Page 1

PRODUCT TECHNICAL INFORMATION

KM-2530KM-2530

KM-2530

KM-2530KM-2530

Version 1-1 December 2001

Issued by: Product Support Department

Page 2

In this

“ Product T echnical Information” Booklet

concerning the KM-2530. We hope that this booklet provides you useful data regarding performance and

construction of this model.

This booklet has been composed of the latest available data. However, specification and design are subject

to change without notification.

©

Kyocera Mita Europe 2001

you will find specifications and relevant technical information

Page 3

Contents

1COPIER

1.1 Specifications

1.1.1 Basic 6

1.1.2 Paper feed 7

1.1.3 Paper eject 7

1.1.4 Paper specifications 7

1.1.5 Lifetime data 7

1.1.6 Optional equipment 8

1.2 Functions

1.2.1 Basic functions 9

1.2.2 Copier functions 9

1.3 Machine construction

1.3.1 Scanning Section 12

1.3.2 Memory 12

1.3.3 Printing Section 12

1.3.4 Photoconductor 12

1.3.5 Charging Section 12

1.3.6 Developing Section 13

1.3.7 Transfer Section 13

1.3.8 Separation Section 13

1.3.9 Fixing Section 13

1.3.10 Charge Erasure Section 13

1.3.11 Cleaning System 13

1.4 Environment and Reliability

1.4.1 Electrical Aspects 14

1.4.2 Room / storage conditions 14

1.4.3 Approvals 14

1.4.4 By-products 14

1.4.5 Maintenance 15

1.4.6 Reliability 15

1.5 Performance

1.5.1 Copy image specifications 16

1.5.2 Image area (margins) 16

1.5.3 Paper feed / conveying 18

1.6 Lifetime of the Consumables and parts

1.6.1 Consumable and main parts 18

1.6.2 Maintenance list 19

1.6.3 Maintenance kits 23

2PRINTER

2.1 Specifications

2.1.1 Basic 24

2.1.2 Paper feed 25

2.1.3 Paper eject 25

2.1.4 Paper specifications 25

Page 4

2.1.5 Room and storage conditions 25

2.2 Performance

2.2.1 Minimum operating environment 26

2.2.2 Printer image performance 26

2.3 Networking

2.3.1 Networking 27

3FACSIMILE

3.1 Facsimile Specifications

3.1.1 Basic 29

3.1.2 Modem 30

3.1.3 Image Quality 30

3.2 Facsimile Functions

3.2.1 Receiving Functions 31

3.2.2 Transmitting Functions 31

3.2.3 Communicative Functions 31

3.2.4 Additional Communicative Functions 31

3.2.5 Communicative Support Functions 32

3.2.6 Transmission Support Functions 32

3.2.7 Receptions Support Functionns 32

3.2.8 Report Function 32

3.2.9 Local Party Information 33

3.2.10 Other Functions 33

4SCAN SYSTEM

4.1 Specifications

4.1.1 Basic 34

4.1.2 Machine Specification 34

4.1.3 Scanner File Utility Specification 35

4.1.4 TWAIN source specifications 36

4.1.5 Address Book specifications 3 6

5SPECIFICATIONS OF OPTIONAL EQUIPMENT

5.1 Document Feeder SRDF-2 and STDF-3

5.1.1 Basic Specification/Reliability SDRF-2 37

5.1.2 Performance SDRF-2 37

5.1.3 Consumable Parts SDRF-2 37

5.1.4 Periodic Maintenance List SDRF-2 38

5.1.5 Basic Specifications/Reliability STDF-3 39

5.1.6 Performance STDF-3 39

5.1.7 Consumable Parts STDF-3 39

5.1.8 Periodic Maintenance List STDF-3 39

5.2 Multi Desk PF-70

5.2.1 Basic Specifications/Reliability 40

5.2.2 Performance 40

5.2.3 Consumable Parts 41

5.2.4 Periodic Miantenance List PF-70 41

Page 5

5.3 Special tray PF-75

5.3.1 Basic Specifications/Reliability 42

5.3.2 Performance 42

5.3.3 Consumable Parts 42

5.4 Auto duplex unit AD-63

5.4.1 Basic Specifications/Reliability 43

5.4.2 Consumable Parts 44

5.4.3 Periodic Maintenance List AD-63 44

5.5 Document Finishers DF-71E and DF-78

5.5.1 Basic Specifications/Reliability DF-71E 45

5.5.2 Stacking Performance DF-71E 45

5.5.3 Stapling Performance DF-71E 46

5.5.4 Consumable Parts DF-71E 46

5.5.5 Periodic Maintenance List DF-71E 46

5.5.6 Basic Specifications/Reliability DF-78 48

5.5.7 Stacking Perforamce DF-78 48

5.5.8 Stapling PerformanceDF-78 48

5.5.9 Consumable Parts DF-78 49

5.5.10 Periodic Maintenance List DF-78 49

5.6 Saddle Finisher DF-75

5.6.1 Basic Specifications Finisher Section 50

5.6.2 Basic Specifications Saddle Stich Section 50

5.6.3 Reliability and Performance 50

5.6.4 Consumable Parts 51

5.6.5 Periodic Maintenance List DF-75 51

5.7 Switchback unit for saddle finisher: RA-1

5.7.1 Basic Specifications/Reliability 52

5.7.2 Consumable Parts 52

5.7.3 Periodic Maintenance List RA-1 52

5.8 Job seperator J-1402

5.8.1 Basic Specifications/ Reliability 53

5.8.2 Consumable Parts 53

5.8.3 Periodic Maintenance List J-1402 53

5.9 Mailbox M-2107

5.9.1 Basic Specifications/Reliability 53

5.9.2 Performance 53

Page 6

Product T echnical Information KM-2530

1COPIER

1.1 Specifications

1.1.1 BASIC

Model KM-2530 (2BH)

Type Desktop

Function Standard: Copier

Option: Network printer / Fax / Network scanner

Copy process Indirect electrostatic

Resolution Scanning section: 600 x 600 dpi

Printing section: 600 x 600 dpi

Originals Sheets, books or 3D objects

Alignment Without DF: Left rear

With DF (optional): Centre

Copy speed Single sided (Paper is fed from the upper drawer , 1:1 magnification) (without DF)

A4: 25 + 1.4 - 0.5 copies/min.

A4R: 20 + 1.4 - 0.5 copies/min.

B4: 18 + 1.4 - 0.5 copies/min.

A3: 15 + 1.4 - 0.5 copies/min.

B5: 25 + 1.4 - 0.5 copies/min.

B5R: 16 + 1.4 - 0.5 copies/min.

DF single sided (normal copy mode / 1 copy of 1 original / paper fed from the upper

drawer, measured excluding the first copy)

DF (A4 / 100%) 25 + 1.4 - 0.5 copies/min.

Memory sort copy (paper fed from the upper drawer)

10 sets of 10 single sided copies from 10 single sided originals (Incl. 1st page)

A4 size: Within ??? sec. or less.

A4R size: Within ??? sec. or less.

Rotation sort copy (paper fed from the upper and second drawers, manual exposure)

` 10 sets of 10 single sided copies from 10 single sided originals (Incl. 1st page)

A4 - A4 . A4R Within ??? sec. or less.

Duplex

10 sets of 5 double sided copies from 10 single sided originals: 267 sec. or less

10 sets of 10 double sided copies from 10 double sided originals: 534 sec. or

less

First copy (A4 / 100%) Manual / AE: 3.9 sec. or less (without DF)

Manual: Approx. 4.0 sec. or less (with DF)

Zoom function With DF 25 ~ 400% (in steps of 1%)

Without DF 25 ~ 200% (in steps of 1%)

Fixed magnifications 35 / 44 / 4 9 / 5 0 / 64 / 70 / 90 / 1 00 / 127 / 141 /

200 / 400 %

Version 1-1 December 2001 6

Kyocera Mita Europe B.V.

© Product Support Department

Page 7

Product T echnical Information KM-2530

Warm up time (20°C / 65%RH) Normal: 60 sec. or less

at the rated voltage Pre-heat mode: 0 sec. (Recovering has priority)

Pre-heat mode 2: 30 sec. or less (Energy Star)

Pre-heat mode 3: E2000 (Energy saving has priority)

Machine size Copier: Approx. 585 (W) x 646 (D) x 745 (H) mm

Copier, DF, optional drawers,

finisher, bypass: Approx. 1436 (W) x 646 (D) mm

Machine weight Copier: KM-2530 Approx. 79 kg

1.1.2 PAPER FEED SYSTEM

System Standard setting: 2 drawers and 1 stack bypass

Optional setting: 2 drawers, 1 stack bypass and 1 paper feed desk (2 drawers)

2 drawers, 1 stack bypass and 1 large paper deck

Capacity Drawer, opt. paper feed desk: 500 or 550 sheets (80 g/m²)

Large paper deck: 3,000 sheets (80 g/m²)

Bypass: 200 sheets (80 g/m²)

Sizes Drawer, optional paper feed desk: A3 ~ A5R, folio (60 ~ 105 g/m²)

Large paper deck: A4, B5 (60 ~ 105 g/m²)

Bypass: A6R ~ A3, folio, envelopes (60 ~ 200 g/m²)

1.1.3 PAPER EJECT SYSTEM

System Inner tray (face down)

Capacity Plain paper: 250 sheets (80 g/m²)

Special paper: up to 250 sheets or less (varies

depending on stacking capacity)

1.1.4 PAPER SPECIFICATIONS

Copy paper size A3 - A6R, folio, envelopes*

Copy paper weight Recommended: 80 g/m²

60 ~ 200 g/m²

Copy paper types OHP, recycled paper, normal plain paper

* Envelopes can only be used when the machine is operated as a printer (optional board is necessary).

The use of envelopes has certain limitations (please see the performance chapter).

1.1.5 LIFETIME DATA

Copier 5 years or 800,000 sheets

( Multiple- to single copy ratio = 4:6)

Maximum monthly volume 85K copies / prints

Drum unit: 400,000 sheets

Developing unit: 400,000 sheets

Fixing unit: 400,000 sheets

Transfer unit: 400,000 sheets

Others: (Please see periodic maintenance list)

Toner Ave. 34K copies/prints average

(measured under the recommended

circumstance: A4 multiple copying / 6 %

duty original)

Version 1-1 December 2001 7

Kyocera Mita Europe B.V.

© Product Support Department

Page 8

Product T echnical Information KM-2530

Installation time: Within 30 minutes (From unpacking to the

first copy; adjustment time excluded)

1.1.6 OPTIONAL EQUIPMENT

Printer unit: Printing System N

(Embedded network card IB-21E)

Network board: IB-21E / SB-1 10

HDD HD-3

Scanner Print / Scan system N

Facsimile kit: Fax System C

Image memory: 16 / 32 / 64 / 128 Mb Dimm

Recommended Dimm only

Platen cover

Document feeder: SRDF-2 and STDF-3

Paper feeder: PF-70 and PF-75

Auto duplex: AD-63

Finisher: 3000sheets Finisher: DF-71E

Copier built in finisher: DF-78

Saddle stich finisher DF-75

Switchback finisher: RA-1

Job separator: J-1402

Mail box: M-2107

Version 1-1 December 2001 8

Kyocera Mita Europe B.V.

© Product Support Department

Page 9

Product T echnical Information KM-2530

1.2 Functions

1.2.1 BASIC

Language selection

Help guidance

Stop / clear

Reset

Auto clear Off, 30 ~ 270 sec. (In steps of 30 sec.)/ Factory default: 60 sec.

Pre-heat Recovering time: 0 seconds, Energy star and E-2000 setting.

Auto Pre-heat Off, 5 ~ 45 min. (in steps of 5 min.) / Factory default: 15 min.

Auto shut-off Off, 15 ~ 240 min. (in steps of 15 min.) / Factory default: 60 min.

Original size detection

Total counter Electronic / mechanical counter (7 digits)

Paper jam detection

Paper jam number correction

Paper size detection

Paper level display

Paper empty detection

Non-stop paper replenishment

Toner level detection

Toner empty detection

Disposed toner overflow detection

Re-try paper feed

Partial operation Duplex unit, paper feed drawer , finisher, bypass unit.

Compulsory ejection Except for jammed paper.

Video correction

Triple access

Silent mode On (0 sec.) / OFF (30 sec.)

Maintenance mode

Service simulation output

Display brightness adjustment

Error detection

Eco mode

1.2.2 COPIER

No. of copies setting: 3 digits up to 999 copies

Copy density control Normal range: 7 or 13 steps (indicated on the LCD)

Automatic density control

Image mode T ext mode / photo mode / text/photo mode (no discrete gradation areas)

Interrupt copy

Auto start

Automatic drawer change

Auto paper selection (APS)

Auto magnification selection (AMS)

X / Y independent magnifications

Programming mode 8 programs

Version 1-1 December 2001 9

Kyocera Mita Europe B.V.

© Product Support Department

Page 10

Product T echnical Information KM-2530

Department management 500 departments / 1-8 digit ID codes/Total copy count / separate copy

counts/limits for respective departments.

Code Copy count reset, check and output.

Margin shift Left margin: 0 - 18 mm (in steps of 1 mm)

Special margin: 0,1 - 18 mm (in steps of 1 mm)

Border erase Sheet border erase: 0 - 18 mm (in steps of 1 mm)

Book border erase: 0 - 36 mm (in steps of 1 mm)

Indefinite border erase: X: 50 - 297 mm (in steps of 1 mm)

Y: 50 - 432 mm (in steps of 1 mm)

Auto duplex copy (when AD-63 has been installed)

Book originals: Right / left / binding or spread

Single sided original

Double sided original

Split copy Book originals: Right binding / left binding

A3 - A4(A3 - A5R - A4/A3 ~ A5R - B5

by SIM) when DF is installed.

Double sided original Duplex mode when using DF

Sheet insertion Cover mode

Inter-sheet mode

Chapter mode

Transparency mode

Transparency and lining paper mode

Non-sort copy

Sort copy Copier only: memory sort / Rotate sort

Group copy (when Finisher has been installed)

Stapling (when Finisher has been installed)

Punching (when Finisher has been installed)

Stacking mode

One scan multi copying

Rotation copy

B/W inverted copying

Mirror image

Page number insertion 3 styles start page 1-10 start no.: 1 - 999

Denominator no.: Auto / Manual

Form overlay Density: 10 steps

N-up Patterns: 2 in 1 / 4 in 1

Border: Solid line / wavy line / cross mark / no line

Magazine binding Binding: Right, Left, saddle stitch

(Saddle stitch is possible after installing the

saddle stitch finisher)

Book magazine binding Binding: Right, Left, saddle stitch

(Cover is added) (Saddle stitch is possible after installing the

saddle stitch finisher)

Size unification (when additional image memory is installed)

Self status report (service simulation modes / jam count /Call

count)

User initial settings

Contiuous scanning, auto rotation Auto rotation / No rotation

Version 1-1 December 2001 10

Kyocera Mita Europe B.V.

© Product Support Department

Page 11

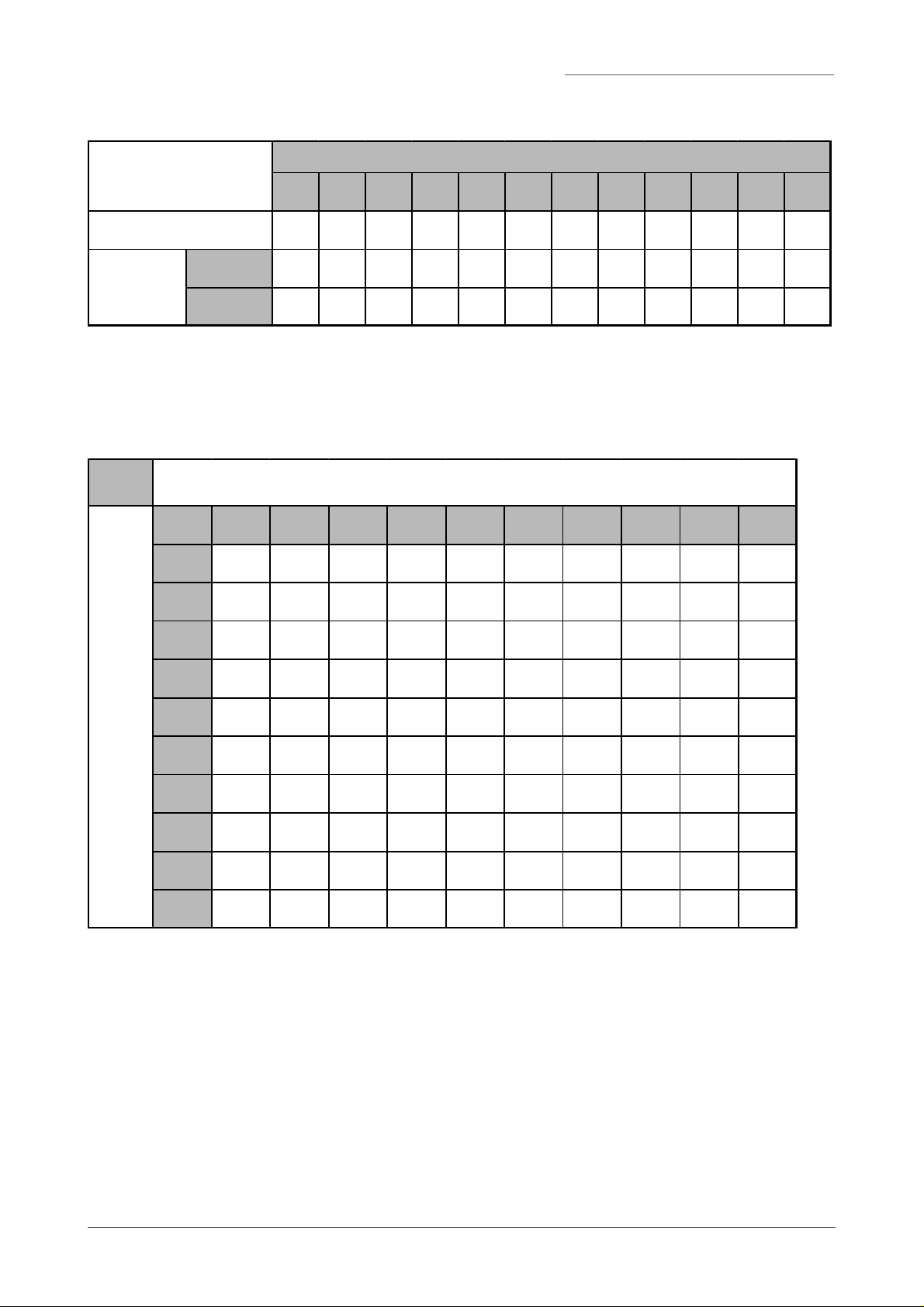

Auto original / paper size detection

A3 B4 A4R A4 B5R B5 A5R A5 A6R Folio DL C5

Product T echnical Information KM-2530

PAPER SIZE

Original size detection

Auto

Drawer

paper size

detection

Bypass

Auto magnification selection

(%)

A3 B4 A4R A4 B5R B5 A5R B6R A6R Foli o

A3

B4

A4R

A4

100 86 70 70 61 61 50 43 35 70

115 100 81 81 70 70 57 50 40 81

141 122 100 100 86 86 70 61 49 100

___ ___ 100 100 86 86 70 61 49 ___

0000000 0

0000000 0

0000000 00

COPY P APER SIZE

B5R

B5

A5R

ORIGINAL DOCUMENT SIZE

B6R

A6R

Folio

163 141 115 115 100 100 81 70 57 115

___ ___ 115 115 100 100 81 70 57 ___

200 173 141 141 122 122 100 86 70 141

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

127 110 90 90 77 77 64 55 44 10

The underlined magnification ratio’s are only valid in “rotate copy” mode.

Version 1-1 December 2001 11

Kyocera Mita Europe B.V.

© Product Support Department

Page 12

Product T echnical Information KM-2530

1.3 Machine Construction

1.3.1 SCANNING SECTION

System Flat bed scanning by CCD

Resolution 600 x 600 dpi

Exposure Constant

Exposure source Noble gas lamp

Exposure adjustment Constant exposure lamp quantity by image processing

1.3.2 MEMORY

Memory Standard: 32 MB DIMM

Bitmap memory Standard: 9 Mb (Used for both scanning and printing)

• When parallel printing: 18 MB

Exclusive use for copier

Option: None

Image storage Standard: 23 MB

• When parallel printing: 14 MB

Option: Max. 160 MB

(Used for both bitmap and image storage)

•32+32 MB, 32+64 MB, 32+128 MB

Exclusive use for copier

Slot: One slot to add 32 MB/64MB/128MB DiMM

100 pins General purpose* DiMM

* Recommended Dimm (chip set) only

Original storage* Standard memory: Approx. 122 pages

Maximum memory: Approx. 802 pages

* A4, 6% original, T ext & photo mode,centre exposure level.

1.3.3 PRINTING SECTION

Printing method Electro-photography semiconductor laser

Resolution Main scanning: 600 dpi

Auxiliary scanning: 600 dpi

1.3.4 PHOTOCONDUCTOR

Shape Drum (∅ 40 mm)

Type +a -Si • C-rich

Peripheral speed ??????????????

1.3.5 CHARGING SECTION

System Scorotron (positive charge)

Charger current ??????????? µA

Cleaning to be cleaned by the user at toner replacement

Version 1-1 December 2001 12

Kyocera Mita Europe B.V.

© Product Support Department

Page 13

Product T echnical Information KM-2530

1.3.6 DEVELOPING SECTION

System Single component “jumping” developer

Toner System: cartridge

Capacity: ?????? g

T oner volume control Piezo electric detection

Developing bias AC positive

Residual toner Disposal tank with overflow detection

1.3.7 TRANSFER SECTION

Transfer section

System Transfer roller (negative charge)

Cleaning No cleaning system

1.3.8 SEP ARA TION SECTION

System DC separation needle with separation claws

1.3.9 FIXING SECTION

System Heat roller fixing

Heater Halogen heater (main: 630 W / sub: 420 W)

Roller control temperature ? ????? °C

Fixing pressure Approx. ?????? N

T emperature control Thermistor detection

Overheat prevention system Thermostat (140 °C)

Fixing rollers Heat roller: Reverse crown-shape

Press roller: Straight

1.3.10 CHARGE ERASURE SYSTEM

System Charge erasure by light

Lamp LED

1.3.11 C LEANING SYSTEM

System Cleaning blade at fixed position

Version 1-1 December 2001 13

Kyocera Mita Europe B.V.

© Product Support Department

Page 14

Product T echnical Information KM-2530

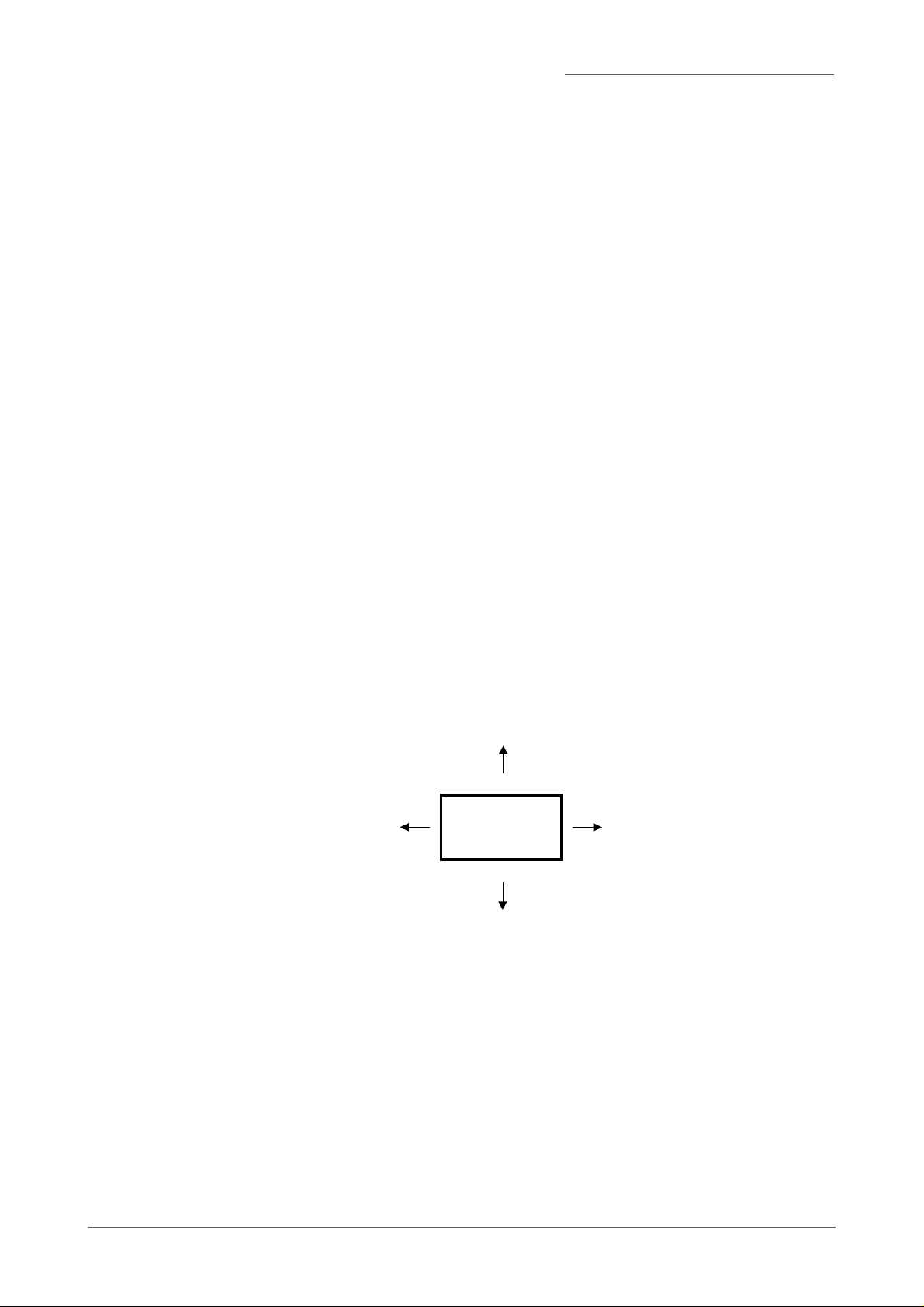

Copier

Rear

Front

100 cm or more

30 cm or more

30 cm or more

30 cm or more

1.4 Environment and Reliability

1.4.1 ELECTRICAL ASPECTS

Rating 230 V / 50 Hz

?????? A (ave.) / ?????? A (max.)

Average power consumption Max.: W/h

Copying: 614 W/h

Standby: 147 W/h

Low power mode: 51 W/h

Transmission: ????? W/h

Reception: ?????? (normal / fine)

Insulation voltage (Rated =<150V) 1000 V/min. or 1200 V/ 1 sec (ACVoltage)

. (150V <Rated=< 300V) 1500 V/min. or 1650 V/ 1 sec

Insulation resistance (Rated =<150V) 1 MΩ or more (by 500 V insulation resistance

meter)

(150V <Rated=< 300V) 2 MΩ or more (by 500 V insulation resistance

meter)

Earth continuity 0.1 Ω or less

1.4.2 ROOM/STORAGE CONDITIONS

Operation T emperature: 10 ~ 35 °C

Humidity: 15 ~ 85 %RH

Storage * Temperature: -20 ~ 40 °C

Humidity: 10 ~ 90 %RH

* Storage conditions include transportation however excludes the machine installation.

Recommended using conditions

1.4.3 APPROV ALS

GS / CE / Blue Angel

1.4.4 BY-PRODUCTS

Noise level Copying: 71.19 dB (JIS Z-8731 acoustics pressure

level) Standby: 39.46 dB

Dust 0.02 mg/m³ per hour (JIS Z-8813 testing

Ozone Average: 0.02 ppm or less

Version 1-1 December 2001 14

method)

Maximum: 0.028 ppm or less (UL-1950 testing method)

© Product Support Department

Kyocera Mita Europe B.V.

Page 15

Product T echnical Information KM-2530

1.4.5 MAINTENANCE

Refer to the appendix for the detailed maintenance list.

Periodic maintenance interval: 400,000 sheets

1.4.6 RELIABILITY DATA

MCBF (Under investigation) 70,000 sheets or more

MCBC (Under investigation) 0.14 or less (Reference value)

MCBJ Single sided Front drawer

(incl. optional drawer): 10,000 sheets or more

Bypass : 2,000 sheets or more

Auto duplex Front drawer

(incl. optional drawer): 3,000 sheets or more

Bypass (2 sided): 1,200 sheets or more

T otal system (Copier+Finisher): 5,500 sheets or more

(MCBF: average number of copies between failure)

(MCBC: monthly call between copies)

(MCBJ: average interval between paper jams)

Reliability data are referring to the machine only under the recommended operation circumstances.

Version 1-1 December 2001 15

Kyocera Mita Europe B.V.

© Product Support Department

Page 16

Product T echnical Information KM-2530

1.5 Performance

1.5.1 COPY IMAGE

Image density (mixed mode) Initial 1.32 or more

Life Average 1.25 or more / Min. 1.00 or more

Image density gap Initial 0.15

Life 0.20

Background density Initial FD ≤ 0.005

Life FD ≤ 0.008

Resolution

(Mixed mode) (Centre/others line pairs/mm)

100% Platen 8/8 line pairs/ mm o r m o re

DF 8/8 linepairs/mm or more

200% Platen 10/10 linepairs/mm or more

DF 9/9 linepairs/mm or more

50% Platen 4.4/4.4 line pairs/mm or more

DF 9/9 linepairs/mm or more

Reproduction of fine lines 8 lines/mm or more (100 %)

10 lines/mm or more (200 %)

4 lines/mm or more (50 %)

Generation copy (Mixed mode) (DIN legibility pattern) 84 point

Magnification tolerance

(mixed mode) 100 % Platen Total length ± 0.8 %

Partial ± 1.0 % at any 50 mm

100 % DF Total length ± 1.5 %

Partial ± 1.5% at any 50 mm

Magnified Platen Total length ± 1.0 %

Partial ± 1.0 % at any 50 mm

Magnified DF Total length ± 1.5 %

Partial ± 1.5 % at any 50 mm

Squareness Platen ± 1.5 mm/375 mm

DF ± 2.5 mm/375 mm

Image distortion Platen Total length ± 1.0 mm/375 mm or less

Partial ± 0.5 mm / 50mm or less

DF Total length ± 1.5 mm/375 mm or less

Partial ± 1.5 mm / 50mm or less

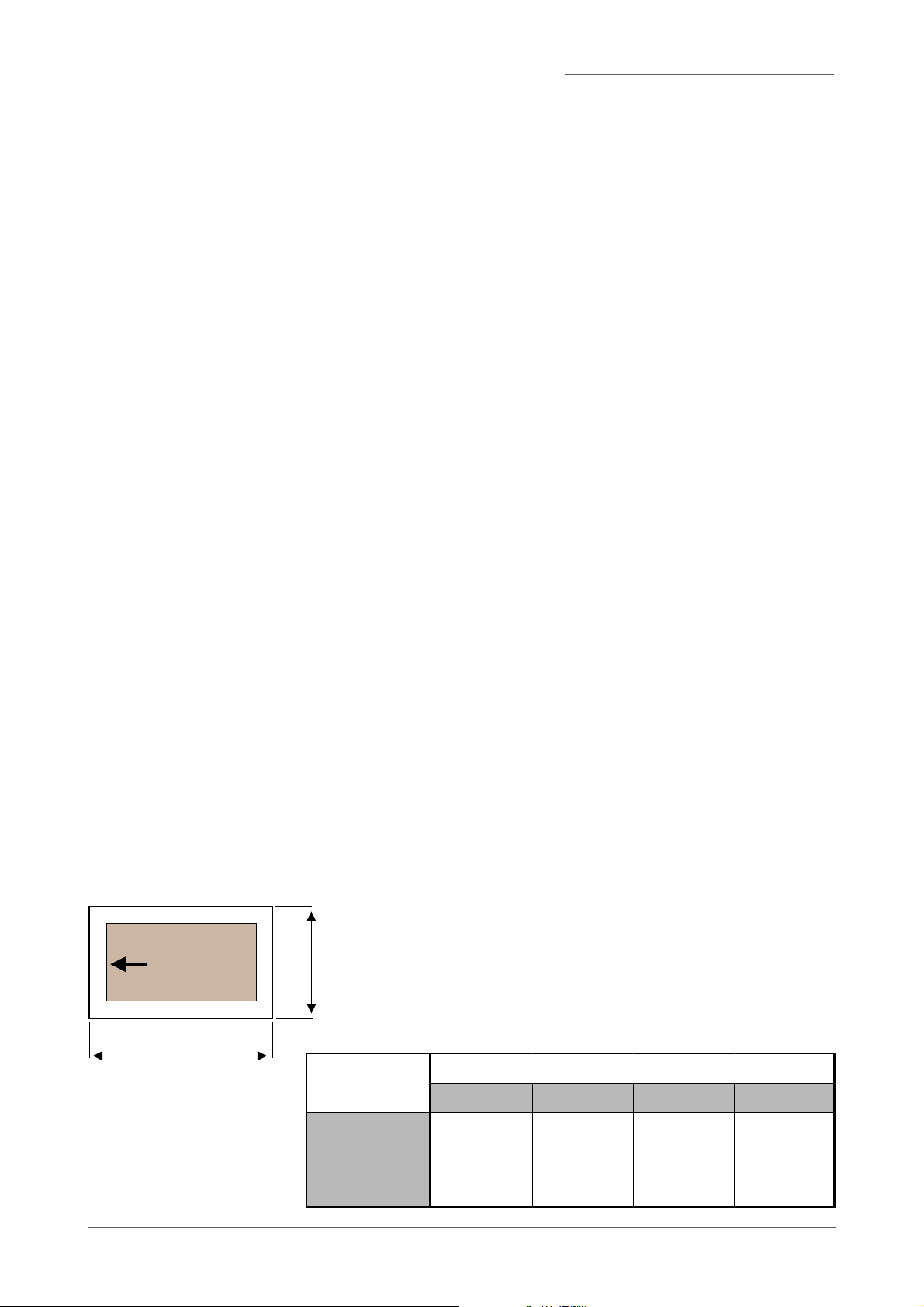

1.5.2 IMAGE AREA

C

B

A

Page length

Version 1-1 December 2001 16

D

Page width

(mm)

M argin w idth

Cop y m argin

im p erfect im age

area

(+2.5 / -1.5)

3.0 or less 4.5 or less 3.0 or less 10.0 or less

Side

ABCD

2.0

3.0 – 2.5

2.0

(+2.5 / -1.5)

Kyocera Mita Europe B.V.

3.0 – 2.5

© Product Support Department

Page 17

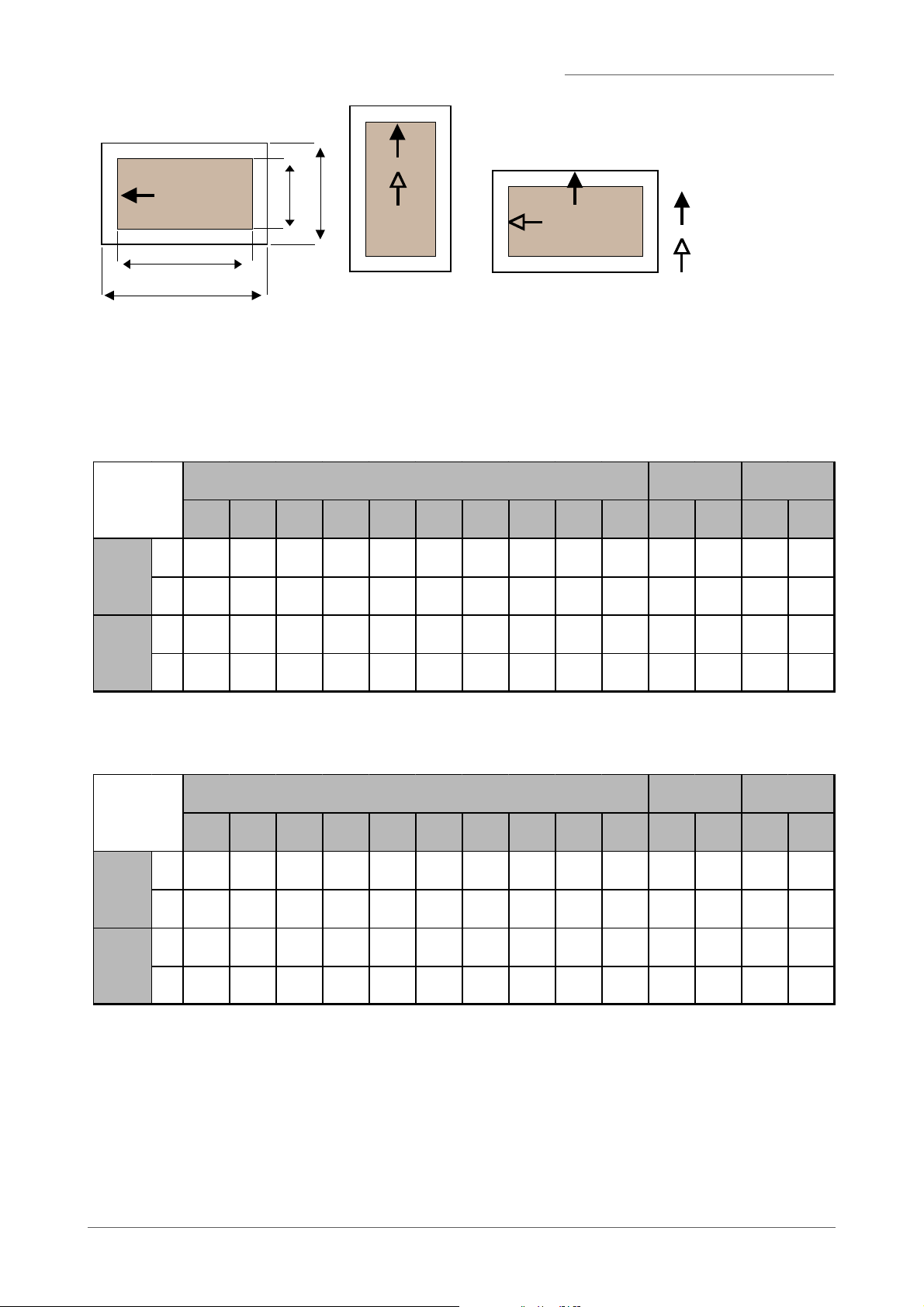

Product T echnical Information KM-2530

C

B

Portrait

(mm)

Paper

sizes

Image

area

X

D

Top of the PC display

Conveying direction

A

Y

Page length

Page width

<Portrait>

<Landscape>

Paper

A3 B4 A4R A4 B5R B5 A5R B6R A6R Folio DL C5 Max. Min.

297.0 257.0 210.0 297.0 182.0 257.0 148.5 128.5 105.0 210.0 110.0 162.0 296.9 97.0

PW

420.0 364.0 297.0 210.0 257.0 182.0 210.0 182.0 148.5 330.0 220.0 228.9 431.8 148.0

PL

284.1 245.0 198.0 288.5 170.0 248.6 136.4 116.5 93.0 266.7 98.0 149.9 284.2 85.7

X

411.5 355.6 288.0 198.0 248.6 170.0 201.5 173.6 140.0 321.5 211.5 220.5 423.3 139.5

Y

Use r se tti n gEnvelope

Landscape

(mm)

Paper

sizes

Image

area

Paper

Use r se tti n gEnvelope

A3 B4 A4R A4 B5R B5 A5R B6R A6R Folio DL C5 Max. Min.

297.0 257.0 210.0 297.0 182.0 257.0 148.5 128.5 105.0 210.0 110.0 162.0 296.9 97.0

PW

420.0 364.0 297.0 210.0 257.0 182.0 210.0 182.0 148.5 330.0 220.0 228.9 431.8 148.0

PL

288.5 248.6 201.5 286.9 173.6 247.1 140.0 120.1 96.5 201.5 101.5 153.5 288 .5 89.9

X

410.0 354.1 286.9 201.5 247.1 172.0 200.0 172.0 138.5 320.0 210.0 218.9 421.6 138.0

Y

Version 1-1 December 2001 17

Kyocera Mita Europe B.V.

© Product Support Department

Page 18

Product T echnical Information KM-2530

1.5.3 Paper Feed/Conveying

Leading edge timing tolerance ± 2.5 mm or less

Paper feed tolerance (skew) ± 1.5 mm or less

Side registration tolerance ± 2.0 mm or less

The parts listed here should be replaced after the indicated number of copies.

1.6 Lifetime of the Consumable and Main Parts

1.6.1 CONSUMABLE AND MAIN PARTS

KM-2530 Consumable Parts

Description Part No. Quantity Lifetime (x1,000 copies)

Pulley , paperfeed 2AR0722 2 40 0

Upper pulley , bypass 6170677 1 400

Pulley , separation 2AR07230 3 400

Pulley , leading feed 2AR07240 3 400

Under cleaning regist 2BL07950 1 400

Guide regist f 2BL16130 1 400

Regist cleaner ass’y 2BL68290 1 400

TR-700 Transfer ass’y 5PLPXHLAPKX 1 400

Developing ass’y 2BJ93010 1 400

Parts,drum ass’y 2BJ93020 1 400

Parts, fixing ass’y 100 2BJ93030 1 400

Parts, fixing ass’y 120 2BJ93040 1 400

Parts, fixing ass’y 230 2BJ93050 1 400

Note

The figures between brackets ( ) show that the mentioned lifetime depends on the number of times that part has

actually been used during operation. The counts can be checked by simulation.

Version 1-1 December 2001 18

Kyocera Mita Europe B.V.

© Product Support Department

Page 19

1.6.2 Maintenance list

Product T echnical Information KM-2530

LIST OF ABBREVIA TIONS

Cl Clean

Lu Lubricate

Re Replace

Ch/Ad Check and adjust

Ch/Re Check and replace if

necessary

Version 1-1 December 2001 19

Kyocera Mita Europe B.V.

© Product Support Department

Page 20

(2BH) P eriodic Maintenance (x1000 counts)

User

Parts Name Parts NoOnDelivery

Call

400 REMARKS

----A<Set Up>

1 TONER ----- RE

2 COPY QUALITY CH CH CH

AD AD AD

B<Cover>

1 CONT ACT GLASS 35912010 CL

Product T echnical Information KM-2530

dry cloth after cleaning w ith alcohol

2 ORIGINAL HOLDER ASS’Y 2AB00111 CL CL

alcohol or dry cloth

C<PF Section>

1 PULLEY,PAPER FEE D 2AR0722 CH RE

alcohol

(CASSETTE X2) CL

2 UPPER PULLEY,BY PASS 6170677 CH RE alc ohol

(BYPASS X1) CL

3 PULLEY,SEPARATION 2AR07230 CH RE

(BYPASS X1,CASSETTE X2) CL

4 PULLEY,LEADING FEED 2AR07240 CH RE alcohol

(BYPASS X1,CASSETTE X2) CL

5 ROLLE R2 BYPASSFEED 2BL06540 CH CL alcohol

CL

6 ROLLER4 BYPASSFEED 2BL06560 CH CL alcohol

CL

7 ROLLER REGIST L 2BL16020 CH CL alcohol

CL

8 PULLEY FEED 2BL16080 CH CL alcohol

(VERTICAL CONV. X4,

TRANSFERCONV.X4)

CL

9 RO L LER A FEED 2BL060 70 CH CL alcohol

X2 C L

10 ROLLER B FEED 2BL06080 CH CL alcohol

CL

11 ROLLER C FEED 2BL06090 CH CL alcohol

CL

12 RIGHT ROLLER REGIST 2BL06270 CH CL alcohol

CL

13 SWITCH REGISTRATION 2BL27420 CH CL dry cloth

CL

14 UNDER CLEANER REGIST 2BL07950 RE

alcohol

15 GUIDE REGIST F 2BL16130 RE

16 REGIST CLEANER ASS’Y 2BL68290 RE

D<Optical Section>

1 LK-700 SCANNER UNIT 5PLPXHNAPKX CH clean dust shield glass w ith dry colth

CL

2 CONTACT GLASS,ADF 2AV12250 CL dry cloth after cleaning w ith alcohol

cleaning if there is problem (longitudinal

line) on the image

3 MIRROR A

2AV12150 CL

Version 1-1 December 2001 20

Kyocera Mita Europe B.V.

© Product Support Department

Page 21

(2BH) P eriodic Maintenance (x1000 counts)

User

On

Parts Name Parts No

4 MIRROR B

2AV12160 CL

Delivery

Call

400 REMARKS

X2

5LENS OPTICAL

-------- CL

Product T echnical Information KM-2530

cleaning if there is problem (longitudinal

line) on the image

cleaning if there is problem (longitudinal

line) on the image

6 REFLECTOR,SCANNER

2AV12110 CL

7 LA MP,SCANNER 2AV12100 CH

8RAIL,OPTICAL

-------- LU

X2

9 SENSOR,ORIGINAL DETECTION

35927290 CH

E <Transfer Sction>

1 TR-700 TRANSFER ASS’Y

5P LPXHLAPKX CL RE

F <Developing Section>

1 DEVELOPING ASS’Y

2BJ93010 CH RE

G <Image Formation Section>

1 PARTS,DRUM ASS’Y

2BJ93020 CH RE

H <Fixing Section>

1 PARTS,FIXING A SS’Y 100

1 PARTS,FIXING A SS’Y 120

1 PARTS,FIXING A SS’Y 230

2 CLAW,PRESS ROLLER

2BJ93030 CH RE

2BJ93040 CH RE

2BJ93050 CH RE

36720493 CH CL

X4 RE

RE

CL

RE

RE

RE

RE

RE

cleaning if there is problem (longitudinal

line) on the image

replace if there is problem on the image

check abnormal noise and jitter

SCANNER RAIL GREASE PG671(P/N 60170000)

alcohol or dry cloth if there is problem

(lighting part and light reception part)

alcohol

I <Eject Section>

1ROLLER EXIT

2BL21020 CH CL

CL

2ROLLER FEED SHIFT

2BL21030 CH CL

CL

3PULLEY EXIT B

2BL21450 CH CL

X4 CL

4PULLEY FEED SHIFT

2BL21330 CH CL

X4 CL

Version 1-1 December 2001 21

alcohol

alcohol

alcohol

alcohol

© Product Support Department

Kyocera Mita Europe B.V.

Page 22

(2BH) P eriodic Maintenance (x1000 counts)

N

User

On

Parts Name Parts No

Delivery

Call

400 REMARKS

K<Others>

1GEARS

-------- CH

CL

2 BUSHINGS

-------- CH

CL

3 PAPER CONVEYANCE SECTIO

-------- CL

Product T echnical Information KM-2530

apply grease TMP1-200G (P/N 66668050)

in ca se of arising

unusual noise

apply grease TMP1-200G (P/N 66668050)

in ca se of arising

unusual noise

alcohol or dry cloth

Version 1-1 December 2001 22

Kyocera Mita Europe B.V.

© Product Support Department

Page 23

Product T echnical Information KM-2530

1.6.3 Maintenance Kit KM-2530

KM-2530 Maintenance Kit KM705E (400K)

Description Part No. Quantity

Drum Parts, drum as’y1

Parts, fixing ass’y1

TR-700 transfer ass’y1

Developing ass’y1

Paper feed rollers 2

Version 1-1 December 2001 23

Kyocera Mita Europe B.V.

© Product Support Department

Page 24

Product T echnical Information KM-2530

2PRINTER

2.1 Specifications

2.1.1 BASIC

Trade name Printing System (N)

Ty pe Hardware: Printer controller board

Exclusive use for KM-2530/3530

Type: Power PC 750

Clock: 350 MHz

Memory System ROM: 4MB DIMM (Dimm slot type)

Font ROM: 4MB (SOP type, mask number: 713)

Main RAM: 32MB SDRAM standard

Option RAM: 16 ---- 128MB x 2 slots 100pin-DIMM

(16, 32, 64, 128MB)

API ROM: 42pin OTP-ROM 2MB socket equipped

Ecomemory Memory saving is accomplished by raster data

compression and decompression by software

Resolution: Fast 1200 / 600 / 300 dpi

With smoothing Resolution enhancement is accomplished by

KIR 2 (Kyocera image refinement).

With enhancement method Corresponding to 1200 dpi

600 dpi mode 2400 x 600 dpi

KIR mode off/on (factory default is on)

Operating environment Applicable OS: Windows 95/98/Me, NT 4.0, 2000 and

Macintosh System 7.6.1 or more

Controller software PDL: Prescribe 2e

Emulation: PCL6 (5e, Xl, PJL)

Line Printer

IBM Proprinter X24E

EPSON LQ-850

DIABLO 630

KC-GL

KPDL3 (Post Script 3 compatible)

AES support

Fonts Outline fonts: 80 fonts

Bitmap fonts: 1 font

Graphics: Prescribe 2e + Jpeg image

command sensor

45 types one dimensional bar codes

1 type PDF417 two dimensional barcode

Connectivity Plug & Play for Windows 95/98/2000

SNMP (Printer MIB support)

Interface High speed parallel interface: 1 port (bi-directional)

Nibble/ECP mode support Comform to IEEE 1284

Serial interface: 1 port (RS232C)

Network interface 1port 10Base-TX/100Base-TX

Optional interface: 1 slot KUIO-LV

JCI: IB-21E / SEH: SB-1 10

Power supply DC-5V

Version 1-1 December 2001 24

Kyocera Mita Europe B.V.

© Product Support Department

Page 25

Product T echnical Information KM-2530

Storage interface H DD 1 slot

Memory card interface: 1 slot

Compact flash card: type 1

Support equipment

Attached software CDROM - KM digital library (printer driver tools)

CDROM - KM Network library including KM netwiewer (network connectivity tools

and utilities)

2.1.2 PAPERFEED

Conform the copier standards

2.1.3 PAPEREJECT

Inner tray: Face-down

Job separator (J-1402) Face-down

DF-71E Main tray Face-down

DF-71E Sub tray Face-up

DF-75 Face-up/down

DF-78 Face-down

M-2107 Face-up/down

The eject capacity is the same as described for the copier.

2.1.4 PAPER SPECIFICATIONS

Print size A3-B6R, Folio and envelopes.

Print type (T .B.D) Plain, preprint, bond, recycled, rough,

letterhead, colour and pre-punched.

Print type (bypass table) Transparency , labels, vellum, envelope,

cardstock and custom

2.1.5 ROOM/STORAGE CONDITIONS

During operation T emperature: 10 to 35 °C

Humidity: 15 to 85 %RH

During storage* T emperature: -20 to 40 °C

Humidity: 10 to 90 %RH

Altitude 0- 15000 m

Approx. 0.6 Atmospheres

Storage period: for 12 months after

production

*During storage includes transportation, however excludes the set-up

Version 1-1 December 2001 25

Kyocera Mita Europe B.V.

© Product Support Department

Page 26

2.2 Performance

2.2.1 MINIMUM OPERATING ENVIRONMENT

Client IBM PC/A T or 100% compatible computer

Wi ndows 95 W i ndows 98 Window s NT 4.0 Window s 2000

Product T echnical Information KM-2530

CPU

Memory

HDD

FDD

CD-ROM

Printer port

Client - Macintosh

CPU

Memory

HDD

FDD

i486SX/25MHz i486DX/66MHz i486SX/25MHz Pentium/133MHz

8MB or more 16M B or more 16MB or more 64MB or more

10MB or more 10MB or m ore 10MB or more 10MB or m ore

One 2HD 3.5-inch floppy di sk drive

One 12-inch CD-ROM drive

IEEE 1284 one port

Macintosh Macintosh

Sy st em 7. 6.1 or more Mac OS 8.x

Power PC

24MB

10MB

One 2HD 3.5-inch floppy di sk drive

CD-ROM

Printer port

One 12-inch CD-ROM drive

Et hernet 1 port

2.2.2 PRINTING IMAGE AREA

Image density Initial: 1.32 or more

Life: 1.25 or more (ave.) / 1.00 or more (min.)

Image density gap Initial: ∆ID ≤ 0.15

Life: ∆ID ≤ 0.20

Background Initial: FD ≤ 0.005

Life: FD ≤ 0.008

Printing magnification ± 0.8 %/total length / ± 0.8 %/50 mm or less

Printing position accuracy Horizontal: ± 2.0 mm

Longitudinal: ± 2.5 mm

Skew: 2.0 mm/200 mm or l ess

Squareness ± 1.5 mm/375 mm or less

Image distortion Total length: ± 1.0 mm/375 mm or less /

± 0.5 mm/50 mm long or less

Version 1-1 December 2001 26

Kyocera Mita Europe B.V.

© Product Support Department

Page 27

Printer margin/ imperfect image area

C

Product T echnical Information KM-2530

B

A

Y

Page length

(mm)

Margin width

Copy margin imperfect image area

2.3 Networking

D

X

Page width

SIDE

ABCD

4.0 – 2.0 6.0 – 2.5 6.0 – 2.0 6.0 – 2.5

10.0 or les s

2.3.1 NETWORKING

TypeHardware: Embedded on the Printing system N

Interface Ethernet / 10 Base T/100 Base TX / RJ45

Multiprotocol support

Interface auto recognition

Applicable protocols IPX/SPX

(Netware Directory Services, Bindery , R/Npriter)

TCP/IP

(BootP , DHCP, RARP, ARP , IP, ICMP , UDF, TCP , FTP, TFTP , LPD)

WINS

SNMP

SMTP

Ethertalk / T okentalk phase 2

Http/ Html

NetBUEI

UNIX (TCP/IP)

SNMP

MIB II and private print server MIB

HTML from 3.x / frame support

Applicable network OS Novel Netware 3.1/3.11/3. 12/4. 1/4. 1 1/5. 0/

Windows NT 3.5X/4.0 and win 2000

Windows 95/98

Mac OS 7.x, 8.x, 9.x

UNIX AIX 3.0, SunOS, HP-UX,

SNMP

MIB II and private print server MIB

HTML from 3.x / frame support

Version 1-1 December 2001 27

Kyocera Mita Europe B.V.

© Product Support Department

Page 28

Product T echnical Information KM-2530

HTML from 3.x / frame support

Configuration management KYOCON Administration software

Kyocera Mita print monitor

FTP

Web browser

SNMP management software

Version 1-1 December 2001 28

Kyocera Mita Europe B.V.

© Product Support Department

Page 29

Product T echnical Information KM-2530

3FACSIMILE

3.1 Specifications

3.1.1 BASIC

Applicable line Subscriber line (1 line)

CCITT G3

TX mode Half duplex

Modulation TCM, QAM and PhM

Coding method MMR, MR and MH

•JBIG is applicable by the running charge

TX speed 33. 6 / 31. 2 / 2 8. 8 / 2 6. 4 / 2 4. 0 / 2 1.6 / 1 9.2 / 1 6.8 / 1 4.4 / 12 .0 / 9. 6 / 7.2 / 4 .8 / 2.4 kbps

Minimum TX time 10 msec./line (normal) / 5 msec./line (fine)

Transmission time Less than 3 sec.

•memory transmission (ECM)

•resolution: normal, no JBIG, no T TI

•exposure level:center

Transmission size Width: 148-297mm

Length 148-1600mm

Size of recording paper A3R-A5R

Quick scanning Less than 2 sec/sheet (A4)

Short protocol With Kyocera Mita models

Pre-procedure: 5 sec. or less

Pre-procedure: 3 sec. or less

Memory Standard memory board

Image memory Standard: 4 Mb

Option: 4 Mb

Bitmap memory Standard: 4 Mb (TX: 2Mb / RX: 2Mb)

Option: 4 Mb

Effective scanning width A3: 289 mm or more

B4R: 249 mm or more

A4R: 202 mm or more

Support equipment/optional equipment: Add-on memory for Fax

Fax TX image quality

B/W resolution Normal: 8 dots/mm x 3.85 lines/mm

Fine: 8 dots/mm x 7.7 lines/mm

Super-fine: 8 dots/mm x 15.4 lines/mm

Ultra-fine: 16 dots/mm x 15.4 lines/mm

Halftone (grey scale) Image processing + fine: 128 levels with error diffusion

Fax RX image quality

B/W resolution Normal: 8 dots/mm x 3.85 lines/mm

Fine: 8 dots/mm x 7.7 lines/mm

Super-fine: 8 dots/mm x 15.4 lines/mm

Ultra-fine: 16 dots/mm x 15.4 lines/mm

•Ultra-fine mode is available when the optional bitmap memory is installed

Version 1-1 December 2001 29

Kyocera Mita Europe B.V.

© Product Support Department

Page 30

3.1.2 MODEM (G3 MODEM)

Product T echnical Information KM-2530

TX mod e

Modulation TCM TCM QAM PhM

TX speed (KBPS)

12.0 / 9.6 / 7.2 / 4.8 / 2.4

Speed variation – 0.01% – 0.01% – 0.01% – 0.01%

Modulation speed (KBPS) 3.429 / 3.2 / 3.0 / 2.8 / 2.4 2.4 2.4 2.4 / 1.6

C ar rie r frequenc y (Hz)

Fre quency va riation – 0.01% – 0.01% – 0.01% – 0.01%

Detection Synchronous Synchronous Synchronous Synchronous

Automatic equalisation Yes Yes Yes Yes

Tonal signal CNG / CED CNG / CED CNG / CED CNG / CED

Tonal signal frequency (Hz) 11 00 / 2100 1100 / 2100 1100 / 2100 1100 / 2100

Modem signal detection range -9 ~ -43 dBm 0 ~ -43 dBm 0 ~ -43 dBm 0 ~ -43 dBm

Output level <0 ~ <-15 dBm <0 ~< -15 dBm <0 ~< -15 dBm <0 ~ <-15 dBm

V34 V17 V29 V27ter

33.6 / 3 1.2 / 28 .8 /

26.4 / 2 4.0 / 21 .6 /

19.2 / 1 6.8 / 14 . 4 /

Low High

1800 2000

1680 1867

1600 1800

14 .4 / 12.0 / 9.6 / 7.2 9 .6 / 7. 2 4 .8 / 2 . 4

1700 1700 1800

3.1.3 IMAGE QUALITY

Fax TX image quality

B/W resolution Normal: 8 dots/mm x 3.85 lines/mm

Fine: 8 dots/mm x 7.7 lines/mm

Super-fine: 8 dots/mm x 15.4 lines/mm

Ultra-fine: 16 dots/mm x 15.4 lines/mm

Halftone (grey scale) Image processing + fine: 128 levels with error diffusion

Fax RX image quality

B/W resolution Normal: 8 dots/mm x 3.85 lines/mm

Fine: 8 dots/mm x 7.7 lines/mm

Super-fine: 8 dots/mm x 15.4 lines/mm

Ultra-fine: 16 dots/mm x 15.4 lines/mm

•Ultra-fine mode is available when the optional bitmap is installed

Fax image

Item Basic S pecification

(a) Fine

N6.5 –1: All pixels shall be black

Threshold

(b) Halftone

N9.5: FD: 0.03 or less

N5.5: ID=0.6–0.35

N2.0: ID≥1.0

Version 1-1 December 2001 30

Kyocera Mita Europe B.V.

© Product Support Department

Page 31

Product T echnical Information KM-2530

3.2 Facsimile Functions

3.2.1 RECEIVING FUNCTIONS

Manual RX

Automatic RX

TAD

Remote switching Initial value: 55 (DTMF only)

FAX/TEL auto switching

3.2.2 TRANSMITTING FUNCTIONS

Numeric key dialing Up to 32 digits

Abbreviated dialing Up to 300 numbers

One touch dial

Program dial

Group dial Up to 80 numbers (incl. One touch / Program / chain / fax service dials)

Chain dial

Fax service dial

Redial Manual / automatic / communication error (not available in the direct TX mode,

retransmitted by the page)

On-hook

Pause

3.2.3 COMMUNICATIVE FUNCTIONS

Direct TX Original could be transmitted from the contact glass

Memory TX Original could be transmitted from the contact glass

Direct RX

Memory RX Confidential RX / Relay RX • Comply with F-Code

3.2.4 ADDITIONAL COMUNNICATIVE FUNCTIONS

Sequential broadcast Up to 300 parties

Polling TX Memory

Polling RX Up to 300 parties

F-Code confidential TX

F-Code confidential RX 15 confidential boxes

F-Code bulletin board TX

F-Code bulletin board RX

F-Code relay broadcast 15confidential boxes

Encryption TX KM model original mode Compatible with Fax System (B)

Encryption RX KM model original mode Compatible with Fax System (B)

Password checking TX ID number and telephone number confirmation

Password checking RX ID number and telephone number confirmation

Memory forward

Version 1-1 December 2001 31

Kyocera Mita Europe B.V.

© Product Support Department

Page 32

Product T echnical Information KM-2530

TX reservation Direct TX / Memory TX, Up to 50 reservations in totoal

Timer TX Up to 50 reservations in total

Interrupt TX Up to 50 reservations in total

Short protocol With Kyocera Mita models

ECM

3.2.5 COMMUNICA TION SUPPORT FUNCTIONS

F-Code confidential BOX output

Manual TX

Address directory book

TX suspension

Line monitor

Destination display

Tone TX

Memory backup When installing 16 MB fulll memory; 60 min.or more

TX result display displayed on LCD

3.2.6 TRANSMISSION SUPPORT FUNCTIONS

Sequential TX Up to 10 TXs

TX information Sender

Bulletin board function Support fuction of memory polling transmission

Comply with F- code

Rotate TX

Duplex TX When SRDF is installed

TX speed setting 33.6 / 14.4 / 9.6 kbps

3.2.7 RECEPTION SUPPORT FUNCTIONS

Out of paper RX Standard memory: 200 pages or more

Optional memory: 530 pages or more

Original: Kyocera Mita ITU-T no.1

Resolution: normal

Density: light

2 in 1 RX 2 pages of A5E original → A4R

Auto reduction RX

Rotate RX

Duplex RX When AD-63 is installed

Paper feed setting Automatic

Fixed drawer

Fixed size

Copy mode switching during RX

Receiving date record

Version 1-1 December 2001 32

Kyocera Mita Europe B.V.

© Product Support Department

Page 33

3.2.8 REPORT FUNCTION

Transaction report TX / R X

Activity report Up to 50 communications

Power failure report

Reservation confirmation report

Timer reservation report

User setting list

Encryption key list

Department management report

Access code list

Abbreviated dial list

One touch dial list

T elephone directory list

Program list

Group list

3.2.9 LOCAL PARTY INFORMATION

Telephone number Up to 20 digits

Name of party 1

ID number

T elephone number settings Up to 5 numbers

ID number settings Up to 5 numbers

Memory forward

Date recording

No of remote switching 00 ~ 99 (2 digits)

Password 0000 ~ 9999 (4 digits)

Encryption key Up to 20 numbers (16 digits)

Product T echnical Information KM-2530

3.2.10 OTHER FUNCTIONS

Memory edition

Remote diagnosis

Departmental fax control 50 departments

•Different control from the copy control

Smoothing RX Convert to 600dpi

Version 1-1 December 2001 33

Kyocera Mita Europe B.V.

© Product Support Department

Page 34

Product T echnical Information KM-2530

4SCAN SYSTEM

4.1 Specifications

4.1.1 BASIC

T yp e PPC network scanner

Option Composition Scanner NIC (NS-30)

Clock PCB

CD-ROM (Scanner Library)

CD-ROM (Paper Port)

Document

Basic function Network Scanner (B/W)

(a) PC transmission (with Scanner File Utility)

(b) E-mail transmission

(c) TWAIN Scan (with TWAIN source)

Interface card NS-30

Interface: 10BASE-T , 100BASE-TX (auto recognition)

Protocol: TCP/IP

Resolution Mainscan x sub scan 600 x 600

Switching selection: 600/400/300/200dpi

Document table

System: Main body; stationary original

With DF; moving original

Documents: Sheets, books, 3-dimensional objects

Alignment: Main body; Left rear

With DF; Center matching

Original specification Paper thickness; applies to copy specification

Paper size; A3 ~ B6, Folio

Type of paper; applies to copy specification

4.1.2 MACHINE SPECIFICATION

Original Size A3R ~ B6R, non-standard

Transmission Size A3 ~ B6, Folio (default size is the same as the original size)

Resolution 600dpi, 400dpi, 300dpi, 200dpi

Gradation level T ext mode: 2 tones/1 dot 256 gradations (error diffusion)

Photo mode: 2 tones/1 dot 256 gradations (error diffusion)

Mix (text and photo) mode: 2 tones/1 dot 256 gradations (error diffusion)

OCR mode: 2 tones/1 dot 256 gradations (error diffusion)

Scanning speed 25 pages/min.

Multiple scanning max. 250 pages

TX Setting

(a)TX mode: Send to PC/E-mail/TWAIN scan

(b)Send from selection: Max. 40 destinations (password check available)

(c)Destination selection:

a)Share address book: Max. 100 destinations (password check available, multiple selection; max.

20 destinations, possible to search address from the intitial letter

b)Personal address book:Max. 100 destinations (password check available, multiple selection; max.

20 destinations, possible to search address from the intitial letter

c)Save to user PC: Possible

•When send to e-mail; you can use the keys on the touch panel for direct address input

Input file name Max.20 characters

Version 1-1 December 2001 34

Kyocera Mita Europe B.V.

© Product Support Department

Page 35

Product T echnical Information KM-2530

User Default Setting Possible to set on copier operation section and web browser

(a)Network setting: TCP/IP setting; IP address

Subnet mask

Default gateway

DHCP/BTTP (ON/OFF)

RARP (ON/OFF)

DNS server (primary)

DNS server (secondary)

DNS domain nam

Host name

SMTP server

(b)Administrator setting: Administrator e-mail address

Administrator password (8-digit number or less)

(c) Scanner default setting: Original type Text, Photo, Text+Photo, OCR

Resolution 600dpi, 400dpi, 300dpi, 200dpi

File format TIFF , PDF

Multiple scanning ON/OFF

File name 16 characters or less

User Registration Possible to register on copier operation section and web browser

(a)PC tx setting

(1)Send to destination: Max. 100 destinations

(2)Send to PC: Registration name: 16 characters or less

Send to PC address: 32 characters or less (IP address or

hostname)

Storing numbers: 001 - 100

(3)Send to PC (group) 16 characters or less

Group members: max. 30

Group password: 8 digits number or less

(b)E-mail tx setting

(1)Basic setting: Subject: 16 letters or less

Contents: 500 letters or less

Lettercode set: US-ASCII, Shift JIS, ISO8859-1

(2)Destinatin registration:Max. 100 destinations

(3)Destination address: Registration name: 16 characters or less

E-mail address: 64 characters or less

Group members: max. 30

(4)TX approval domain: 500 characters or less

(5)TX domain limitation: 500 characters or less

(6) Data size limitation: Low (512KB), Mid(1024KB), High(2048KB), no limit

(c)Sender address Registration: max.40

Registration name: 16 characters or less

E-mail address: 64 characters or less

Address book for PC addresses: IP address or host name

Password: 8 digits number or less

Signature: 256 characters or less

•Possible to set from web browser and address editor

4.1.3 SCANNER FILE UTILITY SPECIFICATIONS

Version Version 2.0

Supporting Model Print/Scan System (L) (3BJ), KM-2530 (2BH), KM-3530 (2BJ), KM_4530

(2BC)/KM-5530 (2BD), KM-C830 (2A6)

Media CD-ROM “Kyocera Mita Scanner Library”

Install Insert CD-ROM, select utility from menu

Install destination Can be selected by user

Register to programm menu Product name displays under menu “Scanner User Software”

Version 1-1 December 2001 35

Kyocera Mita Europe B.V.

© Product Support Department

Page 36

Product T echnical Information KM-2530

Operating environment

(1) PC IBM PC/AT compatible

CPU: pentium 133MHz or more (150MHz for Windows ME)

RAM: 64MB or more

HDD: 20MB or more free space

(2) OS Interface: Ehternet

Windows 95 (OSR2), 98 (second edition), NT4.0 (SP5), 2000, ME

4.1.4 TWAIN SOURCE SPECIFICATION

Version Ver.1.00

Media CD-ROM “Kyocera Mita Scanner Library”

Install Insert cd-rom, selct utility form menu

Install destination Under OS directory /TWAIN_32 (or start function from TWAIN support

program)

Setting function: Original size A3 ~ B6, Folio

Original orientation Select icon; portrait/long ways, portrait side

ways, landscape/long ways, landscape/side

ways

Tx Size A3 ~ B6, Folio

Original type T ext, Photo, Text&Photo, OCR

Resolution 600dpi, 400dpi, 300dpi, 200dpi

Scaning seeting Auto start: conducts multiple scanning when

using DF

Split duplex original possible when using DF

Pre-view function None

Operating environment

(1) PC IBM PC/AT compatible

CPU: pentium 133MHz or more (150MHz for Windows ME)

RAM: 64MB or more

HDD: 20MB or more free space

(2) OS Interface: Ethernet

Windows 95 (OSR2), 98 (second edition), NT4.0 (SP5), 2000, ME

(3) Evaluated application Windows Imaging

Adobe Photoshop

4.1.5 ADDRESS BOOK SPECIFICATIONS

Version Ver.1.00

Media CD-ROM “Kyocera Mita Scanner Library”

Install Insert cd-rom, selct utility form menu

Install destination C:/ProgrammFiles/KyoceraMita/Address Book Utility

Import function

(a) Import file Address Book data file

CSV file (only for e-mail address)

(b) Import item Address Book register data

Name, e-mail address, comment

(c) Check function Checks the max. number of charactes allowed, displays warning

Operating environment

(1) PC IBM PC/AT compatible

CPU: pentium 133MHz or more (150MHz for Windows ME)

RAM: 64MB or more

HDD: 20MB or more free space

(2) OS Interface: Ethernet

Windows 95 (OSR2), 98 (second edition), NT4.0 (SP5), 2000, ME

(3) Evaluated application Outlook Express

Version 1-1 December 2001 36

Kyocera Mita Europe B.V.

© Product Support Department

Page 37

Product T echnical Information KM-2530

5SPECIFICATIONS OF OPTIONAL EQUIPMENT

5.1 Document Feeder SDRF-2 and STDF-3

5.1.1 BASIC SPECIFICATIONS / RELIABILITY SDRF-2

T yp e Copier mounted document feeder

Alignment Centre (face-up)

Original Sheet

Original size A3 ~ A5R, folio (140 (W) x 140 (L) mm ~ 216 (W) x 1,700 (L) mm)

Paper weight ADF mode: 35 ~ 160 g/m²

RADF mode: 60 ~ 110 g/m²

Capacity A4 ~ A5R: Max. 70 sheets (80 g/m²)

A3, B4: Max. 50 sheet (80 g/m²)

MDBJ 5,000 sheets

MDBMF Multiple feeding: 2,500 sheets

Skew: 500 sheets

(MDBJ: average interval between original document jams)

(MDBMF: average interval between original document misfeedings)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.1.2 PERFORMANCE SDRF-2

Leading edge timing tolerance ADF mode: ± 2.0 mm or less

RADF mode: ± 2.0 mm or less

Skew feed tolerance ADF mode: 2.0 mm or less

RADF mode: 3.0 mm or less

Side registration tolerance ADF mode: ± 2.0 mm or less

RADF mode: ± 3.0 mm or less

Machine life 5 years or 800,000 sheets

Maintenance interval 50,000 sheets

Power source Electrically connected to the copier

Machine size Approx. 553 (W) x 478 (D) x 121 (H) mm

Weight Approx. 10.5 kg

5.1.3 CONSUMABLE PARTS SDRF-2

Description Part Number Quantity Lifetime

Pulley, Leading Feed 3BC07010 1 according to the

cassette counter

Pulley, Separation 3BC07020 2 idem

Version 1-1 December 2001 37

Kyocera Mita Europe B.V.

© Product Support Department

Page 38

5.1.4 PERIODIC MAINTANCE LIST SDRF-2

CH=check CL=clean AD=adjust LU=lubrication RE=replace

(3C0)

Parts Name

ASet up

1COPY QUALITY -

Cover

B

CONTACT GLASS,

1

ADF

2 COVERS - CL CL CL CL CL CL Clean with alcohol

C Original feed section

PULLY, LEADING

1

FEED

PULLEY,

2

SEPERATION

ROLLER,

3

REGISTRATION

FRONT PULLEY,

4

READING

PULLEY B,

5

REGISTRATION

6 SWITCH L, FEED 63227150

Parts

Number

2AV12250

3B C0701 0 CL RE RE RE RE RE Clean with alcohol

3B C0702 0 CL RE RE RE RE RE Clean with alcohol

X2

3BC08050 CL CL CL CL CL Clean with alcohol or a dry cloth

3AL08480 CL CL CL CL CL Clean with alcohol or a dry cloth

X2

3BC08220

X3

Periodic Maintenance (100x counts)

On

User

Delivery

CHADCHADCHADCHADCHADCHADCH

100K 200K 300K 400K 500K

Call

CH

CL CL CL CL CL Clean front and back with alcohol or dry cloth

CL

CHCLCHCLCHCLCHCLCH

CH

CL CL CL CL CL Clean with alcohol or a dry cloth

CL

AD

CL

Product T echnical Information KM-2530

Remarks

Clean with alcohol or a dry cloth

Original Conveying

D

Section

LOWER ROLLER,

1

CONVEYING

UPP ER ROLLE R ,

2

CONVEYING

UPP ER ROLLE R

3

CONVEYING

GUIDE,

4

CONVEYING

COVER,

5

CONVEYING

PULLEY

INNER ROL LER,

6

CONVEYING

INNER P ULLEY,

7

CONVEYING

PULLEY, EJECT

8

Original Reversing

E

Section

ROLLER, LOOP 3AL100 20 CL CL C L CL C L Clean with alcohol or a dry cloth

1

2 PULLEY, EJECT 3AL08170

3 ROLLER, EJECT 3AL08130 CL Clean with alcohol or a dry cloth

F Table Section

FILTER CF

1

SENSOR

3AL08112 CL CL CL CL CL Clean with alcohol or a dry cloth

3AL08161 CL CL CL CL CL Clean with alcohol or a dry cloth

3AL08140 CH CH C H CH CH Clean when necessary,

X2

3AL08033 CL CL CL CL CL Clean with alcohol or a dry cloth

3AL0803-

02

3BC08150 CL

3AL08100 CL

X2

3AL08170

X2

78706241

CL CL CL CL CL

CHCLCHCLCHCLCHCLCH

CHCLCHCLCHCLCHCLCH

CH

CL CL CL CL CL Clean with alcohol

CL

Clean with alcohol or a dry cloth

Clean the opposite side of the timer senser

Remove the front, back, right cover and mount of

the conveying pulley. Clean with alcohol

Remove the front, back, right cover and mount of

the conveying pulley. Clean with alcohol

Clean when necessary, use alcohol or a dry cloth

CL

Clean when necessary, use alcohol or a dry cloth

CL

Others

G

MAT, ORIGINAL

1

HOLDER

SHEET, ORIGINAL

2

HOLDER

SP ON GE, ORIGINAL

3

SIZE INDICATION

3AL04060 CL CL CL CL CL Clean with alcohol or a dry cloth

3AL08401 CL CL CL CL CL Clean with alcohol or a dry cloth

35912531

CH

CL CL CL CL CL

CL

Version 1-1 December 2001 38

Clean with alcohol or a dry cloth. It is attached to

the main machine.

© Product Support Department

Kyocera Mita Europe B.V.

Page 39

Product T echnical Information KM-2530

5.1.5 BASIC SPECIFICATIONS/RELIABILITY STDF-3

T yp e Copier mounted document feeder

Single sided sheet through DF

Alignment Centre

Original size A3 ~ A5R, folio

Paper weight 50 ~ 160 g/m²

Capacity A4 ~ A5R: Max. 70 sheets (50~80 g/m²)

A3, B4: Max. 50 sheets (50~80 g/m²)

Process speed Original exchange speed: 15 sheets/min. (A4 lateral direction)

Original scanning speed: 100mm/sec. (at 100% magnification)

•200% enlargement to 50% reduction: 50 to

200mm/sec.

Leading edge misalignment ±2.mm or less

Front to rear misalignment ±2.mm or less

SDF mode None

Power source Supplied by copier

Machine size Approx. 525 (W) x 478 (D) x 121 (H) mm

Machine life 5 years or 30,000 sheets

Weight 2,25kg or less

Maintenance periodic: 50,000 copies

MDBF 50,000 copies

(MDBF: average interval between original document failures)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.1.6 PERFORMANCE STDF-3

Leading edge misalignment ±2.mm or less

Skew feed tolerance Right/left gap (A4) 2.0 mm or less

Right/left gap (A3) 3.0 mm or less

Front to rear misalignment ±2.mm or less

5.1.7 CONSUMABLE PARTS STDF-3

Description Part Number Quantity Lifetime

No info available at this moment.

5.1.8 PERIODIC MAINTENANCE LIST STDF-3

No info available at this moment.

Version 1-1 December 2001 39

Kyocera Mita Europe B.V.

© Product Support Department

Page 40

Product T echnical Information KM-2530

5.2 Multi Desk PF-70

5.2.1 BASIC SPECIFICATIONS / RELIABILITY

T yp e Loading type on copier

System Fr ont r etar d

Number of drawers 2

Size detection Automatic

Interface Communication: Controlled by copier

Connector: General-purpose connector

Power source Supplied by copier

Paper size A3 ~ A5R, folio

Paper weight 60 ~ 105 g/m

2

Paper type Standard paper/semi standard / recycled paper/special paper (color paper;

Georgia Pacific)

Paper setting position Center

Capacity 550 sheets (80 g/m2) x2

•Up to 275 sheets of specified standard paper (with moisture unadjusted) can

be set in a standard operation environment.

•PF-70 can not be stacked

Casette humidifying heater Available as a spare part

Required attachment None

Machine size Approx. 585 (W) x 590 (D) x 315 (H) mm

Weight Approx. 26kg

Machine life 5 years or 800,000 sheets

Maintenance periodic: 400,000 sheets

main replaceable parts: Paper feed pulley , seperation pulley , paper

forwarding pulley

MCBJ 10,000 sheets

MCBF 70,000 sheets

(MCBJ: average number of copies between paper jams)

(MCBF: average number of copies between failures)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.3.2 PERFORMANCE

Leading edge misalignment Conform the copier specifications (±2.5mm)

Skew feed tolerance Conform the copier specification (right/left gap 1.5mm or less)

Right to left misalignment Conform the copier specification (2.0mm or less)

Paper conveying performance Number of conveyed sheets per minute: 25 sheets/min.

Paper conveying speed 315.458mm/sec

Version 1-1 December 2001 40

Kyocera Mita Europe B.V.

© Product Support Department

Page 41

Product T echnical Information KM-2530

5.2.3 CONSUMABLE PARTS

Description Part Number Quantity Lifetime

Right Pulley , Paper Feed 3390660 2 according to the

cassette counter

Pulley , Sparation 2AR07220 2 idem

Pulley Leading Feed 2AR07230 2 idem

5.2.4 PERIODIC MAINTENANCE LIST PF-70

CH=check CL=clean AD=adjust LU=lubrication RE=replace

Periodic

(3CC)

Parts

Number

Parts Name

Maintenance (x1000

counts)

On

Delive-

ry

User

Call

500*

Remarks

ASet Up

1 PAPER LINE -

PF Section

B

ROLLER VE RTICAL

1

CONVEYING

RIGHT PULLEY, FEED

2

PULLEY, PAPER FEED

3

PULLEY, SEPARATION

4

PULLEY, LEADING FEED

5

CLUTCHES,

REGISTRATI ON

6

2AR07420 CL Clean with alcohol or a dry cloth

33906660 CL Clean with alcohol or a dry cloth

X2

2AR07220

X2

2AR07230

X2

2AR0740

X2

2AC06230

X3

CH

AD

CH

CL

CH

CL

CH

CL

CH

RE

Check the center alignment gap

(check after the center adjustment of

the copier)

RE Clean with alcohol

RE Clean with alcohol

RE Clean with alcohol

CH Check the paper feed condition

*maintenance conform the copier

Version 1-1 December 2001 41

Kyocera Mita Europe B.V.

© Product Support Department

Page 42

Product T echnical Information KM-2530

5.3 Special Tray PF-75

5.3.1 BASIC SPECIFICATIONS/RELIABILITY

T yp e Loading type on copier

System Friction retard

Number of drawers 1

Size detection Manual setting

Interface Communication: Controlled by copier

Connector: General-purpose connector

Power source Supplied by copier

Paper size A4

Paper weight 60 ~ 105 g/m

Paper type Standard paper/semi standard / recycled paper/special paper (color paper;

Georgia Pacific)

Paper setting position Center

Capacity 3,000 sheets of specified standard paper (with moisture unadjusted) can

be set in a standard operation environment.

Casette humidifying heater Available as a spare part

Required attachment None

Machine size Approx. 585 (W) x 590 (D) x 315 (H) mm

Weight Approx. 22kg

Machine life 5 years or 800,000 sheets

Maintenance Periodic: 400,000 sheets

Main replaceable parts: Paper feed pulley , seperation pulley , paper

MCBJ 10,000 sheets

MCBF 70,000 sheets

2

forwarding pulley, torque limiter , paper

forwarding pulley ass’y

(MCBJ: average number of copies between paper jams)

(MCBF: average number of copies between failures)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.3.2 PERFORMANCE

Leading edge misalignment Conform the copier specifications (±2.5mm)

Skew feed tolerance Conform the copier specification (right/left gap 1.5mm or less)

Right to left misalignment Conform the copier specification (2.0mm or less)

Paper conveying performance Number of conveyed sheets per minute: 25 sheets/min.

Paper conveying speed 315.458mm/sec

5.3.3 CONSUMABLE PARTS

Description Parts Number Quantity Lifetime

H-Pick roller 5A707600 2 500 or conform

maintenance of the copier

Pulley, paper feed 5FH06010 1 idem

Pulley , separation 5FH06020 1 idem

C-Pick Pulley 5A707580 1 idem

Clutches - 1 idem

Version 1-1 December 2001 42

Kyocera Mita Europe B.V.

© Product Support Department

Page 43

5.3.4 PERIODIC MAINTENANCE LIST PF75

CH=check CL=clean AD=adjust LU=lubrication RE=replace

(5FF)

Parts Name

ASet Up

Parts

Number

Periodic Maintenance

(x1000 counts)

On

Delivery

User

Call

Product T echnical Information KM-2530

Remarks

500*

1 PAPE R LINE -

BPF Section

H-PICK ROLLER

1

PULLEY, PAPER

2

FEED

PULLEY,

3

SEPARATION

4 C-PICK PULLEY 5A707580

TLP1241(C5)

5

SNS-SPI-338

6

7CLUTCHES -

5A707600

X2

5FG06010

5FH06020

5AA09040 CL Airbrush

X3

5A707980 CL Airbrush

X4

CH

AD

CH

RE

Check the center alignment gap

(after the center adjustment of the

copier)

CL

RE

CL

RE

CL

RE

CL

RE

CH Check paper feed condition

Clean with alcohol or dry cloth

Clean with alcohol or dry cloth

Clean with alcohol or dry cloth

Clean with alcohol or dry cloth

*maintenance conform the copier

5.4 Auto Duplex Unit AD-63

5.4.1 BASIC SPECIFICATIONS / RELIABILITY

T yp e Internal

Paper conveying/ejection

Alignment: Center

Paper conveying speed: 100mm/s, 300mm/s (Duplex switchback-

refeed)

Refeeding system: Stackless

Paper size A3 ~ A5R, folio

Paper weight 75 ~ 80 g/m²

Paper type Standard/semi-standard/recycled/special paper

Control Controlled by copier

Power source Supplied by copier

Machine life 5 years or 300,000 sheets

Periodic maintenance 100,000 sheets

Version 1-1 December 2001 43

Kyocera Mita Europe B.V.

© Product Support Department

Page 44

Product T echnical Information KM-2530

Main replacebale parts Rollers: 100,000 sheets; Cleaning

Machine size Approx. 390 (W) x 56 (D) x 171 (H) mm

Weight Approx. 1 kg

Leading edge timing tolerance Conform the copier specification

Skew feed tolerance Conform the copier specification

MCBJ Conform the copier specification

MCBF Conform the copier specification

(MCBJ: average number of copies between paper jams)

(MCBF: average number of copies between failures)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.4.2 CONSUMABLE PARTS

There are no consumable parts

5.4.3 PERIODIC MAINTENANCE LIST AD-63

CH=check CL=clean AD=adjust LU=lubrication RE=replace

(3CX)

Parts Name

A

Paper Conveying section

1

ROLLER DU FEED UP 2BL07020

2

ROLLER DU FEED LOW 2B L07030

B

Other

1

GEARS -

2

BUSHINGS -

Parts

Number

Periodic

Maintance

(x1000

counts)

CH

CL

CH

CL

Remarks

CL alcohol

CL alcohol

CHCLapply grease TMP-200G (P/N 66668050) if

unusual no ise arises

CHCLapply grease TMP-200G (P/N 66668050) if

unusual no ise arises

3

PAPER C ONV. SECT. -

Version 1-1 December 2001 44

CH

CL

alcohol or dry cloth

*maintenance conform the copier

© Product Support Department

Kyocera Mita Europe B.V.

Page 45

Product T echnical Information KM-2530

5.5 Document Finisher DF-71E and DF-78

5.5.1 BASIC SPECIFICATIONS/RELIABILITY DF-71E

T yp e Floor type

System Bin-shifting system

Number of bins 2 bins, (Main tray/Sub tray)

Interface In combination with copier

Power source Supplied by copier; serial interface (9600bps)

Attachment Preset (only when copier is installed)

Paper size A3W ~ A6R, Folio

Paper weight Non-sort: 60 ~ 200 g/m

Punch: 60 ~ 160g/m

Staple: 60 ~ 200g/m

Paper type Standard paper/semi standard / recycled paper/special paper

Paper feed performance Alignment: Center

Copy direction: Main tray: Face down

Sub tray: Face down/face up

Reversing function: Natural reversing ejecting is available when

ejecting to the main tray

Stacking capacity Sub tray Non-Punch: 150-250 sheets

Punch: 150-250 sheets

Main tray Non-staple/punch:3000 sheets (2-50 sheets/set)

Staple: 3000 sheets (60 sets)

Staple/punch: 3000 sheets (60 sets)

Punch: 3000 sheets (incl. offsets)

Processing tray (Mid-conveying tray) 30-50 sheets

Machine size Approx. 617 (W) x 584 (D) x 960 (H) mm

Weight Approx. 40kg

Machine life 5 years or 2,400,000 sheets or more

Maintenance Periodic: 150,000 sheets or more

Maintenance parts: Staple unit: 400,000 times

Others: See periodic maintenance list

MCBJ The section to processing tray or sub-tray: 60,000 sheets or more

The section from procesing tray to main tray: 20,000 sheets or more

MCBF 1,000,000 sheets or more

2

2

2

(MCBJ: average number of copies between paper jams)

(MCBF: average number of copies between failures)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.5.2 STACKING PERFORMANCE DF-71E

Stacking coherence B5, B5R, A5R papers and enveloppes are excepted, but there is no dropping

or paper jam

<Sub Tray>

Left-Right: 30 mm or less

Front-Rear: 50 mm or less

< Main Tray >

Non-staple mode: Each sheet: Left-Right: 15 mm or less (2 ~ 14 sheets/set)

35 mm or less (15 ~ 50 sheets/set)

Front-Rear: 10 mm or less (2 ~ 1500 sheets/set)

15 mm or less (1501 ~3000 sheets/set)

Stacking trouble frequency 0.1% (counted in all modes, based on the number of sets)

Version 1-1 December 2001 45

Kyocera Mita Europe B.V.

© Product Support Department

Page 46

Product T echnical Information KM-2530

Each set: Left-Right: 20mm or less

Front-Rear: 30 mm or less

Staple mode: Each sheet: Left-Right: ±1.5 mm or less

Front-Rear: ±1.5 mm or less

Each set: There is no dropping or disorders

5.5.3 ST APLING PERFORMANCE DF-71E

Stapling accuracy: Left-Right: ± 2.5 mm or less

Front-Rear: ± 2.5 mm or less

Stapling position irregularity: 0.1 % or less

Punching accuracy: Pitch of the holes: ±0.5mm or less

Left-Right: 2.0mm or less

Front-Rear: 2.0 mm or less

5.5.4 CONSUMABLE PARTS DF-71E

Description Part Number Quantity Lifetime (x1000copies)

Punch ass’y (metric) 3C100040 1 400K

Punch ass’y (inch) 3C100050 1 idem

Pulley, leading feed 3C108110 2 300K

T orque limiter , bypass 33906430 1 idem

5.5.5 PERIODIC MAINTENANCE LIST DF-71E

See next page

Version 1-1 December 2001 46

Kyocera Mita Europe B.V.

© Product Support Department

Page 47

Product T echnical Information KM-2530

5.5.5 PERIODIC MAINTENANCE LIST DF-71E

CH=check CL=clean AD=adjust LU=lubrication RE=replace

(3CG)

Part Name

ASet Up

1COPY QUALITY -

BCover

REAR STAC K SE NSOR

1

PCB

FRONT STACK

2

SENSOR PCB

3 COVER - C L CL C L CL CL Clean with alcohol or a dry cloth

C Additional Function

1 SWITCH, FEED 63227020 CL CL CL CL CL Airbrush

PUNCH ASS’Y

2

(METRIC)

3PUNCH ASS’Y (INCH) 3C 100 05 0

Parts

Number

3AK28020 CL CL CL CL CL Airbrush

3AK28030 CL CL CL CL CL Airbrush

3C100040

Periodic Maintenance (x1000 count)

On

Delivery

CH

AD

User

300-

Call

CHADC HADCHADCHADCH

600K 900K 1200K

K

CHRECHRECH

CHRECHRECH

Remarks

Check the position of the punch

AD

Check the counts of the punch by

preforming sim. Replace when

counts are at 400K or more and

RE

deficiency occurs

Check the counts of the punch by

preforming sim. Replace when

counts are at 400K or more and

RE

deficiency occurs

DConveying Section

JAM DETECTION

1

SWITCH

2 PULLEY, CONVEYING 3AK16030 CL CL CL CL Clean with alcohol or a dry cloth

ROLLER FEED IN

3

ASS’Y SP

ROLLER A1, FEED

4

SHIFT (X1) METRIC

(X2) INCH

ROLLER B1, FEED

5

SHIFT (X2) METRIC

(X1) INCH

ROLLER B, FEED

6

SHIFT

7 PULLEY, FEED SHIFT 3BD08050 CL CL CL CL Clean with alcohol or a dry cloth

8 PULLEY, REVERSE 73210430 CL CL C L CL Clean with alcohol or a dry cloth

9 SWITCH L, REVERSE 63227150 CL C L C L CL Ai rbrush

PULLEY, LEADING

10

FEED

TORQU E LIMITER ,

11

BYPASS

E Eject Section

STATIC ELIMIN ATOR,

1

EJECT

2 ROLLER, EJECT MAIN 3AK06010 CL CL CL CL Clean with alcohol

PULLEY FEEDBACK

3

4 ROLLER, EJECT SUB 3AK16010 CL CL CL CL Clean with alcohol

5 PULLEY, LOOP FEED 63210170 CL C L C L CL Clean with alcohol

78727110 CL CL CL CL CL Airbrush

3BD68020 CL CL RE CL Clean with alcohol or a dry cloth

3C108030 CL CL CL CL Clean with alcohol or a dry cloth

3C108040 CL CL CL CL Clean with alcohol or a dry cloth

3BD08040 CL CL CL CL Clean with alcohol or a dry cloth

3C108110

33906430

63212210 CH CH CH

(X2)

62221110 CL CL CL CL Clean with alcohol

(X2)

CHRECHRECHRECH

CHRECHRECHREReplace when "Pulley Leadng Feed"

Replace when the external diameter

of sponge gets smaller tha n that of

RE

POM.

has not worked

Remove the dust or paper dust if it is

CH

on the brush, replace if the brush is

RE

worn, broken or rolled

Version 1-1 December 2001 47

Kyocera Mita Europe B.V.

© Product Support Department

Page 48

Product T echnical Information KM-2530

5.5.6 BASIC SPECIFICATIONS/RELIABILITY DF-78

T y p e Copier built in type

System Stapling or shift ejection after copying

Number of trays 1 tray (Main tray only)

Paper size A3W ~ B5E, Folio

Paper weight 60 ~ 105g/m

Paper type Standard paper/semi standard / recycled paper

Paper feed performance Alignment: Center

Shift ejection: Non staple mode only

Eject unit: Staple: max. 30 sheets

Load capacity Non-staple: 250 sheets (≤A4)

Staple: 130 ~250 sheets

Machine size Approx. 310 (W) x 410 (D) x 160 (H) mm

Weight Approx. 9kg or less

Machine life 5 years or 1,000,000 sheets

Maintenance Periodic: 500,000 sheets or more

Maintenance parts: Rollers; 500,000 sheets (cleaning)

MCBJ The section to processing tray: 5,000 sheets or more

The section from processing tray to main tray: 2,500 sheets or more

MCBMF Single sided copy: 3,000 sheets or more

Duplex copy: 1,800 sheets or more

MCBF 100,000 sheets or more

2

Non-staple: max. 30 sheets

500 sheets (≥A4)

Others: See periodic maintenance list

(MCBJ: average number of copies between paper jams)

(MCBMF: average number of copies between misfeedings)

(MCBF: average number of copies between failure)

Reliability data are referring to the machine only under the recommended operation circumstances.

5.5.7 STACKING PERFORMANCE DF-78

Non-staple mode: Each sheet: Left-Right: 15 mm or less (2 ~ 14 sheets/set)

35 mm or less (15 ~ 30 sheets/set)

Front-Rear: 10 mm or less

Each set: Left-Right: 20mm or less

Front-Rear: 45mm or less

There is no dropping

Staple mode: Each sheet: Left-Right: ±3 mm or less

Front-Rear: ±3 mm or less

Each set: Left-Right: ±20mm or less

Front-Rear: ±20mm or less

Stacking trouble frequency 0.5% or less (counted in all modes, based on the number of sets)

5.5.8 ST APLING PERFORMANCE DF-78

Stapling accuracy: Left-Right: ± 4mm or less

Front-Rear: ± 4mm or less

Stapling position irregularity: 1 % or less

Misstapling 0.005 %

Version 1-1 December 2001 48

Kyocera Mita Europe B.V.

© Product Support Department

Page 49

5.5.9 CONSUMABLE PARTS DF-78

There are no Consumable Parts

5.5.10 PERIODIC MAINTENANCE LIST DF-78

CH=check CL=clean AD=adjust LU=lubrication RE=replace

P er iodic Ma inte nanc e

(3B5)

Parts Number

Parts Name

A Conveying Sec t ion

(x1000 counts)

On

Delivery

User

Call

Product T echnical Information KM-2530

Remarks

500*

1 FILTER CF SENSOR 78706240