Mita-Kyocera FS175375 Electrophotographics system

Chapter Four OPERATION OVERVIEW

Chapter Four

Electrophotographics system 4-4

Amorphous-silicon drum 4-5

Charging the drum 4-6

Toner 4-7

Exposure 4-8

Scanner unit 4-10

Scanning laser 4-12

Development 4-14

Developing roller bias 4-20

Transfer 4-22

Fusing 4-23

Drum cleaning and erasing static charge 4-24

Typical photo process timing chart 4-25

Paper feeding system 4-26

Paper feed components/signals 4-27

Cassette feeding 4-28

Manual/multi purp ose tray feeding 4-29

Paper jam sensing 4-30

Basic engine functions 4.32

Basic sequence of operation 4-33

Engine controller system 4-34

Flash memory 4-34

High-voltage generator 4-34

Laser scanner control 4-35

Polygon motor control 4-35

Safety interlock 4-36

The engine gate array 4-37

Pin assignment 4-38

Power supply 4-42

OPERATION OVERVIEW

Logic controller system 4-44

Logic controller sp ecifications 4-45

Printing data processing 4-48

API ROM socket (U14) 4-49

API ROM socket pin assignment 4-50

System ROMs (U4 to U7) 4-51

RAM (U15 to U18) 4-51

Memory card slot interface 4-52

Option interface 4-52

Option interface pin assignment 4-54

Option interface pin assignment - Continued 4-55

Parallel interfa ce 4-56

Serial interface 4-56

Debugging outputs 4-57

Engine interface 4-57

Engine interface connector assignment 4-58

Signals used for the engine interface 4-59

Engine interface signals 4-60

Electrophotographics system

Electrophotography is the technology used in laser printing which transfers data representing texts

or graphics objects into a visible image which is developed on the photosensitive drum, finally

fusing on paper, using light beam generated by a laser diode.

The key features for the electrophotography system used in the printer are:

Operation overview

Electrophotographics system

!

600 dpi resolution

!

Newly developed amorphous silicon drum with no heating device

!

Diode laser scanning

!

Mono component toner

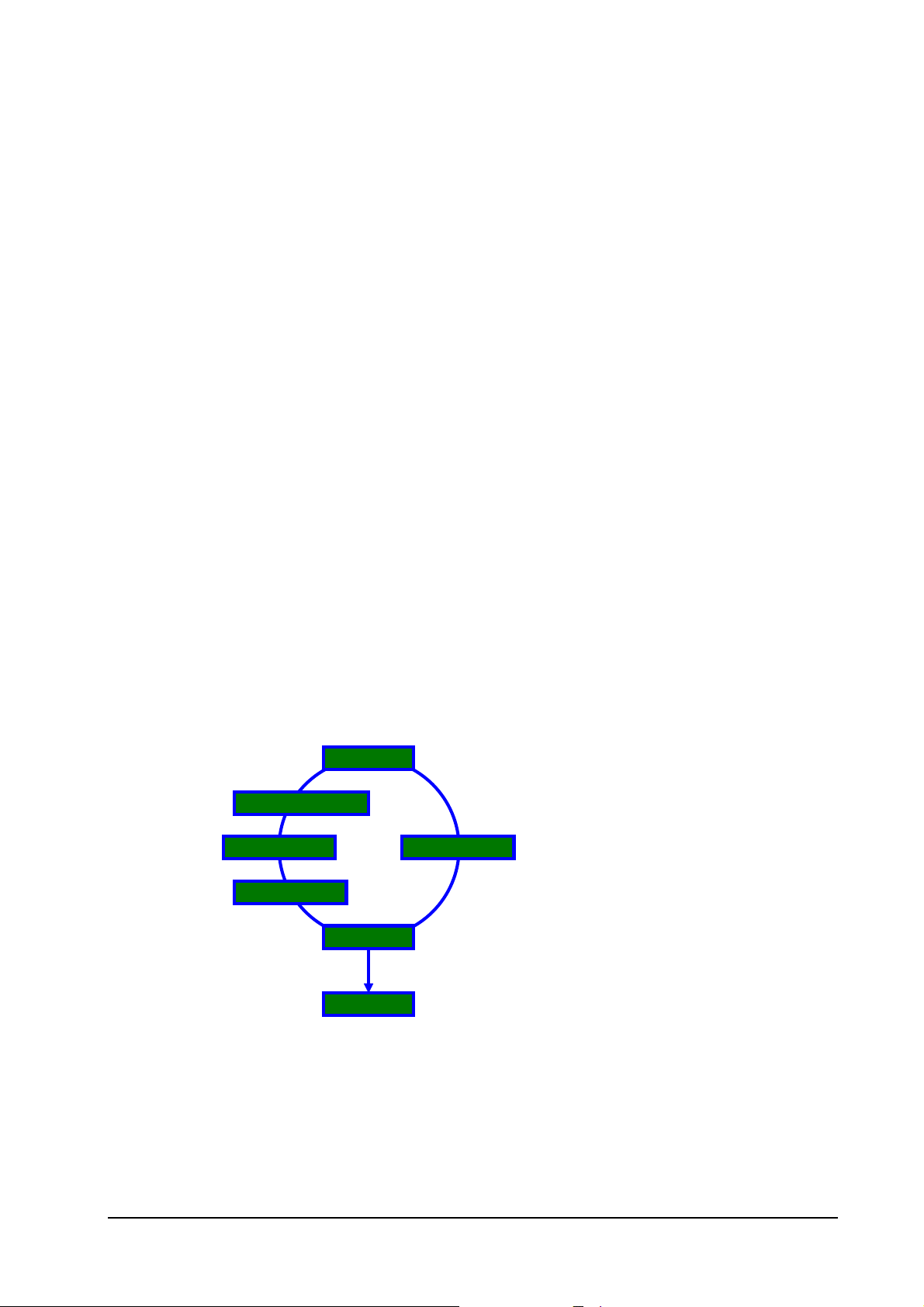

The electrophotography system of the printer performs a cyclic action made of seven steps as

shown below.

2 Exposure

1 Main Charging

3 Developing7 Erasing

6 Cleaning

4 Transfer

5 Fusing

4-4

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

Amorphous-silicon drum

The printer uses the long lasting amorphous silicon drum. The drum surface is a composite of five

substances coated in five layers as shown below.

A

B

C

D

E

AAAA

Secondary protection layer

BBBB

Primary protection layer (1µµµµm)

CCCC

Photoconductor αααα-Si

DDDD

Carrier block (1-3

EEEE

Aluminum base

The primary and secondary layers are for protecting the amorphous silicon layer underneath. The

amorphous silicon layer is of photoconductive, meaning it can be electronically conductive when

exposed to a (laser) light source to effectively ground electrons charged on its outer surface to the

ground. This layer is approximately 9µm thick.

The carrier block layer lies between the amorphous silicon layer and the aluminum base cylinder

and prevents the backward electron flow, from the base cylinder to the drum’s outer surface, which

might give adverse effect (usually “ghost”) on the print quality.

µµµµ

m)

Drum unit

4-5

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

Charging the drum

Figure below is a simplified diagram of the electrophotographics components. Charging the drum

is done by the main charger wire (in the main charger unit) marked A in the diagram.

A

B

As the drum (B) rotates in a “clean (neutral)” state, its photoconductive layer is given a uniform,

positive (+) electrical charge dispersed by the main charger wire (A).

Due to high-voltage scorotron charging, the cha rging wire can get cont aminated by oxidiz ation and

therefore must be cleaned periodically from time to time using the method explained in section

Main charger unit

such as black streaks caused by the oxide ac-cumulated around the charging wire.

on page 3-7. Cleaning the charging wire prevents print quality problems

4-6

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

Toner

The toner is fed from the toner pack TK-20/H. The toner is comprised of the following substances

as depicted below.

Single component toner TK-20/H

A B C D -

A

B

C

D

Resin

Ferrite

Silica

Polisher

4-7

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

Exposure

The charged surface of the drum (“B”) is then scanned by the laser beam from the scanner unit

(“A”).

A

B

4-8

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

The laser beam is switched on for a black dot and off for a white (blank) dot according to the print

data. Whenever it is illuminated by the laser beam, the electrical resistance of the photoconductor

is reduced, the potential on the photoconductor is also lowered to 20V, effectively driving the

charge through the a-Si layer down to the aluminum base.

LASER BEAM

+++++

a-Si LAYER

ALUMINUM

++++

----

240V-260V

LASER BEAM

++++

20V

0V

4-9

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

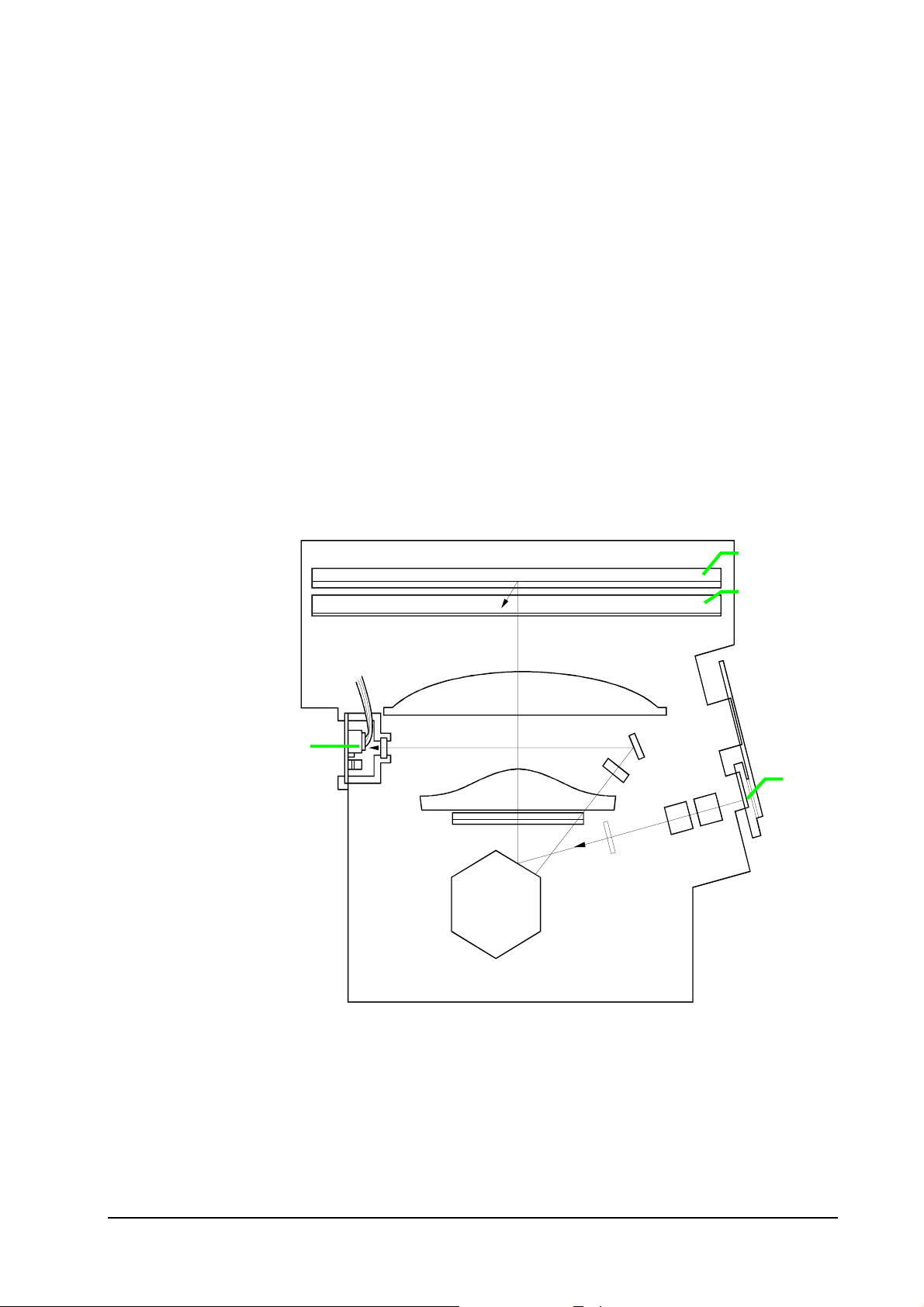

Scanner unit

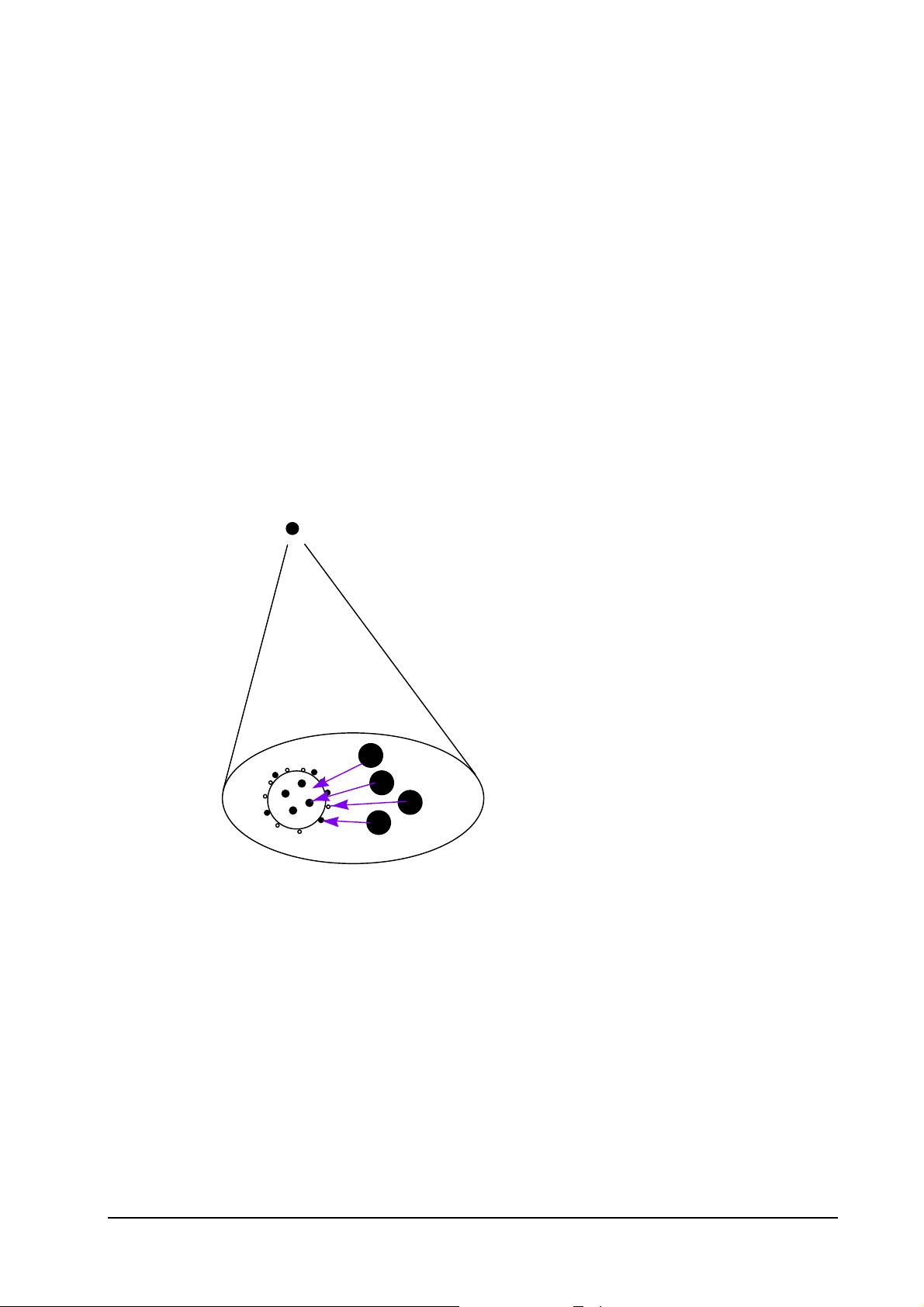

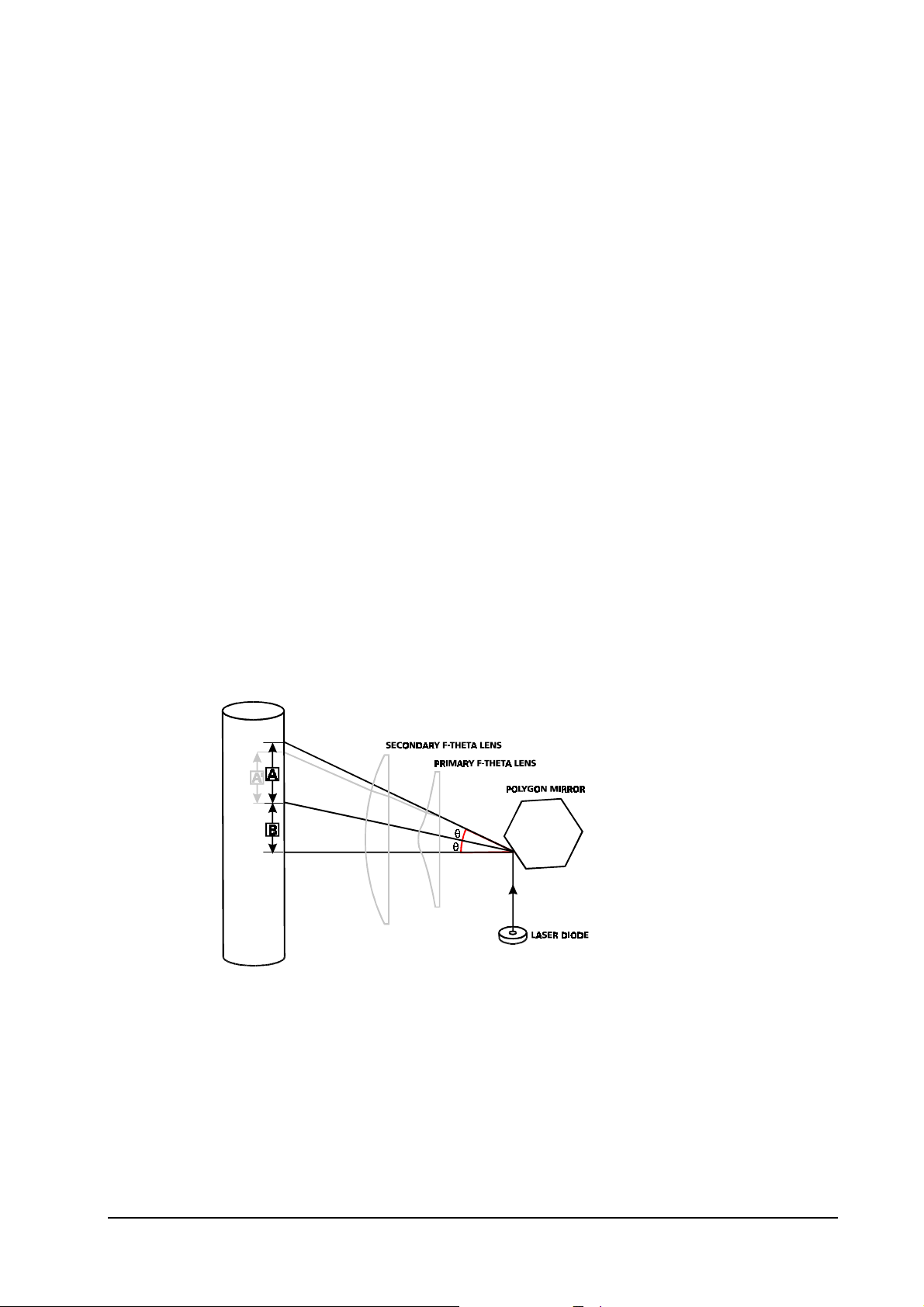

The 600 dpi scanner unit includes the diode laser that produces the 670 nm wavelength laser beam.

This wavelength is specifically designed to match the photoconductive response of amorphous silicon.

+

To drum

'

&

%

*

$

#

(

)

"

4-10

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

"

Laser diode -

#

Collimeter lens -

$

Cylindrical lens -

%

Polygon mirror (motor) -

one scanned line width on the drum when laser beam scans on it.

&

Primary f-theta lens -

'

Secondary f-theta lens -

edges. The effective length of line (“A,” “B” below) the laser beam draws on the drum becomes longer as the laser beam

hits closer to the drum edges. In the figure below, distances represented by “A” and “B” are not the same (A>B) until the

f-theta lenses are provided between the polygon mirror and the drum (A’=B).

emits diffused, visible laser.

aligns the laser beam to the cylindrical lens.

compensates the slant angle at which the laser beam hits a polygon mirror segment.

has six mirror segments around its octagonal circumference; each mirror corresponding to

See below.

The primary (above) and secondary f-theta lenses equalize focusing distortion on the drum

(

Diversion mirror -

the drum.

)

Protective glass -

*

Sensor mirror -

+

Beam detect or sensor -

engine controller to start activating the paper feeding system.

diverts the laser beam vertically onto the drum. Note the diffused laser beam finally pin-points on

prevents dust, debris, etc., from entering the scanner assembly.

bends the very first shot of a laser scan towards the beam detection sensor (See next.).

when shone by the sensor mirror above, this photosensor generates a trigger signal for the

4-11

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

Scanning laser

The laser beam hits one of six polygonal mirrors. As the mirror revolves (at the revolution of

18,700 rpm for model FS-1750; 27,000 rpm for model FS-3750), the laser beam reflects off of it

and reaches the charged drum surface in a lengthwise manner.

A pair of (plastic) lenses provides focusing the horizontally sweeping laser beam onto the drum.

As the drum rotates, the laser beam sweeps the entire length of the drum so that the drum’s entire

circumference is exposed to the laser beam. The revolution of the polygon mirror motor and the

drum itself is timing-controlled so that each successive sweeping of the laser beam produces a

inch offset. The printer’s controller system continuously turns the laser beam on and off to put a

dot at every

1

/

inch distance horizontally. The diameter of a dot is typically 70 µm.

600

Synchronizing the output data with one scanning line is achieved by the photo sensor provided

next to the first mirror. At the beginning of each laser sweeping, the beam hits the photo sensor

which in turn sends a command to the logic controller for synchronization.

1

/

600

4-12

FS-1750/FS-3750 Series

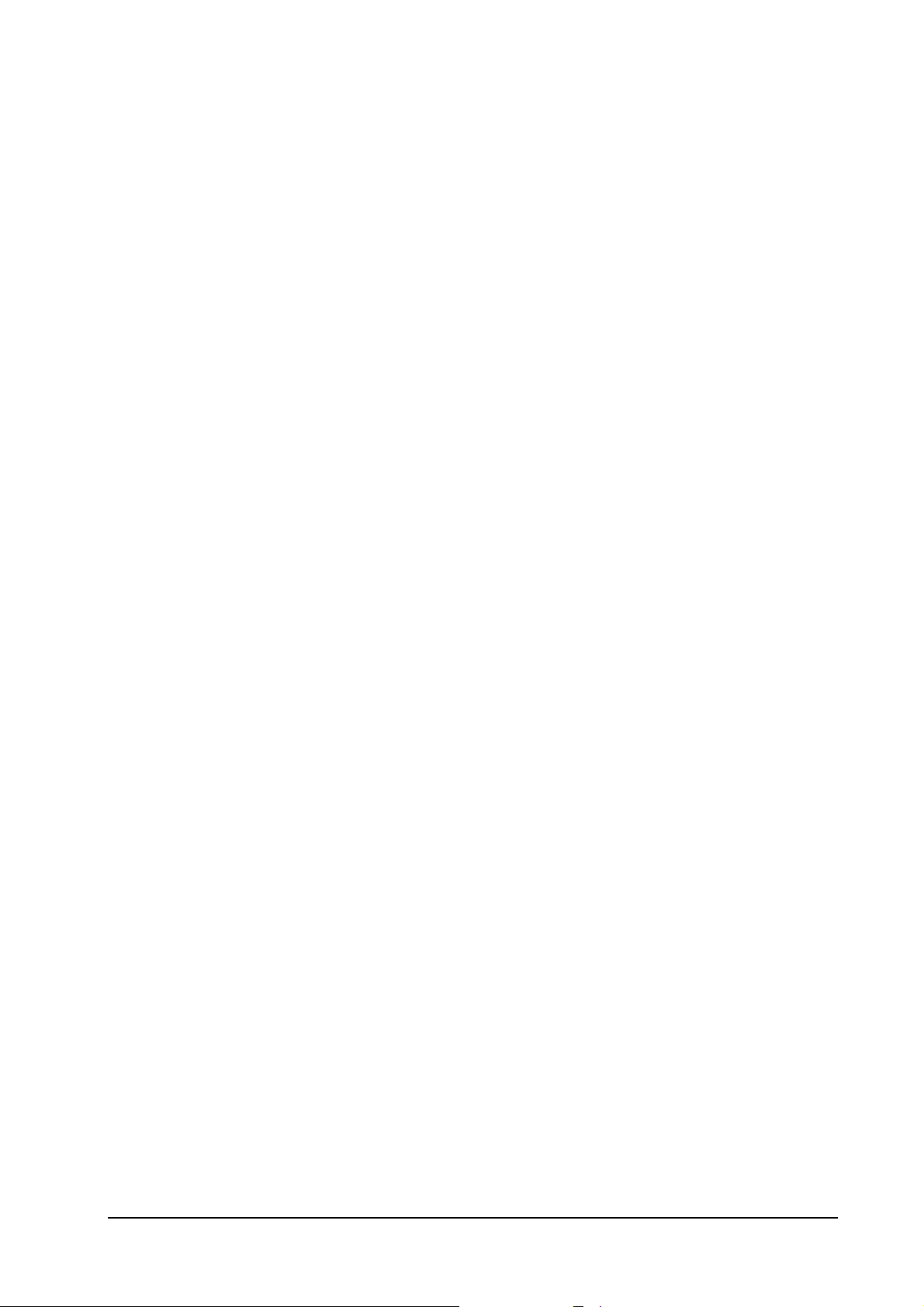

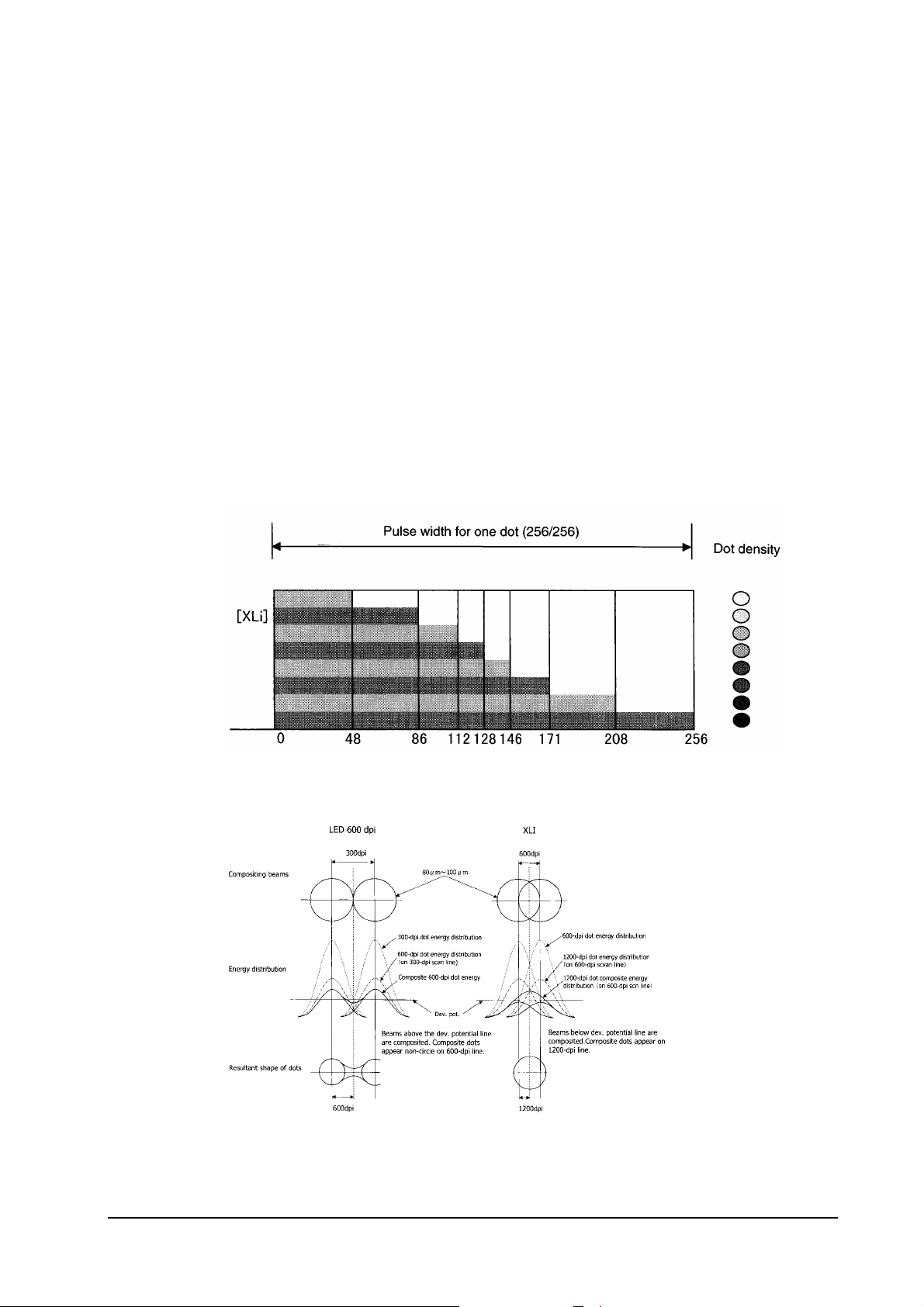

Pseudo-1200 dpi Resolution Theory

Image Processing

Gray Scaler (Dither)

Image Processing

Operation overview

Electrophotographics system

Data Process in g Flow

Computer Controller

The amount of

data deployed in

VRAM for A4 at

600dpi

PCL etc.

1200dot/25.4mm×200mm=9449bit

287mm=13560bit

×

1200dot/25.4mm

PCL

KIR Light

Medium

Dark

Data Deployment in Video RAM

A4 size data

9449×13560

=16.02MB

PCL-6 Ver.1.1, HP LJ-6P (Supported by Kyocera printers)

PCL-6 Ver.2.0, HP LJ-4000 (Unsupported by Kyocera printers)

PCL-5e

PCL-6, Ver.2.0

PCL-EX (similar to PS/2)

4-13

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

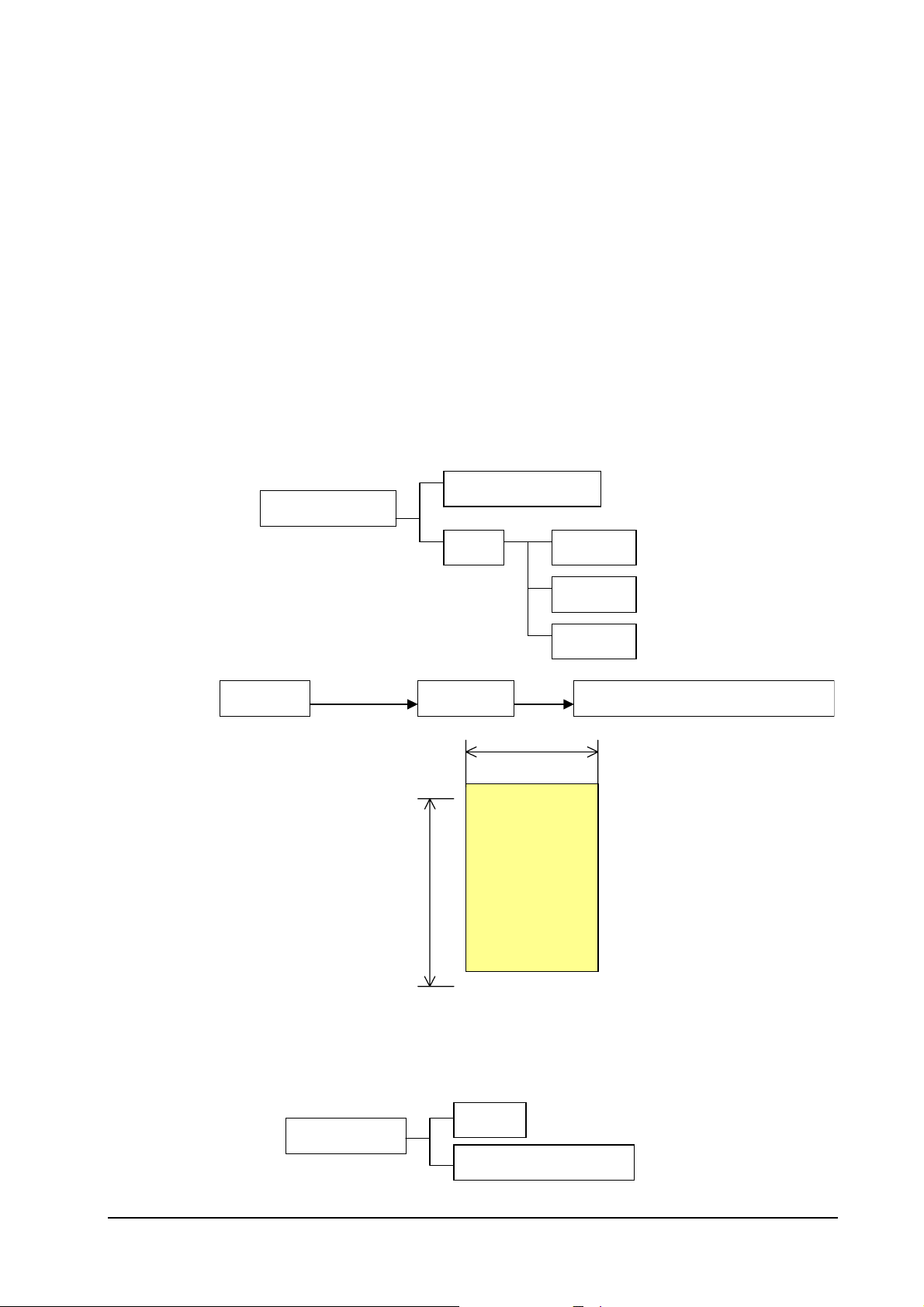

KIR

600dpi(KIR OFF)

Jagged

representation

With KIR, dots of half or

quadruple sizes (grey

boxes at right) are

added or remove d

within the area of 7 by 3

dots.

Duration of laser emission

Light

Jagged dots are replaced by

the voids. The resultant printed

output becomes light (or thin).

Medium

Voids evenly replaces the

jagged areas. The resultant

printed output remain as the

original.

4-14

Dark

New dots are supplemented

around the jagged areas,

causing the resultant printed

output to be dark (or thick).

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

Gray scale and dither

Though monochrome printers can only render black or white (2-value) for a dot, it can provide 256 grey

scape levels on a cell that is constituted by 256 dots in a 16 by 16 cell. This cell is referred to as a pixel or a

half-tone cell. This method of recognising a pixel as a dot to prevent degradation of the printing resolution is

called the grayscale technique.

If dots placed within a pixel is expressed by the typical 2-value data, the data will be in 256 bits as

“01000110...” By expressing the number of dots to be placed in a pixel by a multi-value (FFh) data, dots

can fill a p ixe l in 8 b its. Th is sc he m e is ca lled th e “ dith er.”

For typical printer language, data are handled as follows:

Prescribe, PCL5e: 2 values (0, 1)

PostScript, PCL EX: Multi value (00h – FFh)

287mm(A4)=6780dot

×

600dot/25.4mm

600dot/25.4mm×200mm(A4)=4725dot

1Pixel (16dot)

As being a new

dot, this dot has

the 256-level of

grey.

1Pixel (16dot)

4-15

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

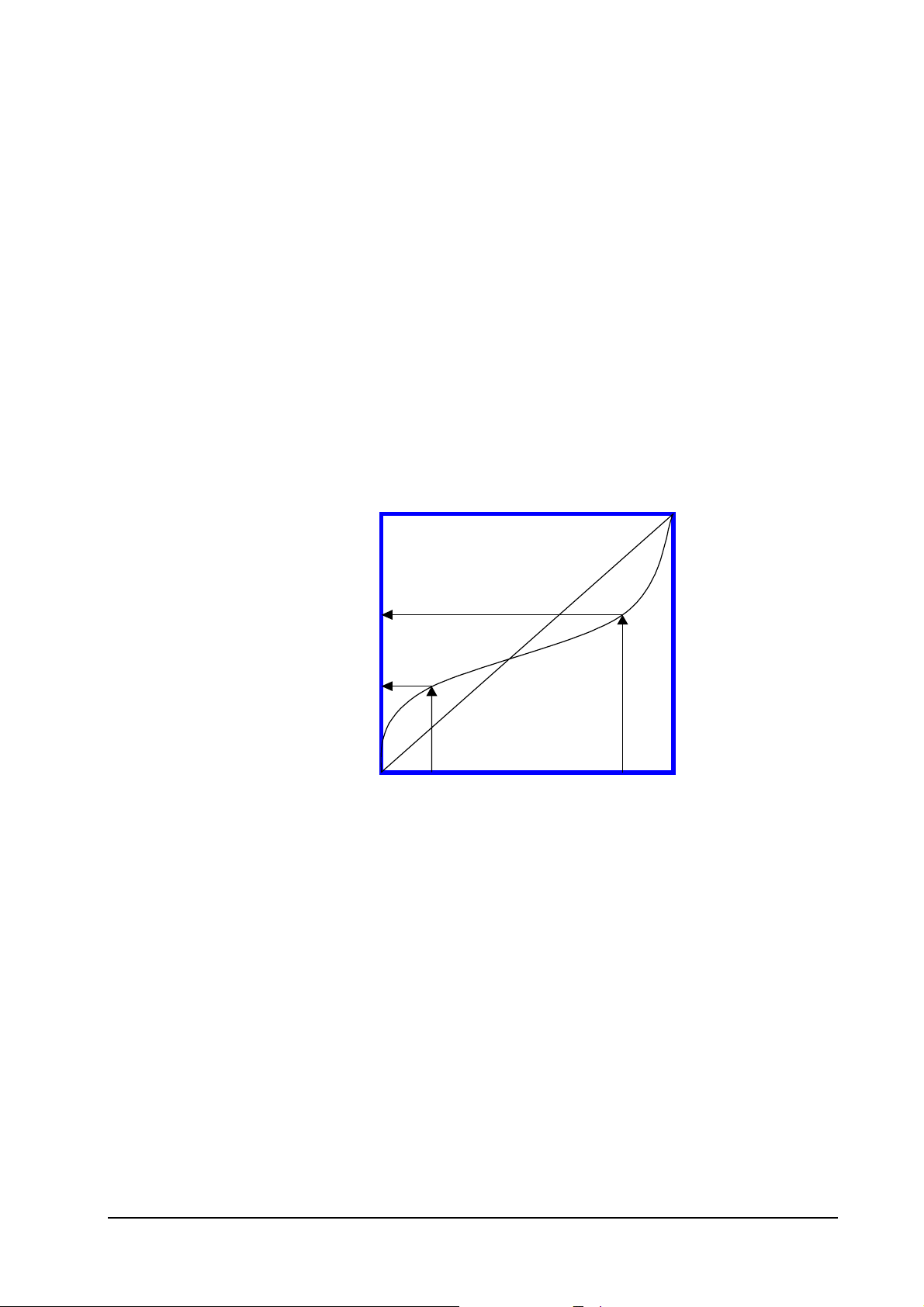

Gamma Correction Curve

For so me p r in t da ta , a d o t in a pixel is not a lway s re p re se n te d a s a d o t when it is p rin te d by the

printer; or, for example, 256 dots in a pixel could be represented as if dots were 256, resulting in

infid elity in th e pr in t ou tput.T h e Gam ma c or re ctio n cu r v e is u se d to co mpe n sa te th e numbe r o f

dots in the origin al p r int d a ta fo r th e o p timu m prin t q u ality.

Nu mb e r o f d o ts o u tp u t

Less dots for the image

(Printing gets lighter.)

More dots for the image

(Printing gets darker.)

256

0

Number of dots input

256

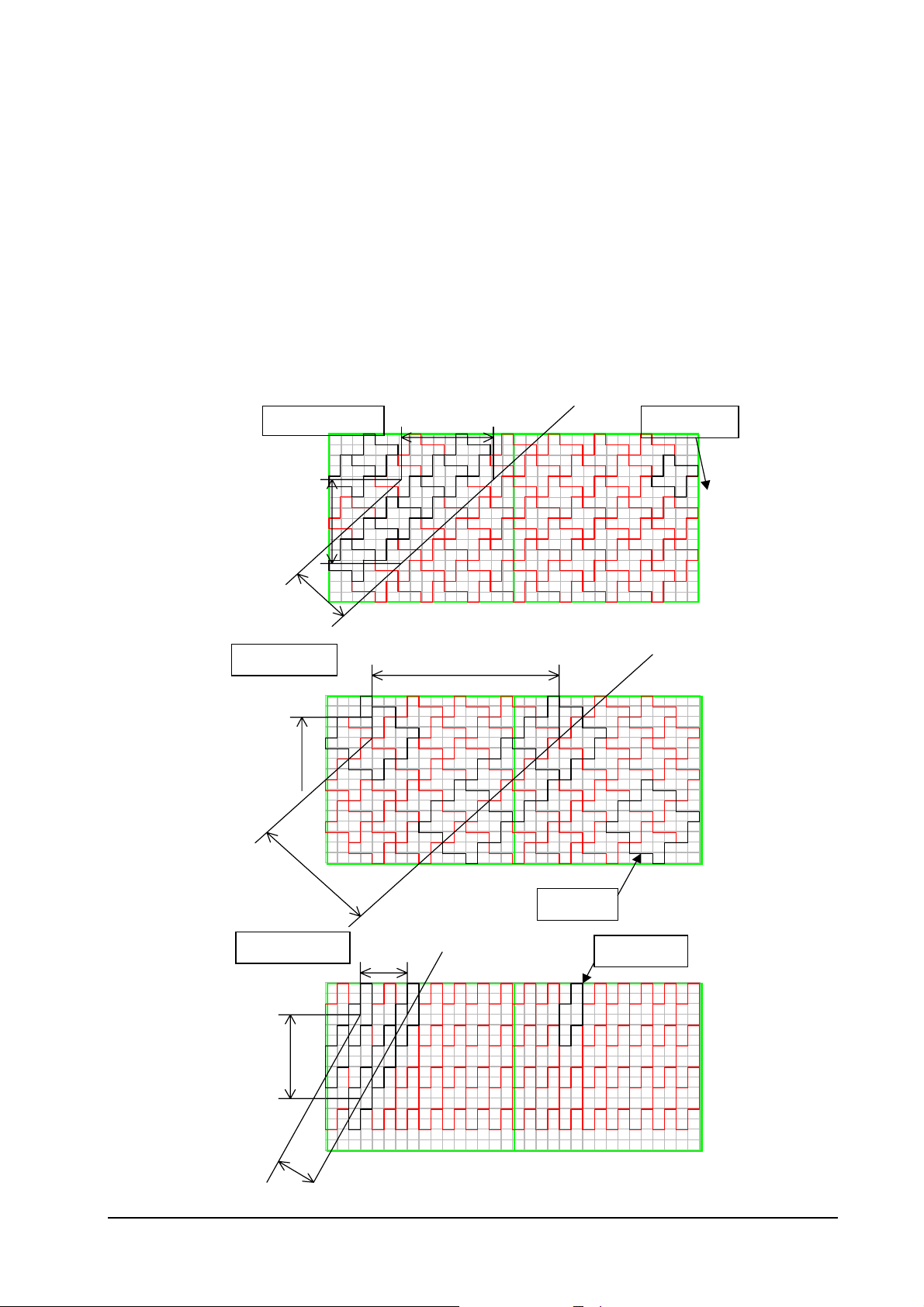

Line of screen and angle of screen

T h e lin e o f s cr ee n is th e n um ber o f th e lin es co n stitu e d b y a p ixe l o r s u b ce lls c o mpris in g a

pixel and expressed in line-per-pitch (lpi). The angle of screen is used to deform the cell,

giving a virtual enhancement in the number of lines (resolution).

T h e n u mbe r o f lin e s o f sc re en is a u to m atic ally d e te rmine d b y th e siz e o f th e ce ll. T h e mo r e th e

num ber of lines of screen, the less the size of the cell, the greyscale level is decreased, and the

resolution becomes high, and vice versa.

T h e lin e s o f sc re en h a s th e fo llo win g re la th ion s h ip w ith r es o lu tio n :

(Printer’s re solu tion/nu mb er o f lines of sc reen )

4-16

2

+1 = Level of greyscale reproduced

FS-1750/FS-3750 Series

45°/212 lines

8-dot pitch=50 lpi(300dpi)

Operation overview

Electrophotographics system

45°

Sub Pixel

4-dot pitch=212lpi

(424dpi)

45°/106 lines

16-dot pitch=75lpi

(150dpi)

8-dot pitch

=106lpi (212dpi)

63.4°/300 lines

8-dot pitch=150lpi

(300dpi)

16-dot pitch=75 lpi (150dpi)

45°

Sub Pixel

4-dot pitch=

300lpi (600dpi)

63.4°

Sub Pixel

8-dot pitch=150lpi

(300dpi)

3.57 dots=300lpi

(600dpi)

4-17

FS-1750/FS-3750 Series

Operation overview

Electrophotographics system

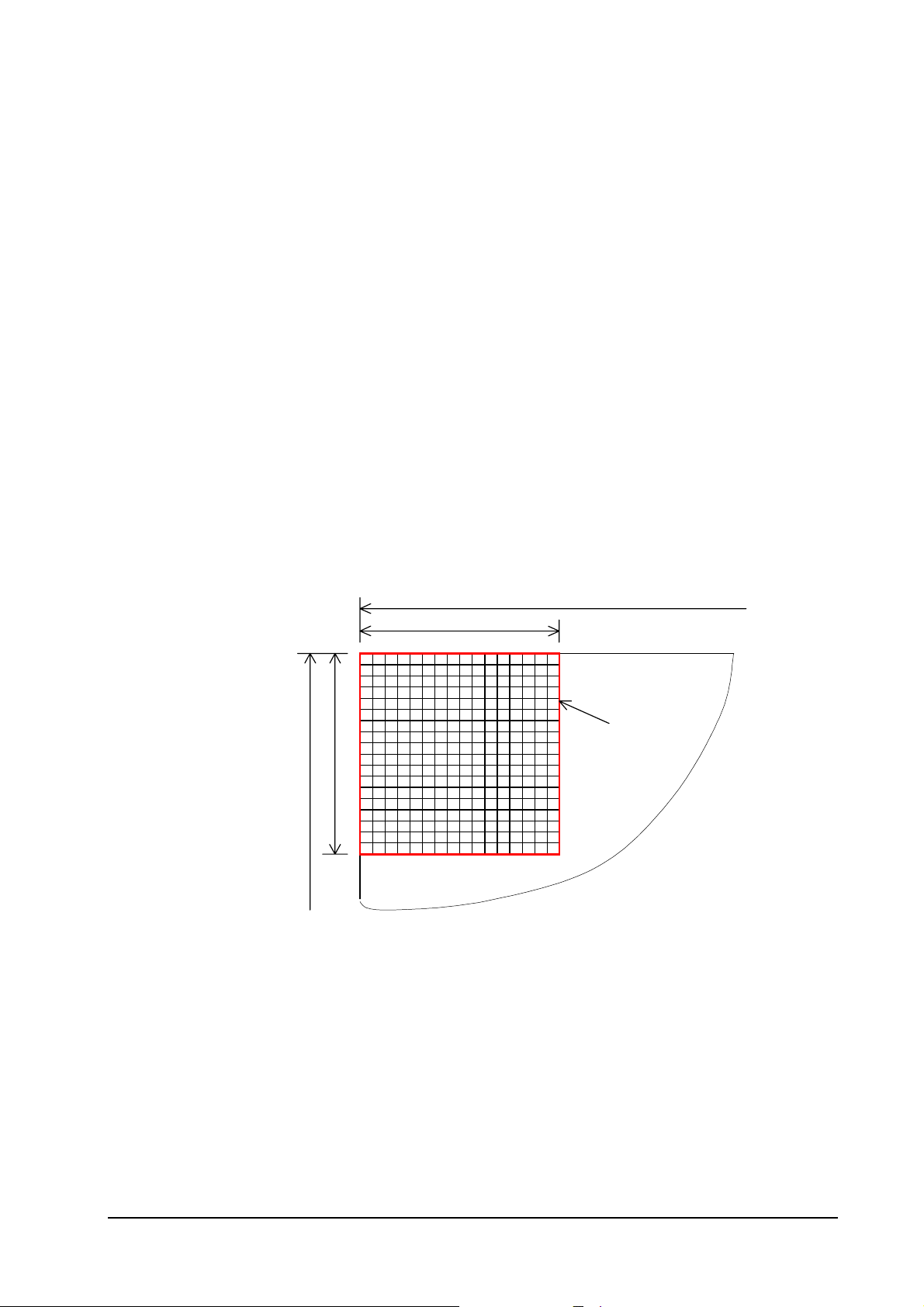

Pulse-sliced laser exposure technology

In XLI technology, the width of a pulse emitted as a dot is divided into eight segments each of

which varies according to the original data to be represented. This allows optimum laser exposure

for the drum according to the properties of the drum such as the sensitivity and development response. In overall, it is possible that the dots are consistently distributed over the photoconductor

in 1200 dpi resolution.

Pulse-sliced laser

4-18

FS-1750/FS-3750 Series

Development

Operation overview

Electrophotographics system

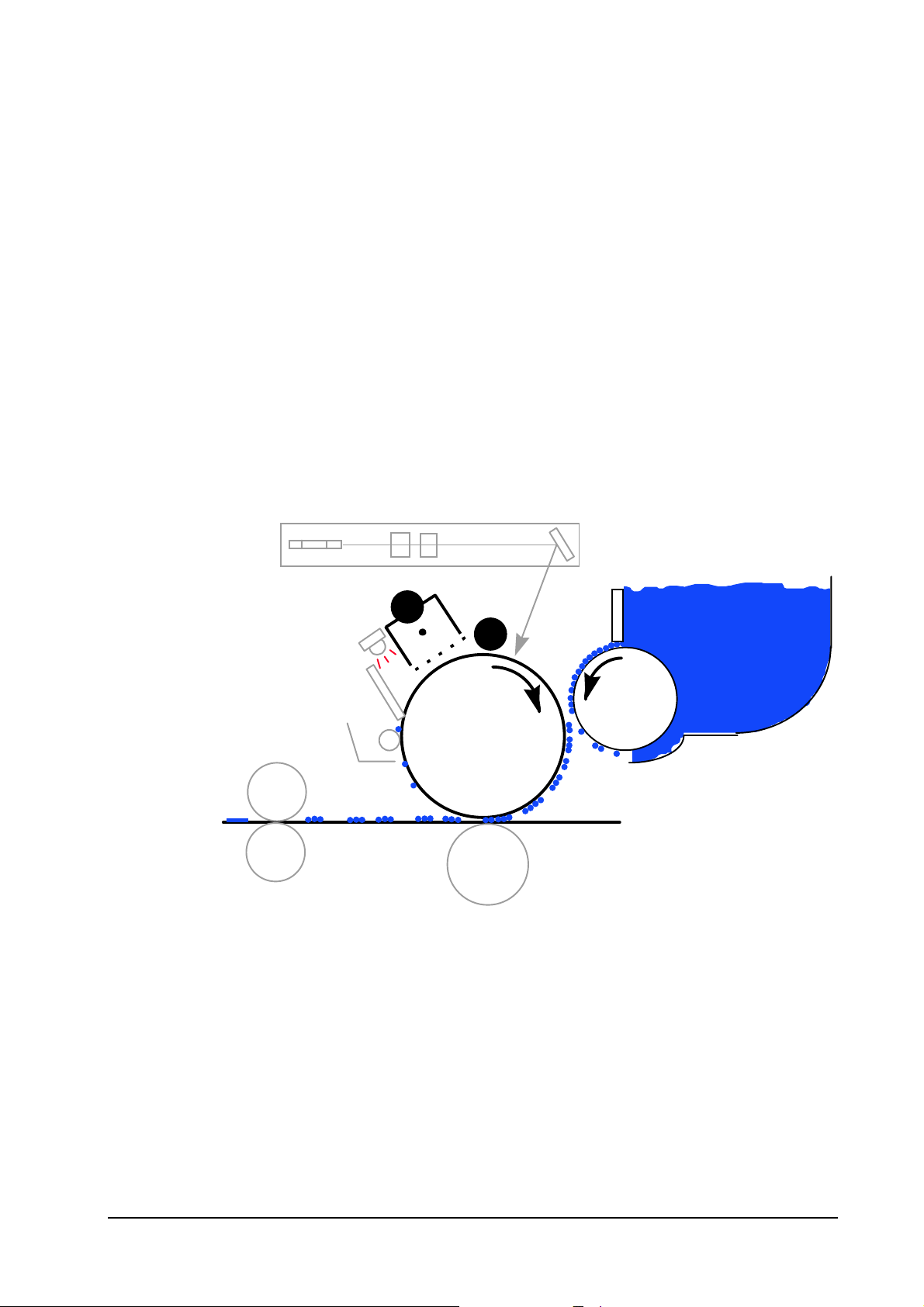

The latent image constituted on the drum is developed into a visible image. The developing roller

contains a 3-pole (

Toner attracts to the developing roller since it is powdery ink made of black resin bound to iron

particles. A magnetized blade positioned approximately 0.3 mm above the developing roller constitutes a smooth layer of toner in accordance with the roller revolution.

S-N-S

) magnet core and an aluminum cylinder rot ating around the magne t core.

Blade

Magnet

Magnetism

0.1mm

N

S

0.3-0.4mm

S

Drum

N

S

Developing roller

4-19

FS-1750/FS-3750 Series

Loading...

Loading...