Mita-Kyocera FS-9100, FS-9500 Service Manual

SERVICE

MANUAL

Published in Sep. ’01

842BL110

2BL70760

Revision 2.0

Revision history

Version Replaced pages RemarksDate

1.0

2.0

July-2001

31-Jan-2002

-

-

-

-

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the printer.

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the printer may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the printer on an infirm or angled surface: the printer may tip over, causing injury. ....

• Do not install the printer in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the printer near a radiator, heater, other heat source or near flammable material.

This may cause fire...........................................................................................................................

• Allow sufficient space around the printer to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance...........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on printers so equipped. Failure to do this may

cause the printer to move unexpectedly or topple, leading to injury. ................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the

printer’s instruction handbook. ..........................................................................................................

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. .............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the printer is correctly connected to an outlet with a ground connection. ...........

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. .........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts........

• Handle the fixing section with care to avoid burns as it can be extremely hot..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. .........................................................................................................

• Do not remove the ozone filter, if any, from the printer except for routine replacement. ..................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ......

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below:....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .........................................................................................................................

• Should smoke be seen coming from the printer, remove the power plug from the wall outlet

immediately.......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas.................................................................................

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................................... 1-1-1

1-1-2 Parts names ............................................................................................................................................. 1-1-3

(1) Printer ............................................................................................................................................... 1-1-3

(2) Operator panel .................................................................................................................................. 1-1-4

1-1-3 Machine cross section.............................................................................................................................. 1-1-5

1-1-4 Drive system............................................................................................................................................. 1-1-6

(1) Drive system 1 (drive motor and eject motor drive trains) ................................................................ 1-1-6

(2) Drive system 2 (paper feed motor drive train)................................................................................... 1-1-7

1-1-1 Specifications

Type ............................................... Desktop laser printer

Printing system...............................Electro photographic system

Paper..............................................Cassette: Plain paper (60 to 90 g/m2)

MP tray: Plain paper (60 to 90 g/m

Special paper: Transparencies, tracing paper, colored paper, letterhead and

envelopes

Note: Use the MP tray for special paper.

Printing sizes..................................Maximum: A3/Ladger

1

Minimum: A5R /5

/2" × 81/2" (When the MP tray is used)

Print speed ..................................... FS-9100DN model [Cassette/MP tray]

A4: 36 pages/33 pages per min.

B4: 22 pages/19 pages per min.

A3: 19 pages/16 pages per min.

Letter: 36 pages/33 pages per min.

Legal: 22 pages/19 pages per min.

Ledger: 19 pages/16 pages per min.

Duplex print

A4/Letter: 29 pages per min.

FS-9500DN model [Cassette/MP tray]

A4: 50 pages/46 pages per min.

B4: 31 pages/27 pages per min.

A3: 26 pages/22 pages per min.

Letter: 50 pages/46 pages per min.

Legal: 31 pages/27 pages per min.

Ledger: 26 pages/22 pages per min.

Duplex print

A4/Letter: 37 pages per min.

First print time ................................7 s or less (A4, Ecopower mode off)

67 s or less (A4, Ecopower mode on)

Warm-up time.................................60 s or less (room temperature 23 °C/73.4 °F, 60% RH)

Paper feed system ......................... 2 universal type cassettes, and MP tray

Paper loading capacity...................Cassette: 500 sheets (80 g/m

MP tray: 200 sheets (80 g/m2, 0.11 mm)

Printout stacking capacity ..............Face down tray: 500 sheets with paper full sensor

Photoconductor .............................. aSi drum (diameter 40 mm)

Charging system ............................ Single positive corona charging

Exposure light source .................... Semiconductor laser

Exposure scanning system ............ Polygon mirror

Developing system.........................Dry, reverse developing (magnetic brush)

Developer: 1-component, magnetism toner

Toner replenishing: automatic from a toner container

Transfer system .............................Transfer roller

Separation system .........................Separation electrode

Fixing system ................................. Heat roller and press roller

Heat source: halogen heaters (120 V specifications: main 600 W, sub 400 W/220-240

V specifications: main 600 W, sub 420 W,

Control temperature: 165 °C/329 °F (at normal ambient temperature)

Abnormally high temperature protection device: 170 °C/338 °F thermostats

Fixing pressure: 107.8 N

Charge erasing system .................. Exposure by cleaning lamp (LED array)

Cleaning system ............................ Cleaning blade

Controller hardware ....................... CPU: Power PC750CX 350 MHz (FS-9100DN model)

Power PC750CX 400 MHz (FS-9500DN model)

Code ROM: 4 MB (2 system DIMM PWBs in sockets)

Font ROM: 4 MB (PCL6 and KPDL3)

Main RAM: 32 MB (standard)

Option expanding RAM: 2 sockets (Maximum 288 MB, including the standard RAM)

Option memory card: 1 slot (CompactFlash card)

Option interface: 2 slots (KUIO-LV)

2

), Thick paper (90 to 200 g/m2)

2

, 0.11 mm)

FS-9100DN/9500DN

1-1-1

FS-9100DN/9500DN

Host computer interface ................. Parallel: Bi-directional parallel (IEEE 1284 Nibble/ECP mode)

Serial: RS-232C

Network: 10Base-T/100Base-TX

Option network interface card (KUIO slot No. 2): 10Base-T/100Base-TX/10Base-2

Controller software .........................Emulation: PCL6, KPDL3, KCGL

Fonts: PCL6, KPDL3

Smoothing ...................................... KIR

Toner saving...................................EcoPrint mode

Resolution ...................................... Fast 1200 mode with KIR, 600 dpi with KIR, 300 dpi with KIR

Dimensions ....................................Printer main unit: 585 (W) × 639 (D) × 615 (H) mm

1

/16" (W) × 253/16" (D) × 243/16" (H)

23

Paper feeder PF-70: 560 (W) × 566 (D) × 251 (H) mm

5

/8" (W) × 221/16" (D) × 1715/16" (H)

21

Paper feeder PF-75: 560 (W) × 566 (D) × 251 (H) mm

215/8" (W) × 221/16" (D) × 1715/16" (H)

Weight ............................................ Printer main unit: 52.5 kg/115.5 lbs (including toner containers)

Paper feeder PF-70: 19.1 kg/42 lbs

Paper feeder PF-75: 22.1 kg/48.6 lbs

Floor requirements ......................... 891 (W) × 560 (D) mm

1

/16" (W) × 221/16" (D)

35

Functions........................................Self-diagnostics, sleep mode (energy saving)

Power source ................................. 120 V AC, 60 Hz, Max. 10.8 A/10.9 A (FS-9100DN/9500DN)

220 - 240 V A C, 50/60 Hz, Max. 5.6 A/5.7 A (FS-9100DN/9500DN)

Power consumption ....................... Maximum: 1400 W

Printing: 680 W/790 W (FS-9100DN/9500DN)

Ready: 140 W/150 W (FS-9100DN/9500DN)

Sleep mode: 16 W or less

Options...........................................Expanding DIMM (16/32/64/128 MB), compact flash card, hard disk unit HD-3, paper

feeder PF-70/75, finisher DF-70/75, barcode reader, network interface card IB-20/21/

21E

1-1-2

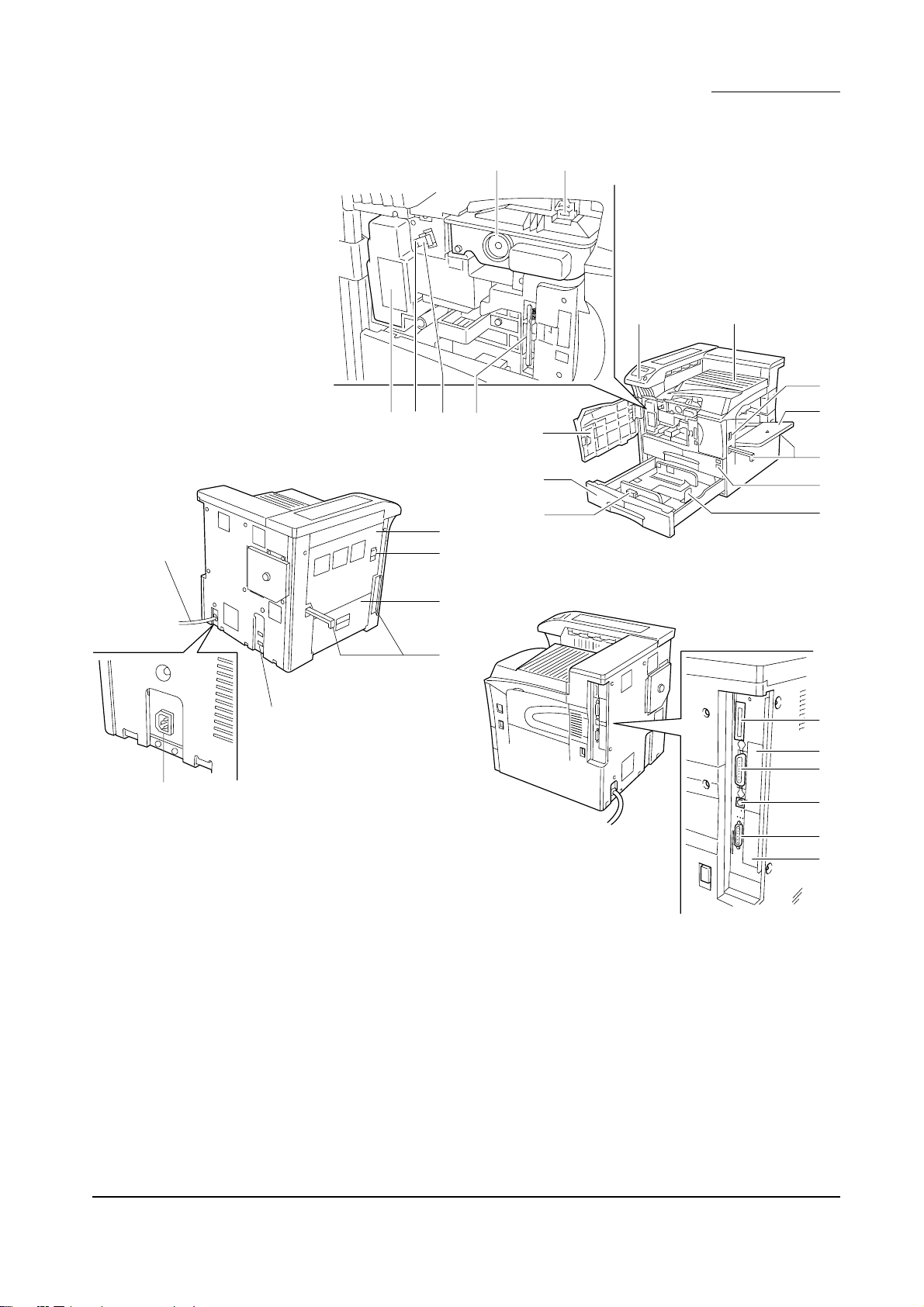

1-1-2 Parts names

FS-9100DN/9500DN

(1) Printer

&

#

$

%

‹

¤

⁄

^

!

2

3

4

@

1

0

9

8

7

6

5

(

*

1 Operator panel

2 Front cover

3 Lower paper cassette

4 Paper guide

5 Paper stopper

6 Upper paper cassette

7 Handles for transport

8 MP (Multi-Purpose) tray

9 Power switch

0 Face-down tray

! Toner container

@ Toner container release lever

# Waste toner box

$ Cleaning knob

% Main charger unit

)

·

—

›

fi

fl

‡

Figure 1-1-1

^ Cleaning brush

& Power cord

* Power cord connector

( Option unit connector

) Handles for transport

⁄ Side cover

¤ Conveying cover lock lever

‹ Conveying cover

› Parallel cable connector

fi Network cable connector

fl Serial cable connector

‡ Optional hard disk unit slot (OPT1/HDD)

— Optional network interface card slot (OPT2)

· Memory card slot

1-1-3

FS-9100DN/9500DN

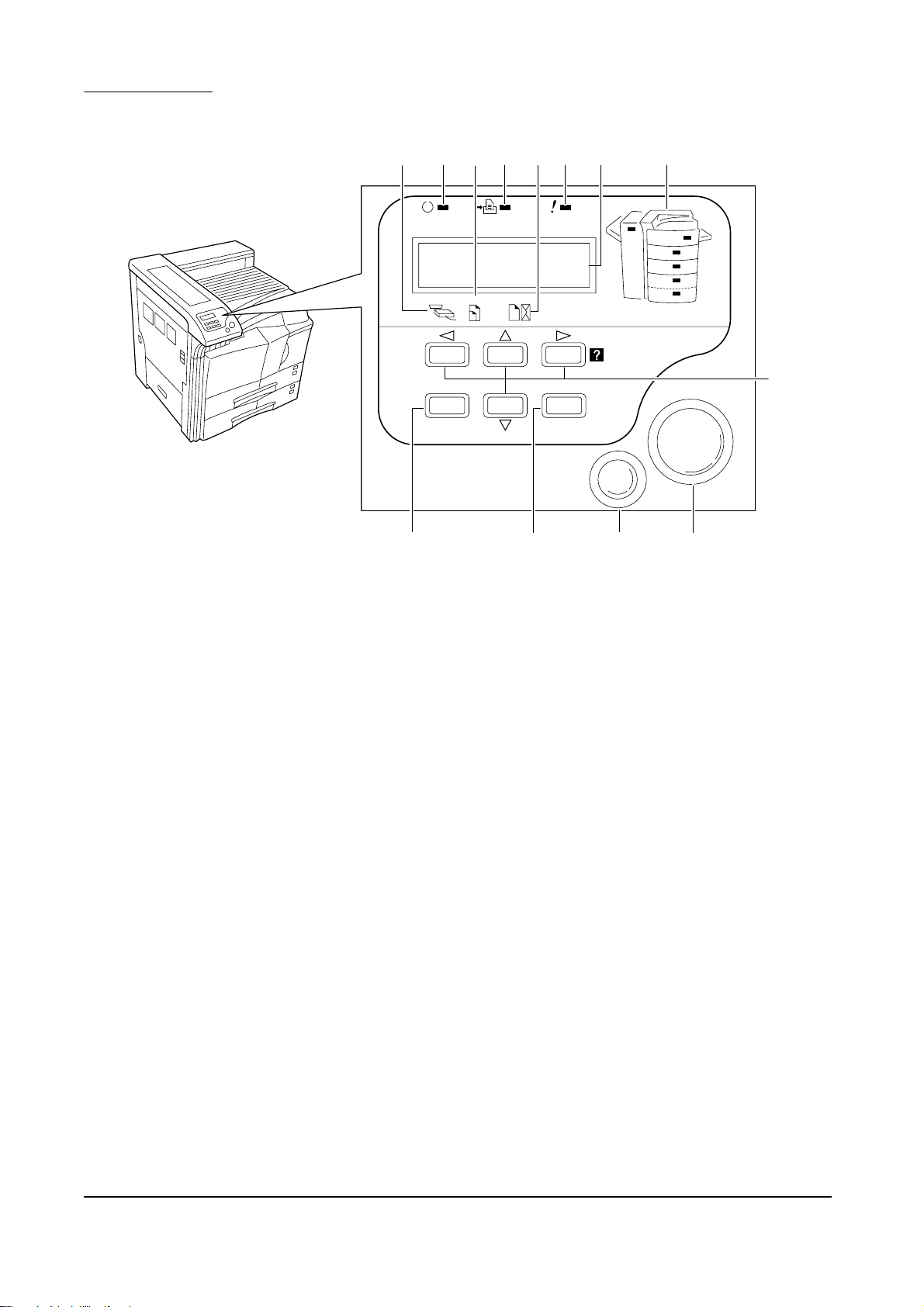

(2) Operator panel

READY

Ready

- - -

A4 PLAIN

INTERFACE SIZE TYPE

MENU

4

8

@

DATA ATTENTION

ENTER

CANCEL

3

97!60

2

#

GO

1

5

Figure 1-1-2

1 GO key

2 CANCEL key

3 ENTER key

4 MENU key

5 Arrow keys

6 Ready indicator

7 Data indicator

8 Attention indicator

9 Message display

0 Interface indicator

! Paper size indicator

@ Paper type indicator

# Paper jam indicator

1-1-4

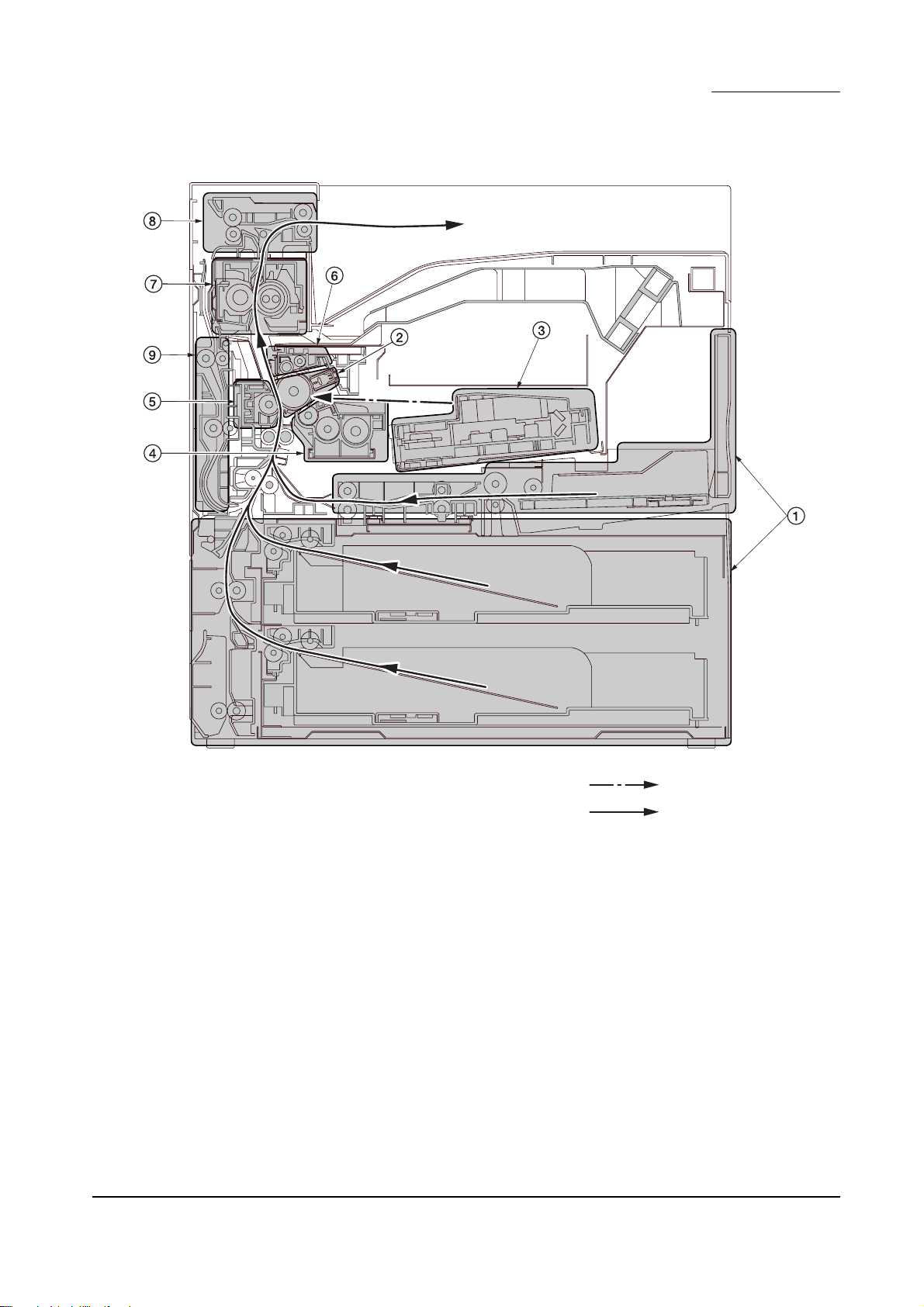

1-1-3 Machine cross section

FS-9100DN/9500DN

Figure 1-1-3 Machine cross section

1 Paper feed section

2 Main charging section

3 Laser scanner unit

4 Developing section

5 Transfer and paper conveying section

6 Cleaning and erasing section

7 Fuser section

8 Eject and switchback section

9 Duplex unit

Light path

Paper path

1-1-5

FS-9100DN/9500DN

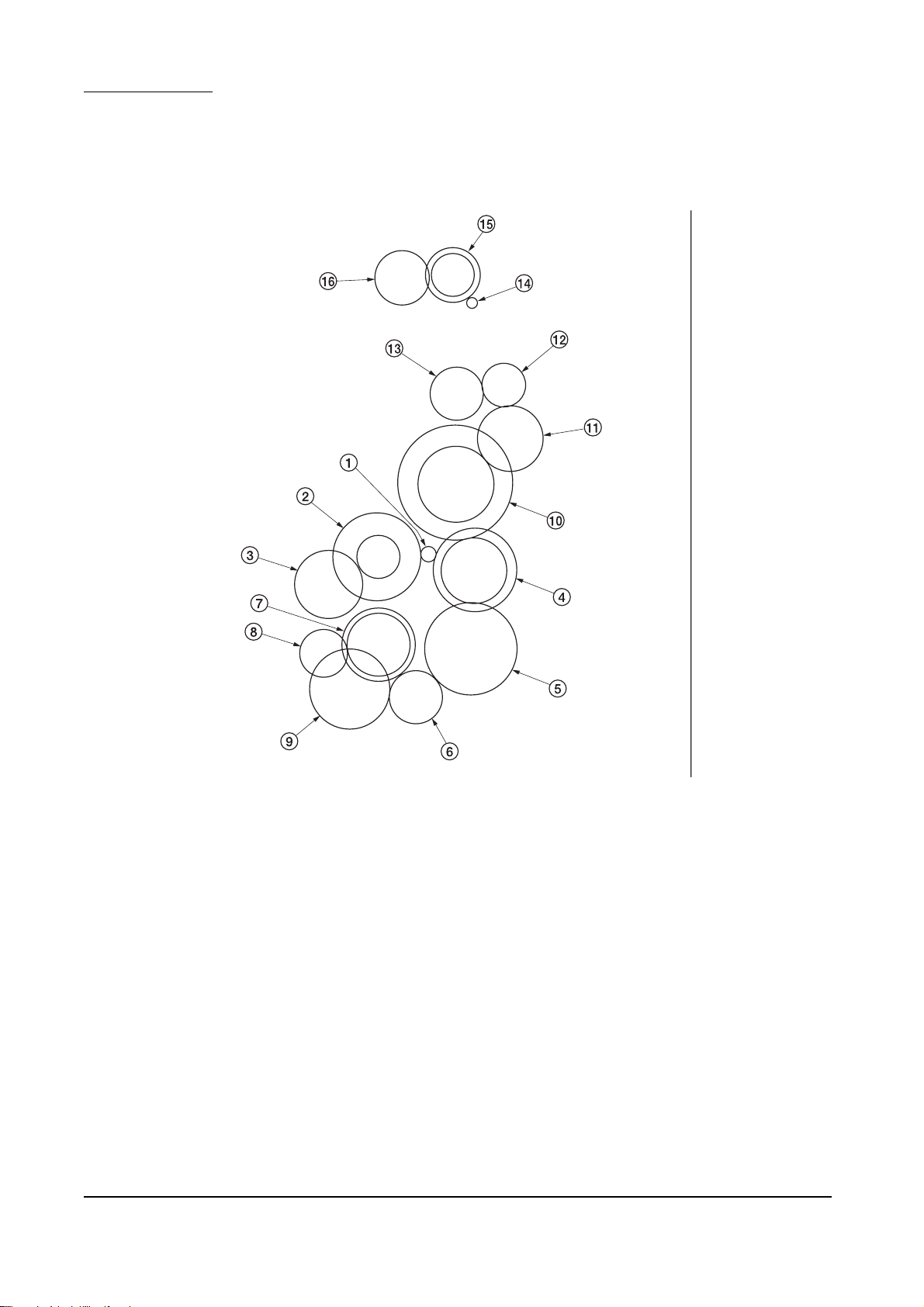

1-1-4 Drive system

(1) Drive system 1 (drive motor and eject motor drive trains)

1-1-6

1 Drive motor gear

2 Drum gear Z76H/Z30H

3 Drum gear Z70H

4 Gear Z76H/Z35H

5 Gear Z50H

6 Gear Z36S/Z31H

7 Gear Z37H/28H

8 Gear Z34H

As viewed from machine rear

Figure 1-1-4

9 Registration clutch gear

0 Gear Z63H/Z45S

! Gear Z37S

@ Gear Z24S

# Joint gear Z32S

$ Eject motor gear

% Gear Z47S/Z28S

^ Eject gear Z30S

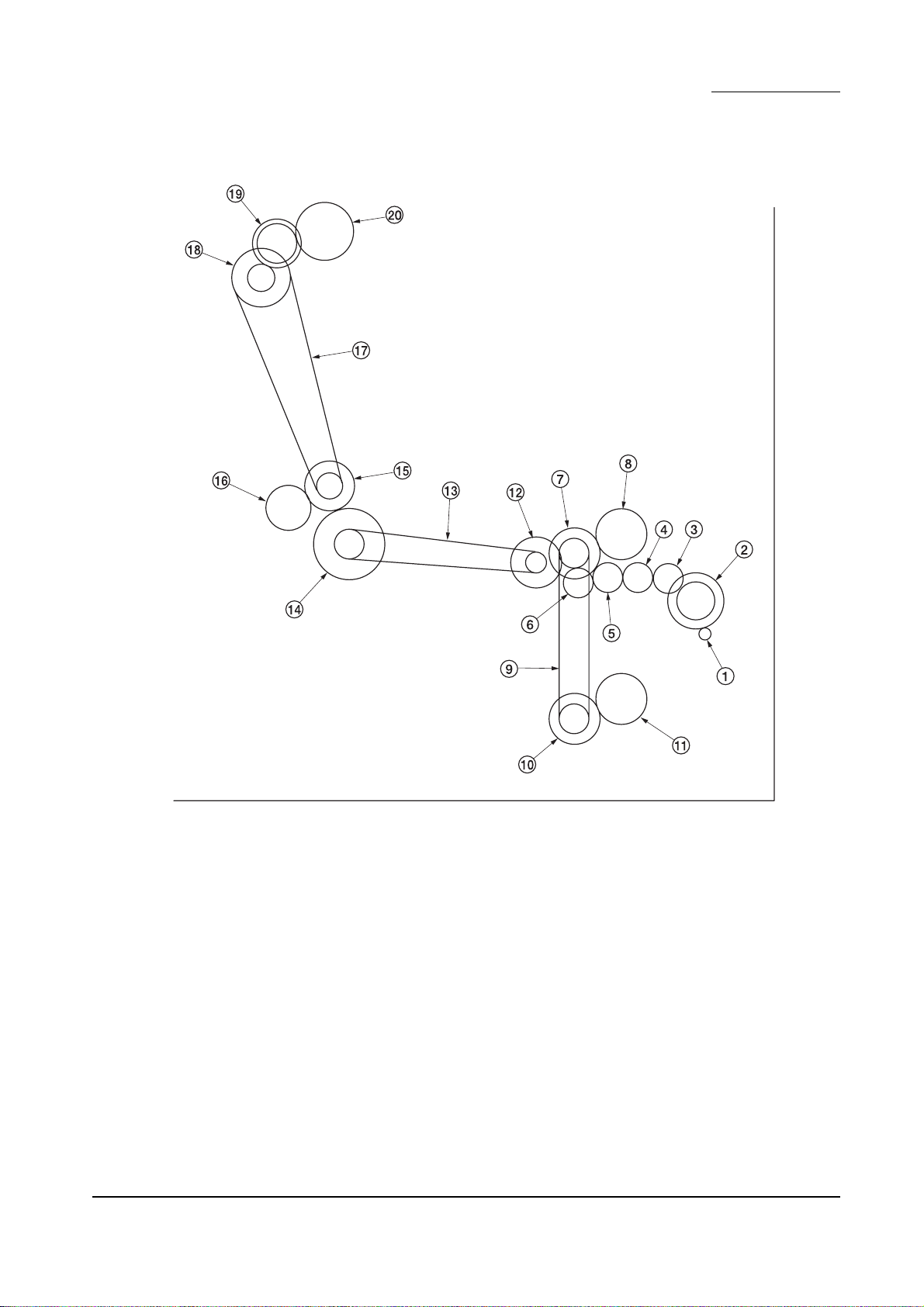

(2) Drive system 2 (paper feed motor drive train)

FS-9100DN/9500DN

Figure 1-1-5

1 Paper feed motor gear

2 Gear Z76H/Z35S

3 Feed gear Z25

4 Feed gear Z25

5 Feed gear Z25

6 Feed gear Z25

7 Gear Z41S/Z24S/P30

8 Upper paper feed clutch gear

9 Paper feed drive belt

0 Gear Z41S/Z24S/P30

As viewed from machine rear

! Lower paper feed clutch gear

@ Gear Z41S/P15

# Bypass drive belt

$ Gear Z60S/P20

% Gear Z41S/P18

^ Gear Z40S/Z32S

& Container drive belt

* Gear Z24S/P40

( Gear Z40S/Z25S

) Container gear

1-1-7

CONTENTS

1-2 Handling precautions

1-2-1 Drum......................................................................................................................................................... 1-2-1

1-2-2 Toner ........................................................................................................................................................ 1-2-1

1-2-3 Installation environment ........................................................................................................................... 1-2-1

FS-9100DN/9500DN

1-2-1 Drum

Note the following when handling or storing the drum.

• When removing the image formation unit, never expose the drum surface to strong direct light.

• Keep the drum at an ambient temperature between –20 °C/–4 °F and 40 °C/104 °F and at a relative humidity not higher

than 85% RH. Avoid abrupt changes in temperature and humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained with oil, clean it.

1-2-2 Toner

Store the toner in a cool, dark place. Avoid direct light and high humidity.

1-2-3 Installation environment

1.Temperature: 10 - 32.5 °C/50 - 90.5 °F

2.Humidity: 20 - 80 % RH

3.Power supply: 120 V AC ±10 %, 10.8 A/10.9 A (FS-9100DN/9500DN)

4.Power source frequency: 50 Hz ±0.2 %/60 Hz ±0.2 %

5.Installation location

• Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other

strong light when removing paper jams.

• Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto

the machine.

• Avoid dust and vibration.

• Choose a surface capable of supporting the weight of the machine.

• Place the machine on a level surface (maximum allowance inclination: 1 ° ).

• Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

• Select a room with good ventilation.

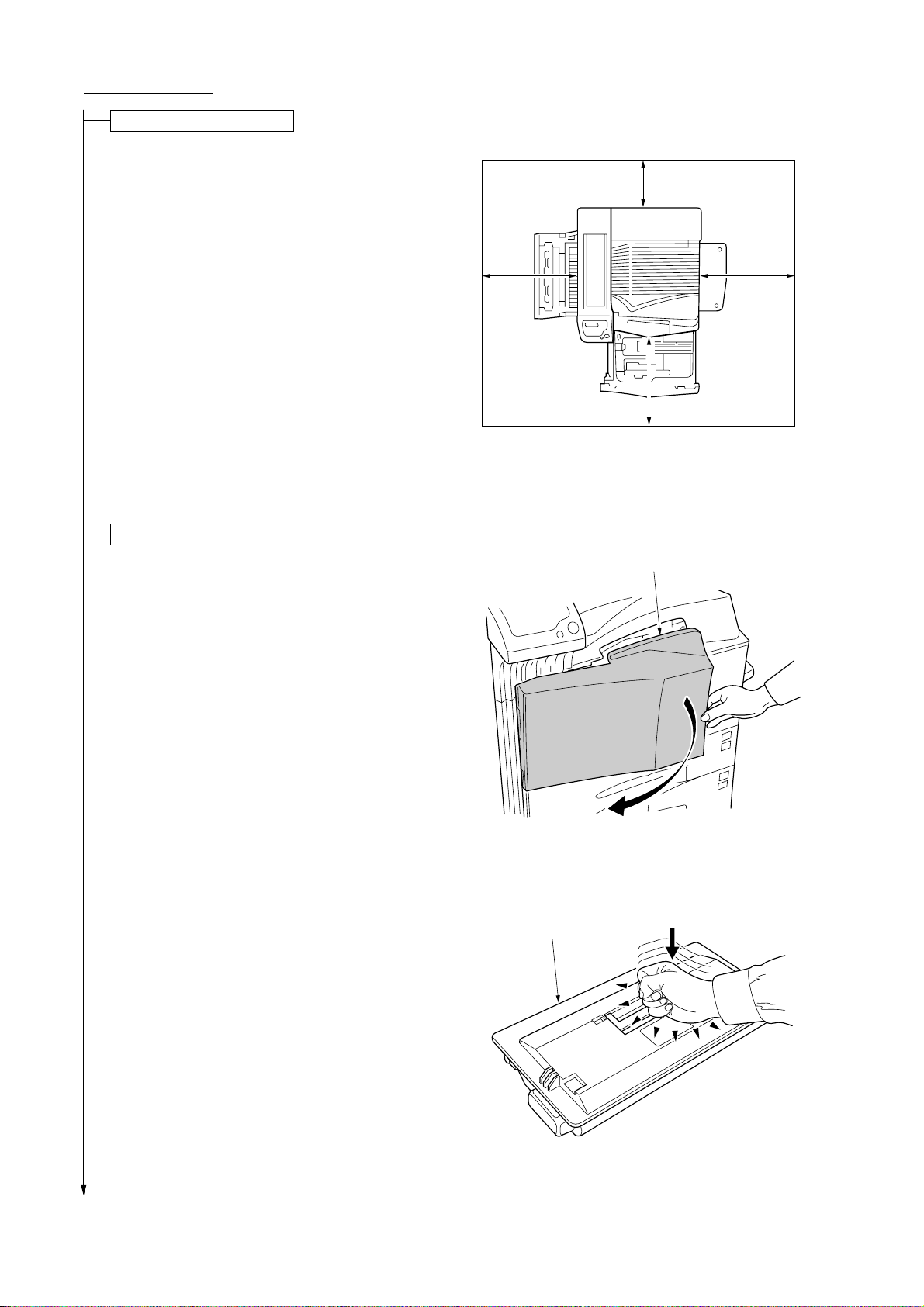

6.Allow sufficient access for proper operation and maintenance of the machine.

Machine front: 100 cm/39

Machine right: 70 cm/27

220 - 240 V AC 10 %, 5.6 A/5.7 A (FS-9100DN/9500DN)

3

/8" Machine rear: 10 cm/315/16"

9

/16" Machine left: 60 cm/235/8"

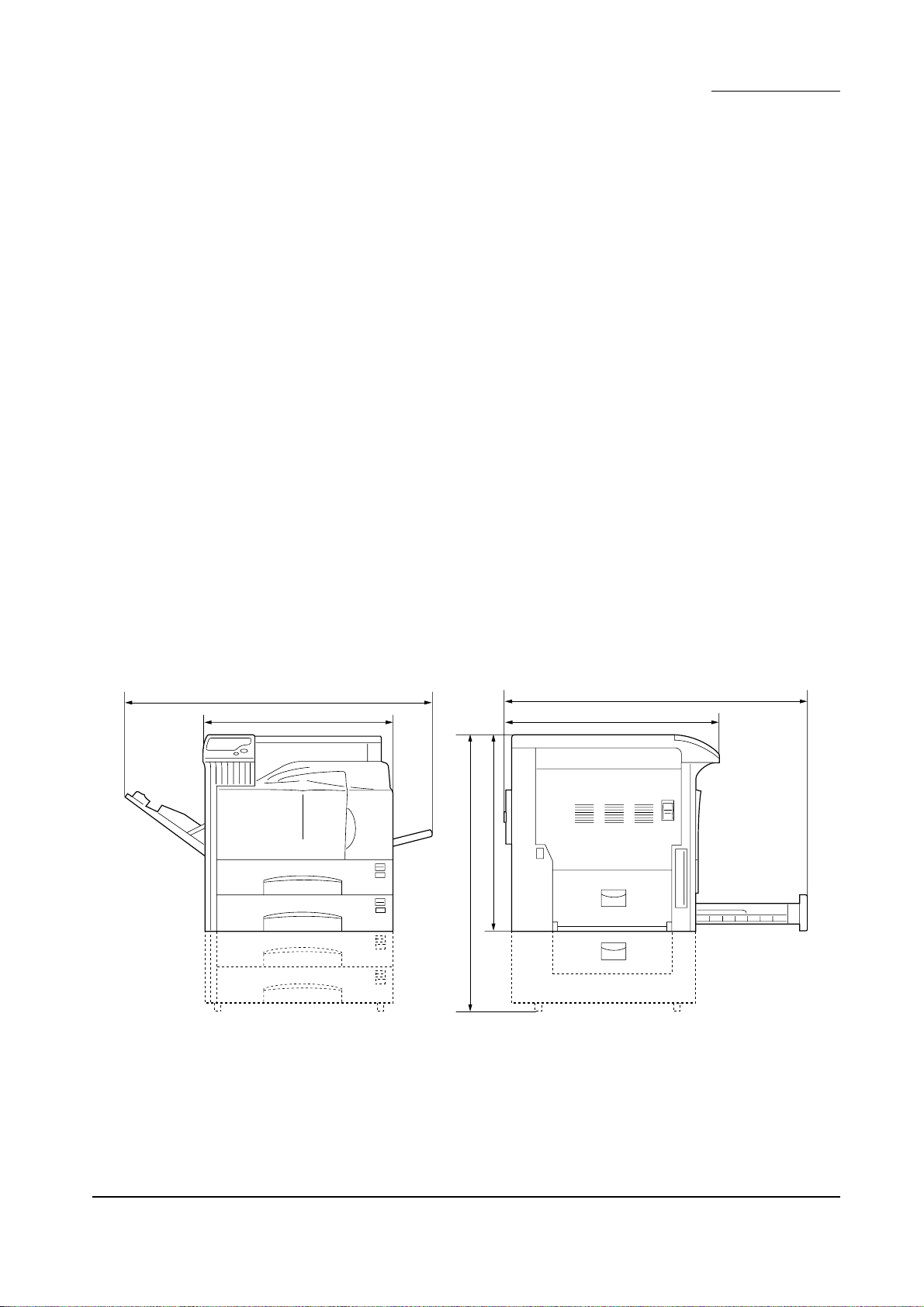

df

a

a: 585 mm/231/16"

b: 615 mm/24

c: 665 mm/26

3

3

/16"

/16"

b

e

d: 1032 mm/40

e: 920 mm/36

f: 1055 mm/41

c

5

/8"

1

/4"

9

/16"

Figure 1-2-1 Installation dimensions

1-2-1

CONTENTS

1-3 Installation

1-3-1 Unpacking and installation ....................................................................................................................... 1-3-1

(1) Installation procedure........................................................................................................................ 1-3-1

1-3-2 Installing the cassette heater (option) ...................................................................................................... 1-3-9

1-3-3 Installing DIMMs (option).........................................................................................................................1-3-11

1-3-4 Installing the network interface card (option).......................................................................................... 1-3-12

1-3-5 Installing the hard disk (option) .............................................................................................................. 1-3-13

1-3-6 Installing the memory card (option) ........................................................................................................ 1-3-14

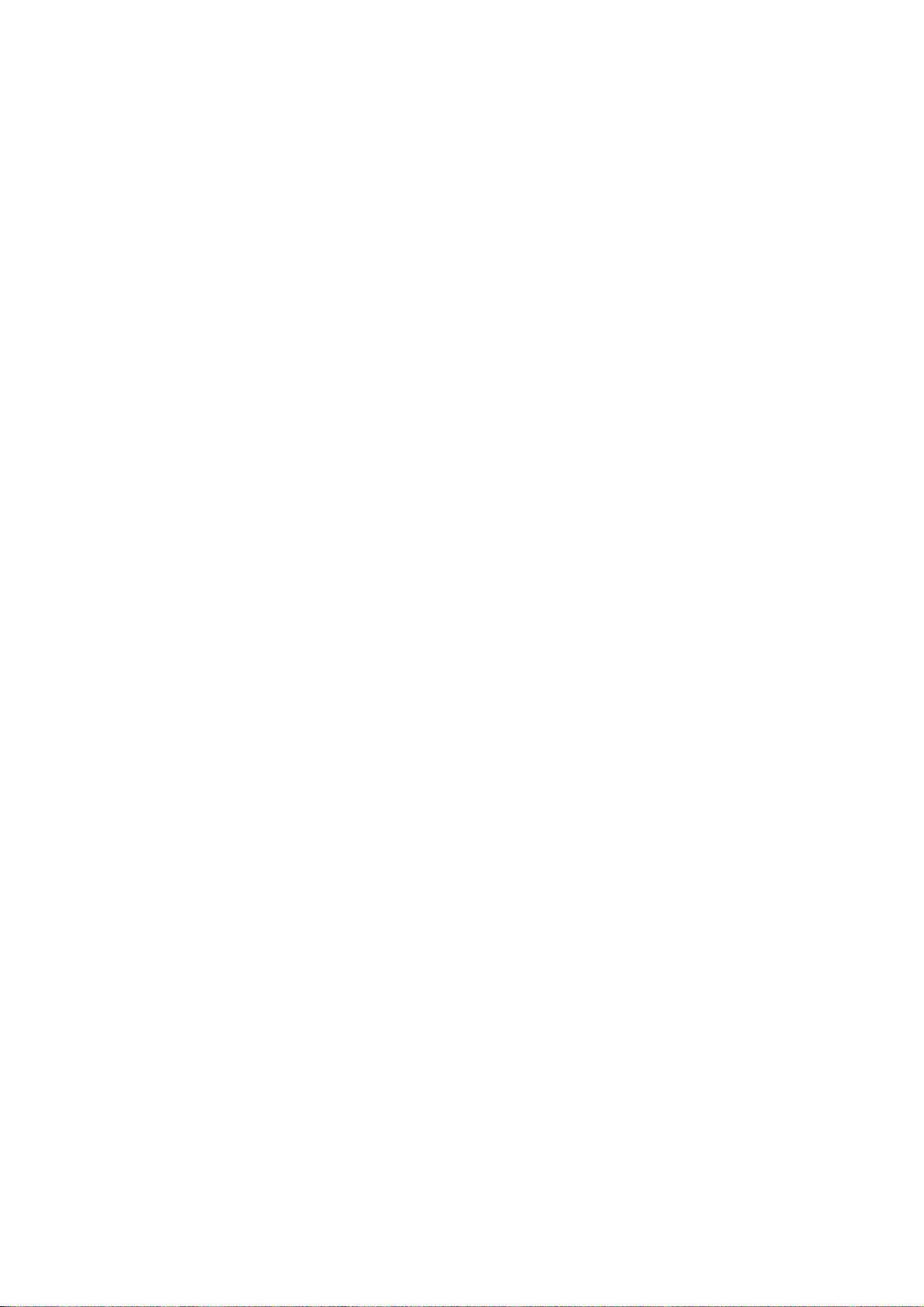

1-3-1 Unpacking and installation

(1) Installation procedure

Removing the tapes.

Placing the proper location.

Installing the toner container.

Installing the waste toner box.

FS-9100DN/9500DN

Start

Unpacking.

Connecting the printer to the computer.

Connecting the power cord.

Printing a status page for test.

Completion of the machine installation.

1-3-1

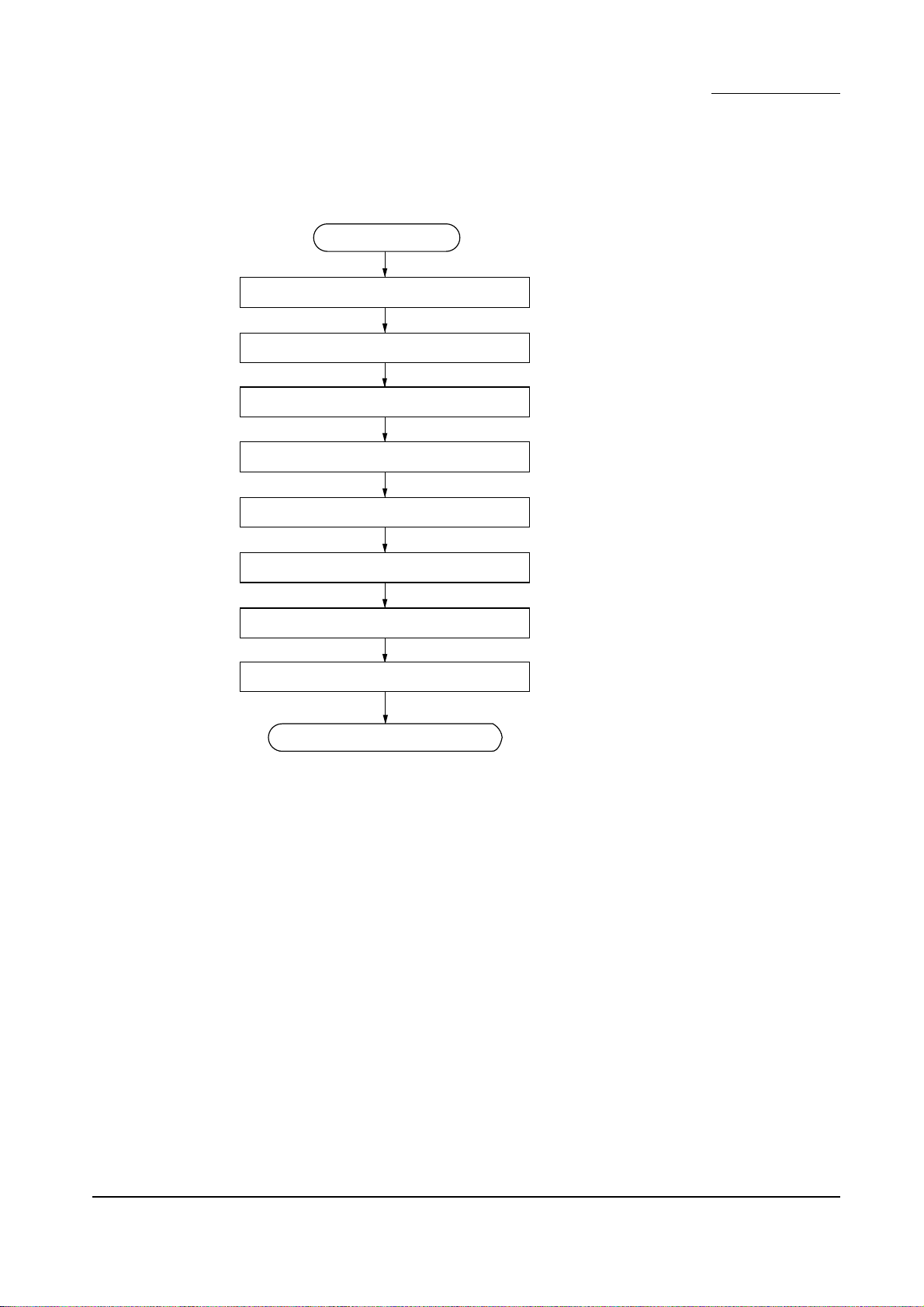

FS-9100DN/9500DN

Unpacking.

Printer

Toner container

Waste toner box

Figure 1-3-1 Unpacking

Paper size plate (4)

CD-ROM

Installation guide

Quick configuration guide

(for network interface)

Power cord

(220-240 V models only)

Figure 1-3-2 List of shipped components

1-3-2

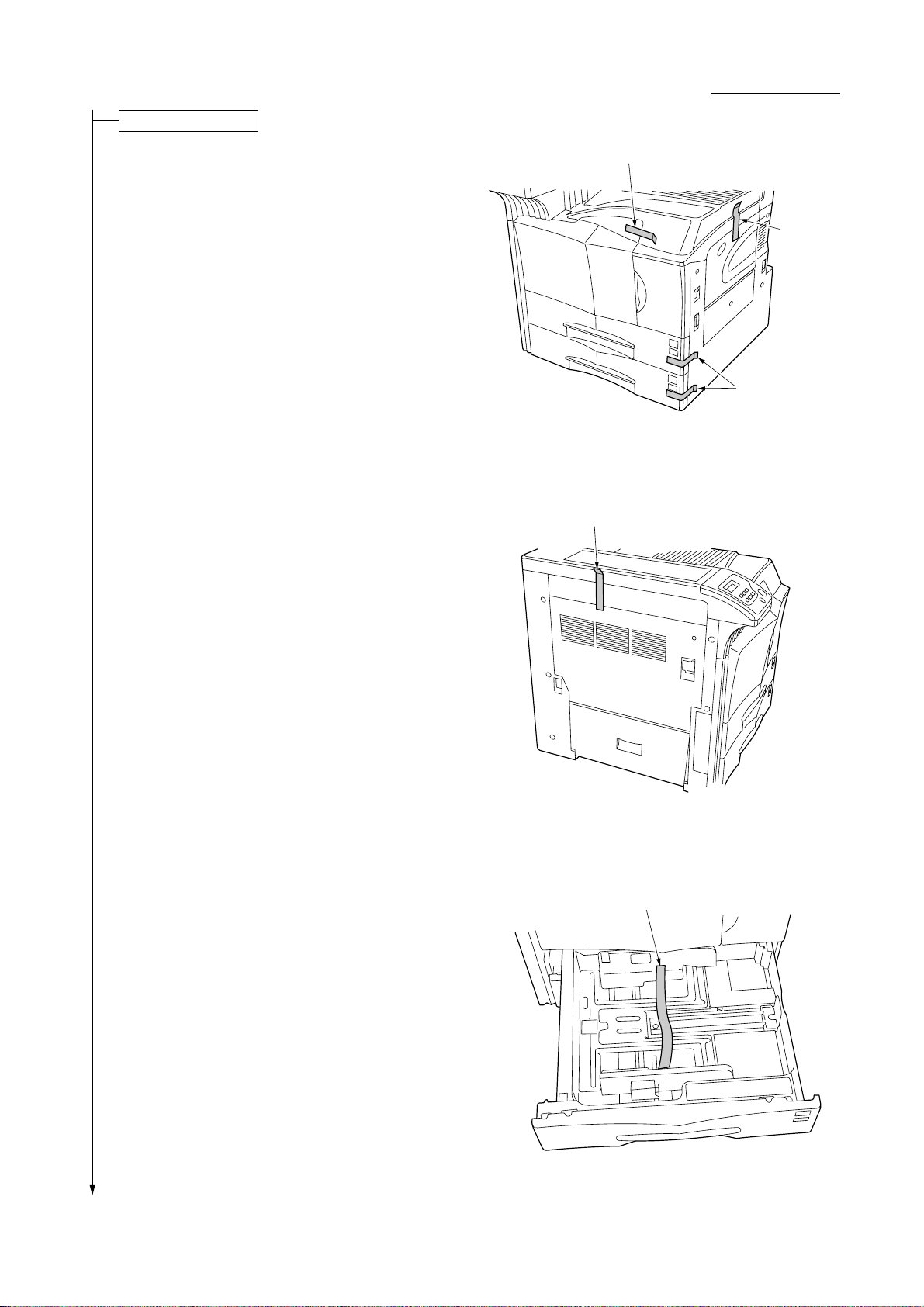

Removing the tapes.

1.Remove the tape holding the front cover.

2.Remove the tape holding the MP tray.

3.Remove the two tapes holding the paper

cassettes.

FS-9100DN/9500DN

Tape

Tape

Tapes

Figure 1-3-3

4.Remove the tapes holding the conveying cover.

5.Pull out the upper paper cassette and remove the

two tapes holding the bottom plate.

6.Pull out the lower paper cassette and remove the

two tapes holding the bottom plate.

Tape

Figure 1-3-4

Tape

Figure 1-3-5

1-3-3

FS-9100DN/9500DN

Placing the proper location.

1.Place the printer in a proper location.

Rear: 10 cm (315/16")

Right:

70 cm (27

9

/16")

Installing the toner container.

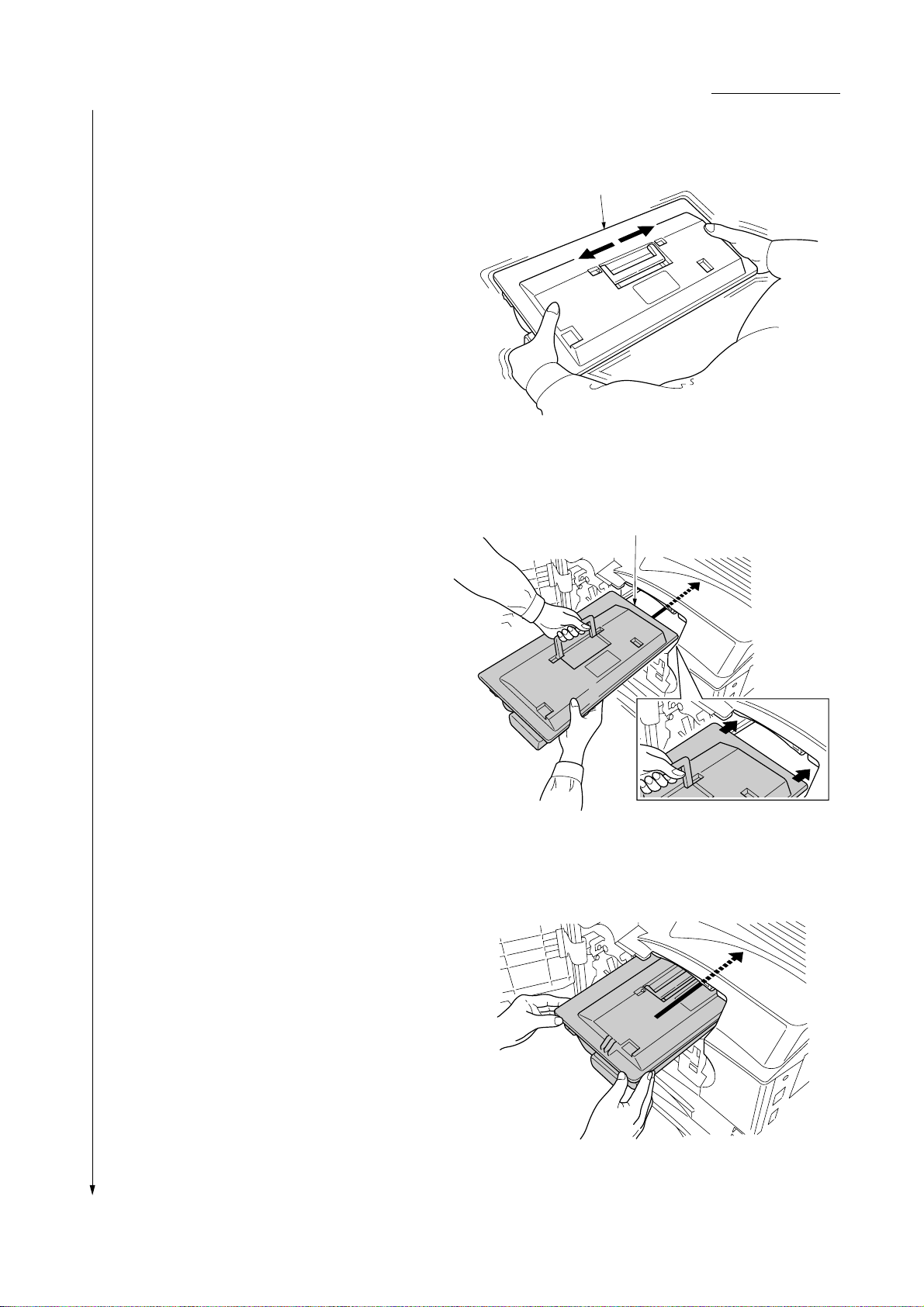

1.Open the printer front cover all the way.

Left:

60 cm (23

5

/8")

Front: 100 cm (39

Figure 1-3-6

Front cover

3

/8")

2.Take out the toner container from the bag.

3.Tap the new toner container on the top 5 to 6

times.

1-3-4

Figure 1-3-7

Toner container

Figure 1-3-8

4.Thoroughly shake the toner container (in the

directions of the arrows) ten times or more to

loosen and mix the toner inside.

FS-9100DN/9500DN

Toner container

Figure 1-3-9

5.Grasp the handle on the toner container and

insert the toner container along the rail of the

printer.

6.Hold the toner container by hands and fully insert

it into the printer.

Toner container

Figure 1-3-10

Figure 1-3-11

1-3-5

FS-9100DN/9500DN

Installing the waste toner box.

1.Install the waste toner box as shown in the figure.

2.Close the front cover.

Waste toner box

Figure 1-3-12

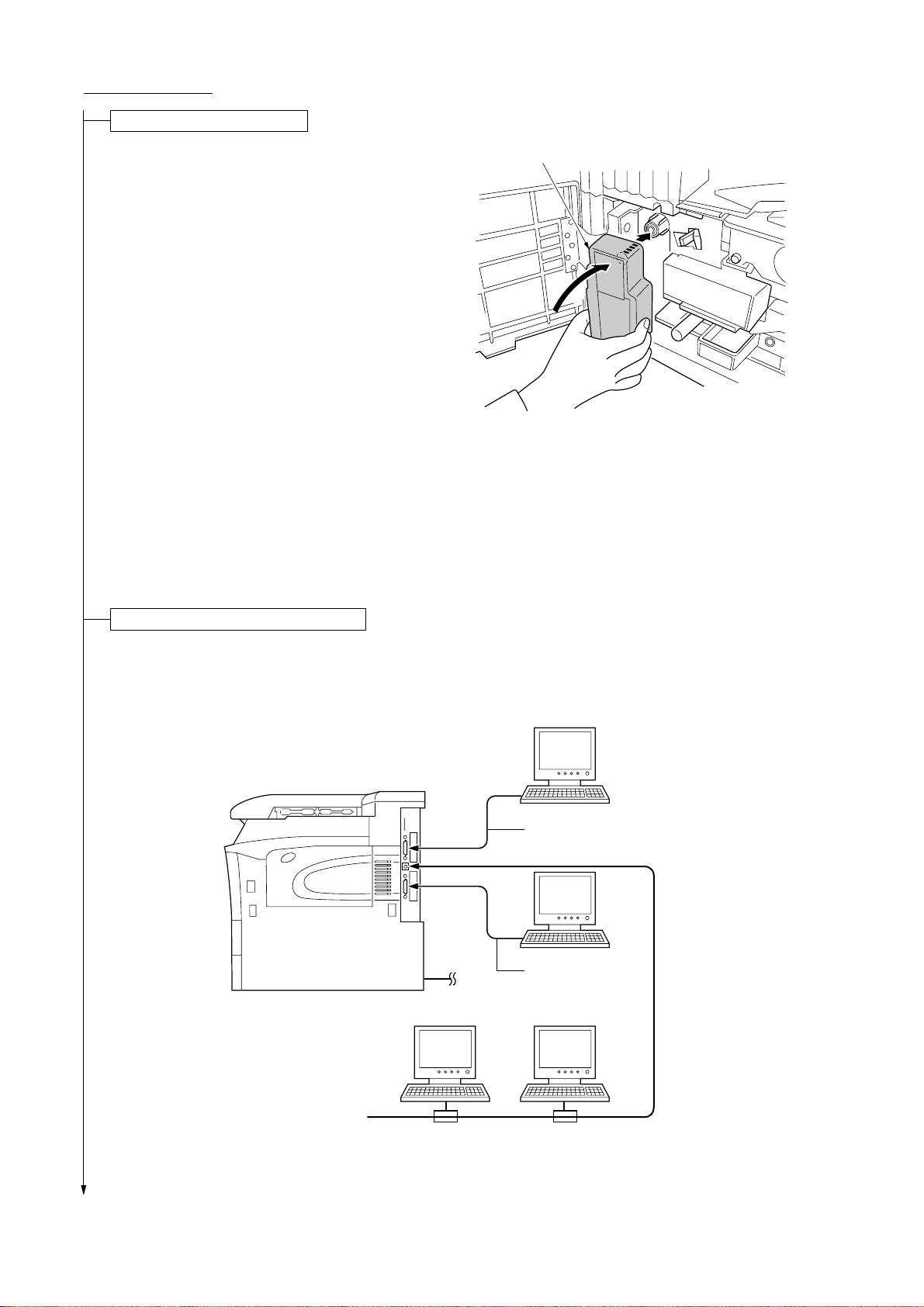

Connecting the printer to the computer.

There are various ways of connecting the printer to the computer , such as through the par allel interf ace connecter , serial

interface connecter, or through the network interface connecter.

Printer (Right side)

Parallel interface

Serial interface

Power cord

Network

1-3-6

Figure 1-3-13

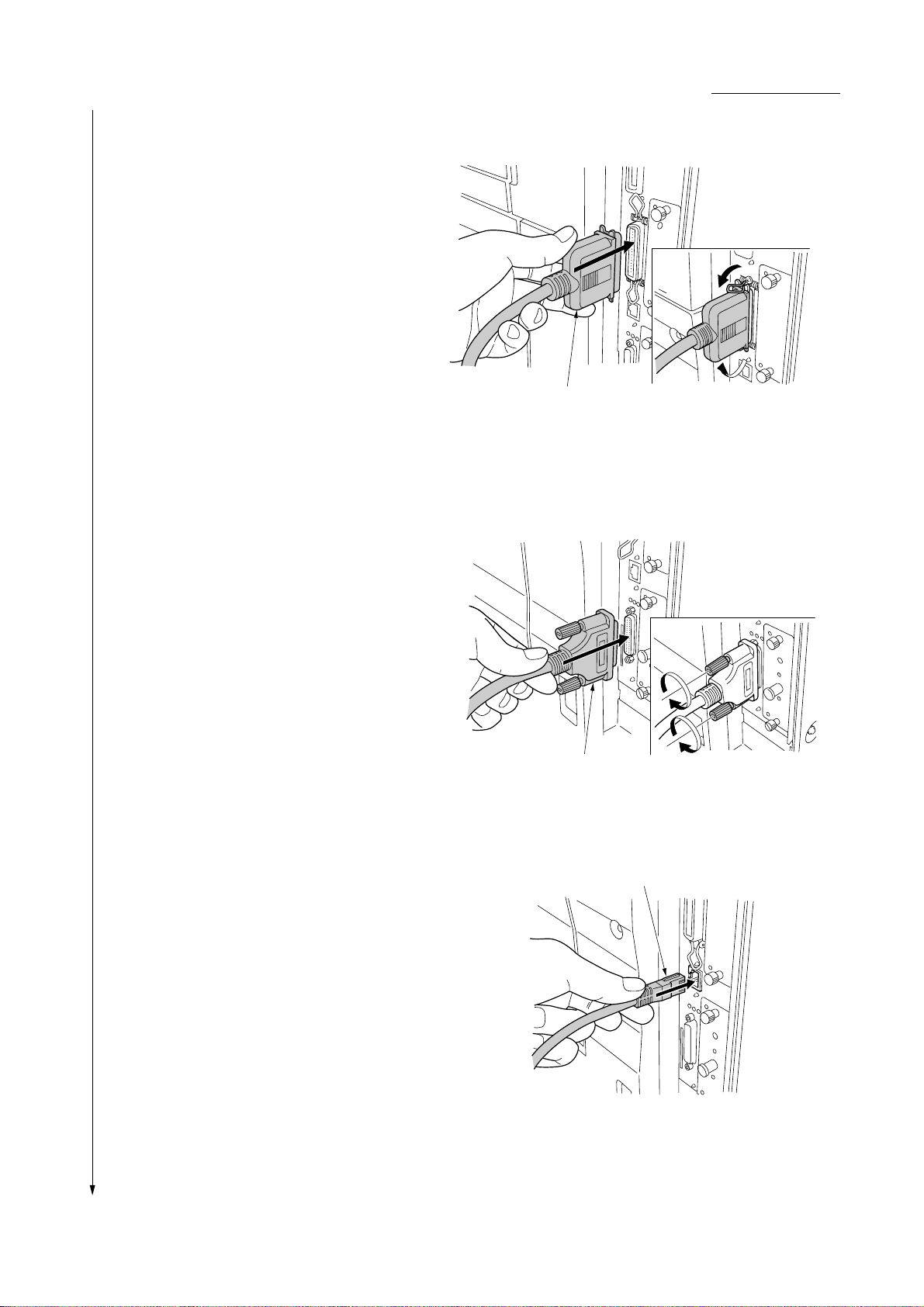

• Parallel interface connection

1.Plug one end of the printer cable (not included)

into the parallel interface connection on the right

side of the printer.

2.Close the clips on both sides to fix the connector

in place.

Plug the other end of the printer cable Into the

computer‘s parallel Interface connection.

• Serial interface connection

FS-9100DN/9500DN

Parallel printer cable

Figure 1-3-14

1.Plug one end of the printer cable (not Included)

Into the serial Interface connection on the right

side of the printer.

2.Securely tighten the screws on both sides of the

connecter.

Plug the other end of the printer cable Into the

computer‘s serial Interface connection.

• Network interface connection

1.Plug the network cable (not included) into the

network interface connection on the right side of

printer.

Serial printer cable

Figure 1-3-15

Network cable

Figure 1-3-16

1-3-7

FS-9100DN/9500DN

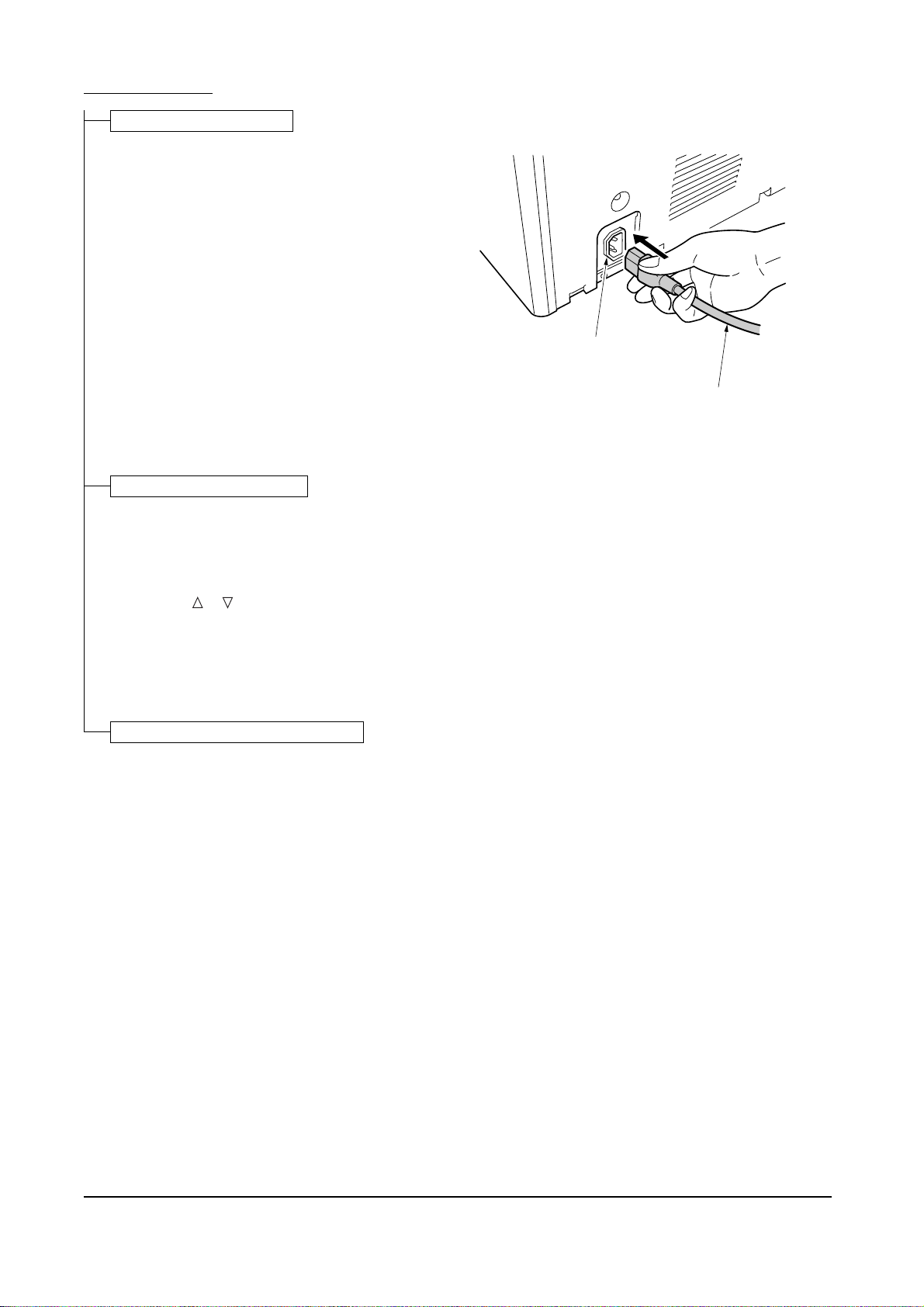

Connecting the power cord.

1.Plug the power cord into the power cord

connector on the rear of the printer. (220 - 240 V

models only)

2.Connect the other end of the power cord into a

power outlet.

Printing a status page for test.

1.Add paper in the paper cassette.

2.Turn on the printer power switch.

"Adding toner" will be displayed and the toner

supply action will be taken for about 8 minutes.

3.Press the MENU key on the operation panel.

4.Press the or key repeatedly until [Print

Status page] is displayed.

5.Press the ENTER key twice. A status page is

printed.

Power cord connector

(220 - 240 V models only)

Power cord

Figure 1-3-17

Completion of the machine installation.

1-3-8

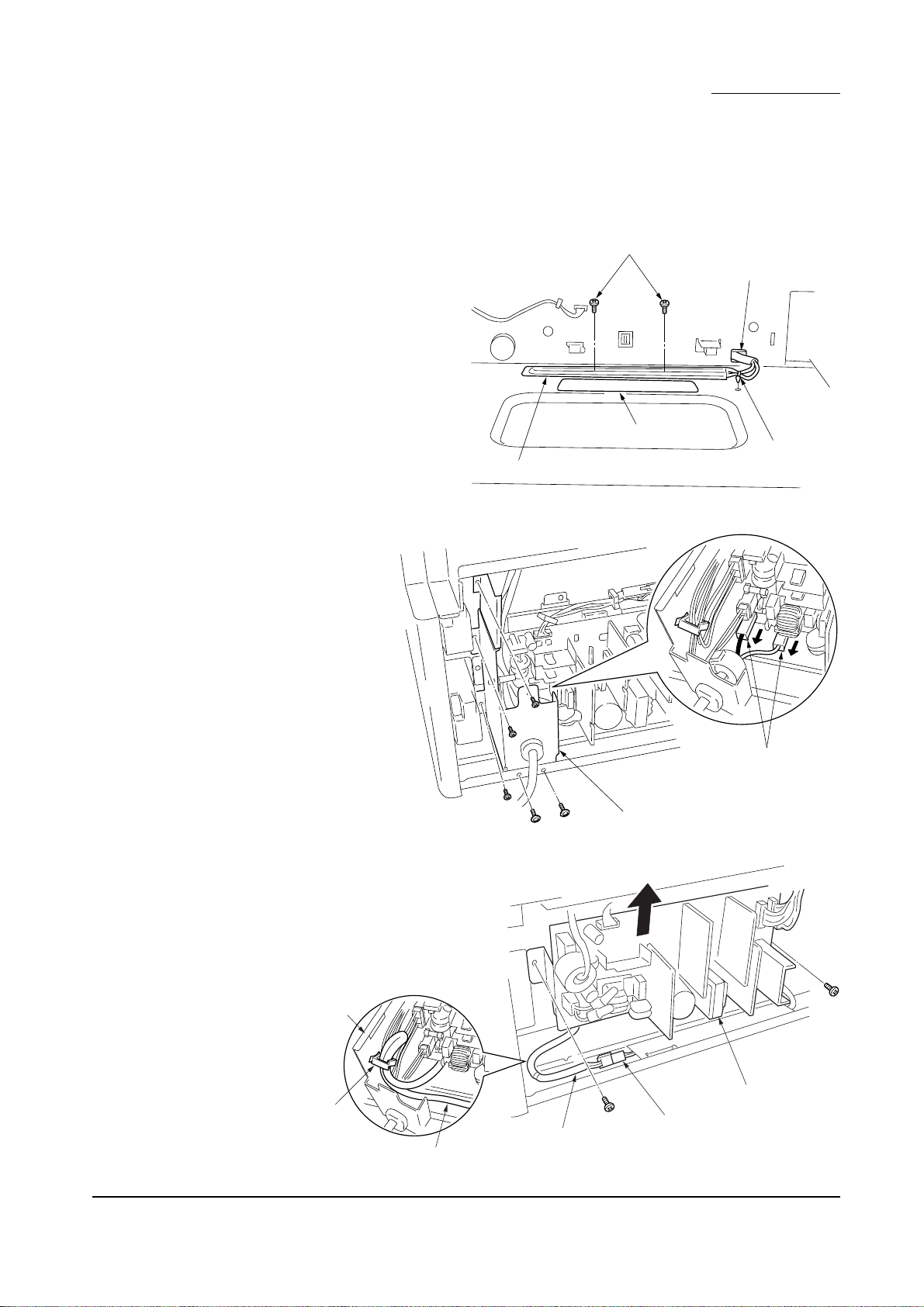

1-3-2 Installing the cassette heater (option)

Cassette heater installation requires the following parts:

• Cassette heater (P/N 34860030): for 120 V specifications

• Cassette heater (P/N 33960020): for 220 - 240 V specifications

• Binding band (P/N M2107120)

•Two binding screws BVM4X6 (P/N B1304060)

• Caution label (P/N 20305130)

• Fax kit label (P/N 3CM05010)

Procedure

1. Pull the upper and lower cassettes out.

2. Install the cassette heater to the bottom of the

machine with two screws (M4X06), and bind

the wire of the cassette heater with the band.

3. Put the wire of the cassette heater out of the

machine through the aperture of the rear

frame.

4. Stick the caution label in front of the cassette

heater.

5. Remove the five screws and the two

connectors and then remove the power

supply mount from the rear side of the

machine.

Pay attention not to reverse the black wire

and white wire when refitting the connector.

FS-9100DN/9500DN

Screws

Aperture

Caution label

Band

Cassette heater

Figure 1-3-18

6. Remove the two screws and pull out the wire

of the cassette heater that has been put out

of the rear frame while raising the power

supply unit.

7. Insert the connector of the cassette heater

into the connector of the machine.

8. Fold the wire of the cassette heater and insert

it into the clamp of the power supply mount

as shown in the figure.

Power supply

mount

Clump

Wire of the cassette heater

Connectors

Power supply mount

Figure 1-3-19

Power supply unit

Connector

Wire of the

cassette heater

Figure 1-3-20

1-3-9

FS-9100DN/9500DN

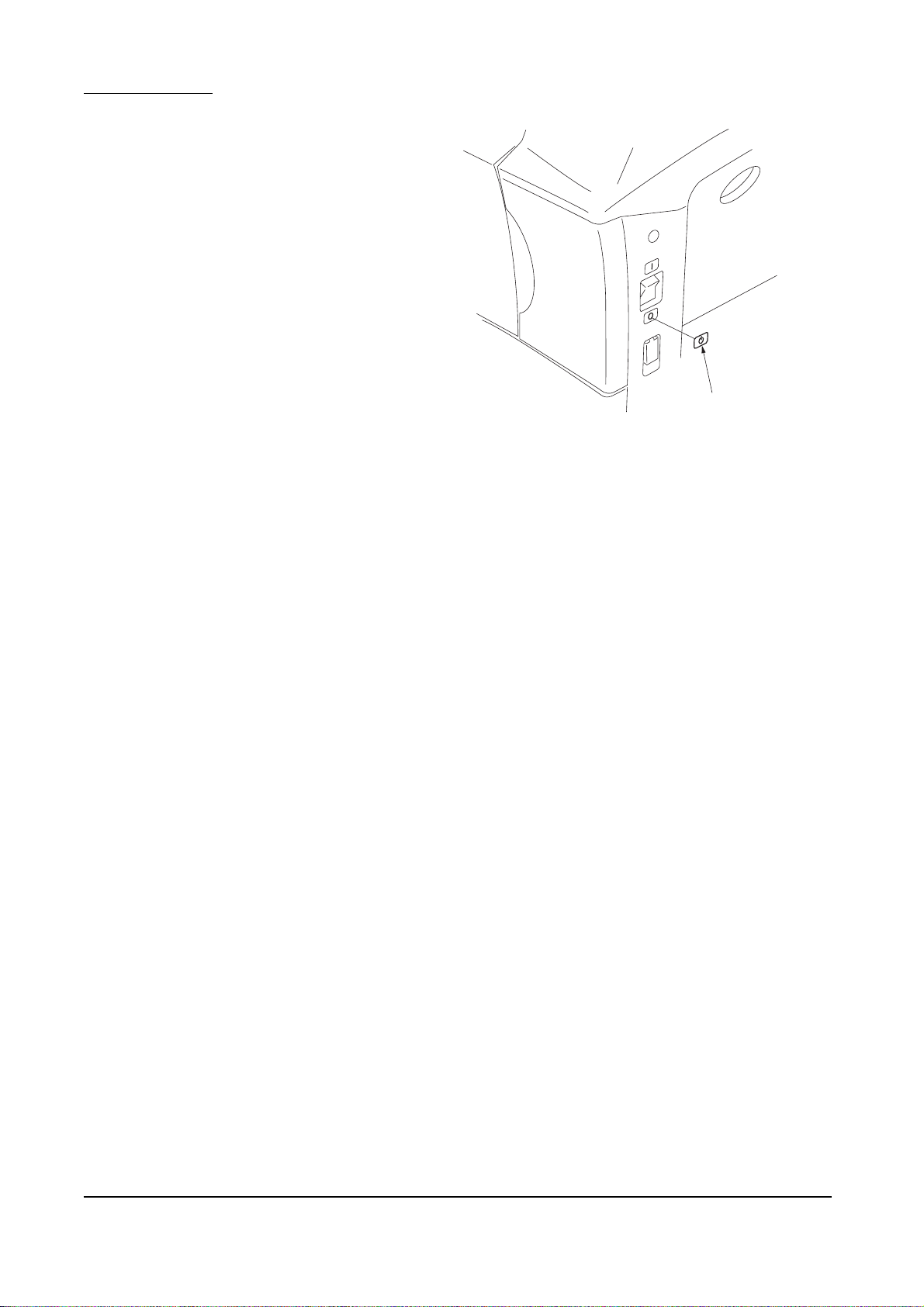

9. Stick the label below the power switch.

10. Refit all the removed parts.

Label

Figure 1-3-21

1-3-10

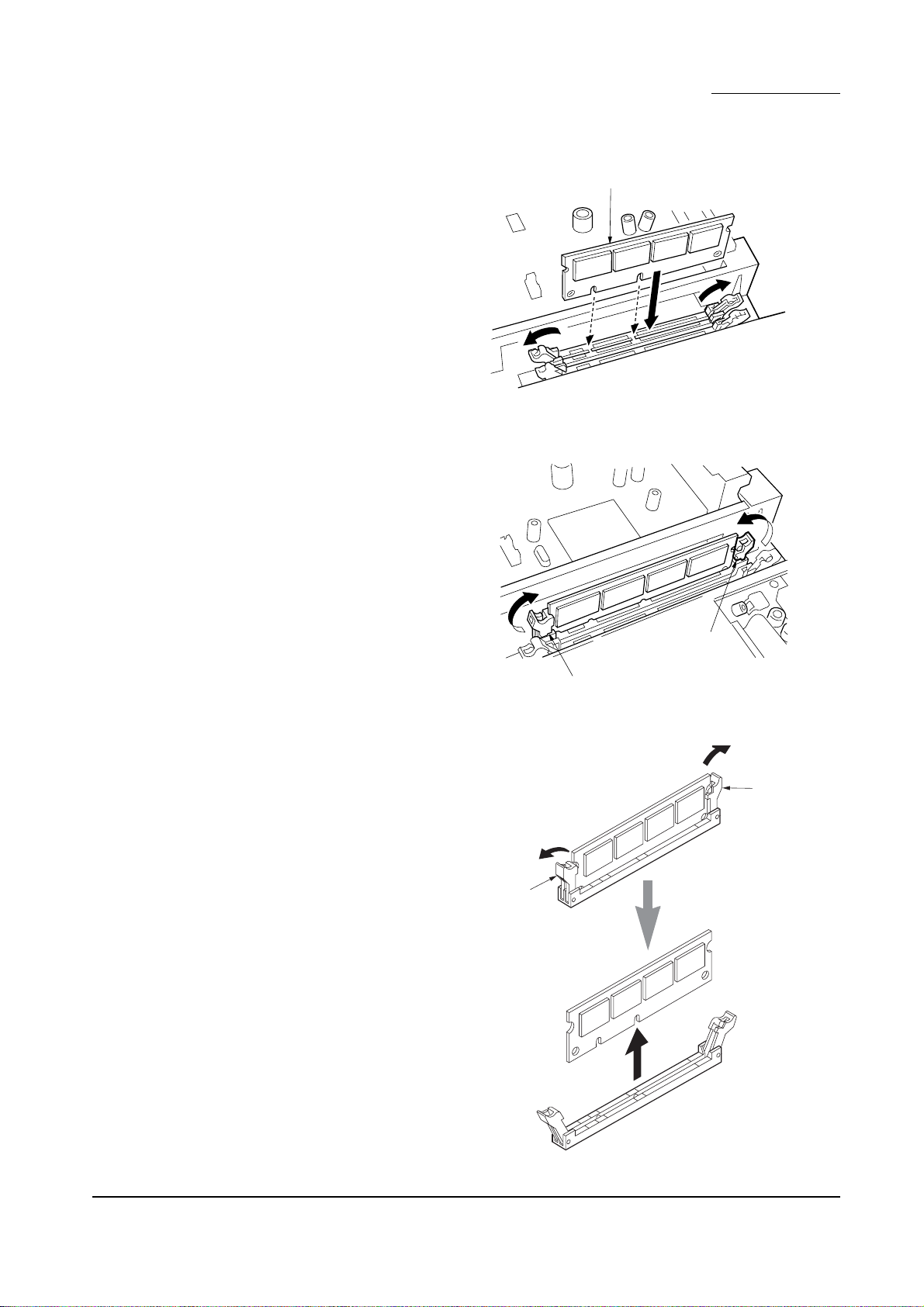

1-3-3 Installing DIMMs (option)

Procedure

• Installing DIMM

1. Remove two screws and then remove the

main controller PWB (see page 1-6-24).

2. Open the clips on both ends of the DIMM

socket.

3. Insert the DIMM into the socket, so that the

notches on the DIMM align with the

corresponding protrusions in the socket.

4. Close the clips of the DIMM socket to secure

the DIMM.

5. When you finish installing the DIMM, reinsert

the main controller PWB into the printer.

FS-9100DN/9500DN

DIMM

Figure 1-3-22

• Removing DIMM

1. To remove a DIMM, carefully pull the end

clips outwards, then pull the DIMM out of the

socket.

Clip

Clip

Figure 1-3-23

Clip

Clip

Figure 1-3-24

1-3-11

FS-9100DN/9500DN

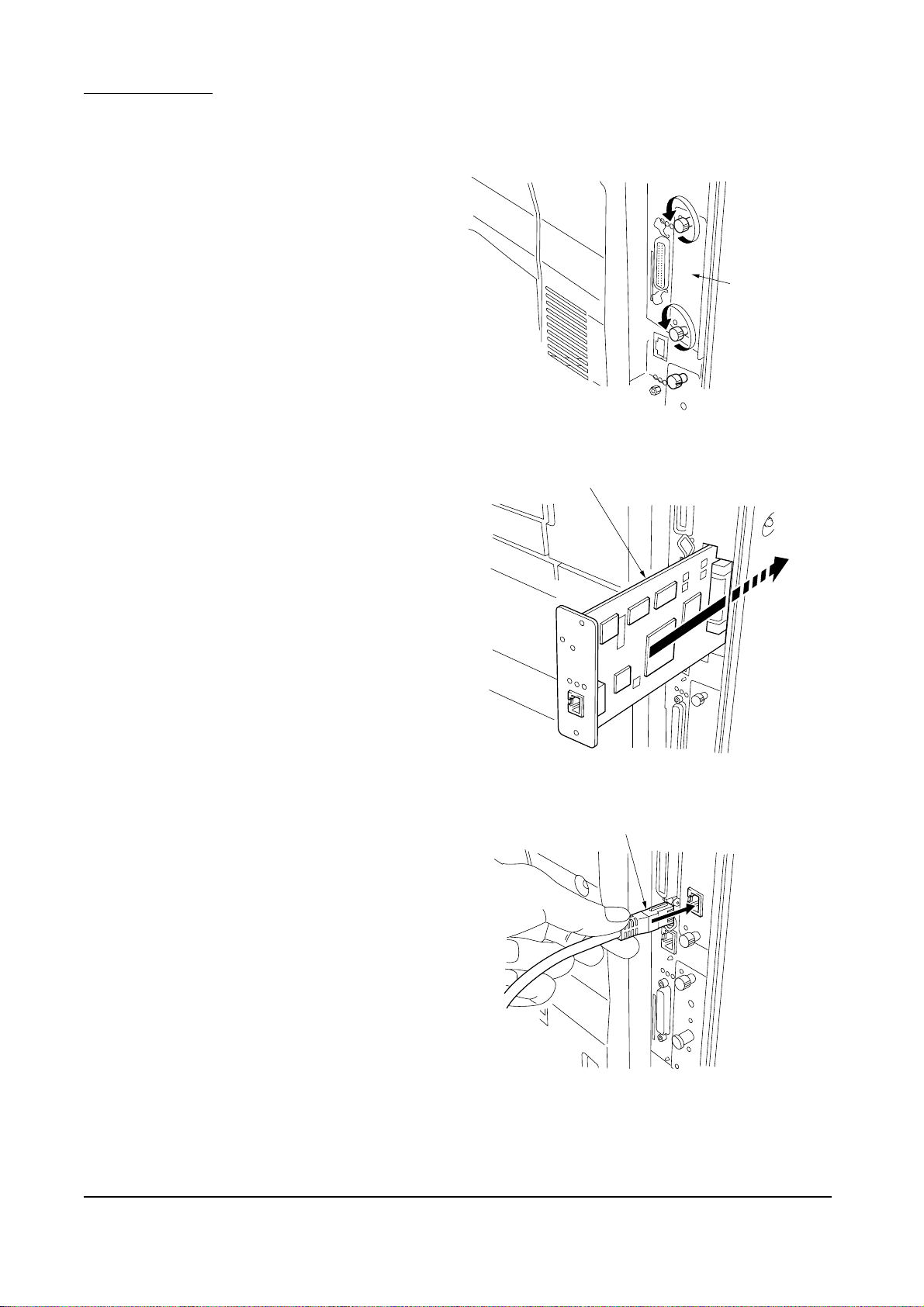

1-3-4 Installing the network interface card (option)

Procedure

1. Remove the two screws from the option

interface slot cover.

Option interface

slot cover

Figure 1-3-25

2. Insert the network interface card and secure it

with the screws removed in step 1.

3. Connect the network cable.

Network interface card

Figure 1-3-26

Network cable

1-3-12

Figure 1-3-27

Loading...

Loading...