Page 1

Troubleshooting

Board layouts

Chapter Six

TROUBLESHOOTING

6-1

FS-1750/FS-3750 Series

Page 2

Troubleshooting

Board layouts

Chapter Six

Board layouts 6-4

Liaison board/KP-504 6-4

Scanner interface board/KP-488 6-5

Engine board connectors/KP-535 6-5

Fuser board/KP-499 6-6

Drum connector/YC-741 (KP-500 board) 6-6

General wiring diagram ➊ 6-76-6

General wiring diagram ➋ 6-8

Diagnostic 6-9

Engine diagnostics flow 6-10

Logic controller diagnostics flow 6-11

General error handling 6-12

Priority 6-12

User-recoverable errors 6-14

Memory card errors 6-17

Service errors 6-19

E0 - Communication error 6-19

E1 - Main motor error 6-19

E2 - Laser scanner motor error 6-21

E3 - Laser beam detection error 6-23

E4 - Fuser heater error 6-25

E5 - Eraser error 6-27

E6 - Flash ROM error 6-29

E9 - Toner motor error 6-29

F0 - Front control panel error 6-31

F1 - System ROM error 6-31

F2 - Main memory error 6-31

F3 - General failure 6-31

False errors - “Paper Feed Unit Open” 6-32

False errors - “Top Cover Open” 6-33

False errors - “Side cover Open” 6-34

False errors - “Missing Waste-toner bottle” 6-35

TROUBLESHOOTING6-1

Print quality problems 6-36

Completely blank printout 6-36

All-black printout 6-36

Dropouts 6-37

Black dots 6-38

Horizontal streaks 6-38

Black vertical streaks 6-39

Unsharp printing 6-39

Grey background 6-40

Dirt on the top edge or back of the paper 6-41

REPETITIVE DEFECTS GAUGE 6-43

6-2

FS-1750/FS-3750 Series

Page 3

CHECKING CASSETTE SIZE SENSORS 6-44

Drum cleaning 6-45

Troubleshooting

Board layouts

6-3

FS-1750/FS-3750 Series

Page 4

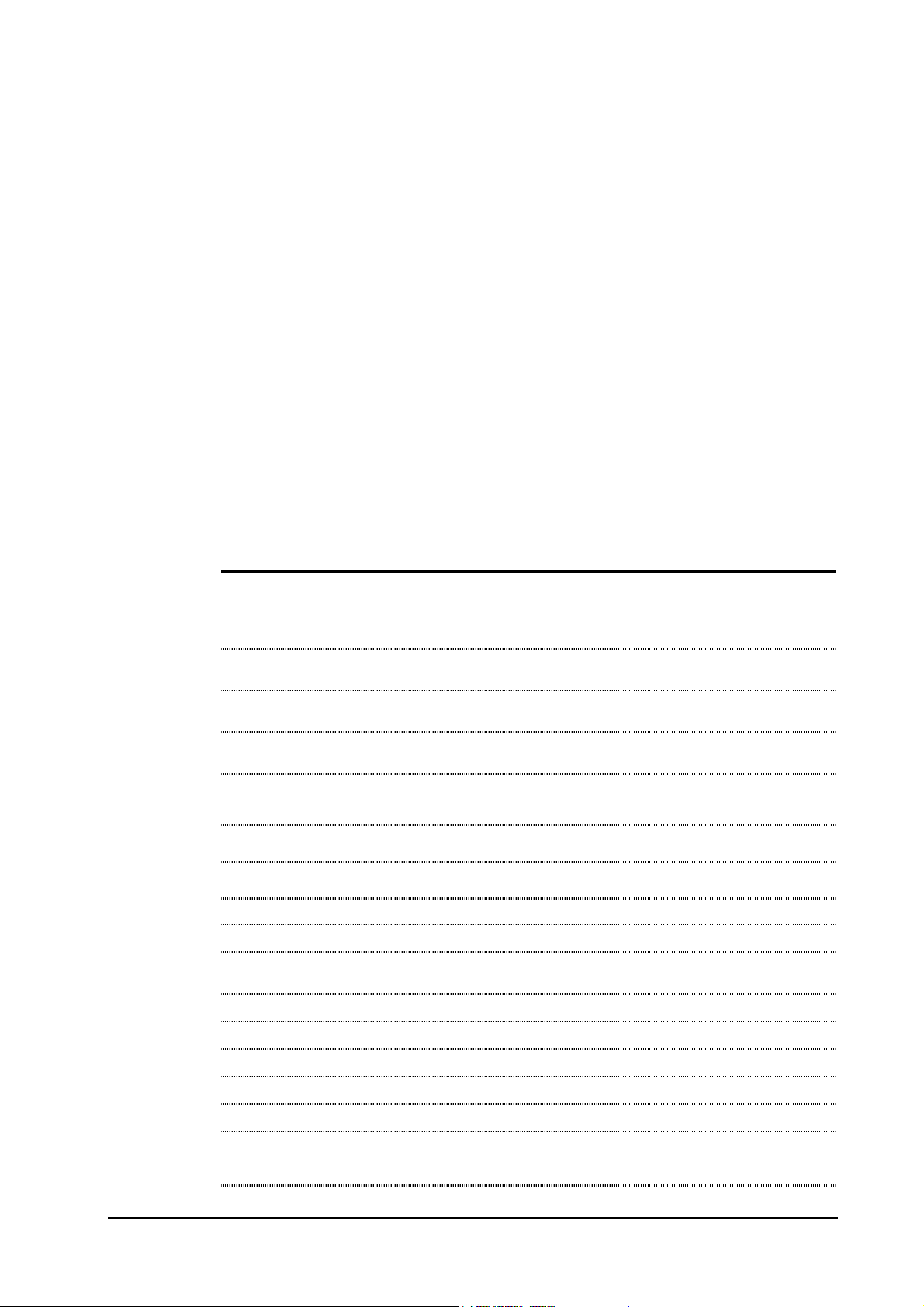

Board layouts

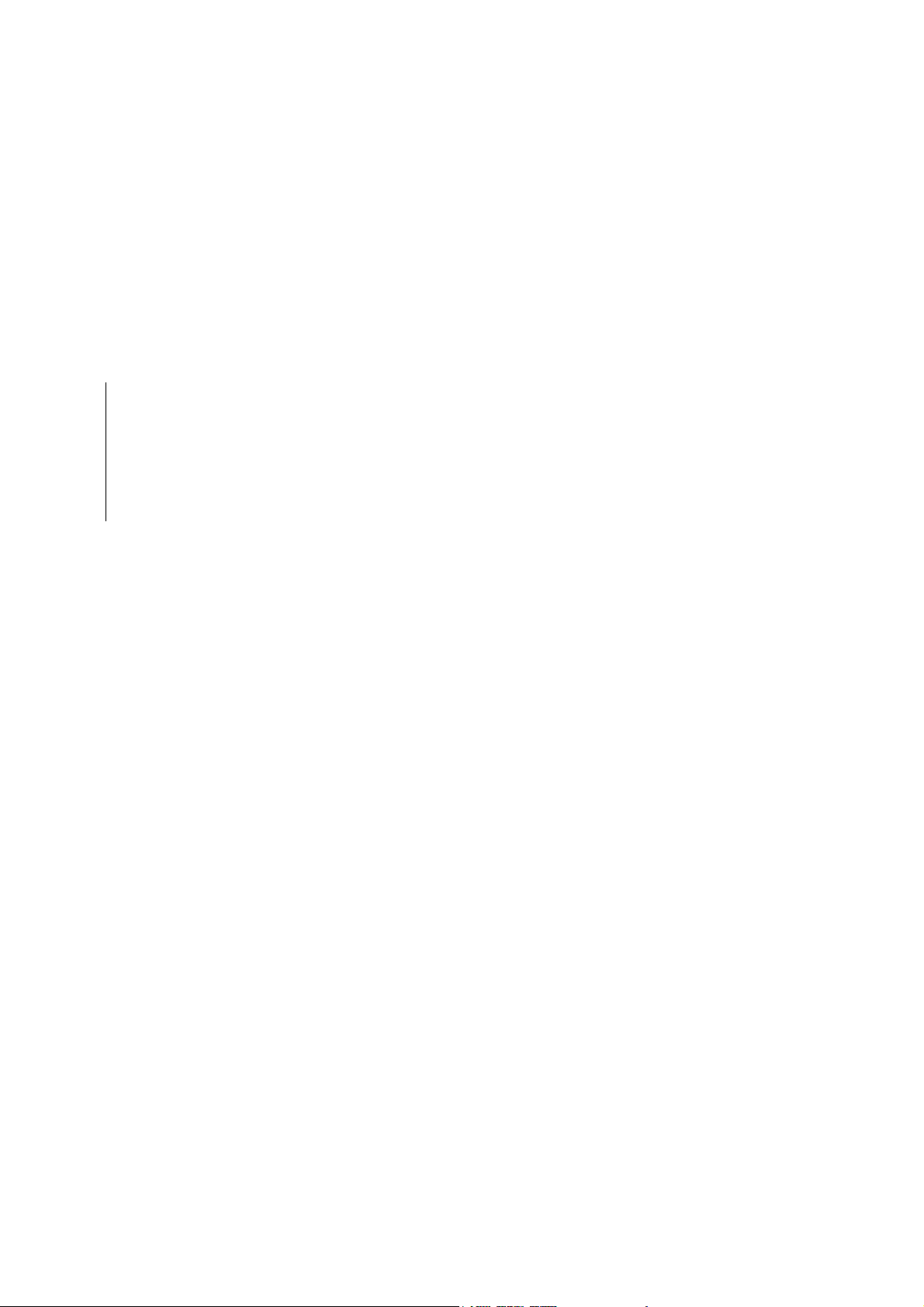

Relay board/KP-504

Troubleshooting

Board layouts

Symbol

(above)

➊

➋

➌

➍

➎

➏

➐

➑

Connector Connected to: Check point

YC806 Fan (large)

YC802 Main motor E1, Pin 3 (MOTOR*)/Pin 1 (+24V)

YC808 Fan (small)

YC803 Registration clutch

YC804 Paper feed clutch

YC801 Engine board E1, Pin 12 (MOTOR*)

YC805 Manual feed clutch

YC807 Front operator panel

6-4

FS-1750/FS-3750 Series

Page 5

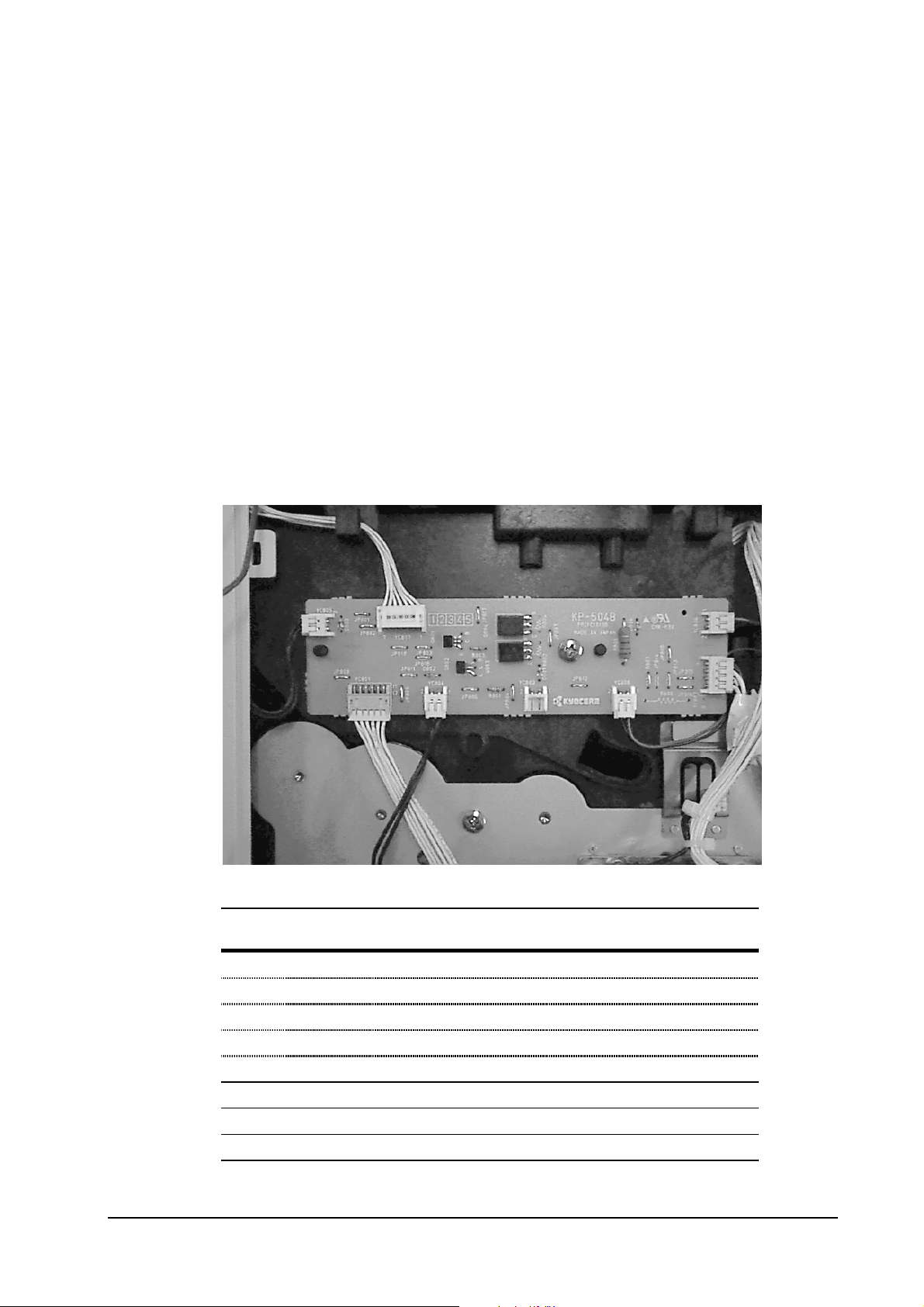

Scanner interface board/KP-488

Troubleshooting

Board layouts

YC675

4 - SCANR*

Engine board connectors/KP-669

+24V - 13

10 - PD*

13 - LASR*

7 - DSCLK

1 - +24V

YC203 (To

scanner

unit)/See

LASR* - 1

PD* - 6

SCNCLK - 8

12 - SCANR*

6-5

FS-1750/FS-3750 Series

Page 6

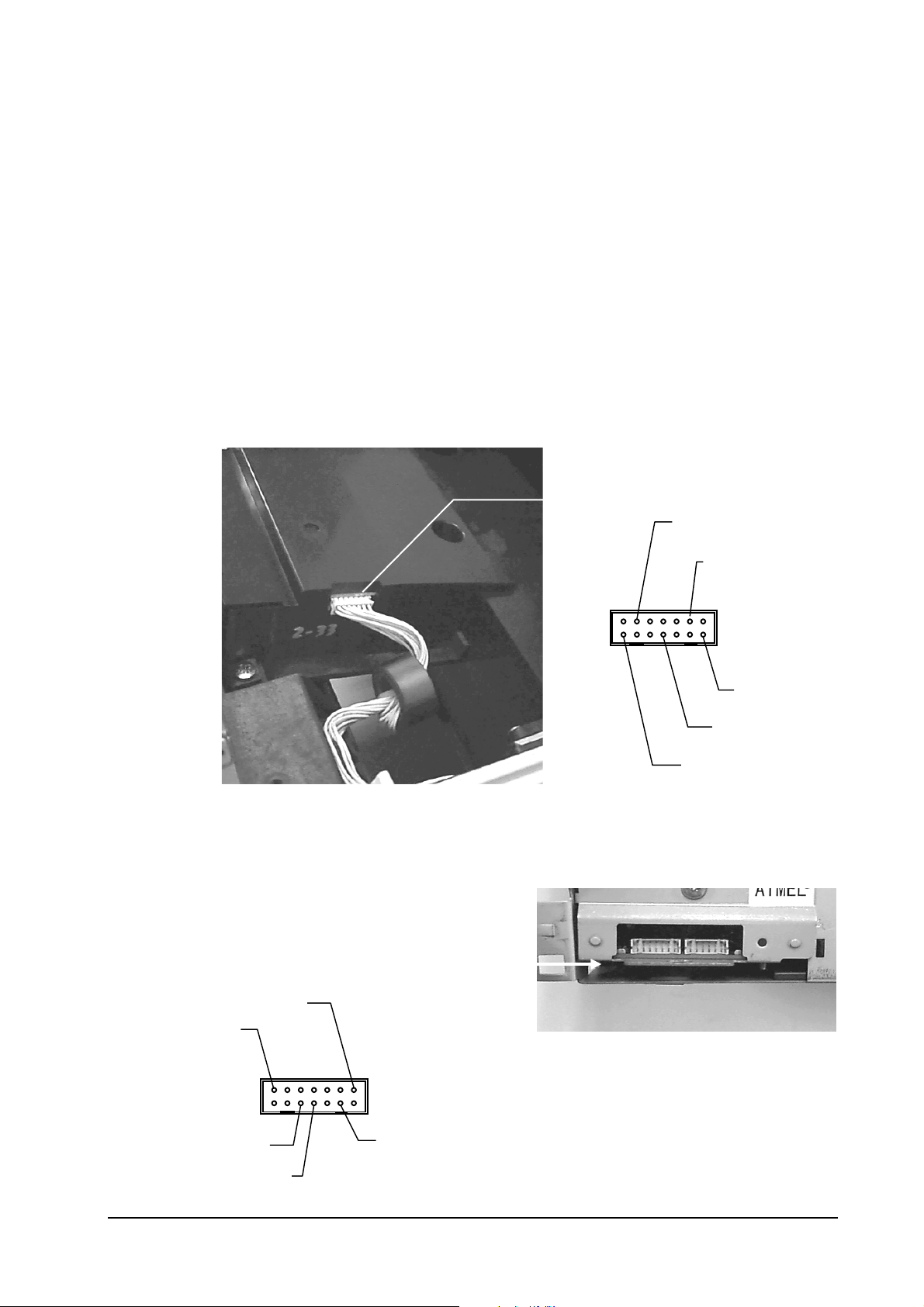

Fuser board/KP-499

Troubleshooting

Board layouts

Drum connector/YC-741 (KP-500 board)

Pin 13

Pin 1

YC721 (➲KP-492)

5 - THERM* 8 - +5V

KP-500 board

6-6

FS-1750/FS-3750 Series

Page 7

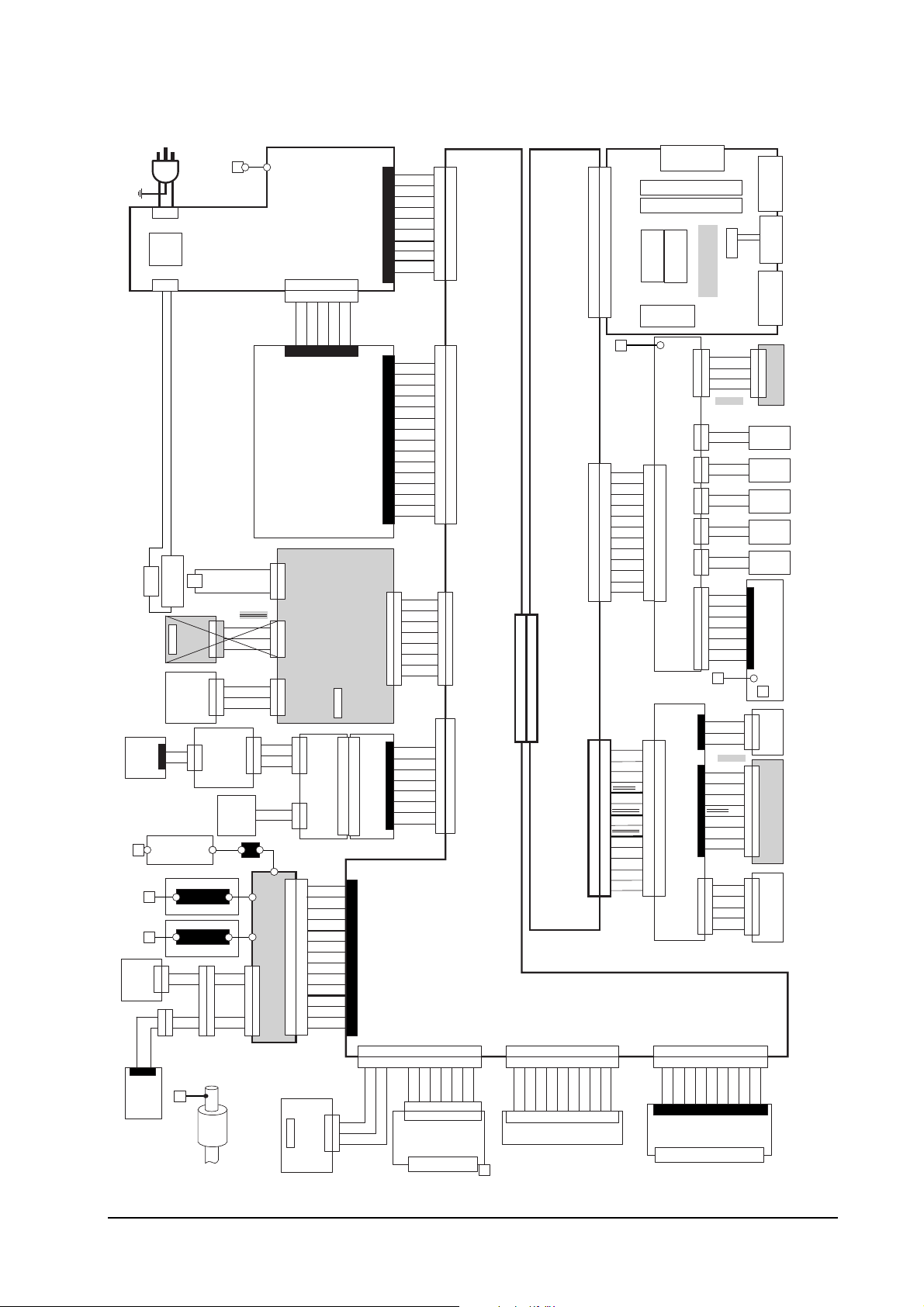

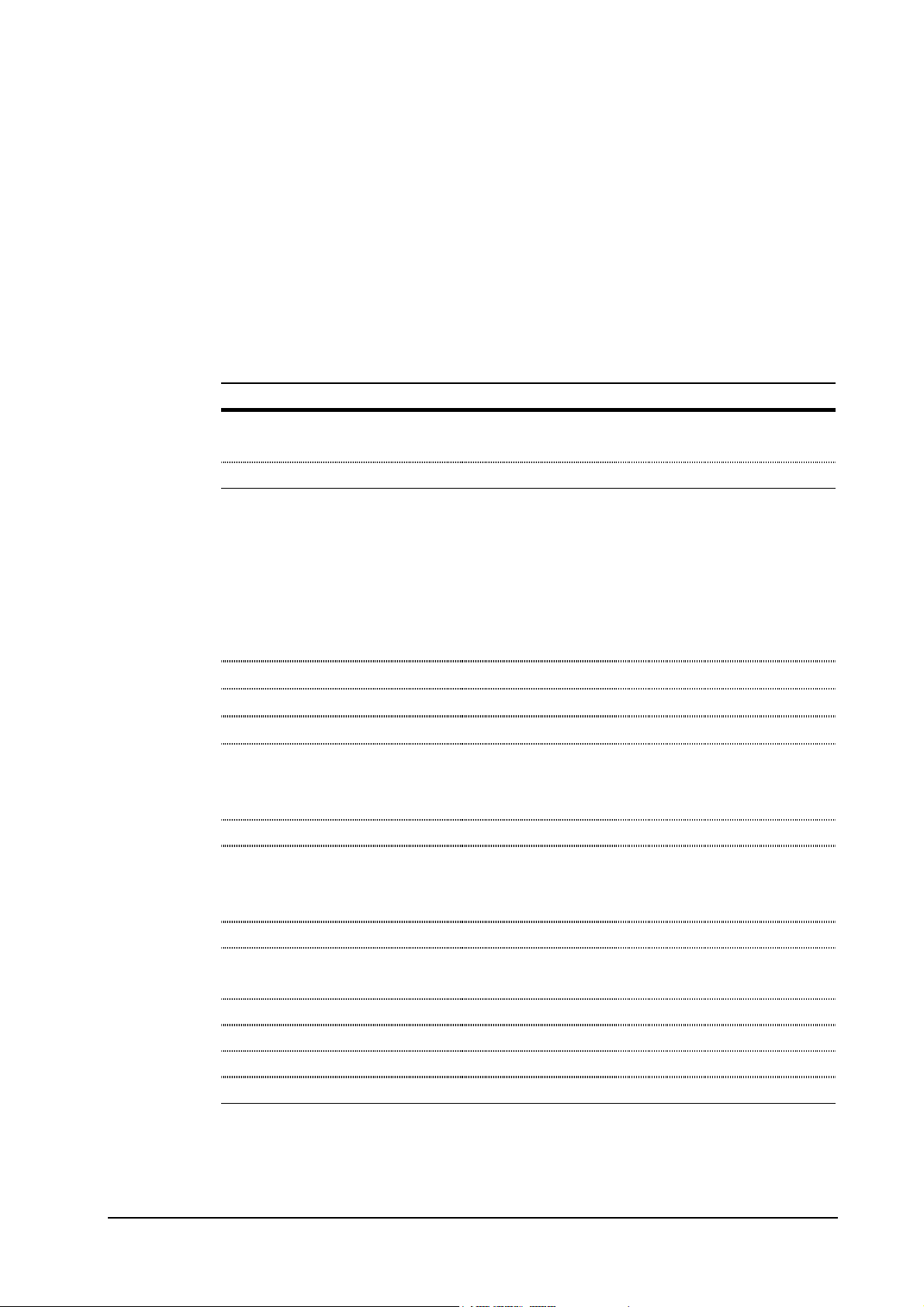

General wiring diagram(FS-1750)

AC IN

S02013

1

2

(CN1)

SWITCH

1

2

(CN2)

S02039 : E

S02012 : U

THERMO CUT OUT

HEATER

SENSOR

FULL

SOLENOID

UP/DOWN

S02021

SENSOR

C

1

E

2

2

ZENER PWB

(KP-501)

TRANSFER ROLLER

MAG ROLLER

TONER

SENSOR

TNEND*

2

2

GND

1

1

TDRV

2

2

+24V

1

1

S02029

S02023

TONER

MOTOR

S02036

POWER

THERMISTER

THERM*

S02019

PAPAER

+5V

1

1

PAPFL*

2

2

GND

3

3

FCUP*

FACE

1

1

+24V

2

2

FDOWN*

3

3

TNFULL PWB

(KP-506)

(YC841)

(YC842)

121

ERASER

TNEND*

1

1

GND

2

2

TDRV

3

3

+24V

4

4

S02022

FEED ROLLER

+5V

1

1

2

2

1

1

2

2

3

3

1

1

2

2

3

3

S02018

+5V

1

1

TNFULL*

2

2

TSEN*

3

3

S02043

ERASER

GND

1

2

HIGH VOLTAGE UNIT

3

4

5

6

7

8

1

1

9

2

2

10

11

12

(CN1)

(CN2)

5

5

13

6

6

14

MANUAL PAPER

POWER SUPPLY UNIT

(CN4)

1

1

6

+24V

(YC702)

+24VCOM

+24VCOM

+24VCOM

SENSOR PWB

(KP-498)

(YC723) (YC724) (YC722)

FUSER PWB

(KP-499)

(YC743)

(YC741)

1

1

2

2

DRUM PWB

3

3

(KP-500)

(YC742)

121

121

2

2

S02381

(旧S02008)

+24V

1

MHVDR*

2

THVDR*

3

HVMON*

4

HVISEL

5

HVCK

6

PSEL*

7

TEND

8

+5V

9

GND

10

MICR

11

GND

12

SCAN

13

MDRV

14

PAPER SENSOR

MANUAL FEED

3

3

2

2

1

1

GND

PD*

+5V

65432

65432

+5V

12345

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

(CN3)

5

6

7

8

9

10

(旧 S02011)

S02385

1

2

3

4

5

6

(YC701)

7

8

9

10

11

12

13

14

15

1

2

(YC721)

3

4

5

6

7

8

(YC821)

(YC822)

1

1

2

2

3

DRUM RELAY

PWB

3

4

4

5

5

(KP-505)

6

6

7

7

8

8

(YC355)

10

8

9

10

8

9

HANDS*

+5V

GND

S02382

GND

1

GND

GND

+5V

+5V

+5V

ZCROSS

HEAT*

PSAVE

+24V

(旧S02010)

SCOVER*

PAPER*

FEEDS*

TNCON*

+24V

+24V

+24V

+24V

FCOVER*

TCOVER

CAST2

CAST1

CAST0

GND

1

2

3

4

5

6

7

8

(旧S02007)

TSEN*

TNFULL*

ERASER

EECSEL

EEDAT

EESCK

GND

+5V

(YC381)

(YC382)

1

2

2

3

3

(YC352)

4

4

5

5

6

6

7

7

8

8

9

9

10

10

S02384

1

1

2

2

3

3

4

4

5

5

6

6

7

(YC358)

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

16

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

10

EPAP*

1

2

3

4

5

6

7

8

9

(YC353)

(YC356)

EMOT*

EUNIT*

(KP-502)

(KP-701)

1234567

1234567

+24V

1234567

1234567

CONNECT PWB

(YC351)

10

10

S02386(旧 S02016)

GND

10

S02036

15

16

S02009

FCUP*

+24V

FDOWN*

PAPFL*

THERM*

EXITJ*

GND

+5V

S02380

1

2

3

4

5

6

7

8

9

10

(YC357) (YC354)

GND

HANDS*

PUNIT*

ENVEROP

FEEDER

PWB

To PF-7E

Engine Controller

(KP-699)

(YC202)

SEL10

SEL11

SEL12

SDATI

SDATO

To OPTION UNIT

(YC201)

(YC204)

10

11

12

(YC203)

10

11

12

13

14

REDY

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

+5V

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SCLK*

(YS1)

(YS2)

(YC1)

(YS3)

S02020

GND

FPCLK

FPDIR

FPDATA

+5V

FAN*

FEDDR*

MFDDR*

MTRCLK

REGDR*

MOTOR

+24V

S02046

LASER*

LONB*

VDO+

+5V

VDOPD*

LSGND

SCNCLK

LSGND

SCRDY*

GND

SCANR*

+24V

GNDP

123456789

123456789

+24V

123456789

(YC4)

S02038

10

12

11

13

14

11

12

10

S02383(旧 S02015)

PC-Card

PC-SIMM

PC-SIMM

PowerPC603e

-100MHz

XLI

ROM (DIMM)

(KP-710)

RELAY PWB

(KP-504)

2

2

1

1

4

4

3

3

6

6

5

5

8

8

7

7

10

9

9

12

11

(YC801)

13

14

APC RELAY PWB

11

12

9

9

10

7

7

8

8

(KP-488)

5

5

6

6

3

3

4

4

1

1

2

2

(YC675)

10

10

+24V

GND

10

(YC354)

(YC371)

Troubleshooting

Board layouts

Centronics

(YC2)

(KP-725)

(YC3)

FUP*

S02044

1

2

3

4

5

6

7

1

2

3

1

2

3

4

5

6

7

8

1

2

3

4

5

FOP*

(YC5)

1

1

1

2

2

2

3

3

3

4

4

4

Regist

Clutch

Feed

Clutch

M.Feed

Clutch

Motor

Box Fan

Motor

1

2

3

1

2

3

4

5

6

7

8

1

2

3

4

5

123456789

123456789

MON*

123456789

RS-232C

OPTION I/F

Main Motor

Fan

Front Panel

(KP-503)

S02037

PD PWB

(KP-483)

APC PWB

(KP-705)

Polygon Motor

VLOW*

S02014

Main Controller

(KP-724)

+24V

(YC802)

1

1

GND

2

2

MOTOR*

3

3

MTRCLK

4

4

S02047

(YC803) (YC804) (YC805) (YC806)

+24V

1

1

REGDR*

2

2

+24V

1

1

FEDDR*

2

2

+24V

1

1

MFDDR*

2

2

FANCOM

1

1

FANDR*

2

2

(YC808)

BFANCOM

1

1

BFANDR*

2

2

S02001

+5V

1

1

FPDAT

2

2

+5V

(YC807)

3

3

FPDIR

4

4

GND

5

5

FPCLK

6

6

GND

7

7

S02025

(YC674)

+5V

1

PD*

2

GND

3

+5V

1

LONB*

2

LASR*

3

(YC673)

VDO+

4

VDO-

5

LSGND

6

LSGND

7

GND

8

+24V

1

1

GND

(YC671)

2

2

SCANR*

3

3

SCRDY*

4

4

SCNCLK

5

5

(YC359)

HSCOPN

HSPAP*

UNIT*

FUX PWB

(KP-493)

To HS-20

S02006

S02004

S02005

(GND)

6-7

FS-1750/FS-3750 Series

Page 8

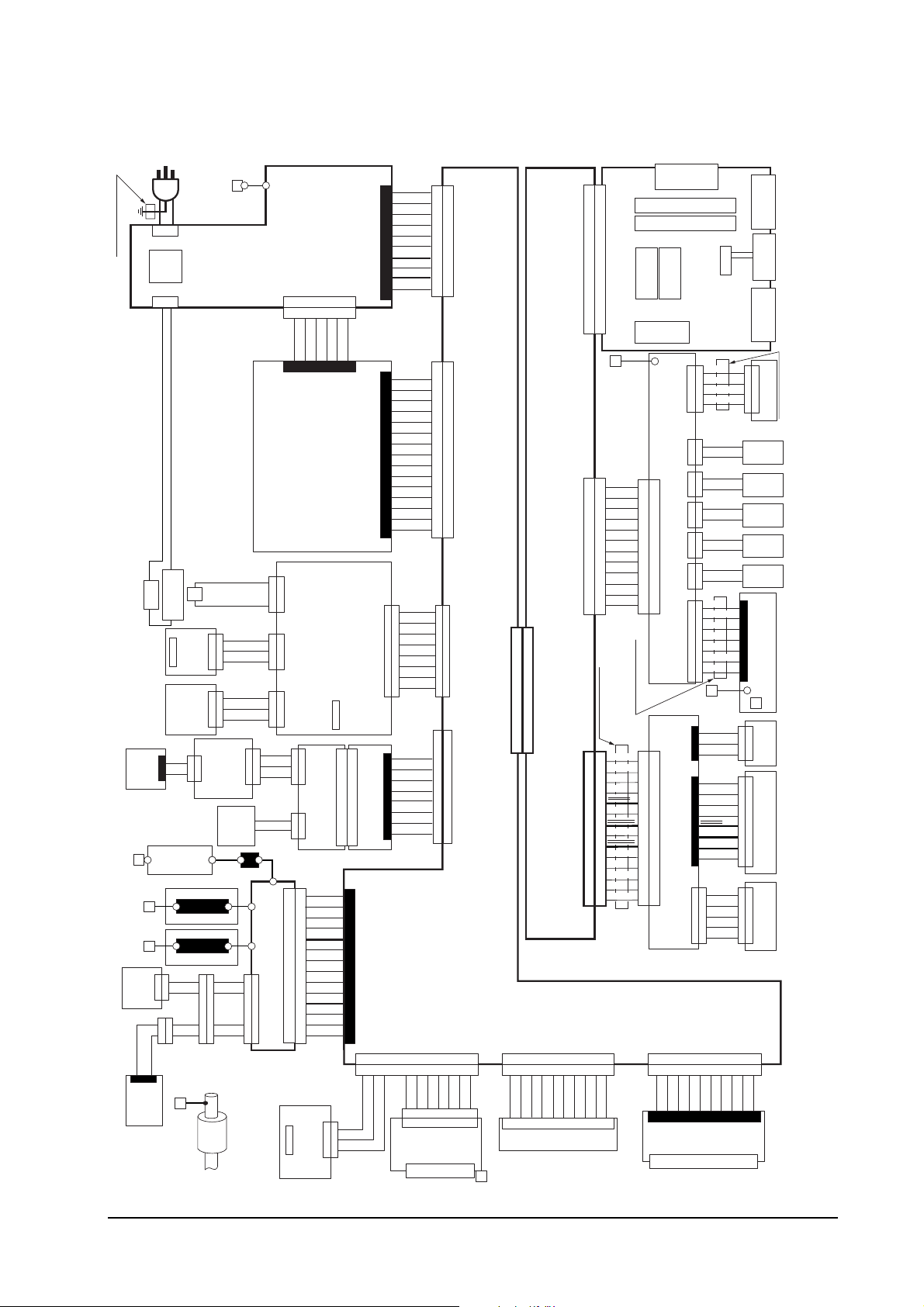

General wiring diagram(FS-3750)

Troubleshooting

Board layouts

TDK HF70T18*6*10

1

2

1

2

THERMO CUT OUT

HEATER

S02021

SENSOR

C

1

E

2

ZENER PWB

(KP-501)

TRANSFER ROLLER

TONER

SENSOR

TNEND*

2

2

GND

1

1

2

2

1

1

S02029

TONER

MOTOR

AC IN

S02013

(CN1)

POWER

SWITCH

(CN2)

S02039 : E

S02012 : U

THERMISTER

SENSOR

PAPAER

FULL

SOLENOID

UP/DOWN

FACE

(YC842)

121

2

MAG ROLLER

1

2

TDRV

3

+24V

4

S02023

S02036

+5V

1

1

PAPFL*

2

2

GND

3

3

FCUP*

1

1

+24V

2

2

FDOWN*

3

3

TNFULL PWB

(KP-506)

ERASER

TNEND*

1

GND

2

TDRV

3

+24V

4

S02022

FEED ROLLER

1

1

6

+5V

(YC723) (YC724) (YC722)

1

1

THERM*

2

2

S02019

1

1

2

2

3

3

1

1

2

2

3

3

S02018

(YC841)

+5V

1

1

TNFULL*

2

2

TSEN*

3

3

S02043

ERASER

GND

1

2

HIGH VOLTAGE UNIT

3

4

5

6

7

8

1

1

9

2

2

10

11

12

(CN1)

(CN2)

5

5

13

6

6

14

MANUAL PAPER

POWER SUPPLY UNIT

(CN4)

+24VCOM

+24VCOM

+24VCOM

+24V

(YC702)

SENSOR PWB

(KP-498)

FUSER PWB

(KP-499)

(YC743)

(YC741)

1

1

2

2

DRUM PWB

3

3

(KP-500)

(YC742)

121

121

2

2

S02381

+24V

1

MHVDR*

2

THVDR*

3

HVMON*

4

HVISEL

5

HVCK

6

PSEL*

7

TEND

8

+5V

9

GND

10

MICR

11

GND

12

SCAN

13

MDRV

14

PAPER SENSOR

MANUAL FEED

GND

3

3

PD*

2

2

+5V

1

1

65432

65432

12345

10

11

12

13

14

+5V

1

2

3

4

5

6

7

8

9

(旧 S02011)

(YC821)

PWB

(KP-505)

(YC355)

10

10

GND

1

GND

2

GND

3

+5V

4

(CN3)

+5V

5

+5V

6

ZCROSS

7

HEAT*

8

PSAVE

9

+24V

10

S02385

SCOVER*

1

PAPER*

2

FEEDS*

3

TNCON*

4

+24V

5

+24V

6

(YC701)

+24V

7

+24V

8

FCOVER*

9

10

TCOVER

11

CAST2

12

CAST1

13

CAST0

14

GND

15

FCUP*

1

1

+24V

2

2

FDOWN*

(YC721)

3

3

PAPFL*

4

4

THERM*

5

5

EXITJ*

6

6

GND

7

7

+5V

8

8

S02380

(YC822)

TSEN*

1

1

TNFULL*

2

2

ERASER

3

DRUM RELAY

3

EECSEL

4

4

EEDAT

5

5

EESCK

6

6

GND

7

7

+5V

8

8

8

9

8

9

HANDS*

+5V

GND

(YC381)

(YC382)

S02382

1

1

2

2

3

3

(YC352)

4

4

5

5

6

6

7

7

8

8

9

9

10

10

S02384

1

1

2

2

3

3

4

4

5

5

6

6

7

(YC358)

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

16

1

2

3

4

5

6

7

8

10

EPAP*

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

EUNIT*

(KP-502)

CONNECT PWB

(KP-701)

(YC353)

(YC356)

1234567

1234567

+24V

EMOT*

1234567

1234567

S02386(旧 S02016)

S02036

(YC351)

10

10

GND

10

(YC202)

SDATI

SDATO

To OPTION UNIT

15

16

S02009

1

2

3

4

5

6

7

8

9

10

(YC357) (YC354)

GND

HANDS*

PUNIT*

ENVEROP

FEEDER

PWB

To PF-7E

(YC201)

Engine Controller

1

1

2

SEL11

(YC203)

SEL10

(YC204)

10

11

12

10

11

12

13

14

REDY

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

11

12

TDK HF70T25*13*15

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

11

12

13

14

SCLK*

+5V

(KP-699)

SEL12

(YS1)

(YS2)

(YC1)

(YS3)

S02020

GND

FPCLK

FPDIR

FPDATA

+5V

FAN*

FEDDR*

MFDDR*

MTRCLK

REGDR*

MOTOR

+24V

S02046

LASER*

LONB*

VDO+

+5V

VDOPD*

LSGND

SCNCLK

LSGND

SCRDY*

GND

SCANR*

+24V

GNDP

123456789

123456789

+24V

123456789

(YC4)

XLI

ROM (DIMM)

(KP-710)

S02038

(KP-504)

2

2

1

1

4

4

3

3

6

6

5

5

8

8

7

7

10

10

9

9

12

12

11

11

(YC801)

TDK HF70T18*6*10

13

13

14

14

11

11

12

12

9

9

10

10

7

7

8

8

5

5

6

6

3

3

4

4

1

1

2

2

(YC675)

10

10

S02383(旧 S02015)

10

(YC354)

(YC371)

PC-Card

PC-SIMM

PC-SIMM

PowerPC603e

Main Controller

-166MHz

(KP-707)

+24V

(YC802)

1

1

GND

2

2

MOTOR*

3

3

RELAY PWB

MTRCLK

4

4

S02002

(YC803) (YC804) (YC805) (YC806)

+24V

1

1

REGDR*

2

2

+24V

1

1

FEDDR*

2

2

+24V

1

1

MFDDR*

2

2

FANCOM

1

1

FANDR*

2

2

(YC808)

BFANCOM

1

1

BFANDR*

2

2

S02001

+5V

1

1

FPDAT

2

2

+5V

(YC807)

3

3

FPDIR

4

4

GND

5

5

FPCLK

6

6

GND

7

7

S02025

(YC674)

+5V

1

PD*

2

GND

3

APC RELAY PWB

+5V

1

LONB*

2

LASR*

3

(YC673)

VDO+

4

VDO-

5

LSGND

6

LSGND

(KP-488)

7

GND

8

+24V

5

5

GND

(YC671)

4

4

SCANR*

3

3

SCRDY*

2

2

SCNCLK

1

1

(YC359)

HSCOPN

HSPAP*

UNIT*

+24V

GND

(KP-493)

To HS-20

(YC3)

S02006

S02044

S02005

FUP*

(GND)

S02044

1

2

3

4

5

6

7

1

2

3

1

2

3

4

5

6

7

8

5

4

3

2

1

FOP*

(YC2)

(YC5)

1

1

1

2

2

2

3

3

3

4

4

4

Regist

Clutch

Feed

Clutch

M.Feed

Clutch

Motor

Box Fan

Motor

1

2

3

1

2

3

4

5

6

7

8

5

4

3

2

1

123456789

123456789

MON*

123456789

Centronics

(KP-708)

RS-232C

OPTION I/F

TDK HF70T18*6*10

Main Motor

Fan

Front Panel

(KP-503)

S02037

PD PWB

(KP-483)

APC PWB

(KP-482)

Polygon Motor

VLOW*

S02014

6-8

FS-1750/FS-3750 Series

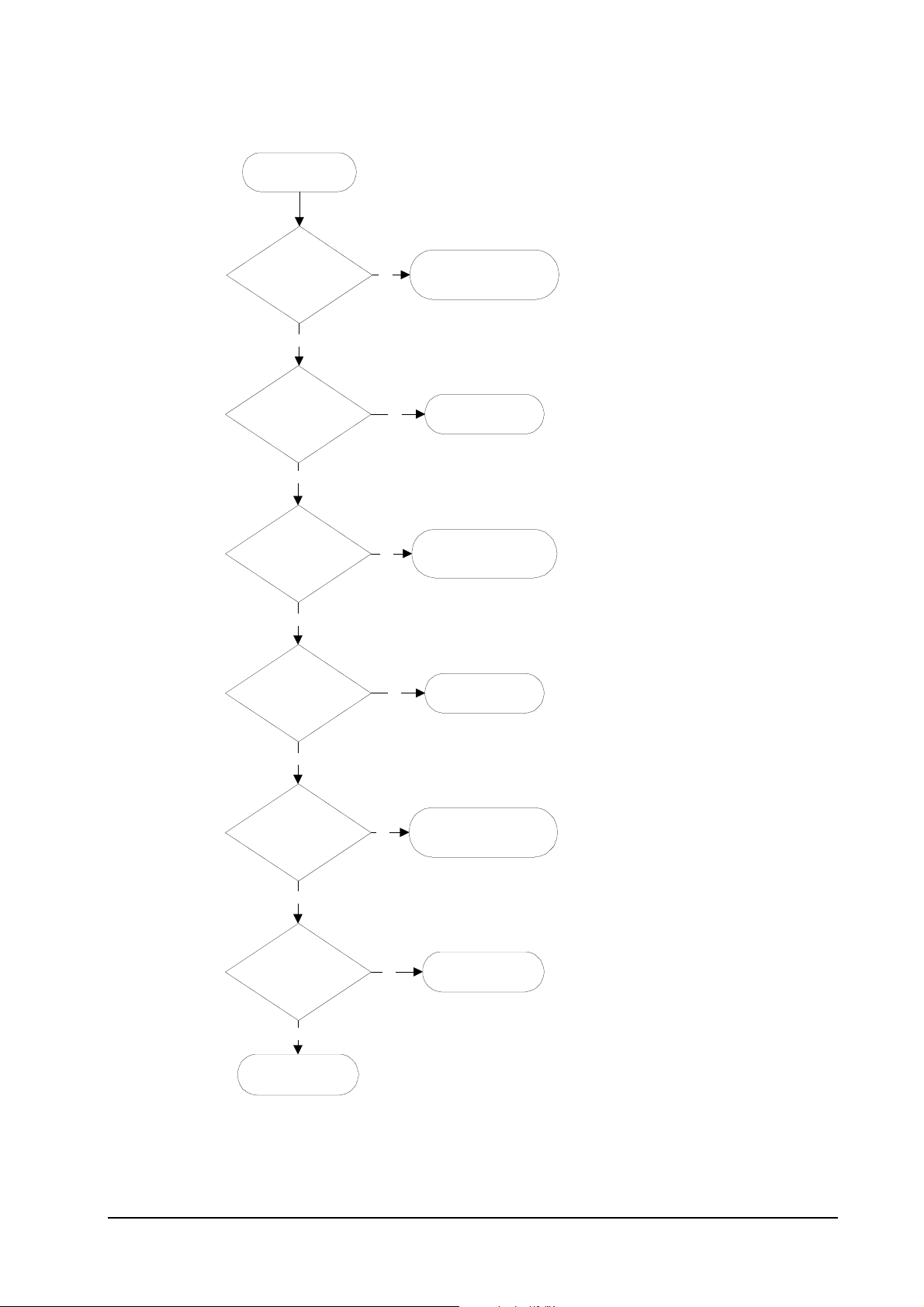

Page 9

Diagnostic

Troubleshooting

User-recoverable errors

The printer automatically executes its self-diagnostic test when it is powered up (displaying Selftest). The sequence and the items to be diagnosed are explained below.

When the printer locates the error with a specific item, it calls for o perator’s attention by showing

the appropriate message on the operator panel display.

The diagnostic test is done on the following systems simultaneously:

• Engine system (

• Controller system (

Flowcharts on the following pages show the order and the items diagnosed in each system.

Note. Diagnostic test is cancelled if one of the user-accessible covers is opened

during the test.

errors)

E

errors)

F

6-9

FS-1750/FS-3750 Series

Page 10

Engine diagnostics flow

Power on

Troubleshooting

User-recoverable errors

1

2

Engine ROM cheksum

OK?

Yes

3

Fuser thermistor OK?

The heater lamp is turned on.

Yes

The scanner polygon motor revolves.

4

Polygon motor OK?

The polygon motor stops revolving.

Yes

The main motor revolves.

The eraser array turns on.

5

Eraser array OK?

No

No

E6 - Engine ROM error

No

No

9

10

E4 - Fuser error

11

E2 - Polygon motor

error

12

E5 - Eraser error

Yes

The eraser array turns off.

6

Main motor OK?

Yes

7

Heater temperature

OK?

The main motor turns off.

Yes

8

Engine is ready.

No

No

13

E1 - Main motor error

14

E4 - Heater error

6-10

FS-1750/FS-3750 Series

Page 11

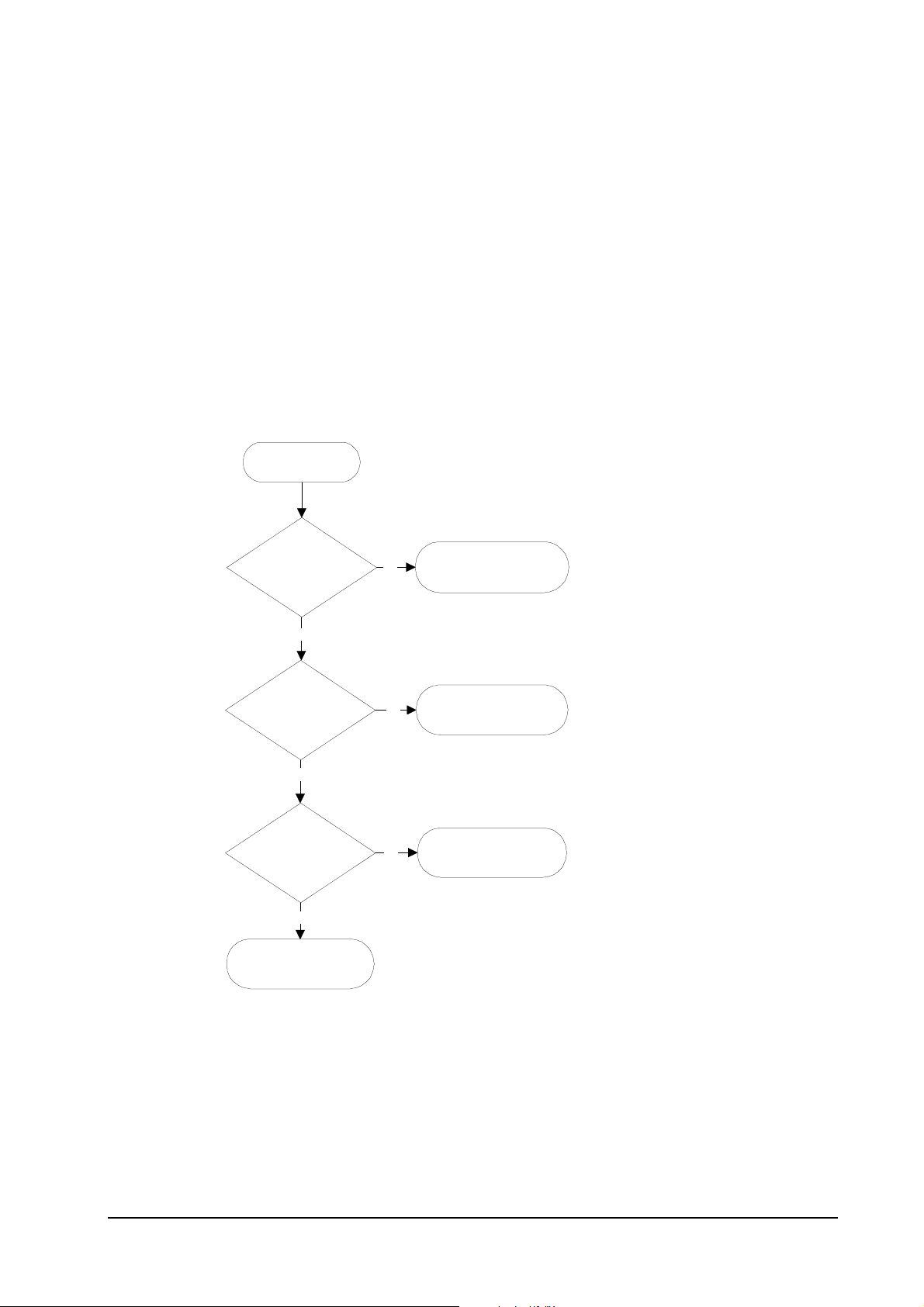

Logic controller diagnostics flow

1

Power on

Troubleshooting

User-recoverable errors

2

System ROM cheksum

OK?

Yes

3

Communication

established between

engine and main

CPUs?

Yes

4

System memory OK?

Yes

5

Controller is ready.

No

No

No

6

F1 - System ROM error

7

E0 - Communication

error

8

F2 - System memory

error

For details on how to react to the results of diagnostics, refer to section

Service errors

on page 6-19.

6-11

FS-1750/FS-3750 Series

Page 12

General error handling

Priority

Each error message has a priority over the others. Thus, if two or more error messages are given

simultaneously, the error message having the highest priority is shown. The priority is as follows

(from the highest to the lowest):

Troubleshooting

General error handling

❂

=Short audio alarm/✺=Long audio alarm

Error message Category Remarks

Call service person …

Call service person F0

I/F occupied

Top cover open

Paper feed unit open

Side cover open

Paper handler cover open

Option stacker cover open

Opt. Feeder 1 (2) rear cover

open

Opt. Stacker unit rear cover

open

Duplex unit rear cover open

Replace Toner/Clean printer❂

Missing Waste-toner bottle

Replace Waste-toner bottle❂

Service error See

Service error See

User-recoverable error If not user-recoverable, see

User-recoverable error If not user-recoverable, see

User-recoverable error If not user-recoverable, see

User-recoverable error When a HS-20/HS-21 is installed.

User-recoverable error When a HS-3E is installed.

User-recoverable error When a PF-20/PF-21 is installed.

User-recoverable error When a SO-6/ST-20 is installed.

User-recoverable error When a DU-20/DU-21 is installed.

User-recoverable error

User-recoverable error If not user-recoverable, see

User-recoverable error

Diagnostics

Diagnostics

“Top Cover Open”

“Paper Feed Unit Open”

“Side cover Open”

“Missing Waste-toner bottle”

section.

section.

, page 6-33.

, page 6-32.

, page 6-34.

False errors -

False errors -

False errors -

False errors -

, page 6-35.

Clean printer … Press CONTINUE❂

Paper jam❂

Remove Opt. Stacker paper❂

Option Stacker paper full❂

Face-down tray paper fill❂

Paper path error❂

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error HS-3E

User-recoverable error FS-3750 only

User-recoverable error

6-12

FS-1750/FS-3750 Series

Page 13

Error message Category Remarks

MEMORY CARD err Insert again

Insert the same MEMORY CARD

Print Cancel?

Memory overflow … Press

CONTINUE❂

Print overrun … Press CONTINUE❂

KPDL error … Press CONTINUE❂

MEMORYCARD err … Press

CONTINUE❂

Opt. ROM error … Press

CONTINUE❂

Troubleshooting

General error handling

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error

Set paper/Press CONTINUE❂

Load paper❂

Add paper✺

Self test

Sleeping

Please wait

PJL OPMSG/STMSG

Processing

Waiting

FormFeed TimeOut

Option interface Error

Toner low TK-20/Clean printer

Warning/Low memory

Battery error/MEMORY CARD

Format error/MEMORY CARD

Warning battery/MEMORY CARD

Ready

User-recoverable error

User-recoverable error

User-recoverable error

-

-

-

-

-

-

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error

User-recoverable error

—

6-13

FS-1750/FS-3750 Series

Page 14

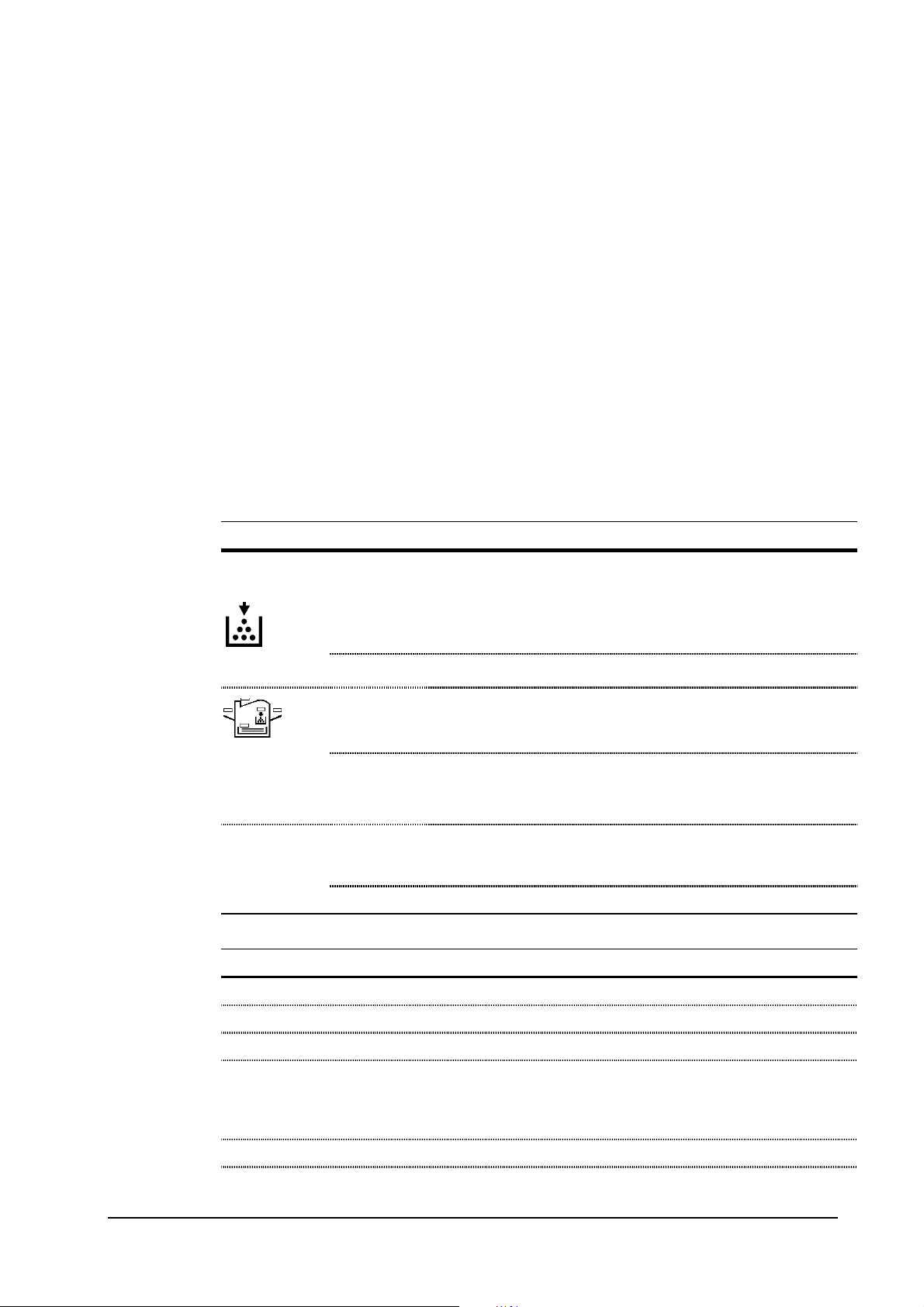

User-recoverable errors

User-recoverable errors do not normally require a service call unless the suggested remedy does

not solve them. The instructions below indicate how to respond to problems indicated by the

operator panel symbolic indicators and by the panel display.

Troubleshooting

User-recoverable errors

Indicator Corrective action

ATTENTION

Message Corrective action

Flashing

Lit

Fast flashing

Slow flashing

Lit

Flashing

Lit

The printer has run low on toner. The toner should be replaced as soon as

possible.

Install a new toner kit. S ee chapter 1.

There is a paper jam. There is a possibility that paper may be jammed at the

point indicated by flashing, open and remove any jammed paper. See

Section

The paper has run out in the paper cassette or multi-purpose tray. Please

insert paper. See Section

This indicates either the current paper feeder or the paper output point.

The printer has insufficient memory available or the printer is warming up

(Pleasewait). Confirm the message indicated on the message display. See

Section

Note the maintenance message on the message display and consult Table

Top cover Open

Side cover Open Open the side cover, then close tightly.

Paper feed unit Open Open the paper feed unit, then close tig htly.

Face-down tray pap er full The face-down tray has become full (approx. 250 pages). Remove all

Add paper Add paper to the paper cassette or multi-purpose tray.

Set paper/Press CONTINUE Add a sheet of paper to the multi-purpose tray (

Open the top cover, then close tight ly.

printed pages from t he face-down tray. When the printer senses that the

face-down tray is empty again, it will continues printing into the facedown tray. (Model FS-3750 only)

6-14

manual mode

FS-1750/FS-3750 Series

), and press

Page 15

User-recoverable errors

Message Corrective action

the CONTINUE key.

Troubleshooting

Load paper

Paper jam Open the top cover or the paper feed unit and correct the paper jam (or

Warning low memory The printer's internal memory is running low due to the number of fonts

Toner low TK-20/Cl ean printer Replace the ton er container using a new t oner kit. See Section …

Replace Toner/Clean pri nter Replace the toner con tainer using a new toner kit. The printer d oes not

Clean printer..Press CONTINUE Please clean the inside of the printer. See Section ...This message will be

ReplaceWaste- toner bottle Replace the old waste toner bottle with the new one which is included in

papersize

The paper size does not match. The size of the paper in the cassette is

different to the size specified by the application software or by

PRESCRIBE II. Either put paper of the specified size into the cassette.

See Section 1.4.If the CONTINUE key is pressed, printing will be

resumed. However, if more than one sheet is to be printed, the same

message will again be displayed from the second sheet onward. It is also

possible to abandon printing by pressing the CANCEL key.

paper mis-feeding in the cassette). See Section …

and macros downloaded. Print a status page to see how much user

memory is left, and try deleting unnecessary fonts and macros. See the

PRESCRIBE II DELF and DELM commands explanation in the

programming manual (CD-ROM).

operate when this message is displayed. See section …

displayed when replacing the toner container after the message

ReplaceTonerCleanprinter has been displayed. After cleani ng the inside of

the printer, press the CONTINUE key and the printer will be ready for

printing.

the TK-20/TK-20H toner kit. The message will also be shown if the waste

toner bottle has become full. The waste toner bottle should be replaced

when the message display eventually shows TonerlowTK-20Cleanprinter.

See Section …

Missing Waste-toner bottle Install the waste toner bottle. See Section ... The printer does not operate

when this message is displayed.

Memory overflow..Press CONTINUEThe total amount of data received by the printer exceeds the pr i nter's

internal memory. Try adding more memory (expansion RAM). Press the

CONTINUE key to resume printing. You can abandon printing by the

CANCEL key.

Print overrun..Press CONTINUE The data transferred to the printer was too complex to print on a page.

Press the CONTINUE key to resume printing. (The page may break in

some pages.)You can abandon printing by the CANCEL key.Note: After

this message has been displayed, Page protect mode will be On. To

maintain optimum use of memory during printing, display >Pageprotect

6-15

FS-1750/FS-3750 Series

Page 16

Troubleshooting

User-recoverable errors

Message Corrective action

from the control panel, and re-select Auto.See the printer’s user’s manual.

MEMORY CARD err/Insertagain The memory card is accidentally removed from the printer's memory card

slot during reading. If you continue reading the memory card, insert the

same memory card into th e sl ot again. The printer again reads it from the

beginning of the data.Note: We recommend that you follow the reading

procedure from the beginning to ensure correct reading of the memory

card.

Insert the same MEMORY CARD You have inserted the wrong memory card when the Insertagain message

was displayed. Remove the wrong memory card from the printer's

memory card slot and i nsert the correct memory card. The printer again

reads it from the beginning of the data.

Format error MEMORY CARD This message appears when the printer is in the ready state and the

memory card is not formatted, and therefore cannot be read or written.

Follow the procedure on Section ... to format the card.

Warning battery MEMORY CARD This message appears when the printer is in the ready state and the battery

in the memory card is low. You can still enter the memory card mode, but

the battery should be changed as soon as possible.

MEMORY CARD err/ ##..Press

CONTINUE

>Read fonts Failed The amount of memory available for the fonts header parts of font is too

I/F occupied This message is displayed when you attempt to use the printer's control

Processing PAR FIT A4 FIT (image FITting) flashes to indicate that a loss of raster data occurred

This message appears when an error occurs during access to the memory

card using the PRESCRIBE II ICCD command or from the printer's

control panel (codes 09 and 11 only). The error is indicated by one of the

numbers ## listed under the Memory card errors which follows.

small to load more fonts. Try deleting unnecessary fonts and macros.

panel to change the environmental setti ngs on the interface from which

data are presently being received.

when the data was compressed to be fitted within the currently available

memory. Flashing FIT extinguishes automatically when the job times out;

the printer receives th e next data from the host computer; or if you press

any key on the printer's control panel. Try adding more memory in the

printer to prevent this error.

Processing PAR 600 A4

ê

Processing PAR 300 A4

Change of the resolution indicator from 600 to 300 (flashing) means that

the job in 600-dpi resolution was not able to run within the currently

available memory. The resolution reverts to 600 dpi automatically when

the job times out; the printer receives the next data from the host

computer; or if you press any key on the printer's control panel. Try

adding more memory in the printer to prevent this error.

6-16

FS-1750/FS-3750 Series

Page 17

Memory card errors

Troubleshooting

User-recoverable errors

Error

code

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

Applicable card

type

SRAM Card size error (An attempt was made to write data of greater than 16 MB in

size.). Reduce the size of the data to be written from the host computer to 16

MB or less; or, a file name could not be found in the memory card.

SRAM No memory card inserted. Insert a pro per memory card.

SRAM/flash Non PCMCIA card. Replace the card with a PCMCIA card.

SRAM Not RAM card. Use a SRAM-type card if you want to write data to an

memory card.

SRAM Memory card battery error. Replace the memory card's internal battery with a

new one.

SRAM Memory card protect error. Release the write protection on the memory card

when you write data to the memory card.

SRAM Non-Kyocera format. Reformat the memory card using MODE SELECT (See

the printer’s user’s manual).

SRAM Partition name error. Follow instructions given attempt in Chapter 2 to

properly name the destination.

SRAM Memory card data full error (An attempt was made to write data exceed i ng

the capacity of the memory card). Abandon the writing operation on the host

computer first. Press CONTINUE key; when the message turns to Waiting,

press FORM FEED key (Ready).

- Reserved

SRAM Data name full (An attempt was made to write more than 127 destination data

names). Press CONTINUE key (Ready).

- Reserved

Flash Erase logic error with flash memory card. Try replacing the memory card.

Flash Non PCMCIA flash card. Replace the card with a PCMCIA flash card.

Flash Unable to write to the flash memory card due to insufficient printer memory.

Reserved

Reserved

Either delete unnecessary macros or fonts stored in the printer, or extend the

printer's available memory.

Meaning

6-17

FS-1750/FS-3750 Series

Page 18

Troubleshooting

User-recoverable errors

Error

code

18

19

Applicable card

type

Flash Writing error. Try replacing the memory card.

-

For details on memory card availability, see section

Reserved

Meaning

Printer specifications

in chapter 1.

6-18

FS-1750/FS-3750 Series

Page 19

Service errors

The printer does not operate when a message beginning with E, F, or C is displayed. The total

numer of pages printed is also indicated. The message is categorized as follows:

Troubleshooting

User-recoverable errors

Message Corrective action

Call service person E

Call service person F

Call service person C

Call service person D

E0 - Communication error

Meaning Suggested causes Corrective action

Communication between the

engine controller and the main

controller is failed.

E1 - Main motor error

Meaning Suggested causes Corrective action

n:123456

n:123456

n: 123456

n: 123456

Mechanical error (n=0, 1, 2, ...). Follow the appropriate instructions provided

in this section.

Controller error (n=0, 1, 2, ...). Follow the appropriate instructions provided in

this section.

Option equipment error (n=0, 1, 2, …). This message pertains to either the

sorter or duplexer. C1 through C3 are relevant to the duplexer; C4 through

to the sorter. See the service manual appropriate to the option used with the

printer.

Engine firmware download error (n=0, 1, 2, …). See section

engine firmware

•

Controller gate array defect

•

Connector failure between the engine and the

main controller

•

Overrun in the engine system, deactivating the

progam flash ROM

in chapter 3.

Verify connector connections.

Replace the engine board and/or

the main controller board.

C6

Updating the

The main motor is overtorqued.

•

Overcurrent in the main motor circuitry due to

an axcessive torque

•

Loose connector

•

Defective gate array on the engine board

•

No response from the main motor due to the

defective motor driver (transistor)

6-19

Follow the flow chart on the next

page.

FS-1750/FS-3750 Series

Page 20

Troubleshooting

User-recoverable errors

Call Service person

1

E1

2

Connect circuit tester

to pin 3 of YC-802 on

KP-504 board.

3

Turn printer power

off, then on.

4

Is pin 3 (MOTOR*) of

YC-802 at low?

Yes

No

8

Connect circuit tester

to pin 10 of YC-801

on KP-504 board.

Turn printer power

5

off, then on again.

6

Square-wave signal

at pin 4/YC-802?

Yes

7

Replace KP-504 board. If

not solved, replace KP-535

board.

No

12

+24V at pin

1/YC-802 on KP-504

board.

Yes

13

Replace main motor. If not

solved, replace harness

between KP-504 and main

9

Is pin 10

(MOTOR*) of

YC-801 at low?

Yes

10

Replace KP-504

board.

No

Replace KP-504 board. If

not solved, replace KP-535

No

11

Replace KP-535

board.

14

board.

6-20

FS-1750/FS-3750 Series

Page 21

E2 - Laser scanner motor error

Meaning Suggested causes Corrective action

The polygon motor does not

deliver a synchronous output (L)

within the predetermined period

of time.

•

Timeout in the predetermined period of lead

time which the scanner motor speed has to be

reached at start up (SCRDY*)

•

Connector insertion error

•

Defective gate array on the engine board

•

Time out dur to the defective scanner motor

driver (transistor)

Troubleshooting

User-recoverable errors

Follow the flow chart on the next

page.

6-21

FS-1750/FS-3750 Series

Page 22

1

Call Service person

E2

2

Connect circuit tester

to pin 4 of YC675 on

KP-488.

Troubleshooting

User-recoverable errors

3

Is pin 4 (SCANR*)

at low?

Yes

4

Turn printer power

off, then on again.

5

Print a status

page.

6

Square-wave signal

at pin 8/YC675 on

KP-488 board?

Yes

7

+24V at pin

1/YC-675 on

KP-488?

No

No

Connect circuit tester

to pin 12 of YC203 on

No

9

KP-535 board.

Turn printer

power off, then

Print a status

Square-wave signal

at pin 8/YC203 on

KP-535 board?

14

on again.

15

page.

16

Yes

10

Turn printer

power off, then

on again.

No

Print a status

page.

12

Is pin 12

(SCANR*) of

YC-203 at low?

Yes

11

No

Yes

8

Replace scanner unit.

17

+24V at pin

13/YC203 on KP-535

board?

Yes

18

Replace harness (S02040)

between KP-535 board ans

scanner unit.

6-22

No

13

Replace KP-535

board.

FS-1750/FS-3750 Series

Page 23

E3 - Laser beam detection error

Meaning Suggested causes Corrective action

Beam detection is failed. The

photo detector board does not

deliver a synchronous output (L).

•

No beam hit due to the laser diode defect

(PD*)

•

Improper connector insertion

•

Soiled/defective beam detector (pin-photo

diode) sensor

•

Defective safety lock

•

Unoperative gate array input port

Troubleshooting

User-recoverable errors

Follow the flow chart on the next

page.

6-23

FS-1750/FS-3750 Series

Page 24

Call Service

person

E3

Connect circuit

tester to pin 13

of YC675/KP488

board.

Turn printer

power on, then

on.

Print a status

page.

Troubleshooting

User-recoverable errors

Is pin 13

(LASR*) at

low?

Yes

Turn printer power

off, then on again.

Print a

status page.

Low-level pulse

at pin 10/YC675

on KP-488

board?

Yes

Turn printer power

off, then on again.

Print a

status page.

No

Connect circuit

tester to pin 1 of

YC203 on KP-535

No

scanner unit.

board.

Replace

Turn printer

power off, then

on again.

Low-level pulse

at pin 6/YC203

on KP-535

board?

Yes

Replace

KP-535 board.

Print a

status page.

Is pin 1

(LASR*) at

low?

Yes

Replace harness

between KP-535 and

scanner unit.

No

Replace harness

between KP-535 board

and scanner unit.

No

Replace

KP-535 board.

6-24

FS-1750/FS-3750 Series

Page 25

E4 - Fuser heater error

The fuser heater is not intact due

to disconnection or the circuit

failure.

Troubleshooting

User-recoverable errors

Meaning Suggested causes Corrective action

•

Blown-out thermistor

•

Improper connector insertion

•

Blown-out halogen heater

•

Blown-out thermostat

•

Comparator defect on the engine board

•

Defective engine CPU (input port)

•

Defective gate array (input/output port

operation)

Follow the flow chart on the next

page.

6-25

FS-1750/FS-3750 Series

Page 26

Call Service

person

E4

"E4" shown

immediately

after power up?

Yes

Troubleshooting

User-recoverable errors

No

Turn printer power

off and remove

power cable.

Measure DC resistance

between pins 5 and

8/YC721 on KP-499

(fuser) board.

Less than 1MΩ?

Yes

Replace KP-535 board. If not

solved, replace KP-494 board. If

not solved, replace harness

between KP-499 and KP-492

boards.

No

Replace fuser

unit.

Heater temp.

persists at

210°C?

No

Replace

fuser unit.

Measure fuser

roller

temperature.

180-220°C

?

Yes

End

Yes

Replace KP-535

board.

No

Replace KP-535 board.

If not solved, replace

power supply.

6-26

FS-1750/FS-3750 Series

Page 27

E5 - Eraser error

The eraser is blown out or the

power supply does not reach to

the eraser.

Troubleshooting

Print quality problems

Meaning Suggested causes Corrective action

•

Blown-out LED chip(s)

•

Connector insertion error

•

Defective gate array (input/output port)

Follow the flow chart on the next

page.

6-27

FS-1750/FS-3750 Series

Page 28

Call Service

person

E5

Replace drum

unit.

Troubleshooting

Print quality problems

Measure DC

resistance between

pins 1 and 13/YC741

on KP-500 board.

Infinity?

Yes

Replace eraser assembly in

drum unit. If not solved,

replace KP-500 board.

No

Replace KP-535 board. If not

solved, replace KP-494

board. If not solved, replace

KP-505 board.

6-28

FS-1750/FS-3750 Series

Page 29

E6 - Flash ROM error

Checksum is erroneous with the

flash ROM.

Troubleshooting

Print quality problems

Meaning Suggested causes Corrective action

•

Data readout error on the flash ROM Replace the engine board.

E9 - Toner motor error

The toner motor is overtorqued.

Meaning Suggested causes Corrective action

•

Overcurrent in the toner motor circuitry due to

an axcessive torque

•

Loose connector

•

Defective gate array on the engine board

•

Defective toner motor overcurrent detector

Follow the flow chart on the next

page.

6-29

FS-1750/FS-3750 Series

Page 30

Call Service

person

E9

Replace with a new

developer unit.

Troubleshooting

Print quality problems

E9 goes

out?

Yes

End

No

Replace KP-535

board.

6-30

FS-1750/FS-3750 Series

Page 31

F0 - Front control panel error

Meaning Suggested causes Corrective action

Troubleshooting

Print quality problems

Communication is failed between

the front panel and the main

controller.

F1 - System ROM error

Meaning Suggested causes Corrective action

Checksum is failed with

EPROMs on the main controller

board.

F2 - Main memory error

Meaning Suggested causes Corrective action

Checksum is failed with the

RAM on the main controller

board.

F3 - General failure

Meaning Suggested causes Corrective action

- Replace the main controller

board. To remove the main

controller board, see page 2-9.

- Replace the main controller

board. To remove the main

controller board, see page 2-9.

- Replace the main controller

board. To remove the main

controller board, see page 2-9.

Miscellaneous failure with the

main controller, other than F0,

F1, and F3, above.

- Turn printer power off, then on

again. If not solved, replace the

main controller board. To remove

the main controller board, see

page 2-9.

6-31

FS-1750/FS-3750 Series

Page 32

False errors - “Paper Feed Unit Open”

Troubleshooting

Print quality problems

6-32

FS-1750/FS-3750 Series

Page 33

False errors - “Top Cover Open”

Troubleshooting

Print quality problems

6-33

FS-1750/FS-3750 Series

Page 34

False errors - “Side cover Open”

Troubleshooting

Print quality problems

6-34

FS-1750/FS-3750 Series

Page 35

False errors - “Missing Waste-toner bottle”

Troubleshooting

Print quality problems

6-35

FS-1750/FS-3750 Series

Page 36

Print quality problems

Print quality problems range from uneven tone to completely blank output. The troubleshooting

procedure for each type of problem is given below.

Completely blank printout

Troubleshooting

Print quality problems

Check the developer unit.

Check main charging potential.

Check the laser scanner.

All-black printout

Check the main charger unit

installation.

• Check that the developer unit is inserted co rrectly

• Check that the developer 's connector is connected

properly.

• Check that toner is adhered around the developing

roller. If no toner appears to be on the roller, try

feeding toner into the developer using the manner

described in chapter 3 (See page 3-13).

• Check the main charging output on the HV board.

This requires removal of the left side cover and the

test equipment: For information, contact Kyocera.

Replace the HV board if high voltage potential is not

available on the board.

• The scanner components within the scanner may be

disordered. Note that the laser scanner is concealed

to protect the components which are susceptible to

dust. It should not be disassembled execept within a

dust-free chamber. Replace the scanner unit if

necessary.

• Open the printer side cover and check that the main

charger unit is correctly seated. To do this, take o u t

the main charger unit from the printer; th en reinstall

it carefully.

Check the grid plate (the mesh

metal bottom part of the charger

unit).

Check the drum bias.

• The grid plate must be flat and fit horizontally in

place. Replace the main charger unit if necessary.

• Make sure the bias from the HV board is correctly

arrived at the drum unit.

6-36

FS-1750/FS-3750 Series

Page 37

Troubleshooting

Print quality problems

Dropouts

Check high voltage potential at the

HV board.

Note the spacing of the defects. Use

the Repetitive defect gauge on

page6-43.

• Check the higi-voltage output on the HV board. This

requires removal of the left side cover and the test

equipment: For information, contact Kyocera.

Replace the HV board if high voltage potential is not

available on the board.

• If the defects occur at regular intervals of 63 mm, the

problem may be a dirty transfer roller. Clean or

replace the tranfer roller.

• If the defects occur at regular intervals of 94 mm, the

problem may be a damaged drum unit or fuser roller.

Replace the drum unit or fuser unit accordingly.

Try changing the transfer bias

potential (Normal or Thick).

Check paper for property.

Check the paper chute installation.

Check the transfer roller

installation.

Check the tranfer bias potential.

• Use the

panel. For details, refer to the user manual

accompanying the printer.

• Paper with rugged surface or dump tends to cause

this type of failure.

• The paper chute (the metallic fixture provided

between the transfer roller and the fuser unit for

antistatic purpose) must not be fit loose. Press the

paper chute down firmly if necessary.

• The transfer roller must be supported by the axle

holder at the both ends. Clean the axle holder to

remove oil and debris. Replace the transfer roller if

necessary.

• Check the transfer bias output on the HV board. This

6-37

MODE SELECT

key on the printer’s control

FS-1750/FS-3750 Series

Page 38

Black dots

Troubleshooting

Print quality problems

requires removal of the left side cover and the test

equipment: For information, contact Kyocera.

Replace the HV board if high voltage potential is not

available on the board.

Note the spacing of the defects. Use

the Repetitive defect gauge on

page6-43.

Horizontal streaks

Check drum ground.

Check main charger contacts.

• If the defects occur at regular intervals of 94 mm, the

problem may be a damaged drum unit or fuser roller.

Replace the drum unit or fuser unit accordingly.

• If the defects occur at random intervals, the toner

may be leaking from the drum unit. Replace the

drum unit.

• If the defects occur at regular intervals of 38 mm, the

problem may be a toner lump on the developing

roller. Remove the lump using a soft brush. Note that

the developing roller surface is fragile: Contact

Kyocera for type of the brush to use.

• The drum axle and its counter part—drum grounding

tab in the printer must be in a good contact. If

necessary, apply a small amount of electroconductive grease onto the tab. See Kyocera for

which type of grease to use.

• Take out the main charger unit; check the electric

terminals to see if they are clean.

The drum unit may be defective.

• Replace the drum unit.

6-38

FS-1750/FS-3750 Series

Page 39

Black vertical streaks

Troubleshooting

Print quality problems

Contaminated main charger wire.

Check the drum surface for a streak

of toner laying lengthwise.

Defective developer unit.

Unsharp printing

Check contamination on the main

charger wire and the grid.

• Clean the main charger wire by pulling the green

colored cleaning knob in and out several times.

• A streak of toner remaining on drum after printing

means that the cleaning blade in the drum unit is not

working properly. Replace the cleaning blade; or

replace the drum unit.

• Replace the developer unit.

• Clean the main charger wire by pulling the green

color main charger wire cleaner know in and out

several times.

Check paper for property.

Check the paper chute installation.

• Paper with rugged surface or dump tends to cause

this type of failure.

• The paper chute (the metallic fixture provided

6-39

FS-1750/FS-3750 Series

Page 40

Troubleshooting

Print quality problems

between the transfer roller and the fuser unit for

antistatic purpose) must not be fit loose. Press the

paper chute down firmly if necessary.

Try changing the transfer bias

potential (Normal or Thick).

Check the transfer roller

installation.

Check the tranfer bias potential.

Check EcoPrint setting.

Refresh drum.

Grey background

• Use the

panel. For details, refer to the user manual

accompanying the printer.

• The transfer roller must be supported by the axle

holder at the both ends. Clean the axle holder to

remove oil and debris. Replace the transfer roller if

necessary.

• Check contamination on the main charger wire and

the grid.

• The EcoPrint mode can provides faint, unsharp

printing because it acts to conserve toner for draft

printing purpose. For normal printing, turn the

EcoPrint mode off by using the

on the printer’s control panel.

• Try cleaning the drum surface using the printer’s

built-in cleaning system specifically prov id ed for this

purpose. For details, refer to page6-45.

MODE SELECT

key on the printer’s control

MODE SELECT

key

Check contamination on the main

charger wire and the grid.

Check the grid plate (the mesh

metal bottom part of the charger

• Clean the main charger wire by pulling the green

color main charger wire cleaner know in and out

several times.

• The grid plate must be flat and fit horizontally in

place. Replace the main charger unit if necessary.

6-40

FS-1750/FS-3750 Series

Page 41

unit).

Troubleshooting

Print quality problems

Check the print density setting.

Check the surface potential of the

drum.

The developer unit may be

defective.

Dirt on the top edge or back of the paper

• The print density may be set too high. Try adjusting

the print density using the

details refer to the printer’s user manual.

• The drum potential should be approximately 240V.

These values may vary depending on production lots

and the measurement is possible only by using the

jig and tool specifically designed for this purpose:

See Kyocera for details. The drum unit will have to

be replaced if it will bear the values far out of the

allowable range.

• If a developer unit which is known to work normally

is available for check, replace the developer

currently used in the printer with it. If the symp tom

disappears, replace the developer unit with a new

one.

MODE SELECT

key. For

Check toner contamination in

various parts.

Check the transfer roller.

Characters out of position

• Dirty edges and back of the paper can be caused by

toner accummulated on such parts as the paper chute,

paper transportation paths, the bottom of the

developer unit, and the fuser inlet. Clean these areas

and parts to remove toner.

• If the transfer roller is contaminated with toner, clean

the transfer roller using a vacuum cleaner; or by

continuously printing a low-density page until the

symptom has faded away.

6-41

FS-1750/FS-3750 Series

Page 42

Troubleshooting

Print quality problems

Check the file or program.

Check the cassette size sensors (if

paper is fed from the cassettes).

• Check the paper setting in the application. Also, if

the PRESCRIBE command is used, check if the

syntax and parameters are correct.

• Check the switches on the KP-498 board. Also,

check the size settings of the paper cassettes (see

page 6-46).

6-42

FS-1750/FS-3750 Series

Page 43

Troubleshooting

Print quality problems

REPETITIVE DEFECTS GAUGE

Use the following measurements for checking repetitive occurrences on the printed page. See the

above section for details.

FIRST OCCURRENCE OF DEFECT

REGISTRARION ROLLER—37.5mm

DEVELOPING ROLLER—38.0mm

TRANSFER ROLLER—63mm

DEVELOPER PULLEY—64.7mm

DRUM UNIT

FUSER PRESS ROLLER

FUSER HEAT ROLLER

—94.0mm

6-43

FS-1750/FS-3750 Series

Page 44

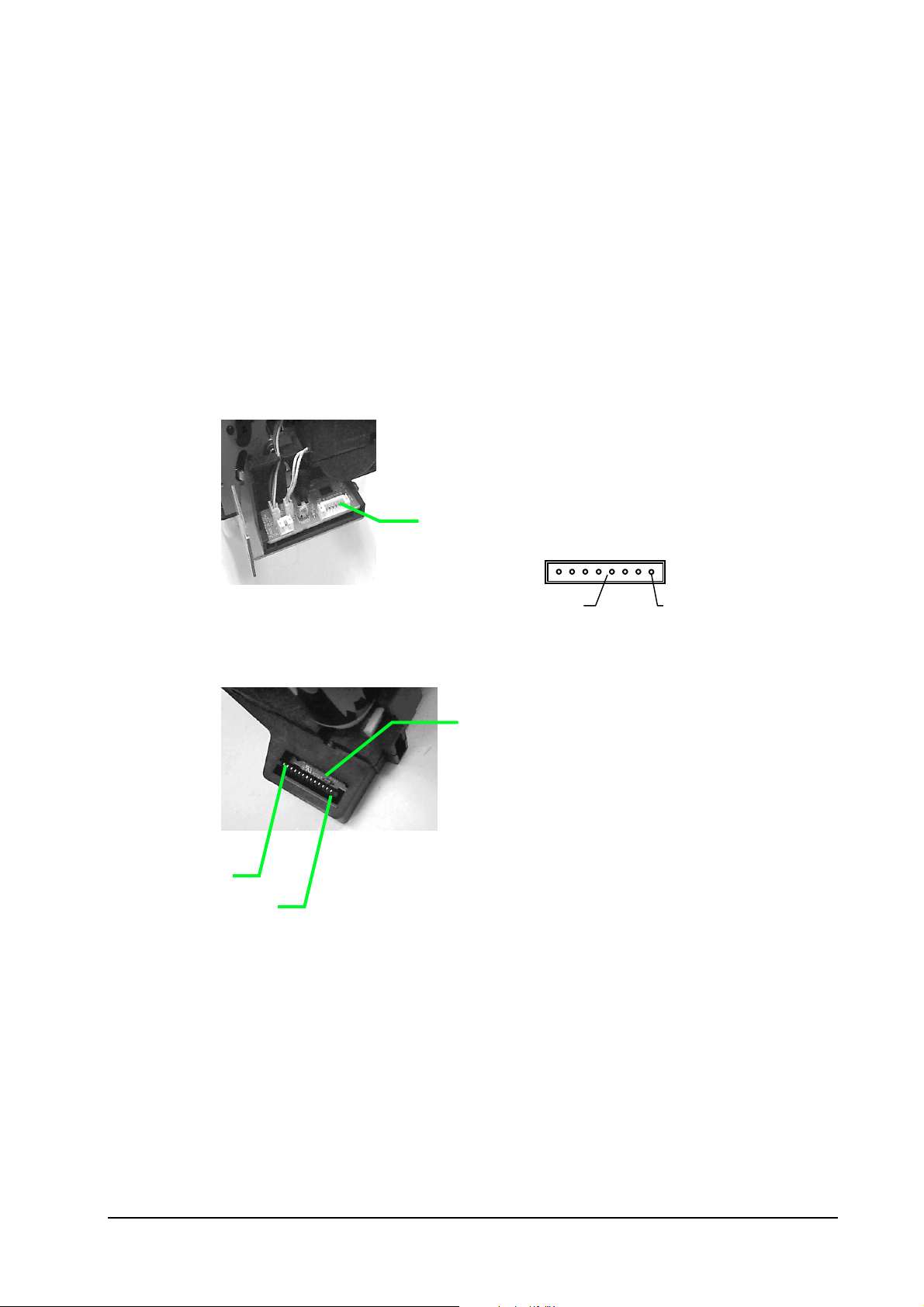

CHECKING CASSETTE SIZE SENSORS

Troubleshooting

Print quality problems

The printer tells the size of paper (cassette) to be fed by means of three sensors on the

KP

board. These sensors (switches) are activated by the pushing pegs on paper cassettes in different

paper sizes. If the sensors are not correctly activated in a correct matrix of activation, paper jam

or printing defects like above may occur.

Cassette size

sensor pushing

rods

Paper size SW701 SW702 SW703

B5 On Off Off

A5 Off On Off

A4 On On Off

Letter Off Off On

Legal On Off On

-498

Cassette not present On On On

Custom Off On On

6-44

FS-1750/FS-3750 Series

Page 45

Drum cleaning

Troubleshooting

Print quality problems

This mode is meant to provide a manual means of drum cleaning in additioin to the regular

cleaning procedure made automatically in a photographics cycle. In this mode, the drum turns for

the period of approximately three minutes with no main charging dispersed over the drum. Since

the cleaning blade in the drum continuously attempt to scrape soils and paper dust on its surface,

the drum can be brought in a clean state.

To clean the drum using this feature, peform the following, top to bottom:

press

press

press

press

press

press

press

press

The drum then starts turning and stops after approx. 3 minutes. The printer reverts to Ready.

MODE

✚

repeatedly until:

4

✚

repeatedly until:

4, the display should show:

✚

, the display should show:

ENTER

ENTER

, the display should show:

then,

Others>

then,

>Service>

>>Developer

>>Drum

?

6-45

FS-1750/FS-3750 Series

Loading...

Loading...