Page 1

PRODUCT TECHNICAL INFORMATION

KM-1810

Preliminary version

April 2001

Issued by: Product Support Department

Page 2

In this ‘

concerning the KM-1810. We hope that this booklet provides you with useful data regarding perf ormance and

construction of this model.

This booklet has been composed of the latest availab le data. Howe v er, specification and design are subject to

change without notification.

©

Product T echnical Information Booklet

Ky ocera Mita Europe 2001

’ you will find specifications and rele vant technical inf ormation

Page 3

Contents

1. General Specifications ...................................................................................................4

1.1 Product Specifications .................................................................................................................. 4

1.1.1 Basic Specifications...................................................................................................................... 4

1.1.2 Copier Specifications .................................................................................................................... 5

1.1.3 Printer specifications (optional printing kit) .................................................................................... 6

1.1.4 Network printer specifications (optional network card) ................................................................. 8

1.1.5 Lifetime data .................................................................................................................................. 9

2 Functions ........................................................................................................................9

2.1 General functions .......................................................................................................................... 9

2.2 Copier funtions .............................................................................................................................. 9

3 Machine Construction..................................................................................................10

3.1 Scanning Section ........................................................................................................................ 10

3.2 Printing section............................................................................................................................ 10

3.3 Photo-Conductor ......................................................................................................................... 10

3.4 Charging Section......................................................................................................................... 10

3.5 Developing Section ..................................................................................................................... 10

3.6 Transfer Section........................................................................................................................... 11

3.7 Separation Section ...................................................................................................................... 11

3.8 Fixing Section.............................................................................................................................. 11

3.9 Charge Erasing ........................................................................................................................... 11

3.10 Cleaning Section ......................................................................................................................... 11

3.11 Memory ....................................................................................................................................... 11

4 T ec hnical Specification ................................................................................................12

4.1 Electrical Aspects ....................................................................................................................... 12

4.2 Environment / safety aspect........................................................................................................ 12

4.2.1 Work environment ....................................................................................................................... 12

4.2.2 Approvals .................................................................................................................................... 12

4.2.3 By-Products (blue Angel testing method).................................................................................... 12

4.3 Maintenance................................................................................................................................ 13

4.4 Reliability Data ............................................................................................................................ 13

5 Performance .................................................................................................................13

5.1 Image quality ............................................................................................................................... 13

5.1.1 Copy Image................................................................................................................................. 13

5.1.2 Print Image (optional printer board is necessary)........................................................................ 14

5.1.3 Image Area.................................................................................................................................. 14

5.2 Paper Feed / Conveying.............................................................................................................. 14

5.3 Wrinles Of Envelopes.................................................................................................................. 15

Appendix 1 Lifetime Of The Consumable & Main P arts............................................................16

Appendix 2 Maintenance List KM-1810 & Optional Equipment..............................................17

Page 4

Product Technical Information KM-1810

1. General Specifications

1.1 Product Specifications

1.1.1 Basic Specifications

Model KM-1810

Type Desktop

Function Standard: Copier

Option: Printer Printing System (M)

Network printer (NC-110)

ST-13

Copy process Indirect electrostatic process copying

Resolution Scanning Section: 600 x 600 dpi

Printing Section: 600 x 600 dpi

Originals Sheets, books 3 dimensional objects

Alignmen t Main body: Left rear

With DF: Centre matching

Paper f eed system

System Standard: Front drawer (1) + Bypass

Optional: F ront drawer (2) + Bypass

Capacity Front dr awer: 250 sheets x 1 (80gsm)

•Up to 275 sheets of specified standard paper

Bypass: 50 sheets (80gsm)

Sizes Front drawer: Folio --- A5R (75 ~ 80 gsm)

Bypass: Folio --- A6R (60 ~ 160 gsm)

•Envelopes can be used in printer mode only.

Paper eject system

System Inner tray (1 way face-down)

Capacity Plain paper: 100 sheets (80 gsm)

Special paper: Up to 50 sheets (varies depending on the stacking

capacity for each paper type)

Warm-up time (20°C/65% RH, at the rated voltage)

Normal: 30 sec. or less

Preheat mode: 30 sec. or less (energy saving has priority.)

10 sec. or less (reco vering has priority.)

Machine size Copier: Approx. 497 (W) x 497 (D) x 445 (H) mm

(3BR) is included.

Preliminary Version April 2001 4 © Service Division.

Kyocera Mita Europe B.V.

Page 5

Product Technical Information KM-1810

Machine weight Copier: Approx. 27kg

Optional equipment

Paper f eeder: ST -13 (3BG) •Max: 1 drawer

Printer kit Printing system (M) (3BM)

Network printer kit NC-110

1.1.2 Copier Specifications

Copy speed Without DF: Normal copy , 100% magnification

A4R: 18 sheets/min, 18 sheets/min

The copy speed has been measured in the f ollowing condition: With memory, sort copy (paper fed from the upper

drawer / 6 % duty) 10 sets of 10 single sided copies from 10 single sided original: 370 sec. or less

First copy (A4 / 100 %) Manual/AE: 6.3 sec. (without DF)

Manual/AE: 6.8 sec. (with DF)

Zoom function 50 ~ 200 % (in steps of 1 %)

Fixed magnifications IRIE

Multiple copying Up to 99 copies

Preliminary Version April 2001 5 © Service Division.

Kyocera Mita Europe B.V.

Page 6

Product Technical Information KM-1810

1.1.3 PRINTER SPECIFICATIONS (OPTIONAL PRINTING KIT)

T rade name Printing System (M)

Type Hardware: Printer controller board

• Built-in board for Digital copier

CPU • Exclusive use for printer

Type: Po wer PC 405

Clock: 200 MHz

Memory • Exclusive use for printer

Code Rom: 4MB DIMM (16 Mbit x 2)

Font Rom: 2MB AGFA Font (16 Mbit x 2)

Main Ram: 8MB (expandable up to 136MB)

• SDRAM

Option Ram: 16 ---- 128MB x 1 slot

100pin-DIMM (16, 32, 64, 128MB)

API ROM: 42pin OTP-ROM 2MB sock et equipped

Printing Speed A4R:18 sheets/min, 18 sheets/min

Resolution: 600x600 dpi

With smoothing equivalent to 1200 dpi to main scanning direction

Resolution enhancement is accomplished by KIR

(Ky ocera image refinement).

With enhancement method Corresponding to 2400 dpi

2 steps: ON / OFF

• Factory setting is KIR on.

Gradation 2 tones / dot

Operating environment Applicable OS: Windows 98/95, NT 4.0, 2000

Macintosh System 7.6.1 or more

Mac OS 8.X

Controller software PDL: Prescribe 2e

Emulation: PCL, PJL

Line Printer

IBM Proprinter X24E

EPSON LQ-850

DIABLO 630

KPDL2 (Post Script 2 compatib le)

AES support

Fonts Outline fonts: 80 fonts

Bitmap fonts: 1 font

Download fonts: KY OCERA format / HP format / True type format.

Graphics Raster graphics: 75, 100, 150, 200, 300, 600 dpi

Vector graphics: line, box, circle, arc, fill pattern etc

One-dimension

bar-code: 45 types

Two-dimension

bar-code: PDF 417 1 type

Connectivity Plug & Play f or Windo ws 95/98/2000

SNMP (Printer MIB support)

Preliminary Version April 2001 6 © Service Division.

Kyocera Mita Europe B.V.

Page 7

Product Technical Information KM-1810

Interface High speed (bi-directional) parallel interface: 1 port

Nibble/ECP mode support

• Comform to IEEE 1284

Optional interface: 1 slot

KUIO-LV • Made by SEH company: NC-110

Po wer supply DC-5V

Memory card interface: 1 slot

Compact flash card: type 1

Support equipment/optional equipment

Attachment software KY OCERA MITA Print Monitor • Network tool

Add-on memory 16 128MB 1 slot • General-purpose 72 pin SIMM, EDO-DRAM 60ns

(Not recomended Hitachi or hyundai Dimm memory).

Network board 10Base T , 100Base TX NC-110

Minimum operating environment

Client-IBM PC/AT or 100% compatible computer

Windows 95 Windows 98 Windows NT 4.0

CPU i486SX/25MHz i486DX/66MHz i486SX/25MH z

Memory 8MB or more 16MB or more 16MB or more

HDD 10MB or more 10MB or more 10MB or more

FDD One 2HD 3.5-inch floppy disk drive

CD-ROM One 12-inch CD-ROM drive

Printer por t IEEE 1284 one por t

Client - Macintosh

Macintosh Macintosh

System 7.6.1 or more Mac OS 8.x

CPU Power PC Powe r PC

Memory 24MB 24MB

HDD 10MB 10MB

FDD One 2HD 3.5-inch floppy disk drive One 2HD 3.5-inch fl oppy disk dri ve

CD-ROM One 12-inch CD-ROM drive One 12-inch CD-ROM drive

Printer por t IEEE 1284 one port

Preliminary Version April 2001 7 © Service Division.

Kyocera Mita Europe B.V.

Page 8

Product Technical Information KM-1810

1.1.4 Network Printer specifications (optional network card)

TypeHardware: Add-on I/F board NC-110

Interface Ethernet / 10 Base T/100 Base TX / RJ45

Multiprotocol support

Interface auto recognition

Applicable protocols IPX/SPX

(Netware Directory Services, Bindery , R/Nprinter)

TCP/IP

(BootP, DHCP, RARP, ARP, IP, ICMP, UDF, TCP, FTP, TFTP, LPD)

WINS

SNMP

SMTP

Ethertalk / Tokentalk phase 2

Http/ Html

NetBUEI

UNIX (TCP/IP)

SNMP

MIB II and private print server MIB

HTML from 3.x / frame support

Applicable network OS Novel Netware 3.1/3.11/3. 12/4. 1/4. 11/5. 0/

Windows NT 3.5X/4.0 and win 2000

Windows 95/98

Mac OS 7.x, 8.x, 9.x

UNIX AIX 3.0, SunOS, HP-UX,

SNMP

MIB II and private print server MIB

HTML from 3.x / frame support

Configuration management KY OCON Administration softw are

K yocera Mita print monitor

FTP

Web browser

SNMP management software

Preliminary Version April 2001 8 © Service Division.

Kyocera Mita Europe B.V.

Page 9

Product Technical Information KM-1810

1.1.5 Lifetime Data

Copier 5 years or 200.000 sheets

Copy volume per month Max: 10.000

Main replaceable parts Photoconduct: 100.000 sheets

Developer: 100.000 sheets

Cleaning blade: 100.000 sheets

Charger: 100.000 sheets

Fixing roller: Check and replace as required.

2 Functions

2.1 General functions

Stop/clear

Auto clear OFF, 30 to 270 sec. (30 sec. increments)

Auto preheat 5 to 45 min. (5 min. increments)

Auto shutoff OFF, 15 to 120 min. (15 min. increments)

• When installing printer , fixing heater is turned

off.

T otal counter Electronic counter

Paper jam detection

Paper jam number correction

Paper size detection Input by user when inserting paper (Cassette

only)

Paper empty detection PF will be displayed

Non-stop paper replenishment •When installing optional cassette

T oner empty detection

Silent mode (0, 5, 10, 15, 30 sec.)

•P olygon motor Stabilization time

Maintenance mode

Error detection

Ecomode

2.2 Copier funtions

No. of copies setting 2 keys, 1 to 99 sheets •Up (+) and down (-) keys

Copy density control Normal range: 3 or 5 steps

LED: 3, Default range: 3 steps

• Possible to switch 3 or 5 steps by user mode

Automatic density control Text & photo mode

Image mode T e xt mode: Error diffusion

Photo mode: Error diffusion

Text / Phote mode: Error diffusion

Manual selection

Magnification copy Zoom, preset magnification ratios, magnification input

Paper size selection Bypass only • Also used for drawer selection

Auto start

Automatic drawer change

Sort copy

Group copy

Multi copy with one scan

N-up Printing

Preliminary Version April 2001 9 © Service Division.

Kyocera Mita Europe B.V.

Page 10

Product Technical Information KM-1810

3 Machine Construction

3.1 Scanning Section

Scanning resolution Main: 600 dpi

Auxiliary: 600 dpi

Reading method: Document table: Document stationary

DF: Document moving

Document alignment Document table: Left rear

DF: Centre matching

Scanning method Mirror scan

Light source Noble gas lamp

Reading device CCD image sensor

Scanning system Flat bed scanning by CCD image sensor

Scanning home position Left

Exposure adjustment By image processing(constant exposure

lamp light quantity)

3.2 Printing section

Printing method Semiconductor laser and electrophotography

Resolution 600 x 600 dpi

3.3 Photo-Conductor

Shape 30 mm diameter drum

Type Positiv e-charged OPC

3.4 Charging Section

Main charging system Single corona charge (+)

Cleaning Present

• Cleaned by user at the replacement of toner

3.5 Developing Section

System Dual-component developer , re versing

Developer volume 470g

Toner feed system Toner cartridge

Capacity: 300g (except for start Toner cartridge which

contains 130g)

life: 7.000 sheets except for start Toner cartridge

which lasts 3000 sheets) 6% Original

Density control system Dev eloper density detection system • W eight

ratio

Developing bias voltage DC + 500V

• Initial, under normal temperature and humidity

T emper ature and humidity sensor

Preliminary Version April 2001 10 © Service Division.

Kyocera Mita Europe B.V.

Page 11

Product Technical Information KM-1810

3.6 Transfer Section

Transfer system Transfer roller (-)• Rated current system

Cleaning Present (PET film)

3.7 Separation Section

System Curvature separation

Claw None

3.8 Fixing Section

System Heat roller

Heater Type: Halogen heater

Rating: 230V specification 1030W (240V)

Control system Thermister detection: ON/OFF control Phase cotrol

Overheat prevention system Thermostat

Fixing roller Shape: Heat roller reverse crown

Press roller straight

3.9 Charge Erasing

Erasing system Lamp exposure

Lamp type LED

3.10 Cleaning Section

Cleaning system Cleaning blade

T oner recycling None

Waste tone tank This tank and toner catridge need to be replaced at the

same time (user changable)

3.11 Memory

T y pe MB-6: Standard memory board

Bipmap memory capacity Standard: 4.5MB (Used for both scanning and printing)

• Also used for image storage

Option: None

Image storage capacity Standard: 11.5MB (Also used for bipmap)

Option: None

Storable original pages

• A4 MTS original with black-to-white ratio of 6%, Text &

photo mode exposure level; center

With memory board: Approx. 30 pages

Preliminary Version April 2001 11 © Service Division.

Kyocera Mita Europe B.V.

Page 12

Product Technical Information KM-1810

4 T echnical Specification

4.1 Electrical Aspects

Rating 220 ~ 240 V / 50 Hz

2.8 A (ave.) / 4.5 A (max.)

Po wer comsumption

Copying: 1100 W

Standby: 66 W

Low power mode: 53 W

Insulation voltage 1500 V/1 min. or 1650 V/1 sec.

Insulation resistance 1 MΩ or more (b y 500 V megger)

Earth continuity 0.1 MΩ or less

4.2 Envir onment / saf ety aspect

4.2.1 W ork environment

Operation Temperature: 10 ~ 32 ºC

Humidity: 20 ~ 80 %RH

During storage Temprature: - 20 ~ 40 ºC

Humidity: 10 ~ 90 %RH

4.2.2 Approvals

GS / CE

4.2.3 By-Products (blue Angel testing method)

Noise level Copying: NC45 or less

Standby:

Ozone Average: 0.1ppm or less (UL standard)

Max.: 0.3ppm or less (UL standard)

Dust 0.2mg/m³ or less (JIS standard)

Preliminary Version April 2001 12 © Service Division.

Kyocera Mita Europe B.V.

Page 13

4.3 Maintenance

Periodic maintenance 100,000 sheets

Av erage maintenance time Within 30 min.

Main replaceable parts Photoconductor: 100,000 sheets

Developer: 100,000 sheets

Cleaning blade: 100,000 sheets

Charger: 100,000 sheets

Fixing roller: Check and replace as required

4.4 Reliability Data

MCBJ Drawer (1 sided): 4,000 sheets or more

Bypass (1 sided): 800 sheets

5 Performance

5.1 Image quality

5.1.1 Copy Image

Product Technical Information KM-1810

Resolution (centre of image) 8 (w/0 DF) / 8 (w / DF) lines/mm or more (100 %)

10 (w/0 DF) / 9 (w / DF) lines/mm or more (200 %)

4.4(w/0 DF) / 4.4 (w / DF) lines/mm or more (50 %)

Reproduction of fine lines 8 lines/mm or more (100 %)

(without DF) 10 lines/mm or more (200 %)

5 lines/mm or more (50 %)

Magnification ratio 100% w/0 DF: ± 1.5% total length / ± 1.5% 50mm or less

100% w/ DF : ± 2.0% total length / ± 2.0% 50mm or less

Squareness w/0 DF: ± 1.5mm / 200mm or less

w/ DF: ± 2.0mm / 200mm or less

Image distortion w/0 DF: ± 1.0mm / 200mm or less / ± 0.5mm / 50mm

w/ DF: 1.5mm / 200mm / 0.5mm / 50mm or less

Preliminary Version April 2001 13 © Service Division.

Kyocera Mita Europe B.V.

Page 14

Product Technical Information KM-1810

5.1.2 Print Image (optional printer board is necessary)

Printing position accuracy Horizontal: ± 2.0mm

Longitudinal: ± 2.5mm

Skew: 2.0mm / 200mm or less

Squareness ± 1.5mm / 200mm or less

Image distortion total length ± 1.0mm / 200mm or less / ± 0.5mm / 50mm or less

5.1.3 Image Area

Copier image

SIDE

(mm)

A B C D

No image area

imperfect image area

3–2.5 3– 2.5 3–2.5 3– 2.5

4.0 4.5 4.0 10.0

Printer image

(mm)

No image area

imperfect image area

A B C D

6.0 – 2.0 6.0 – 2.5 6.0+2.0 6.0 – 2.5

___ ___ ___ 10 or less

SIDE

5.2 Paper Feed / Conveying

Leading edge misalignment F ront draw er: ±2.5mm or less

Bypass: ±2.5mm or less

Skew paper feed F ront dra wer: ±2.0mm/200mm or less

Bypass: ±2.0mm/200mm or less

Right-to-left misalignment Front dr awer: ±2.0mm or less

Bypass: ±3.0mm or less

Preliminary Version April 2001 14 © Service Division.

Kyocera Mita Europe B.V.

Page 15

5.3 Wrinkles of envelopes

Reference figure

A side

Product Technical Information KM-1810

D side

Reference figure

D side

C side

A side

C side

B side

B side

Wrinkles

Paper con veying direction

Judgement exclusion area

Paper con veying direction

Preliminary Version April 2001 15 © Service Division.

Kyocera Mita Europe B.V.

Page 16

Product Technical Information KM-1810

APPENDIX 1 LIFETIME OF THE CONSUMABLE & MAIN PARTS

The parts listed here should be replaced after the indicated number of copies.

______________________________________________________________________________________________

Description Part No. Quantity Lifetime (x1,000 copies)

_____________________________________________________________________________________________

MAINTENANCE KIT (T.B.A.)

KM-1810 CH/CL P ART S

____________________________________________________________________________________________________

Description P art No. Quantity

________________________________________________________________________________________________

Pulley, paper feed 2A106010 1

Pulley, B, paper feed 2A106170 1

Pulley, bypass 2A106510 1

Pulley, Paper feed 3A707020 1

Pulley, leading feed 3A707030 1

Pulley, paper feed 3BR07040 1

Mirror A 2A112111 1

Mirror B 2A112120 1

Roller, transfer, Metric 2A116200 1

Parts, roller heat(SP) 2A193060 1

Parts, roller press(SP) 2A193070 1

Separation claw, heat roller 2A120071 1

Thermistor, fixing 2A120080 1

Note

The figures between brackets () show that the mentioned lifetime depends on the number of times that part has actually been used

during operation. The counts can be checked by simulation.

Preliminary Version April 2001 16 © Service Division.

Kyocera Mita Europe B.V.

Page 17

Product Technical Information KM-1810

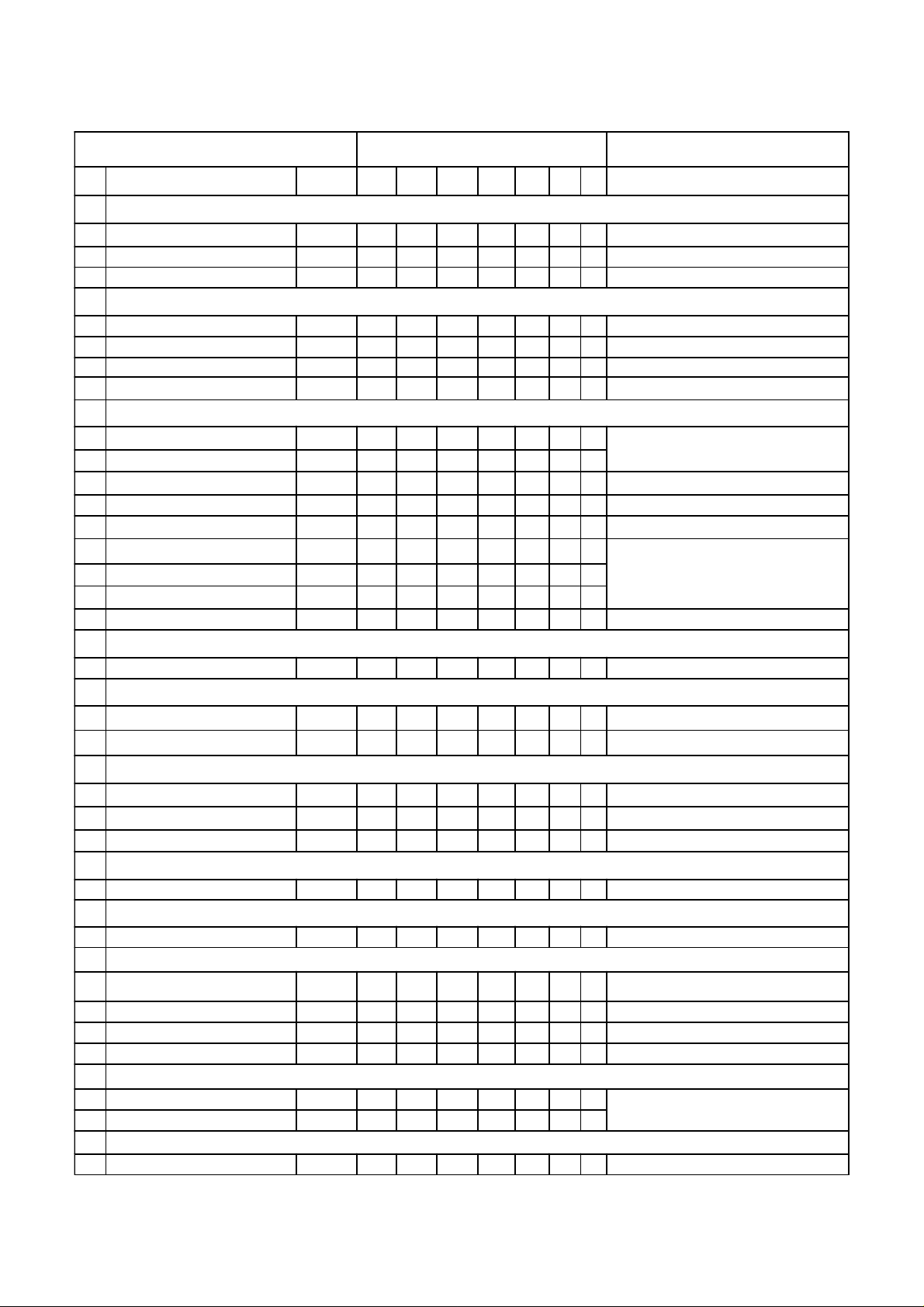

APPENDIX 2 MAINTENANCE LIST KM-1810 & OPTIONAL EQUIPMENT

LIST OF ABBREVIATIONS

Cl Clean

Lu Lubricate

Re Replace

Ch/Ad Check and adjust

Ch/Re Check and replace if necessary

0 On delivery

U/C User's call

Preliminary Version April 2001 17 © Service Division.

Kyocera Mita Europe B.V.

Page 18

Product Technical Information KM-1810

KM-1810 COPY Q’TY (X 1,000 COPIES)

DESCRIPTION Part No. Set up U/C 100 REMARKS

A SETUP

1 Developer

2 Toner

3 Image quality

B

1 Contact glass, DF 2A112130 Alcohol or dry cloth

2 Contact glass 2A112160 Alcohol or dry cloth

3 Mat, Original holder 3BP11150 Alcohol or dry cloth

4 Sheet, Reading 3BP11300 Alcohol or dry cloth (except for KM-1505)

C

1 Lef t r oller, registration 2A106020

2 Right roller, registration 2A106031

3 Pulley, Paper feed 2A106010

4 Pulley, B, Paper feed 2A106170

5 Pulley, Bypass 2A106510

6 Pulley, Paper feed 3A707020

7 Pulley, Leading feed 3A707030

8 Pulley, Paper feed 3BR07040

9 Other rol l er s CL

D DUPLEX

PAPER FEED and CONVEYING SECTION

Ch/CL

Ch/CL CL

Ch/CL CL

Ch/CL CL

Ch/CL CL

Ch/CL CL

COVER

Alcohol or dry cloth

Alcohol or dry cloth

Alcohol or dry cloth

Alcohol or dry cloth

Alcohol or dry cloth (only KM-1810)

E OPTICAL SECTION

1 Mirror A 2A112111 Ch/CL

2 Mirror B 2A112120

FIMAGE FORMATION

1 Set, Drum(Neutral) 2A182010

2 Main charger ass’y 2A168011

3 Roller, Tran sfer, Metr ic 2A116200

G DEVELOPING

1 Developer

H CLEANING

1 Parts, Blade cleaning B(SP) 2A193050

I FIXING

1 Parts, Roller heat(SP) 2A193060 Ch /CL CL

2 Parts, Roller Press(SP) 2A193070

3 Separation claw, heat roller 2A120071

4 Thermistor, fixing 2A120080

J PAPER EJECT

1 Rolle r, ejec t 2A121010

2 Pulley, feed shift 68720160

K OTHERS

1 Paper conveying section Alcohol or dry cloth

Ch/CL

RE

CL RE

Ch/CL CL

RE

RE

Ch/CL CL

Ch/CL CL

Ch/CL CL

CL

CL

Cleaned by cleaning pad

Vacuum

Alcoholl, no replace necessary until 200K with

normal use

Alcohol

Alcohol or dry cloth

Preliminary Version April 2001 18 © Service Division.

Kyocera Mita Europe B.V.

Loading...

Loading...