Page 1

Laser printer

SERVICE

MANUAL

Published in Dec. ’01

Page 2

Revision history

Version Replaced pages RemarksDate

1.0

5-Dec-2001

Page 3

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 4

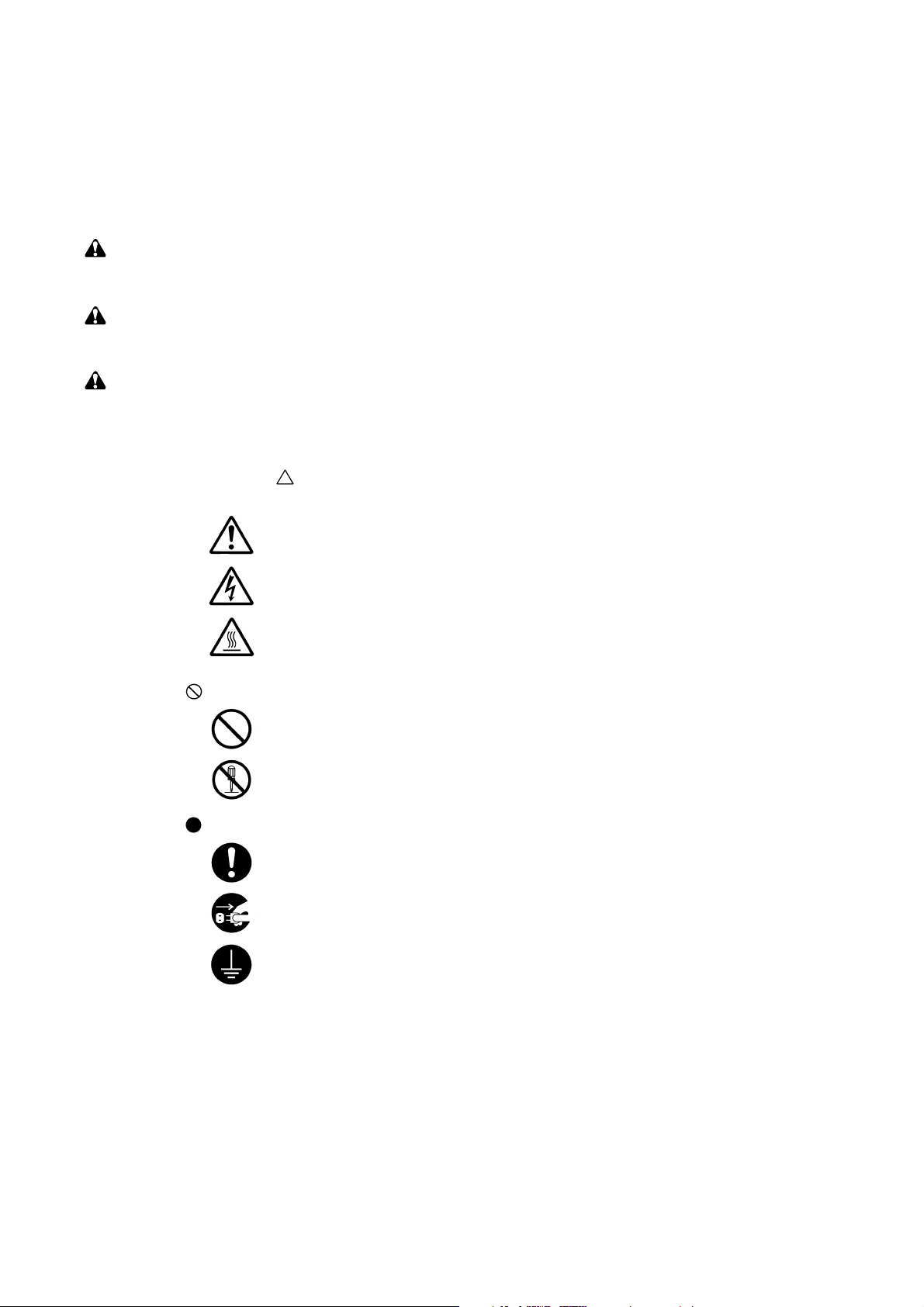

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the printer.

Page 5

1. Installation Precautions

WARNING

•Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the printer may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

•Do not place the printer on an infirm or angled surface: the printer may tip over, causing injury. ....

•Do not install the printer in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the printer near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the printer to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on printers so equipped. Failure to do this may

cause the printer to move unexpectedly or topple, leading to injury. ................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

•Advice customers that they must always follow the safety warnings and precautions in the

printer’s instruction handbook. ..........................................................................................................

Page 6

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. .............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

•When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the printer is correctly connected to an outlet with a ground connection. ...........

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

•Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. .........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. .........................................................................................................

• Do not remove the ozone filter, if any, from the printer except for routine replacement. ..................

Page 7

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

•Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ......

•Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

·Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

·Always wash hands afterwards.

•Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .........................................................................................................................

• Should smoke be seen coming from the printer, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

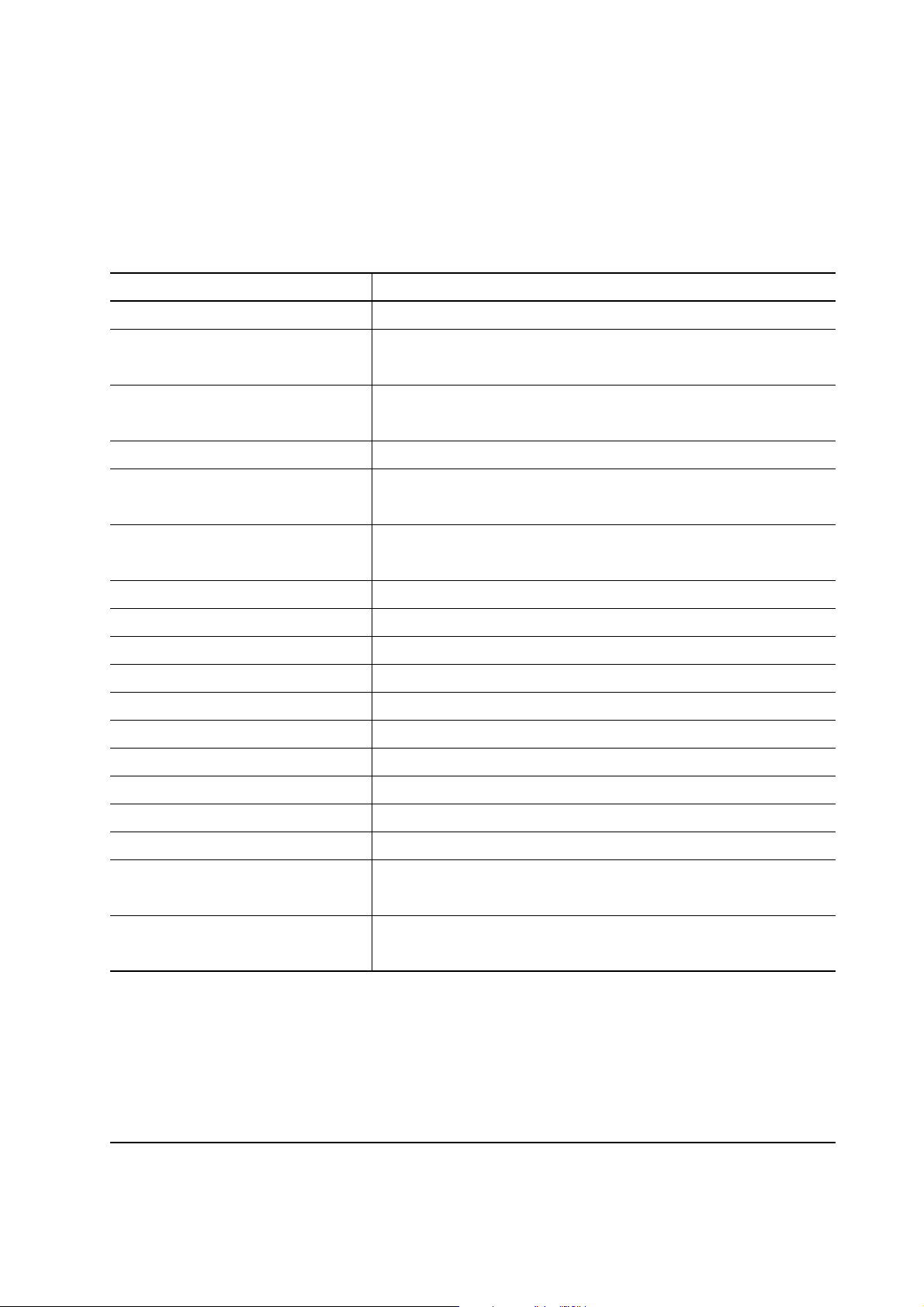

Page 8

Contents

Chapter 1

1-1 Printer specifications ....................................................................................................................................... 1-3

1-2 Names of parts ................................................................................................................................................ 1-6

1-3 Safety information ............................................................................................................................................1-7

1-4 Environmental requirements ..........................................................................................................................1-10

1-5 About the toner container .............................................................................................................................. 1-14

Chapter 2

2-1 Unpacking ........................................................................................................................................................2-3

2-2 Installing the printer ......................................................................................................................................... 2-4

2-3 Using the operator panel ............................................................................................................................... 2-15

Chapter 3

3-1 Maintenance/Adjustments ............................................................................................................................... 3-3

Chapter 4

4-1 Electrophotographic system ............................................................................................................................ 4-3

4-2 Paper feeding system .................................................................................................................................... 4-15

4-3 Electrical control system ................................................................................................................................ 4-18

Chapter 5

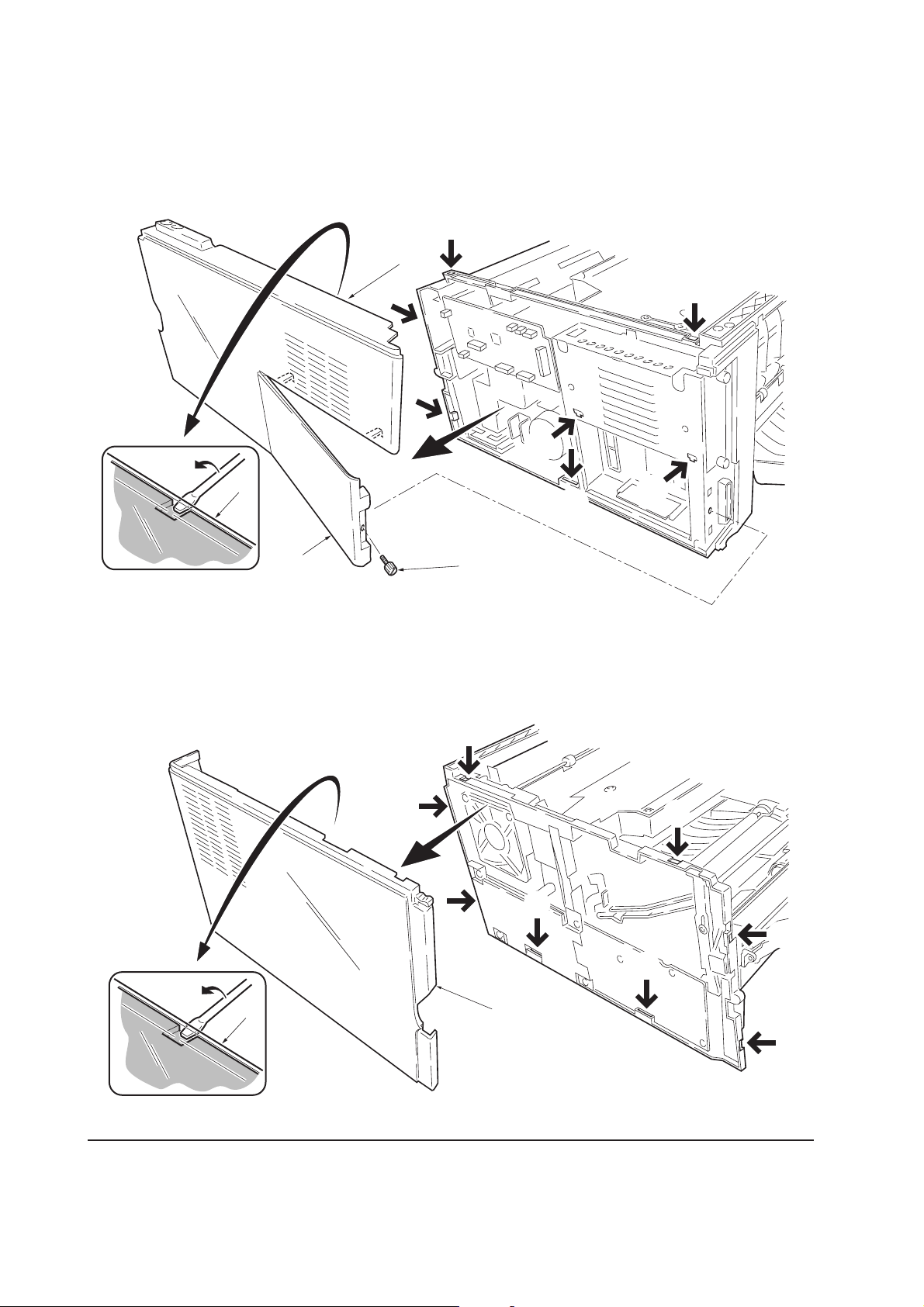

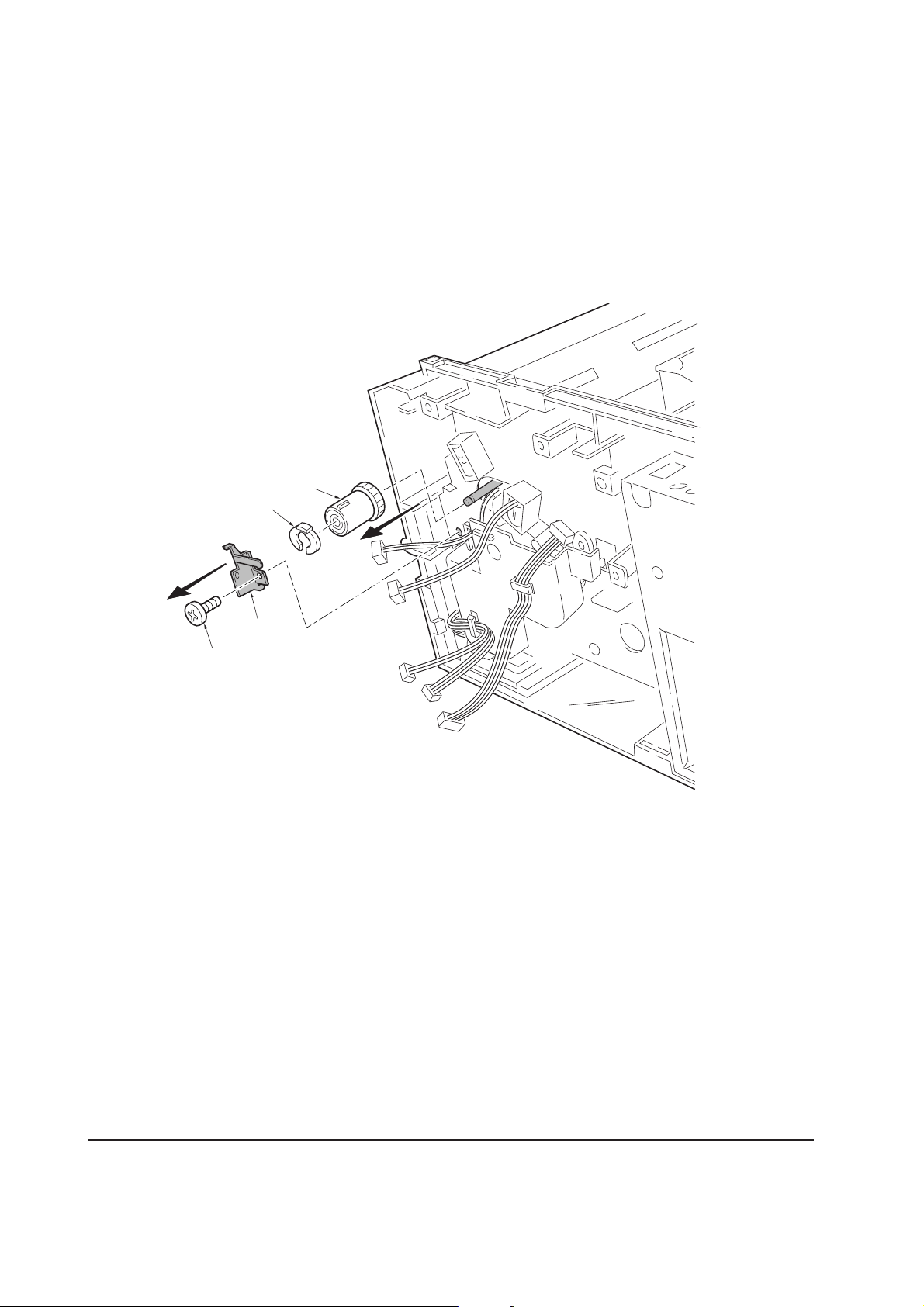

5-1 General instructions .........................................................................................................................................5-3

5-2 Disassembly .................................................................................................................................................... 5-4

Chapter 6

6-1 Troubleshooting ...............................................................................................................................................6-3

Appendix A

Timing charts ........................................................................................................................................................ A-3

Wiring diagram ...................................................................................................................................................... A-9

Appendix B

Status page ........................................................................................................................................................... B-3

Appendix C

Parallel interface ................................................................................................................................................... C-3

USB interface ........................................................................................................................................................ C-6

Serial interface (Optional) ..................................................................................................................................... C-7

1-1-1

Page 9

Chapter 1

Product Information

Page 10

Chapter 1 Contents

1-1 Printer specifications ...................................................................................................................... 1-3

1-1-1 Specifications ............................................................................................................................ 1-3

(1) Engine ................................................................................................................................. 1-3

(2) Controller ............................................................................................................................. 1-4

(3) Weight and dimensions ....................................................................................................... 1-4

(4) Power requirements ............................................................................................................ 1-5

(5) Environmental requirements ............................................................................................... 1-5

1-2 Names of parts ................................................................................................................................. 1-6

1-2-1 Name of parts ............................................................................................................................ 1-6

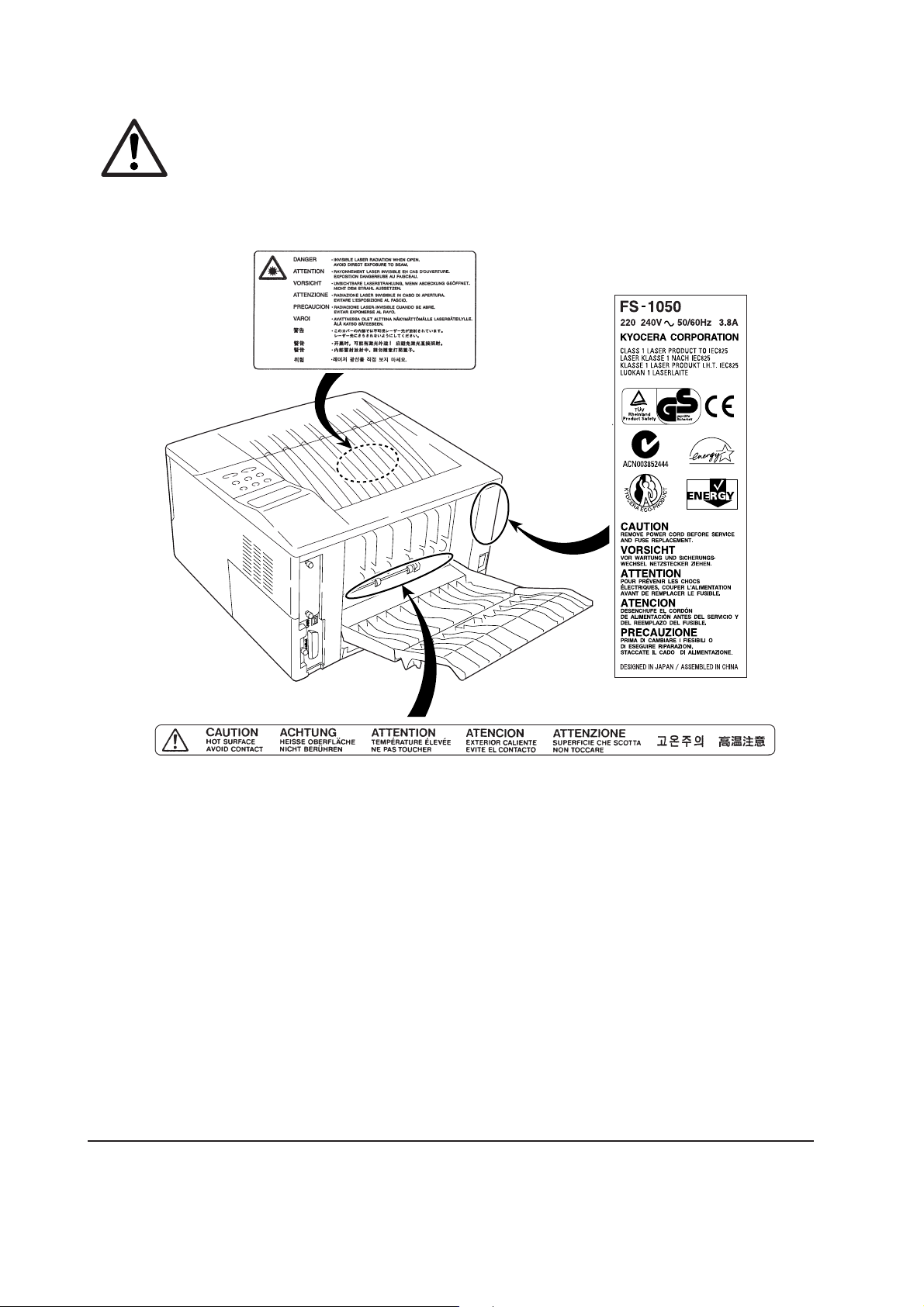

1-3 Safety information ........................................................................................................................... 1-7

1-3-1 Safety information ...................................................................................................................... 1-7

(1) Laser safety ......................................................................................................................... 1-7

(2) Laser notice ......................................................................................................................... 1-7

(3) Laser caution label on the scanner unit ............................................................................... 1-7

(4) CDRH regulations (U.S.A.) .................................................................................................. 1-9

(5) Ozone concentration ........................................................................................................... 1-9

(6) Optional equipment ............................................................................................................. 1-9

(7) Important note on the interface connectors ......................................................................... 1-9

1-4 Environmental requirements ........................................................................................................ 1-10

1-4-1 Environmental conditions ........................................................................................................ 1-10

(1) Clearance ...........................................................................................................................1-11

(2) Places to avoid .................................................................................................................. 1-12

(3) Note on power ................................................................................................................... 1-12

(4) Removing the printer ......................................................................................................... 1-13

1-5 About the toner container ............................................................................................................. 1-14

1-5-1 Toner container ........................................................................................................................ 1-14

(1) Toner container handling ................................................................................................... 1-14

(2) Toner container storage ..................................................................................................... 1-15

Page 11

1-1 Printer specifications

1-1-1 Specifications

(1) Engine

Item Specification

Print method

Print speed (when printing

multiple pages)

Resolution (dpi)

Smoothing

First print (A4 or letter, 23 °C),

depends on input data

Warm-up time at 23 °C

Maximum duty cycle (A4)

Process unit life expectancy

Developing

Laser diode

Main charger

Transferring

Separation

Drum cleaning

Drum discharging

Fuser

Paper

Capacity of paper feed trays

(80 g/m2 [0.11 mm thickness])

Electrophotography laser scan

14 pages/min. (A4)

15 pages/min. (Letter)

Fast 1200 mode (1800 horizontal/600 vertical)

600 horizontal/600 vertical

KIR (Kyocera Image Refinement)

22 seconds or less

10 seconds or less (from sleep mode)

15 seconds or less (from power on)

100,000 pages of printing or 3 years, whichever reached first

Mono component developer

Visible laser

Scorotron positive charging

Negative charger roller

Curvature separation

Blade

Eraser lamp (LED array)

Heat roller and press roller

Plain paper: Legal to A5

Cassette: 250 sheets, MP tray: 50 sheets

Capacity of output trays

(80 g/m2 [0.11 mm thickness])

Face-up: 30 sheets, Face-down: 150 sheets

FS-1050

1-3

Page 12

(2) Controller

Item Specification

CPU

System ROM

Font ROM

Optional font ROM (Dip socket)

Main (Video) RAM

Expanding RAM (DIMM slot × 1)

Host interface

Page description language

Standard emulation modes

PowerPC405/200MHz

4 MB Flash DIMM

2 MB (16 M bit × 1)

1 MB (Optional KPDL2 Upgrade kit)

16 MB (Standard-equipped on main board)

Maximum 144 MB (Including the standard 16 MB main RAM)

(Accepts any of 16/32/64/128 MB DIMM)

Parallel: High-speed, bidirectional (IEEE1284)

USB: Revision 1.1 standards

Serial (option) : RS-232C/RS-422A, Max. speed: 115.2 Kbps

(Optional serial interface board)

KUIO-LV (3.3 V)

Prescribe 2e

PCL6, Diablo 630, IBM proprinter X24E, Epson LQ850, Line

printer, KPDL2

(3) Weight and dimensions

Item Specification Item S

Main unit (excl. protrusions)

Width: 378 mm (147/8 inches)

Height: 244 mm (83/4 inches)

Depth: 375 mm (143/4 inches)

Weight: 9.8 Kg (2015/16 lb.)

FS-1050

1-4

Page 13

(4) Power requirements

Item Specification Item S

Vo ltage/current requirement

Watts

220 to 240 V AC ±10 %, 50/60 Hz ±2 %/3.8 A

Normal operation: 265 W

Maximum: 818 W

Standby: 13 W

Sleeping: 5 W

(5) Environmental requirements

Item Specification Item S

Operating temperature and

10 to 32.5 °C (50 to 90.5 °F), 20 to 80 %RH

humidity

Maximum altitude

2,000 m (6,500 feet)

Noise emission (Excluding peaks,

measured at 1 m from printer,

as per ISO7779)

50 dB (A) maximum/28 dB (A) at standby/unmeasureably low

at sleeping)

1-5

FS-1050

Page 14

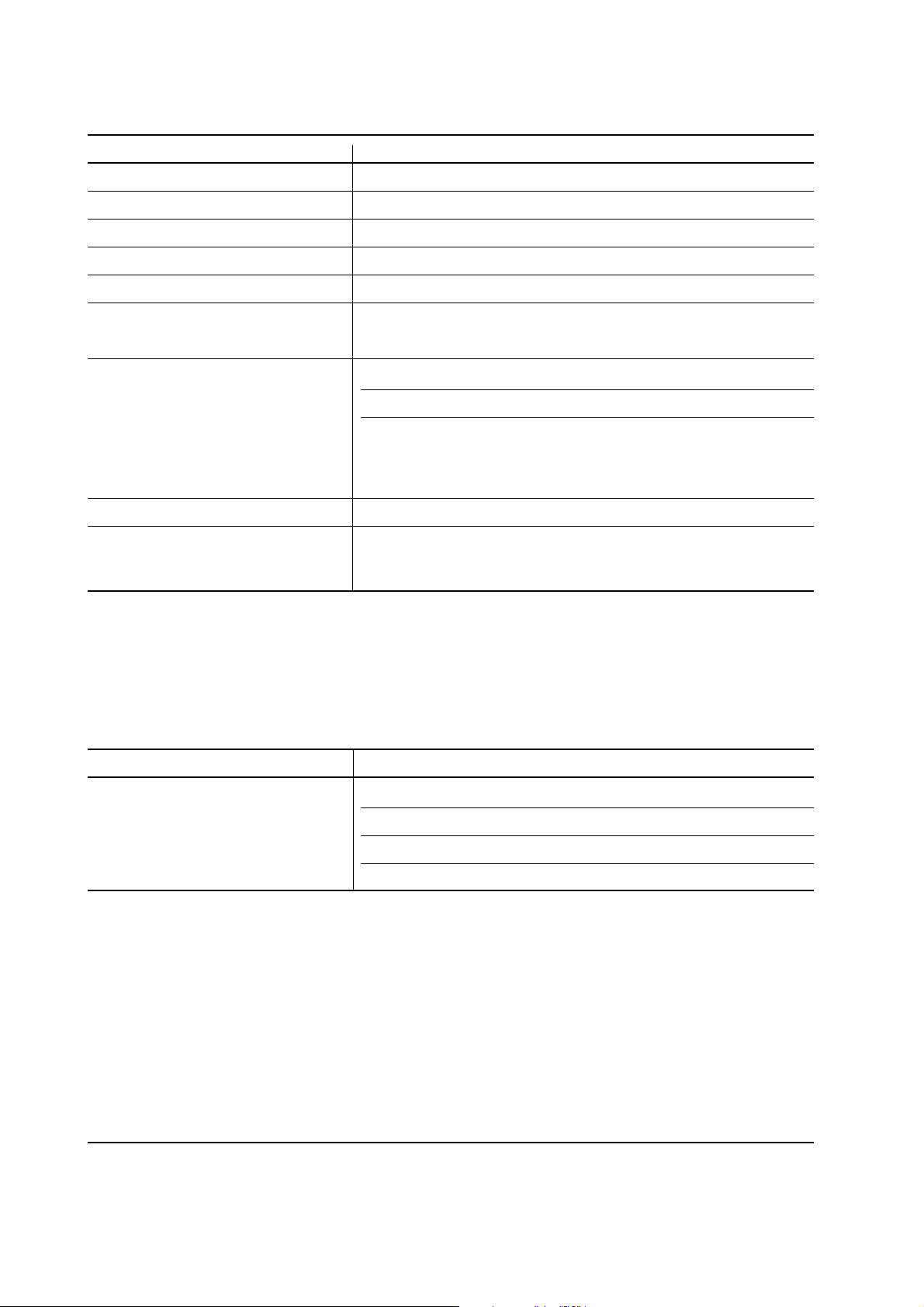

1-2 Names of parts

1-2-1 Name of parts

1

8

7

!

0

6

2

3

5

4

9

1 Top cover

2 Face-down output tray

3 Face-up output tray

4 Side cover

5 Operator panel

6 Front cover

7 Paper cassette

Figure 1-2-1 Name of parts

@

#

8 MP tray

9 Option card slot

0 Parallel interface connector

! USB interface connector

@ Power switch

# AC inlet

FS-1050

1-6

Page 15

1-3 Safety information

1-3-1 Safety information

(1) Laser safety

This printer is certified as a Class 1 laser product under the U.S. Department of Health and Human

Services (DHHS) Radiation Performance Standard according to Radiation Control for Health and

Safety Act of 1968. This means that the printer does not produce hazardous laser radiation. Since

radiation emitted inside the printer is completely confined within protective housings and external

covers, the laser beam cannot escape from the printer during any phase of user operation.

(2) Laser notice

This printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter for

Class I (1) laser products, and elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 825.

(3) Laser caution label on the scanner unit

The laser scanner unit has the following label affixed atop. Observe these cautionary statements

and figures when handling the laser scanner unit.

1-7

FS-1050

Page 16

WARNING Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Label on the scanner unit

(Inside the printer)

Label on the left cover rear side

-

FS-1050

Label on the fuser unit

Figure 1-3-1 Caution labels

1-8

Page 17

(4) CDRH regulations (U.S.A.)

The Center of Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration

implemented regulations for laser products on August 2, 1976. These regulations apply to laser

products manufactured after August 1, 1976. Compliance is mandatory for products marketed in

the United States. A label indicating compliance with the CDRH regulations must be attached to

laser products marketed in the United States.

(5) Ozone concentration

The printers generate ozone gas (O3) which may concentrate in the place of installation and cause

an unpleasant smell. To minimize concentration of ozone gas to less than 0.1 ppm, we recommend

you not to install the printer in a confined area where ventilation is blocked.

(6) Optional equipment

The printer may be optionally installed with the following units:

• PF-17 Paper feeder (250 sheets)

• Serial interface board

• Network interface card

• Memory card

(7) Important note on the interface connectors

Be sure to turn off printer power before connecting or disconnecting an interface cable to the printer.

For protection against static discharge which may be applied to the printer’s internal electronics

through the interface connector(s), keep any interface connector which is not in use capped using

the protective cap supplied.

1-9

FS-1050

Page 18

1-4 Environmental requirements

1-4-1 Environmental conditions

The Environmental requirements section on page 1-5 should be observed to ensure the optimum

operation of the printer. The use of the printer in a location which does not satisfy the requirements

may result in troubles and risk shortening its service life.

The printer will work best if it is installed in a location that is:

• Level and well supported (Place the printer on a table or desk.)

• Not exposed to sunlight or other bright light (not next to an uncurtained window). Do not place

the printer on an unstable cart, stand or table.

• Near an AC wall outlet, preferably one that can be used for the printer alone. The outlet should

have a ground slot, or an adapter should be used. If you use an extension cord, the total length of

the power cord plus extension cord should be 17 feet or 5 meters or less.

• Well ventilated, not too hot or cold, and not too damp or dry (See section Environmental

requirements on page 1-5). If you install the printer where the temperature or humidity is outside

the requirements in section Environmental requirements in chapter 1, the best print quality may

not be expected and there will be an increased chance of paper jams.

• Provide a sufficient clearances around the printer to ensure ventilation and ease of access. (See

section Clearance on next page).

FS-1050

1-10

Page 19

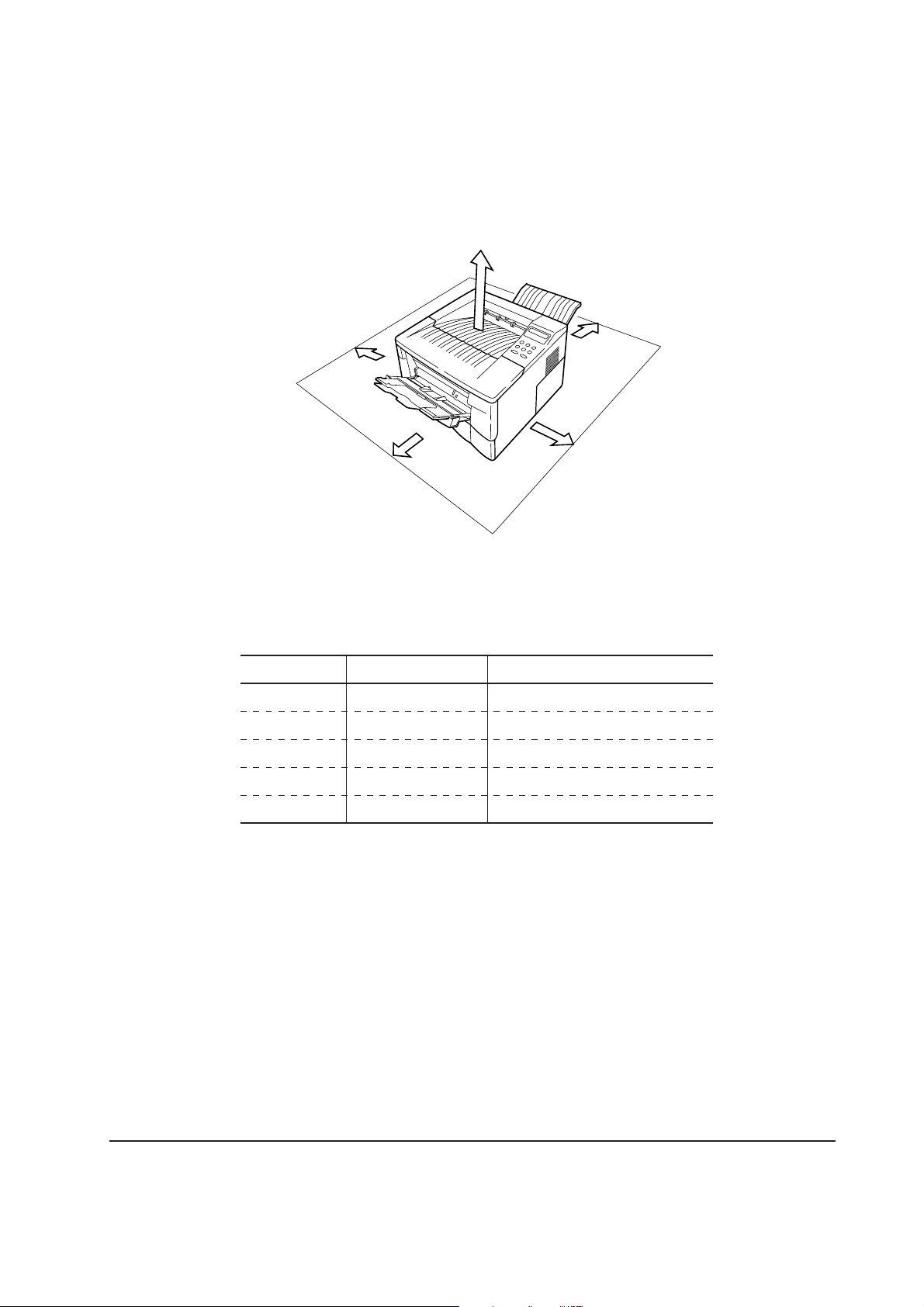

(1) Clearance

5

1

2

3

4

Allow the necessary minimum clearance on all sides of the printer as diagrammed below.

Figure 1-4-2 Clearances

Ref. Clearance Dimensions

1 Left 25 cm (9-7/8 inches)

2 Front 50 cm (19-11/16 inches)

3 Right 25 cm (9-7/8 inches)

4 Back 40 cm (15-3/4 inches)

5 Above 30 cm (11-13/16 inches)

FS-1050

1-11

Page 20

(2) Places to avoid

Avoid installing the printer in locations exposed to:

• Direct drafts of hot or cold air.

• Direct drafts of outside air. (Avoid locations next to outside doors.)

• Sudden temperature or humidity changes.

• Any source of high heat, such as a radiator or stove.

• Excessive dust. Dust and smoke may cause contamination on the laser scanner window, causing

print quality problem.

• Vibration.

• Ammonia fumes or other harmful fumes. (In case of fumigating the room or saturate it with

insecticide, remove the printer first.)

• Avoid greenhouse-like rooms. (Because of sunlight and humidity.)

• Avoid enclosed spaces that block ventilation.

• Avoid sites more than 6,500 feet or 2,000 meters above sea level.

(3) Note on power

Use only the power source voltage conforming to the printer’s rated power voltage. Do not use

other power sources.

• Disconnect the printer from the power source before attempting removal or replacement of an

electrical component or a printed-circuit board.

• The printer should not be connected to a power source until the instruction is given to do so

when performing tests described in this manual.

• In connecting the printer power, exercise an extreme care in handling the power supply or any

other electric parts which may give an electric shock.

• Before performing maintenance or repair, power from both the power source and the associated

peripheral devices (computer, sorter, etc.) should be disconnected, unless otherwise specified.

• To avoid possible electrical shock, extreme caution must be exercised in handling the power

cord and any other electrical part.

• An easily accessible socket outlet must be provided near the equipment.

WARNING As the disconnect device is not incorporated in the printer’s AC primary

circuit, an easily accessible socket outlet must be provided near the equipment.

FS-1050

1-12

Page 21

(4) Removing the printer

Observe the following precautions in removal and transportation of the printer.

• Be sure to repack the printer in its original carton.

• Do not leave the printer, toner container, process unit and other printer modules inside a vehicle

if the outdoor temperature is more than 25 °C. As unexpectedly high temperature may develop

inside when a vehicle is parked for a long period of time, the drum, toner container, process unit

and the supplies should be removed from the vehicle. The vehicle during transportation should

be parked in the shade or with the window open to allow minimum air circulation or the adequate

air conditioning should be made.

• Should the printer be left in a vehicle, it may not be exposed to the temperature change of more

than 7 °C within 30 minutes.

• Before removing the printer to a warm place, wrap it in a blanket, etc., before crating it. Allow

approximately two to three hours after having moved after uncrated. Failure to observe the

above may result in moisture condensation which will affect the performance of the printer.

1-13

FS-1050

Page 22

1-5 About the toner container

1-5-1 Toner container

The printer should use a TK-17 toner kit. To ensure the high print quality and long service life, the

following handling precautions should apply.

CAUTION As the Ecosys printers are designed to ensure the optimum print quality when

used with Kyocera’s proprietary toner, Kyocera do not recommend to use any

refilled toner containers that may be available commercially. This is because

Kyocera have no means of control over how such refilled toner could affect the

print quality and the reliability of the printer.

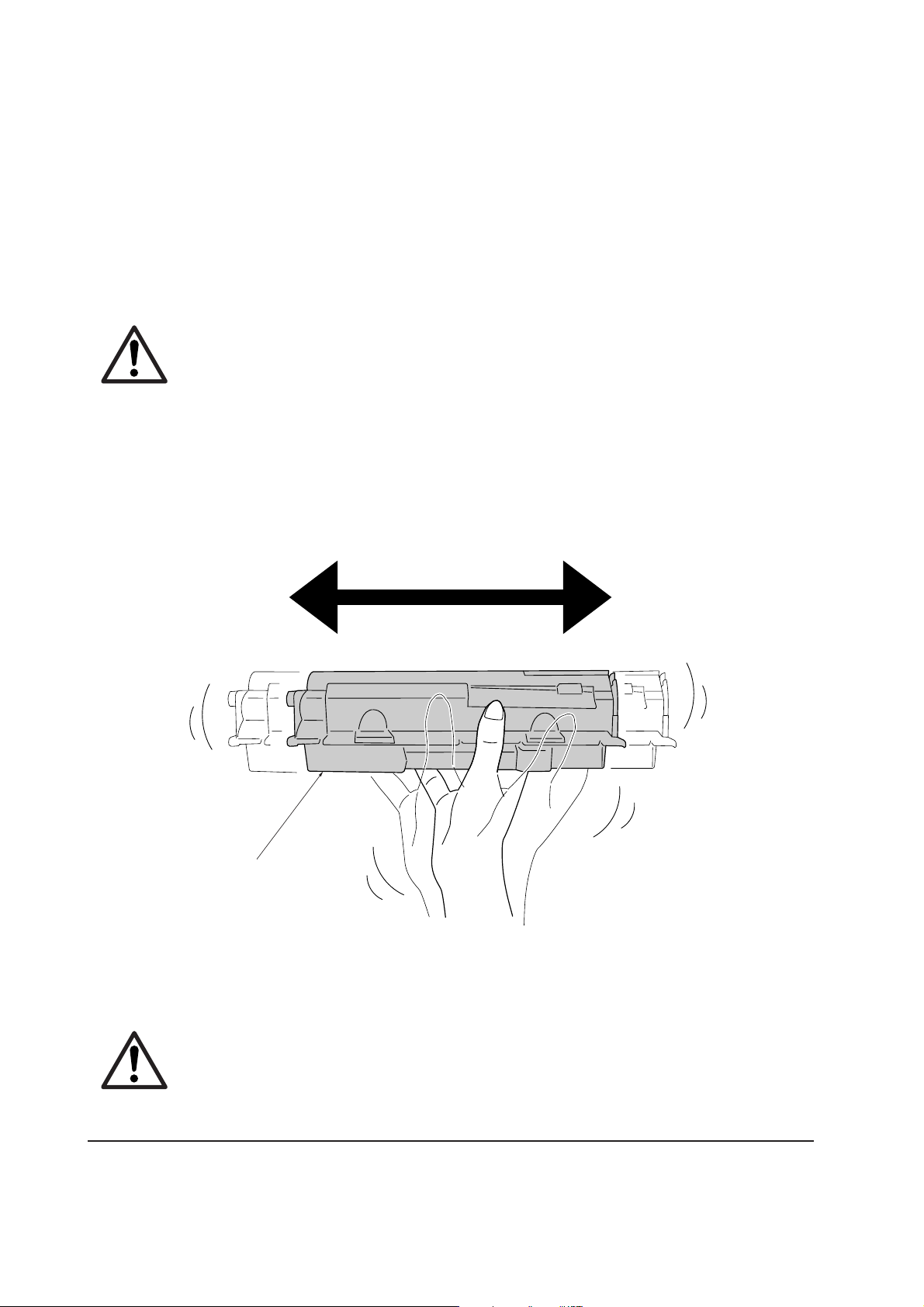

(1) Toner container handling

To loosen and mix the toner inside before use, with the label side down, thoroughly shake the toner

container 1 horizontally at least five times.

1

Figure 1-5-1 Toner container handling

CAUTION Do not attempt to disassemble or refill the toner container.

FS-1050

1-14

Page 23

(2) Toner container storage

The toner contained in the container is susceptible to temperature and humidity. To ensure the high

print quality, store the toner container in a place that satisfies the following environmental conditions:

Temperature: -20 to 40 °C (-4 to 104 °F)

Humidity: 15 to 90 % RH

NOTE If the toner container is removed from the printer’s developer unit, put it in a

protective bag and keep it in a dark place.

CAUTION If the printer is shipped for return, etc., do not ship it with the toner container

installed. Otherwise, toner may leak and contamination may result in the

printer.

1-15

FS-1050

Page 24

Chapter 2

Installation/Operation

Page 25

Chapter 2 Contents

2-1 Unpacking......................................................................................................................................... 2-3

2-1-1 Unpacking and inspection ......................................................................................................... 2-3

2-2 Installing the printer ........................................................................................................................ 2-4

2-2-1 Installing the toner container ..................................................................................................... 2-4

2-2-2 Expanding memory .................................................................................................................... 2-8

(1) Minimum memory requirements .......................................................................................... 2-8

(2) DIMM specifications ............................................................................................................ 2-8

(3) Notes on handling DIMM ..................................................................................................... 2-9

(4) Installing the DIMM ............................................................................................................ 2-10

(5) Testing the expansion memory ........................................................................................... 2-11

(5) Installing the memory card (CompactFlash) ...................................................................... 2-12

(6) Installing the network interface card .................................................................................. 2-14

2-3 Using the operator panel............................................................................................................... 2-15

2-3-1 Operator panel ......................................................................................................................... 2-15

(1) LED Indicators ................................................................................................................... 2-15

(2) keys ................................................................................................................................... 2-16

(3) LCD message display ....................................................................................................... 2-17

Interface indicator ................................................................................................................... 2-18

Paper size indicator ................................................................................................................ 2-18

2-3-2 Menu selection system ............................................................................................................ 2-19

(1) Menu selection and sequence ........................................................................................... 2-19

Page 26

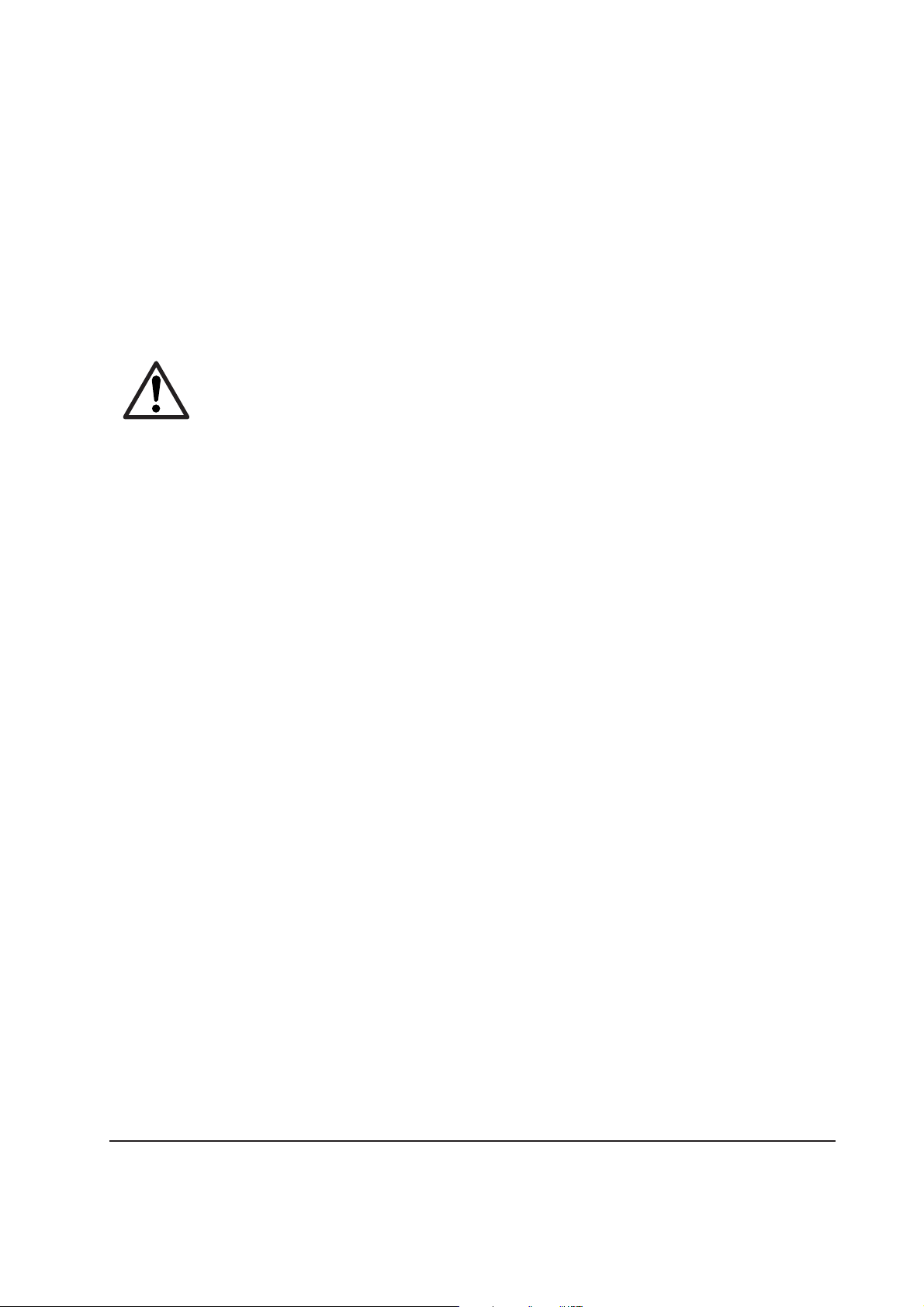

2-1 Unpacking

2-1-1 Unpacking and inspection

The package should contain the printer and the accessories as shown in the figure below. Remove

the printer and all the accessories from the package. For unpacking, place the box containing the

printer on a flat, stable surface. Remove the manuals, toner kit, and other items located on top of the

spacer and remove the spacer. Carefully remove the printer.

Cleaning cloth

Power cord

Printer

Installation guide

Toner container (TK-17)

Kyocera Mita digital library

CD-ROM

Figure 2-1-1 Unpacking (1)

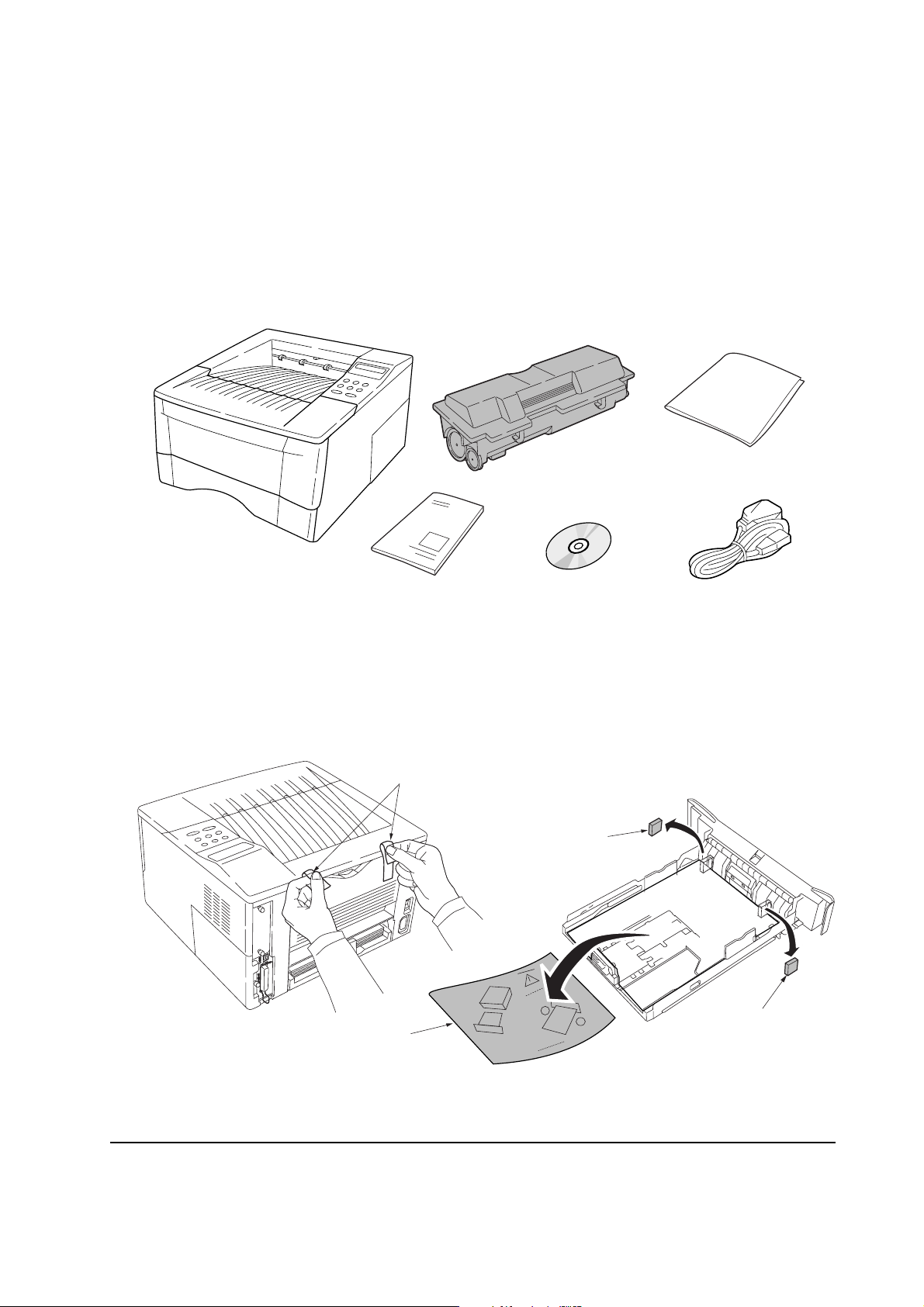

Remove the tape on the rear side of the printer, and remove the two spacers and the printed notice

from the paper cassette.

Tapes

Spacer

Printed notice

Figure 2-1-2 Unpacking (2)

2-3

Spacer

FS-1050

Page 27

2-2 Installing the printer

Installing the printer requires several steps. Proceed as follows in sequence. If the option paper

feeder is used with the printer, begin installation with connecting the printer and the paper feeder.

For details, refer to the optional Paper feeder’s Service Manual.

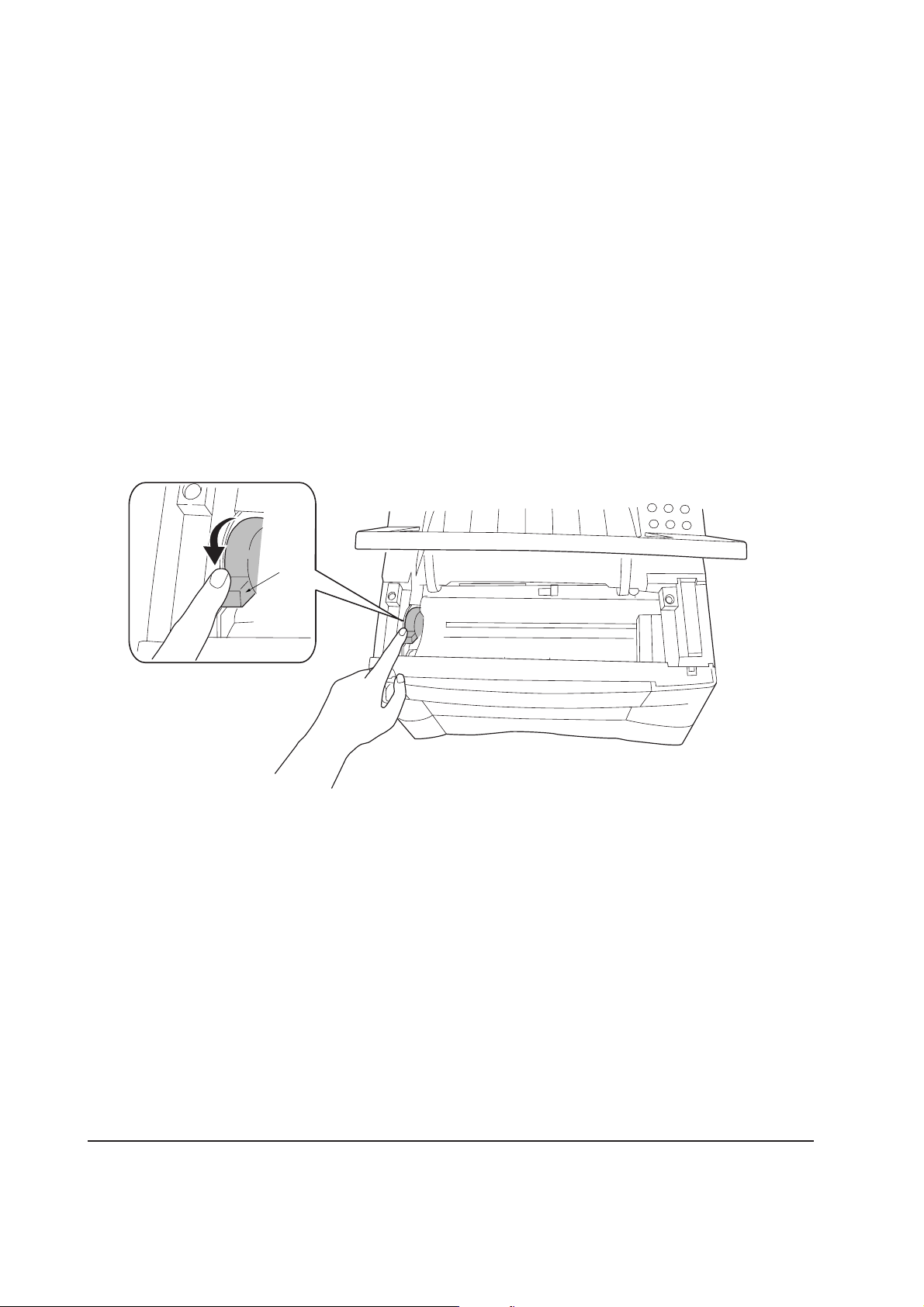

2-2-1 Installing the toner container

1. Open the top cover all the way.

2. Confirm that the lock lever #1 1 is in the release (forward) position. If not, pull it forward until

it is in the release position.

1

Figure 2-2-1 Confirming the lock lever #1

FS-1050

2-4

Page 28

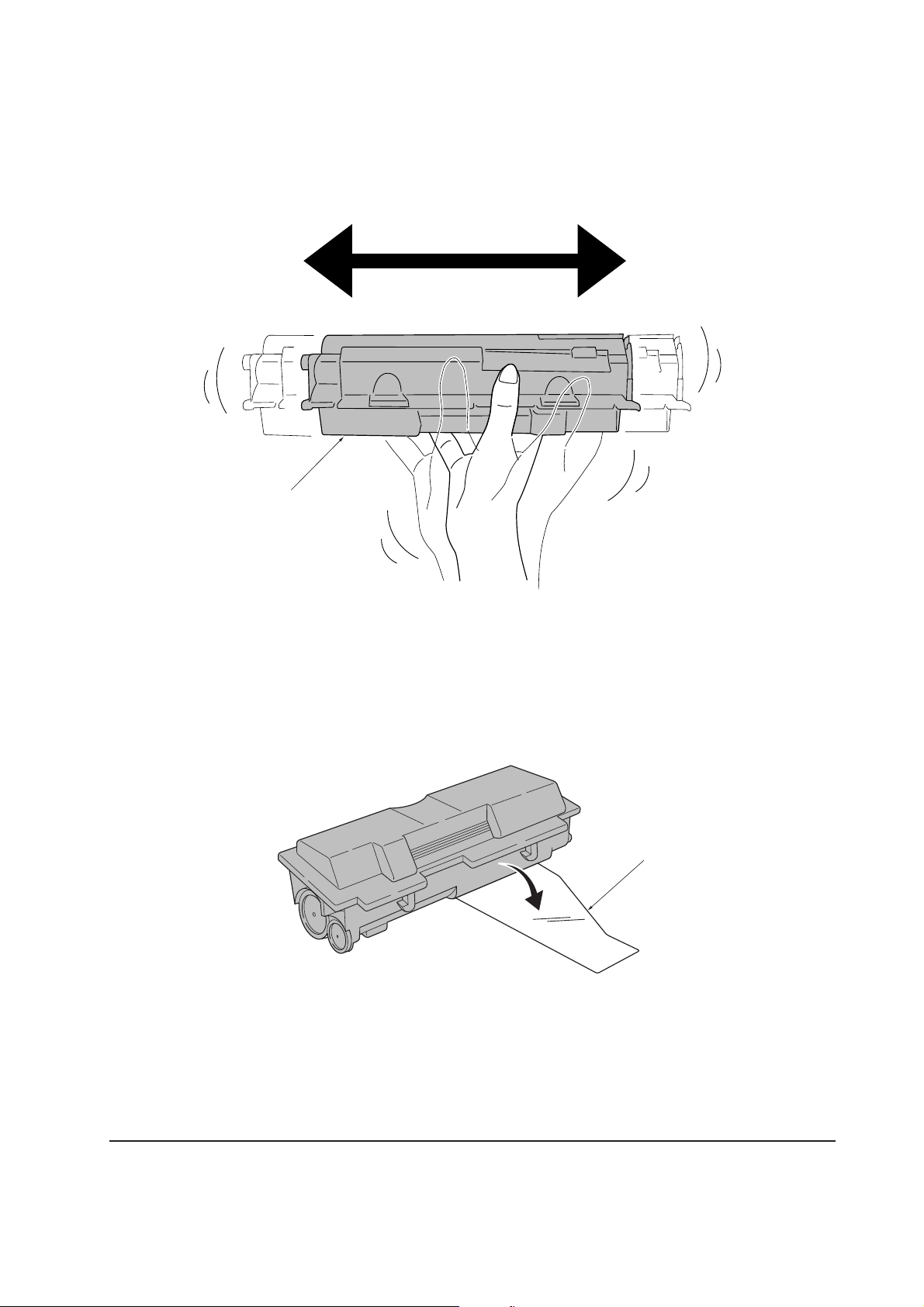

3. Take the toner container 2 from the bag. Hold it with the protective seal 3 (orange-colored)

facing up. Shake the toner container 2 horizontally at least five times. This ensures that the

toner is evenly distributed inside.

2

Figure 2-2-2 Shaking the toner container

4. Carefully remove the protective seal 3.

Figure 2-2-3 Removing the protective seal

3

2-5

FS-1050

Page 29

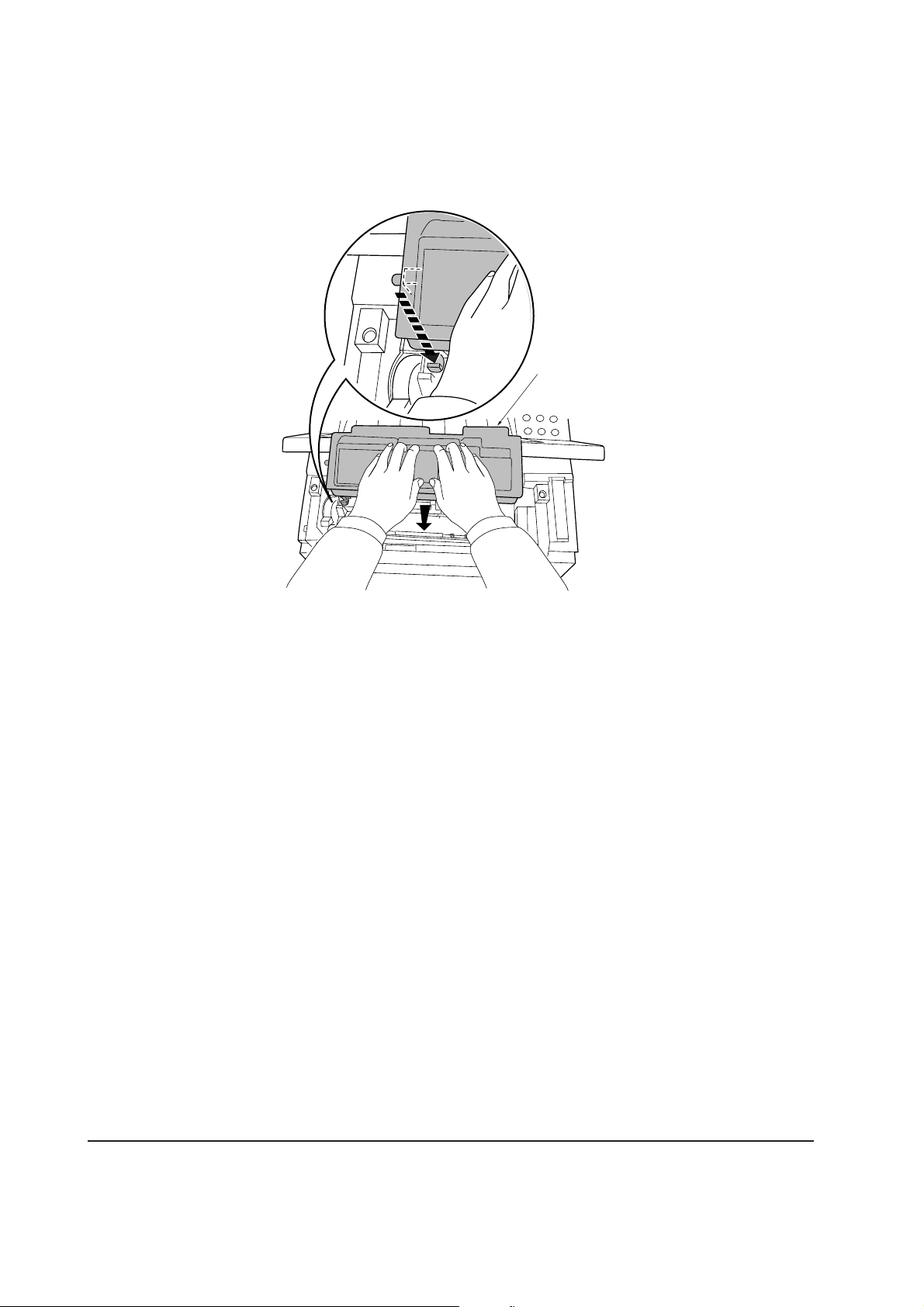

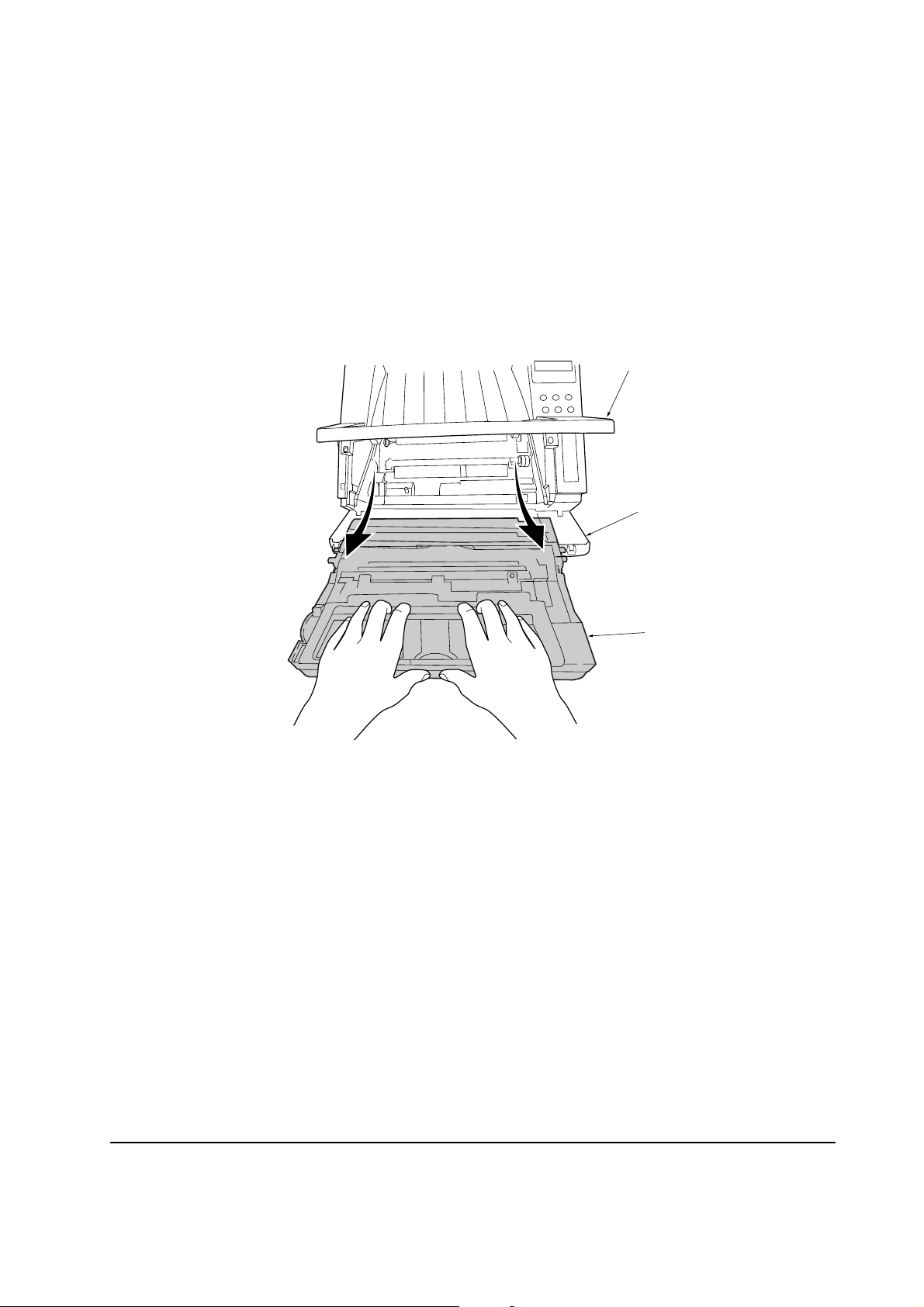

5. Install the toner container 2 into the printer.

6. Push firmly on the top of the toner container 2 at the positions marked [PUSH HERE].

2

Figure 2-2-4 Installing the toner container

FS-1050

2-6

Page 30

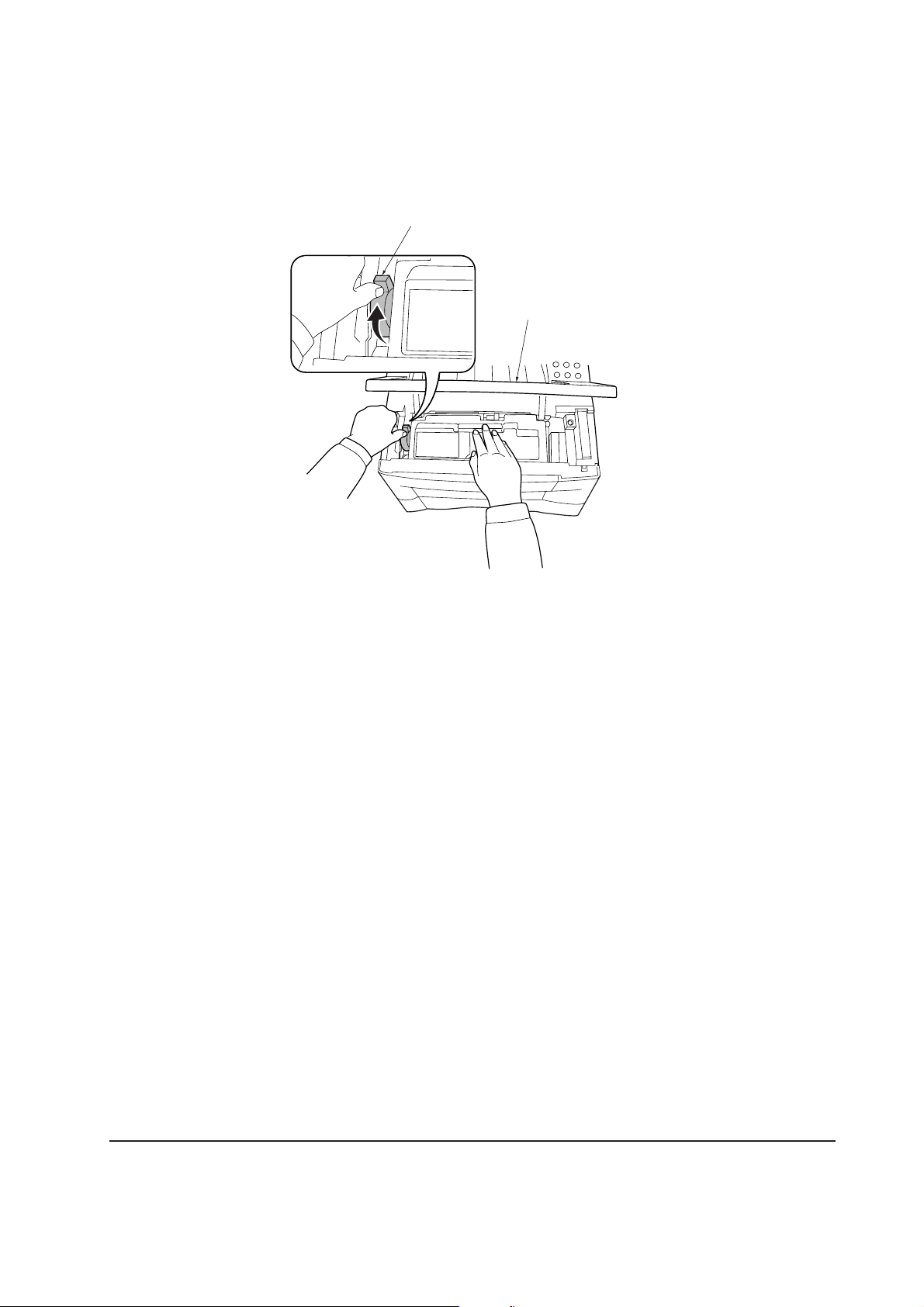

7. Push the lock lever #1 1 to the lock position.

8. Close the top cover 4.

1

LOCK

UNLOCK

LOCK

UNLOCK

4

Figure- 2-2-5 Locking the toner container

NOTE The printer is shipped from the factory with no toner supplied in its developer

(Process unit). When the printer is first switched on after the toner container is

installed in the manner above, there will be a delay of several minutes before

the printer gets ready to print a job.

This delay is necessary for the printer to fill the developer reservoir with a

sufficient amount of toner to continuously support a print job. The period of

time is approximately 15 minutes.

If the toner low or replace toner indication does not go off after installing the

new toner container, take the toner container out once, shake it well, then

install again.

2-7

FS-1050

Page 31

2-2-2 Expanding memory

The FS-1050 printer comes standard equipped with 16 MB of main memory on the main board.

Printer memory can be expanded to up to the maximum 144 MB (16 + 128 MB).

(1) Minimum memory requirements

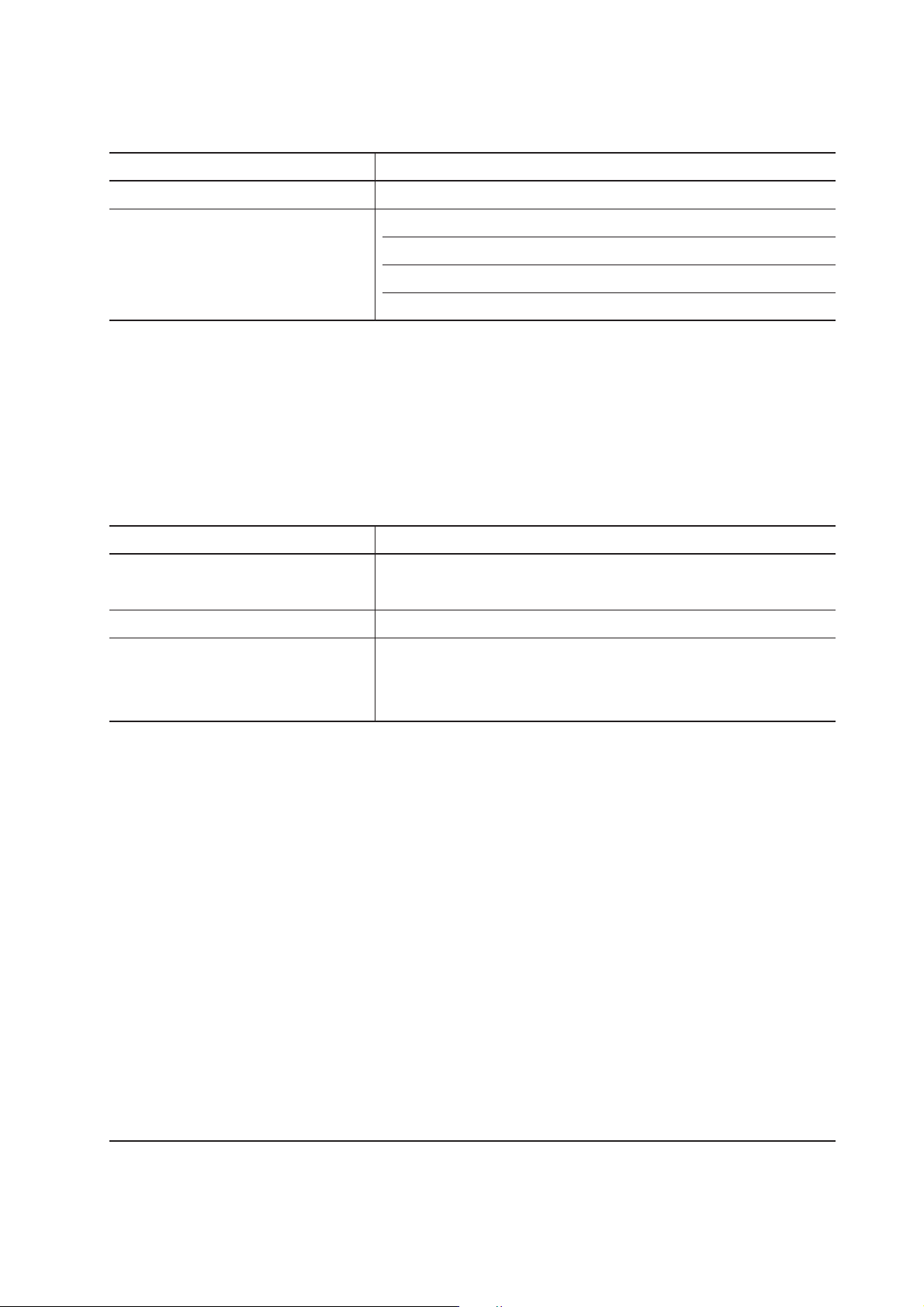

Refer to the table below for minimum memory requirements in various environments.

Resolution

Printing environment (Emulation) 300 dpi 600 dpi

HP LaserJet 5P (factory setting) 2 MB 2 MB

HP LaserJet 5P with resource protection - 10 MB

(2) DIMM specifications

Memory size in MB 16, 32, 64, 128 MB

Number of pins 100 pins

Access speed 66 MHz

Parity None

Bus width 32 bits

FS-1050

2-8

Page 32

(3) Notes on handling DIMM

Before proceeding to install DIMM, read the following notes for handling the main board and

DIMMs:

• Protect the electronics by taking these precautions:

• Before touching a DIMM, touch a water pipe or other large metal object to discharge yourself

of static electricity. While doing the work, it is recommended that you wear an antistatic wrist

strap.

• Touch the main board and DIMM only by the edges, not in the middle.

Figure 2-2-6 Handling DIMM

2-9

FS-1050

Page 33

(4) Installing the DIMM

The main board of the printer is equipped with one socket for memory expansion. Expansion memory

is available in the form of DIMM (Dual In-line Memory Module).

CAUTION Take precautions that no foreign substances such as metal chips or liquid get

inside the printer during the installation process. Operation of the printer during

the presence of a foreign substance may lead to fire or electric shock.

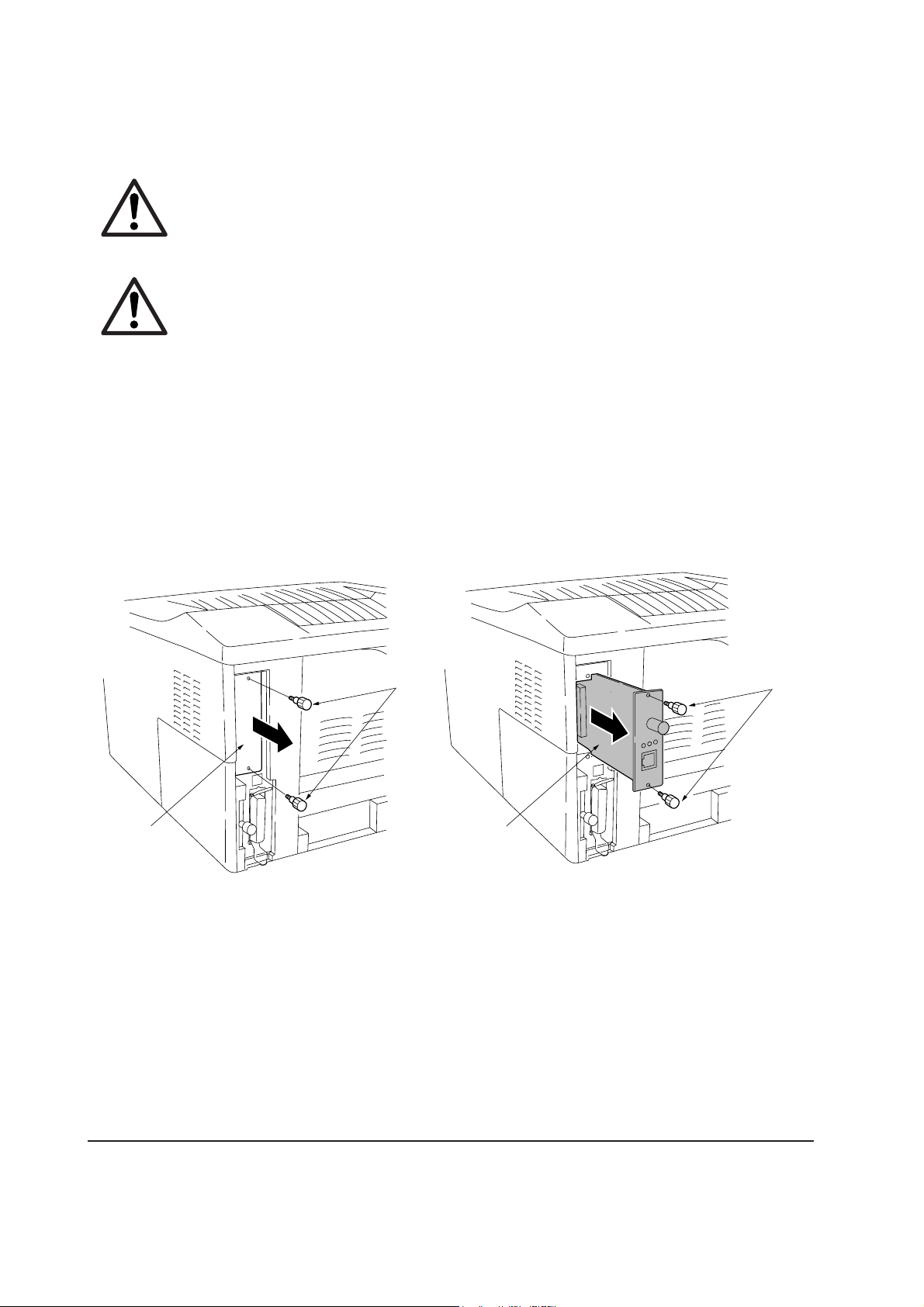

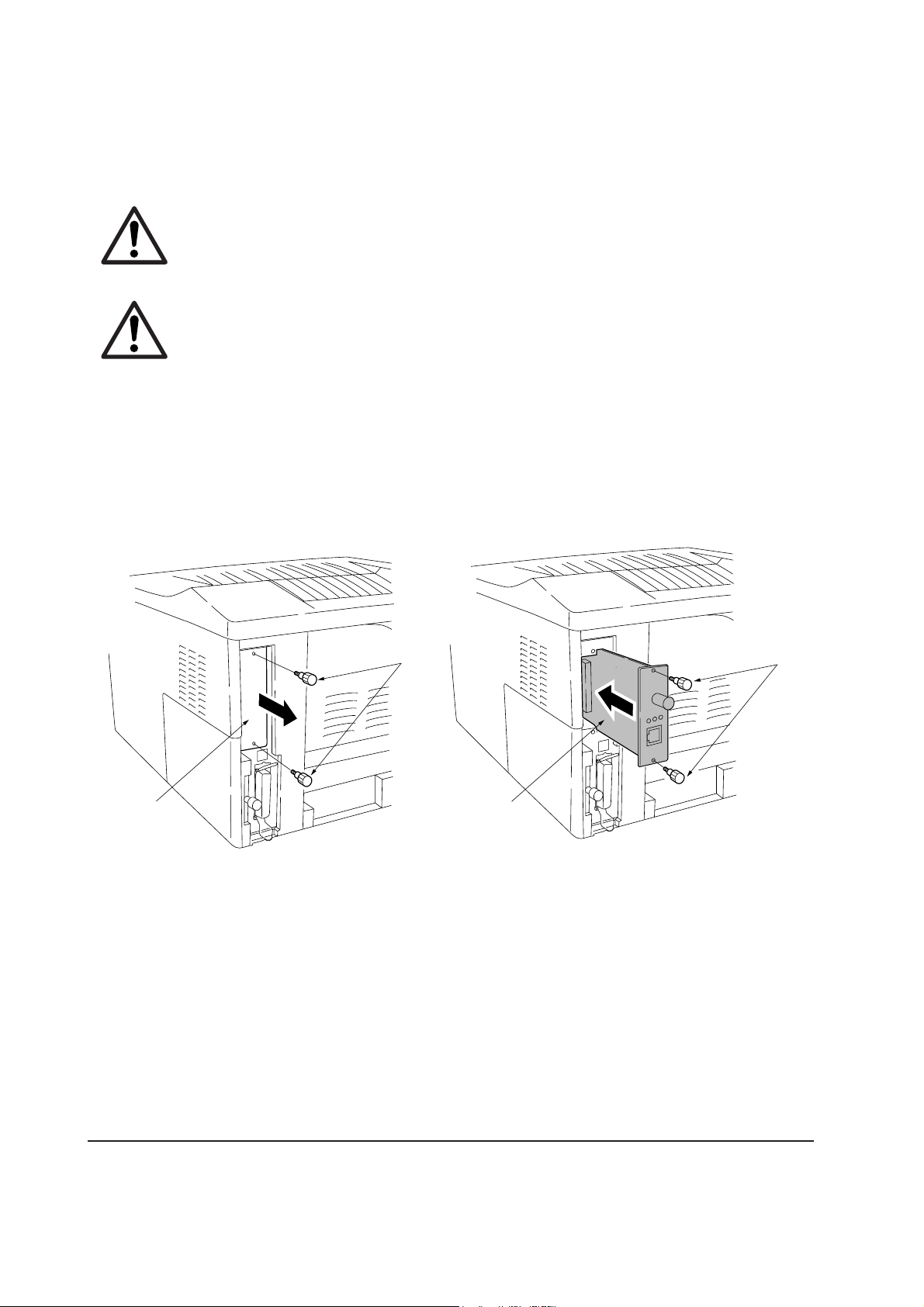

WARNING Turn the printer’s power switch off. Unplug the printer’s power cable and

disconnect the printer from the computer or the network.

Remove the side cover 1 as shown in the figure below.

Step 1

Step 2

Remove

one screw.

1

1

Figure 2-2-7 Removing side cover

FS-1050

2-10

Page 34

Open the clips 2 on both ends of the DIMM socket 3. Insert the DIMM 4 into the DIMM socket

3 so that the notches on the DIMM align with the corresponding protrusions in the slot. Close the

clips 5 on the DIMM slot to secure the DIMM.

2

Step 1

4

2

5

Step 2

5

3

Figure 2-2-8 Inserting the DIMM

(5) Testing the expansion memory

After installing DIMM in the printer, test the printer to see if the installation has been successful. To

test the expansion memory, turn printer power on and print a status page. If the installation has been

successful, the Available Memory item of the status page will show the expanded memory size

corresponding to the amount of memory added.

FS-1050

2-11

Page 35

(5) Installing the memory card (CompactFlash)

The main board of the printer is equipped with one slot for memory card.

CAUTION Take precautions that no foreign substances such as metal chips or liquid get

inside the printer during the installation process. Operation of the printer during

the presence of a foreign substance may lead to fire or electric shock.

WARNING Turn the printer’s power switch off. Unplug the printer’s power cable and

disconnect the printer from the computer or the network. Never insert or

remove a memory card while the printer power is ON.

Failure to turn the power switch OFF will immediately halt the printer with a

Memory card err20 message (this message may not always appear).

It also could result in any damage to the printer’s electronic parts or the

memory card. Turn the power switch ON again to restart the printer.

Remove the two screws 1 from the option interface slot cover 2 and remove the slot cover (or

network interface card 3 or the serial Interface board) .

2

1

3

Figure 2-2-9 Removing the option interface slot cover

1

FS-1050

2-12

Page 36

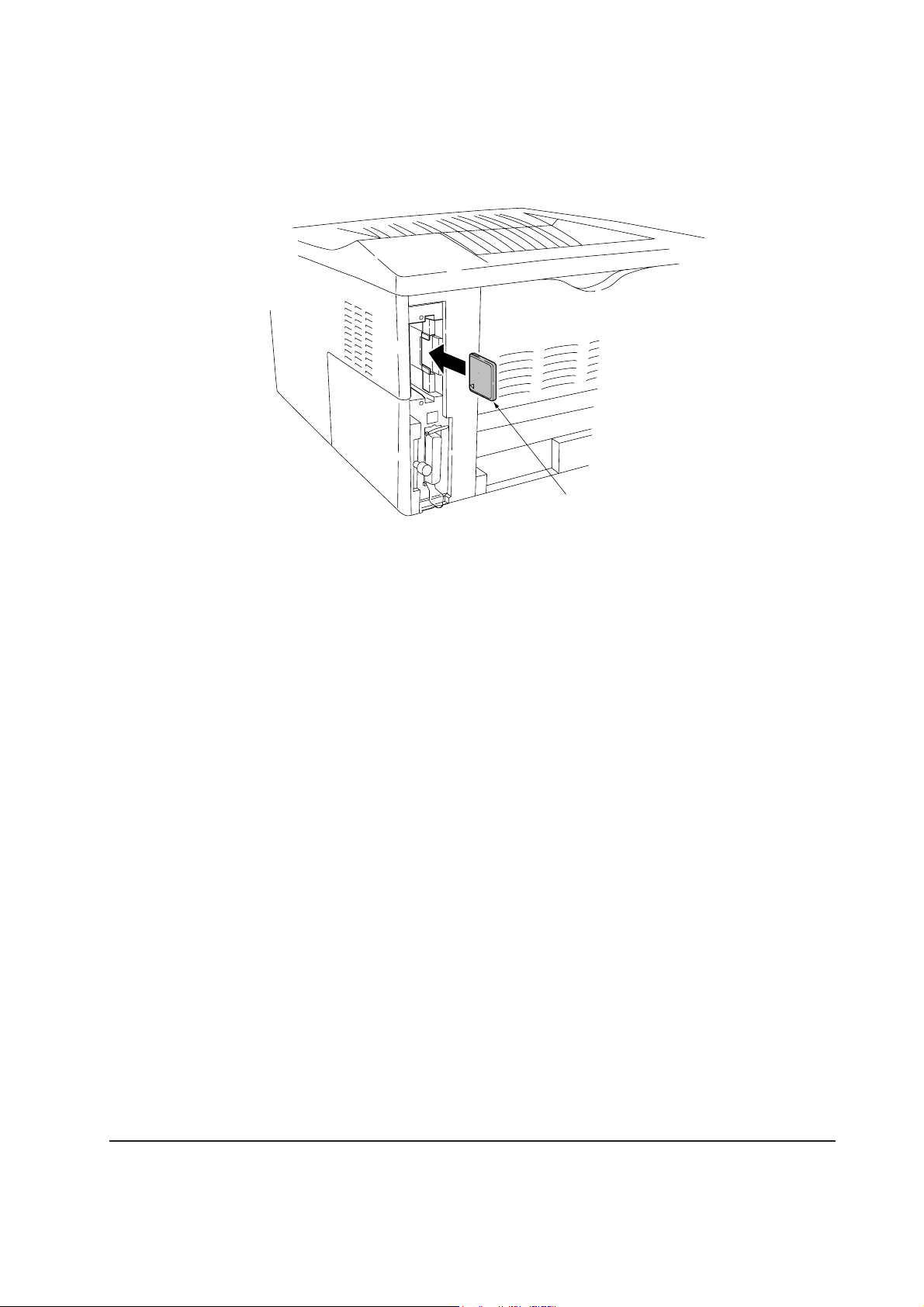

Insert the memory card 4 in the slot. Insert as shown in the figure. Push it in all the way. Close and

secure the slot cover (or network interface card or the serial Interface board) .

4

Figure 2-2-10 installing the memory card

2-13

FS-1050

Page 37

(6) Installing the network interface card

If the serial interface board kit is installed, remove it to use the network interface card.

CAUTION Take precautions that no foreign substances such as metal chips or liquid get

inside the printer during the installation process. Operation of the printer during

the presence of a foreign substance may lead to fire or electric shock.

WARNING Turn the printer’s power switch off. Unplug the printer’s power cable and

disconnect the printer from the computer or the network. Never insert or

remove a network interface card while the printer power is ON.

Remove the two screws 1 from the option interface slot cover 2 and remove the slot cover ( or

the serial Interface board) .Insert the network interface card 3 in the slot. Insert as shown in the

figure. Push it in all the way. Secure the network interface card by using two screws 1.

2

1

3

Figure 2-2-11 installing the memory card

1

FS-1050

2-14

Page 38

2-3 Using the operator panel

This section provides explanation on how to use the printer’s operator panel for basic operation.

For details, refer to the printer’s User’s Manual.

2-3-1 Operator panel

The printer’s operator panel has the following LED indicators, keys, and LCD message display.

Note that adjustments to the printer parameters made using these keys may be overridden by those

made from within the application software.

INTERFACE SIZE TYPE

READY

1

DATA ATTENTION

9

7

6

MENU ENTER

5

CANCEL

GO

Figure 2-3-1 Operator panel

(1) LED Indicators

LED Indicator Condition Description

1 READY indicator

Flashing

Lit

Indicates errors that you can correct himself or herself.

Indicates that the printer is online and ready.

@

3

2

0

8

!

4

2 DATA indicator

Off

Flashing

Lit

Off

Indicates that the printer is offline. The printer can

receive data, but will not print it. The indicator can also

signal that printing has been manually or automatically

stopped due to an error.

Indicates a data transfer in process.

Indicates either that data is being processed, or that data

is being written to the memory card.

Indicates that the printer is idle.

FS-1050

2-15

Page 39

LED Indicator Condition Description

3 ATTENTION

indicator

Flashing

Lit

Indicates that paper has run out, that memory is

insufficient, that toner is low, or other warning messages.

Indicates common errors (such as controller errors),

when mechanical maintenance is needed or indicates a

problem that requires a call to the service center.

Off

Indicates the printer is operating normally.

(2) keys

Key Function

4 GO key

• Switches the printer online and offline (even offline, the printer can

receive data).

• Cancels specific errors.

5 CANCEL key

• Cancels a printing job.

To cancel, proceed as follows:

1. Make sure if Processing appears on the message display.

6 MENU key

2. Press the CANCEL key.

3. Print Cancel? appears on the message display and then interface to be

canceled.

Parallel Serial (appears only when an optional serial interface is present)

Option (appears only when an optional network interface card is

installed)

Press the CANCEL key again if you wish to stop the cancellation of

printing.

4. Select the interface to cancel using the or key and then press the ENTER

key.

Printing from the selected interface will stop. Cancelling data appears

in the message display and printing stops after the current page is

printed.

• Resets numeric values or cancels a setting procedures.

• When pressed during mode selection, it ends the setting and the printer

returns to the Ready condition.

• Used to select the emulation, font, character code set; to read a memory

FS-1050

card; and more.

2-16

Page 40

Key Function

7 Key

Used to access desired items or input numeric values. In some control

procedures, the < and > keys are used to access or exit submenu items.

8 key

Used to access desired items or input numeric values. In some control

procedures, the < and > keys are used to access or exit submenu items.

9 < key

0 > key

! ENTER key

Used as the < key in mode selection.

Used as the > key in the mode selection function.

Confirms numeric values and other selections.

(3) LCD message display

The LCD message display @ gives information in the form of short messages. The eight messages

listed below are displayed during normal warm-up and printing. Other messages appear when the

printer needs the operator’s attention as explained in Chapter 6 Troubleshooting.

Message Meaning

Self test

Please wait

The printer is self-testing after power-up.

Please wait The printer is warming up and is not ready.

Ready

Processing

Sleeping

Cancelling data

Waiting

FormFeed TimeOut

The printer is ready to print.

The printer is receiving data, generating graphics, reading a

memory card or printing.

The printer is in Sleep mode. The printer wakes from Sleep

mode whenever a key on the operator panel is pressed, the

cover is opened or closed, or data is received. The printer

then warms up and goes online. The time that the printer takes

to enter Sleep mode depends on the Sleep Timer setting.

Jobs inside the printer are being cancelled. To cancel a job,

see the table on page 1-5.

The printer is waiting for the end-of-job command before

printing the last page. Pressing the GO key allows you to

obtain the last page immediately.

The printer is printing the last page after a waiting period.

2-17

FS-1050

Page 41

Interface indicator

The LCD message display also shows the interface that is currently used in the from of the following abbreviations:

Message Meaning

PAR Standard bidirectional parallel interface

USB Standard USB interface

SER Optional serial interface (RS-232C)

OPT Optional network interface card

--- No interface is currently used.

Each interface has a time-out time of 30 seconds during which the other interface should wait to receive a print

job. Even a print job has been complete on the interface, you should wait for this period until the other

interface begins printing the job

.

Paper size indicator

The LCD message display also provides information about the paper size of the paper cassette. While the

printer is Processing data to print, the paper size indicator switches to indicate the paper size selected by the

application software. The following abbreviations are used to indicate paper sizes.

Message Paper size

A4 ISO A4 (21 × 29.7 cm)

DL ISO DL (11 × 22 cm) *

A5 ISO A5 (14.8 × 21 cm)

C5 ISO C5 (16.2 × 22.9 cm) *

A6 ISO A6 (10.5 × 14.8 cm) *

b5 ISO B5 (17.6 × 25 cm) *

B5 JIS B5 (18.2 × 25.6 cm)

EX Executive (7-1/4 × 10-1/2 inches) *

B6 JIS B6 (12.8 × 18.2 cm) *

FS-1050

#6 Commercial 6-3/4 (3-5/8 × 6-1/2 inches) *

LT Letter (8-1/2 × 11 inches)

#9 Commercial 9 (3-7/8 × 8-7/8 inches) *

LG Legal (8-1/2 × 14 inches)

HA Japanese postcard (10 × 14.8 cm) *

MO Monarch (3-7/8 × 7-1/2 inches) *

OH Return postcard (20 × 14.8 cm) *

BU Business (4-1/8 inches) *

CU Custom size (14.8 × 21 cm to 21.6 × 35.6 cm)

* with only the MP tray feeding

2-18

Page 42

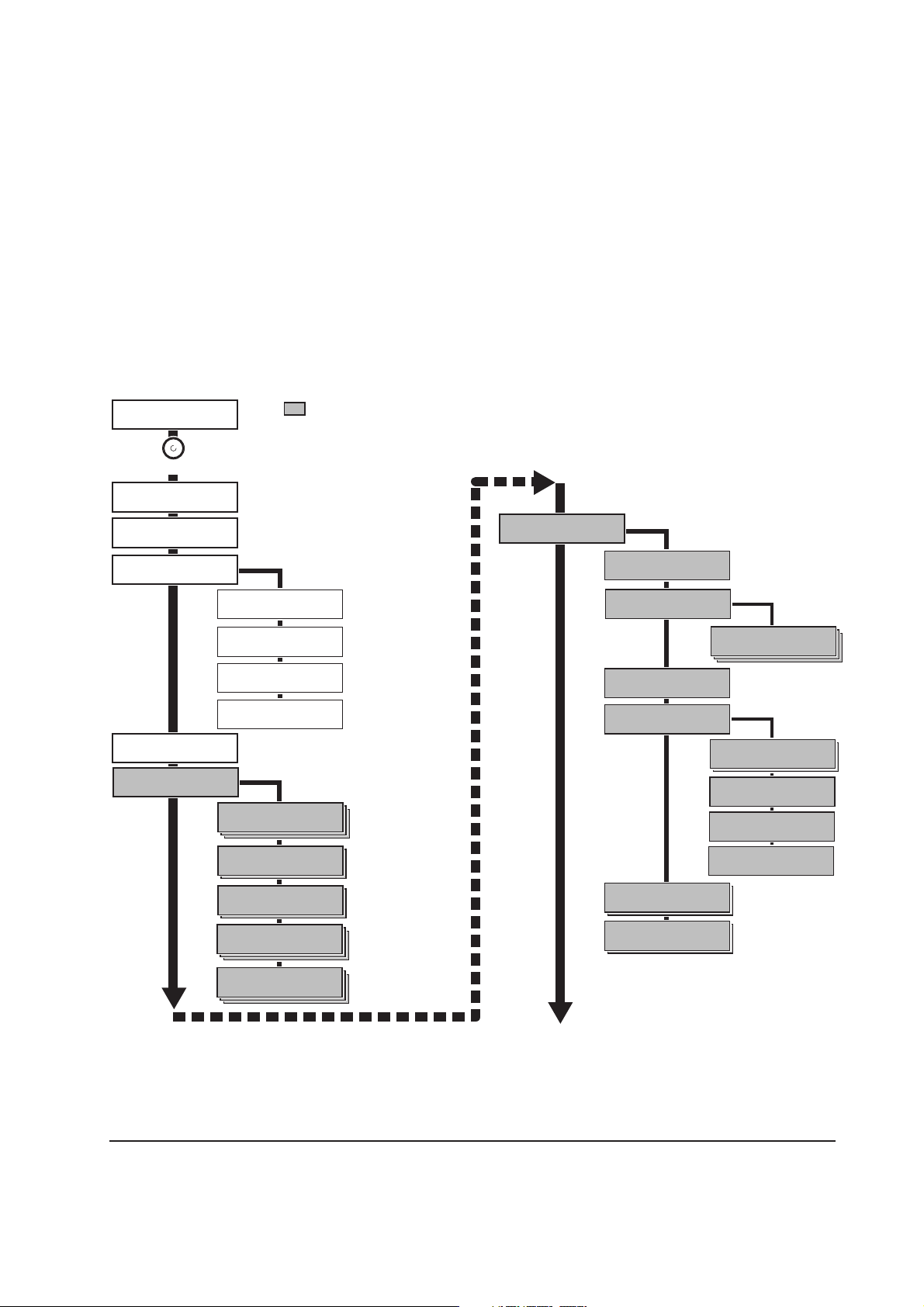

2-3-2 Menu selection system

The MENU key on the operator panel allows you to use the menu selection system to set or change

the printer environment such as the paper source, emulation, etc. Settings can be made when Ready

is indicated on the printer message display. The printer obeys the most recently received printer

settings sent from the application software, or from the printer driver, which take priority over

operator panel settings.

(1) Menu selection and sequence

The following is the hierarchy diagram of the menu selection system of the printer.

Ready

PAR A4

MENU

Print

Menu Map

Print

Status Page

Inter face >

Parallel

>Parallel I/F

Nibble (high)

>Parallel I/F

Auto

>Parallel I/F

Normal

>Parallel I/F

High Speed

Inter face >

USB

Interface >

Serial

>Bau rate

9600

>Data Bits

8

>Stop Bits

1

>Parity

None

These items will not

show unless the printer

is installed with the

applicable option unit.

Interface >

Option

>NetWare

Off

>NetWare >

On

>>NetWare Frame

Auto

>TCP/IP

Off

>TCP/IP >

On

>>DHCP

On

>>IP Address

000.000.000.000

>>Subnet Mask

000.000.000.000

>>Gateway

000.000.000.000

>Ether Talk

Off

>Opt. StatusPage

Off

>Protocol

DTR (pos.)&XON

Continued on next page.

FS-1050

2-19

Page 43

Emulation >

PCL 6

>Code set

ISO-6 ASCII

Emulation >

KPDL

>Print KPDL errs

Off

>Print KPDL errs

On

Emulation >

KPDL (AUTO)

>Alt. Emulation

PCL 6

>Print KPDL errs

Off

>Print KPDL errs

On

Emulation >

IBM Proprinter

Emulation >

Line printer

Emulation >

DIABLO 630

Emulation >

EPSON LQ-850

Font >

Internal

>Font Select >

Internal

> I000

>Courier

Regular

>Courier

Dark

>Letter Gothic

Regular

>Letter Gothic

Dark

>Size

012.00 point(s)

>Pitch

10.00 cpi

>Font Select >

Option

> I000

>Courier

Regular

>Courier

Dark

>Letter Gothic

Regular

>Letter Gothic

Dark

>Size

012.00 point(s)

>Pitch

10.00 cpi

>Code Set

IMB PC-8

>List of

Internal Fonts

>List of

Opton Fonts

Page set >

>Copies

001

>Orientation

Portrait

>Orientation

Landscape

>Page Protect

Auto

>Page Protect

On

>LF Action

LF only

>LF Action

CR and LF

>LF Action

Ignore LF

>CR Action

LF only

>CR Action

CR and LF

>CR Action

Ignore CR

FS-1050

>Wide A4

Off

>Wide A4

On

Continued on next page.

2-20

Page 44

Print Quality >

>KIR Mode

On

>KIR Mode

Off

>Ecoprint Mode

Off

>Ecoprint Mode

On

>Resolution

Fast 1200 mode

>Resolution

300 dpi

>Resolution

600 dpi

Opt. ROM >

>Read Data

>List of

Partitions

RAM Disk Mode

On

RAM Disk Mode

Off

>Read Data

>Write Data

>Delete Data

>RAM Disk Size

Paper Handling >

>MP Tray Mode

Cassette

>MP Tray Mode

First

>MP Tray Size

A4

>MP Tray Type

Plain

>Cassette Size

A4

>Cassette Size

Custom

>>Unit

mm

>>Unit

inch

>>X Dimension

210mm

>>Y Dimension

356mm

>Cassette Type

Plain

>Feed Select

Cassette

>Feed Select

MP Tray

>Override A4/LT

Off

>Type Adjust >

Custom 1

>Reset Type

Adjust

>List of

Partitions

Memory Card >

>Read Fonts

>Read Data

>Write Data

>Delete Data

>List of

Partitions

>>Paper Weight

Normal

>>Paper Weight

Heavy (Thick)

>>Paper Weight

Light (Thin)

>>Print Density

03

LIFE Counters >

>Total Print

0123456

>New Toner

Installed

Continued on next page.

FS-1050

2-21

Page 45

Others >

>MSG language

English

>Form Feed

Time Out 030sec.

>Sleep Timer >

015 min.

>>Sleep Mode

On

>>Sleep Mode

Off

>Print HEX-DUMP

>Printer Reset

>Resource prot.

Off

>Resource prot.

Permanent

>Resource prot.

Perm / Temp

>Auto Continue

Mode Off

>Auto Continue >

Mode On

>>Auto Continue

Timer 030sec.

>Service >

>>Print

Status Page

>>Developer

FS-1050

2-22

Page 46

Chapter 3

Maintenance/Adjustments

Page 47

Chapter 3 Contents

3-1 Maintenance/Adjustments .............................................................................................................. 3-3

3-1-1 Life expectancy of modules ....................................................................................................... 3-3

3-1-2 Toner container .......................................................................................................................... 3-4

(1) When to replace the toner container ................................................................................... 3-4

(2) Notes on changing toner container ..................................................................................... 3-4

(3) Toner container replacement ............................................................................................... 3-5

(4) Toner saver mode (EcoPrint) ............................................................................................... 3-6

3-1-3 Cleaning the printer ................................................................................................................... 3-7

(1) Cleaning the registration roller ............................................................................................ 3-8

(2) Cleaning the main charger wire ........................................................................................... 3-8

3-1-4 Updating the firmware ............................................................................................................... 3-9

(1) Firmware program data format ............................................................................................ 3-9

(2) Downloading the firmware from the parallel interface ....................................................... 3-10

(3) Downloading the firmware from the memory card ............................................................. 3-12

(4) Downloading errors ........................................................................................................... 3-14

Page 48

3-1 Maintenance/Adjustments

3-1-1 Life expectancy of modules

The table below shows the nominal life expectancy for modules. Detailed part information for each

module (except toner container) can be found in Parts Catalog.

Table 3-1-1 Life expectancy of modules

Kit Module Nominal life (pages) Remarks

TK-17 Toner container 6,000 User-replaceable

PU-42 Process unit 100,000 User-replaceable

3-3

FS-1050

Page 49

3-1-2 Toner container

Assuming an average toner coverage of 5 % with EcoPrint mode turned off, the toner container

will need replacing approximately once every 6,000 printed pages.

Table 3-1-2 Toner container

Kit Life in pages

TK-17 6,000

Based on letter or A4 size paper; average print density of 5 %.

NOTE In the case of a new printer in which a toner kit has been installed for the first

time, the number of copies that can be printed will be approximately 3,000.

(1) When to replace the toner container

When the printer runs low on toner, the Toner indicator flashes on the operation panel. Be sure to

promptly replace the toner container and clean the inside of the printer when this message appears.

If the printer stops printing while the Toner indicator is lit, replace the toner container to continue

printing.

(2) Notes on changing toner container

Observe the following cautions when replacing the toner container:

• Do not attempt to disassemble the old toner container and reuse the waste toner inside.

• Keep magnetic media such as floppy disks away from the toner container.

• Be sure to clean the parts as instructed in this section at the same timing of replacing toner

container.

• Use of the toner kit TK-17 is highly recommended for the optimum operation of the printer.

FS-1050

3-4

Page 50

(3) Toner container replacement

To replace the toner container, open the top cover. Pull lock lever #1 1 to the release [UNLOCK]

position, then pull lock lever #2 2 to the release (right) position.

1

2

Figure 3-1-1 Releasing Lock levers #1 and #2

Gently remove the old toner container 3.

Figure 3-1-2 Removing the old toner container

3

3-5

FS-1050

Page 51

Put it in the supplied plastic bag 4 and dispose of it.

4

Figure 3-1-3 Disposal of the old toner container

NOTE Although the toner container is made from non-harmful, flammable material,

be sure to dispose of it according to laws and regulations.

Proceed with the instructions provided in chapter 2, Installing the toner container on page 2-4 to

complete installation of the new toner container.

(4) Toner saver mode (

EcoPrint

)

The EcoPrint enables to reduce the amount of toner consumed on the page so as to save printing

costs by drastically extending the toner container life. EcoPrint mode is factory-set to off and

turned on by using the operator panel (MENU) For details refer to the printer’s User’s Manual.

FS-1050

3-6

Page 52

3-1-3 Cleaning the printer

1

2

3

To avoid print quality problems, the following printer parts must be cleaned with every toner container

replacement.

To clean the printer, first, remove the process unit from the printer.

Open the top cover 1 and front cover 2. Lift the process unit 3 together with the toner container

out of the printer.

Figure 3-1-4 Removing the process unit

NOTE The drum in the process unit is sensitive to light. Never expose the drum even

to normal office lighting (500 lux) for more than five minutes.

FS-1050

3-7

Page 53

(1) Cleaning the registration roller

Use the supplied wiper cloth 1 to clean dust and dirt away from the registration roller 2 (metal).

2

1

Figure 3-1-5 Cleaning the registration roller

(2) Cleaning the main charger wire

Slide the charger cleaner knob (green colored) back and forth 2 to 3 times, then return it to its

[CLEANER HOME POSITION].

1

1

Figure 3-1-6 Cleaning the main charger wire

After cleaning is done, install the process unit in the printer, using the reverse manner as above.

Close the front cover and top cover.

FS-1050

3-8

Page 54

3-1-4 Updating the firmware

Updating the system (controller) firmware is possible by downloading the firmware through the

parallel interface or through the memory card (CompactFlash). These firmware programs are directly

overwritten in the system DIMM [board KP-893] (Flash ROM type only) on the main board.

The operator panel message in different languages can also be downloaded through the parallel

interface or through the memory card (CompactFlash).

(1) Firmware program data format

Kyocera supplies the following types of data for updating firmware of the different purposes:

• System firmware

The data to be downloaded are supplied in the following format:

System firmware file name example

A93K8000.bcmp

compression

Boot program is included.

Version code: Version 80.00

ID code for Kyocera

Machine code: FS-1050 (A93)

Figure 3-1-9 Firmware program data format

3-9

FS-1050

Page 55

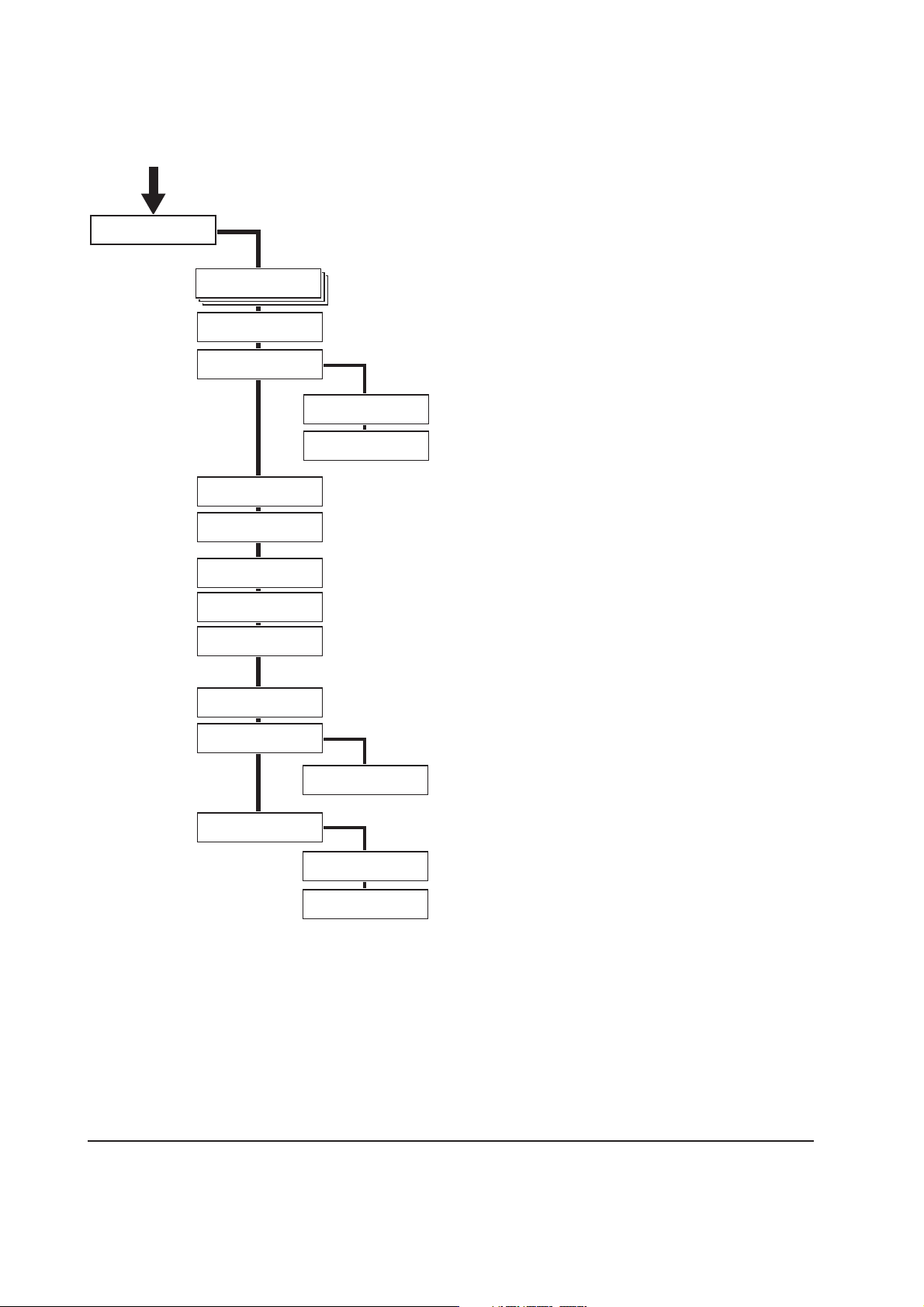

(2) Downloading the firmware from the parallel interface

This section explains how to download firmware data from the parallel interface. The printer system

can automatically recognize whether the data to be overwritten is for controller firmware.

CAUTION Downloading the firmware takes several minutes. Do not turn power off during

downloading.

NOTE MS-DOS is required for a downloading from the parallel interface. The

computer must be connected to the printer with a parallel cable.

1 Turn power switch on.

2 At the DOS prompt, send the command to the printer that engages the printer in the supervisor

mode.

3 Copy the firmware data to the printer. (See the flow chart below)

[System firmware ex. A93K8000.bcmp]

Start

1

Power switch: On

Message display

Self test

Ready

2

>ECHO !R!UPGR'SYS';EXIT;>PRN

>Supervisor mode

Parallel waiting

3

>COPY/B A938000.bcmp PRN

PC display

FS-1050

To the next page

3-10

Page 56

4 Supervisor mode. The parallel interface is waiting for the firmware data.

5 Receiving the firmware data.

6 The system DIMM or flash ROM is overwritten with the new firmware data.

7 Firmware downloading is finished. (When more than one data are down loaded, the data display

can be changed by pressing any key.)

8 Turn power switch off and on.

9 Check the that printer gets Ready.

From the previous page

: Shows only included

firmeware of boot program

(".bcmp" extension file).

A: u= Extracting

W= Writing

V= Verifiying

B: Version

C: Year/Month/Day

D: [Checksum]

E: Means more than one data

4

Supervisor mode

parallel waiting

Message display

5

data receiving

>>>>>>>>>>>

6

BootROM

erase&write

DIMM erasing #??

DIMM writing

<<<<<<<<<<u

B

7

80.00S

01/08/07[1234] 2

CD

8

Power switch: Off/On

9

Ready

A

E

End

Confirm that the status page shows the new system firmware version (See Appendix B on page B-

4). If the message display indicates download error, refer to section Downloading errors on page 3-

14.

FS-1050

3-11

Page 57

(3) Downloading the firmware from the memory card

To download data written in a memory card (CompactFlash) to the printer, proceed as explained in

this section.

CAUTION Downloading firmware takes several minutes. Do not turn power off during

downloading. If downloading is interrupted by an accidental power failure,

etc., the system DIMM may have to be replaced.

NOTE The firmware program data must be stored to the root directory of the memory

card (CompactFlash).

1 Turn power switch off.

2 Remove the two screws and then remove the slot cover. Insert the memory card in the printer’s

memory card slot.

3 Turn power switch on.

4 The printer is automatically engaged in the supervisor mode.

Start

2

Power switch: Off

1

3

Power switch: On

Self test

Memory

card

Message display

FS-1050

To the next page

3-12

Page 58

5 Data are transferred to the RAM on the main board.

6 The system DIMM or Flash ROM is overwritten with the new firmware data.

7 Firmware download is finished. (When more than one data are down loaded, the data display

can be changed by pressing any key.

8 Turn power switch off.

9 Remove the memory card and then secure the slot cover by using two screw.

0 Turn power switch on.

! Check the printer gets Ready.

From the previous page

4

Supervisor mode

Message display

5

Supervisor mode

CF-CARD Reading

6

BootROM

erase&write

DIMM erasing #??

DIMM writing

<<<<<<<<<<u

B

7

80.00S

01/08/07[1234] 2

CD

Powe r switch: Off

8

: Shows only included firmeware of boot program

(".bcmp" extension file).

A: u= Extracting

W= Writing

V= Verifiying

B: Version

C: Ye ar/Month/Day

D: [Checksum]

E: Means more than one data

A

E

9

0

Powe r switch: On

!

Ready

Memory

card

End

Confirm that the status page shows the new system firmware version (See Appendix B on page B-

4). If the message display indicates download error, refer to section Downloading errors on page 3-

14.

FS-1050

3-13

Page 59

(4) Downloading errors

The following messages are indicated on the message display when an error occurred during

downloading the firmware data.

Error message Description Corrective action

download header

error [##]

##: Error code 20 to 26.

system download

error [##]

##: Error code 40 to 59.

receive

error [##]

##: Error code 80 or 81.

Deficit of the file header

Deficit of the data header

File checksum error

Data checksum error

File header version error

Data header version error

Incompatibility of firmware and

system DIMM board

Defective system DIMM board

Improper connection of parallel cable

between PC and printer

Defective parallel cable

Obtain the correct firmware.

Confirm whether the firmware

is applicable to this printer.

Replace the system DIMM

board.

Check the contact between PC

and the printer’s interface

connector.

Replace the parallel cable.

If the corrective action above does not solve the problem, replace engine board (KP-882). See page

5-11.

FS-1050

3-14

Page 60

Chapter 4

Operation Overview

Page 61

Chapter 4 Contents

4-1 Electrophotographic system .......................................................................................................... 4-3

4-1-1 Electrophotographic cycle ......................................................................................................... 4-3

Process unit mechanism ........................................................................................................... 4-4

(1) Main charging ...................................................................................................................... 4-5

Photo conductive drum ............................................................................................................. 4-5

Charging the drum .................................................................................................................... 4-6

(2) Exposure ............................................................................................................................. 4-7

Laser scanner unit .................................................................................................................... 4-8

Drum surface potential .............................................................................................................. 4-9

(3) Development ..................................................................................................................... 4-10

(4) Transfer ..............................................................................................................................4-11

(5) Fusing ................................................................................................................................ 4-12

Fuser unit mechanism ............................................................................................................ 4-13

(6) Cleaning ............................................................................................................................ 4-14

4-2 Paper feeding system .................................................................................................................... 4-15

4-2-1 Paper feed control ................................................................................................................... 4-16

Paper feeding mechanism ...................................................................................................... 4-17

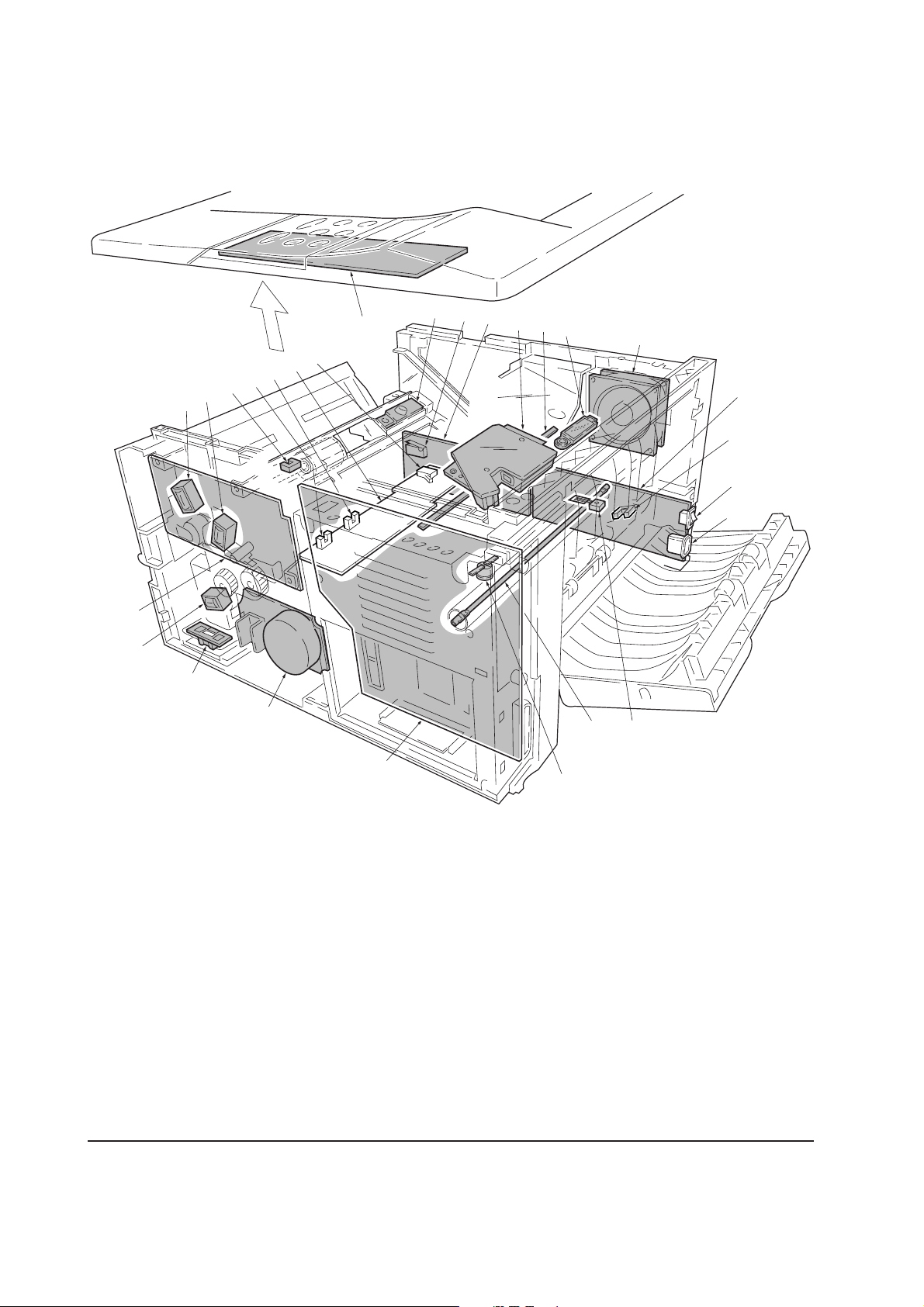

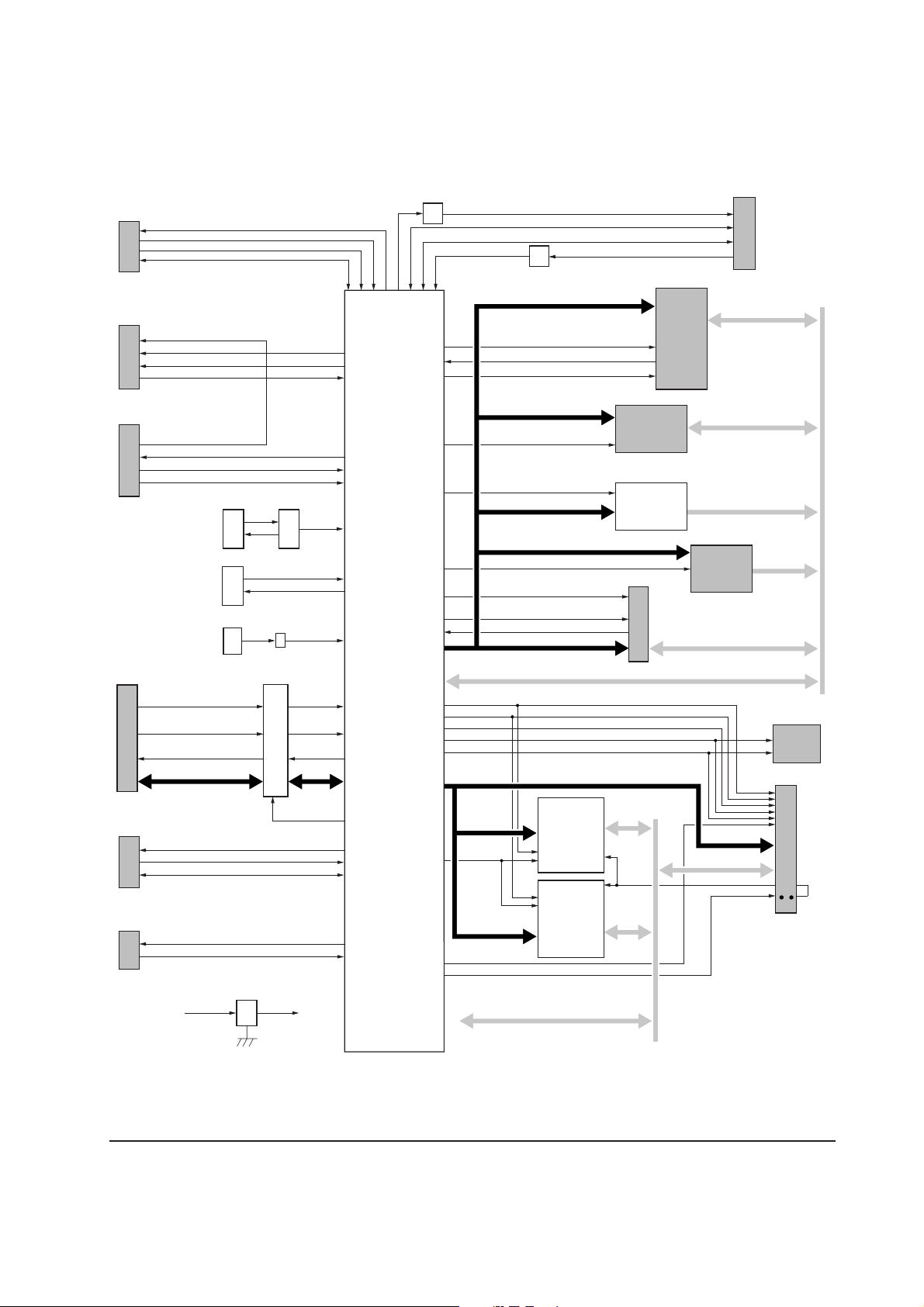

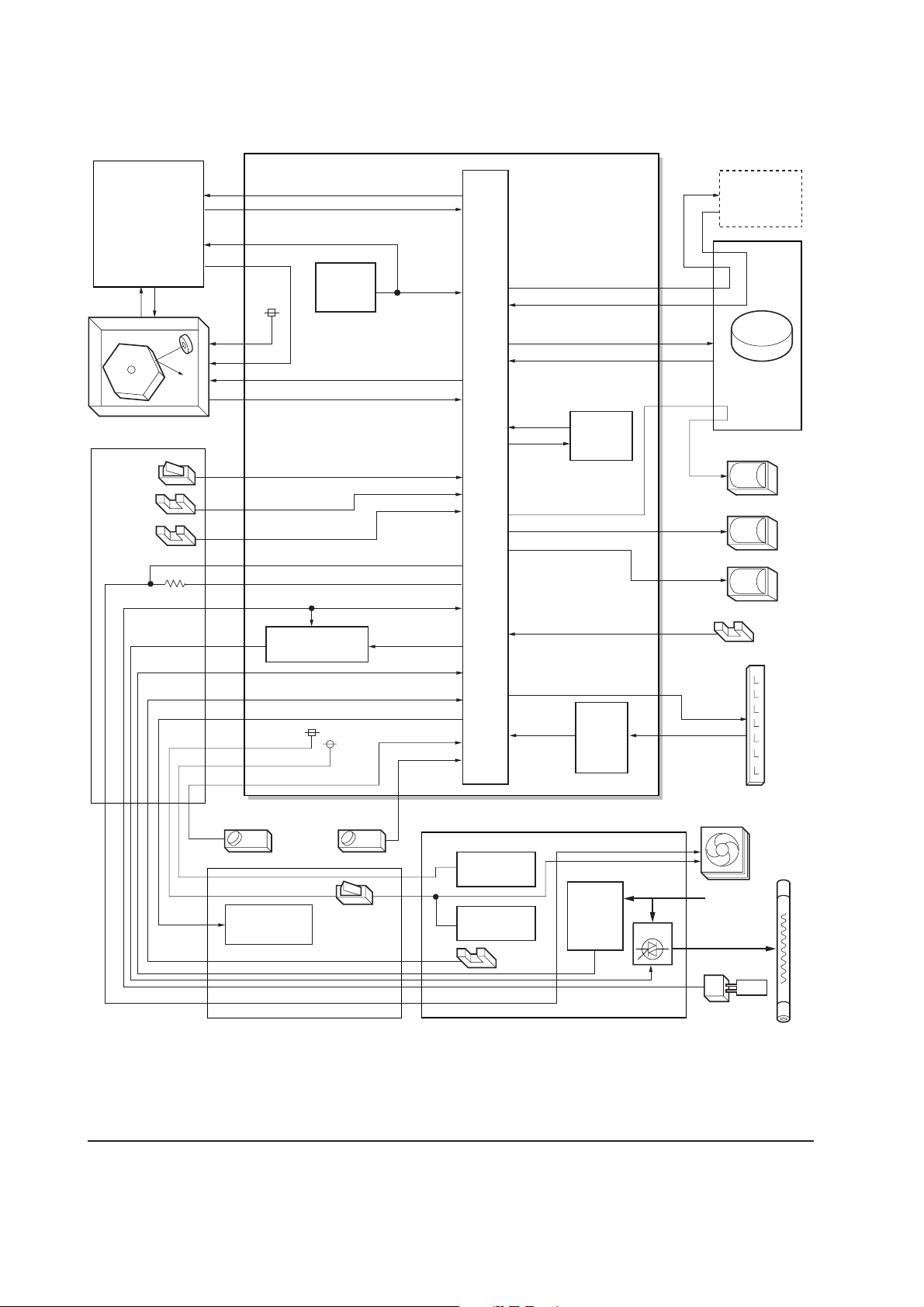

4-3 Electrical control system .............................................................................................................. 4-18

4-3-1 Electrical parts layout .............................................................................................................. 4-18

4-3-2 Operation of circuit boards ..................................................................................................... 4-19

(1) Main board ........................................................................................................................ 4-19

(2) Engine board ..................................................................................................................... 4-20

Eraser lamp control circuit ...................................................................................................... 4-21

Polygon motor control circuit .................................................................................................. 4-25

(3) Power supply board ........................................................................................................... 4-26

(4) Bias board ......................................................................................................................... 4-27

(5) High voltage board ............................................................................................................ 4-28

Interlock switch ....................................................................................................................... 4-29

Page 62

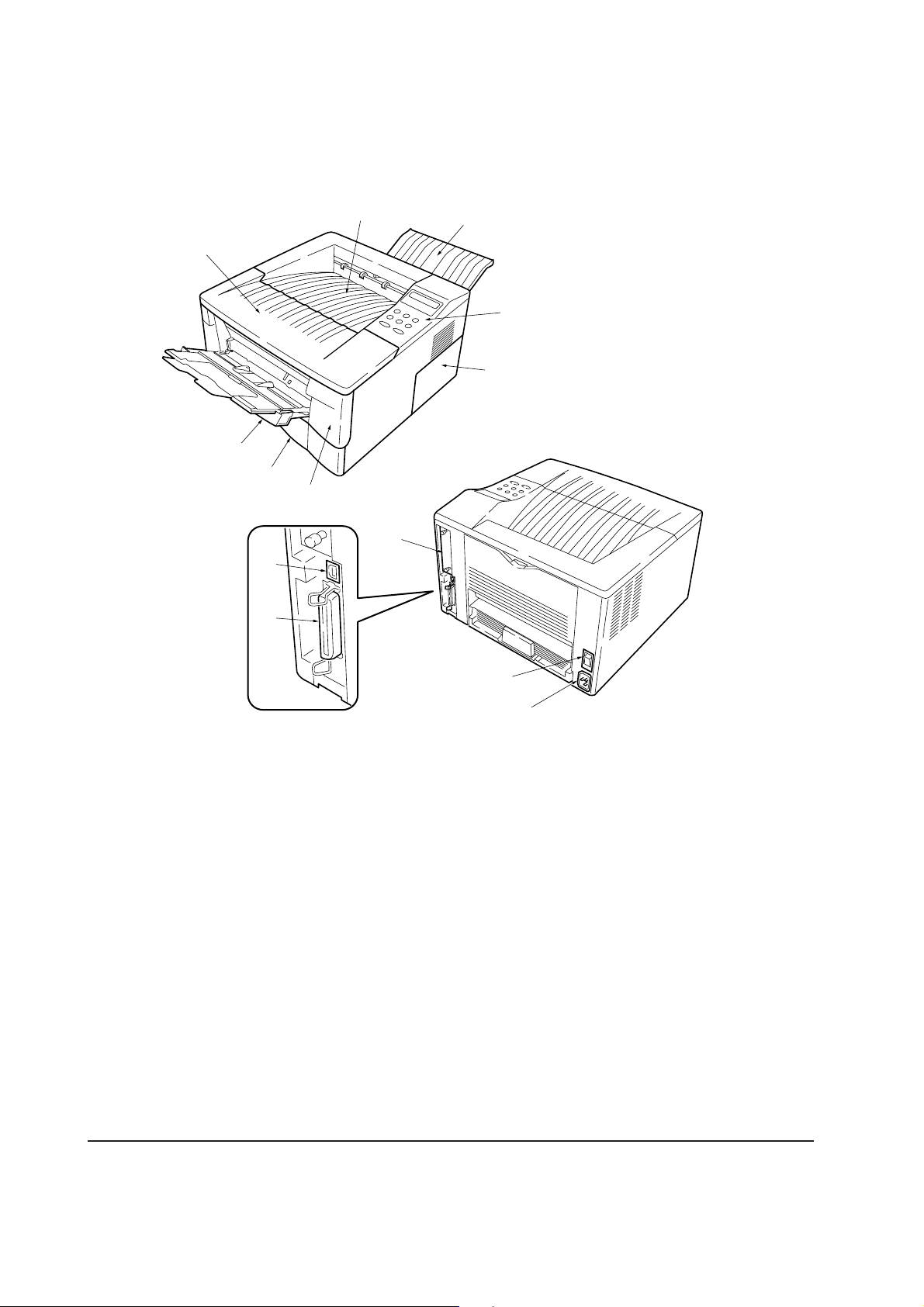

4-1 Electrophotographic system

Electrophotography is the technology used in laser printing which transfer data representing texts

or graphics objects into a visible image which is developed on the photosensitive drum, finally

fusing on paper, using light beam generated by a laser diode.

This section provides technical details on the printer’s electrophotography system.

4-1-1 Electrophotographic cycle

The electrophotography system of the printer performs a cyclic action made of six steps as follows.

Each step is technically explained in the following sections.

Laser scaner unit

Process unit

1

Main charging

2

Exposure

Drum

6

Cleaning

5

Fusing

Fuser unit

4

Transfer

3

Developing

Figure 4-1-1 Electrophotographic cycle

The sections for main charging, exposure (drum), developing, and cleaning are modularized in one

Process unit PU-42.

4-3

FS-1050

Page 63

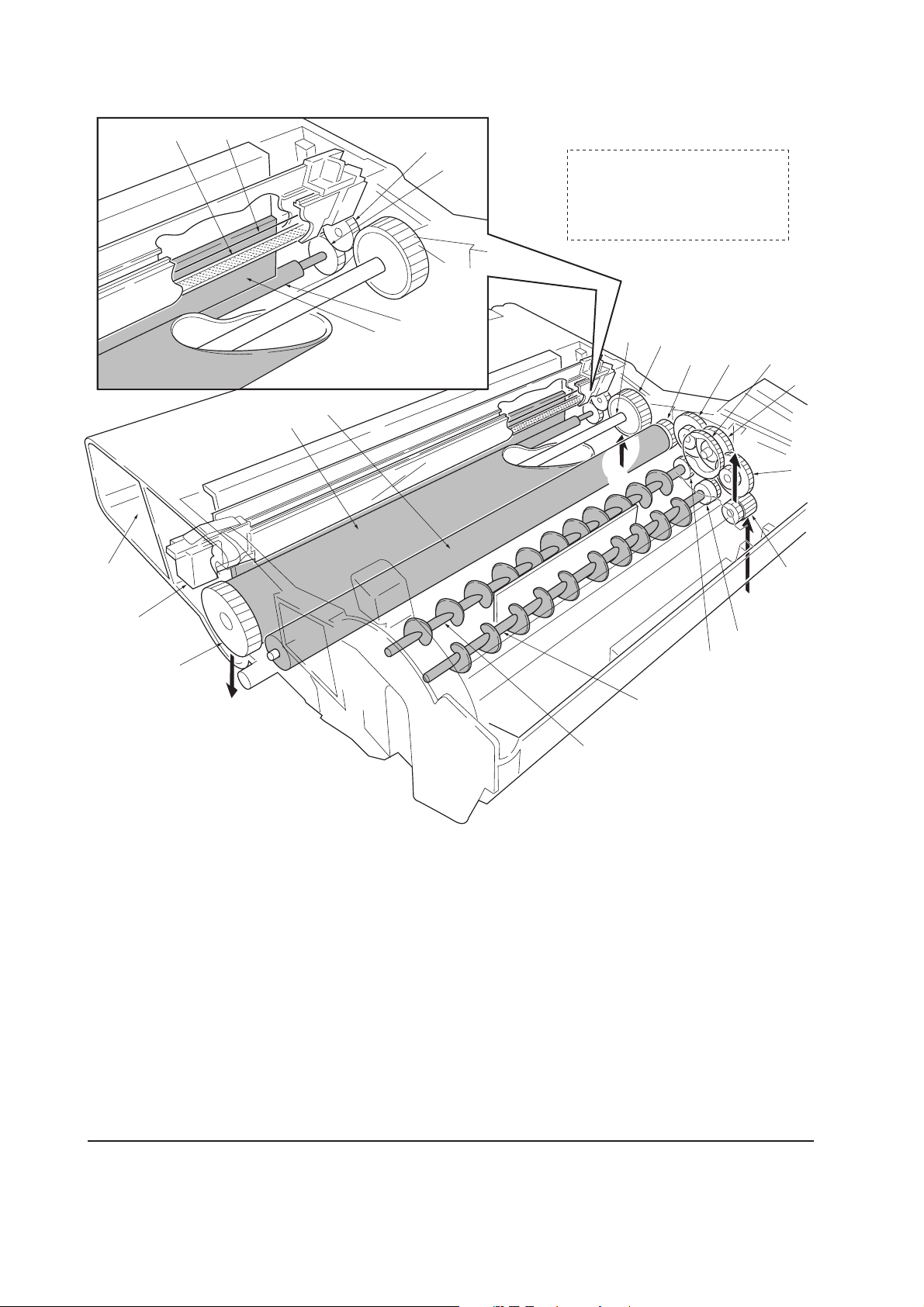

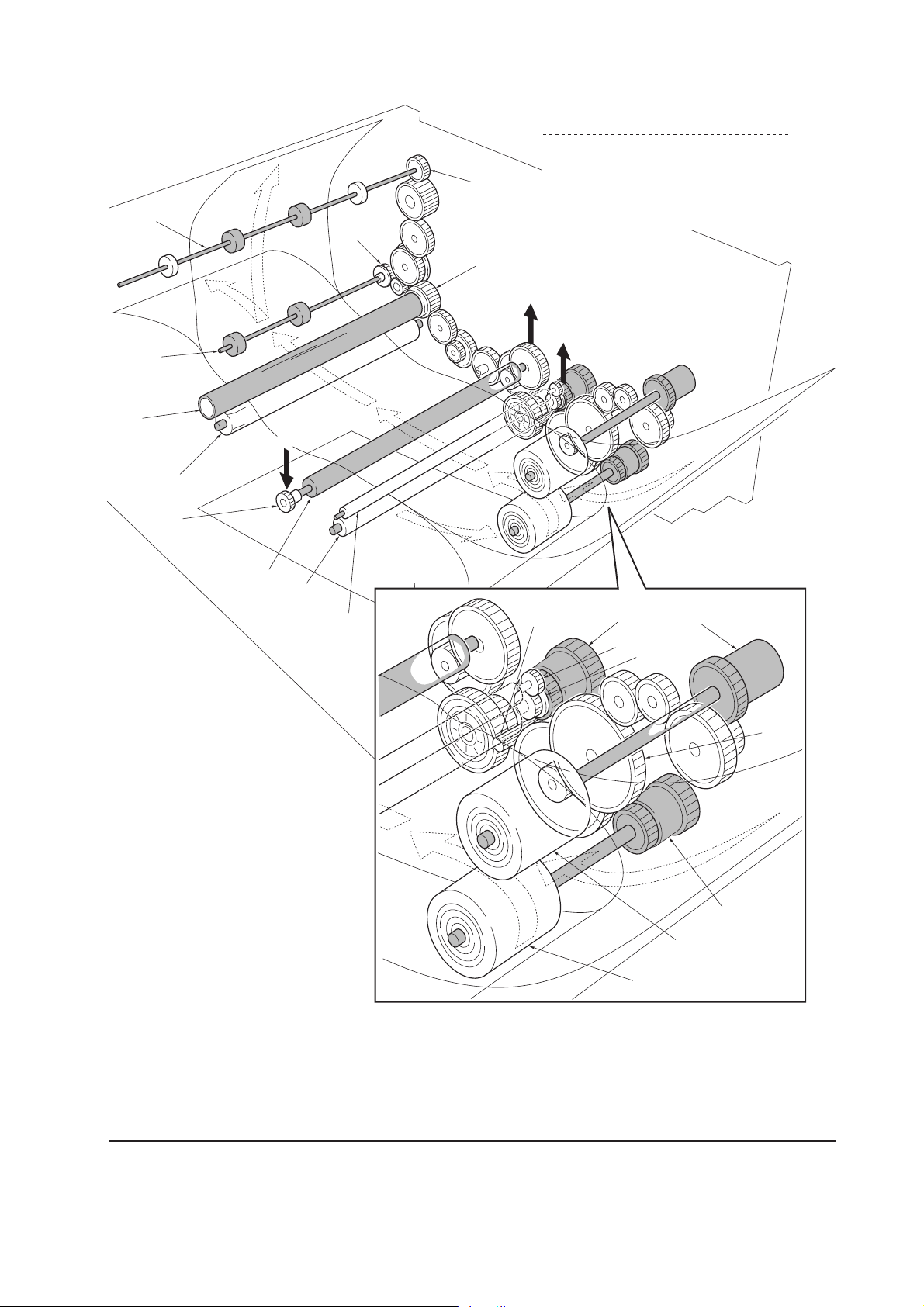

Process unit mechanism

‹

3

2

%

4

⁄

¤

)

(

Driving power train

A For drum (From main unit)

B For toner container, developing

roller, etc. (From main unit)

C For main unit (Transfer roller)

D For toner container

&

^

0

89

D

A

7

6

5

1

*

C

1 Main charger unit

2 Charger wire

3 Grid

4 Developing roller

5 Gear Z14-Z18

6 Gear Z14-Z36

7 Gear Z18-Z36

8 Free gear Z40

9 Gear Z18-Z35H

0 MAG gear Z24H

! Mixer gear Z20 B

@ Mixer gear Z20 A

# DLP screw B

$ DLP screw A

% Drum

^ Drum gear Z35H

B

!

@

#

$

& Drum shaft

* Drum gear Z36

( Sweep gear Z13

) Idle gear 18H

⁄ Cleaning blade

¤ Sweep roller

‹ Waste toner reservoir

FS-1050

Figure 4-1-2 Process unit mechanism

4-4

Page 64

(1) Main charging

Photo conductive drum

The durable layer of organic photoconductor (OPC) is coated over the aluminum cylinder base.

The OPC tend to reduce its own electrical conductance when exposed to light. After a cyclic process

of charging, exposure, and development, the electrostatic image is constituted over the OPC layer.

Since the OPC is materialized by resin, it is susceptible to damage caused by sharp edges such as a

screwdriver, etc., resulting in a print quality problem. Also, finger prints can cause deterioration of

the OPC layer, therefore, the drum (in the process unit) must be handled with care. Substances like

water, alcohol, organic solvent, etc., should be strictly avoided.

As with all other OPC drums, the exposure to a strong light source for a prolonged period can cause

a print quality problem. The limit is approximately 500 lux for less than five minutes. If the drum

(process unit) remains removed form the printer, it should be stored in a cool, dark place.

Photo conductive layer

Aluminum base cylinder

Figure 4-1-3 Photo conductive drum

4-5

FS-1050

Page 65

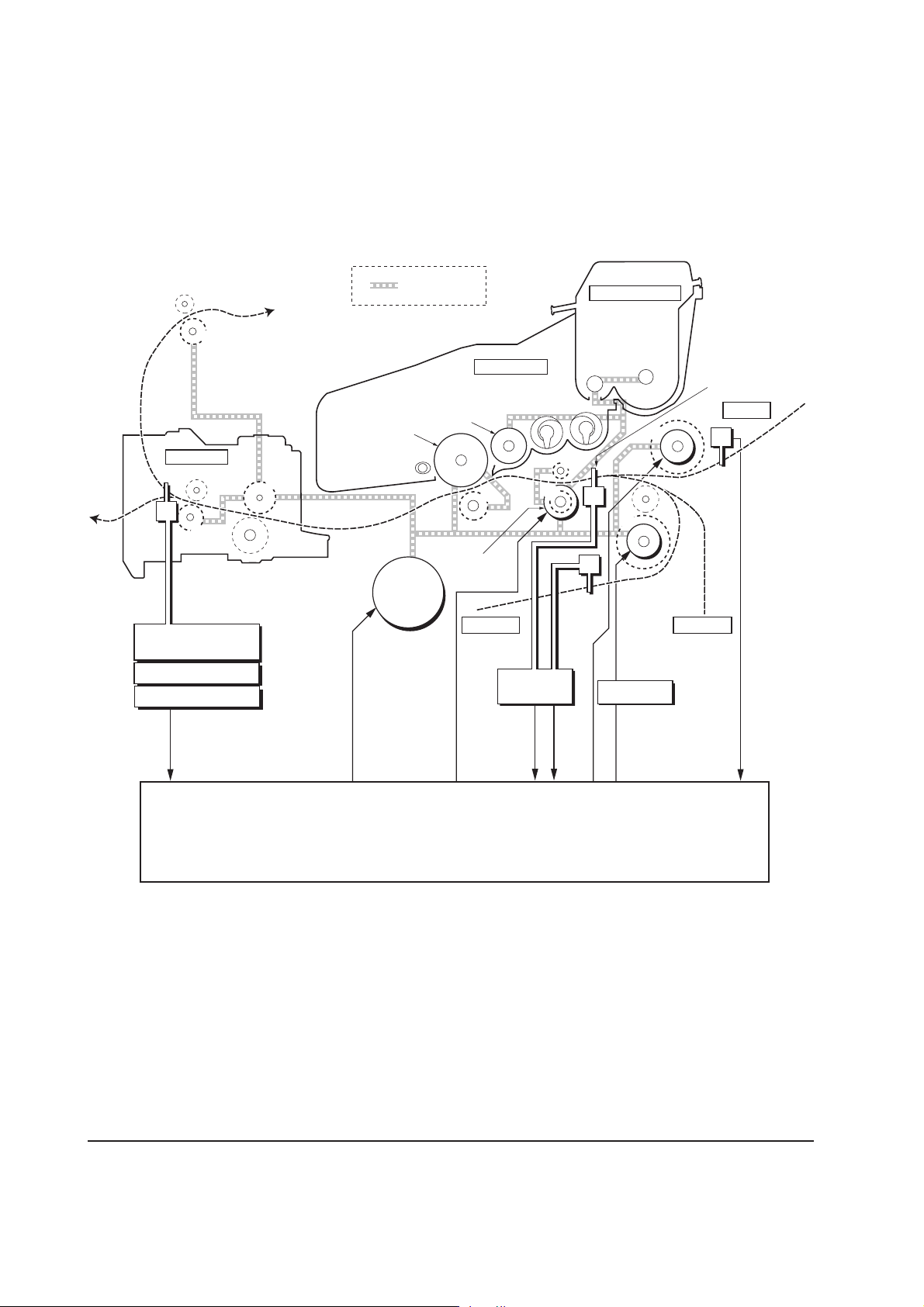

Charging the drum

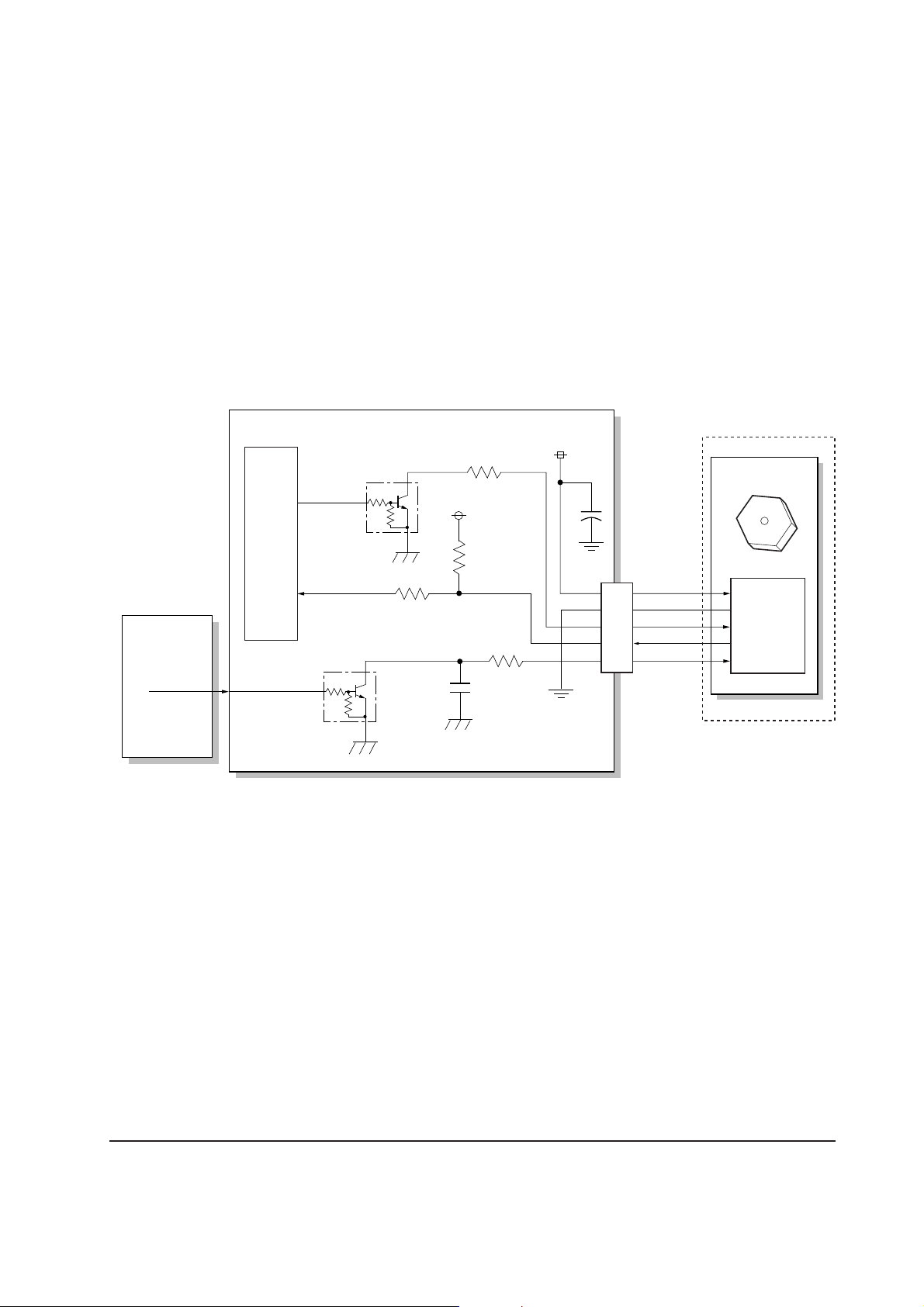

The following shows a simplified diagram of the electrophotographic components in relation to the

engine system. Charging the drum is done by the main charger unit A.

Zener

board

KP-788

High voltage board

YC-M

Main charging output

A

B

Bias

board

MHVDR

C

Engine board

YC12-5CN2-A4

Figure 4-1-4 Charging the drum

As the drum C rotates in a “clean (neutral)” state, its photoconductive layer is given a uniform,

positive (+) corona charge dispersed by the main charger wire B.

Due to high-voltage scorotron charging, the charging wire can get contaminated by oxidization

after a long rum. Therefore, it must be cleaned periodically from time to time using the method

explained in chapter 3. Cleaning the charging wire prevents print quality problems such as black

streaks.

FS-1050

4-6

Page 66

(2) Exposure

The charged surface of the drum A is then scanned by the laser beam from the laser scanner unit

B.

B

A

Figure 4-1-5 Exposure

The laser beam (780 nm wavelength) beam is dispersed as the polygon motor (polygon mirrors)

revolves to reflect the laser beam over the drum. Various lenses and mirror are housed in the

scanner unit, adjust the diameter of the laser beam, and focalize it at the drum surface.

FS-1050

4-7

Page 67

Laser scanner unit

3

2

4

1

6

5

Diversion mirror

Figure 4-1-6 Laser scanner unit

Name Description

1 Laser diode Emits diffused, visible laser.

2 Cylindrical lens Compensates the vertical angle at which the laser beam hits a polygon

mirror segment.

3 Polygon mirror (motor) Has six mirror segments around its hexagonal circumference; each

mirror corresponding to one scanned line width on the drum when

laser beam scans on it.

4 F-theta lens The f-theta lens equalizes focusing distortion on the far ends of the

drum.

5 Sensor mirror Bends the very first shot of a laser scan towards the beam detection

sensor (6).