Page 1

R

DC-2050

DC-2050

SERVICE

MANUAL

Published in Oct. ’99

841AF110

DC-2050 (MCE) S/M

Page 2

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended

by the manufacturer. Dispose of used batteries according to

the manufacturer’s instructions.

CAUTION

Double-pole/neutral fusing.

Page 3

SERVICE

MANUAL

DC-2050

Page 4

R

Safety precautions

This booklet provides safety warnings and precautions for our service

personnel to ensure the safety of their customers, their machines as well

as themselves during maintenance activities. Service personnel are

advised to read this booklet carefully to familiarize themselves with the

warnings and precautions described here before engaging in

maintenance activities.

Page 5

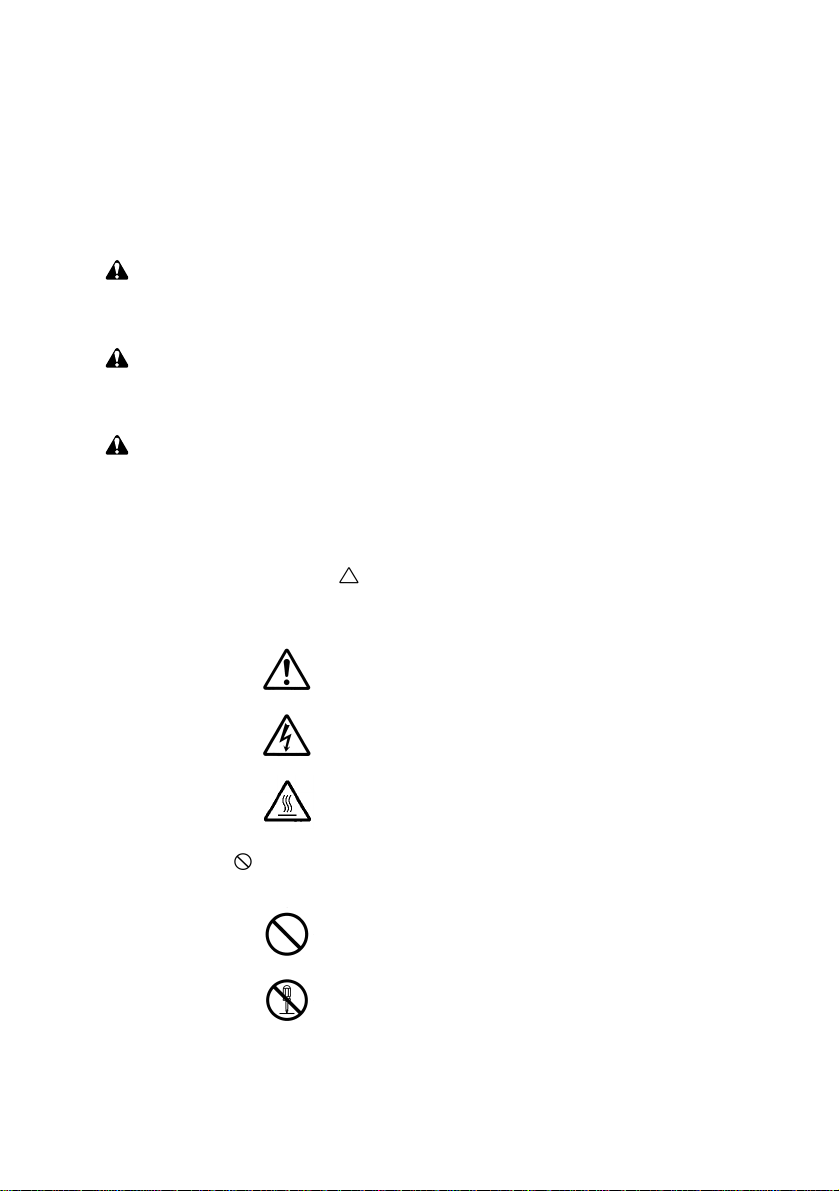

Safety warnings and precautions

Various symbols are used to protect our service personnel and

customers from physical danger and to prevent damage to their

property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from

insufficient attention to or incorrect compliance with warning

messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient

attention to or incorrect compliance with warning messages

using this symbol.

CAUTION: Bodily injury or damage to property may result from

insufficient attention to or incorrect compliance with warning

messages using this symbol.

Symbols

The triangle (

and caution. The specific point of attention is shown inside

the symbol.

) symbol indicates a warning including danger

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is

shown inside the symbol.

General prohibited action.

Disassembly prohibited.

Page 6

indicates that action is required. The specific action

required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified.

Avoid multiple connections to one outlet: they may cause fire or electric

shock. When using an extension cable, always check that it is

adequate for the rated current. ...............................................................

• Connect the ground wire to a suitable grounding point. Not grounding

the copier may cause fire or electric shock. Connecting the earth wire

to an object not approved for the purpose may cause explosion or

electric shock. Never connect the ground cable to any of the following:

gas pipes, lightning rods, ground cables for telephone lines and water

pipes or faucets not approved by the proper authorities.........................

CAUTION

• Do not place the copier on an infirm or angled surface: the copier may

tip over, causing injury. ...........................................................................

• Do not install the copier in a humid or dusty place. This may cause fire

or electric shock......................................................................................

• Do not install the copier near a radiator, heater, other heat source or

near flammable material. This may cause fire. .......................................

• Allow sufficient space around the copier to allow the ventilation grills to

keep the machine as cool as possible. Insufficient ventilation may

cause heat buildup and poor copying performance................................

Page 7

• Always handle the machine by the correct locations when moving it. ....

• Always use anti-toppling and locking devices on copiers so equipped.

Failure to do this may cause the copier to move unexpectedly or

topple, leading to injury. ..........................................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner

or developer is accidentally ingested, drink a lot of water to dilute it in

the stomach and obtain medical attention immediately. If it gets into the

eyes, rinse immediately with copious amounts of water and obtain

medical attention.....................................................................................

• Advice customers that they must always follow the safety warnings and

precautions in the copier’s instruction handbook. ...................................

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting

machine disassembly. ............................................................................

• Always follow the procedures for maintenance described in the service

manual and other related brochures. ......................................................

• Under no circumstances attempt to bypass or disable safety features

including safety mechanisms and protective circuits. .............................

• Always use parts having the correct specifications. ...............................

• Always use the thermostat or thermal fuse specified in the service

manual or other related brochure when replacing them. Using a piece

of wire, for example, could lead to fire or other serious accident............

• When the service manual or other serious brochure specifies a

distance or gap for installation of a part, always use the correct scale

and measure carefully. ...........................................................................

• Always check that the copier is correctly connected to an outlet with a

ground connection. .................................................................................

Page 8

• Check that the power cable covering is free of damage. Check that the

power plug is dust-free. If it is dirty, clean it to remove the risk of fire or

electric shock. .........................................................................................

• Never attempt to disassemble the optical unit in machines using lasers.

Leaking laser light may damage eyesight...............................................

• Handle the charger sections with care. They are charged to high

potentials and may cause electric shock if handled improperly..............

CAUTION

• Wear safe clothing. Avoid wearing loose clothing or accessories such

as ties which may be caught in rotating sections....................................

• Use utmost caution when working on a powered machine. Keep away

from chains and belts..............................................................................

• Handle the fixing section with care to avoid burns as it can be

extremely hot..........................................................................................

• Check that the fixing unit thermistor, heat and press rollers are clean.

Dirt on them can cause abnormally high temperatures. .........................

• Do not remove the ozone filter, if any, from the copier except for

routine replacement. ...............................................................................

• Do not pull on the AC power cord or connector wires on high-voltage

components when removing them; always hold the plug itself...............

• Do not route the power cable where it may be stood on or trapped. If

necessary, protect it with a cable cover or other appropriate item. ........

• Treat the ends of the wire carefully when installing a new charger wire

to avoid electric leaks. ............................................................................

• Remove toner completely from electronic components..........................

• Run wire harnesses carefully so that wires will not be trapped or

damaged.................................................................................................

Page 9

• After maintenance, always check that all the parts, screws, connectors

and wires that were removed, have been refitted correctly. Special

attention should be paid to any forgotten connector, trapped wire and

missing screws. ......................................................................................

• Check that all the caution labels that should be present on the machine

according to the instruction handbook are clean and not peeling.

Replace with new ones if necessary.......................................................

• Handle greases and solvents with care by following the instructions

below: .....................................................................................................

· Use only a small amount of solvent at a time, being careful not to

spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the

covers or turning the main switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause

sparks when exposed directly to fire in a furnace, etc. .........................

• Should smoke be seen coming from the copier, remove the power

plug from the wall outlet immediately. ..................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents

such as alcohol, other than the specified refiner; it may generate toxic

gas. .........................................................................................................

Page 10

CONTENTS

I THEORY AND CONSTRUCTION SECTION

1-1 Specifications

1-1-1 Specifications ................................................................................ 1-1-1

1-2 Handling Precautions

1-2-1 Drum ............................................................................................. 1-2-1

1-2-2 Developer and toner...................................................................... 1-2-1

1-3 Mechanical Construction

1-3-1 Part names and their functions ..................................................... 1-3-1

1-3-2 Machine cross section................................................................... 1-3-3

1-3-3 Drive system ................................................................................. 1-3-4

1-3-4 Mechanical construction ................................................................ 1-3-6

II ELECTRICAL SECTION

2-1 Electrical Parts Layout

2-1-1 Electrical parts layout .................................................................... 2-1-1

2-2 Detection of Paper Misfeed

2-2-1 Paper misfeed detection ............................................................... 2-2-1

2-2-2 Paper misfeed detection conditions .............................................. 2-2-2

2-3 Operation of the PCBs

2-3-1 Composite PCB............................................................................. 2-3-1

2-3-2 Main PCB ...................................................................................... 2-3-3

2-3-3 Operation unit PCB ........................................................................ 2-3-8

III SET UP AND ADJUSTMENT SECTION

3-1 Installation

3-1-1 Unpacking and installation ............................................................ 3-1-1

3-1-2 Setting initial copy modes ........................................................... 3-1-16

3-1-3 Installing the key counter (option) ............................................... 3-1-17

3-1-4 Installing the dehumidifier (service part) ..................................... 3-1-19

3-2 Simulation

3-2-1 Simulations.................................................................................... 3-2-1

3-3 Assembly and Disassembly

3-3-1 Precautions for assembly and disassembly .................................. 3-3-1

3-3-2 Paper feed section ........................................................................ 3-3-3

3-3-3 Main charging section ................................................................. 3-3-17

3-3-4 Exposure section......................................................................... 3-3-20

3-3-5 Drum section ............................................................................... 3-3-40

3-3-6 Developing section ...................................................................... 3-3-46

3-3-7 Transfer and separation section.................................................. 3-3-49

3-3-8 Cleaning section.......................................................................... 3-3-54

3-3-9 Fixing and eject section............................................................... 3-3-57

3-3-10 Others ......................................................................................... 3-3-67

3-4 PCB Initial Settings

3-4-1 Replacing the main PCB ............................................................... 3-4-1

3-4-2 Adjustment-free variable resistors (VR) ........................................ 3-4-4

3-5 Self Diagnostics

3-5-1 Self-diagnostic function ................................................................. 3-5-1

1AF

1-1-1

Page 11

1AF

3-6 Troubleshooting

3-6-1 Image formation problems ............................................................ 3-6-1

3-6-2 Paper misfeeds ........................................................................... 3-6-16

3-6-3 PCB terminal voltages ................................................................. 3-6-19

3-6-4 Electrical problems ...................................................................... 3-6-30

3-6-5 Mechanical problems .................................................................. 3-6-38

3-7 Appendixes

Timing chart No. 1 ...................................................................................... 3-7-1

Timing chart No. 2 ...................................................................................... 3-7-2

Timing chart No. 3 ...................................................................................... 3-7-3

Composite PCB 1/3 .................................................................................... 3-7-4

Composite PCB 2/3 .................................................................................... 3-7-5

Composite PCB 3/3 .................................................................................... 3-7-6

Operation unit PCB..................................................................................... 3-7-7

Main PCB ................................................................................................... 3-7-8

General connection diagram ...................................................................... 3-7-9

General wiring diagram ............................................................................ 3-7-10

1-1-2

Page 12

I

THEOR Y AND

CONSTRUCTION

SECTION

I Theory and

Construction Section

DC-2050 (MCE) S/M

Page 13

CONTENTS

1-1 Specifications

1-1-1 Specifications...................................................................................... 1-1-1

1AF

1-1-5

Page 14

1AF

1-1-6

Page 15

1AF

1-1-1 Specifications

Type ……………………………Desktop

Copying system ………………Dry, indirect electrostatic system

Originals ………………………Sheets, books and 3-dimensional

Maximum size: A3/11" × 17"

Original feed system …………Fixed

Copy paper …………………… Plain paper: 60 – 80 g/m2 for drawer feed

60 – 200 g/m2 for bypass feed

Special paper: OHP film, colored paper and letter head

Note: Use the bypass for special paper.

Copying sizes …………………Maximum: A3/11" × 17"

Minimum: A6R/51/2" × 81/2"

Magnification ratios …………… 64 – 141%, 1% increments

Fixed ratios:

Metric

1:1 ± 0.8%, 1:1.410/1:1.270/1:1.220/1:1.150/1:1.100/

1:1.060/1:0.910/1:0.900/1:0.860/1:0.810/1:0.770/

1:0.750/1:0.700/1:0.650/1:0.640

Inch

1:1 ± 0.8%, 1:1.290/1:1.210/1:0.780/1:0.770/1:0.730/

1:0.640

Copy speeds…………………… At 100% magnification:

A4/11" × 81/2": 20 copies/min.

A3/11" × 17": 12 copies/min.

B4 (257 × 364 mm)/81/2" × 14": 13 copies/min.

First copy time ………………… 4.9 s or less (A4/11" × 81/2", 100% magnification,

manual exposure)

Warm-up time ………………… 45 s or less (room temperature 20°C/68°F, 65% RH)

Paper feed system ……………Automatic feed from the paper drawer

Capacity: 250 sheets of 80 g/m

Manual feed from the bypass table

Capacity: 50 sheets of 80 g/m

Multiple copying ……………… 1 – 100 copies

Photoconductor ……………… OPC (drum diameter 60 mm)

Charging system ……………… Single positive corona charging (drum potential: 850 V DC)

Exposure system ………………Slit exposure

Lens …………………………… Fixed-focal lens, f: 215 mm, F8.0

Light source ……………………Halogen lamp, 350 W

Developing system ……………Dry, magnetic brush

Developer: 2-component, ferrite carrier and N27T black

toner

Toner density control: toner sensor

Toner replenishing: automatic from a toner hopper

Transfer system ……………… Single positive corona charging, 5.2 kV DC

Separation system …………… Single AC corona charging, 4.1 kV AC

2

2

1-1-1

Page 16

1AF

Fixing system …………………Heat roller

Heat source: halogen heater (980 W)

Control temperature: 175°C/347°F (at normal ambient

temperature)

Abnormally high temperature protection devices:

140°C/284°F and 150°C/302°F thermostats

Fixing pressure: 127.4 N

Charge erasing system ……… Exposure by cleaning lamp

Cleaning system ……………… Cleaning blade

Functions ……………………… (1) Self-diagnostics

(2) Simulation

(3) Auto clear (30 – 270 s, in intervals of 30 s)

(4) Auto start

(5) Auto shutoff (15 – 120 min, in intervals of 15 min)

(6) Auto preheat/energy saving (5 – 45 min,

in intervals of 5 min)

(7) Auto exposure

(8) Photo mode

(9) Manual magnification selection

(10) Auto magnification selection (by original size entry)

(11) Auto paper selection (by original size entry)

(12) Auto selection (when the ADF is used)

Power source …………………220 – 240 V AC, 50/60 Hz, 6.3 A

Rated power consumption …… 1450 W

Dimensions ……………………775 (W) × 590 (D) × 375 (H) mm

301/2" (W) × 231/4" (D) × 143/4" (H)

Weight …………………………Approx. 39 kg/85.8 lbs.

Floor requirements …………… 1145 (W) × 590 (D) mm

451/16" (W) × 231/4" (D)

Accessories …………………… Copy tray

Options …………………………Key counter, ADF

1-1-2

Page 17

CONTENTS

1-2 Handling Precautions

1-2-1 Drum ................................................................................................... 1-2-1

1-2-2 Developer and toner ........................................................................... 1-2-1

1AF

1-1-7

Page 18

1AF

1-1-8

Page 19

1AF

1-2-1 Drum

Note the following when handling or storing the drum.

• When removing the image formation unit, never expose the drum surface to strong direct

light.

• Keep the drum at an ambient temperature between –20°C/ –4°F and 40°C/104°F and at

a relative humidity not higher than 85%RH. Avoid abrupt changes in temperature and

humidity.

• Avoid exposure to any substance which is harmful to or may affect the quality of the drum.

• Do not touch the drum surface with any object. Should it be touched by hands or stained

with oil, clean it.

• If the machine is left open for more than 5 minutes for maintenance, remove the drum and

store it in the drum storage bag (P/N 78369020).

1-2-2 Developer and toner

Store the developer and toner in a cool, dark place. Avoid direct light, high humidity and

temperature.

1-2-1

Page 20

CONTENTS

1-3 Mechanical Construction

1-3-1 Part names and their functions ........................................................... 1-3-1

1-3-2 Machine cross section ........................................................................ 1-3-3

1-3-3 Drive system ....................................................................................... 1-3-4

1-3-4 Mechanical construction ..................................................................... 1-3-6

(1) Paper feed section ...................................................................... 1-3-6

(1-1) Paper feed from the paper drawer.................................... 1-3-8

(1-2) Paper feed from the bypass table ..................................... 1-3-9

(2) Main charging section ............................................................... 1-3-10

Surface potential correction control........................................... 1-3-13

(3) Exposure section....................................................................... 1-3-15

Exposure control for manual exposure and photo modes......... 1-3-18

Exposure control for auto exposure mode ................................ 1-3-19

Light intensity correction for enlargement and reduction

modes........................................................................................ 1-3-20

Light intensity correction by the user setting ............................. 1-3-20

(4) Developing section .................................................................... 1-3-21

Formation of the magnetic brush............................................... 1-3-23

Toner density control................................................................. 1-3-25

Correcting toner sensor output voltage ..................................... 1-3-27

Toner level detection ................................................................. 1-3-30

(5) Transfer and separation section................................................ 1-3-31

(6) Cleaning section........................................................................ 1-3-34

(7) Charge erasing section ............................................................. 1-3-35

(8) Fixing and eject section............................................................. 1-3-37

Heating the heat roller and detecting temperature.................... 1-3-39

Fixing temperature control......................................................... 1-3-40

Paper separation ....................................................................... 1-3-42

1AF

1-1-9

Page 21

1AF

1-1-10

Page 22

E E

A

A A

EA

A

E

1AF

E

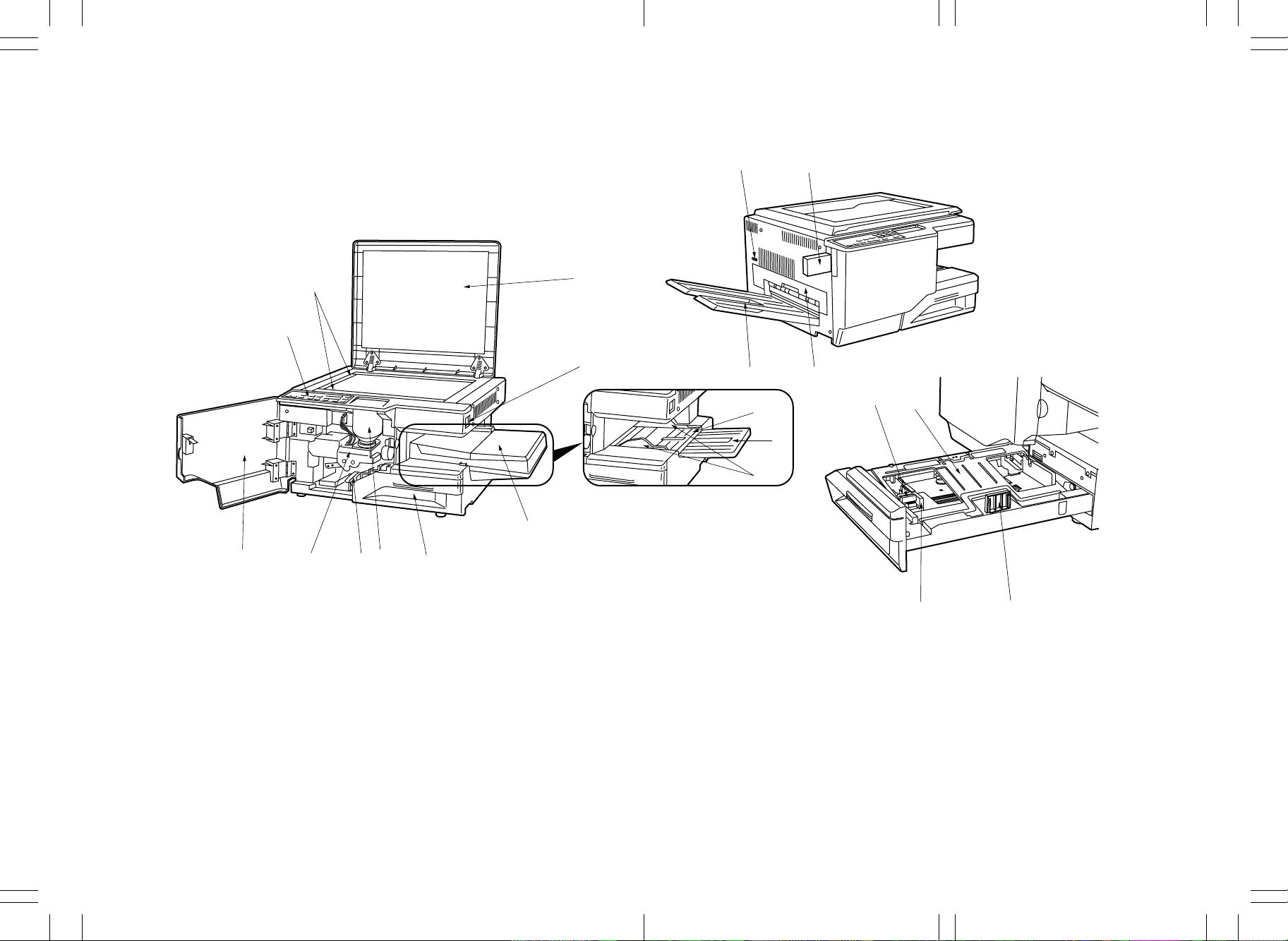

1-3-1 Part names and their functions

2

$

3

%

1

4

^&

5

(

*

6

7

#

@

E

!

1. Operation panel

2. Original size indicator

3. Original holder

4. Main switch

5. Bypass table

6. Auxiliary table

7. Insertion guides

0

9

8

Figure 1-3-1

8. Paper drawer

9. Toner cartridge

10. Paper conveying section lever

11. Image formation unit

12. Front cover

13. Bypass cover

14. Total counter

)

15. Key counter (option)

16. Copy tray

17. Eject cover

18. Drawer bottom plate

19. Width guide tab

20. Width guide

21. Length guide

⁄

1-3-1

E

A

E E

A A

EA

DC-2050 (MCE) S/M

A

Page 23

EE E

AA A

A

A

E

E

1AF

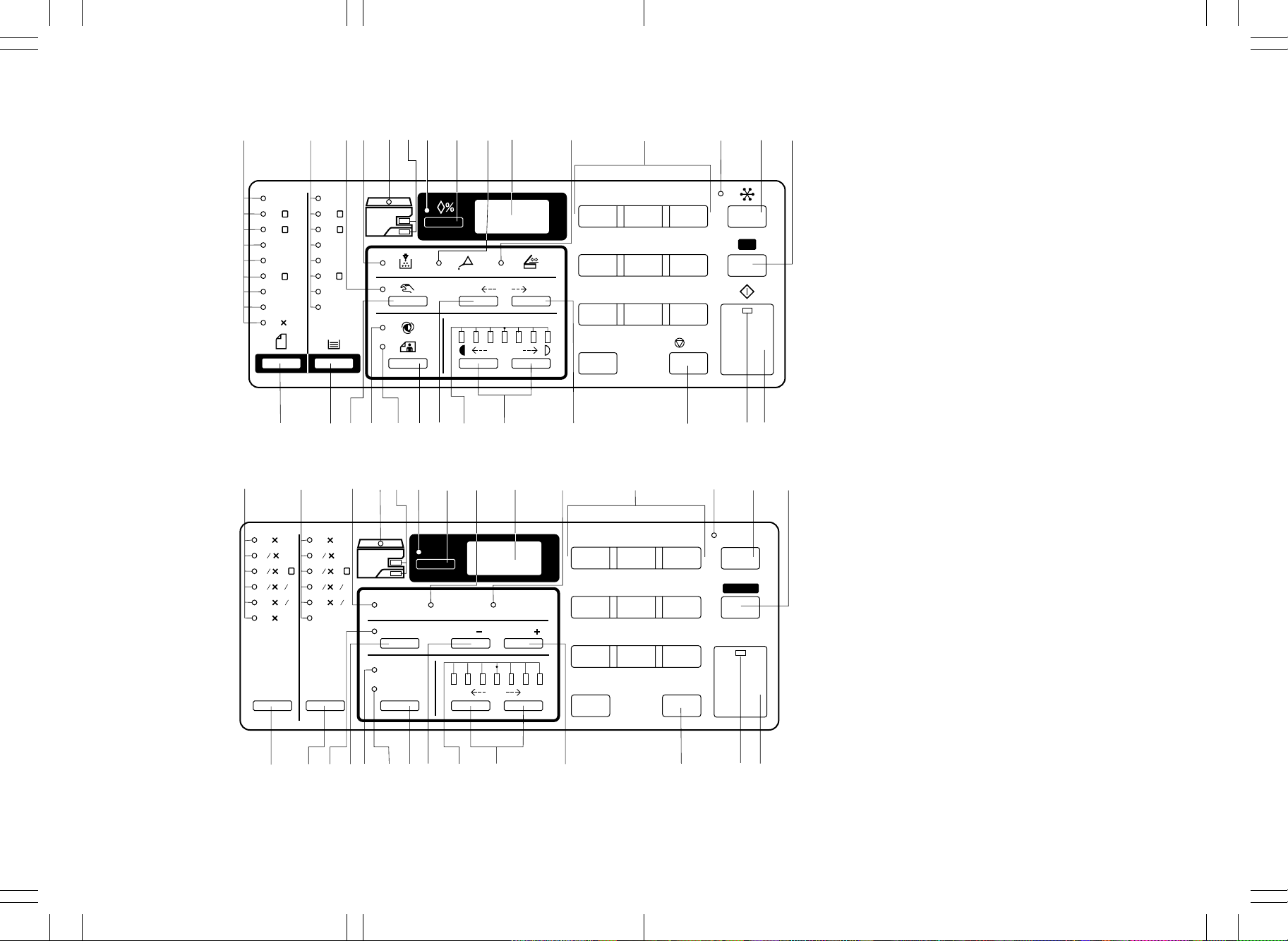

Metric

°

fl

^

‹

›

¤

&

*()

⁄

7

1

23

1. Auto selection key

2. Auto selection indicator

3. All clear/reset key

4. Print key

5. Copy start indicator

A3

R

A4

R

A5

A4

B4

R

B5

B5

Folio

11 15

A3

A4

A5

A4

B4

B5

Folio

U

12

R

141%

%

4

7

5

8

R

R

64%

34567

12

0

3

6. Stop/clear key

7. Numeric keys

C

6

A

8. Exposure adjustment keys

9. Exposure indicators

10. Auto/manual exposure key

9

11. Auto exposure indicator

12. Photo original indicator

13. Zoom-up key

/

C

14. Zoom-down key

15. Manual key

16. Manual indicator

17. Copy quantity/magnification display

18. Recall % key

19. Zoom copy indicator

20. Paper source indicators

21. Check paper size/direction indicator

22. Maintenance indicator

23. Add toner indicator

Inch

°

‡

fl

fi

%

‹

!

›

@#$

0

)

(

*

9

¤

8

&

⁄

7

6

2

5

1

4

3

24. ADF jam indicator

25. Paper select key

26. Paper size indicators

27. Original select key

28. Original size indicator

11 17

1

2

8 14

1

2

8 11

121

5 8

11

8

11 15

11 17

1

2

8 14

1

R R

2

8 11

121

2

5 8

1

2

11

U

Auto

Selection

Recall %

12

3

%

2

1

2

8

Add Toner

Manual

Maintenance

Zoom

( )

Check

Paper Size /

Direction

( )

Zoom

4

7

5

8

6

9

Reset

Print

Original

‡

fi

Paper

Select

Auto

Photo

Original

%^

0!@

$

Dark

9

Light

8

0

#

Stop/

Clear

6

5

4

Figure 1-3-2 Operation panel

1-3-2

E

A

EE E

AA A

DC-2050 (MCE) S/M

E

A

Page 24

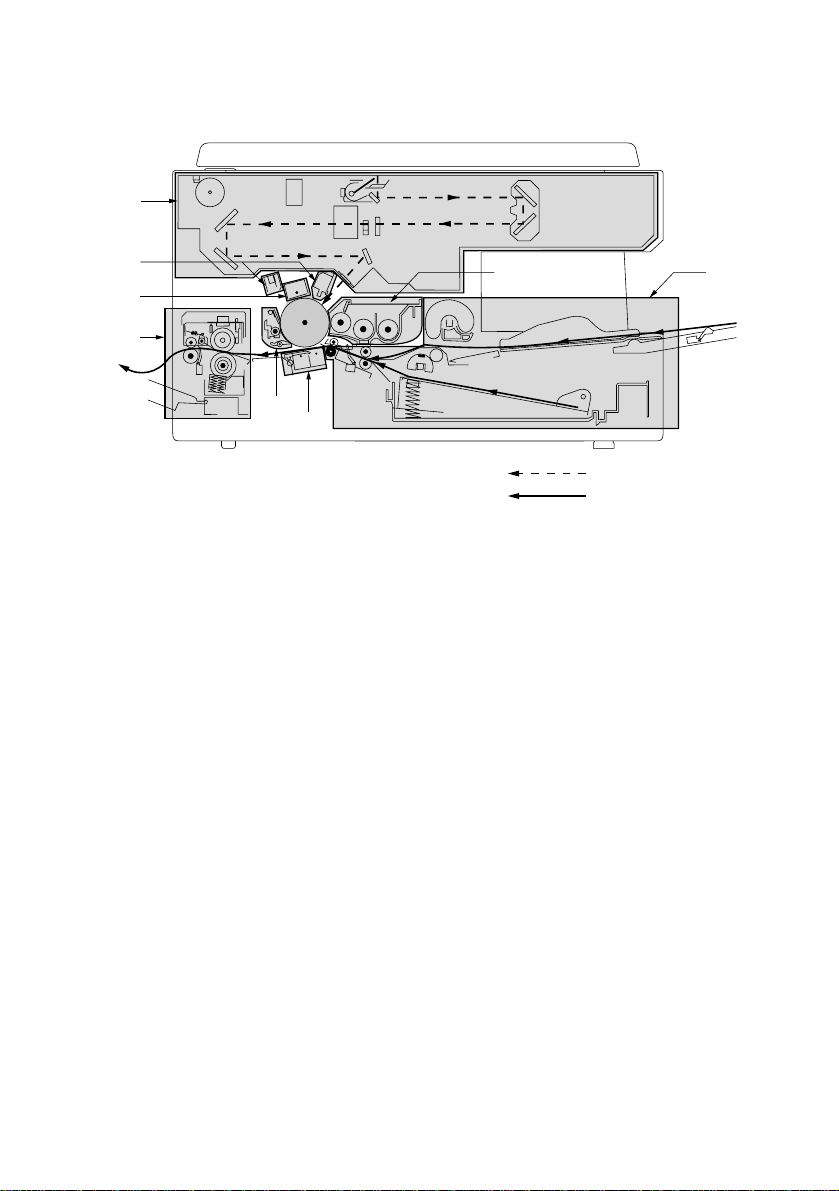

1-3-2 Machine cross section

3

1AF

7

2

8

4

6

5

Figure 1-3-3 Machine cross section

1. Paper feed section (page 1-3-6)

2. Main charging section (page 1-3-10)

3. Exposure section (page 1-3-15)

4. Developing section (page 1-3-21)

5. Transfer and separation section (page 1-3-31)

6. Cleaning section (page 1-3-34)

7. Charge erasing section (page 1-3-35)

8. Fixing and eject section (page 1-3-37)

1

Light path

Paper path

1-3-3

Page 25

1AF

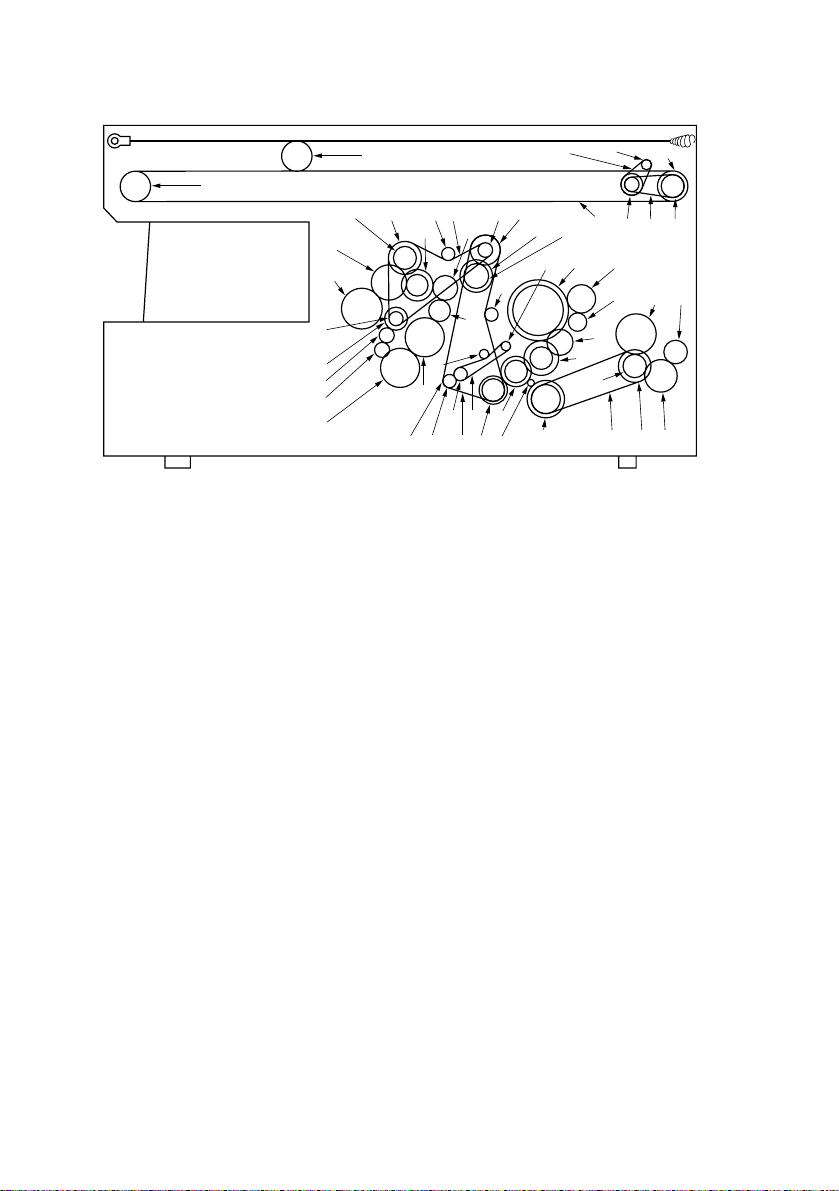

1-3-3 Drive system

Ú

¸

fi

fl

„

´

‰

ˇ

!

Figure 1-3-4 Drive system – copier main body

1. Drive motor gear

2. Gear 60/40

3. Gear 60/24

4. Gear 64/20

5. Gear 23

6. Gear 60/50

7. Blade thrust gear 31

8. Toner recycle gear 19

9. Developing drive belt

10. Pulley 16 (machine rear)

11. Gear 25 (machine front)

12. Registration gear 15/30

13. Feed belt

14. Registration collar

15. Pulley 15

16. Tension pulley 15

17. Gear 33/14 (machine rear)

18. Developing gear 32 (machine front)

19. Developing gear 23

20. Developing gear 30

21. Paper feed drive belt

22. Tension pulley 15

23. Pulley 32

24. Gear 18

25. Idle gear 38

26. Bypass gear 38

¤‹›

‡°

$

‚

&*

⁄

^

·

@#

90

123

As viewed from machine rear

27. Gear 30/18

28. Gear 25

29. Idle gear

30. Idle gear 38

31. Paper feed gear 38

32. Pulley 14

33. Gear 20

34. Retard gear 18

35. Limiter gear 15

36. Gear 80/34

37. Fixing drive belt

38. Pulley 30

39. Fixing drive gear 22

40. Heat roller gear 40

41. Eject idle gear 30

42. Eject gear 22

43. Scanner motor pulley

44. Scanner drive pulley 1

45. Scanner drive pulley 2

46. Scanner drive belt 1

47. Scanner drive belt 2

48. Scanner wire drum

49. Scanner wire

50. Scanner wire pulley

51. Scanner wire pulley

Ó

Ò

()

%

67

5

4

Ø

Á¨ˆ

Î

Ï˝

Ô

∏ŒÍ

8

Å

1-3-4

Page 26

1AF

67

Figure 1-3-5 Drive system – image formation unit

1. Blade thrust gear 31

2. Toner recycle gear 19

3. Magnet roller gear 17

4. Developing idle gear 19

14

235

As viewed from machine rear

5. Left spiral gear (machine rear)

6. Developing gear 28 (machine front)

7. Developing gear 31 (machine front)

1-3-5

Page 27

1AF

1-3-4 Mechanical construction

(1) Paper feed section

@%932

8

4

5

#

!

⁄

0

$

*7& ^6

Figure 1-3-6 Paper feed section

1 Bypass table

2 Bypass lift

3 Bypass upper pulley

4 Bypass lower pulley

5 Bypass lower guide

6 Drawer bottom plate

7 Drawer spring

8 Paper feed pulleys A and B

9 Upper registration roller

0 Lower registration roller

! Registration stopper

1

)(

@ Upper pre-transfer roller

# Lower pre-transfer roller

$ Registration guide

% Upper pre-transfer guide

^ Bypass solenoid (BYPSOL)

& Paper feed solenoid (PFSOL)

* Registration solenoid (RSOL)

( Bypass paper length switch (BYPPLSW)

) Bypass paper width switch (BYPPWSW)

⁄ Registration switch (RSW)

1-3-6

DC-2050 (MCE) S/M

Page 28

1AF

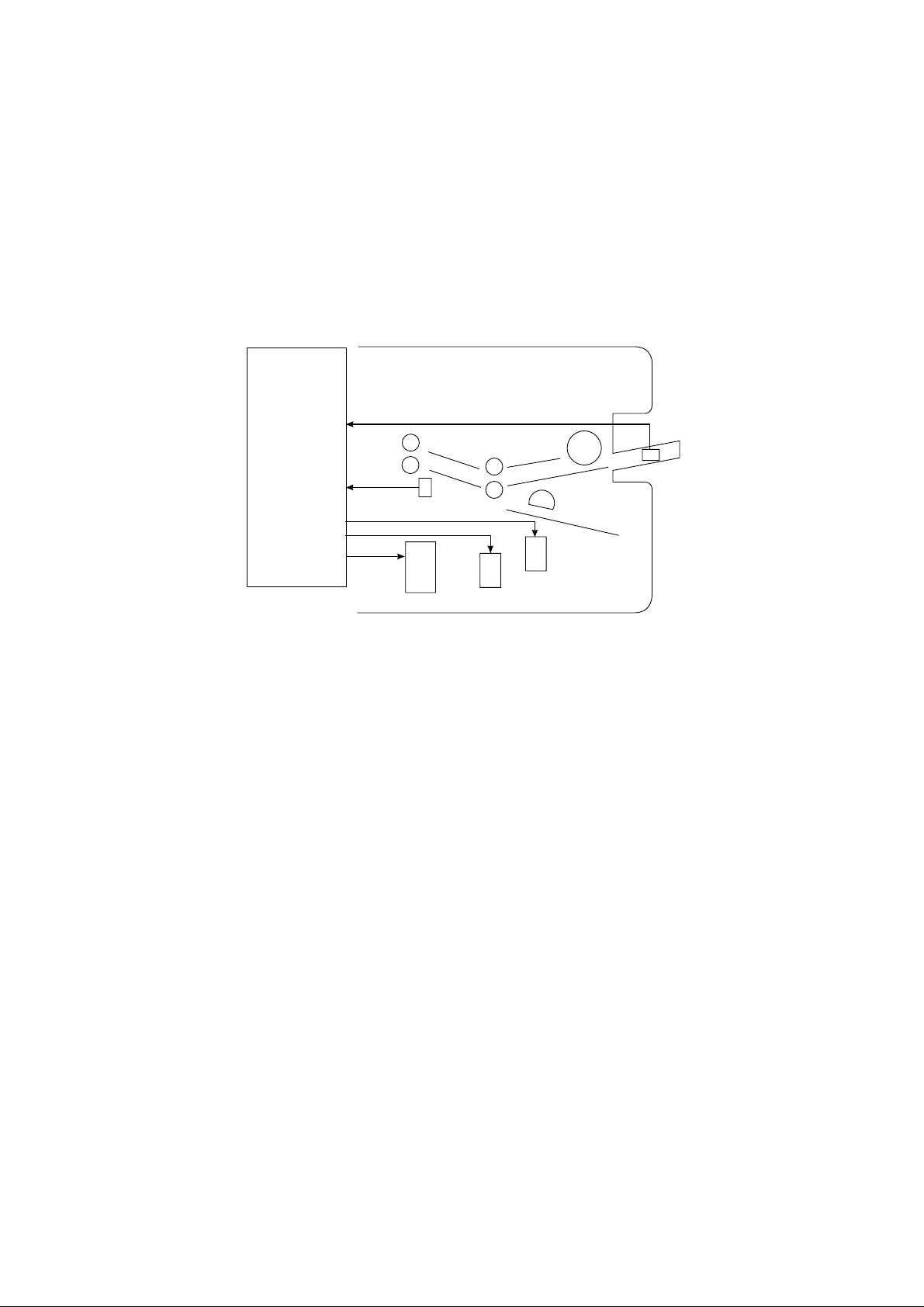

The paper feed section consists of the primary feed and secondary feed subsections.

Primary feed conveys paper from the paper drawer or the bypass table to the upper and

lower registration rollers, at which point secondary paper feed takes place and the paper

travels to the transfer section in sync with the exposure timing.

CN12-2

CN17-2

CN2-2

CN2-4

CN14-2

MPCB

RSOL

RSW

PFSOL

Figure 1-3-7 Paper feed section block diagram

BYPPLSW

BYPSOL

1-3-7

DC-2050 (MCE) S/M

Page 29

1AF

(1-1) Paper feed from the paper drawer

The paper drawer consists of the drawer bottom plate, drawer springs and other components

and can hold up to 250 sheets of copy paper.

Paper is fed out of the drawer by the rotation of paper feed pulleys A and B.

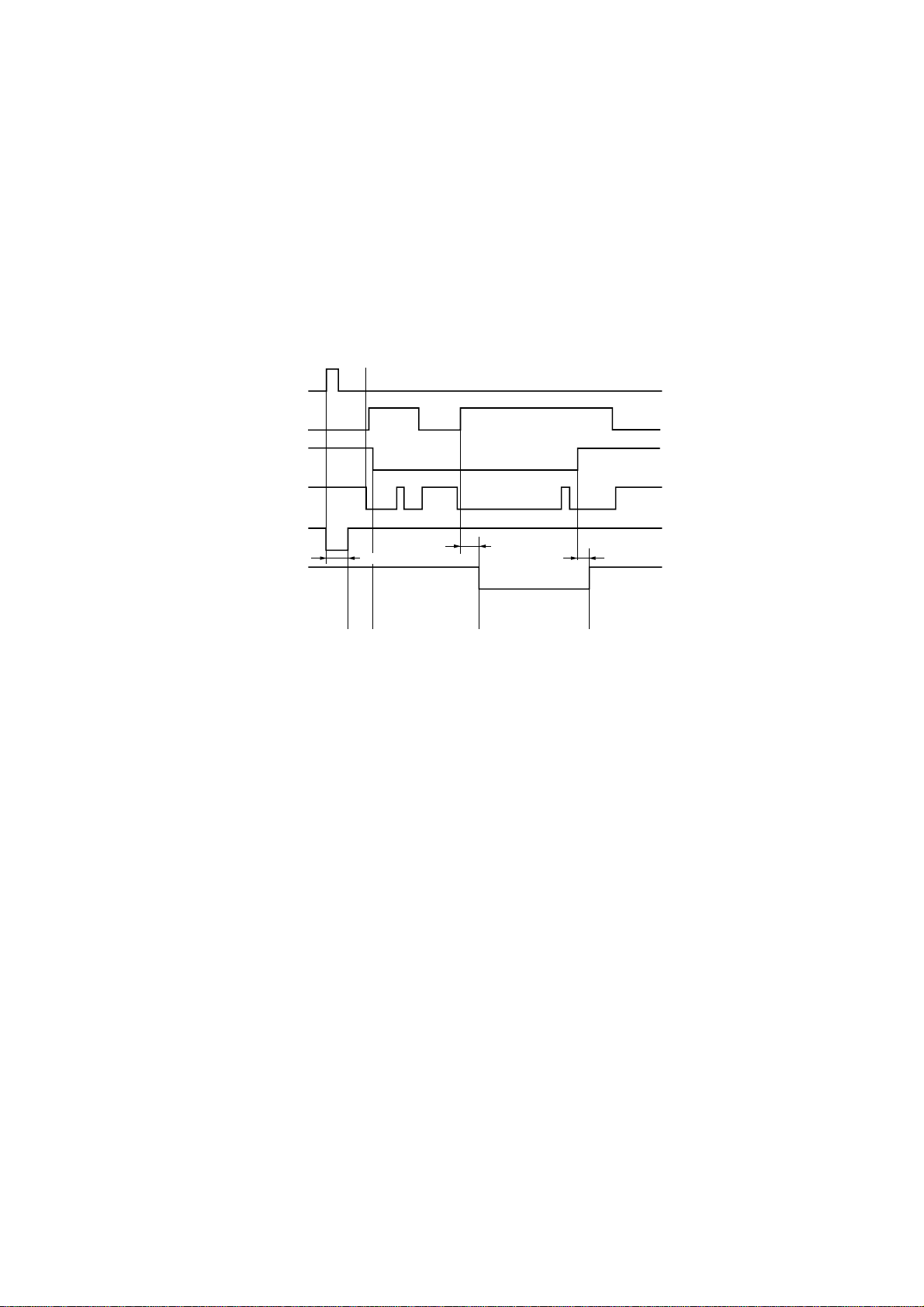

Prescan start

Print key

HPSW

RSW

SM

PFSOL

RSOL

250 ms

A

BC D

147 P+140 ms *

1

100 ms

Auto exposure mode, A4/11" × 81/2" copy paper, magnification ratio 100%

*1 Varies depending on the setting by simulation 27.

Timing chart 1-3-1 Paper feed from the paper drawer

A When the print key is pressed, the paper feed solenoid (PFSOL) turns on for 250 ms,

rotating paper feed pulleys A and B to perform primary feed. Then the paper is fed by

the upper and lower registration rollers and its leading edge stops at the registration

stopper to create slack in the paper before registration.

B The leading edge of the paper turns the registration switch (RSW) on.

C The scanner starts scanning and the home position switch (HPSW) turns off. After 147

pulses + 140 ms, the registration solenoid (RSOL) turns on and the registration stopper

lowers. The lower registration and pre-transfer rollers convey the paper to start

secondary feed.

D 100 ms after the trailing edge has turned the registration switch (RSW) off, the registration

solenoid (RSOL) turns off to complete secondary paper feed.

1-3-8

DC-2050 (MCE) S/M

Page 30

1AF

(1-2) Paper feed from the bypass table

The bypass table can hold up to 50 sheets of paper at one time.

When the print key is pressed, the bypass solenoid (BYPSOL) turns on, rotating the bypass

upper pulley, while the bypass lift is raised until the paper comes into contact with the bypass

upper pulley. The paper on the bypass table is then conveyed to the secondary paper feed

section.

The bypass lower pulley rotates opposite to the paper feed direction so that the torque limiter

prevents multiple sheets from being fed at one time.

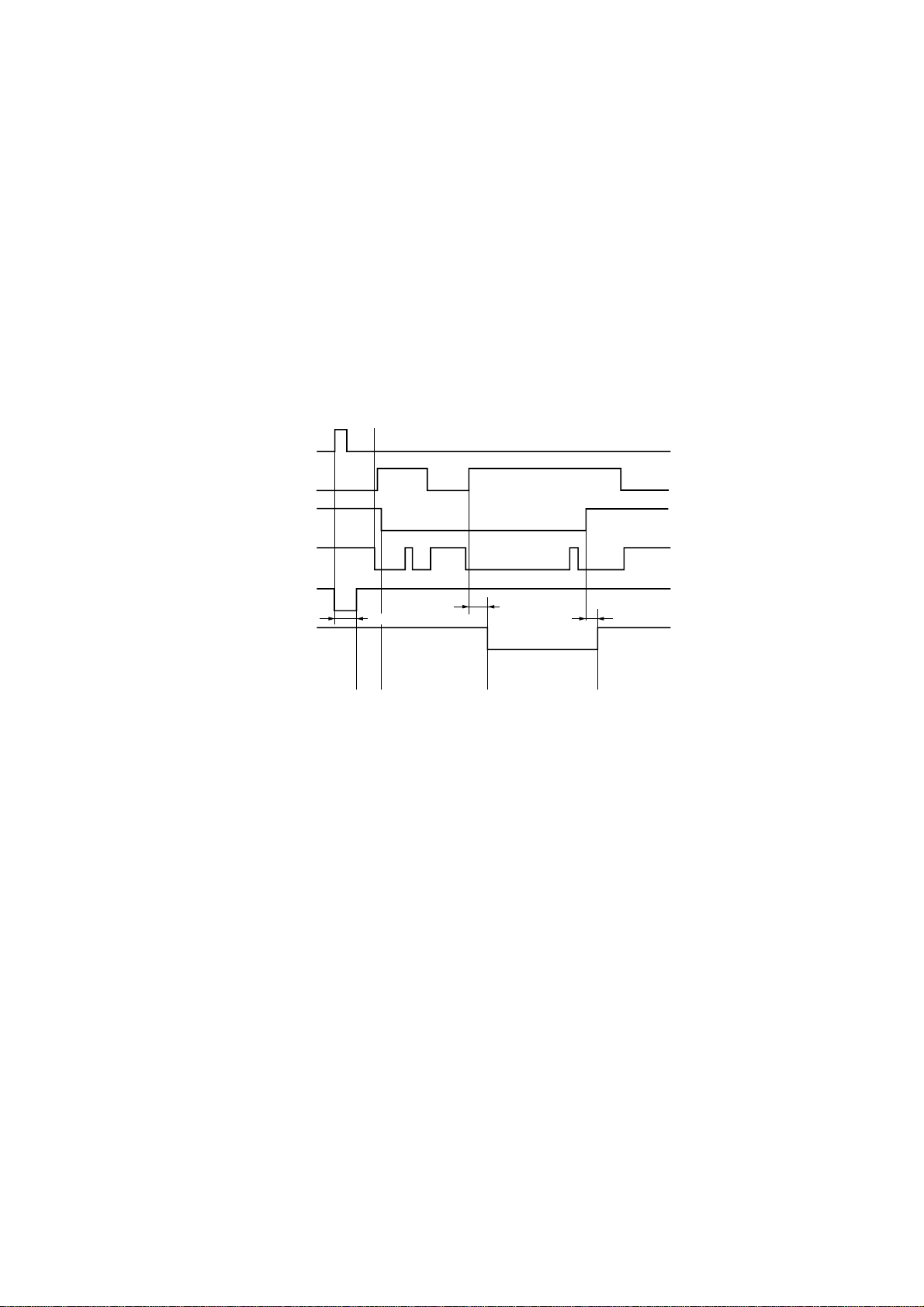

Prescan start

Print key

HPSW

RSW

SM

BYPSOL

RSOL

250 ms

A

BC D

147 P+140 ms *

1

100 ms

Auto exposure mode, A4/11" × 81/2" copy paper, magnification ratio 100%

*1 Varies depending on the setting by simulation 27.

Timing chart 1-3-2 Paper feed from the bypass table

A When the print key is pressed, the bypass solenoid (BYPSOL) turns on for 250 ms, which

raises the bypass lift and rotates the bypass lower pulley to perform primary paper feed.

The paper is then fed by the upper and lower registration rollers until the leading edge

stops at the registration stopper to create slack in the paper before registration.

B The leading edge of the paper turns the registration switch (RSW) on.

C The scanner starts scanning and the home position switch (HPSW) turns off. After 147

pulses + 140 ms, the registration solenoid (RSOL) turns on and the registration stopper

lowers. The lower registration and pre-transfer rollers convey the paper to start

secondary feed.

D 100 ms after the trailing edge of the paper turns the registration switch (RSW) off, the

registration solenoid (RSOL) turns off to complete secondary paper feed.

1-3-9

DC-2050 (MCE) S/M

Page 31

1AF

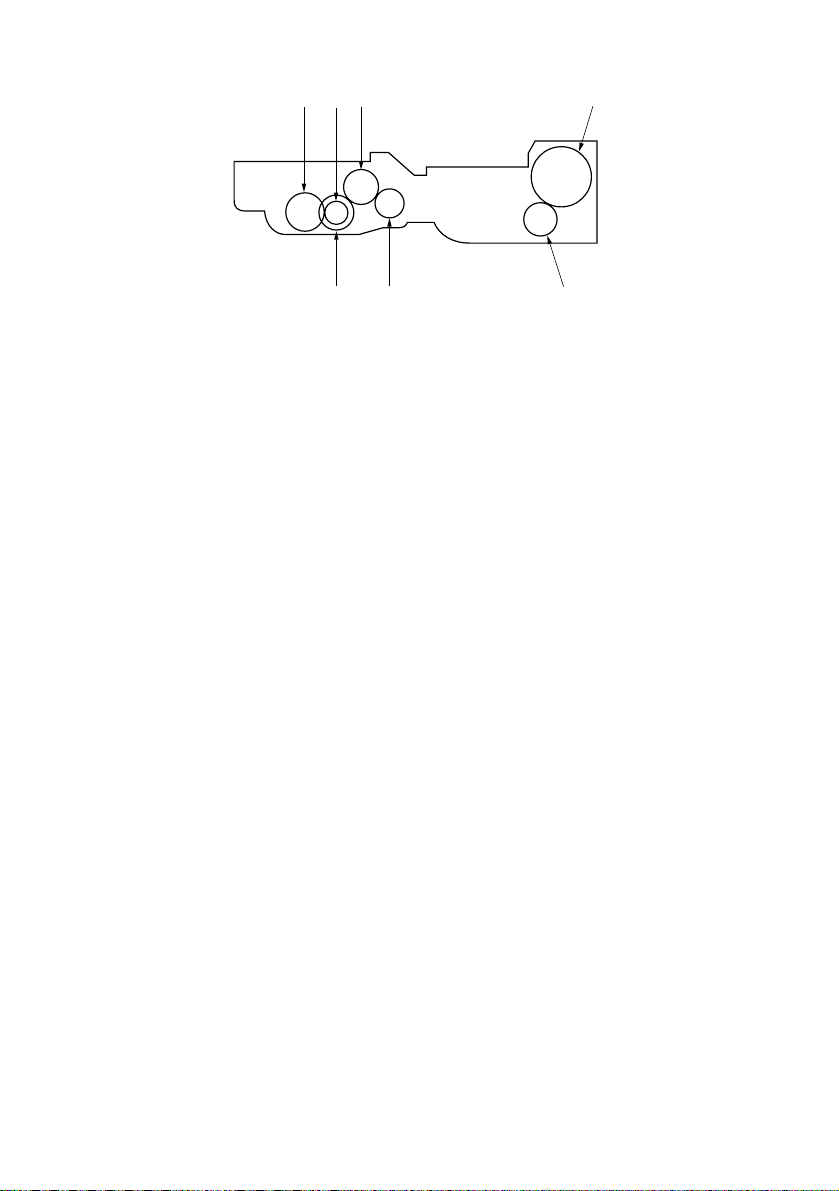

(2) Main charging section

The main charging section consists of the drum and main charger. The drum is electrically

charged uniformly by means of a grid to form a latent image on the surface.

Main charger

Tungsten wire

Main charger grid

Figure 1-3-8 Main charging section

1-3-10

DC-2050 (MCE) S/M

Page 32

5

1AF

8

9

7

!

6

Figure 1-3-9 Main charger

1 Main charger front housing

2 Main charger rear housing

3 Main charger shield

4 Tungsten wire

5 Main charger grid

6 Grid tension plate

CN2-1

CPCB

CN1-21

CN1-27

CN1-24

CN1-20

MPCB

24 V DC

MC REM

ALARM

GRID CONT

DB REM

4

@

3

1

7 Main charger front lid

8 Main charger rear lid

9 Charger spring

0 Charger terminal

! Charger wire retainer pin

@ Film

CN2-1

CN1-7

CN1-1

CN1-4

CN1-8

HVTPCB

0

2

MC

Grid

Drum

Figure 1-3-10 Main charging section block diagram

DC-2050 (MCE) S/M

1-3-11

Page 33

1AF

Scanner return start

Print key

SM

BL

MC REM

300 ms

All on

Forward Reverse

50 ms

AB C

Timing chart 1-3-3 Main charging

A 300 ms after the print key is pressed, all the blank lamps (BL) turn on.

B 50 ms after the all blank lamps (BL) have turned on, main charging starts.

C As soon as the scanner starts to return, main charging ends.

1-3-12

DC-2050 (MCE) S/M

Page 34

1AF

Surface potential correction control

The drum surface potential is corrected for the external temperature and humidity. If the

external temperature is 24°C/75.2°F or less and the absolute humidity exceeds 25.0 g/m3,

the drum surface potential is corrected as in the table bellow. The external temperature and

relative humidity are detected by the external temperature thermistor (ETTH) and humidity

sensor (HUMSENS) and the absolute humidity is calculated from these values. The surface

potential is corrected by varying the grid control voltage (GRID CONT) output from the main

PCB (MPCB) to the high-voltage transformer PCB (HVTPCB).

Table 1-3-1 Surface potential correction value vs. absolute humidity

Absolute

humidity

(g/m3)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

9.5

10.0

Correction

value

(V)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Absolute

humidity

(g/m3)

10.5

11.0

11.5

12.0

12.5

13.0

13.5

14.0

14.5

15.0

15.5

16.0

16.5

17.0

17.5

18.0

18.5

19.0

19.5

20.0

Correction

value

(V)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Absolute

humidity

(g/m3)

20.5

21.0

21.5

22.0

22.5

23.0

23.5

24.0

24.5

25.0

25.5

26.0

26.5

27.0

27.5

28.0

28.5

29.0

29.5

30.0

Correction

value

(V)

0

0

0

0

0

0

0

0

0

0

–4

–8

–12

–16

–20

–24

–28

–32

–36

–40

1-3-13

DC-2050 (MCE) S/M

Page 35

1AF

45

40

35

)

3

30

100%

80%

25

20

15

Absolute humidity (g/m

10

5

0

10

50

15

59

20

68

Temperature (°C/°F)

25

77

30

86

Figure1-3-11 Absolute humidity vs. relative humidity

Table 1-3-2 Surface potential correction value vs. external temperature

Temperature

(°C/°F)

1/33.8

2/35.6

3/37.4

4/39.2

6/42.8

7/44.6

8/46.4

9/48.2

10/50

11/51.8

12/53.6

0/32

5/41

Correction

value (V)

Temperature

83

80

77

73

70

67

63

60

57

53

50

47

43

(°C/°F)

13/55.4

14/57.2

15/59

16/60.8

17/62.6

18/64.4

19/66.2

20/68

21/69.8

22/71.8

23/73.4

24/75.2

25/77

Correction

value (V)

Temperature

40

37

33

30

27

23

20

17

13

10

7

3

0

(°C/°F)

26/78.8

27/80.6

28/82.4

29/84.2

30/86

60%

40%

20%

(°C)

35

(°F)

95

Correction

value (V)

Relative humidity (%)

0

0

0

0

0

1-3-14

DC-2050 (MCE) S/M

Page 36

(3) Exposure section

1AF

& $4 % 987@#

5

6

(

Figure 1-3-12 Exposure section

1 Mirror 1

2 Mirror 2

3 Mirror 3

4 Mirror 4

5 Mirror 5

6 Mirror 6

7 Halogen lamp (HL)

8 Optical section thermostat (TH3)

9 Lens

0 Light source unit 1

! Light source unit 2

@ Main reflector

# Auxiliary reflector

$ Scanner motor (SM)

% Optical section fan motor (OPFM)

^ AE sensor (AES)

& Home position switch (HPSW)

* Lens home position switch (LHPSW)

( Dust filter

32 !

1

0

^

*

1-3-15

DC-2050 (MCE) S/M

Page 37

1AF

This copier employs a slit exposure system with a fixed original table, and a halogen lamp

(HL) as the light source.

The optical section consists of light source units 1 and 2. Light source unit 1 carries the

halogen lamp and the main and auxiliary reflectors. Each unit travels from one side of the

machine to the other along scanner rails at machine front and rear. When an enlargement

or a reduction ratio is selected, the scanning speeds of the two light source units and the

positions of the lens and mirrors 4 and 5 are changed, altering the distance between the

original and the drum. At any magnification ratio, light source unit 2 travels at a half speed

of unit 1.

A cooling fan is installed to exhaust heat generated by the halogen lamp. If an abnormally

high temperature is detected around light source unit 1, the optical section thermostat (TH3)

shuts off the supply to the halogen lamp.

Original

HPSW AES

SM

CN8-1 –

CN8-6

CN7-2

HL

CN5-5

LM

CN5-7 –

TH3

CN5-12

MPCB

Figure 1-3-13 Exposure section block diagram

LHP

SW

CPCB

CN1-1

CN1-3

CN2-7CN4-5

HL CONT

CN5-2

1-3-16

DC-2050 (MCE) S/M

Page 38

1AF

Scan start

Scanner return start

10 P

480 ms

1687 P

Forward Reverse

G

Print key

HPSW

SM

HL

Prescan start

10 P

480 ms

1232 P

Forward

Reverse

AB FECD

Auto exposure mode, A4/11" × 81/2" original

Timing chart 1-3-4 Scanner travel

A When the print key is pressed, the halogen lamp (HL) lights at the intensity for prescan.

B 480 ms after the halogen lamp (HL) has turned on, the scanner motor (SM) rotates

forward for prescan.

C After rotating forward 1232 pulses, the scanner motor (SM) reverses to return the

scanner to the home position. At the same time, the halogen lamp (HL) turns off.

D 10 pulses after the home position switch (HPSW) has been turned on, the scanner motor

(SM) turns off and the scanner stops. At the same time, the halogen lamp (HL) lights for

exposure.

E 480 ms after turning off, the scanner motor (SM) rotates forward for scanning.

F After rotating forward for 1687 pulses, the scanner motor (SM) reverses to return the

scanner to the home position. At the same time, the halogen lamp (HL) turns off.

G 10 pulses after the home position switch (HPSW) has turned on, the scanner motor (SM)

turns off and the scanner stops.

1-3-17

DC-2050 (MCE) S/M

Page 39

1AF

Exposure control for manual exposure and photo modes

The halogen lamp light intensity for manual exposure and photo modes is calculated from

the data obtained by running simulation 24.

Light intensity value

Manual exposure mode

Photo mode

Drum potential 850 V DC

Drum potential

680 V DC

Drum potential

680 V DC

0

1-2

1-3

1-4

1-5

1-6

1-7

23456

1

7 7-1

7-2 7-3 7-4 7-5

Exposure scale (Exp.)

7-6

Figure 1-3-14 Exposure gradient setting

• Exposure control for manual exposure mode

The gradient between Exp. 1-2 and Exp. 7 is determined from the halogen lamp light

intensity values for Exp. 1, Exp. 4 and Exp. 7 set in simulation 24. For exposure settings Exp.

7-1 and above the drum potential is set 170 V below the normal level and the light intensity

is reduced since the intensity at such high exposure levels cannot be increased by simply

increasing the halogen lamp control voltage. The amount of exposure for the high settings

between Exp. 7-1 and Exp. 7-6 is determined by the halogen lamp light intensity value for

Exp. 7-1 set in simulation 24 and the gradient between Exp. 4 and Exp. 7.

• Exposure control for photo mode

The drum potential is set 170 V below the normal level and the halogen lamp light intensity

value is set low for photo mode.

The halogen lamp light intensity value for photo-mode Exp. 4 is determined by running

simulation 24. The light intensity for manual-mode Exp. 1-4 is used as the value for photomode Exp. 1, which determines the gradient between Exp. 1 and Exp. 4 for photo mode.

Similarly, the light intensity for manual-mode Exp. 7-3 is used as the value for photo-mode

Exp. 7, which determines the gradient between photo-mode Exp. 4 and Exp. 7.

1-3-18

DC-2050 (MCE) S/M

Page 40

1AF

Exposure control for auto exposure mode

In auto exposure mode, the halogen lamp lights at the intensity set for mode 1 in simulation

22 to perform prescan. The exposure level to copy that particular original is determined by

using the value read in by the AE sensor.

Scanner

movement

Original leading edge

AE detection (prescan)

Exposure

Original

Figure 1-3-15 AE sensor detection width

Halogen lamp voltage

Drum potential 680 V DC

0

Manual-mode Exp. 7-1

Mode 3, sim. 22

(NPTC level)

AE sensor read-in value

Drum potential 850 V DC

Mode 2, sim. 22

(NTC level)

Original leading edge

148 mm

100 mm

Detection width

Manual-mode Exp. 4

Figure 1-3-16 Exposure control for auto exposure mode

The halogen lamp voltage is controlled so that the lamp lights at the intensity for manualmode Exp. 4 when the AE sensor read-in value is the NTC level set in mode 2 by simulation

22, and at the intensity for manual-mode Exp. 7-1 when the read-in value is the NPTC level

set in mode 3.

In auto exposure mode, the drum potential is decreased by 170 V from the normal level and

the halogen lamp voltage is increased when the AE sensor read-in value is below the setting

for mode 3 in simulation 22. When the AE sensor read-in value falls in the range between

the mode 3 and mode 2 settings by simulation 22, the halogen lamp voltage is controlled

based on the gradient determined by the values set by simulation 24. For read-in values

above the mode 2 setting of simulation 22, the halogen lamp voltage is kept at a constant

level so that the lamp lights at the intensity for manual-mode Exp. 4.

1-3-19

DC-2050 (MCE) S/M

Page 41

1AF

Light intensity correction for enlargement and reduction modes

The halogen lamp light intensity for enlargement and reduction modes is determined by the

value for copying at 100% magnification and the correction values set by simulation 29.

Light intensity correction value

Mode 1, sim. 29

(141%)

Mode 2, sim. 29

(64%)

0

64 100 141

Magnification

ratio (%)

Figure 1-3-17 Correction of light intensity for reduction and enlargement modes

The correction values for reduction (64%) and enlargement (141%) copying are linked by

a straight line through the value for 100% magnification, and the light intensity is corrected

for individual magnification ratios according to the gradients.

Light intensity correction by the user setting

The light intensity data can be corrected in exposure adjustment of the user settings by

pressing an exposure adjustment key in manual exposure mode or the auto/manual

exposure key in auto exposure mode for 5 s. The light intensity correction value is 0 at Exp.

4 and changes at 4 bits per 0.5 steps of the exposure scale.

Light intensity correction value (bits)

18

0

4 bits

–18

0.5 steps

14 7

Exposure scale (Exp.)

Figure 1-3-18 Light intensity correction by user setting

1-3-20

DC-2050 (MCE) S/M

Page 42

1AF

(4) Developing section

The developing section consists of the developing assembly and toner hopper.

Developing

assembly

Figure 1-3-19 Developing section

The developing assembly consists of the developing roller where a magnetic brush is

formed, doctor blade and the developing spirals that agitate the developer.

In the toner hopper new toner from the toner cartridge is mixed with residual toner recovered

from the cleaning section, and the mixture is conveyed to the developing assembly.

The amount of toner in the toner hopper is monitored by the toner level sensor (TLDS).

1-3-21

DC-2050 (MCE) S/M

Page 43

1AF

Toner hopper

Cleaning assembly

Cleaning spiral

Hopper paddle A

Hopper spiral

Developing assembly

Right developing spiral

Left developing spiral

Toner level sensor

Toner feed motor

Hopper paddle B

Toner flow

Figure 1-3-20 Toner recycling

1-3-22

DC-2050 (MCE) S/M

Page 44

1AF

Formation of the magnetic brush

The developing roller consists of a magnet roller with five poles and a sleeve roller. Rotation

of the sleeve roller around the magnet roller entrains developer, which in turn forms a

magnetic brush at pole N1 on the magnet roller. The height of the magnetic brush is

regulated by the doctor blade; the developing result is affected by the positions of the poles

on the magnet roller and the position of the doctor blade.

A developing bias voltage generated by the high-voltage transformer PCB (HVTPCB) is

applied to the developing roller to provide image contrast.

Magnetic poles on the magnet roller

654

A

70°

S1

70°

N2

2

A: distance between the doctor blade and

developing roller: 0.6 ± 0.05 mm

Figure 1-3-21 Forming the magnetic brush

1 Developing unit housing

2 Developing roller

3 Toner sensor (TNS)

13

4 Doctor blade

5 Right developing spiral

6 Left developing spiral

N1

N1: 850 × 10

N2: 600 × 10

S1: 600 × 10

S2: 600 × 10

S3: 500 × 10

S2

–4

± 50 × 10–4T

–4

± 50 × 10–4T

–4

± 50 ×10–4T

–4

± 50 ×10–4T

–4

± 50 ×10–4T

60°

S3

70°

1-3-23

DC-2050 (MCE) S/M

Page 45

1AF

CN11-5

CN11-6

MPCB

CN11-9

CN11-10

CN11-3

CN11-1

CN1-20

TNS SIG

TNS CONT

DB REM

TLDS

TNS

CN1-8

HVTPCB

TFM

Developing bias

Figure 1-3-22 Developing unit block diagram

Toner density is detected by the toner sensor (TNS).

The sensor section of the toner sensor detects the ratio of toner to carrier in the developer

near it and converts it into a voltage. As more toner is used, the ratio of toner to carrier

decreases, increasing the toner sensor output voltage.

When the ratio drops below the specified value, the increase in toner sensor output voltage

triggers toner replenishing. When toner is added and the ratio of toner to carrier returns to

normal, the toner sensor output voltage drops to the point where toner replenishing stops.

1-3-24

DC-2050 (MCE) S/M

Page 46

1AF

Toner density control

Toner density is controlled by switching the toner feed motor on/off using as the reference

the toner sensor output based on the toner sensor initial output value set when simulation

60 was executed when the developer was set. The toner sensor output is also used for toner

empty detection in the toner hopper. On this device, a magnetic proximity sensor toner level

sensor (TLDS) is also used, but the toner remaining amount is not detected until the toner

empty state is detected from the toner sensor output voltage.

When no toner is detected by

the TLDS, the add toner

Toner sensor

output voltage (V)

AP detection level

(3.56)

Toner empty end

level (3.21)

Toner feed motor

on level (2.72)

Toner feed motor

off level (2.70)

“AP” blinks on the

copy quantity display.

indicator lights here.

max. 3 min.

max. 3 min.

Forced toner

feed

If the level does not go down even

after the additional forced toner

feed, the add toner indicator

lights here.

Intermittent feed (3

minutes max.) until the

toner feed motor off

level is reached.

Copy operation

AB C D E

Forced feed (continuous operation)

Intermittent feed (1 s on/0.5 s off)

Figure 1-3-23

A When the toner sensor output voltage exceeds the toner feed motor on level, the toner

feed motor intermittent feed (1 s on, 0.5 s off) operation is carried out to feed the toner.

B When the toner is fed and the toner sensor output voltage falls below the toner feed motor

off level, the intermittent feed operation is stopped.

C When the toner in the toner hopper runs low and, even though the toner intermittent feed

operation is continued, the toner sensor output voltage rises above the AP detection

level, “AP” blinks on the copy quantity display and the toner feed motor forced feed

(continuously on) operation starts. At the same time, the amount of toner remaining is

detected by the toner level sensor.

1-3-25

DC-2050 (MCE) S/M

Page 47

1AF

D If the toner sensor output voltage falls to the toner empty end level within the toner feed

motor forced feed operation time (3 minutes max.), the copier returns to the ready state

and intermittent feed operations (3 minutes max.) are carried out until the toner sensor

output voltage drops to the toner feed motor off level. If the toner sensor output voltage

does not fall to the toner empty end level within the forced feed operation time, the

following operations are carried out according to the state of the toner level sensor.

A: When the toner level sensor detects that there is no toner remaining.

After the forced feed operation time ends, the add toner indicator lights.

B: When the toner level sensor does not detect that there is no toner remaining.

The forced feed operation is continued for an extra period of no more than three

minutes.

E If the toner sensor output voltage does not return to the toner empty end level within the

additional forced feed operation time, after the end of the additional forced feed

operation time, the add toner indicator lights.

If the toner sensor output voltage falls to the toner empty end level within the additional

forced feed operation time, the copier retums to the ready state and intermittent feed

operations (3 minutes max.) are carried out until the toner sensor output voltage drops

to the toner feed motor off level.

Toner sensor output

voltage (V)

AP detection level

Toner empty end

Toner feed motor

Toner feed motor

(3.56)

level (3.21)

on level (2.72)

off level (2.70)

Toner cartridge replacement

6 min. max.

Forced toner feed

If forced feed does not lower

the level, the add toner

indicator stays lit.

The add toner indicator turns

off and intermittent feed

continues (3 minutes max.)

until the toner feed motor

off level is reached.

Copy operation

GF

Figure 1-3-24

F After the toner cartridge is replaced, the forced feed operation (6 minutes max.) is started

by turning safety switch 1 off/on. During the forced feed operation time, the toner is fed

and when the toner sensor output voltage reaches the toner empty end level, the “AP”

goes out and the copier goes into the ready state. Further intermittent feed operations

(3 minutes max.) are carried out until the toner sensor output voltage reaches the toner

feed motor off level.

G If the toner sensor output voltage does not reach the toner empty end level within the

forced feed operation time, the add toner indicator stays lit even after the end of the

forced feed operation time.

1-3-26

DC-2050 (MCE) S/M

Page 48

II

ELECTRICAL

SECTION

II Electrical Section

DC-2050 (MCE) S/M

Page 49

CONTENTS

2-1 Electrical Parts Layout

2-1-1 Electrical parts layout.......................................................................... 2-1-1

1AF

1-1-11

Page 50

1AF

1-1-12

Page 51

2-1-1 Electrical parts layout

1AF

5

3

Machine front Machine inside Machine rear

1

2

4

Figure 2-1-1 Layout of electrical parts: PCBs

1. Main PCB (MPCB) ............................................. Controls the other PCBs and

electrical components.

2. Composite PCB (CPCB) .................................... Contains safety switch 1 and

noise filter; generates 24 V and

5V DC; and controls the halogen

lamp and fixing heater.

3. High-voltage transformer PCB (HVTPCB) ......... Performs main charging;

generates developing bias and

high voltage for transfer and

separation charging.

4. Humidity sensor PCB (HUMPCB)...................... Detects absolute humidity.

5. Operation unit PCB (OPCB) .............................. Consists of operation keys and

display LEDs.

2-1-1

Page 52

1AF

11

12 10

2

18

14

13

3

17

9

Machine front Machine inside Machine rear

16

15

8

4

19

1

20

5

7

6

Figure 2-1-2 Layout of electrical parts: switches and sensors

1. Main switch (MSW) ............................................ Turns the AC power on and off.

2. Safety switch 1 (SSW1) ..................................... Breaks the safety circuit when the

front cover is opened, and resets

paper jam detection.

3. Safety switch 2 (SSW2) ..................................... Breaks the safety circuit when the

eject cover is opened, and resets

paper jam detection.

4. Drawer switch (CASDSW) ................................. Detects the presence or absence

of the paper drawer.

5. Bypass paper length switch (BYPPLSW) .......... Detects the length of paper on the

bypass table.

6. Bypass paper width switch (BYPPWSW) .......... Detects the width of paper on the

bypass table.

7. Bypass table extended detection switch

(BYPEDSW) ...................................................... Detects when the bypass table is

extended to use long paper.

8. Registration switch (RSW) ................................. Controls the secondary paper

feed start timing.

9. Eject switch (ESW) ............................................ Detects a paper jam in the fixing

section.

10. AE sensor (AES)................................................ Detects the original density.

11. Home position switch (HPSW)........................... Detects the scanner in the home

position.

12. Lens home position switch (LHPSW) ................ Detects the lens in the home

position.

13. Toner cartridge detection switch 1

(TCDSW1) ......................................................... Detects the presence or absence

of the toner cartridge.

2-1-2

Page 53

1AF

14. Toner cartridge detection switch 2

(TCDSW2) ......................................................... Detects the presence or absence

of the toner cartridge.

15. Toner sensor (TNS) ........................................... Detects the toner density in the

developing unit.

16. Toner level sensor (TLDS)................................. Detects the toner level in the toner

hopper.

17. Fixing unit thermistor (FTH) ............................... Detects the heat roller

temperature.

18. Drum thermistor (DTH) ...................................... Detects the drum section

temperature.

19. Humidity sensor (HUMSENS)............................ Detects the external humidity.

20. External temperature thermistor (ETTH) ........... Detects the external temperature.

2-1-3

Page 54

1AF

2

6

7

5

3

4

1

10

Machine front Machine inside Machine rear

9

8

Figure 2-1-3 Layout of electrical parts: motors and solenoids

1. Drive motor (DM) ............................................... Drives the machine.

2. Scanner motor (SM) .......................................... Drives the optical system.

3. Lens motor (LM) ................................................ Drives the lens and mirrors 4 & 5.

4. Toner feed motor (TFM) .................................... Replenishes toner.

5. Optical section fan motor (OPFM) ..................... Cools the optical section.

6. Internal cooling fan motor (ICFM) ...................... Cools the machine interior.

7. Ozone exhaust fan motor (OEFM)..................... Exhausts ozone.

8. Paper feed solenoid (PFSOL)............................ Primary paper feed from the

paper drawer.

9. Bypass solenoid (BYPSOL)............................... Performs primary paper feed from

the bypass table, and operates

the bypass lift.

10. Registration solenoid (RSOL) ............................ Operates the registration stopper.

2-1-4

Page 55

7 9

1

1AF

8

5,6

4

Machine front Machine inside Machine rear

3

2

Figure 2-1-4 Layout of electrical parts: other electrical parts

1. Halogen lamp (HL)............................................. Performs exposure.

2. Cleaning lamp (CL) ............................................ Removes residual charge from

the drum surface.

3. Blank lamps (BL) ............................................... Remove charge from non-image

forming areas of the drum

surface.

4. Fixing heater (H) ................................................ Heats the heat roller.

5. Fixing unit thermostat 1 (TH1) ........................... Prevents overheating in the fixing

section.

6. Fixing unit thermostat 2 (TH2) ........................... Prevents overheating in the fixing

section.

7. Optical section thermostat (TH3) ....................... Prevents overheating in the

optical system.

8. Total counter (TC).............................................. Displays the total number of

copies produced.

9. *Solid state relay (SSR) ..................................... Controls the fixing heater.

* For 230 V specifications only.

2-1-5

Page 56

CONTENTS

2-2 Detection of Paper Misfeed

2-2-1 Paper misfeed detection ..................................................................... 2-2-1

2-2-2 Paper misfeed detection conditions .................................................... 2-2-2

1AF

1-1-13

Page 57

1AF

1-1-14

Page 58

1AF

2-2-1 Paper misfeed detection

When a paper jam occurs, the copier immediately stops copying and the copy quantity/

magnification display on the operation unit shows PF, J30, J40 or J50 indicating the location

of the jam.

Paper jam counts sorted by the detecting conditions can be checked by jam code in

simulation 74.

To remove paper jammed in the copier, open the drawer, open the front cover and operate

the paper conveying section lever, open the eject cover, or open the eject cover and detach

the fixing unit guide.

To reset the paper misfeed detection, open and close the front or eject cover to turn safety

switch 1 or 2 off and on.

Metric

• %

Inch

• Recall %

PF: no paper feed (or, no paper present in the drawer)

J30: paper jam in the registration section

J40: paper jam in the paper conveying or fixing section

J50: paper jam in the eject section

Figure 2-2-1 Misfeed location indication

ESW RSW

RSOL PFSOL

Figure 2-2-2 Misfeed detection

BYPSOL

2-2-1

Page 59

1AF

2-2-2 Paper misfeed detection conditions

No paper feed (PF)

• The registration switch (RSW) does not turn on within 1500 ms after the paper feed

solenoid (PFSOL) has turned on during drawer paper feed.

PFSOL

RSW

1500 ms

Off

On

Off

On

Timing chart 2-2-1

• The registration switch (RSW) does not turn on within 2500 ms after the bypass

solenoid (BYPSOL) has turned on during bypass paper feed.

BYPSOL

RSW

2500 ms

Off

On

Off

On

Timing chart 2-2-2

Paper jam in the registration section (J30)

• The registration switch (RSW) is on when the main switch is turned on or when the

front or eject cover is closed.

• The registration switch (RSW) does not turn off within 3580 ms after the registration

solenoid (RSOL) has turned on.

RSOL

RSW

3580 ms

Off

On

Off

On

Timing chart 2-2-3

2-2-2

Page 60

1AF

Paper jam in the paper conveying or fixing section (J40)

• The eject switch (ESW) does not turn on within 1650 ms after the registration solenoid

(RSOL) has turned on [except for the 1200 ms from the registration switch (RSW)

turning off when the drive does not stop].

RSOL

ESW

1650 ms

Off

On

Off

On

Timing chart 2-2-4

Paper jam in the eject section (J50)

• When the eject switch (ESW) is on when the main switch is turned on or when the

front or eject cover is closed, a forced-ejection is performed; the eject switch (ESW)

does not turn off within 2800 ms.

ESW

2800 ms

Off

On

Timing chart 2-2-5

• The eject switch (ESW) does not turn off within 3580 ms after the eject switch (ESW)

has turned on.

ESW

3580 ms

Off

On

Timing chart 2-2-6

2-2-3

Page 61

CONTENTS

2-3 Operation of the PCBs

2-3-1 Composite PCB .................................................................................. 2-3-1

2-3-2 Main PCB............................................................................................ 2-3-3

(1) Fixing unit abnormally high temperature/shorted thermistor detection

circuit.................................................................................................... 2-3-4

(2) Toner feed motor drive circuit .............................................................. 2-3-5

(3) Scanner motor drive circuit .................................................................. 2-3-6

(4) Reset circuit ......................................................................................... 2-3-7

2-3-3 Operation unit PCB .............................................................................. 2-3-8

1AF

1-1-15

Page 62

1AF

1-1-16

Page 63

2-3-1 Composite PCB

1AF

AC

input

H

HL

HL CONT

H REM

Noise

filter

circuit

section

L1

TH

602

TH

601

PC3

MSW

SSW1

PT2

PWM

signal/

voltage

converter

circuit

Q602

PT1

PC4

AVR circuit section

Halogen

lamp

light

intensity

control

IC

(HIC)

DH

Noise

filter

circuit

L001

Power source

circuit section

Rectifying

circuit

D001

24 V DC

smoothing/

output

circuit

D201/

C201/

C207

CPCB

Switching

circuit IC1

Figure 2-3-1 Composite PCB block diagram

C101

Q101

PC1 PC2

Output

feedback

circuit

5 V DC

smoothing/

output

circuit

IC3

TRNS

24 V DC

output

5 V DC

output

The composite PCB (CPCB) consists of three circuit sections: noise filter, power source and

AVR.

• Noise filter circuit section

The noise filter circuit consists of choke coil L1, a resistor and capacitor. These attenuate

external noise and prevent noise generated by the composite PCB (CPCB) and other

electrical components from escaping out of the copier via the AC line.

• Power source circuit section

The power source circuit section is a switching regulator which converts the AC input into

5 V and 24 V DC outputs. This section consists of the noise filter circuit, rectifying circuit,

switching circuit, 24 V DC smoothing/output circuit, 5 V DC smoothing/output circuit and

output feedback circuit.

The noise filter circuit consists of choke coil L001 and a capacitor. Any external noise that

has passed through the preceding noise filter circuit section is attenuated here, while the

switching noise generated in this section is prevented from escaping out via the AC line. The

AC input is full-wave rectified by diode bridge D001 and then smoothed by smoothing

2-3-1

Page 64

1AF

capacitor C101 in the rectifying circuit. The switching circuit turns FET Q101 on and off via

switching control IC1, turning current to the primary coil of switching transformer TRNS on

and off. The 24 V DC smoothing/output circuit converts the current induced in the secondary

coil of TRNS into a stable 24 V DC output via diode D201 and smoothing capacitors C201

and C207. The 5 V DC smoothing/output circuit converts the 24 V DC output from the 24

V DC smoothing/output circuit into a stable 5 V DC using regulator IC3. Switching control

IC1 regulates the 24 V DC supply by controlling the switching operation of FET Q101

depending on the signal fed back by the output feedback circuit via photocoupler PC1. If an

overvoltage occurs on the 24 V or 5 V DC output, the output feedback circuit sends that

information to switching control IC1 via photocoupler PC2, inhibiting IC1.

• AVR circuit section

The AVR circuit section consists of the PWM signal/voltage converter circuit, a halogen

lamp control subsection with the halogen lamp light intensity control IC (HIC), and a

switching subsection with thyristors TH601 and TH602 that turn the fixing heater (H) and

halogen lamp (HL) on and off.

Control signal H REM from the main PCB turns photocoupler PC4 on when low. This allows

current to flow from transistor Q602 to photocoupler PT1, turning PT1 on, which applies a

trigger voltage to the gate of thyristor TH602, causing it to conduct and allow current to flow

to fixing heater (H) to turn it on. Transistor Q602 is turned on by the zero-crossing signal from

the halogen lamp light intensity control IC (HIC), so thyristor TH602 conducts and the

current flows to the fixing heater every time 0 V is crossed.

The halogen lamp light intensity is controlled by control signal HL CONT from the main PCB.

HL CONT is a PWM signal turned on and off at a duty ratio set by the halogen lamp light

intensity data. This signal is converted into a voltage by the PWM signal/voltage converter

circuit and is output to the halogen lamp light intensity control IC (HIC). This adjusts the

phase of the photocoupler PT2 on-timing based on the halogen lamp light intensity data

converted into a voltage, using an internal zero-crossing signal as a reference. When

photocoupler PT2 is turned on, a trigger voltage is applied to the gate of thyristor TH601,

changing the time that TH601 conducts. This changes the level of the voltage applied to the

halogen lamp terminals, so regulating the halogen lamp light intensity.

2-3-2

Page 65

2-3-2 Main PCB

Fixing

H REM

unit

abnormally

high

temperature/

shorted

thermistor

detection

circuit

Scanner

motor

drive

circuit

FTH

H

CPCB

Switches

and

sensors

Motors

and

solenoids

SM

HVTPCB

MPCB

Address bus

Data bus

EPROM

CPU

(IC11)

(IC9)

NVRAM

(IC3)

Address

decoder

circuit

Chip Select

Reset

circuit

_RESET

I/O

(IC6)

WD

Figure 2-3-2 Main PCB block diagram

Toner

feed

motor

drive

circuit

1AF

TFM

OPCB

BL

Solenoids

Switches

The main PCB (MPCB) consists of the CPU (IC11), EPROM (IC9), NVRAM (IC3) and I/O

(IC6) as major components.

Based on the control programs in EPROM (IC9) and the data in NVRAM (IC3), the CPU

(IC11) controls the overall copier system by exchanging input and output signals with the

components connected to it directly or indirectly through I/O (IC6) via the address bus, data

bus and other control signals.

Other circuitry components of the main PCB are the fixing unit abnormally high temperature/

shorted thermistor detection circuit, toner feed motor drive circuit, scanner motor drive

circuit and reset circuit.

2-3-3

Page 66

1AF

(1) Fixing unit abnormally high temperature/shorted thermistor detection circuit

S

CN11-25

CPCB

FTH

CN11-26

H

H REM

CN4-6

SG

S

SG

SG

R96

R98

IC20

6

–

5

+

S

7

TR3

65

CPU

(IC11)

3

39

I/O

(IC6)

Figure 2-3-3 Fixing unit abnormally high temperature/shorted thermistor

detection circuit

The fixing unit abnormally high temperature/shorted thermistor detection circuit forces the

fixing heater control signal H REM off if the fixing temperature reaches an abnormally high

level. This hardware safety function backs up the software-controlled shorted fixing unit

thermistor/abnormally high temperature detection feature (self-diagnostic code C64).

As the fixing temperature rises, the resistance of the fixing unit thermistor (FTH) decreases.

This increases the voltage at pin 6 of comparator IC20. When the voltage exceeds the

abnormality detection level set by resistors R96 and R98 at pin 5 of comparator IC20, the

output at pin 7 goes low, turning transistor TR3 off; this shuts off the fixing heater control

signal H REM output from pin 3 of the CPU (IC11), forcing off the fixing heater (H) controlled

via the composite PCB (CPCB).

2-3-4

Page 67

(2) Toner feed motor drive circuit

1AF

_RESET

CPU

(IC11)

74

73

Pin 2

(IN1)

Pin 3

(IN2)

IC14 input voltage waveform

S

VCC1VCC

7

INH1

2

IN1

3

IN2

18

2

9

MONI

6

OUT1

4

OUT2

IC14

P G

+24 V

0 V

–24 V

Output voltage waveform

across CN11-5 and CN11-6

CN11-5

CN11-6

TFM

Figure 2-3-4 Toner feed motor drive circuit

The toner feed motor drive circuit generates a pseudo-AC supply to run the toner feed motor

(TFM), an AC motor.

Pulse signals output from the CPU (IC11) to pins 2 and 3 of driver IC14 alternate the

polarities of the 24 V DC in the transistor H-bridge circuit incorporated in driver IC14. This

voltage is output across CN11-5 and CN11-6 as a pseudo-AC supply.

2-3-5

Page 68

1AF

(3) Scanner motor drive circuit

S

1

Vcc

SM

CN8-2

CN8-5

CN8-1

CN8-3

CN8-4

CN8-6

24 V DC

+

P G

8

Td1

10

Td2

12

N.C.

2

A

3

A

6

B

7

B

P.GND

VrefA

VrefB

S.GND

OUT

P G

9

11

5

CPU

10

11

8

9

(IC11)

13

A

15

A

14

IN

B

16

B

IC2

Figure 2-3-5 Scanner motor drive circuit

The scanner motor drive circuit controls the scanner motor (SM), a stepping motor. Driver

IC2 turns the output current to the scanner motor coil on and off depending on the pulse

signal from the main PCB.

2-3-6

Page 69

(4) Reset circuit

S G

s

1AF

WD

s

1

WD

2

S G

3

4

TC

_RES1

GND

IC17

+

_RES2

VCC

ADJ