Page 1

&KDSWHU#7 23(5$7,21# 7+(25<

&RQWHQWV

714#(OHFWURSKRWRJUDSKLFV#V\VWHP/#SDJH#705

(OHFWURSKRWRJUDSKLF#V\VWHP/#SDJH#705

$PRUSKRXV0VLOLFRQ#GUXP/#SDJH#705

&KDUJLQJ#WKH#GUXP/#SDJH#706

7RQHU/#SDJH#707

([SRVXUH/#SDJH#707

6FDQQHU#XQLW/#SDJH#708

6FDQQLQJ#ODVHU/#SDJH#70:

'HYHORSPHQW/#SDJH#70:

'HYHORSLQJ#UROOHU#ELDV/#SDJH#70;

7RQHU#VHQVRU/#SDJH#70<

7UDQVIHU/#SDJH#70<

)XVLQJ/#SDJH#7043

'UXP#FOHDQLQJ#DQG#HUDVLQJ#VWDWLF#FKDUJH/#SDJH#7044

7\SLFDO#SKRWR#SURFHVV#WLPLQJ#FKDUW/#SDJH#7045

715#3ULQW#WLPLQJ#FKDUWV/#SDJH#7046

716#3DSHU#IHHGLQJ#V\VWHP/#SDJH#704:

&DVVHWWH#IHHGLQJ/#SDJH#704;

0XOWL#SXUSRVH#WUD\#IHHGLQJ/#SDJH#704;

3DSHU#MDP#VHQVLQJ/#SDJH#704<

717#%DVLF#HQJLQH#IXQFWLRQV/#SDJH#7053

%DVLF#VHTXHQFH#RI#RSHUDWLRQ/#SDJH#7053

718#(QJLQH#FRQWUROOHU#V\VWHP/#SDJH#7054

)ODVK#PHPRU\/#SDJH#7054

3ULQW#GHQVLW\#FRQWURO/#SDJH#7054

+LJK0YROWDJH#JHQHUDWRU/#SDJH#7054

/DVHU#VFDQQHU#FRQWURO/#SDJH#7054

3RO\JRQ#PRWRU#FRQWURO/#SDJH#7054

6DIHW\#LQWHUORFN/#SDJH#7055

7KH#HQJLQH#JDWH#DUUD\/#SDJH#7056

3LQ#DVVLJQPHQW/#SDJH#7056

3RZHU#VXSSO\/#SDJH#7059

719#/RJLF#FRQWUROOHU#V\VWHP/#SDJH#705;

3ULQWLQJ#GDWD#SURFHVVLQJ/#SDJH#7063

6\VWHP#520/#SDJH#7063

0DLQ#5$0/#SDJH#7063

0HPRU\#FDUG#VORW#LQWHUIDFH/#SDJH#7064

2SWLRQ#LQWHUIDFH/#SDJH#7064

3DUDOOHO#LQWHUIDFH/#SDJH#7066

6HULDO#LQWHUIDFH/#SDJH#7066

(QJLQH#LQWHUIDFH/#SDJH#7066

6LJQDOV#XVHG#IRU#WKH#HQJLQH#LQWHUIDFH/#SDJH#7067

(QJLQH#LQWHUIDFH#EORFN#GLDJUDP/#SDJH#7068

Page 2

(OHFWURSKRWRJUDSKLFV#V\VWHP

714 (OHFWURSKRWRJUDSKLFV#V\VWHP

Electrophotography is the technology used in laser printing which transfers data representing

texts or graphics objects into a visibl e imag e which is developed on the photosensitive drum,

finally fusing on paper, using light beam generated by a laser diode.

The key features for the electrophotography system used in the printer are:

600 dpi resolution

•

Newly developed amorphous silicon drum with no heating device

•

Diode laser scanning

•

Mono component toner

•

(OHFWURSKRWRJUDSKLF#V\VWHP

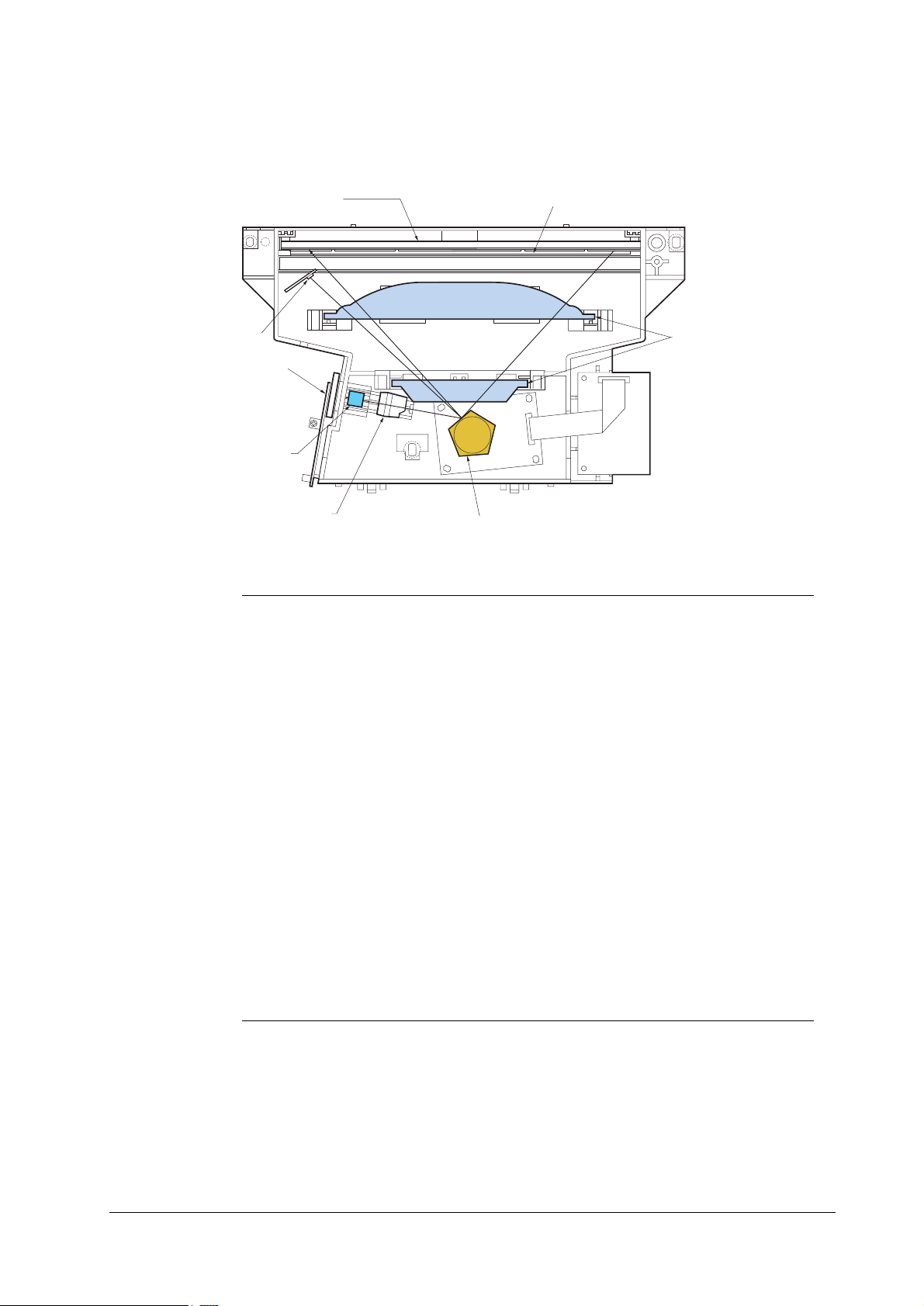

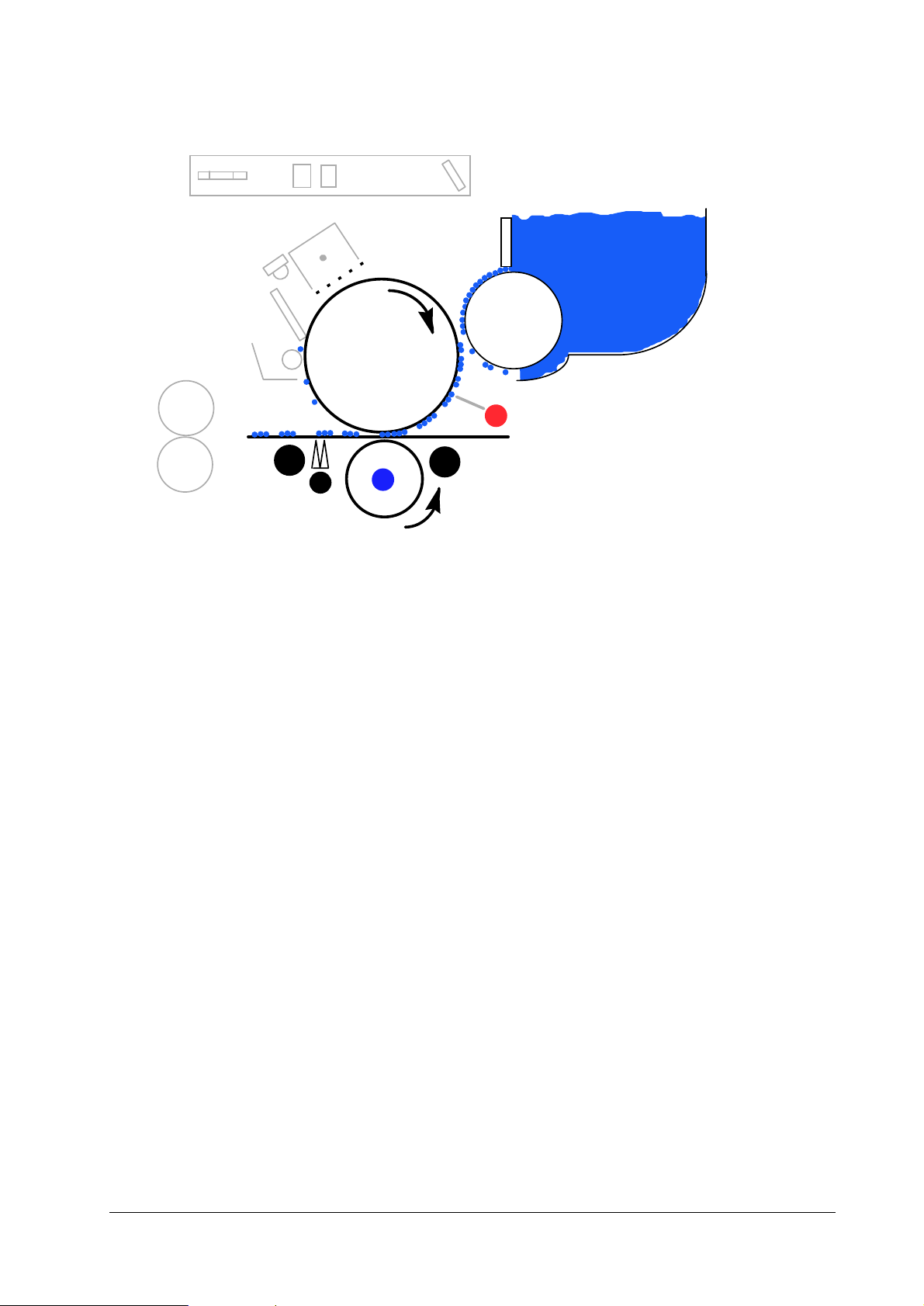

The electrophotography system of the printer performs a cyclic action made of seven steps as

diagrammed below.

)LJXUH#714 (OHFWURSKRWRJUDSKLF#F\FOH

2SHUDWLRQ#WKHRU\

([SRVXUH

&KDUJLQJ

(UDVXUH

'UXP#FOHDQLQJ

7UDQVIHU

)XVLQJ

'HYHORSPHQW

$PRUSKRXV0VLOLFRQ#GUXP

The printer uses the long lasting amorphous silicon drum. The drum surface is a composite of

five substances coated in five layers as shown in page 4-3, Figure 4.2.

4-2

)609<33

Page 3

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

)LJXUH#715 $PRUSKRXV#VLOLFRQ#GUXP

D06L#OD\HU

$

%

$OXPLQXP#OD\HU

The amorphous silicon layer is photoconductive, reducing its electrical conductivity when

exposed to laser light.

$

%

'UXP#XQLW

&KDUJLQJ#WKH#GUXP

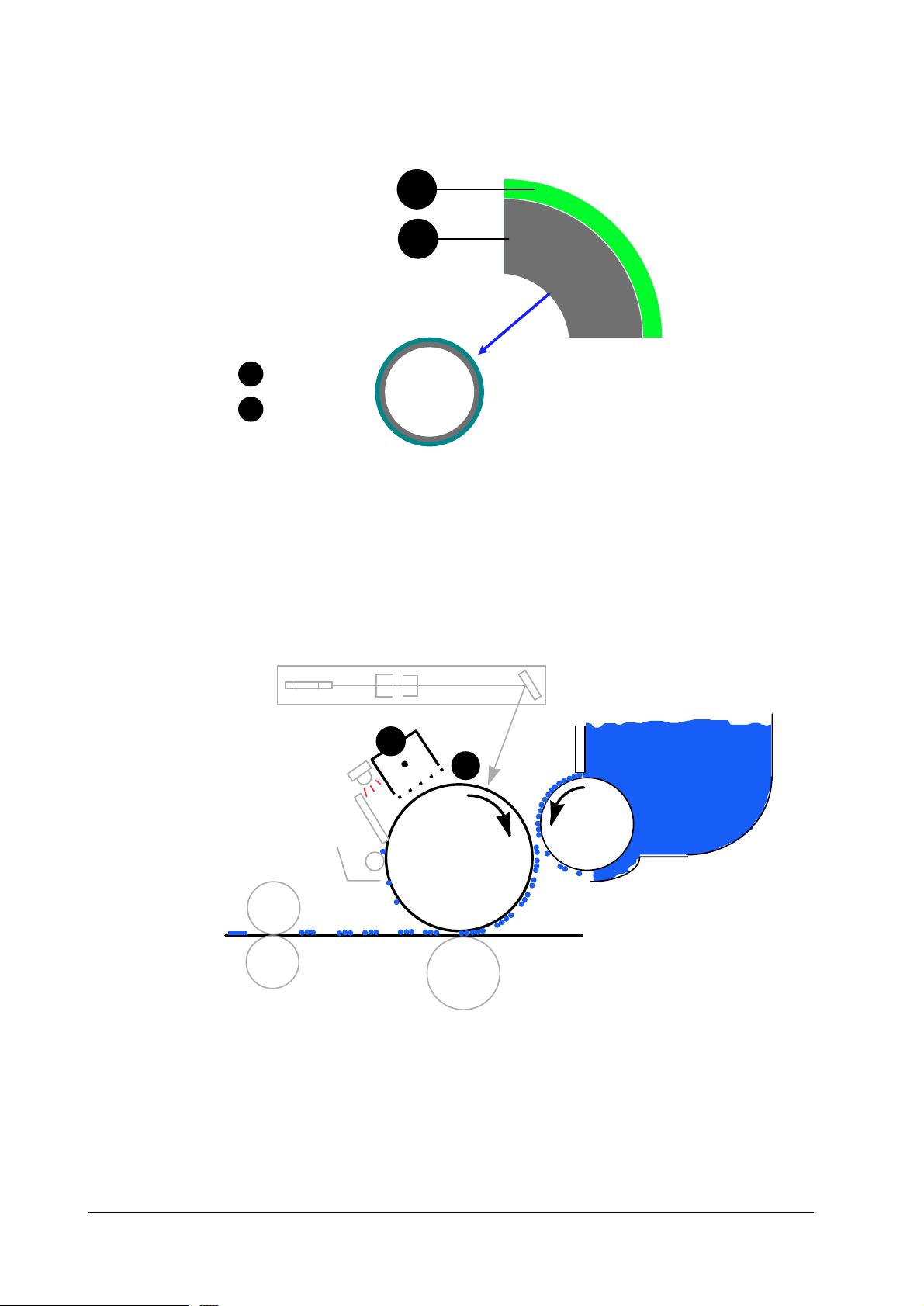

Figure below is a simplified diagram of the electrophotographics components. Charging the

drum is done by the main charger wire (in the main charger unit) marked “A” in the diagram.

$

%

)609<33

As the drum (“B” above) rotates in a “clean (neutral)” state, its photoconductive layer is given a

uniform, positive (+) electrical charge dispersed by the main charger wire (“A”).

Due to high-voltage scorotron charging, the charging wire can get contaminated by oxidization

and therefore must be cleaned periodically from time to time using the method explained on

page 3-5,

such as black streaks caused by the oxide accumulated around the charging wire.

&OHDQLQJ#WKH#SULQWHU

. Cleaning the charging wire prevents print quality problems

4-3

Page 4

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

7RQHU

The toner is fed from the toner pack TK-20/H. The toner is comprised of the following substances.

6LQJOH#FRPSRQHQW#WRQHU#7.0532+

Resin

$#0#

Ferrite

%#0#

Silica

�#

Polisher

'#0#

$

%

&

'

([SRVXUH

The charged surface of the drum ("B") is then scanned by the laser beam from the scanner unit

("A").

$

%

4-4

)609<33

Page 5

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

The laser beam is switched on for a black dot and off for a white (blank) dot according to the

print data. Whenever it is illuminated by the laser beam, the electrical resis-tance of the photoconductor is reduced, the potential on the photoconductor is also lowered to 20 V, effectively

driving the charge through the a-Si layer down to the aluminum base.

/DVHU#EHDP

D06L#OD\HU

$OXPLQXP

3RVLWLYH#FKJ1

.#.#.#.#.

3RVLWLYH#FKJ1

1HJDWLYH#FKJ1

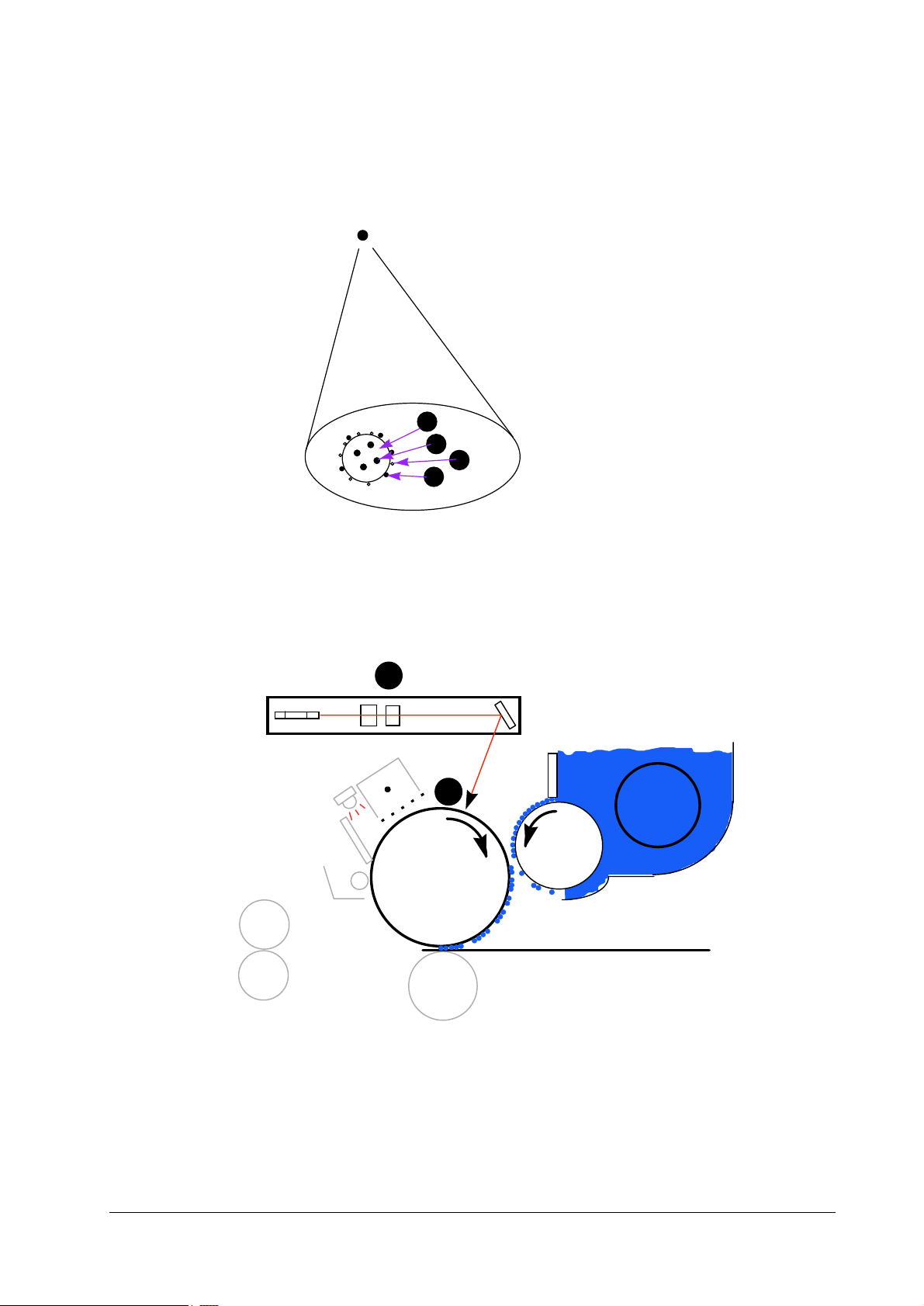

6FDQQHU#XQLW

The 600 dpi scanner unit includes the diode laser that produces the 670 nm wave-length laser

beam. This wavelength is specifically designed to match the photocon-ductive response of

amorphous silicon.

.#.#.#.

#

#0###0##0###0

.#.#.#.

57305939

5730593#9

53#9

3#9

/DVHU#EHDP

)609<33

4-5

Page 6

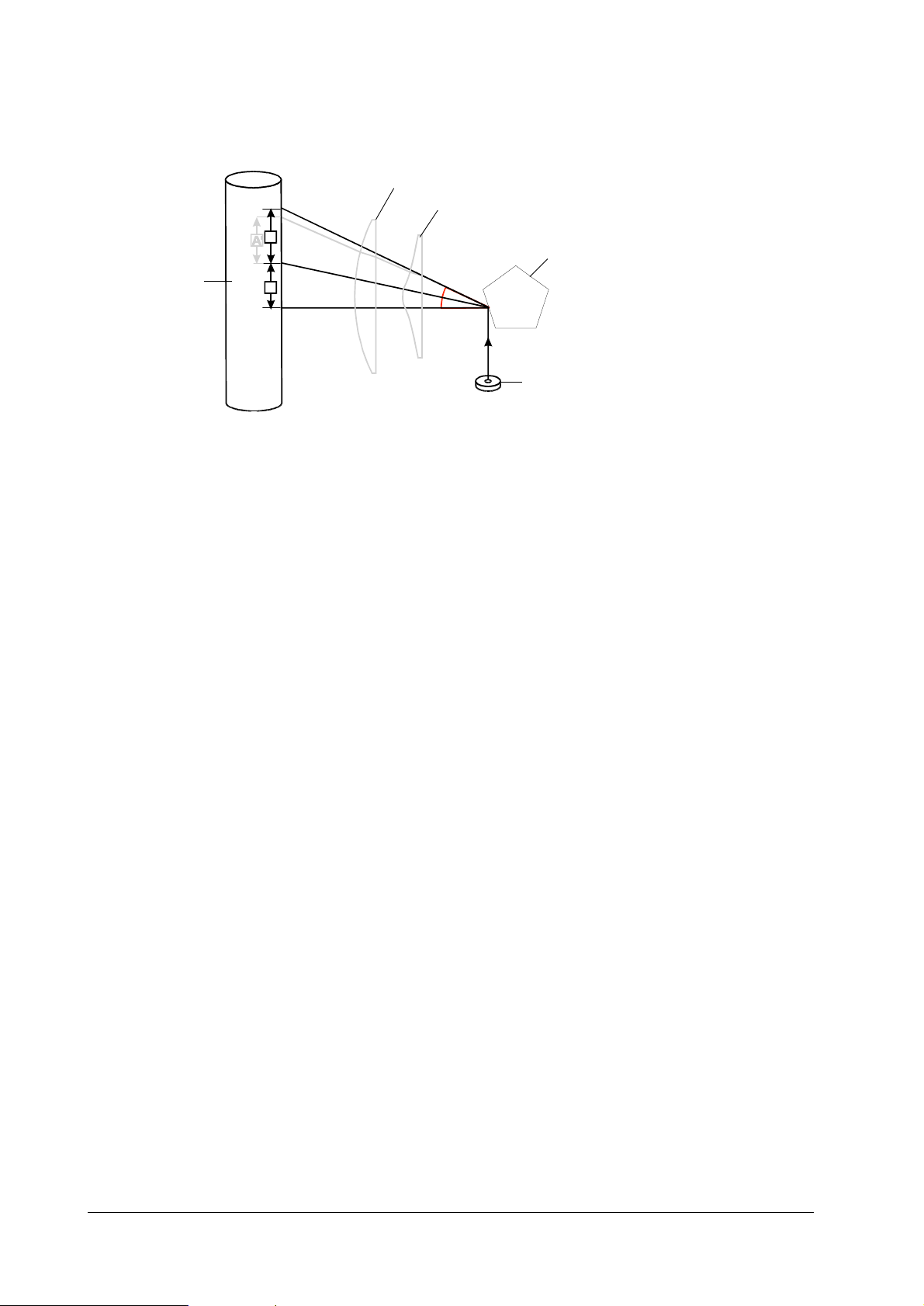

)LJXUH#716 /DVHU#VFDQQHU#XQLW

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

'RZQYHUWLQJ#PLUURU

3KRWR#GLRGH

/DVHU#GLRGH

&ROOLPHWHU#OHQV

&\OLQGRULFDO#OHQV

7DE O H#71#4## )XQFWLRQ#RI#VFDQQHU#FRPSRQHQW³

&RPSRQHQW )XQFWLRQ

Laser diode Emits diffused, visible laser.

Collimeter le ns Aligns the laser be am to the cylindrical lens.

Cylindrical lens Compensates the slant angle at which the laser beam hits a polygon mirror

segment.

Polygon mirror (motor) Has six mirror segments around its oc ta gonal circumference; each mirror

corresponding to one scanned line width on the drum when laser beam

scans on it.

Primary f-theta lens See page 4-7, Figure 4.4 and below.

Secondary f-theta lens See page 4-7, Figure 4.4. The primary (above) and secondary ftheta lenses

equalize focusing distortion on the drum edges. The effective length of

line ("A," "B" below) the lase r bea m draws on the drum becomes longer

as the laser beam hits closer to the drum edges. In the figure below, dis-

tances represented by "A" and "B" are not the same (A>B) until the ftheta

lenses are provided be tween the polygon m irror and the drum (A=B) .

Diversion mirror diverts the laser beam vertica ll y onto the drum. Note the diffused la ser

beam finally pin-point s on the drum.

Protective glass Pre ve nts dust, debris, etc., from entering the scanner asse m bly.

Sensor mirror Bends the very first shot of a laser scan towards the beam detection sensor

(See next.).

Beam detector sensor When shone by the sensor mirror above, this photosensor generates a trig-

ger signal for the engine controller to start a ctivating the paper feeding

system.

&RYHU#JODVV

)0WKHWD#OHQVHV

3RO\JRQ#PLUURU2PRWRU

4-6

)609<33

Page 7

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

)LJXUH#717 )XQFWLRQ#RI#)0WKHWD#OHQVHV

6HFRQG#)0WKHWD#OHQV

)LUVW#)0WKHWD#OHQV

'UXP

$

%

T

T

3RO\JRQ#PLUURU

/DVHU#GLRGH

6FDQQLQJ#ODVHU

The laser beam hits one of 5 sides of t he polygo nal mi rror. As the mi rror rev olves (at the revo lution of 26600 rpm), the laser beam reflects off of it and reaches the charged drum surface in a

lengthwise manner.

A pair of (plastic) lenses provides focusing the horizontally sweeping laser beam onto the drum.

As the drum rotates, the laser beam sweeps the entire length of the drum so th at the drumís

entire circumference is exposed to the laser beam. The revolution of the polygon mirror motor

and the drum itself is timing-controlled so that each suc-cessive sweeping of the laser beam produces a 1/600 inch offset. The printer’s controller system continuously turns the laser beam on

and off to put a dot at every 1/600 inch distance horizontally. The diameter of a dot is typically

70 to 80 µm. When KIR is on, the intensity of the beam is switched in fou r deg rees compensating for the smoothed image.

Synchronizing the output data with one scanning line is achieved by the photo sensor provided

next to the first mirror. At the beginning of each laser sweeping, the beam hits the photo sensor

which in turn sends a command to the logic controller for syn-chronization.

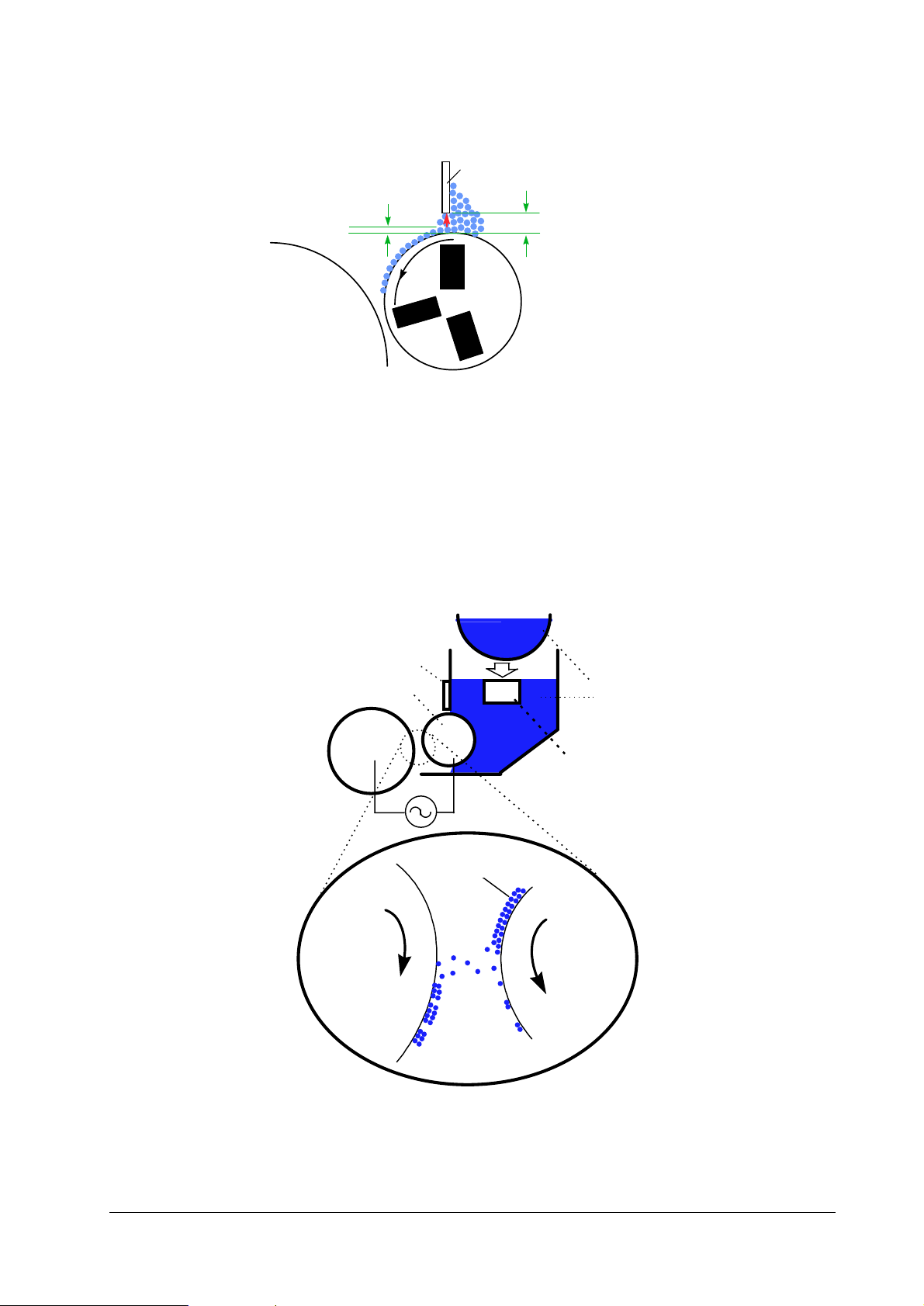

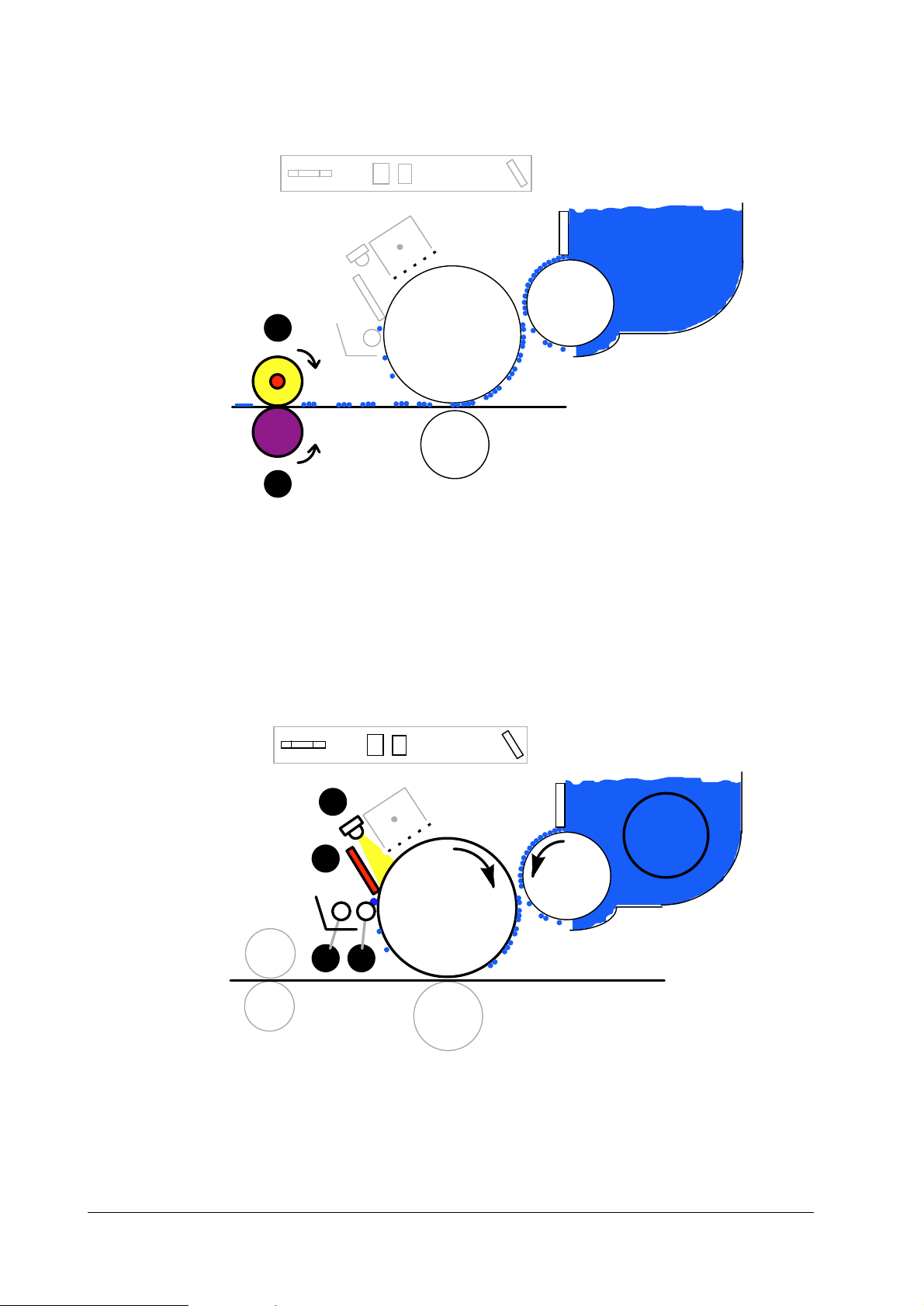

'HYHORSPHQW

The latent image constituted on the drum is developed into a visible image. The de-veloping

roller contains a 3-pole (S-N-S) magnet core and an aluminum cylinder ro-tating around the

magnet core. Toner attracts to the developing roller since it is pow-dery ink made of black resin

bound to iron particles. A magnetized blade positioned approximately 0.3 to 0.4 mm above the

developing roller constitutes a smooth layer of toner in accordance with the roller revolution.

)609<33

4-7

Page 8

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

'HYHORSLQJ

EODGH

314#PP

'UXP

3160317#PP

6

0DJQHWLF

1

UROOHU

6

'HYHORSLQJ#UROOHU#ELDV

The developing roller is connected to a AC-weighted, positive DC power source. Toner on the

developing roller is given a positive charge. The positively charged toner is then attracted to the

areas of the drum which was exposed to the laser l ight. The non- exposed areas of th e drum repel

the positively-charged toner as these areas maintain the positive charge.

The developing roller is also biased with an ac potential to apply com pensation to the toner’s

attraction and repelling actions for more contrast in the development.

'HY1#EODGH

'HY1#UROOHU

'UXP

$&.'&

'UXP

7RQHU

7RQHU#VHQVRU

'HY1#UROOHU

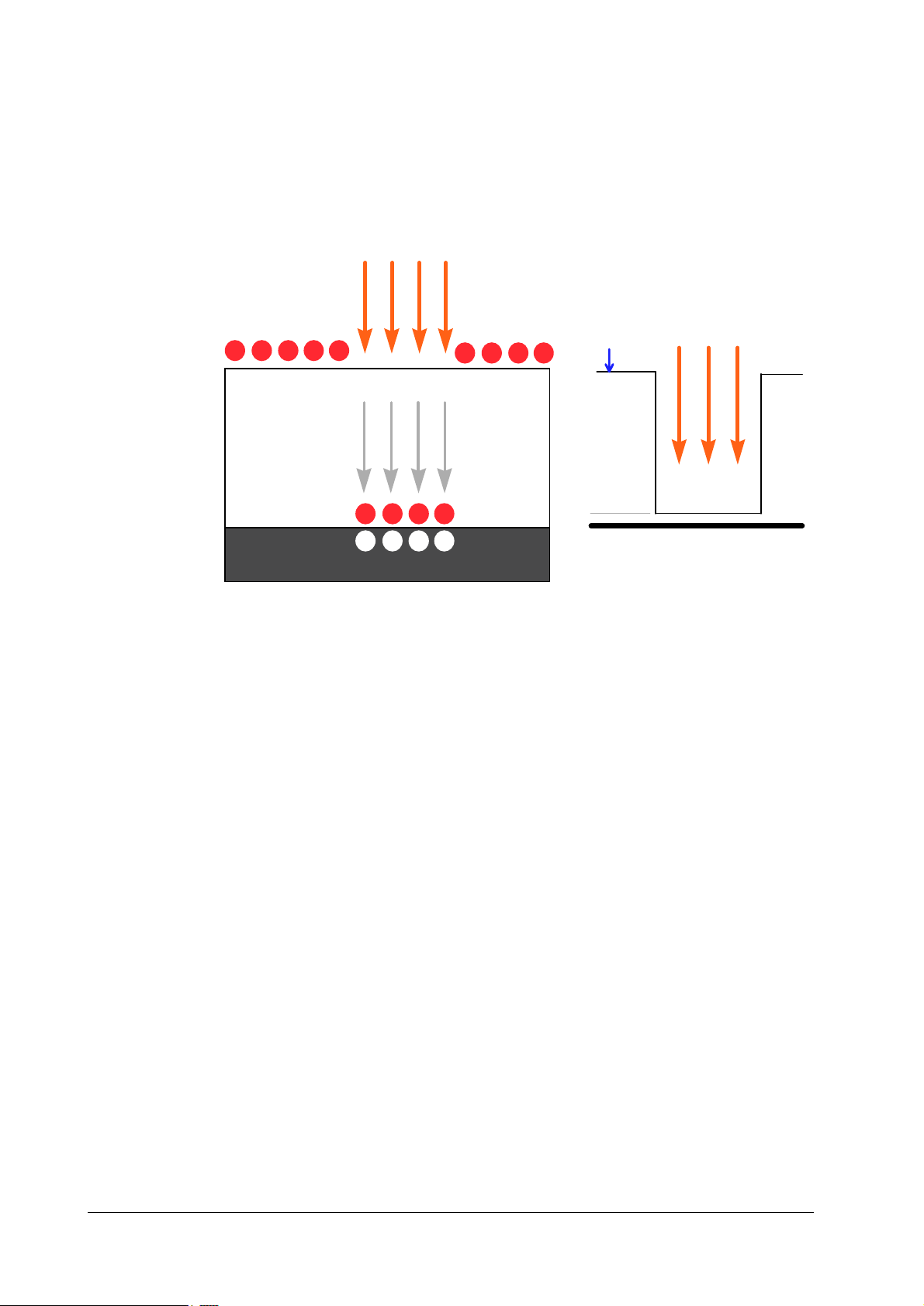

The following diagram depicts the change in the drum surface potential during development.

The vertical distance rerepresents the depth of bias potential.

4-8

)609<33

Page 9

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

%LDV#GHSWK#LV#GHWHUPLQHG#VR

DV#WR#SUHYHQW#JUD\#EDFNJURXQG1

9R DSSUR[1#573#WR#593#9

......

53#9

'HYHORSPHQW

([SRVXUH

......

'HY1#UROOHU#ELDV

4;3#9#'&.$&

7RQHU #VHQVRU

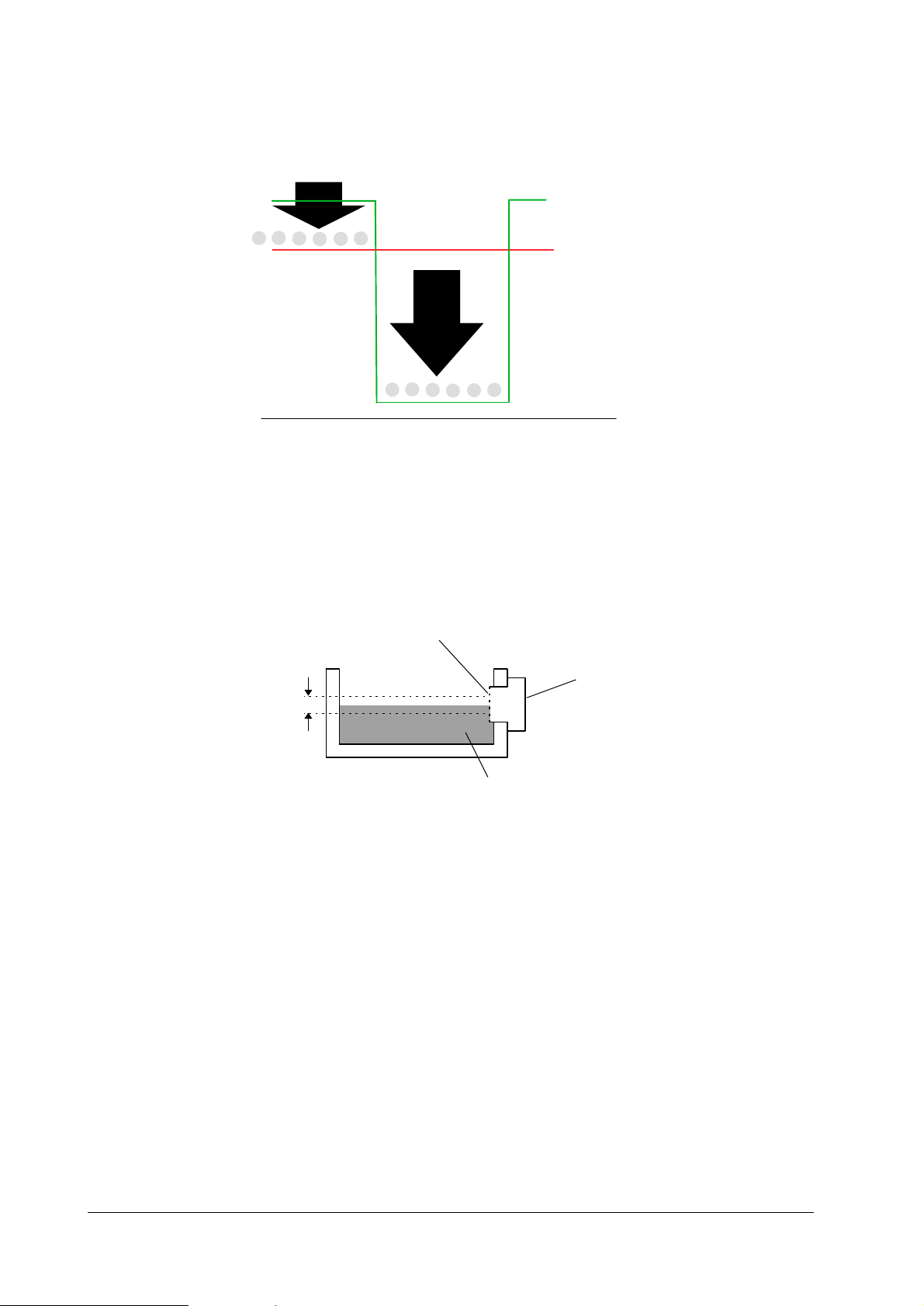

The toner replenishment sensor is provided within the developer. As the toner supply from the

toner container dwindles and the toner level low e rs in the reservoir, the sensor translates it

through its diaphragm, urging the toner motor to feed more toner.

'LDSKUDJP

6HQVRU

6HVLQJ#KHLJKW

7RQHU

7UDQVIHU

The image developed by toner on the drum (“A” below) is transferred onto the paper using the

electric charge attraction given by the toner itself and the transfer roller (“B” below). The transfer roller is negatively biased so that the positively charged toner is attracted onto the paper

while it is pinched by the drum and the transfer roller.

The paper is automatically peeled off the drum because of the small diameter of the drum. To

prevent thin paper wrapping around the drum, the static discharger brush is provided to reduce

the attraction of the negatively charged paper to the positiv ely charged drum.

)609<33

4-9

Page 10

.

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

%

.

The nominal transfer bias is set to approximately -1.80 kV (limit) with the current of 65±2 mA.

Since thicker paper (91 to 200 g/m

more bias potential for the satisfactory transferring process, the transfer bias is user-switchable

to -2.45 kV (limit) by using the printerís operator panel. Double-sided printing using a DU-25

duplexer automatically increases the transfer bias to the above value.

)XVLQJ

The toner on the paper is permanently fused onto the paper as it passes between the florin-finished heat roller (“A” below) and the pressure roller (“B” below) in the fuser unit. The toner is

molten and pressed into the paper. The heat roller has a halogen lamp, t urning frequ ently on and

off to maintain a preheat temperature at approxi-mately 175°C.

The heat roller temperature is constantly monitored by the engine control circuit us-ing a thermistor. For safety against overheating, the fuser system is protected by a triac which automatically opens power to the halogen lamp. If the temperature ex-ceeds 350°C, it activates the

thermo-cut device to interrupt open power to the halo-gen lamp.

0

$

2

) such as postcards, OHP, envelopes, etc., tend to require

4-10

)609<33

Page 11

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

$

%

'UXP#FOHDQLQJ#DQG#HUDVLQJ#VWDWLF#FKDUJH

The drum needs to be physically cleaned of toner remaining on its surface in the pre-vious rotation. The cleaning blade (A below) is constantly pressed against the drum and scrapes the residual toner on the drum off to the refresher roller (B below). The refresher roller drives the toner to

the spiral (fins) roller (C below) at one end of which the waste toner bottle is connected to collect the waste toner.

'

$

%&

)609<33

After the drum is physically cleaned, it then must be cleaned to an electrically neu-tral state.

This is necessary to erase any residual positive charges, ready to accept th e next uniform charg e.

The residual charge is canceled by exposing the drum to the light emitted from the eraser LED

4-11

Page 12

2SHUDWLRQ#WKHRU\

(OHFWURSKRWRJUDSKLFV#V\VWHP

(D above) in the similar manner as described in page 4-6. This lowers the electrical conductivity

of the drum surface making the re-sidual charge on the drum surface escape to the ground.

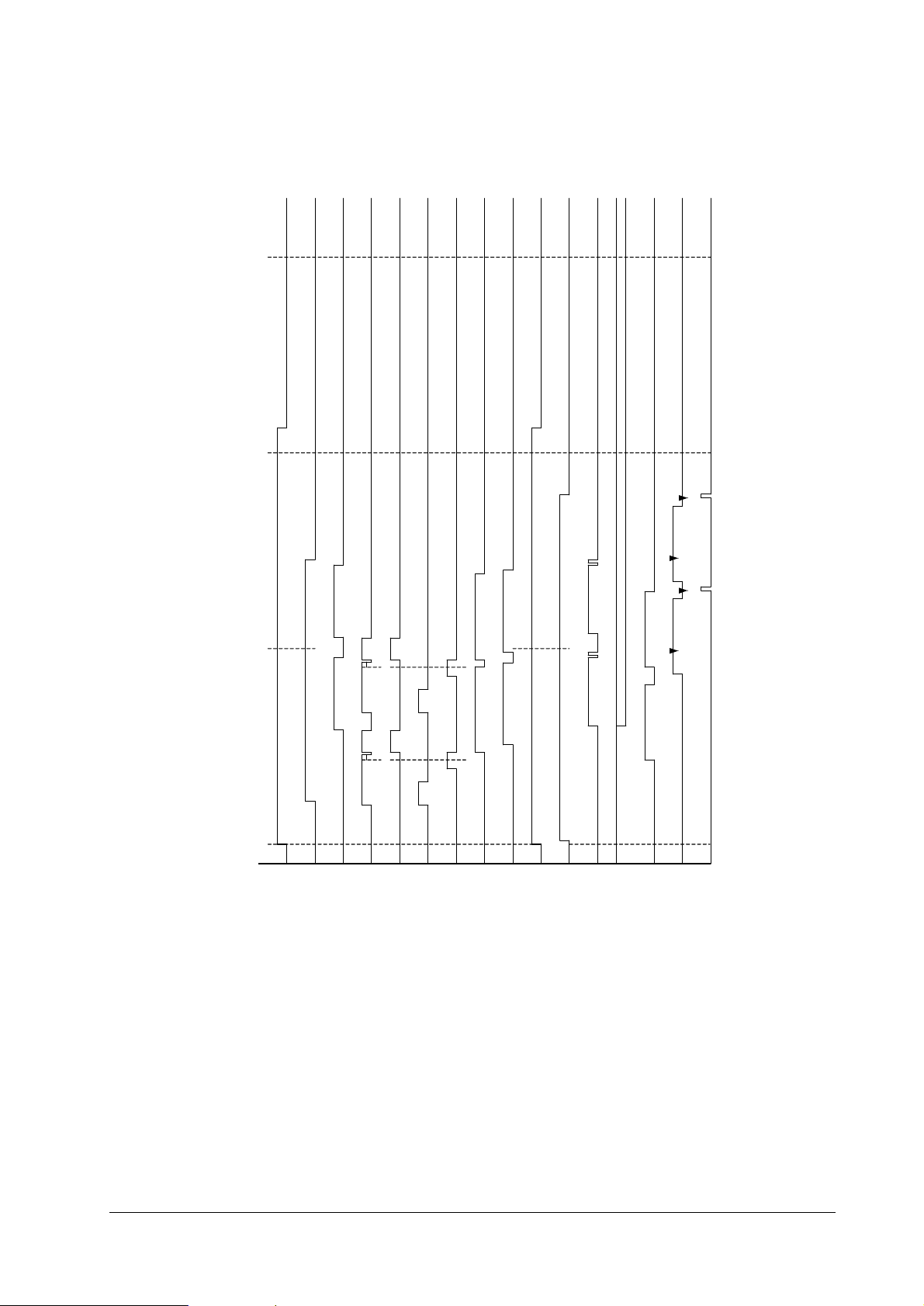

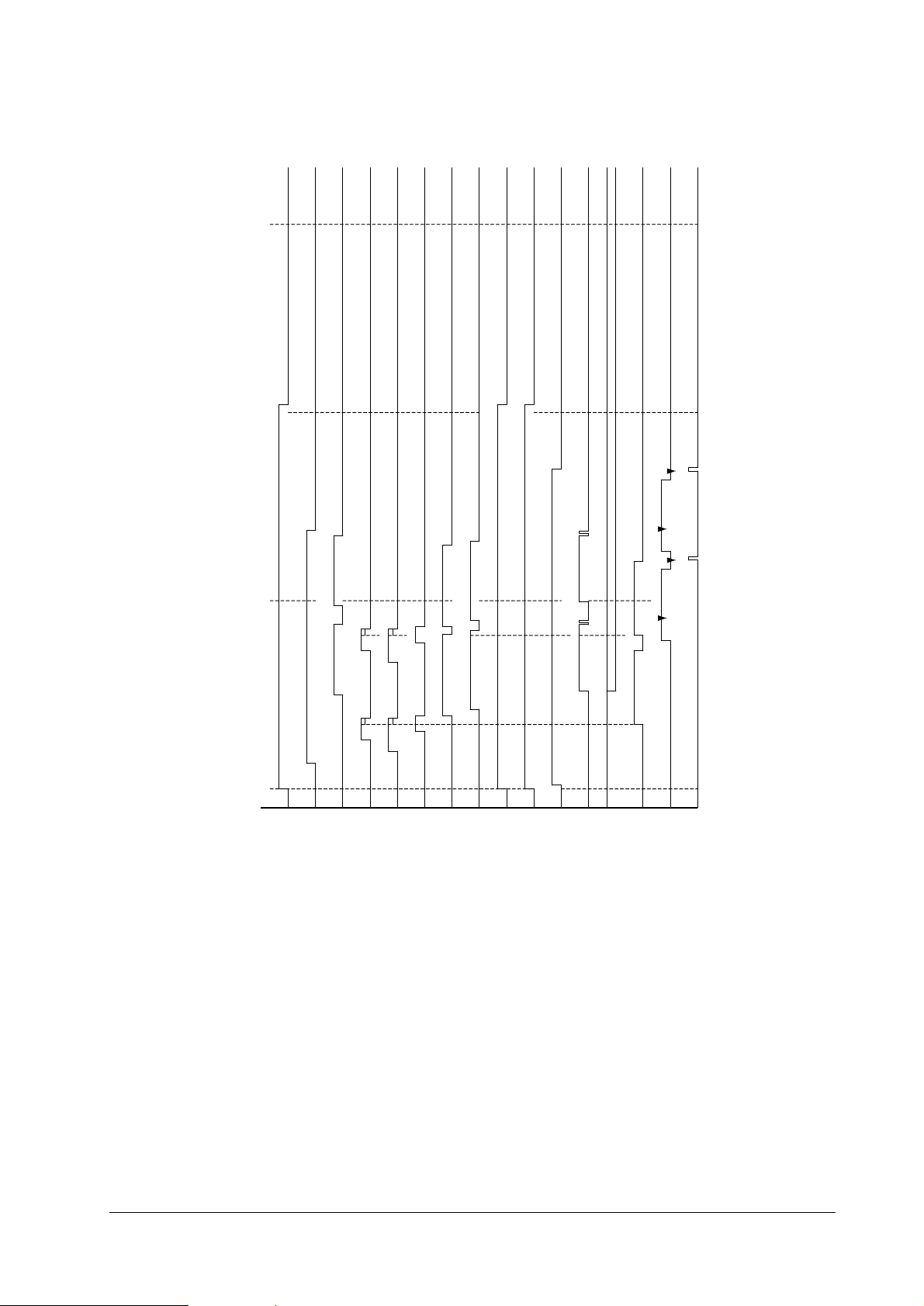

7\SLFDO#SKRWR#SURFHVV#WLPLQJ#FKDUW

The following chart shows the signals used for photo processing. These signals acti-vate the corresponding device in the fol low in g t imi ng s equences. A simple description for t hes e signals follow.

)LUVW#SDJH 6HFRQG#SDJH

02725

3$3(5

0+9'5

(5$6(

%,$6

7+9'54

639'5

7DE O H#71#5## )XQFWLRQV#RI#VLJQDOV

6LJQDO )XQFWLRQ

MHVDR (Main High Voltage DRive) Drives main charger with high voltage bias. This signal is kept on during

ERASER Turns on the eraser (LED array) as soon as the motor begins revolving (A

BIAS Turns on the developer bias (on the magnet roller). The duration of this

THVDR (Transfer High Voltage

DRive)

SPVDR (SeParation Vias DRive) Turns the separation charge bias on and off. The duration of SPVDR

$

%

&

(

'

)

*

the job is processed.

above).

signal is dependent on th e current paper size (B) and turns off between

pages (C).

Turns on the transfer bias. Note that the transfer bias is reverse (+300 V)

at the beginning of a print job (D)until the paper is actua ll y fed onto the

transfer roller. This pre ve nts contamination on the back side of paper by

effectively repelling the toner during the paper is not present between the

drum and the transfer roller. The transfer bias is kept on during a print job

(E).

turned on (F) varies depending on the size of the page. SPVDR is off

between pages (G).

4-12

)609<33

Page 13

2SHUDWLRQ#WKHRU\

0

10 1

10094

MOTOR

(MAIN

MOTOR)

6

39

MHVDR

(MAIN

CHARGER)

2381 423

4

43 6

99

THVDR1

(TRANSFER

CHARGER1)

2381

THVDR2

(TRANSFER

CHARGER2)

1000 1

3362 411

FEDDR

(CASS1

FEED

CLUTCH)

1400 181

3

62

41

9

REGDR

(REGIST

CLUTCH)

181

4001

41

9 6363

LASER

VSREQ

VSREQ

1999

4092

4361 64

4

BIAS

10094

ERASER

10094

CHVON

100 8382

SCANER

2482

423

436

4844 6

99 6

2

SPVDR1

(SEPARATE

CHARGER1)

4301 6663

2482

SPVDR2

(SEPARATE

CHARGER2)

1

86 3

46 3948

908

FEEDS

(FEED

SENSER)

3819

30

6181 8092

EXITJ

(JAM

SENSER)

4411 6

3

9

831

COUNT

3ULQW#WLPLQJ#FKDUWV

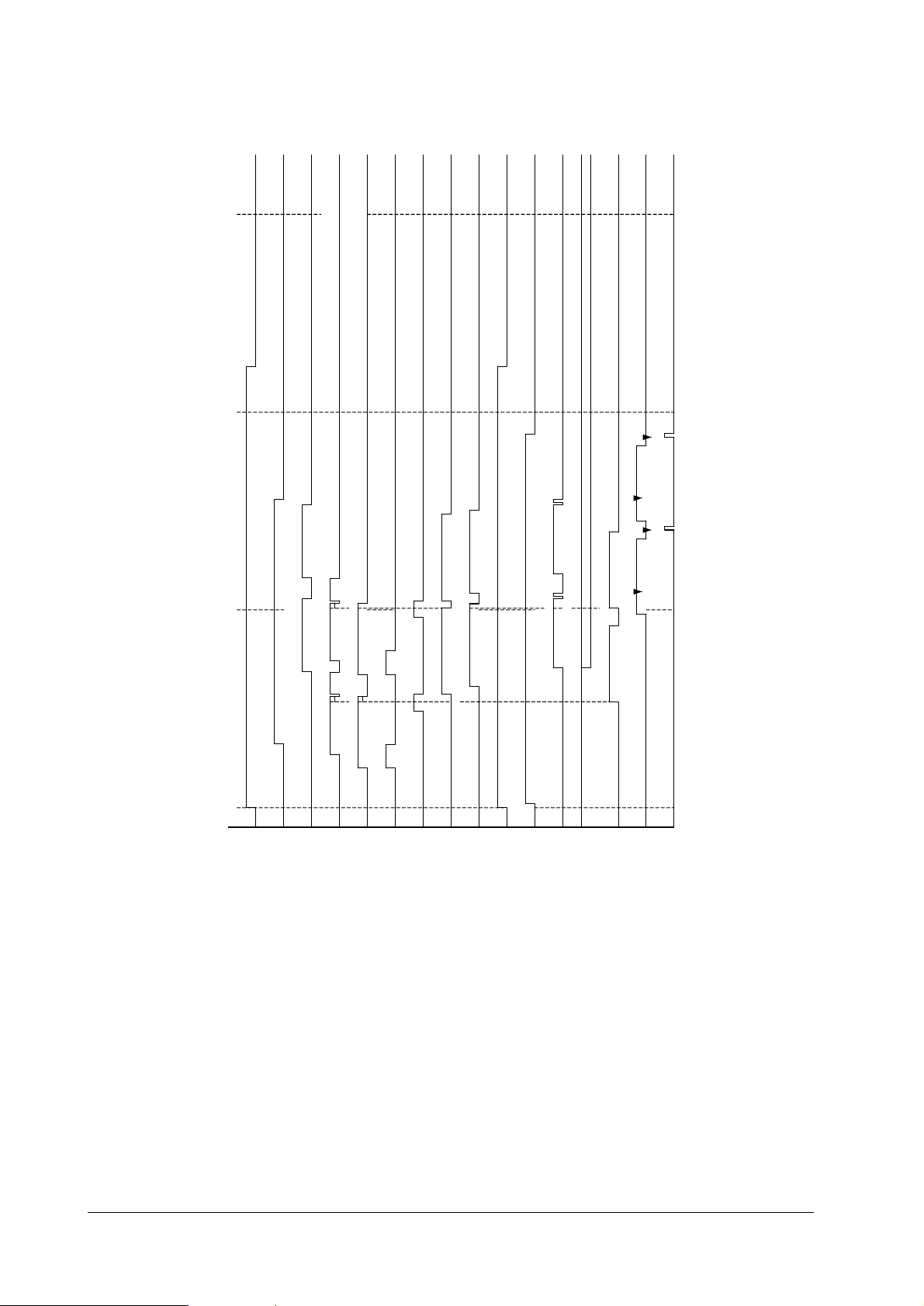

715 3ULQW#WLPLQJ#FKDUWV

The following charts show timings among those signals the engine controller issues to control

printing. The charts include different timings depending on the paper sizes and paper sources.

)LJXUH#718 0DLQ#FDVVHWWH2$8#RU#$7/#+)HHG#VSHHG#>)(''5@ 5541;33#PP2V,

5

5

2 PRINT PROCESS TIMING A5/A4Y( 210 mm ) DRUM SPEED 110.000 mm/s FS-6900

7

555

7

7

5

5

7

7

7

755

7

7

7

7

7

7

5

5

5

7

5

5

77

55

5

57

221.800 mm/s 25.40 ppm 1.269 msec

)609<33

MOTOR

MHVDR

(MAIN MOTOR)

(MAIN CHARGER)

THVDR1

(TRANSFER CHARGER1)

FEDDR

THVDR2

(CASS1 FEED CLUTCH)

(TRANSFER CHARGER2)

LASER

REGDR

(REGIST CLUTCH)

4-13

BIAS

ERASER

CHVON

SPVDR1

SCANER

(SEPARATE CHARGER1)

SPVDR2

(SEPARATE CHARGER2)

EXITJ

FEEDS

(JAM SENSER)

(FEED SENSER)

COUNT

Page 14

)LJXUH#719 3)059#IHHGHU2$8#RU#$7/#+)HHG#VSHHG#>)(('4@ 5;3175#PP2V,

0

10 1

10632

MOTOR

(MAIN

MOTOR)

1093

2

MHVDR

(MAIN

CHARGER)

2919

4

281

13

THVDR1

CHARGER1)

1000

2293

23

33

46

4

1

MON1

(FEED1

MOTOR)

2901

263

23

4

1

MSL1

SPEED

CHENGE)

2901

263

1000 1600 3362 3962

CLON1

ROLLER

CLUTCH)

1930

23

4292

4

1

REGDR

(REGIST

CLUTCH)

23

4

39 4

1

6901

LASER

VSREQ VSREQ

2

3

4630

4899 6992

BIAS

10632

ERASER/CHVON

100 8920

SCANER

3020

4

4903

382

13

26

SPVDR1

CHARGER1)

4839

201

3020

SPVDR2

CHARGER2)

2160 4084 4

22 6446

FEEDS

(FEED

SENSER)

43

6268 6

19 8630

EXITJ

(JAM

SENSER)

4949

311

6493 88

COUNT

280 42 / 25 40 1 269

5

2SHUDWLRQ#WKHRU\

3ULQW#WLPLQJ#FKDUWV

55

5

2 PRINT PROCESS TIMING A5/A4Y( 210 mm ) DRUM SPEED 110.000 mm/s FS-6900

77

7

MOTOR

(MAIN MOTOR)

7

7

7

7

775 5

55

55

MHVDR

MON1

THVDR1

(MAIN CHARGER)

(TRANSFER CHARGER1)

5

5

7

7

55

MSL1

CLON1

(FEED1 MOTOR)

(FEED1 SPEED CHENGE)

(FEED1 ROLLER CLUTCH)

7

7

7

7

5

55

55

LASER

REGDR

(RESIST CLUTCH)

7

5

BIAS

ERASER/CHVON

5

7 7

7

5

775

SPVDR1

SCANER

7

5

FEEDS

SPVDR2

(SEPARATE CHARGER1)

(SEPARATE CHARGER2)

7

7

57

EXITJ

(FEED SENSER)

COUNT

(JAM SENSER)

4-14

)609<33

Page 15

2SHUDWLRQ#WKHRU\

0

10 1

111

2

MOTOR

(MAIN

MOTOR)

1613

9

MHVDR

(MAIN

CHARGER)

3439

29

801

6

THVDR1

(TRANSFER

CHARGER1)

13

0

2813

28

5

3

12

1

23

MON1

(FEED1

MOTOR)

3421

83

1000

2813

3362

1

MON2

(FEED2

MOTOR)

1000 1600 3362 3962

CLON2

(FEED2

ROLLER

CLUTCH)

24

028

4812

23

REGDR

(REGIST

CLUTCH)

28

0

9

23

421

LASER

VSREQ

VSREQ

30

1

0

419

12

BIAS

111

2

ERASER/CHVON

100 9440

SCANER

3

40

29

423

902

6

8

SPVDR1

(SEPARATE

CHARGER1)

3

9

21

3

40

SPVDR2

(SEPARATE

CHARGER2)

2680

4604

042 6966

FEEDS

(FEED

SENSER)

48

6

88

239 91

0

EXITJ

(JAM

SENSER)

469

831

013 93

COUNT

3ULQW#WLPLQJ#FKDUWV

)LJXUH#71: 6HFRQG#3)059#IHHGHU2$8#RU#$7/#+)HHG#VSHHG#>)(('5@ 5;3175#PP2V,

5

5

5

2 PRINT PROCESS TIMING A5/A4Y( 210 mm ) DRUM SPEED 110.000 mm/s FS-6900

5

75

5

7

57

77

7

55

5

7

75 5

5

7

7

5

57

75

5

7

5

75

5

75

77

5

5

5

5

75 5

57 5

5

57 77

7

5

5 5

5

5

77

5

5

5

5

7

7

7

5

77

7

280.42 mm/s 25.40 ppm 1.269 msec

)609<33

MOTOR

MHVDR

(MAIN MOTOR)

(MAIN CHARGER)

MON1

(FEED1 MOTOR)

MON2

(FEED2 MOTOR)

THVDR1

(TRANSFER CHARGER1)

CLON2

REGDR

(RESIST CLUTCH)

(FEED2 ROLLER CLUTCH)

4-15

LASER

BIAS

ERASER/CHVON

SPVDR1

SCANER

(SEPARATE CHARGER1)

SPVDR2

(SEPARATE CHARGER2)

EXITJ

FEEDS

(JAM SENSER)

(FEED SENSER)

COUNT

Page 16

)LJXUH#71; 03#WUD\2$82$7<#+)HHG#VSHHG#>03@ 5371:6;#PP2V,

0

10 1

10218

MOTOR

(MAIN

MOTOR)

6

9 6863

MHVDR

(MAIN

CHARGER)

2

0

4361 486

6

23

THVDR1

(TRANSFER

CHARGER1)

1300 18

9

3662

4241

MPFSOL

(MP

FEED

SOLENOIDO)

1000 18

9 3362 4241

MPLSOL

(MP

LIFT

SOLENOIDO)

1

24 3886

REGDR

(REGIST

CLUTCH)

1941 4303

1941

412

4303 648

LASER

VSREQ

VSREQ

2123 4216 448

6

8

BIAS

10218

ERASER

10218

CHVON

100 8

06

SCANER

68

1

2606

4361

4489

4968

6

23

68

1

SPVDR1

(SEPARATE

CHARGER1)

442

6

8

2606

SPVDR2

(SEPARATE

CHARGER2)

1

10

36

0

40

2 6032

FEEDS

(FEED

SENSER)

3943

8

4

630

8216

EXITJ

(JAM

SENSER)

4

3

689

60

9 8441

COUNT

5

2SHUDWLRQ#WKHRU\

3ULQW#WLPLQJ#FKDUWV

5

5

5

2 PRINT PROCESS TIMING A5/A4Y( 210 mm ) DRUM SPEED 110.000 mm/s FS-6900

MOTOR

(MAIN MOTOR)

7

7

5

5

7

MHVDR

THVDR1

(MAIN CHARGER)

(TRANSFER CHARGER1)

7

7

MPLSOL

MPFSOL

(MP LIFT SOLENOIDO)

(MP FEED SOLENOIDO)

7

5

5

REGDR

(RESIST CLUTCH)

57

5

LASER

BIAS

ERASER

CHVON

5

7

SPVDR1

SCANER

(SEPARATE CHARGER1)

7

7

5

SPVDR2

(SEPARATE CHARGER2)

5

5

5

7

7

7

FEEDS

(FEED SENSER)

7

7

5

5

EXITJ

(JAM SENSER)

204.738 mm/s 25.40 ppm 1.269 msec

COUNT

4-16

)609<33

Page 17

2SHUDWLRQ#WKHRU\

3DSHU#IHHGLQJ#V\VWHP

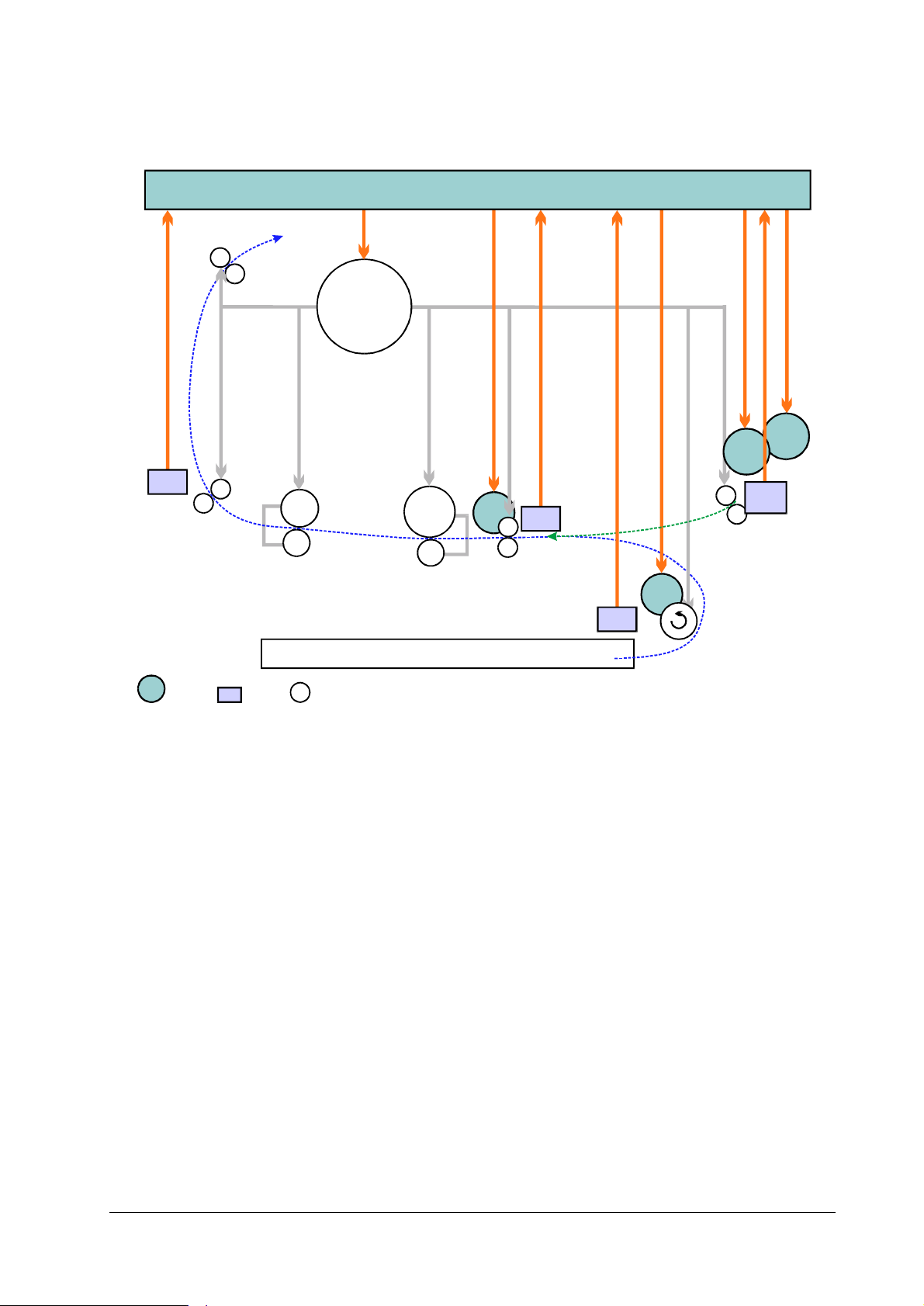

716 3DSHU#IHHGLQJ#V\VWHP

The paper feeding system picks up paper fr om the p aper cassett e or the manual feeding t ray and

at a precise timing feeds it to the electropho tography system fo r de-veloping image on the p aper.

It finally delivers the printed page to either the face-down or face-up tray.

The figure below shows the paper feeding path within the printer.

)DFH0GRZQ#RXWSXW#WUD\

0DQXDO#IHHG#

UROOHU.FOXWFK

.VHQVRU

(MHFW#UROOHUV

)XVHU#UROOHUV

5HJLVW1#UROOHUV.FOXWFK.VHQVRU

'UXP

6HSDUDWLRQ#FKDUJHU

)HHG#UROOHU.

FOXWFK.

VHQVRU

7UDQVIHU#UROOHU

3DSHU#+&DVVHWWH,

Following on the next page is another diagram showing locations of sensors, roller, and solenoids arranged along with this pape r pa th.

)609<33

4-17

Page 18

)LJXUH#71< 7UDQVSRUWDWLRQ#V\VWHP#GLDJUDP

(QJLQH#&RQWUROOHU

2SHUDWLRQ#WKHRU\

3DSHU#IHHGLQJ#V\VWHP

([LW

VHQVRU

(;,7--

([LW#UROOHUV

)DFH0GRZQ#UROOHUV

0DLQ#PRWRU

+HDW#5ROOHU

3UHVVXUH#5ROOHU

02725-

7UD QV IHU #UROOHU

3DSH U#&DVVHWWH

'UXP

5(*'5-

5HJLVW1

FOXWFK

5HJLVW#UROOHUV

5HJLVW

VHQVRU

3DSH U

VHQVRU

3$3(5-

)HHG

FOXWFK

)(''5-

0DQXDO

FOXWFK

IHHG

03)&/+-

VROHQRLG

0DQXDO

IHHG

VHQVRU

+$1'6-

0DQXDO

IHHG

03)62/-

)(('6-

&OXWFKHV 6HQVRUV 5ROOHUV

&DVVHWWH#IHHGLQJ#

The main logic controller sends the PRINT* signal to the engine controller after fin-ishing data

processing. The engine controller CPU then starts the main motor (MOTOR*), polygon motor,

registration rollers, and the fuser heater. The eng ine controller then issues the FEDDR* signal to

connect the main motor power to the paper feed tires. The tires feed the top sheet in the paper

stack in the cassette towards the registration rollers until the paper reaches the registration jam

sensor (JAMR). As the engine controller sends VSREQ to the main logic controller, the main

logic controller subse-quently issues VDO to activate the registration rollers, thus starting to

feed paper towards the drum.

The paper is advanced to the drum, to the fuser unit, triggering the exit sensor (EXITJ*), and

finally delivered either to the face-down tray or the face-up tray as switched by the ou tput stack

selector tab.

0XOWL#SXUSRVH#WUD\#IHHGLQJ

The printer recognizes the existence of paper on the multi purpose tray when the manual feed

sensor is pushed up (HANDS*).

When the print data is ready, the engine controller sends MPFSOL* to raise the lif t board by th e

solenoid. After 300 ms, the MPFCLH* signal is issued to rotate the feed roller and sends the

paper towards the registration rollers. As the registration sensor detects the paper, the lift board

lowers. The registration rollers pulls and sends the paper forwards for development.

3$35 3$7+ 1&'5

4-18

)609<33

Page 19

2SHUDWLRQ#WKHRU\

3DSHU#IHHGLQJ#V\VWHP

3DSHU#MDP#VHQVLQJ

The registration sensor and the exit (fuser) sensor keep track of the paper sent through the printerís paper path by watching the time of period during which either sensor is kept activated.

5HJLVWUDWLRQ#VHQVRU

reflector (shiny mirror surface) at the end of the actuator is in the position that can reflect the

light to shine the receptor. As the top edge of the paper reaches the registration sensor, the

reflector is pushed up and the light is interrupted(2), triggering the sensor.

Pickup of paper in the cassette is triggerred by the FEDDR* signal which drives the clutch for

the feed roller.

—A photo reflector sensor is used. While the paper is not present (1), the

➊

➋

([LW#VHQVRU

the fuser board. The actuator is in the way back at the fuser outlet. The re-flector at one end of

the actuator is normally seated in-between the photo transmitter and sensor (1). It is dressed

away out of them when the paper in the fuser sensor pushed up the actuator (2), allowing the

light to hit the receptor and turning the sensor circuit on.

—This is a photo penetration sensor, combined with an actuator arm ex-tending to

➊

➋

On detecting a paper jam, the engine controller stops printing action and shows the

message. After removing paper jam, the printer resumes printing when either the toner access

door or the feed assembly is once opened and closed. If paper jammed past the exit sensor, the

printer will not attempt to print the same page.

The printer reverts to normal operation wh en the top cover o r the paper feed unit is once o pened

and closed after removal of jam. If the paper was jammed clearing the eject sensor, the printer

does not print the same page when recovered.

Paper jam

)609<33

4-19

Page 20

717 %DVLF#HQJLQH#IXQFWLRQV

This section presents a general functional overview of the engine system of the printer. It was

intended to provide a comprehensive knowledge on basic functions that the engine system performs during printing. The following printer functions are covered:

Engine controller system

•

Main logic controller system

•

Paper feed system

•

Power system

•

%DVLF#VHTXHQFH#RI#RSHUDWLRQ

The following figure is a simplified block diagram of the printer engine system. Details on each

segment follow.

)LJXUH#7143 (QJLQH#V\VWHP

2SHUDWLRQ#WKHRU\

%DVLF#HQJLQH#IXQFWLRQV

)DFH0XS#6WDFN

6FDQQHU#8QLW

'LRGH

3RO\JRQ#0LUURU

)XVHU#8QLW

)DFH0GRZQ#6WDFN

/DVHU

+HDW#5ROOHU

$3&

&LUFXLW

'UXP#8QLW

0DLQ#&KDUJHU

D06L#'UXP

7UDQVIHU#5ROOHU

3DSHU#)HHG#5ROOHU

0XOWLSXUSRVH

7UD\

+RVW#&RPSXWHU

,QWHUIDFH

0DLQ#/RJLF#&RQWUROOHU

/DVHU#%HDP

'HYHORSHU#8QLW

'HYHORSHU

5ROOHU

(QJLQH#&RQWUROOHU

7RQQHU

&RQWDLQHU

3DSHU#)HHG#8QLW

%*50B%$61&'5

3DSHU#&DVVHWWH

4-20

)609<33

Page 21

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

718 (QJLQH#FRQWUROOHU#V\VWHP

The engine controller provides control over all print engine activities. It drives laser, coordinates

the electrophotography process with print data from the main logic con-troller. The engine system also manages information collected back from sensors, etc., so that a message is given in

case of need for user attention.

The engine controller is responsible for the following systems, explained step by step in the following sections.

)ODVK#PHPRU\

The engine controller uses a flash memory to store environmental parameters that does not

require a battery backup. The flash memory is driven by +5 V power and de-signed to stand

reading and writing for nominally 100,000 times.

3ULQW#GHQVLW\#FRQWURO

The print density is adjusted by means of changing the clock frequency of the developer bias

system. The density is higher when the clock frequency is high; the density is lower when the

clock frequency is low.

+LJK0YROWDJH#JHQHUDWRU

Two main clocks of HVCLK1 and HVCLK2 are program-divided to g enerat e the oscillator output. This is up-verted using a transformer in the high-voltage circuit. The divisor frequency is

determined by the 8-bit register. The oscillation is toggled by the engine CPU.

/DVHU#VFDQQHU#FRQWURO

In order to activate the laser scanner, the engine controller does the following tasks:

Forced laser activation timing

•

Laser diode current limit

•

Laser power control output

•

Beam detection photo-sensor output

•

Polygon motor activation

•

Polygon motor readiness detection

•

3RO\JRQ#PRWRU#FRQWURO

The output frequency signal to the polygon motor is generated by the engine gate ar-ray as it

divides the engine system clock (16 MHz). The polygon motor is of 26,596 rpm and the frequency is 2659.57 Hz.

)609<33

As the laser beam reaches the beam detector sensor, the sensor board generates the horizontal

synchro signal (PD*). This signal makes the engine gate array consequently turn the video output signal (VDO*) and the APC signal (LONB*) high which respectively activate the laser light

and the APC controller.

The engine CPU attempts to detect the horizontal synchronization signal so that the laser diode

is normally trigger ed. If the horizo ntal sync hronizatio n output is not found af ter the laser dr iving

4-21

Page 22

current control (LENB*) is set low, the engine CPU recognizes it as the failure on the APC

board and gives the E3 error.

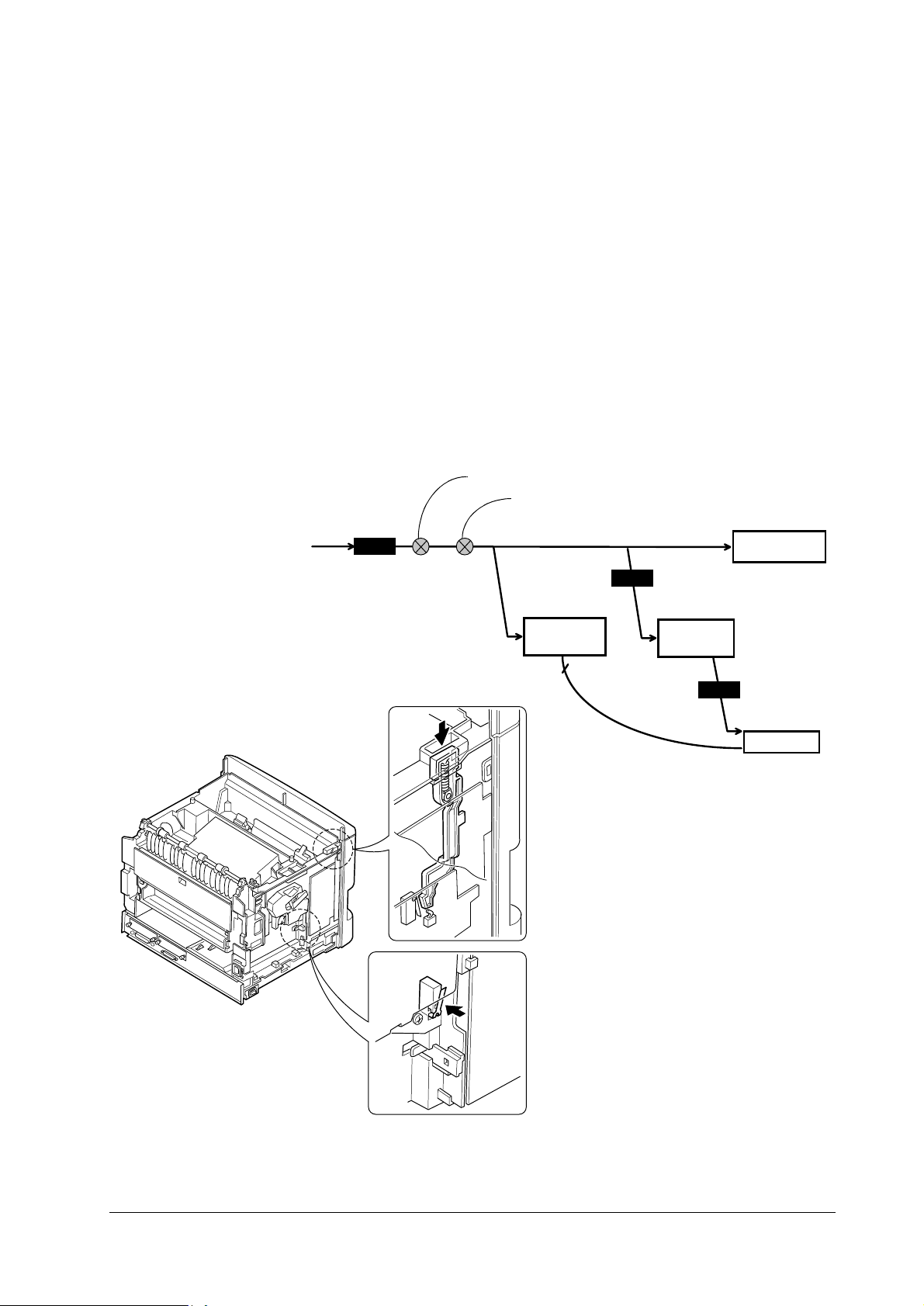

6DIHW\#LQWHUORFN

For safety purpose, micro switches are provid ed to sense that either the top (t oner access) or sid e

(drum access) cover is open. These switches, when the applicable cover is open, open and disconnect the DC power to the laser scanner as follows.

The laser emission is deactivated when either cover is open in the following system.

The interlock power su pply of +5 V i s g enerated by downv erting the +2 4 V DC power u sing the

3-terminal regulator. The +5 V DC is used as the power supply for the scanner APC circuit that

is cut out when either cover is open. At the same time as the cover is open, the control signal

output for the scanner unit, that is derived from the engine gate array, is set to the high-impedance state.

)LJXUH#7144 ,QWHUORFN#V\VWHP

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

7RS #FRYHU#VZLWFK

/HIW#FRYHU#VZLWFK

.579'&

(QJLQH

J2D

9

7RS #FRYHU#VZLWFK

/HIW#FRYHU#VZLWFK

.579'&

60WHUP1

UHJXODW1

.89'&

3RO\JRQ#PRW1

$3&

4-22

)609<33

Page 23

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

7KH#HQJLQH#JDWH#DUUD\

The engine gate array is a supplementary device to the Engine CPU. The gate array is a CMOS

type, 4100-gate, 100-pin QFP that has the following internal blocks.

Address decoder

•

Registers

•

Interrupt handler

•

Ports A to F

•

Data selector

•

Overrun detector

•

Port mode controller

•

Kyocera I/O controller

•

Print density controller

•

Laser power controller

•

Decoder g/a flash

•

High-voltage clock genera tor

•

Test-print controller

•

Engine CPU address-hold controller

•

Interlock controller

•

3LQ#DVVLJQPHQW

Pin assignment for the engine gate array is ta ble on the followin g pages. The dev ice in Remarks

column means those which the signal is forwarded to.

7DE O H#71#6## J2D#SLQ#DVVLJQPHQW³426

3LQ#QR1 6LJQDO J2D#VLJQDO ,Q22XW )XQFWLRQ /RJLF 5HPDUNV

1 THVDR1* THVDR OUT Transfer charger voltage 1 Neg. HV board

2 CHVON* REVBN OUT Transfer bias control output, L: On Neg. HV board

3 VDD VDD Power terminal (+5 V)

4 VSS VSS Power terminal (Ground)

5 MHVDR* MHVDR OUT Main charger control output, L: On Neg. HV board

6 B IAS* BIAS OUT Bias DC volt age control output, L: 100 V , H:

100 V

7 E RASE* ERAS EN OUT Eraser control output, L: O n Neg. Eraser

8 FDNSD* PC3 OUT Face-down solenoid control output, L: On Neg. FU/D solenoid

9 FAN * PC2 OUT Fan motor c ont rol out put , L: On Pos. Fan (Body, C-

10 EXITJ* PA1 IN Fuser sensor input, H: No paper Neg. Fuser

11 WTONR* PA0 IN Wast e toner bottle full detection, L: ful l Neg. 12 OPSEL2 PB5 OUT Option uni t selec t code 2 Neg. Option unit

13 THVDR2* PD4 OUT Transfer charger voltage control output 2 Neg. HV board

14 FEEDS* PA2 IN Registration sensor input, L: No paper - 15 VSS VSS Power terminal (Ground)

16 PAPER* PA4 IN Cassette paper detection, L: Empty

Neg. HV board

box)

)609<33

4-23

Page 24

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

7DE O H#71#6## J2D#SLQ#DVVLJQPHQW³526

3LQ#QR1 6LJQDO J2D#VLJQDO ,Q22XW )XQFWLRQ /RJLF 5HPDUNV

17 HANDS* PA3 IN Multi paper feed slot paper detection, L: Paper Neg. MP unit

18 TNCON* PB1 I N Waste toner reservoir dete c ti on, L: Insta lled Neg. 19 OPSEL1 PB4 OUT Option unit select code 1 Neg. O ption unit

20 OPSEL0 PB3 OUT Option unit select code 0 Neg. O ption unit

21 RDY* PB2 OUT Print ready output, L: Ready - 22 PHEAT PC5 OUT Not used Pos. 23 FUPSD* PC4 OUT Face-up solen oid contro l output, L: On Neg. FU/D solenoid

24 SPVDR1* PD1 OUT Reve rse bi a s control out put , L: On Neg. HV board

25 SPVDR2* PD0 OUT Re ve rse bi as current control output Neg. HV board

26 TEST1 TEST1 IN G/A test input 1, H: Test mode Jumper

27 TEST0 TESTN IN G/A test mode, L: Test mode Fixed high

28 VDD VDD Power terminal (+5 V)

29 VSS VSS Power terminal (Ground)

30 TESTCLK TSTCLK IN G/A test clock Fixed low

31 ILOCK PB0 IN Interlock input, L: Interlock on Pos. 32 ERRDY* PA5 I N Eraser blow-out det., L: Blown E ra ser

33 THSBY PD5 OUT Fuser heater control, L: Print; H: Idle Fuser

34 FRMCE* FCS* OUT Flash ROM chip select Neg. Flash ROM

35 MPFSOL* PC1 OUT Multi paper feed solenoid control, L: On Neg. MP unit

36 FEDDR* PC0 OUT Paper pickup roller clutch control, L: On Neg. Clutch

37 REGDR* PD7 OUT Regist. roller clutch control, L: Off Pos. Clutch

38 SCCLK SCCLK OUT Polygon motor clock Pos. Scanner

39 PDIN PDIN IN Beam de te c t Neg. Scanner

40 VSS VSS Power terminal (Ground)

41 NON LATCH OUT Not used Pos. 42 NON DSCLK OUT Not used Pos. 43 NON SDATA OUT Not used Pos. 44 VDOUT VDOUT OUT Video data Neg. Scanner

45 LASER PC7 OUT Laser diode drive control Pos. Scanner

46 LONB* LONB OUT APC control, L: Sampling Neg. Scanner

47 SCANR* PC6 OUT Polygon motor contro l, L: O n Neg. Sc anner

48 SCRDY* PA7 IN Polygon motor ready, L: Ready Neg. Scanner

49 MOTOR* PD3 OUT M a in mot or c ontrol, L: On Neg. Main motor

50 EGIR* PF0 OUT System error interrupt, L: interrupted Pos. 51 X1 CKO0 OUT Clock (Engine CPU)

52 X2 CKO1 OUT Clock (Engine CPU)

53 VDD VDD Power terminal (+5 V)

54 VSS VSS Power terminal (Ground terminal)

55 CLCK* CLCKN IN G/A test clock clear, L: Clearing Fixed high

56 XTO XTO IN Oscillator (16.9344 [MHz])

57 XTI XTI IN Oscillator (16.9344 [MHz])

58 GAINT INTO OUT Engine error interrupt, H: interrupted Pos. 59 RESET* RST N IN Power on re set Neg.

60 ASTB ASTB IN Engine CPU ASTB

61 WR* WRN IN Engine CPU WR* Neg.

62 RD* RDN IN Engine CPURD* Neg.

4-24

)609<33

Page 25

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

7DE O H#71#6## J2D#SLQ#DVVLJQPHQW³626

3LQ#QR1 6LJQDO J2D#VLJQDO ,Q22XW )XQFWLRQ /RJLF 5HPDUNV

63 A16 A 16 IN Engine CPU address

64 A15 EA15 IN Engine CPU address

65 VSS VSS Power terminal (Ground)

66 A14 EA14 IN Engine CPU address

67 A13 EA13 IN Engine CPU address

68 A12 EA12 IN Engine CPU address

69 AD7 AD7 IN/OUT Engine CPU address/data bus

70 AD6 AD6 IN/OUT Engine CPU address/data bus

71 AD5 AD5 IN/OUT Engine CPU address/data bus

72 AD4 AD4 IN/OUT Engine CPU address/data bus

73 AD3 AD3 IN/OUT Engine CPU address/data bus

74 AD2 AD2 IN/OUT Engine CPU address/data bus

75 AD1 AD1 IN/OUT Engine CPU address/data bus

76 AD0 AD0 IN/OUT Engine CPU address/data bus

77 EA7 EA7 OUT Engine CPU address ROM address

78 VDD VDD Power terminal (+5 V)

79 VSS VSS Power terminal (Ground)

80 EA6 EA6 OUT Engine CPU address ROM address

81 EA5 EA5 OUT Engine CPU address ROM address

82 EA4 EA4 OUT Engine CPU address ROM address

83 EA3 EA3 OUT Engine CPU address ROM address

84 EA2 EA2 OUT Engine CPU address ROM address

85 EA1 EA1 OUT Engine CPU address ROM address

86 EA0 EA0 OUT Engine CPU address ROM address

87 MPLSOL* PD2 IN Multi paper feed clutch control, L: On Neg. MP unit

88 HEATT PD6 OUT Fuser heater control, H: On Fuser

89 VIDEO VDOIN IN Video data Neg. Scanner

90 VSS VSS Power terminal (Ground)

91 PDOUT* PDOUT* OUT Beam detect sensing Neg. Main log. board

92 S/C SC IN/OUT Main I/F status command M ain I/F

93 SCLK SCLK IN Main I/F status command clock Main I/F

94 CBSY* CBSYN IN Main commands in transmission Neg. Main I/F

95 SBSY* SBSYN OUT Engine status in transmission Neg. Main I/F

96 CINH* CINHN OUT Engine busy Neg. Main I/F

97 HVCLK1 HVCK1 OUT HV unit clock 1 HV board

98 HVCLK2 HVCK2 OUT HV unit clock 2 HV board

99 TONER PA6 IN Remaining toner sensing , L: Empty HV board

100 PSEL HVOL OUT Transfer bias (Thick/normal paper) HV board

)609<33

4-25

Page 26

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

3RZHU#VXSSO\

The power supply contains the AC and DC power and distribution circuitry on the board. The

high voltage generator is not included on this board but on the separate high-voltage board.

The power supply circuit is diagrammed on page 4-27, Figure 4.12.

$&#LQSXW#DQG#UHFWLILHU

line filter circuit (L4, L5, C3, etc.) and rectified by diode array BD1 to DC power. Transistor Q1

performs switching of the DC power output for downverting it to the 24 V and 5 V AC voltage

by means of transformer T1.

57#9#'&#SRZHU#OLQH

C18 and delivered to connectors CN5 for distribution. The 24 V DC power is referred to as

VDD or VDDCOM and is used by the following components in the en-gine system:

Face-up/down stack solenoids

•

Clutches (registration, feed, manual-feed)

•

Eraser

•

Fans

•

High-voltage generator (board)

•

Main motor and laser polygon motor

•

Clutches, motors, solenoids within the option units

•

The 24 V DC power is forcibly interrupted for safety whenever the printer top cover or the drum

unit access door is opened. For details, see page 4-22,

8#9#'&#SRZHU#OLQH

etc., like as for the 24 V DC power line. It also delivered to CN3 and CN4. The 5 V DC power

is referred to as VCC and is comprehensivel y used by t he mai n control-ler, sensors, engine controller, etc.

—Either 120 V or 230 V AC power arriving at CN1 is fed to the AC

—The 24 V AC at the secondary output of T1 is rectified by D1 and C13/

6DIHW\#LQWHUORFN

—The 5 V AC at the secondary output of T1 is rectified by D2 and C14/1 5,

.

3RZHU#SURWHFWLRQ#FLUFWXLW

tection circuit is provided to avoid damaging the circui t.

)XVHU#KHDWHU#SRZHU#FRQWURO

across CN2. The heater is switched on and off as being controlled by TRIAC TRC1. TR C1 turns

on the heater when HEATCOM (pin 8) at CN3 is energized by command from the engine controller.

—In case of short-circuiting in the 5 V or 24 V DC load side , a pro-

—On the AC primary side, the fuser heater is wired in series

4-26

)609<33

Page 27

2SHUDWLRQ#WKHRU\

(QJLQH#FRQWUROOHU#V\VWHP

)LJXUH#7145 3RZHU#VXSSO\#FLUFXLW#GLDJUDP

)609<33

4-27

Page 28

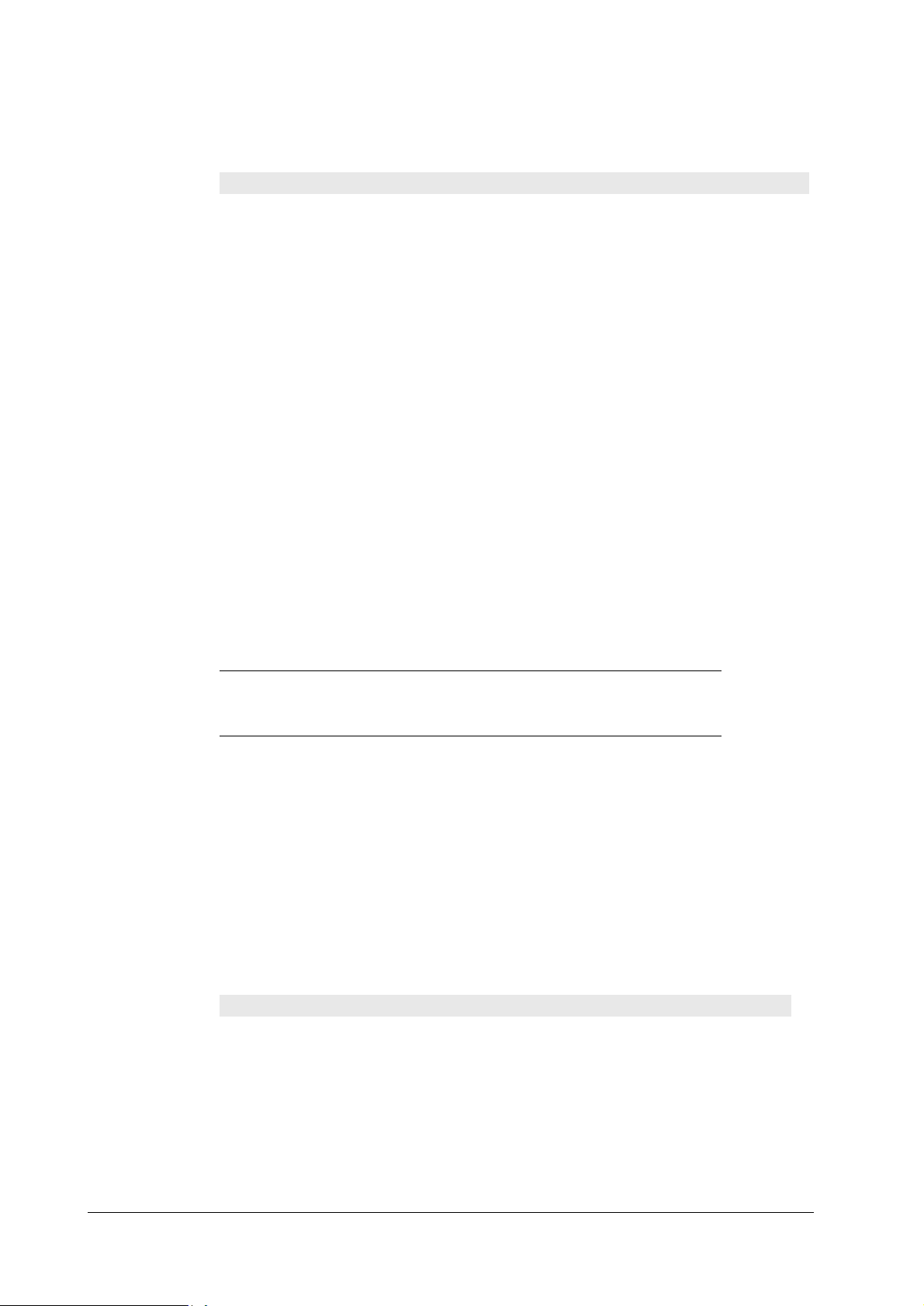

719 /RJLF#FRQWUROOHU#V\VWHP

The logic controller system does the following:

Communicates with the host computer to receive data at one of the printer’s in-terface

•

Analyzes and translates the print data to be the dot data in the raster memory

•

Communicates with the engine system to discern radiness for printing

•

Stores fonts and macro information

•

The main logic controller has specifications as shown in the following section. A simplified diagram is shown on page 4-29, Figure 4.13.

7DE O H#71#7## 0DLQ#FRQWUROOHU#VSHFLILFDWLRQV

,WHP 6SHFLILFDWLRQ

CPU PowerPC603e-100MHz

System ROM size 4 MB (16 Mbit × 2)

RAM size Standard 16 MB SIMM

Max. 64 MB (2 PC SIMM slots)

Fonts Resident 4 MB (32 Mbit × 1)

Socket 2 MB [PK-5 (Option)]

API ROM 512 kB

Memory card 1 slot/JEIDA 4.2 or PCMCIA 2.0

Interface Parallel High-speed bi - directional [IEEE 12 8 4]

Serial RS-232C/RS-422A

Option 2 slots

Engine communic at ion mode Serial interface

Front panel com . m ode Serial interface

Others Sm oothing KIR (Vector compensation)

Toner savor EcoPrint [On/Off]

Reduction Main and sub scan

Video clock 26.2186 MHz

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

4-28

)609<33

Page 29

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

)LJXUH#7146 0DLQ#FRQWUROOHU#EORFN#GLDJUDP

1998.12.25

YC1

IOA2-16,21

Option I/F

(OPT2/HDD)

Option I/F

(OPT1)

YC2

IOA2-16,21

LD0-15

OP1CSN CTLRDY1 OP1DACKN LIORN1 LIOWN1

OP1ACKN OP1IRN OP1DREQ

LD0-15

FLASH ROM/MASK ROM

(1M*16)*2

DIMM

Code

ROM

YS1

LDO

LS373x3

OP2CSN CTLRDY2 OP2DACKN LIORN2 LIOWN2

OP2ACKN OP2IRN OP2DREQ

U4-6

IOA5-22

IOA2-24

A2-24

Address

D0-31

Data

LD0-15

EDEVALTN

ABBN

YC3

U7 U8J U9E

(FONT:4MB, Option:2MB, API:512K)

MASK ROM/EPROM

BICA1

LS367x4

U12-15

X1

X’tal(Video)

IOCA1

IOA2-24 BICA2-24

IOA2-21

LD0-15

FA0

D32CSN00-01,D32OEN0,D32WEN0

D32A02-04

FONTOEN1-3

DPPBCLK(33.33MHz)

CARD

LS245x2

U16,17

X2

TBM(System)

26.2186MHz

DD0-31

DRAM

U10-11

BICD0-15

LD0-15

OE

(1M*16)*2

CARDDET1,2

YC6

CPRDY PRINTN VSYNCN VDATA

RDYN OUTPEN VSREQN PDOUTN

CARDCEHN CARDCELN CARDOEN CARDWEN

CARDREGN CARDRSTN

CARDRDY CARDWP BVD1,2

66.6667MHz

YS2

SIMM

SLOT2

RESETN

OE

YS3

4,8,16,32MB

Engine I/F

FPDIR FPCLK

FPDATA

SC

ESIGIR SBSYN CINHN

CBSYN SCLK

OE

16MB

SIMM

SLOT1

(4,8,16,32MB)

RESETN

U25

HCT08

3.3V

REGULATOR

U24

3.3V

CPUBCLK(33.33MHz)

RESETN

CPUABBN

A0-29D0-31

TT1 TT3 TSIZ0-2 TBSTN DBBN

AACKN TAN TEAN

CARDDET1,2

APPBCLK(33.33MHz)

A0-29

CPU

U1

PPC603e-100MHz

AACKN

TAN

TEAN

INTN

LD0-15 D0-31 A20-29

LV161284

U18,21

ACT1284

FS-6900 Controller Block Diagram

Parallel I/F

BUSY ACK PERROR

FAULT SELECT etc

STB SELECTI

INIT AUTOFD etc

YC4

CPULBGN CYCCODE0-2 DMAREADN

DPPTAN LOADN BNDEWN

APP+ DPP+

U2 U3

CEND0-7

U20 HC221

Data1-8

MBCG46533 uPD82280

RSSEL

456

CDIR COEN

MRASN0

CAS

DRWEN0

U22

Serial I/F

TXD RTS DTR

YC5

MRA0-10

MC145407

RXD

CTS DSR

8

7

123

ORASUN3

ORASLN3

9

RDA

U23

MAX488

RDB

SDA SDB

ORASUN4

ORASLN4

RESETN

ORA0-10

DRWEN1

LDO

DBTXD

DBRXD

DBCLK

Debugger

YC7

OUTPEN VSREQN

:No mounted

)609<33

4-29

Page 30

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

3ULQWLQJ#GDWD#SURFHVVLQJ

The printer communicates with the host computer for receiving the print data at one of the

printer’s interfaces and temporarily store them in the interface buf fer. The main logic controller

analyzes the data for translating them into the dot data ac-cording to the original print image.

The resultant dot data are depicted in the raster memory (DRAM’s).

While data processing is in course, on the other hand, the main logic controller CPU talks to the

engine CPU via the engine interface, to discern the readiness of the printer’s engine for printing.

If the engine is ready to start printing, the main controller issues print signal to-wards the engine

controller which request the paper feed. In synchronization with the procerssion of the paper

within the printer, video data in the raster memory is released. Thus the video data are transfered

to the laser scanner together with the horizontal synchronization signal and the video clock.

On reception of the video data, the laser diode turns on and off to constitutes the print image

over the drum. The image on the drum, referred to as the static latent image, is applied with

toner, transferred onto the paper, and finally fused perma-nently on the paper by means of heat

and pressure.

6\VWHP#520

The system DIMM (YS1) accommodates system codes. The DIMM mounts two flash ROMs.

For firmware upgrade, the system DIMM is detachable for easy replacement.

7DE O H#71#8## 6\VWHP#520

Socket No. YS1

Pins 72 (DIMM)

Size 4 Mbyte

Composition 16 Mbit × 2

Access speed <100 ns

0DLQ#5$0

The RAM temporarily stores print data and font information transferred from the host buffers.

The standard RAM size is 4 MB. The size of the RAM is expandable using comprehensive PC

SIMMs.

7DE O H#71#9## 0DLQ#5$0

Number of RAMs 2

Socket Nos. U10, U11

Number of pins 42, SOJ

Size 4 MB

Composition 2 MB (1 MB × 16 bits × 2)

Access speed <80 ns

4-30

)609<33

Page 31

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

The expansion SIMM should incorporate the following features:

7DE O H#71#:## ([SDQVLRQ#6,00

Number of SIMM sockets

Socket Nos. YS2

Number of pins 72

Size 4/8/16/32 MB

Access speed <80 ns

1

0HPRU\#FDUG#VORW#LQWHUIDFH

The controller accepts a SRAM or flash type memory card that comforms to the PCMCIA (version 2.1) or JEIDA 4.2 standards.

2SWLRQ#LQWHUIDFH

The printer has two open slots for installing an optional interface card (such as a se-rial interface

card or an Ethernet network interface card) and/or a harddisk drive. This interface utilizes DMA

data transfer for optimum performance.

&DXWLRQ 7KH#KDUGGLVN#GULYH#PXVW#EH#LQVWDOOHG#LQWR#WKH#OHIW0KDQG#VLGH#VORW#

+ZKLFK#LV#FORVHU#WR#WKH#SDUDOOHO#LQWHUIDFH,1#

The option interface has the following features:

7DE O H#71#;## 2SWLRQ#LQWHUIDFH

Card connector 60

Applicable interface card SEH EcoLAN 2000E

Applicable harddisk

drive

Kyocera HD-2 (2 GB)

The following table shows pin assignments for the option slots.

7DE O H#71#<## 2SWLRQ#LQWHUIDFH#SLQ#DVVLJQPHQW³426

3LQ#1R1 6LJQDO 'LUHFWLRQ 'HVFULSWLRQ

1 (A1) +5 V — —

2 (B1) +5 V — —

3 (A2) +5 V — —

4 (B2) NC — Reserved

5 (A3) GND — —

6 (B3) NC — Reserved

7 (A4) NC — Reserved

8 (B4) A15 In System address 15

9 (A5) GND — —

10 (B5) A14 In System address 14

11 (A6) A13 In System address 13

12 (B6) A12 In System address 12

13 (A7) A11 In System address 11

)609<33

4-31

Page 32

7DE O H#71#<## 2SWLRQ#LQWHUIDFH#SLQ#DVVLJQPHQW³526

3LQ#1R1 6LJQDO 'LUHFWLRQ 'HVFULSWLRQ

14 (B7) A10 In System address 10

15 (A8) A9 In System address 9

16 (B8) A8 In System address 8

17 (A9) GND — —

18 (B9) A7 In System address 7

19 (A10) A6 In System address 6

20 (B10) A5 In System address 5

21 (A11) A4 In System address 4

22 (B11) A3 In System address 3

23 (A12) A2 In System address 2

24 (B12) A1 In System address 1

25 (A13) GND — —

26 (B13) NC — Reserved

27 (A14) OP2IF* In Option interface select (L)

28 (B14) OP2ACK* Out Data acknowledge (L)

29 (A15) OP2IR* Out Interrupt Request (l)

30 (B15) NC — —

31 (A16) RDY In Kyocera Board Ready

32 (B16) DREQ Out DMA Request

33 (A17) GND 34 (B17) DMACK* In DMA Acknowledge (L)

35 (A18) IOR* In I/O Read Strobe (L)

36 (B18) IOW* In I/O Write Strobe (L)

37 (A19) R E S E T* In Reset (L)

38 (B19) NC 39 (A20) D15 In/Out System Data 15

40 (B20) D14 In/Out System Data 14

41 (A21) GND 42 (B21) D13 In/Out System Data 13

43 (A22) D12 In/Out System Data 12

44 (B22) D11 In/Out System Data 11

45 (A23) D10 In/Out System Data 10

46 (B23) D9 In/Out System Data 9

47 (A24) D8 In/Out System Data 8

48 (B24) D7 In/Out System Data 7

49 (A25) GND 50 (B25) D6 In/Out System Data 6

51 (A26) D5 In/Out System Data 5

52 (B26) D4 In/Out System Data 4

53 (A27) D3 In/Out System Data 3

54 (B27) D2 In/Out System Data 2

55 (A28) D1 In/Out System Data 1

56 (B28) D0 In/Out System Data 0

57 (A29) GND 58 (B29) +5 V -

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

4-32

)609<33

Page 33

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

7DE O H#71#<## 2SWLRQ#LQWHUIDFH#SLQ#DVVLJQPHQW³626

3LQ#1R1 6LJQDO 'LUHFWLRQ 'HVFULSWLRQ

59 (A30) +5 V 60 (B30) +5 V -

3DUDOOHO#LQWHUIDFH

The parallel interface supports the protocols defined by the IEEE 1284 standards. To gain conformity to these standards, the printer supports the ECP an d nibble modes.

Details on the signals on the parallel interface are described in the appropriate ap-pendix in this

manual.

6HULDO#LQWHUIDFH

The printer incorporates a port for the seri al interface. The serial interface controller is included

within the gate array and supports both the RS-232C and RS-422A protocols. Since the RS232C support is designed to be compatible with SNMP (Simple Network Management Protocol), CTS and DSR signals are included. Switching to either mode is toggled by changing a

jumper wire arrangement on the controller board. A 25-pin D-sub connector is used for the

serial port. The RS-422A extra signal lines are assigned to some of the vacant RS-232C terminals. (See Appendix A for the interface later in this manual for details.)

The serial interface has the following features:

7DE O H#71#43##6HULDO#LQWHUIDFH

Connector type 25-p in, D-sub

Baud rates/sec. 300/600/1200/2400/4800/9600/19200/38400/57600/115200

Modes RS-232C/RS-422A (switchable)

(QJLQH#LQWHUIDFH

The interface to the engine system is based on the serial interface, not the parallel in-terface that

was used with the previous line-up of the Ecosys printers. The serial-to-parallel conversion is

executed on a hardware basis.

The engine board is detachable from the printer at its interface connector. The engine interface

connector has the following pin assisngments:

Engine interface connector assignment is as follows (“*” means negative-logic.):

7DE O H#71#44##(QJLQH#LQWHUIDFH#FRQQHFWRU#DVVLJQPHQW³425

3LQ#1R1 7HUPL Q DO 6LJQDO 3LQ#1R1 7H U P L Q D O 6LJQDO

A1 GND GND B1 GND GND

A2 VCC VC C B2 VCC VCC

A3 VCC VC C B3 VCC VCC

A4 RPORT EGIR* B4 D/CZ NC (Reserved)

A5 VSREQZ VSREQ* B5 SBSYZ SBSY*

A6 CBSYZ CBSY* B6 SCLK SCLK

A7 S/CZ SC B7 CPRDY CPRDY

A8 RDYZ RDY* B8 CINHZ CINH*

)609<33

4-33

Page 34

7DE O H#71#44##(QJLQH#LQWHUIDFH#FRQQHFWRU#DVVLJQPHQW³525

3LQ#1R1 7HUPL Q DO 6LJQDO 3LQ#1R1 7HUP LQ D O 6LJQDO

A9 RXD NC (Reserved) B9 VCC VCC

A10 TXD NC (Reserved) B10 FRM/BYZ NC (Reserved)

A11 FPDATA FPDAT B11 VSYNCZ VSYNC*

A12 PRINTZ PRINT* B12 PDZ PDOUT*

A13 RESETZ RST* B13 FPSCLK FPCK

A14 LEN OUTPE* B14 VDO VIDEO

A15 GND GND B15 FPDRC FPDR

A16 GND GND B16 GND GND

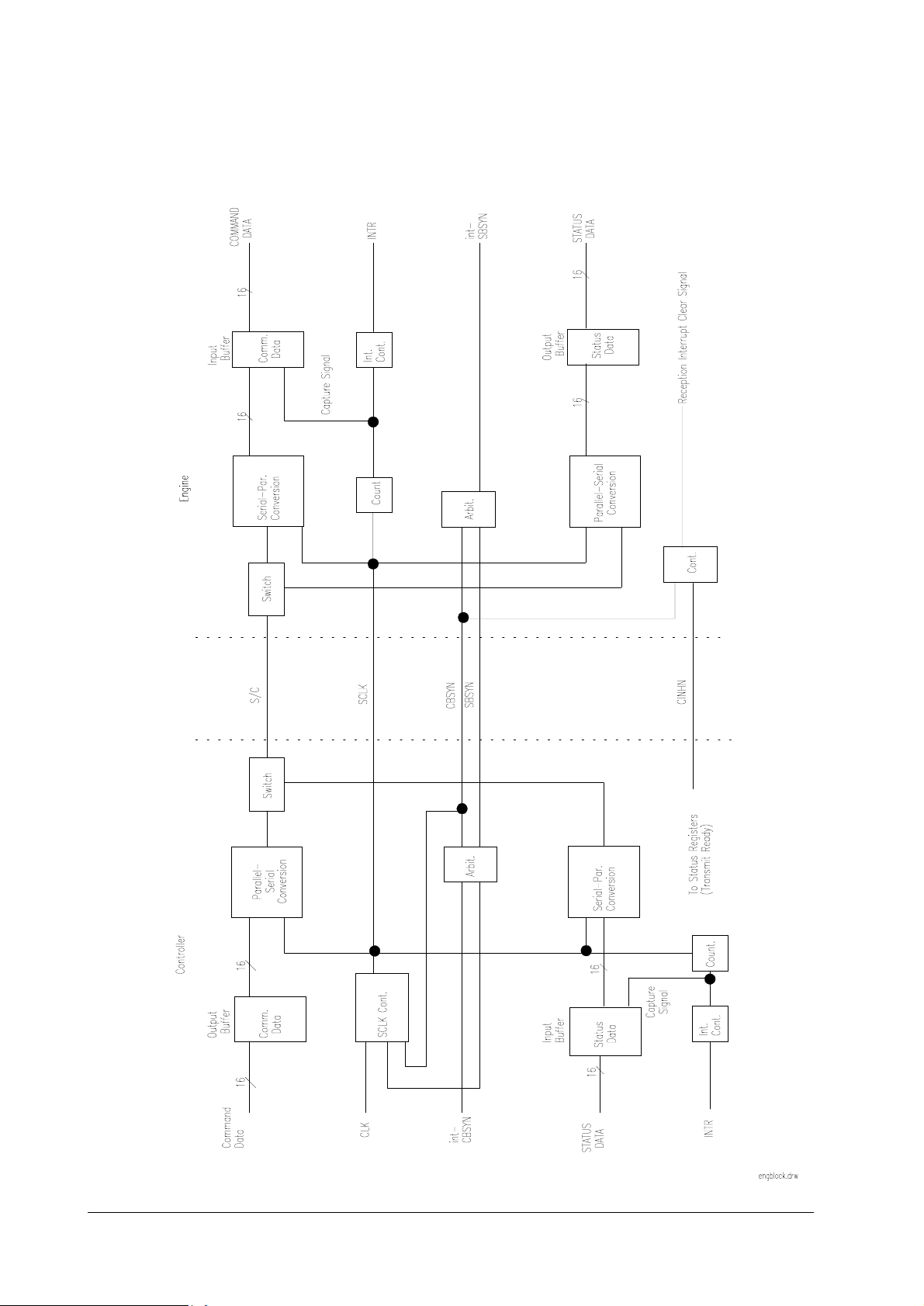

6LJQDOV#XVHG#IRU#WKH#HQJLQH#LQWHUIDFH

The following signals are used for the engine interface communication. Figure on next page

shows a simplified function diagram of the engine interface and the signals.

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

7DE O H#71#45##(QJLQH#LQWHUIDFH#VLJQDOV

6LJQDO 0HDQLQJ $FWLYH 'HILQLWLRQ

SBSYN Status-BuSY-

sigNal

CBSYN Command-

BuSY-sigNal

S/C Status-data/

Command-data

SCLK Serial CLocK - Th e wi dth of the clock pulse is approx. 1µsec (960 ns). SCLK

CINHN Command IN-

Hibit sigNal

Low Determines which direction for the engine system to tra nsfer

the status data. If SBSYN is true, the controller is unable to

transfer the co mmand da ta to ward s th e engi ne s yste m. Th e con troller can read in the status data transferred from the engine

system by forwading SCLK to the engine.

Low Determines which direction for the controller system to transfer

the command data. If CBSYN is true, the co ntrolle r can transfer

the command data towards the en gine system by forwading

SCLK to the engine system

- This is a bi-directional seria l da tum containing the stat us da ta

and command data as well as attributive information. The transfer data commences wit h LSB, then to MSB.

is the clock delivered by the controller and used to synchro-nize

the status data and command data with each other.

Low This signal inhibits the signal transmission. If CINHN is low,

the controller is not allowed to ready the transmission data.

This inhibit is cancelled when the engine controller reads in the

reception data.

4-34

)609<33

Page 35

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

(QJLQH#LQWHUIDFH#EORFN#GLDJUDP

)609<33

4-35

Page 36

This page left blank intentionally

2SHUDWLRQ#WKHRU\

/RJLF#FRQWUROOHU#V\VWHP

4-36

)609<33

Loading...

Loading...