Page 1

2. Installation, Setup, and Repacking

2. Installation, Setup, and Repacking

2.1 Installation Requirements

2.1.1 Environment

Temperature Range: 10°C to 32.5°C [50°F to 90.5°F] (T emperature fluctuation: ±10°C per hour or less)

Humidity Range: 15% RH to 80% RH (Humidity fluctuation: ±20 °C per hour or less)

Weight: 51 kg (112 lbs.)

Precautions for installation

Place the unit on a stable, level surface.

Do not install the unit under the following conditions:

• Extremely high or low temperature

• Extremely high or low humidity

• Direct exposure to sunlight

• Areas of high dust concentration

• Areas of poor ventilation

• Areas exposed to chemical fumes

• Areas with extreme vibration

• Directly in air conditioning flow

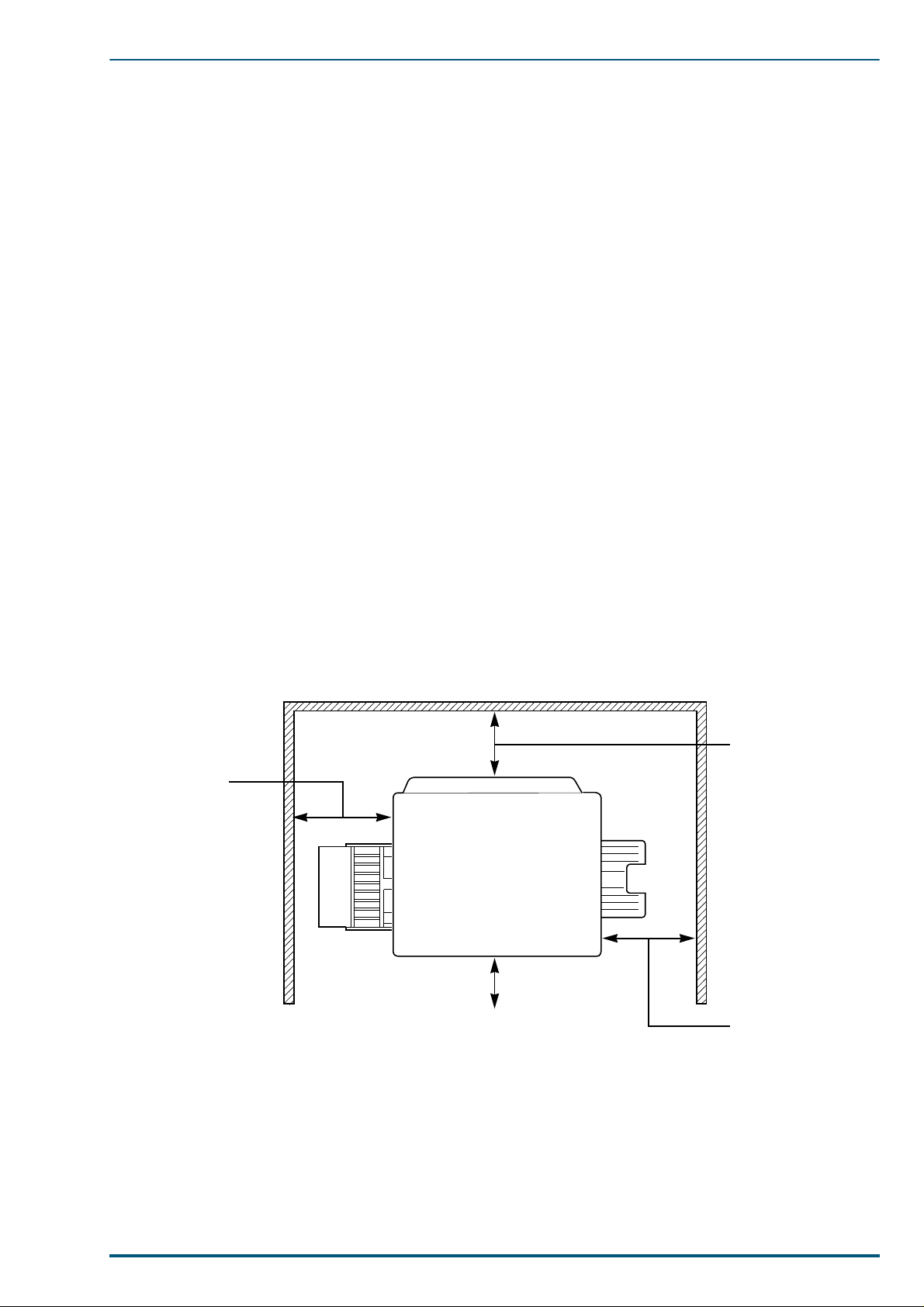

2.1.2 Minimum Space Requirements

Allow air flow around the printer to prevent overheating. The following minimum spaces are required:

Rear

35 cm (13.8")

Controller Board

45 cm (17.7")

Output

tray

Left Right

Multi-purpose Tray

Front cover

50 cm (19.7")60 cm (23.6")

13

Page 2

FS-5900C Service Manual

2.2 Setup

2.2.1 Removing the Packing Material

1. Remove the plastic bag from the printer.

2. Remove any adhesive tape that holds the output tray against the printer.

Note:

Do not throw away the packing materials. They may be required to ship or transport the printer in

the future. To provide optimum print quality , the unit must be kept upright and level during unpacking.

2.2.2 Installing the Optional Paper Feeder

Warning:

Warning:

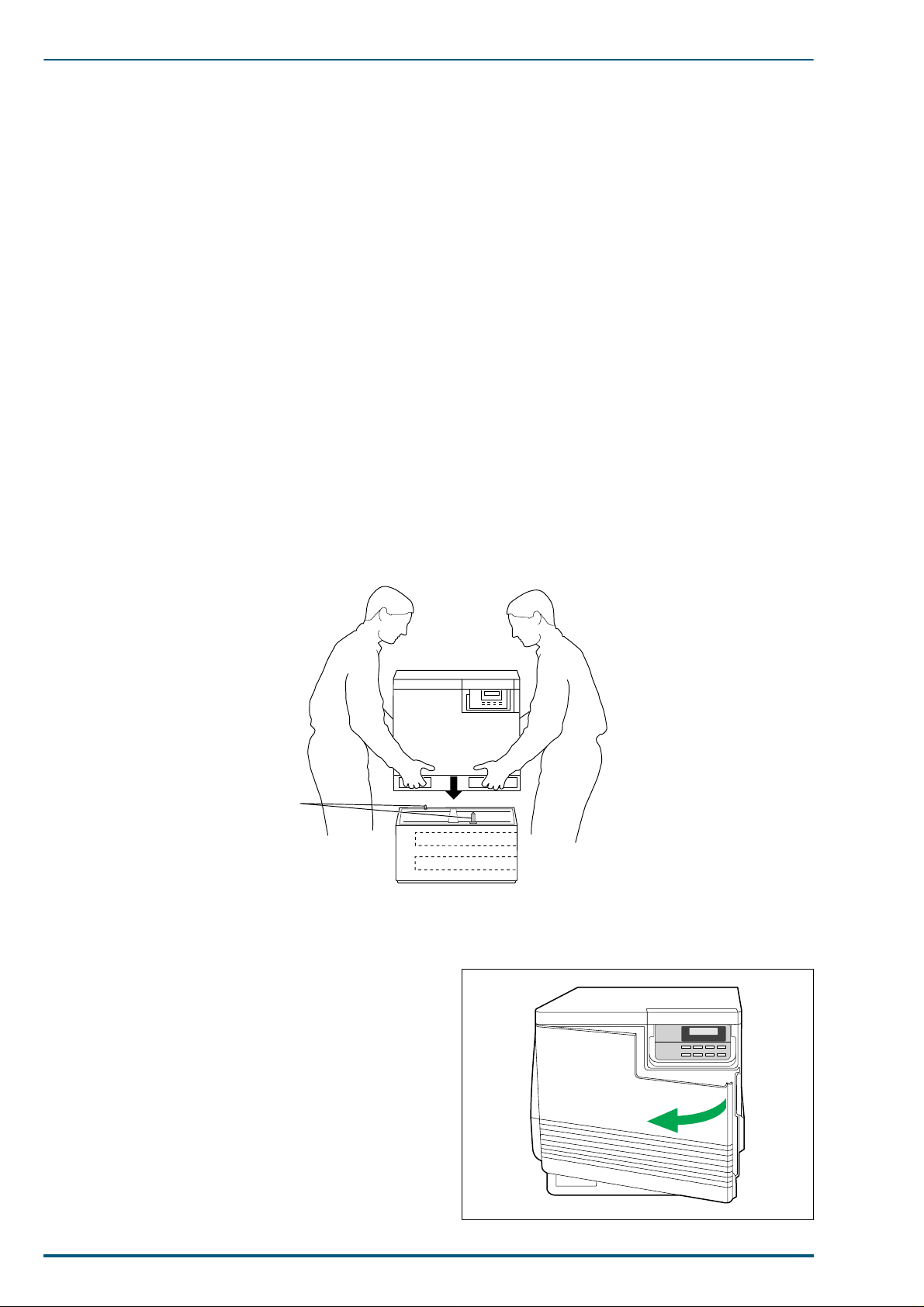

1. Place the paper feeder on a solid table or cart selected for the printer.

2. Place the printer on top of the paper feeder. Always kee p the printer upright.

3. Make sure that the left and right alignment pins fit in the holes in the base of the printer.

The printer weighs about 51 kg (112 lbs.) and the paper feeder weighs about 14.4 kg (36.3 lbs.).

Observe standard precautions for lifting heavy objects.

The printer is not permanently attached to the paper feeder. When moving the printer, turn

the power off and remove the power cord, then move the pieces separately; moving the printer

incorrectly may damage it and may cause personal injury.

Alignment pins

(Left door side) (Cassette slots side)

2.2.3 Preparing the Imaging Unit

1. Open the front door.

Paper Feeder

14

Page 3

2. Turn the upper green lever clockwise until it stops

and the arrows are aligned. (This applies tension to

the internal belts).

3. Close the front cover.

2.2.4 I nstalling the Toner Developers

2. Installation, Setup, and Repacking

Note:

The toner developers shipped with the printer are starter developers. They are installed in exactly

the same manner as t h e standard developers; the only difference i s that the starter developers have

less toner. (Page life expectancy is 5,000 pages for all toner developers except black which has a life

expectancy of 6,000 pages.)

1. Remove the packaging from the toner developer.

2. Remove the shipp ing cover from the developer.

Caution:

Do not tilt the developer to avoid possible

toner spillage.

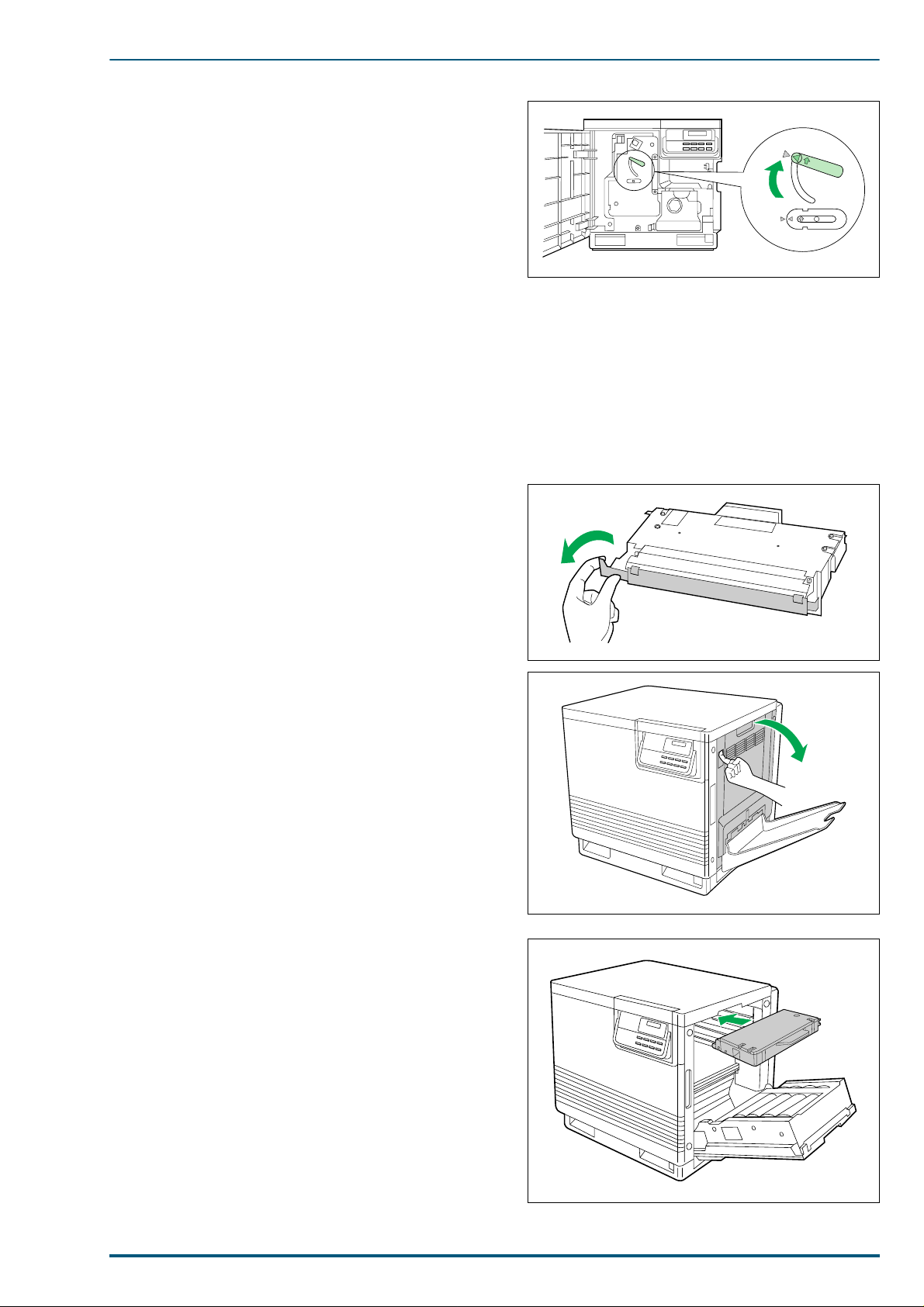

3. Open the printer’s right side door.

Caution:

Do not leave the right side door open for a

long time; the imaging unit inside is exposed

to light and will be damaged.

4. Insert the toner developer in the appropriately

labeled slot. From top to bottom, the developer order

is BLACK, CYAN, MAGENTA, and YELLOW.

15

Page 4

FS-5900C Service Manual

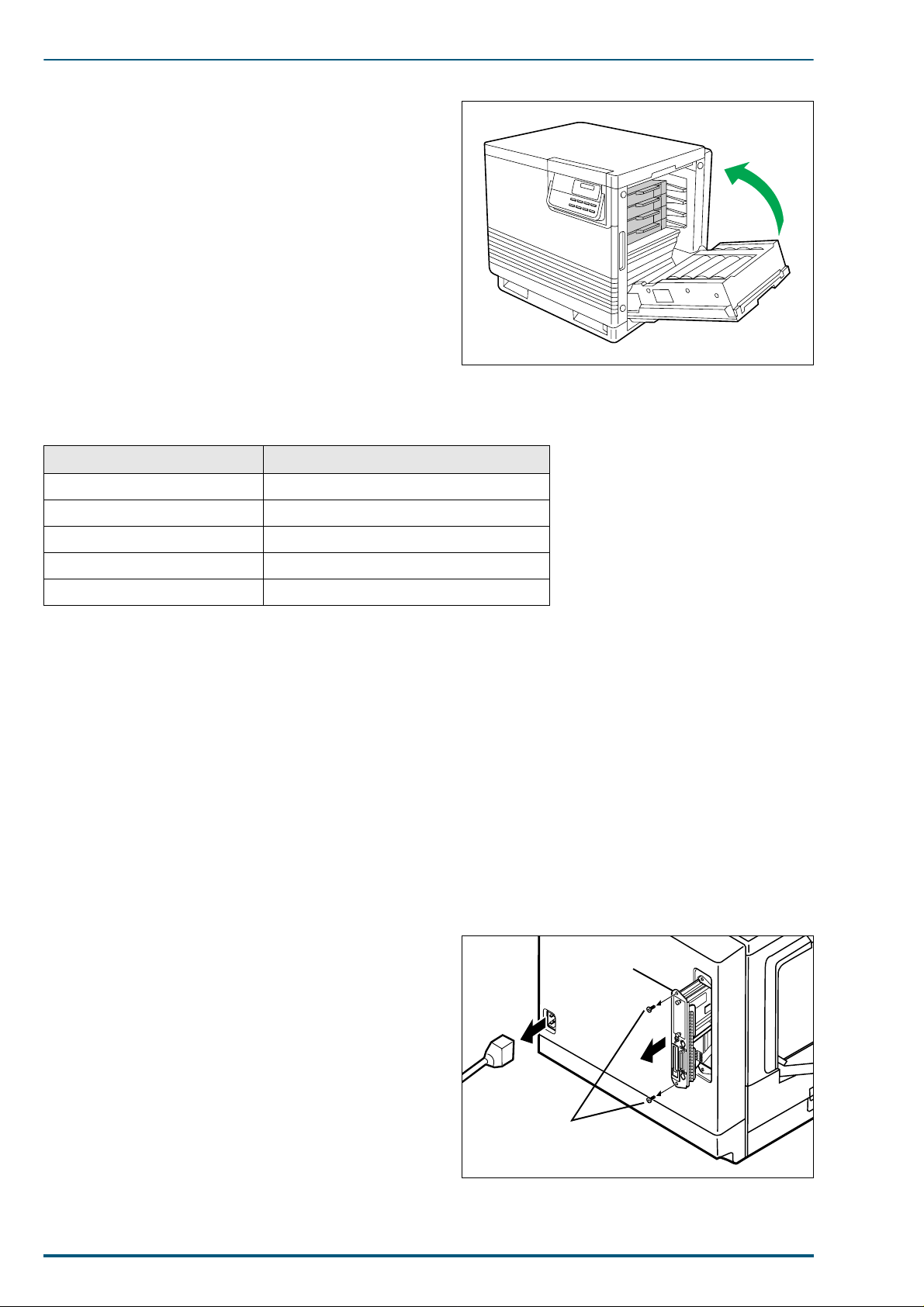

5. Repeat steps 1, 2 and 4 for each toner developer.

6. When all the toner developers have been installed,

close the right side door.

Note: Save all packing material for shipping purposes.

2.2.5 Adding Paper or Transparencies

The printer is shipped with one media cassette of either Letter or A4 paper size. The printer can also use

five different cassettes as follows:

Tray Size

A4 Paper 210 × 297 mm (8.27" × 11.7")

A4 Transparency 210 × 297 mm (8.27" × 11.7")

Letter Paper 8.5" 11" (216 × 279 mm)

Letter Transparency 8.5" × 11" (216 × 279 mm)

Legal paper 8.5" × 14" (216 × 356 mm)

Notes:• Make sure that correct media is loaded. Each cassette is designed and labeled for only paper or

transparency. If the wrong media type is loaded in a tray, an error message will be displayed

when printing is attempted.

• If the paper feeder is installed and the automatic tray switching feature (for example, for a large

print job) is used, make sure that all trays in the printer at any one time are the same media type

and size.

• To optimize the printer’s performance, always use clean, unused media.

• Be careful not to leave fingerprints on the media, which can result in a smudged print.

• Reusing media that has been fed through the printer (for exampl e, after jams or if the media is

ejected without being printed) can reduce the life of the consumables and paper path components.

2.3 Installing RAM SIMMs (Option)

1. Turn off the printer. Do not unplug the printer; this preserves a ground path to dissipate static charges.

2. Remove the two screws from the controller board.

3. Pull out the controller board.

Controller Board

4. When installing a single RAM SIMM:

Insert a memory module in connector YS3 or YS4 and

tilt the module down until it locks in place. When the

SIMM is properly inserted, a tab on each end of the

connector slips into a hole on each end of the RAM

SIMM. Also, a pawl on each end of the connector

latches around each end of the RAM SIMM to lock it

in place. Go to step 6.

16

~AC IN

Screws

Page 5

5. When installing two RAM SIMMs:

YS4

YS3

Controller Board

a b

HOT SURFACE INSIDE

Insert the appropriate memory module in connector

YS3 and YS4 and tilt the module down until it locks

in place. When the SIMM is properly inserted, a tab

on each end of the connector slips into a hole on each

end of the RAM SIMM. Also, a pawl on each end of

the connector latches around each end of the RAM

SIMM to lock it in place.

6. Reinstall the controller board.

7. Reinstall the two screws.

2.4 Replacing the Fuser Unit

1. Remove the new fuser from its packaging; keep th e

fuser upright.

2. Installation, Setup, and Repacking

2. Open the front doo r. T urn the small green thumb-

screw counterclockwise to unlock the fuser.

Caution:

The fuser is hot; to avoid personal injury,

wait approximately 10 minutes for the fuser

to cool before touching it.

3. Grasping the green tab on the right, slide the fuser

out until the safety catch stops it. Press the green

lever on the left to release the safety catch.

17

Page 6

FS-5900C Service Manual

4. Hold the fuser as shown and slide it out of the

printer. Dispose of the fuser as normal office waste.

Caution: The fuser weighs approximately 3.2 kg (7.11

lbs.). Take care when handling it.

5. Insert the new fuser into the printer.

6. Turn the small green thumbscrew clockwise to lock

the fuser. Close the front door.

2.5 Replacing the Imaging Unit

1. Open the front door. Loosen the two thumbscrews by

turning them counterclockwise. Turn the lower green

lever 180° counterclockwise.

18

Page 7

2. Grasping the front gree n handle, slide the unit out

until it catches. Lift up the green handle on the left.

Pull the imaging unit out of the printer.

Caution: The imaging unit weighs approximately 6.5

kg (14.3 lbs.). Always use the handles when

lifting it.

3. If the imaging unit is to be reinstalled, cover it with

an empty box or place it in a dark cabinet to protect it

from light exposure. If the unit is to be discarded,

dispose of it as normal office waste.

Important:

Do not expose the imaging unit to light for more than

approximately 45 seconds, or irreversible damage may

result.

2. Installation, Setup, and Repacking

4. Remove the new imaging unit from the packaging.

The imaging unit is extremely light-sen sitive. Leave

the protective plastic sheet on the imaging unit

immediately before installin g it.

Note:

Save all packing material for future shipping purpose.

19

Page 8

FS-5900C Service Manual

5. Remove the used filter by pulling it forward. Dispose

of the filter as normal office waste. Insert the new

filter.

6. Turn the upper green lever clockwise until it stops.

Ozone Filter

7. Remove the protective plastic sheet.

Important:

• Do not touch the green surface. Fingerpri nts may affect

the print quality.

• Do not expose the imaging unit to light for more than

45 seconds, or irreversible damage may result.

8. Grasp the green handles and i nstall the new unit into

the printer. Release the left handle and push the unit

in until it stops.

Plastic Sheet

Handles

9. T urn the lower green lev er clockwise 180° to lock the

imaging unit. T ight en the t wo gree n t humbscrew s by

turning them clockwise. Close the front door.

20

Page 9

2. Installation, Setup, and Repacking

2.6 Repacking

Should the printer need to be transported or shipped, prepare the unit in the following manner:

Note:

It is highly recommended tha t users keep the ori ginal cart on and all packing ma terials. Observe the

following instructions when moving the printer:

Use the original carton and all of the original packing material.

•

Improper repacking of the printer may result in a service charge to repair the unit or a cleaning

•

charge to remove spilled toner.

Since the printer uses dry toner, extreme care must be taken when handling. The printer should

•

be handled in the upright (vertical) position.

Materials Required

Original printer, accessory cartons, and other packing materials

•

Newspaper or drop cloth

•

Shipping tape and scissors

•

1. Turn off the printer; remove the power cord and all interface cables.

2. Remove the media cassette(s) from the printer;

remove the media from the cassette(s).

3. Press down on a media cassette’s metal plate. Place the plastic shipping lock into the media cassette as

shown.

Metal Plate

Shipping Look

(1)

(2)

(3)

4. Reinsert the media cassette into the printer; use adhesive tape to secure the cassette to the printer.

5. If the other media casse ttes are in sta lle d, repa ck them for s hi pping or st orage in t heir ori gina l ship pi ng

boxes.

21

Page 10

FS-5900C Service Manual

6. Open the printer’s front door. Loosen the two thumb-

screws by turning them counterclockwise. Turn the

lower green lever 180° counterclockwise.

7. Grasping the front green handle, sli de the unit out

until it catches. Lift up the green handle on the left.

Pull the imaging unit out of the printer.

Caution: The imaging unit weighs approximat e ly 6.5

kg (14.3 lbs.). Always use the handles when

lifting it.

8. Wrap the imaging unit with a protective black plastic

sheet.

Important:

• Do not touch the green surface. Fingerpri nts may affect

print quality.

• Do not expose the imaging unit to light for more than

45 seconds, or irreversible damage may result.

9. Move the upper lever 90° counterclockwise; this is

necessary to protect the imaging unit during shipment.

Handles

Plastic Sheet

22

Page 11

10.Insert the imaging unit into the packaging.

Paper Feeder

Left Side Door

Cover

Tabs

Transfer Roller

2. Installation, Setup, and Repacking

11.Open the left side door. Using the green handles,

slide the paper feeder out.

12.Push in on green tabs to unlock the cover. Raise the

cover until it catches in the open position.

13.Rotate the transfer roller’s green handles up. Lift out

the transfer roller/waste bin.

23

Page 12

FS-5900C Service Manual

14.Rotate the handles down and wrap the transfer unit

with a piece of paper and adhesive tape.

Note: Do not touch or bump the roller as it can damage

the roller.

15. Install the plastic cover and insert the transfer unit

into a plastic bag and seal the end tightly. Install the

transfer unit into the packaging.

Note: Use the plastic cover that is attached to the new

TR-81 transfer unit.

16.Remove the four toner developers; install the protec-

tive cover for each developers; repack them for shipping or storage in their original shipping boxes.

Plastic Cover

Plastic Bag

17.Wipe off any loose toner in and around the printer.

Note: If a toner vacuum is available, it is the best tool

for cleaning spilled toner. Do not use a standard

office vacuum; the toner will not be retained by

typical vacuum dust collectors.

18.Close all printer doors and secure them with adhesive tape.

19.Raise the output tray and secure it to the printer

with adhesive tape. If a paper feeder is not installed,

go to Step 21.

20.If a paper feeder is installed:

Lift the printer up and away from the paper feeder.

Safety Caution:

The printer weighs approximately 41.4 kg (91.2 lbs.) and

the paper feeder weighs 14.4 kg (31.5 lbs.). Observe

standard precautions for lifting heavy objects.

24

Page 13

Repack the paper feeder in its origina l shipping box.

21.Repack any other accessories in the original shipping box.

22.Repack the printer in the original shipping box. Make

sure that the printer is upright and level when moving. See the diagram on this page.

2. Installation, Setup, and Repacking

25

Loading...

Loading...