Page 1

JACKET(KM4230/5230) 1/1/32, 0:071

SERVICE

MANUAL

Published in Feb. ’00

842A3110

Page 2

Service

Service

Manual

Manual

LABEL(KM4230/5230) 1/1/32, 0:171

KM-4230/5230 (MCE) S/M

Page 3

Safety precautions

This booklet provides safety warnings and precautions for our service

personnel to ensure the safety of their customers, their machines as well

as themselves during maintenance activities. Service personnel are

advised to read this booklet carefully to familiarize themselves with the

warnings and precautions described here before engaging in

maintenance activities.

Safety precautions (MCE) 1/1/32, 0:181

Page 4

Safety warnings and precautions

Various symbols are used to protect our service personnel and

customers from physical danger and to prevent damage to their

property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from

insufficient attention to or incorrect compliance with warning

messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient

attention to or incorrect compliance with warning messages

using this symbol.

CAUTION: Bodily injury or damage to property may result from

insufficient attention to or incorrect compliance with warning

messages using this symbol.

Symbols

The triangle (

and caution. The specific point of attention is shown inside

the symbol.

) symbol indicates a warning including danger

General warning.

indicates a prohibited action. The specific prohibition is

shown inside the symbol.

Safety precautions (MCE) 1/1/32, 0:182

Warning of risk of electric shock.

Warning of high temperature.

General prohibited action.

Disassembly prohibited.

Page 5

indicates that action is required. The specific action

required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified.

Avoid multiple connections to one outlet: they may cause fire or electric

shock. When using an extension cable, always check that it is

adequate for the rated current. ...............................................................

• Connect the ground wire to a suitable grounding point. Not grounding

the copier may cause fire or electric shock. Connecting the earth wire

to an object not approved for the purpose may cause explosion or

electric shock. Never connect the ground cable to any of the following:

gas pipes, lightning rods, ground cables for telephone lines and water

pipes or faucets not approved by the proper authorities.........................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may

tip over, causing injury. ...........................................................................

• Do not install the copier in a humid or dusty place. This may cause fire

or electric shock......................................................................................

• Do not install the copier near a radiator, heater, other heat source or

near flammable material. This may cause fire. .......................................

• Allow sufficient space around the copier to allow the ventilation grills to

keep the machine as cool as possible. Insufficient ventilation may

cause heat buildup and poor copying performance................................

Safety precautions (MCE) 1/1/32, 0:183

Page 6

• Always handle the machine by the correct locations when moving it. ....

• Always use anti-toppling and locking devices on copiers so equipped.

Failure to do this may cause the copier to move unexpectedly or

topple, leading to injury...........................................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner

or developer is accidentally ingested, drink a lot of water to dilute it in

the stomach and obtain medical attention immediately. If it gets into the

eyes, rinse immediately with copious amounts of water and obtain

medical attention.....................................................................................

• Advice customers that they must always follow the safety warnings and

precautions in the copier’s instruction handbook....................................

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting

machine disassembly. ............................................................................

• Always follow the procedures for maintenance described in the service

manual and other related brochures.......................................................

• Under no circumstances attempt to bypass or disable safety features

including safety mechanisms and protective circuits. .............................

• Always use parts having the correct specifications. ...............................

• Always use the thermostat or thermal fuse specified in the service

manual or other related brochure when replacing them. Using a piece

of wire, for example, could lead to fire or other serious accident............

• When the service manual or other serious brochure specifies a

distance or gap for installation of a part, always use the correct scale

and measure carefully. ...........................................................................

• Always check that the copier is correctly connected to an outlet with a

ground connection. .................................................................................

Safety precautions (MCE) 1/1/32, 0:184

Page 7

• Check that the power cable covering is free of damage. Check that the

power plug is dust-free. If it is dirty, clean it to remove the risk of fire or

electric shock. .........................................................................................

• Never attempt to disassemble the optical unit in machines using lasers.

Leaking laser light may damage eyesight...............................................

• Handle the charger sections with care. They are charged to high

potentials and may cause electric shock if handled improperly..............

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as

ties, make sure they are safely secured so they will not be caught in

rotating sections......................................................................................

• Use utmost caution when working on a powered machine. Keep away

from chains and belts..............................................................................

• Handle the fixing section with care to avoid burns as it can be

extremely hot..........................................................................................

• Check that the fixing unit thermistor, heat and press rollers are clean.

Dirt on them can cause abnormally high temperatures. .........................

• Do not remove the ozone filter, if any, from the copier except for

routine replacement. ...............................................................................

• Do not pull on the AC power cord or connector wires on high-voltage

components when removing them; always hold the plug itself...............

• Do not route the power cable where it may be stood on or trapped. If

necessary, protect it with a cable cover or other appropriate item. ........

• Treat the ends of the wire carefully when installing a new charger wire

to avoid electric leaks. ............................................................................

• Remove toner completely from electronic components..........................

• Run wire harnesses carefully so that wires will not be trapped or

damaged.................................................................................................

Safety precautions (MCE) 1/1/32, 0:185

Page 8

• After maintenance, always check that all the parts, screws, connectors

and wires that were removed, have been refitted correctly. Special

attention should be paid to any forgotten connector, trapped wire and

missing screws. ......................................................................................

• Check that all the caution labels that should be present on the machine

according to the instruction handbook are clean and not peeling.

Replace with new ones if necessary.......................................................

• Handle greases and solvents with care by following the instructions

below: .....................................................................................................

· Use only a small amount of solvent at a time, being careful not to

spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the

covers or turning the main switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause

sparks when exposed directly to fire in a furnace, etc..........................

• Should smoke be seen coming from the copier, remove the power

plug from the wall outlet immediately. ..................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents

such as alcohol, other than the specified refiner; it may generate toxic

gas. .........................................................................................................

Safety precautions (MCE) 1/1/32, 0:186

Page 9

CONTENTS

I THEORY AND CONSTRUCTION SECTION

1-1 Specifications

1-1-1 Specifications ................................................................................ 1-1-1

1-2 Handling Precautions

1-2-1 Drum ............................................................................................. 1-2-1

1-2-2 Developer and toner...................................................................... 1-2-1

1-3 Mechanical Construction

1-3-1 Parts names and their functions.................................................... 1-3-1

1-3-2 Machine cross section................................................................... 1-3-4

1-3-3 Drive system ................................................................................. 1-3-5

1-3-4 Mechanical construction................................................................ 1-3-8

II ELECTRICAL SECTION

2-1 Electrical Parts Layout

2-1-1 Electrical parts layout .................................................................... 2-1-1

2-2 Detection of Paper Misfeed

2-2-1 Paper misfeed detection ............................................................... 2-2-1

2-2-2 Paper misfeed detection conditions .............................................. 2-2-2

2-2-3 Original misfeed detection........................................................... 2-2-14

2-2-4 Original misfeed detection conditions ......................................... 2-2-15

2-3 Operation of the PCBs

2-3-1 Power source PCB ........................................................................ 2-3-1

2-3-2 Engine PCB................................................................................... 2-3-3

2-3-3 Main PCB ...................................................................................... 2-3-4

2-3-4 Memory copy PCB ........................................................................ 2-3-6

2-3-5 Scanner motor PCB ...................................................................... 2-3-8

2-3-6 CCD PCB ...................................................................................... 2-3-9

2-3-7 DF driver PCB ............................................................................. 2-3-11

2-3-8 Operation unit main PCB,operation unit right PCB,and

operation unit left PCB ................................................................ 2-3-12

2-3-9 Deck main PCB (42 ppm: optional/52 ppm: standard) ................ 2-3-16

2A3/4

III SET UP AND ADJUSTMENT SECTION

3-1 Installation

3-1-1 Unpacking and installation ............................................................ 3-1-1

3-1-2 Setting initial copy modes ........................................................... 3-1-29

3-1-3 Installing the memory copy kit

(42 ppm: optional/52 ppm: standard) .......................................... 3-1-30

3-1-4 Installing the image memory SIMM (option)................................ 3-1-33

3-1-5 Installing the optical heater (service part) ................................... 3-1-35

3-1-6 Installing the drawer heater (service part) ................................... 3-1-38

3-1-7 Installing the key counter (option) ............................................... 3-1-41

3-1-8 Installing the dehumidfier heaters (service part) ......................... 3-1-44

3-1-9 Installing the MMD host monitorig system device

(optional for 120 V specifications only) ....................................... 3-1-47

CONTENTS (2A3/4/E) 1/1/32, 0:091

1-1-1

Page 10

2A3/4

3-2 Maintenance Mode

3-2-1 Maintenance mode........................................................................ 3-2-1

3-2-2 Copier management.................................................................... 3-2-99

3-3 Assembly and Disassembly

3-3-1 Precautions for assembly and disassembly .................................. 3-3-1

3-3-2 Paper feed section ........................................................................ 3-3-3

3-3-3 Optical section............................................................................. 3-3-23

3-3-4 Main charging section ................................................................. 3-3-42

3-3-5 Drum section ............................................................................... 3-3-45

3-3-6 Developing section ...................................................................... 3-3-51

3-3-7 Transfer and separation section.................................................. 3-3-56

3-3-8 Cleaning section.......................................................................... 3-3-59

3-3-9 Fixing section .............................................................................. 3-3-64

3-3-10 Feedshift and duplex section ...................................................... 3-3-80

3-3-11 SRDF section .............................................................................. 3-3-89

3-3-12 Large paper deck section

(42 ppm: optional/52 ppm: standard) ........................................ 3-3-102

3-4 PCB Initial Settings

3-4-1 Replacing the main PCB ............................................................... 3-4-1

3-4-2 Replacing the main PCB ROMs .................................................... 3-4-2

3-4-3 Adjustment-free variable resisters (VR) ........................................ 3-4-3

3-5 Self-Diagnosis

3-5-1 Self-diagnosis................................................................................ 3-5-1

3-6 Troubleshooting

3-6-1 Image formation problems ............................................................ 3-6-1

3-6-2 Paper misfeeds ........................................................................... 3-6-18

3-6-3 PCB terminal voltages................................................................. 3-6-33

3-6-4 Electrical problems ...................................................................... 3-6-73

3-6-5 Mechanical problems .................................................................. 3-6-97

3-7 Appendixes

Timing chart No. 1 .................................................................................... 3-7-1

Timing chart No. 2 .................................................................................... 3-7-2

Timing chart No. 3 .................................................................................... 3-7-3

Timing chart No. 4 .................................................................................... 3-7-4

Timing chart No. 5 .................................................................................... 3-7-5

Timing chart No. 6 .................................................................................... 3-7-6

Timing chart No. 7 .................................................................................... 3-7-7

Timing chart No. 8 .................................................................................... 3-7-8

Timing chart No. 9 .................................................................................... 3-7-9

Timing chart No. 10 ................................................................................ 3-7-10

Timing chart No. 11 ................................................................................ 3-7-11

Timing chart No. 12 ................................................................................ 3-7-12

Power source PCB 1/2 ........................................................................... 3-7-13

Power source PCB 2/2 ........................................................................... 3-7-14

Engine PCB 1/2 ...................................................................................... 3-7-15

Engine PCB 2/2 ...................................................................................... 3-7-16

Main PCB 1/9.......................................................................................... 3-7-17

Main PCB 2/9.......................................................................................... 3-7-18

Main PCB 3/9.......................................................................................... 3-7-19

Main PCB 4/9.......................................................................................... 3-7-20

1-1-2

CONTENTS (2A3/4/E) 1/1/32, 0:092

Page 11

2A3/4

Main PCB 5/9.......................................................................................... 3-7-21

Main PCB 6/9.......................................................................................... 3-7-22

Main PCB 7/9.......................................................................................... 3-7-23

Main PCB 8/9.......................................................................................... 3-7-24

Main PCB 9/9.......................................................................................... 3-7-25

Memory copy PCB 1/12.......................................................................... 3-7-26

Memory copy PCB 2/12.......................................................................... 3-7-27

Memory copy PCB 3/12.......................................................................... 3-7-28

Memory copy PCB 4/12.......................................................................... 3-7-29

Memory copy PCB 5/12.......................................................................... 3-7-30

Memory copy PCB 6/12.......................................................................... 3-7-31

Memory copy PCB 7/12.......................................................................... 3-7-32

Memory copy PCB 8/12.......................................................................... 3-7-33

Memory copy PCB 9/12.......................................................................... 3-7-34

Memory copy PCB 10/12........................................................................ 3-7-35

Memory copy PCB 11/12........................................................................ 3-7-36

Memory copy PCB 12/12........................................................................ 3-7-37

Scanner motor PCB................................................................................ 3-7-38

CCD PCB................................................................................................ 3-7-39

DF driver PCB......................................................................................... 3-7-40

Operation unit main PCB 1/2 .................................................................. 3-7-41

Operation unit main PCB 2/2 .................................................................. 3-7-42

Operation unit right PCB......................................................................... 3-7-43

Operation unit left PCB ........................................................................... 3-7-44

Deck main PCB ...................................................................................... 3-7-45

Interface PCB ......................................................................................... 3-7-46

SRDF connection diagram...................................................................... 3-7-47

General connection diagram (42 ppm copier) ........................................ 3-7-48

General connection diagram (52 ppm copier) ........................................ 3-7-49

SRDF wiring diagram.............................................................................. 3-7-50

Large paper deck wiring diagram ........................................................... 3-7-51

CONTENTS (2A3/4/E) 1/1/32, 0:093

1-1-3

Page 12

I

THEOR Y AND

CONSTRUCTION

SECTION

I Theory and

Construction Section

JACKET(KM4230/5230) 1/1/32, 0:072

Page 13

CONTENTS

1-1 Specifications

1-1-1 Specifications ...................................................................................... 1-1-1

2A3/4

CONTENTS (2A3/4/E) 1/1/32, 0:095

1-1-5

Page 14

2A3/4

1-1-1 Specifications

Copier (42 ppm copier)

Type …………………………… Desktop

Copying system ……………… Dry, indirect electrostatic system

Originals ………………………Sheets and books

Original feed system ………… Fixed

Copy paper ……………………Drawer and duplex unit: Plain paper (64 – 80 g/m2)

Copying sizes ………………… Maximum: A3/11" × 17"

Magnification ratios …………… Manual mode: 25 – 400%, 1% increments

Copy speed ……………………At 100% magnification in memory copy mode:

First copy time ………………… 4.5 s or less (A4/11" × 81/2", 100% magnification,

Warm-up time …………………120 s or less (room temperature 20˚C/68˚F, 65%RH)

Paper feed system ……………Automatic feed

Photoconductor ………………OPC (drum diameter 60 mm)

Charging system ……………… Single positive corona charging, 670 – 730 µA

Exposure light source ………… Semiconductor laser

Exposure scanning system … Polygon mirror

Maximum size: A3/11" × 17"

Bypass table: Plain paper (60 – 160 g/m2)

Special paper: Transparencies, tracing paper, colored

paper, letterhead and envelopes (only when used as a

printer)

Note: Use the bypass table for special paper.

Minimum: A6R/51/2" × 81/2"

During duplex copying

Maximum: A3/11" × 17"

Minimum: A5R/51/2" × 81/2"

Auto copy mode: Fixed ratios

Metric

1:1 ± 0.1%, 1:4.00/1:2.00/1:1.41/1:1.06/1:0.75/

1:0.70/1:0.50/1:0.25

Inch

1:1 ± 0.1%, 1:4.00/1:2.00/1:1.29/1:1.21/1:0.78/

1:0.64/1:0.50/1:0.25

A4/11" × 81/2": 42 copies/min.

A4R/81/2" × 11": 32 copies/min.

A3/11" × 17": 24 copies/min.

B5 : 42 copies/min.

B5R : 36 copies/min.

B4 (257 × 364)/81/2" × 14": 28 copies/min.

When the SRDF is used (at 100% magnification):

A4/11" × 81/2": 42 copies/min.

upper drawer, manual copy density control)

Capacity:

Drawers: 550 sheets

Manual feed

Capacity:

Bypass: 100 sheets

1-1 (2A3/4/E) 1/1/32, 2:451

1-1-1

4230/5230 (MCA) S/M

KM4230/5230 (MCE) S/M

Page 15

2A3/4

Developing system …………… Dry, reverse developing (magnetic brush)

Developer: 2-component, ferrite carrier and N29T black

toner

Toner density control: toner sensor

Toner replenishing: automatic from a toner cartridge

Transfer system ………………Single negative corona charging, –210 µA

Separation system ……………Single AC corona charging

Fixing system ………………… Heat roller

Heat source: halogen heaters (main 850 W, sub 850 W)

Control temperature: 180˚C/356˚F (at normal ambient

temperature)

Abnormally high temperature protection devices:

140˚C/284˚F thermostat

Fixing pressure: 210 N

Charge erasing system ………Exposure by cleaning lamp

Cleaning system ………………Cleaning blade

Scanning system ……………… Flat bed scanning by CCD image sensor

Bit map memory ………………12 MB (standard)

Image storage memory ………32 MB (standard)

Resolution ………………………600 × 600 dpi

Light source …………………… Inert gas lamp (12 W)

Dimensions …………………… 627 (W) × 748 (D) × 841 (H) mm

2411/16" (W) × 297/16" (D) × 331/8" (H)

Weight ………………………… 129 kg/283.8 lbs

Floor requirements ……………1287 mm (W) × 748 (D)mm

505/16" (W) × 297/16" (D)

Functions ……………………… (1) Self-diagnostics

(2) Preheat

(3) Automatic copy density control

(4) Original size detection

(5) Automatic paper selection

(6) Automatic magnification selection

(7) Enlargement/reduction copy

(8) Fixed ratio selection

(9) Size zoom mode

(10) XY zoom mode

(11) Photo mode

(12) Duplex copy

(13) Margin copy

(14) Print page numbers function

(15) Split copy

(16) Border erasing

(17) Sheet copy

(18) Transparency backing sheet function

(19) Form overlay

(20) Combine copy

(21) Booklet + cover copy

(22) Sort copy

(23) Invert copy

(24) Mirror image mode

1-1-2

1-1 (2A3/4/E) 1/1/32, 2:452

4230/5230 (MCA) S/M

KM4230/5230 (MCE) S/M

Page 16

2A3/4

(25) Program copy

(26) Setting change mode

(27) Job build mode

(28) Department control

(29) Weekly timer

(30) Language selection

Power source ………………… 120 V AC, 60 Hz, 10.5 A

220 – 240 V AC, 50 or 60 Hz, 4.9 A

Power consumption …………… 1300 W (for 120 V specifications)

1200 W (for 220-240 V specifications)

Options ………………………… Paper feed desk, large paper deck, finisher, key counter,

key card*, printer unit, memory copy board, additional

memory (16 MB/32 MB), booklet stitcher, MMD host

monitoring system device* and copy tray*.

* for 120 V specifications only

1-1 (2A3/4/E) 1/1/32, 2:453

1-1-3

4230/5230 (MCA) S/M

KM4230/5230 (MCE) S/M

Page 17

2A3/4

Copier (52 ppm copier)

Type …………………………… Console

Copying system ……………… Dry, indirect electrostatic system

Originals ……………………… Sheets and books

Maximum size: A3/11" × 17"

Original feed system ………… Fixed

Copy paper ……………………Drawer and duplex unit: Plain paper (64 – 80 g/m2)

Bypass table: Plain paper (60 – 160 g/m2)

Special paper: Transparencies, tracing paper, colored

paper, letterhead and envelopes (only when used as a

printer)

Note: Use the bypass table for special paper.

Copying sizes ………………… Maximum: A3/11" × 17"

Minimum: A6R/51/2" × 81/2"

During duplex copying

Maximum: A3/11" × 17"

Minimum: A5R/51/2" × 81/2"

Magnification ratios …………… Manual mode: 25 – 400%, 1% increments

Auto copy mode: Fixed ratios

Metric

1:1 ± 0.1%, 1:4.00/1:2.00/1:1.41/1:1.06/1:0.75/

1:0.70/1:0.50/1:0.25

Inch

1:1 ± 0.1%, 1:4.00/1:2.00/1:1.29/1:1.21/1:0.78/

1:0.64/1:0.50/1:0.25

Copy speed …………………… At 100% magnification in memory copy mode:

A4/11" × 81/2": 52 copies/min.

A4R/81/2" × 11": 35 copies/min.

A3/11" × 17": 26 copies/min.

B5 : 52 copies/min.

B5R : 42 copies/min.

B4 (257 × 364)/81/2" × 14": 31 copies/min.

When the SRDF is used (at 100% magnification):

A4/11" × 81/2": 42 copies/min.

First copy time ………………… 4.5 s or less (A4/11" × 81/2", 100% magnification,

upper drawer, manual copy density control)

Warm-up time …………………180 s or less (room temperature 20˚C/68˚F, 65%RH)

Paper feed system …………… Automatic feed

Capacity:

Drawers: 550 sheets

Manual feed

Capacity:

Bypass: 100 sheets

Photoconductor ………………OPC (drum diameter 60 mm)

Charging system ………………Single positive corona charging, 670 – 730 µA

Exposure light source ………… Semiconductor laser

Exposure scanning system … Polygon mirror

Developing system …………… Dry, reverse developing (magnetic brush)

Developer: 2-component, ferrite carrier and N29T black

toner

1-1-4

1-1 (2A3/4/E) 1/1/32, 2:454

4230/5230 (MCA) S/M

KM4230/5230 (MCE) S/M

Page 18

Toner density control: toner sensor

Toner replenishing: automatic from a toner cartridge

Transfer system ………………Single negative corona charging, –210 µA

Separation system ……………Single AC corona charging

Fixing system ………………… Heat roller

Heat source: halogen heaters (main 850 W, sub 850W)

Control temperature: 190˚C/374˚F (at normal ambient

temperature)

Abnormally high temperature protection devices:

140˚C/284˚F thermostat

Fixing pressure: 210 N

Charge erasing system ………Exposure by cleaning lamp

Cleaning system ………………Cleaning blade

Scanning system ……………… Flat bed scanning by CCD image sensor

Bit map memory ………………12 MB (standard)

Image storage memory ………32 MB (standard)

Resolution ………………………600 × 600 dpi

Light source …………………… Inert gas lamp (12 W)

Dimensions …………………… 627 (W) × 748 (D) × 1131 (H) mm

2411/16" (W) × 297/16" (D) × 449/16" (H)

Weight ………………………… 160 kg/352 lbs

Floor requirements ……………1287 mm (W) × 748 (D)mm

505/16" (W) × 297/16" (D)

Functions ……………………… (1) Self-diagnostics

(2) Preheat

(3) Automatic copy density control

(4) Original size detection

(5) Automatic paper selection

(6) Automatic magnification selection

(7) Enlargement/reduction copy

(8) Fixed ratio selection

(9) Size zoom mode

(10) XY zoom mode

(11) Photo mode

(12) Duplex copy

(13) Margin copy

(14) Print page numbers function

(15) Split copy

(16) Border erasing

(17) Sheet copy

(18) Transparency backing sheet function

(19) Form overlay

(20) Combine copy

(21) Booklet + cover copy

(22) Sort copy

(23) Invert copy

(24) Mirror image mode

(25) Program copy

(26) Setting change mode

(27) Job build mode

2A3/4

1-1 (2A3/4/E) 1/1/32, 2:455

1-1-5

4230/5230 (MCA) S/M

KM4230/5230 (MCE) S/M

Page 19

2A3/4

(28) Department control

(29) Weekly timer

(30) Language selection

Power source ………………… 120 V AC, 60 Hz, 10.5 A

220 – 240 V AC, 50 or 60 Hz, 4.9 A

Power consumption …………… 1200 W (for 120 V specifications)

1300 W (for 220-240 V specifications)

Options ………………………… Finisher, key counter, key card*, printer unit, additional

memory (16 MB/32 MB) , MMD host monitoring system

device* and copy tray*

* for 120 V specifications only

SRDF

Original feed system ………… Automatic feed

Originals ……………………… Sheets

Original weights ……………… Single-sided original mode: 35 – 160 g/m

Double-sided original mode: 50 – 120 g/m

2

2

Original paper …………………Plain paper, thermal paper, art paper, colored paper

Original sizes …………………A3 – A5R, folio/11" × 17" – 81/2" × 51/2"

No. of originals …………………Up to 50 sheets (A3, B4, folio, 11" × 17", 81/2" × 14")

Up to 70 sheets (up to A4/11" × 81/2")

Up to 50 sheets in the auto selection mode

Art or thermal paper must be fed individually.

Power source ………………… Electrically connected to the copier

Large paper deck

Paper ……………………………Plain paper (64 – 80 g/m2)

Paper size ………………………A4/11" × 81/2", B5

Capacity ………………………3000 sheets (1500 sheets × 2)

No. of stacks …………………… 2

Power source ………………… Electrically connected to the copier

1-1-6

1-1 (2A3/4/E) 1/1/32, 2:456

4230/5230 (MCA) S/M

KM4230/5230 (MCE) S/M

Page 20

CONTENTS

1-2 Handling Precautions

1-2-1 Drum ................................................................................................... 1-2-1

1-2-2 Developer and toner ........................................................................... 1-2-1

2A3/4

CONTENTS (2A3/4/E) 1/1/32, 0:097

1-1-7

Page 21

2A3/4

1-2-1 Drum

Note the following when handling or storing the drum.

• When removing the image formation unit, never expose the drum surface to strong direct

light.

• Keep the drum at an ambient temperature between –20°C/–4°F and 40°C/104°F and at

a relative humidity not higher than 85% RH. Avoid abrupt changes in temperature and

humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained

with oil, clean it.

• If the machine is left open for more than 5 minutes for maintenance, remove the drum and

store it in the drum storage bag (Part No. 78369020).

1-2-2 Developer and toner

Store the developer and toner in a cool, dark place. Avoid direct light and high humidity.

1-2 (2A3/4/E) 1/1/32, 2:431

1-2-1

PointSource Vi500 (MCE) S/M

Page 22

CONTENTS

1-3 Mechanical Construction

1-3-1 Parts names and their functions ......................................................... 1-3-1

1-3-2 Machine cross section ........................................................................ 1-3-4

1-3-3 Drive system ....................................................................................... 1-3-5

1-3-4 Mechanical construction ..................................................................... 1-3-8

(1) Paper feed section ...................................................................... 1-3-8

(1-1) Paper feed from the drawers ............................................ 1-3-8

(1-2) Paper feed from the bypass table.................................... 1-3-13

(2) Main charging section ................................................................ 1-3-16

(3) Optical section ............................................................................ 1-3-19

Original scanning........................................................................1-3-20

Image printing............................................................................ 1-3-22

(4) Developing section .................................................................... 1-3-25

Formation of magnetic brush..................................................... 1-3-27

Toner density control................................................................. 1-3-29

Correcting toner feed start level ................................................ 1-3-31

Toner level detection ................................................................. 1-3-34

Toner hopper lockup detection.................................................. 1-3-35

(5) Transfer and separation section ................................................ 1-3-36

Charger wire cleaning ............................................................... 1-3-38

(6) Cleaning section ........................................................................ 1-3-40

(7) Charge erasing section ............................................................. 1-3-41

(8) Fixing section ............................................................................ 1-3-43

Heating the heat roller and detecting temperature .................... 1-3-45

Fixing temperature control......................................................... 1-3-46

Paper separation ....................................................................... 1-3-48

(9) Feedshift and eject section........................................................ 1-3-49

(10) Duplex section ........................................................................... 1-3-51

Duplex copying operation timing ............................................... 1-3-54

(11) SRDF......................................................................................... 1-3-57

(11-1) Original feed section....................................................... 1-3-57

Original feed timing......................................................... 1-3-59

(11-2) Original switchback section ............................................ 1-3-60

Operation of original switchback..................................... 1-3-62

(11-3) Original conveying section.............................................. 1-3-63

Original switchback/conveying timing............................. 1-3-65

(12) Large paper deck (42 ppm: optional/52 ppm: standard) ........... 1-3-67

(12-1) Right cassette primary paper feed.................................. 1-3-69

(12-2) Left cassette primary paper feed .................................... 1-3-72

(12-3) Raising and lowering the lifts.......................................... 1-3-74

(12-4) Detecting the paper level................................................ 1-3-76

2A3/4

CONTENTS (2A3/4/E) 1/1/32, 0:099

1-1-9

Page 23

A A

E E

A

EA

A

E

2A3/4

E

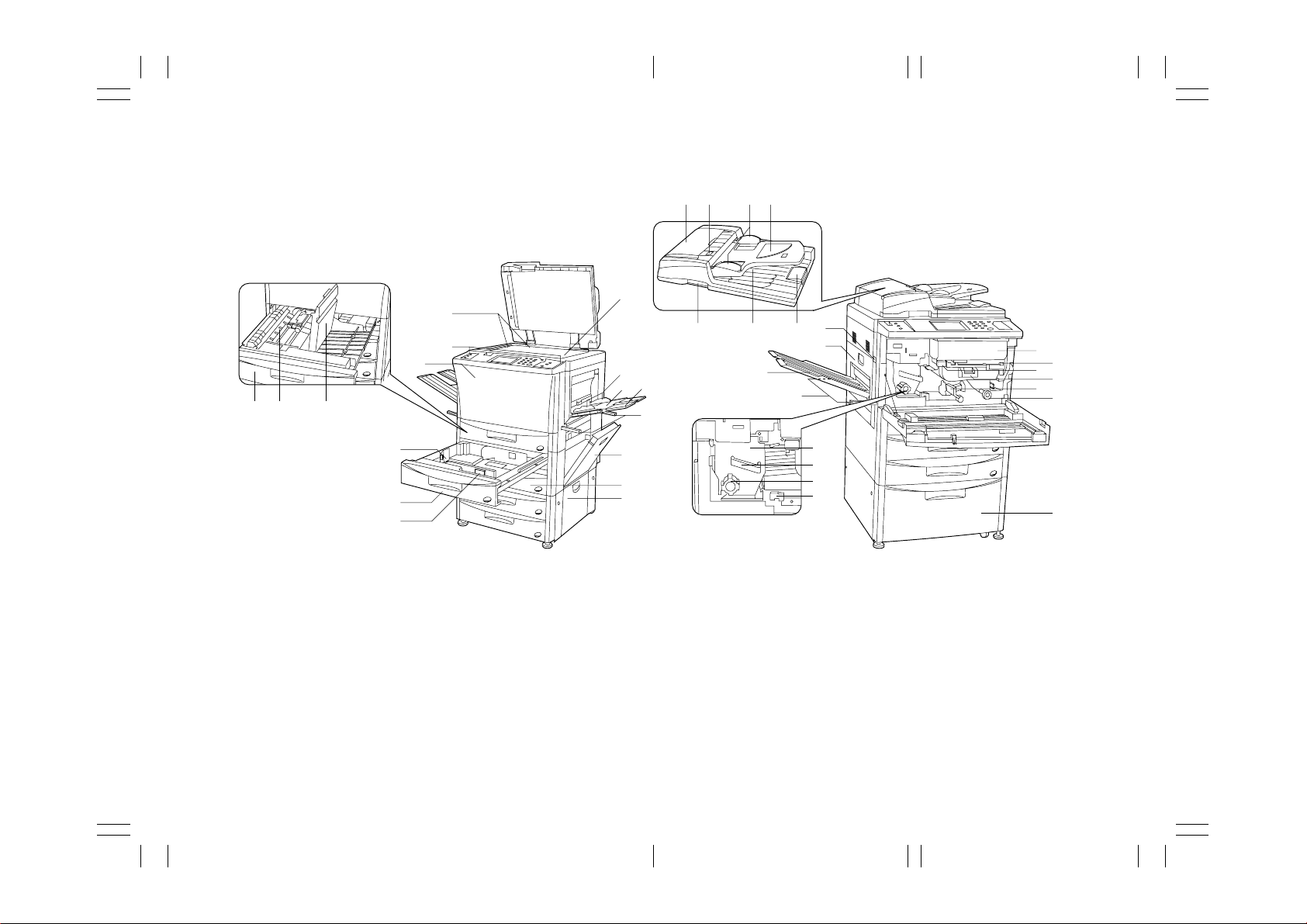

1-3-1 Part names and their functions

• 42 ppm copier

^

&*(

1

2

90 !

#

@

$

7

3

5

8

%

¨

)⁄¤

64

fi

Á

Á

‹

›

„

´

‰

ˇ

fl

°

‚

‡

·

Œ

ˆ

Figure 1-3-1-a

1 Contact platen

2 Original size indictor lines

3 Operation panel

4 Bypass table

5 Insert guide

6 Support guide

7 Front cover

8 Right cover

9 Duplex unit

0 Re-feeding section

! Duplex unit cover

@ Upper drawer

# Length guide tab

$ Width guide tab

% Lower drawer

^ DF original reversing cover

& Original set indicator

* Original insertion guides

( Original table

) DF opening/closing lever

⁄ Original ejection cover

¤ Paper ejection guide

‹ Main switch

› Left cover

fi Copy tray*

fl Toner cartridge

‡ Toner cartridge release lever

° Image formation unit release button

· Image formation unit handle

‚ Paper transfer unit release lever

1

ΠPaper feed section knob

„ Fixing unit

´ Fixing unit handle

‰ Fixing knob

ˇ Fixing unit release lever

Á Handles for transport

¨ Paper feed desk*

ˆ Large paper deck*

*1: Optional for 120 V specifications.

*2: Optional.

2

2

1-3-1

E

A

1-3-1 (2A3/4/E) 1/1/32, 21:011

A A

E E

EA

2AD (MCA)

E

A

Page 24

AA A

EE E

A

A

E

2A3/4

• 52 ppm copier

E

¤⁄)(

Î

6

fl

‡

°

Î

‹›fi

·

‚

Œ

„

´

‰

0

7

1

2

3

5

4

8

ˇ

^

*

9

!

&

@

$

#

Ø

∏

Å

Í

ˆ

Á

¨

%

Figure 1-3-1-b

1 Contact platen

2 Original size indictor lines

3 Operation panel

4 Bypass table

5 Insert guide

6 Support guide

7 Front cover

8 Right cover

9 Upper drawer

0 Length guide tab

! Width guide tab

@ Lower drawer

# Large paper deck

$ Deck side cover

% Drawer

^ Deck front cover

& Lifts

* Paper side guides

( DF original reversing cover

) Original set indicator

⁄ Original insertion guides

¤ Original table

‹ DF opening/closing lever

› Original ejection cover

fi Paper ejection guide

fl Main switch

‡ Left cover

° Copy tray*

· Toner cartridge

‚ Toner cartridge release lever

ΠImage formation unit release button

„ Image formation unit handle

´ Paper transfer unit release lever

‰ Paper feed section knob

ˇ Duplex unit

Á Re-feeding section

¨ Duplex unit cover

ˆ Duplex unit handle

Ø Fixing unit

∏ Fixing unit handle

Å Fixing knob

Í Fixing unit release lever

Î Handles for transport

* Optional for 120 V specifications.

1-3-2

E

A

1-3-1 (2A3/4/E) 1/1/32, 21:012

AA A

EE E

2AD (MCA)

E

A

Page 25

A A

E E

A

EA

A

E

2A3/4

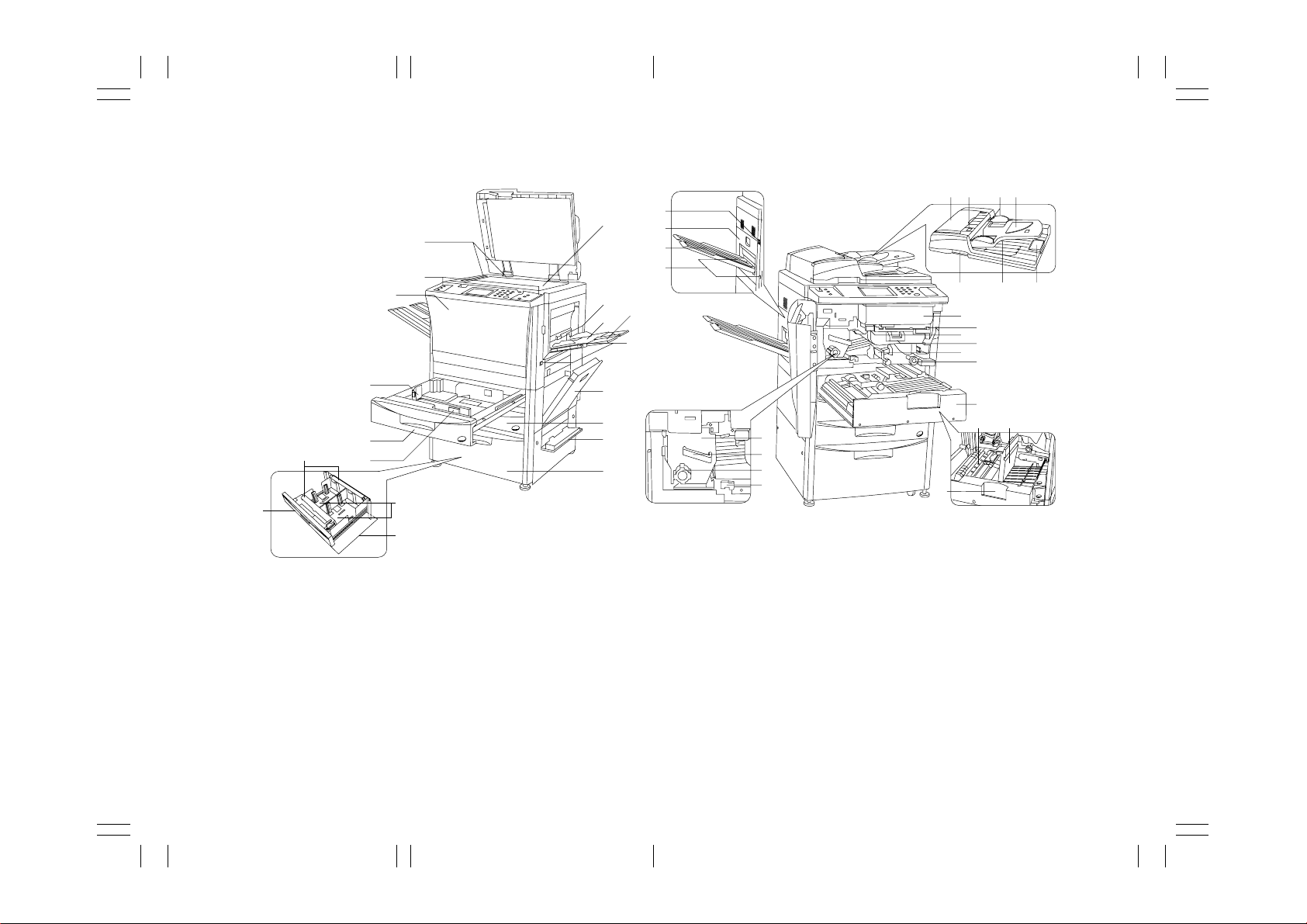

Metric

1 Punch mode key

2 Punch mode indicator

3 Staple sort mode key

4 Staple sort mode indicator

5 Sorter mode key

6 Sort mode indicator

7 Group mode indicator

8 Brightness adjustment control

9 Data indicator

0 Program key

! Manual key

@ Add job key

# Copier/printer switching key

$ Touch panel

% Numeric keys

^ Stop/clear key

& Print key

* Print indicator

( Reset key

Inch

) Auto selection key

⁄ Auto selection indicator

¤ Energy saver key

‹ Energy saver indicator

› Interrupt key

fi Interrupt indicator

E

Figure 1-3-2 Operation panel

1-3-3

E

A

1-3-1 (2A3/4/E) 1/1/32, 21:013

A A

E E

EA

2AD (MCA)

E

A

Page 26

AA A

EE E

A

A

E

2A3/4

E

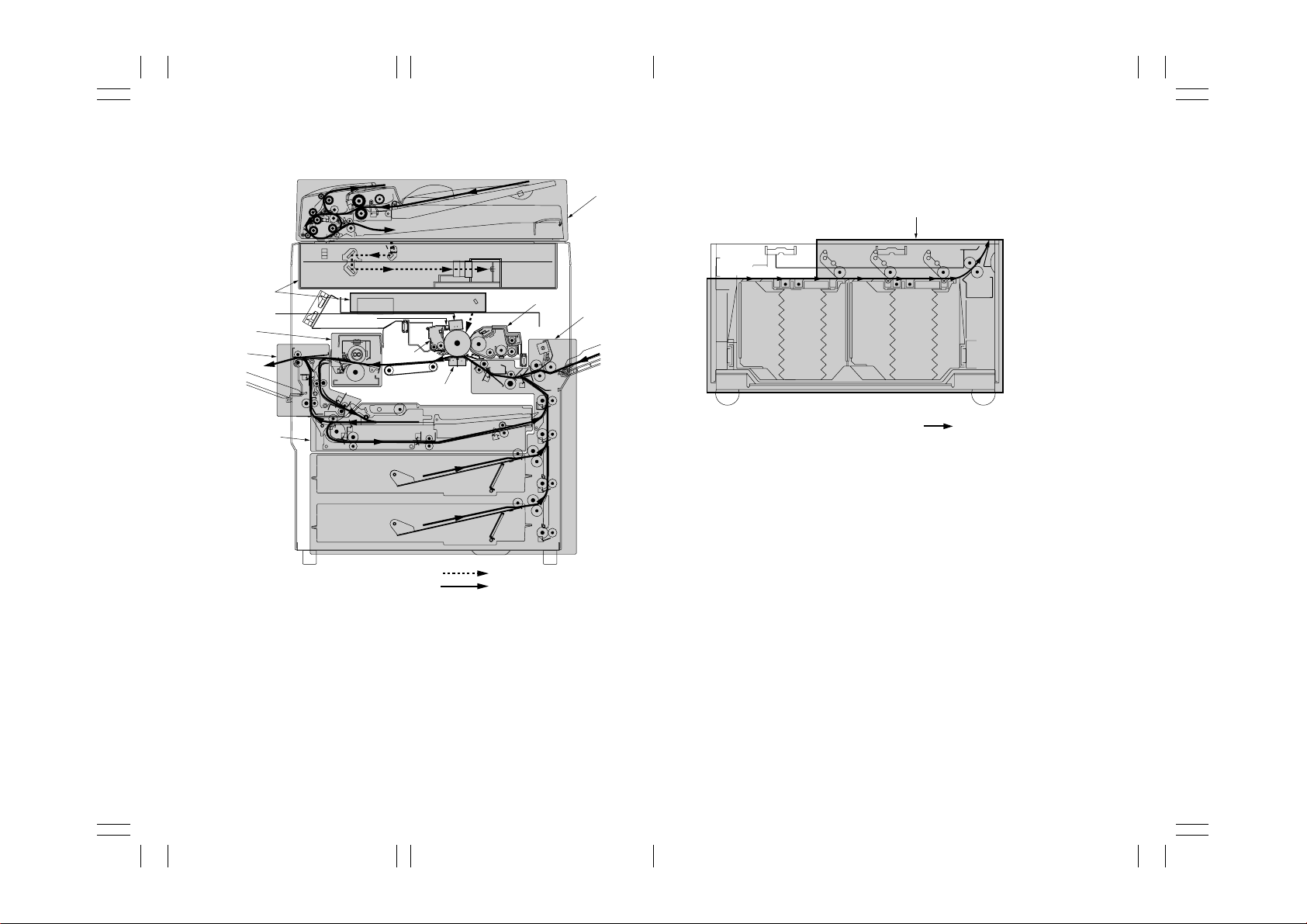

1-3-2 Machine cross section

9

8

3

2

7

!

4

1

6

Large paper deck

(page 1-3-67)

5

0

Figure 1-3-4 Machine cross section—Large paper deck

(42 ppm: optional/52 ppm: standard)

Paper path

Light path

Paper and original path

Figure 1-3-3 Machine cross section—copier and SRDF

1 Paper feed section (page 1-3-8)

2 Main charging section (page 1-3-16)

3 Optical section (page 1-3-19)

4 Developing section (page 1-3-25)

5 Transfer and separation section (page 1-3-36)

6 Cleaning section (page 1-3-40)

7 Charge erasing section (page 1-3-41)

8 Fixing section (page 1-3-43)

9 Feedshift and eject section (page 1-3-49)

0 Duplex section (page 1-3-51)

! SRDF (page 1-3-57)

1-3-4

E

A

1-3-1 (2A3/4/E) 1/1/32, 21:014

AA A

EE E

2AD (MCA)

E

A

Page 27

A A

E E

A

EA

A

E

E

2A3/4

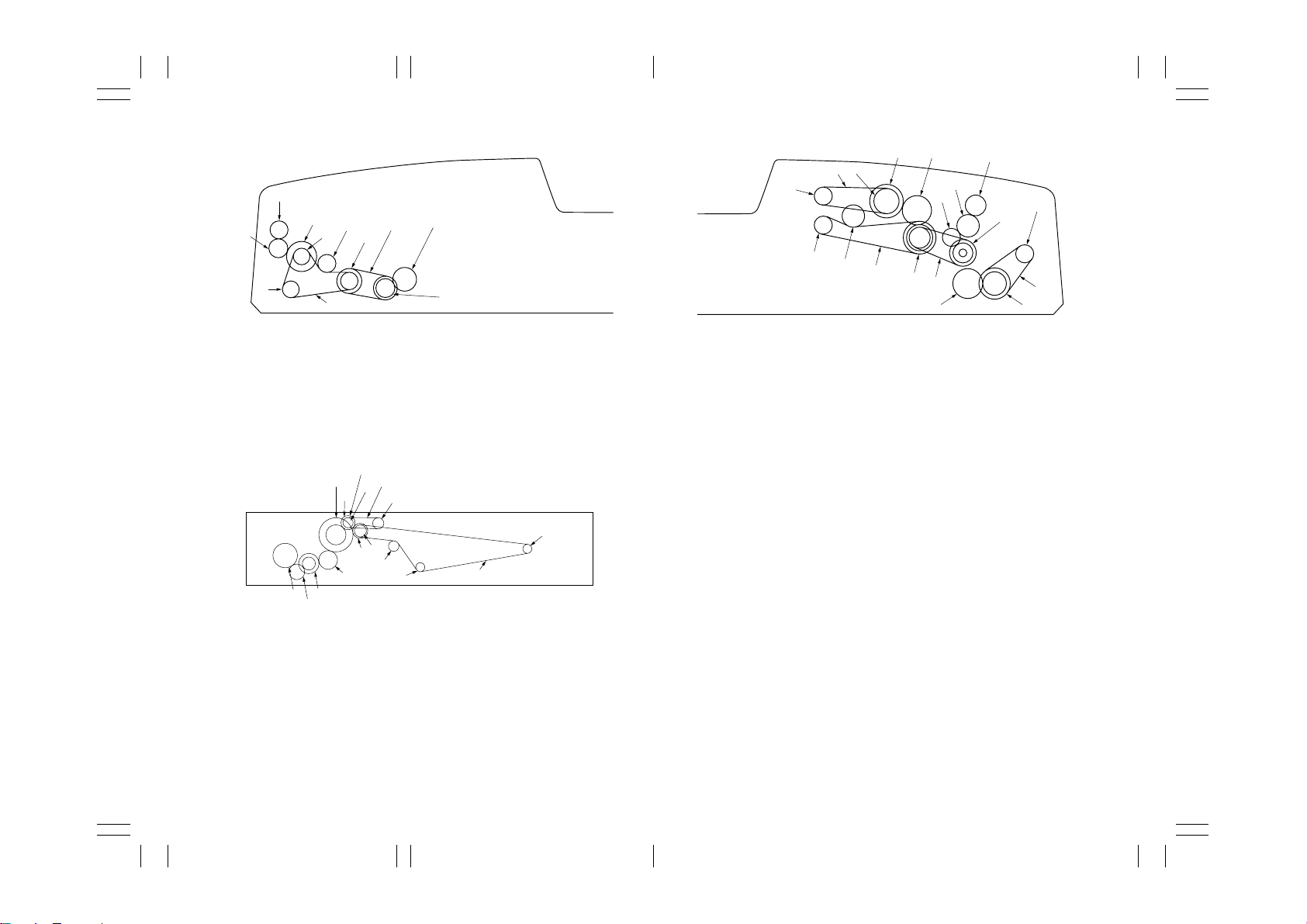

1-3-3 Drive system

7

6

5

3

9

@

0

“

*

‚

·

Î

7

1

8

$

%

^&

ˆ

„

Œ

‰

˝

Ò

Ï

Ú

◊

Â

¯

As viewed from the machine front

! Gear 35/29

@ Developing drive gear

# Gear 31

$ Gear 24

% Gear 20

^ Registration clutch gear

& Upper registration roller gear

* Lower registration roller gear

( Gear 39/25

) Gear 30

8

3

4

2

(

)

⁄

¤

°

!

#

‡

‹

Ø

fi

›

fl

¨

Í

ˇ

Á

´

Å

Ó

∏

Ô

¸

˛

Ç

¡

™

£

˘

ı

˜

¢

¿

∞

§

⁄ Gear 37

¤ Gear 20

‹ Bypass paper feed clutch gear

› Gear 18

fi Gear 16

fl Lower bypass paper feed pulley gear

‡ Gear 16

° Bypass forwarding pulley gear

· paper feed motor gear

‚ Gear 55/45

ΠFeed clutch 5 gear

„ Gear 30

´ Feed clutch 4 gear

‰ Gear 47

ˇ Gear 40

Á Gear 28

¨ Gear 34

ˆ Lower feed roller gear

Ø Upper feed roller gear

∏ Gear 30

Å Gear 28

Í Feed clutch 1 gear

Î Idle pulley 38/23

Ï Paper feed drive belt

˝ Idle pulley 31/42

Ó Feed clutch 2 gear

Ô Upper paper feed clutch gear

Upper paper feed pulley gear

Ò Gear 21

Ú Forwarding pulley gear

¸ Gear16

˛ Lower paper feed pulley gear

Ç Paper feed tension pulley

◊ Idle pulley 31/42

ı Lower paper feed clutch gear

˜ Upper paper feed pulley gear

Gear 21

¯ Forwarding pulley gear

˘ Gear 16

¿ Lower paper feed pulley gear

¡ Feed clutch 3 gear

™ Feed roller 3 pulley

£ Feed drive belt

¢ Feed idle pulley

∞ Tension pulley 10

§ Feed roller 4 pulley

¶ Paper conveying motor gear

• Idle gear 43

ª Duplex unit input gear

º Pulley 63/32

œ Paper conveying drive belt

∑ Pulley 36/32

® Idle gear 36/36

† Idle gear 30

¥ Gear 26

ø Paper conveying roller

π Paper conveying belt

“ Paper conveying pulley

‘ Fixing drive gear

« Idle gear 30

å Idle gear 26

ß Idle gear 26

∂ Gear 19

ƒ Pulley 22

© Gear 19

˙ Feedshift drive belt

∆ Tension pulley 22

˚ Pulley 22

¬ Gear 20/28

… Idle gear 29

Ω Idle gear 30

≈ One-way gear

ç Idle gear 20

√ Eject speed switching clutch gear

∫ Gear 26

µ Idle gear 26

≤ Idle gear 20

≥ Gear 23

÷ Pulley 28

` Eject drive belt

1 Tension pulley 28

2 Eject roller pulley

3 Scanner motor pulley

4 Scanner drive belt

5 Scanner drive pulley

6 Scanner wire drum

7 Scanner wire

8 Scanner wire pulley

8

2

`

1

÷

≥

ß

∂ƒ

©

˙

ç

√

≈∫

≤

µ

1 Drive motor gear

2 Idle pulley 63/35

3 Cleaning drive belt

4 Idle pulley 40/38

5 Blade thrust gear

6 Cleaning spiral gear

7 Idle pulley 80/26

8 Drum drive belt

9 Drum drive tension pulley

0 Drum drive pulley

8

4

‘

®

«

å

¬

∑

…

∆

Ω

˚

ªº

5

6

†

π

ø

¥

œ

¶

•

Figure 1-3-5 Drive system—copier

1-3-5

E

A

A A

E E

EA

1-3-1 (2A3/4/E) 1/1/32, 21:025

2AD (MCA)

E

A

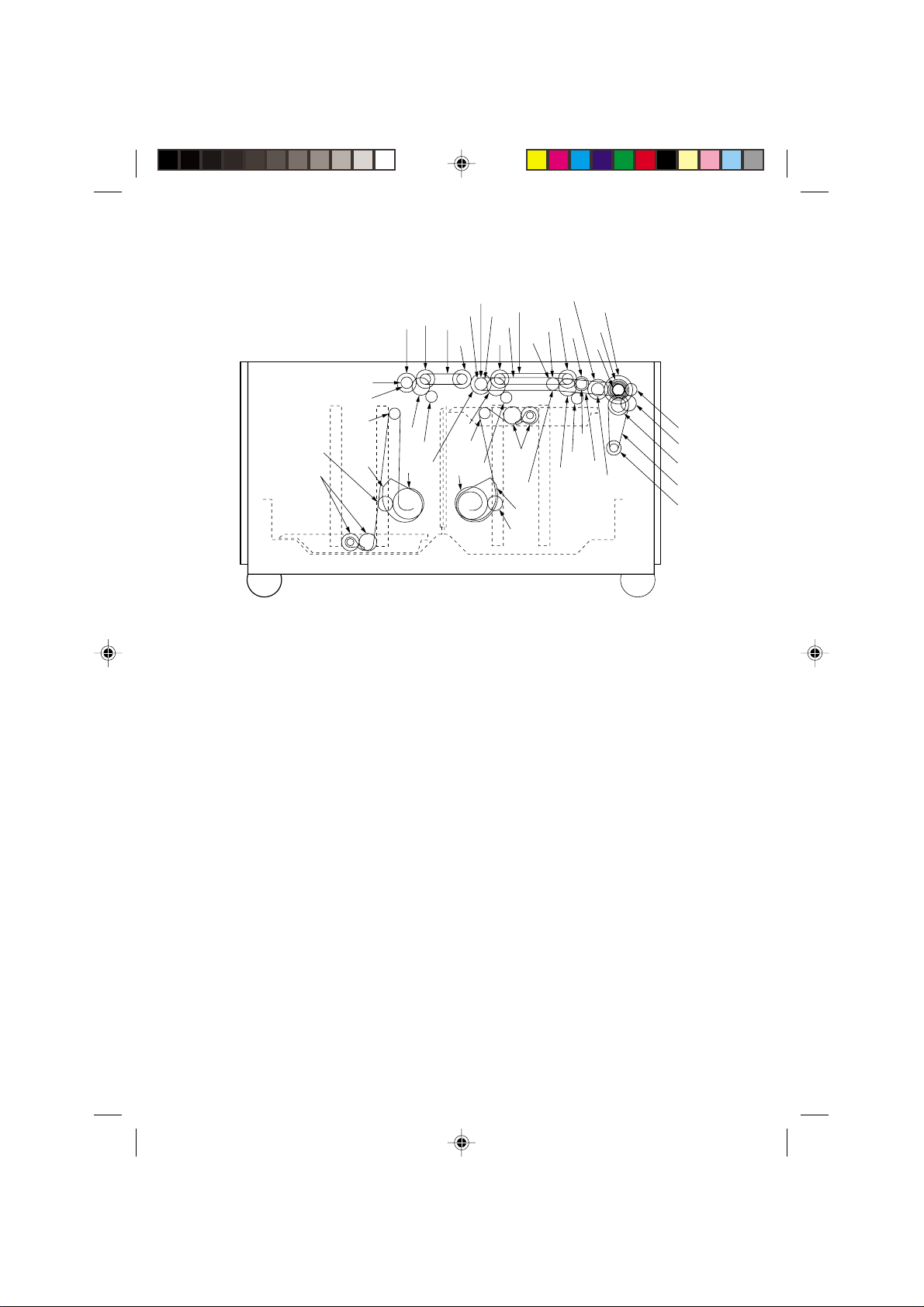

Page 28

AA A

6

95

43

!

@

0

*

%

&

$

2

8

7

1

^

#

As viewed from machine rear

EE E

A

A

E

2A3/4

E

8

6

7

5

9

1

4

!

Figure 1-3-6 Drive system—SRDF (inside front of machine)

1 Lower original conveying pulley 25/18 7 Joint gear 14

2 Gear 18/25 8 JAM release gear 14

3 Eject gear 18 9 Tension pulley

4 Middle original conveying pulley 18 0 Eject drive belt

5 Upper original conveying pulley 18 ! Conveying drive belt 2

6 JAM release gear 24

0

1

6

7

8

0

9

3

2

As viewed from machine front

Figure 1-3-7 Drive system—SRDF (inside rear of machine)

1 Original feed motor pulley 0 DF registration pulley 28/18

2 Pulley 35/22/22 ! Idle gear 15

3 Idle gear 26 @ Idle gear 20

4 Original feed clutch gear # Switchback gear 18

5 DF original feed pulley 28 $ DF registration drive belt

6 DF forwarding pulley 20 % Gear 22/35

7 Tension pulley ^ Original conveying motor pulley

8 Original feed drive belt & Gear 28

9 DF forwarding belt * Original conveying drive belt 1

^

@

!

$

2

3

5

4

Figure 1-3-8 Drive system—Duplex section

1 Duplex joint gear 9 Forwarding pulley 27

2 Gear 28 0 Gear 18

3 Duplex registration gear 20/30 ! Gear 26

4 Gear 26 @ Paper conveying pulley 40

5 Switchback roller gear # Paper conveying drive belt

E

6 Forwarding drive gear 18 $ Paper conveying tension pulley

7 Pulley 22 % Paper conveying pulley 20

8 Forwarding belt ^ Paper conveying pulley 20

1-3-6

%

#

As viewed from machine front

E

A

AA A

EE E

1-3-1 (2A3/4/E) 1/1/32, 21:026

2AD (MCA)

A

Page 29

2A3/4

9

(

5

%

3

$

)

$

$

*

5

%

5

%

&

⁄

¤

›

$

fi

#

4

fi

$

¤

⁄

#

^

‹

&

As viewed from machine front

Figure 1-3-9 Drive system—Large paper deck

(42 ppm: optional/52 ppm: standard)

1 Belt 180-6

2 Paper feed clutch 1

3 Paper feed clutch 2

4 Paper conveying clutch

5 Gear 20

6 Gear 26

7 Gear 50-20

8 Gear 35-1-20

9 Pulley 18

0 Gear 43-20

! Pulley S2M-18

@ Gear 16

# Roller 0.8-20

$ Pulley 20, gear 32

% One-way drum

^ Pulley 18-OW

& Pulse gear

* Belt 258

( Belt 234

) Belt 144

⁄ Gear 1.0-24

¤ Lift pulley

‹ Left lift belt assembly

› Right lift belt assembly

fi Paper deck motor gear

fl Pulley 16

$

$

2

6

#

@

8

fl

(

7

5

5

6

0

1

!

1-3-2 (2A3/4/E) 1/1/32, 2:397

1-3-7

Page 30

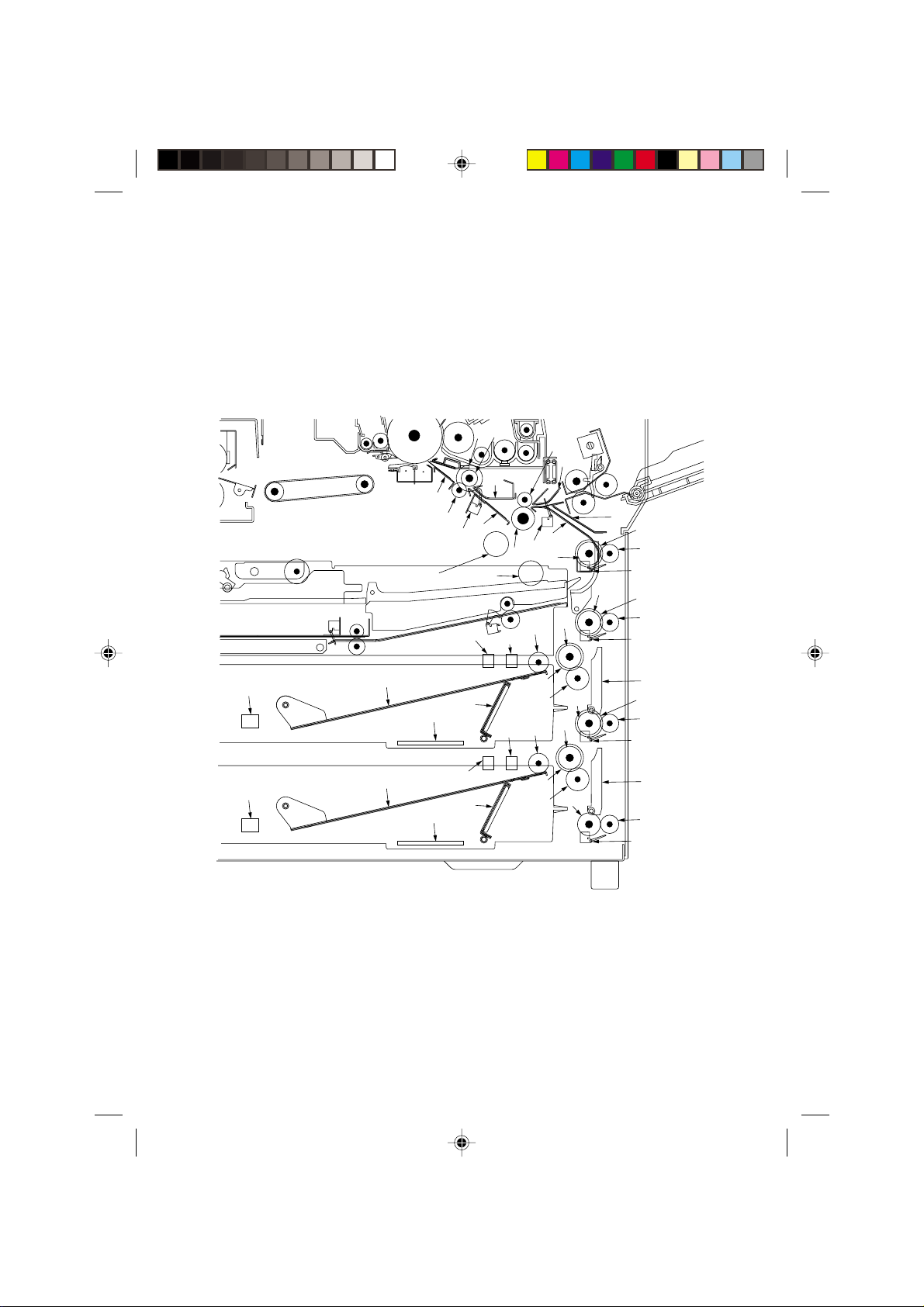

2A3/4

1-3-4 Mechanical construction

(1) Paper feed section

The paper section consists of the primary feed and secondary feed subsections.

Primary feed conveys paper from the upper drawer, lower drawer or bypass table to the

upper and lower registration rollers, at which point secondary feed takes place and the

paper travels to the transfer section in sync with the printing timing.

(1-1) Paper feed from the drawers

$

·

4

6

^

*

°

%

Ø

„

&

‡

‚

5

ˆ

1

8

9

2

0

7

›

#

‰

fi

#

ˇ

∏

Å

Figure 1-3-10 Drawer paper feed and secondary paper feed sections

1-3-8

)

)

Í

Î

⁄

´

⁄

Œ

1

¤

3

‹

3

2

@

!

(

fl

#

Á

(

#

¨

1-3-2 (2A3/4/E) 1/1/32, 2:398

Page 31

2A3/4

1 Forwarding pulley

2 Upper paper feed pulley

3 Lower paper feed pulley

4 Upper feed roller

5 Lower feed roller

6 Upper feed guide plate

7 Middle feed guide plate

8 Lower feed guide plate

9 Feed roller 1

0 Feed roller 2

! Feed roller 3

@ Feed roller 4

# Feed pulley

$ Upper registration roller

% Lower registration roller

^ Upper registration guide

& Lower registration guide

* Lower pre-transfer guide

( Feed guide

) Drawer lift

⁄ Lift operation plate

¤ Upper paper feed clutch (PFCL-U)

‹ Lower paper feed clutch (PFCL-L)

› Feed clutch 1 (FCL1)

fi Feed clutch 2 (FCL2)

fl Feed clutch 3 (FCL3)

‡ Feed clutch 4 (FCL4)

° Feed clutch 5 (FCL5)

· Registration clutch (RCL)

‚ Upper paper switch (PSW-U)

ΠLower paper switch (PSW-L)

„ Upper lift limit switch (LICSW-U)

´ Lower lift limit switch (LICSW-L)

‰ Paper feed switch 1 (PFSW1)

ˇ Paper feed switch 2 (PFSW2)

Á Paper feed switch 3 (PFSW3)

¨ Paper feed switch 4 (PFSW4)

ˆ Feed switch (FSW)

Ø Registration switch (RSW)

” Upper paper length switch

(PLSW-U)

Å Lower paper length switch

(PLSW-L)

Í*Upper paper width switch

(PWSW-U)

Î*Lower paper width switch

(PWSW-L)

* For inch specifications only.

1-3-2 (2A3/4/E) 1/1/32, 2:399

1-3-9

Page 32

2A3/4

Each drawer consists of a lift driven by the lift motor and other components. Each

drawer can hold up to 550 sheets of paper.

Paper is fed from the drawer by the rotation of the forwarding pulley and upper paper

feed pulley. The lower paper feed pulley prevents multiple sheets from being fed at one

time, via the torque limiter.

CN13-4

CN13-7

CN13-10

CN13-13

CN8-B11

RCL

CN8-B2

CN13-1

CN12-A2

CN8-B9

CN12-A4

CN12-A8

CN15-3

CN15-9

CN15-13

CN12-A10

CN15-4

CN15-10

CN15-14

EPCB

LICSW-U

LICSW-L

RSW

FCL5

FCL4

PSW-U

PSW-L

PFCL

U

PFCL

L

FSW

FCL1

PFSW1

FCL2

PFSW2

FCL3

PFSW3

PFSW4

Figure 1-3-11 Drawer paper feed section block diagram

1-3-10

1-3-2 (2A3/4/E) 1/1/32, 2:3910

Page 33

Image ready

2A3/4

Print key

FCL4

FSW

RSW

FCL5

RCL

PFM

DM

PFCL-U

FCL2

PFSW2

FCL1

PFSW1

Auto copy density control, copy paper: A4/11" × 8

174 ms

250 ms

100 ms

50 ms

163 ms

28 ms

ABC D E F G H J K

58 ms

35 ms

100 ms

74 ms 80 ms

35 ms

1

/2", magnification ratio 100%

Timing chart 1-3-1 Paper feed from the upper drawer

1-3-2 (2A3/4/E) 1/1/32, 2:3911

1-3-11

Page 34

2A3/4

A When the print key is pressed, the paper feed motor (PFM) turns on, and 250 ms later

the drive motor (DM) turns on to start drive for the paper feed section.

B 100 ms after the print key is pressed, the upper paper feed clutch (PFCL-U) turns on,

and the upper and lower paper feed pulleys rotate to start the primary paper feed.

C 50 ms after the upper paper feed clutch (PFCL-U) turns on, feed clutch 2 (FCL2) turns

on, and feed roller 2 rotates.

D 28 ms after the leading edge of the paper turns paper feed switch 2 (PFSW2) on, feed

clutch 1 (FCL1) turns on, and feed roller 1 to rotates.

E 163 ms after paper feed switch 2 (PFSW2) turns on, the upper paper feed clutch (PFCL-

U) turns off.

F 174 ms after the leading edge of the paper turns paper feed switch 1 (PFSW1) on, feed

clutch 4 (FCL4) turns on, and the lower feed roller rotates at high speed to create slack

in the paper before registration.

G 58 ms after the trailing edge of the paper turns paper feed switch 2 (PFSW2) turns off,

feed clutch 2 (FCL2) turns off.

H 35 ms after the leading edge of the paper turns the registration switch (RSW) on, feed

clutches 1 and 4 (FCL1 and FCL4) turn off.

I 74 ms after image ready signal turn on, the registration clutch (RCL) turns on, causing

the upper and lower registration rollers to rotate to start secondary paper feed.

Simultaneously, feed clutch 5 (FCL5) turns on and the lower feed roller rotates at low

speed.

J 100 ms after the trailing edge of the paper turns the feed switch (FSW) off, feed clutch

5 (FCL5) turns off.

K 80 ms after the trailing edge of the paper turns the registration switch (RSW) off, the

registration clutch (RCL) turns off.

1-3-12

1-3-2 (2A3/4/E) 1/1/32, 2:3912

Page 35

(1-2) Paper feed from the bypass table

2A3/4

!

9

7

8

Figure 1-3-12 Bypass paper feed section

1 Bypass table

2 Bypass upper guide

3 Bypass lower guide

4 Bypass stopper

5 Bypass friction plate

6 Bypass forwarding pulley

7 Bypass upper paper feed pulley

8 Bypass lower paper feed pulley

0

2

6

#

5

3

4

9 Bypass paper feed clutch

(BYPPFCL)

0 Bypass solenoid (BYPSOL)

! Bypass paper switch (BYPPSW)

@ Bypass paper length switch

(BYPPLSW)

# Bypass paper width switch

(BYPPWSW)

$ Bypass table extended detection

switch (BYPEDSW)

1

$

@

The bypass table can hold up to 100 sheets of paper at one time.

When the start key is pressed, the bypass solenoid (BYPSOL) turns on, unlocking the

bypass stopper and lowering the bypass forwarding pulley until it comes into contact

with the paper. This conveys paper placed on the bypass table to the bypass upper and

lower paper feed pulleys. The bypass paper feed clutch (BYPPFCL) then turns on,

transmitting the drive motor (DM) drive to these pulleys to start primary paper feed.

The bypass lower paper feed pulley rotates opposite to the paper feed direction so that

the torque limiter prevents multiple sheets from being fed at one time.

1-3-2 (2A3/4/E) 1/1/32, 2:3913

1-3-13

Page 36

2A3/4

CN14-A8

CN14-A4

CN14-A7

CN8-B11

RCL

BYPPSW

BYP

PFCL

BYPSOL

Print key

FSW

RSW

FCL5

RCL

PFM

DM

BYPSOL

BYPPFCL

CN8-B2

CN13-1

CN12-A2

CN8-B9

EPCB

RSW

FCL5

FSW

FCL4

Figure 1-3-13 Bypass paper feed section block diagram

Image ready

115 ms 100 ms65 ms

74 ms 80 ms

250 ms

100 ms

300 ms

90 ms

200 ms

AB C D E G H I J

Auto copy density control, copy paper: A5R/5

Timing chart 1-3-2 Paper feed from the bypass table

1-3-14

1-3-2 (2A3/4/E) 1/1/32, 2:3914

F

1

/2" × 81/2", magnification ratio 25%

Page 37

2A3/4

A When the print key is pressed, the paper feed motor (PFM) turns on, and 250 ms later

the drive motor (DM) turn on to start drive for the paper feed section.

B 100 ms after the print key is pressed, the bypass solenoid (BYPSOL) turns on. The

bypass stopper is then unlocked, and the bypass forwarding pulley lowers to forward the

paper.

C 300 ms after the bypass solenoid (BYPSOL) turns on, the bypass paper feed clutch

(BYPPFCL) turns on, and the upper and lower bypass paper feed pulleys rotate to start

primary paper feed.

D 115 ms after the leading edge of the paper turn the feed switch (FSW) on, feed clutch

5 (FCL5) turns on, and the lower feed roller rotates at low speed to create slack in the

paper before registration.

E 200 ms after the feed switch (FSW) turns on, the bypass paper feed clutch (BYPPFCL)

turns off.

F 90 ms after feed clutch 5 (FCL5) turns on, the bypass solenoid (BYPSOL) turns off.

G 65 ms after the leading edge of the paper turns the registration switch (RSW) on, feed

clutch 5 (FCL 5) turns off.

H 74 ms after the image ready signal turns on, the registration clutch (RCL) turns on, and

the upper and lower registration rollers rotate to start secondary paper feed.

Simultaneously, feed clutch 5 (FCL5) turns on and lower feed roller rotates at low speed.

I 100 ms after the trailing edge of the paper turns the feed switch (FSW) off, feed clutch

5 (FCL5) turns off.

J 80 ms after the trailing edge of the paper turns the registration switch (RSW) off, the

registration clutch (RCL) turns off.

1-3-2 (2A3/4/E) 1/1/32, 2:3915

1-3-15

Page 38

2A3/4

(2) Main charging section

The main charging section consists of the drum and the main charger assembly.

The main charger assembly charges the drum so that a latent image is formed on the

surface, the charger grid ensuring the charge is applied uniformly.

Main charger assembly

Main charger grid

Tungsten wire

Drum

Figure 1-3-14 Main charging section

1-3-16

1-3-2 (2A3/4/E) 1/1/32, 2:3916

Page 39

!

2A3/4

0

3

1

5

Figure 1-3-15 Main charger

1 Main charger front housing

2 Main charger rear housing

3 Main charger front lid

4 Main charger rear lid

5 Main charger shield

CN5-B1

CN5-B13

CN5-B11

CN5-B12

EPCB

24 V DC

MC REM

MC ALM

GRID CONT

6

2

6 Tungsten wire

7 Charger spring

8 Charger terminal

9 Charger pin

0 Main charger grid

! Grid tension plate

CN1-13

CN1-1

CN1-3

CN1-2

TB

HVTPCB

4

9

7

8

MC

Grid

Drum

Figure 1-3-16 Main charging section block diagram

1-3-2 (2A3/4/E) 1/1/32, 2:3917

1-3-17

Page 40

2A3/4

Print key

CFM1

ESW

520 ms

MC REM

PFM

AB C

Auto copy density control, copy paper: A4/11" × 8

360 ms

300 ms

290-30000 ms

1

/2", magnification ratio 100%

Timing chart1-3-3 Main charging

A When the print key is pressed, the paper feed motor (PFM) turns on.

B 520 ms after the paper feed motor (PFM) turns on, main charging (MC REM) starts.

C 300 ms after cooling fan motor 1 (CFM1) turns off, main charging (MC REM) is

completed.

1-3-18

1-3-2 (2A3/4/E) 1/1/32, 2:3918

Page 41

2A3/4

(3) Optical section

The optical section consists of the scanner, mirror frame and image scanning unit for

scanning and the laser scanner unit for printing.

6

4

$

5

1 Scanner

2 Mirror frame

3 Mirror 1

4 Mirror 2

5 Mirror 3

6 Exposure lamp (EL)

7 Reflector

7

2

Figure 1-3-17 Optical section

8

9

1

3

8 Image scanning unit

9 Lens

0 Optical rail

! Laser scanner unit (LSU)

@ CCD PCB (CCDPCB)

# Scanner motor (SM)

$ Scanner home position switch

(SHPSW)

!

0

@

#

1-3-2 (2A3/4/E) 1/1/32, 2:3919

1-3-19

Page 42

2A3/4

Original scanning

The original image is illuminated by the exposure lamp (EL) and scanned by the CCD

PCB (CCDPCB) in the image scanning unit via the three mirrors, the reflected light

being converted to an electrical signal.

The scanner and mirror frame travel to scan on the optical rails on the front and rear of

the machine to scan from side to side. The speed of the mirror frame is half the speed

of the scanner. When the SRDF is used, the scanner and mirror frame stop at the DF

original scanning position to start scanning.

Original

SHPSW

CN4-2

SM

CN2-1–

CN2-6

CN1-1–

CN5-1–

SMPCB INPCB

CN3-1–

CN3-6

CN1-16

CN5-16

CN1-1–

CN1-140

MPCB

CN1-1–

CN1-6

EL

CN2-1

CN7-1–

CN7-13

CN2-4

CN8-1–

LSU

Drum

CCDPCB

CN11-1–

CN11-11

CN8-5

CN12-1–

CN12-7

CN9-1–

CN9-4

CN1-1–

Figure 1-3-18 Optical section block diagram

1-3-20

1-3-2 (2A3/4/E) 1/1/32, 2:3920

CN1-140

EPCB

CN7-1–

CN7-2

Page 43

2A3/4

Print key

Fwd. rotation

SM

Rev. rotation

SHPSW

FVSYNC signal

410 P

414 P

9921 P

AB

Manual copy density control, copy paper: A3/11" × 17", magnification ratio 100%

CD

110 P

Timing chart 1-3-4 Scanner operation

A When the print key is pressed, the scanner motor (SM) reverses for 410 pulses and

then rotates forward.

B 414 pulses after the scanner motor rotates forward, the FVSYNC signal turns on for

9921 pulses for scanning.

C The scanner motor (SM) reverses to return the scanner to the home position.

D 110 pulses after the scanner home position switch (SHPSW) turns on, the scanner

motor (SM) turns off, and the scanner stops at its home position.

1-3-2 (2A3/4/E) 1/1/32, 2:3921

1-3-21

Page 44

2A3/4

Image printing

The image data scanned by the CCD PCB (CCDPCB) is processed on the main PCB

(MPCB) and transmitted as image printing data to the laser scanner unit (LSU). By

repeatedly turning the laser on and off, the laser scanner unit forms a latent image on

the drum surface.

• Laser scanner unit

Collimator lenses

Laser diodes (LD)

LD control PCB

BD sensor mirror

Oject mirror

Beam spritter

Lens 1

Lens 3

Lens 2

Polygon mirror

Polygon motor (PM)

Lens 4

Figure 1-3-19 Laser scanner unit (1)

1-3-22

1-3-2 (2A3/4/E) 1/1/32, 2:3922

BD sensor

Motor drive PCB

Cylindrical correcting lens

Page 45

2A3/4

1

2

6

5

7

3

5

8

9

0

1 Laser diodes: Generate the laser beams that form the latent image on the drum.

2 Collimator lenses: Collimate the diffused laser beams emitted from the laser diodes into

cylindrical beams.

3 Beam splitter: Refracts the laser beam emitted from one of the laser diodes so that it

becomes parallel to the other laser beam, and sends those two beams to lens 1.

4 Polygon mirror: 6-faced mirror that rotates at approximately 29527 rpm. Each face

reflects the laser beams toward the drum in the horizontal (main) scan direction. The

motion of the beams across the drum forms one scan line.

5 Lenses 1, 2, 3 and 4: Maintain scanning speed across the drum and beam diameters

constant. These lenses also correct the vertical alignment of the polygon mirror so that

the focal plane of the laser beams are always on the drum.

6 Object mirror: Reflects the laser beams onto the drum surface.

7 BD sensor mirror: Directs a laser beam to the BD sensor to generate the horizontal sync

signal.

8 Cylindrical correcting lens: Corrects for the deviation of the laser beam reflected by the

BD sensor mirror.

9 BD sensor: Detects the laser beam reflected by BD sensor mirror, and sends the

detection signal to the main PCB (MPCB). The main PCB (MPCB) uses this signal to

determine the horizontal scanning signal timing.

0 Glass dust filter: Prevents dust from entering the unit.

Drum

Figure 1-3-20 Laser scanner unit (2)

5

4

1-3-2 (2A3/4/E) 1/1/32, 2:3923

1-3-23

Page 46

2A3/4

The dimensions of the laser beam are as shown in Figure 1-3-19.

70 µm

65 µm

Figure 1-3-21

Scanning in the main direction is provided by the rotating polygon mirror, while scanning

in the auxiliary direction is provided by the rotating drum, forming a static latent image

on the drum.

The static latent image of the letter “A”, for example, is formed on the drum surface as

shown in Figure 1-3-22. Electrical charge is dissipated on the area of the drum surface

irradiated by the laser.

The focal point of the laser beam is moved line by line, and adjacent lines slightly

overlap each other.

1-3-24

1-3-2 (2A3/4/E) 1/1/32, 2:3924

Main

scanning

direction

Auxilary

scanning

direction

: laser beam is on

Figure 1-3-22

Page 47

(4) Developing section

The developing section consists of the developing unit and the toner recycling

assembly.

2A3/4

Developing unit

Toner sub hopper

Figure 1-3-23 Developing section

The developing unit consists of the developing roller where a magnetic brush is formed,

the doctor blade and the developing spirals that agitate the developer.

The toner recycling assembly consists of the toner main and sub-hoppers. In t he main

hopper new toner from the toner cartridge is mixed with residual toner recovered from

the cleaning section. The mixture is conveyed by the sub-hopper to the developing unit.

The toner level detection sensor (TLDS) checks whether or not toner remains in the

main hopper.

1-3-2 (2A3/4/E) 1/1/32, 2:3925

1-3-25

Page 48

2A3/4

Toner cartridge

Toner level sensor

Toner recycle paddle A

Toner cartridge paddle

Toner hopper lockup sensor

Toner cartridge spiral

Toner recycle paddle B

Toner recycle spiral

Cleaning unit

Cleaning spiral

Toner feed motor

Toner main hopper

Toner recycle motor

1-3-26

1-3-2 (2A3/4/E) 1/1/32, 2:3926

Main hopper spiral

Toner sub hopper

Sub hopper spiral

Figure 1-3-24 Toner recycling

Developing unit

Toner flow

Page 49

2A3/4

S2

N3

S1

N1

N2

43.5°

59°

85.5°

74.5°

Magnetic poles on the developing roller

Formation of magnetic brush

The developing roller consists of a magnet roller with five poles and a sleeve roller.

Rotation of the sleeve roller around the magnet roller entrains developer, which in turn

forms a magnetic brush at pole N1 on the magnet roller. The height of the magnet brush

is regulated by the doctor blade; the developing result is affected by the position of the

poles on the magnet roller and the position of the doctor blade.

A developing bias voltage generated by the high-voltage transformer (HVTPCB) is

applied to the developing roller to provide image contrast.

4

A

2

5

1

A: Distances beteen the doctor blade and

developing roller: 0.53 ± 0.05 mm

Figure 1-3-25 Forming a magnetic brush

1 Developing unit housing

2 Developing roller

3 Toner sensor (TNS)

4 Doctor blade

6

7

3

5 Developing spiral A

6 Developing spiral B

7 Developing spiral C

N1: 830

N2: 630

N3: 450

S1: 860

S2: 700

× 10

× 10

× 10

× 10

× 10

–4

T

–4

T

–4

T

–4

T

–4

T

1-3-2 (2A3/4/E) 1/1/32, 2:3927

1-3-27

Page 50

2A3/4

CN2-A5

CN2-A6

CN2-A7

CN2-A8

CN2-B3

CN2-A10

CN2-B11

CN2-B9

CN5-B10

CN5-B8 CN1-6

CN5-B1 CN1-13

EPCB

TFM–

TFM+

TRM–

TRM+

TLDS

TLS

TNS SIG

TNS CONT

DB REM

DB CONT

24 V DC

TRM

CN1-4

HVTPCB

TFM

TNS

CN2

DB

Figure 1-3-26 Developing section block diagram

Toner density is detected by the toner sensor (TNS).

The sensor section of the toner sensor detects the ratio of toner to carrier in the

developer near it and converts it into a voltage. As more toner is used, the ratio of toner

to carrier decreases, increasing the toner sensor output voltage.

When the ratio drops below the specified value, the increase in toner sensor output

voltage triggers toner replenishing. When toner is added and the ratio of toner to carrier

returns to normal, the toner sensor output voltage drops to the point where toner

replenishing stops.

1-3-28

1-3-2 (2A3/4/E) 1/1/32, 2:3928

Page 51

2A3/4

Toner density control

Toner density control is conducted using the TARGET value as the reference which is

the toner sensor initial output value set by maintenance item U130 when developer is

loaded for the first time.

Toner being replenished message

Toner sensor

output voltage (V)

Toner empty detection

level

Toner empty reset level

Toner feed start level

(TARGET by U130)

Toner feed stop level

Toner request message

(Toner cartridge to be replaced.)

Aging:

1 min: during copying

Copying

AB CD EF G H IJ

Figure 1-3-27 Toner density control

A When the toner sensor output voltage exceeds the toner feed start level, the toner feed

motor (TFM) and the toner recycle motor (TRM) operate intermittently—on for 0.5 s and

off for 1.5 s, and on for 1.0 s and off for 1.0 s, respectively—to replenish toner.

B As toner is replenished, the toner sensor output voltage drops below the toner feed stop

level and replenishing stops.

C Both the toner feed motor (TFM) and toner recycle motor (TRM) operate intermittently—

on for 0.5 s and off for 0.5 s—to replenish toner until the toner sensor output voltage

reaches the toner empty reset level after exceeding the toner feed start level.

D The toner feed motor (TFM) and toner recycle motor (TRM) operate intermittently—on

for 1.0 s and off for 1.0 s, and on for 1.5 s and off for 0.5 s, respectively—to replenish

toner until the toner sensor output voltage reaches the toner empty detection level after

exceeding the toner feed reset level

E When the toner sensor output voltage exceeds the toner empty detection level after

toner replenishing is carried out, the toner being replenished message appears. Both the

toner feed motor (TFM) and toner recycle motor (TRM) then operate intermittently—on

for 1.5 s and off for 0.5 s—for 1 min. for aging. If the voltage fails to fall to the toner empty

reset level, the toner request message appears.

1-3-2 (2A3/4/E) 1/1/32, 2:3929

1-3-29

Page 52

2A3/4

F When the toner sensor output voltage drops to the toner empty reset level, the toner

being replenished message disappears, and both the toner feed motor (TFM) and toner

recycle motor (TRM) operates intermittently—on for 0.5 s and off for 0.5 s—to replenish

toner.

G When toner is replenished, the toner sensor output voltage drops below the toner feed

stop level and replenishing stops.

H After the toner cartridge is replaced, both the toner feed motor (TFM) and toner recycle

motor (TRM) operate intermittently—on for 1.5 s and off for 0.5 s—to replenish toner.

I When the toner sensor output voltage drops to the toner feed stop level, the toner request

message disappears. Both the toner feed motor (TFM) and toner recycle motor (TRM)

then operate intermittently—on for 1.0 s and off for 1.0 s—to replenish toner.

J When toner is replenished, the toner sensor output voltage drops to the toner feed stop

level and replenishing stops.

1-3-30

1-3-2 (2A3/4/E) 1/1/32, 2:3930

Page 53

2A3/4

(g

)

Correcting toner feed start level

The toner feed start level is corrected based on the absolute humidity and the drive time

so that toner density becomes proper depending on the change of the humidity and the

drive time.

• Correction based on the absolute humidity

Correction at the toner

feed start level (V)

0.74

B

0

– 0.16

0 3.09 10.8

C

A

Maintenance item U130 performed.

35.9

D

Absolute humidity

/m

3

Figure 1-3-28 Correction based on the absolute humidity

A When maintenance item U130 is carried out for initial developer setting, the toner sensor

control voltage (CONTROL) is set so that the toner sensor outputs 2.01 V when the

absolute humidity is 10.8 g/m3.

B When the absolute humidity is between 0 and 10.8 g/m3, the toner feed start level is

decreased with the absolute humidity so that the toner sensor output voltage drops.

C When the absolute humidity is between 10.8 and 35.9 g/m3, the toner feed start level is

increased with the absolute humidity so that the toner sensor output voltage rises.

D When the absolute humidity exceeds 35.9 g/m3, the toner feed start level is increased

by 0.74 V to regulate the toner sensor output.

1-3-2 (2A3/4/E) 1/1/32, 2:3931

1-3-31

Page 54

2A3/4

Computing the absolute humidity

The external humidity sensor (EHUMSENS) and external temperature thermistor

(ETTH) are located on the humidity sensor PCB (HUMPCB). The external humidity

sensor (EHUMSENS) converts the relative humidity detected by the humidity sensing

element into a voltage and sends it to the engine PCB (EPCB). The main PCB

(MPCB)computes the absolute humidity based on this EHUMSENS signal and the

temperature (ETTH signal) detected by the external temperature thermistor (ETTH).

EPCB

HUMPCB

Humidity sensing element

ETTH

43ETTH