Page 1

SERVICE

MANUAL

Published in Oct. ’02

Page 2

Revision history

Version Data Replaced pages Remarks

1.0

1.1

1.2

8-Oct-2002

17-Feb-2003

10-Mar-2003

1-1-3

1-7-1, 1-7-2, 1-7-4

-

-

Page 3

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

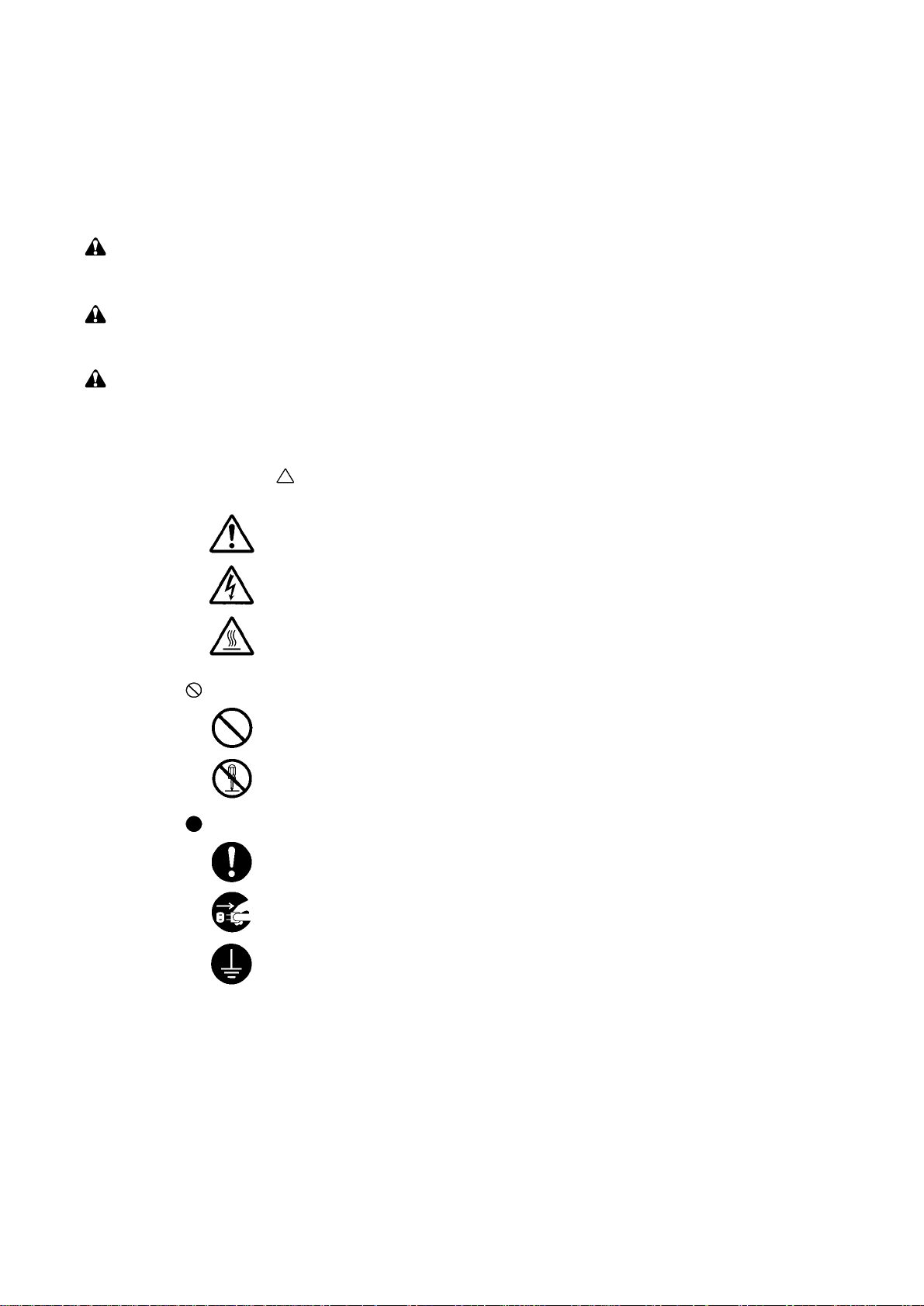

Page 4

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 5

1. Installation Precautions

WARNING

•Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

•Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

•Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

•Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

•Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

•Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

•Always handle the machine by the correct locations when moving it. ..............................................

•Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

•Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

•Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

Page 6

2. Precautions for Maintenance

WARNING

•Always remove the power plug from the wall outlet before starting machine disassembly...............

•Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

•Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

•Always use parts having the correct specifications...........................................................................

•Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

•When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

•Always check that the copier is correctly connected to an outlet with a ground connection. ............

•Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

•Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight...............................................................................................................................

•Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly..................................................................................................

CAUTION

•Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

•Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

•Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

•Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

•Do not remove the ozone filter, if any, from the copier except for routine replacement....................

Page 7

•Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

•Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

•Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

•Remove toner completely from electronic components. ...................................................................

•Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

•After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

•Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

•Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

•Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

•Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

•Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas.................................................................................

Page 8

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Parts names ......................................................................................................................................... 1-1-4

(1) Printer............................................................................................................................................. 1-1-4

(2) Operation panel.............................................................................................................................. 1-1-5

1-1-3 Machine cross section.......................................................................................................................... 1-1-6

1-1-4 Drive system ........................................................................................................................................ 1-1-7

(1) Drive system................................................................................................................................... 1-1-7

1-2 Handling Precautions

1-2-1 Process unit ......................................................................................................................................... 1-2-1

1-2-2 Toner container .................................................................................................................................... 1-2-1

1-2-3 Installation environment ....................................................................................................................... 1-2-1

1-3 Installation

1-3-1 Unpacking and installation ................................................................................................................... 1-3-1

(1) Installation procedure ..................................................................................................................... 1-3-1

1-3-2 Installing expansion memory (optional)................................................................................................ 1-3-8

1-3-3 Installing network interface card (optional)........................................................................................... 1-3-9

1-3-4 Installing hard disk unit (optional)....................................................................................................... 1-3-10

1-3-5 Installing memory card (optional) ....................................................................................................... 1-3-11

FS-6020

1-4 Service Mode

1-4-1 Service mode ....................................................................................................................................... 1-4-1

(1) Executing service mode ................................................................................................................. 1-4-1

1-5 Troubleshooting

1-5-1 Paper misfeed detection ...................................................................................................................... 1-5-1

(1) Paper misfeed indication ................................................................................................................ 1-5-1

1-5-2 Self-diagnosis....................................................................................................................................... 1-5-2

(1) Self-diagnostic function .................................................................................................................. 1-5-2

(1-1) Error code 2000 [E1] (main motor error) ............................................................................... 1-5-3

(1-2) Error code 4000 [E2] (polygon motor error)........................................................................... 1-5-4

(1-3) Error code 4200 [E3] (laser output error)............................................................................... 1-5-5

(1-4) Error code 6000 [E4] (fixing heater lamp/fixing thermistor error)........................................... 1-5-6

(1-5) Error code 6020 [A2] (abnormally high fixing temperature error) .......................................... 1-5-7

(1-6) Error code 6400 [A0] (fixing heater lamp control zero-cross signal detection error) ............. 1-5-8

(1-7) Error code F0 [F0]

(communication error between the operation panel PWB and main PWB)........................... 1-5-8

(1-8) Error code F010 [F1] (code ROM checksum error)............................................................... 1-5-9

(1-9) Error code F020 [F2] (main PWB RAM checksum error) .................................................... 1-5-10

(1-10) Error code F030 [F3] (main PWB controller error)............................................................... 1-5-11

(1-11) Error code F040 [E0]

(communication error between engine/high voltage PWB and main PWB controller)......... 1-5-11

(1-12) Error code F050 [E6] (engine/high-voltage flash memory checksum error)........................ 1-5-12

(1-13) Error code F080 [E6] (system firmware download error)..................................................... 1-5-12

(1-14) Error code 0420 [C0]

(serial communication error between paper feeder and engine/high voltage PWB) ........... 1-5-13

(1-15) Error code 1210 [C2] (duplexer slide guide home position detection error) ........................ 1-5-15

(1-16) Error code 2610 [B2] (paper feeder 1 feed motor error)...................................................... 1-5-16

(1-17) Error code 2620 [B3] (paper feeder 2 feed motor error)...................................................... 1-5-16

(1-18) Error code 2630 [B4] (paper feeder 3 feed motor error)...................................................... 1-5-16

(1-19) Error code 2640 [B5] (paper feeder 4 feed motor error)...................................................... 1-5-16

1-1-1

Page 9

FS-6020

1-5-3 Electrical problems ............................................................................................................................. 1-5-17

(1) Even if the top cover is closed, the message “Close top cover” remains.............................. 1-5-17

(2) Even if the rear cover is closed, the message “Close rear cover” remains.......................... 1-5-17

(3) The message “Paper Jam” remains. .......................................................................................... 1-5-17

(4) The message “Face-down tray paper full” remains. ........................................................ 1-5-17

(5) The paper size is not recognized as the size set with the paper size dial of the cassette............ 1-5-18

(6) The message “Self test” remains when the printer is started................................................. 1-5-18

(7) No message is displayed when the power switch is turned on. (All dots of LCD are on.) ............ 1-5-18

(8) No message is displayed when the power switch is turned on. (All dots of LCD are off.) ............ 1-5-18

1-5-4 Image formation problems ................................................................................................................. 1-5-19

(1) No image appears. (entirely white) ............................................................................................... 1-5-20

(2) No image appears. (entirely black) ............................................................................................... 1-5-20

(3) Image is light as a whole. ............................................................................................................. 1-5-21

(4) Background is gray. ...................................................................................................................... 1-5-21

(5) A white line appears longitudinally. .............................................................................................. 1-5-21

(6) A black line appears longitudinally. .............................................................................................. 1-5-22

(7) A black line appears laterally. ....................................................................................................... 1-5-22

(8) One side of the print image is darker than the other. ................................................................... 1-5-22

(9) Black dots appear on the image. .................................................................................................. 1-5-23

(10) Image blurs. .................................................................................................................................. 1-5-23

(11) Image is displaced toward the rear side of paper. ........................................................................ 1-5-23

(12) Paper creases. ............................................................................................................................. 1-5-24

(13) Offset occurs. ............................................................................................................................... 1-5-24

(14) Image is partly missing. ................................................................................................................ 1-5-24

(15) Fixing is poor. ............................................................................................................................... 1-5-25

(16) Image becomes dim. .................................................................................................................... 1-5-25

(17) Image is inclined. .......................................................................................................................... 1-5-25

1-6 Assembly and Disassembly

1-6-1 Precautions for assembly and disassembly ......................................................................................... 1-6-1

(1) Precautions ..................................................................................................................................... 1-6-1

1-6-2 Covers .................................................................................................................................................. 1-6-2

(1) Detaching and refitting the top cover .............................................................................................. 1-6-2

(2) Detaching and refitting the left cover .............................................................................................. 1-6-3

(3) Detaching and refitting the right cover ............................................................................................ 1-6-4

(4) Detaching and refitting the rear cover ............................................................................................ 1-6-5

(5) Detaching and refitting the front cover ............................................................................................ 1-6-6

1-6-3 Paper feed section ............................................................................................................................... 1-6-7

(1) Detaching and refitting the feed and pickup rollers ........................................................................ 1-6-7

(2) Detaching and refitting the paper feed unit..................................................................................... 1-6-8

(3) Detaching and refitting the MP tray feed roller ............................................................................. 1-6-10

(4) Detaching and refitting the MP tray feed unit ............................................................................... 1-6-11

(5) Detaching and refitting the retard roller ........................................................................................ 1-6-13

(6) Detaching and refitting the drive assembly ................................................................................... 1-6-14

1-6-4 Laser scanner unit section ................................................................................................................. 1-6-15

(1) Detaching and refitting the laser scanner unit .............................................................................. 1-6-15

1-6-5 Process unit section ........................................................................................................................... 1-6-16

(1) Detaching and refitting the main charger unit ............................................................................... 1-6-16

1-6-6 Transfer/separation section................................................................................................................ 1-6-17

(1) Detaching and refitting the transfer roller and separation charger unit......................................... 1-6-17

1-6-7 Fixing section ..................................................................................................................................... 1-6-18

(1) Detaching and refitting the fixing unit ........................................................................................... 1-6-18

(2) Detaching and refitting the fixing heater lamp .............................................................................. 1-6-19

(3) Detaching and refitting the heat roller ........................................................................................... 1-6-21

(4) Detaching and refitting the press roller ......................................................................................... 1-6-22

(5) Detaching and refitting the fixing thermistor and separator .......................................................... 1-6-23

(6) Detaching and refitting the fixing thermostat ................................................................................ 1-6-24

1-1-2

Page 10

1-6-8 PWBs ................................................................................................................................................. 1-6-25

(1) Detaching and refitting the main PWB.......................................................................................... 1-6-25

(2) Detaching and refitting the engine/high voltage PWB .................................................................. 1-6-26

(3) Detaching and refitting the power source PWB............................................................................ 1-6-29

1-7 Firmware

1-7-1 Downloading firmware.......................................................................................................................... 1-7-1

(1) Format for the firmware files........................................................................................................... 1-7-1

(2) Downloading firmware via the parallel interface............................................................................. 1-7-2

(3) Downloading firmware using the memory card .............................................................................. 1-7-3

(4) Downloading the message data ..................................................................................................... 1-7-5

2-1 Mechanical construction

2-1-1 Paper feed/conveying section .............................................................................................................. 2-1-1

(1) Paper feed section/paper cassette................................................................................................. 2-1-1

(2) MP tray feed section....................................................................................................................... 2-1-3

(3) Conveying section .......................................................................................................................... 2-1-4

2-1-2 Process unit section ............................................................................................................................. 2-1-5

(1) Development section...................................................................................................................... 2-1-5

(2) Main charger/drum section............................................................................................................. 2-1-7

2-1-3 Laser scanner unit section ................................................................................................................... 2-1-9

(1) Laser scanner unit.......................................................................................................................... 2-1-9

2-1-4 Transfer/separation section................................................................................................................ 2-1-12

2-1-5 Cleaning section................................................................................................................................. 2-1-13

2-1-6 Fixing section ..................................................................................................................................... 2-1-15

2-1-7 Face-down eject/feedshift section ...................................................................................................... 2-1-17

FS-6020

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

(1) Main frame...................................................................................................................................... 2-2-1

(2) Process unit, laser scanner and fixing unit..................................................................................... 2-2-3

2-3 Operation of the PWBs

2-3-1 Power source PWB .............................................................................................................................. 2-3-1

2-3-2 Engine/high voltage PWB .................................................................................................................... 2-3-3

(1) Fixing heater lamp control circuit.................................................................................................... 2-3-4

(2) Fixing heater lamp lighting runaway prevention - fixing thermistor

disconnection detection circuit........................................................................................................ 2-3-5

(3) Interlock switch - eco-power circuit................................................................................................. 2-3-6

(4) Optional equipment identification circuit......................................................................................... 2-3-7

2-3-3 Main PWB .......................................................................................................................................... 2-3-11

2-4 Appendixes

Timing chart No. 1 Paper cassette feeding, two A4 size papers ................................................................. 2-4-1

Timing chart No. 2 Paper cassette feeding, two A4R size papers............................................................... 2-4-2

Timing chart No. 3 Paper cassette feeding, two A3 size papers ................................................................. 2-4-3

Timing chart No. 4 Paper cassette feeding, two B5 size papers ................................................................. 2-4-4

Timing chart No. 5 Paper cassette feeding, two B4 size papers ................................................................. 2-4-5

Timing chart No. 6 Paper cassette feeding, two letter size papers.............................................................. 2-4-6

Timing chart No. 7 Paper cassette feeding, two letter R size papers .......................................................... 2-4-7

Timing chart No. 8 Paper cassette feeding, two legal size papers .............................................................. 2-4-8

Timing chart No. 9 Paper cassette feeding, two ledger size papers............................................................ 2-4-9

Timing chart No. 10 MP tray feeding, two A4 size papers ......................................................................... 2-4-10

Timing chart No. 11 MP tray feeding, two A4R size papers ...................................................................... 2-4-11

Timing chart No. 12 MP tray feeding, two A3 size papers ......................................................................... 2-4-12

Timing chart No. 13 MP tray feeding, two B5 size papers ......................................................................... 2-4-13

Timing chart No. 14 MP tray feeding, two B4 size papers ......................................................................... 2-4-14

Timing chart No. 15 MP tray feeding, two letter R size papers.................................................................. 2-4-15

1-1-3

Page 11

FS-6020

Timing chart No. 16 MP tray feeding, two letter size papers ..................................................................... 2-4-16

Timing chart No. 17 MP tray feeding, two legal size papers...................................................................... 2-4-17

Timing chart No. 18 MP tray feeding, two ledger size papers ................................................................... 2-4-18

Timing chart No. 19 MP tray feeding, two custom size papers.................................................................. 2-4-19

Wiring diagram ............................................................................................................................................. 2-4-20

Repetitive defects gauge .............................................................................................................................. 2-4-21

1-1-4

Page 12

This page is intentionally left blank.

Page 13

FS-6020

1-1-1 Specifications

Type................................................ Desktop

Printing system .............................. Electrophotographic printing

Paper..............................................Cassette: Plain paper (60 to 90 g/m

Recycled paper (60 to 90 g/m

Thick paper (90 to 105 g/m2)

MP tray: Plain paper (60 to 90 g/m

Recycled paper (60 to 90 g/m

Thick paper (90 to 200 g/m

2

Special paper: Transparencies, labels, envelopes, postcards, tracing paper

Printing sizes.................................. A4 (297 × 420 mm)

B4 (257 × 364 mm)

A4R (210 × 297 mm)

A4 (297 × 210 mm)

B5 (257 × 182 mm)

Folio (210 × 182 mm)

Ledger (11" × 17")

Legal (8.5" × 14")

Letter-R (11" × 8.5")

Letter (11" × 8.5")

Non-standard size (148 to 297 mm × 210 to 432 mm: cassette)

Non-standard size (70 to 148 mm × 297 to 450 mm: MP tray)

Print speed .....................................Cassette (Values within [ ] are speed of printing through an optional duplexer DU-

400.)

A4: 20 pages/minutes [20 images/minutes]

A3: 11 pages/minutes [11 images/minutes]

B4: 12 pages/minutes [12 images/minutes]

A4R: 15 pages/minutes [15 images/minutes]

B5: 17 pages/minutes [17 images/minutes]

A5: 20 pages/minutes [20 images/minutes]

Ledger: 11 pages/minutes [11 images/minutes]

Legal: 13 pages/minutes [13 images/minutes]

Letter: 20 pages/minutes [20 images/minutes]

Letter-R: 16 pages/minutes [16 images/minutes]

MP tray (in cassette mode)

A4: 20 pages/minutes

A3: 11 pages/minutes

B4: 12 pages/minutes

A4R: 15 pages/minutes

B5: 17 pages/minutes

A5: 20 pages/minutes

Ledger: 11 pages/minutes

Legal: 13 pages/minutes

Letter: 20 pages/minutes

Letter-R: 16 pages/minutes

First print time ................................Standby mode: 22 seconds or less (A4) [when the EcoPower mode is on]

Sleep mode: 22 seconds or less (A4) [when the EcoPower mode is on]

Standby mode: 12 seconds or less (A4) [when the EcoPower mode is off]

Sleep mode: 22 seconds or less (A4) [when the EcoPower mode is off]

Warm-up time................................. Sleep mode: 28 seconds or less (room temperature 23 °C, 60 % RH)

Power on: 60 seconds or less (room temperature 23 °C, 60 % RH)

Paper feed system ......................... One universal type cassette, and one MP tray

Paper loading capacity................... Cassette: 250 sheets (75 g/m

MP tray: 100 sheets (75 g/m

Duplexer: No stack

Paper eject system.........................Face down; 250 sheets (75 g/m

Photoconductor .............................. OPC drum (diameter 30 mm)

Charging system ............................ Scorotron (positive charging)

Exposure light source.....................Semiconductor laser

Developing system......................... One-component dry developing (reverse developing)

Developer: One-component magnetic toner

Toner replenishing: Automatic from the toner container

2

)

2

)

2

)

2

)

)

2

, 0.1 µm)

2

, 0.1 µm)

2

, 0.1 µm) equipped with face-down paper full sensor

1-1-1

Page 14

FS-6020

Transfer system.............................. Roller transfer (negative charging)

Separation system .........................Small radius curvature separation and separation charger brush (positive charging)

Fixing system ................................. Heat roller system

Charge erasing system .................. Exposure by eraser lamp (LED)

Cleaning system.............................Counter blade

Controller hardware........................CPU: Power PC405 (200 MHz)

Code ROM: 4 MB (32 Mbit × 2)

Font ROM: 4 MB (32 Mbit × 1)

Main RAM: 16 MB in standard configuration (on-board); can be expanded to 144 MB

(standard 16 MB + 128 MB) at the maximum by adding optional expansion memory

Optional expansion RAM: 1 slot

100-pin DIMM (16, 32, 64 or 128 MB)

Interface ......................................... Parallel: High-speed (bi-directional), IEEE 1284 Nibble/ECP mode

USB: Full-Speed USB2.0

Serial (optional): RS-232C, maximum speed 115.2 Kbps

Serial interface board IB-11 must be installed.

Network (optional): 10 Base-TX/100 Base-TX/10 Base-2

Network interface card: IB-21 (10 Base-TX/100 Base-TX/10 Base-2)

Network interface card IB-21E (10 Base-TX/100 Base-TX)

Wireless LAN card IB-22 must be installed.

Controller software ......................... a) Emulation

(1) Standard

Line Printer

IBM Proprinter X24E

Epson LQ-850

KCGL

Diablo 630

PCL6 (PCL5e + PCLXL protocol class 2.0)

(2) Option

Japanese KPDL3 (PostScript 3 compatible) UG-13

b) Fonts:

(1) Western fonts

Bitmap fonts: 1 Line Printer bitmap fonts

Outline fonts: 80 outline fonts

79 bitmap emulate downloadable font: Kyocera Mita format/HP format

c) Graphic:

(1) Raster graphic:

75, 100, 150, *200, 300, 600* dpi

(*200 dpi is supported when the resolution is 600 dpi.)

(2) V ector graphic:

Line, Box, Circle, Arc, Fill pattern etc.

(3) Bar code:

One-dimensional bar code: 45 types

Two-dimensional bar code: 1 type (PDF-417)

(4) Text:

TEXT, RTXT etc.

(5) Others:

Macro, JOBx, Device setting etc.

d) Connectivity

plug & play, Windows 95/98/ME/NT4.0/2000/XP

SNMP (KM-NET viewer)

Smoothing ...................................... KIR: equivalent to 2400 dpi, two levels by On and Off

(Available only in 600 dpi mode or fast 1200 mode; On at the factory default setting)

Toner saving................................... EcoPrint mode

Resolution ...................................... Fast 1200 mode: 1800 × 600 dpi

600 dpi mode: 600 × 600 dpi

300 dpi mode: 300 × 300 dpi

(Fast 1200 mode at the factory default setting)

Gray scale ...................................... Fast 1200 mode: 220 levels

600 dpi mode: 203 levels

Dimensions ....................................Main unit: 467 × 410 × 310 mm/18

3

/8" × 161/8" × 123/16" (W × D × H)

Weight ............................................Main unit: 18 kg/39.7 lbs

1-1-2

Page 15

FS-6020

Power source ................................. 120 V AC, 60 Hz (U.S.A./Canada)

220-240 V AC, 50/60 Hz (European countries)

Power consumption ........................ Maximum: 961 W

Normal operating: 382 W

Ready: 21 W

EcoPower: 8 W

Current ........................................... 10.8 A: 21 W (U.S.A./Canada)

7.2 A: 21 W (European countries)

Noise .............................................. Printing: 54 dB(A)

Ready: 31 dB(A)

Options ........................................... Expansion memory (one of 16/32/64/128 MB 100-pin DIMM), KPLD3 upgrade kit UG-

13, memory card (CompactFlash), hard disk unit (Microdrive), network interface card

IB-20 (10 BASE-T/100BASE-TX/10BASE-2), network interface card IB-21E (10

BASE-T/100BASE-TX), wireless network interface card IB-22 (compatible to IEEE

802.11b), serial interface board IB-11, paper feeder PF-400 (250 sheets [60 to 105 g/

2

m

] × 1 cassette, A3, A4, A4R, A5, B4, B5, folio, ledger, legal, let5ter, and letter-R),

duplexer DU-400

1-1-3

Page 16

FS-6020

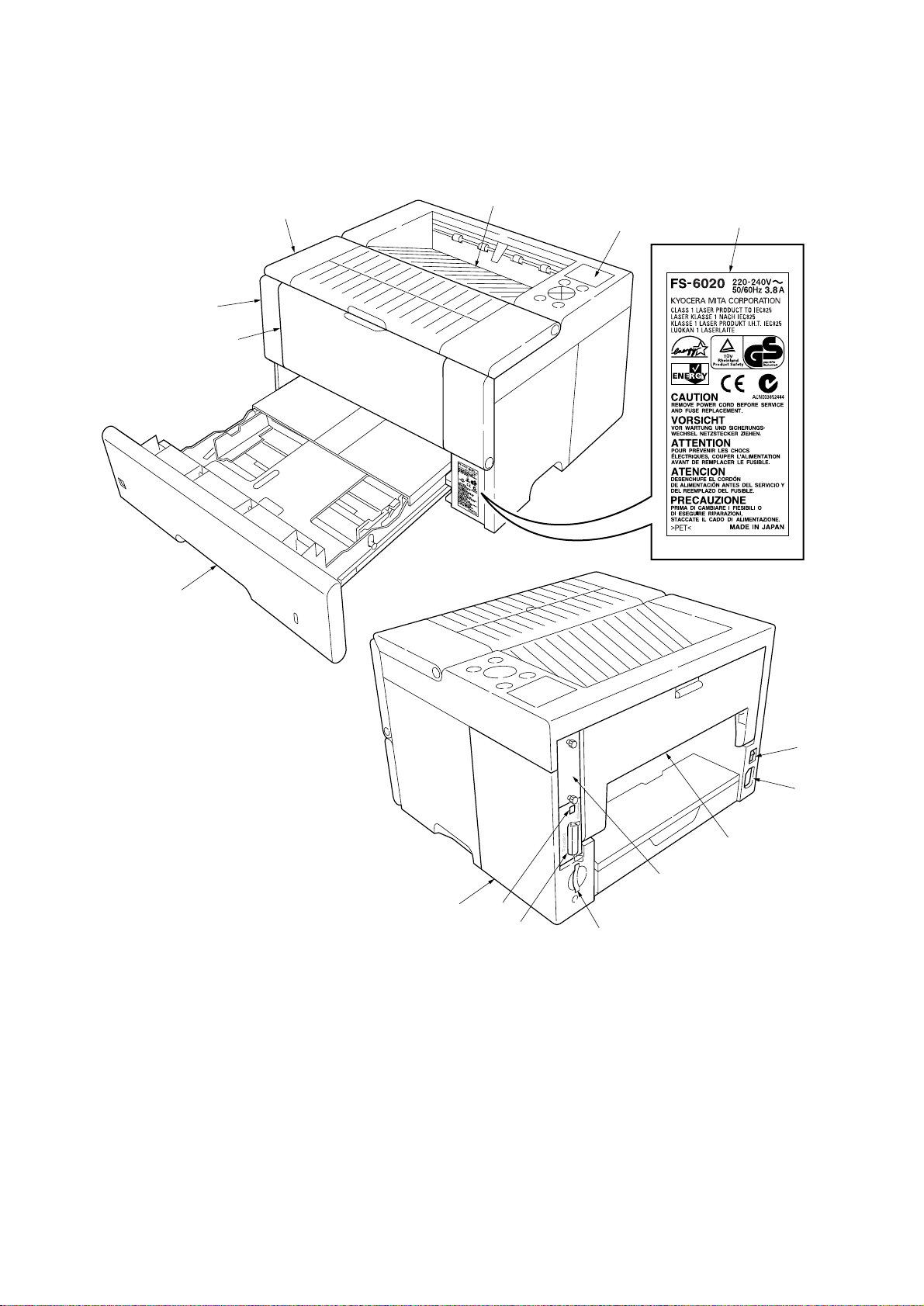

1-1-2 Parts names

(1) Printer

6

2

5

3

4

1

%

1 Operation panel

2 Front cover

3 Top cover

4 Face-down tray

5 MP tray

6 Paper cassette

7 Optional interface slot cover

8 Power switch

7

Figure 1-1-1

9 AC inlet

0 Rear cover

! Optional interface slot

@ Memory card slot

# Parallel interface

$ USB interface

% Caution label

$

#

8

9

0

!

@

1-1-4

Page 17

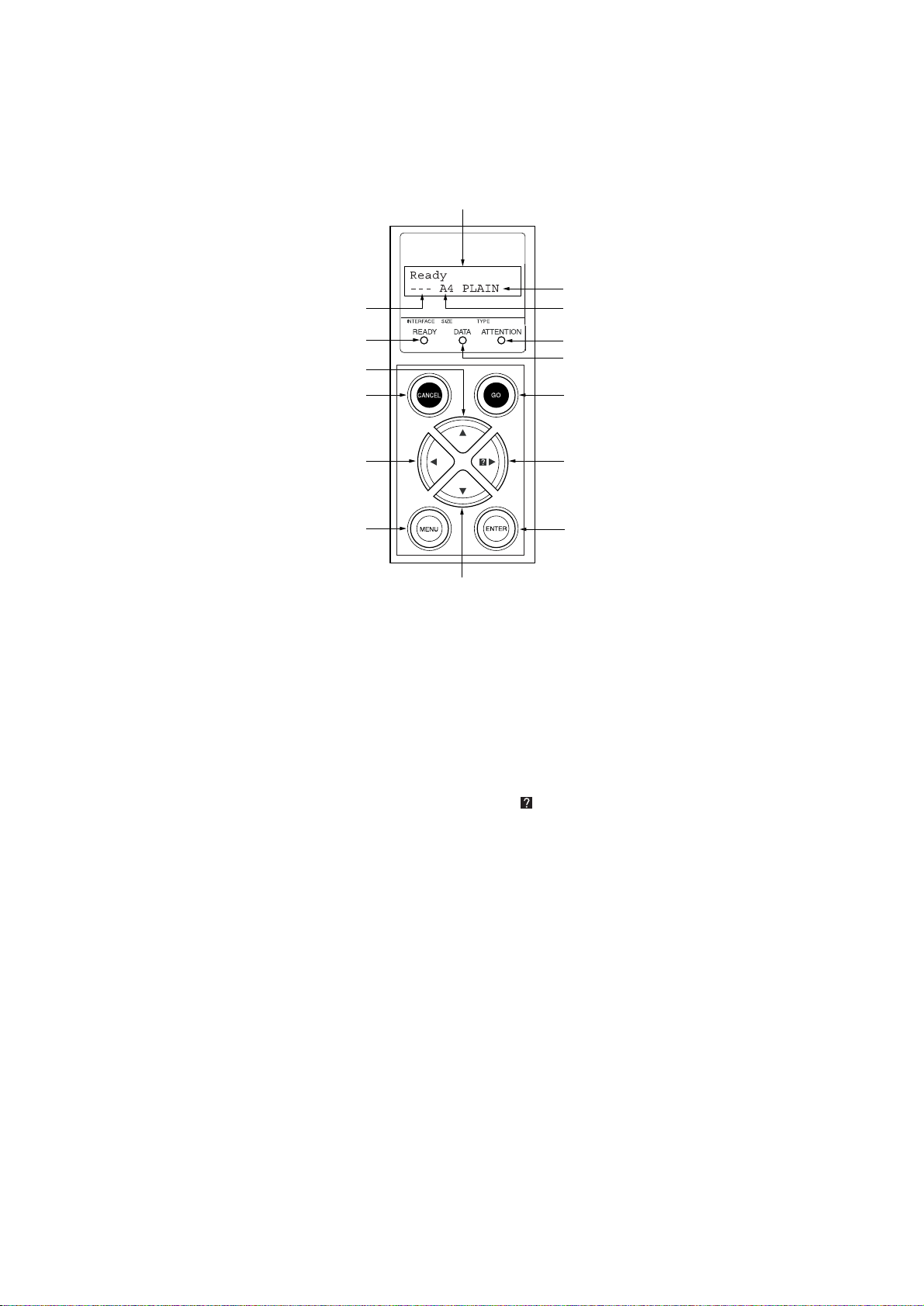

(2) Operation panel

2

FS-6020

1

4

3

5

!

9

#

0

1 Message display

2 Interface indicator

3 Paper size indicator

4 Paper type indicator

5 READY indicator

6 DATA indicator

7 ATTENTION indicator

8 ENTER key

@

Figure 1-1-2

7

6

%

$

8

9 CANCEL key

0 MENU key

! M key

@ N key

# O key

$

P key

% GO key

1-1-5

Page 18

FS-6020

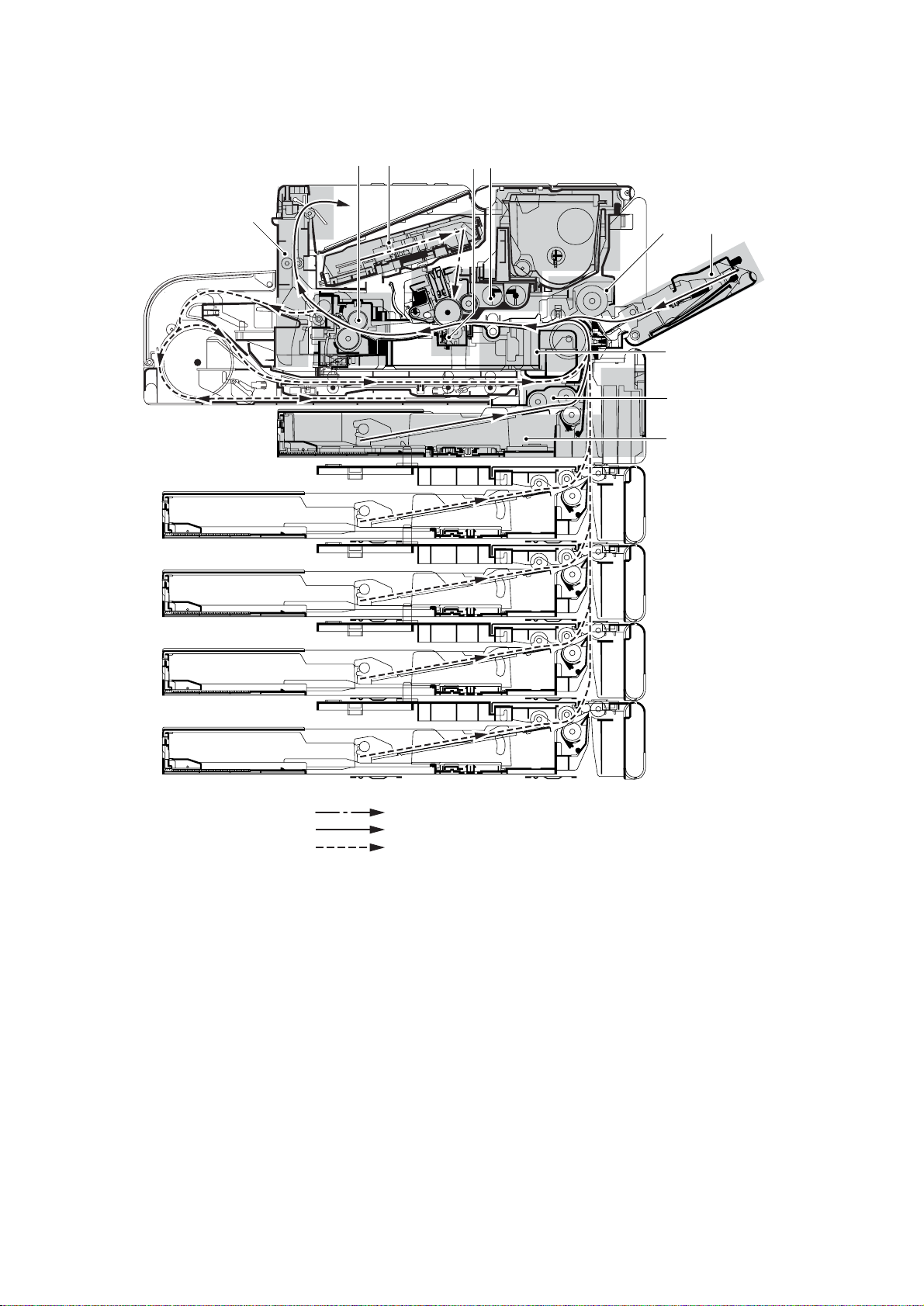

1-1-3 Machine cross section

0

69

8

7

5

4

3

2

1

1-1-6

Laser output path

Paper path

Paper path (optional paper feeder and duplexer)

Figure 1-1-3 Machine cross section

1 Paper cassette

2 Paper feed section

3 Conveying section

4 MP tray

5 MP tray feed section

6 Laser scanner unit section

7 Process unit section

8 Transfer/separation section

9 Fixing section

0 Face-down eject/feedshift section

Page 19

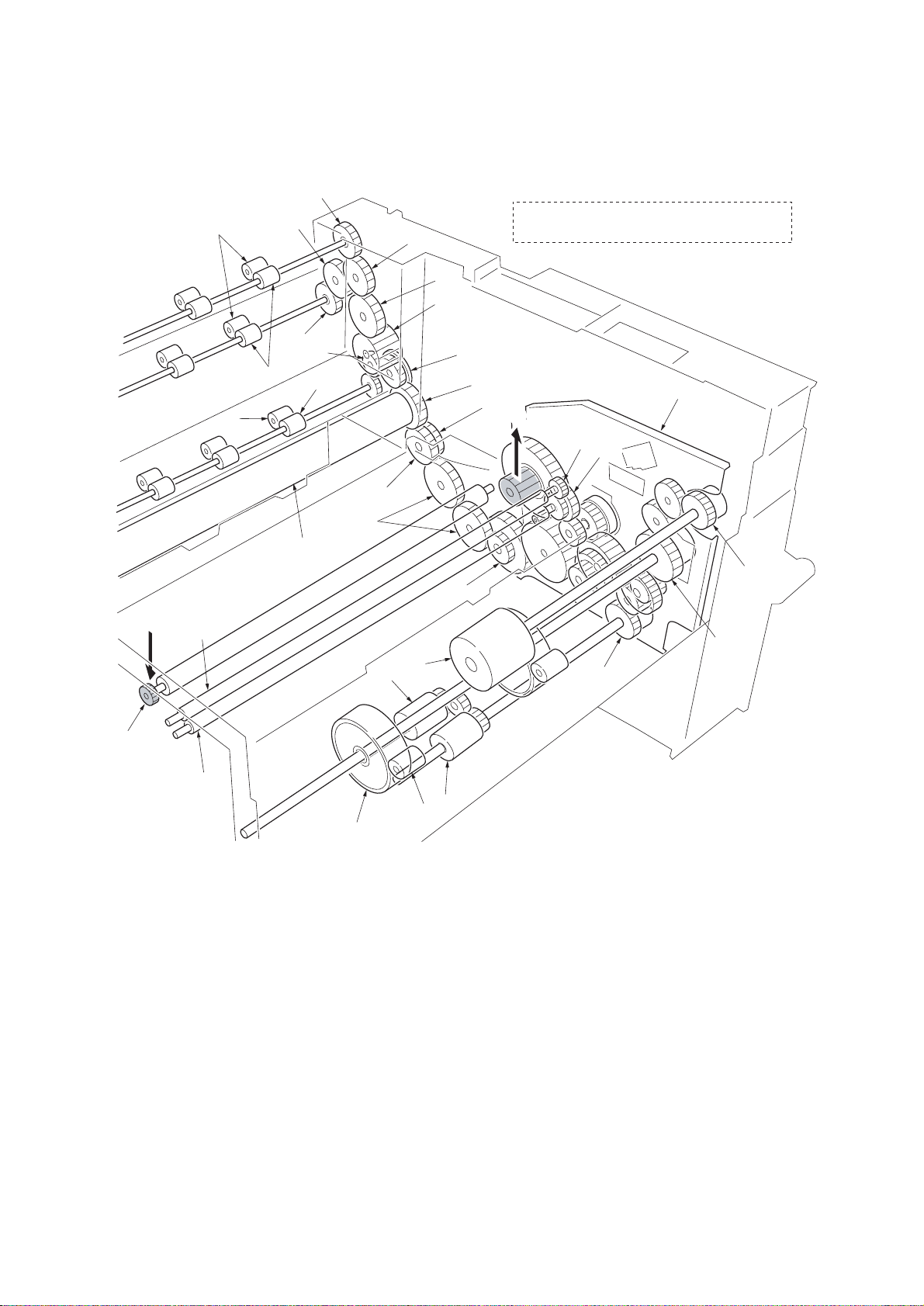

1-1-4 Drive system

(1) Drive system

FS-6020

6

A

5

2

‚

3

!

6

Œ

°

·

$

@

⁄

!

*

0

9

fl

^

fi

A Driving is linked with the process unit (drum).

#

A

8

7

(

1

&

¤

%

4

1 Drive assembly

2 Pinch roller

3 Face-down roller

4 Upper registration roller

5 Lower registration roller

6 Face-down roller gear Z18

7 Registration roller gear Z32-Z31

8 Registration roller gear Z24

9 Joint gear Z31

0 Gear Z35

! Idle gear Z25

)

‹

›

Figure 1-1-4

@ Free gear Z34S

# Free gear Z29S

$ Gear Z52S

% Transfer roller gear Z18

^ Gear Z24S-Z96H

& MP tray feed pulley

* MP tray feed roller

( Feed clutch (gear)

) Feed roller

⁄ Pickup roller

¤ Middle feed clutch (gear)

‹ Pinch roller

› Middle feed roller

fi Heat roller gear Z36

fl Fixing joint gear Z32

‡ Fixing idle gear Z22

— Eject gear Z22

· Eject roller

‚ Eject pulley

ΠHeat roller

1-1-7

Page 20

FS-6020

This page is intentionally left blank.

1-1-8

Page 21

1-2-1 Process unit

Note the following when handling or storing the process unit.

• When removing the process unit, never expose the drum surface to strong direct light.

• Avoid abrupt changes in temperature and humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained with oil, clean it.

1-2-2 Toner container

Store the toner container in a cool, dark place. Avoid direct light and high humidity.

1-2-3 Installation environment

1.Temperature: 10 - 32.5°C/50 - 90.5°F

2.Humidity: 20 - 80%RH

3.Power supply: 120 V AC, 10.8 A (U.S.A./Canada)

4.Power source frequency: 50 Hz ±2%/60 Hz ±2%

5.Installation location

• Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other

strong light when removing paper jams.

• Avoid extremes of temperature and humidity, abrupt ambient temperature changes, and hot or cold air directed onto

the machine.

• Avoid dust and vibration.

• Choose a surface capable of supporting the weight of the machine.

• Place the machine on a level surface (maximum allowance inclination: 1° ).

• Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

• Select a room with good ventilation.

6.Allow sufficient access for proper operation and maintenance of the machine.

Machine front: 1000 mm/39

Machine right: 700 mm/27

220 - 240 V AC, 7.2 A (European countries)

3

/8" Machine rear: 100 mm/315/16"

1

/2" Machine left: 600 mm/235/8"

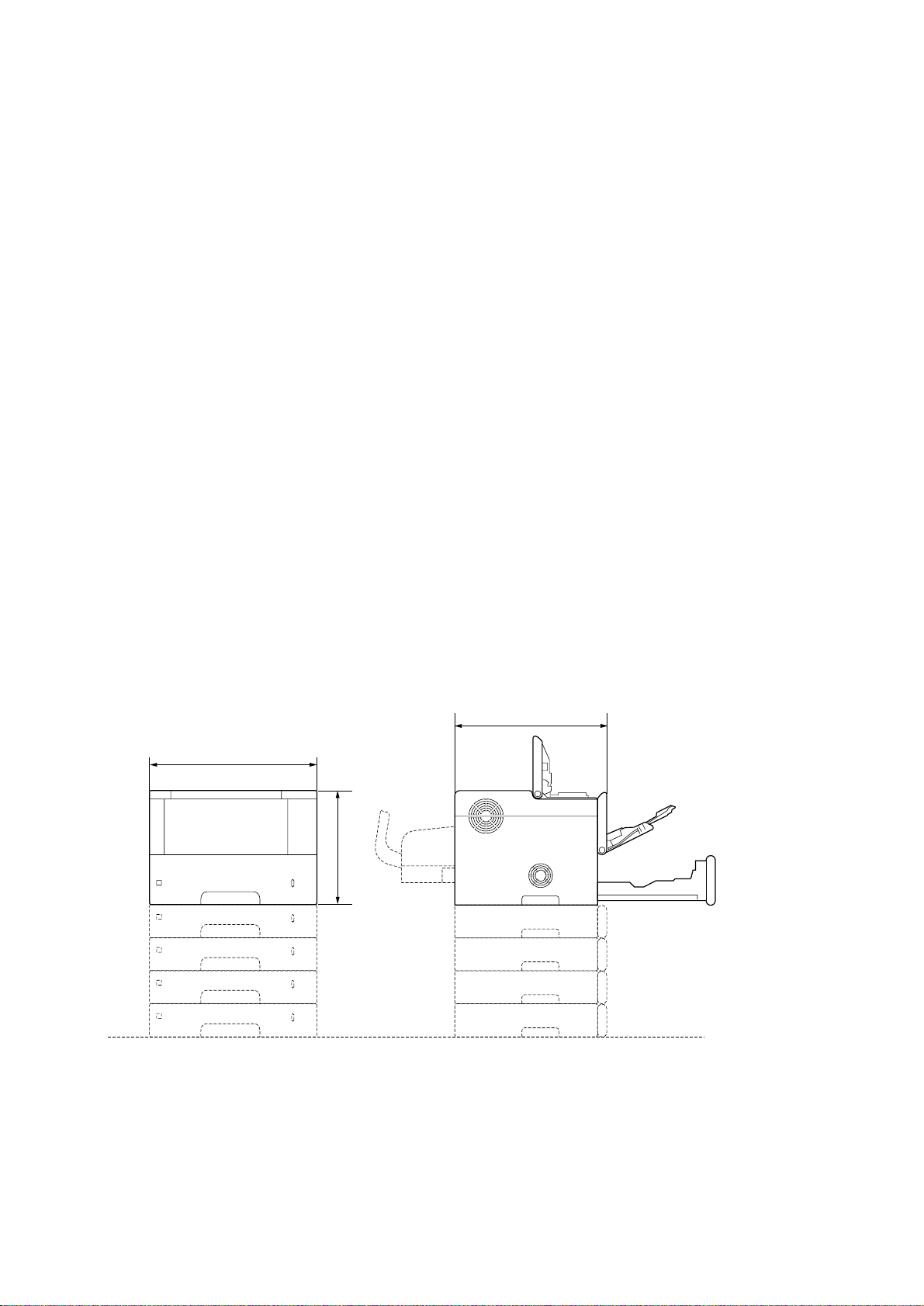

FS-6020

c

a

b

a: 467 mm/183/8"

b: 310 mm/12

c: 410 mm/16

3

1

/16"

/8"

Figure 1-2-1 Installation dimensions

1-2-1

Page 22

FS-6020

This page is intentionally left blank.

1-2-2

Page 23

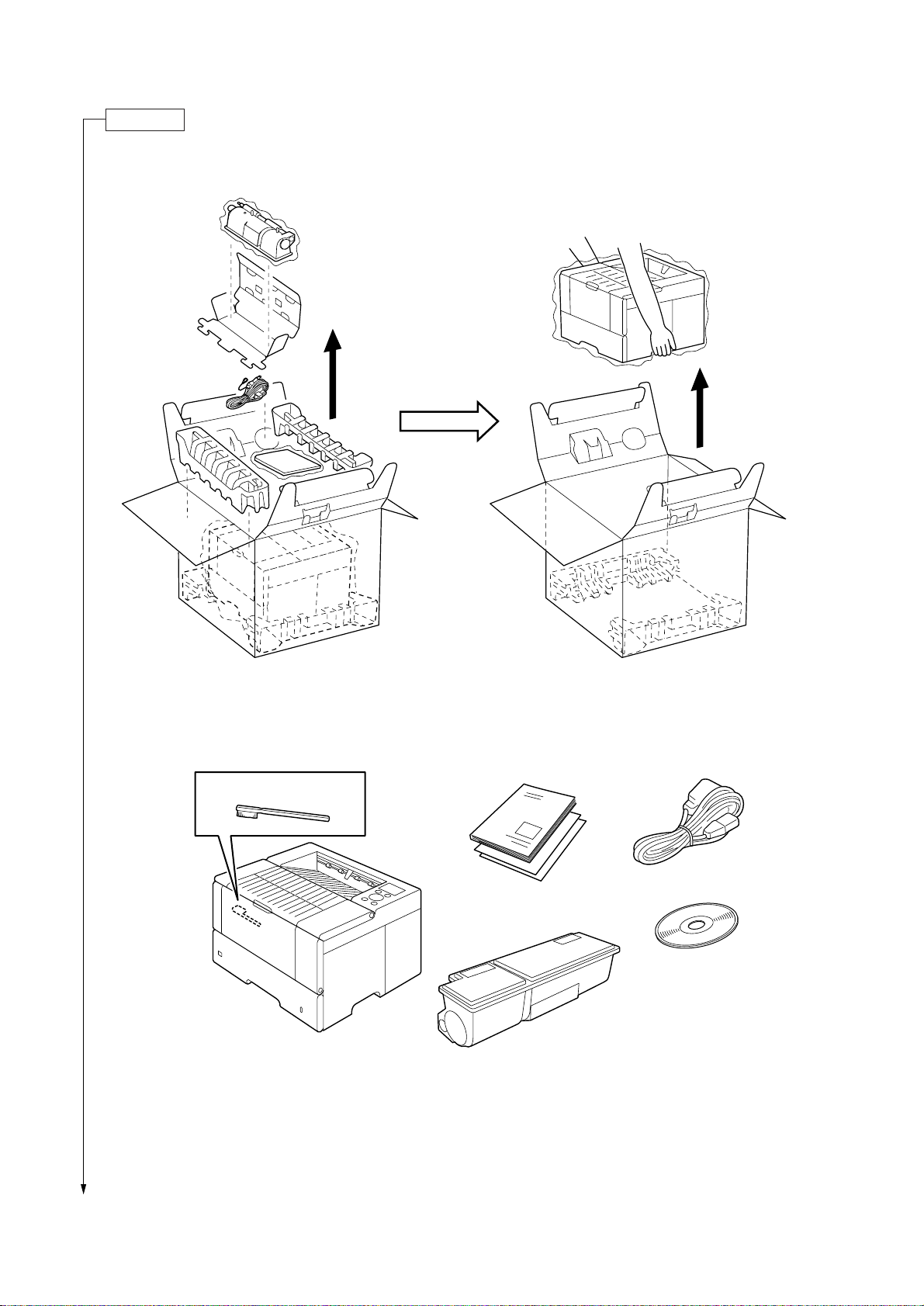

1-3-1 Unpacking and installation

(1) Installation procedure

FS-6020

Start

Unpacking.

Installing the toner container.

Connecting the printer cable.

Connecting the power cord.

Loading paper.

Printing a status page for test.

Completion of the machine installation.

1-3-1

Page 24

FS-6020

Unpacking.

Unpack as shown in the figure below.

Separation charger

cleaning brush

Printer FS-6020

Figure 1-3-1 Unpacking

Power cord

Operation Guide

Kyocera Mita

digital library

CD-ROM

Toner container TK-400

Figure 1-3-2 Shipped components

1-3-2

Page 25

Installing the toner container.

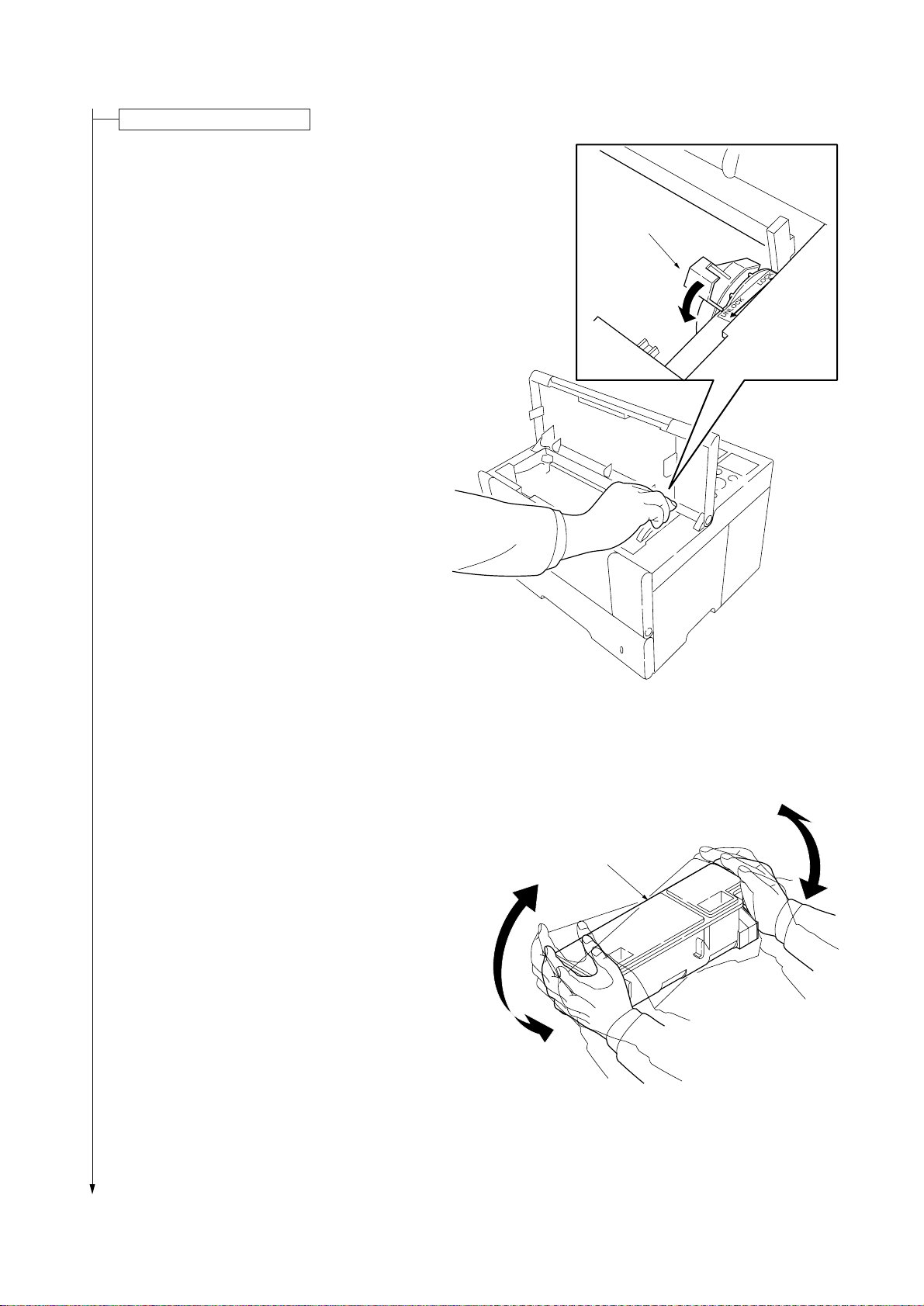

1.Open the top cover.

2.Turn the lock lever to the UNLOCK position.

(LOCK position at shipping)

FS-6020

Lock lever

3.Shake the toner container more than ten times to

loosen the toner.

Figure 1-3-3

Toner container

Figure 1-3-4

1-3-3

Page 26

FS-6020

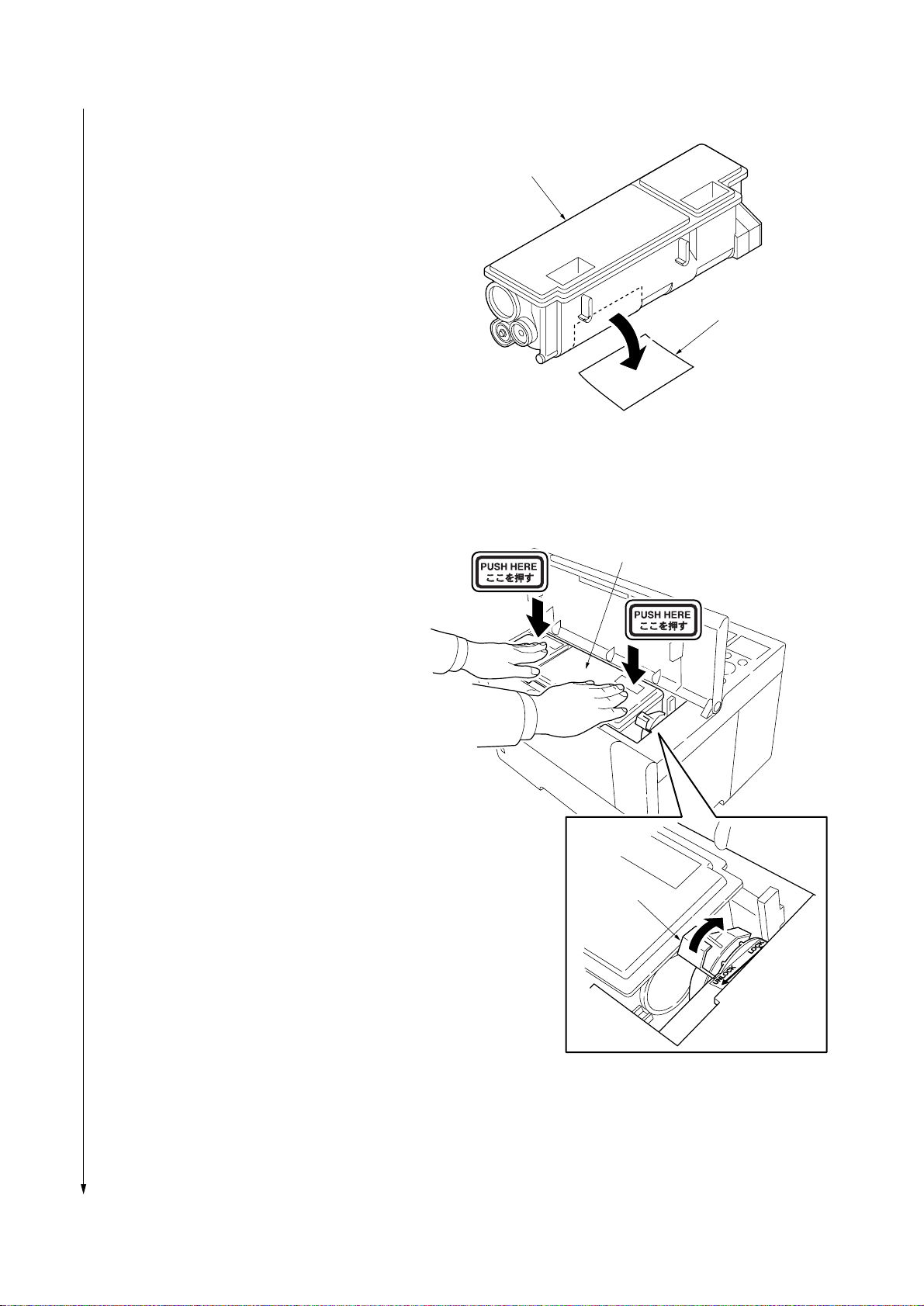

4. Remove the protective seal from the toner

container.

5. Install the toner container into the printer.

6. Push the upper part of the toner container on

which “PUSH HERE” is printed until the container

clicks.

7. Turn the lock lever to the LOCK position.

8. Close the top cover.

Toner container

Protective seal

Figure 1-3-5

Toner container

1-3-4

Lock lever

Figure 1-3-6

Page 27

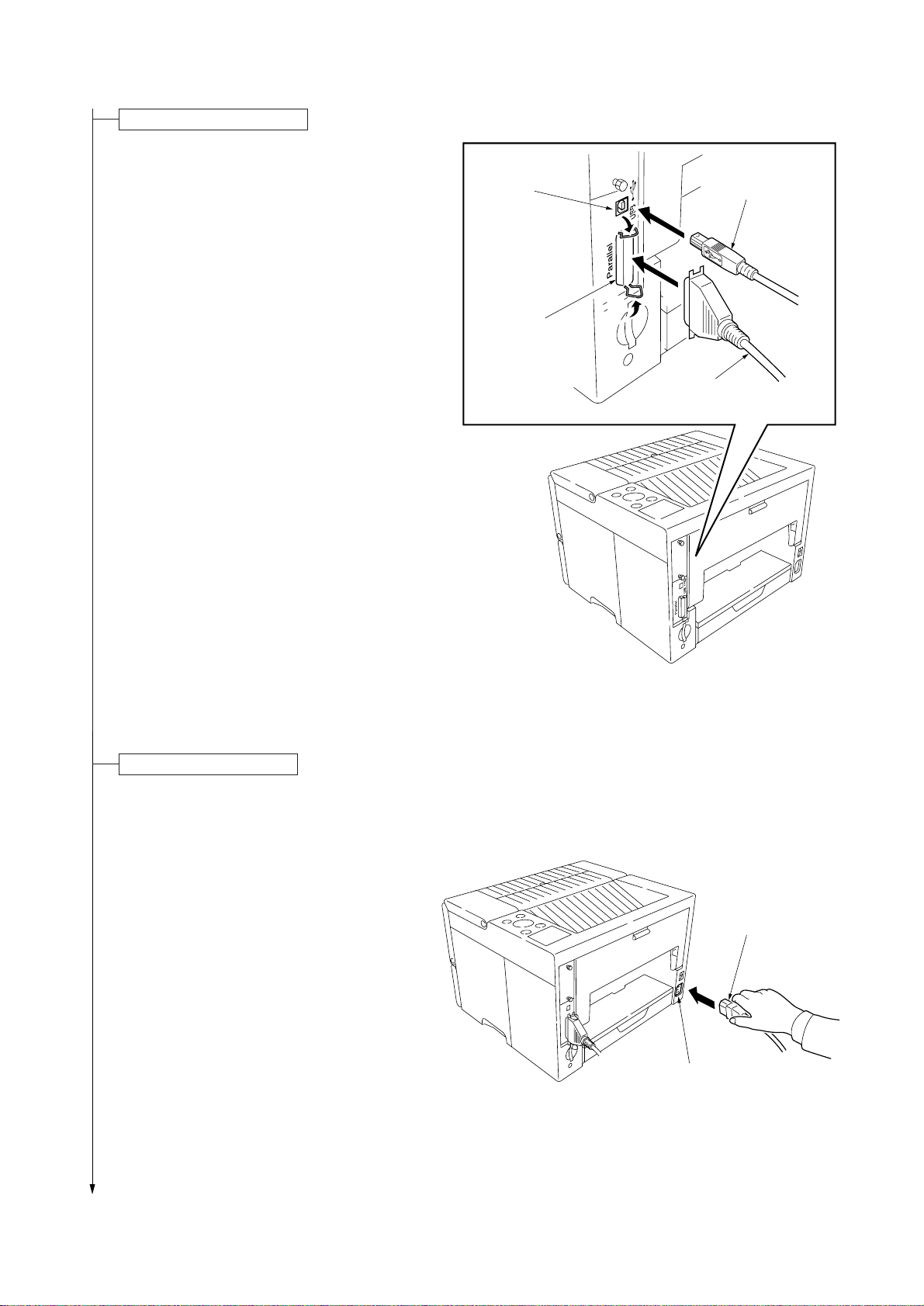

Connecting the printer cable.

For connection to a computer, parallel interface or

USB interface can be used in the standard

configuration. If an optional network interface card

or serial interface card is installed, network

connection or serial interface connection is

available.

1.Connect the parallel interface cable or the USB

interface cable to their relevant interface

connector.

USB interface

connector

Parallel

interface

connector

2

2

FS-6020

USB interface

cable

1

Parallel interface

cable

Connecting the power cord.

1. Connect the power cord to the AC inlet.

Figure 1-3-7

Power cord

AC inlet

Figure 1-3-8

1-3-5

Page 28

FS-6020

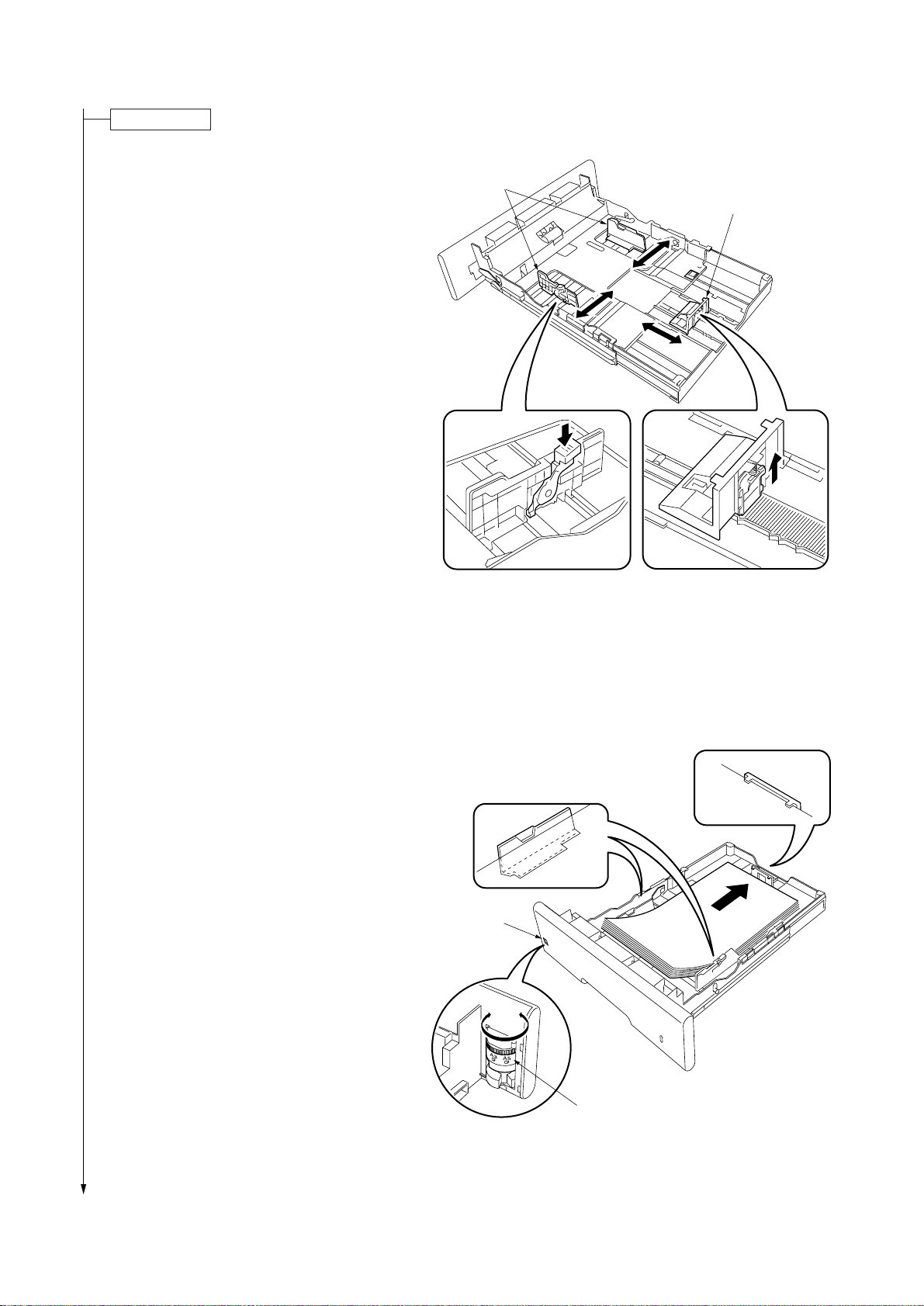

Loading paper.

1. Remove the cassette from the printer.

2. Adjust the paper guides and the paper stopper

according to the paper size to be used.

3. Set the stack of paper that does not exceed the

paper upper limit marks on the paper guides and

the paper stopper by aligning the top of the stack

and placing the rear side first. (Approximate 250

sheets of 0.1 mm thick paper can be loaded.)

Paper guides

Paper stopper

4. Turn the paper size dial so that the size of the

loaded paper is indicated in the paper size

indication window.

If “OTHER” is selected, paper size setting must

be performed on the operation panel of the

printer.

5. Install the cassette into the printer.

Figure 1-3-9

Paper size

indication

window

1-3-6

Paper size dial

Figure 1-3-10

Page 29

Printing a status page for test.

1.Turn on the printer power switch. Initialization of

the machine will start. The message will change

from “Self test” to “Please Wait Adding

toner” and then change to “Ready” when

initialization is complete (after approximately 15

minutes).

2.Use the following key operation to print a status

page for test.

1 Press the MENU key when “Ready” is

displayed.

2 Press the N key to display “Print Status

Page”.

3 Press the ENTER key to display “Print

Status Page?”.

4 Press the ENTER key. “Processing” will be

displayed and status page printing will start.

When printing is complete, “Ready” will appear

again.

3.Check to see if the printout of the status page is

proper.

FS-6020

Completion of the machine installation.

1-3-7

Page 30

FS-6020

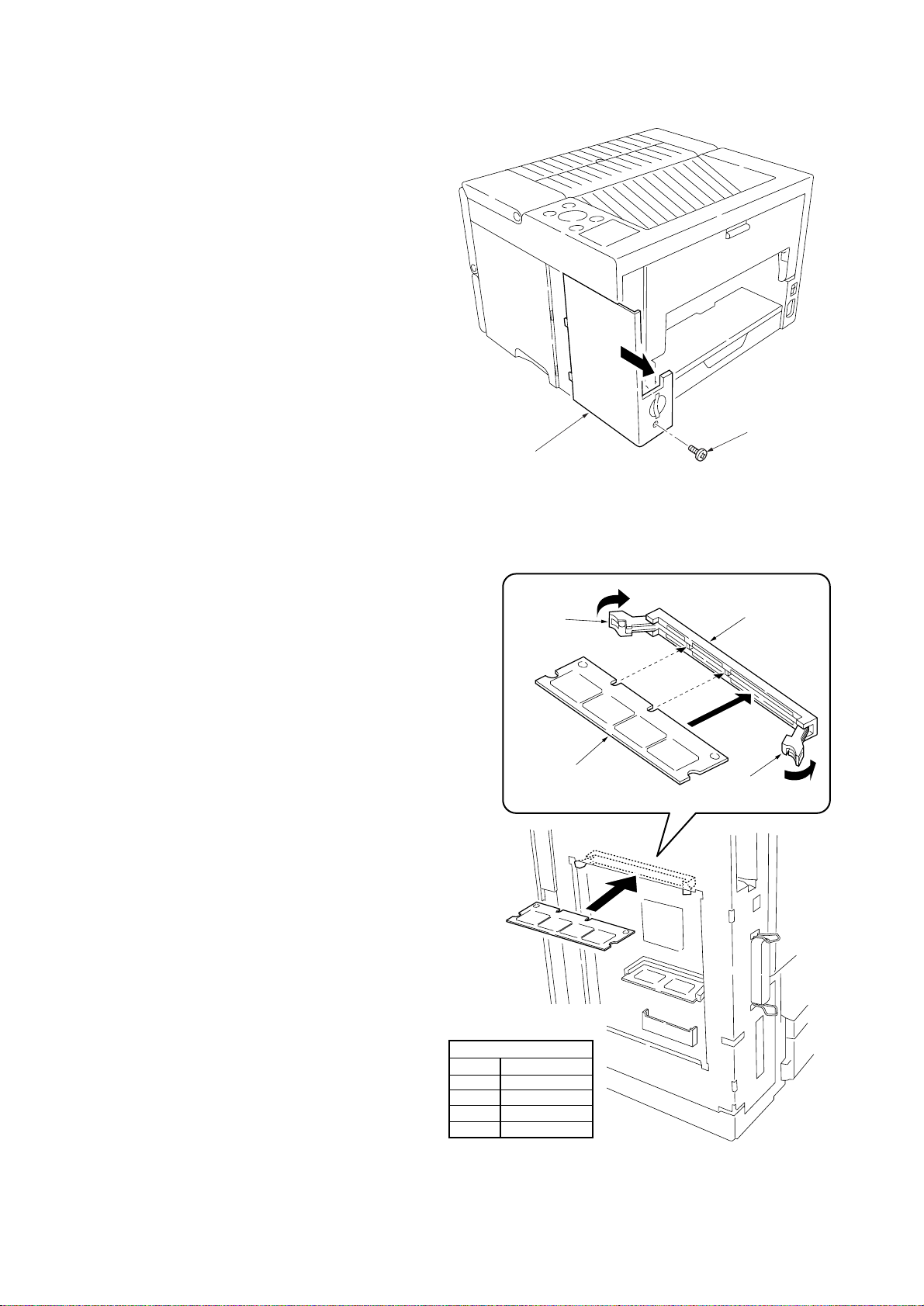

1-3-2 Installing expansion memory (optional)

Procedure

1. Turn off the printer power switch.

Cautions

Do not insert or remove expansion memory

while the printer power is on. Doing so may

cause damage to the printer or the expansion

memory.

2. Remove one screw and then remove the

optional interface slot cover.

3. Open the stoppers of the memory socket.

Screw

Optional interface

slot cover

Figure 1-3-11

4. Insert the memory so that the two notches of

the memory are engaged with the projections

of the memory socket.

* Memory produced by Melco Inc. of which

the operation has been confirmed is

recommended.

5. Close the stoppers of the memory socket.

6. Reattach the optional interface slot cover to

its original position.

7. Print a status page to check the memory

expansion.

* If memory expansion has been properly

performed, information on the installed

memory is printed and the total memory

capacity has been increased.

(Memory capacity at shipping is 16 MB.)

Stopper

Memory

Recommended memory

(Operation has been checked.)

Produced by Melco Inc.

Capacity

16 MB

32 MB

64 MB

128 MB

Part number

PM-HP-16M-KC

PM-HP-32M-KC

PM-HP-64M-KC

PM-HP-128M-KC

Memory socket

Stopper

1-3-8

Figure 1-3-12

Page 31

1-3-3 Installing network interface card (optional)

Procedure

1. Remove the two screws and then remove the

optional interface slot cover.

2. Insert the network interface card into the

optional interface slot.

3. Use the two screws to secure the network

interface card.

Cover

Optional interface slot

Network

interface

card

FS-6020

IB-22

Screws

4. Connect the network cable (in the case of IB20 or IB-21E).

5. Perform the network setting. (See IB-2x quick

configuration guide.)

Setting items for wireless network interface card IB-22

Variable name Setting range

Wireless LAN Mode

SSID

Channel

Encryption(WEP)

WEP key

Ad hoc/802.11 Ad hoc/

Infrastruccture/Automatic

Any string (up to 32 characters)

Depends on the setting range

available for the wireless NIC.

DISABLE/64 bit/128 bit

Hexadecimal setting (00-FF)

64 bits = 10 digits

128 bits = 26 digits

Screws

Network interface card that can be installed

Part number Specifications Remarks

IB-20 10 Base-TX,100 Base-TX,10 Base2

IB-21E 10 Base-TX,100 Base-TX

IB-22 Compatible to IEEE 802.11b

Wireless LAN

Figure 1-3-13

Network interface

card

Network cable

Figure 1-3-14

1-3-9

Page 32

FS-6020

1-3-4 Installing hard disk unit (optional)

Procedure

1. Remove one screw and then remove the

optional interface slot cover.

Screw

Optional interface

slot cover

2. Insert the hard disk unit into the hard disk

socket.

3. Reattach the optional interface slot cover to

its original position.

4. Format the hard disk. (Refer to the operation

guide.)

Hard disk unit

Figure 1-3-15

Hard disk socket

Hard disk units that can be installed

(Microdrive)

Manufactured by IBM

Capacity

340 MB

512 MB

1 GB

Model number

DMDM-10340

DSCM-10512

DSCM-11000

1-3-10

Figure 1-3-16

Page 33

1-3-5 Installing memory card (optional)

Procedure

1. Turn off the printer power switch.

Cautions

Do not insert or remove a memory card

while the printer power is on. Doing so may

cause damage to the printer or the memory

card.

2. Insert the memory card into the memory card

slot.

* A memory card of which the operation has

been confirmed is recommended. (Refer to

the CF guideline.)

3. Format the memory card. (Refer to the

operation guide.)

FS-6020

Memory card slot

Memory card

Figure 1-3-17

1-3-11

Page 34

FS-6020

This page is intentionally left blank.

1-3-12

Page 35

FS-6020

1-4-1 Service mode

The printer is equipped with various service modes that can be accessed with MENU key operation on the operation

panel.

(1) Executing service mode

Message display

Ready

--- A4 PLAIN

1 Press the MENU key.

Print

Menu Map

2 Press the M or N key several times

until “Other >” is displayed.

Other >

Service mode items

>>Print

Status Page

>>Eraser

>>Print

Event Log

>>Developer

>MSG Language

English

3 Press the ENTER key.

>Service >

4 Press the M or N key several times

until “>Service >” is displayed.

5 Press the key.

To print a status page for service purchase.

See page 1-4-2.

To print a test pattern for detecting eraser lamp disconnection.

See page 1-4-5.

To print an event log (EVENT LOG).

(*Displayed when the set value of FRPO Ι1 is 1.)

See page 1-4-6.

To perform initialization after replacing the process unit.

See page 1-4-9.

>>Drum

To perform drum surface refreshing.

See page 1-4-9.

1-4-1

Page 36

FS-6020

Service items Description

Printing a status page for service purpose

>>Print

Status Page

Description

Prints a status page for service purpose. The status page includes various printer settings

and service data.

Purpose

To acquire printer setting environment and service data information.

Procedure

1. Enter the service mode [>>Print Status Page].

2. Press the ENTER key. “Print Status Page?” will be displayed.

3. Press the ENTER key. Two status pages will be printed. (The second status page includes

service information.)

Service information

(See the next page.)

Main PWB firmware version

Firmware version: 91.01

Firmware version: 91.01

Service Information

[0104/0086][C2][34.00EFLB][03/03] Total page 9690

/t/P00/S00/F00/N00/D20:lotte

/0020/0020/1061/0811/ 0/ 0/ 0/ 0/ 0/ 0/ 0/

/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/AAAAAAA/AAAAAAA/

/AAAAAAA/

/0000/0000/0000/0000/0000/

/RS2/FF/[0003-0003]/AI.E/81/06

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/00800080/00008000/00000080/80000000/00000000/00000000/00000000/

/03030303/03030303/03030303/03000000/00000000/03030303/03030303/

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

SN:SPL9200010

Released date of the firmware

Released: 10/Sep/2002

Released: 10/Sep/2002

1-4-2

Fig. 1-4-1 Status page for service

Page 37

FS-6020

Service items Description

Details of service information

Service information

[0104/0086][C2][34.00EFLB][03/03] Total page 9690

123 4

/t/P00/S00/F00/N00/D20:lotte

6

7890 !

/0020/0020/1061/0811/ 0/ 0/ 0/ 0/ 0/ 0/ 0/

@

#

/AAAAAAA/AAAAAAA/

$

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

%

/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/AAAAAAA/

^

/AAAAAAA/AAAAAAA/AAAAAAA/

&

/AAAAAAA/

*

/0000/0000/0000/0000/0000/

(

5

/RS2/FF/[0003-0003]/AI.E/81/06

)⁄

¤‹›fi

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

fl

/00800080/00008000/00000080/80000000/00000000/00000000/00000000/

‡

/03030303/03030303/03030303/03000000/00000000/03030303/03030303/

°

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

·

SN:SPL9200010

‚

Table 1-4-1 Details of service information

Item Description

1 Engine ROM information

2 Operation panel information

3 Boot ROM information

[Mask ROM version/flash ROM version]

[Operation panel mask version]

[Boot ROM version]

Upper 6 digits: Boot ROM version

Lower 3 digits: Flash DIMM type

MXI: Macronix

FUB: Fujitsu (bottom type)

FUT: Fujitsu (top type)

FLB: Fujitsu (29LV160B)

FLT: Fujitsu (29LV160T)

HUB: Hyundai (bottom type)

HUT: Hyundai (top type)

---: Other manufacturers

***: Mask DIMM

1-4-3

Page 38

FS-6020

Service items Description

Item Description

4 Software jumper switch information

(hexadecimal)

5 Total page

6 Toner installation information (displayed

only when the mode is set)

7 Parallel I/O information

8 Serial I/O error code (Not supported by this

machine)

9 Operation panel lock status (displayed only

when locked)

0 NVRAM error (displayed only when any

error has occurred)

! NVRAM downloading status

@ Printable area setting

# Left offset for each paper source

$ Page counter according to paper size

% Page counter according to paper feeder (2

or 3)

^ Page counter according to paper feeder (4

or 5)

[First byte/second byte (displayed in OEM mode only)]

First byte

Bit 0 = 1: (Fixed)

Bit 1 = 0: Overseas; 1: Domestic (Japan)

Bit 2, 3 (Not used)

Bit 4 = 0: Kyocera; 1: OEM

Bit 5 = 0: For Europe; 1: For US

Bit 6 = 0: Non MICR mode; 1: MICR mode

Bit 7 = 0: Kyocera; 1: Kyocera Mita

Second byte: Displayed in OEM mode only.

Total print page count

(Toner installation mode display) Standby mode

(After prescribe command TNRE “INST” is entered, until the

power is turned off)

00: Normal

Bit 0: Framing error

Bit 1: Overrun error

Bit 2: Parity error

01: Partial lock

02: Full lock

01: ID error

02: Version error

03: Checksum error

04: NVRAM crash error

00: Normal (not downloaded)

Bit 0: Font data

Bit 1: Host data

Bit 2: Macro data

Bit 3: Program data

Bit 4: Operation panel message data (file name displayed)

Bit 5: OEM data (file name displayed)

Bit 6: Reserved

Bit 7: Error occurred

/Top offset/Left offset/Page length/Page width

/MP tray/Cassette 1/Cassette 2/Cassette 3/Cassette 4

/Cassette 4/Duplexer

/Legal/Small/

“Small” means sizes smaller than legal and that can be fed.

/Feeder 2 (total)/Feeder 2 (small)/Feeder 2 (large)

/Feeder 3 (total)/Feeder 3 (small)/Feeder 3 (large)

* “Total” is calculated by adding the number for “small” to 2 ×

number for “large” (double count).

* “Small” means sizes of which the length in the sub-scan

direction is less than 335 mm (length of legal size), and

“large” means sizes of which the length is 335 mm or more.

/Feeder 4 (total)/Feeder 4 (small)/Feeder 4 (large)/Feeder 5

(total)/Feeder 5 (small)/Feeder 5 (large)

* “Total” is calculated by adding the number for “small” to 2 ×

number for “large” (double count).

* “Small” means sizes of which the length in the sub-scan

direction is less than 335 mm (length of legal size), and

“large” means sizes of which the length is 335 mm or more.

1-4-4

Page 39

Service items Description

Item Description

FS-6020

& Duplexer life counter

* Maintenance kit counter

( Optional unit version

) Serial interface information

⁄ Drum sensitivity information

¤ Optional unit information

‹ Average printing ratio (2 digits for integer

part, 1 digit for decimal part)

› Operation panel message language

fi Toner capacity setting

fl Engine parameter setting

‡ Media type attributes

— Media type attributes

· Memory SPD information (slot 1)

‚ Machine serial number

/Duplexer (total)/Duplexer (small)/Duplex er (large)/

* “Total” is calculated by adding the number for “small” to 2 ×

number for “large” (double count).

* “Small” means sizes of which the length in the sub-scan

direction is less than 335 mm (length of legal size), and

“large” means sizes of which the length is 335 mm or more.

/Feeder 2/Feeder 3/Feeder 4/Feeder 4/Duplexer/

RS2: RS-232C RS4: RS-422A

Upper 2 bytes

Bit 0: MPF

Bits 1 to 6: Feeders 1 to 6 (6 is not supported)

Bit 7: Duplexer

Bits 8 to 15: Reserved

Lower 2 bytes

Bit 0:

Bit 1: Face-up (not supported)

Bits 2 to 15: Reserved

Printing ratio for the total period from shipping

(displayed in %)

PMSG command setting (decimal)

Decimal (× 100 sheets)

Hexadecimal, 32 bytes (64 digits)

Media type setting value from 1 to 28 (fixing temperature,

paper thickness, duplex printing)

(14 to 20 are unused and always 0x00.)

Media type setting value from 1 to 28 (print density)

(14 to 20 are unused and always 0x00.)

Bus error if all digits are “E”.

-

1-4-5

Page 40

FS-6020

Service items Description

Printing a test pattern for detecting eraser lamp disconnection

>>Eraser

Description

Prints a page that includes a test pattern (black bar with approximately 1 cm width) using

high voltage output control of engine/high voltage PWB. If the eraser operates normally, the

black bar is printed. If the eraser does not operate normally, the bar is not printed.

Purpose

To check for disconnection based on printing of the black bar. The conventional selfdiagnostic function does not check the eraser lamp disconnection error (error code 5300

[E5]).

Procedure

1. Load paper into the paper cassette.

2. Enter the service mode [>>Eraser].

3. Press the ENTER key. Message “>>Eraser ?” will be displayed.

4. Press the ENTER key.

5. A status page or a menu map will be printed. If the eraser lamp is normal, a page

including a test pattern (black bar with approximately 1 cm width) is printed.

Approximately

1 cm

Black bar

Paper

Fig. 1-4-2 Test pattern for detecting eraser lamp disconnection

1-4-6

Page 41

Service items Description

[0114][C2][37.00HFLB][03]

SN:SPL2700012

Firmware version: 91.01

7 519 02.11.48.02.09.01.88.21.73.FA.A8.C0

Paper jam/Printer unit

6 515 02.11.48.01.09.01.88.11.73.FA.A8.C0

Paper jam/Printer unit

5 166 02.11.48.01.09.01.88.11.73.FA.A8.C0

Paper jam/Printer unit

4 71 02.11.48.02.09.01.88.21.73.FA.A8.C0

Paper jam/Printer unit

3 71 02.11.48.01.09.01.88.11.73.FA.A8.C0

Paper jam/Printer unit

2 64 02.11.32.01.91.00.88.32.74.04.A8.C0

Paper jam/Cassette 2

1 57 02.11.32.01.91.00.88.32.74.04.A8.C0

Paper jam/Cassette 2

Released: 10/Sep/2002

Number Page Count Code

Event list

Total page 522

Printing an event log (EVENT LOG)

>>Print

Event Log

Description

Prints the history of paper misfeeds and self-diagnostic errors including up to 16 items from

the latest item. (If the number of errors exceeds 16, errors will be deleted sequentially from

the oldest one.)

Purpose

To allow machine malfunction analysis based on the frequency of paper misfeeds and selfdiagnostic errors.

Procedure

1. Enter the service mode [>>Print Event log].

2. Press the ENTER key. “>>Print Event Log?” will be displayed.

3. Press the ENTER key. A sheet of event log will be printed.

FS-6020

Fig. 1-4-3 Event log (EVENT LOG)

Details of event list

The event list includes the following information.

A Number Prints a list of error history (1 to 16). A smaller number means an older

event.

B Number of pages Number of pages printed when an error occurred

C Description Indicates the description of error.

D Code Code 1 identifies an error and codes 2 to 9 indicate the details.

The value 02 of code 1 means a paper misfeed. See code table (1).

The value 99 of code 1 means a self-diagnostic error. See code table (2).

Number Page Count Code

A B

7 519 02.11.48.02.09.01.88.21.73.FA.A8.C0

6 515 02.11.48.01.09.01.88.11.73.FA.A8.C0

5 166 02.11.48.01.09.01.88.11.73.FA.A8.C0

4 71 02.11.48.02.09.01.88.21.73.FA.A8.C0

3 71 02.11.48.01.09.01.88.11.73.FA.A8.C0

2 64 02.11.32.01.91.00.88.32.74.04.A8.C0

1 57 02.11.32.01.91.00.88.32.74.04.A8.C0

1 2 3 4 5 6 7 8

Paper jam/Printer unit

Paper jam/Printer unit

Paper jam/Printer unit

Paper jam/Printer unit

Paper jam/Printer unit

Paper jam/Cassette 2

Paper jam/Cassette 2

9-(a) 9-(b)

7 519 02.11.48.02.09.01.88.21.73.FA.A8.C0

Paper jam/Printer unit

Fig. 1-4-4 Details of event list

D

C

1-4-7

Page 42

FS-6020

Service items Description

Table 1-4-2 Code table (1)

Code digit and

description

1 Identification

code

2 Error type

(hexadecimal)

3 Paper

misfeed

location

(ASCII)

4 Paper

misfeed

sensor

location

(hexadecimal)

5 Cause of

paper

misfeed

(hexadecimal)

6 Paper

source

(hexadecimal)

7 Paper size

(hexadecimal)

Details of code

02: Paper misfeed

11: Paper misfeed

31: Cassette 1

Printer

32: Cassette 2

33: Cassette 3

34: Cassette 4

35: Cassette 5

42: MP tray

47: Rear cover

48: Inside the printer

49: Duplexer

01: Paper feed sensor [32]

Paper feed sensor [33]

Paper feed sensor [34]

Paper feed sensor [35]

Registration sensor [48]

Switchback timing

sensor [49]

02: Eject sensor [47]

Refeed rear edge

sensor [49]

03: Refeed eject sensor [49]

99: Not determined

Values within [ ] indicate paper

Duplexer

Paper feeder 1

Paper feeder 2

Paper feeder 3

Paper feeder 4

01

02

47

(Rear cover)

02

49

(Inside the printer)

48

01

03

(Cassette 1)

(Cassette 2)

(Cassette 3)

(Cassette 4)

(Cassette 5)

01

01

01

01

(MP tray)

31

32

33

34

35

misfeed locations.

01: Paper did not pass within a specified time.

02: Paper did not arrive within a specified time.

09: Paper remains longer than a specified time. (other than 01 and 02)

11: Paper misfeed occurred when paper is being transported.

91: Paper remains when power is turned on.

99: Others (Paper stopped due to external cause such as opening of a cover during

printing.)

00: MP tray 04: Cassette 4 08: Duplexer

01: Cassette 1 (in the printer) 05: Cassette 5 99: Reserved

02: Cassette 2 06: Reserved

03: Cassette 3 07: Reserved

01: Monarch 0D: A5 22: 216 × 316 (mm)

02: Business 0E: A6 24: A3 wide

03: International DL 0F: B6 25: Ledger wide

04: International CS 10: Commercial #9 27: 8K

05: Ex ecutive 11: Commercial #6 28: 16K

06: Letter size 12: ISO B5 32: Statement

07: Legal size 13: Custom size 33: Folio

08: A4 1E: C4 34: Western type 2

09: B5 1F: Postcard 35: Western type 4

0A: A3 20: Reply-paid postcard 86: Letter-R

0B: B4 21: Oficio II 88: A4-R

0C: Ledger size 22: 216 × 310 mm 89: B5-R

42

1-4-8

Page 43

Service items Description

FS-6020

Code digit and

description

8 Main cause

of paper

misfeed

(hexadecimal)

9 (a) Misfed

paper width

(hexadecimal)

(b) Misfed

paper length

(hexadecimal)

Details of code

10: Paper does not arrive at the registration sensor.

11: Paper does not pass the registration sensor.

12: Paper remains at the registration sensor when power is turned on.

20: Paper does not arrive at the eject sensor.

21: Paper does not pass the eject sensor.

22: Paper remains at the eject sensor when power is turned on.

30: Paper does not arrive at the paper feeder 1 feed sensor.

31: Paper does not pass the paper feeder 1 feed sensor.

32: Paper remains at the paper feeder 1 feed sensor when power is turned on.

40: Paper does not arrive at the paper feeder 2 feed sensor.

41: Paper does not pass the paper feeder 2 feed sensor.

42: Paper remains at the paper feeder 2 feed sensor when power is turned on.

50: Paper does not arrive at the paper feeder 3 feed sensor.

51: Paper does not pass the paper feeder 3 feed sensor.

52: Paper remains at the paper feeder 3 feed sensor when power is turned on.

60: Paper does not arrive at the paper feeder 4 feed sensor.

61: Paper does not pass the paper feeder 4 feed sensor.

62: Paper remains at the paper feeder 4 feed sensor when power is turned on.

A1: Paper does not arrive at the duplexer switchback timing sensor.

A2: Paper does not arrive at the duplexer refeed rear edge sensor.

A3: Paper does not pass the duplexer switchback timing sensor.

A4: Paper does not arrive at the duplexer refeed eject sensor.

A5: Paper does not pass the duplexer refeed rear edge sensor.

A6: Paper does not pass the duplexer refeed eject sensor.

A7: Duplexer overflow (Third sheet is commanded when second sheet remains.)

A8: Duplexer drive signal output from the printer while paper is transported turns off.

A9: Paper remains in the duplexer when power is turned on.

AA: The rear cover of the duplexer is opened while paper is transported.

B1 to B3, C1: Reserved

E0: Paper misfeed occurs due to forced stop when an error occurs during printing. (such

as opening of a cover)

F0 to FF: Paper misfeed by another cause

0000 to FFFF [in 0.1 mm]

Example: 73FA (hexadecimal) = 29690 (decimal) = 296.9 mm

0000 to FFFF [in 0.1 mm]

Example: A8C0 (hexadecimal) = 43200 (decimal) = 432.0 mm

1-4-9

Page 44

FS-6020

Service items Description

Table 1-4-3 Code table (2)

Code digit and

description

1 Identification

code

(hexadecimal)

2 Self-

diagnostic

error code

[Upper digit

of former 2

digits]

(hexadecimal)

3 Self-

diagnostic

error code

[Lower digit

of former 2

digits]

(hexadecimal)

4 to 8

(Remarks) Self-diagnostic error codes E0 and F0 to F2 are not recorded.

99: Self-diagnostic error

10: A

11: B

12: C

13: D

14: E

00: 0 06: 6 12: C

01: 1 07: 7 13: D

02: 2 08: 8 14: E

03: 3 09: 9 15: F

04: 4 10: A

05: 5 11: B

Unused

Details of code

>>Developer

>>Drum

Initialization after replacing the process unit (toner installation mode)

Description

Replenishes toner rapidly from the toner container into the process unit.

Purpose

To execute after replacing the process unit to replenish toner rapidly into the process unit that

includes no toner.

Procedure

1. Enter the service mode [>>Developer].

2. Press the ENTER key. Message “>>Developer?” will be displayed.

3. Press the ENTER key. Message “Ready” will be displayed.

4. Turn off and then on the printer. The toner installation mode will start after warm-up is

complete, and “Please Wait Adding toner” will be displayed during this operation.

The operation will be complete after approximately 15 minutes.

* To cancel this mode, use the following procedure instead of turning on the power while

pressing all cassette size switches like in the former models. Turn off and then on the

printer to restart the printer. Enter the service mode [>>Developer] during warm-up. Run

this mode again. Then this mode will be canceled.

Drum surface refreshing

Description

Rotates the drum approximately 5 minutes with toner lightly on the overall drum using the

high-voltage output control of the engine/high voltage PWB. The cleaning blade in the

process unit scrapes toner off the drum surface to clean it.

Purpose

To clean the drum surface when image failure occurs due to the drum. This mode is effective

when dew condensation on the drum occurs.

Procedure

1. Enter the service mode [>>Drum].

2. Press the ENTER key. Message “>>Drum?” will be displayed.

3. Press the ENTER key. Drum surface refreshing will start and finish after approximately 3

minutes.

1-4-10

Page 45

FS-6020

1-5-1 Paper misfeed detection

(1) Paper misfeed indication

When a paper misfeed occurs, the printer immediately stops printing and displays the paper misfeed message on the

operation panel. To remove paper misfed in the printer, open the front cover or the rear cover or pull out the paper cassette.

7

8

Paper misfeed location

Figure 1-5-1 Paper misfeed message display

2

Paper Jam

MP tray

9

6

6

6

1

5

5

5

Paper misfeed message

4

3

Printer

1 Registration sensor

2 Face-down tray paper full sensor

3 Paper gauge sensor

4 MP tray paper feed sensor

Paper feeder (optional)

5 Paper feed sensor

6 Paper gauge sensor

Duplexer (optional)

7 Switchback timing sensor

8 Refeed rear edge sensor

9 Refeed paper eject sensor

5

6

Figure 1-5-2 Paper misfeed detection

1-5-1

Page 46

FS-6020

1-5-2 Self-diagnosis

(1) Self-diagnostic function

This printer is equipped with a self-diagnostic function. When a problem is detected, the printer stops printing and an error

message is displayed on the operation panel. An error message consists of a message prompting contact to service

personnel, total print count, and a four-digit error code (2 digits for F0 only) indicating the type of the error. (The display varies

a little with the type of the error.)

Error codes 2000 to 6040

Call service

2000:0123456

Error codes F010 to F080

Call service

F010

Error code F0

Call service

person F0

Figure 1-5-3 Error message display

Error code

Error code

Error code

1-5-2

Page 47

FS-6020

(1-1) Error code 2000 [E1] (main motor error)

Detection conditions

• The main motor ready signal (MOTRDYN) does not become ready (low level) a specified time after the main motor drive

signal (MOTONN) is turned on.

• The main motor ready signal (MOTRDYN) does not become ready (low level) a specified time after the main motor drive

signal (MOTONN) is turned off.

Corrective measures

Start

Is there any damage to

the harness (S02814) between

the engine/high voltage PWB and the

main motor or improper connection at the

YC12 connector on the

engine/high-voltage

PWB?

Yes

* Possible defective locations

(causes)

• Engine/high voltage PWB

• Fixing unit

• Power source PWB

• Large load applied to

the main motor

No

If any problem is found on the

harness or the connector,

repair or replace it.

Turn on the printer, connect a tester

or an oscilloscope, and measure as

follows.

Is the voltage at

pin No. 1 (+24V3) of

the main motor connector DC

24 V in the printer

standby mode?

Yes

Print a status page.

Does the level at

pin No. 3 (MOTONN) of

the main motor connector change

from H to L in synchronization

with activation of the

motor?

No

No

OK?

End

Yes

No

Print a status page.

Does the level at pin

No. 4 (MOTRDYN) of the

main motor connector change from H to

L after activation of the motor

(after approximately 2

seconds)?

Yes

Replace the engine/high voltage

PWB. (See page 1-6-26.)