Page 1

Fax System (F)

SERVICE

MANUAL

Published in Jul. ’02

843DB110

Page 2

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 3

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 4

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

Page 5

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement....................

Page 6

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

Page 7

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................................ 1-1-1

1-1-2 Parts names and their functions ............................................................................................................ 1-1-4

(1) Main body ...................................................................................................................................... 1-1-4

(2) Operation panel ............................................................................................................................. 1-1-5

(3) Basic fax screen on the touch panel .............................................................................................. 1-1-6

1-1-3 Mechanical construction ........................................................................................................................ 1-1-8

1-2 Installation

1-2-1 Unpacking and installation .................................................................................................................... 1-2-1

(1) Unpacking and installation ............................................................................................................. 1-2-1

1-2-2 Setting and registering data .................................................................................................................. 1-2-9

(1) Settings .......................................................................................................................................... 1-2-9

(2) Registration .................................................................................................................................. 1-2-10

1-2-3 Installing the optional memory module DIMM ..................................................................................... 1-2-11

1-3 Maintenance Mode

1-3-1 Maintenance mode ................................................................................................................................ 1-3-1

(1) Maintenance mode item list ........................................................................................................... 1-3-1

(2) Contents of maintenance mode items ........................................................................................... 1-3-4

1-4 Error Code

1-4-1 Error codes ............................................................................................................................................ 1-4-1

(1) Error code ...................................................................................................................................... 1-4-1

(2) Table of general classification ........................................................................................................ 1-4-2

(2-1) U004XX error code table: Interrupted phase B ..................................................................... 1-4-4

(2-2) U006XX error code table: Problems with the unit ................................................................. 1-4-5

(2-3) U008XX error code table: Page transmission error ............................................................... 1-4-5

(2-4) U009XX error code table: Page reception error .................................................................... 1-4-5

(2-5) U010XX error code table: G3 transmission ........................................................................... 1-4-6

(2-6) U011XX error code table: G3 reception ................................................................................ 1-4-8

(2-7) U017XX error code table: V.34 transmission ...................................................................... 1-4-10

(2-8) U018XX error code table: V.34 reception ............................................................................ 1-4-10

(2-9) U023XX error code table: Relay command abnormal reception ......................................... 1-4-10

(2-10) U044XX error code table: Encrypted transmission ............................................................. 1-4-10

3DB

1-5 Self Diagnosis

1-5-1 Self-diagnosis ........................................................................................................................................ 1-5-1

(1) Self diagnostic codes ..................................................................................................................... 1-5-1

1-5-2 Troubleshooting .................................................................................................................................... 1-5-3

1-6 Requirements on PCB Replacement

1-6-1 Updating the firmware ........................................................................................................................... 1-6-1

(1) Updating the firmware on the fax control PCB (Flash ROM) ......................................................... 1-6-1

(2) Updating the firmware on the fax control PCB (Compact Flash card) ........................................... 1-6-4

2-1 Electrical Parts Layout

2-1-1 Electrical parts layout ............................................................................................................................ 2-1-1

2-2 Operation of the PCBs

2-2-1 Fax control PCB .................................................................................................................................... 2-2-1

2-2-2 NCU PCB .............................................................................................................................................. 2-2-7

2-2-3 Auxiliary power source PCB ................................................................................................................ 2-2-11

1-1-1

Page 8

3DB

1-1-1 Specifications

Type .......................................................... Optional Fax Kit

Compatibility.............................................. Group 3

Line Requirement ...................................... Subscription telephone line

Transmission Speed .................................. Within 3 seconds (33600 bps, JBIG, ITU-T #1 chart)

Modem Speed ........................................... 33600/31200/28800/26400/24000/21600/19200/16800/14400/12000/9600/

7200/4800/2400 bps

Data Compression .................................... JBIG/MMR/MR/MH

Error Correction......................................... ECM

Maximum Document Dimensions ............. Width: 11" [297 mm] Length: 63" [1600 mm]

Automatic Document Feeder Capacity ..... Duplex document processor: Max. 100 pages, document processor: Max. 70

pages

Auxiliary Scanning Line Density ................ Horizontal × Vertical

Normal (8 dots/mm × 3.85 lines/mm)

Fine (8 dots/mm × 7.7 lines/mm)

Super fine (8 dots/mm × 15.4 lines/mm)

Ultra fine (16 dots/mm × 15.4 lines/mm)

Recording Resolution ................................ 600 dpi × 600 dpi

Grayscale .................................................. 128 levels (Value differential diffusion)

Speed-Dial Keys ....................................... Max. 600 destinations

Broadcast Transmission ............................ Max. 300 destinations

Polling Reception ...................................... Max. 300 locations

Installed Bitmap Memory .......................... 4 MB

Installed Imaging Memory ......................... 4 MB (including 1 MB of working memory)

Management Reports and Lists ................ Activity Report, Confirmation List, User Setting List, One-Touch Key List,

Telephone Directory List, Program Dial List, Group Dial List, Encryption Key

List, Restricted Access Report, Department List

Options ...................................................... Memory module DIMM (8 MB)

Functions................................................... See pages 1-1-2 to 1-1-3.

1-1-1

Page 9

3DB

Reception functions Manual reception

Automatic reception

Fax/telephone auto selection

TAD reception

D.R.D. reception*

1

Remote switching

Transmission functions One-touch dialing*

Program dialing*

Group dialing*

Chain dialing*

2

2

2

2

Redialing (manual/automatic)

Dial confirmation

Communication functions Direct feed transmission

Memory transmission

Direct reception

Memory reception (F-coded confidential reception and relay broadcast

reception)

Additional communication functions Broadcast transmission (up to 300 numbers)

Polling communication

Encrypted communication

Password check communication

Memory fax forwarding

Reserved transmission

Timer transmission

Interrupt transmission

Short protocol

ECM

F-coded transmission

F-coded confidential reception

F-coded bulletin board communication

F-coded relay broadcast

Supplementary communication functions Printing out from F-coded confidential box

Manual transmission

Telephone directory

Transmission destination display

Tone transmission

3

Memory back-up (60 min.*

)

Entry into F-coded bulletin board

Communication result display

Supplementary transmission functions Batch transmission

TTI transmission

Bulletin board

Rotation transmission

Duplex transmission*

4

Initial communication speed setting

Supplementary reception functions Memory reception

2-in-1 reception

Auto reduce reception

Rotation reception

Duplex reception*

5

Recording paper setting (auto selection, fixed size or fixed cassette)

During-reception copying

Reception date and time recording

1-1-2

Page 10

Reports Activity report

Transmission report

Reception report

Power failure report

Delayed communication report

Confirmation report

User settings list

Encryption key list

Management report

Department list

One-touch key list

Telephone directory list

Program dial list

Group dial list

F-code confidential box list

F-code relay box list

Encryption box list

Network fax setting list

Others Memory editing

Remote diagnosis

Department control for faxes

Network fax functions

3DB

*6

*6

*1: For 120 V specifications only.

*2: To be registered under one-touch keys. Up to 600 one-touch keys can be used for one-touch dialing, program dialing,

group dialing and chain dialing.

*3: When the optional memory module DIMM is installed.

*4: Available only when the duplex document processor is installed.

*5: Available only when the duplex unit is installed.

*5: When the printer/scanner kit is installed.

1-1-3

Page 11

3DB

1-1-2 Parts names and their functions

(1) Main body

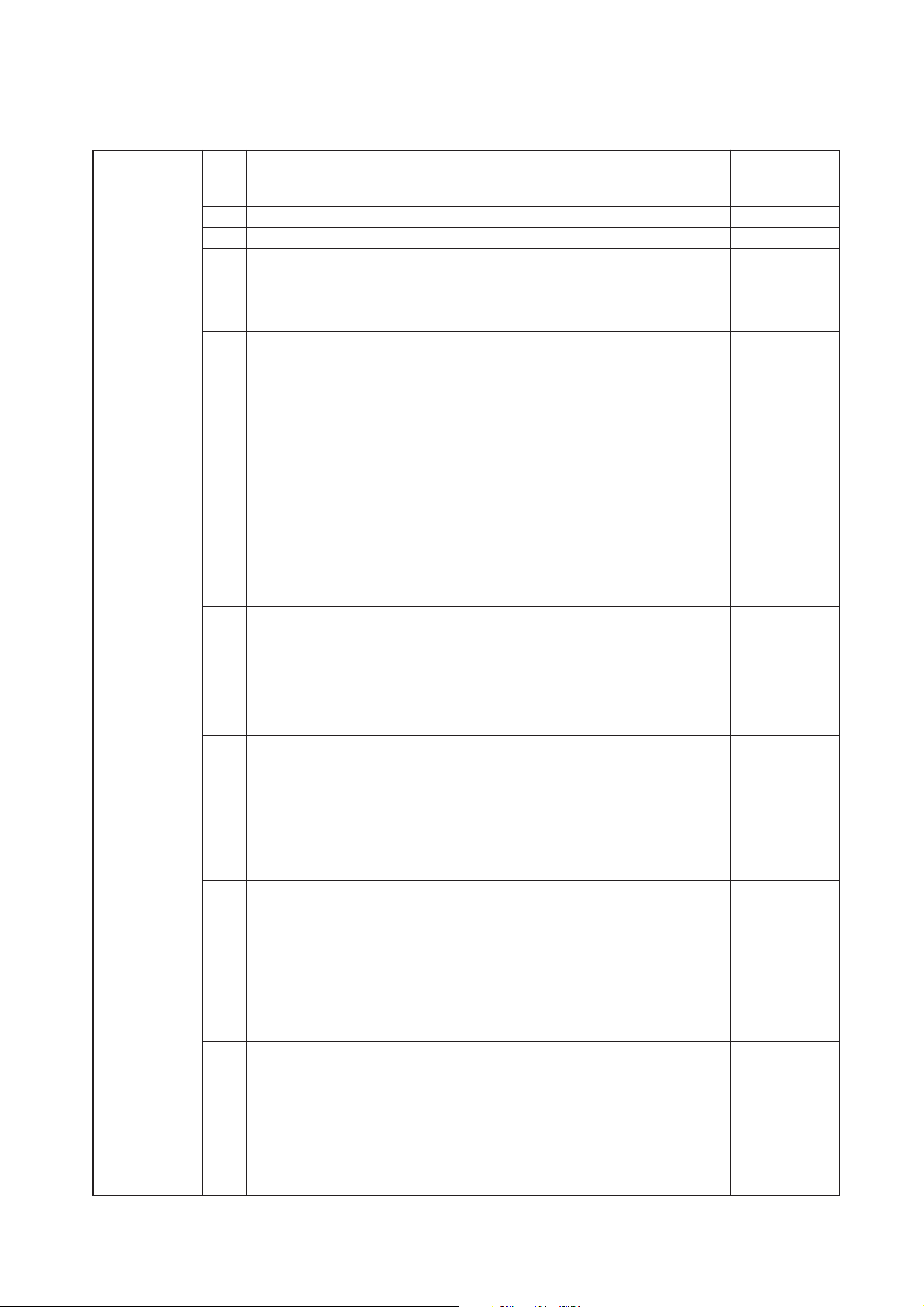

Figure 1-1-1

Figure 1-1-2

1 Operation panel ..................................... Use the operation panel to perform the procedures required for fax

communication.

2 Fax storage section ................................ Received documents are ejected and stored face-down in the fax storage

section. Up to 250 sheets can be stored in this section at one time.

3 Drawers .................................................. This fax machine comes standard with two drawers installed. Each drawer

2

can hold up to 500 sheets of plain paper (60 g/m

- 105 g/m2).

4 Multi-Bypass .......................................... Paper can be set in the Multi-Bypass as well. In order to use the Multi-

Bypass, it is necessary to select “ON” under “Turning Manual Paper Feed

ON/OFF”.

5 Telephone jack (T) .................................. Use this jack to connect a separately purchased telephone to the fax.

6 Line jack (L) ........................................... Use this jack to connect the fax to a telephone line using the modular cord.

7 Main switch ............................................ Turn this switch ON ( | ) in order to perform fax and copy operations. The

message display will light and operation will be possible.

• Document Processor

There are 2 optional document processors available for use with this machine: the document processors for feeding onesided documents, and the duplex document processor for using both sides of 2-sided documents.

* Both the document processor and duplex document processor can be used with the 25 copies per minute machine.

However, only the duplex document processor can be used with the 35/40 copies per minute machine.

8 Document table...................................... Set the documents to transmit on the table. Up to 100 sheets of up to 11" × 8

1

/2" [A4] size paper, or up to 70 sheets of 8 1/2" × 14" or 11" × 17" [A3 or

Folio] size paper, can be set at one time when installing the duplex document

1

processor. Up to 70 sheets of up to 11" × 8

sheets of 8

1

/2" × 14" or 11" × 17" [A3 or Folio] size paper, can be set at one

/2" [A4] size paper, or up to 50

time when installing the document processor.

9 Document insert guides ......................... Adjust these guides to match the width of the documents.

10 Document processor reversing cover..... Open this cover if a document jams.

11 Document eject cover ............................ Documents are ejected onto this cover after being scanned.

1

12 Eject guide ............................................. Open this guide when transmitting documents of a large size such as 8

/2"

×14" or 11" × 17" [A3 or Folio].

13 Document processor open/close lever ... Operate this lever when opening and closing the document processor.

14 Document set indicator .......................... This indicator indicates the status of the documents set in the document

processor. Documents are set properly when the indicator is lit green.

1-1-4

Page 12

(2) Operation panel

3DB

Figure 1-1-3

1 Touch panel......................... Indicates operation procedures as well as trouble with the machine. Keys related to

operational procedures which appear on the touch panel with their name displayed are

indicated in this handbook within double quotation marks. In addition, you will be

instructed to “touch” any keys which appear on the touch panel rather than “press” them.

(Ex.: Touch the “xxx” key.)

2 Keypad ................................ Use the keypad to enter fax numbers, etc.

* Even if your telephone service is for pulse dialing, press the star (*) key and any key

pressed on the keypad after that will transmit the related tone signal. (Inch version

only)

3 Start key .............................. Press this key when you want to initiate a fax communication.

4 Fax key/Fax indicator .......... Press this key when you want to switch between the Copy Operation and Fax Operation

modes. The Fax indicator is lit when the machine is in the Fax Operation mode.

5 Fax data indicator ............... This indicator blinks during a fax communication. When received documents or other

data are being stored in memory, this indicator will flash and then light continuously.

6 Reset key ............................ Press this key when you want to cancel an operation in progress and have the touch

panel return to the initial mode settings.

7 Stop/Clear key..................... Press this key when you want to delete registered fax numbers or names, as well as

when you want to stop an operation in progress.

8 Fax Priority key ................... Press this key when you want to give priority to printing out a received fax during a copy

operation.

9 Default key .......................... Press this key when you want to perform settings related to the various default modes for

the fax functions of this machine.

Interrupt key/indicator lamp ..

10

Press this key when you want to interrupt a fax reception in order to make copies. The

indicator lamp in the Interrupt key will light when the machine is in the Interrupt mode.

1-1-5

Page 13

3DB

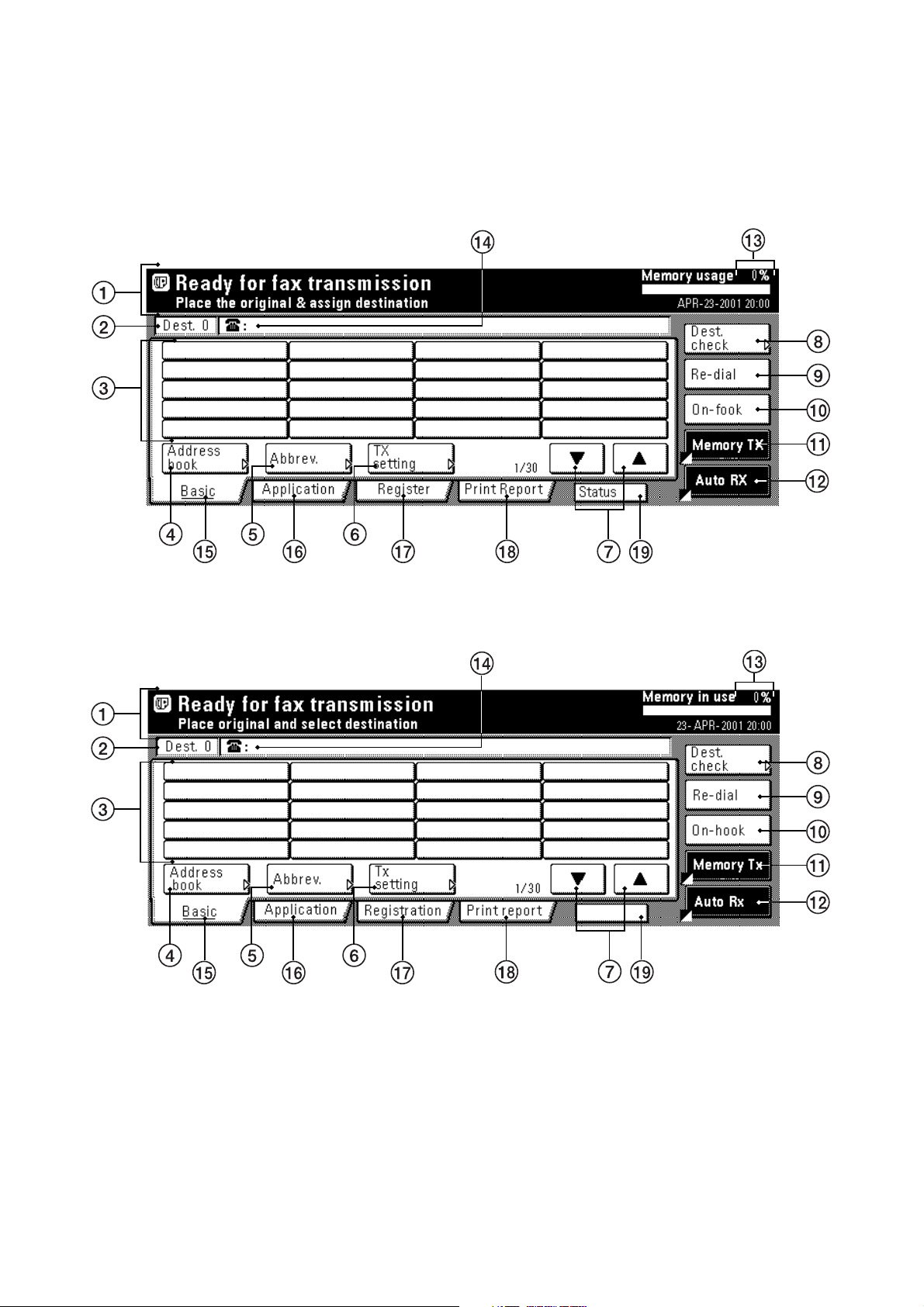

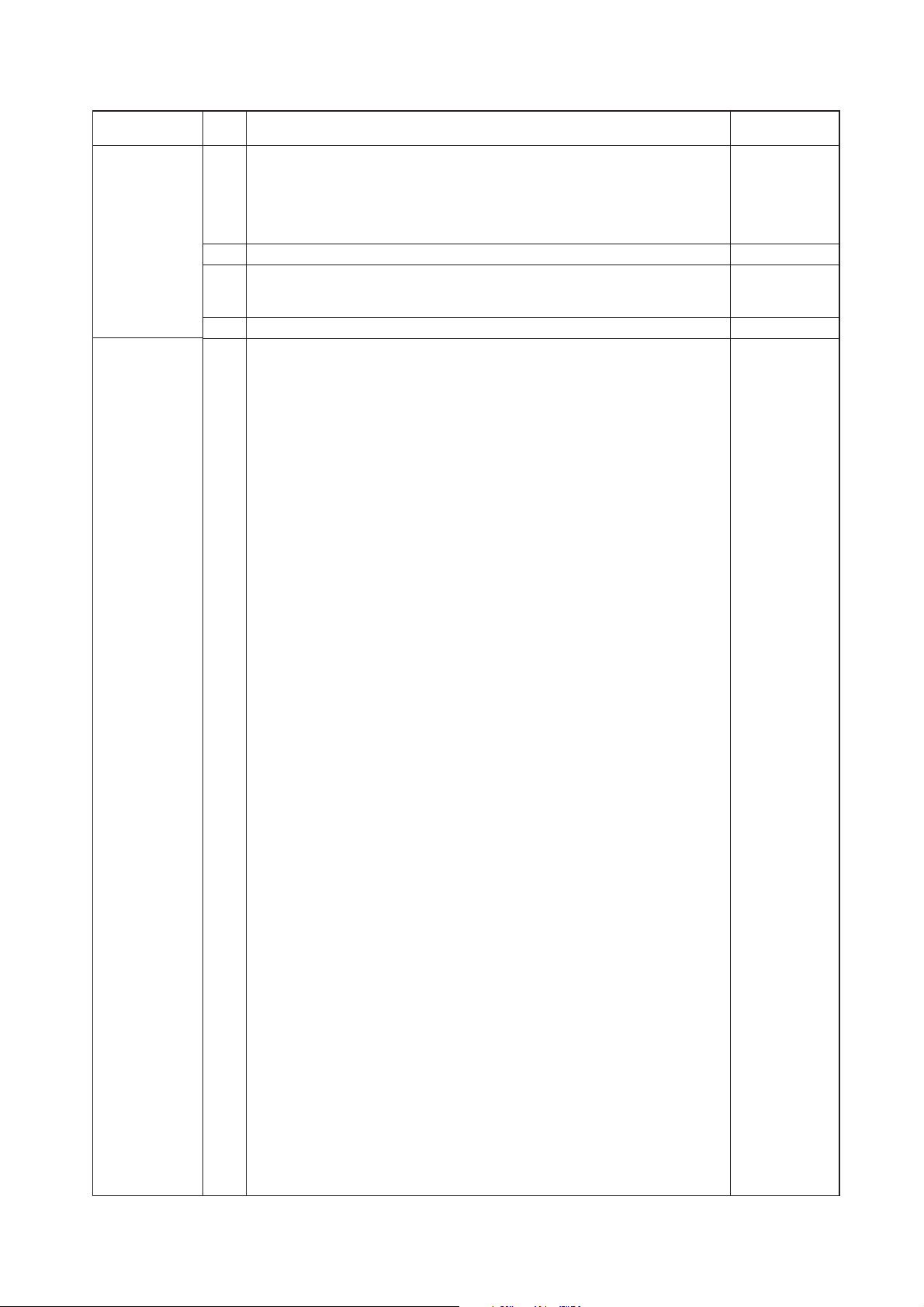

(3) Basic fax screen on the touch panel

The initial screen that appears in the touch panel when you press the Fax key in any other mode in order to change to the

Fax Operation mode is called the “basic fax screen”. The following contains information on the basic keys which are

displayed in this screen and their functions.

Inch

Metric

Act status

1-1-6

Figure 1-1-4

Page 14

3DB

1 Message display ........................... Current status, the next step in a procedure and error messages are shown in the

message display.

2 Number of destinations display ..... The number of destinations that you have chosen to dial to is shown in this area.

3 Speed-dial keys............................. Keys that you have registered to function as either a one-touch key, a group dial

key (G), a program key (P) or a chain dial key (C) are displayed here.

4 “Address book” key ....................... Touch this key when you want to use the address book.

5 “Abbrev.” key ................................. Touch this key when you want to use the abbreviated number that a destination

number is registered under in order to dial that number.

6 “TX setting” key ............................. Touch this key when you want to perform settings related to transmission

conditions such as the size of the documents to be transmitted, the image quality

of those documents, the contrast at which you want to send them and the time

when they should be sent. Once you press this key, the TX Setting screen will

appear.

” and “ ” cursor keys............... Use these keys when you want to display speed-dial keys other than those which

7 “

are currently displayed.

8 “Dest. check” key .......................... Touch this key when you have entered multiple destination fax numbers using

speed-dial keys, etc., and you want to check the list of those numbers.

9 “Re-dial” key .................................. Touch this key when you want to have the fax automatically redial the most

recently dialed number

10 “On-hook” key ............................... When a separately purchased telephone is connected to this fax machine and you

touch this key, you can dial a destination number without having to pick up the

receiver.

11 “Memory TX” / “Dir. Feed Tx” key .. When you want to switch between the Memory Transmission mode (“Memory Tx”)

and the Direct Feed Transmission mode (“Dir. Feed Tx”). The mode will change

each time you touch this key.

12 Reception mode select key ........... Touch this key when you want to select a different reception mode. The display will

change to the reception mode selection screen where you can select the desired

reception mode by touching the “Auto RX”, “Manual RX” or “Answering Machine”

key, as appropriate.

13 Memory bar ................................... Indicates the amount of data stored in memory. As documents are being stored,

the bar will move towards “100%” indicating that the data stored in memory is

increasing. Once it reaches “100%”, no more documents can be stored in memory.

14 Fax number display ....................... The number that you have entered to dial is displayed here.

15 “Basic” key .................................... Touch this key when you want to return to the basic fax screen.

16 “Application” key ........................... Touch this key when you want to use one of the various functions of this fax

machine such as polling, etc.

17 “Register” [“Registration”] key ....... Touch this key when you want to perform one of the various registration

procedures of this fax machine.

18 “Print Report” key .......................... Touch this key when you want to print out one of the various reports or lists of this

fax machine.

19 “Status” [“Act status”] key .............. This key is displayed during a transmission, reception or printout. Touch this key

when you want to verify the contents of the operation.

1-1-7

Page 15

3DB

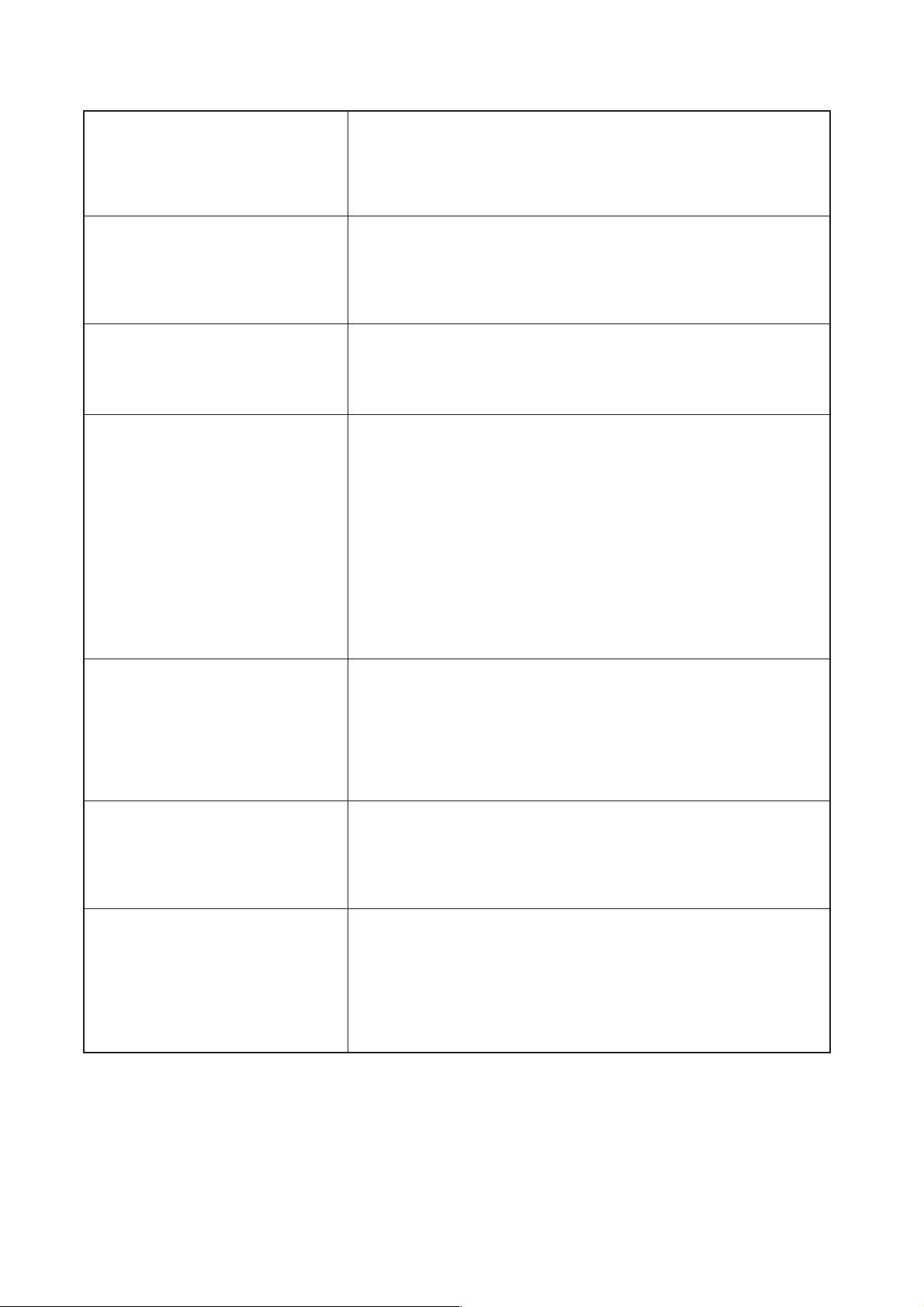

1-1-3 Mechanical construction

PSPCB

CN8

1

LIVE(OUT)

MSW

LIVE

2

(IN)

TB3

MPCB

MSW REM

2

CN31

OPCB

24V

RELAY OUT

RELAY IN

1

NEUTRAL IN

TB2

TB1

APSPCB

TB3

1-1

1-5

1-4

5.2V

GND

RELAY REM

12V

1-3

1-2

GND

SP

BUBAT

SPEAKER

A.GND

BATT

G(5V)

YC8

6

5

3

1

7

8

9

YC7

1

2

YC6

1

2

YC4

DIMM (optional)

Memory Module

FCPCB

LINE

TEL

NCUPCB

YC3

YC1

CN44

Figure 1-1-5

The fax system consists of the fax control PCB (FCPCB), NCU PCB (NCUPCB), auxiliary power source PCB (APSPCB),

speaker (SP), backup battery (BUBAT) and optional memory module DIMM.

1-1-8

Page 16

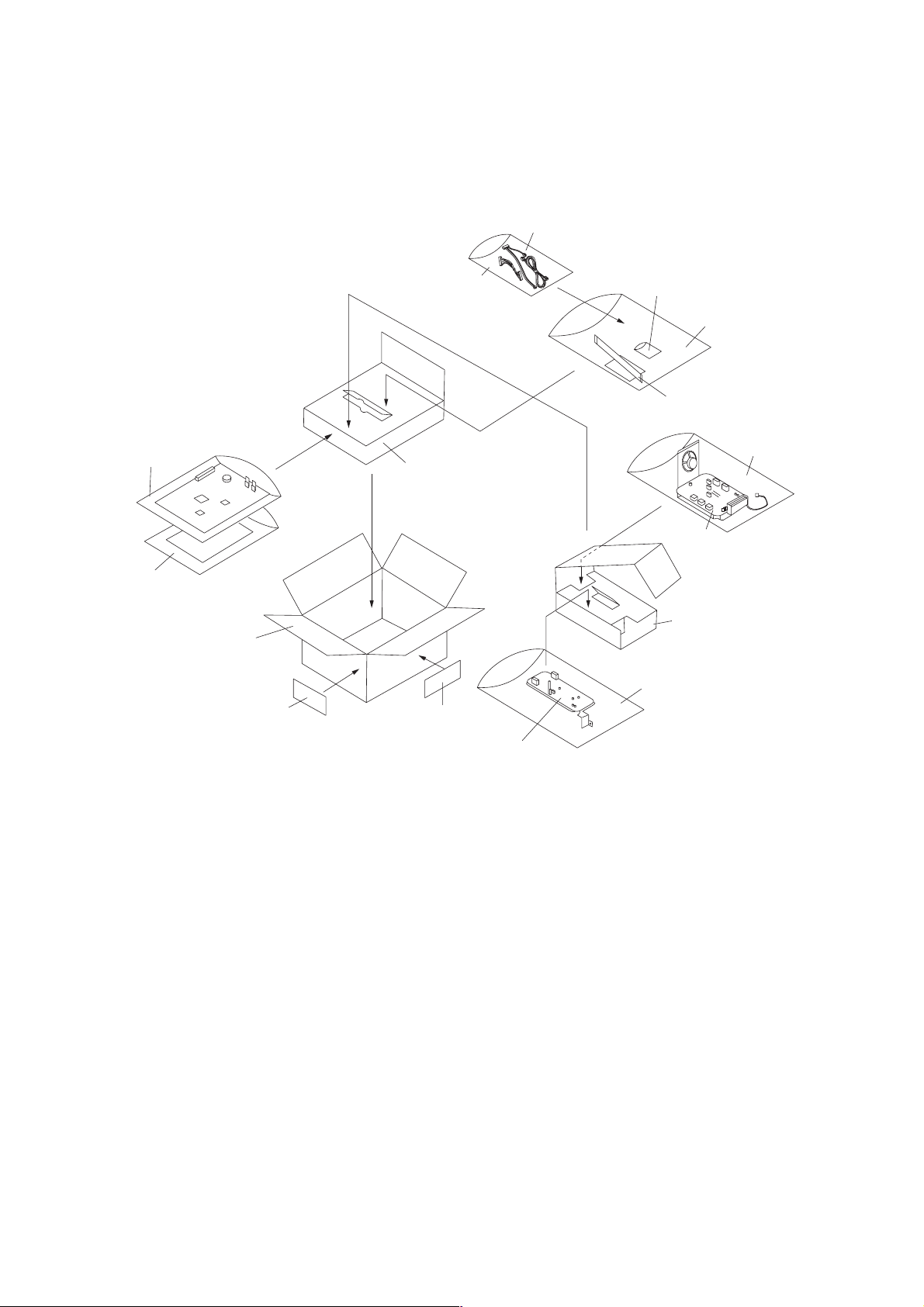

1-2-1 Unpacking and installation

(1) Unpacking and installation

3DB

790

12

*(

¤

‹

⁄

‹

!

%^

&

8@#$›

4

3

)

6

Figure 1-2-1 Unpacking

1 Fax control PCB

2 Antistatic air-padded bag

3 NCU board assembly

4 Antistatic air-padded bag

5 Auxiliary power source PCB

assembly

6 Antistatic air-padded bag

7 NCU cable

8 FCC68 label*

9 FAX-PCB-Power cable

0 “B” modular connector cable*

! Plastic bag

@ NW-FAX CD-ROM

# Fax cable

5

$ IC line label*

% TP-A chrome binding screw M3 ×

06

^ Plastic bag

& Plastic bag

* Operation guide

( Plastic bag

) Upper spacer

⁄ Bottom spacer

¤ Outer case

‹ Barcode labels

› Fax-kit label sheet

*For 120 V specifications only.

1-2-1

Page 17

3DB

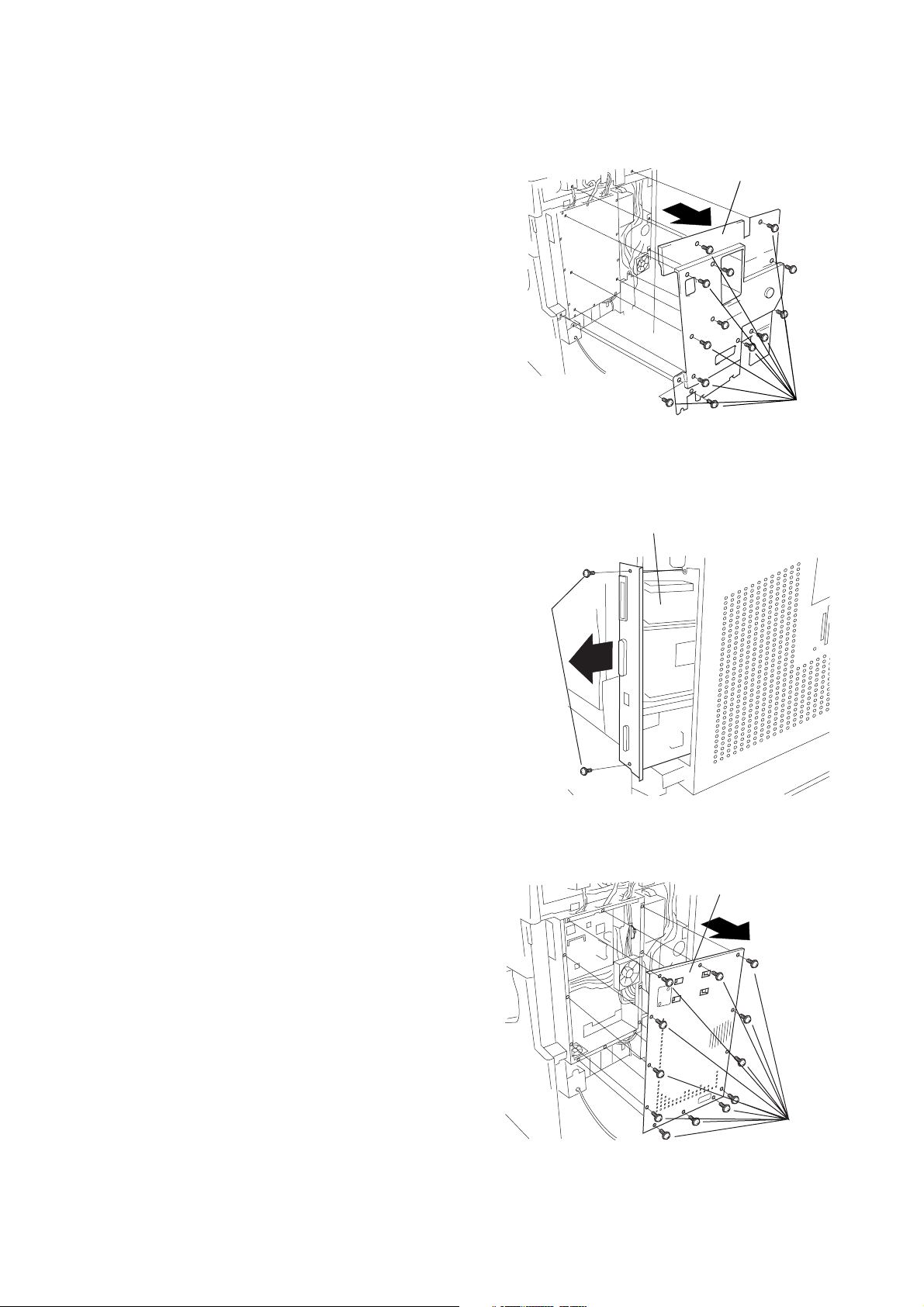

Turn the machine’s main switch to OFF and unplug the copier from the power supply before starting this procedure.

<Procedure>

1. Remove 13 screws and take off the rear cover.

Rear cover

Screws

Figure 1-2-2

2. If the printing system is installed, remove the 2 screws and pull the

printing system out of the controller box.

3. Remove 13 screws and take off the controller-box cover.

Printing system

Screws

Figure 1-2-3

Controller-box cover

1-2-2

Screws

Figure 1-2-4

Page 18

3DB

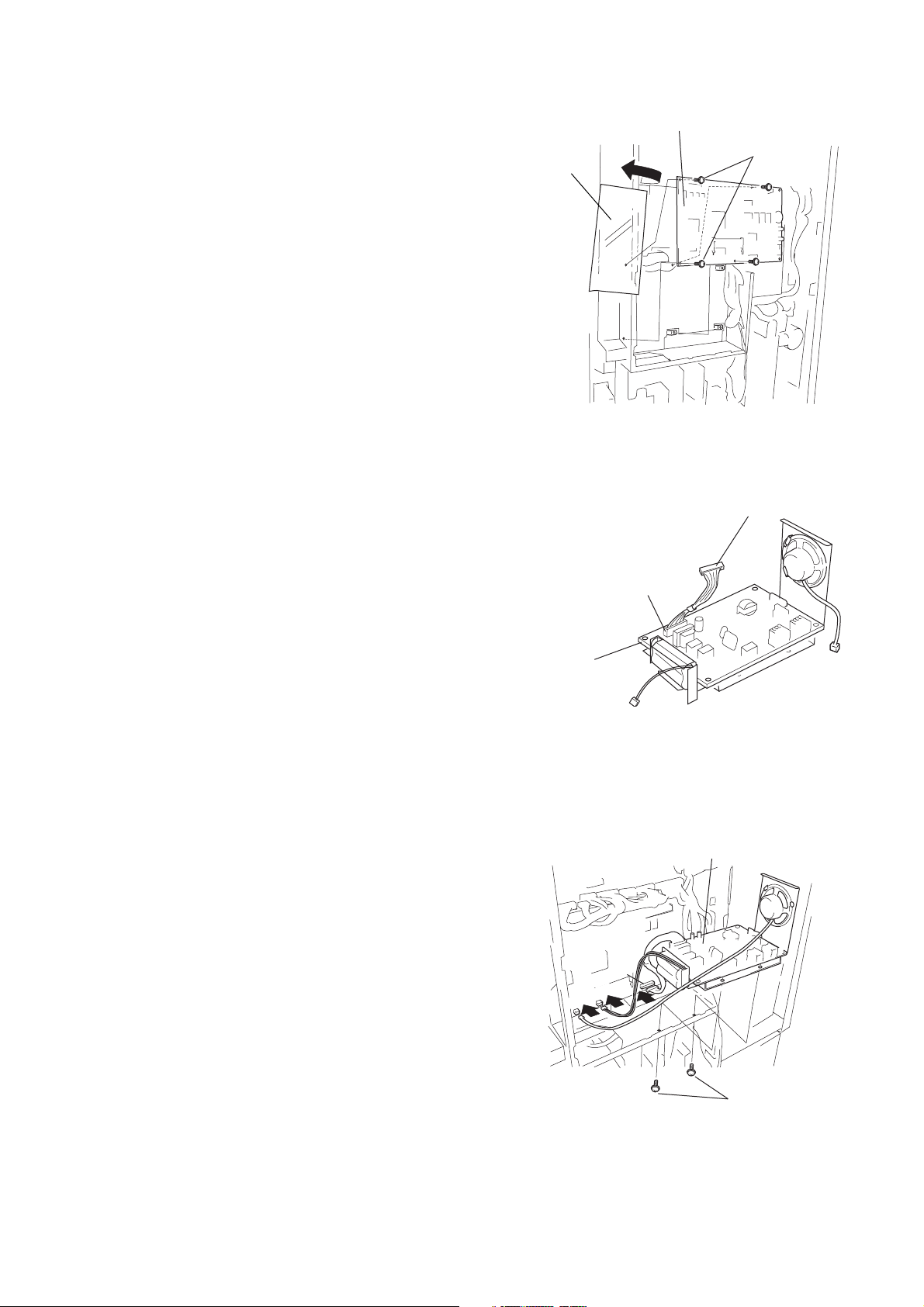

g

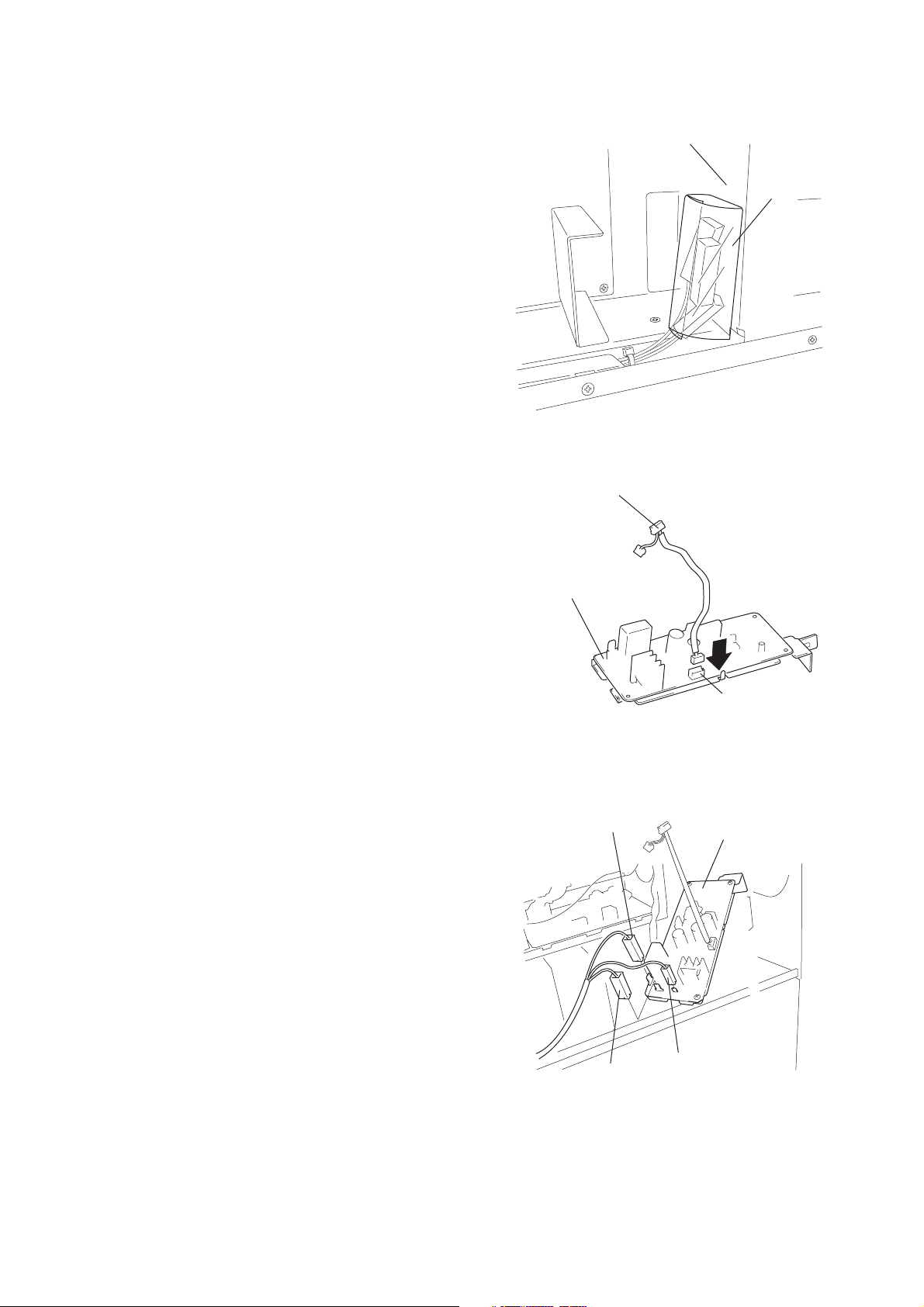

4. Move the shielding cover out of the way to the left, and fasten the

fax control PCB into place using four M3 × 06 chrome binding

screws.

5. Connect the NCU cable to connector CN1 on the NCU board

assembly.

Shielding cover

Fax control PCB

Figure 1-2-5

M3 × 06 chrome

binding screws

NCU cable

6. Fasten the NCU board assembly into place from the bottom with

two M3 × 06 chrome binding screws.

7. Connect the three connectors from the NCU board assembly to the

corresponding connectors on the fax control PCB, as follows:

• Speaker 2-pin connector → YC7

• NCU cable connector → YC3

• Battery connector → YC6

NCU board assembly

YC3

YC6

YC7

CN1

Figure 1-2-6

NCU board assembly

M3 × 06 chrome

screws

bindin

Figure 1-2-7

1-2-3

Page 19

3DB

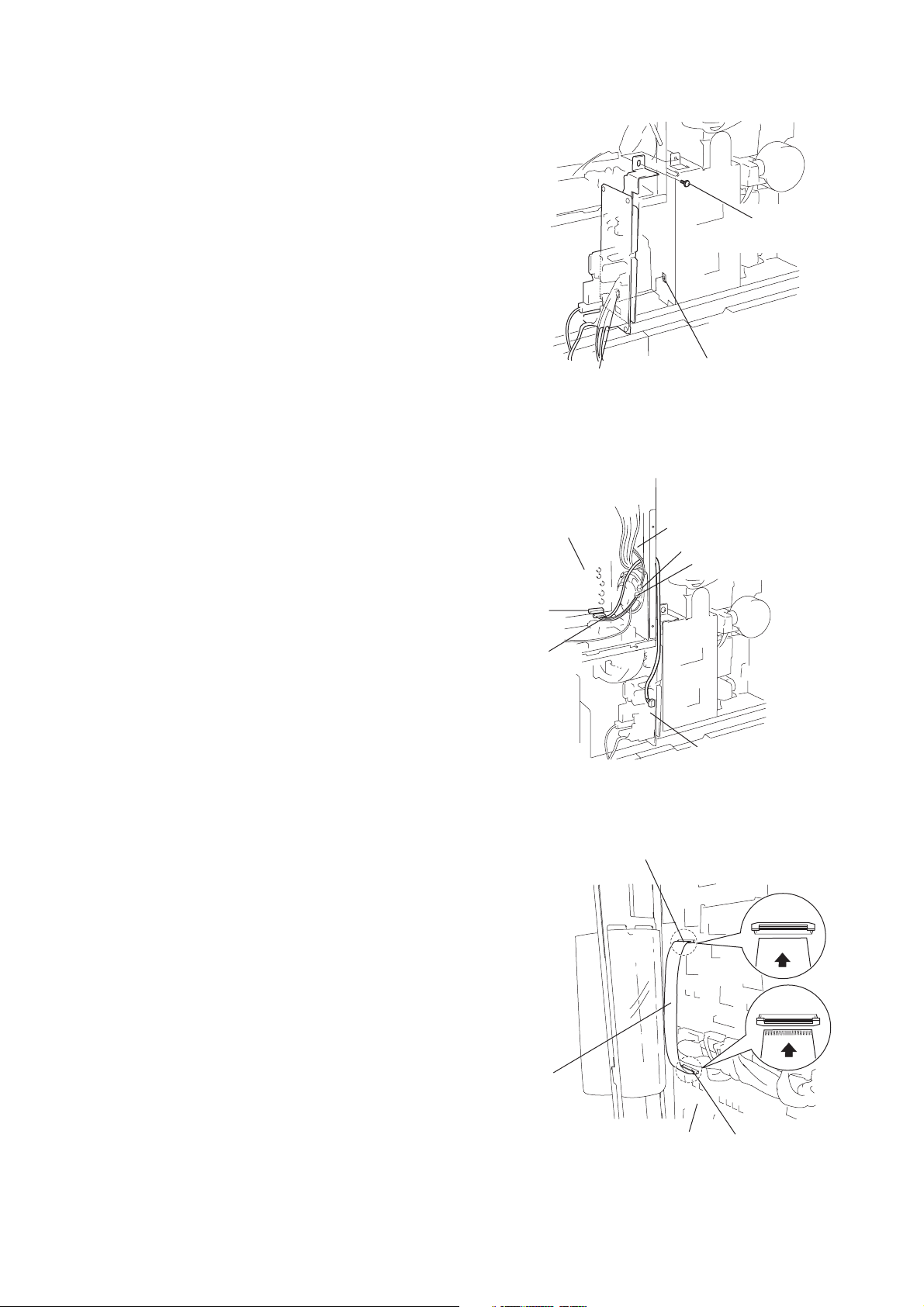

8. Remove the film that fixes the three positive connectors of the

power source PCB from the optional interface mounting plate.

Important: Dispose of the film that has been removed.

9. Connect the FAX-PCB-Power cable to connector CN1 on the

auxiliary power source PCB assembly.

Optional interface

mounting plate

Film

Figure 1-2-8

FAX-PCB-Power cable

10. Connect the three positive connectors on the power board to the

corresponding connectors on the auxiliary power source PCB

assembly as follows.

• White positive connector → TB1 (white)

• Green positive connector → TB2 (green)

• Small white positive connector → TB3

Auxiliary power source

PCB assembly

Green positive

connector

CN1

Figure 1-2-9

Auxiliary power source

PCB assembly

TB2

TB3

TB1

1-2-4

White positive

connector

Small white

positive connector

Figure 1-2-10

Page 20

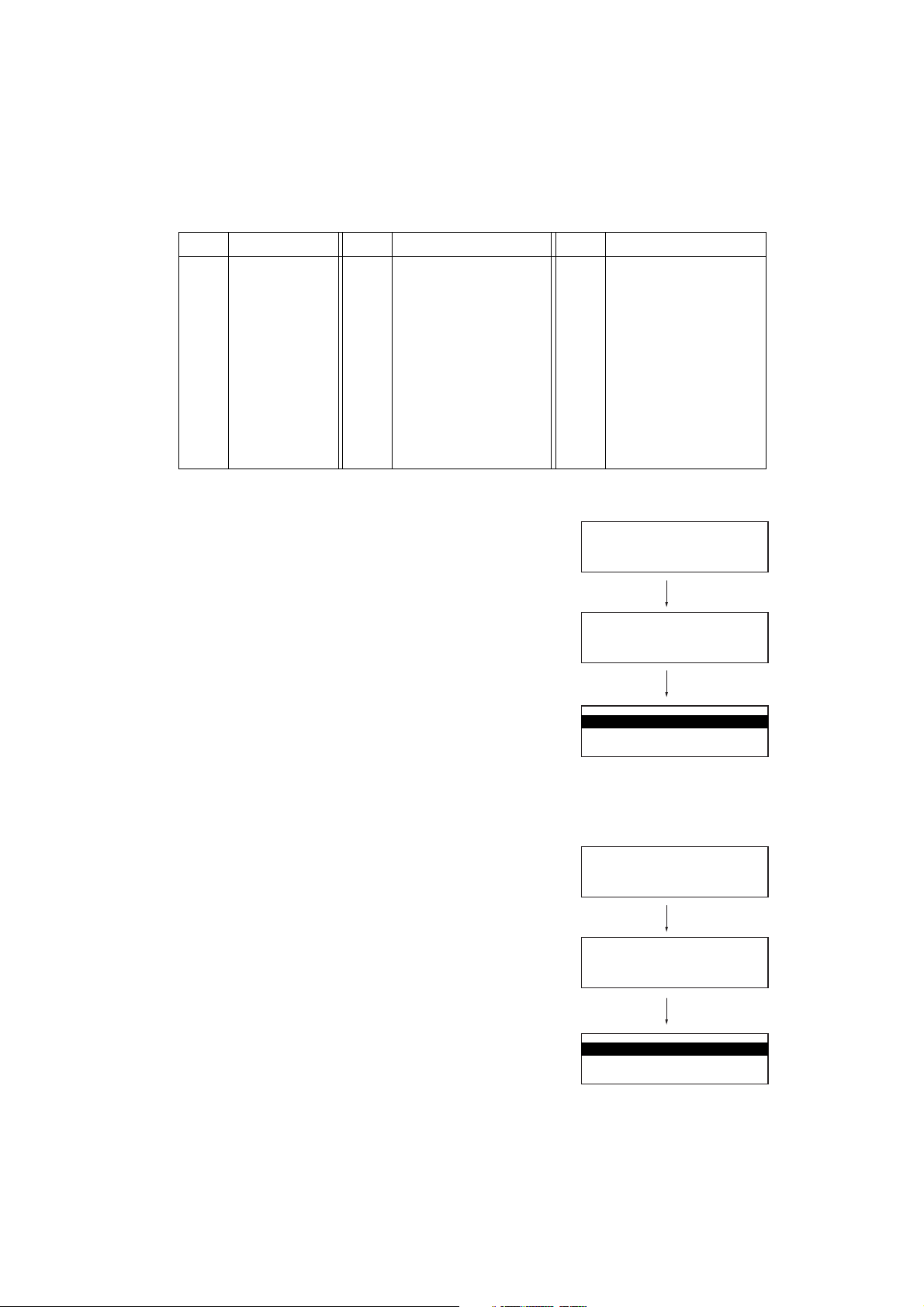

11. Fit the catch on the auxiliary power unit into the mount hole in the

y

copier, and fasten the auxiliary power unit into place with one M3 ×

06 chrome binding screw.

3DB

M3 × 06 chrome

binding screw

12. Through the opening of controller-box above the speaker, connect

the FAX-PCB-Power cable on the auxiliary power source PCB

assembly to connector YC8 on the fax control PCB.

13. Connect the 2-pin connector to the 2-pin connector with green

cable.

Fax control PCB

FAX-PCB-Power

YC8

cable

Catch

Mount hole

Figure 1-2-11

Opening

2-pin connector (green cable)

2-pin connector

Auxiliary power source

PCB assembl

Figure 1-2-12

14. Unlock YC1 on the fax control PCB by pulling its connector

housing.

15. Hold the fax cable with its conductive side facing up, insert it into

connector YC1, then push the housing back in to lock the

connector.

16. Hold the other end of the fax cable with its conductive side facing

down, and connect it to connector CN44 on the main PCB. (Pull

the CN44 housing out to release the connector lock, then insert the

cable, and then push the housing back in.)

Important: Be sure to push the fax cable all the way in, and be sure

that the connection is straight. A poor connection may result in a

variety of problems.

17. Refit the controller-box cover.

Fax cable

CN44

Fax control PCB

Figure 1-2-13

CN44

YC1

YC1

1-2-5

Page 21

3DB

18. Remove 1 screw and take off the modular cover.

19. Hang the modular cover onto the holes on the controller-box cover,

and fasten it into place with 1 screw.

20. If the printing system was installed, refit the printing system into the

controller box.

21. Refit the rear cover.

Screw

Modular cover

Figure 1-2-14

120 V specifications only

22. Adhere the IC line label and FCC68 label to the rear cover at the

locations indicated in the diagram.

Screw

Holes

Modular cover

Figure 1-2-15

IC line label

FCC68 label

1-2-6

Figure 1-2-16

Page 22

23. Take the power label from the fax-kit label sheet, and adhere it to

the copier directly under the main switch.

24. Take the alphabet labels from the fax-kit label sheet, and adhere

them above the corresponding numeric keys on the operation

panel.

• In Asia, use the “PQRS TUV WXYZ” label, and do not use the

“PRS TUV WXZ” and “OPER” labels.

Main switch

Alphabet labels

Figure 1-2-17

Management

ABC DEF

1

23

MNOJKL

4756

PQRS TUV

WXYZ

98

OPER

0

Reset

Interrupt

S

Start

Stop/

Clear

3DB

Power label

Energy Sever

25. Connect the telephone circuit to the L terminal by inserting the

modular connector cable into the line terminal (L).

Important: On 120 V specifications, use the included “B” modular

connector cable to make the connection.

Figure 1-2-18

Line terminal (L)

Modular connector

cable

Figure 1-2-19

1-2-7

Page 23

3DB

Initialization procedure after installation of facsimile system

1. Insert the machine power plug to the wall outlet and turn the main

switch on.

2. Run maintenance item U601.

3. Enter a destination code using the numeric keys (refer to the

destination code list) and then press the start key.

* Enter a destination code with three digits.

Code

000

009

080

084

088

108

126

136

137

152

156

4. Enter the OEM code (000) and then press the start key.

5. Confirm that the display is changed as shown in the illustration.

* At the position of @, the version number of the software is

displayed.

6. Press the cursor key to change the display to maintenance item

U602.

Destination

Japan

Australia

Hong Kong

Indonesia

Israel

Malaysia

New Zealand

Peru

Philippines

Middle East

Singapore

Code Code

159

169

181

242

243

253

Destination Destination

South Africa

Thailand

U.S.A.

South America

Saudi Arabia

CTR21 (European nations)

Italy

Germany

Spain

U.K.

Netherlands

253

Sweden

France

Austria

Switzerland

Belgium

Denmark

Finland

Portugal

Ireland

Norway

254

INI. KEEP DATA

COMPLETED XXX 000

INI. KEEP DATA

COMPLETED V@.@@

Taiwan

7. Press the start key and confirm that the display is changed as

shown in the illustration.

* At the position of @, the version number of the software is

displayed.

8. After completing the installation, run a communications test to

confirm that the fax system is working correctly.

SELECT THE MAINTENANCE NUMBER.

Initial keep data U601

Figure 1-2-20

INI. SHIP DATA

COMPLETED XXX 000

INI. SHIP DATA

COMPLETED V@.@@

SELECT THE MAINTENANCE NUMBER.

Initial ship data U602

Figure 1-2-21

1-2-8

Page 24

1-2-2 Setting and registering data

After setting up the machine, set or register the following data.

(1) Settings

3DB

• Setting the type of telephone line*

1

Select the setting (pulse or tone) according to the type of telephone line to be used.

• Setting the TTI transmission

Select whether or not to add the transmit terminal identifier (TTI) to the transmitting document.

• Setting report output condition

• Select the output condition for the management report (output or not output by department).

• Select the output condition for the activity report (output or not output after every 50 communications)

• Select the output condition for the transmission report (output or not output after each transmission)

• Select the output condition for the reception report (output or not output after each reception)

• Select the output condition for the timer communication report (output or not output after each timer programming).

• Select the output condition for the network fax transmission report.*

2

• Setting the password check communication

Select whether or not to perform password check communication.

• Setting the memory fax forwarding

Select whether or not to perform memory fax forwarding.

• Setting the bulletin board

Select whether or not to use the bulletin board during polling transmission.

• Setting the number of rings for automatic reception

Select the number of rings (1 to 15) that sound after call reception until fax data reception starts in the auto reception

mode.

• Setting the number of rings for TAD reception

Set the number of rings (1 to 15) that sound after call reception until fax data reception starts in the TAD reception

mode.

• Setting the number of rings for fax/telephone auto select mode*

1

Set the number of rings (0 to 15) that sound after call reception until fax data reception starts in the fax/telephone auto

select mode.

• Setting the speaker volume

Set the volume of the speaker in the on-hook mode (4 levels).

• Setting the alarm buzzer volume

Set the volume of the alarm that sounds during events such as when an error occurs (3 levels).

• Setting the monitoring volume

Set the volume for the sounds from the speaker (4 levels).

• Setting the document size for scanning from the document processor

Select the setting (“Standard size original” or “Long original”) for scanning the original fed from the document processor.

• Setting the default transmission mode

Select the transmission mode (memory transmission or direct feed transmission) to be used in the initial mode.

• Setting the reception mode

Select an automatic reception mode (automatic fax reception, fax/telephone auto selection or D.R.D. reception*

1

).

• Setting reception date and time recording

Select whether or not to record the date and time on received documents.

• Setting the paper feed selection mode

Select the paper feed mode (“Auto Selection mode”, “Fixed Size mode” or “Fixed Cassette mode”) for printing received

fax or reports.

• Setting the manual paper feed

Select whether or not to use the multi-bypass to feed paper for printing received faxes.

• Setting 2-in-1 reception

Select whether or not to output two successively-received A5/8

• Setting duplex reception*

Select whether or not to print received documents on both sides of the paper.

• Setting the network fax reception*

Set to perform network fax reception.

• Setting for saving the documents for transmission*

Select whether or not to save the transmitted documents on the server computer.

• Setting the file type*

3

2

2

2

1

/2" × 51/2" documents onto one A4R/81/2" × 11" page.

Select the file type in which the documents for transmission, or of received documents, will be saved in the server

computer.

• Setting remote diagnosis

Set to take advantage of our remote diagnosis system.

• Setting the restricted access

Turn the restricted access on or off.

*1: For 120 V specifications only.

*2: When the printer/scanner kit is installed.

*3: When the duplex unit is installed.

1-2-9

Page 25

3DB

(2) Registration

• Date and time

Set the current date and time.

• Self station information

Register the self telephone number, self station name and self station ID.

• One-touch dialing

Register destination fax (telephone) numbers and names under one-touch keys. Up to 600 entries can be registered.

• Group dialing

Register multiple destination fax (telephone) numbers and names under a one-touch key for group dialing. Up to 50

entries can be registered as group dial keys or program keys.

• Program dialing

Register frequently used communication modes or fax numbers under one-touch keys. Up to 50 entries can be

registered as program dial keys or group keys.

• Chain dialing

Register chain numbers and names under one-touch keys.

• F-code confidential boxes

Register F-code confidential boxes for F-code based confidential communication. Up to 100 boxes can be registered.

• F-code relay boxes

Register F-code relay box for F-code based relay broadcast communication. Up to 15 boxes can be registered.

• Encryption boxes

Register encryption boxes for receiving encrypted transmissions. Up to 15 boxes can be registered.

• Permit telephone numbers and IDs

Register the password (permit telephone number or ID) for password check communication.

• Fax forwarding

Register the destination and designated hours for fax forwarding.

• Remote switching number

Change the remote switching number, which is set to “55” at the factory, for receiving faxes using the telephone

connected to the machine.

• Remote test ID

Register the designated remote test ID for remote diagnosis.

• Management password

Register a 4-digit password, which is set to “6482” at the factory, for encrypted communication.

• Access codes

Register access codes for restricted access. Up to 50 codes can be registered.

• Cipher key password

Register a 16-digit cipher key password for encrypted communication.

• File name (transmission/reception)*

Register the default file name when documents which have been transmitted or received using the network fax

functions are saved in the designated folder.

• IP address / Host name*

Register the IP address or host name of the server computer in which documents which have been received using the

network fax functions are saved.

• Administrator’s e-mail address*

Register the e-mail address of the computer to be notified in case of an error, as well as where to send Transmission

and Reception Reports.

• Save folder number*

Register the number of the folder in which documents which have been transmitted or received using the network fax

functions will be saved.

*When the printer/scanner kit is installed.

1-2-10

Page 26

1-2-3 Installing the optional memory module DIMM

Memory module DIMM installation on the fax control PCB requires the following parts:

8 MB memory module DIMM (P/N: 2AW6001)

<Procedure>

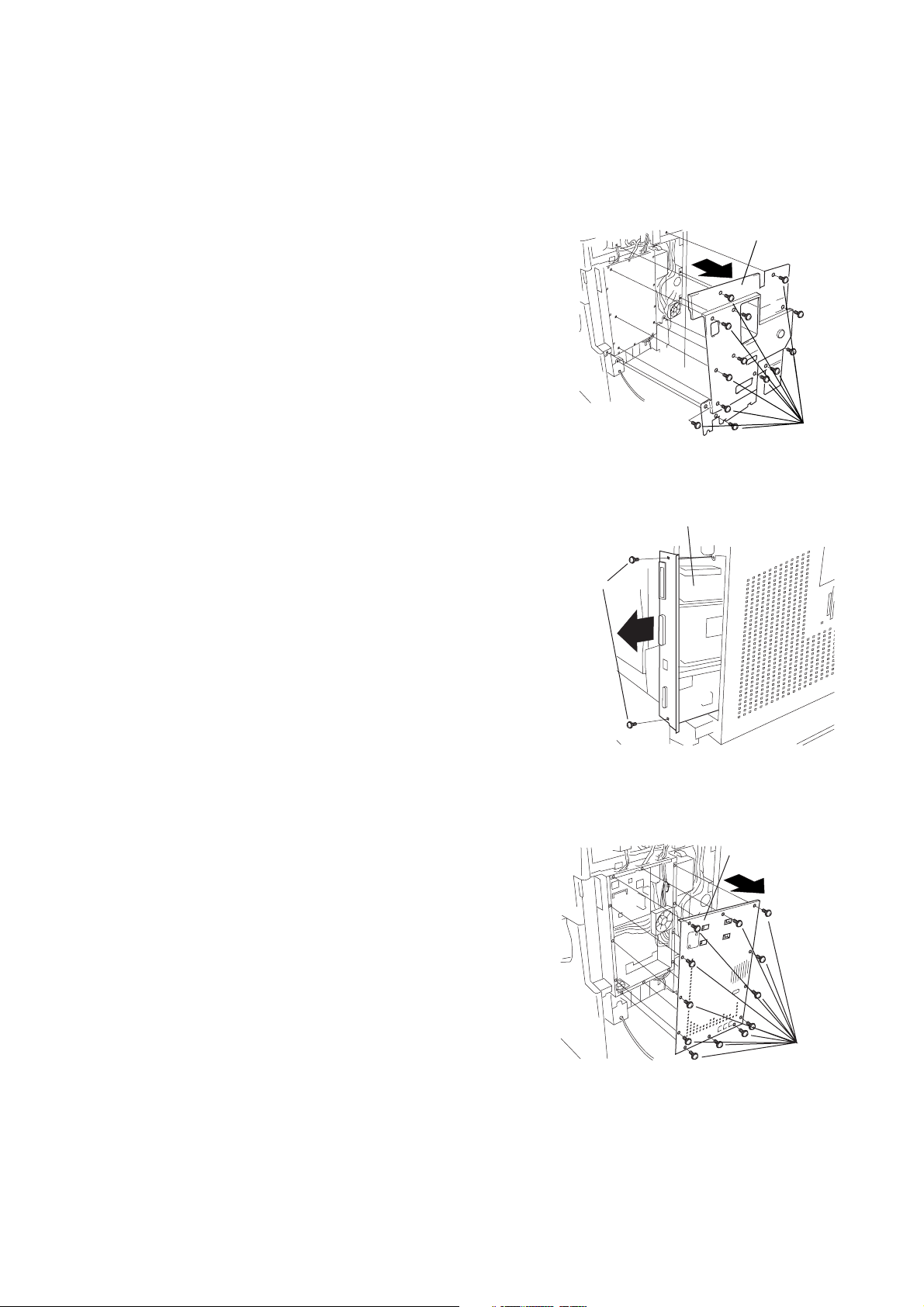

1. Remove 13 screws and take off the rear cover.

3DB

Rear cover

Screws

Figure 1-2-22

2. If the printing system is installed, remove the 2 screws and pull the

printing system out of the controller box.

3. Remove 13 screws and take off the controller-box cover.

Printing system

Screws

Figure 1-2-23

Controller-box cover

Figure 1-2-24

Screws

1-2-11

Page 27

3DB

4. Insert the memory module DIMM (8MB) at an angle into the

memory slot on the fax control PCB.

Important: The memory module DIMM (8MB) must be installed

onto the fax control PCB. Please be sure that you do not install it

onto the main PCB.

5. Push the free end of the module down toward the fax control PCB.

6. Refit all removed parts.

Memory module DIMMMemory slot

Figure 1-2-25

1-2-12

Page 28

1-3-1 Maintenance mode

(1) Maintenance mode item list

Section

Fax

Item

No. setting*

U600 Initializing all data —

U601 Initializing permanent data —

U602 Setting factory defaults —

U603 Setting the user registration data

• Setting the self telephone number —

• Setting the type of telephone line —

• Setting the number of rings in the fax/telephone auto select mode —

• Setting remote diagnostic transmission —

U604 Clearing data

• Clearing transmission history —

• Initializing the management password —

• Initializing the F-code confidential box ID —

• Initializes the F-code relay box ID —

• Initializes the encription box ID —

U605 Setting the system (operational)

• Setting how to proceed if memory becomes full

during memory transmission —

• Setting an alarm for when reception is completed —

• Selecting if auto reduction in the auxiliary direction is to be performed —

• Setting the addition of an image to the report —

• Setting the error report display format —

• Setting the line-monitoring period —

• Setting the one-shot detection time for remote switching —

• Setting the continuous detection time for remote switching —

• Setting the initial condition of fax image scanning quality —

U606 Setting the system (operation unit and display)

• Setting the conditions under which an error indicator turns off —

• Setting the date format —

• Setting if the image scanning quality in fax mode is initialized —

• Setting if the scanning density in fax mode is initialized —

• Setting whether to skip unregistered abbreviated numbers

and one-touch key numbers on the list —

• Setting the used port entry in the activity report —

U607 Setting the system (communication 1)

• Setting the auto redialing interval —

• Setting the number of times of auto redialing —

• Setting the communication starting speed —

• Setting the reception speed —

• Setting the mode for remote switching —

• Setting the transmission intervals —

• Sets the loop current detection before dialing —

• Sets the DIS signal to 4 bytes —

U608 Setting transmission

• Setting the method to process errors —

• Setting the number of times of DIS signal reception —

• Setting the reference for RTN signal output —

• Setting the waiting period to prevent echo problem at the sender —

• Setting the waiting period to prevent echo problem at the receiver —

• Setting ECM transmission —

• Setting ECM reception —

• Setting the criteria for receiving a TCF signal 1 —

• Setting the frequency of the CED signal —

U609 Setting communication time

• Setting the T0 time-out time —

• Setting the T1 time-out time —

• Setting the T2 time-out time 69

• Setting the Ta time-out time 30

• Setting the Tb1 time-out time 20

• Setting the Tb2 time-out time 80

• Setting the Tc time-out time 60

• Setting the Td time-out time —

Maintenance item contents

3DB

Initial

1-3-1

Page 29

3DB

Section

Fax U610 Setting the modem output level

Item

No. setting

• Setting the modem output level —

• Adjusting the modem output level —

U611 G3 cable equalizer

• Setting the G3 transmission cable equalizer —

• Setting the G3 reception cable equalizer —

U612 Setting the modem detection level —

U613 Setting the DTMF output level

• Setting the DTMF (high-frequency group) output level —

• Setting the DTMF (low-frequency group) output level —

U614 Adjusting the DTMF output level

• Adjusting the DTMF (high-frequency group) output level —

• Adjusting the DTMF (low-frequency group) output level —

U615 Setting the NCU

• Setting the connection to PBX/PSTN —

• Setting PSTN dial tone detection —

• Setting busy tone detection —

• Setting for a PBX —

U616 Adjusting the ratio of make-to-break of dial pulses

• Make time (10 PPS) —

• Make time (20 PPS) —

U617 Outputting lists

• Settings list —

• Action list —

• Own-status report —

• Protocol list —

• One-touch dialing ECM setting list —

U650 Setting the system 1

• Setting the number of lines to be ignored when receiving a fax

at 100% magnification 3

• Setting the number of lines to be ignored when receiving a fax

in the auto reduction mode 3

• Setting the number of lines to be ignored when receiving a fax (A4R, letter)

in the auto reduction mode 3

• Setting the recording width for inch specifications —

• Setting automatic printing of the protocol list —

U651 Setting the system 2

• Setting the variation range in the auxiliary scanning direction

for rotation reception 3

• Setting the number of adjustment lines for automatic reduction 7

• Setting the number of adjustment lines for automatic reduction

when A4 paper is set 22

• Setting the number of adjustment lines for automatic reduction

when letter size paper is set 26

U660 Setting the system (communication 2)

• Setting the criteria for receiving a TCF signal 2 —

• Setting the short protocol transmission —

• Setting the reception of a short protocol transmission —

• Setting the CNG detection times in the fax/ telephone auto select mode —

• Turning ECM for one-touch dialing on/off —

U670 Setting the system (communication 3)

• Setting if V.34 transmission is available —

• Setting the V.34 symbol speed (3429 Hz) —

• Setting the V.34 symbol speed (3200 Hz) —

• Setting the V.34 symbol speed (3000 Hz) —

• Setting the V.34 symbol speed (2800 Hz) —

U680 Displaying the fax board ROM version —

Maintenance item contents

Initial

1-3-2

Page 30

3DB

Section

Fax

Others

Item

No. setting

U881 Using the flash-memory jig

• Saving data from SRAM into the jig —

• Writing data from the jig into RAM —

• Writing the boot program into the jig —

• Reading one-touch/abbreviated dial information —

• Writing one-touch/abbreviated dial information —

U882 Setting the software switches —

U894 Performing board test

• Performing tests on SRAM and DRAM —

• Performing tests on optional memory —

U898 Setting the ports for maintenance mode —

U992 Checking or clearing the printer/fax count —

Maintenance item contents

Initial

1-3-3

Page 31

3DB

(2) Contents of maintenance mode items

Maintenance

item No.

U600 Initializing all data

Description

Initializes software switches and all data in the SRAM on the fax control PCB, according to the destination and

OEM.

Purpose

Used to initialize the fax control PCB.

Method

1. Press the start key. The screen for entering the destination code is displayed.

Enter a destination code using the numeric keys (refer to the destination code list on page 1-3-5 for the

destination code).

INI. ALL DATA

COUNTRY CODE:000

2. Press the start key. The screen for entering the OEM code is displayed.

There is no operation necessary on this screen.

INI. ALL DATA

OEM CODE:000

3. Press the start key. Data initialization starts. To cancel data initialization, press the stop/clear key.

4. After data initialization, the entered destination and OEM codes are displayed, and the ROM version is

displayed two seconds later.

Description

INI. ALL DATA

COMPLETED 000 000

INI. ALL DATA

COMPLETED V1.00

Caution

If initialized with “000” (code for Japan) entered as the destination code, service call code C0820 (fax control

PCB problem) will be detected. Be sure to enter the correct destination code. If C0820 (fax control PCB

problem) is detected, press the COPY key to put the machine in the copy mode, open the front cover and then

execute this maintenance item again to enter the correct destination code and initialize data.

1-3-4

Page 32

3DB

Maintenance

item No.

U600

(cont.)

U601 Initializing permanent data

Destination code list

Code

000

009

080

084

088

108

126

136

137

152

156

Description

Initializes software switches other than that for machine data on the fax control PCB according to the

destination and OEM.

Purpose

Used to initialize the fax control PCB without changing user registration data and factory settings.

Method

1. Press the start key. The screen for entering the destination code is displayed.

Enter a destination code using the numeric keys (refer to the destination code list on page 1-3-5 for the

destination code).

Destination

Japan

Australia

Hong Kong

Indonesia

Israel

Malaysia

New Zealand

Peru

Philippines

Middle East

Singapore

Code

159

169

181

242

243

253

Description

Destination

South Africa

Thailand

U.S.A.

South America

Saudi Arabia

CTR21 (European nations)

Italy

Germany

Spain

U.K.

Netherlands

Code

253

254

Destination

Sweden

France

Austria

Switzerland

Belgium

Denmark

Finland

Portugal

Ireland

Norway

Taiwan

INI. KEEP DATA

COUNTRY CODE:000

2. Press the start key. The screen for entering the OEM code is displayed.

There is no operation necessary on this screen.

INI. KEEP DATA

OEM CODE:000

3. Press the start key. Data initialization starts. To cancel data initialization, press the stop/clear key.

4. After data initialization, the entered destination and OEM codes are displayed, and the ROM version is

displayed two seconds later.

INI. KEEP DATA

COMPLETED 000 000

INI. KEEP DATA

COMPLETED V1.00

Caution

If initialized with “000” (code for Japan) entered as the destination code, service call code C0820 (fax control

PCB problem) will be detected. Be sure to enter the correct destination code. If C0820 (fax control PCB

problem) is detected, press the COPY key to put the machine in the copy mode, open the front cover and then

execute this maintenance item again to enter the correct destination code and initialize data.

1-3-5

Page 33

3DB

Maintenance

item No.

U602 Setting factory defaults

Description

Initializes software switches other than that for machine data and the SRAM on the fax control PCB, according

to the destination and OEM.

Purpose

Used to initialize the fax control PCB to the factory default.

Method

1. Press the start key. Data initialization starts. To cancel data initialization, press the stop/clear key.

2. After data initialization, the entered destination and OEM codes are displayed, and the ROM version is

displayed two seconds later.

INI. SHIP DATA

COMPLETED 000 000

INI. SHIP DATA

COMPLETED V1.00

Description

1-3-6

Page 34

3DB

Maintenance

item No.

U603 Setting the user registration data

Description

Makes user settings to enable the use of the copier as a fax.

Purpose

To be run after installation of the facsimile kit if necessary.

Start

1. Press the start key. The screen for selecting an item is displayed.

2. Press the appropriate item.

The screen for the selected item appears.

Display

SELF TEL No.

LINE TYPE

RINGS (F/T) #

REMOTE DIAG

Setting the self telephone number

1. Enter the telephone number using the numeric keys.

Up to 20 digits can be entered.

To correct the entered telephone number or to delete the stored telephone number, reset by pressing the

stop/clear key.

2. Press the start key.

3. To return to the screen for selecting an item, press the stop/clear key.

The item-selection screen does not reappear until registration or deletion processing is completed.

Setting the type of telephone line

1. Change the setting using the numeric keys.

Display

1: DTMF

2: 10

3: 20

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the number of rings in the fax/telephone auto select mode

Use this if the user wishes to adjust the number of rings that occur before the unit switches into fax receiving

mode when fax/telephone auto-select is enabled.

1. Change the setting using the numeric keys.

Number of fax/telephone rings

DTMF

10 PPS

20 PPS

Sets the self telephone number.

Sets the type of telephone line.

Sets the number of rings in fax/telephone auto select mode.

Sets remote diagnostic transmission.

Description

Description

Description

Description

Setting range

0 to 15

If you set this to 0, the unit will start fax reception without any ringing.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting remote diagnostic transmission

1. Enter 1 or 2 using the numeric keys to select if remote diagnostic transmission is to be enabled.

Display

1: ON

2: OFF

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item No. is

displayed.

Remote diagnostic transmission is enabled.

Remote diagnostic transmission is disabled.

Description

1-3-7

Page 35

3DB

Maintenance

item No.

U604 Clearing data

Description

Initializes data related to the fax transmission such as transmission history and IDs.

Purpose

Used to clear the transmission history or if an ID has been forgotten.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Press the appropriate item.

Initialization processing starts. When processing is finished, the screen displays "COMPLETED".

Display

COMM. REC

MANAGE PW

F-CODE ID

F-CODE ID

ENCRPT ID

3. To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item No. is

displayed.

U605 Setting the system (operational)

Description

Makes settings for fax transmission regarding operation.

Start

1. Press the start key. The screen for selecting an item is displayed.

2. Press the appropriate item.

The screen for the selected item appears.

Clears the activity report, error list, action list, transmission history

of each department as listed on the department control report,

transmission history for displaying the transmission results,

document number, timer program information, protocol list, and

other transmission history such as image data, excluding items

regarding the machine variation adjustment.

Initializes the management password.

Initializes the F-code confidential box ID.

Initializes the F-code relay box ID.

Initializes the encription box ID.

Description

Description

Display

MEM. FULL

FIN. ALARM

AUTO REDU

ADD IMAGE

ERR. CODE

MONITOR

TIME (ONE)

TIME (CON)

RESOLUT

Setting how to proceed if memory becomes full during memory transmission

Used to select whether to send only stored data or to display an error indication and cancel transmission if

memory becomes full during memory transmission.

1. Enter 1 or 2 using the numeric keys to change the setting.

Display

1: CONT

2: STOP

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Sets how to proceed if memory becomes full

during memory transmission.

Sets an alarm for when reception is completed.

Selects if auto reduction in the auxiliary direction

is to be performed.

Sets for the addition of an image to the report.

Sets the error report display format.

Sets the line-monitoring period.

Sets the one-shot detection time for remote switching.

Sets the continuous detection time for remote switching.

Sets the initial condition of fax image scanning quality.

Whether to continue memory transmission or to

clear the memory can be selected by the user.

Memory is forcibly cleared.

Description

Description

1-3-8

Page 36

3DB

Maintenance

item No.

U605

(cont.)

Setting an alarm for when reception is completed

1. Enter 1 or 2 using the numeric keys to change the setting.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Selecting if auto reduction in the auxiliary direction is to be performed

Sets whether to receive a long document by automatically reducing it in the auxiliary direction or at 100%

magnification.

1. Enter 1 or 2 using the numeric keys to change the setting.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the addition of an image to the report

Selects if an image is to be added to the transmission report.

1. Enter 1 or 2 using the numeric keys to change the setting.

Display

1: ON

2: OFF

Display

1: ON

2: OFF

Display

1: ON

2: OFF

Description

Description

An alarm rings.

An alarm does not ring.

Description

Auto reduction is performed if the received

document is longer than the fax paper.

Auto reduction is not performed.

Description

Image added.

Image not added.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the error report display format

Selects the format of the transmission report when a transmission error occurs.

1. Change the setting using the numeric keys.

Display

1: WORDS

2: CODE

3: MIX

Records an error message (BUSY, OK, ERROR or STOP).

Records a six-digit error code.

Records either an error message or code.

Description

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the line-monitoring period

Sets the period to monitor the line. By monitoring a transmission from the start to the end, it can be checked

whether the transmission was correct or not.

1. Change the setting using the numeric keys.

Display

1: END

2: DIS

Until transmission is completed.

After dialing is completed until reception of a DIS signal.

Description

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the one-shot detection time for remote switching

Sets the detection time when one-shot detection is selected for remote switching. (This setting item will be

displayed, but the setting made is ineffective.)

1. Change the setting using the numeric keys.

Description

One-shot detection time for remote switching

Setting range

0 to 255 (× 5 : ms)

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

1-3-9

Page 37

3DB

Maintenance

item No.

U605

(cont.)

U606 Setting the system (operation unit and display)

Setting the continuous detection time for remote switching

Sets the detection time when continuous detection is selected for remote switching. (This setting item will be

displayed, but the setting made is ineffective.)

1. Change the setting using the numeric keys.

Description

Continuous detection time for remote switching

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the initial condition of fax image scanning quality

Set to the resolution that is most frequently used by the user.

1. Change the setting using the numeric keys.

Display

1: S

2: F

3: SF

4: UF

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item No. is

displayed.

Description

Makes settings for fax transmission regarding the operation unit and display.

Start

1. Press the start key. The screen for selecting an item is displayed.

Note: Since this model does not provide LED error indicators, this setting has no affect on actual operation.

Display

ALARM LED OFF

DATE PATTERN

RESO. LOCK

DENS. LOCK

REPORT SKIP

REPORT ADD

PORT

Setting the conditions under which an error indicator turns off

1. Enter 1 or 2 using the numeric keys to change the setting.

Display

1: RESET

2: COMM

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Description

Standard

Fine

Super fine

Ultra fine

Description

Sets the conditions under which an error indicator turns off.

Sets the date format.

Sets if the image scanning quality in fax mode is initialized.

Sets if the scanning density in fax mode is initialized.

Sets whether to skip unregistered abbreviated numbers

and one-touch key numbers on the list.

Sets used port entry in the activity report.

Description

An error indicator turns off only when the

reset key is pressed.

An error indicator turns off when any key is

pressed, an original is inserted or the next

transmission is started.

Description

Setting range

0 to 255 (× 5 : ms)

1-3-10

Page 38

3DB

Maintenance

item No.

U606

(cont.)

Setting the date format

Selects the date format on the respective reports and sender’s information record.

1. Change the setting using the numeric keys.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting if the image scanning quality in fax mode is initialized

Sets if the resolution is to be initialized when fax operation is complete.

1. Enter 1 or 2 using the numeric keys to change the setting.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting if the scanning density in fax mode is initialized

Sets if the scanning density is initialized when fax operation is complete.

1. Enter 1 or 2 using the numeric keys to change the setting.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting whether to skip unregistered abbreviated numbers and one-touch key numbers on the list

Sets whether to skip unregistered abbreviated numbers and one-touch key numbers on the list.

1. Enter 1 or 2 using the numeric keys to change the setting.

Display

1: YMD

2: MDY

3: DMY

Display

1: ON

2: OFF

Display

1: ON

2: OFF

Display

1: ON

2: OFF

Description

Order

Year/month/day

Month/day/year

Day/month/year

Description

Resolution is initialized.

Resolution is not initialized.

Description

Density is initialized.

Density is not initialized.

Description

Unregistered numbers are skipped.

Unregistered numbers are not skipped.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting port entry in the activity report

Sets whether to enter used port in the activity report. (This setting need not be changed particularly.)

1. Enter 1 or 2 using the numeric keys to change the setting.

Display

1: ON

2: OFF

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item. The screen for selecting a maintenance item No. is

displayed.

Port is entered.

Port is not entered.

Description

1-3-11

Page 39

3DB

Maintenance

item No.

U607 Setting the system (communication 1)

Description

Makes settings for fax transmission regarding the communication.

Start

1. Press the start key. The screen for selecting an item is displayed.

2. Press the appropriate item.

The screen for the selected item appears.

Display

INTERVAL

TIMES

TX SPEED

RX SPEED

REMOTE

CALL INT

DC LOOP

DIS 4BYTE

Setting the auto redialing interval

Change the setting to prevent the following problems: fax transmission is not possible due to too short redial

interval, or fax transmission takes too much time to complete due to too long redial interval.

1. Change the setting using the numeric keys.

Redialing interval

Sets the auto redialing interval.

Sets the number of times of auto redialing.

Sets the communication starting speed.

Sets the reception speed.

Sets the mode for remote switching.

Sets the transmission intervals.

Sets the loop current detection before dialing.

Sets the DIS signal to 4 bytes.

Description

Description

Description

Setting range

1 to 9 (min.)

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the number of times of auto redialing

1. Change the setting using the numeric keys.

Description

Number of redialing

When set to 0, no redialing is performed.

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the communication starting speed

Sets the initial communication speed when starting transmission. When the destination unit has V.34 capability,

V.34 is selected for transmission, regardless of this setting.

1. Change the setting using the numeric keys.

Display

1: 144

2: 96

3: 48

4: 24

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

Setting the reception speed

Sets the reception speed that the sender is informed of using the DIS or NSF signal. When the destination unit

has V.34 capability, V.34 is selected, regardless of the setting.

1. Change the setting using the numeric keys.

Display

1: 144

2: 96

3: 48

4: 24

2. Press the start key. The value is set.

3. To return to the screen for selecting an item, press the stop/clear key.

V.17, 14400 bps

V.17, 9600 bps

V.27ter, 4800 bps

V.27ter, 2400 bps

V.17, V.33, V.29, V.27ter

V.29, V.27ter

V.27ter

V.27ter (fallback only)

Description

Description

Setting range

0 to 9

1-3-12

Page 40

3DB

Maintenance

item No.

U607

(cont.)

Setting the mode for remote switching

Sets the signal detection method for remote switching. Be sure to change the setting according to the type of

telephone connected to the machine.

1. Enter 1 or 2 using the numeric keys to change the setting.