Page 1

Service Manual

LASER PRINTER

Ecosys FS-1200

Page 2

FS-1200 Service Manual

©Kyocera Corporation 1996—1999 All rights reserved. Export Edition

Conventions/Preface

Notice

The information in this manual is subject to

change without notification. Additional

pages may be inserted in future editions.

The user is asked to excuse any technical

inaccuracies or typographical errors in the

present edition.

No responsibility is assumed if accidents

occur while the user is following the

instructions in this manual. No

responsibility is assumed for defects in the

printer's firmware.

The contents of this manual are protected

by copyright. No part of this manual may

be reproduced or copied by any means

without the permission of the copyright

holder. The printer's firmware (contents of

its read-only memory) is similarly

protected by copyright.

Trademark Notice

PRESCRIBE is a registered trademark of

Kyocera Corporation. PRESCRIBE II,

KIR, Kyocera Image Refinement, and

Ecosys are trademarks of Kyocera

Corporation.

Diablo 630 is a product of Xerox

Corporation. IBM Proprinter X-24E is a

product of International Business Machine

Corporation. Epson LQ-850 is a product of

Seiko Epson Corporation. HP LaserJet IV,

5Si, 5M, and HP-7475A are product of

Hewlett-Packard Company. HewlettPackard, PCL, and HP-GL are registered

trademarks of Hewlett-Packard Company.

Centronics is a trade name of Centronics

Data Computer Corp.

PowerPC is a trademark of International

Business Machines Corporation.

EnergyStar is a U.S. registered mark.

This Kyocera page printer uses

PeerlessPrintXL to provide the HP LaserJet

compatible PCL6 language emulation.

PeerlessPrintXL is a trademark of The

Peerless Group, Redondo Beach, CA

90278, U.S.A.

This product was developed using the

TM

Tornado

Real Time Operating System

and Tools from Wind River Systems.

Contains UFST

TM

and MicroType® from

Agfa Corporation.

Warning:

This equipment has been certified to

comply with the limits for a Class B

computing device, pursuant to Subpart J of

Part 15 of FCC Rules. Only peripherals

(computer input/output devices, terminals,

etc.) certified to comply with the Class B

limits may be attached to this equipment.

Operation with non-certified peripherals is

likely to result in interference to radio and

TV reception.

Check that the cable is wired correctly. If

an IBM communication adapter cable type

1502067 is used, it will have to be

resoldered the wiring at the printer end of

the cable. The procedure is as follows.

ii

Page 3

Conventions

Throughout this manual, the following conventions are used:

Color is available when viewed online to emphasize important items.

CAPITAL letters are used to name printer parts and assemblies.

Conventions/Preface

Italic letters refer related chapters or sections or documentations.

Bold letters are also used for emphasis wherever italics may cause a confuse.

This symbol followed by

which, if ignored, could result in personal injury, and/or irrevocable damage to the printer.

When followed by

precautions which, if ignored, could result in damage to the printer.

Warning

Caution

denotes that the following paragraph(s) includes precautions

this symbol denotes that the following paragraph(s) include the

iii

Page 4

About the chapters ...

Unless otherwise specified, the contents of this manual apply to all printer models of Ecosys FS-

1200.

The manual is comprised of the followin g chapters:

Conventions/Preface

Chapter Contents

One - Product information Includes printer specifications, product appearances, safety

Two - Installation and operation Provides how to install and operate the printer.

Three - Maintenance Instructs maintenance to be conducted periodically on the printer.

Four - Operation overview Explains basic functions of the printer methcnism including engine

Five - Disassembly Instructs removal of parts for replacing them.

Six - Troubleshooting Provides countermesure to follow for troubleshooting.

Appendix Contents

A - Printer interface Information regarding the printer’s parallel and serial (Optional)

B - Status page Explains detail of the service information on the status page.

C - Paper specifications Explains how to choose the right paper.

Separate Contents

Parts catalog Information o f parts for ordering.

The manual will be supplemented with chapters or appendixes accordingly.

information, etc.

and logic controller systems.

interfaces.

iv

Page 5

Conventions/Preface

REVISION HISTORY

Version Date Replaced pages Remarks

1.00 1-Oct-99 -

This document was created using Microsoft® Word 95. To obtain its intended view of the

document, the following fonts must be installed in addition to those already installed under

Windows 95 by default: Century Schoolbook (regular/italic/bold), Humanist 777

(regular/italic), and Humanist 777 Black (black).

VISIT US AT OUR INTERNET HOME PAGE:

http://www.kyocera.com

v

Page 6

Conventions/Preface

vi

Page 7

Chapter One PRODUCT INFORMATION

Page 8

Chapter One

Printer identification labeling 1-3

Printer Specifications 1-4

Recommended flash cards 1-7

Front and rear views 1-8

Front view (FS-1700/3700) 1-8

Paper feed unit 1-9

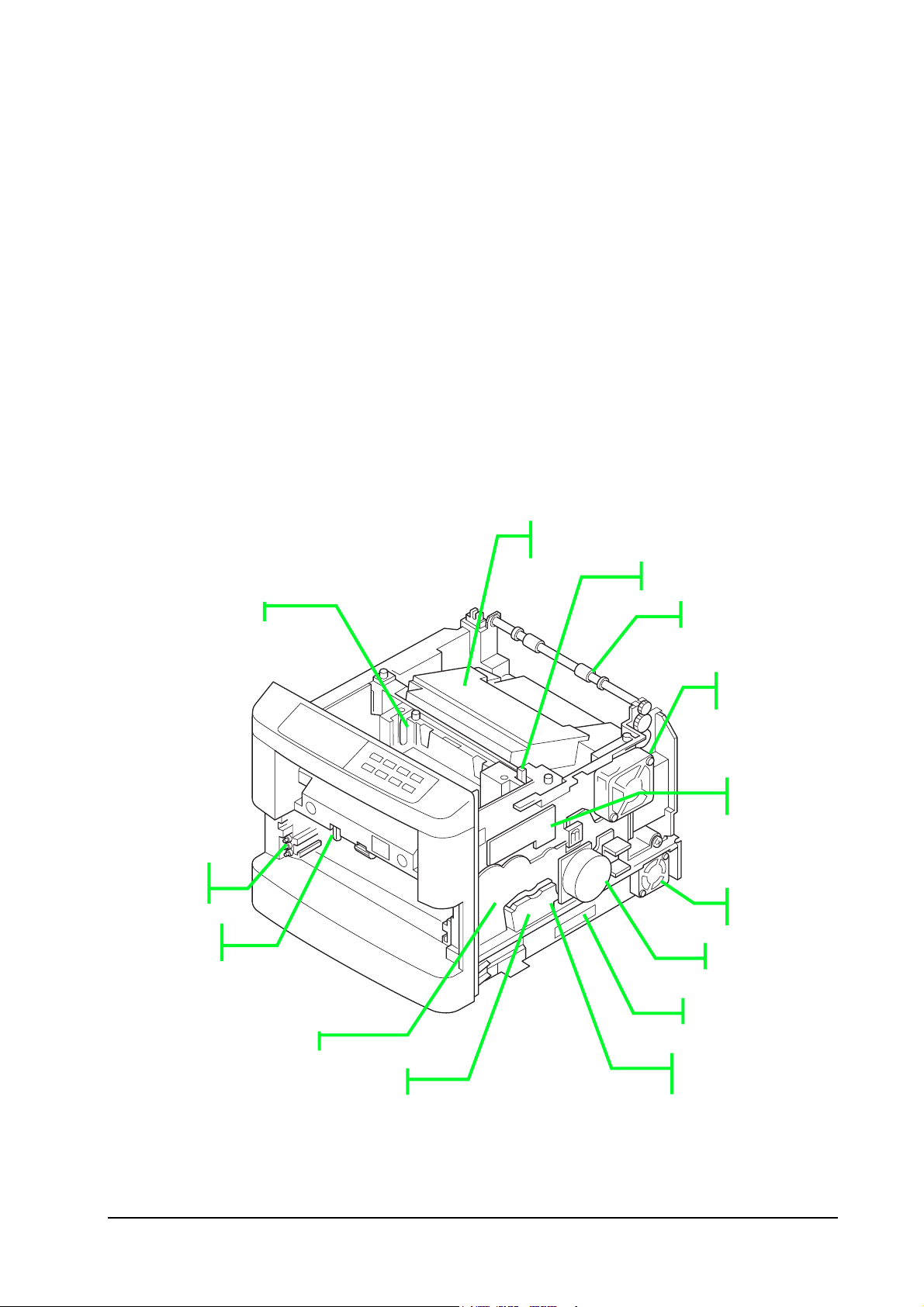

Internal assemblies ➊ 1-10

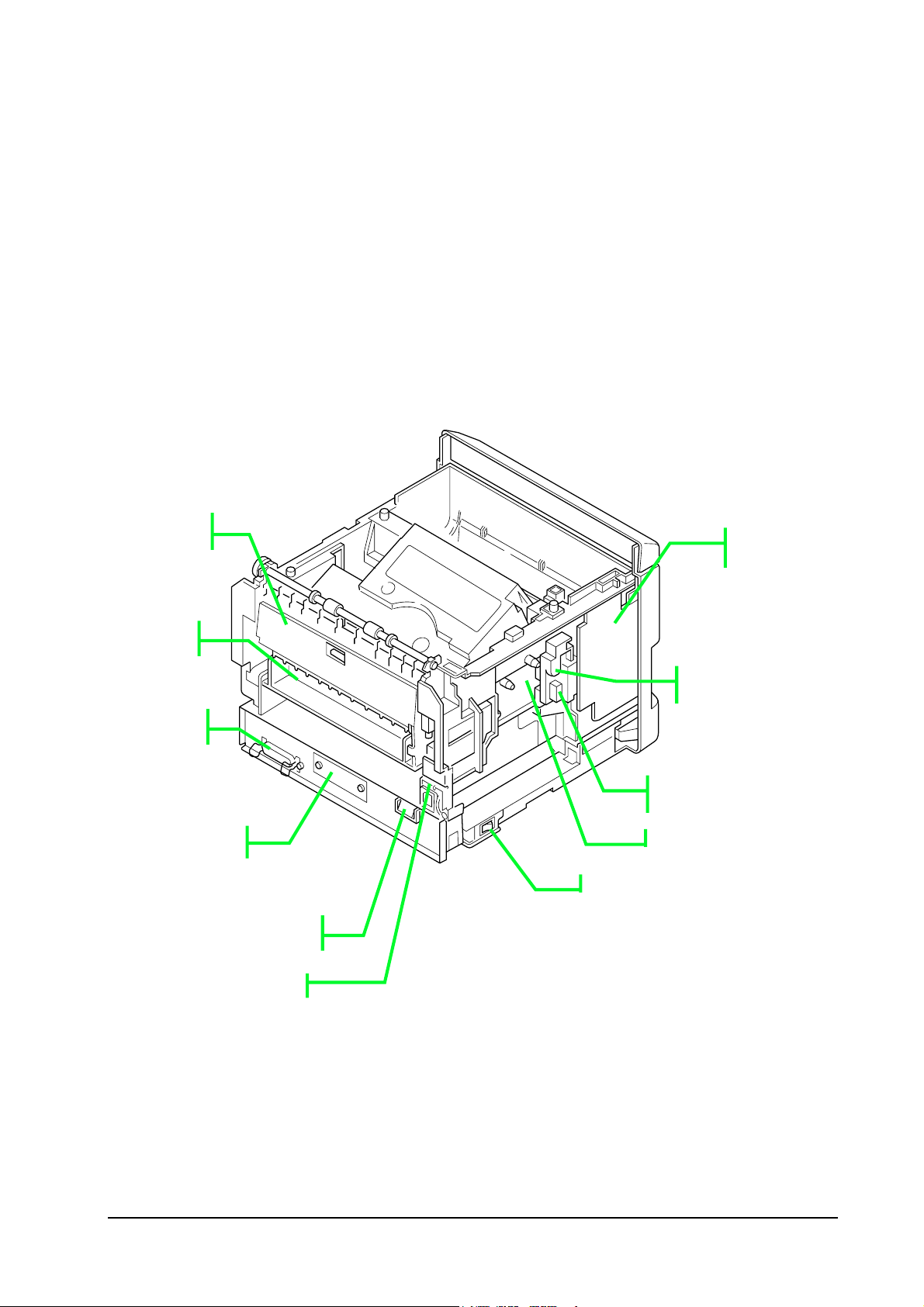

Internal assemblies ➋ 1-11

Safety information 1-12

Laser safety 1-12

Laser notice 1-12

CDRH regulations 1-13

Ozone concentration 1-13

FCC notice 1-13

Important note on the interface connectors 1-15

Canadian Department of Communications compliance statement 1-16

Avis de conformité aux normes du ministère des Communications du Canada 1-16

ISO 7779 1-16

Environmental requirements 1-17

Environmental conditions 1-17

Clearance 1-19

Places to avoid 1-20

Note on power 1-21

CONTENTS 1

About the toner 1-23

Toner container handling 1-23

Toner storage 1-24

Page 9

Printer identification labeling

The printer bears its model and serial numbers at its back.

The label also contains other safety precautions.

Product information

Printer identification labeling

Europe/Asia version

US/Canada version

1-3

FS-1200

Page 10

Printer Specifications

ENGINE

Specification

Product information

Printer Specifications

Print method Electrophotography laser scan

Print speed (A4 or letter, when printing

multiple copies of the same page)

Resolution (dpi) 600 horizontal/600 vertical

Smoothing KIR 2 (2400 horizontal/600 vertical)

First print (A4 or letter), depends on

input data

Warm-up time at 23°C or 68°F 55 seconds or less

Maximum duty cycle 20,000 pages/month

Laser diode Visible laser

Main charger Scorotron wire

Transferring Biased roller

Separation Charging

Drum cleaning Blade

Drum discharging LED array

Fuser Heat and pressure

Paper Plain paper (See

Capacity of paper feed tray 250 sheets

Capacity of output trays 250 sheets

12 pages/minute

15 seconds or less

Appendix B

)

1-4

FS-1200

Page 11

CONTROLLER

Specification

CPU Power PC 71MHz RISC Proccesor

System ROM size 4MB (16 Mb×2)

Resident font ROM size 4MB (32 Mb×1)

Option fonts ROM 16Mbits (PK-4)

Main RAM 4MB (2 MB×2)

Additional RAM (SIMM) 64MB maximum

Memory card SRAM or flash, JEIDA 4.2/PCMCIA 2.1

Recommended flash cards

See

in this chapter.

Product information

Printer Specifications

Host interface Parallel/option

Page description language Prescribe II

Standard emulation modes HP LaserJet 5M, HP LaserJet 5Si, IBM

WEIGHT AND DIMENSIONS

Specification

Width 37.3 cm (14.7”)

Height 31 cm (12.2”)

Depth 38.3 cm (15.1”)

Weight (Main unit) 14.3 kg (30 lb.)

Proprinter X24E, Diablo 630, Epson LQ850, line printer

1-5

FS-1200

Page 12

POWER REQUIRMENTS

Specification

Voltage requirements US/Canada 120V AC ±10%, 60Hz ±2%

Europe/Asia 220-240V AC±10%, 50 or 60Hz ±2%

Watts Maximum 580 W

Printing 311 W

Standby 105 W

Sleeping 16 W

Maximum current US/Canada 5 A

Europe 2.8 A

Product information

Printer Specifications

ENVIRONMENTAL REQUIREMENTS

Specification

Operating temperature and humidity

Maximum altitude 2,000 m (6,500 feet)

Noise emission 50 dB maximum/39 dB at standby

10°C to 32.5°C (50°F to 90.5°F), 20

to 80% RH

1-6

FS-1200

Page 13

Product information

Printer Specifications

Recommended flash cards

FS-1200 Series printers provide support for a JEIDA/PCMCIA category of memory card in both

SRAM and flash types.

Following is a list of makes and models of flash cards recommended for use with the printers.

Note that the flash card to be used should be operable on 5V

DC

.

Model Capacity

AMD AmC001CFLKA 1 MB

AmC002CFLKA 2 MB

AmC004CFLKA 4 MB

AmC004DFLKA 4 MB

AmC008DFLKA 8 MB

AmC010CFLKA 10 MB

Fujitsu MB98A81063 1 MB

MB98A81183 2 MB

MB98A81273 4 MB

MB98A81373 8 MB

MB98A81473 16 MB

Panasonic BN-02MHF4C (CC) 2 MB

BN-04MHF4C (CC) 4 MB

Intel Series 2+/iMC004FLSP 4 MB

Centennial FL01M-20-11114-03 1 MB

FL02M-20-11114-03 2 MB

1-7

FS-1200

Page 14

Front and internal views

Front view

Product information

Front and internal views

Paper exit roller

Power switch

Waste

toner/drum

access door

Front operator

panel

Paper feed unit

release lever

Paper cassette

1-8

Paper size indicator

FS-1200

Page 15

Paper feed unit

Product information

Front and internal views

Paper size

indicator

Maulti-purpose

tray

Paper feed unit

Paper feed unit

release lever

1-9

Memory card slot

FS-1200

Page 16

Product information

Front and internal views

Internal assemblies

Developer unit

➊

Laser scanner

assembly

Toner container release lever

Paper exit roller

Upper frame

venti fan

Relay board

KP-504

Cassette paper

size switches

Manual feed

actuator

Drive assembly

Feed roller clutch

1-10

Controller venti

fan

Main motor

Memory card slot

Registration

roller clutch

FS-1200

Page 17

Product information

Front and internal views

Internal assemblies

Rear paper

jam access

Face-up

paper

Parallel

interface

Option

➋

High voltage

board

Main charger

terminal

Drum connector

YC821

Face-up stacker

connector

AC inlet

1-11

FS-1200

Page 18

Product information

Front and internal views

Safety information

Laser safety

This printer is certified as a Class 1 laser product under the U.S. Department of Health and Human

Services (

Safety Act of 1968. This means that the printer does not produce hazardous laser radiation. Since

radiation emitted inside the printer is completely confined within protective housings and external

covers, the laser beam cannot escape from the printer during any phase of user operation.

) Radiation Performance Standard according to Radiation Control for Health and

DHHS

Laser notice

The printer is certified in the U.S. to conform to the requirements of

DHHS

21

Subchapter for

CFR

Class I (1) laser products, and elsewhere is certified as a Class I laser product conforming to the

requirements of

IEC

825.

Class I laser products are not considered to be hazardous. The printer contains internally a Class

IIIb (3b) laser that is nominally a 5 milliwatt laser operating in the wavelength region of 780

nanometers. The laser system and printer are designed so there is never any human access to laser

radiation above a Class I level during normal operation, user maintenance, or prescribed service

condition.

Laser product labels are located on top of the laser scanner:

Laser scanner

1-12

FS-1200

Page 19

Product information

Front and internal views

Warning - Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

CDRH regulations

The Center of Devices and Radiological Health (

) of the U.S. Food and Drug Administration

CDRH

implemented regulations for laser products on August 2, 1976. These regulations apply to laser

products manufactured after August 1, 1976. Compliance is mandatory for products marketed in

the United States. A label indicating compliance with the

regulations must be attached to

CDRH

laser products marketed in the United States.

Ozone concentration

Laser printers generate ozone gas (O

) which may concentrate in the place of installation and

3

cause an unpleasant smell. To minimize the concentration of ozone gas, we recommend that the

laser printer not be installed in a confined area lacking ventilation.

FCC notice

This device complies with Part 15 of the

Rules. Operation is subject to the following two

FCC

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the

Rules. These limits are designed to provide reasonable protection

FCC

against harmful interference in a residential installation. Th is equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communication. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

1-13

FS-1200

Page 20

Product information

Front and internal views

-

Reorient or relocate the receiving antenna.

-

Increase the separation between the equipment and receiver.

-

Connect the equipment into an ou tlet o n a circuit different from that to which the

receiver is connected.

-

Consult the dealer or an experienced radio/

technician for help.

TV

Change or modifications not expressly approved by the manufacturer for compliance could void

the user’s authority to operate the equipm en t.

Interference cable to the computer shall be used with shielded circular cable.

Any modification without prior permission may cause harmful interface. If any

modification/change is introduced to this equipment without prior permission, Kyocera, as the

manufacturer, cannot guarantee compliance with

To use equipment which does not comply with

rules.

FCC

rules is prohibited. The printer may be

FCC

optionally installed with the follo wing units:

CONFORMING TO CLASS B LIMITS:

•

-20 Duplexer/DU-21

DU

-20 Paper Handler/Stacker

•

HS

-20 Paper Feeder/PF-21

•

PF

-20mini Paper Feeder/PF-21mini

•

PF

-6 Sorter/Stacker

•

SO

-20 Bulk Paper Stacker

•

ST

-3 AppleTalk Interface Board

•

IB

1-14

FS-1200

Page 21

Product information

Front and internal views

Important note on the interface connectors

Be sure to turn off printer power before connecting or disconnecting an interface cable to the

printer. For protection against static discharge which may be applied to the printer's internal

electronics through the interface connector(s), keep any interface connector which is not in use

capped using the protective cap supplied.

Warning - This equipment has been certified to comply with the limits for

a Class B computing device, pursuant to Subpart J of Part 15 of FCC Rules.

Only peripherals (computer input/output devices, terminals, etc.) certified

to comply with the Class B limits may be attached to this equipment.

Operation with non-certified peripherals is likely to result in interference

to radio and TV reception.

1-15

FS-1200

Page 22

Product information

Front and internal views

Canadian Department of Communications compliance statement

This Class B digital apparatus complies with Canadian ICES-003.

Avis de conformité aux normes du ministère des Communications du

Canada

Cet appareil numérique de la classe B est conforme á la norme NMB-003 du Canada.

ISO 7779

Maschinenlärminformationsverordnung 3.

beträgt 70 dB(A) oder weniger gemäß

ISO

, 18.01.1991: Der höchste Schalldruckpegel

GSGV

7779.

1-16

FS-1200

Page 23

Environmental requirements

Environmental conditions

Product information

Environmental requirements

The

ENVIRONMENTAL REQUIREMENTS

optimum operation of the printer. The use of the printer in a location which does not satisfy the

requirements may result in troubles and risk shortening its service life.

The printer will work best if it is installed in a location that is:

r

Level and well supported (Place the printer on a sturdy table or desk.)

r

Not exposed to sunlight or other bright light (not next to an uncurtained window). Do not

place the printer on an unstable cart, stand, or table.

r

Near an

wall outlet, preferably one that can be used for the printer alone (See section

AC

section on page 1-6 should be observed to ensure the

1-17

FS-1200

Page 24

Product information

Environmental requirements

POWER REQUIRMENTS

on page 1-6). (The outlet should have a ground slot, or an adaptor

should be used. If you use an extension cord, the total length of the power cord plus extension

cord should be 17 feet or 5 meters or less.

r

Well ventilated, not too hot or cold, an d not too damp or dry (See section

REQUIREMENTS

on page 1-6). If you install the printer where the temperature or humidity is

ENVIRONMENTAL

outside the requirements in section Environmental requirements in chapter 1, the best print

quality may not be expected and there will be an increased chance of paper jams.

r

Provide a sufficient clearances around the printer to ensure ventilation and ease of access. See

section

Clearance

on page 1-19.)

1-18

FS-1200

Page 25

Product information

Environmental requirements

Clearance

Allow the necesary minimum clearance on all sides of the printer (below). A total space of 92 by

138 cm (36 by 54”) is needed.

➎

➊

➋

Clearance Dimensions

➊

Left

Front

Right

Back

Above

➋

➌

➍

➎

30 cm (12”)

60 cm (24”)

25 cm (10”)

40 cm (16”) or 20 cm (8”) if optional the face-up tray

is not installed.

30 cm (12”)

➍

➌

1-19

FS-1200

Page 26

Environmental requirements

Places to avoid

Avoid installing the printer in locations exposed to:

• Direct drafts of hot or cold air.

• Direct drafts of outside air. (Avoid locations next to outside doors.)

Product information

• Sudden temperature or humidity changes.

• Any source of high heat, such as a radiator or stove.

• Excessive dust. Dust and smoke may cause contamination on the laser scanner window,

causing print quality problem.

• Vibration.

• Ammonia fumes or other harmful fumes. (In case of humigating the room or saturate it with

insecticide, remove the printer first.)

• Avoid greenhouse-like rooms. (Because of sunlight and humidity.)

• Avoid enclosed spaces that block v e ntilation.

• Avoid sites more than 6500 feet or 2000 meters above sea level.

1-20

FS-1200

Page 27

Product information

Environmental requirements

Note on power

• Use only the power source voltage conforming to the printer’s rated power voltage (See the

1-21

FS-1200

Page 28

Product information

Environmental requirements

POWER REQUIRMENTS

• Disconnect the printer from the power source before attempting removal or re-placement of an

electrical component or a printed-circuit board.

• The printer should not be connected to a power source until the instruction is given to do so

when performing tests described in this manual.

• In connecting the printer power, exercise an extreme care in handling the power supply or any

other electric parts which may give an electric shock.

• Before performing maintenance or repair, power from both the power source and the

associated peripheral devices (computer, sorter, etc.) should be disconnected, unless otherwise

specified.

• To avoid possible electrical shock, extreme caution must be exercised in handling the power

cord and any other electrical part.

Warning!

Warning! /Wornung!

Warning!Warning!

on page 1-6). Do not use other power sources.

As the disconnect device is not incorporated in the printer's AC primary circuit, an easily

accessible socket outlet must be provided near the equipment.

If the printer is used with the optional Sorter (SO-6) or Stacker (ST-20), in order to avoid shortcircuiting, it should be ensured that these devices are plugged securely into their respective power

outlets.

Da kein Trennschalter in den Wechselstrom-Primärkreis des Druckers eingebaut ist, muß eine

leicht zugängliche Steckdose in der Nähe des Gerätes vorhanden sein.

Wenn der Drucker mit dem gesonderten Sorter (SO-6) oder Stapler (ST-20) verwendet wird, muß

darauf geachtet werden, daß diese Geräte einwandfrei an separate Steckdosen angeschlossen sind,

um Kurzschluß zu vermeiden.

1-22

FS-1200

Page 29

About the toner

The printer should use Kyocera TK-25 Toner Kit. To ensure the high print quality and long service

life, the following handling precautions should apply.

Caution - As the Ecosys printers are designed to ensure the optimum print

quality when used with the Kyocera’s proprietary toner, Kyocera do not

recommend to use any refilled toner containers that may be available

commercially. This is because Kyocera have no means for control over how

such refilled toner could affect the print quality and the reliability of the

printer.

Product information

About the toner

Toner container handling

To loosen and mix the toner inside, with the label side down, thoroughly shake the toner container

(in the direction of the arrow) ten times or more.

Do not attempt to disassemble or refill the toner container.

1-23

FS-1200

Page 30

Product information

About the toner

Toner storage

The toner contained in the container is susceptible to temperature and humidity. To ensure the

high print quality, store the toner container in a place that satisfy the following environ mental

conditions:

Note.

Temperature -20°C to 40°C (-4°F to 104°F)

Humidity 15 to 90% RH

If the toner container is removed from the printer’s developer unit, put it in a protective bag and

keep it in a dark place.

Caution -

Caution - If the printer is shipped for return, etc., do not ship it with the

Caution - Caution toner container installed. Otherwise, toner may leak and contamination

may result in the printer.

1-24

FS-1200

Page 31

Product information

About the toner

1-25

FS-1200

Page 32

Chapter Two INSTALLATION/OPERATION

Page 33

Chapter Two

Unpacking and Inspection 2-3

Unpacking 2-3

Installing toner 2-4

Installing the waste toner bottle 2-6

Developer initialization 2-6

Loading paper 2-7

Expanding memory 2-8

Minimum memory requirements 2-8

SIMM to be used 2-8

Notes on handling the main circuit board and SIMMs 2-9

Removing the main circuit board 2-9

Installing SIMMs 2-11

Testing the expansion memory 2-13

Using the Control Panel 2-14

Indicators 2-14

Front panel keys 2-15

Mode selection menu 2-15

Service mode 2-19

CONTENTS

Page 34

Unpacking and Inspection

Examine the package for any signs of damage that may have been caused during shipping. If the

carton is found badly damaged, leave the carton unopened and immediately notify the carrier

before accepting it.

Installation and operation

Unpacking and Inspection

Unpacking

While unpacking the printer, check th at the listed parts are all present.

(D)

(C)

(B)

(E)

(A)

Printer

(A)

Waste tonar bottle

(D)

User’s Manual and Kyocera DigitalLibra (CD ROM), including the printer

drivers and manuals.

(B)

Tonar container

2-3

(C)

Power cord

(E)

Plastic bag for Developer Unit

FS-1200

Page 35

Installing toner

Installation and operation

Unpacking and Inspection

Take the toner container from the toner kit (

(5 to 6 times).

Peel off the seal ➋ on the bottom of the toner container by carefully pulling off.

-25) supplied with the printer. Give it a good shake

TK

2-4

•

FS-1200

Page 36

Installation and operation

Unpacking and Inspection

Insert the toner container in the printer as belo w.

developer unit ➌ as show in the figure.

Install the toner container

➊

on the

➊

➌

Caution - To avoid trouble (toner spilling, etc.), the toner container must

be correctly seated and locked in the printer. To do this, press the far side

of the container

➊

at the

PUSH HERE

marks until a click is heard.

2-5

FS-1200

Page 37

Installation and operation

Unpacking and Inspection

Installing the waste toner bottle

The waste toner bottle ➍ is also supplied. It must be installed inside the drum access door ➎ in the

left side of the printer. Open the drum access door and install it as shown.

➎

➍➍

Developer initialization

The printer is shipped from the factory with no toner supplied in its developer unit. When the

printer is first switched on after the toner container is installed in the manner above, there will be a

delay of several minutes before the printer gets ready to print a job.

This delay is necessary for the printer to fill the developer reservoir with a sufficient amount of

toner to continuously support a print job.

The period of time for this delay varies depending on model: approximately 7 minutes for model

-1200 (12-ppm).

FS

Since the automatic implementation of the developer initialization is done only once at first

switching power on, if a new developer is in stalled in the printer, the developer must be initialized

manually using the service mode on the front panel. Refer to the section

the new developer

on page 3-12.

Feeding toner into

2-6

FS-1200

Page 38

Loading paper

The paper cassette provided with the printer can accommodate paper sizes from A5 to legal, by

adjusting the position of the paper guides and the paper stopper. Paper sizes that are not standard

sizes (custom sizes) but within the size limitations can also be loaded into the cassette. When

loading custom sizes into the cassette, the size must be input into the printer on the control panel.

Installation and operation

Loading paper

Turn the paper size dial so that the size of the paper you are going to use appears in the paper size

window.

When the paper size dial is set to "Custom" th e paper size must be set into the printer o n the control panel.

Paper Size Dial

2-7

Paper Size Window

FS-1200

Page 39

Expanding memory

Expanded printer memory enables to print more complex pages, download more fonts, and define

more macros.

It begins by explaining how to remove the main circuit board from the printer, and explains how

to install a

requirements for the printer with various options installed are listed in the table below. Refer to

this table for obtaining a rough approximation on how much memory is required for a particular

need.

DIMM

Installation and operation

Expanding memory

(dual in-line memory module) on the main circuit board. The minimum memory

Minimum memory requirements

Resolution

Printing environment 300 dpi 600 dpi

HP emulation 4MB 4MB

HP+duplex 4MB 5MB

HP+KPDL 4MB 4MB

HP+KPDL+duplex 4MB 5MB

HP+KPDL+resource protection n/a 10MB

HP+KPDL+resource protection+duplex n/a 14MB

DIMM to be used

Memory size in MB

Number of pins

Bus width

8, 16, 32, 64

100(JEDEC

standard)

32 bits

Reference:

Guideline for SDRAM DIMM Support with Kyocera Ecosys Printers.

2-8

FS-1200

Page 40

Notes on handling the main circuit board and DIMM

Protect the electronics by taking these precautions:

Installation and operation

Expanding memory

r

Before touching the main circuit board, touch a water pipe or other large metal

object to discharge yourself of static electricity. While doing the work, it is

recommended that you wear an antistatic wrist strap.

r

r

Touch the main circuit board and

Follow the instructions the

DIMM

only by the edges.

DIMM

manufacturer provides.

Removing the main circuit board

The main circuit board of the printer is equipped with one socket for memory expansion.

Expansion memory is available in the form of a

DIMM

.

Turn the printer’s power off. Unplug the printer’s power cable and

disconnect the printer from the computer or the network.

2-9

FS-1200

Page 41

Installation and operation

Expanding memory

Remove the PC card that may be inserted in the PC card slot at the left side of the printer.

Turn the power switch ➏ off. Remove the main circuit board ➐ by removing the three (plated)

screws ➑ from the rear cover.

The diagram below examples model FS-1700 and FS-3700.

‘

Pull the main circuit board all the way out of th e printer.

Caution - Before pulling the board out, clean an area on the table, etc., at

the back of the printer’s rear panel. Foreign objects, accidentally sticking

to the back of the main board, can cause serious damage to the printer.

Refer to the diagram on page 2-11. Locate the sockets for memory expansion on the main board.

These sockets have 100 pins and are symbolized as YS102.

2-10

FS-1200

Page 42

Installation and operation

Expanding memory

DIMM sockets

Installing DIMM

Insert the DIMM into the socket as shown. Open the clips ➊ on both ends of the DIMM slot.

Insert the DIMM ➋ into the memory slot, so that the notches on the DIMM align with the

corresponding protusions in the slot. Close the clips ➋ DIMM slot to secure the DIMM ➊.

2-11

FS-1200

Page 43

•

Installation and operation

Expanding memory

Œ

Œ

2-12

FS-1200

Page 44

Testing the expansion memory

Installation and operation

Expanding memory

After installing

To test the expansion memory, turn printer power on and print a status page.

If the installation has been successful, the Total memory (Memory Allocation) of the status page

will show the expanded memory size corresponding to the amount of memory added.

in the printer, test the printer to see if the in stallation has been successful.

DIMM

2-13

FS-1200

Page 45

Using the Control Panel

Installation and operation

Using the Control Panel

The printer’s control panel have

access to the printer’s conditions.

Indicators

➋

➌

➎

➍

Indicator Status Function

ONLINE/Green

DATA/Green

ATTENTION/Red

Manual feed indicator/

Face-down stack indicator/

Face-up stack indicator/

Cassette feed indicator/

Toner indicator/

➊

➌

•

•

indicators and a quartz message display to provide a quick

LED

➊

Flashing A memory error (See chapter 6) has occurred.

Steady The printer is on-line and ready prints received data.

Off The printer is off-line. The printer stores but not print received data.

Flashing The printer is receiving data at its interface.

Steady Indicates either that data is being processed, or that data is being written

Flashing A service call is required. Read the message on the message display.

Steady The printer needs attention for a problem that can be cleared by the user.

➋

to the memory card.

(Also, see chapter 6.)

Lights when paper is fed from the multi-purpose feed tray, bulk (front

loading) feeder, or the option envelope feeder if installed. If this flashes,

paper jam is suggested in a particular location, refer to chapter 6.

Lights when printed pages are delivered to the face-down output

tray(optional). If this flashes, paper jam is suggested in a particular

location, refer to chapter 6.

Lights when printed pages are delivered to the face-up output tray, or to

the option stacker if installed. If this flashes, paper jam is suggested in a

particular location, refer to chapter 6.

Flashing: indicates the possibility that paper may be jammed at this

point, open and remove any jammed paper.

Lit: indicates when paper is fed from the paper feed cassette.

Flashes when the toner supply is low to request replenishing.

2-14

FS-1200

Page 46

Front panel keys

Installation and operation

Using the Control Panel

Key Function

ONLINE

CONTINUE

STACK

FORM FEED

CANCEL

MODE/EXIT

FEED

STATUS/ENTER

Switches the printer on-line and off-line.

Depending on the message being indicated, there are cases where operation will

continue after pressing this key. If such a message is displayed, operation will

be resumed after pressing this key.

Selects whether printed pages are delivered to the face-down, face-up tray, or

optional sorter/stacker (if installed).

Prints and feeds out one page.

Abandons a printing job, resets numeric values, or cancels a setting procedure.

Enters/exits the mode selection menu. See

Selects the cassette feed or multi purpose tray feed.

Prints a page of information on the printer’s current status. (The printer must be

on-line.).

Mode selection menu

below.

Mode selection menu

The

MODE

key on the control panel allows to set or change the printer environment such as the

number of copies to make, emulation, etc., and to print a font list, manipulating a memory card,

etc.

During operating in the mode selection, several front panel keys serve exclusively for its

secondary function as labeled beside them (

EXIT, +, -, ENTER

, 3,4). The diagram on the next

page gives a full load map to the full options and the sequence of mode selection as well as usage

of these secondary keys.

2-15

FS-1200

Page 47

Installation and operation

Using the Control Panel

2-16

FS-1200

Page 48

Installation and operation

Using the Control Panel

2-17

FS-1200

Page 49

Installation and operation

Using the Control Panel

2-18

FS-1200

Page 50

Installation and operation

Using the Control Panel

Service mode

Within Others option, the Service mode can be accessed by authorized service personnel.

This mode provides two special treatments for service purpose: cleaning on the drum surface (see

page 6-45) and accelerating initial toner replen ishment for a new developer (see page 3-13).

The service mode is available only when the pr inter is ready. While in service mode, the printer

accepts print data but does not print it.

For details, see chapter 3, page 3-13.

2-19

FS-1200

Page 51

Chapter Three

MAINTENANCE/ADJUSTMENTS

3-1

FS-1200

Page 52

Chapter Three

Life expectancy of modules 3-3

Toner containers 3-4

Toner container replacement 3-4

Waste toner bottle 3-5

Toner saver mode (EcoPrint) 3-6

Cleaning the printe r 3-7

Main charger unit 3-7

Paper Feed Unit 3-11

Replacing the developer 3-12

Shipping the developer unit 3-12

Feeding toner into the new developer 3-13

Updating the engine firmware 3-14

Engine/front panel data format 3-15

Downloading data from the parallel interface 3-16

Downloading data from a memory card 3-17

Downloading errors 3-17

Adjusting the transfer bias for thick paper 3-18

CONTENTS 3-1

Page 53

Life expectancy of modules

The table below shows the nominal life expectancy for modules. Detailed part

information for each module (except toner containers) can be found in chapter 7,

Parts Catalog

.

Maintenance

Life expectancy of modules

Module Nominal life

(pages)

Toner container 5,000 TK-25

Drum unit 100,000 DK-28

Developer unit 300,000 DV-28

Fuser unit 300,000 FK-28

Model

3-3

FS-1200

Page 54

Toner containers

The toner container is the only consumable that the printer requests replacement

during normal operation (user-replaceable). The following toner containers are

available for use with model

FS

Maintenance

Toner containers

-1200.

Model Life in pages* No. of waste toner bottles included

TK-25 5,000 One

* Based on letter or A4 size paper; average print density of 5%.

Toner container replacement

The printer gives two steps of user attention as explained below. The first one is the

warning that the toner is almost run out. This is the earliest chance for the user to

replace the toner container and clean various parts inside the printer (See section

Cleaning the printer

Toner low TK-25 Clean printer

If the user continues to use the printer, the printer will print approximately 50 pages

(A4 or Letter size paper, 5% average toner density), eventually the toner supply being

exhausted at which point the printer will stop printing and the following message

will be displayed:

Replace Toner Clean printer

This instructs to install a new toner kit to bring the printer back in normal operation.

Cleaning various parts inside must be also done in this occasion (See section

Cleaning the printer

on page 3-7):

on page 3-7).

To replace the toner container !, pull the toner container release lever " to right as

shown.

3-4

FS-1200

Page 55

!

Maintenance

Toner containers

"

Then, refer to section

After installing the new toner container, several parts in the printer must be cleaned

as instructed in section

If the toner container has been replaced when the message

Replace Toner Clean printer

was displayed, the message

Clean printer.. press CONTINUE

will be displayed after replacement. After cleaning the inside of the printer following

the procedure shown below, press the

and the printer will be ready for printing.

The printer can get ready for printing approximately 15 seconds after replacing the

toner container.

Waste toner bottle

Locate the new waste toner bottle in the toner kit, and install in the printer

according to section

Note that the printer has a sensor to monitor the presence of the waste toner bottle.

The printer does not operate without a bottle installed.

Installing toner

Cleaning the printer

Installing the new waste toner bottle

on page 2-4 to install the new toner container.

on page 3-7.

CONTINUE

key; the message will disappear

on page 2-6.

For the reference, the waste toner bottle can hold up to 100g of waste toner. The

nominal amount of waste toner derived after 10,000 pages have been printed is 20 to

30g (Letter or A4 size paper; average toner density of 5%).

3-5

FS-1200

Page 56

Maintenance

Toner containers

Toner saver mode (

The

EcoPrint

save printing costs by drastically extending t he toner container life. EcoPrint mode is

factory-set to off and turned on by the printer’s front control panel (also accessible

through the application software with the assistance of the printer driver). See

details in the

The

EcoPrint

enables to reduce the amount of toner consumed on the page so as to

Mode Select Menu

setting has no effect on the print speed.

EcoPrint

)

roadmap in chapter 2.

3-6

FS-1200

Page 57

Cleaning the printer

g

To avoid print quality problems, the following printer parts must be cleaned with

every toner container replacement.

Main charger unit

Maintenance

Cleaning the printer

The main charger unit should b e cleaned in its two parts - the wire and grid (See the

picture below.) - whenever the toner container i s changed. Cleaning of the main

charger can be done without needing any tools thanks to its self-cleaning system.

Charger wire

Grid

Contact for the main

er bias

char

3-7

FS-1200

Page 58

Maintenance

Cleaning the printer

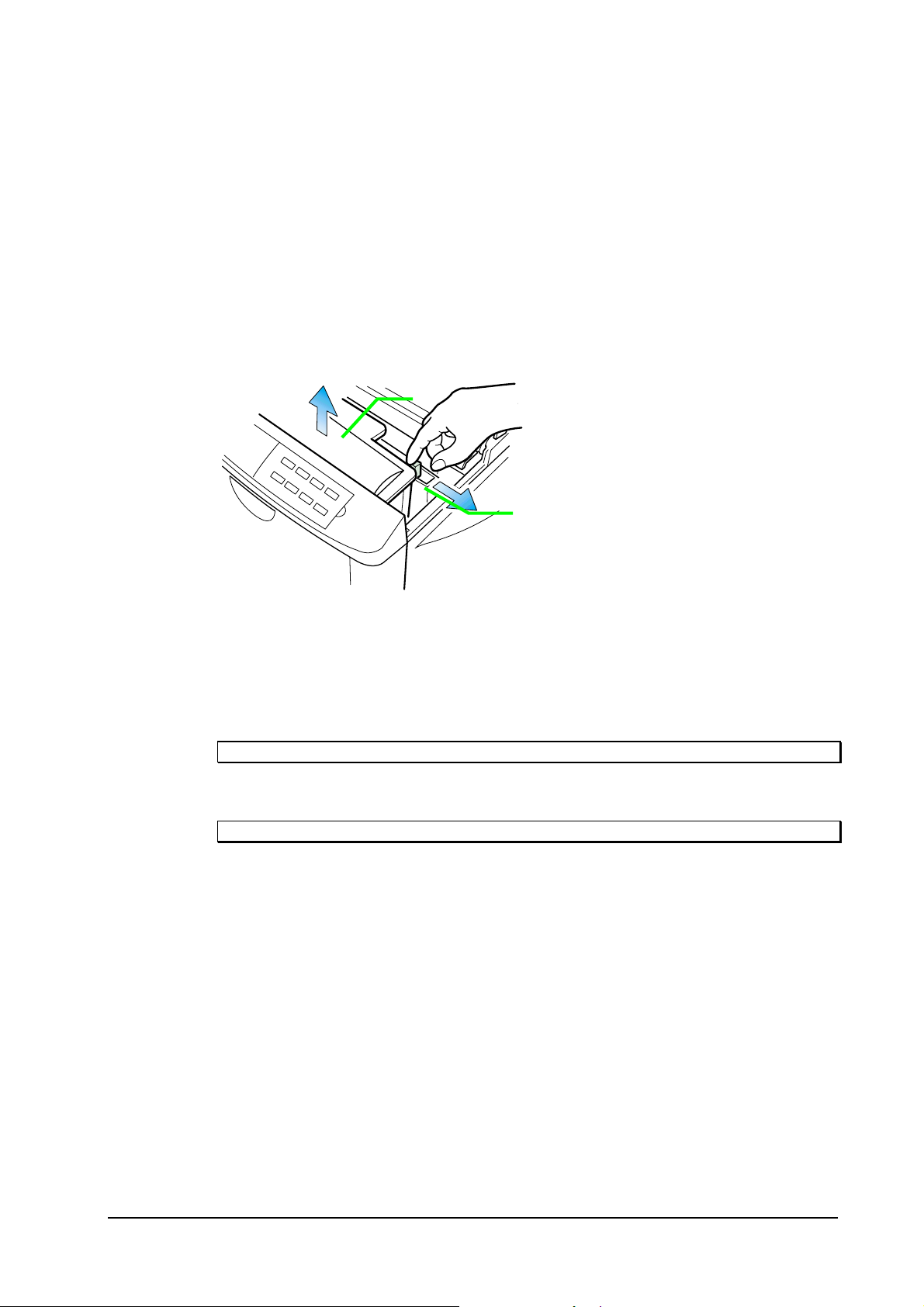

To clean the main charger, first open the drum access door ➊. Pull the cleaning knob

(green) ➋ slowly in and out a few times. This pulls a cleaning pad inside the drum

unit along the wire.

➋

➊

Then, clean the grid using the grid cleaner supplied with the toner kit.

Take the grid cleaner ➌ from protective bag in the new toner kit, and remove the cap

➍.

➍

Pad - impregnated with water

➌

3-8

FS-1200

Page 59

Maintenance

Cleaning the printer

The grid cleaner pad is impregnated with water. Perform the following cleaning

procedure before the pad dries.

Attach the grid cleaner ➌ to the printer with the pad uppermost, as shown in the

diagram below.

➌

3-9

FS-1200

Page 60

Maintenance

Cleaning the printer

After attaching the grid cleaner ➌, repeat the action of slowly pulling out and then

pushing back in the main charger unit itself

the previous section

the previous section) at least 5 times. It is easier to pull out the main charger for the

the previous sectionthe previous section

first time if it is raised slightly, as shown in the figure.

main charger unit itself ➎➎➎➎ (not the green knob that was used in

main charger unit itself main charger unit itself

not the green knob that was used in

not the green knob that was used innot the green knob that was used in

To release the

main charger unit

for pulling, first

pull it up…

Then, pull it

➎

➌

The grid part underneath the main cha rger is cleaned by this procedure. W hen the

grid is clean, remove the grid cleaner from the printer and dispose of it. The grid

cleaner is not re-usable. After cleaning the charger wire, push the cleaning knob all

the way in and close the drum access door.

horizontally out.

3-10

FS-1200

Page 61

Maintenance

Cleaning the printer

Paper Feed Unit

To avoid print quality problems due to paper dust and debris, clean the paper feed

unit ➊ in the following manner.

Pull the paper feed unit release lever up and draw the paper feed unit all the way out

until it stops. Wipe the paper dust on the registration roller ➋ and the paper ramp ➌

using the wiper cloth ➍ included in the toner kit.

Do not touch the transfer roller

paper ramp.

➍

➌

➎

➊

(black sponge roller) when wiping the

➎

➋

3-11

FS-1200

Page 62

Replacing the developer

In case that the developer unit is to be removed from the printer for shipment or

replacing to a new one, it should be handled following the instructions below.

Also, a new developer unit, after installing, needs a special treatment that repletes

the developer with toner for printing. This can be done by using the front control

panel (See section

Feeding toner into the new developer

Maintenance

Replacing the developer

on page 3-13).

Shipping the developer unit

The printer is supplied with a plastic bag that should be retained for future shipment

of the developer.

Flap down the magnet roller protective cover, then refer to the diagram below:

➊

Put the developer into the plastic bag

Plastic bag

.

3-12

FS-1200

Page 63

Maintenance

Replacing the developer

Feeding toner into the new developer

The new developer unit is shipped from the factory with no toner contained. The

developer can be automatically repleted with toner when a toner container is

installed onto it and the printer is turned on. However, because the toner reservoir in

the developer has a large capacity, it requires a lengthy period of time until a

substantial amount of toner has been fed to get the printer ready. (A new developer

needs approximately 200g for triggering the sensor inside.)

A great many seconds of time for this is greatly deducted by using the service menu

in the printer’s mode select routine as accessed by its front control panel. Follow

these steps to use this feature, top to bottom (For details on using the front control

panel keys, refer to section

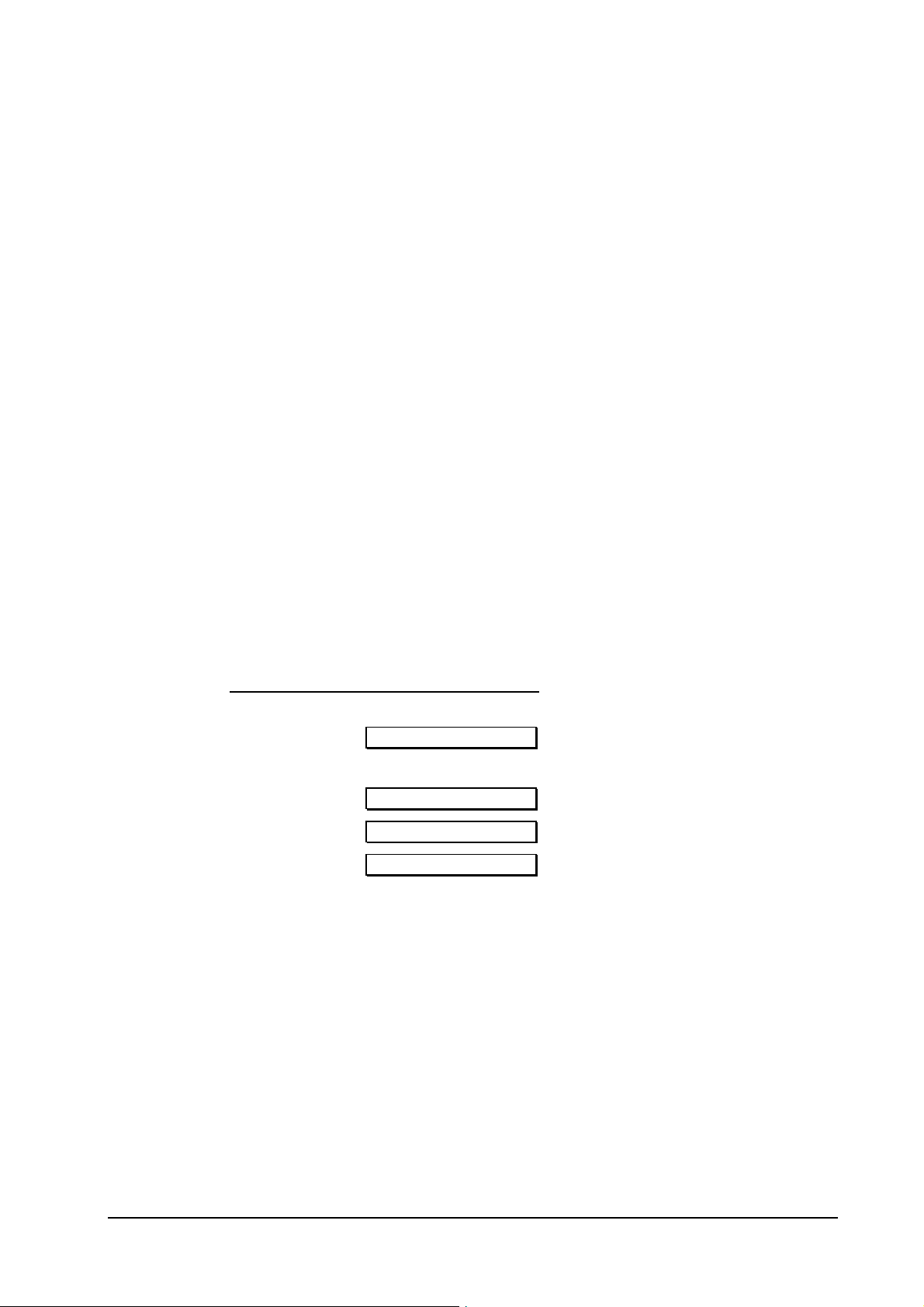

Key to press: Display to show:

Mode Select Menu

diagram on page 2-16.

MODE

✚ (repeatedly)

Others>

4

✚ (repeatedly)

4

ENTER

ENTER

Turn printer power off, then on.

>Service>

>>Developer

>>Developer?

The printer enters the

service mode and the

developer u n i t an d t h e

toner feeder motor are

continually activated.

When printer power is turned on again, the printer continually engages in this mode

for a period of approximately 7 minutes for model

-1200, after which the printer

FS

reverts to the ready state.

3-13

FS-1200

Page 64

Updating the engine firmware

The printer accepts update of the engine firmware as well as th e localized front panel

message data through the parallel interface. Updating using these data is

implemented by directly rewriting the flash memory in the printer’s engine board.

The printer must be in the

firmware.

supervisor

Maintenance

Updating the engine firmware

mode (See page 3-16) to update the engine

Note.

Note.

This applies the engine firmware only. The controller firmware is updated by

replacing

Kyocera supplies three types of data for updating the engine firmware depending on

the purpose of update. These are:

#

#

#

These data may be stored in a memory card for field use. To store (write) data in a

memory card, and reread them into the printer through the slot, refer to the printer’s

User’s Manual

Each single data must be written on a memory card. Do not write more than one data

on a memory card.

.

DIMM

Engine firmware data

Front panel initialization data (required to reprogram the panel message)

Front panel message data

.

3-14

FS-1200

Page 65

Updating the engine firmware

Engine/front panel data format

The data is identified using the following naming syntax:

Maintenance

De4630.dat

➊ ➋➌ ➍

Identifies…

de:

➊

➋

➌

➍

Engine firmware data

dm

: Front panel message data

46

: FS-1200

Version of data

dat

: Engine firmware data

dan

: Panel message data for Danish

swe

: Panel message data for Swedish

ita

: Panel message data for Italian

spa

: Panel message data for Spanish

3-15

FS-1200

Page 66

Updating the engine firmware

Downloading data from the parallel interface

To download data from the parallel interface:

Perform, from top to bottom: Then the display shows:

Turn printer power on. Make sure the printer is

Ready

.

At the DOS prompt, execute the following command:

!R! BOOT “SPR”;

—Do not add an EXIT; command in the abo ve.

Note

The display should indicate

Supervisor Mode

.

Ready

Supervisor mode

Maintenance

DOS COPY the data to download from the host

computer.

Check the display reverts to

Turn power off, then on again. Check the display

shows Ready. If not, refer to

section that follows.

Ready

.

Downloading errors

Downloading

Ready

Confirm the status page shows the new engine version (See

the message display indicates

Call service person Dn (n=0, 1, …)

Downloading data from a memory card on page 3-17.

Appendix B

, refer to section

, page B-4). If

3-16

FS-1200

Page 67

Updating the engine firmware

Downloading data from a memory card

To download data written in a memory card to the printer:

Perform, from top to bottom: Then the display to show:

Insert the memory card in the printer’s memory card

slot (at the right side).

Turn printer power on. The printer automatically reads

data in the memory card, indicating

the message panel.

When the data is successfully read, the message display

indicates

Turn printer power off.

Remove the memory card from the printer.

Turn printer power on again. Check the display shows

Ready. If not, refer to Downloading errors section that

follows.

Supervisor mode

.

Downloading

on

Downloading

Supervisor mode

Ready

Maintenance

Confirm the status page shows the new engine version (See

the message display indicates

Call service person Dn (n=0, 1, …)

Appendix B

, refer to section

, page B-4). If

Downloading errors below.

Downloading errors

The following messages are indicated on the message display when an error occurred

during downloading data.

Error message Meaning Corrective action

Call service person

D0—

Checksum error

Call service person

D1

—Machine

compatibility error

Call service person

D2—

Version compatibility

error

Call service person

Checksum error occurred during

downloading. The engine ROM is

empty.

The data to be downloaded is not

compatible with the printer.

The version of the data does not

match the current engine version.

The data to be downloaded is Obtain the co rrect data.

3-17

Turn printer power off once, then

on again. Try downloading again.

Obtain correct data for the

printer mo del.

Obtain the correct version of

data.

FS-1200

Page 68

D3—

Data error corrupted.

Maintenance

Updating the engine firmware

3-18

FS-1200

Page 69

Adjusting the transfer bias for thick paper

Adjusting the transfer bias for thick paper

Maintenance

Printing on paper with extra thickness of 91 to 200 g/m2, such as postcards,

envelopes, etc., tend to result in faint printing because of insufficient penetration of

transfer bias developer at the transfer roller. For the satisfactory transferring process

on different paper thickness, the transfer bias is user-switchable from -1.8 kV to -2.5

kV (limit), or vice versa, by using the printer’s operator panel.

To increase the transfer bias for a type of thick paper, perform the following steps,

top to bottom:

Key to press: Display to show:

MODE

✚ (repeatedly)

ENTER

✚

ENTER

Double-sided printing using a DU-20/DU-21 duplexer automatically introduces the

higher setting of the transfer bias.

Paper type

Normal

Paper type

Normal ?

Paper type

Thick ?

The transfer bias is raised

for thick paper.

OHP

,

3-19

FS-1200

Page 70

This page left intentionally blank

Maintenance

Updating the engine firmware

3-20

FS-1200

Page 71

Chapter Four OPERATION OVERVIEW

Page 72

Chapter Four

Electrophotographics system 4-4

Photoconductive drum 4-5

Charging the drum 4-6

Toner 4-7

Exposure 4-8

Scanner unit 4-10

Scanning laser 4-12

Development 4-13

Developing roller bias 4-14

Transfer 4-16

Fusing 4-17

Drum cleaning and erasing static charge 4-18

Typical photo process timing chart 4-19

Paper feeding system 4-21

Paper feed components/signals 4-22

Cassette feeding 4-23

Manual/multi purp ose tray feeding 4-24

Paper jam sensing 4-25

Print timing charts 4-27

Basic engine functions 4-32

Basic sequence of operation 4-33

OPERATION OVERVIEW

Engine controller system 4-34

Flash memory 4-34

High-voltage generator 4-34

Laser scanner control 4-35

Polygon motor control 4-35

Safety interlock 4-36

The engine gate array 4-37

Pin assignment 4-38

Power supply 4-42

Logic controller system 4-44

Logic controller sp ecifications 4-45

Printing data processing 4-47

API ROM socket (U103) 4-48

API ROM socket pin assignment 4-49

System ROM (YS101) 4-50

RAM (U109,U110) 4-51

Memory card slot interface 4-51

Option interface 4-51

Option interface pin assignment 4-52

Parallel interfa ce 4-53

Page 73

Serial interface (Option) 4-53

Debugging outputs 4-54

Engine interface 4-54

Engine interface connector assignment 4-55

Signals used for the engine interface 4-56

Engine interface signals 4-57

Page 74

Electrophotographics system

Electrophotography is the technology used in laser printing which transfers data representing texts

or graphics objects into a visible image which is developed on the photosensitive drum, finally

fusing on paper, using light beam generated by a laser diode.

The key features for the electrophotography system used in the printer are:

Operation overview

Electrophotographics system

!

600 dpi resolution

!

Newly developed organic photoconductor drum with no heating device

!

Diode laser scanning

!

Mono component toner

The electrophotography system of the printer performs a cyclic action made of seven steps as

shown below.

2 Exposure

1 Main Charging

3 Developing7 Erasing

6 Cleaning

4 Transfer

5 Fusing

4-4

FS-1200

Page 75

Operation overview

Electrophotographics system

Photoconductive drum

The durable layer of organic photoconductor (OPC) is coated over the aluminum cylinder base.

The OPC tends to reduce its own electrical conductance when exposed to light. After a cyclic

process of charging, exposure, and development, the electrostatic image is constituted over the

OPC layer.

Since the OPC is materialized by resin, it is susceptible to damage caused by sharp edges such as a

screwdriver, etc., resulting in a print quality problem. Also, finger prints can cause deterioration of

the OPC layer, therefore, the drum unit (in the process unit) must be handled with care. Substances

like water, alcohol, organic solvent, etc., should be strictly avoided.

As with all other OPC drums, the exposure to a strong light souce for a prolonged period can cause

a print quality problem. The limit is approximately 500 lux for less than five minutes. If the drum

unit (process unit) remains removed from the printer, it should be stored in a cool, dark place.

Photoconductive layer

Aluminum base cylinder

4-5

FS-1200

Page 76

Operation overview

Electrophotographics system

Charging the drum

Figure below is a simplified diagram of the electrophotographics components. Charging the drum

is done by the main charger wire (in the main charger unit) marked A in the diagram.

A

B

As the drum (B) rotates in a “clean (neutral)” state, its photoconductive layer is given a uniform,

positive (+) electrical charge dispersed by the main charger wire (A).

Due to high-voltage scorotron charging, the charging wire can get cont aminated by oxidiz ation and

therefore must be cleaned periodically from time to time using the method explained in section

Main charger unit

such as black streaks caused by the oxide ac-cumulated around the charging wire.

on page 3-7. Cleaning the charging wire prevents print quality problems

4-6

FS-1200

Page 77

Operation overview

Electrophotographics system

Toner

The toner is fed from the toner pack TK-25. The toner is comprised of the following substances as

depicted below.

Single component toner TK-25

A

B

C

D

Resin

A -

Magnetite

B -

Silica

C -

Polisher

D -

4-7

FS-1200

Page 78

Operation overview

Electrophotographics system

Exposure

The charged surface of the drum (“B”) is then scanned by the laser beam from the scanner unit

(“A”).

A

B

4-8

FS-1200

Page 79

Operation overview

Electrophotographics system

The laser beam is switched on for a black dot and off for a white (blank) dot according to the print

data. Whenever it is illuminated by the laser beam, the electrical resistance of the photoconductor

is reduced, the potential on the photoconductor is also lowered to 95V, effectively driving the

charge through the OPC layer down to the aluminum base.

+++++

OPC LAYER

ALUMINUM

LASER BEAM

++++

----

++++

350-390V

95V

0V

LASER BEAM

4-9

FS-1200

Page 80

Operation overview

Electrophotographics system

Scanner unit

The 600 dpi scanner unit includes the diode laser that produces the 670 nm wavelength laser beam.

This wavelength is specifically designed to match the photoconductive response of the OPC drum.

+

To drum

'

&

%

*

$

(

)

#

"

4-10

FS-1200

Page 81

Operation overview

Electrophotographics system

"

Laser diode -

#

Collimeter lens -

$

Cylindrical lens -

%

Polygon mirror (motor) -

one scanned line width on the drum when laser beam scans on it.

&

Primary f-theta lens -

'

Secondary f-theta lens -

edges. The effective length of line (“A,” “B” below) the laser beam draws on the drum becomes longer as the laser beam

hits closer to the drum edges. In the figure below, distances represented by “A” and “B” are not the same (A>B) until the

f-theta lenses are provided between the polygon mirror and the drum (A’=B).

emits diffused, visible laser.

aligns the laser beam to the cylindrical lens.

compensates the slant angle at which the laser beam hits a polygon mirror segment.

has six mirror segments around its octagonal circumference; each mirror corresponding to

See below.

The primary (above) and secondary f-theta lenses equalize focusing distortion on the drum

(

Diversion mirror -

the drum.

)

Protective glass -

*

Sensor mirror -

+

Beam detect or sensor -

engine controller to start activating the paper feeding system.

diverts the laser beam vertically onto the drum. Note the diffused laser beam finally pin-points on

prevents dust, debris, etc., from entering the scanner assembly.

bends the very first shot of a laser scan towards the beam detection sensor (See next.).

when shone by the sensor mirror above, this photosensor generates a trigger signal for the

4-11

FS-1200

Page 82

Operation overview

Electrophotographics system

Scanning laser

The laser beam hits one of six polygonal mirrors. As the mirror revolves (at the revolution of

17,000 rpm for model FS-1200), the laser beam reflects off of it and reaches the charged drum surface in a lengthwise manner.

A pair of (plastic) lenses provides focusing the horizontally sweeping laser beam onto the drum.

As the drum rotates, the laser beam sweeps the entire length of the drum so that the drum’s entire

circumference is exposed to the laser beam. The revolution of the polygon mirror motor and the

drum itself is timing-controlled so that each successive sweeping of the laser beam produces a

inch offset. The printer’s controller system continuously turns the laser beam on and off to put a

dot at every

1

/

inch distance horizontally. The diameter of a dot is typically 70 µm.

600

Synchronizing the output data with one scanning line is achieved by the photo sensor provided

next to the first mirror. At the beginning of each laser sweeping, the beam hits the photo sensor

which in turn sends a command to the logic controller for synchronization.

1

/

600

4-12

FS-1200

Page 83

Operation overview

Electrophotographics system

Development

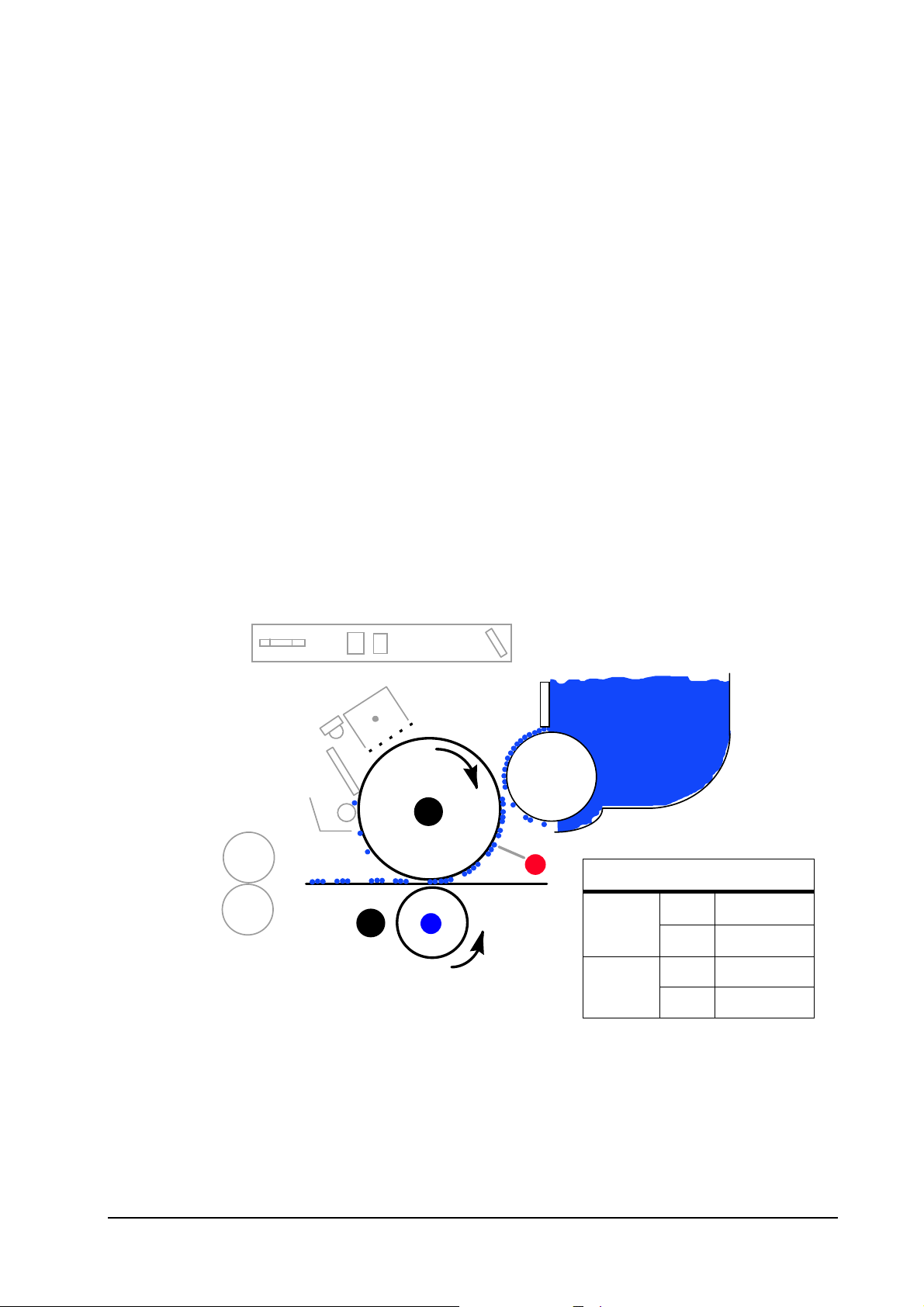

The latent image constituted on the drum is developed into a visible image. The developing roller

contains a 3-pole (

Toner attracts to the developing roller since it is powdery ink made of black resin bound to iron

particles. A magnetized blade positioned approximately 0.25-0.35 mm above the developing roller

constitutes a smooth layer of toner in accordance with the roller revolution.

S-N-S

) magnet core and an aluminum cylinder rot ating around the magne t core.

Drum

0.1mm

Magnetism

N

N

S

S

Blade

Magnet

0.25-0.35mm

S

Developing roller

4-13

FS-1200

Page 84

Developing roller bias

p

r

A

Operation overview

Electrophotographics system

The developing roller is connected to a

AC

-weighted, positive DC power source. Toner on the developing roller is given a positive charge. The positively charged toner is then attracted to the areas

of the drum which was exposed to the laser light. (The gap between the drum and the developing

roller is approximately 0.3 mm.) The non-exposed areas of the drum repel the positively-charged

toner as these areas maintain the positive charge.

The developing roller is also biased with an ac potential to apply compensation to the toner’s attraction and repelling actions for more contrast in the development.

Blade

Develo

Drum

. rolle

Toner

Toner sensor

C+DC

Toner

Drum

Develop. roller

4-14

FS-1200

Page 85

Operation overview

Electrophotographics system

Adjusted to prevent grey background

Surface

potential =

370V

+

+++ ++

Developing

Developing

+++ + ++

95V

Developing roller bias

240V DC+1.4kV AC

(f=2.4 kHz)

A toner replenishment sensor is provided within the developer. As the toner supply from the toner

container dwindle s and the toner level lowers in the reservoir, the sensor t ranslates it through i ts

diaphragm, urgi ng t he toner motor to feed more toner.

Sensable

level

Diaphragm

Toner

Developer unit

4-15

Toner sensor

FS-1200

Page 86

Operation overview

Electrophotographics system

Transfer

The image developed by toner on the drum (“A” below) is transferred onto the paper using the

electric charge attraction given by the toner itself and the transfer roller (“B” below). The transfer

roller is negatively biased so that the positively charged toner is attracted onto the paper while it is

pinched by the drum and the transfer roller.

The paper is automatically peeled off the drum because of the small diameter of the drum. To prevent thin paper wrapping around the drum, the static discharger brush is provided to reduce the attraction of the negatively charged paper to the positively charged drum.

A

+

B

-

Current

Voltage

Transfer bias

5µA

10µA

1.8KV Normal

2.5KV Thick

Normal, thick

B5 and smaller

The nominal transfer bias is set to approximately -1.8 kV (limit) with the current of 5µA. Since

thicker paper (91 to 200 g/m

2

) such as postcards,

OHP

, envelopes, etc., tend to require more bias

potential for the satisfactory transferring process, the transfer bias is user-switchable to -2.5 kV

DU

(limit) by using the printer’s operator panel. Double-sided printing using a

-20/

DU

-21 duplexer

automatically increases the transfer bias to the above value.

4-16

FS-1200

Page 87

Operation overview

Electrophotographics system

Fusing

The toner on the paper is permanently fused onto the paper as it passes between the florin-finished

heat roller (“A” below) and the pressure roller (“B” below) in the fuser unit. The toner is molten

and pressed into the paper. The heat roller has a halogen lamp, turning frequently on and off to

maintain a preheat temperature at approximately 180°C.

The heat roller temperature is constantly monitored by the engine control circuit using a thermistor. For safety against overheating, the fuser system is protected by a triac which automatically

opens power to the halogen lamp. If the temperature exceeds 350°C, it activates the thermo-cut

device to interrupt open power to the halogen lamp.

A

B

4-17

FS-1200

Page 88

Operation overview

Electrophotographics system

Drum cleaning and erasing static charge

The drum needs to be physically cleaned of toner remaining on its surface in the previous rotation.

The cleaning blade (A below) scrape against the drum to remove the waste toner. To collect the

waste toner, the waste toner bottle is connected to the end of the spiral roller (C below).

B

A

C

After the drum is physically cleaned, it then must be cleaned to an electrically neutral state. This is

necessary to erase any residual positive charges, ready to accept the next uniform charge. The

residual charge is canceled by exposing the drum to the light emitted from the eraser LED (

above) in the similar manner as described in page 4-6. This lowers the electrical conductivity of

the drum surface making the residual charge on the drum surface escape to the ground.

B

4-18

FS-1200

Page 89

Operation overview

Electrophotographics system

Typical photo process timing chart

The following chart shows the signals used for photo processing. These signals activate the corresponding device in the following timing sequences. A simple description for these signals follow.

MOTOR

PAPER

MHVDR

ERASER

BIAS

THVDR:

Page 1 Page 2

A

B

C

E

D

MHVDR (Main High Voltage DRive) -

kept on during the job is processed.

ERASER

BIAS -

on the current paper size (B) and turns off between pages (C).

- turns on the eraser (

turns on the developer bias (on the magnet roller). The duration of this signal is dependent

drives main charger with high voltage bias. This signal is

LED

array) as soon as the motor begins r evolving (A above).

4-19

FS-1200

Page 90

Operation overview

Electrophotographics system

THVDR (Transfer High Voltage Drive) -

verse (+520V) at the beginning of a print job (D)until the paper is actually fed onto the transfer

roller. This prevents contamination on the back side of paper by effectively repelling the toner

during the paper is not present between the drum and the transfer roller. The transfer bias is kept

on during a print job (E).

turns on the transfer bias. Note that the transfer bias is re-

4-20

FS-1200

Page 91

Paper feeding system

The paper feeding system picks up paper from the paper cassette or the manual feeding tray and at

a precise timing feeds it to the electrophotography system for developing image on the paper. It finally delivers the printed page to either the face-down or face-up tray.

The figure below shows the paper feeding path within the printer.

Operation theory

Paper feeding system

)

#

(

'

%

&

$

"

"

Paper (cassette). #Paper feed roller+clutch+sensor. $Registration rollers+clutch+sensor. %Drum.

&

Transfer roller. 'Fuser rollers. (Exit rollers+sensor.)Manual feed roller+clutch+sensor.

Following on the next page is another diagram showing locations of sensors, roller, and solenoids

arranged along with this paper path.

4-21

FS-1200

Page 92

Paper feed components/signals

*

EXITJ

JAM0

Face-dow n r ol lers

Engine Controller

*

MMOT*

MOTOR

Operation theory

Paper feeding system

MFDDR*HANDS

FDCL2*

*

MFEED*

*

REGDR

REGCL*

JAMR

FEEDS

JAM0

*

*

PAPER

FEDDR

FDCL1*

Exit

sensor

Exit rollers

Clutches Sensors Rollers

Main motor

Heat Roller

Pressure Roller

Drum

Transfer roller

Paper Ca ssett e

Regist.

clutch

Regist rollers

Regist

sensor

Paper

sensor

Feed

clutch

Manual

feed

clutch

Manual

feed

sensor

PAPRPATH.CDR

4-22

FS-1200

Page 93

Cassette feeding

Operation theory

Paper feeding system

The main logic controller sends the

essing. The engine controller

tion rollers, and the fuser heater. The engine controller then issues the

PRINT

* signal to the engine controller aft er finishing data p roc-

CPU

then starts the main motor (

MOTOR*

), polygon motor, registra-

FEDDR*

signal to connect the

main motor power to the paper feed tires. The tires feed the top sheet in the paper stack in the cassette towards the registration rollers until the paper reaches the registration jam sensor (FEEDS*).

As the engine controller sends VSREQ* to the main logic controller, the main logic controller subsequently issues VSYNC* to activate the registration rollers, thus starting to feed paper towards

the drum.

The paper is advanced to the drum, to the fuser unit, triggering the exit sensor (

EXITJ*

), and finally

delivered either to the face-down tray or the face-up tray as switched by the output stack selector

tab.

4-23

FS-1200

Page 94

Operation theory

Paper feeding system

Manual/multi purpose tray feeding

The printer recognizes the existence of paper on the manual feed or multi purpose tray when the

manual feed sensor is pushed up (

In manual paper feed mode, the paper placed on the manual feeding tray or multi purpose tray is

drawn in when the manual feed clutch is energized by the

roller.

HANDS

).

FEDDR*

signal to drive the manual feed

The subsequent print process is identical to the above section.

4-24

FS-1200

Page 95

Operation theory

Paper feeding system

Paper jam sensing

The registration sensor and the exit (fuser) sensor keep track of the paper sent through the printer’s

paper path by watching the time of period during which either sensor is kept activated.

Registration sensor -

flector (shiny mirror surface) at the end of the actuator is in the position that can reflect the light to

shine the receptor. As the top edge of the paper reaches the registration sensor, the reflector is

pushed up and the light is interrupted(➋), triggering the sensor.

A photo reflector sensor is used. While the paper is not present (➊), the re-

➊

➋

4-25

FS-1200

Page 96

Operation theory

Paper feeding system

Exit sensor -

fuser board. The actuator is in the way back at the fuser outlet. The reflector at one end of the actuator is normally seated in-between the photo transmitter and sensor (➊). It is dressed away out of

them when the paper in the fuser sensor pushed up the actuator (➋), allowing the light to hit the receptor and turning the sensor circuit on.

This is a photo penetration sensor, combined with an actuator arm extending to the

➊

➋

On detecting a paper jam, the engine controller stops printing action and shows the “Paper jam”

message. After removing paper jam, the printer resumes printing when either the toner access door

or the feed assembly is once opened and closed. If paper jammed past the exit sensor, the printer

will not attempt to print the same page.

Paper coming from the paper cassette should pass the registration sensor in a predetermined period

of time that begins with the feed clutch turned on (FEDDR*).

4-26

FS-1200

Page 97

Print timing charts

Operation theory

Print timing charts

4-27

FS-1200

Page 98

Operation theory

Print timing charts

4-28

FS-1200

Page 99

Operation theory

Print timing charts

4-29

FS-1200

Page 100

Operation theory

Print timing charts

4-30

FS-1200

Loading...

Loading...