Page 1

Chapter 2 OPERATION THEORY

Contents

General 2

Basic operations 3

Outline 3

Outline of electrical circuits 3

Finisher driver input/output 5

Feed and drive systems 9

Outline 9

Face-down paper ejection 1 0

Normal stacking 10

Job offset 10

Stapling 11

Face-up paper ejection 12

Normal stacking 12

Feeding and ejection 13

Outline 13

Face-down feeder (inversion operations)/paper ejection operations 16

Face-up feeder, paper ejection operations 16

Job offset 16

Staple operations 18

Outline 18

First page operations 19

Second and subsequent page operations 21

Last page operations 22

Tray operations 23

Stapler unit 25

Tray loading volume detection 26

Stacking mode details 26

Jam detection 27

Power supply 30

Outline 30

Protection functions 30

Page 2

OPERATION THEORY

General

2.1 General

This chapter provides explanations on the purpose, role and mechanical system of

each function, as well as providing an outline of the operational timing of each part

by function.

The descriptions of the digital circuits for this device include signals names without slashes (“/”) for H and PSNS electrical signal levels, and signal names with

slashes, such as L and /SCNON.

H and other signal names without slashes (“/”) are true (indicating that the signal

has been output) at the supply voltage level and false (indicating that the signal

has not been output) at the G ND leve l. L and other s ignal s name s wit h sla she s are

true at the ND level and false at the supply voltage level.

This device uses a microcomputer. However, as it is impossible to run an internal

operation check on a microcomputer, the explanation for the microcomputer operations has been omitted.

Also, as it is a pre-requisite for the internal printed circuit board to be untampered

with by the customer, simple summaries with the use of block diagrams have been

used in this manual to cover the descriptions of these printed circuit boards. Owing

to this, the explanations for circuits only cover the two areas from the sensors to

the input areas of the main substrates and from the output area of the main substrates to the load, and block diagrams are used to explain each function.

DF-30/DF-31

2-2

Page 3

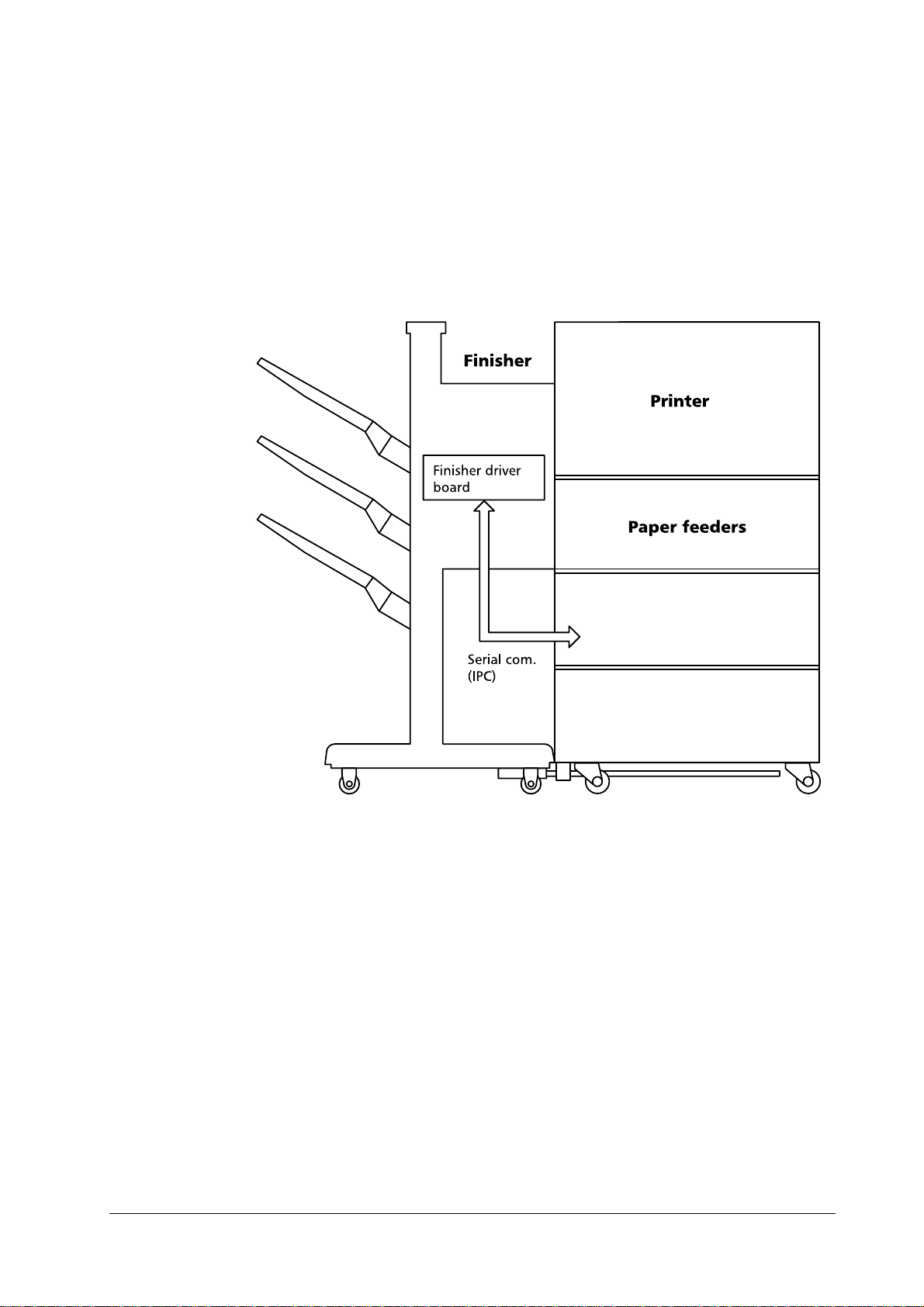

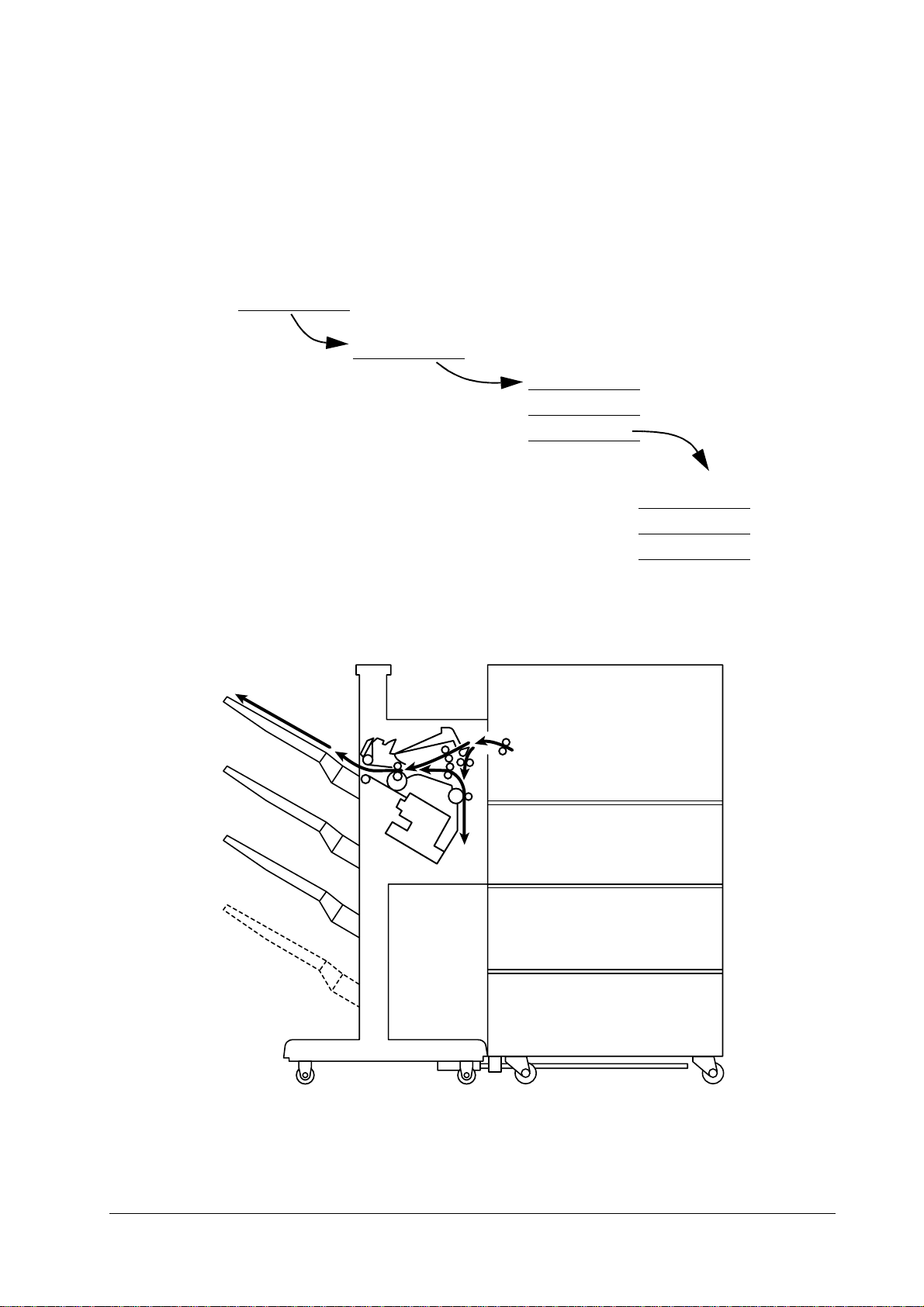

2.2 Basic operations

Outline

The finisher performs the face-down ejection and fa ce-up ejection of paper fed

through from the printer. The job offset and stapling functions are available with

face-down ejection.

These operations are controlled by the finisher driver’s circuit board.

OPERATION THEORY

Basic operations

Figure 2.1

Outline of the finisher

Outline of electrical circuits

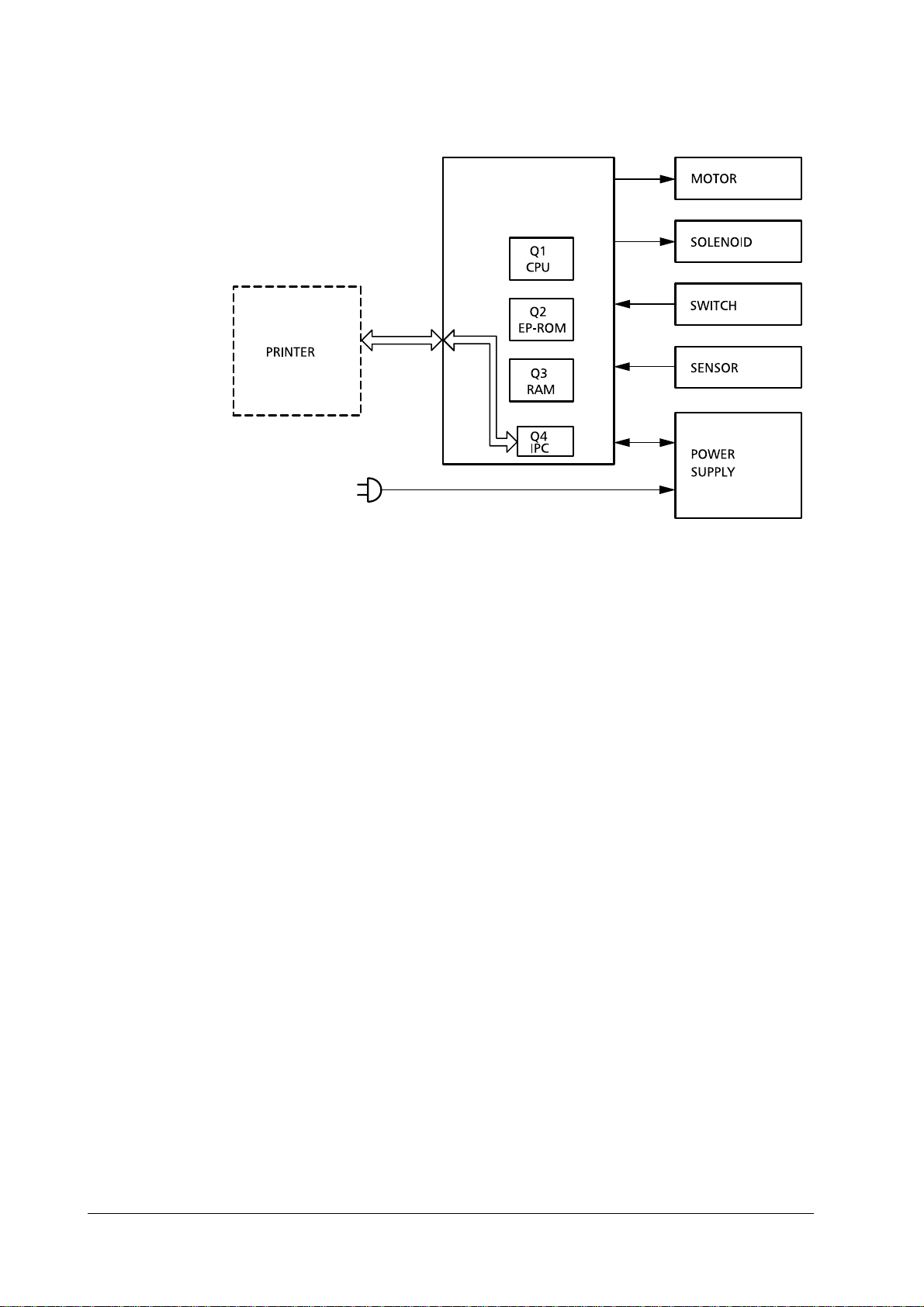

The finisher’s operational sequence is controlled by the finisher driver’s circuit

board. A 16-bit microcomputer (CPU) is used in the finisher driver’s circuit board,

and this performed serial communications with the sequential control.

The finisher driver operates the solenoids and motors, etc., in accordance with the

various commands that are transmitted from the option controller via the serial

communications line. The finisher driver also notifi es the option controller of sensor and switch information via the serial communications line.

The major roles of the ICs mounted in the finisher driver are as follows.

Q1 (CPU). Sequential control.

•

Q2 (EP-ROM). Sequential programs built in.

•

Q3 (RAM). Used for backing up the initial data.

•

Q4 (IPC). Used for communications control.

•

The diagram below shows the signal flow between the finisher and the printer.

2-3

Page 4

OPERATION THEORY

Basic operations

Figure 2.2

Signal flow between the finisher and the printer

DF-30/DF-31

2-4

Page 5

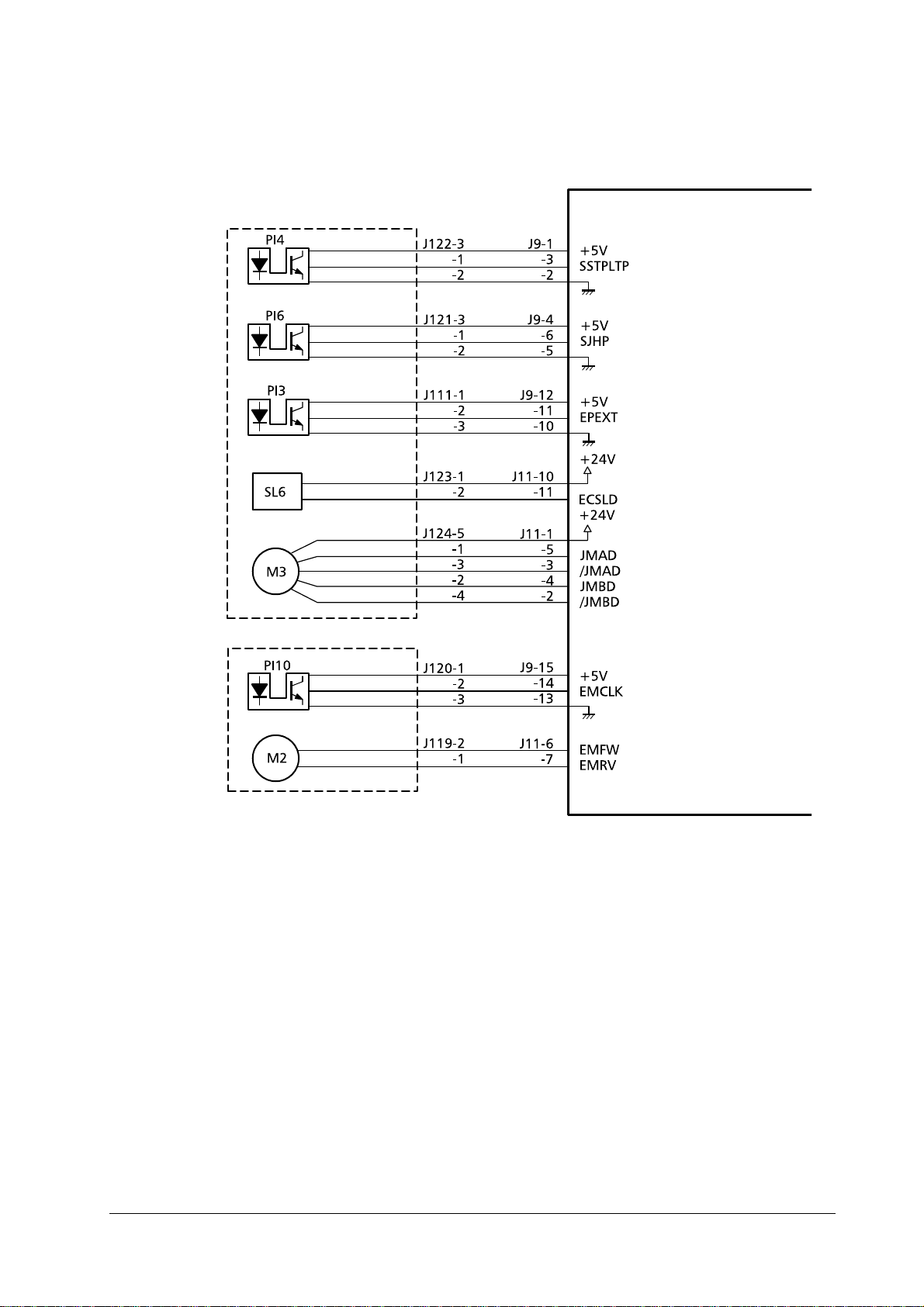

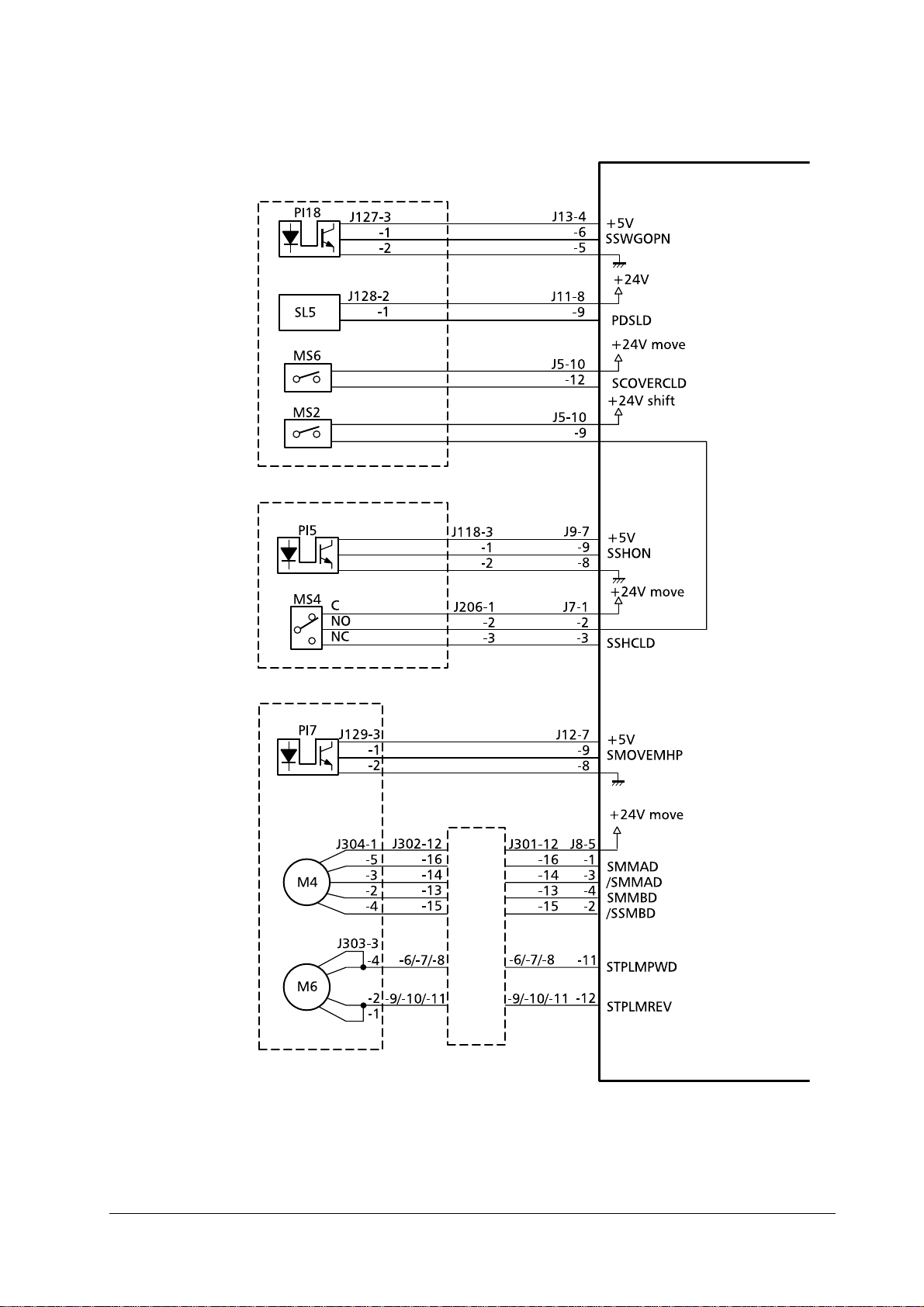

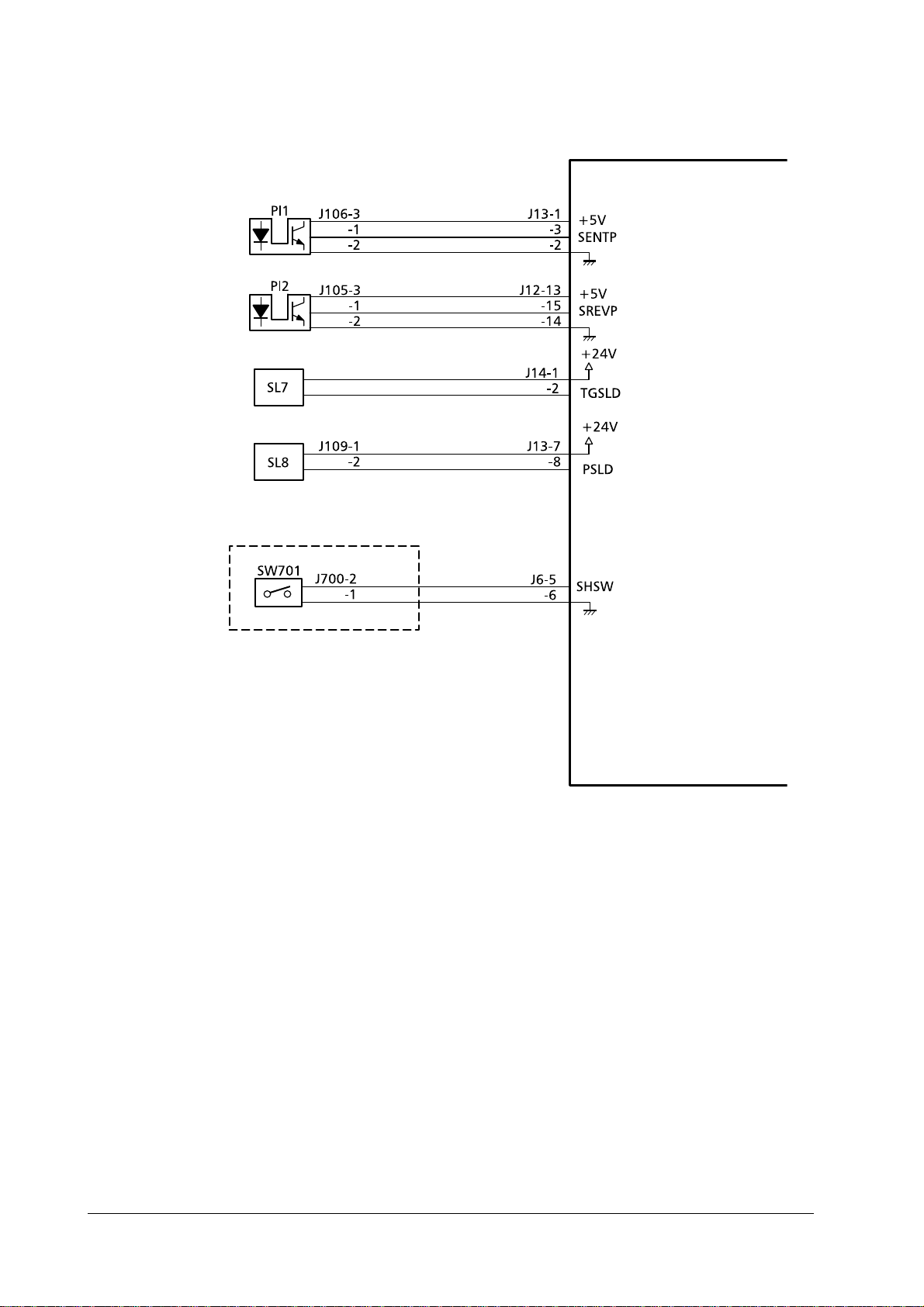

Finisher driver input/output

OPERATION THEORY

Basic operations

Staple tray paper

detection sensor

Matching board

home position

detection sensor

Paper ejectio n

detection sensor

Base board

shelter solenoi d

Matching board

movement mo tor

Staple tray assembly

Finisher driver circuit board

"L" when the sensor

detects paper.

"L" when the sensor

detects the matchi n g

board’s home position.

"L" when the sensor

detects paper.

The base board is

sheltered when "L".

Control signals for

the matching board

movement mo tor

Paper ejection

motor clock

detection sensor

Paper ejection

motor

Pulse emitted in

accordance with the

revolution speed of

the ejection motor

Control signals for

the paper ejection motor

2-5

Page 6

OPERATION THEORY

Basic operations

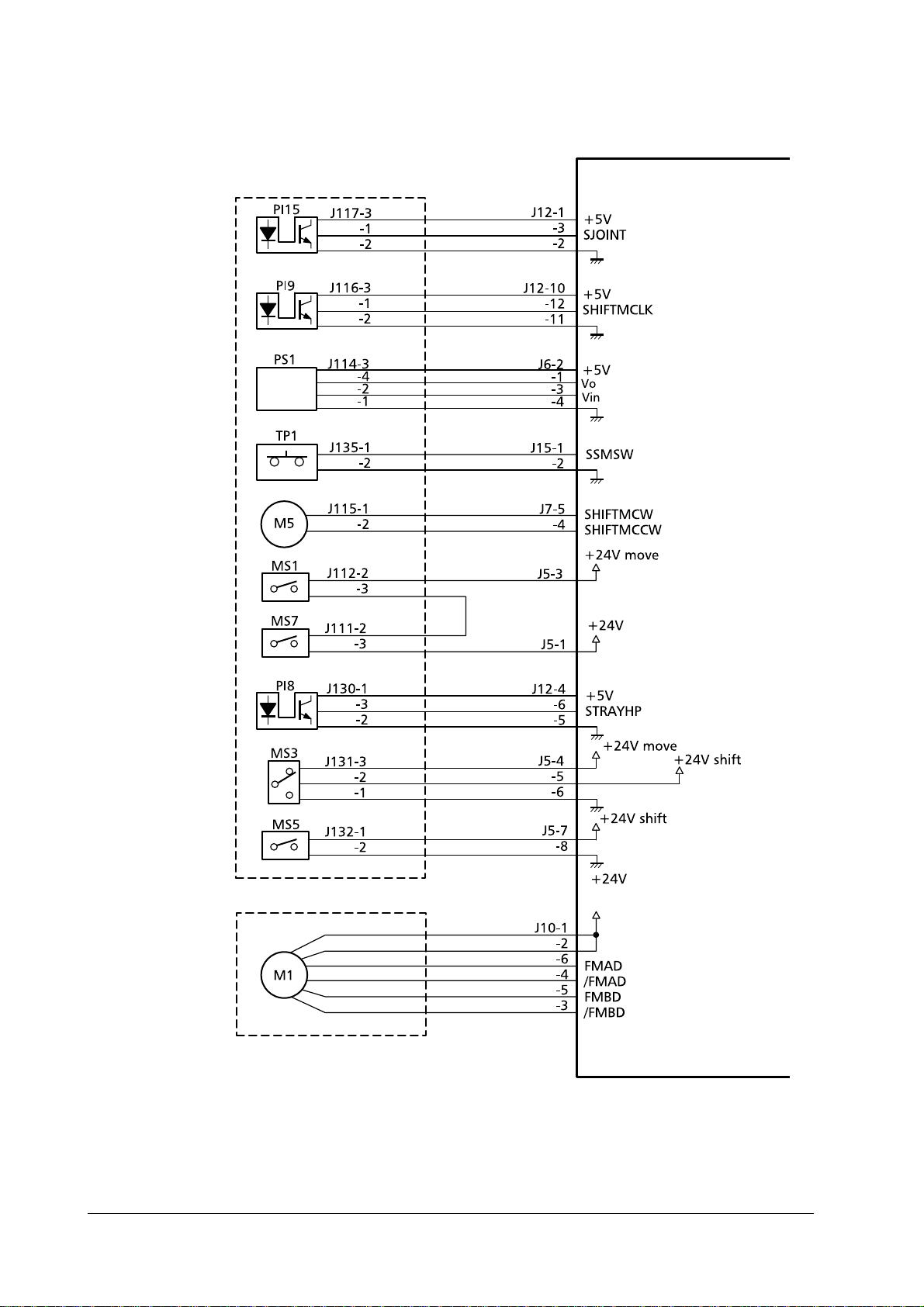

Frame assembly

Joint sensor

Tray elevation

motor clock

detection sensor

Distance sensor

Tray elevation

motor temperature sensor

Tray elevation

motor

Top cover open/

close detection

switch

Front cover open/

close detection

switch

Tray home position detection

sensor

"L" when connected to the

printer.

Pulse emitted in

accordance with

the revolution

speed of the tray

elevation motor .

Control signal for

the distance sensor

"L" when the

temperature of

the tray elevation

motor is high.

Control signals for

the tray elevation

motor.

"L" when the sensor detection the

tray’s home position.

Safety area

detection switch

Tra y uppe r limit

detection switch

Feeder motor

Control signal for

the feeder mot o r.

DF-30/DF-31

2-6

Page 7

OPERATION THEORY

Basic operations

Swing guide

assembly detection sensor

Paddle drive solenoid

Swing guide

open/close detection switch

Swing guide

open/close detection switch

Shutter close

detection sensor

Shutter open

detection sensor

Swing guide assembly

Shutter guide assembly

Finisher driver circuit board

"L" when the

swing guide is

open.

Paddle revolves

when "L".

"H" when the

shutter is

closed.

"H" when the

shutter is closed

Stapler home

position detection sensor

Intermediate circuit board

Stapler move ment motor

Staple motor

Staple unit

"L" when the stapler’s home position is detected.

Liaision

board

Control signals for

the stapler movement motor.

Control signals

for the stapler

motor

2-7

Page 8

OPERATION THEORY

Basic operations

Finisher driver circuit board

Inlet paper

detection sensor

Inversion paper

detection sensor

Inversion roller

drive solenoid

Face-up flapper

solenoid

Staple exchange

completion

switch

"L" when the sensor detects

paper.

"L" when the sensor detects

paper.

Inversion roller

revolved when

"L".

Paper fed face-up

when "L".

Staple exchange completion

switch circuit board

Staple operations

started when "H".

DF-30/DF-31

2-8

Page 9

OPERATION THEORY

2.3 Feed and drive systems

Outline

This device stacks, shifts, staples and ejects paper to the tray in accordance with

the commands transmitted from the printer.

The four different methods of paper ejection are explained below.

Paper ejection methods

Face-down ejection

Feed and drive systems

Normal stacking

Job offset

Staple

One on the left-hand side

One on the right-hand side

Two in the center

Figure 2.3

Feed and drive sys tem

2-9

Page 10

OPERATION THEORY

Feed and drive systems

Face-down paper ejection

Normal stacking

The paper is ejected to the tray face down after being inverted.

Tray

Printed output

Top guide

Face-up tran sport

roller

Eject roller #1

Eject roller #2

Bottom guide

Tr ansport roller #2

Face-up

diverter

Transport

roller #1

Job offset

The job offset operates in two ways: First- page-only mode and whole-set-of-pages

mode.

In the first-page-only mode, the first piece of paper is inverted and fed through to

the staple tray . The piece of paper is then shifted forward by approximately 30mm,

and ejected face down to the tray.

The second and subsequent pieces of paper are inverted and ejected to the tray

without being fed into the staple tray.

DF-30/DF-31

•

First page

Tray

Swing guide

Paper ejection roller #1

Stopper

Feed roller #2

Paper ejection

roller #2

Staple tray

2-10

Page 11

•

Second and subsequent pages

Tray

Second and subsequent pages

First page

Swing guide

OPERATION THEORY

Feed and drive systems

Paper ejection roller #1

Tray

Stopper

Staple tray

Feed roller #2

In the whole set of pages mode (defa ult), the whole page of a print jo b is fed into the

staple tray so that the jop is shifted forward. The subsequent job as a whole is not

shifted but delivered in a normal manner, allowing every other job is shifted to

each other.

Stapling

The pages are inverted, stacked in the staple tray, stapled and then ejected to the

tray.

Tray

Paper

Staple

Swing guide

Tray

Stopper

Staple tray

2-11

Page 12

OPERATION THEORY

Feed and drive systems

Figure 2.4

One staple on the le ft-hand side (1)

One staple on the right-hand side (2, angled)

Positions of stapling

Paper width/2

Two staples in the center (3)

One staple on the right-hand side (2, horizontal)

Face-up paper ejection

Normal stacking

The paper is ejected face-up to the tray without being inverted.

Tray

Paper

1

2

3

Upper guide

Paper ejection roller #1

Paper ejection roller #2

Face-up feed roller

Lower guide

Test staples (Not used)

Feed roller #2

1

2

3

Face-up

diverter

Feed roller #1

DF-30/DF-31

Inversion roller

2-12

Page 13

OPERATION THEORY

Feed and drive systems

Feeding and ejection

Outline

When the paper fed through from the printer is to be laid face down in the tray, the

inversion operation is performed.

The feed motor (M1) is a stepping motor, and the paper ejection motor (M2) is a DC

motor. The forward and reverse operation for these motors is controlled by the

microcomputer (CPU) in the finisher driver’s circuit board.

Three photo-interrupters, the inlet paper detection sensor (P11), the inversion

detection sensor (P12) and the paper ejection detection sensor, are situated along

the paper’s feed route, and these check whether the paper has reached it s destination or is still in transit.

The finisher driver will judge that a paper jam has occurred if the paper does not

reach or pass each sensor within a pre-determined period of time. In this event,

operations are halted and notification of the jam is sent to the printer.

2-13

Page 14

OPERATION THEORY

Feed and drive systems

Finisher driver circuit board

Table 2.1 Detection signals

(1)

(2)

(3)

(4)

(5)

PS1:

PI1:

P12:

P13:

P14:

DF-30/DF-31

Staple tray pap er detection sign al

T ray stacking volume dete ct ion signal

Paper ejection detection signal

Inverted paper detection signal

Inlet paper detection signal

Distance senso r

Inlet paper detection sensor

Inverted paper detection sensor

Paper ejection detection sensor

Staple tray paper detection sensor

2-14

Page 15

OPERATION THEORY

Finisher driver circuit board

Feed and drive systems

Table 2.2 Motors/solenoids— (1 / 2)

M1:

M2:

M3:

M4:

M5:

SL5:

SL7:

SL8:

(1)

(2)

(3)

2-15

Feed moto r

Paper ejection motor

Matching board’s movement motor

Stapler movement motor

Tray elevation motor

Paddle drive solenoid

Inversion roller driver solenoid

Face-up flapper drive solenoid

Stapler movement motor drive signal

Tray elevation motor drive s ignal

Matching board movement motor drive signal

Page 16

OPERATION THEORY

Feed and drive systems

Table 2.2 Motors/solenoids— (2 / 2)

(4)

(5)

(6)

(7)

(8)

Paper ejectio n m o to r dr ive signal

Paddle solenoid drive signal

Feed motor drive signal

Inversion solenoid drive signal

Face-up flapper solenoid drive signal

Face-down feeder (inversion op erations)/paper ejection operations

The feeder motor (M1) and paper ejection motor (M2) are started up when the finisher driver receives a paper ejection signal from the printer, and feeder roller #1,

feeder roller #2, paper ejection roller #1 and paper ejection roller #2 are put into

motion. By starting up fee der ro lle r #1 , a si ngle s heet of pap er is t rans fe rred t o the

inverter . A paper detection s ensor (P11) located at the inlet detects the bottom edge

of the paper, and after transferring it to the prescribed position, the inversion roller

driver’s solenoid (SL7) is activated and the M1 driver starts up the inversion roller.

This conveys the paper through to an inverted position. On ce the paper has been

inverted, it is passed through to the feeder guide by the inversion roller operating

in the reverse direction. The paper is then fed and ejected by feeder roller #1,

feeder roller #2, paper ejection roller #1 and paper ejection roller #2.

Face-up feeder, paper ejection operations

When the paper trans ferred fr om the printer t o the tray is to b e ejec ted face up, the

feeder motor (M1) and th e paper ejecti on motor (M2) a re put into mo tion by a p aper

ejection signal received by the finisher driver from the printer, and the face-up

feeder roller, paper ejection roller #1 and pap er e jecti on ro lle r #2 ar e st ar ted up. At

the same time, the face-up flapper driver solenoid (SL8) is activated, and the flapper is switched across to the face-up side. This enables the paper to be fed and

ejected without being inverted.

Job offset

Shift operations move only the first piece of p aper or whole set of paper (default) fo r

each job, and eject the second and subsequent pieces of paper without moving

them.

The paper is moved with the matching board, and the matching board home position detection sensor (P16) detects whether this board is at the home position or

not.

The matching board movement motor (M3) is activated when the power supply is

switched on in order for the finisher driver to return the matching board to the

home position. If the matching board is already in the home position, the system

enters the stand-by mode. As the distance for moving the matc hing board is

extended when paper other tha n A3 and A4 (horizonta l) is us ed, the fi nisher dr iver

moves the matching board to the stand-by position.

1

The finisher driver hal ts the operation of the paper ejection motor (M2) after the

first piece of paper has passed the far end of paper ejection roller #1. The gear is

1. The stand-by position is 5mm outside of the paper’s edge.

DF-30/DF-31

2-16

Page 17

OPERATION THEORY

Feed and drive systems

then moved to the swing guide drive assembly after the M2 motor has been put into

reverse. This transmits the operation of M2 across to the gear and raises the swing

guide. The swing guide is raised until it is detected by the swing guide open detection sensor (PI18) and then halted.

The paper is returned to the staple tray by the rubber surface fitted to paper ejection roller #1 when the sw ing gui de is rais ed. Th e paper retu rned to the st aple tray

is then detected by the staple tray paper detection sensor (PI4).

The matching board movement motor (M3) is then activated and the paper moved

by 30mm. Depending on the size of the paper, there are cases where it cannot be

moved by 30mm as it will interfere with the left-hand edge. In this event, the base

board shelter solenoid (SL6) is set at ON, and the paper is moved 30mm after the

left-hand base board has been sheltered.

The finisher driver activates M3 in the reverse direction and moves the matching

board to the stand-by position after the paper has been moved.

The finisher driver then activates M2 in the reverse direction to lower the swing

guide. M2 is run in the forward direction when the swing guide open/close detection switch (MS2) is set at ON, and paper ejection roller #2 is activated. This ejects

the paper to the tray. The second and subsequent pieces of paper for each job are

ejected to the tray without shift movement.

Left-hand base board

Base board shelter solenoid

Matching

board

Matching board

home position

detection sensor

Matching board

movement motor

Paper

For information on modes of stapling available, see page 2-12.

2-17

Page 18

OPERATION THEORY

Feed and drive systems

Staple operations

Outline

The staple operations staple together a specified quantity of paper in the stapler

unit.

The position of the staples will differ in accordance with the stapler motor and the

size of the paper. Refer to table 2-2-1 for further details.

The stapler home position detection sensor (PI7) detects whether the stapler unit is

at the home position or not.

The finisher driver activates the stapler movement motor (M4) after receiving the

start signal from the printer, and moves the stapler unit to the central stand-by

position (note).

Note

Table 2.3 Positions of staples

The central stand-by position is the location where the stapler unit is situated prior to the

paper being returned to the stapler tray in order to prevent the stapler operations being rendered impos sible owing to th e paper curlin g u p in side the staple tray.

Staple mode A3 A4R

One, on left-hand side

One, on right-hand side

Two, centered

Test (Not used)

Refer to page 12, table 2.4 on (1) to (5) for details.

B5/

B4

(2) (3)

(4)

Ldg

(1)

(5)

Ltr/

Ltr A4 Lgl Otrs

R

DF-30/DF-31

2-18

Page 19

Stapler home

position sensor

OPERATION THEORY

Feed and drive systems

Paper

Stapler

movement

motor

Stapler unit

First page operations

The finisher driver halts the operation of the paper ejection motor (M2) after the

first piece of paper has passed the far end of paper ejection roller #1. The gear is

then moved to the swing guide drive assembly after the M2 motor has been put into

reverse. The swing guide is raised by M2 until it is detected by the swing guide

open detection sensor (PI18) and then halted. The paddle drive solenoid is then set

at ON, and the feed motor drive operates the paddle.

The paper is returned to the staple tray by the rubber surface fitted to paper ejection roller #1 when the swing guide is opened where it is detected by the staple tray

paper detection sensor (PI4).

The matching board movement motor (M3) is activated and the pieces of paper are

matched up.

2-19

Page 20

OPERATION THEORY

Feed and drive systems

Swing guide

Swing guide open

detection sensor

Swing guide open

detection switch

Paper ejection

roller #2

Swing guide

Fist page of paper

Paper ejection

roller #2

Tray

Feed m otor clock

detection sensor

Paper eject io n motor

Paper ejection roller #1

Rubber roller

Staple tray

DF-30/DF-31

Stapler unit

2-20

Page 21

OPERATION THEORY

Feed and drive systems

Second and subsequent page operations

The finisher driver halts the operation of the paper ejection motor (M2) when th e

bottom edge of the second and subsequent pieces of paper have passed 20mm

through paper ejection roller #1. The paddle drive solenoid is then set at ON, and

the feed motor (M1) drive ope rates the paddle. This returns the pa per to the s tapler

tray, activates the matching board movement motor (M3) and matches up the

pieces of paper.

Paddle

Paddle driver

solenoid

piece of pape r

Second and subsequent

pieces of paper

Swing guideSecond or the subsequent

First piece of paper

Stopper

Stapler unit

Paddle

Paper ejection roller #1

Rubber roller

Tray

Paper ejectio n

roller #2

Staple tray

Stapler unit

2-21

Page 22

OPERATION THEORY

Feed and drive systems

Last page operations

The finisher driver sta rts up M3 once again after the matching process has been

completed for the last piece of paper in order to move the matching board to the

staple matching position (note #1). The multiple sheets of paper are then matched

up and the motor halted. The finisher driver then activates M2 in the reverse direction and lowers the swing guide.

The finisher driver activates the stapling process in accordance with the specified

staple mode transmitted from the printer (refer to fig.2-2-12 on page 2-19) and staples the pages together.

The finisher driv er activat es M3 when t he stapli ng process has been completed an d

moves the matching bo ar d to t he shel ter p osi ti on ( not e #2 ) whe n t he p aper i s being

ejected. The paper ejection mot or (M2) is then ac tiva ted i n the forwa rd dir ectio n to

operate ejection ro ller #2 and eject the stapled pages to the tr ay.

Swing guide

Note

Paper ejection roller #2

Paper ejection motor

1. The staple matching position is 0.5mm inside the horizontal width of the pa per. 2. The shelter position during paper ejection is 5.0mm outside of the horizontal width of the paper.

DF-30/DF-31

2-22

Page 23

Swing guide

Paper

Paper ejection

roller #2

OPERATION THEORY

Feed and drive systems

Staple tray

Stapler unit

Tray operations

The finisher driver is equip ped wit h three trays , and pa per can be eject ed to ei ther

of these trays. The trays are moved upwards and downwards with the tray elevation motor (M5). The position of each tray is detected by the tray elevation motor

clock detection sensor (PI9) with the amount of encoder pulse s fitted to M5. The

tray home position detection sensor (PI8) detects whether the trays are at their

home positions or not.

2-23

Page 24

OPERATION THEORY

Feed and drive systems

Tr ay #1

Tr ay #2

Tray guide

T r ay upp er lim it detection

switch

Tr ay #3

Tray elevation motor

Safe area detection switch

The finisher driver raises and lowers the tray guide until it is aligned with the

paper ejection outlet specified by the printer.

The upper limit for the tray is detected by the tray upper limit detection switch

(MS5). The tray elevation motor (M5) is halted when the finisher driver sets MS5

to ON.

Tray elevation motor clock

detection sensor

Encoder

Tray home position sensor

DF-30/DF-31

The height of the paper eje c ted t o t he tray i s detect ed by t he d ista nce se nsor (PS1 ).

The tray is lowered when the height of the paper reaches the stipulated value.

The 24V power supply to the tray elevation motor is cut off and the finisher driver

operations halted if the safe area detection switch (MS3) is set at ON when the

shutter and swing guide are open.

The finisher driver will noti fy the printer that a fault has occurred with the tray

elevation motor in the following cases:

2-24

Page 25

OPERATION THEORY

Feed and drive systems

When the home position detection process does not end within 16.5 seconds of it starting.

1

When the tray elevation motor clock detection sensor (PI9) does not detect the tray eleva-

2

tion motor clock detection signal (SHIFTMCLK) within 0.2 seconds of tray elevation

starting.

When the tray upper limit detection switch (MS5) is set at ON during tray elevation.

3

Stapler unit

Staple operations are performed by the staple motor (M6), and stapling is completed for each revolution of the cam.

The home position for the cam is detected by the staple operation home position

detection sensor (PT2) being set at ON.

The forward and reverse operations of the staple motor (M6) are controlled by a

microcomputer (CPU) situated on the finisher driver circuit board.

The staple operations are returned to the initial status by the finisher driver operating M6 in the reverse direction when PT2 is OFF and continuing to operate until

PT2 is ON.

The staple detection sensor (PT1) detects where staples exist within the staple cartridge.

The staple motor (M6) cannot be operated unless the swing guide close detection

switches (MS2, MS6) are ON (with the swing guide closed). This is a safety protection function to prevent the stapler from operating when fingers are inside.

The finisher driver will notify the option controller of a fault with the staple motor

in the following cases:

When the home position detection process does not end within 0.5 seconds of it starting.

1

When the staple operation home position detection sensor (PT2) is not set at ON within

2

0.5 seconds of staple operations being started.

Also, the finisher driver will judge a staple jam if the staple operation home position detection sensor (PT2) is not set at ON within 0.5 seconds of it being set at

OFF after staple operations have been started, and the staple motor (M6) will be

operated in the reverse direction until PT2 is set at ON. The printer will also be

notified of the jam.

Staple cartridge

Staple ejection

plate

Staple anvil

Staple sensor

Staple motor

Staple operation home position sensor

2-25

Page 26

OPERATION THEORY

Feed and drive systems

Cam

Tray loading volume detection

The number of pages and stacks (staple number) of paper ejected to the tray is

recorded by the finisher driver, and the height of the paper surface is detected by

the distance sensor (PS1). The maximum amount of paper that can be stacked in

each tray is shown in the table below.

The finisher driver will halt operations when the conditions outlined in the table

have been satisfied, and the printer will be notified that the tray is full.

Table 2.4 Loding capacities

Tray #

Tray #1 88mm 88mm, 300 pages or 30 stacks 48mm, 300 pages or 30 stacks

Tray #2 95mm 95mm, 300 pages or 30 stacks 48mm, 300 pages or 30 stacks

Tray #3 95mm 95mm, 300 pages or 30 stacks 48mm, 300 pages or 30 stacks

Stacking mode details

Mode #1.

For the normal stacking of pages of the same size, of small sizes1 or dur-

ing job offset.

Mode #2.

When height, number of pages and number of stacks are relevant for sta-

ples only.

Tray mode (See

12 3

details

below.)

(note #3)

(note #3)

(note #3)

Mode #3.

sizes

Note

1. Small sizes include A4 vertical/horizontal, letter vertical/horizontal, B5 and A5

2. Large sizes include A3, B4, legal and ledger

DF-30/DF-31

Number of pages and stacks are only relevant for stapled paper.

Other cases (cross-mode stacking and cross-s ize stacking, including large

2

).

2-26

Page 27

OPERATION THEORY

Feed and drive systems

Distance sensor

Paper

Jam detection

The printer is equipped with the fol lowing paper detection sen sors to determine the

existence of paper and to determine that the paper is being fed correctly:

•

- Inlet paper detection sensor (PI1)

•

- Paper inversion detection sensor (PI2)

•

- Paper ejection detection sensor (PI3)

A jam is determined by detecting if the paper has been fed through to the sensor at

a certain time pre-set in the microcomputer (CPU) located on the finisher driver.

The finisher’s paper ejection operations are halted if the CPU determines that a

jam has occurred, and this is notified to the printer.

Delayed jam (delayed jam at the inlet sensor).

The CPU determines a delayed jam if the

paper does not arrive at the inlet’ s de tection sens or despite b eing fed the prescribed

distance (approximately 300mm) after the paper ejection signal is received from

the printer.

L1 = approximately 300mm

PINT

L1

Jam check

PINT

L1

Paper ejection signal

Inlet paper detection sensor (PI1)

Feeder motor (M1)

2-27

Normal

Abnormal

Page 28

OPERATION THEORY

Feed and drive systems

Accumulated jam #1 (inlet sensor accumulated jam).

lated jam has occurred when the inlet paper d etection sensor (PI1) detects t he front

edge of the paper but not the back edge after the paper has been fed the stipulated

distance.

Jam check

Inlet paper detection sensor (PI1)

Feed motor (M1)

L2 = the approximate size of the paper X 2mm

Accumulated jam #2 (paper ejection detection sensor delayed jam).

an accumulated jam has occurred when the inlet paper detection sensor (PI1)

detects the front edge of the paper but the paper does not arrive at the paper ejection detection sensor (PI3 ) even after the paper has been fed the stipulated distance.

PINT

L

L

Normal

The CPU judges that an accumu-

PINT

L

L

Abnormal

The CPU judges that

Inlet paper detection sensor (PI1)

Jam check

Paper ejection detection sensor (PI3)

Feed motor (M1)

L3 = approximately 360mm (for straight paper ejection), approximately 340mm (for inverted

paper ejection)

Accumulated jam #2 (paper ejection detection sensor delayed jam).

an accumulated jam has occurred when the paper ejection detection sensor (PI3)

detects the front edge of the paper but not the back edge after the paper has been

fed the stipulated distance.

PINT

L

Normal

PINT

L

Abnormal

The CPU judges that

DF-30/DF-31

2-28

Page 29

OPERATION THEORY

Feed and drive systems

Jam check

Inlet paper detection sensor (PI3)

Feed motor (M1)

L4 = the approximate size of the paper X 2mm

Power on jam.

The CPU judges that a po wer on jam ha s occurred if paper i s det ected

by either the inlet paper detec tion sensor (PI1 ), the inverted pa per detectio n sensor

(PI2) or the paper ejection detection sensor (PI3) when the power supply to the finisher is switched on.

PINT

L

Normal

PINT

L

Abnormal

2-29

Page 30

OPERATION THEORY

Power supply

2.4 Power supply

Outline

This devices uses a remote switch system for the power supply.

The printer outputs a power on signal (PWRON-IN) to the power supply assembly

when the power switch to the printer is turned on, and the power supply is

switched on. The power supply circuit supplies +24V to the finisher driver when

the PWRON-IN signal is "H".

This +24V is used to drive the feed motor, paper ejection motor, solenoids and other

elements. The finisher driver generate +5V, which is used for the sensors and the

integrated circuits in the finisher driver’s circuit board.

A block diagram is provided below.

Protection functions

The +24V power supply circuit is equipped with an excess current protection circuit

to automatically cut off the output voltage when short circuits or other trouble is

triggered and excess currents flow in order to prevent the power supply circuit

from being damaged.

Consequently, the power switch to the printer is switched off when the excess current protection function is activated and no DC voltage is output from the power

supply circuit, and the power is switched on again after the trouble with the load

has been repaired.

DF-30/DF-31

2-30

Loading...

Loading...