Page 1

Color laser printers

SERVICE

MANUAL

Published in July ’01

842BM110A

2BM70760A

Revison 2.5

Page 2

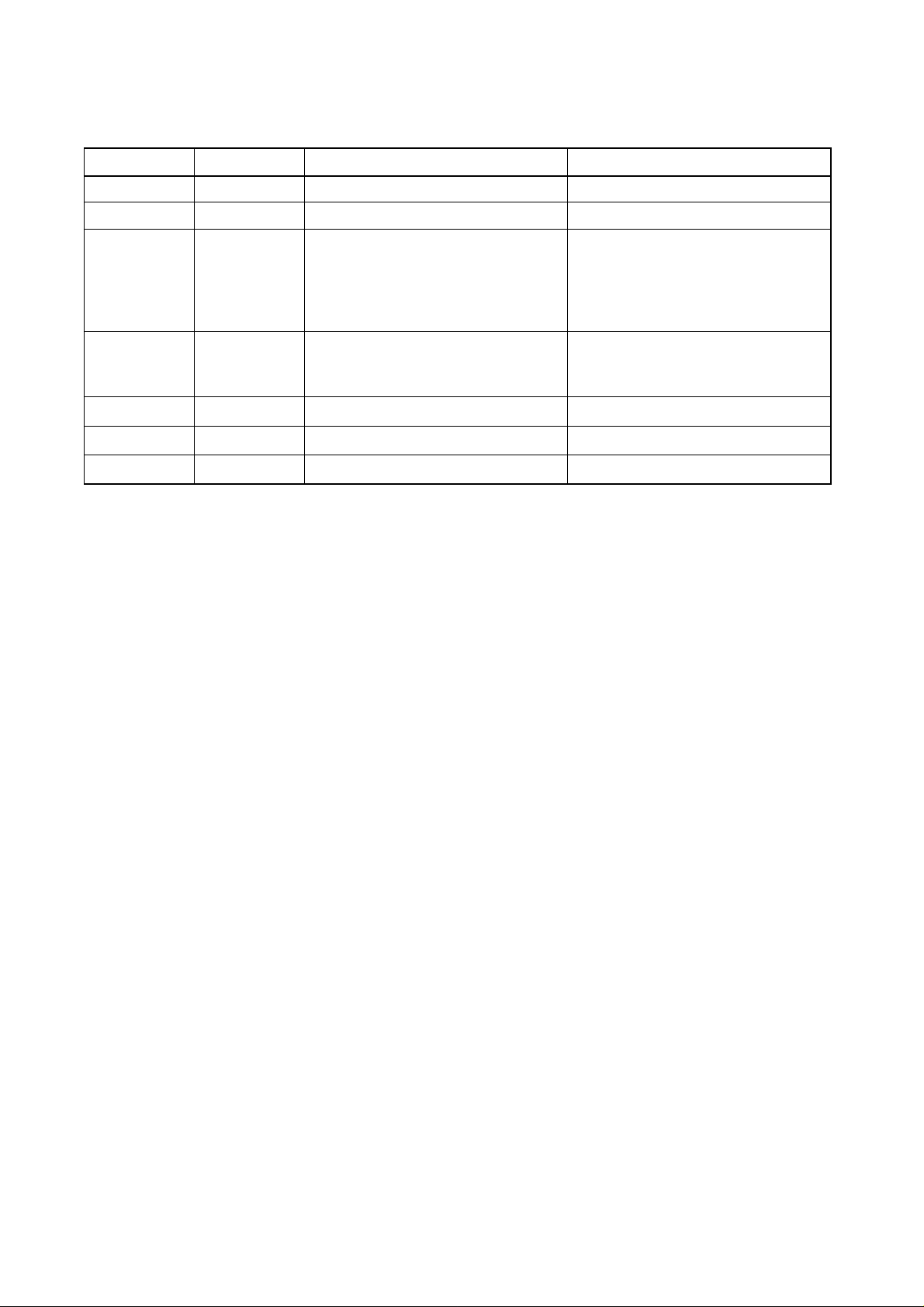

Revision history

Version Replaced pages RemarksDate

1.0

2.0

2.1

2.2

2.3

2.4

2.5

July-2001

20-Aug-2001

03-Sep-2001

26-Sep-2001

17-Oct-2001

03-Dec-2001

31-Jan-2002

-

1-3-12, 16, 17

1-6-10, 21, 22, 24, 39, 42

2-1-2, 5, 13, 16, 19, 22, 27, 32, 35

2-2-5

2-4-2

1-4-3, 4, 5, 6, 8, 23, 24, 25, 26, 27

1-6-4, 45

2-4-3

2-1-35

1-5-32, 33, 34, 35, 36, 37, 38, 39

1-5-28

-

-

-

-

Missing page

-

Page 3

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 4

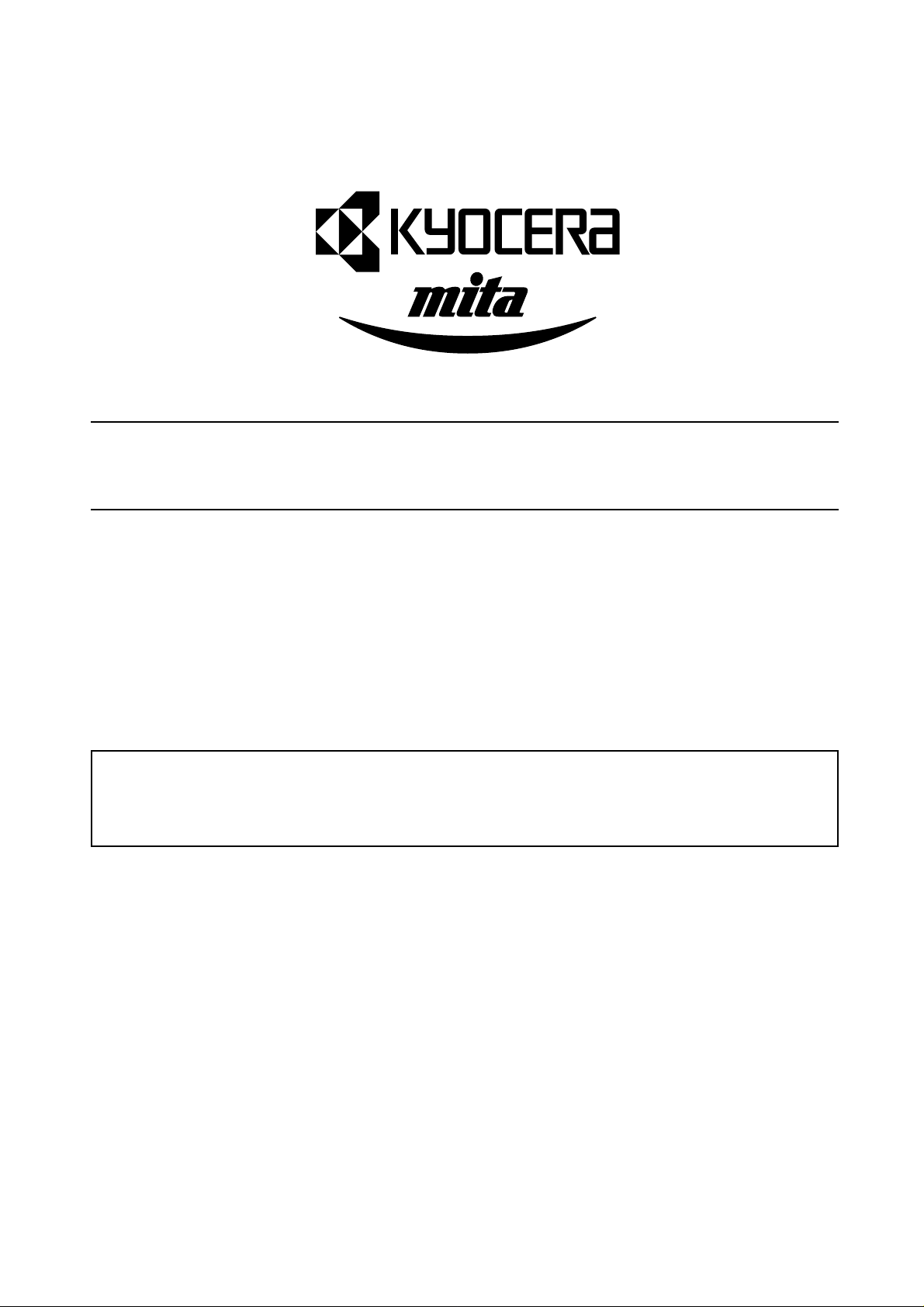

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the printer.

Page 5

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the printer may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the printer on an infirm or angled surface: the printer may tip over, causing injury. ....

• Do not install the printer in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the printer near a radiator, heater, other heat source or near flammable material.

This may cause fire...........................................................................................................................

• Allow sufficient space around the printer to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance...........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on printers so equipped. Failure to do this may

cause the printer to move unexpectedly or topple, leading to injury. ................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the

printer’s instruction handbook. ..........................................................................................................

Page 6

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. .............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the printer is correctly connected to an outlet with a ground connection. ...........

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. .........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts........

• Handle the fixing section with care to avoid burns as it can be extremely hot..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. .........................................................................................................

• Do not remove the ozone filter, if any, from the printer except for routine replacement. ..................

Page 7

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ......

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below:....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .........................................................................................................................

• Should smoke be seen coming from the printer, remove the power plug from the wall outlet

immediately.......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas.................................................................................

Page 8

FS-8000C/CD/CN

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................................... 1-1-2

1-1-2 Parts names and their functions............................................................................................................... 1-1-4

(1) Printer ............................................................................................................................................... 1-1-4

(2) Operation panel ................................................................................................................................ 1-1-5

1-1-3 Cross section view ................................................................................................................................... 1-1-6

1-2 Handling Precautions

1-2-1 Drum......................................................................................................................................................... 1-2-2

1-2-2 Developer and toner container ................................................................................................................. 1-2-2

1-2-3 Installation environment ........................................................................................................................... 1-2-2

1-3 Installation

1-3-1 Unpacking and installation ....................................................................................................................... 1-3-2

(1) Installation procedure........................................................................................................................ 1-3-2

1-4 Service Mode and Maintenance

1-4-1 Service mode ........................................................................................................................................... 1-4-2

(1) Executing service mode.................................................................................................................... 1-4-2

(2) Contents of service mode items........................................................................................................ 1-4-3

1-4-2 Maintenance............................................................................................................................................1-4-11

(1) Replacing the toner container ..........................................................................................................1-4-11

(2) Cleaning the main charger unit ....................................................................................................... 1-4-13

(3) Cleaning the printer......................................................................................................................... 1-4-16

(4) Replacing the oil roller unit.............................................................................................................. 1-4-20

(5) Cleaning the heat and press/heat rollers of paper dust .................................................................. 1-4-21

(6) Cleaning the fuser unit .................................................................................................................... 1-4-22

1-4-3 Downloading printer firmware for upgrade ............................................................................................. 1-4-23

(1) Format for the firmware files ........................................................................................................... 1-4-23

(2) Downloading firmware via the parallel interface ............................................................................. 1-4-24

(3) Downloading firmware using the memory card............................................................................... 1-4-25

(4) Downloading message data............................................................................................................ 1-4-27

1-5 Troubleshooting

1-5-1 Paper misfeed detection........................................................................................................................... 1-5-2

(1) Paper misfeed indication................................................................................................................... 1-5-2

(2) Paper misfeed detection sensors...................................................................................................... 1-5-3

1-5-2 Self-diagnosis........................................................................................................................................... 1-5-4

(1) Self-diagnostic function..................................................................................................................... 1-5-4

1-5-3 Image formation problems...................................................................................................................... 1-5-32

(1) No image appears (entirely white). ................................................................................................. 1-5-33

(2) No image appears (entirely black). ................................................................................................. 1-5-33

(3) Dirt on the top edge. ....................................................................................................................... 1-5-33

(4) Dirt on the back side. ...................................................................................................................... 1-5-34

(5) Image is too light............................................................................................................................. 1-5-34

(6) Background is visible. ..................................................................................................................... 1-5-34

(7) A white line appears longitudinally. ................................................................................................. 1-5-35

(8) A line appears longitudinally............................................................................................................ 1-5-35

(9) Oily streaks (15 cm intervals) appears at the top of the page longitudinally................................... 1-5-35

(10) A line appears laterally. ................................................................................................................. 1-5-36

1-1-1

Page 9

FS-8000C/CD/CN

(11) One side of the print image is darker than the other. .................................................................... 1-5-36

(12) Dots appear on the image............................................................................................................. 1-5-36

(13) The leading edge of the image is misaligned with the original image........................................... 1-5-37

(14) Paper creases............................................................................................................................... 1-5-37

(15) Offset occurs................................................................................................................................. 1-5-37

(16) Image is partly missing. ................................................................................................................ 1-5-38

(17) Fusing is poor................................................................................................................................ 1-5-38

(18) Dragged dirt lines appears............................................................................................................ 1-5-38

1-6 Assembly and Disassembly

1-6-1 Precautions for assembly and disassembly ............................................................................................. 1-6-2

(1) Precautions ....................................................................................................................................... 1-6-2

1-6-2 Paper feed section ................................................................................................................................... 1-6-3

(1) Detaching and refitting the MP tray unit............................................................................................ 1-6-3

(2) Detaching and refitting the MP tray feed roller and MP tray retard roller .......................................... 1-6-4

(3) Detaching and refitting the face-down unit........................................................................................ 1-6-5

(4) Detaching and refitting drive assembly B.......................................................................................... 1-6-6

(5) Detaching and refitting drive assembly A.......................................................................................... 1-6-6

(6) Detaching and refitting the paper conveying belts ............................................................................ 1-6-7

(7) Detaching and refitting the paper conveying fan motors 1 and 2...................................................... 1-6-8

(8) Detaching and refitting the upper and lower registration rollers........................................................ 1-6-9

(9) Detaching and refitting the middle roller ......................................................................................... 1-6-10

1-6-3 Laser scanner unit...................................................................................................................................1-6-11

(1) Detaching and refitting the laser scanner unit..................................................................................1-6-11

1-6-4 Main charger unit.................................................................................................................................... 1-6-13

(1) Detaching and refitting the main charger unit ................................................................................. 1-6-13

(2) Detaching and refitting the main charger grid ................................................................................. 1-6-13

1-6-5 Drum unit................................................................................................................................................ 1-6-14

(1) Detaching and refitting the drum unit .............................................................................................. 1-6-14

1-6-6 Primary transfer unit ............................................................................................................................... 1-6-15

(1) Detaching and refitting the primary transfer unit ............................................................................. 1-6-15

(2) Detaching and refitting the cleaning brush unit............................................................................... 1-6-15

1-6-7 Developers (and toner feed section) ...................................................................................................... 1-6-16

(1) Detaching and refitting the developers ........................................................................................... 1-6-16

(2) Detaching and refitting the waste toner duct assembly .................................................................. 1-6-18

(3) Detaching and refitting the black toner feed assembly ................................................................... 1-6-19

(4) Detaching and refitting the black toner container feed assembly ................................................... 1-6-19

(5) Detaching and refitting the black toner feed drive assembly .......................................................... 1-6-20

1-6-8 Secondary transfer unit .......................................................................................................................... 1-6-21

(1) Detaching and refitting the transfer roller and the separation charger unit ..................................... 1-6-21

(2) Detaching and refitting the secondary transfer unit shift clutch ...................................................... 1-6-23

1-6-9 Fuser unit (and drive section)................................................................................................................. 1-6-24

(1) Detaching and refitting the fuser unit .............................................................................................. 1-6-24

(2) Detaching and refitting the fuser top cover and upper separator bracket ....................................... 1-6-24

(3) Detaching and refitting the upper and lower fuser thermistors ....................................................... 1-6-26

(4) Detaching and refitting the upper and lower thermostats ............................................................... 1-6-28

(5) Detaching and refitting the upper and lower heater lamps ............................................................. 1-6-29

(6) Detaching and refitting the heat roller and the press/heat roller ..................................................... 1-6-30

(7) Detaching and refitting the separators of lower separator bracket ................................................. 1-6-34

(8) Detaching and refitting drive assembly C ....................................................................................... 1-6-35

1-6-10 PWBs and high voltage units ............................................................................................................... 1-6-36

(1) Detaching and refitting the main controller PWB ............................................................................ 1-6-36

1-1-2

Page 10

FS-8000C/CD/CN

(2) Detaching and refitting the engine controller PWB ......................................................................... 1-6-37

(3) Detaching and refitting the power supply unit ................................................................................. 1-6-38

(4) Detaching and refitting the developing/cleaning brush bias high voltage unit ................................ 1-6-40

(5) Detaching and refitting the main charger high voltage unit............................................................. 1-6-41

(6) Detaching and refitting the separation charger high voltage unit.................................................... 1-6-42

(7) Detaching and refitting the paper feeder/options relay PWB .......................................................... 1-6-44

(8) Detaching and refitting the transfer roller bias high voltage unit ..................................................... 1-6-44

1-6-11 Others................................................................................................................................................... 1-6-45

(1) Detaching and refitting the ozone filter ........................................................................................... 1-6-45

2-1 Mechanical Construction

2-1-1 Paper feed unit and secondary transfer unit ............................................................................................ 2-1-2

(1) Paper feed unit.................................................................................................................................. 2-1-2

(2) Secondary transfer unit..................................................................................................................... 2-1-5

2-1-2 MP tray unit .............................................................................................................................................. 2-1-6

2-1-3 Laser scanner unit.................................................................................................................................... 2-1-8

2-1-4 Developer ............................................................................................................................................... 2-1-10

(1) Y ellow developer..............................................................................................................................2-1-11

(2) Magenta developer ......................................................................................................................... 2-1-14

(3) Cyan developer............................................................................................................................... 2-1-17

(4) Black developer .............................................................................................................................. 2-1-20

(5) Transition of toner for development ................................................................................................ 2-1-24

2-1-5 Drum unit and main charger unit ............................................................................................................ 2-1-25

(1) Drum unit ........................................................................................................................................ 2-1-25

(2) Main charger unit ............................................................................................................................ 2-1-29

2-1-6 Primary transfer unit ............................................................................................................................... 2-1-30

(1) Primary transfer unit....................................................................................................................... 2-1-30

(2) Cleaning brush unit ......................................................................................................................... 2-1-30

2-1-7 Fuser unit ............................................................................................................................................... 2-1-35

2-1-8 Face-down tray unit................................................................................................................................ 2-1-38

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ............................................................................................................................... 2-2-2

(1) Main frame, Face-down unit, and MP tray unit ................................................................................. 2-2-2

(2) Developers, drum unit and main charger unit ................................................................................... 2-2-3

(3) Primary transfer, secondary transfer, paper feed, and fuser units .................................................... 2-2-5

(4) Main frame rear and controller box ................................................................................................... 2-2-6

2-3 PWB Operation and Connector Signal Assignment

2-3-1 Engine controller PWB [KP-801] .............................................................................................................. 2-3-2

2-3-2 Main controller PWB [KP-800].................................................................................................................2-3-11

2-4 Appendixes

Connection diagram........................................................................................................................................... 2-4-2

Maintenance kits................................................................................................................................................ 2-4-3

Periodic maintenance procedures ..................................................................................................................... 2-4-4

1-1-3

Page 11

Chapter I

Page 12

CONTENTS

1-1 Specifications....................................................................................1-1-2

1-1-1 Specifications ........................................................................................................................................... 1-1-2

1-1-2 Parts names and their functions............................................................................................................... 1-1-4

(1) Printer ............................................................................................................................................... 1-1-4

(2) Operation panel ................................................................................................................................ 1-1-5

1-1-3 Cross section view ................................................................................................................................... 1-1-6

Page 13

FS-8000C/CD/CN

1-1-1 Specifications

Type ............................................... Console type color laser printer

Printing system...............................Electro photographic four colors (cyan, magenta, yellow, and black) printing. 4-cycle

intermediate transfer drum.

Paper..............................................Cassette: Plain paper (64 to 90 g/m

MP tray: Plain paper (64 to 90 g/m

Special paper: Transparencies, tracing paper, colored paper, letterhead and

envelopes

Note: Use the MP tray for special paper.

Printing sizes.................................. Maximum: A3/Ledger

1

Minimum: A6R /5

/2" × 81/2"/Folio (When the MP tray is used.)

Print speed ..................................... A4: 8 pages/30 pages per min. [Color/Monochrome]

A4-R*: 4 pages/15 pages per min. [Color/Monochrome]

A5: 8 pages/15 pages per min. [Color/Monochrome]

B5: 4 pages/15 pages per min. [Color/Monochrome]

A3: 4 pages/15 pages per min. [Color/Monochrome]

Letter: 8 pages/30 pages per min. [Color/Monochrome]

Letter-R*: 4 pages/15 pages per min. [Color/Monochrome]

Legal: 4 pages/15 pages per min. [Color/Monochrome]

Note (*): MP tray only

First copy time................................ 28 s/17 s [Color/Monochrome]

Note: A4, Ecopower mode off, room temperature 23° C/73.4 °F, 60 % RH

Warm-up time.................................Approximately 300 s or less (room temperature 23° C/73.4 °F, 60 % RH)

Paper feed system ......................... FS-8000C/CN model: Paper feeder PF-30A (2 universal type cassettes) and MP

(Multi purpose) tray

FS-8000CD model: Duplex unit PD-30 (1 universal type cassette) and MP (Multi

purpose) tray

Paper loading capacity................... Cassette: 500 sheets (80 g/m

MP (Multi purpose) tray: 150 sheets (80 g/m

Printout stacking capacity .............. Face-down tray: 500 sheets with paper full sensor

Face-up tray: 150 sheets (80 g/m2, 0.11 mm)

Photoconductor .............................. aSi drum (diameter 80 mm)

Charging system ............................ Single positive corona charging

Exposure light source .................... Semiconductor laser

Exposure scanning system ............ Polygon mirror

Developing system......................... Dry, reverse developing (magnetic brush)

Developer: 2-component

Toner density control: T/C sensor

Toner replenishing: automatic from the toner container

Transfer system .............................Primary: Intermediate transfer drum (diameter 160 mm)

Secondary: Transfer roller

Separation system .........................AC corona separation charging

Fixing system ................................. Heat roller and press/heat roller (soft type, diameter 45 mm)

Heat source: 2 halogen heaters (500 W)

Control temperature: 185 °C/365 °F (at normal ambient temperature)

Abnormally high temperature protection device: thermostats

Charge erasing system .................. Exposure by eraser lamp (LED array)

Cleaning system ............................Drum: Cleaning blade

Primary (intermediate) transfer drum: Fur brush

Controller hardware .......................CPU: Power PC750CX 400 MHz

Code ROM: 8 MB (2 system DIMM PWBs in sockets)

Font ROM: 4 MB (PCL and KPDL)

Main RAM: 64 MB (standard)

Option expansion RAM: 2 sockets (Maximum 256 MB, including the standard RAM)

Option memory card: 1 slot (CompactFlash card)

Option interface*: 2 slots (KUIO LV)

Note (*): A network interface card is standard-installed with FS-8000CN.

2

)

2

), Thick paper (90 to 220 g/m2)

2

, 0.11 mm)

2

, 0.11 mm)

1-1-2

Page 14

FS-8000C/CD/CN

Host computer interface................. Parallel: Bi-directional parallel (IEEE 1284 Nibble/ECP mode)

Serial: RS-232C, 115.2 kbps maximum

Option: KUIO 2 slots

Controller software .........................Emulation: PCL 5C, KPDL, KCGL

Fonts: PCL, PS, PRESCRIBE

Smoothing ...................................... KIR (monochrome mode only)

Toner saving...................................EcoPrint mode (monochrome mode only)

Resolution ...................................... 600 × 600 dpi

Dimensions ....................................Printer main unit: 590 × 585 × 429 mm (W × D × H)

1

/4" × 235/16" × 167/8" (W × D × H)

23

Paper feeder PF-30A: 560 × 566 × 251mm (W × D × H)

223/8" × 221/4" × 97/8" (W × D × H)

Duplex unit PD-30: 560 × 566 × 251 mm (W × D × H)

223/8" × 221/4" × 97/8" (W × D × H)

Weight ............................................ Printer main unit: 76.3 kg/167.86 lbs (including toner containers and oil roller unit)

Paper feeder PF-30A: 19.1 kg/40.02 lbs

Duplex unit PD-30: 22.1 kg/48.62 lbs

Floor requirements ......................... 891× 560 mm (W × D)

1

/16" × 221/16" (W × D)

35

Functions........................................Self-diagnostics, sleep mode (energy saving)

Power source ................................. 120 V AC, 60 Hz, 11.5 A

220 – 240 V AC, 50/60 Hz, 5.8 A

Power consumption ....................... Maximum: 1318 W (120 V), 1323 W (220 – 240 V)

Printing: 412 W (120 V), 437 W (220 – 240 V)

Ready: 177 W (120 V), 184 W (220 – 240 V)

Sleep mode: 34 W/37 W* (120 V), 35 W/38 W* (220 – 240 V)

Note (*): Network model

Options...........................................Expansion DIMM (32/64/128 MB), memory card, network interface card IB-20/IB-21/

IB-21E, hard disk unit, paper feeder PF-30A, duplex unit PD-30*, mailbox sorter SO-

30, document finisher DF-31, bulk stacker ST-30, barcode reader BC-1, caster CA-

31, caster kit CA-31B

Note (*): Optional for FS-8000C/CN models.

1-1-3

Page 15

FS-8000C/CD/CN

1-1-2 Parts names and their functions

(1) Printer

6

2

3

4

5

7

°

1

8

·

(

‚

9

*

&

^

%

Figure 1-1-1

0

#

!

@

)

¤

$

⁄

‹

›

‡

fl

fi

1-1-4

1 Side cover

2 Face-down tray

3 Cyan toner container

4 Magenta toner container

5 Yellow toner container

6 Paper stopper

7 Main charger unit

8 Black toner container

9 Waste toner bottle

0 Primary transfer unit

! Release lever

@ Secondary transfer unit (transfer roller

and separation charger unit)

# Separation charger wire cleaner

$ Paper feed unit

% Fuser unit

^ Front cover

& Oil roller unit

Cautions:

The power cord must keep plugged from power at least 30 minutes since the power switch is turned off.

In case the power plug must be unplugged immediately after power-off for service purpose, pull out the

paper feed unit so that the fuser unit is away from developers to avoid toner lumping due to the heat from

the fuser unit.

* Left paper guide

( Face-up tray

) MP tray

⁄ Parallel interface connector

¤ Paper feeder/duplex unit side cover

‹ Serial interface connector

› Memory card slot

fi Network interface card*

fl Hard disk unit*

‡ Filter duct

Power switch

· Power cord connector

‚ Paper feeder*3 or duplex unit*

*1: Standard-installed with FS-8000CN model only

2

: Option

*

3

: Standard-installed with FS-8000C model

*

4

*

: Standard-installed with FS-8000CD model

2

or Network interface card*2 slot [OPT2/HDD]

1

slot [OPT1]

4

Page 16

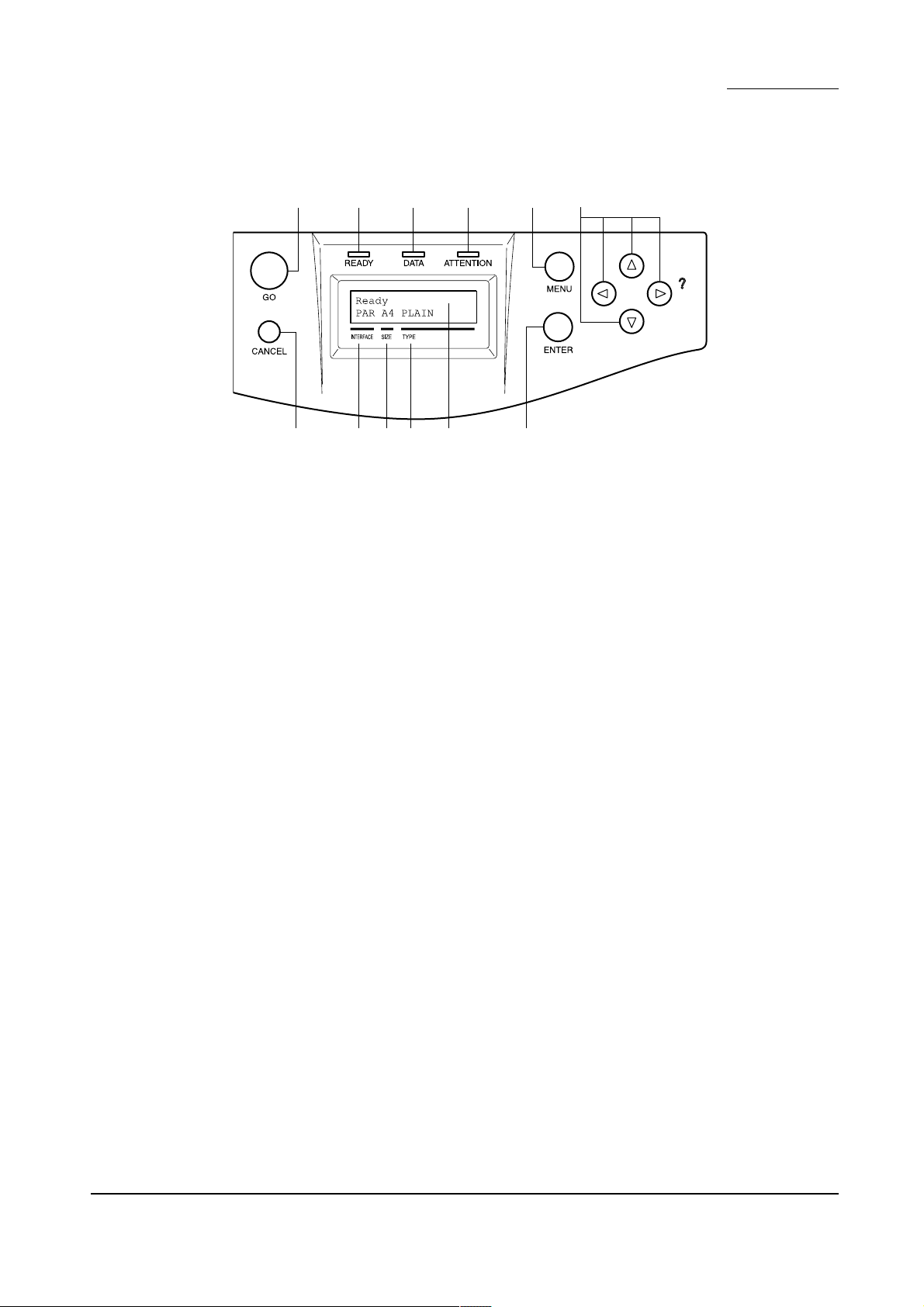

(2) Operation panel

FS-8000C/CD/CN

31678 5

02!@ 9 4

Figure 1-1-2

1 Go key (GO)

2 Cancel key (CANCEL)

3 Menu keys (MENU)

4 Enter key (ENTER)

5 Arrow keys

6 Ready indicator (READY)

7 Data indicator (DATA)

8 Attention indicator (ATTENTION)

9 Message display

0 Interface indicator (INTERFACE)

! Paper size indicator (SIZE)

@ Paper type indicator (TYPE)

1-1-5

Page 17

FS-8000C/CD/CN

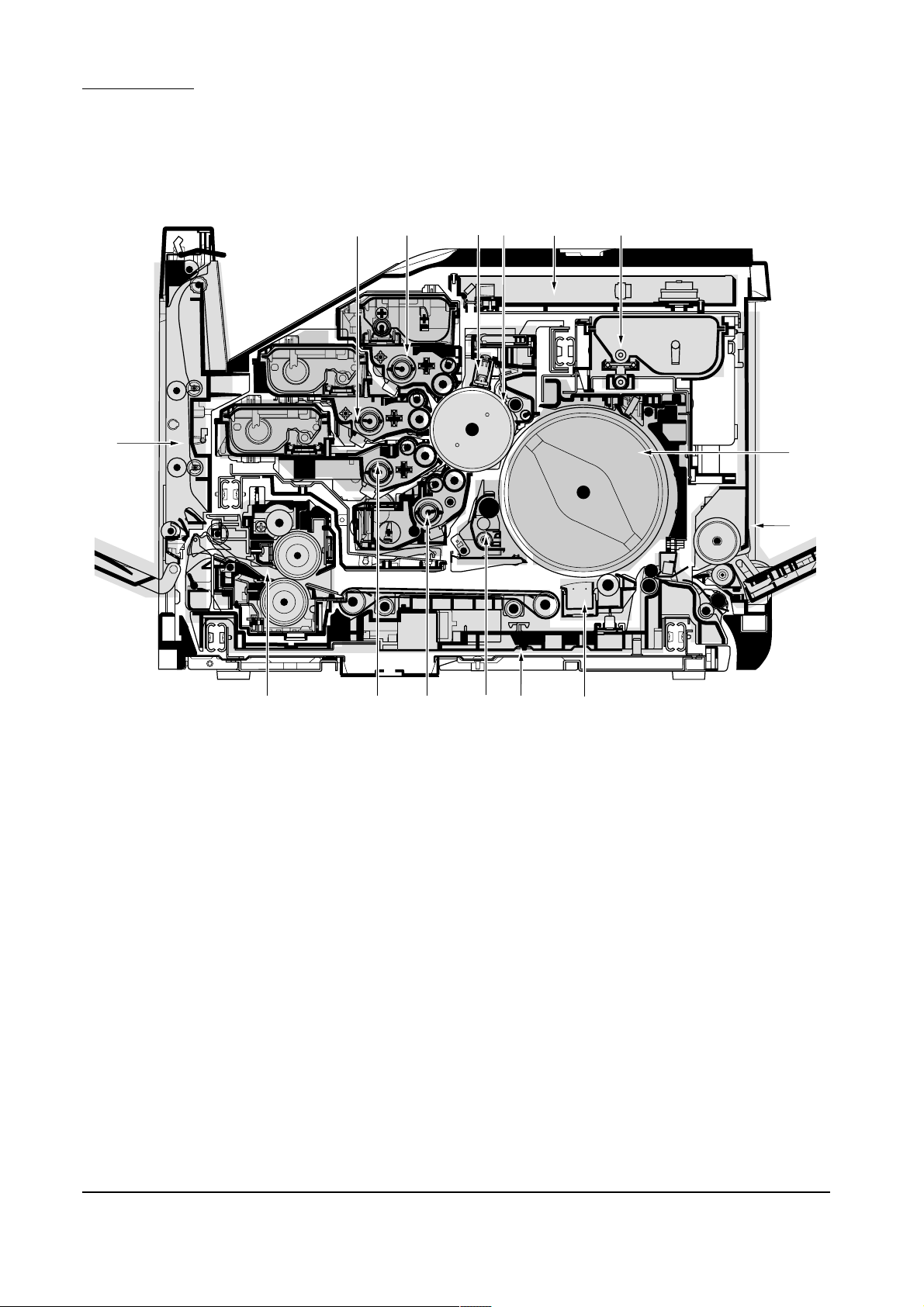

1-1-3 Cross section view

%

7

6

4

5

3

0

!

1

$ 298

Figure 1-1-3 Cross section view

1 MP tray unit

2 Paper feed unit

3 Laser scanner unit

4 Main charger unit

5 Drum unit

6 Yellow developer and yellow toner container

7 Magenta developer and magenta toner container

8 Cyan developer and cyan toner container

9 Black developer

0 Black toner container

! Primary transfer unit

@ Cleaning brush unit

# Secondary transfer unit

$ Fuser unit

% Face-down unit

@

#

1-1-6

Page 18

CONTENTS

1-2 Handling Precautions .......................................................................1-2-2

1-2-1 Drum......................................................................................................................................................... 1-2-2

1-2-2 Developer and toner container ................................................................................................................. 1-2-2

1-2-3 Installation environment ........................................................................................................................... 1-2-2

Page 19

1-2 Handling precautions

FS-8000C/CD/CN

1-2-1 Drum

Note the following when handling or storing the drum.

• Keep the drum at an ambient temperature between –20°C/–4°F and 40°C/104°F and at a relative

humidity not higher than 85 % RH. Avoid abrupt changes in temperature and humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained with oil, clean it.

1-2-2 Developer and toner container

Store the developer and toner container in a cool, dark place. Avoid direct light and high humidity.

1-2-3 Installation environment

1.Temperature: 10 - 32.5°C/50 - 90.5°F

2.Humidity: 15 - 80 %RH

3.Power supply: 120 V AC ±10 %, 11.5 A

4.Power source frequency: 50 Hz ±0.2 %/60 Hz ±0.2 %

5.Installation location

• Avoid direct sunlight or bright lighting.

• Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto

the machine.

• Avoid dust and vibration.

• Choose a surface capable of supporting the weight of the machine.

• Place the machine on a level surface (maximum allowance inclination: 1° ).

• Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases, and chlorine-based organic solvents.

• Select a room with good ventilation.

6.Allow sufficient access for proper operation and maintenance of the machine.

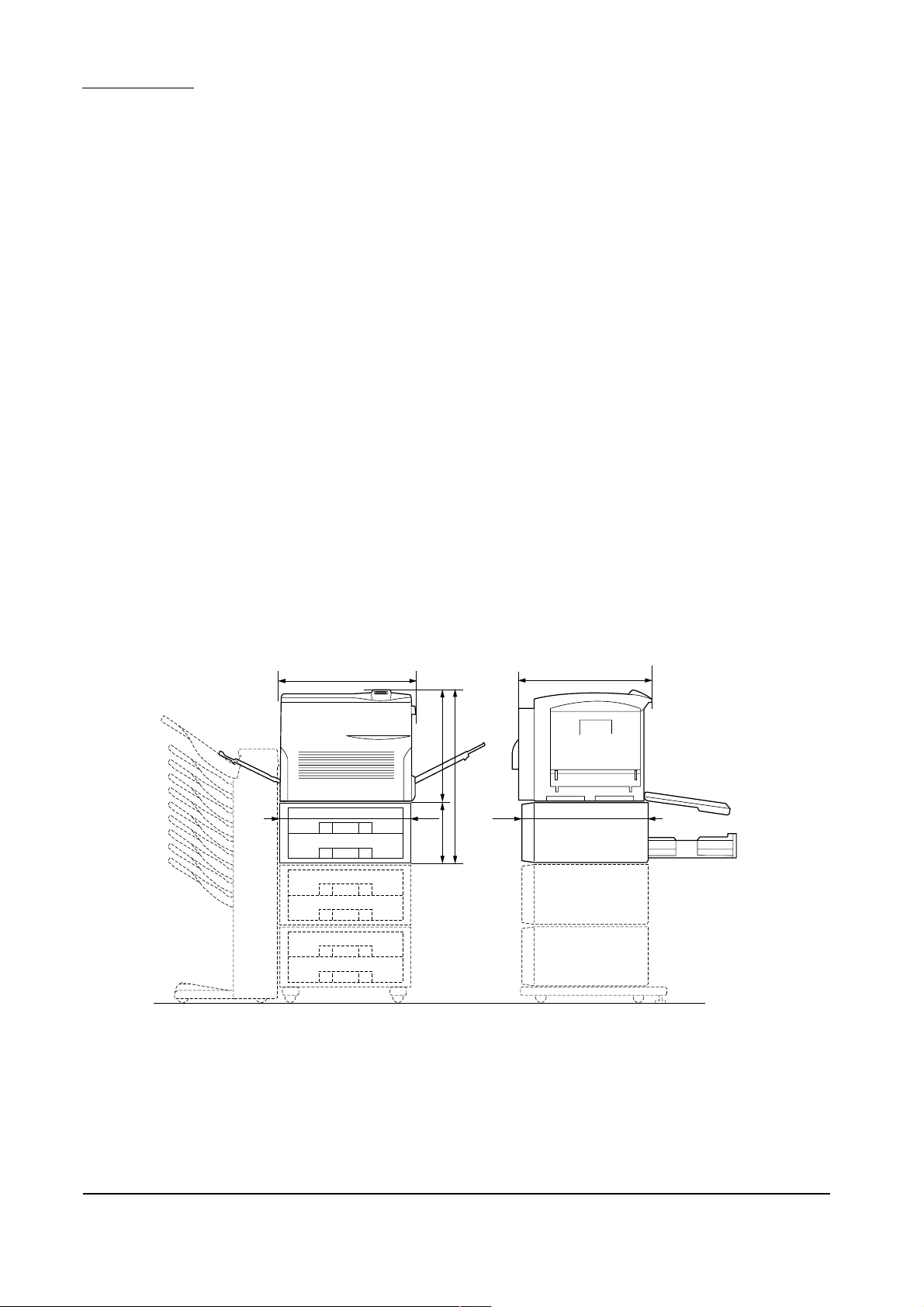

Machine front: 600 mm/23

Machine right: 500 mm/19

220 - 240 V AC 10 %, 5.8 A

5

/8" Machine rear: 300 mm/1113/16"

11

/16" Machine left: 500 mm/1911/16"

a

1

a: 590 mm/23

b: 585 mm/23

c: 680 mm26

/4"

5

/16"

3

/4"

d: 429 mm/167/8"

d

c

ef

g

e: 560 mm/22

f: 566 mm/22

g: 251 mm/9

b

3

/8"

1

/4"

7

/8"

1-2-2

Figure 1-2-1 Installation dimensions

Page 20

CONTENTS

1-3 Installation .........................................................................................1-3-2

1-3-1 Unpacking and installation ....................................................................................................................... 1-3-2

(1) Installation procedure........................................................................................................................ 1-3-2

Page 21

1-3 Installation

FS-8000C/CD/CN

1-3-1 Unpacking and installation

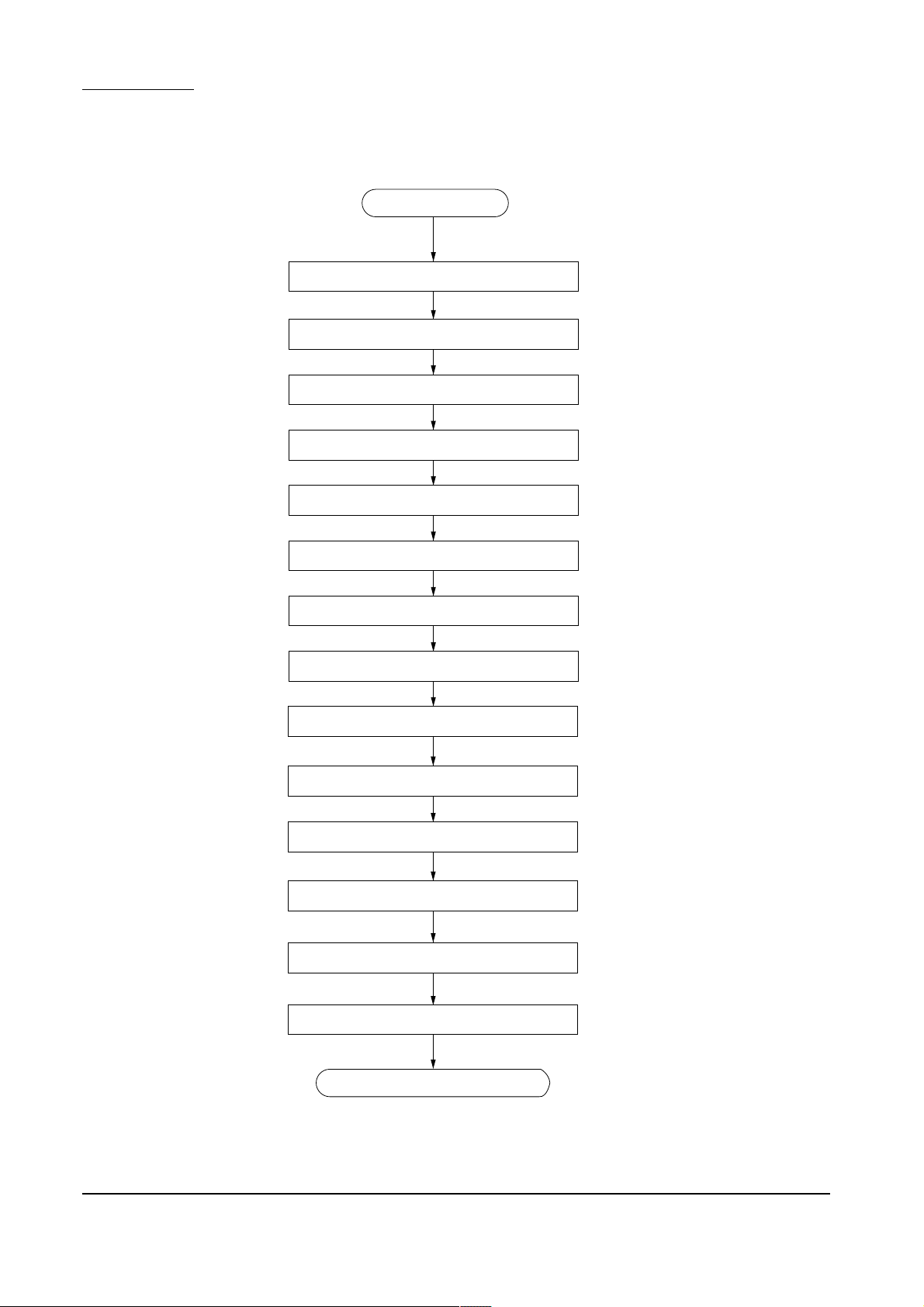

(1) Installation procedure

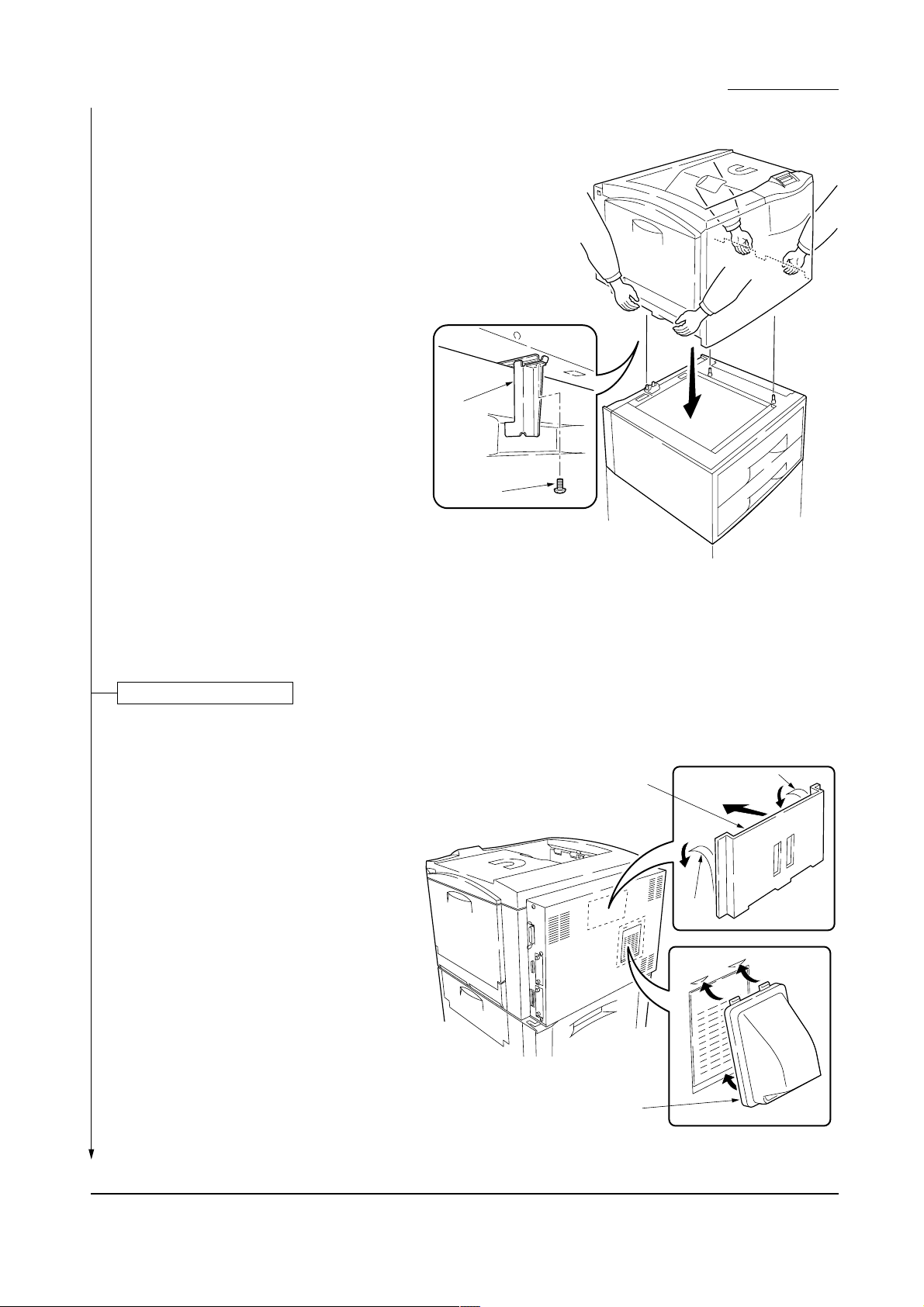

Attaching the casters (purchased separately)

Joining the printer and the paper feeder(s)

Start

Unpacking

Removing the tape

Attaching the accessories

Placing the printer in a proper location

Installing the fuser unit and the oil roller unit

Securing the heat and press/heat rollers

Installing the secondary transfer unit

Installing the waste toner bottle

Installing the four developers

Installing the toner containers

1-3-2

Making connectors to the computer

Printing a status page for test

Completion of the machine installation

Page 22

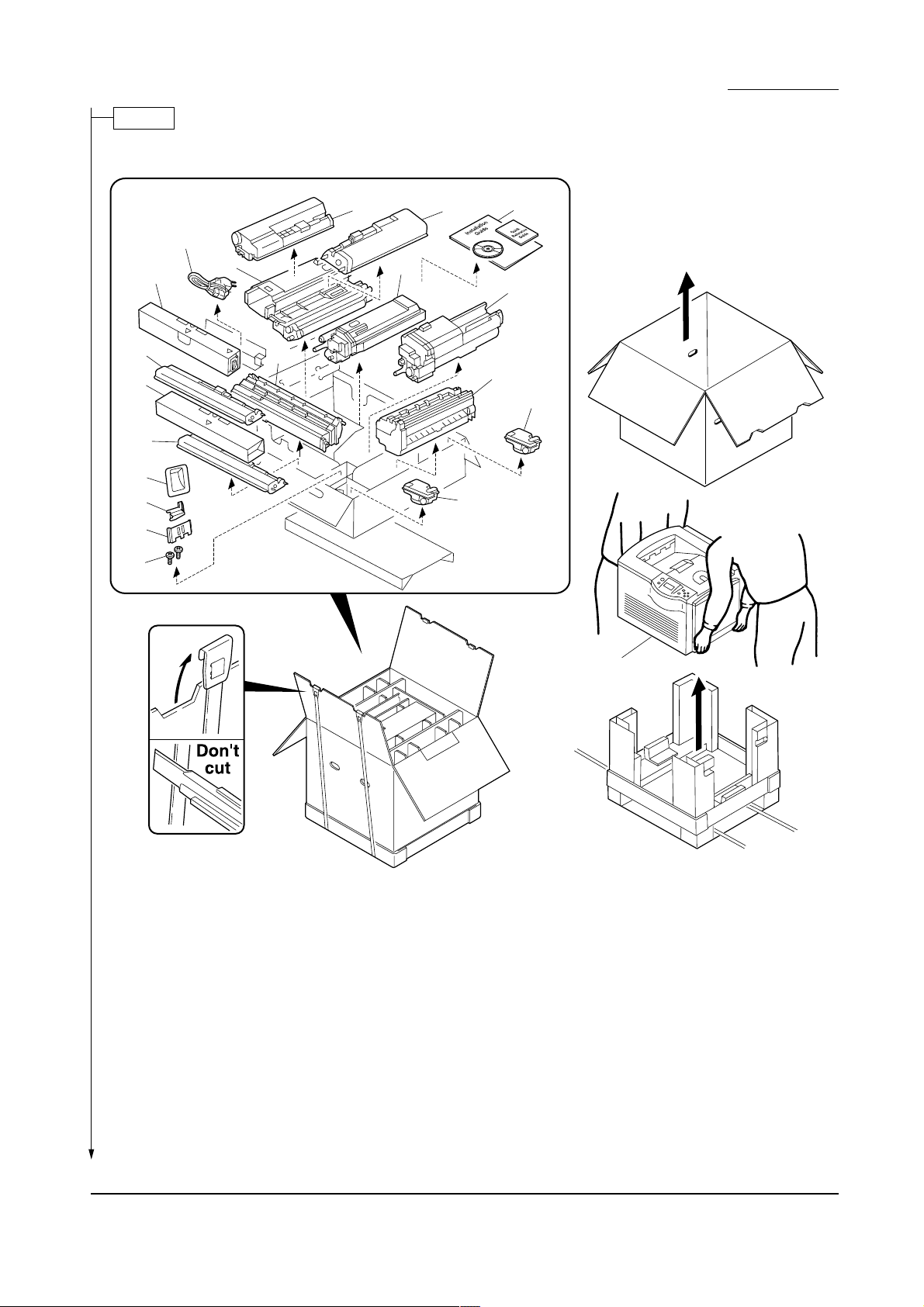

Unpack.

• Printer

LS-8000C/CD/CN

7

!

^

&

*

(

8

@

%

3

6

9

4

0

2

5

#

$

$

Figure 1-3-1 Unpacking (Printer)

1 Printer

2 Documents (Installation guide,

Quick reference guide, and

CD-ROM)

3 Cyan developer

4 Magenta developer

5 Yellow developer

6 Black developer

7 Cyan toner container

8 Magenta toner container

9 Yellow toner container

1

0 Black toner container

! Secondary transfer unit

@ Oil roller unit

# Fuser unit

$ Waste toner bottles

% Power cord

^ Filter duct

& Joint jig

* Quick reference guide holder

( Screws (Two)

Warning:

Lift the printer by more than two persons. The printer weighs approx. 76 kg.

1-3-3

Page 23

FS-8000C/CD/CN

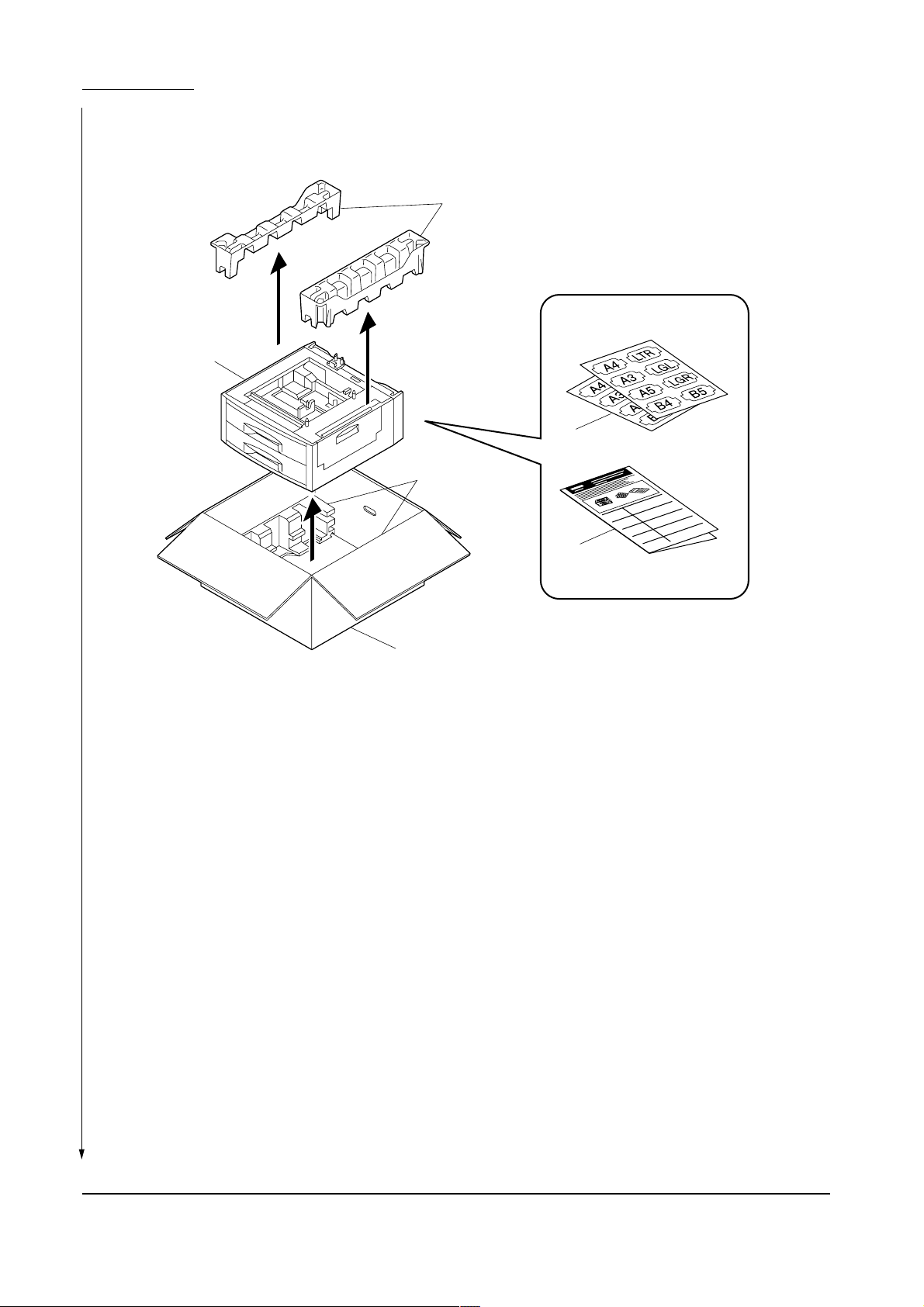

• Paper feeder (or duplex unit)

1

4

3

4

2

5

Figure 1-3-2 Unpacking the paper feeder (or duplex unit)

1 Paper feeder (or duplex unit)

2 Installation manual

3 Paper size indication plate

4 Pads

5 Packing case

Warning:

The paper feeder (duplex unit) weighs approx.19 kg (22 kg).

1-3-4

Page 24

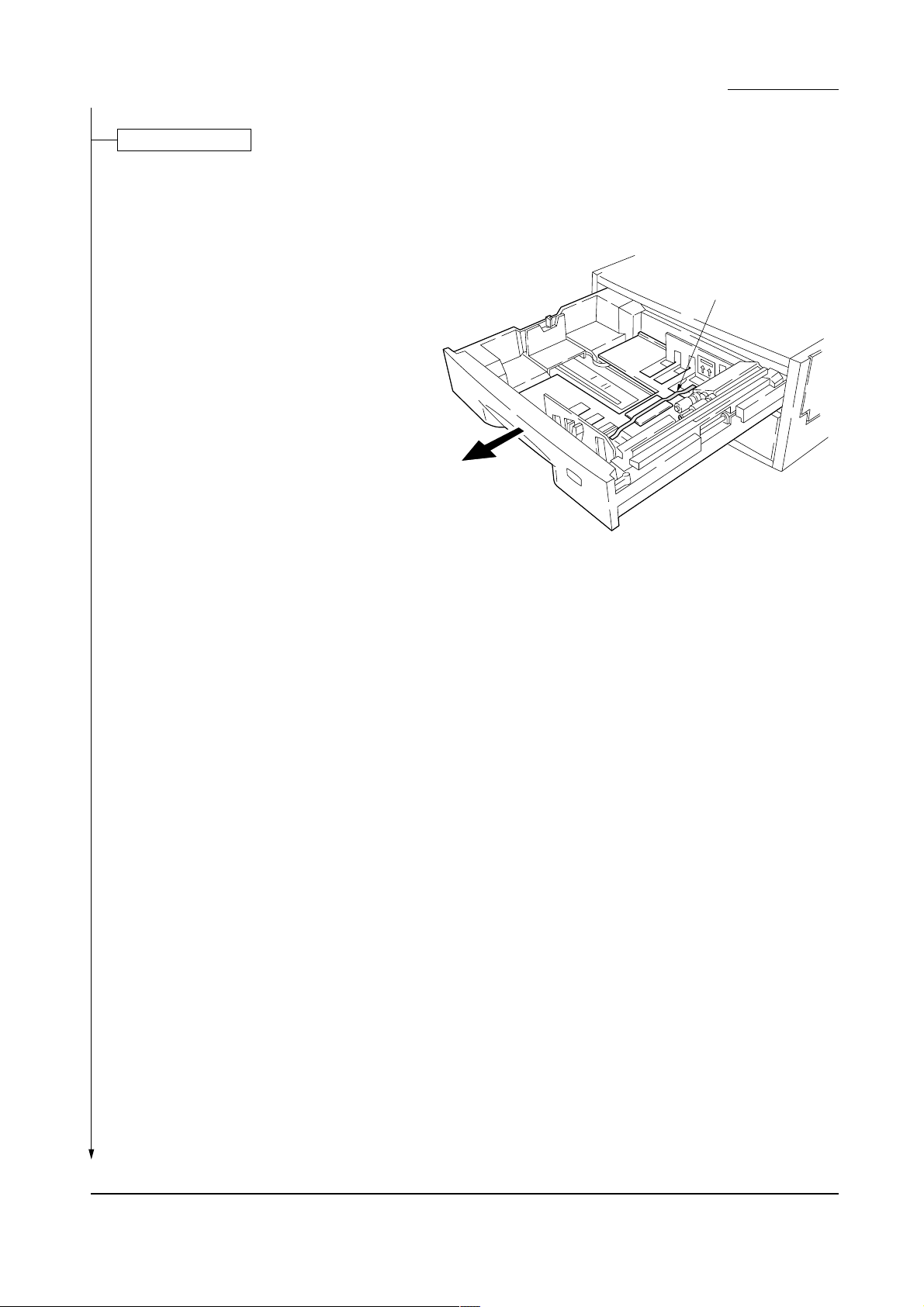

Removing the tape

1. Draw the upper and lower paper cassettes and

then remove the transportation tape.

LS-8000C/CD/CN

Tape

Figure 1-3-3

1-3-5

Page 25

FS-8000C/CD/CN

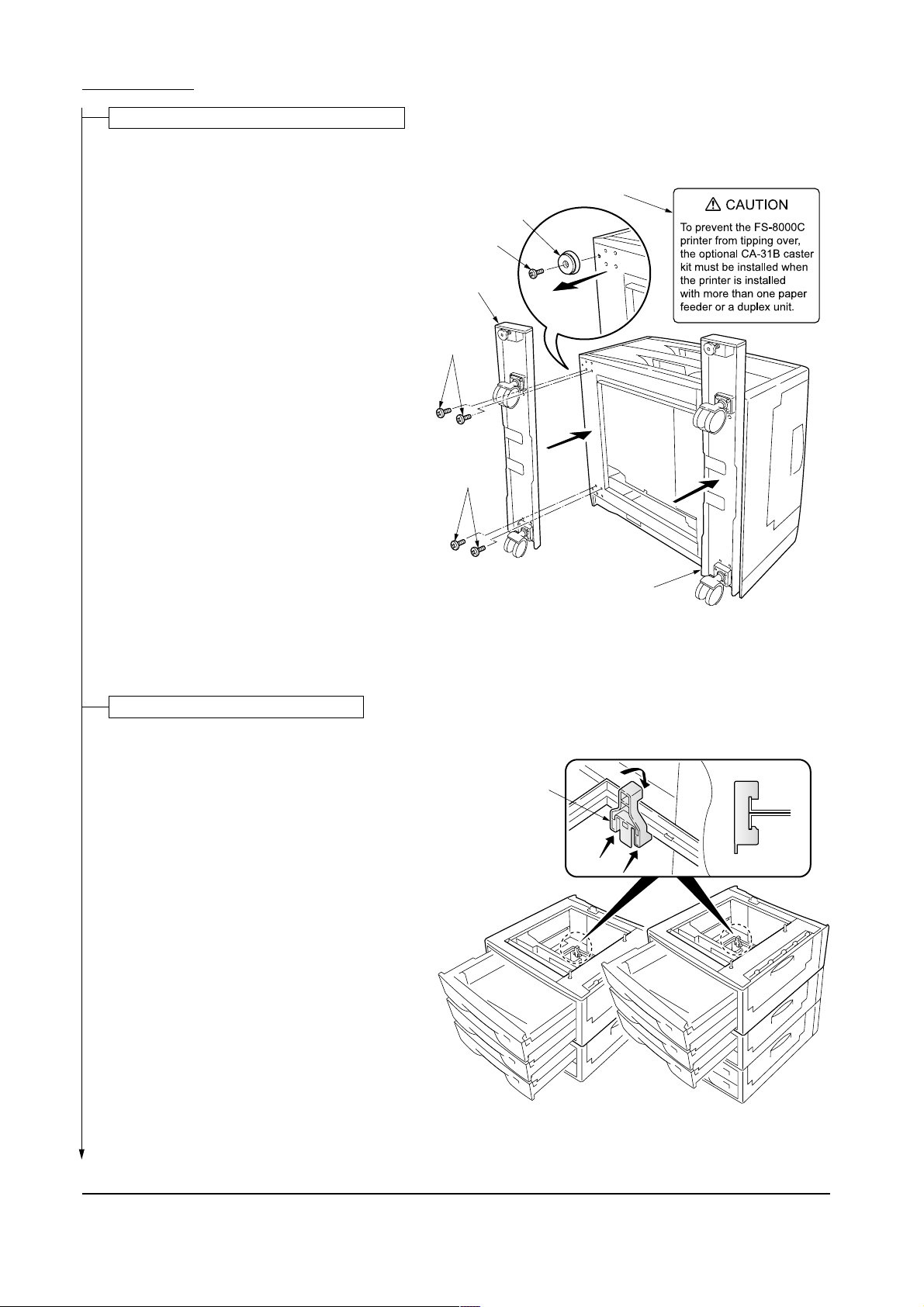

Attaching the casters (purchased separately)

Caution

To prevent the printer from tipping over because

of weight of the printer and the upper paper

drawers, the CA-31B caster kit must be installed

at the bottom-most paper feeder, when an

optional paper feeder or duplex unit is installed

with the printer.

Caution labels have been attached to the paper

feeder and the duplex unit.

Caution label

Foot

Screw

Caster base

1. Stand the paper feeder with the rear side on the

floor.

2. Remove each one screw to remove four feet.

3. Install two optional caster bases onto the bottom

of the paper feeder by using four screws for

each. Be sure to face the longer end towards the

front of the paper feeder.

Joining the printer and paper feeder(s)

1. Using the topple-resistant bracket (supplied with

the caster kit CA-31B), stack and join the bottom

and middle paper feeders.

2. Place the printer on top of the paper feeders (by

more than two persons).

Screws

Screws

Caster base

Figure 1-3-4

Side view

Topple-resistant

bracket

1-3-6

Figure 1-3-5

Page 26

3. Join the printer and topmost paper feeder with

the joint jig provided using one screw.

Warning:

Lift the printer by more than two persons. The printer

weighs approx. 76 kg.

LS-8000C/CD/CN

Joint jig

Screw

Attaching the accessories

1. Install the filter duct.

2. Install the quick reference guide holder. Peel the

protective tape off from the holder when attaching

the holder.

Figure 1-3-6

Quick reference guide holder

Tape

Tape

Filter duct

Figure 1-3-7

1-3-7

Page 27

FS-8000C/CD/CN

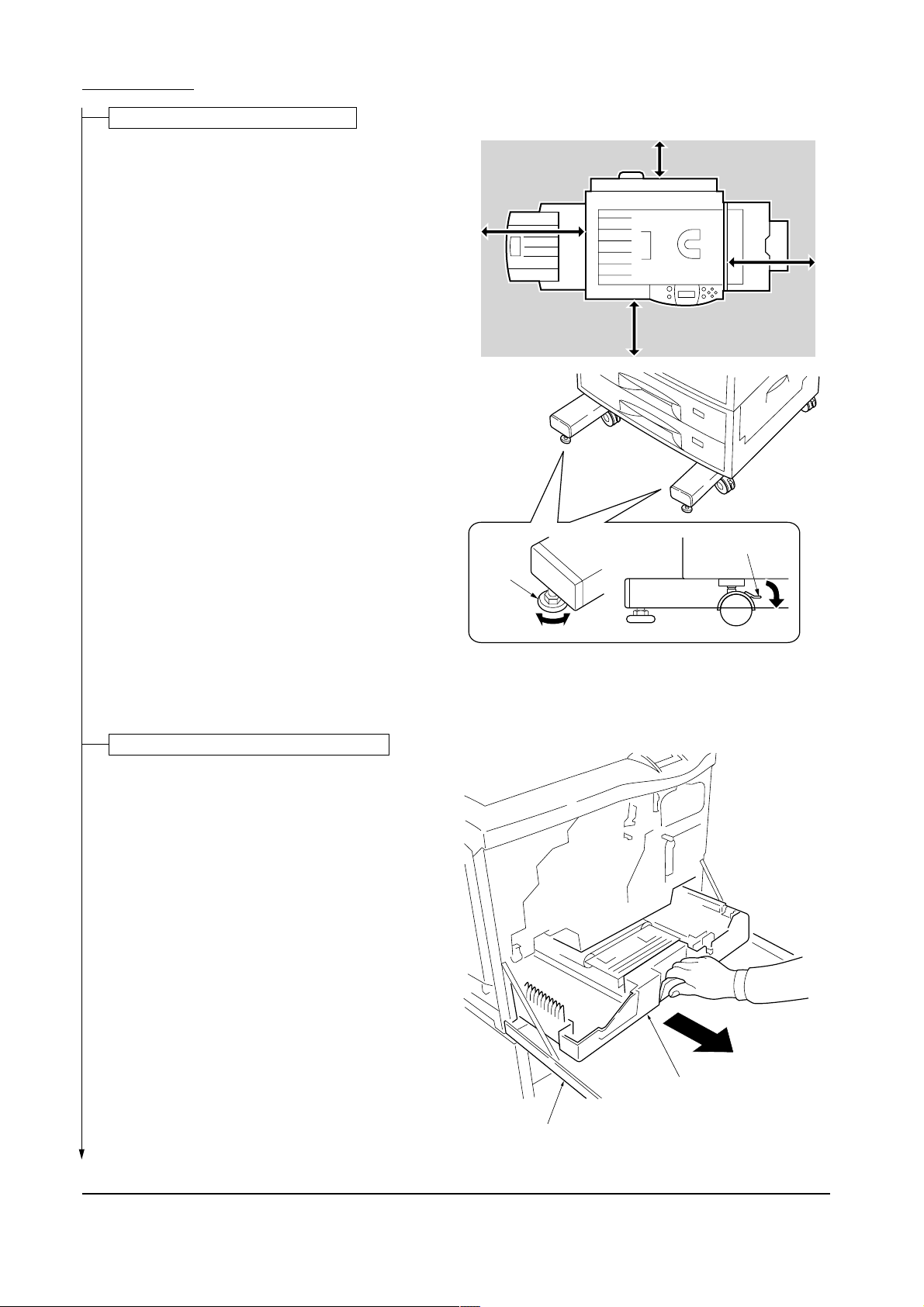

Placing the printer in a proper location

1. Place the paper feeder in a proper location.

2. Lock the stopper for each caster and turn the

height adjuster clockwise until the adjuster

reaches the floor. This fixes the printer in place.

Left: 50 cm

(19-11/16 inches)

Front: 60cm

(23-5/8 inches)

Height

adjuster

Rear: 30cm

(11-13/16 inches)

Right: 50cm

(19-11/16 inches)

Stopper

Installing the fuser unit and the oil roller unit

1. Open the front cover.

2. Pull out thoroughly the paper feed unit.

Figure 1-3-8

Paper feed unit

1-3-8

Front cover

Figure 1-3-9

Page 28

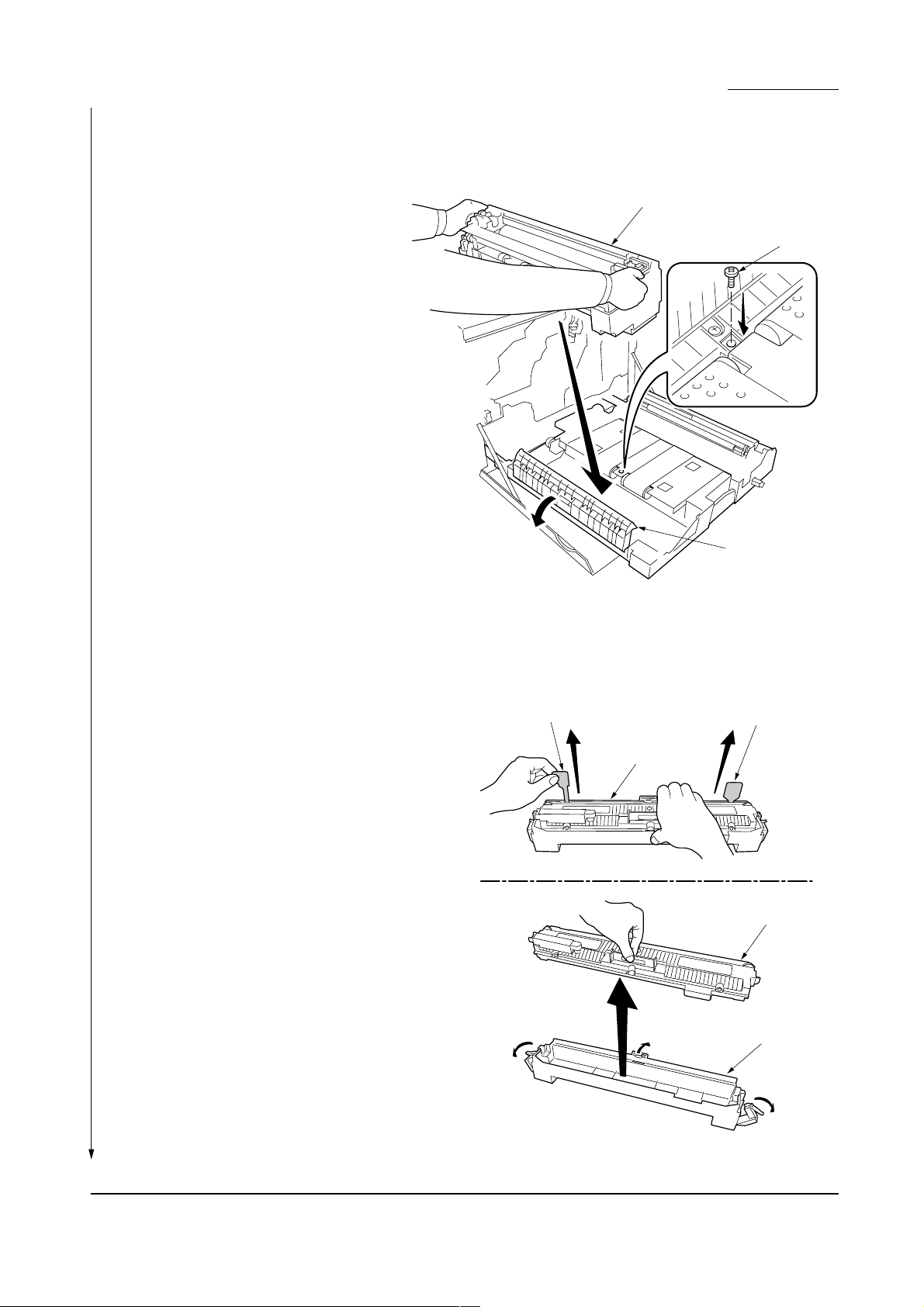

3. Open the left paper guide by pulling down the

green-colored handle.

4. Insert the fuser unit onto the paper feed unit.

5. Secure the fuser unit with the screw.

LS-8000C/CD/CN

Fuser unit

Screw

6. Remove the oil seal tapes at both ends of the oil

roller unit.

7. Take out the oil roller unit from the case.

Oil seal tape

Left paper guide

Figure 1-3-10

Oil seal tape

Oil roller unit

Oil roller unit

Figure 1-3-11

Case

1-3-9

Page 29

FS-8000C/CD/CN

8. Install the oil roller unit onto the fuser unit until it

is locked at both ends.

Oil roller unit

Figure 1-3-12

Securing the heat and press/heat rollers

The pressure between heat roller and press/heat

roller are kept released during transportation. Secure

the pressure by the following:

1. Open the fuser top cover by lowering the lock

buttons.

2. Firmly tighten two screws until they stop.

Screws

Lock button

Lock button

Fuser top cover

1-3-10

Figure 1-3-13

Page 30

Installing the secondary transfer unit

1. Connect the tab from the paper feed unit to the

terminal of the secondary transfer unit.

2. Fit the fulcrums of secondary transfer unit on the

bushes and then put it on the paper feed unit.

LS-8000C/CD/CN

Secondary transfer unit

Bush

Bush

Paper feed unit

Installing the waste toner bottle

1. Install the waste toner bottle.

Terminal

Tab

Figure 1-3-14

Waste toner bottle

Figure 1-3-15

1-3-11

Page 31

FS-8000C/CD/CN

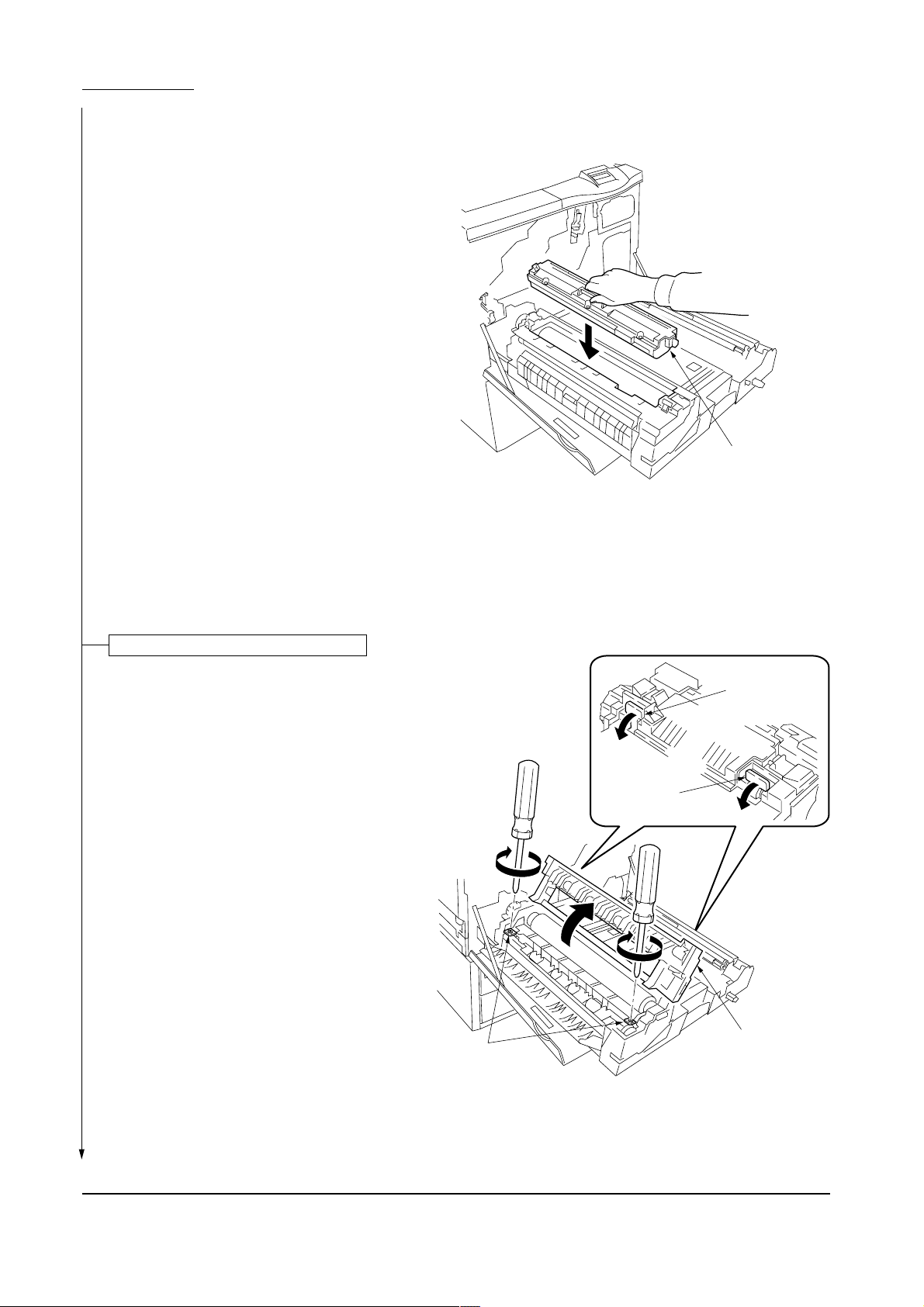

Installing the four developers

1. Remove one screw.

2. Remove the lock pin from the primary transer

unit.

3. Release the (green-colored) lock lever.

4. Draw the primary transfer until it stops.

5. While pushing the gray lever, pull out the

primary transfer unit.

6. Pull out the primary transfer unit from the

printer. Make sure not to scratch the round

surface, especially at its bottom.

7. Close the paper feed unit.

Gray Lever

Screw

Lock Lever

Lock pin

Primary transfer unit

8. Unscrew screws A and B. Free the two

stoppers.

9. Pull out the process frame.

Figure 1-3-16

Stopper

Screw B

Screw A

Screw A

Stopper

Screw B

1-3-12

Process frame

Figure 1-3-17

Page 32

LS-8000C/CD/CN

10. Detach the two tags.

11. Remove the front and rear stoppers.

Tag

Tag

Front stopper

Figure 1-3-18

Rear stopper

1-3-13

Page 33

FS-8000C/CD/CN

12. Peel off the tapes and then remove the

protective pad from each developer unit.

Developer

Tapes

Protective pad

Figure 1-3-19

1-3-14

Page 34

LS-8000C/CD/CN

13. Set each developer in its corresponding position

in the process frame.

Process frame

Black developer

Developing roller

Cyan developer

Magenta developer

Yellow developer

Figure 1-3-20

1-3-15

Page 35

FS-8000C/CD/CN

14. Close the process frame and then lock the two

stoppers.

15. Fix two screws A first, and then fix two B screws.

Stopper

Screw B

Screw A

Screw A

Stopper

Screw B

16. Pull out the paper feed unit.

17. Replace the primary transfer unit.

18. Close the lock lever.

19. Close the paper feed unit.

20. Secure the screw.

Process frame

Figure 1-3-21

Primary transfer unit

Screw

1-3-16

Lock lever

Paper feed unit

Figure 1-3-22

Page 36

Installing the toner containers

1. Shake each toner container well before use.

2. Install the four toner containers into their

corresponding developers.

3. Close the front cover.

LS-8000C/CD/CN

Toner container

Black

Yellow

Magenta

Cyan

Front cover

Making connections to the computer

1. Connect the printer cable to the printer parallel

connector. Connect the other end to the

computer.

NOTE: To install the network interface card for

connecting the printer to the network, refer to the

documentation supplied with the network

interface card. (Standard-installed with FS8000CN model only.)

2. Connect the power cord to the printer power inlet.

Figure 1-3-23

Parallel interface connector

Network interface card

Figure 1-3-24

1-3-17

Page 37

FS-8000C/CD/CN

Printing a status page for test

1. Add paper in the paper cassette.

2. Connect the power cord to the power out

let.

3. Turn on the printer power switch, and then

wait until [Print Ready] is displayed.

4. Press the MENU key on the operation

panel.

5. Press the

Status page] is displayed.

6. Press the ENTER key twice. A status page

is printed.

Completion of the machine installation

key repeatedly until [Print

1-3-18

Page 38

CONTENTS

1-4 Service Mode and Maintenance

1-4-1 Service mode ........................................................................................................................................... 1-4-2

(1) Executing service mode.................................................................................................................... 1-4-2

(2) Contents of service mode items........................................................................................................ 1-4-3

1-4-2 Maintenance............................................................................................................................................1-4-11

(1) Replacing the toner container ..........................................................................................................1-4-11

(2) Cleaning the main charger unit ....................................................................................................... 1-4-13

(3) Cleaning the printer......................................................................................................................... 1-4-16

(4) Replacing the oil roller unit.............................................................................................................. 1-4-20

(5) Cleaning the heat and press/heat rollers of paper dust .................................................................. 1-4-21

(6) Cleaning the fuser unit .................................................................................................................... 1-4-22

1-4-3 Downloading printer firmware for upgrade ............................................................................................. 1-4-23

(1) Format for the firmware files ........................................................................................................... 1-4-23

(2) Downloading firmware via the parallel interface ............................................................................. 1-4-24

(3) Downloading firmware using the memory card............................................................................... 1-4-25

(4) Downloading message data............................................................................................................ 1-4-27

Page 39

1-4 Service mode and maintenance

FS-8000C/CD/CN

1-4-1 Service mode

The printer is equipped with the service mode that can be accessed in the menu system. The service mode is intended

for use by the service person for maintenance and service for the items explained in the following sections.

(1) Executing service mode

Message display

Ready

PAR A4 PLAIN

1 Press the MENU key.

Print

Menu Map

2 Press the or key several times

until [Others >] is displayed.

Print

Status page

To print a status page for the user information.

See the operation guide for details.

Others >

3 Press the key.

Service mode items

To scroll

these items,

press the

or key

repeatedly.

>MSG Language >

English

>Service >

>>Print

Status Page

>>Print

Test Page 1

>>Print

Test Page 2

>>Drum

>>Maintenance

[A]

>>Maintenance

[B]

>>Maintenance

[C]

4 Press the or key several times

until [>Service >] is displayed.

5 Press the key.

To print a status page for service purpose.

See page 1-4-3.

To print a test page, mode 1.

See page 1-4-7.

To print test pages, mode 2.

See page 1-4-7.

To performing a drum surface refreshing.

See page 1-4-8.

To reset the counter after replacing maintenance kit A.

See page 1-4-8.

To reset the counter after replacing maintenance kit B.

See page 1-4-9.

To reset the counter after replacing maintenance kit C.

See page 1-4-9.

1-4-2

>>Maintenance

[D]

To reset the counter after replacing maintenance kit D.

See page 1-4-10. Note: For countries other than European

countries and Australia.

Page 40

(2) Contents of service mode items

FS-8000C/CD/CN

DescriptionService items

>>Print

Status Page

Printing a status page for service purpose

Description

Service information on the status page include various information and settings for the printer,

including service statistics, etc.

Purpose

To understand the machine environments and general settings.

Procedure

Enter the service mode [>>Printing Status Page].

Press the ENTER key. The status page is printed. (See the figure below.)

Completion

Controller firmware version*

Software version:

Released date of the firmware

Released: 1/Jun/2001

Service information

[A008] [C1] [7.12] [01/01] Total page 9762

/P00/S00/F00/N00/D10:DM0301.DAN/AA

/0020/0020/1061/0811/ 0/ 0/ 0/ 0/ 0/ 0/ 0/ 0/

/AAADCFE/AAADCFE/

/AAADCFE/AAAGFAI/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/

/AADBABG/AADBABG/AAAJHGC/AAADCFE/AAADCFE/AAADCFE/AAADCFE/AAAJHGC/AAAJHGC/AADBABG/

/AAADCFE/AAAAABFGBJ/AAAAABFJDB/AAAAABGCED/AAAAABGIGI/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/RS2/[0007-0003]/1/19/60

/AF.A/AF.B/AF.C/AF.D/43/4E/48/40/FF/FF/FF/FF/

/20832091/9120A020/20202091/91900000/00000000/20202020/20202020/

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

DN:GJC1702075 SN:UVE1700190

Service information (See the next page.)

Figure 1-4-1

1-4-3

Page 41

FS-8000C/CD/CN

Service items Description

Detail of service information

Service information

[A008] [C1] [7.12] [01/01] Total page 9762

1

/P00/S00/F00/N00/D10:DM0301.DAN/AA

6

/0020/0020/1061/0811/ 0/ 0/ 0/ 0/ 0/ 0/ 0/ 0/

/AAADCFE/AAADCFE/

/AAADCFE/AAAGFAI/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/

/AADBABG/AADBABG/AAAJHGC/AAADCFE/AAADCFE/AAADCFE/AAADCFE/AAAJHGC/AAAJHGC/AADBABG/

/AAADCFE/AAAAABFGBJ/AAAAABFJDB/AAAAABGCED/AAAAABGIGI/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

23 4 5

789 0 !

#

&

*

@

$

%

^

(

)

¤

‹

‹

⁄

/RS2/[0007-0003]/1/19/60

›

/AF.A/AF.B/AF.C/AF.D/43/4E/48/40/FF/FF/FF/FF/

/20832091/9120A020/20202091/91900000/00000000/20202020/20202020/

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

DN:GJC1702075 SN:UVE1700190

‰

·

fi

fl

ˇ

‡

°

‚

Œ

„

´

Item Description

1 Engine controller PWB flash ROM Information

2 Operation panel PWB mask ROM information

3 Boot ROM Information

4 Software jumper switch information

(Hexadecimal)

[ROM version]

[ROM version]

[ROM version]

First byte

Bit 0: 1: (fixed)

Bit 1: 0: Overseas 1: Domestic (Japan)

Bit 2: (Not used)

Bit 3: (Not used)

Bit 4: 0: Kyocera 1: OEM

Bit 5: 0: For Europe 1: for U.S.

Bit 6: 0: Non MICR mode 1: MICR mode

Bit 7: 0: Kyocera 1: Kyocera Mita

Second byte

OEM information: Displayed in OEM mode only.

1-4-4

Page 42

Item Description

5 Total page counter

6 Parallel I/O information

7 Serial I/O error code

8 Operation panel key lock status

(Displayed only when locked)

9 NVRAM error code

(Displays only when error occurred)

0 NVRAM downloading status

! Engine error information

@ Printable area information

# Left offset

$ Page counter according to paper size

% Page counter according to paper source

^ Page counter according to paper output

& Life counter

* Color page counter

( Pixel counter

) Maintenance kit A counter

⁄ Maintenance kit B counter

¤ Maintenance kit C counter

‹ Maintenance kit D counter

FS-8000C/CD/CN

DescriptionService items

00: Normal

Bit 0: Overrun error

Bit 1: Framing error

Bit 2: Parity error

01: Partial lock

02: Full lock

01: ID error

02: Version error

03: Checksum error

04: NVRAM crush error

00: None downloaded

bit 0: Font data

bit 1: Host data

bit 2: Macro data

bit 3: Program data

bit 4: Operation panel message data

bit 5: OEM data

bit 6: Reserved

bit 7: Error occurred

/Top offset / Left offset /Page length /Page width

MP tray/Cassette 1 /Cassette 2 /Cassette 3 /Cassette 4 /

Cassette 5 /Cassette 6 /Duplexer

/A3 /A4 /

/Cassette 1 /Cassette 2 /Cassette 3 /Cassette 4

/Cassette 5 /Cassette 6 /Duplexer /

/Mailbox sorter /Bulk stacker /Document finisher /

/Drum unit /Primary transfer unit /Secondary transfer unit

/Cyan developer /Magenta developer/Yellow developer /

Black developer /Fuser unit /Oil roller unit /Main charger

unit

/Cyan /Magenta /Yellow /Black /

Four occurrences (from the left to the right) of image

counts at which maintenance kit A was replaced. The

right-most code indicates the current count.

Four occurrences (from the left to the right) of page

counts at which maintenance kit B was replaced. The

right-most code indicates the current count.

Four occurrences (from the left to the right) of image

counts at which maintenance kit C was replaced. The

right-most code indicates the current count.

Twelve occurrences (from the left to the right, top to

bottom) of page counts at which maintenance kit D was

replaced. The right-bottom code indicates the current

count. Note: Maintenance kit D is for countries other than

European and Australia.

(File name displayed)

1-4-5

Page 43

FS-8000C/CD/CN

Service items Description

Item Description

› Serial interface information

fi Option unit information

fl Operation panel message language

‡ Current temperature

Current humidity

· Average print density (%)

‚ Color calibration result

ΠMedia type attributes

„ SPD information (slot 1)

´ SPD information (slot 2)

‰ Drum serial number

ˇ Printer serial number

RS2: RS-232C

First 2 byte Second 2 byte

bit 0: MP tray bit 0: Face-up tray

bit 1: Cassette 1 bit 1: Face-down tray

bit 2: Cassette 2 bit 2: Reserved

bit 3: Cassette 3 bit 3: Reserved

bit 4: Cassette 4 bit 4: Document finisher

bit 5: Cassette 5 bit 5: Mailbox sorter

bit 6: Cassette 6 bit 6: Reserved

bit 7: Duplex unit bit 7: Bulk stacker

bit 8 to 15: Reserved bit 8 to 15: Reserved

PMSG command settings (decimal)

0 to 100 °C (in 1 °C increment, “-“= Humidity/temperature

sensor is abnormal.)

50 to 90 % RH (in 2 % increment)

/Cyan /Magenta /Yellow /Black

Last Previous

/Cyan /Magenta /Yellow /Black /Cyan /Magenta /Yellow /Black /

Media type 1 to 28 (See table below)

Media type attributes

Paper feed

source

No.

Media type

MP tray

1 Plain Y Y 0 2 0

2 Transparency Y N 3 0 1

3 Preprinted Y Y 0 2 0

4 Labels Y N 1 1 1

5 Bond Y N 1 1 1

6 Recycled Y Y 0 2 0

7 Vellum Y Y 0 2 0

8 Rough Y Y 0 1 1

9 Letter head Y Y 0 2 0

10 Color Y Y 0 2 0

11 Prepunched Y Y 0 2 0

12 Envelope Y N 1 1 1

13 Cardstock Y N 1 1 1

14 Coated Y N 0 1 1

Shaded area: Not changeable.

Paper

feeders

cassettes

1 to 6

Attributes

(default)

Fuser

Transfer Transfer

speed

Duplex

Paper feed

source

No.

Media type

MP tray

15-20 Reserved - - - - -

21 Custom 1 Y Y 0 2 0

22 Custom 2 Y Y 0 2 0

23 Custom 3 Y Y 0 2 0

24 Custom 4 Y Y 0 2 0

25 Custom 5 Y Y 0 2 0

26 Custom 6 Y Y 0 2 0

27 Custom 7 Y Y 0 2 0

28 Custom 8 Y Y 0 2 0

Paper feed source attribute: Y= Yes N= No

Media type attributes:

[Transfer] [Fuser speed] [Duplex]

0= Normal 0= 1/4 0= Enable

1= Thick 1= 1/2 1= Disable

3= Extra thick 2= Normal

Paper

feeders

cassettes

1 to 6

Attributes

(default)

Fuser

speed

Duplex

1-4-6

Page 44

FS-8000C/CD/CN

DescriptionService items

>>Printing

Test Page 1

Printing a test page, mode 1

Description

Printing a test page that has four colors printed on a sheet.

Purpose

To check the activation of the developers.

Start

Enter the service mode [>>Printing Test Page 1].

Press the ENTER key. The test page is printed.

Completion

Cyan

Magenta

Yellow

Black

Figure 1-4-2

>>Printing

Test Page 2

Printing test pages, mode 2

Description

Prints four sheets in individual colors.

Purpose

To check the activation of the developers.

Start

Enter the service mode [>>Printing Test Page 2].

Press the ENTER key. Four test pages are printed.

Completion

Cyan

Magenta Yellow Black

Figure 1-4-3

1-4-7

Page 45

FS-8000C/CD/CN

Service items Description

>>Drum

>>Maintenance

[A]

Drum surface refreshing

Description

The drum rotates for approximately 5 minutes without printing operation.

Purpose

To clean the drum surface when an image problem occurs.

Start

Enter the service mode [>>Drum].

Press the ENTER key. The drum surface refreshing starts and automatically finishes.

Completion

Counter reset for the maintenance kit A

Description

The "Install MK [A]" message means that maintenance kit A should be replaced at every

400,000 images of printing. The interval counter must be reset using this service item.

MK-800A Maintenance kit A includes the following units:

• Drum unit: DK-800 DRUM UNIT [Part No.: 5PLPXARAPKX]

(including MC-800 MAIN CHARGER ASSY and FILTER KIT)

• Primary transfer unit: TR-800P PRI TRANSFER UNIT [Part No.: 5PLPXASAPKX]

(including CLEANER ASSY)

• Secondary transfer unit: TR-800S SEC TRANSFER UNIT [Part No.: 5PLPXATAPKX]

Purpose

To reset the life counter for the components included in maintenance kit A.

Start

Replace the drum unit (See page 1-6-13).

Replace the primary transfer unit (See page 1-6-15).

Replace the secondary transfer unit (See page 1-6-21).

Replace the ozone filter (See page 1-6-45).

Enter the service mode (>>Maintenance [A]).

Press the ENTER key. The counter for each component is reset immediately.

Completion

1-4-8

Note:

Occurrences of resetting the maintenance kits are recorded on the service status page in

number of pages or images at which the maintenance kit was replaced (See page 1-4-5).

This may be used to determine the possibility that the counter was errorneously or

unintentionally reset.

Page 46

FS-8000C/CD/CN

DescriptionService items

>>Maintenance

[B]

Counter reset for the maintenance kit B

Description

The "Install MK [B]" message means that maintenance kit B should be replaced together at

every 200,000 pages of printing. The interval counter must be reset using this service item.

MK-801B*1/MK-800B*2 Maintenance kit B includes the following units:

• Black developer: DV-800K DEVELOPER BLACK [Part No.: 5PLPXAXAPKX]

• Fuser unit (including oil unit): FK-800(E) FUSER UNIT (E) [Part No.: 5PLPXAUAPKE]

FK-800(U) FUSER UNIT (U) [Part No.: 5PLPXAVAAMA]

• Separation charger unit: SC-800 SEPARATE CHARGER [Part No.: 5PLPXBRAPKX]

1

: For European countries and Australia. *2: For U.S., Canada, and Asian countries. (The

*

separation charger unit is not included. For details on the maintenance kits, see page 2-4-3.)

Purpose

To reset the life counter for the components included in maintenance kit B.

Start

Replace the black developer (See page 1-6-16).

Replace the fuser unit with oil roller unit (See page 1-6-24).

Replace the separation charger unit [European countries and Australia only] (See page 1-6-

22).

Enter the service mode (>>Maintenance [B]).

Press the ENTER key. The counter for each component is reset immediately.

Completion

Note:

Occurrences of resetting the maintenance kits are recorded on the service status page in

number of pages or images at which the maintenance kit was replaced (See page 1-4-5).

This may be used to determine the possibility that the counter was errorneously or

unintentionally reset.

>>Maintenance

[C]

Counter reset for the maintenance kit C

Description

The "Install MK [C]" message means that maintenance kit C should be replaced together at

every 200,000 images of printing. The interval counter must be reset using this service item.

MK-800C Maintenance kit C

• Yellow developer: DV-800Y DEVELOPER YELLOW [Part No.: 5PLPXBAAPKX]

• Magenta developer: DV-800M DEVELOPER MAGENTA [Part No.: 5PLPXAZAPKX]

• Cyan developer: DV-800C DEVELOPER CYAN [Part No.: 5PLPAYAPKX]

Purpose

To reset the life counter for the components included in maintenance kit C.

Start

Replace the cyan, magenta, and yellow developers (See page 1-6-16).

Enter the service mode (>>Maintenance [C]).

Press the ENTER key. The counter for each component is reset immediately.

Completion

Note:

Occurrences of resetting the maintenance kits are recorded on the service status page in

number of pages or images at which the maintenance kit was replaced (See page 1-4-5).

This may be used to determine the possibility that the counter was errorneously or

unintentionally reset.

1-4-9

Page 47

FS-8000C/CD/CN

Service items Description

>>Maintenance

[D]

Counter reset for the maintenance kit D

The following procedure is not necessary for European countries and Australia.

Description

The "Install MK [D]" message means that maintenance kit D (Separation charger unit) should

be replaced together at every 100,000 pages of printing. The interval counter must be reset

using this service item.

MK-800D Maintenance kit D

• Separation charger:

(MK-800D)SC-800 SEPARATE CHARGER [Part No.: 5PLPXBRAPKX]

Purpose

To reset the life counter for the separation charger unit.

Start

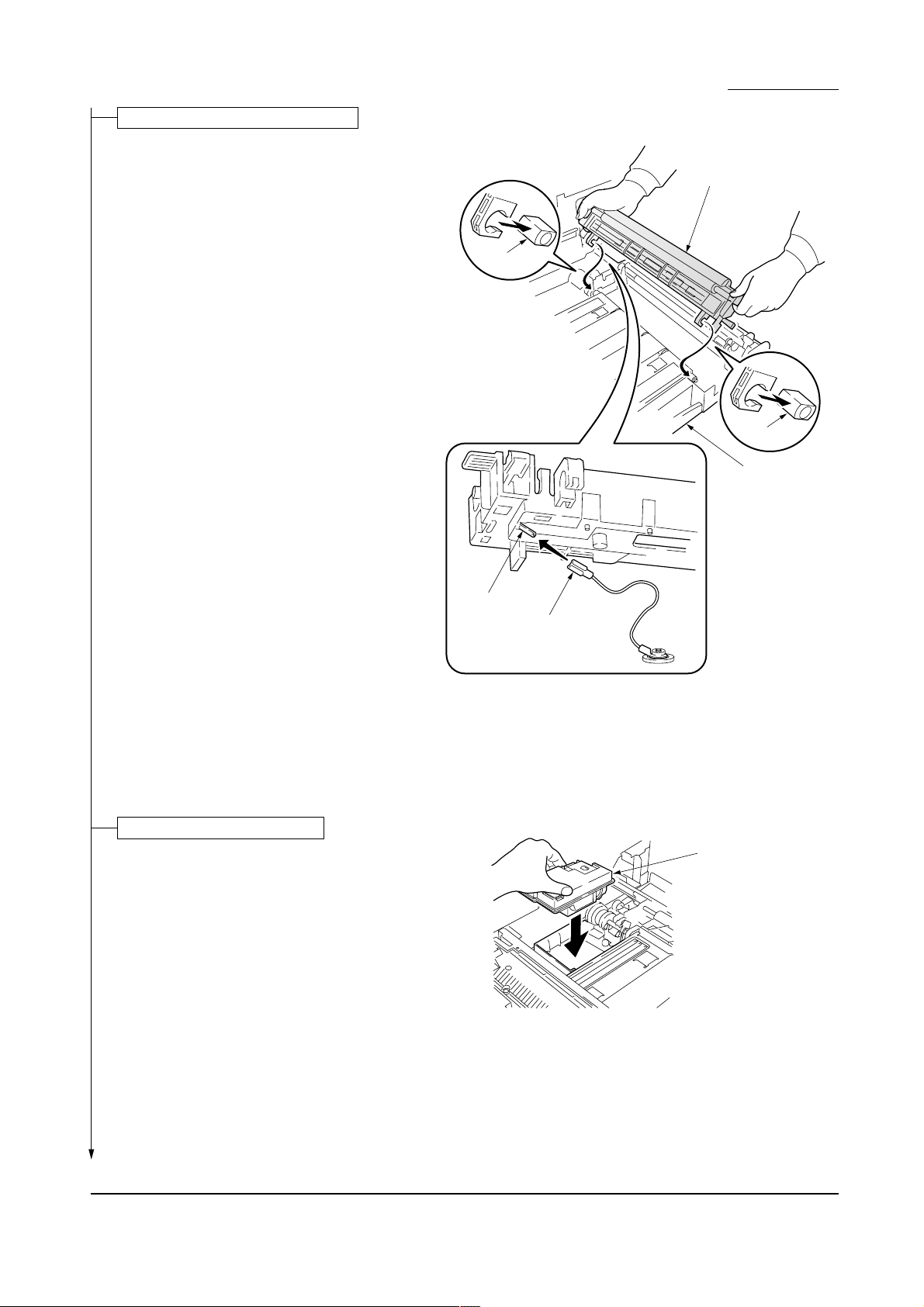

Pull the projection of the separation charger unit and then remove it from the secondary

transfer unit.

Place the new separation charger unit with its cleaning knob inserted in the opening at the

Separation charger unit

Secondary transfer unit

Projection

Figure 1-4-4

front of the secondary transfer unit. then, push the rear end of the separation charger unit so

that it is fully seated in the secondary transfer unit.

Separation charger unit

Secondary transfer unit

Cleaning knob

Figure 1-4-5

Enter the service mode (>>Maintenance [D]). Press the ENTER key. The counter for the

separation charger unit is reset immediately.

Completion

Note:

Occurrences of resetting the maintenance kits are recorded on the service status page in

number of pages or images at which the maintenance kit was replaced (See page 1-4-5).

This may be used to determine the possibility that the counter was errorneously or

unintentionally reset.

1-4-10

Page 48

FS-8000C/CD/CN

1-4-2 Maintenance

(1) Replacing the toner container

The life of the toner containers depends on the amount of toner required to accomplish your printing jobs. When 5 %

coverage (a typical business document) of individual toner colors is assumed for A4 or letter size paper in landscape

orientation, without using draft (EcoPrint [monochrome printing only]) mode:

• The TK-82K black toner container lasts an average of 25,000 monochrome pages.

• Each of the TK-82C cyan, TK-82M magenta, and TK-82Y yellow toner containers lasts an average of 10,000 color

images.

The toner containers packed with the new printer are starter toner containers. The black starter toner container lasts an

average of 12,500 monochrome pages. Each of the cyan, magenta, and yellow starter toner containers lasts an average

of 5,000 color images.

Procedure

1. Open the front cover.

2. While pushing down the lever (blue-colored)

at the front of the toner container to unlock

the container, pull the toner container out.

Black

Cyan

Yellow

Magenta

Figure 1-4-6

1-4-11

Page 49

FS-8000C/CD/CN

3. Take the new toner container out of the toner

kit. To loosen and redistribute the toner

inside, hold the container and rotate the

container back and forth at least 10 times.

4. Insert the new toner container all the way in.

The container is locked automatically when it

is properly seated.

Toner container

Black

Yellow

Magenta

Cyan

5. Tilt the lever to the right and then remove the

waste toner bottle.

6. Install the new waste toner bottle (Supplied in

the new toner kit).

Cautions:

• Do not cap the opening on the new waste

toner bottle.

Waste toner bottle

Figure 1-4-7

Lever

1-4-12

Figure 1-4-8

Page 50

FS-8000C/CD/CN

(2) Cleaning the main charger unit

The main charger unit needs to be cleaned periodically as it gets contaminated with dioxide after a long usage. The main

charger is comprised of two main parts — the wire and the grid — both of which should be cleaned separately as

instructed below.

Follow the procedure below to cleaning the main charger unit:

Procedure

• Main charger wire

1. Open the front cover.

2. Grasp the cleaning knob (green-colored).

Gently pull the cleaning knob out and push it

back in. Repeat this several times.

Cleaning knob

Figure 1-4-9

1-4-13

Page 51

FS-8000C/CD/CN

• Main charger grid

1. Take the grid cleaner out of the toner kit. Take

the grid cleaner out of the protective bag and

remove the cap.

2. Attach the grid cleaner to the printer with the

pad facing up.

Cap

Grid cleaner

Figure 1-4-10

3. Push the main charger unit release lever

upward.

4. Slightly lift the main charger unit, and gently

pull the gray-colored main charger handle out

and push it back in.

5. Repeat this several times. These movements

clean the grid.

6. After cleaning is finished, remove the grid

cleaner from the printer and discard it.

7. Close the front cover.

Cautions:

• The grid cleaner cannot be reused.

Grid cleaner

Figure 1-4-11

Release lever

Main charger unit

Figure 1-4-12

1-4-14

Page 52

• Main charger shield

1. Remove the main charger unit from the drum

unit.

2. Detach the main charger grid from the hooks.