Interface ports 100Base-TX, 10Base-T / Par allel port

Floppy disk One 1 .44 Mb 3.5-inch 2HD FD D

CD-ROM One drive

Clients (Windows)

CLIENTS Windows

OS Windows 3.1 Windows 95 Windows 98 Wind ows NT4.0

CPU

RAM 8 Mb o r more 8 M b o r mo re 1 6 Mb or mo re 16 Mb or mor e

HDD

Pentium 166 M Hz

32 Mb

HD 2 Gb

i38 6SX / 25 MHz i486SX / 25 MHz i486DX / 66 MHz i48 6SX/25 MHz

10 Mb or mor e 10 Mb or mo re 10 Mb or mor e 1 0 Mb or mo re

Interface ports 100Base-TX, 10Base-T

Floppy disk One 1 .44 Mb 3.5-i nch 2HD FDD

CD-ROM One drive

Clients (Macintosh)

CLIENTS Macintosh

OS System 7 .5 or Ma c OS 8

CPU

RAM 16 Mb 16 Mb

HDD

Interface ports 100Base-TX, 10Base-T

Floppy disk One 1 .44 Mb 3.5-inch 2HD FD D

CD-ROM One drive

Power PC4 03 Power PC4 03

10 Mb 10 Mb

Preliminary Version August 2000 6 © Technical Department

Kyocera Mita Europe B.V.

Page 7

Product Technical Information KM-6230

Resolution Max. 600 x 600 dpi (without smoothing)

Gradation 2 tones / dot

Print sizes A3 ~ A6R, envelopes, custom sizes

Print speed A4: 62 ppm

A3: ?? ppm

B4: ?? ppm

PDL Standard: PCL 6 / PostScript level 2

Font Standard: 35 Intelli fonts / 10 True Type f onts

35 Alternative fonts

1.2 Paper Specifications

Copy paper sizes A3 ~ A6R, folio, envelopes

Copy paper weight Recommended: 80 g/m²

Drawer: 60 ~ 80 g/m²

Front dec k: 60 ~ 160 g/m²

Bypass: 6 0 ~ 200 g/m²

Copy paper types OHP, recycled paper , normal plain paper

1.3 Lifetime Data

Copier 5 years or 3,600,000 sheets

Developer 300,000 sheets

Toner 30,000, sheets

(measured under the recommended circumstance: A4R

multiple and single copy ratio 5:5 copying / 6 % image ratio)

2 Functions

2.1 Basic Functions

Language selection Factory defaul: English

Help guidance

Stop/clear

All clear

Auto clear ON / OFF 30 ~ 270 sec. (in steps of 30 sec) / Factory

default: 90 sec.

Preheat 30 / 90 sec. (restoration time) / Factory def ault: 90 sec.

Auto preheat On / off, 5 ~ 45 min. (in steps of 5 min.) / Factory

default: 15 min.

Auto shutoff On / off, 5 ~ 240 min. (in steps of 15 min.) / Factory

default: 90 min.

Weekly timer On / off / Factory default: off

Total counter 7 digit mechanical counter

Paper jam detection

Paper jam number correction

P aper size detection

Paper le vel detection Front deck only

Paper empty detection

Non-stop paper loading Additional paper can be loaded while copying / printing.

Non-stop toner loading

Toner level detection

Toner empty detection

Disposal toner over detection

Re-try paper feed

Partial operation

Dual access

Display density adjustment

Maintenance mode

Error detection

Preliminary Version August 2000 7 © Technical Department

Kyocera Mita Europe B.V.

Page 8

Product Technical Information KM-6230

2.2 Copier Functions

No. of copies setting 1 ~ 999 copies

Copy density control Normal: 7 or 13 levels

Max.: 13 or 25 levels

Automatic density control

Image modes Text / photo / mix modes

Automatic paper selection

Automatic magnification selection

Magnification copy Zoom / preset magnification ratios / fixed magnification

ratios / XY independent zoom

Original size detection

P aper size selection

Interrupt mode

Auto start

Automatic drawer change

Mode program

Short-cut key

Mode setting confirmation

Copy time display

Department control 1,000 department / 4 digits

Margin shift Left margin: 6 ~ 18 mm (in steps of 1 mm) / Factory default: 6 mm

Custom margin: 1 ~ 18 mm (in steps of 1 mm)

Border erase Sheet: 6 / 12 / 18 mm

Book: 6 / 12 / 18 mm

Custom: X: 94 ~ 214 mm (in steps of 8 mm) / Y: 60 ~ 296 mm

(in steps of 4 mm)

Auto duplex copy Book originals (right binding / left binding) / 1 sided

originals / 2 sided originals / mixed (1-sided / 2sided)

originals (only with the DF)

Split copy Book originals: A3 → A4 / A3

2 sided originals: Only with the DF

Sheet insertion Cover / inter-sheet / chapter modes

Presentation mode

Sort copy Memory sort / rotation sort (without finisher)

Memory sort (with finisher)

Group copy

Auto stapling Only with the finisher

Auto punching Only with the finisher

Multiple copies with 1 scan

Rotation copy

Job built function

B/W inversion copy

Mirror image copy

Page number insertion 3 styles at the lower middle / -9 ~ 999 page

Form overlay 10 density levels

N-up copy 2 in 1 / 4 in 1

Magazine binding Right / left binding

Book magazine binding Right / left binding

Size unification

Job reservation Up to 9 jobs

Pause The settings of the staple mode, punch mode and

number of copies can be changed.

Service simulation out put

User settings

Preliminary Version August 2000 8 © Technical Department

Kyocera Mita Europe B.V.

Page 9

Product Technical Information KM-6230

3MACHINE CONSTRUCTION

3.1 Scanning Section

Resolution 600 x 600 dpi

Exposure source Florescent lamp / 24 W

3.2 Printing Section

System Electro-photography by semiconductor laser

Resolution 600 x 600 dpi

3.3 Photoconductor

Shape Drum (Ø 84 mm)

Type Positive charge

Drum surface potential + 450 V

Rotation speed 320 mm/sec.

3.4 Charging Section

System corona charging (+) by 2 charge wires

Discharge 900 µA

3.5 Developing Section

System Dual component magnetic brush developing

Developer capacity 1700g N32D (2 bottles of 850grams)

Toner System: Bottle

Capacity: 1260 g (N32T)

T/D ratio 5 : 95 (toner : developer by weight)

Density control Developer density detection (toner sensor)

Developing bias DC + 500 V

Clearance 0.625 mm (between drum and developing roller)

0.75 mm (between developing roller and doctor blade)

Sensor Temperature / humidity sensor

3.6 Transfer Section

System Transfer belt

Transfer current 1,2~ 1,3 KV (20 °C / 65 %RH)

3.7 Separation Section

System Transfer belt

Preliminary Version August 2000 9 © Technical Department

Kyocera Mita Europe B.V.

Page 10

Product Technical Information KM-6230

3.8 Fixing Section

System Heat / pressure fixing

Heater Main heater: Halogen heater (240 V / 1350 W)

Sub heater: Halogen heater (240 V / 380 W)

Control Thermister detection

Roller control temperature 185 °C (at an ordinary temperature)

Fixing pressure Approx. 80 N

Overheat ing preve ntion 195 °C ( thermostats)

Fixing roller Heat roller: PTFE / PFA in verted crown-shaped roller

Press roller: PF A flat surface roller

3.9 Charge Erasure Section

System Charge erasure by light

Lamp LED

3.10 Cleaning Section

System Blade

Material P olyurethane

3.11 Memory

System Memory board

Standard setting Bitmap memory: 64 MB

Image memory: 8.5 MB (HDD standard)

Image storage capacity 8.5 GB: Approx. 15,461 pages (A4 60% original)

4 T ec hnical Specifications

4.1 Electrical Aspects

Rating 220 ~ 240 V / 50 Hz

4.9 A (ave.) / 10 A (max.)

Power consumption Copying: ? W/h or less

Standby: ? W/h or less

Low power mode: ? W/h or less

Insulation voltage 1500 V/min. or 1650 V/sec.

Insulation resistance 2 MΩ or more (by 500 V megger)

Earth continuity 0.1 Ω or less

Preliminary Version August 2000 10 © Technical Department

Kyocera Mita Europe B.V.

Page 11

Product Technical Information KM-6230

4.2 Envi ronment/Safety Aspect

4.2.1 Work Environment

Operation Temperature: 10 ~ 35 °C

Humidity: 15 ~ 85 %R H

Storage Temperature: -20 ~ 40 °C

Humidity: 10 ~ 90 %R H

4.2.2 Approvals

GS / CE

4.2.3 By-products [Blue Angel testing method]

Noise level Copying: 71 dB

Stand-by: 53 dB

Ozone 0,008 mg/m³

Dust 0,029 mg/m³

Styrene 0,059 mg/m³

4.3 Maintenance

Refer to the appendix 2 for the detailed maintenance list.

Maintenance interval 300,000 sheets

Aver age maintenance time 60 min. or less

4.4 Reliability Data

MDBJ 6,000 sheets

MDBMF Multiple feeding: 3000 sheets

Skew: 500 sheets

MCBC 150,000 sheets

MCBJ Simplex (drawer): 30,000 sheets

Simplex (bypass): 3,000 sheets

Duplex (drawer): 20,000 sheets

Duplex (bypass): 2,000 sheets

MCBMF Simplex (drawer): 18,000 sheets

Simplex (bypass): 2,000 sheets

Duplex (drawer): 12,000 sheets

Duplex (bypass): 2,000 sheets

(MCBC: average interval between service calls)

(MCBJ: average interval between paper jams)

(MCBMF: average interval between paper misfeeds)

(MDBJ: average interval between original document jams)

(MDBMF: average interval between original document misfeeds)

Reliability data are referring to the machine only under the recommended operation circumstances.

Preliminary Version August 2000 11 © Technical Department

Kyocera Mita Europe B.V.

Page 12

Product Technical Information KM-6230

5 Performance

5.1 Image Quality

5.1.1 Copy Image

Resolution (centre of image) 10 lines/mm or more (1:1)

5 lines/mm or more (50 %)

10 lines/mm or more (200 %)

Reproduction of fine lines 10 lines/mm or more (1:1)

5 lines/mm or more (50 %)

10 lines/mm or more (200 %)

Magnification tolerance 100 % (w/o DF): ± 0.8 % or less (total length)

± 0.8 % or less (partial)

100 % (w/ DF): ± 1.5 % or less (total length)

± 1.5 % or less (partial)

Others (w/o DF): ± 1.0 % or less (total length)

± 1.0 % or less (partial)

Other (w/ DF): ± 1.5 % or less (total length)

± 1.5 % or less (partial)

Squareness Without DF: ± 1.5 mm/375 mm or less

With DF: ± 2.5 mm/375 mm or less

Image distortion Without DF: ± 1.0 mm/375 mm or less (total length)

± 0.5 mm/50 mm or less (partial)

With DF: ± 1.0 mm/375 mm or less (total length)

± 0.5 mm/50 mm or less (partial)

Preliminary Version August 2000 12 © Technical Department

Kyocera Mita Europe B.V.

Page 13

5.1.3 Image Area

Copier

C

B X

!

Product Technical Information KM-6230

SIDE

D

PW

(mm)

A B C D

A

Y

PL

Printer

C

B X

!

A

Y

PL

Effective Image Area (printer)

C

D

Margin width 6–2.0 6–2.0 6–2.0 6–2.0

Copy margin

imperfect im age area

PW

Margin width

Copy margin

imperfect im age area

___ ___ ___ ___

SIDE

(mm)

A B C D

___ ___ ___ ___

___ ___ ___ ___

!

B X

!

A

Y

PL

D

PW

↑↑

↑

↑↑

↑

↑↑

<P ortrait> <Landscape>

!

↑↑

↑↑

↑: top of the PC display

↑↑

!: conveying direction

Preliminary Version August 2000 13 © Technical Department

Kyocera Mita Europe B.V.

Page 14

Printer (continue)

Effective Image Area: Protrait & Landscape (Under Evaluation)

Portrait

Product Technical Information KM-6230

PAPER

SIZE

IMAGE

AREA

Landscape

PAPER

SIZE

IMAGE

AREA

PAPER ENVELOPE

(mm)

A3 B4 A4 A4R B5 B5R A5R Folio DL C5 Min. Max.

PW

297.0 257.0 297.0 210.0 257.0 182.0 148.0 210.0 110.0 162.0 98.4 269.9

PL

420.0 364.0 210.0 297.0 182.0 257.0 210.0 330.0 220.0 229.0 148.0 431.8

X 283.8 243.8 284.2 197.1 244.2 169.3 135.8 197.1 96.9 149.0 84.7 283.8

Y

407.2 351.3 197.1 284.2 169.3 244.2 197.3 317.3 207.3 220.5 135.1 419.3

PAPER ENVELOPE

(mm)

A3 B4 A4 A4R B5 B5R A5R Folio DL C5 Min. Max.

PW

297.0 257.0 297.0 210.0 257.0 182.0 148.0 210.0 110.0 162.0 98.4 269.9

PL

420.0 364.0 210.0 297.0 182.0 257.0 210.0 330.0 220.0 229.0 148.0 431.8

X 284.2 244.3 283.8 197.3 243.8 169.3 135.8 197.3 100.9 149.3 85.0 283.8

Y

407.1 350.9 197.3 283.8 169.3 243.8 197.3 317.0 207.3 216.1 134.8 419.3

USER

SETTING

USER

SETTING

5.2 Paper feed / conveying

Leading edge timing tolerance

(mm)

Side registration to lerance

(mm)

Paper feed tolerance (skew)

(mm)

Paper curl

(mm)

Simplex

Drawer – 2.5

Bypass – 2.5

Duplex (refeed) – 3.5

Drawer 2.0 or less

Simplex

Bypass 2.0 or less

Duplex (refeed) 3.0 or less

Drawer 1.5 or less

Simplex

Bypass 1.5 or less

Duplex (refeed) 2.0 or less

Simplex 10 or less

Duplex 10 or le ss

Preliminary Version August 2000 14 © Technical Department

Kyocera Mita Europe B.V.

Page 15

Product Technical Information KM-6230

APPENDIX 1 LIFETIME OF THE CONSUMABLE PARTS

The parts listed here should be replaced after the indicated number of copies.

KM-6230 Consumable Parts

Description P art No. Quantity Section

Parts, blade cleaning (SP) 36793312 1 300k

Brush, cleaning 2A018050 1 300k

Terminal, cleaning brush 36718110 1 300k

Felt, cleaning 2A020330 1 300k

Lower roller , cleaning 2A020340 1 300k

P arts, belt transf er (SP) 36793281 1 600k

Roller , tr ansfer 2A016020 1 600k

Brush, belt cleaning 2A016040 1 600k

Parts front shield, cleaning (SP) 36793670 1 600k

MC Cleaning pad ass’y 2A068220 2 600k

Grid cleaning pad ass’y 36768080 1 600k

Developing blade ass’y 2A000220 1 600k

Upper seal, developing 2A014360 1 600k

Filter, de v eloping 2A014460 1 600k

P arts, upper cov er cleaning (SP) 36793341 1 600k

Lower blade ass’y 2A068210 1 600k

Roller, heat 2A020010 1 600k

Roller , pressure 2A020020 1 600k

DF Consumable Parts

Description P art No. Quantity Lifetime (x1,000 Original feeding)

Pulley leading feed 3BC07010 1 100K

Pulley separation 3BC07020 2 100K

Note

The figures between brackets () show that the mentioned lifetime depends on the number of times that the part has actually been

used during operation. The counts can be checked by simulation.

Preliminary Version August 2000 15 © Technical Department

Kyocera Mita Europe B.V.

Page 16

Product Technical Information KM-6230

APPENDIX 2 MAINTENANCE LIST KM-6230, ST-11 DF & F-4330

LIST OF ABBREVIATIONS

CL Clean

Lu Lubricate

Re Replace

Ch/Ad Check and adjust

Ch/Re Check and replace if necessary

0 On delivery

U/C User's call

Preliminary Version August 2000 16 © Technical Department

Kyocera Mita Europe B.V.

Page 17

Product Technical Information KM-6230

KM-6230 COPY Q’TY (X 1,000 COPIES) Page 1 of 3

DESCRIPTION Part No.

On

Delivery

U/C 300K 600K 900K 1200K 1500K REMARKS

A SETUP

1 Developer (x2) Re Re Re Re Re Re

2 Toner Re

3 Copy quality

Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad

B COVER

1 Cover

CH CL CL CL CL CL

C PAPER FEED SECTION

1 Belt,Paper Feed (4)

2 Upper Roller, Conveying (2)

3 Left Pulley LCF (x 2)

4 C-Pick P ulley

5 Pulley, Pi c k -Up (x 2)

6 Pulley, Paper Feed (x 2)

7 Lower Pulley, Paper Feed (x 3)

8 Roller, SB Leading Feed

2A007010

2A007120

2A006190

5A707580

60906161

36706290

33906060

36707050

CL CL CL CL CL

CL CL CL CL CL

CL/RE CL/RE CL/RE CL/RE CL/RE

CL/RE CL/RE CL/RE CL/RE CL/RE

CL CL/RE CL/RE CL/RE CL/RE

CL CL/RE CL/RE CL/RE CL/RE

CL CL/RE CL/RE CL/RE CL/RE Alcohol or dry cloth

CL CL/RE CL/RE CL/RE CL/RE Alcohol or dry cloth

Alcohol and dry cloth

Alcohol and dry cloth.

Alcohol or dry cloth

Alcohol or dry cloth

9 Upper Pulley, Bypass

10 Lower Pulley, Bypass

11 Upper Roller, Registration

12 Lower Roller, Registration

61706770

61706780

36706511

36706520

CL CL/RE CL/RE CL/RE CL/RE Alcohol or dry cloth

CL CL/RE CL/RE CL/RE CL/RE

CL CL/RE CL/RE CL/RE CL/RE

CL CL/RE CL/RE CL/RE CL/RE

13 Guides CL CL CL CL CL

14 Rollers CL CL CL CL CL

D DUPLEX UNIT SECTION

1 Pla t e Sp r ing , D r um G r oung

2A022050

Ch/ReLUCh/ReLUCh/ReLUCh/Re

CH

LU

2Clutches CH/RE CH CH CH CH CH

E PAPER CONVEYING SECTION

Alcohol and cloth

CH: Replace if the

contact surface is

dameged.

LU: Lubricate conductive

grease GE334C(PNA0199040)

After 600K

OR when replace it with

new one.

CH: Check the reading

edge timing, Paper feed

condition and etc.

1 Parts, Belt Transfer (SP)

2 Ro lle r, Transfe r

3 Brush, Belt Cleaning

4 Rear Guide, Transfer

5 Parts Front Shield, Cleani ng (SP)

36793281

2A016020

2A016040

36716383

36793670

RE RE

RE RE

RE RE

CL CL CL CL CL Vacuum or dry cloth

CL RE CL RE CL

Preliminary Version August 2000 17 © Technical Department

Kyocera Mita Europe B.V.

Page 18

Product Technical Information KM-6230

KM-6230 COPY Q’TY (X 1,000 COPIES) Page 2 of 3

DESCRIPTION Parts No.

On

delivery

U/C 300K 600K 900K 1200K 1500K REMARKS

F OPTICAL SECTION

1 Contact glass, ADF

2 Contact glass

3 Mirror A

4 Mi rror B ( X 2)

5 Lens, scanner

6 Reflector, scanner

7 Lamp, scanner

8 Rail, scanner

Sensor, Original Detection

9

(120V x2 , 230/240V x1)

35911450

35912010

2AC12140

2AC12150

2AC12130

2A012010

35927290

CL CL CL CL CL

CL CL CL CL CL

CL CL CL CL CL

CL CL CL CL CL

CL CL CL CL CL

CL CL CL CL CL

Ch/Re Ch/Re Ch/Re Ch/Re Ch/Re Dry cloth.

Lu Lu Lu Lu Lu

CL CL CL CL CLl Alcohol or dry cloth

G IMAGE F OR M ATION SE C TION

1 Set, Drum For 6230

2 Electrode A, Drum Heater ( x 2 )

2A082010

36708040

CH/CL CH/CL CH/CL CH/CL CH/CL

Ch/Re Ch/Re Ch/Re Ch/Re Ch/Re Dry cloth

Alcohol and dry cloth

Dry cloth

Scanner rail grease

84032165

(P/N 60170000)

CH:Check the scrach on

the Dru.m

Clen wi th Bemkot

3 Rear Pin, Drum Flange (x 2 )

4 Parts Sensor Surface Potenti a (SP)

5 Main Charger Ass’y

6 * Wire, Main Charger

7 . Lamp, Cleaning Lamp

8. Grid Ass’y

9 . Rear Charger Housing Ass’y

10 Rear Drum Electrode Wire Ass’y

11 Front Drum Electrode Wire Ass’y

12 MC Cleaning Pad Ass’y (x 2)

13 Grid Cleaning Pad Ass’y

14 Upper Front Gui de, Transfer

36708190

34093331

2A000070

36908040

2A068170

2A068180

36701012

36701021

2A068220

36768080

36716550

Ch/Re Ch/Re Ch/Re Ch/Re Ch/Re

CL CL CL CL CL

CL CL CL CL CL

RE RE RE RE RE

CL CL CL CL CL

CL CL CL CL CL

CL CL CL CL CL

CL Ch/Re Ch/Re Ch/Re Ch/Re

CL Ch/Re Ch/Re Ch/Re Ch/Re

RE RE

RE RE

CL CL CL CL CL

H DEVELOPING SECTION

1 Developing Ass’y

2 Developing Blade Ass’y

3 Lower S haft, Develo p ing

4 Upper Seal, Developing

5 Filter, Developing

Toner Cartridge Section of

6

Toner Hopper

2A000211

2A000220

36714280

2A014360

2A014460

CL CL CL CL CL

RE RE

CL CL Ch/Re Ch/Re Ch/Re

CL RE CL RE CL

CL RE CL RE CL Vacuum

CL CL CL CL CL

7 Seals CL CL CL CL CL

Air blow (Do not

vacuum)

Clean the base with wet

cloth (with water) and

with dry cloth

Alcohol or dry cloth

Vacuum or dry cloth

Preliminary Version August 2000 18 © Technical Department

Kyocera Mita Europe B.V.

Page 19

Product Technical Information KM-6230

KM-6230 COPY Q’TY (X 1,000 COPIES) Page 3 o f 3

DESCRIPTION Part No.

On

Delivery

U/C 300K 600K 900K 1200K 1500K REMARKS

I CL E ANIN G S EC T ION

1 Cleaning Ass’y

2 Parts, Blade CLEANING ( SP)

3 Separation Claw Ass’y

4 Brush, Cleaning

5 Parts, Upper Cover Cleaning (SP)

6 Terminal, Cleaning Brush

7 Lower Blade Ass’y

8 Disposal Tank Ass’y ( x 2)

9 Seals

2A000661

36793312

2A000670

2A018050

36793341

36718110

2A068210

36700520

CL CL CL CL CL

RE RE RE RE RE

CH/Re CH/Re CH/Re CH/Re CH/Re

RE RE RE RE RE

CL RE CL RE CL Vacuum or dry cloth

RE RE RE RE RE

CL RE CL RE CL

RE RE RE RE RE

CL CL CL CL CL

J F IXIN G S E CT ION

1 Ro lle r He a t

2 Roller, P re s s ure

3 Felt, Cleaning

2A020010

2A020020

2A020330

CL RE CL RE CL

CL RE CL RE CL

RE RE RE RE RE

Dry cloth

CL: Cleaning oil

(SH200CV

50CC)(PN75770000)

4 Lower Roller, cleaning

5 Ther m is t or, F ixing

6 Separation Claw B ( x 7 )

7 Cla w, Pre s s Roller ( x 4)

8 Guides

2A020340

18520201

61720750

36720493

RE RE RE RE RE

CH/CL CH/CL CH/CL CH/CL CH/CL

CH/Re CH/Re CH/Re CH/Re CH/Re

CH/Re CH/Re CH/Re CH/Re CH/Re

CL CL CL CL CL

9 Rollers CL CL CL CL CL

K EJECT SECTION

1 Guides

2 Rollers

CL CL CL CL CL

CL CL CL CL CL

L SWITCAB LE FEEDER & DUPLEX SECTION

1 Guides CL CL CL CL CL

2 Rollers CL CL CL CL CL

Alcohol or dry cloth

Preliminary Version August 2000 19 © Technical Department

Kyocera Mita Europe B.V.

Page 20

Product Technical Information KM-6230

DF FOR KM-6230 COPY Q’TY (X 1,000 COPIES) Pag e 1 of 1

DESCRIPTION Part No.

On

Delivery

U/C 100K 200K 300K 400K 500K REMARKS

A SETUP

1 Copy quality Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad

B COVER

1 Contact Glass, ADF 35911450

2 Cover

CH/CL CH/CL CL CL CL CL

CL CL CL CL CL CL

C ORIGIN AL F E ED S EC T ION

1 Pulley, Leading Feed

Pulley, Separation (x2)

2

3 Roller, Registration

4 Front Pulley, Reading (x2)

5 Pulley, Registration (x3)

6 Switch L, Feed

3BC07010

3BC07020

3BC08050

3AL08480

3BC08100

63227150

CL RE RE RE RE RE

CL RE RE RE RE RE

CL CL CL CL CL

CL CL CL CL CL

CH/CL CH/CL CH/CL CH/CL CH/CL

CH/CL CL CL CL CL CL

Alcohol or dry cloth

Alcohol

Cle a n wi t h A lc o hol when

visi ting the use r.

Dry cloth or alcohol

CH:Clean if it is dirty

when checkin (CL:Dry

cloth or alcohol)

Airbrush or dry cloth

D ORIGINAL CON V EYING SE C T ION

1 Lower Roller, Conveying

2 Upper Roller, Conveying (x2)

3 Upper Pulley, Conveying (x2)

4 Guide, Conveying

5 Cover, Conveying Pulley

6 Inner Ro lle r, C o nveyi ng

7 Inner Pulley, Conveyi ng (x2)

8 Pulley, Eject (X2)

3AL08112

3AL08161

3AL08140

3AL08033

3AL08302

3BC08150

3AL08100

3AL08170

CL CL CL CL CL

CL CL CL CL CL

CH/CL CH/CL CH/CL CH/CL CH/CL

CL CL CL CL CL Dry cloth or alcohol

CL CL CL CL CL

CH/CL CH/CL CH/CL CH/CL CH/CL

E ORIGIN AL REVERSING SECTION

1 Roller, Loop

2 Pulley, Eject (x2)

3 Roller, E je c t

3AL10020

3AL08170

3AL08130

CL CL CL CL CL

CH/CL CH/CL CH/CL CH/CL CH/CL

F TABLE SECTION

Dry cloth or alcohol

CH:Clean if it is dirty when

checking. (CL:Dry cloth or

alcohol

Clean the opposite side of

ti m ing s ens er.

CL

CL

Remove four items of

front/back/right cover and

mo un t , c onveying p ul l ey.

CL:Alcohol

Dry cloth or alcohol

CL Dry cloth or alcohol

1 Filter CF Sensor

78706241

CH/CL CL CL CL CL CL

CL: Alcohol

GOTHERS

1 Mat, Original Holder

3AL04060

CL CL CL CL CL

Dry cloth or alcohol

2 Sheet, Original Holder

Sponge, Original Size

3

Indicator

3AL08401

35912531

CH/CL CL CL CL CL CL

CL CL CL CL CL

It is eqipped with the main

body

Preliminary Version August 2000 20 © Technical Department

Kyocera Mita Europe B.V.

Page 21

ST----1 1 COPY Q’TY (X 1,000 COPIES) Page 1 of 1

Parts N a me Part N o .

On

Delivery

U/C 300K 600K 900K 1200K 1500K REMARKS

A COVER

Product Technical Information KM-6230

1 Cover

CH CL CL CL CL CL

B PF SECTION

1 Belt, Paper Feed ( x 4 )

2A007010

CL CL CL CL CL Alcohol or dry cloth

2 Guides CL CL CL CL CL

3 Rollers CL CL CL CL CL

4Clutches CH/Re CH CH CH CH CH

Alcohol or dry cloth

CH: Check the reading edge

timing, paper feed condition

and etc.

Preliminary Version August 2000 21 © Technical Department

Kyocera Mita Europe B.V.

Page 22

Product Technical Information KM-6230

F-4330 C OPY Q’TY (X 1,000 COPIES) Page 1 of 1

DESCR IPTION Part No. 0 U/C 300K 600K 900K 1200K RE MARKS

A SETUP

1 Copy quality Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch/Ad Ch punch positions

B EJECT SECTION

1 Rear stack sensor PCB

3AK28020

CL CL CL CL CL

Air brush

2 Front stack sensor PCB

3AK28030

CL CL CL CL CL

3 Cover CL CL CL CL CL Alcohol or dry cloth

C EJECT SECTION

1 Switch, feed 63227020

Punch a ss ’y (metric)

2

(For Me tri c)

Punch As s ’y (INCH)

3

(For INCH)

3BD00051

3BD00061

CL CL CL CL CL

CH/Re Ch/Re Ch/Re

CH/Re Ch/Re Ch/Re

Air brush

Ch the punch count (by S IM). Re at 400K

or more or if there is a problem

D EJECT SECTION

1 Jam detection swi tch 78727110

2 Pulley, Conveying

4 Roller A, Feed Shift (x2)

5 Roller B, Feed Shift (x2)

3AK16030

3BD16071

3BD08030

3BD08040

CL CL CL CL CL

CL CL CL CL

CL CL CL CL

CL CL CL CL

CL CL CL CL

Air brush

Alcohol3 Roller, Feed IN

CL CL CL CL

CL CL CL CL

7 Pulley, Reverse (x4)

3BD08050

73210430

E EJECT SECTION

1 Static eliminator, eject (2)

2 Roller, E je c t Mai n

3 Pulley, Feedback (x4)

4 Roller, Eject SUB

5 Pulley, Loop Feed

63212210

3AK06010

62221110

3AK16010

63210170

CH CH CH Ch/Re

CL CL CL CL

CL CL CL CL

CL CL CL CL

CL CL CL CL

Alcohol6 Pulley, Feed Shift (x12)

Ch / Re if the brushes are worn, broken

or orlled

Alcohol

Alcohol

Preliminary Version August 2000 22 © Technical Department

Kyocera Mita Europe B.V.

Page 23

Product Technical Information KM-6230

APPENDIX 3 MAINTENANCE KITS KM-6230

KM-6230 Maintenance kit 300 K (5832A030)

Description P art No. Quantity Section

Parts, blade cleaning (SP) 36793312 1 C

Brush, cleaning 2A018050 1 C

Terminal, cleaning brush 36718110 1 C

Felt, cleaning 2A020330 1 F

Lower roller , cleaning 2A020340 1 F

KM-6230 Maintenance kit 600 K (5832A060)

Description P art No. Quantity Section

P arts, belt transf er (SP) 36793281 1 PF

Roller , tr ansfer 2A016020 1 PF

Brush, belt cleaning 2A016040 1 PF

Parts front shield, cleaning (SP) 36793670 1 PF

MC Cleaning pad ass’y 2A068220 2 I

Grid cleaning pad ass’y 36768080 1 I

Developing blade ass’y 2A000220 1 D

Upper seal, developing 2A014360 1 D

Filter, de v eloping 2A014460 1 D

P arts, upper cov er cleaning (SP) 36793341 1 C

Lower blade ass’y 2A068210 1 C

Roller, heat 2A020010 1 F

Roller , pressure 2A020020 1 F

Preliminary Version August 2000 23 © Technical Department

Kyocera Mita Europe B.V.

Loading...

Loading...