Page 1

FS-5900C Service Manual

9. Troubleshooting

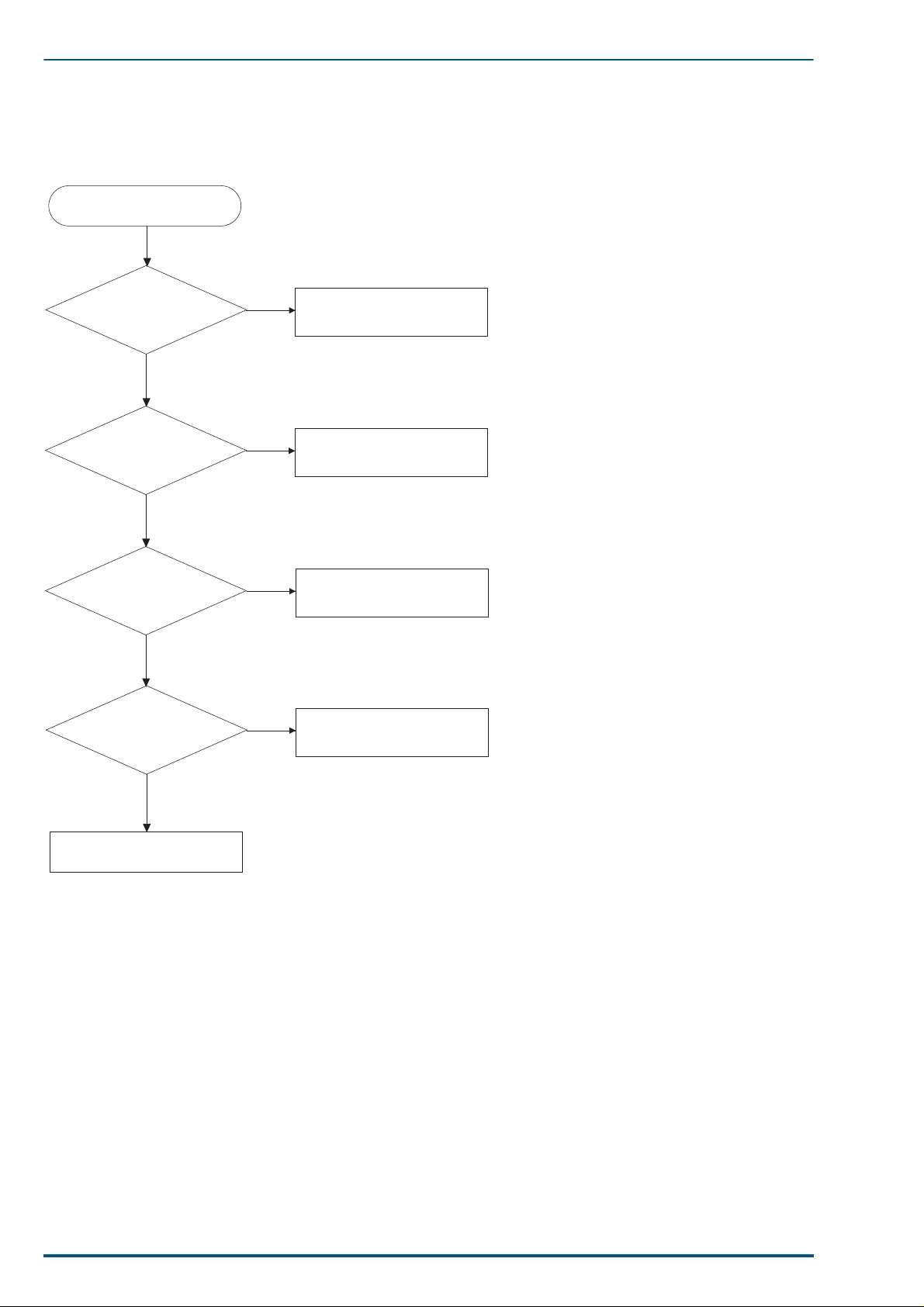

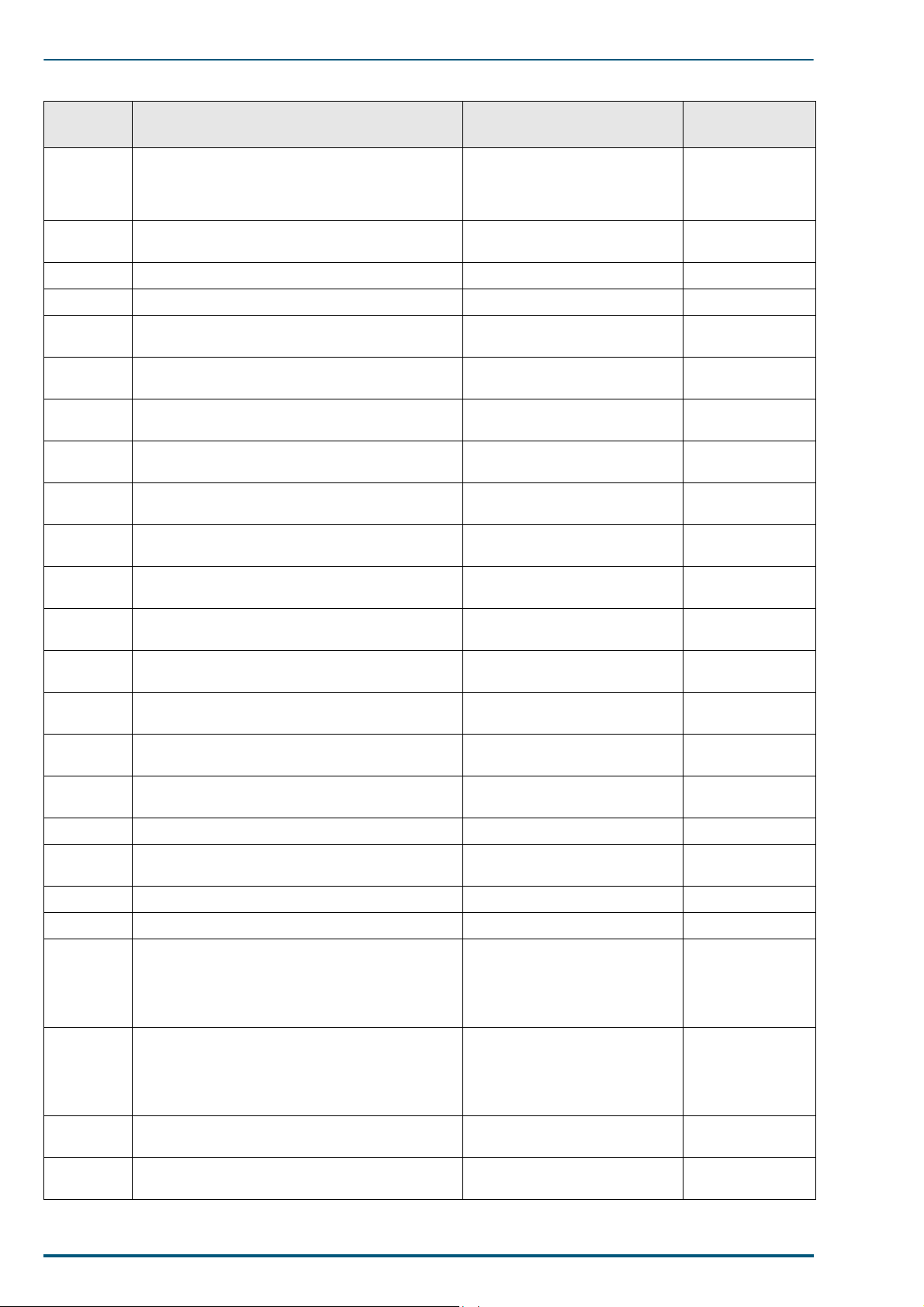

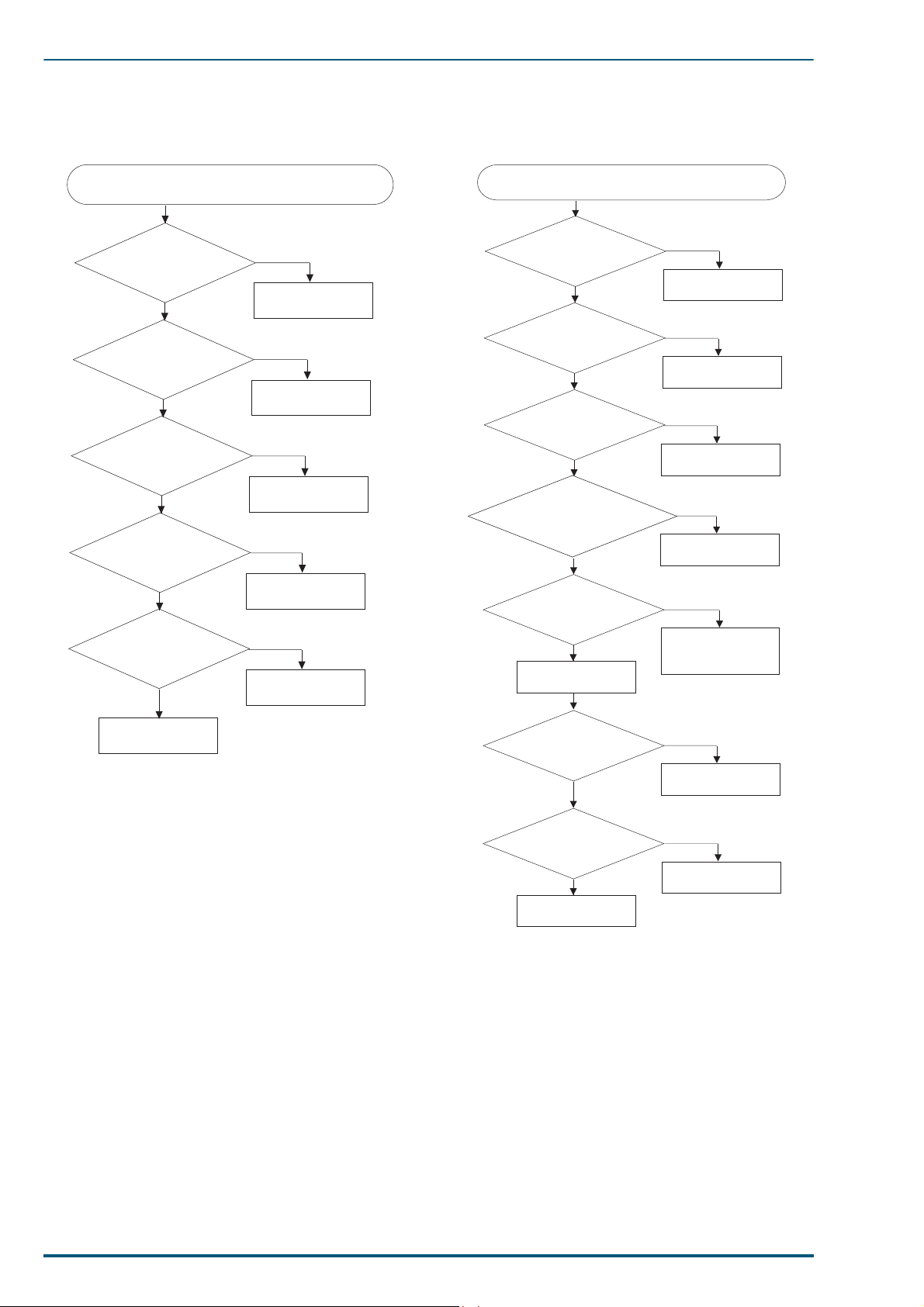

9.1 Initial Troubleshooting Flowchart

Start

Is a message

displayed?

Y

Is an error code

displayed?

N

Is print quality

normal?

Y

Does paper feed

normally?

N

Y

N

N

No Message Section

(Section 9.6)

Error Message Section

(Section 9.2)

Print Quality Section

(Section 9.4)

Paper Jam Section

(Section 9.3)

Y

End

102

Page 2

9. Troubleshooting

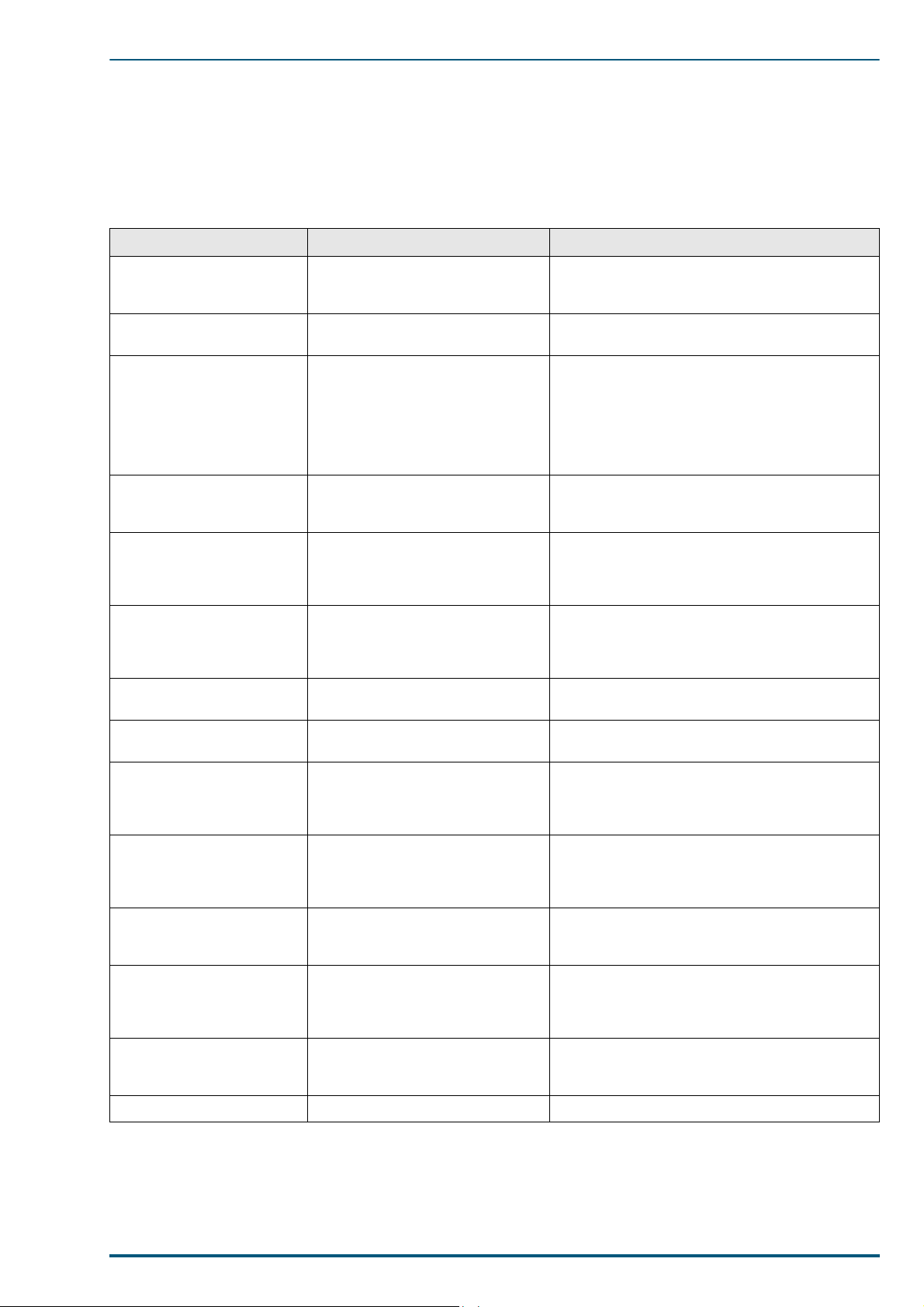

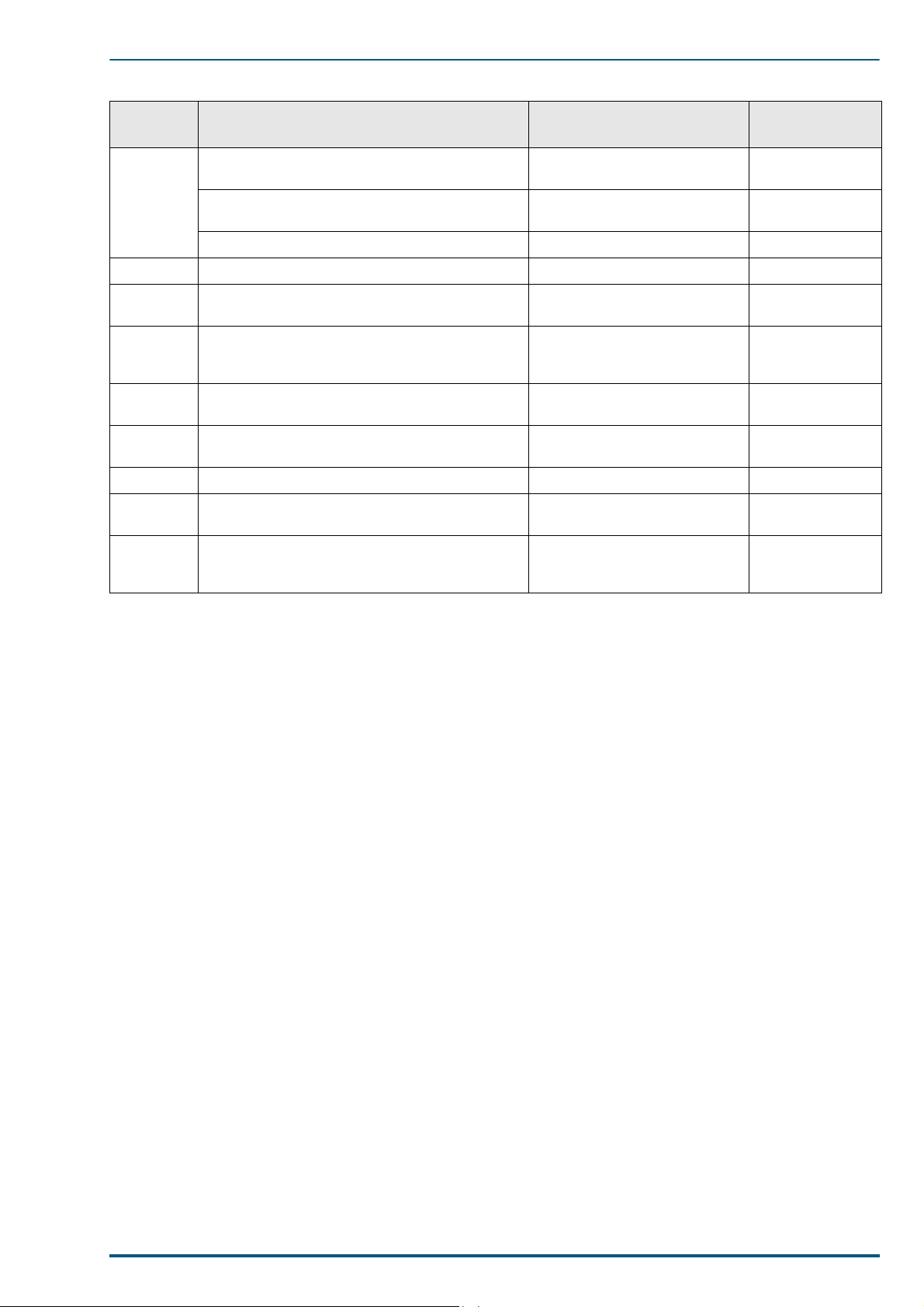

9.2 Error Messages

The printer indicates error conditions using the ON and blinking states of the ATTENTION indicator. When

the ATTENTION indicator is lit in red, it shows call service error status. When it is blinking, it shows user

correctable error status.

9.2.1 Error Messag es

Error Message Possible Cause Corrective Action

Add paper

paper source

<

Battery error

MEMORY CARD

Call service

person##:#######

Cassette 1

not loaded

Cassette 2

not loaded

Cassette 3

not loaded

Format error

<Media>

Front/Right

cover Open

HARDDISK error##

Press CONTINUE

>

The paper source is out of paper. Add paper to the paper cassette (Cassette 1),

The memory card’s battery is run

out or not installed.

A failure requiring the attention of

service personnel has occurred.

The printer’s media cassette is not

loaded in the printer, or not closed

fully in position.

The paper feeder’s top media cassette is not loaded in the paper

feeder, or not closed fully in posision.

The paper feeder’s bottom media

cassette is not loaded in the paper

feeder, or not closed fully in posision.

The hard disk or memory card is

not formatted.

The front or right sid e cover is

open.

The printer has encountered an

error during access to th e option

harddisk.

option paper feeder’s cassettes (Cassette 2 and

3), or multi-purpose tray (MP Tray).

Insert a new battery in the memory card. (See

the memory card manufacturer’s instruction.)

Note the corresponding error code (## followed by

the colon) and the total printed pages1 (#######

preceded by the colon). Turn printer power off

and call for service. For details, see section 9.2.2

Call Service person Codes. (The total printed

pages is not shown when the error code is F 0

[Communication error].)

Insert the media cassette, or close it securely.

(Cassette 1 is shown as Cassette w hen no option

paper feeder is installed.)

Insert the top media cassette, or close it securely.

(This message is shown only when the printer is

installed with an option paper feeder.)

Insert the bottom media cassette, or close it

securely. (This message is shown only when the

printer is installed with an option paper feeder.)

Format the media. See the appropriate section in

the User’s Manual for details.

Check both covers and close them tightly.

Note the error code (##) preceded by the HARDDISK error message. Then, press

clear the error situation. Refer to the appropriate

section in the User’s Manual for details.

CONTINUE

to

I/F occupied

Imaging unit

not locked

Insert the same

MEMORY CARD

KPDL Error ##

Press CONTINUE

Left cover Open

The front control panel operation

you attempted is not possible

because that interface is receiving

data.

The imaging unit is not locked

properly because its lever is not

lifted.

A different memory card was

inserted following the

&$5'#HUU2,QVHUW#DJDLQ

sage.

The printer encountered an error

during processing data in KPDL

mode.

The left side cover is open. Close it tightly.

0(025<#

mes-

Wait until the data transfer is completed on that

interface.

Lift the imaging unit lever fully up.

Reinsert the same memory card as was removed

previously into the printer’s memory card slot.

Note the error code of ## and press

clear the error situation. See the app r opriate section in the User’s Manual for details.

CONTINUE

to

103

Page 3

FS-5900C Service Manual

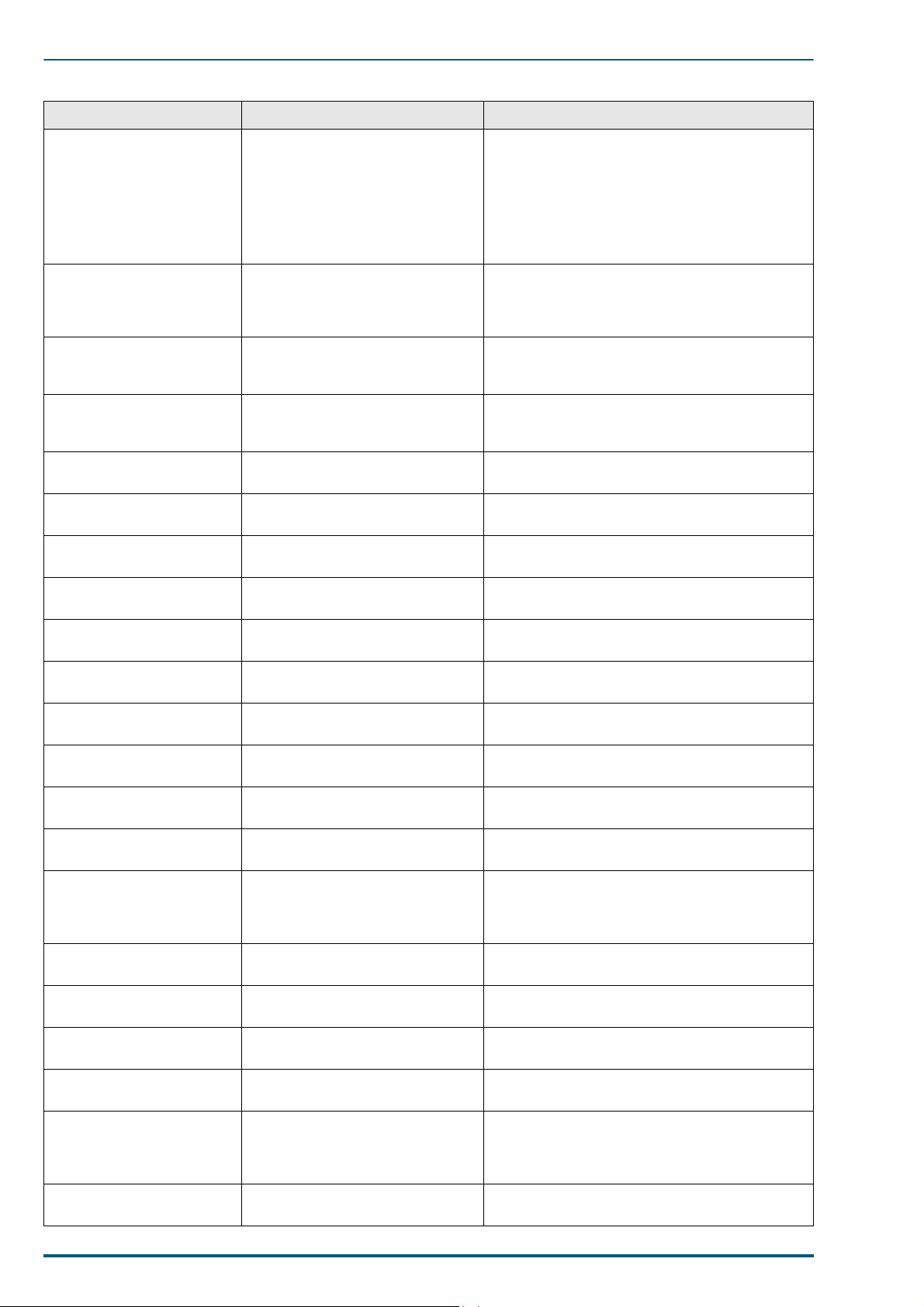

Error Message Possible Cause Corrective Action

Load paper

<paper size>

MEMORYCARD err##

Press CONTINUE

MEMORY CARD err

Insert again

Memory overflow

Press CONTINUE

Missing FK-81

Fuser KIT

Missing IU-81

Imaging unit

Missing OS-81

Oil supply roll

Missing Toner

TD-81C (Cyan)

The paper size does not match. Put the media cassette loaded with the paper of

the correct size as specified by the a pplication

software into the printer. To resume printing

using the current media cassette, press CONTINUE.

(You must press CONTINUE every time one sheet

has been printed, be ca use the sam e me ssa ge w il l

again be displayed from the second sheet

onward.) To abandon printing, press CANCEL.

The printer has encountered an

error during access to t he memory

card.

The memory card was removed

during the memory card operatin.

The print data from the computer

is larger than the printer can fit in

its memory.

The fuser kit is not installed in the

printer.

The imaging unit is n ot i nstalle d i n

the printer.

The oil supply rolle r is not installe d

in the printer.

The cyan toner developer is not

installed in the print e r.

Look at the error code of ## preceded b y MEM ORYCARD err. Then, press CONTINUE to clear the

error situation. Refer to the appropriate section

in the User’s Manual.

Re-insert the same memory card into the

printer’s memory card sl ot. The printer will continue with the memory card operation.

Press CONTINUE to print the data. Install additional memory or use a lower resolution print

quality.

Install the fuser kit.

Install the imaging unit .

Install the oil supply rol le r.

Install the cyan toner developer.

Missing Toner

TD-81K (Black)

Missing Toner

TD-81M (Magenta)

Missing Toner

TD-81Y (Yellow)

Missing

Charger unit

Missing paper

feeder unit

Option feeder

Left cover Open

Opt. ROM error

Press CONTINUE

Option interface

Error ##

Output tray

paper full

PJL OPMSG/STMSG The printer encountered an error

The black toner developer is not

installed in the print e r.

The magenta toner developer is not

installed in the print e r.

The yellow toner developer is not

installed in the print e r.

The charger unit is not installed in

the printer.

The paper feeder unit is not

installed in the print e r.

The paper feeder’s left side cover is

open.

The printer has encountered an

error while accessing data in the

option EPROM (on the printer

main board).

The printer has detected an error

on the option inte rface.

The output tray has become full. Remove paper from the output tray.

during processing PJL commands.

Install the black toner developer.

Install the magenta toner developer .

Install the yellow toner developer.

Install the charger unit in the imaging unit.

Install the paper feeder unit.

Close it tightly.

Press CONTINUE to print the data processed so far.

Replace the option EPROM.

Note the error code of ## and consult your Kyocera dealer.

Press CONTINUE to print the page processed so far.

Paper jam

Location

<

Print overrun

Press CONTINUE

Replace FK-81

Fuser KIT

>

104

Paper has become jammed. Remove jammed paper according to the appropri-

The printer has received print data

that is too complex to finish processing in time with the operation

of the printer mechanism.

The fuser is worn out. Replace the fuser ki t now.

ate section in the User’s Manual.

Press CONTINUE to print the data. Install addi-

tional memory or use a lower resolution print

quality.

Page 4

9. Troubleshooting

Error Message Possible Cause Corrective Action

Replace IU-81

Imaging unit

Replace OS-81

Oil supply roll

Replace Toner

TD-81C (Cyan)

Replace Toner

TD-81K (Black)

Replace Toner

TD-81M (Magenta)

Replace Toner

TD-81Y (Yellow)

Reset Transf.Roll

Press ENTER

Set paper

Press CONTINUE

Toner low

TD-81C (Cyan)

The imaging unit is worn out. Replace the imaging unit now.

The oil supply roller is worn out. Replace the oil supply roller now.

The cyan toner developer is empty. Replace the cyan toner developer now.

The black toner developer is empty. Replace the black toner developer now.

The magenta toner developer i s

empty.

The yellow toner developer is

empty .

The printer is waiting for your

input of confirming that you have

replaced the trans fer roller and

resetting its counter (User’s Manual ☞ P. 105).

The multi-purpose tray is empty. Add a sheet of paper to the multi-purpose tray,

The cyan toner developer is almost

empty.

Replace the magenta toner developer now.

Replace the yellow toner developer now.

Press ENTER and the printer resets the transfer

unit counter to 0000000.

and press CONTINUE key. (This message

appears when the multi-purpose tray is in manual mode.

Replace the cyan toner developer as soon as possible.

Toner low

TD-81K (Black)

Toner low

TD-81M (Magenta)

Toner low

TD-81Y (Yellow)

Warning FK-81

Fuser KIT

Warning IU-81

Imaging unit

Warning TR-81

Transfer roller

Warning battery

MEMORY CARD

Warning

Low memory

The black toner developer is almost

empty .

The magenta toner developer i s

almost empty.

The yellow toner developer is

almost empty.

The fuser kit is wearing out. Replace the fuser kit as soon as possible.

The imaging unit is wearing out. Replace the imaging unit as soon as possible.

The transfer roller is wearing out. Replace the transfer roller as soon as possible.

The memory card’s battery is running out.

The printer’s internal memory is

insufficient to complete the printing.

9.2.2 Call Service person Codes

LCD

Display

Printer Status Possible Cause Recovery

Replace the black toner developer as soon as possible.

Replace the magenta toner developer as soon as

possible.

Replace the yellow toner developer as soon as

possible.

Change the memory card battery as soon as possible. (See the memory card manufacturere’s

instruction.)

Press CONTINUE key to print the page processed so

far. Remove any unnecessary fonts or macros in

the printer or install additional memory.

A2 Fuser temperature is over 210 °C. High temperature error See section 9.5.10

A2 Fuser temperature does not reach 100 °C within

200sec, 165 °C within 500 sec. During warming

up, or it is less t han 120 °C du ring stan dby, and it

does not return to set temperature within 100sec

after a low temperature error occurred during

printing.

Temperature rising error See section 9.5.10

105

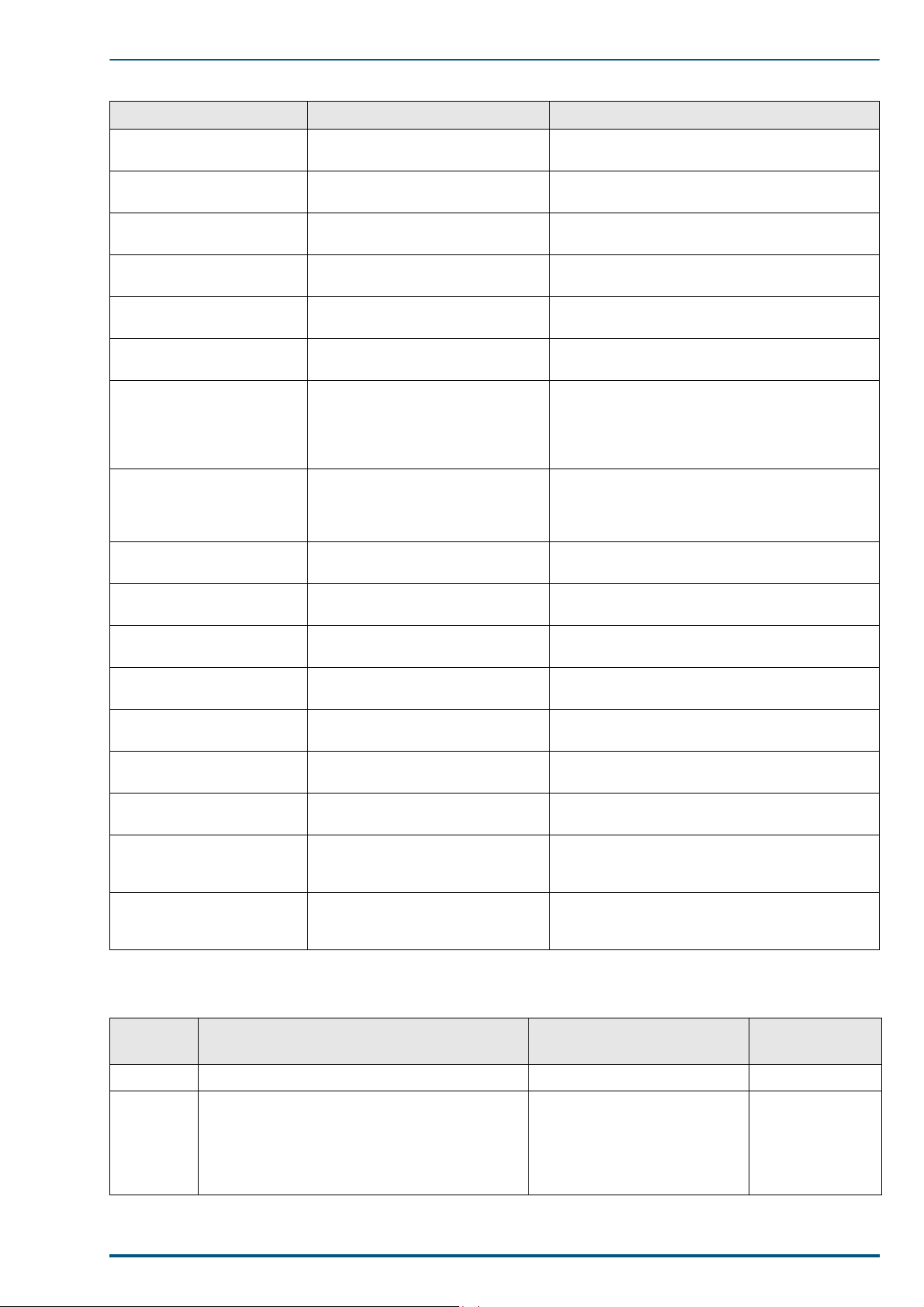

Page 5

FS-5900C Service Manual

LCD

Display

A5 1. Main charger Arc discharge of co ntact has

occurred.

2. DEV, FTR, STR bias short circuit of contact

voltage has occurred.

A6 Fuser/Toner Developer fan is not rotating at nor-

mal speed.

A7 Power supply fan is not rotating at normal speed. Power supply fan error See section 9.5.12

A8 Ozone fan is not rotating at normal speed. Ozone fan error See section 9. 5.13

A9 Multi-Purpose Pickup Roller movement error

occurred

AA T oner Developer Drive motor (sleeve motor) is not

phase-locked and is not rotating at normal speed.

AB Paper feed motor is not phase-locked and is not

rotating at normal speed.

AC OPC home and IT home are not synchronous. OPC asynchronous with inter-

AD OPC home is not detected within 4.5 sec. during

rotation of main motor.

AE IT home is not detected within 0.32 sec. during

rotation of main motor.

AF The cleaning blade did not reached to non-clean-

ing position or cleaning position within 0.7 sec.

B7 The media transfer roller did not reach to trans-

fer position or home position within 0.9 sec.

B8 The dev. unit did not reach contact position or

home position within 1 sec.

B9 The dev. unit did not reach contact position or

home position within 1 sec.

BA The dev. unit did not reach contact position or

home position within 1 sec.

BB The dev. unit did not reach contact position or

home position within 1 sec.

BC Engine SRAM check error Engine SRAM check error See section 9.5.19

Printer Status Possible Cause Recovery

Charger error See section 9.5.4

Fuser/T oner Developer fan error See section 9.5.2

Multi-Purpose Pickup Roller

movement error

Toner Developer Drive motor

(sleeve motor) unlocked

Paper feed motor unlocked See section 9.5.15

mediate transfer unit

Position error of the OPC unit See section 9.5.6

Position error of the intermediate transfer unit

Cleaning blade movement erro r See section 9.5.8

Media transfer roller movement error

Cyan developing unit movement

error

Magenta developing unit movement error

Yellow developing unit movement error

Black developing unit movement error

See section 9.5.17

See section 9.5.14

See section 9 .5 .5

See section 9 .5 .7

See section 9 .5 .9

See section 9 .5 .1

See section 9 .5 .1

See section 9 .5 .1

See section 9 .5 .1

BD Engine EEPROM check error. Printing is contin-

ued.

BE EEPROM (Imaging unit) check error EEPROM (Imaging unit) Error See section 9.5.22

BF EEPROM (Fuser unit) check error EEPROM (Fuser unit) Error See section 9.5.23

DE Imaging unit type mismatch Imaging Unit being used is not

DF Fuser unit type mismatch Fuser Unit being used is not

E0 Parity error occurs or no response comes back

from engine.

E1 Main motor is not phase-locked and is not rotat-

ing at normal speed.

Engine EEPROM check error See section 9.5.20

Replace Im aging

intended for use with the

printer.

intended for use with the

printer.

Engine communication Error See section 9.5.21

Main motor unlocked See section 9.5.16

Unit with the one

recommende by

Kyocera for the

printer.

Replace Fuser

Unit with the one

recommended by

Kyocera for the

printer.

106

Page 6

9. Troubleshooting

LCD

Display

E2,E3 Laser scanner motor is not phase-locked and is

not rotating at normal speed.

L-sync signal is not detected after APC (Auto

Power Control).

Irregular L-sync signal is detected. L-Sync short See section 9.5.3

E4 Fuser thermistor is disconnected. Thermistor open error See section 9.5.11

E6 Engine progra m RO M checksum error Engine Program RO M check-

F0 Controller board system lock error System does not lock because of

F1 Controller checksum error Checksum failed on Controller

F2 RAM Read/write error Checksum has failed on Con-

F3 System error General controller failure. See section 9.5.27

F7 Option font ROM checksum error Checksum has failed on option

Memory

Overflow

Memory overflow has occurred. Print data is larger than the

Printer Status Possible Cause Recovery

Laser scanner motor unlocked See section 9.5.3

L-Sync over See section 9.5.3

sum error

failure on communication with

the printer panel.

ROM.

troller RAM.

font ROM.

capacity of the memory

installed.

See section 9.5.18

See section 9.5.24

Replace Main

Controller Board.

See section 9.5.26

Replace the option

font ROM.

See section 9.5.25

107

Page 7

FS-5900C Service Manual

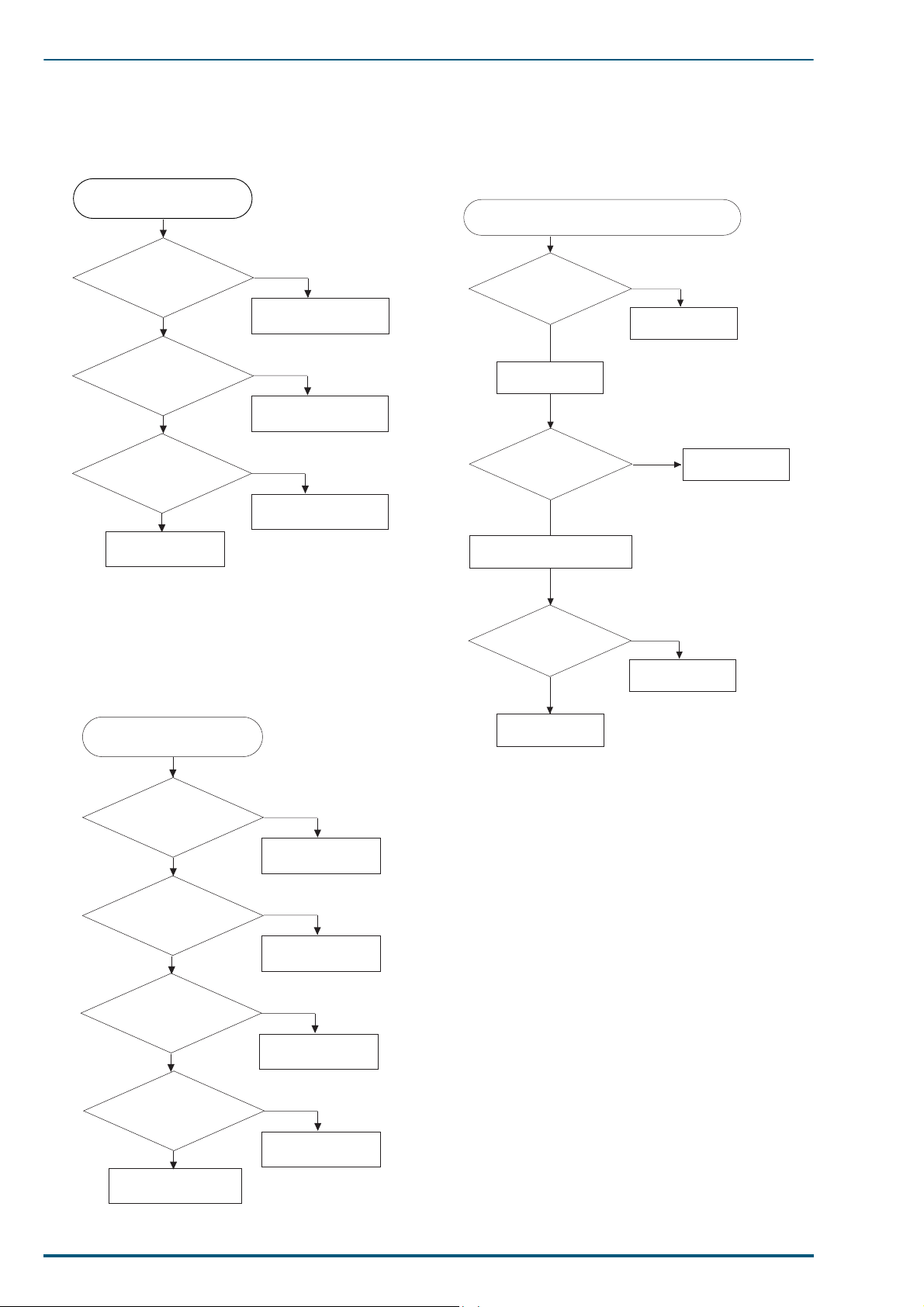

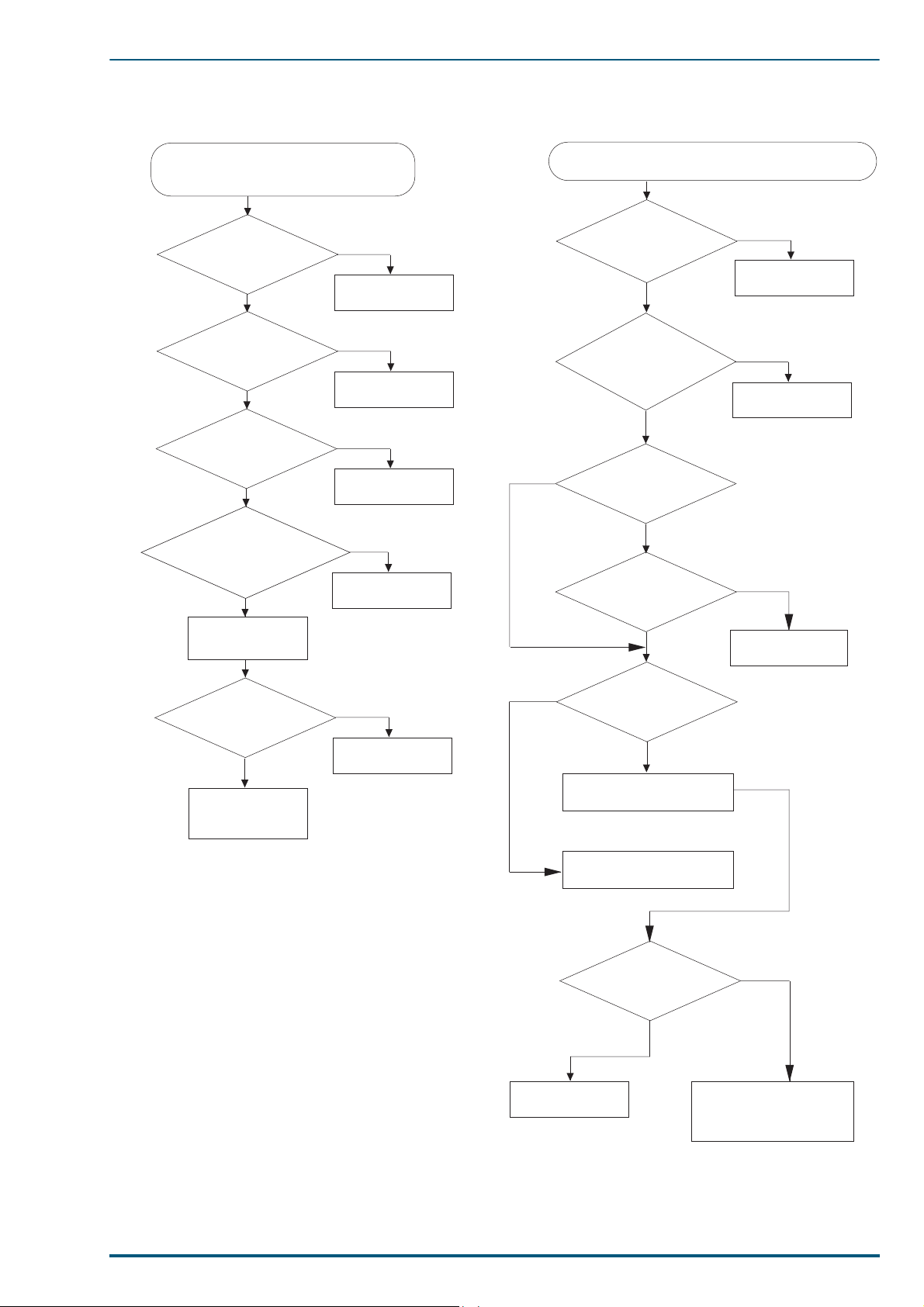

9.3 Jam

9.3.1 Print Media Problem

Printer Media Problem

Is the print media

being used within

specification?

Y

*

Is print media in

good condition?

Y

Is the correct tray

being used?

Y

Check again.

*

Inspect the print media for bent,

torn or folded corners etc.

N

Use print media that is

within specification.

N

Use undamaged print

media.

N

Use the correct tray.

9.3.3 Printer cannot distin guish

between paper and t ransparen cy.

Printer cannot distinguish between

paper and transparency.

Is the appropriate

media tray being

used?

Y

Replace the sensor

board.

Is printer work

OK?

N

If necessary, reinstall the

original board.

N

Use the appropriate

media tray.

Y

End

9.3.2 Print Media skews.

Printer Media skews.

Does the pickup

roller pickup the

media evenly?

Y

Are the MPT paper

guides snugly

adjusted against the

media?

Y

Are the corners of

the media under the

tray tabs?

Y

N

Check and clean

the pickup roller.

N

Adjust or replace

the paper guides.

N

Set the media

under the tabs.

Is the cable

connected to the

sensor board

normal?

Y

Replace the engine

control board.

N

Replace the cable

(CN11).

108

Is the paper guide on

the left door normal?

Y

Check for obstacle

blocking the paper path.

@

N

Remove burs or

foreign obstructions.

Page 8

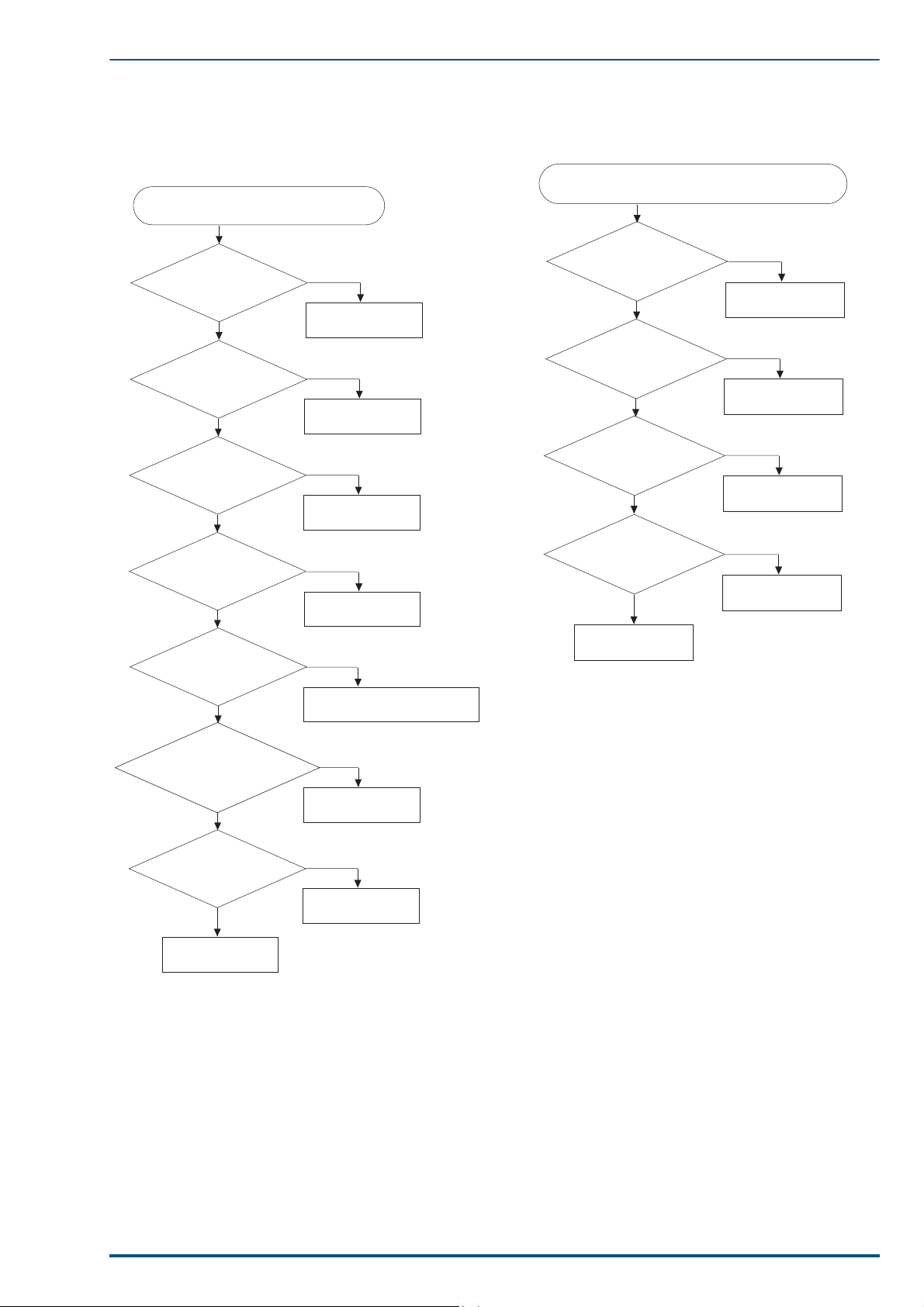

9. Troubleshooting

N

N

N

Y

Clean the pickup

rollers.

Paper jams midway in the paper feeder.

(Front panel displays Paper Jam/B.)

Are the pickup

rollers clean?

Y

* Is the paper guide

on the left door

normal?

* Check for burrs or foreign obstructions.

Y

Clean the paper

feed rollers.

Are the paper feed

rollers clean?

Y

Replace the clutch

assembly.

Does the pickup

roller clutch work

properly?

Check again.

N

Remove burrs or

foreign obstructions.

9.3.4 Paper jams at the media cassette.

Paper jams at the media tray.

(Front panel displays Paper Jam/A.)

Are the pickup

rollers clean?

Y

Is the paper feed

motor normal?

Y

Are the gears

normal?

Y

N

Clean the pickup

rollers.

N

Replace the paper

feed motor.

N

Replace the gear.

9.3.5 Paper jams mi dway in the p aper

feeder .

* Is the pickup roller

correctly installed?

Y

Does the pickup

roller solenoid

work properly?

Y

Are the cables and

connectors between

paper feed unit board

and engine control board

normal?

Y

Are the other

areas of the paper

feeder normal?

Y

Check again.

*

Flat side of the cam-shaped pickup rollers

face down prior to pick a sheet of paper.

N

Install the pickup

roller properly.

N

Check or replace the solenoid

and paper feed unit board.

N

Replace the

defective parts.

N

Replace the

defective parts.

109

Page 9

FS-5900C Service Manual

9.3.6 Paper jams at the second bias

transfer roller.

Paper jams at the second bias transfer roller.

(Front panel displays Paper Jam/B.)

Is the transfer

roller correctly

installed?

Y

Does the

registration sensor arm

properly interrupt the

sensor?

Y

Are the registration

rollers clean?

Y

Does the

registration clutch

work properly?

Y

Are the registration

springs installed

properly?

Y

N

Install the transfer

roller correctly.

N

Correct movement

of the sensor arm.

N

Clean the

registration rollers.

N

Replace the

registration clutch.

N

Install the springs

properly.

9.3.7 Fuser Jams

Fuser Jams.

(Front panel displays Paper Jam/C.)

Are the Fuser

gears normal?

Y

Can the fuser

knob be turned

normally?

Y

Does the fuser exit

sensor arm operate

properly?

Y

Are the cables and

connectors for fuser

exitboard, exit sensor board

and engine control board

normal?

Y

Does the paper

ejection roller

rotate?

Y

Replace the engine

control board.

N

Replace the fuser

unit.

N

Replace the fuser.

N

Correct movement

of the sensor arm.

N

Replace the cable

and connector.

N

Check the toner

cartridge selector/

paper-eject unit.

Check again.

Does the trouble

still occur?

Y

Fuser cleaning pad

Is

clean?

Y

Replace the fuser

unit.

N

N

Clean fuser

cleaning pad

End

110

Page 10

9. Troubleshooting

Is the multi-purpose feed

motor fixed to metal plate

properly?

N

N

Y

Correct movement

of the arm.

Multi-purpose Tray Jams.

(Front panel displays Paper Jam/A.)

Does the

multi-purpose tray

sensor arm actuate its

sensor properly?

Y

Replace the cable.

Is the

cable from the paper

feeder to the engine control

board (CN604)

normal?

Y

N

Does the multipurpose pickup

roller shaft rotate?

*2 Replace the paper feed

unit board or engine

control board.

Y

N

Is the retard pad

able to move up

and down?

Repair the retard

pad.

N

Y

Replace the multi-purpose

feed motor.

Does the multipurpose pickup

roller shaft rotate?

N

Y

End

Correct the multi-purpose

feed motor.

9.3.8 Eject Jams 9.3.9 Multi-purpose Tray Jams

Eject Jams.

(Front panel displays Paper Jam/D

or Paper Jam/E.)

Are all the ejection

rollers clean?

Y

*1 Are the switch

back levers

normal?

Y

Does the

paper ejection sensor

arm actuate its sensor

Are the cable and connector

properly?

Y

to the engine control

board (CN611) normal?

Y

*2 Replace the

engine control

board.

N

Clean the ejection

rollers.

N

Correct movement

of the levers.

N

Correct movement

of the sensor arm.

N

Replace the cable.

Does the trouble still

occur?

Y

Check the toner

cartridge selector/

paper eject unit.

Ensure that the levers are not bent and do not

1

*

interfere with paper movement.

When replacing the engine control board,

2

*

remove EEP ROM (IC6) from the original

engine control board and install it on the new

engine control board.

N

End

111

Page 11

FS-5900C Service Manual

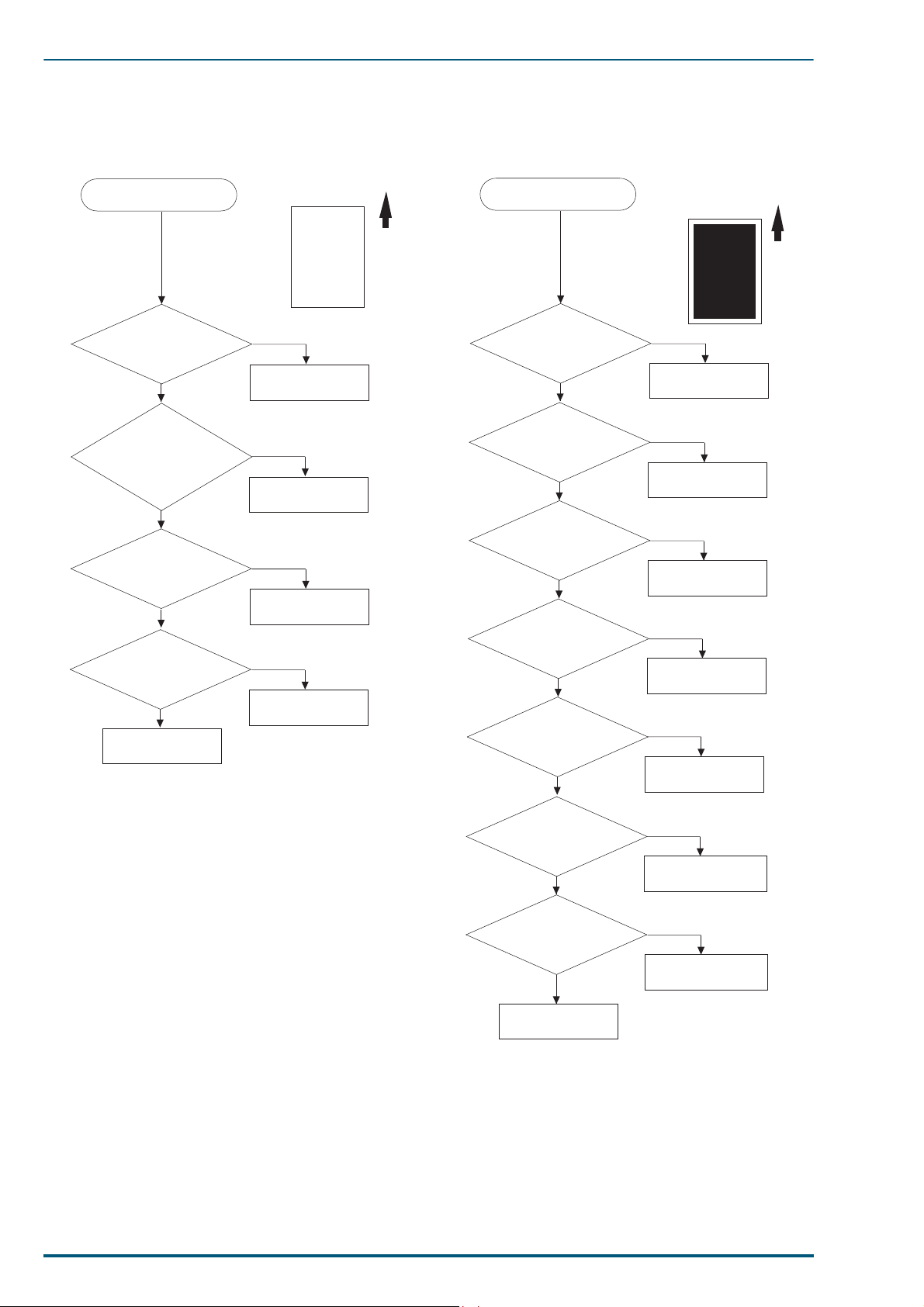

9.4 Print Quality

9.4.1 Blank Print 9.4.2 A ll-black Print

Blank Print

Is the laser unit

normal?

Y

Is the toner

cartridge selector pushing

the toner cartridge into

contact with the

belt?

Y

Is the toner

cartridge drive unit

normal?

Is the imaging unit

normal?

Y

*1

Replace the engine

*1

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

*2

When replacing the Printer Main Control Board,

remove IC9 from the original Printer Main Control

Board and install it on the new Printer Main Control

Board.

control board.

N

Replace the laser

unit.

N

Check the toner

cartridge selector.

N

Repair the toner

cartridge drive unit.

N

Replace the

imaging unit.

Paper Travel

All-black Print

Is the imaging unit

installed properly?

Y

Is the scorotron

charger normal?

Y

Is the imaging unit

normal?

Y

Is the high voltage

board normal?

Y

Is the laser unit

normal?

Y

Is the engine

control board

normal?

Y

Is the printer

control board

normal?

Y

N

Install the imaging

unit properly.

N

Replace the

scorotron charger.

N

Replace the

imaging unit.

N

Replace the high

voltage board.

N

Replace the laser

unit.

N

*1

Replace the engine

control board.

N

*2

Replace the printer

control board.

Paper Travel

112

Check again.

Page 12

9.4.3 Missing Primary Colour 9.4.4 Light Print

Check again.

Paper Travel

N

Y

Correct connection

to the second bias

transfer roller.

Is the high

voltage connector to the

second bias transfer

roller normal?

Light Print

N

Y

Clean the path.

Is the path laser

beam travels

clean?

N

Y

Check the toner

cartridge selector.

Is the

toner cartridge

selector pushing the

toner cartridges into full

contact with

the belt?

N

Y

Replace the

imaging unit.

Is the imaging

unit normal?

N

Y

Replace the second

bias transfer roller.

Is the second

bias transfer

roller normal?

N

Y

Replace the fuser.

Is the fuser

normal?

Missing Primary Colour

9. Troubleshooting

Is the toner

cartridge of the

missing color

normal?

Y

Is the cable

from the cartridge

selector to the engine

control board (CN21)

normal?

Y

Is the toner

cartridge selector pushing

the toner cartridge into

contact with the

belt?

Y

Is the toner

cartridge drive

unit normal?

Y

*Is the engine

control board

normal?

Y

N

Replace the toner

cartridge.

N

Replace the cable.

N

Check the toner

cartridge selector.

N

Repair the toner

cartridge drive unit.

N

Replace the engine

control board.

Check again.

*

When replacing the Engine Control Board,

remove EEPROM (IC6) from the original Engine

Control Board and install it on the new Engine

Control Board.

113

Page 13

FS-5900C Service Manual

9.4.5 Repeated spots or lines on print

in-line with each other.

Repeated spots or lines on

print in-line with each other.

*

Measure the spacing

between the spots ( or

thin horizontal lines)

Paper Travel

Space Possible cause and remedy.

1.5 mm

26 mm

(1200 dpi)

34 mm

(600 dpi)

76 mm

Imaging unit gears poorly meshing.

Replace the imaging unit.

Replace the toner cartridge.

Replace the toner cartridge.

Replace the second bias transfer

roller.

9.4.6 Dark Vertical Line in Pr int

Dark Vertical Line

in Print

P

Is the scorotron

charger normal?

Y

Is the OPC belt

normal?

Y

Is the dark line of

one primary colour?

Y

N

Replace the

scorotron charger.

N

Replace the

Imaging unit.

N

Replace the toner

cartridge.

Paper Travel

94 mm

103 mm

125 mm

*

The distance between the repeating spots

indicates the source of the problem.

Thin horizontal lines, depending on problem,

the distance between lines may range from

1.5mm between each line to 103mm between

each line.

Imaging unit belt defect. Replace

the imaging unit.

Paper feeder drive gear broken

tooth. Repair the paper feeder.

Fuser roller defect. Replace the

fuser.

Is the path laser

beam travels

clean?

Y

Is the imaging unit

normal?

Y

Is the fuser unit

normal?

Y

Check again.

N

Clean the path.

N

Replace the

imaging unit.

N

Replace the fuser

unit.

114

Page 14

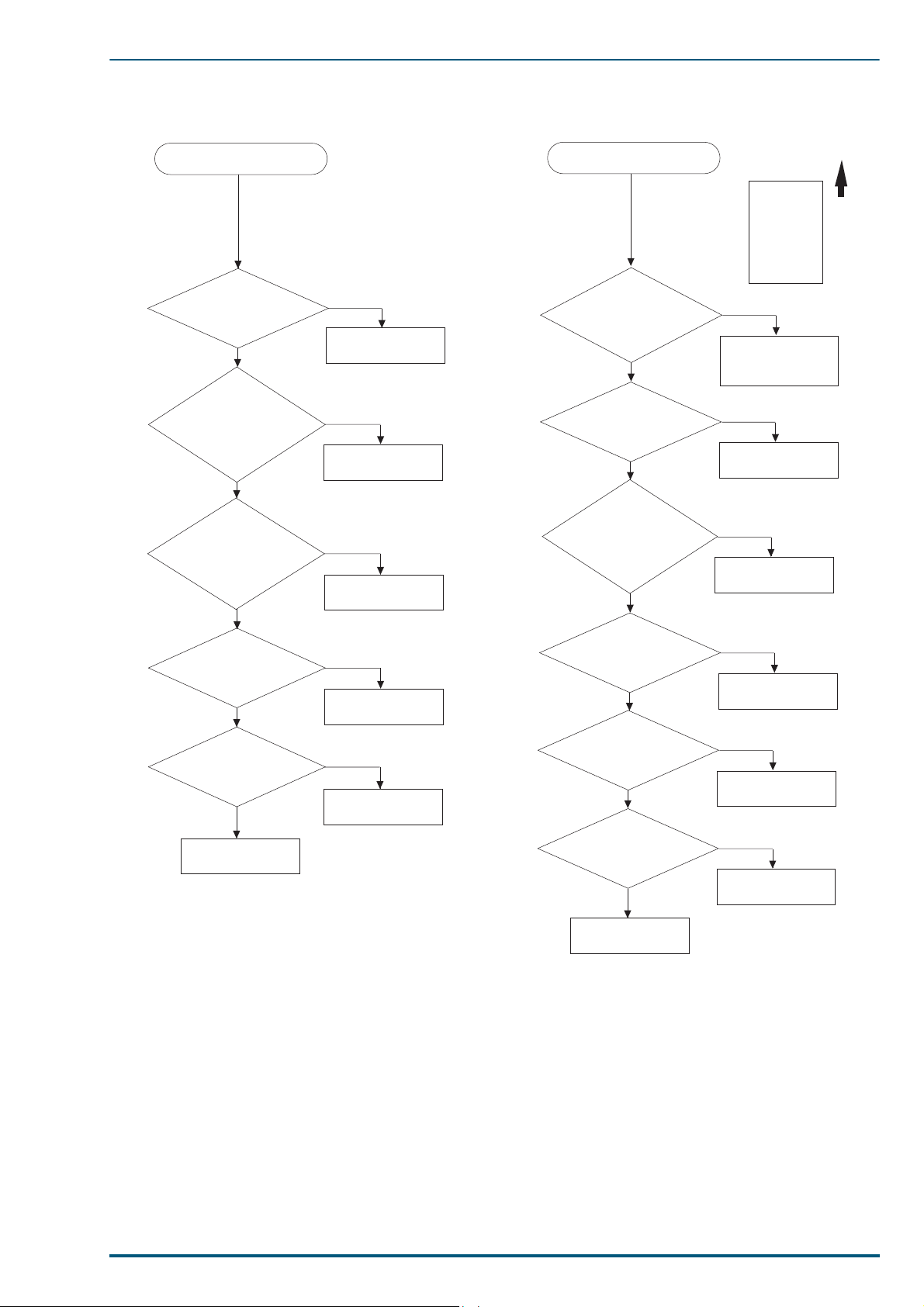

9. Troubleshooting

N

Clean or replace

the charger.

Is the scorotron

charger normal?

Y

N

Replace that colour's

toner cartridge.

Is excess

printing in background

of one primary colour?

Y

N

Replace the high

voltage board.

Is the high voltage

board normal?

Y

Check again.

Dirty Background

N

Replace the

toner cartridge.

Is the toner

cartridge roller

normal?

Y

Partial Black Dots

N

Replace the

imaging unit.

Are the OPC belt

and accumulator

belt normal?

Y

N

Replace the

fuser unit.

Are the fuser

rollers normal?

Y

Check again.

9.4.7 White horizontal line or band in

all the colours of a print

White horizontal line or band

in all the colours of a print

Is the imaging unit

normal?

Y

Is the secondary

bias transfer roller

normal?

Y

Check again.

N

Replace the

imaging unit.

N

Replace the

secondary bias

transfer roller.

9.4.9 Dirty Background

9.4.8 Mis-transfer, missing portions

of toner

Mis-transfer, missing

portions of toner

Is the imaging unit

normal?

Y

Is the heat roller of

the fuser normal?

Y

Check again.

9.4.10 Partial Black Dots

N

Replace the

imaging unit.

N

Replace the fuser.

115

Page 15

FS-5900C Service Manual

9.4.11 Dark Irregular Streaks in All

Colours

Dark Irregular Streaks in All Colours

Is the waste toner

box of the imaging

unit normal?

Y

Check again.

N

Replace the

imaging unit.

9.4.13 Unfused or Partially Fused Printing

Unfused or Partially Fused Printing

Is the paper

in good condition and

appropriate for a laser

printer?

Y

Is the fuser normal?

Y

Check again.

N

Use appropriate

paper.

N

Replace the

fuser unit.

9.4.12 Ghosting

Ghosting

*1

Is the toner

cartridge normal?

Y

Check again.

*1

Ghosting with some images is unavoidable because

of the colour structure of the images. If a colour is

used at one part of the image area and the same

colour is used again at a later area, it is very possible

to get ghosting of the first image into the second

image area after one revolution of the toner cartridge

developer roller. This occurs because the charge that

is created from the first use of the colour was not

totally extinguished, a small residual charge remains

associated with the colour, resulting in the second

use of the colour to be darker in the same areas as

the first image resulting in the first image ghosting

into the second image when the same colour is

issued.

*2

A new toner cartridge exhibits less ghosting.

Ghosting increase as toner cartridges age.

*3

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control

.

Board and install it on the new Engine Control Board

N

*2

Replace the

toner cartridge.

9.4.14 Image is skewed on the paper.

Image is skewed on the paper.

Is the paper feed unit

installed?

Y

Are the intermediate

and registration rollers

normal?

Y

Is the engine control

board normal?

Y

Check again.

N

Install the paper

feed unit properly.

N

Repair the paper

feed unit.

N

*3

Replace the engine

control board.

116

Page 16

9. Troubleshooting

N

Install the paper

feed unit properly.

Is the paper feed unit

properly installed?

Image is not centered on the

print when it should be.

N

Clean the rollers.

Are the intermediate

and registration rollers

clean?

Y

N

Check the paper

feed unit .

Is the paper feed unit

normal?

Y

N

Adjust the print

position

(section 7.1).

Is the print position

calibration correct?

Y

Y

N

Replace the

engine control

board.

Is the engine control

board normal?

Check again.

Y

*

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

9.4.15 Stains on Back of Print

Stains on Back of Print

Is the second bias

transfer roller

clean?

Y

Is the paper path

of the paper feed

unit clean?

Y

Are the fuser

rollers normal?

Y

Is

Fuser cleaning pad

clean?

Y

Check again.

N

Clean the roller

with a dry, lint free

cloth.

N

Clean the paper

path of the paper

feed unit.

N

Replace the fuser

unit.

N

Clean fuser

cleaning pad

9.4.17 Image is not centered on the

print when it should be.

9.4.16 No Printing on Edge of Print

No Printing on Edge of Print

Is a single primary

colour is missing?

Can each toner

cartridge be moved

forward normally toward

the imaging unit?

metal pads on the end

of the toner cartridge

Y

Y

Are the two

normal?

Y

N

Replace that colour's

toner cartridge.

N

Check the toner

cartridge selector.

N

Replace the toner

cartridge.

Are the cams of the

toner cartridge selector

normal?

Y

Check again.

N

Repair the toner

cartridge selector.

117

Page 17

FS-5900C Service Manual

9.5 Printer Error (Call Service person)

9.5.1 BB/B8/B9/BA

LCD Message Possible Cause

Call Service person BB

Call Service person B8

Call Service person B9

Call Service person BA

Black developing unit movement error

Cyan developing unit movement error

Magenta developing unit movement error

Yellow developing unit movement error

Push the error

developer towards

the OPC and check

that it moves.

Y

Does Developer

Cam of door move

normally in power

on initializing?

(Please compare with other

developers.)

(When door is opened, manually

depress the +24 V interlock switch

Y

turned on.)

N

Replace developer.

N

Replace Cam Motor & Cam

Gear Unit.

Is the same message

still displayed on the

LCD?

Y

Replace guide rail for

developer.

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

N

N

N

Is the cable for Cam

Motor Unit damaged?

N

*

Replace engine control

board.

*

When replacing the Engine Control Board, remove EEPROM (IC6) from the original Engine Control Board and

install it on the new Engine Control Board.

Y

Replace the cable.

Is the same message

still displayed on the

LCD?

Y

118

N

OK

Page 18

9.5.2 A6

LCD Message Possible Cause

Call Service person A6

Fuser/Toner Cartridge fan

error for Developer Unit

Fuser/Toner Cartridge fan is not rotating at normal

speed.

9. Troubleshooting

9.5.3 E2/E3

Call Service person E2

Call Service person E3

Check the connection

between engine control board

and LSU.

Is +24V outputted to

CN24 pins No.1 and

No.2 on the engine

control board?

Y

Replace the Fuser/Toner

Cartridge fan.

N

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

*

Replace the engine control board.

LCD Message Possible Cause

Scanner motor is not phase-locked and is not rotating at normal speed.

L-Sync Signal is not detected after APC, or Irregular L-Sync signal is

detected.

Check : Is the error message still displayed on the LCD?

Are the cables

connected

correctly?

Y

*

Replace the engine control

board.

Check

Y

End

N

N

Connect them correctly.

*

When replacing the Engine Control

Board, remove EEPROM (IC6) from

the original Engine Control Board and

install it on the new Engine Control

Board.

Replace LSU.

Y

Check

N

Check or replace the cables.

Check

Y

End

N

119

Page 19

FS-5900C Service Manual

9.5.4 A5

LCD Message Possible Cause

Call Service person A5 1. Abnormal spark discharge of Charger.

Check the charger unit.

2. Short circuit of FTR or DEV output.

Is the charger wire

cut?

N

Check the imaging unit.

Is the imaging unit

locked to Engine

firmly?

Y

Check the connection

between engine control board

and high voltage board (HVB).

Is the cable

connected

correctly?

Y

N

N

Replace charger unit.

Lock the imaging unit.

Connect it correctly.

Check

N

Check

N

Check

Y

Y

Y

120

Y

Check the connection of

charger or grid wire and each

output terminal.

Are they OK?

Y

12

N

N

Replace the output wire or

the output terminal.

Check

N

Y

Page 20

12

Check for a short circuit of

the FTR and DEV.

9. Troubleshooting

Is each of them

shorted to F.G.?

N

Replace the high voltage

board (HVB).

Check

N

Replace the engine control

*

board.

Check

Y

Y

Replace the output wire or

the output terminal.

Y

Check

N

Y

N

Replace the imaging unit.

* When replacing the Engine Control Board, remove EEPROM (IC6) from the original Engine Control

Board and install it on the new Engine Control Board.

OK

121

Page 21

FS-5900C Service Manual

9.5.5 AC

LCD Message Possible Cause

Call Service person AC OPC asynchronous with accumulator belt.

Check the imaging unit.

OPC home number and accumulator belt home number are not

synchronous.

Is the imaging unit

locked to Engine

firmly.

Y

Check the connection

between engine control

board and imaging unit.

Is the cable

connected

correctly?

Y

Check the connection between

engine control board and the

accumulator belt home sensor

board.

Is the cable

connected

correctly?

N

N

Lock the imaging unit.

Connect it correctly.

N

Connect it correctly.

Check

N

Check

N

Check

Y

Y

Y

122

Y

Check the accumulator belt

home sensor board.

Is the sensor

board gap clean?

Y

34

N

N

Clean the gap.

Check

N

Y

Page 22

34

Replace the imaging unit.

9. Troubleshooting

Check

N

*

Replace the engine control

board.

Check

N

•

Replace the cable between engine control

board and imaging unit.

•

Replace the sensor board and cable.

*

When replacing the Engine Control Board, remove EEPROM (IC6) from the original Engine Control

Board and install it on the new Engine Control Board.

Y

Y

OK

123

Page 23

FS-5900C Service Manual

9.5.6 AD

LCD Message Possible Cause

Call Service person AD OPC home is not detected within 4.5 sec during the

Check the color imaging unit.

main motor rotates.

Is the imaging unit

locked.

Y

Check the connection

between engine control board

and imaging unit.

Is the cable

connected

correctly?

Y

Replace the imaging unit.

Check

N

N

Y

Lock the imaging unit.

Connect it correctly.

Check

N

Check

N

Y

Y

N

*

Replace the engine control

board.

Check

N

Replace the cable between

engine control board and

imaging unit.

124

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

Y

OK

Page 24

9.5.7 AE

LCD Message Possible Cause

Call Service person AE Position error of the intermediate transfer unit

Position error of the

intermediate transfer unit

9. Troubleshooting

Does Main Motor

rotate?

Y

Is the imaging unit

locked in the

printer?

Y

Is the home sensor

case dirty with

toner?

N

N

Y

N

Y

Are motor control

signals sent from

engine control

board?

Y

Replace the Motor.

Is the error

message still

displayed on the

LCD?

Lock the unit in the printer.

Clean the case.

N

*

Replace engine control

board.

N

Is the error

message still

displayed on the

LCD?

Y

Is the error

message still

displayed on the

LCD?

Y

N

N

Replace the imaging unit.

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

Replace the Home Position

Sensor Board.

Is the error

message still

displayed on the

LCD?

Y

*

Replace Engine Control

Board.

Is the error

message still

displayed on the

LCD?

Y

N

N

OK

125

Page 25

FS-5900C Service Manual

9.5.8 AF

LCD Message Possible Cause

Call Service person AF Cleaning blade movement error

Replace imaging unit.

Is the same message

still displayed on the

LCD?

Y

*

Replace engine control board.

Is the same message

still displayed on the

LCD?

Y

Replace cleaning board.

Is the same message

still displayed on the

LCD?

N

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

N

N

Replace cleaning cam.

126

Y

OK

Page 26

9.5.9 B7

LCD Message Possible Cause

Call Service person B7 Paper transfer roller movement error

Paper transfer roller

movement error

9. Troubleshooting

Is the transfer roller

in the lower

position at the first

stage?

Y

Is the transfer roller

position sensor arm

broken?

Y

Does the transfer

roller clutch work

normally?

(Are the spring and the armature

installed properly?)

Y

Does the paper feed

unit board work

normally?

(Is the connector connected

Y

correctly?)

N

Set the transfer roller in the

normal (lower) position.

N

N

N

Change the transfer roller

position arm.

Replace the transfer roller

clutch.

Replace the paper feed until

board and reconnect the

connector.

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

N

N

N

N

*

Replace the engine control

board.

*

When replacing the Engine Control Board, remove EEPROM (IC6) from the original

Engine Control Board and install it on the new Engine Control Board.

OK

127

Page 27

FS-5900C Service Manual

9.5.10 A2

LCD Message

Call Service person A2 1. Fuser temperature is over 210˚C

A2 is displayed on the LCD.

Is the voltage

between pin9 and

10 (CN25 ) 0V?

N

Is pin9 (CN1) or

pin1 (CN301) a

low level?

Y

*

Replace the engine control

board.

Y

N

*

When replacing the Engine Control Board, remove EEPROM (IC6)

from the original Engine Control Board and install it on the new Engine

Control Board.

Is the thermistor

shortcircuited?

Replace the power supply.

Possible Cause

Y

N

Check the harness between

CN25 and the thermistor.

Replace the thermistor.

128

Page 28

9. Troubleshooting

LCD Message

Call Service person A2

A2 is displayed on the LCD.

Is the resistance

between CN204 pins

No.1 and No.3 10Ω

or less?

N

Is the thermostat

or the thermal fuse

open?

N

Possible Cause

2.

Fuser temperature does not reach 100˚C within 200sec,165˚C within 500sec during warming

up, or it is less than 120˚C during standby, and it does not return to set temperature within

100 sec after the low temperature error occurred during printing.

Y

Y

Does the thermistor

contact the heat

roller properly?

N

Replace the fuser unit.

Y

Replace the low voltage power

supply.

Repair or replace

the thermistor.

Check the following

connections:

1.Heater lead and drawer

connector lead.

2.Drawer connector lead and

thermostat terminal.

3.Thermostat terminal and

thermal fuse terminal.

4.Thermal fuse terminal and

heater lamp lead.

N

Repair or replace connections.

Y

Is the resistance of

N

the heater open?

Y

Replace the fuser unit drawer

connector.

Replace the fuser heater.

129

Page 29

FS-5900C Service Manual

9.5.11 E4

LCD Message Possible Cause

Call Service person E4 Fuser thermistor is disconnected.

E4 is displayed on the LCD.

9.5.12 A7

Is CN25 connected

properly?

Y

Is the resistance

between CN25 pins

NO.9 and NO.10

123KΩ (20°C )

or less?

Y

*

Replace the engine control

board.

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board and

install it on the new Engine Control Board.

N

N

Connect CN25 properly.

Is the thermistor

normal?

Y

N

Replace the thermistor.

Check the connection

between CN25 and the

thermistor, then repair or

replace it.

130

LCD Message Possible Cause

Call Service person A7 Power supply fan is not rotating at normal speed.

A7 is displayed on the LCD.

Is 24V outputted

between pin 1 and

pin 2 at CN30.

Y

Replace the power supply

cooling fan.

N

Replace the power supply.

Page 30

9.5.13 A8

9. Troubleshooting

LCD Message Possible Cause

Call Service person A8 Ozone fan is not rotating at normal speed.

Ozone fan error

Is +24V outputted

between CN9 pins

No.1 and No.2 on

the engine control

board ?

Y

Replace the ozone fan.

N

*

*

Replace the engine control board

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

.

131

Page 31

FS-5900C Service Manual

9.5.14 AA

LCD Message Possible Cause

Call Service person AA Toner cartridge drive motor (sleeve motor) unlocked

Replace developer unit.

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control

Board and install it on the new Engine Control

Board.

*

Replace engine control

board.

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

Replace imaging unit.

Is the same message

still displayed on the

N

Is the motor cable

damaged?

Replace the cable.

N

LCD?

Y

N

LCD?

Y

Y

N

Is the same message

still displayed on the

LCD?

Y

Replace the toner cartrdige

drive motor (sleeve motor).

Is the same message

still displayed on the

LCD?

Y

Replace the gear unit.

N

N

OK

132

Page 32

9.5.15 AB

LCD Message Possible Cause

Call Service person AB Paper feed motor unlocked

9. Troubleshooting

Does the paper

feed motor rotate

smoothly?

Y

Does the gear of the rear

chassis rotate normally?

Y

Does the gear of the paper

feed unit rotate normally?

Y

Does the gear of fuser

rotate normally?

Y

N

Replace the paper feed

motor.

Is the same message

still displayed on the

LCD?

N

Y

N

Replace the gear having the

problem.

Is the same message

still displayed on the

LCD?

N

Y

Replace the gear having the

N

problem and check the

rotation system of the paper

feed unit.

Is the same message

still displayed on the

LCD?

N

Y

N

Replace the gear having the

poblem and check the

rotation system of the fuser.

Is the same message

still displayed on the

LCD?

N

Y

Does the gear of the

toner cartridge unit

rotate normally?

N

Replace the gear having the

poblem and check the rotation

system of the selector / papereject unit.

Y

Is the cable for the

motor damaged?

Y

Replace the cable.

N

Replace imaging unit.

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

Is the same message

still displayed on the

Is the same message

still displayed on the

Is the same message

still displayed on the

*

Replace the engine control

board and check the

connection of the connector.

N

LCD?

Y

N

LCD?

Y

N

LCD?

Y

OK

133

Page 33

FS-5900C Service Manual

9.5.16 E1

LCD Message Possible Cause

Call Service person E1 Main motor unlocked

Is the imaging kit

installed

properly?

Y

Do the OPC belt and the

Transfer belt of imaging

unit rotate?

Y

Does the main

motor work

normally?

Y

Is the connector of

main motor cable

connected

properly?

Y

N

N

Install it properly.

N

Replace the imaging unit.

N

Replace the main motor.

Connect it properly.

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

Is the same message

still displayed on the

LCD?

Y

N

N

N

N

Is the main motor

cable damaged?

N

*

Replace the engine control

board.

*

When replacing the Engine Control Board, remove EEPROM (IC6) from the

original Engine Control Board and install it on the new Engine Control Board.

Y

Replace the cable.

Is the same message

still displayed on the

LCD?

Y

N

OK

134

Page 34

9.5.17 A9

9. Troubleshooting

LCD Message Possible Cause

Call Service person A9 Multi-purpose pickup roller movement error

9.5.18 E6

Multi-Purpose Pickup Roller

Movement error.

Does the Multi-

Purpose Pickup

Roller Shaft

rotate?

Y

*

Replace the paper feeder

unit board or engine control

board.

*

When replacing the Engine Control Board,

remove EEPROM (IC6) from the original

Engine Control Board and install it on the

new Engine Control Board.

N

LCD Message Possible Cause

Call Service person E6 Engine Program ROM checksum error

Repair the retard pad.

N

Is the retard pad

able to move up

and down?

Y

Is the multi-

purpose feed motor

fixed to metal plate

properly?

Y

N

Fix to metal plate properly.

Replace the paper feeder

unit board or engine control

board.

9.5.19 BC

Engine Program ROM

checksum error occurs.

Replace the Engine Program

ROM.

LCD Message Possible Cause

Call Service person BC Engine SRAM check error

Engine SRAM check error

occurs.

Replace the Engine SRAM.

135

Page 35

FS-5900C Service Manual

9.5.20 BD

Call Service person BD Engine EEPROM check error

Engine EEPROM check error

occurs.

Replace the Engine

EEPROM.

9.5.21 E0

LCD Message Possible Cause

Call Service person E0

LCD Message Possible Cause

Communication Error of Printer Main Control Board

and Engine Control Board.

Is the cable between

Engine Control Board

and Printer Main Control

Board connected

properly?

Y

Is the Engine

Control Board OK?

Y

Is the Printer Main

Control Board OK?

Y

N

N

N

Connect the Engine cable securely.

Recheck.

*1

Replace the Engine Control Board.

Recheck.

Recheck.Recheck.

*2

Replace Printer Main Control Board.

Recheck.

End

*1

When replacing the Engine Control Board, remove EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

136

*2

When replacing the Printer Main Control Board, remove IC9 from the original Printer Main Control Board

and install it on the new Printer Main Control Board.

Page 36

9.5.22 BE 9.5.23 BF

Connect CN25 properly.

Set the fuser unit properly.

Connect CN601 properly.

EEPROM (fuser unit) Error

Is CN25 connected

properly?

Is the fuser unit set

in the printer

properly?

Is CN601

connected

properly?

N

Y

Y

Call Service person

BF

EEPROM (fuser unit) Error

LCD Message Possible Cause

N

N

Call Service

person F0

Controller board system lock

error.

OK?

N

Y

Check or replace Printer

Main Control Board or

Relay Board.

LCD Message

Possible Cause

*

End

When replacing the Printer Main Control Board, remove

System DIMM's from the original Printer Main Control Board

and install it on the new Printer Main Control Board.

*

Wiring between Main Controller

Board and Relay Board; or

Relay Board and Printer Panel.

LCD Message Possible Cause

Call Service person

BE

EEPROM (imaging unit)

Error

EEPROM (imaging unit) Error

9. Troubleshooting

Is CN10 connected

properly?

Y

Is the imaging unit

in the printer

properly?

Y

Is CN628

connected

properly?

Y

Replace the imaging unit.

OK?

N

Connect CN10 properly.

N

Set the imaging unit properly.

N

Connect CN628 properly.

9.5.24 Call Service person F0

N

*

End

*

When replacing the Engine Control Board, remove

EEPROM (IC6) from the original Engine Control Board

and install it on the new Engine Control Board.

Replace engine control

board.

137

Page 37

FS-5900C Service Manual

9.5.25 Memory Overflow

LCD Message Possible Cause

Memory Overflow Print data is larger than the capacity of the memory

Lower the resolution of the

printing image by using Print

Setup.

installed

OK?

Y

9.5.26 Call Service person F2

LCD Message Possible Cause

Call Service person F2

Replace Option SIMM(s).

N

RAM Read/Write Error

Add memory to the printer.

End

138

OK?

Y

END

N

Check or replace Printer Main

Controller Board.

Page 38

9.5.27 Call Service person F3

LCD Message Possible Cause

Call Service person F3

Turn printer power off,

then on again

9. Troubleshooting

An exceptional failure has occured during the task

management (such as a buss error).

OK?

Y

END

N

Check or replace Printer Main

Controller Board.

139

Page 39

FS-5900C Service Manual

9.6 No Message Section

Start

Power switch ON

Is the power

supply cooling fan

working?

Y

Check the voltage at CN301

of power supply unit at 5V,

5VIP, 24V.

N

Connect the AC cord, then

Is the AC cord

connected to the

printer?

Y

Check the voltage at CN201

of power supply unit.

Is the voltage 120V?

Y

Replace the power supply,

then repeat the procedure

from START.

N

repeat the procedure from

START.

N

Replace the AC cord, then

repeat the procedure from

START.

140

Are the voltages

normal?

Y

Check the display panel and

cables.

Is the display

panel OK?

Y

Exit

N

N

Replace the power supply,

then repeat the procedure

from START.

Replace display panel or

cables.

Loading...

Loading...