Page 1

Page 2

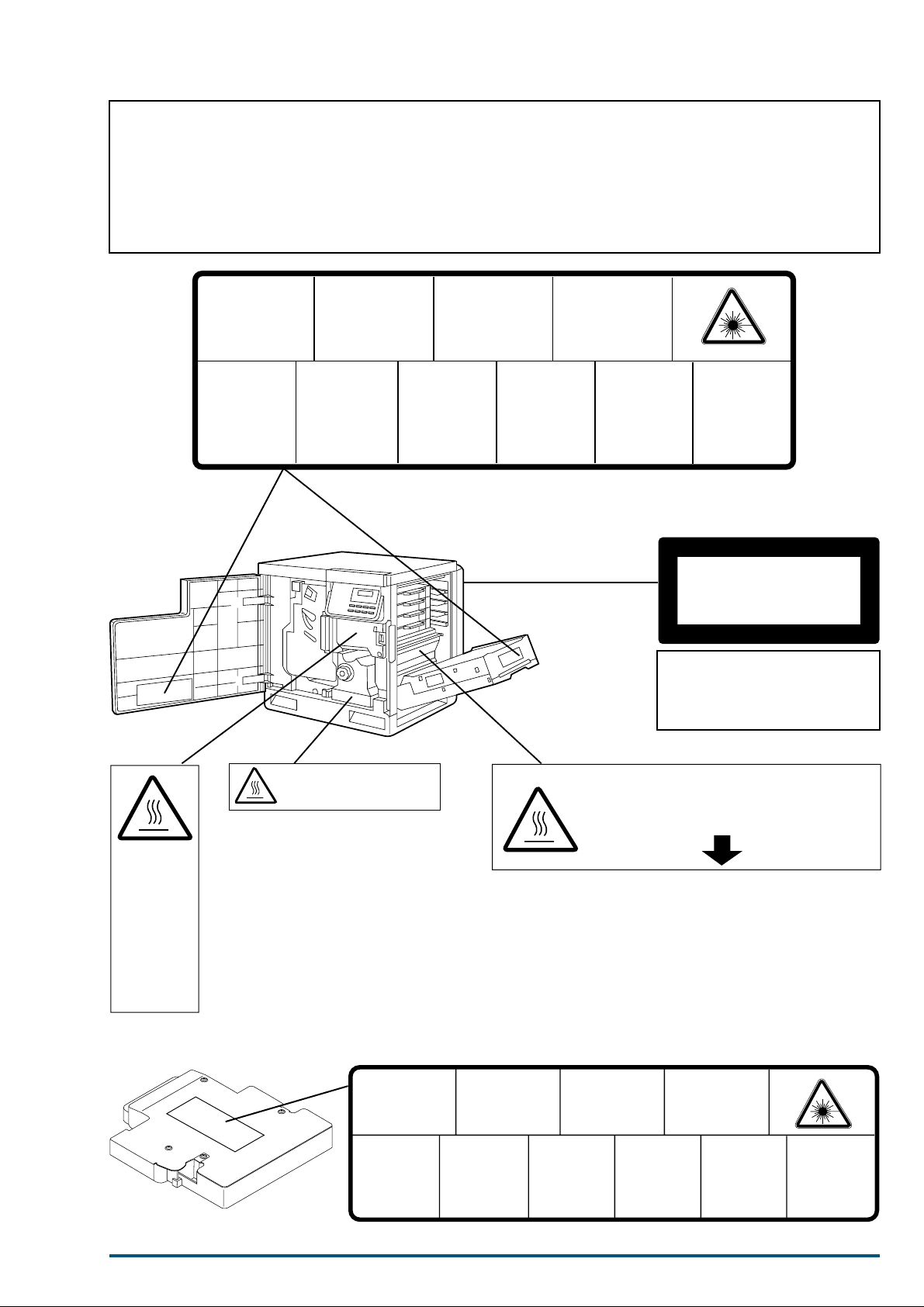

WARNING

CLASS

KLASSE

CLASSE

CLASE

1 LASER PRODUCT

1 LASER PRODUKT

1 LASER PRODUIT

1 LÁSER PRODUCTO

ATTENTION:

Rayonnement laser invisible

dangereux en cas

d'ouverture.

EXPOSITION DANGEREUSE

AU FAISCEAU.

VARNING:

Osynlig laserstrålning

när denna del är

öppnad.

STRÅLEN

ÄR FARLIG.

VARO!:

Näkymätöntä

avattaessa olet

alttiina lasersäteilylle.

ÄLÄ KATSO

SÄTEESEN.

VARNING:

Osynlig laserstrålning

när denna del är

öppnad.

BETRAKTA EJ

STRÅLEN.

ADVARSEL:

Usynlig laserstråling

ved åbning.

UNDGÅ

UDSÆTTELSE FOR

STRÅLING.

PELIGRO:

Cuando se abre, se

producen radiaciones

invisibles de láser.

EVÍTESE LA

EXPOSICIÓN

A TALES RAYOS.

DANGER:

Invisible laser radiation

when open.

AVOID DIRECT

EXPOSURE TO BEAM.

CAUTION:

Invisible laser radiation

when open.

AVOID EXPOSURE

TO BEAM.

VORSICHT:

Unsichtbare Laserstrahlung,

wenn Abdeckung geöffnet.

NICHT DEM STRAHL

AUSSETZEN.

ADVARSEL:

Usynlig laserstråling

når deksel åpnes.

UNNGÅ

EKSPONERING

FOR STRÅLEN.

PJQTA0325ZA

This service information is designed for experienced repair technicians only and is not designed for use by the general

public.

It does not contai n w arnings o r caut ions to adv ise n on-tech nical indi vi duals of pot ential dange rs in att emptin g to s ervice a

product. Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the product or products dealt with in this service information by anyone else could result

in serious injury or death.

DANGER:

Invisible laser radiation

when open and interlock

defeated.

AVOID DIRECT

EXPOSURE TO BEAM.

PELIGRO:

Cuando se abre y se

invalida el bloqueo, se

producen radiaciones

invisibles de láser.

EVÍTESE LA

EXPOSICIÓN

A TALES RAYOS.

CAUTION:

Invisible laser radiation

when open and

interlocks defeated.

AVOID EXPOSURE

TO BEAM.

VARNING:

Osynlig laserstrålning när denna

del är öppnad och

spärrar är

urkopplade.

STRÅLEN

ÄR FARLIG.

VORSICHT:

Unsichtbare Laserstrahlung,

wenn Abdeckung geöffnet

und Sicherheitsverriegelung

überbrückt.

NICHT DEM STRAHL

AUSSETZEN.

VARO!:

Näkymätöntä

avattaessa ja

suojalukitus

ohitettaessa olet

alttiina lasersäteilylle.

ÄLÄ KATSO

SÄTEESEEN.

ATTENTION:

Rayonnement laser invisible

dangereux en cas

d'ouverture et lorsque

la sécurité est neutralisée.

EXPOSITION DANGEREUSE

AU FAISCEAU.

VARNING:

Osynlig laserstrålning

när denna del är

öppnad och spärren är

urkopplad.

BETRAKTA EJ

STRÅLEN.

ADVARSEL:

Usynlig laserstråling

ved åbning når

sikkerhedsafbrydere

er ude af funktion.

UNDGÅ

UDSÆTTELSE FOR

STRÅLING.

Laser diode properties

Laser output : 5 mW max

Wavelength : 780 nm

Emission duration : Continuous

Class 3B

ADVARSEL:

Usynlig laserstråling

når deksel åpnes og

sikkerhedslås brytes.

UNNGÅ

EKSPONERING

FOR STRÅLEN.

(220-240 VAC equipment)

CAUTION:

HOT SURFACE INSIDE

CAUTION:

HOT SURFACE

INSIDE

ATTENTION:

SURFACE

CHAUDE

CI-INTERIEUR

VORSICHT:

HEISSE FLÄCHE

INTERN

ATENCION:

SUPERFICIE

CALIENTE

EN EL INTERNO

Laser Scanning Unit (LSU)

CAUTION:HOT SURFACE BELOW

ATTENTION:SURFACE CHAUDE CI-DESSOUS

VORSICHT:HEIßE OBERFLÄCHE DARUNTER

ATENCION:SUPERFICIE CALIENTE ABAJO

i

Page 3

FS-5900C Service Manual

1. Introduction

1.1 Specifications ................................................................................................................. .................... 1

1.2 Options, Accessories and Supplies...................................................................................................... 5

1.3 Control Panel Overview ...................................................................................................................... 6

1.3.1 Message Display........................................................................................................................ 6

1.4 Rear Panel........................................................................................................................................... 8

1.4.1 Connectors................................................................................................................................. 8

1.4.2 Network card............................................................................................................................. 8

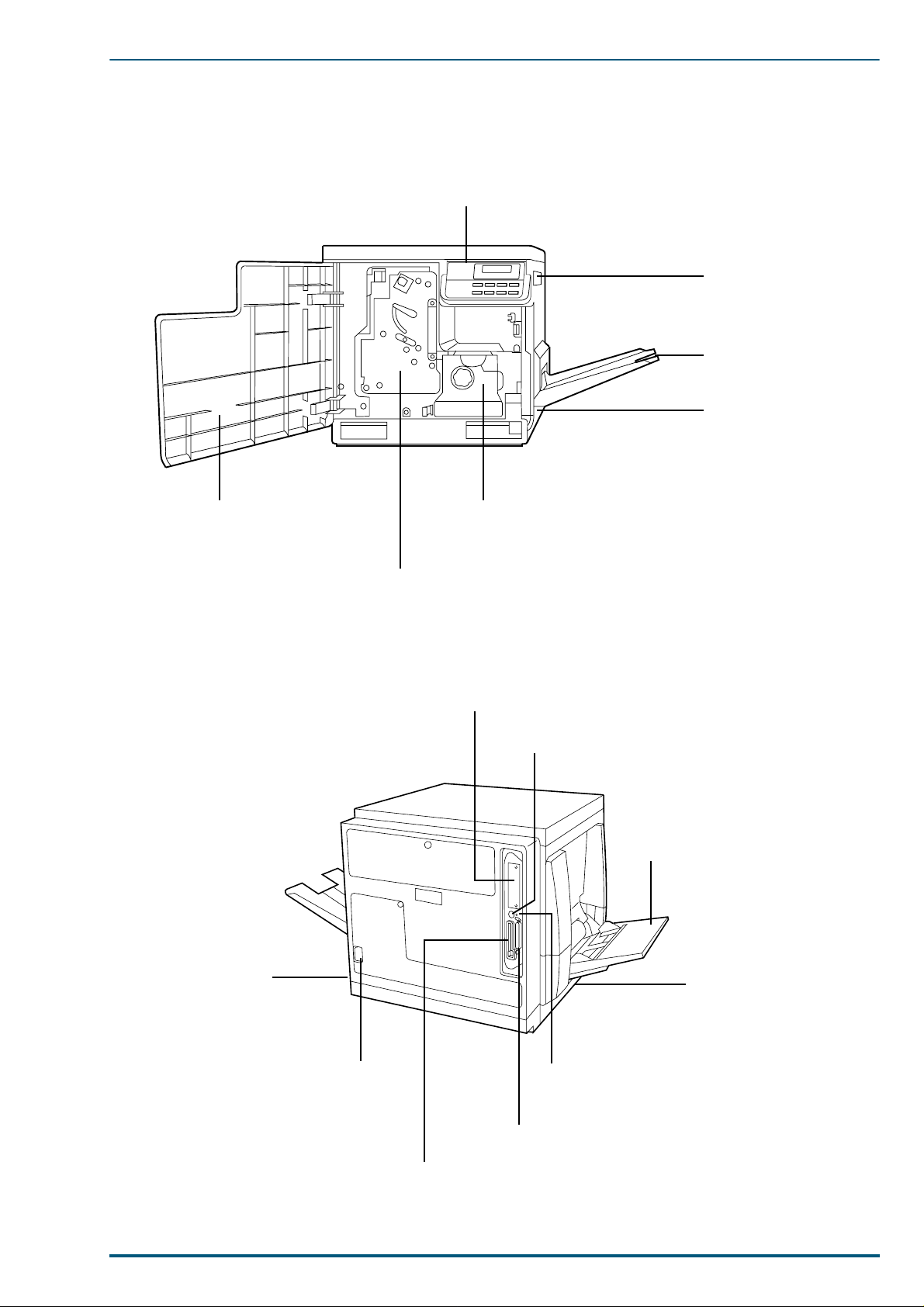

1.5 Parts Identification ............................................................................................................................. 9

1.5.1 Front side view.......................................................................................................................... 9

1.5.2 Rear side view ........................................................................................................................... 9

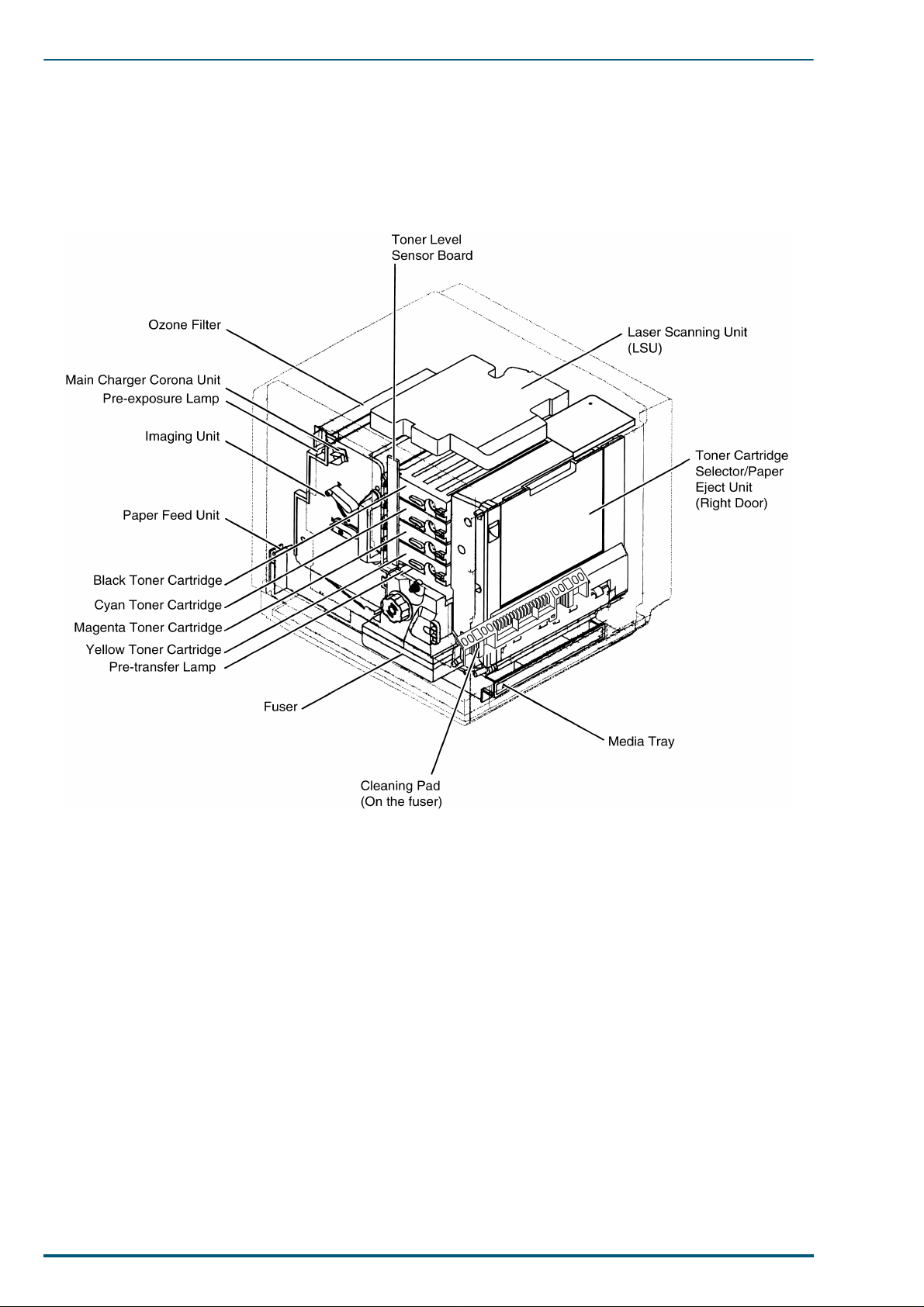

1.6 Component Layout...........................................................................................................................10

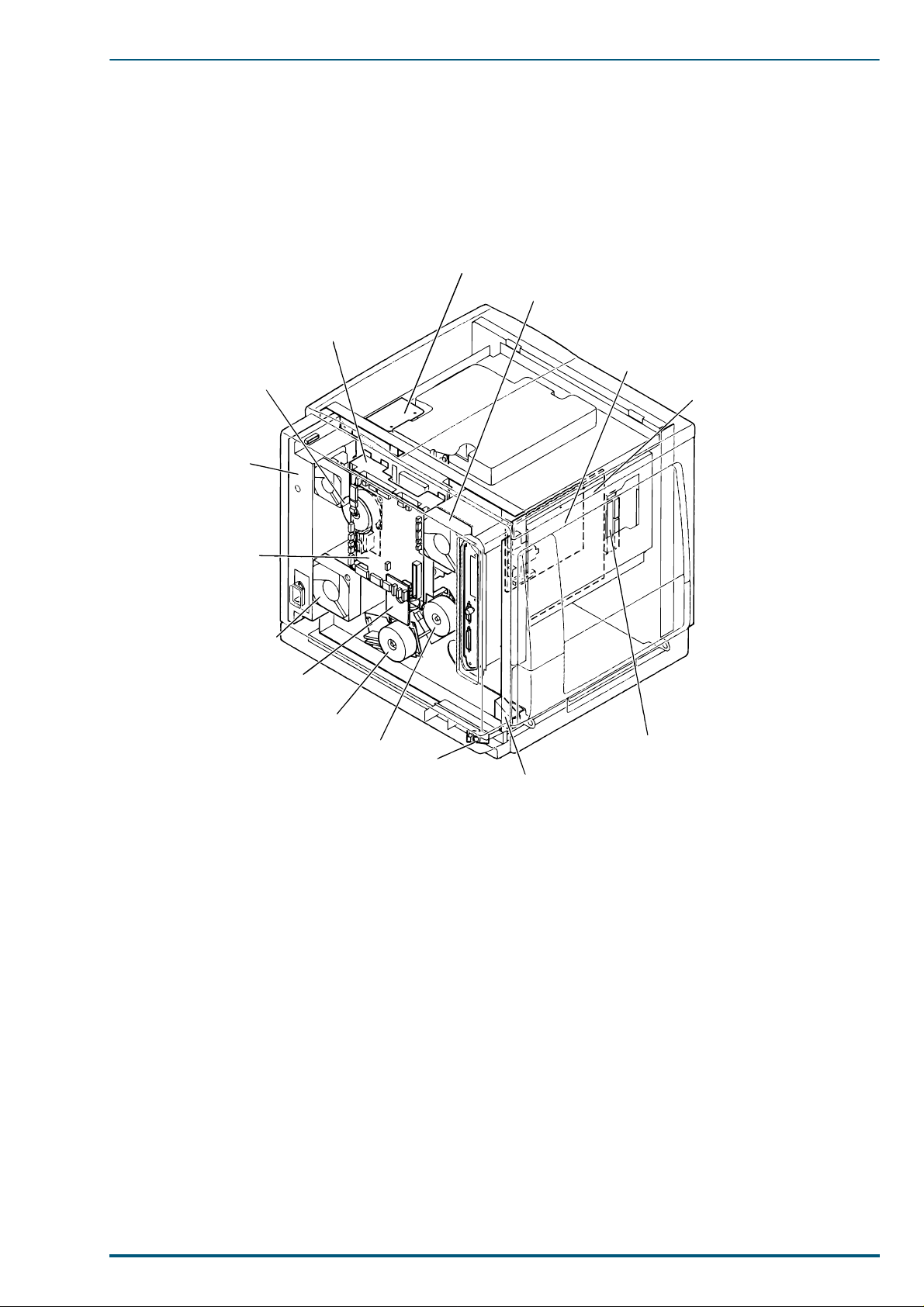

1.7 Electrical Components......................................................................................................................11

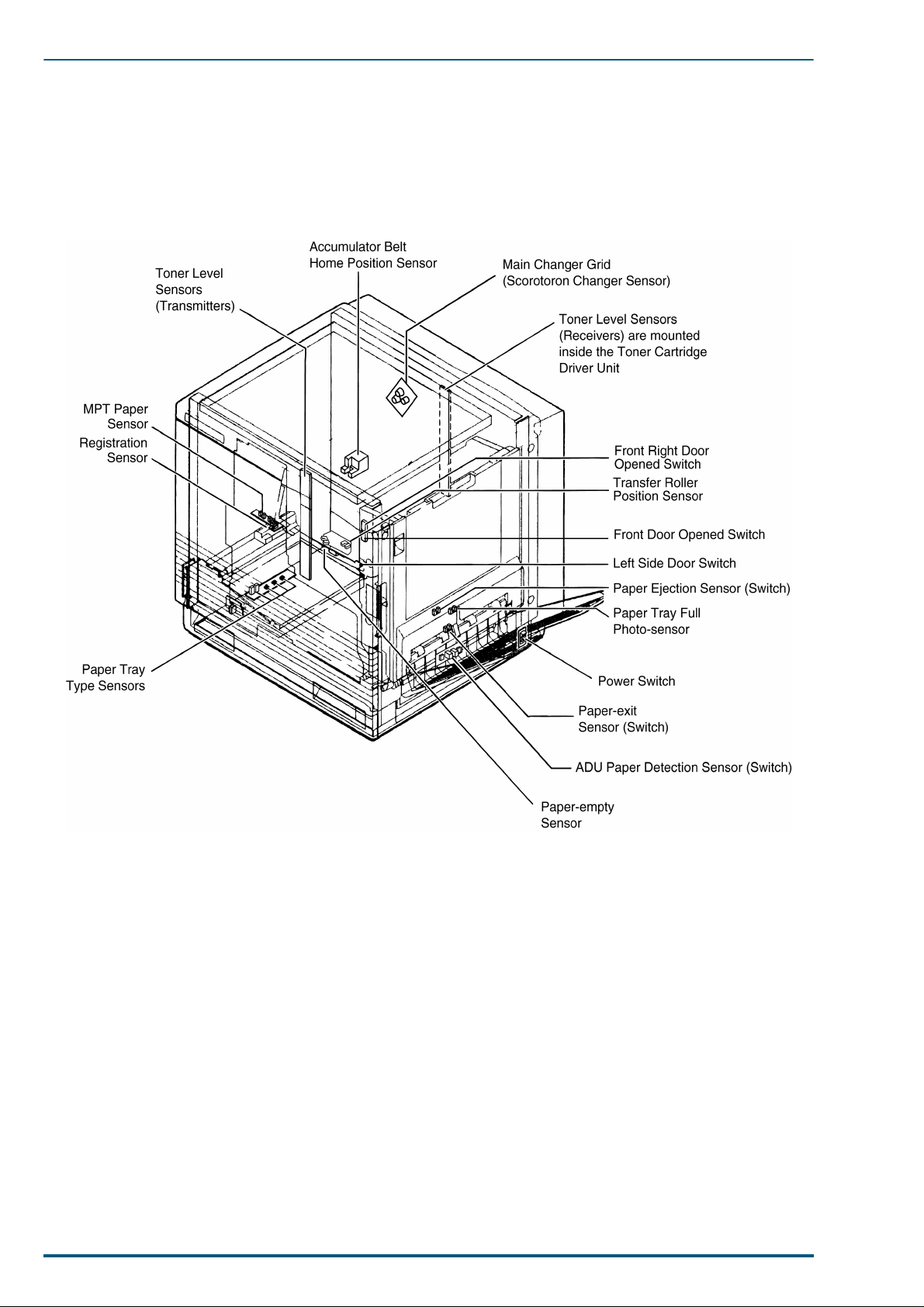

1.8 Switches/Sensors Identification ........................................................................................................12

2. Installation , Setup, an d Repa cking

2.1 Installation Requirements................................................................................................................. 13

2.1.1 Environment............................................................................................................................ 13

2.1.2 Minimum Space Requirements .............................................................................................. 13

2.2 Setup................................................................................................................................................14

2.2.1 Removing the Packing Material............................................................................................. 14

2.2.2 Installing the Optional Paper Feeder ....................................................................................14

2.2.3 Preparing the Imaging Unit ...................................................................................................14

2.2.4 Installing the Toner Developers............................................................................................. 15

2.2.5 Adding Paper or Transparencies............................................................................................ 16

2.3 Installing RAM SIMMs (Option) ........................................................................................................16

2.4 Replacing the Fuser Unit...................................................................................................................17

2.5 Replacing the Imaging Unit.............................................................................................................. 18

2.6 Repacking.........................................................................................................................................21

3. Mode Selection

3.1 Navigating through the Menus ........................................................................................................29

3.1.1 Display Information........................................................ ...... ....... ...... ....... ...... ....... ...... .. ..... .... 29

4. Mechanical Functions

4.1 Drive Mechanism/Image Process General Description....................................................................... 30

4.2 Print Process.....................................................................................................................................32

4.2.1 Discharging and Charging...................................................................................................... 32

4.2.2 Laser Exposure and Scanning................................................................................................32

4.2.3 Developing............................................................................................................................... 34

4.2.4 Toner Transfer to the Accumulator Belt ................................................................................ 35

4.2.5 Paper Pickup ...........................................................................................................................35

4.2.6 Toner Transfer to Paper..........................................................................................................36

4.2.7 Fusing and Exiting.................................................................................................................. 36

ii

Page 4

Table of Contents

5. Removal and Replacement Procedures

5.1 Upper Rear, Lower Rear and Top Covers............................................................................................38

5.2 Left Side Cover and Multi-purpose Tray ............................................................................................38

5.3 Operation Panel Cover and Printer LCD Board..................................................................................39

5.4 Safety Interlock Switches and Toner Empty Sensor Board (T)............................................................40

5.5 Front Cover and Bottom Front Cover................................................................................................4 1

5.6 Front Right Side, Rear Right Side and Lower Right Side Covers.........................................................42

5.7 Left Side Cover..................................................................................................................................43

5.7.1 Left Side Cover Removal .........................................................................................................43

5.7.2 Left Side Cover Sub Assembly................................................................................................43

5.8 Printer Main Control Board, HSYNC Board and Network Relay Board...............................................44

5.8.1 Printer Main Board Removal..................................................................................................44

5.8.2 Printer Main Control Board Disassembly, HSYNC Board and Network Relay Board........44

5.9 Paper Feed Unit ................................................................................................................................4 5

5.9.1 Paper Feed Unit Removal .......................................................................................................45

5.9.2 Paper Feed Unit Board and MP Tray Paper Out/Registration Sensor Board......................45

5.9.3 Transfer Roller Clutch, Transfer Roller Holder, Cleaning Roller Holder and

Registration Roller...................................................................................................................46

5.9.4 MP Tray Retard Pad................................................................................................................48

5.9.5 MP Tray Motor, MP Tray Pickup Roller and MP Tray Pickup Roller Shaft.........................49

5.9.6 Pickup Roller, Pickup Roller Shaft Assembly and Paper Empty Sensor Arm .....................51

5.9.7 Paper Feed Roller and Paper Feed Unit Frame.....................................................................52

5.10 Toner Developer Selector/Paper-eject Unit.........................................................................................53

5.10.1 Toner Developer Selector/Paper-eject Unit Removal.............................................................53

5.10.2 Covers, Sensor Boards (Paper Ejection, Paper Exit, Paper Tray Full) and

Paper Ejection Roller....... ...... ....... ...... ....... ...... ...... ....... .................................................... .. .... .54

5.10.3 Cam Motor Board, Toner Developer Movement Sensor Board and Toner Selector Cam....56

5.10.4 Joint Gear and Face Down Switch Back Solenoid.................................................................57

5.10.5 Switch Back Shaft, Switch Back Roller and Face Down Switch Gate..................................58

5.11 Engine Control Board Shield Cover...................................................................................................60

5.12 Laser Scanning Unit (LSU).................................................................................................................60

5.13 Power Supply Unit............................................................................................................................61

5.13.1 Power Supply Unit Removal ...................................................................................................61

5.13.2 Power Supply Unit Sub Assembly..........................................................................................61

5.14 Engine Control Board .......................................................................................................................6 2

5.15 Fuser/Toner Developer Fan Motor and Ozone Fan Motor ..................................................................62

5.16 Main Motor, Paper Feed Motor and Left Side Cover Switch..............................................................63

5.17 Transfer Roller Bias Terminal, FTR Bias Terminal, Home Sensor Board and Fuser Joint Connector ......63

5.18 IT Cleaning Solenoid Board and Toner Developer Drive Motor/Toner Developer Drive Unit ...............64

5.18.1 Removal (IT Cleaning Solenoid Board and Toner Developer Drive Motor/

Toner Developer Drive Unit)...................................................................................................64

5.18.2 Toner Developer Drive Unit Sub Assembly............................................................................65

5.19 Printer Main Control Board Holder, Printer Panel Relay Board and High Voltage Board ....................67

5.20 IT Belt Cleaning Drive Gears, Cleaning Clutch Shaft Assembly, Main Motor Bracket, Imaging Unit

Coupling Connector, Fuser Coupling Connector and Optional 2nd Feeder

Coupling Connector..........................................................................................................................68

iii

Page 5

FS-5900C Service Manual

5.21 Cassette Detection Sensor Board...................................................................................................... 69

5.22 Pre-Exposure Eraser and Pre-Transfer Boards.................................................................................... 69

5.23 Pre-Transfer Board Bracket and Toner Developer Guide Rails ............................................................70

5.23.1 Pre-transfer Board Bracket .................................................................................................... 70

5.23.2 Toner Developer Guide Rails.................................................................................................. 71

5.24 Cassette Guide, Fuser Guide Frame and Fuser/Paper Feed Unit Drive Gears...................................... 72

5.25 Fuser Unit Component (Heat Lamp, Thermal Fuse and Thermostat)................................................. 73

6. Electrical Circuit Description

6.1 Engine Block Diagram ......................................................................................................................75

6.2 Printer Main Control Board Block Diagram.......................................................................................76

6.3 Basic engine functions......................................................................................................................77

6.4 Engine controller system.................................................................................................................. 77

6.4.1 Configuration memory............................................................................................................ 77

6.4.2 High-voltage generator ................................ ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... .... 77

6.4.3 Laser scanner control.............................................................................................................. 77

6.4.4 Polygon motor control ............................................................................................................. 77

6.5 Safety interlock.................................................................................................................................77

6.5.1 The engine gate array............................................................................................................. 78

6.5.2 Power supply ............................ ....... ................................................... ....... .............................. 85

6.6 Logic controller system..................................................................................................................... 87

6.6.1 Printing data processing.........................................................................................................89

6.7 Main logic component .....................................................................................................................89

6.8 Print engine (video) interface ...........................................................................................................92

6.8.1 Physical Characteristics .........................................................................................................93

6.9 Interface Signals...............................................................................................................................94

6.9.1 Signal functions....................................................................................................................... 94

6.9.2 Serial control lines .................................................................................................................. 95

7. Setting the Colour Density

8. Preventative Maintenance

8.1 General................................................................................................................. .... ........................99

8.2 Recommended Tools.........................................................................................................................99

8.3 Recommended Cleaning...................................................................................................................99

8.4 Maintenance Tables........................................................................................................................100

8.4.1 User Maintenance.................................................................................................................100

8.4.2 Service Maintenance.......... ...... ....... ................................................... ....... ...... ...................... 10 1

9. Troubleshooti ng

9.1 Initial Troubleshooting Flowchart ................................................................................... ........... .....102

9.2 Error Messages............................................................................................................................... 103

9.2.1 Error Messages...................................................................................................................... 103

9.2.2 Call Service person Codes..................................................................................................... 105

iv

Page 6

Table of Contents

9.3 Jam.................................................................................................................................................108

9.3.1 Print Media Problem .............................................................................................................108

9.3.2 Print Media skews. ................................................................................................................108

9.3.3 Printer cannot distinguish between paper and transparency. ............................................108

9.3.4 Paper jams at the media cassette. ........................................................................................109

9.3.5 Paper jams midway in the paper feeder. ..............................................................................109

9.3.6 Paper jams at the second bias transfer roller.......................................................................110

9.3.7 Fuser Jams.............................................................................................................................110

9.3.8 Eject Jams..............................................................................................................................111

9.3.9 Multi-purpose Tray Jams......................................................................................................111

9.4 Print Quality....................................................................................................................................112

9.4.1 Blank Print.............................................................................................................................112

9.4.2 All-black Print........................................................................................................................112

9.4.3 Missing Primary Colour ........................................................................................................113

9.4.4 Light Print..............................................................................................................................113

9.4.5 Repeated spots or lines on print in-line with each other.....................................................114

9.4.6 Dark Vertical Line in Print ...................................................................................................114

9.4.7 White horizontal line or band in all the colours of a print ..................................................115

9.4.8 Mis-transfer, missing portions of toner.................................................................................115

9.4.9 Dirty Background ..................................................................................................................115

9.4.10 Partial Black Dots..................................................................................................................115

9.4.11 Dark Irregular Streaks in All Colours...................................... ...... ....... ...... ....... ...... ....... .....116

9.4.12 Ghosting .................................................................................................................................116

9.4.13 Unfused or Partially Fused Printing....................................................................................116

9.4.14 Image is skewed on the paper. ..............................................................................................116

9.4.15 Stains on Back of Print..........................................................................................................117

9.4.16 No Printing on Edge of Print.................................................................................................117

9.4.17 Image is not centered on the print when it should be. ........................................................117

9.5 Printer Error (Call Service person) ...................................................................................................118

9.5.1 BB/B8/B9/BA..........................................................................................................................118

9.5.2 A6............................................................................................................................................119

9.5.3 E2/E3......................................................................................................................................119

9.5.4 A5............................................................................................................................................120

9.5.5 AC...........................................................................................................................................122

9.5.6 AD...........................................................................................................................................124

9.5.7 AE...........................................................................................................................................125

9.5.8 AF ...........................................................................................................................................126

9.5.9 B7............................................................................................................................................127

9.5.10 A2............................................................................................................................................128

9.5.11 E4............................................................................................................................................130

9.5.12 A7............................................................................................................................................130

9.5.13 A8............................................................................................................................................131

9.5.14 AA ...........................................................................................................................................132

9.5.15 AB ...........................................................................................................................................133

9.5.16 E1............................................................................................................................................134

9.5.17 A9............................................................................................................................................135

9.5.18 E6............................................................................................................................................135

9.5.19 BC ...........................................................................................................................................135

9.5.20 BD...........................................................................................................................................136

9.5.21 E0............................................................................................................................................136

9.5.22 BE ...........................................................................................................................................137

v

Page 7

FS-5900C Service Manual

9.5.23 BF...........................................................................................................................................137

9.5.24 Call Service person F0 .......................................................................................................... 137

9.5.25 Memory Overflow............................ ...... ....... ...... ....... ...... ...... ................................................ 138

9.5.26 Call Service person F2 .......................................................................................................... 138

9.5.27 Call Service person F3 .......................................................................................................... 139

9.6 No Message Section.......................................................................................................................140

vi

Page 8

1. Introduction

1.1 Specifications

CPU PowerPC 603e (100 MHz)

Printing Method Semiconductor Laser

1. Introduction

Printer

Host I/F Standard : Bidirectional Parallel, Serial (8-pin DIN)

Print Speed The speeds listed in the following table represent the time the printer pro-

Resolution 600 × 600 dpi

Paper Output Up to 500 sheets [75 g/m

Option: Network inte rface card

duces multiple prints on various media and resolution (Continuous

throughput rate).

Continuous Print Speeds (ppm)

Simplex

600 × 600 dpi

Plain Paper colour: 4

Legal colour: 2

Labels, Coated, Card Stock, 2nd Side colour: 2

Transparency colour: 2

1200 × 1200 dpi

Plain Paper colour: 2

Legal colour: 1

Labels, Coated, Card Stock, 2nd Side colour: 2

Duplex

600 × 600 dpi

Plain Paper colour: 2

Legal colour: 1

1200 × 1200 dpi

Plain Paper colour: 1

Legal colour: 0.5

1200 × 1200 dpi (additional RAM required)

2

(20 lbs.)]

mono: 16

mono: 8

mono: 8

mono: 8

mono: 8

mono: 4

mono: 8

mono: 4

mono: 2

mono: 2

mono: 1

RAM Standard 48 MB (expandable to a maximum of 112 MB with optional

Operating Environment Temperature: 10 to 32.5 °C (50 to 90.5 °F)

Storage Environment Temperature: 0 to 40 °C (32 to 104 °F)

Best Print Quality Temperature: 16 °C to 27 °C (59 °F to 77 °F)

Operating Altitude 0 to 2,500 m (8,000 ft.)

Storage Altitude 0 to 4,000 m (13,125 ft.)

Warm Up Time Less than 330 seconds (at 22 °C, 50 %RH)

Dimensions of Standard

Unit (without Paper Feeder)

SIMMs)

Humidity: 15 to 80 % RH

Humidity: 10 to 80 % RH

Humidity: 36 to 63 % RH

Height: 462 mm (18.2")

Depth: 493 mm (19.4")

Width: 510 mm (20.1") [784 mm (30.9") with the output tray]

1

Page 9

FS-5900C Service Manual

Printer

Mass (Weight) of standard

unit with all consumables

(without optional Paper Feeder)

51 Kg (112 lbs.)

Voltage 120 VAC ±10 %

Frequency 60 Hz

Power Consumption 920 W Max.

210 W (standby)

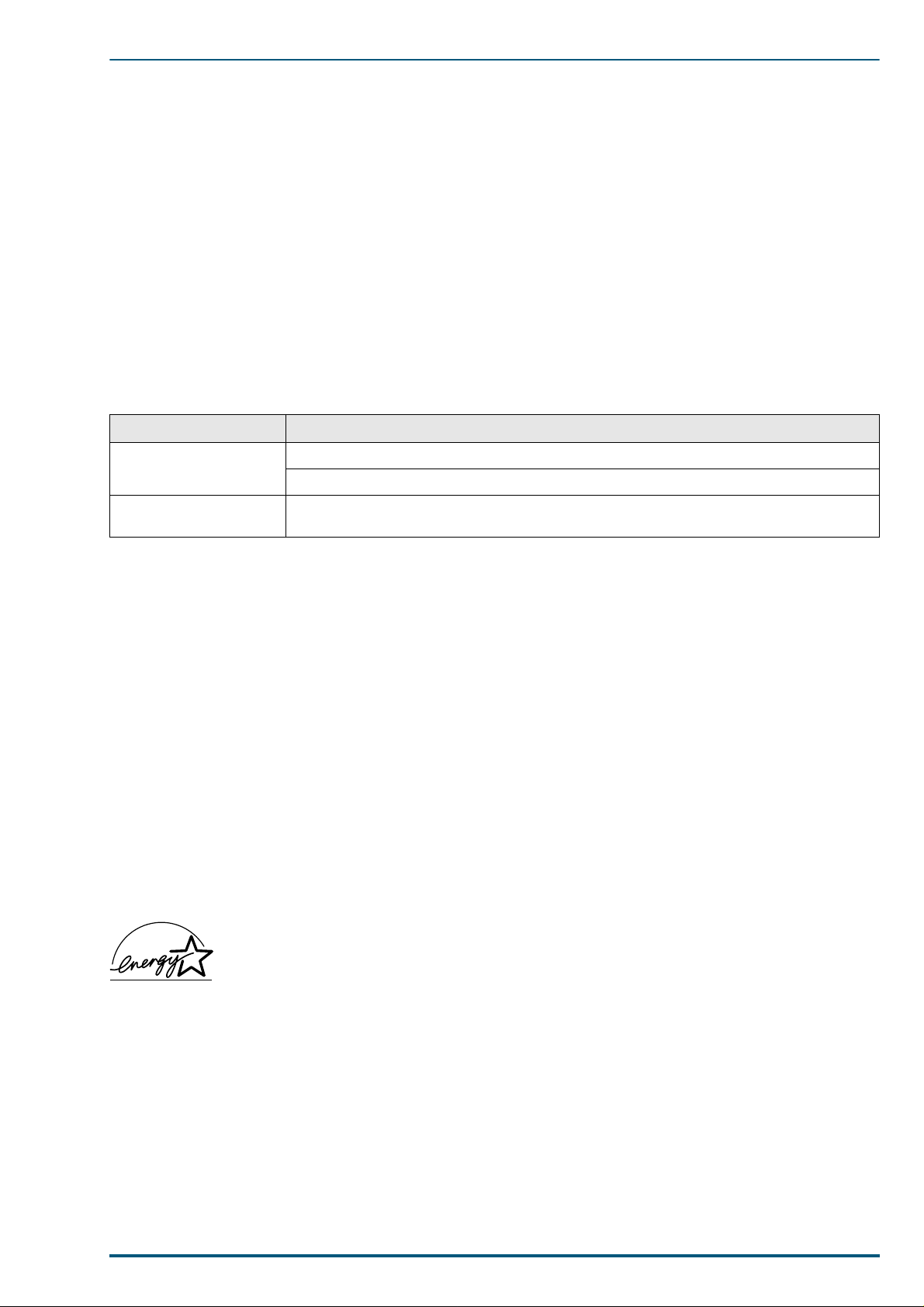

Less than 45 W (Energy Star mode), meeting the Energy Star power conser-

vation requirements

Noise Level 53 dB(A) [Printing mode]

47 dB(A) [Standby mode]

Density Control Variable (through the operator panel [MODE key])

Fusing System Heat and Pressure Rollers

Photoreceptor Organic Photoconductor (OPC) Belt

Development Process One component non magnetic development

Toner Yielding

(5% image area)

12,000 pages average (Black toner developer),

10,000 pages average (C.M.Y toner developers)

Safety and EMC Standard For the 120 VAC version: UL 1950 listed

FCC Part 15, Subpart B Class B, certified

Paper Weight Media cassette*

Simplex

mono: 60 to 105 g/m

colour:75 to 105 g/m

2

(16 to 28 lbs.)

2

(20 to 28 lbs.)

Paper

Duplex

mono: 75 to 90 g/m

colour:75 to 90 g/m

2

(20 to 24 lbs.)

2

(20 to 24 lbs.)

Multi-purpose tray

Simplex only

mono: 75 to 165 g/m

colour:75 to 165 g/m

2

(20 to 44 lbs.)

2

(20 to 44 lbs.)

Thickness 3.7 to 7.5 mils (1 mil=1/1000")

Moisture Content 4% to 6%

Smoothness 100 to 300 Sheffield

Acid Content 5.5 PH minimum

Fusing Compatibility Must not scorch, melt, offset material or release hazard ous emissions when

heated to 200 °C (392 °F) for 0.1 second

Cutting Dimensions ±0.0313 inch of normal, corners 90° ±4°

Grain Long grain

Cut Edge Conditions Cut with sharp blades, no paper dust

Ash Content Not to exceed 10 %

Curl No allowable curl toward the side to be printed

Packing Polylaminated moisture proof ream wrap

Paper Size A4 8.3" × 11.7" (210 × 297 mm)

Legal 8.5" × 14" (216 × 356 mm)

Letter 8.5" × 11" (216 × 279 mm)

Transparency Size A4 8.3" × 11.7" (210 × 297 mm)

Letter 8.5" × 11" (216 × 279 mm)

2

Page 10

1. Introduction

Types of paper to avoid

1. Extremely smooth or shiny paper or paper that is highly textured

2. Letterhead imprinted with low temp erature or thermography. These materials may transfer onto the fusing roller

and cause damage. Any pre-printed paper should use inks compatible with 200 °C (392 °F) for 0.1 second.

3. Damaged or wrinkled paper, or paper with irregularities such as tabs, staples, etc.

4. Multipart forms or carbonless paper

5. Paper with a 25% or more cotton and/or fiber content

6. Ink jet paper (It may transfer onto the fuser roller and cause damage.)

* We do not recommend the use of 1 05 g/m

paper feed problems may be experienced.

2

(28 lbs.) paper in areas of high or low humidity and temperature since

Device Cables (Not included with the Printer)

Cables Description

Parallel/Centronics

Serial Requires a Kyocera cable adaptor SA-80 which converts 8-pin DIN to 25-pin DSUB config-

36-pin high-density plug to 25-pin DSUB plug; less than 2.0 m (6.56 ft.)

Connects the printer to a PC parallel port

uration.

Specifications are subject to change without notice.

Trademark Acknowledgements

Windows is a registered trademark of Microsoft Corporation in the United States and/or other countrie s.

Pentium is a registered trademark of Intel Corporation.

Corel is a trademark of Corel Corporation.

Adaptec is a registered trademark of Adaptec, Inc.

Centronics is a trademark of Centronics Data Computer Corporation.

TextBridge is a registered trademark of Xerox Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

All other acknowledgments are trademarks or registered trademarks of their respective holders.

Acrobat Reader copyright 1987-1999 Adobe Systems Incorporated. All rights reserved.

As an Energy Star Partner, Kyocera Corporation has determined that this product meets

the Energy Star g uidel ines fo r e nergy ef fici ency. The international Energy StarSM Lo go i s

valid in U.S.A., Europe and Japan only.

All about media

• The recommended media is as follows:

Letter/Legal: Hammermill LASERPRINT 90 g/m

A4: NEUSIEDLER COLOR COPY 90 g/m

For the finest resolution and the brightest, most consistent colours, use a high grade laser paper. The

weight of the paper should be 60-105 g/m

2

(16-28 lbs.) paper in the media cas settes; and 75-120 g/m2 (20-

32 lbs.) in multi-purpose tray.

Transparency: 3M CG3700 and 3M CG3710

2

(24 lbs.)

2

(24 lbs.)

3

Page 11

FS-5900C Service Manual

• Labels

Use only full 8.5" × 11" or A4 label sheets rath er tha n die-cut l abel sheets t hrough t he mult i-purp ose tray.

Die-cut labels may peel off from their backing and stick inside the imaging unit or fuser.

• Envelopes

This printer prints black text only using the following high quality #10 laser envelopes with diagonal

steams. Do not insert more than one envelope at a time.

• A thin, sharply creased leading edge.

2

• Paper weight of 90 g /m

(24 lbs.)

• Flat and free of curls, wrinkles, nicks, etc.

• Make sure that the media cassettes are free of dust. Du st and dirt in a media cassette can be transferred

to the paper or transparency, resulting in poor print quality.

• Handle paper and transparencies with both hands at the edges to avoid creases and fin gerprints, which

can result in poor print quality.

• Store paper and transparencies in the original dust-free package.

• To prevent transparencies or paper from sticking together, fan them before loading into the appropriate

media cassette.

• If the optional paper feeder is used: A media cassette can be installed in any of the three tray slots; however, the transparency tray should only be inserted in the upper and middle tray slots.

Margins and Print Area

When the printer places an image on media, the image (print area) is a bit smaller than the media size.

Page margins adjustment may be needed in an application software to match the pr int area.

The following table lists the page sizes, the maximum print areas, and the margins for the media sizes supported in KPDL emulation, 600dpi.

Media

cm/inch Points Horizontal Vertical

A4 21.0 × 29.7 595 × 842 112 120 4736 × 6784

B5 18.2 × 25.7 516 × 729 174 97 3950 × 5875

ISO B5 17.6 × 25.0 499 × 708 99 102 3958 × 5700

Legal 8.5 × 14 inches 612 × 1008 86 136 4928 × 8128

Letter 8.5 × 11 inches 612 × 792 86 132 4928 × 6336

Executive 7.25 × 10.5 inches 522 × 756 100 100 4150 × 6100

Page Size Edge limitis (A) (dot)

B

Horizontal

edge limit

Printable area

Direction of paper

feeding

Printable area (B) (dot)

A

Vertical edge limit

RAM and printer capabilities

The printer features 16 Mbytes of base RAM and a 32-Mbyte SIMM fit in the one of the three connectors

that accept 4, 8, 16 and 32-Mbyte RAM SIMMs. With additional RAM memory the printer’s capabilities

increase as follows:

4

Page 12

1. Introduction

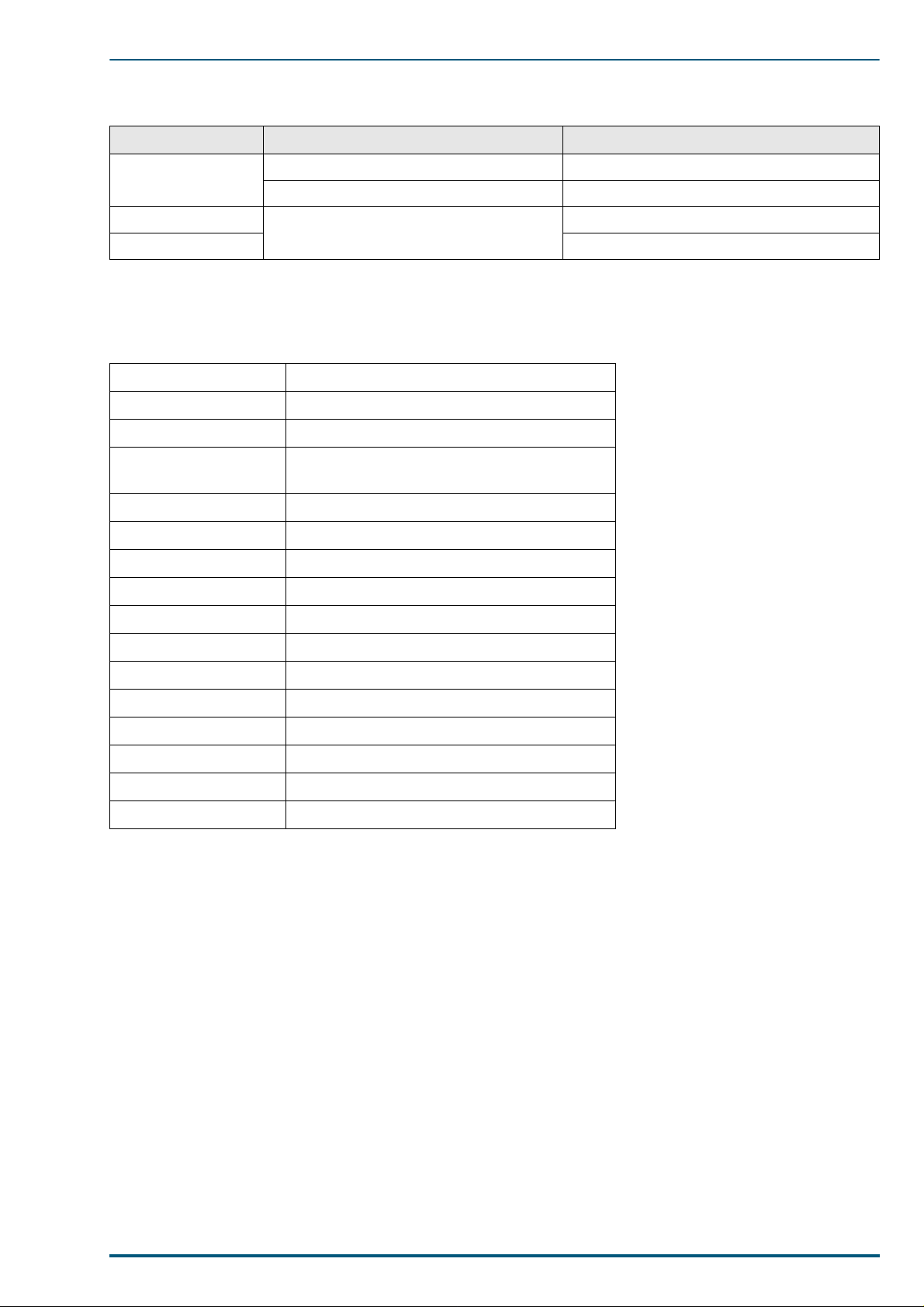

When using the Printer Driver and Utilities

Total Memory Selectable Print Quality Mode Printable without Memory Overflow

48 MB (Stan dard)

56 MB (8MB added)

72 MB (24MB added) Letter, A4, Legal

* Documents can be printed on Legal size paper when the print style is set to Color Graphics provided the data size of

the documents is small.

Fast (300 dpi) Letter, A4, Legal

Standard (600 dpi) Letter, A4*

Letter, A4*

High Quality (1200 dpi)

1.2 Options, Accesso r ies and Supplies

Item Description

PF-81

PF-81D

HB-7SNMP

EcoLAN 2000E

TD-81K

TD-81C

TD-81M

TD-81Y

Paper Feeder

Paper Feeder/Duplex Unit

Network Card for Ethernet

Toner developer: Black

Toner developer: Cyan

Toner developer: Magenta

Toner developer: Yellow

FK-81

IU-81

TR-81

OS-81

SA-80

HD-2C

CP-81

MC-81

Fuser

Imaging unit

Transfer unit

Oil Supply Roll

Serial Adapter

HDD unit (2GB)

Cleaning pad for the fuser

Main charger

5

Page 13

FS-5900C Service Manual

1.3 Control Panel Overview

The printer has the following displays and keys. Simple explanation the displays follows. For a full information on using them, refer to the printer’s User’s Manual (also on the CD-ROM).

1.3.1 Message Display

The message display displays the printer’s operati onal mode. Messages which are displayed and their

meanings are as follows:

Message Meaning

Self test

Please wait

Ready

Processing

Waiting

FormFeed TimeOut

Interface Indicator

The interface indicator indicates the interface over which data is currently being received or was last

received. The current interface is indicated by one of the following messages:

The printer is self-testing after power-up and is not ready to print. This message appears only

at power-up.

The printer is warming up and is not ready to print.

The printer is ready to print.

The printer is processing print data or in the middle of printing.

The last page remains unprinted. The printer waits awhile and eventually generates a form

feed allowing the last page to be printed. (The length of time depends on the form feed timeout

setting.) The printing will begin immediately when the

card is being used this can indicate the printer is waiting for data to be written.

An automatic form feed has been generated.

Form Feed

key is pressed. If a memory

Display Description

PAR

SER

OPT

Note:

The display will blink while the printer is receiving data and continue blinking until the interface is

Parallel interface

Serial interface

Optional interface (if a network interface card is installed)

released, even after data transmission is finished.

6

Page 14

1. Introduction

Resolution Indicator

This shows the current printing resolution in either 1200 or 600 dpi (dot-per-inch).

Paper Size Indicator

This indicator indicates the paper size of the cassette currently selected. The following abbreviations are

used to indicate the paper sizes:

Indicator Paper Size

A4

EX

B5

LT

LG

b5

* These paper sizes can only be fed from the MP tray.

ISO A4 (21 × 29.7 cm)

Executive (7-¼ × 10-½ inches)*

JIS B5 (18.2 × 25.7 cm)*

Letter (8-½ × 11 inches)

Legal (8-½ × 14 inches)

ISO B5 (17.6 × 25.0 cm)*

Copy Indicator

This indicator indicates the number of copies to print from 001 to 999. This number is reduced as printing

proceeds.

7

Page 15

FS-5900C Service Manual

1.4 Rear Panel

1.4.1 Connectors

The rear panel is equipped with the following interface connectors:

• Parallel (high densit y conne cto r)

• Serial (8-pin mini DIN-type connector)

A converter cable that allows the serial connector to a DSub connector is opt ionally available by the model

number SA-80.

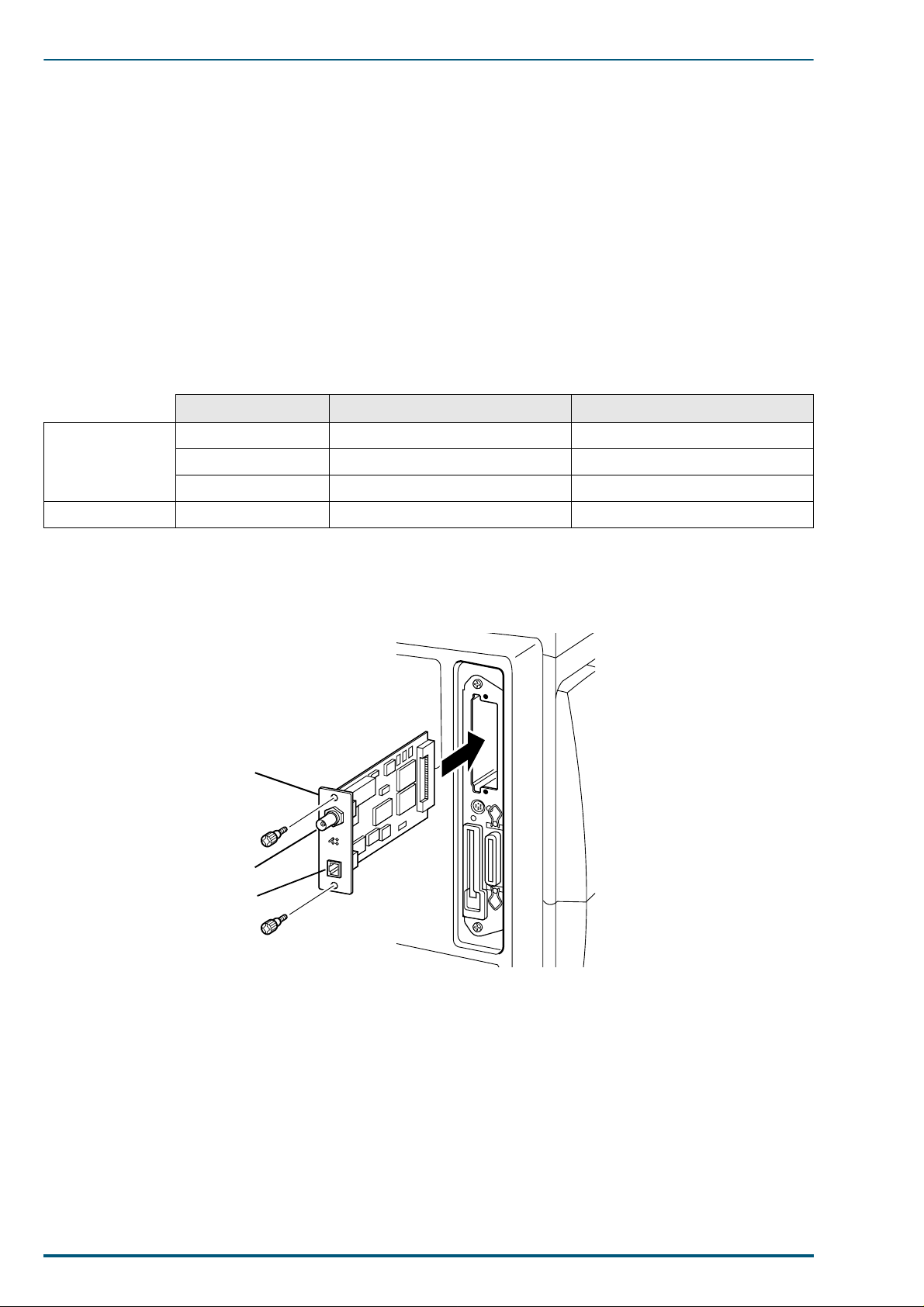

1.4.2 Network card

The network interface card is available in either Ethernet or TokenRing protocol as follows.

See your nearest dealer of the manufacturer for availability.

Manufacturer Model Applicable country

HBM HB-7SNMP Available in UK and France

Ethernet

Token Ring SEH IC69-Token-KYO2 All countries

Two LEDs on the face of the optional network card verify LAN connection and network activity.

DPI EcoLAN 2000E Available in USA and Japan

SEH IC59-ETHER-KYO2 Other countries

Installing the Network Card

Example:

HB-7SNMP EcoLAN 2000E

10BASE2

10BASE-T

8

Page 16

1.5 Parts Identification

1.5.1 Front side view

1. Introduction

Control panel

Right side cover

Output tray

Media cassette

Front cover

1.5.2 Rear side view

Fuser

Imaging unit

Network interface card slot

Serial interface connector

Multi-purpose (MP) tray

Power switch

AC inlet

Left side cover

[Media thickness switch*]

* Accessible by opening the

left side cover

Harddisk access

indicator

Parallel interface co nnect or

Memory card connector

9

Page 17

FS-5900C Service Manual

1.6 Component Layout

10

Page 18

1.7 Electrical Components

Toner Cartridge

Drive Unit

Toner

Cartridge

Motor

Power

Supply

Unit

1. Introduction

Polygon Motor

Driver Board

Ozone Fan

High Voltage

Board

Main Control Board

Engine

Control

Board

Fuser/Toner

Cartridge Fan

Cleaning Board

Paper Feed Motor

Main Motor

Temperature/

Humidity

Sensor Board

Interconnect

Board

Lower Door Open

Sensor

11

Page 19

FS-5900C Service Manual

1.8 Switche s/Sensors Identification

12

Page 20

2. Installation, Setup, and Repacking

2. Installation, Setup, and Repacking

2.1 Installation Requirements

2.1.1 Environment

Temperature Range: 10°C to 32.5°C [50°F to 90.5°F] (Temperature fluctuation: ±10°C per hour or less)

Humidity Range: 15% RH to 80% RH (Humidity fluctuation: ±20 °C per hour or less)

Weight: 51 kg (112 lbs.)

Precautions for installation

Place the unit on a stable, level surface.

Do not install the unit under the following conditions:

• Extremely high or low temperature

• Extremely high or low humidity

• Direct exposure to sunlight

• Areas of high dust concentration

• Areas of poor ventilation

• Areas exposed to chemical fumes

• Areas with extreme vibration

• Directly in air conditioning flow

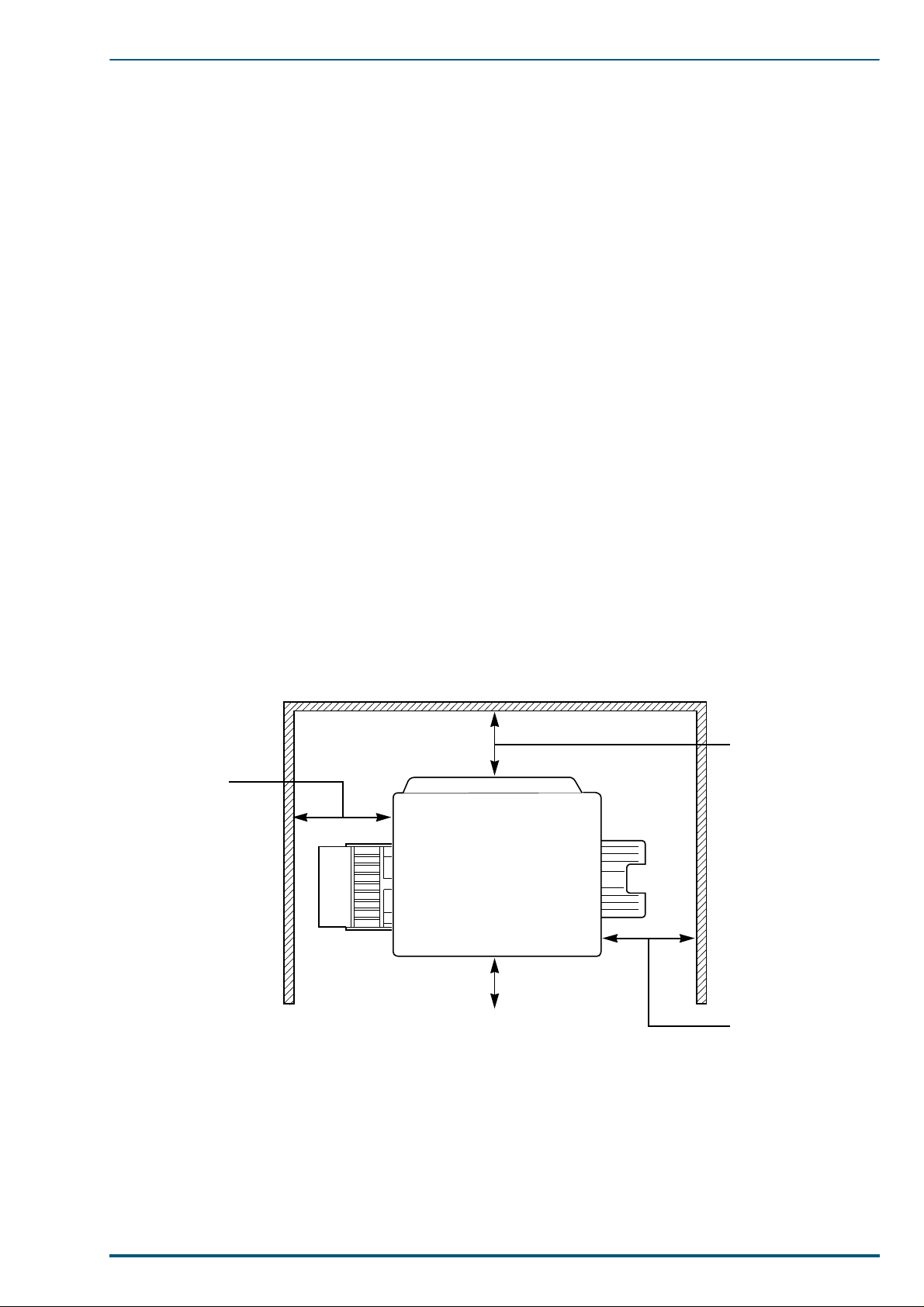

2.1.2 Minimum Space Requirements

Allow air flow around the printer to prevent overheating. The following minimum spaces are required:

Rear

35 cm (13.8")

Controller Board

45 cm (17.7")

Output

tray

Left Right

Multi-purpose Tray

Front cover

50 cm (19.7")60 cm (23.6")

13

Page 21

FS-5900C Service Manual

2.2 Setup

2.2.1 Removing the Packing Material

1. Remove the plastic bag from the printer.

2. Remove any adhesive tape that holds the output tray against the printer.

Note:

Do not throw away the packing materials. They may be required to ship or transport the printer in

the future. To provide optimum print quality , the unit must be kept upright and level during unpacking.

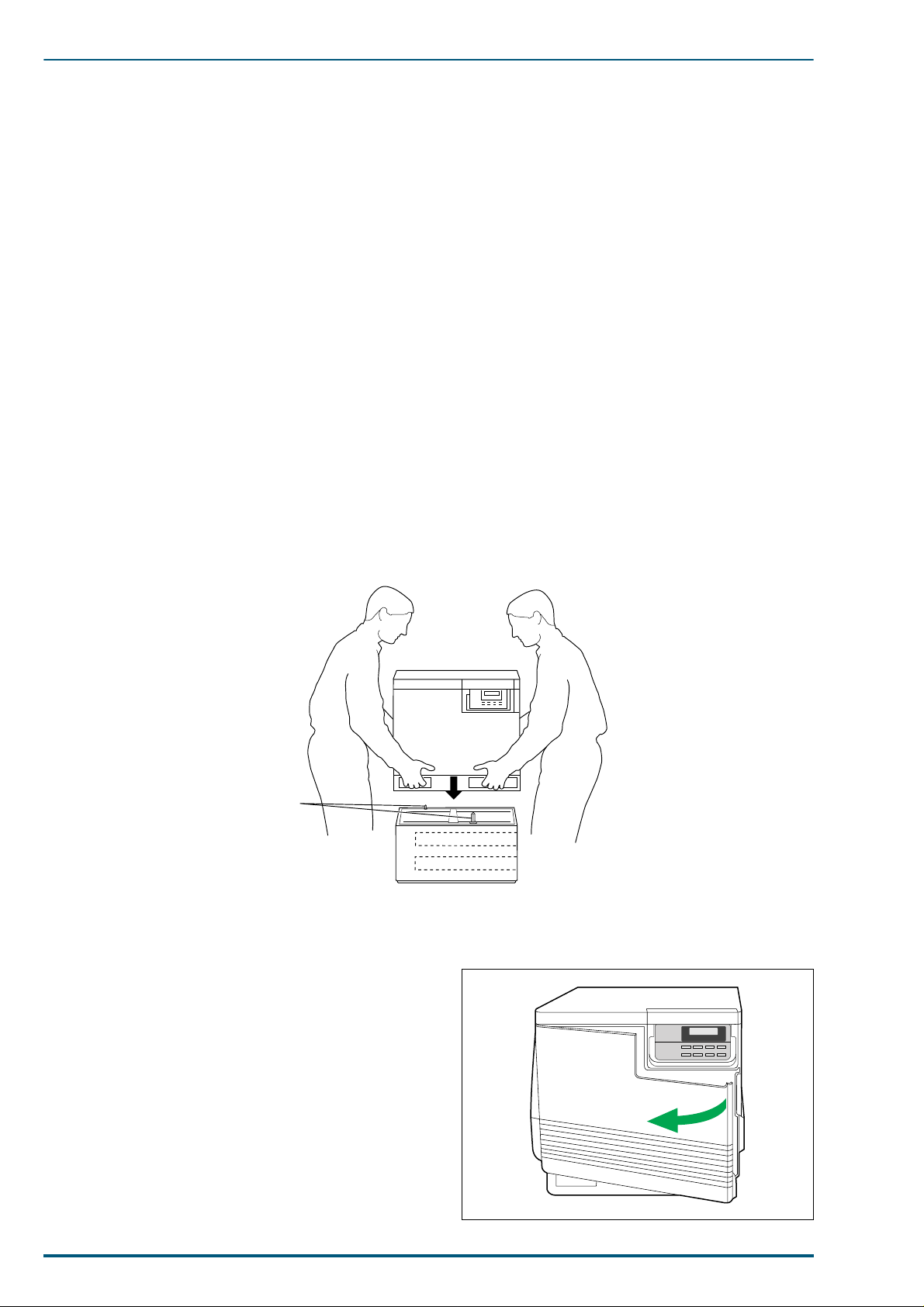

2.2.2 Installing the Optional Paper Feeder

Warning:

Warning:

1. Place the paper feeder on a solid table or cart selected for the printer.

2. Place the printer on top of the paper feeder. Always keep the printer upright.

3. Make sure that the left and right alignment pins fit in the holes in the base of the printer.

The printer weighs about 51 kg (112 lbs.) and the paper feeder weighs about 14.4 kg (36.3 lbs.).

Observe standard precautions for lifting heavy objects.

The printer is not permanently attached to the paper feeder. When moving the printer, turn

the power off and remove the power cord, then move the pieces separately; moving the printer

incorrectly may damage it and may cause personal injury.

Alignment pins

(Left door side) (Cassette slots side)

2.2.3 Preparing the Imaging Unit

1. Open the front door.

Paper Feeder

14

Page 22

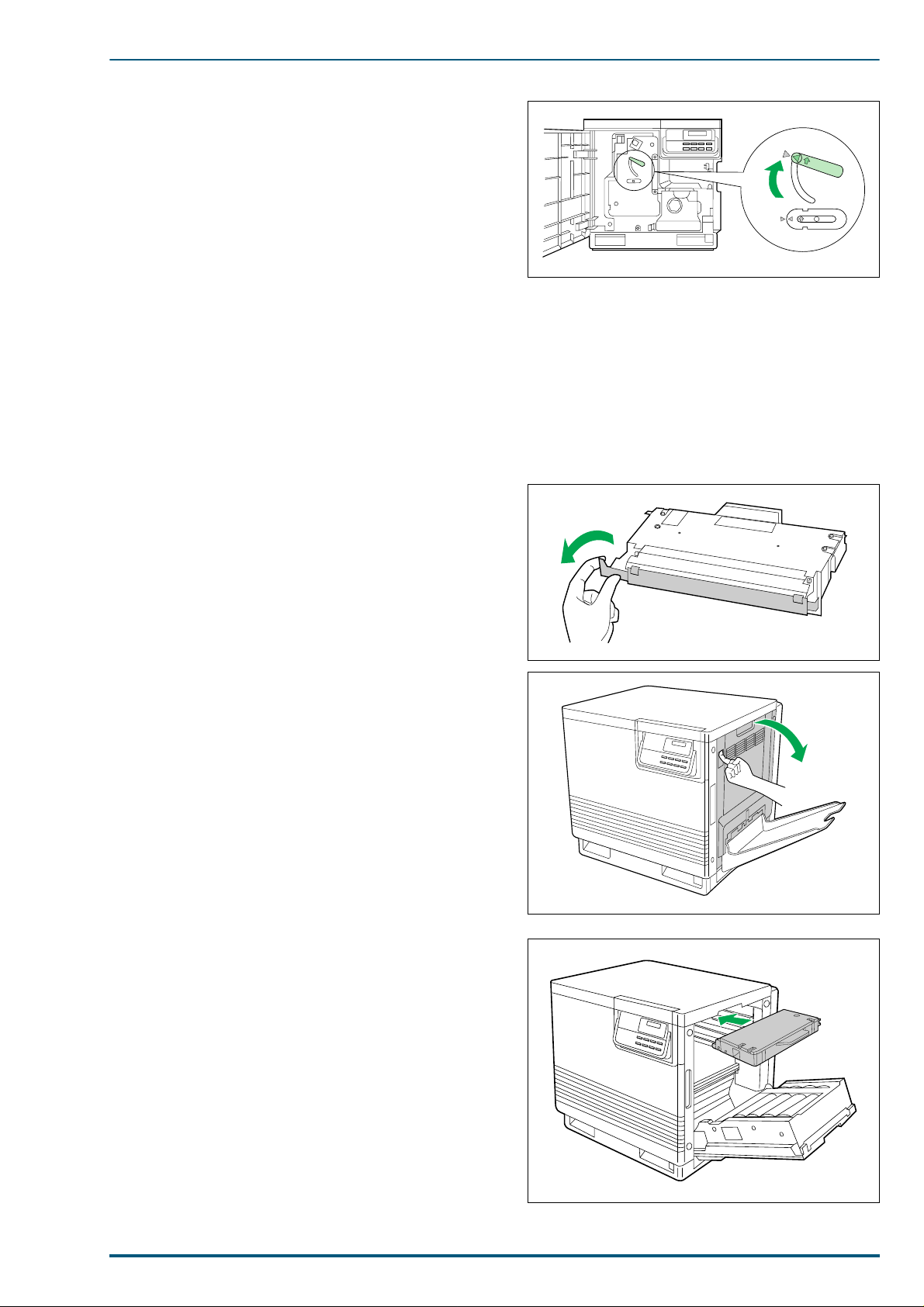

2. Turn the upper green lever clockwise until it stops

and the arrows are aligned. (This applies tension to

the internal belts).

3. Close the front cover.

2.2.4 Installi ng the Toner Developers

2. Installation, Setup, and Repacking

Note:

The toner developers shipped with the printer are starter developers. They are installed in exactly

the same manner as t h e standard developers; the only difference is that the starter developers have

less toner. (Page life expectancy is 5,000 pages for all toner developers except black which has a life

expectancy of 6,000 pages.)

1. Remove the packaging from the toner developer.

2. Remove the shipp ing cover from the developer.

Caution:

Do not tilt the developer to avoid possible

toner spillage.

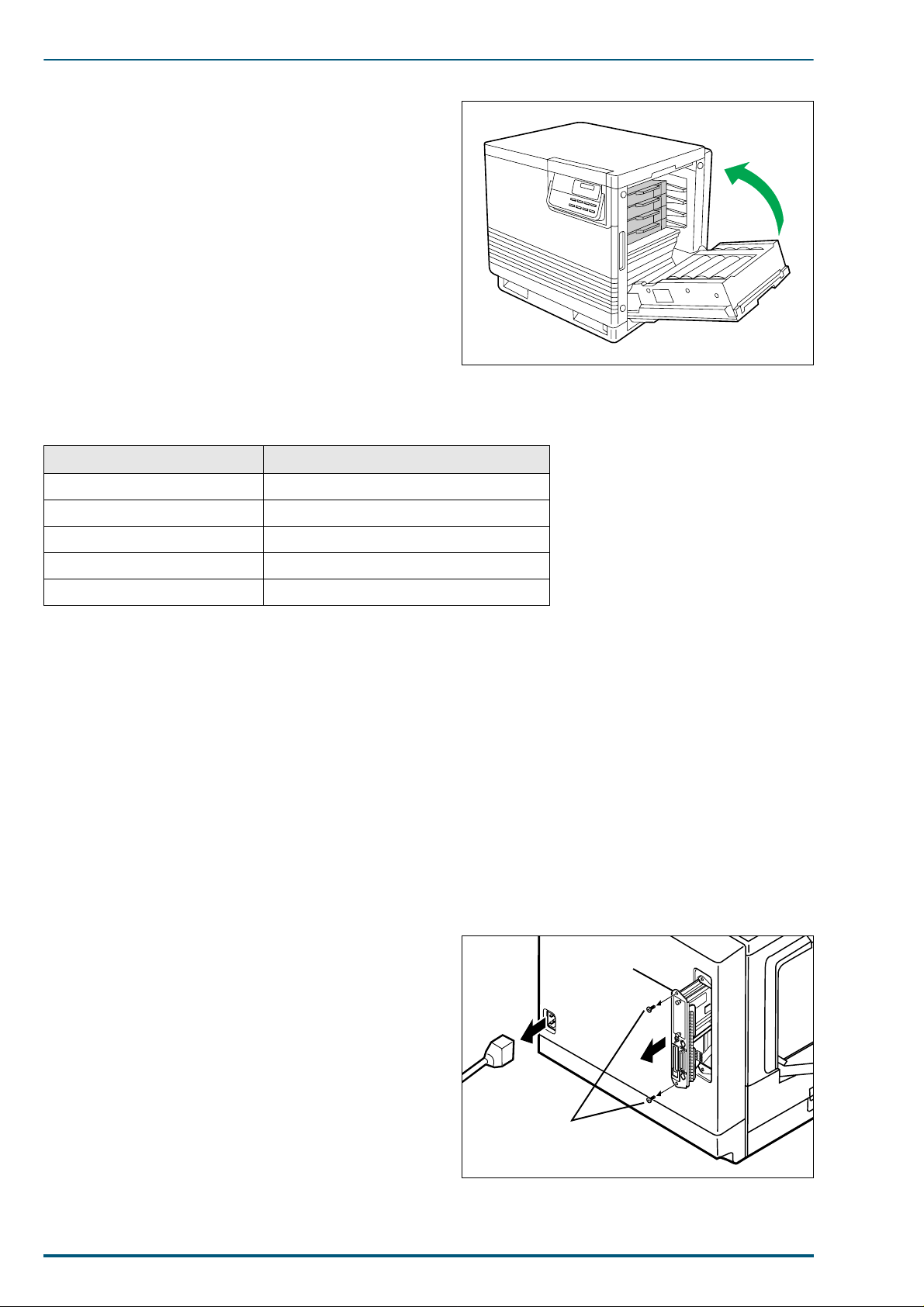

3. Open the printer’s right side door.

Caution:

Do not leave the right side door open for a

long time; the imaging unit inside is exposed

to light and will be damaged.

4. Insert the toner developer in the appropriately

labeled slot. From top to bottom, the developer order

is BLACK, CYAN, MAGENTA, and YELLOW.

15

Page 23

FS-5900C Service Manual

5. Repeat steps 1, 2 and 4 for each toner developer.

6. When all the toner developers have been installed,

close the right side door.

Note: Save all packing material for shipping purposes.

2.2.5 Adding Paper or Transparencies

The printer is shipped with one media cassette of either Letter or A4 paper size. The printer can also use

five different cassettes as follows:

Tray Size

A4 Paper 210 × 297 mm (8.27" × 11.7")

A4 Transparency 210 × 297 mm (8.27" × 11.7")

Letter Paper 8.5" 11" (216 × 279 mm)

Letter Transparency 8.5" × 11" (216 × 279 mm)

Legal paper 8.5" × 14" (216 × 356 mm)

Notes:• Make sure that correct media is loaded. Each cassette is designed and labeled for only paper or

transparency. If the wrong media type is loaded in a tray, an error message will be displayed

when printing is attempted.

• If the paper feeder is installed and the automatic tray switching feature (for example, for a large

print job) is used, make sure that all trays in the printer at any one time are the same media type

and size.

• To optimize the printer’s performance, always use clean, unused media.

• Be careful not to leave fingerprints on the media, which can result in a smudged print.

• Reusing media that has been fed through the printer (for example, after jams or if the media is

ejected without being printed) can reduce the life of the consumables and paper path components.

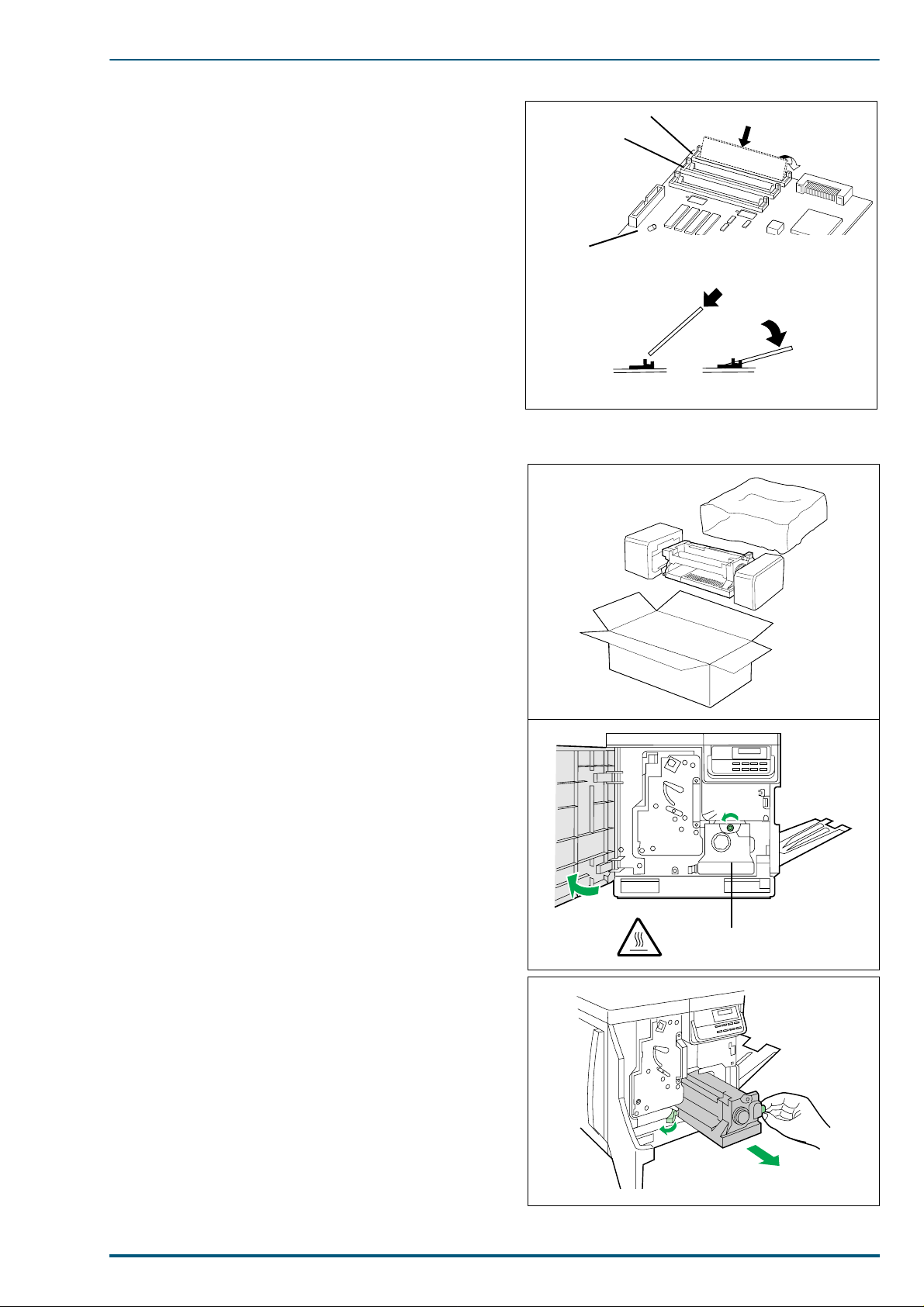

2.3 Installing RAM SIMMs (Option)

1. Turn off the printer. Do not unplug the printer; this preserves a ground path to dissipate static charges.

2. Remove the two screws from the controller board.

3. Pull out the controller board.

Controller Board

4. When installing a single RAM SIMM:

Insert a memory module in connector YS3 or YS4 and

tilt the module down until it locks in place. When the

SIMM is properly inserted, a tab on each end of the

connector slips into a hole on each end of the RAM

SIMM. Also, a pawl on each end of the connector

latches around each end of the RAM SIMM to lock it

in place. Go to step 6.

16

~AC IN

Screws

Page 24

5. When installing two RAM SIMMs:

YS4

YS3

Controller Board

a b

HOT SURFACE INSIDE

Insert the appropriate memory module in connector

YS3 and YS4 and tilt the module down until it locks

in place. When the SIMM is properly inserted, a tab

on each end of the connector slips into a hole on each

end of the RAM SIMM. Also, a pawl on each end of

the connector latches around each end of the RAM

SIMM to lock it in place.

6. Reinstall the controller board.

7. Reinstall the two screws.

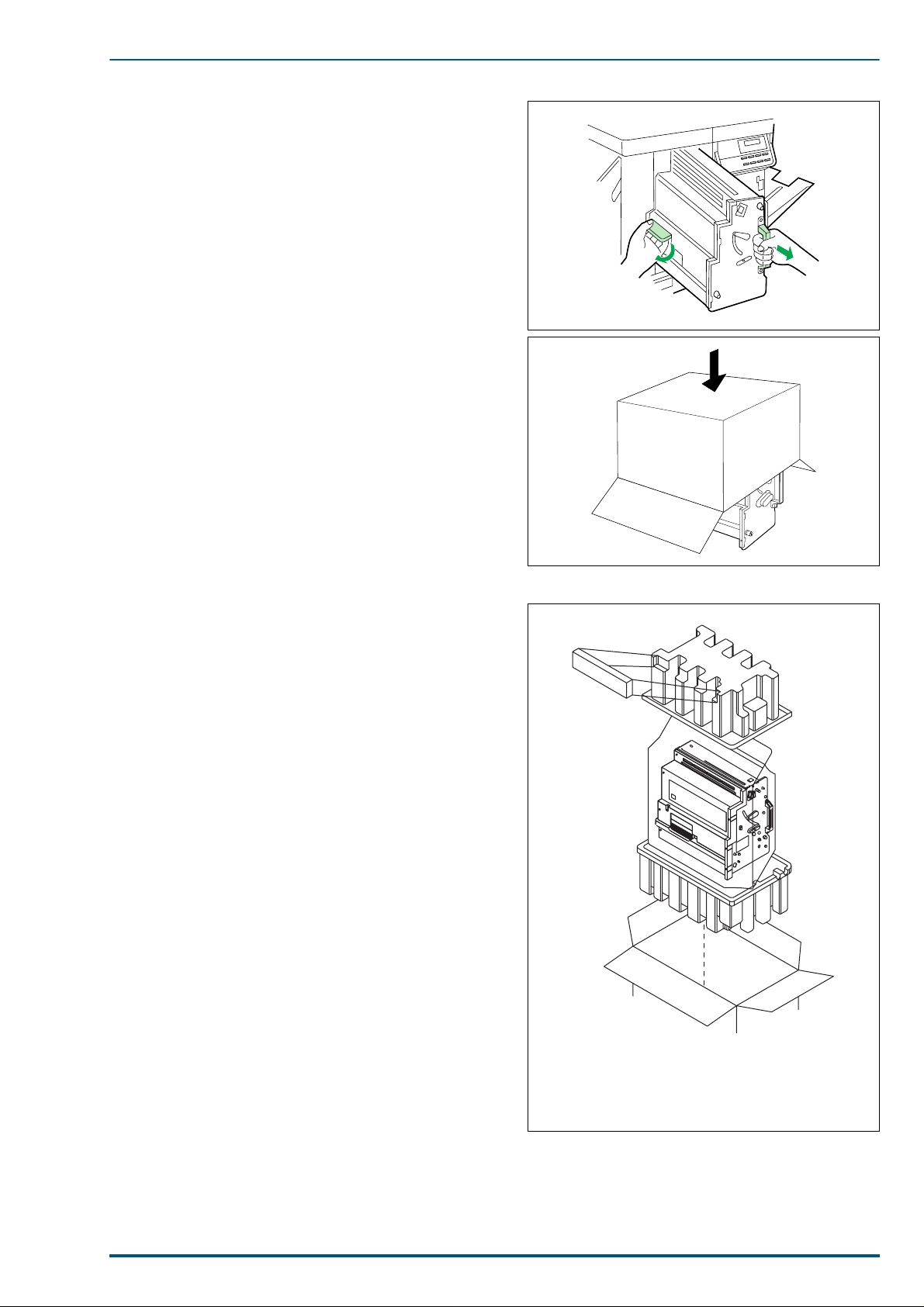

2.4 Replacing the Fuser Unit

1. Remove the new fuser from its packaging; keep the

fuser upright.

2. Installation, Setup, and Repacking

2. Open the front doo r. Turn the small green thumb-

screw counterclockwise to unlock the fuser.

Caution:

The fuser is hot; to avoid personal injury,

wait approximately 10 minutes for the fuser

to cool before touching it.

3. Grasping the green tab on the right, slide the fuser

out until the safety catch stops it. Press the green

lever on the left to release the safety catch.

17

Page 25

FS-5900C Service Manual

4. Hold the fuser as shown and slide it out of the

printer. Dispose of the fuser as normal office waste.

Caution: The fuser weighs approximately 3.2 kg (7.11

lbs.). Take care when handling it.

5. Insert the new fuser into the printer.

6. Turn the small green thumbscrew clockwise to lock

the fuser. Close the front door.

2.5 Replacing the Imaging Unit

1. Open the front door. Loosen the two thumbscrews by

turning them counterclockwise. Turn the lower green

lever 180° counterclockwise.

18

Page 26

2. Grasping the front gree n handle, slide the unit out

until it catches. Lift up the green handle on the left.

Pull the imaging unit out of the printer.

Caution: The imaging unit weighs approximately 6.5

kg (14.3 lbs.). Always use the handles when

lifting it.

3. If the imaging unit is to be reinstalled, cover it with

an empty box or place it in a dark cabinet to protect it

from light exposure. If the unit is to be discarded,

dispose of it as normal office waste.

Important:

Do not expose the imaging unit to light for more than

approximately 45 seconds, or irreversible damage may

result.

2. Installation, Setup, and Repacking

4. Remove the new imaging unit from the packaging.

The imaging unit is extremely light-sensitive. Leave

the protective plastic sheet on the imaging unit

immediately before installin g it.

Note:

Save all packing material for future shipping purpose.

19

Page 27

FS-5900C Service Manual

5. Remove the used filter by pulling it forward. Dispose

of the filter as normal office waste. Insert the new

filter.

6. Turn the upper green lever clockwise until it stops.

Ozone Filter

7. Remove the protective plastic sheet.

Important:

• Do not touch the green surface. Fingerprints may a ffect

the print quality.

• Do not expose the imaging unit to light for more than

45 seconds, or irreversible damage may result.

8. Grasp the green handles and i nstall the new unit into

the printer. Release the left handle and push the unit

in until it stops.

Plastic Sheet

Handles

9. T urn the lower green lev er clockwise 180° to lock the

imaging unit. T ight en the t wo gree n t humbscrew s by

turning them clockwise. Close the front door.

20

Page 28

2. Installation, Setup, and Repacking

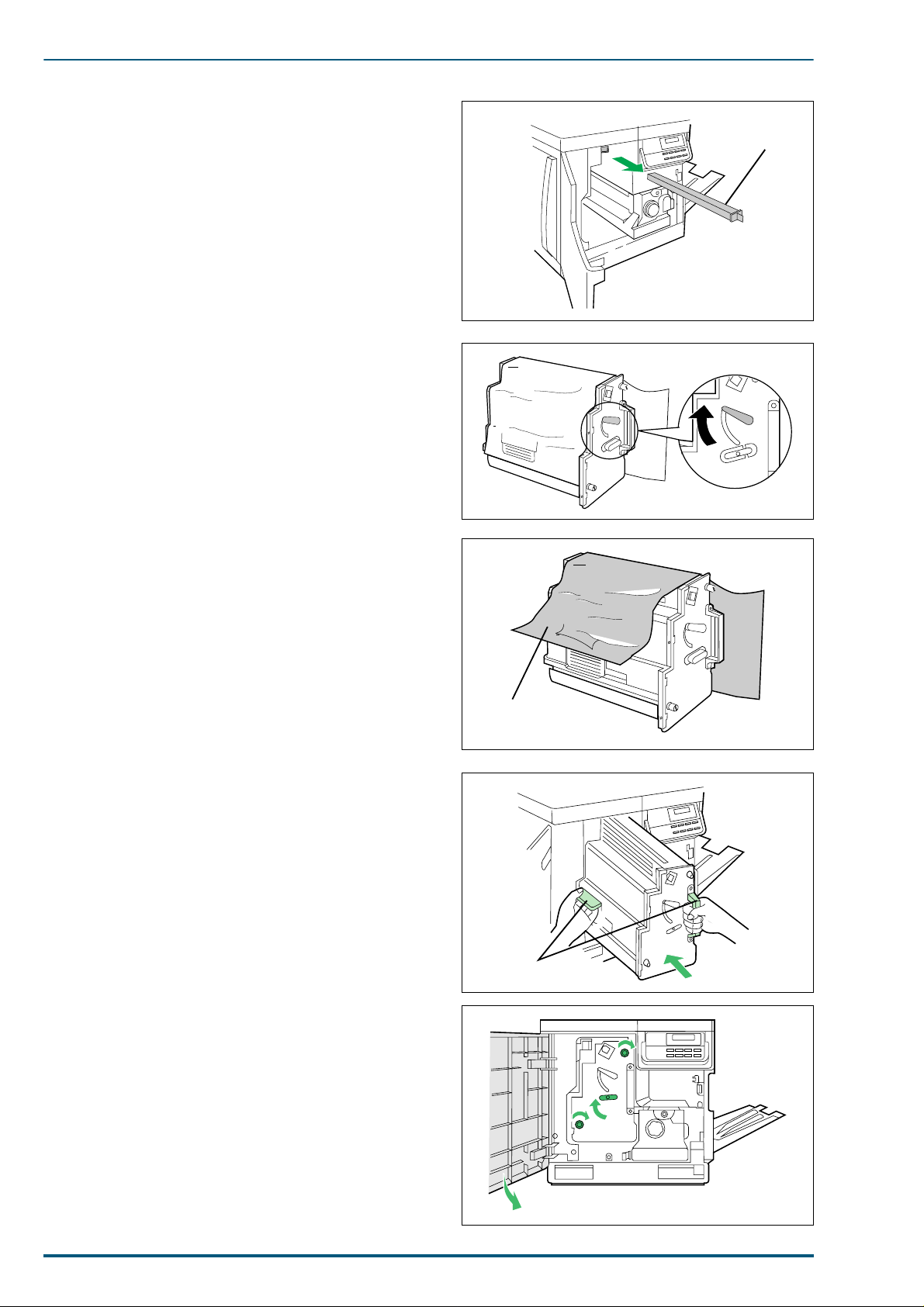

2.6 Repacking

Should the printer need to be transported or shipped, prepare the unit in th e following manner:

Note:

It is highly recommended tha t users keep the ori ginal cart on and all packing ma terials. Observe the

following instructions when moving the printer:

Use the original carton and all of the original packing material.

•

Improper repacking of the printer may result in a service charge to repair the unit or a cleaning

•

charge to remove spilled toner.

Since the printer uses dry toner, extreme care must be taken when handling. The printer should

•

be handled in the upright (vertical) position.

Materials Required

Original printer, accessory cartons, and other packing materials

•

Newspaper or drop cloth

•

Shipping tape and scissors

•

1. Turn off the printer; remove the power cord and all interface cables.

2. Remove the media cassette(s) from the printer;

remove the media from the cassette(s).

3. Press down on a media cassette’s metal plate. Place the plastic shipping lock into the media cassette as

shown.

Metal Plate

Shipping Look

(3)

(1)

(2)

4. Reinsert the media cassette into the printer; use adhesive tape to secure the cassette to the printer.

5. If the other media casse ttes are in sta lle d, repa ck them for s hi pping or st orage in t heir ori gina l ship pi ng

boxes.

21

Page 29

FS-5900C Service Manual

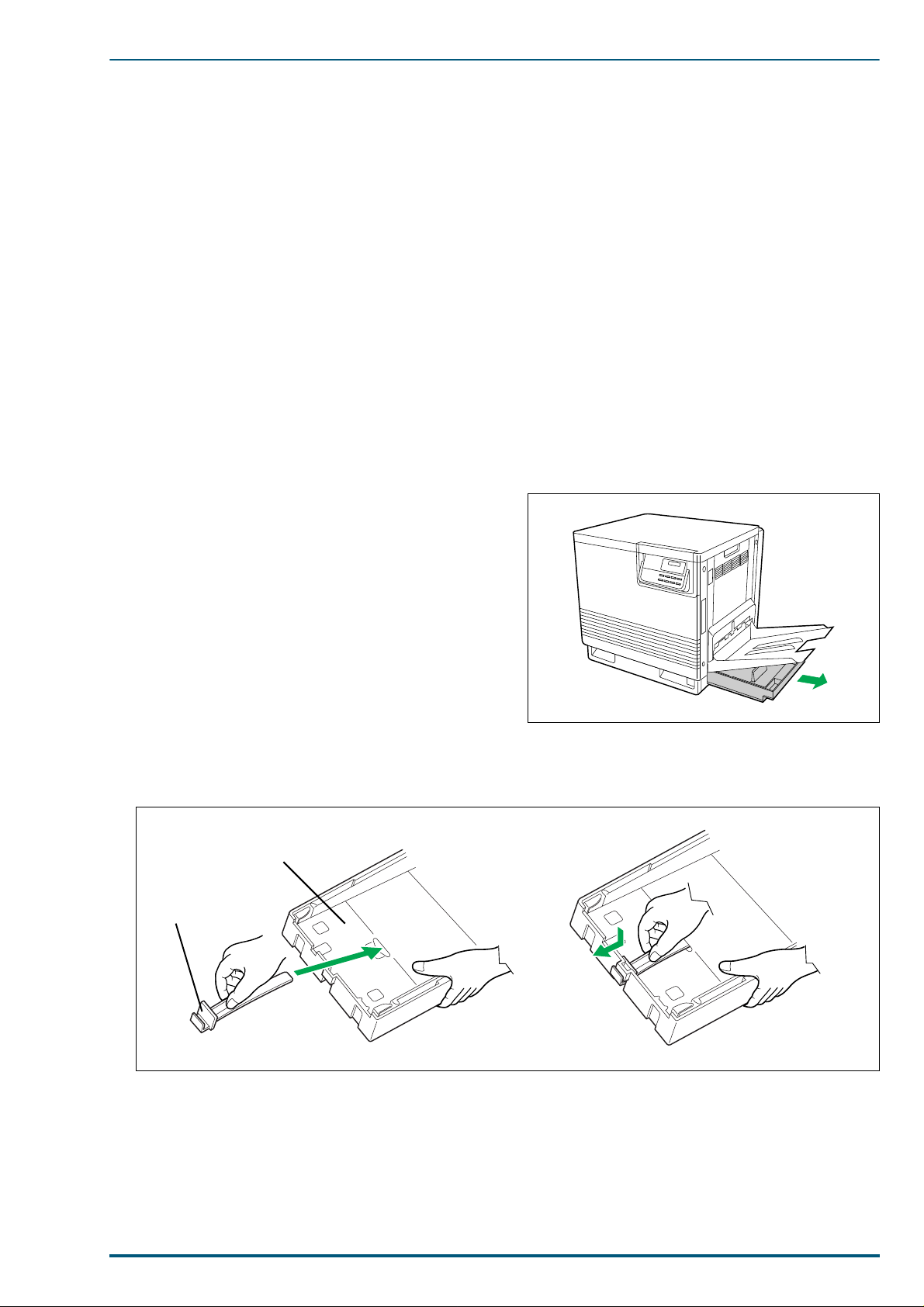

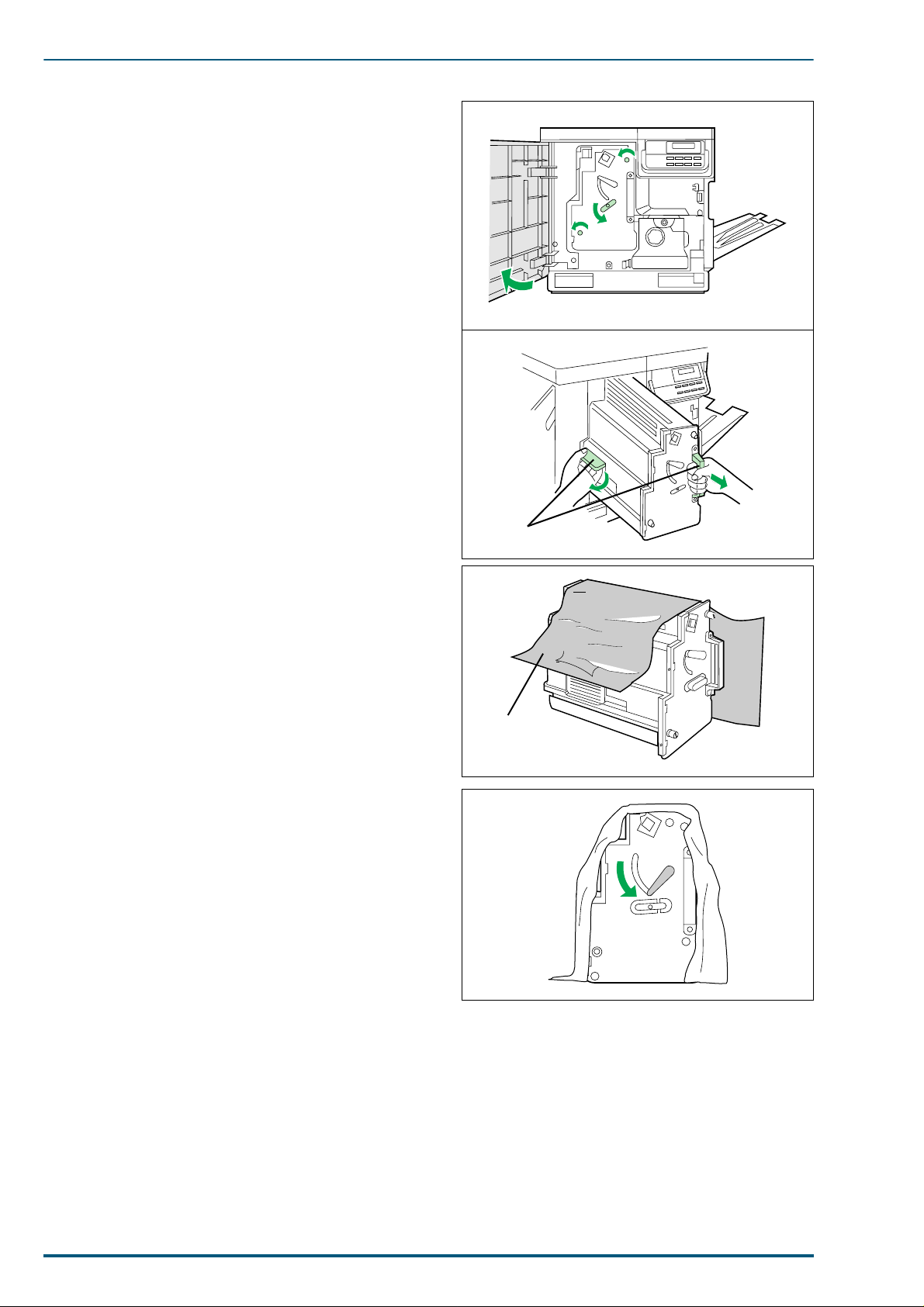

6. Open the printer’s front door. Loosen the two thumb-

screws by turning them counterclockwise. Turn the

lower green lever 180° counterclockwise.

7. Grasping the front green handle, sli de the unit out

until it catches. Lift up the green handle on the left.

Pull the imaging unit out of the printer.

Caution: The imaging unit we igh s app rox imate ly 6.5

kg (14.3 lbs.). Always use the handles when

lifting it.

8. Wrap the imaging unit with a protective black plastic

sheet.

Important:

• Do not touch the green surface. Fingerprints may a ffect

print quality.

• Do not expose the imaging unit to light for more than

45 seconds, or irreversible damage may result.

9. Move the upper lever 90° counterclockwise; this is

necessary to protect the imaging unit during shipment.

Handles

Plastic Sheet

22

Page 30

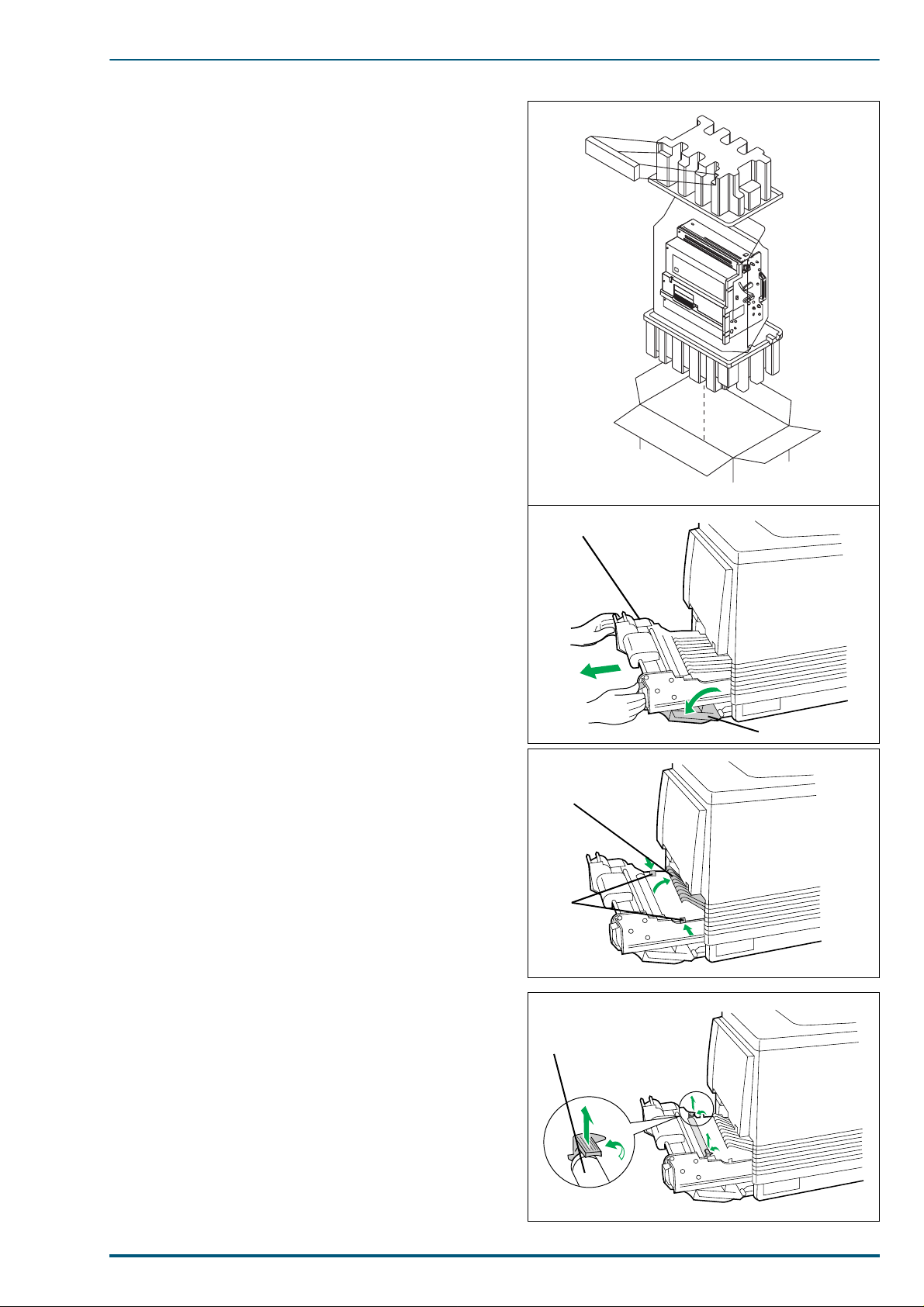

10.Insert the imaging unit into the packaging.

Paper Feeder

Left Side Door

Cover

Tabs

Transfer Roller

2. Installation, Setup, and Repacking

11.Open the left side door. Using the green handles,

slide the paper feeder out.

12.Push in on green tabs to unlock the cover. Raise the

cover until it catches in the open position.

13.Rotate the transfer roller’s green handles up. Lift out

the transfer roller/waste bin.

23

Page 31

FS-5900C Service Manual

14.Rotate the handles down and wrap the transfer unit

with a piece of paper and adhesive tape.

Note: Do not touch or bump the roller as it can damage

the roller.

15. Install the plastic cover and insert the transfer unit

into a plastic bag and seal the end tightly. Install the

transfer unit into the packaging.

Note: Use the plastic cover that is attached to the new

TR-81 transfer unit.

16.Remove the four toner devel opers; install the protec-

tive cover for each developers; repack them for shipping or storage in their original shipping boxes.

Plastic Cover

Plastic Bag

17.Wipe off any loose toner in and around the printer.

Note: If a toner vacuum is available, it is the best tool

for cleaning spilled toner. Do not use a standard

office vacuum; the toner will not be retained by

typical vacuum dust collectors.

18.Close all printer doors and secure them with adhesive tape.

19.Raise the output tray and secure it to the printer

with adhesive tape. If a paper feeder is not installed,

go to Step 21.

20.If a paper feeder is installed:

Lift the printer up and away from the paper feeder.

Safety Caution:

The printer weighs approximately 41.4 kg (91.2 lbs.) and

the paper feeder weighs 14.4 kg (31.5 lbs.). Observe

standard precautions for lifting heavy objects.

24

Page 32

Repack the paper feeder in its origina l shipping box.

21.Repack any other accessories in the original shipping box.

22.Repack the printer in the original shipping box. Make

sure that the printer is upright and level when moving. See the diagram on this page.

2. Installation, Setup, and Repacking

25

Page 33

FS-5900C Service Manual

3. Mode Selection

This section explains the menu levels and options which can be set using the control panel MODE key. The

MODE key can be used to display all of the menus in the following diagram:

Ready

PAR 600 A4 001

MODE

Parallel

Serial

Option

Number of copies

PCL 5C

Emulation >

KPDL

KPDL (AUTO)

Font >

Bitmap

Scalable

Page orientation

Portrait

Landscape

Press the MODE key.

001

>Interface

>Emulation

>Parallel I/F

>Code set

ISO-6 ASCII

>

>Print KPDL errs

Off

*2

)

(

On

>Bitmap font

00001

>

>AudreyTwo-Regular

SWC

>Size

012.00 point (s)

>Pitch

Nibble (high)

High Speed

Normal

Auto

10.00 cpi

(

(*1)

*3

These items will not show unless the

printer is installed with the applicable

option unit/kit.

>Baud rate

9600

>Data bits

8

>Stop bits

1

>Parity

None

>Protocol

DTR (pos.)&XON

>Barcode mode

On

Off

)

*1:

Depending on the emulation selected,

*1

: Depending on the emulation selected,

the following code sets are available.

the following set >code sets are

available.

Opt. ROM >

HARD DISK >

RAM DISK mode >

Continued on next page

>Read data

>List of partitions

>Read data

(*4)

>RAM DISK size

>Read data

>Write data

>Delete data

>Print VMB data Tray:

>List of Partitions

>List of VMB

C5LCP

dnapamtiB

stnoFelbalacS

IICSA6-OSI

nedewS11-OSI

nailatI51-OSI

niapS71-OSI

yawroN06-OSI

ecnarF96-OSI

8-namoRPH

lageLSU

8-CPMBI

058-CPMBI

6nitaLOSI

.K.U4-OSI

8htaM

tnofiP

ynamreG12-OSI

1nitaL49-AMCE

)N/D(8-CPMBI

ISO Latin 9

stnoFelbalacS

ylnO

htamSP

txetSP

gnihsilbupSM

swodniW

tlabniW

potkseD

2nitaLOSI

5nitaLOSI

1nitaLswodniW

2nitaLswodniW

5nitaLswodniW

577-CP

2nitaL258-CP

4001-CP

hsikruT-CP

hsotnicaM

26

Page 34

Continued from previous page

MEMORY CARD > >Read fonts

>Read data

>Write data

>Delete data

>Format

>List of Partitions

3. Mode Selection

Paper handling >

Colour mode >

Colour >

Matching

Colour >

Calibration

>MP tray mode

>MP tray size

>MP tray type

>Duplex mode

>Auto cassette

>Override A4/LT

>Monochrome

>Colour

>Quick Colour

>RGB Simulation

>Vivid mode

>Black

10

>Yellow

10

>Magenta

10

>Cyan

10

>Print Calibration Page

Life counters >

Continued on next page

>Total print

1234567

>TransferRoller >

1234567

>Imaging unit

1234567

>Fuser KIT

1234567

>Oil supply roll

1234567

>Main Charger

1234567

>Cleaning Pad >

1234567

>>Reset Transfer

roller ?

>>Reset Cleaning

Pad ?

27

Page 35

FS-5900C Service Manual

Continued from previous page

Others >

>MSG language

English

>Form Feed

Time out 030sec.

>Sleep timer

060 min

>Print HEX-DUMP

>List of

resident Fonts

>Printer Reset

>LF action

LF only

CR and LF

Ignore LF

>CR action

CR only

CR and LF

Ignore CR

*5

(

(*6)

)

>Ecoprint mode

Off

>Resolution

>Resource prot.

Off

*2:

The printer can be set to print error data

during KPDL em ulation. If thi s is set to 2Q,

error data will be printed if trouble occurs

during printing. This is set to

leaving the factory.

*3:

*4:

*5:

*6:

*7:

6L]H

The >

Courier

3LWFK

>

fonts.

The

played when an optional hard disk unit

is installe d.

Any value from 0 to 495 [seconds] in 5second increments. (The printer does not time out with

the value set to 0.)

Any value from 0 to 120 [minutes] in 5-minute increments.

For service purpose only.

menu is not available for the

LetterGothic

and

menu to scale these fixed

5$0#',6.#PRGH

2II

before

fonts. Use the

menu is not dis-

>Buzzer

Off

>Service >

On

Permanent

Perm / Temp

On

>>Print

Test page 2

>>Print

Test Page 1

>>TransferRoller

? Type X

>>Print

Status Page

(*7)

28

Page 36

3. Mode Selection

3.1 Nav igating through the Menus

The menus are in the hierarchy as shown in the diagram above. Use the + and – keys to move between

menus in the same level (“vertically” in the table). The + key shows the next menu, while the – key shows

the previous one. Change levels by using the and keys. The key moves to lower levels (sub-menus),

while the key moves to higher levels.

2, 4, 6

3

5, 7

1, 8

To make change to a specific item, for example, the sleep mode timeout time, proceed as follows :

1. Press the MODE key.

The message display will show one of the first level menus (Level 1 in the table on pages 25 and 26)

depending on the previous selection.

2. Press + until Others > is shown on the display.

3. Press .

The message display will show one of the second level menus (Level 2 in the table on pages 25 and 26)

belonging to the Others menu above depending on the previous selection.

4. Press + until Sleep timer is shown on the display.

5. To change the timeout value, press ENTER.

If you want to abandon setting, press CANCEL, then press MODE.

6. Press + repeatedly to increase the timeout time; press – repeatedly to decrease the timeout time until

the desired timeout time (in minutes) is displayed.

7. Press ENTER to confirm the new setting.

You can abandon the new setting by pressing CANCEL, then MODE.

8. To quit the mode selection sequence, press EXIT.

3.1.1 Display Information

Life Counters

Section menu Description

Imaging unit

Transfer Roller

Fuser Kit

Oil supply roll

Total print

A count of the total number of images fed since the Imaging unit was last replaced.

A count of the total number of pages fed since the Transfer Roller was last replaced.

A count of the total number of pages fed since the Fuser Kit was last replaced.

A count of the total number of pages fed since th e Oil supply roll was las t replaced.

A count of the total number of pages fed since the product is shipped.

29

Page 37

FS-5900C Service Manual

4. Mechanical Functions

4.1 Drive Mechanism/Image Process General Description

Drive Mechanism

Eight DC servomotors are used to transmit drive to each mechanical block within the engine. The main

motor transmits drive to the imaging unit. The paper feed motor transmits drive to the paper feed unit,

fuser unit and toner developer selector/paper eject unit. The toner developer motor transmits drive to the

toner developers. Four cam motors in the toner developer selector/paper eject unit mov e the toner develop er

to their development position. The MP tray paper feed motor in the paper feed unit is the stepping motor

and feeds the paper in the multi-purpose tray.

The paper feed unit, laser scanning unit, toner developers, fuser unit and toner developer selector/paper

eject unit are designed for easy removal from the printer for ea sy maintenance.

Print Process

The laser printer creates an image on paper using a technique called laser electrophotography. The printer

uses the electrog raphic process known as t he disc harged are a deve lopment, or write bla ck. In this process, a

digitally modulated laser scans laterally across a rotating OPC belt that has been negatively charged.

Wherever the belt is exposed by the laser beam, the image is written and toner is transferred.

To generate a color image, the OPC belt must complete four rotations, one for each primary color and black.

During each successive pass, the laser exposes the portions of belt that correspond to the primary color’s

component of the image. Toner is attracted to the laser-exposed portions of the belt.

As each color layer is developed on the OPC belt, they are transferred to the accumulator belt until all four

color layers eventually reside one on top of the o ther on the accumulator belt . At this point, a sheet of pap er

is advanced under the accumulator belt and the toner is transferred to the sheet of paper. The paper

advances to the fuser, where heat and pressure permanently bond the toner to the paper. From the fuser,

the paper is driven to the output tray.

A cleaning blade scrapes residual toner from the OPC belt before the next primary color toner is applied to

the belt. This prevents contamination of the next color layer. The cleaning blade is in constant contact with

the belt. An accumulator belt cleaner scapes residual toner from the accumulator belt. This preve nts “ghosting” of the next print. The blade only comes in contact with the belt after the accumulated toner layers are

transferred to the sheet of paper.

Drive Unit Layo u t

Toner Developer Selector/

Paper-eject Unit

Cam Motor

Laser Scanning Unit (LSU)

Imaging Unit

30

Main Motor

Paper Feed Unit

MP Tray Paper Feed Motor Paper Feed Motor

Toner Developer

Toner Developer

Drive Motor

Fuser Unit

Page 38

Print Process

4. Mechanical Functions

2

Laser Scanning Unit (LSU)

Multipurpose

Tray Pickup

Roller

5

Intermediate

Rollers

Pickup

Roller

Transfer Roller

(+300 V)

1

Erase Lamp

OPC Belt

Cleanning Blade

OPC Belt Cleaner

4

First Bias

Transfer

Roller

Accumulator

Belt

Registration

Rollers

Scorotron Charger

+500 ~ 700 v

6

Waste

Toner

Bin

Cleaning

Roller

(+500 to 2600,

depending on

media and

humidity)

Second Bias

Transfer

Roller

OPC Belt

Accumulator

Belt Cleanning Blade

On-Off

Supply

Roller

Toner Cartridges

Black

Cyan

Magenta

Yellow

Pre-Transfer Lamp

Fuser

3

Toner Cartridge

Selector Cam

Take-up Roller

Heated Roller

Pressure

Roller

7

Each block is explained in the following sections:

1. 4.2.1 Discharge and Charging

2. 4.2.2 Laser Exposure and Scanning

3. 4.2.3 Developing

4. 4.2.4 Toner Transfer to the Accumulator Belt

5. 4.2.5 Paper Pickup

6. 4.2.6 Toner Transfer to Paper

7. 4.2.7 Fusing and Exiting

31

Page 39

FS-5900C Service Manual

OPC Belt

Laser Beam from LSU

4.2 Print Process

4.2.1 Discharging and Charging

Discharge

The print process begins when the OPC belt passes by

the erase lamp. The belt is rotating at 100 mm-per-second for 600 dpi printing or 53 mm-per-second for 1200

dpi printing. The light of the erase lamp, which is a horizontal row of red LEDs, removes random negative

charges from the OPC belt. Before pre-exposure, the surface of the belt varies from -500 volts to +50 volts. After

pre-exposure, the surface of the belts is 0 to -20 volts.

The pre-erase lamp is called the erase lamp since it

erases negative charges from the belt.

Charge

The electrostatic potential of the belt is not uniform following discharging. As the belt rotates, it passes a scorotron charger, which bombards the belt with negative

charges. The scorotron charger behaves somewhat like a

vacuum tube. The grid of the charger, held at a potential

of between -450 volts to -600 volts and coupled with the

varying voltage potential on any discrete point on the

belt’s surface, determines how many electrons can flow

from the corona wire onto that point of the belt’ s surface.

The corona wire is charged to -5 kilovolts with a constant

current of -400µA. The varying electron output from the

scorotron, directly based on the varying charge of the belt

surface, ensures a uniform negative potential of -440

volts or -590 volts on the belt surface, depending on the

selected dot-per-inch printing and ambient temperature.

Erase Lamp

Scorotron

Charger

Tungsten Wire

OPC Belt

Grid -450 ~ -600v

-5kv

4.2.2 Laser Exposure and Scanning

Laser Exposure

As the OPC belt rotates, the uniformly charged belt is

exposed by the modulated laser beam. The verticallymoving belt passes in front of the horizontall y scanning

laser beam, and negative charges on the belt surface are

neutralized by the beam. This forms a latent image.

Laser output power is either 0.26 mW or 0.33 mW,

depending on whether the printer is printing in 1200

dots per inch (dpi) mode or 600 dpi mode. The laser exposure, the negative potential on the belt varies from -440

volts or -590 volts (unexposed) to -10 or -20 volts (fully

exposed).

32

Page 40

4. Mechanical Functions

Laser Scanning

A laser diode generates the laser beam, and lenses and mirrors in the laser scanner direct the beam at the

photoconductive belt. The beam is made parallel by the collimator lens and is directed at the rotating polygonal mirror. The mirror rotates at a constant 25,197 revolutions per minute. This transforms the beam into

a horizontally scanning beam, which is directed through the f-θ primary lens, altering the beam’s angular

rotation motion into a constant horizontal motion. The toric correction lens corrects the beam for any vertical misregistration. Next, the beam reflects off of a mirror and passes through a window where it scans

across the rotating photoconductive belt. At the beginning of e ach horizontal sweep, the horizon tal sync mirror deflects the laser beam to the horizontal sync sensor. This informs the engine control board that the

laser beam is beginning its horizontal sweep and that it can begin to modulate the signal with the data to be

printed on that line of the image.

Laser Diode

Collimator Lens

Horizontal-Sync Mirror

Polygon Mirror

Fθ Lens

Horizontal-Sync Sensor

Mirror

Fθ Lens

33

Page 41

FS-5900C Service Manual

4.2.3 Developing

Developing

As the OPC belt co nti nue s t o ro ta te, i t pa sse s b y the fou r

toner developers. Each cartridge is selectively camdriven forward to bring its developer roller into direct

contact with the belt at the appropriate time.

The currently activated toner developer’s developer

roller is charged to a potential between -120 to -260 volts.

Toner is attracted to the exposed portions of the belt in

reverse proportion to the negative charge. The greatest

amount of toner is transferred to the most positive potential. The developer roller rotates at 1.8 (600 dpi printi ng)

or 2.13 (1200 dpi printing) times the speed of the OPC

belt to ensure a constant supply of toner.

OPC Belt

Developer Roller

(-120 to -260v)

Doctor Blade

Supply

Roller

Paddles

Black

Cyan

Magenta

As the belt advances, it passes the pre-transfer lamp,

Yellow

which, like the discharge lamp, removes remaining negative charges from the unexposed portions of the belt.

Inside each toner developer is a toner supply roller that

rotates in the opposite direction from the developer

roller. This supplies a layer of toner onto the developer

Pre-transfer

Lamp

Toner Cartridges

Cartridge Selector Cam

roller. The doctor blade smooths and evenly distributes

the toner on the developer roller. Gear-driven paddles

churn the toner and keep it fluidized and moving

towards the developer roller.

Toner Developer Drive

Drive is supplied from the toner developer drive motor. At the proper time, the clutch corresponding with

the currently selected toner developer is activated by a signal from the CPU, transmitting drive to the

clutch gear via idle gears. Drive is then transmitted to the developer rollers.

The toner level sensing receiver board detects whether each of the four toner developers contains sufficient

toner. This board is paired with the toner level sensing transmitter board and functions as the photo sensors.

Toner Developer Drive Motor

Clutch Gear

Developer Roller

Black

34

Clutch Gear

Developer Roller

Clutch Gear

Developer Roller

Clutch Gear

Developer Ro ller

Cyan

Magenta

Yellow

Toner Developers

Page 42

4.2.4 Toner Transfer to the Accumulator Belt

OPC BeltCleaning Blade

OPC Belt

+500 to 700v

Accumulator

Belt Home

Sensor

First Bias

Transfer

Roller

Accumulator

Belt

Multipurpose

Tray Pickup

Roller

Registration

Roller

Registration

Sensor

Intermediate

Rollers

Pickup Rollers

MP Tray Paper

Out Sensor

MP Tray Paper

Feed Motor

Paper Empty

Sensor

Paper Cassette Sensor

Terminal for detecting

paper cassette

As the OPC belt rotates, it comes in contact with the

accumulator belt, which is rotating at the same speed.

Located under the accumulator belt at the contact point

with the OPC belt, the first bias transfer roller carries a

charge that varies between +500 and +700 volts (based

on the sensed temperature, humidity and print speed).

This strong potential attracts and holds the toner from

the OPC belt to the accumulator belt. The accumulator