Page 1

FS-5900C Service Manual

4. Mechanical Functions

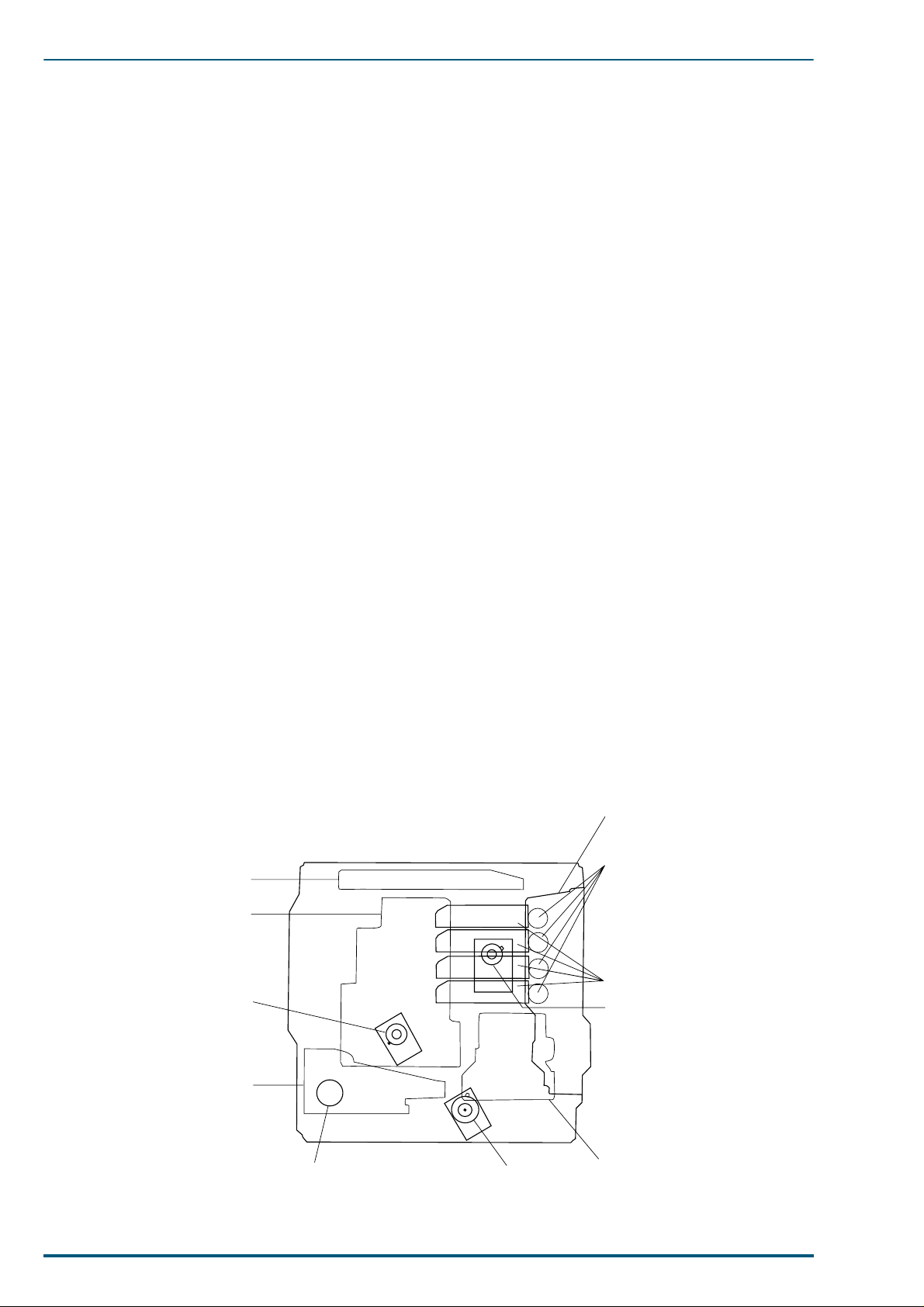

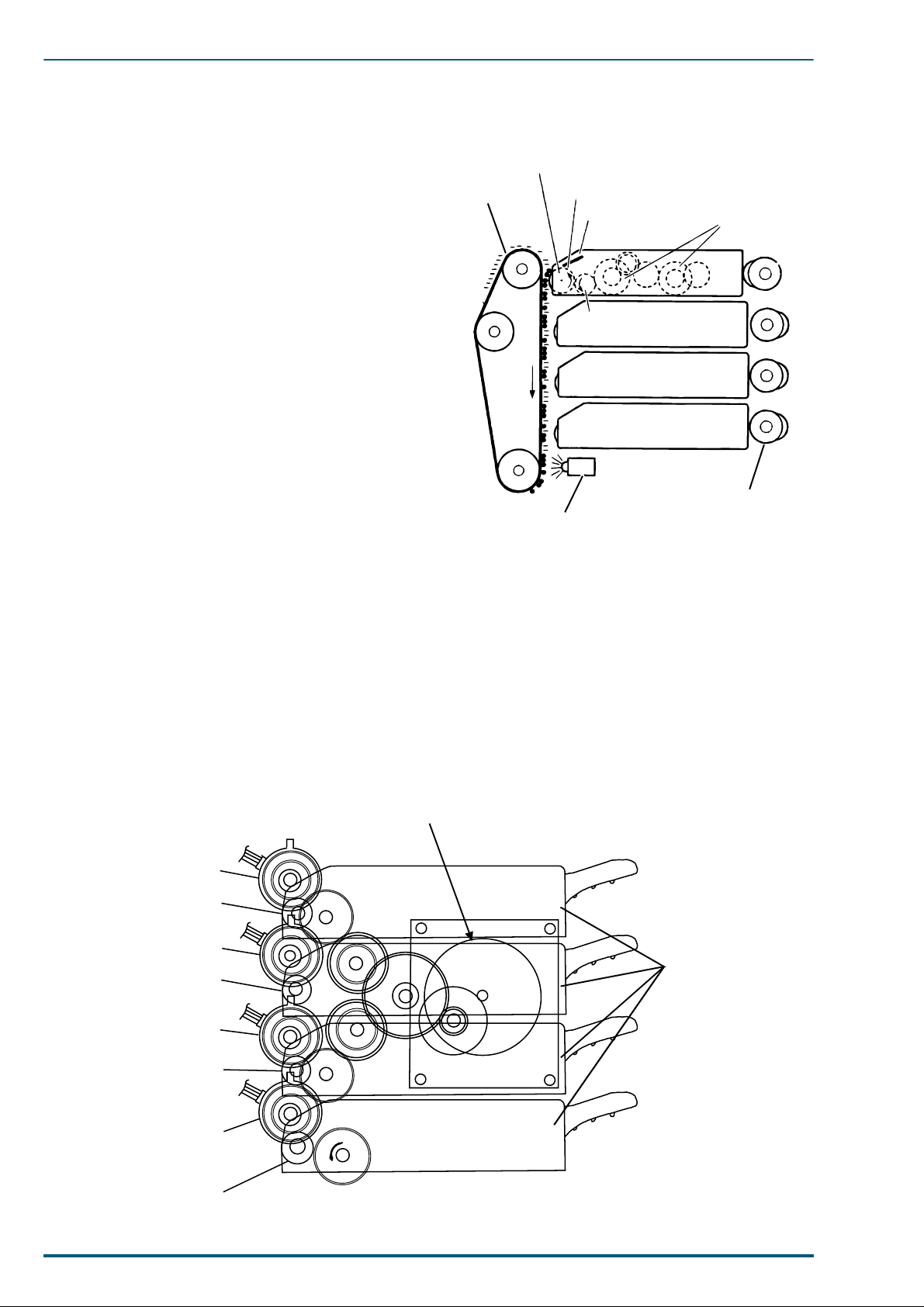

4.1 Drive Mechanism/Image Process General Description

Drive Mechanism

Eight DC servomotors are used to transmit drive to each mechanical block within the engine. The main

motor transmits drive to the imaging unit. The paper feed motor transmits drive to the paper feed unit,

fuser unit and toner developer selector/paper eject unit. The toner developer motor transmits drive to the

toner developers. Four cam motors in the toner developer selector/paper eject unit mov e the toner develop er

to their development position. The MP tray paper feed motor in the paper feed unit is the stepping motor

and feeds the paper in the multi-purpose tray.

The paper feed unit, laser scanning unit, toner developers, fuser unit and toner developer selector/paper

eject unit are designed for easy removal from the printer for easy maintenance.

Print Process

The laser printer creates an image on paper using a technique called laser electrophotography. The printer

uses the electrog raphic process known as t he disc harged are a deve lopment, or write bla ck. In this process, a

digitally modulated laser scans laterally across a rotating OPC belt that has been negatively charged.

Wherever the belt is exposed by the laser beam, the image is written and toner is transferred.

To generate a color image, the OPC belt must complete four rotations, one for each primary color and black.

During each successive pass, the laser exposes the portions of belt that correspond to the primary color’s

component of the image. Toner is attracted to the laser-exposed portions of the belt.

As each color layer is developed on the OPC belt, they are transferred to the accumulator belt until all four

color layers eventually reside one on top of the o ther on the accumulator belt . At this point, a sheet of pap er

is advanced under the accumulator belt and the toner is transferred to the sheet of paper. The pape r

advances to the fuser, where heat and pressure permanently bond the toner to the paper. From the fuser,

the paper is driven to the output tray.

A cleaning blade scrapes residual toner from the OPC belt before the next primary color toner is applied to

the belt. This prevents contamination of the next color layer. The cleaning blade is in constant contact with

the belt. An accumulator belt cleaner scapes residual toner from the accumulator belt. This preve nts “ghosting” of the next print. The blade only comes in contact with the belt after the accumulated toner layers are

transferred to the sheet of paper.

Drive Unit Layo u t

Toner Developer Selector/

Paper-eject Unit

Cam Motor

Laser Scanning Unit (LSU)

Imaging Unit

30

Main Motor

Paper Feed Unit

MP Tray Paper Feed Motor Paper Feed Motor

Toner Developer

Toner Developer

Drive Motor

Fuser Unit

Page 2

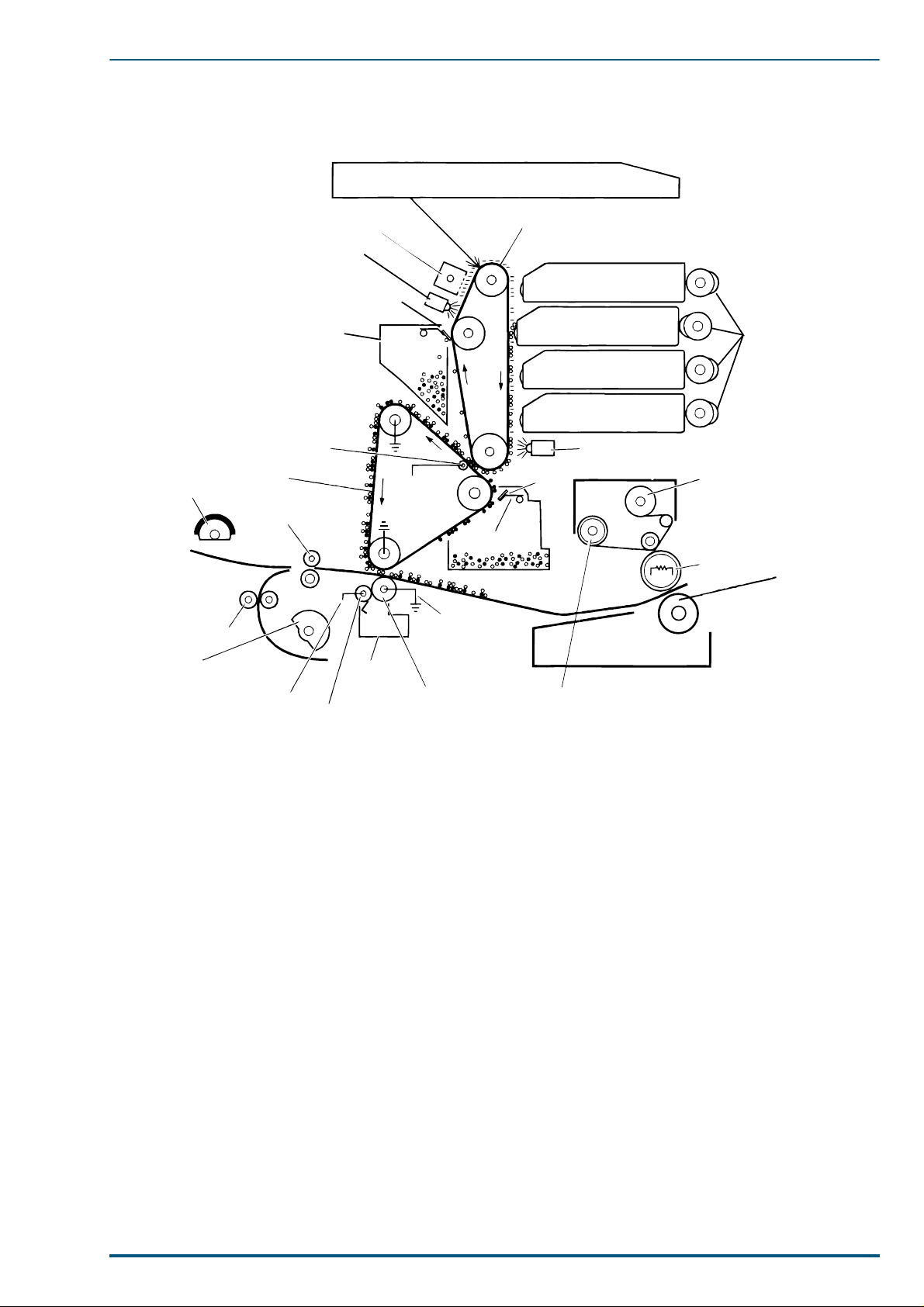

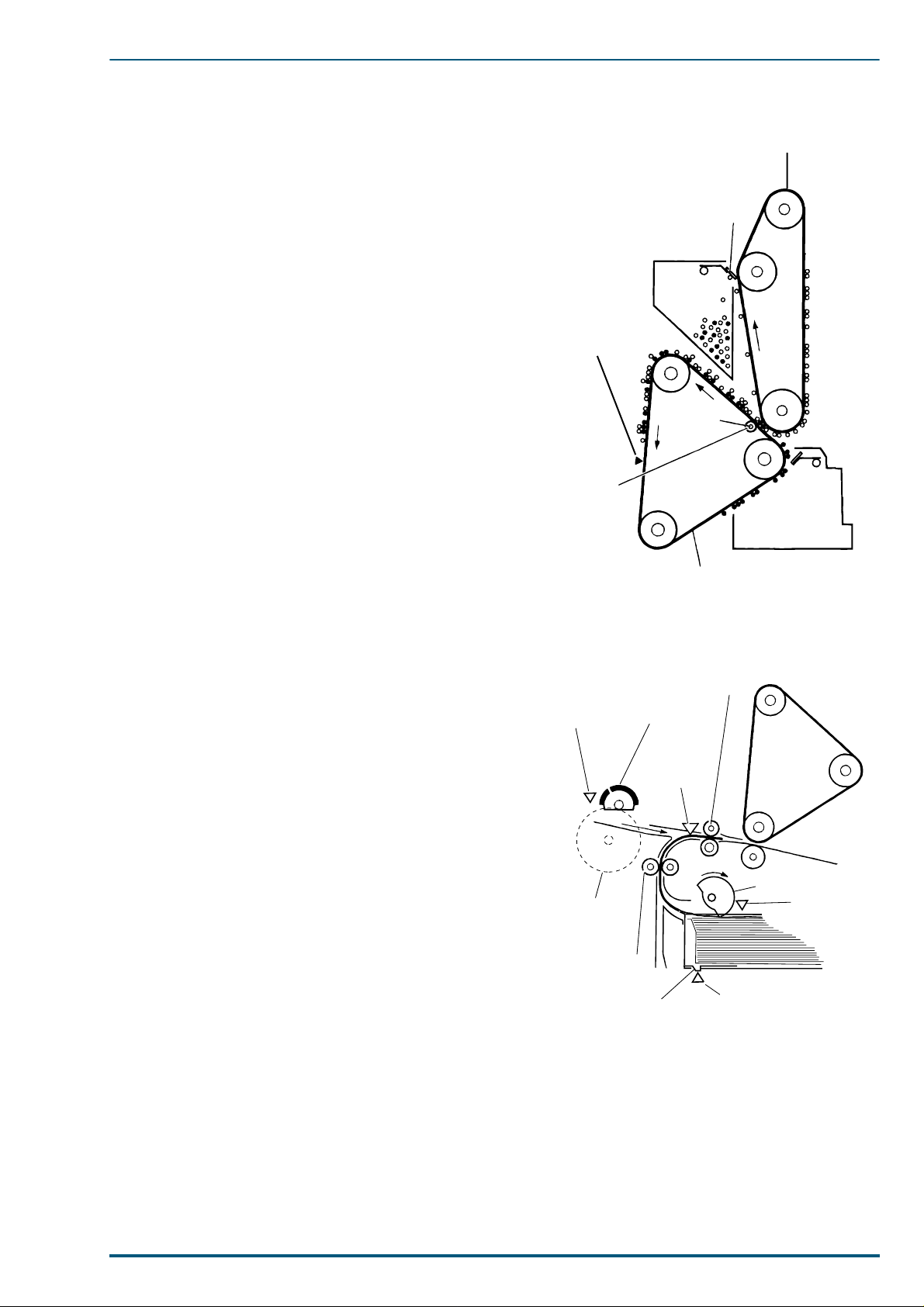

Print Process

4. Mechanical Functions

2

Laser Scanning Unit (LSU)

Multipurpose

Tray Pickup

Roller

5

Intermediate

Rollers

Pickup

Roller

Transfer Roller

(+300 V)

1

Erase Lamp

OPC Belt

Cleanning Blade

OPC Belt Cleaner

4

First Bias

Transfer

Roller

Accumulator

Belt

Registration

Rollers

Scorotron Charger

+500 ~ 700 v

6

Waste

Toner

Bin

Cleaning

Roller

(+500 to 2600,

depending on

media and

humidity)

Second Bias

Transfer

Roller

OPC Belt

Accumulator

Belt Cleanning Blade

On-Off

Supply

Roller

Toner Cartridges

Black

Cyan

Magenta

Yellow

Pre-Transfer Lamp

Fuser

3

Toner Cartridge

Selector Cam

Take-up Roller

Heated Roller

Pressure

Roller

7

Each block is explained in the following sections:

1. 4.2.1 Discharge and Charging

2. 4.2.2 Laser Exposure and Scanning

3. 4.2.3 Developing

4. 4.2.4 Toner Transfer to the Accumulator Belt

5. 4.2.5 Paper Pickup

6. 4.2.6 Toner Transfer to Paper

7. 4.2.7 Fusing and Exiting

31

Page 3

FS-5900C Service Manual

OPC Belt

Laser Beam from LSU

4.2 Print Process

4.2.1 Discharging and Charging

Discharge

The print process begins when the OPC belt passes by

the erase lamp. The belt is rotating at 100 mm-per-second for 600 dpi printing or 53 mm-per-second for 1200

dpi printing. The light of the erase lamp, which is a horizontal row of red LEDs, removes random negative

charges from the OPC belt. Before pre-exposure, the surface of the belt varies from -500 volts to +50 volts. After

pre-exposure, the surface of the belts is 0 to -20 volts.

The pre-erase lamp is called the erase lamp since it

erases negative charges from the belt.

Charge

The electrostatic potential of the belt is not uniform following discharging. As the belt rotates, it passes a scorotron charger, which bombards the belt with negative

charges. The scorotron charger behaves somewhat like a

vacuum tube. The grid of the charger, held at a potential

of between -450 volts to -600 volts and coupled with the

varying voltage potential on any discrete point on the

belt’s surface, determines how many electrons can flow

from the corona wire onto that point of the belt’ s surface.

The corona wire is charged to -5 kilovolts with a constant

current of -400µA. The varying electron output from the

scorotron, directly based on the varying charge of the belt

surface, ensures a uniform negative potential of -440

volts or -590 volts on the belt surface, depending on the

selected dot-per-inch printing and ambient temperature.

Erase Lamp

Scorotron

Charger

Tungsten Wire

OPC Belt

Grid -450 ~ -600v

-5kv

4.2.2 Laser Exposure and Scanning

Laser Exposure

As the OPC belt rotates, the uniformly charged belt is

exposed by the modulated laser beam. The verticallymoving belt passes in front of the horizontall y scanning

laser beam, and negative charges on the belt surface are

neutralized by the beam. This forms a latent image.

Laser output power is either 0.26 mW or 0.33 mW,

depending on whether the printer is printing in 1200

dots per inch (dpi) mode or 600 dpi mode. The laser exposure, the negative potential on the belt varies from -440

volts or -590 volts (unexposed) to -10 or -20 volts (fully

exposed).

32

Page 4

4. Mechanical Functions

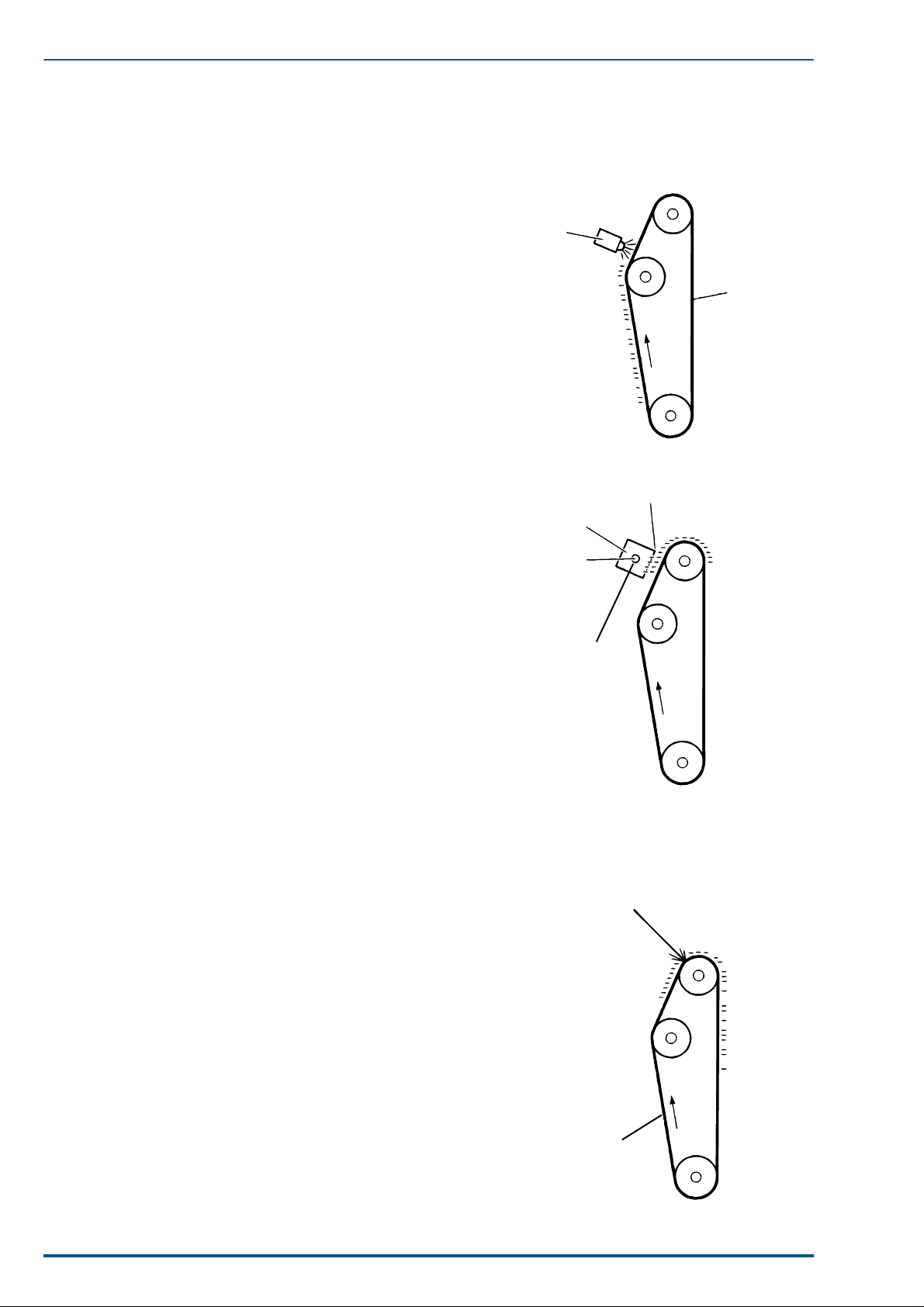

Laser Scanning

A laser diode generates the laser beam, and lenses and mirrors in the laser scanner direct the beam at the

photoconductive belt. The beam is made parallel by the collimator lens and is directed at the rotating polygonal mirror. The mirror rotates at a constant 25,197 revolutions per minute. This transforms the beam into

a horizontally scanning beam, which is directed through the f-θ primary lens, altering the beam’s angular

rotation motion into a constant horizontal motion. The toric correction lens corrects the beam for any vertical misregistration. Next, the beam reflects off of a mirror and passes through a window where it scans

across the rotating photoconductive belt. At the beginning of e ach horizontal sweep, the horizon tal sync mirror deflects the laser beam to the horizontal sync sensor. This informs the engine control board that the

laser beam is beginning its horizontal sweep and that it can begin to modulate the signal with the data to be

printed on that line of the image.

Laser Diode

Collimator Lens

Horizontal-Sync Mirror

Polygon Mirror

Fθ Lens

Horizontal-Sync Sensor

Mirror

Fθ Lens

33

Page 5

FS-5900C Service Manual

4.2.3 Developing

Developing

As the OPC belt co nti nue s t o ro ta te, i t pa sse s b y the fou r

toner developers. Each cartridge is selectively camdriven forward to bring its developer roller into direct

contact with the belt at the appropriate time.

The currently activated toner developer’s developer

roller is charged to a potential between -120 to -260 volts.

Toner is attracted to the exposed portions of the belt in

reverse proportion to the negative charge. The greatest

amount of toner is transferred to the most positive potential. The developer roller rotates at 1.8 (600 dpi printi ng)

or 2.13 (1200 dpi printing) times the speed of the OPC

belt to ensure a constant supply of toner.

OPC Belt

Developer Roller

(-120 to -260v)

Doctor Blade

Supply

Roller

Paddles

Black

Cyan

Magenta

As the belt advances, it passes the pre-transfer lamp,

Yellow

which, like the discharge lamp, removes remaining negative charges from the unexposed portions of the belt.

Inside each toner developer is a toner supply roller that

rotates in the opposite direction from the developer

roller. This supplies a layer of toner onto the developer

Pre-transfer

Lamp

Toner Cartridges

Cartridge Selector Cam

roller. The doctor blade smooths and evenly distributes

the toner on the developer roller. Gear-driven paddles

churn the toner and keep it fluidized and moving

towards the developer roller.

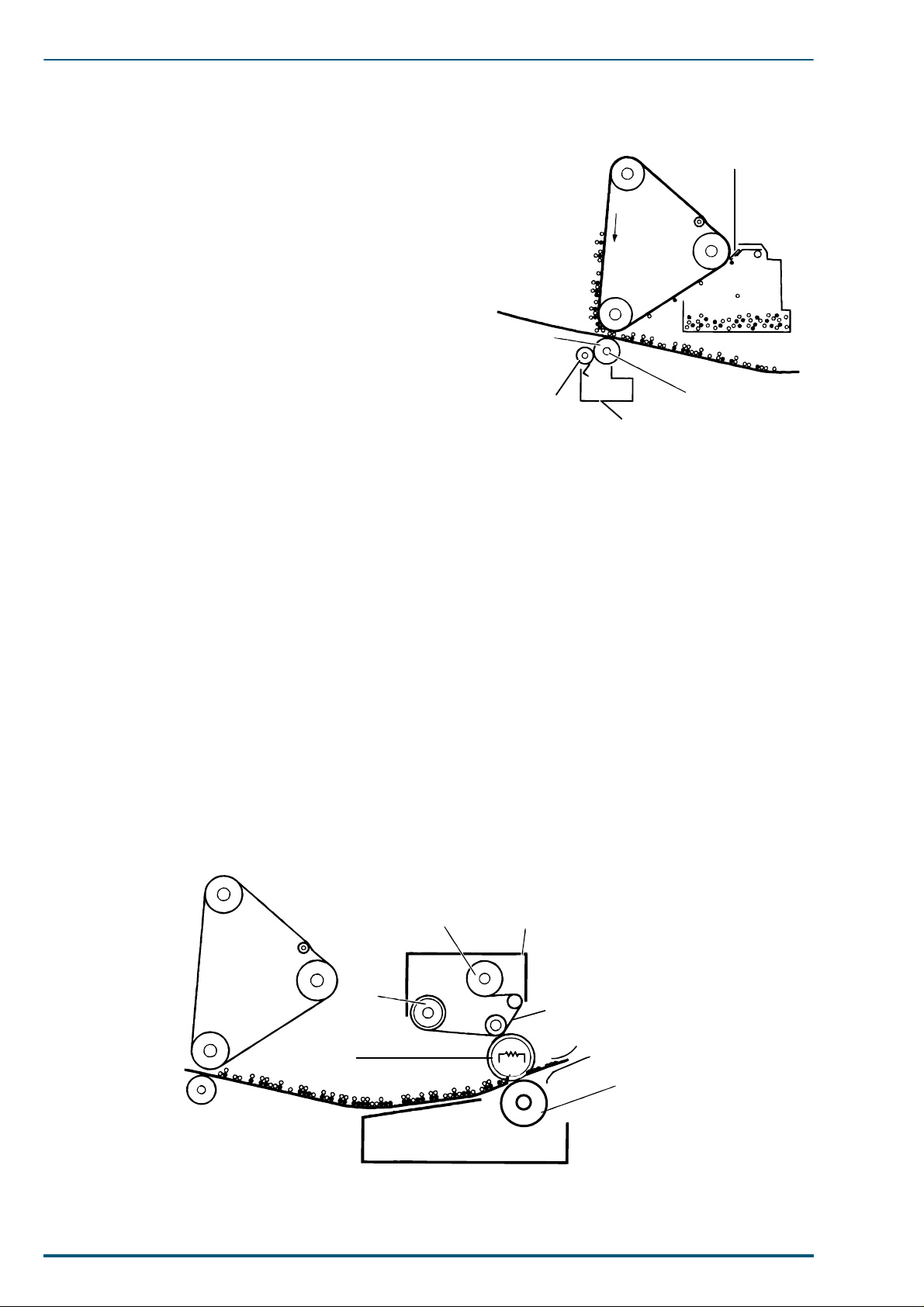

Toner Developer Drive

Drive is supplied from the toner developer drive motor. At the proper time, the clutch corresponding with

the currently selected toner developer is activated by a signal from the CPU, transmitting drive to the

clutch gear via idle gears. Drive is then transmitted to the developer rollers.

The toner level sensing receiver board detects whether each of the four toner developers contains sufficient

toner. This board is paired with the toner level sensing transmitter board and functions as the photo sensors.

Toner Developer Drive Motor

Clutch Gear

Developer Roller

Black

34

Clutch Gear

Developer Roller

Clutch Gear

Developer Roller

Clutch Gear

Developer Ro ller

Cyan

Magenta

Yellow

Toner Developers

Page 6

4.2.4 Toner Transfer to the Accumulator Belt

OPC BeltCleaning Blade

OPC Belt

+500 to 700v

Accumulator

Belt Home

Sensor

First Bias

Transfer

Roller

Accumulator

Belt

Multipurpose

Tray Pickup

Roller

Registration

Roller

Registration

Sensor

Intermediate

Rollers

Pickup Rollers

MP Tray Paper

Out Sensor

MP Tray Paper

Feed Motor

Paper Empty

Sensor

Paper Cassette Sensor

Terminal for detecting

paper cassette

As the OPC belt rotates, it comes in contact with the

accumulator belt, which is rotating at the same speed.

Located under the accumulator belt at the contact point

with the OPC belt, the first bias transfer roller carries a

charge that varies between +500 and +700 volts (based

on the sensed temperature, humidity and print speed).

This strong potential attracts and holds the toner from

the OPC belt to the accumulator belt. The accumulator

belt makes four complete rotations, one for each of the

four toner layers. The accumulator belt home-position

sensor sync signal, generated from a timing mark on the

accumulator belt, informs the engine control board when

to begin expo sin g t he O P C be lt wi th information to b ui ld

the next tone r lay er. At tha t time, the a ccumul ator belt i s

rotated to the proper position to transfer the toner layer

in proper registration with the previous layer(s).

Any toner remaining on the OPC belt after the transfer

to the accumulator belt is scraped off by the OPC belt

cleaning blade, which is always in contact with the belt.

This leaves the OPC bel t cl ean f or t he next la yer of to ner

to be transferred from the toner developers.

4. Mechanical Functions

4.2.5 Paper Pickup

The cam-shaped pickup rollers are driven by the paperfeed motor and force a sheet of pape r between the intermediate rollers. The pickup roller completes only one

rotation to pick a sh eet of media . This will push the s heet

of paper to the intermediate rollers but does not pick a

second sheet. Alternately, depending on the user’s selection, media may be picked from the multi-purpose tray.

The multi-purpose tray pickup roller is driven by the

M.P.T paper feed motor and feeds a shee t of media or an

envelope into the registration rollers.

The intermediate rollers advance the sheet of paper to

the registration rollers. The paper is driven lightly

against the stationary registration rollers to create a

slight buckle in the paper , aligning the sheet of paper. At

this point, the paper remains stationary (since the registration roller’s clutch is not yet energized) until the

image is ready to be printed on the paper. T h e registration sensor detects whether the sheet of paper arrived at

the aligning rollers after being properly picked and

traveling through the intermediate rollers.

The paper feed unit has the MP tray paper out sensor,

paper empty sensor and paper cassette sensor. The MP

tray paper out sensor detects whet her the paper i s set on

the manual feed tray. The paper empty sensor detects

whether the paper is set i n the paper cass ette. The paper

cassette sensor detects paper cassette presence and

paper size.

35

Page 7

FS-5900C Service Manual

4.2.6 Toner Tr ansfer to Paper

Once all four layers of toner reside up on the accumulator belt, the registration roller clutch is energized to

advance a sheet of paper (which has alre ady been picked)

to the second bias tra ns fer rolle r. The toner image on the

rotating accumulator and the paper that is being fed into

the image unit are synchronized for proper alignment.

The leading edge of the toner image on the accumulator

belt is aligned 5 mm from the leading edge of the paper.

A strong positive voltage in the second bias transfer

roller attracts the toner from the accumulator belt to the

paper. The transfer roller voltage varies from +500 to

+2600 volts based on the ambient temperature, humidity ,

print speed and media being prin ted upon. T he p aper (o r

transparency film) advances at the same speed as the

accumulator belt.

As the toner is being transferred to the paper, the accumulator belt cleaning blade is activated. This blade

scrapes any remaining traces of toner from the accumulator belt prior to the next image transfer. Residual toner

is removed from the second bias transfer roller by a

cleaning roller that is held at a potential that is +300v

higher than the second bias transfer roller. A blade

scrapes the toner off the cleaning roller into the toner

waste bin.

Second Bias

Transfer Roller

Cleaning

Roller (+300 V

higher than

STR)

Accumulator Belt

Cleaning Blade

+500 to 2600 V

Waste

Toner

Bin

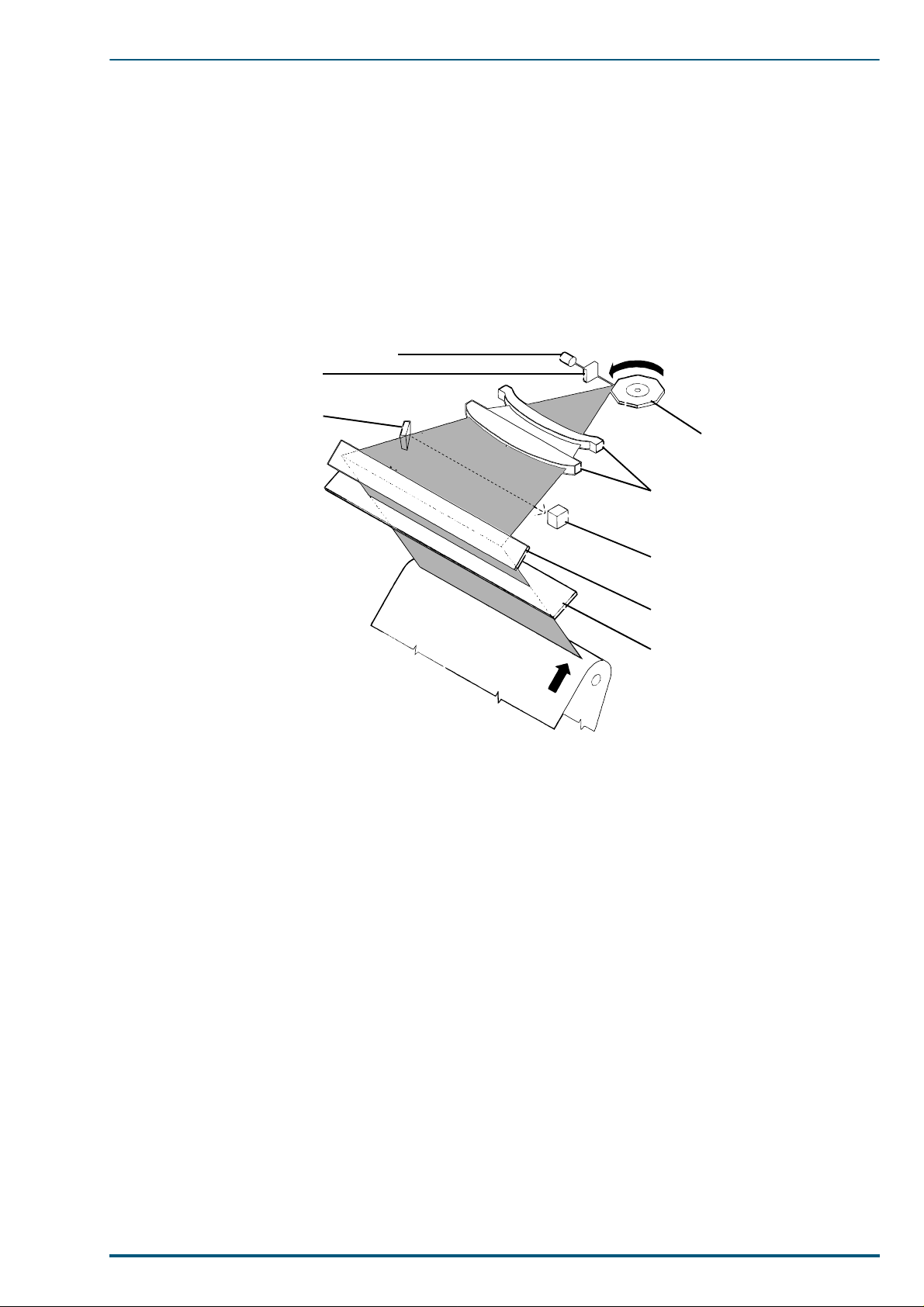

4.2.7 Fusing and Exiting

Fusing

After the toner image has been applied to the paper, it passes through the fuser. A heated roller melts the

toner and pressure drives it into the paper. The melted toner bonds to the paper. An oil supply keeps the

heated roller lubricated so that the melted toner does not adhere to the roller. After fusing, the paper

advances to the output tray. When the printer is idle, the heated roller is held at a temperature of 150 °C.

The heated roller is set to 156 °C for 600 dpi printing and 137 °C for 1200 dpi printing. For transparency

film and other media the fuser is set to 160 °C and ran at half speed. The paper ejection sensor detects the

sheet of paper as it leaves the fuser.

Take-Up

Roller

Supply

Roller

Heated

Roller

Fuser Roll

Oil (soaked)

Pressure

Roller

36

Fuser

Page 8

4. Mechanical Functions

Reverser

The reverser allows

the prints to exit to

the exit tray printed

side down

Output Tray

Paper Full

Sensor

Paper Exit

Sensor

Output

Tray

Paper Ejection

Sensor

Fuser

Switchback

Support Roller

Switchback

Roller

Switchback

Support

Roller

Paper ejection

roller #1

Switchback

Gate

Switchback

Roller Shaft

Switchback

Solenoid

Paper Path

Eject

If face up eject is selected, the paper goes directly to the output tray unde r the switchback gate, printed side

up.

Paper Ejection

Sensor

Output Tray

Paper Full Sensor

Paper Path

Paper Exit

Sensor

Output

Tray

Fuser

Or, if face down eject is selected, the switchback

solenoid on the toner developer selector/paper eject

unit is activated to hold th e s wi tchb a ck ga te i n t he

down position, allowing the paper to be fed to the

reverser, which drives the sheet up a narrow channel. At this time, the switchback shaft linked with

the switchback gate moves to position A. At the

proper time, the switchback solenoid is turned off,

which returns the switchback gate to the up position. Also, the switchback shaft moves to position

B. These movements reverse direction and routes

the sheet of paper to the output tray printed side

down. This is appropriate for a collated series of

prints that need to remain in first-to-last order.

The paper exit sensor detects the sheet of paper as

it enters the exit rollers.

Switchback Gate

Position A

Switchback

Gate

Switchback

Shaft

Paper

Position B

Paper Path

Paper ejection roller #2

37

Loading...

Loading...