Page 1

DF-610

DF-610

DF-600

DF-600

MT-1

MT-1

BF-1

BF-1

PH-3A

PH-3A

PH-3C

PH-3C

SERVICE

MANUAL

Published in Nov. ’01

843B8110

Page 2

CAUTION

Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent

type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

CAUTION

Double-pole/neutral fusing.

Page 3

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 4

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING:Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION:Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

Page 5

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. ............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. .............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .....

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. ..........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ..........

• Always handle the machine by the correct locations when moving it. ..............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may

cause the copier to move unexpectedly or topple, leading to injury..................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is

accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention

immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain

medical attention. ..............................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. ........................................................................................................................

Page 6

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety

mechanisms and protective circuits. .................................................................................................

• Always use parts having the correct specifications...........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related

brochure when replacing them. Using a piece of wire, for example, could lead to fire or other

serious accident. ...............................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ...............................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If

it is dirty, clean it to remove the risk of fire or electric shock. ............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ..............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause

electric shock if handled improperly. .................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections...........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. .......

• Handle the fixing section with care to avoid burns as it can be extremely hot. .................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures...........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement....................

Page 7

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ......................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ..............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ...................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten

connector, trapped wire and missing screws. ..................................................................................

• Check that all the caution labels that should be present on the machine according to the

instruction handbook are clean and not peeling. Replace with new ones if necessary. ...................

• Handle greases and solvents with care by following the instructions below: ....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the main

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet

immediately. ......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than

the specified refiner; it may generate toxic gas. ................................................................................

Page 8

CONTENTS

1-1 Specifications

1-1-1 Specification ......................................................................................................................................... 1-1-1

1-1-2 Part names and functions .................................................................................................................... 1-1-3

1-1-3 Machine cross sectional view ............................................................................................................... 1-1-4

1-1-4 Machine drive system .......................................................................................................................... 1-1-5

(1) Finisher (paper feed and conveying section) ................................................................................ 1-1-5

(2) Finisher (main tray driving section) ............................................................................................... 1-1-6

(3) Multi job tray .................................................................................................................................. 1-1-6

(4) Centerfold unit ............................................................................................................................... 1-1-7

(5) Punch unit ..................................................................................................................................... 1-1-7

1-2 Installation

1-2-1 Unpacking and installing the machines ................................................................................................ 1-2-1

(1) Finisher ......................................................................................................................................... 1-2-1

(2) Multi job tray .................................................................................................................................. 1-2-8

(3) Centerfold unit ............................................................................................................................. 1-2-18

(4) Punch Unit .................................................................................................................................. 1-2-32

1-3 Maintenance Mode

1-3-1 Maintenance mode ............................................................................................................................... 1-3-1

(1) Executing a maintenance item ...................................................................................................... 1-3-1

(2) Contents of maintenance mode items .......................................................................................... 1-3-2

3B8/9

1-4 Troubleshooting

1-4-1 Paper misfeed detection ...................................................................................................................... 1-4-1

(1) Paper misfeed indication ............................................................................................................... 1-4-1

(2) Paper misfeed detection conditions .............................................................................................. 1-4-2

(3) Paper misfeeds ............................................................................................................................. 1-4-3

1-4-2 Self-diagnostic function ........................................................................................................................ 1-4-4

(1) Self-diagnostic display .................................................................................................................. 1-4-4

(2) Self diagnostic codes (finisher) ..................................................................................................... 1-4-5

1-4-3 Electrical problem ............................................................................................................................... 1-4-13

(1) Finisher ....................................................................................................................................... 1-4-13

(2) Centerfold unit ............................................................................................................................. 1-4-19

(3) Multi job tray ................................................................................................................................ 1-4-21

(4) Punch unit ................................................................................................................................... 1-4-22

1-4-4 Mechanical problem ........................................................................................................................... 1-4-23

(1) Finisher ....................................................................................................................................... 1-4-23

(2) Centerfold unit ............................................................................................................................. 1-4-24

(3) Multi job tray ................................................................................................................................ 1-4-25

1-5 Assembly and Disassembly

1-5-1 Finisher ................................................................................................................................................ 1-5-1

(1) Correcting paper curling ................................................................................................................ 1-5-1

(2) Correcting centerfold-stapling (for multi finisher only) ................................................................... 1-5-2

1-5-2 Centerfold unit ...................................................................................................................................... 1-5-3

(1) Removing and mounting the centerfold blade .............................................................................. 1-5-3

(2) Adjusting the paper folding position .............................................................................................. 1-5-5

1-5-3 Punch unit ............................................................................................................................................ 1-5-6

(1) Centering punch-holes .................................................................................................................. 1-5-6

(2) Setting margin from the leading edge to punch holes .................................................................. 1-5-7

(3) Adjusting the stop position of the punch clutch (reference) .......................................................... 1-5-8

1-1-1

1-6 Requirements on PCB Replacement

1-6-1 Replacing the finisher main PCB ......................................................................................................... 1-6-1

1-6-2 Upgrading the version of the firmware of the finisher main PCB ......................................................... 1-6-2

Page 9

3B8/9

2-1 Mechanical Construction

2-1-1 Finisher ................................................................................................................................................ 2-1-1

(1) Paper insertion section ................................................................................................................. 2-1-1

(2) Feedshift section ........................................................................................................................... 2-1-2

(3) Intermediate tray section ............................................................................................................... 2-1-5

(4) Paper eject section ..................................................................................................................... 2-1-13

2-1-2 Multi job tray ....................................................................................................................................... 2-1-15

2-1-3 Centerfold unit .................................................................................................................................... 2-1-17

2-1-4 Punch unit .......................................................................................................................................... 2-1-20

2-2 Electrical Parts Layout

2-2-1 Electric parts layout .............................................................................................................................. 2-2-1

(1) PCBs (finisher) .............................................................................................................................. 2-2-1

(2) Switches and sensors (finisher) .................................................................................................... 2-2-2

(3) Clutches and solenoids (finisher) .................................................................................................. 2-2-4

(4) Motors and others (finisher) .......................................................................................................... 2-2-5

(5) Stapler ........................................................................................................................................... 2-2-6

(6) PCBs (centerfold unit) ................................................................................................................... 2-2-7

(7) Switches and sensors (centerfold unit) ......................................................................................... 2-2-8

(8) Motors and solenoids (centerfold unit) .......................................................................................... 2-2-9

(9) Switches and motors (multi job tray) ........................................................................................... 2-2-10

(10) Switches, clutches, solenoids and motors (punch unit) .............................................................. 2-2-11

2-3 Operation of the PCBs

2-3-1 Finisher main PCB ............................................................................................................................... 2-3-1

2-3-2 Centerfold unit main PCB ................................................................................................................... 2-3-10

2-4 Appendixes

Timing chart No.1 ............................................................................................................................................ 2-4-1

Timing chart No.2 ............................................................................................................................................ 2-4-2

Timing chart No.3 ............................................................................................................................................ 2-4-3

Timing chart No.4 ............................................................................................................................................ 2-4-4

Periodic maintenance procedure ..................................................................................................................... 2-4-5

List of maintenance parts ................................................................................................................................ 2-4-8

Optional devices supplied parts list ............................................................................................................... 2-4-10

Centerfold unit wiring diagram ....................................................................................................................... 2-4-12

General wiring diagram ................................................................................................................................. 2-4-13

1-1-2

Page 10

1-1-1 Specification

Finisher

Type ............................................... Floor type

Number of trays.............................. Multi finisher: 2 trays, simple finisher: 1 tray

Tray capacity .................................. <Metric specification>

Main tray [80 g/m2 weight paper]

• When NOT stapling — A3, B4 (257 × 364 mm): 1500 (1000) sheets;

A4, A4R, Folio: 3000 (2000) sheets

• When stapling 2 copies — A3, B4 (257 × 364 mm): 700 (500) sheets;

A4, A4R: 1000 (1000) sheets

• When stapling 3 – 4 copies — A3, B4 (257 × 364 mm): 700 (500) sheets;

A4, A4R: 1000 (1000) sheets

• When stapling 5 – 10 copies — A3, B4 (257 × 364 mm): 800 (500) sheets;

A4, A4R: 1100 (1100) sheets

• When stapling 11 – 20 copies — A3, B4 (257 × 364 mm): 1000 (750) sheets;

A4, A4R: 1200 (1200) sheets

• When stapling 21 – 30 copies — A3, B4 (257 × 364 mm): 1500 (1000) sheets

• When stapling 21 – 49 copies — A4, A4R: 2000 (2000) sheets

• When stapling 50 copies — A4, A4R: 3000 (2000) sheets

* Description in ( ) is written for the simple finisher.

Sub tray (multi finisher only) [80 g/m

A3, B4 (257 × 364 mm): 200 sheets

A4, A4R, A5R, A6R, Folio: 200 sheets

<Inch specification>

2

Main tray [75 g/m

weight paper]

• When NOT stapling — 11" × 17", 8

1

8

/2" × 11", 11" × 81/2": 3000 (2000) sheets

• When stapling 2 copies — 11" × 17", 8

1

/2" × 11", 11" × 81/2": 1000 (1000) sheets

8

• When stapling 3 – 4 copies — 11" × 17", 8

1

/2" × 11", 11" × 81/2": 1000 (1000) sheets

8

• When stapling 5 – 10 copies — 11" × 17", 8

1

8

/2"x11", 11" × 81/2": 1100 (1100) sheets

• When stapling 11 – 20 copies — 11" × 17": 1000 (750) sheets;

1

/2" × 14": 1200 (750) sheets, 81/2" × 11", 11" × 81/2": 1200 (1200) sheets

8

• When stapling 21 – 30 copies — 11" × 17", 8

• When stapling 21 – 49 copies — 8

• When stapling 50 copies — 8

* Description in ( ) is written for the simple finisher.

Sub tray (multi finisher only) [75 g/m2 weight paper]

1

11" × 17", 8

1

8

/2" × 11", 11" × 81/2", 51/2" × 81/2": 200 sheets

/2" × 14": 200 sheets

Stapling capacity ............................ A3, B4 (257 × 364 mm), 11" × 17", 8

1

11" × 8

/2": 50 sheets [75 – 80 g/m2 weight paper]

Power source ................................. Copier

Dimensions (W × D × H) ................ 796 × 640 × 950 mm

5

/16" × 253/16" × 373/8"

31

Weight ............................................ Multi finisher: Approx. 78 kg/171.6 lbs.

Simple finisher: Approx. 77 kg/169.4 lbs.

2

weight paper]

1

/2" × 14": 1500 (1000) sheets;

1

/2" × 14": 700 (500) sheets;

1

/2" × 11", 11" × 81/2": 2000 (2000) sheets

1

/2" × 11", 11" × 81/2": 3000 (2000) sheets

1

/2" × 14": 30 sheets; A4, A4R, B5, 81/2" × 11",

1

/2" × 14": 700 (500) sheets;

1

/2" ×14": 800 (500) sheets;

1

/2" × 14": 1500 (1000) sheets

3B8/9

1-1-1

Page 11

3B8/9

Multi Job Tray (option)

Number of trays.............................. Job tray: 5

Paper size ...................................... A3, B4 (257 × 364 mm), A4, A4R, A5R, B6R, Folio, 11" × 17", 81/2" × 14", 81/2" × 11",

1

11" × 8

Tray capacity .................................. A3, B4 (257 × 364 mm), 11" × 17", 8

/2"

1

/2" × 14": 100 sheets (75 – 80 g/m2 weight

paper)

1

A4 – B6R, Folio, 8

/2" × 11", 11" × 81/2": 150 sheets (75 – 80 g/m2 weight paper)

Dimensions (W × D × H) ................ 368 × 392 × 573 mm

141/2" × 157/16" × 229/16"

Weight ............................................ Approx.15 kg/33 lbs.

Centerfold unit (option for multi finisher)

Foldable sizes ................................ A3, B4 (257 × 364 mm), A4R, 11" × 17", 8

Foldable number of sheets ............ 1 – 16 (no stapling for 1 sheet)

Maximum number for storage ........ 5 or less copies in a set: 30 sets

6 – 10 copies in a set: 20 copies

11 – 16 copies in a set: 10 sets

2

Paper thickness ............................. 60 – 200 g/m

(only one cover for 81 g/m2 or more)

Punch unit (option for multi finisher)

2

Available sizes ............................... 75 – 80 g/m

weight paper

A3, B4 (257 × 364 mm), A4, A4R, B5, B5R, Folio, 11" × 17", 8

1

8

/2" × 11", 11" × 81/2"

1

/2" × 11"

1

/2" × 14",

1-1-2

Page 12

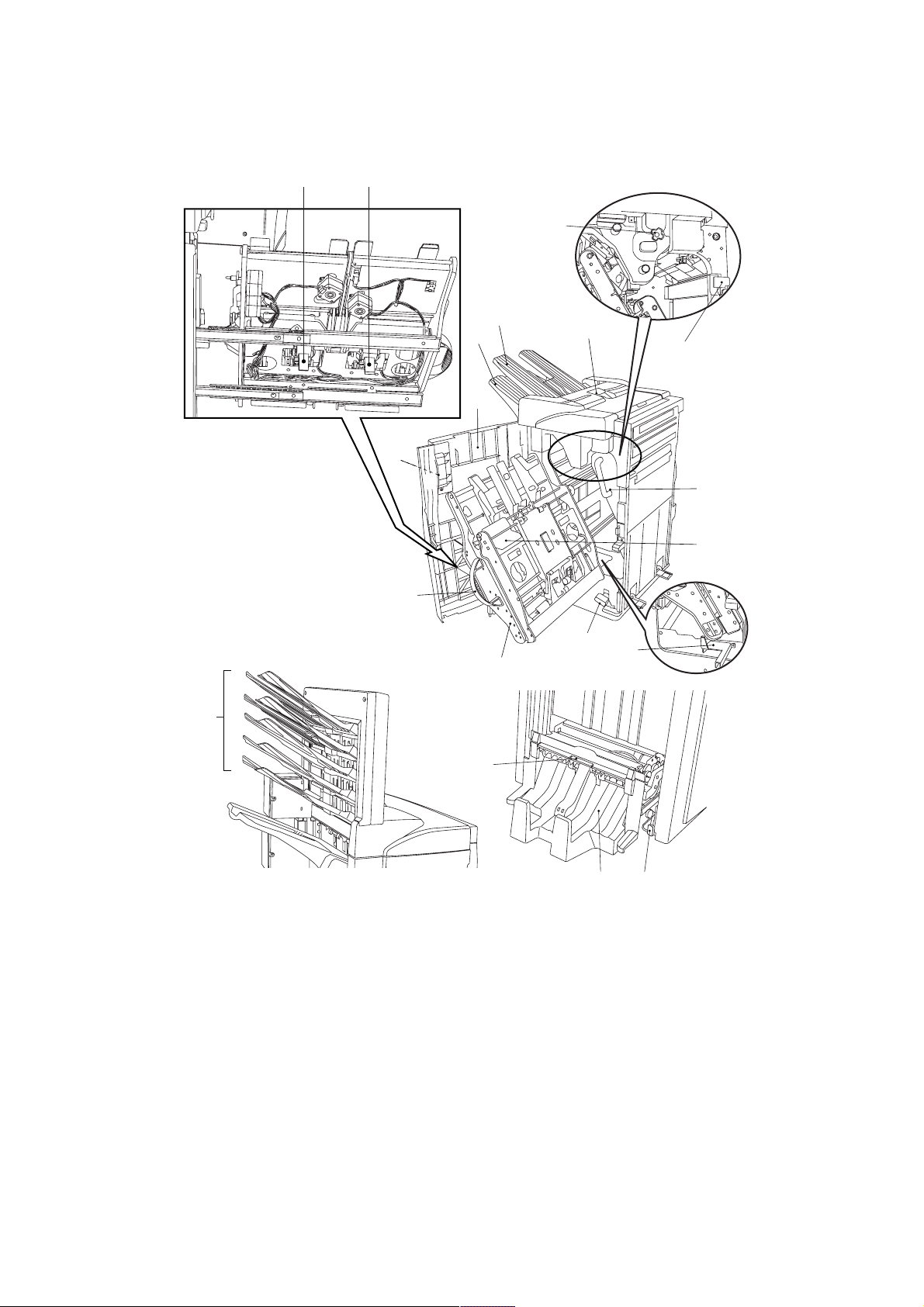

1-1-2 Part names and functions

3B8/9

!

0

4

7

1

3

8

2

5

@

#

9

$

Finisher

1 Main tray

2 Sub tray*

3 Front cover

4 Front cover handle

5 Upper cover

6 Intermediate tray

7 Intermediate tray handle

8 Conveyor knob

9 Intermediate tray release lever

0 Staple holder B*

! Staple holder A

@ Coupling section guide lever

%

^

6

&

*

(

Figure 1-1-1

Punch unit (option for multi finisher)

# Punch waste box

Multi job tray (option)

$ Job trays Nos.1 – 5

Centerfold unit (option for multi finisher)

% Unit release lever

^ Unit release handle

& Conveyor guide lever

* Storage cover

( Centerfold unit installation buttons

* For multi finisher only.

1-1-3

Page 13

3B8/9

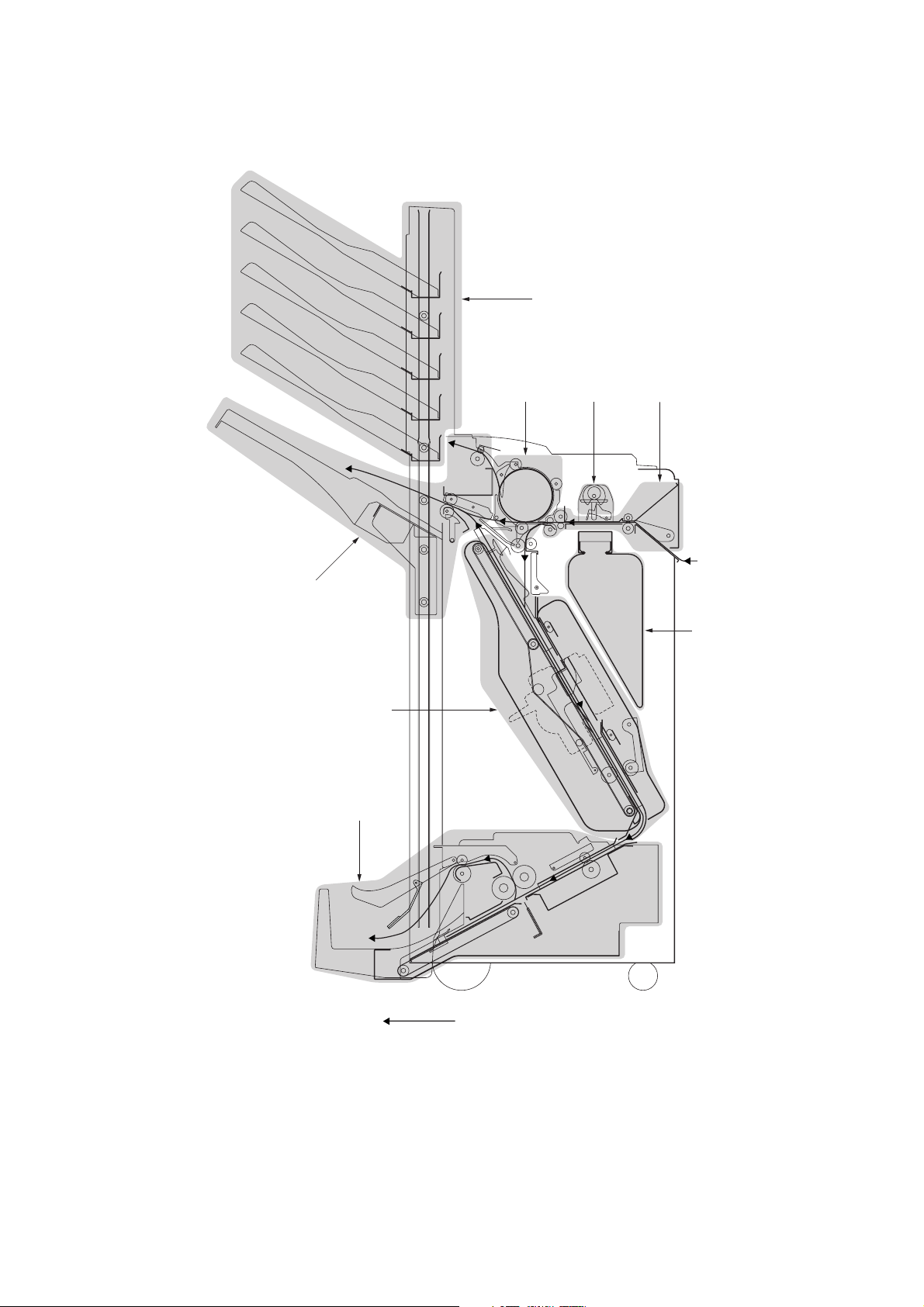

1-1-3 Machine cross sectional view

5

217

4

7

3

6

Paper path

1-1-4

1 Paper insertion section

2 Feedshift section

3 Intermediate tray section

4 Paper ejection section

Figure 1-1-2

5 Multi job tray (option)

6 Centerfold unit (option for multi finisher)

7 Punch unit (option for multi finisher)

Page 14

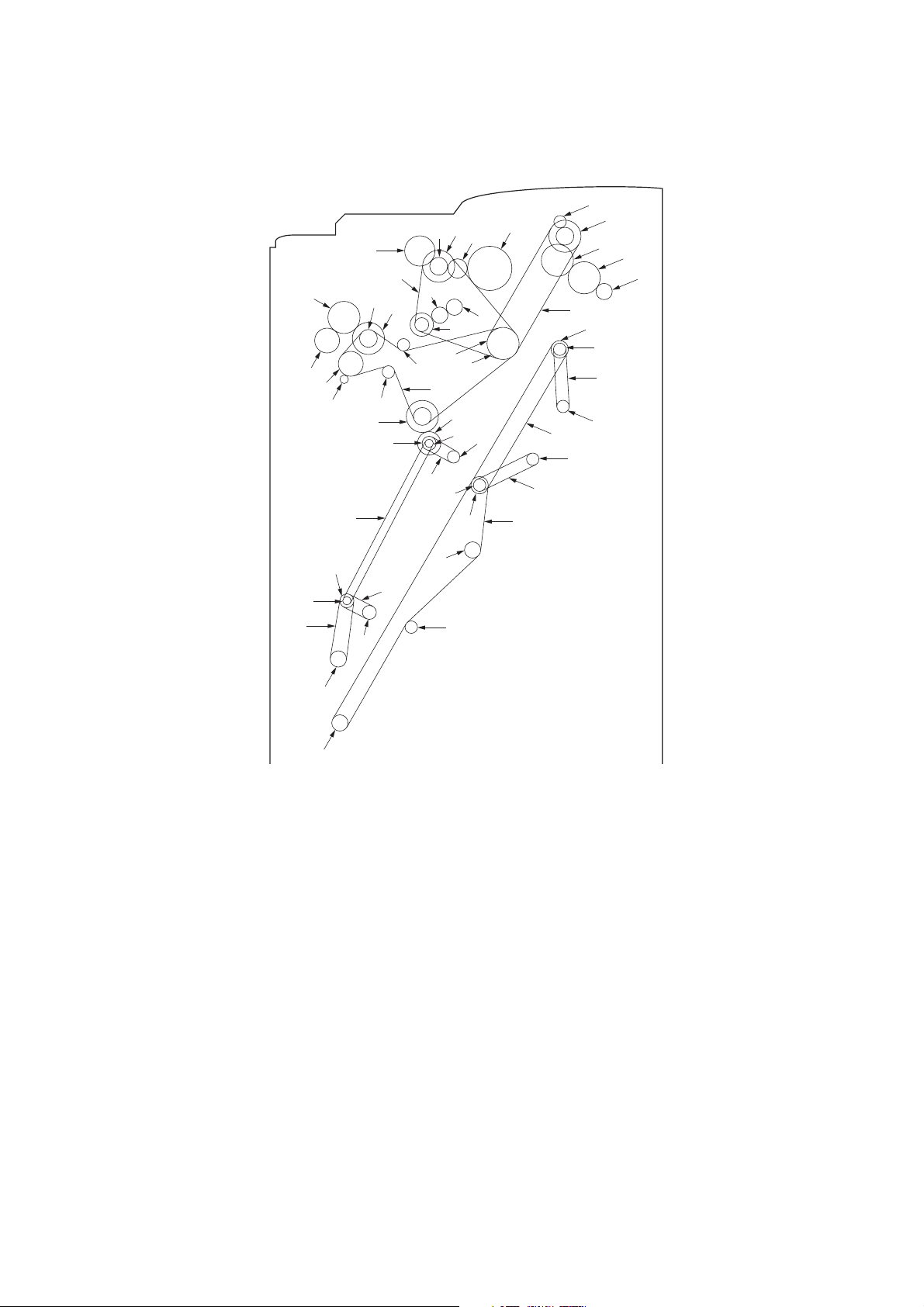

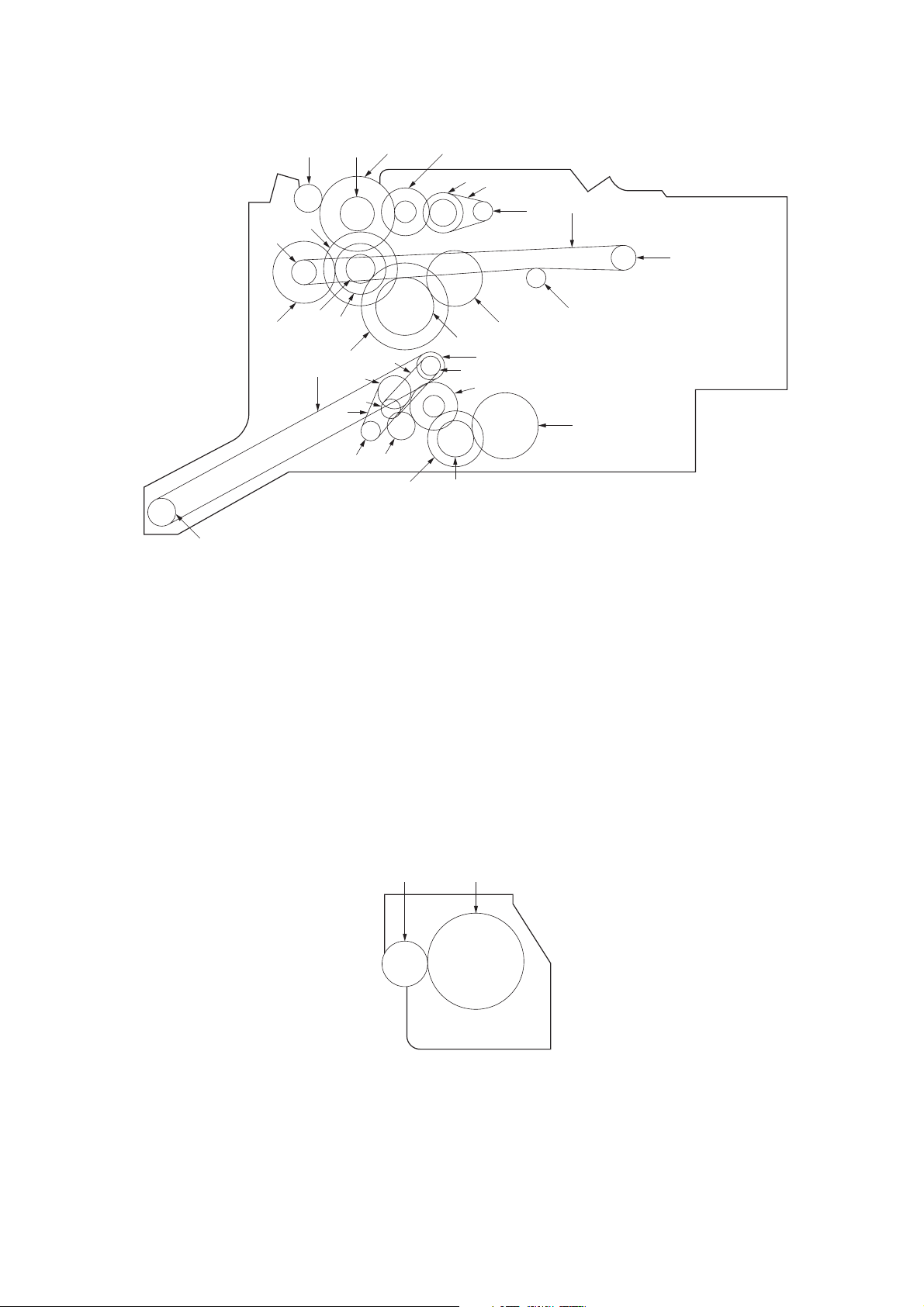

1-1-4 Machine drive system

˛

(1) Finisher (paper feed and conveying section)

fi

(

9

6

2

1

´

0

4

7

3

‚

5

⁄

Œ

›

8

*

Ó

‹

)

°

·

!

˝

fl

¤

„

‡

Ò

Ô

Ï

@

&

Î

Í

Å

”

$

3B8/9

#

%

^

1 Paper conveying motor gear

2 Pulley 37/48

3 Gear 40

4 Pulley 30

5 Tension pulley

6 Paper conveying clutch gear*

7 Tension pulley

8 Timing belt C

9 Paper entry roller gear

0 Gear Z40/P30

! Pulley 31 (machine rear)

@ Eject drive belt

# Gear Z21/38

$ Gear 40

% Gear 40

^ Eject roller gear

& Sub eject roller gear*

* Pulley 25 (machine front)

ˇ

‰

Á

ˆ

¨

Ø

( Siding drum drive belt

) Gear Z31/P18

⁄ Torque limiter gear 20

¤ Torque limiter gear 20

‹ Pulley 36

› Gear 20

fi Siding drum clutch gear*

fl Gear 26

‡ Gear 53

° Intermediate tray joint gear

· Pulley 16

‚ Pulley 20

ΠFeed belt

„ Upper forwarding roller

´ Pulley drive belt

‰ Pulley 16

ˇ Pulley 20

Á Feed belt

Ú

¸

Figure 1-1-3

¨ Lower forwarding roller

ˆ Paper forwarding pulley belt

Ø Pulley 27

∏ Upper paper conveying belt motor pulley

Å Intermediate tray drive belt

Í Pulley 20

Î Pulley 20

Ï Upper paper conveying belt

˝ Pulley 20

Ó Pulley 20

Ô Intermediate tray drive belt

Lower paper conveying belt motor pulley

Ò Lower paper conveying belt

Ú Pulley 20

¸ Tension pulley

˛ Pulley 20

* For multi finisher only.

1-1-5

Page 15

3B8/9

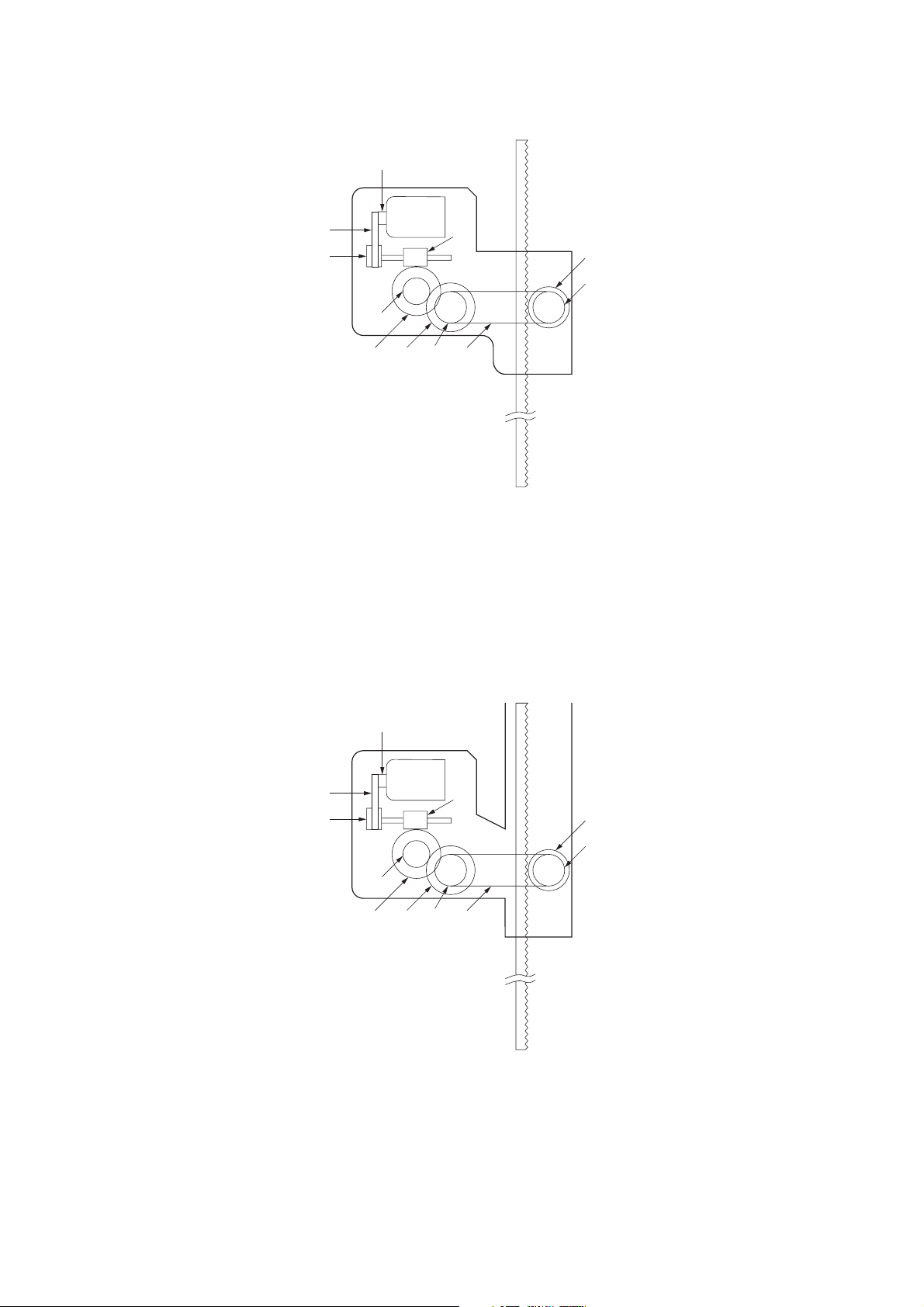

(2) Finisher (main tray driving section)

1

2

4

3

6

7

5

1 Main tray elevation motor pulley

2 Feed belt

3 Pulley 27

4 Worm gear

5 Gear 50

6 Gear 18

9

8

Figure 1-1-4

!

0

7 Gear 51

8 Pulley 20S

9 Tray drive belt

0 Pulley 20S

! Gear 26

(3) Multi job tray

1

2

4

3

6

7

5

1 Multi job tray elevation motor pulley

2 Feed belt

3 Pulley 27

4 Worm gear

5 Gear 50

6 Gear 18

9

8

Figure 1-1-5

!

0

7 Gear 51

8 Pulley 20S

9 Tray drive belt

0 Pulley 20S

! Gear 26

1-1-6

Page 16

(4) Centerfold unit

3B8/9

›

%

$

6

8

9

‹

#

fl

0

7

fi

‡

(

„

)

·

45

3

2

!

¤

⁄

°

‚

Figure 1-1-6

@

1

^

&

*

Œ

1 Main motor pulley

2 Belt 118P2M6

3 Gear 22/40

4 Gear 33/15

5 Gear 51

6 Manual roller gear

(conveyor guide knob)

7 Gear 22

8 Gear 51

9 Gear 19

0 Gear 50/15

(5) Punch unit

! Gear 16/25

@ Gear 16/25

# Bypass pulley gear

$ Gear 58

% Pulley 28

^ Paper drive belt

& Pulley 28

* Idle pulley 15

( Centering plate motor pulley

) Belt 124

⁄ Pulley 22

12

¤ Pulley 20

‹ Paper conveying belt

› Pulley 20

fi Blade motor pulley

fl Belt 126P2M6

‡ Gear 22/40

° Gear 33/15

· Gear 40

‚ Gear 22

ΠGear 50

„ Manual roller gear

Figure 1-1-7

1 Punch motor gear

2 Punch clutch gear

1-1-7

Page 17

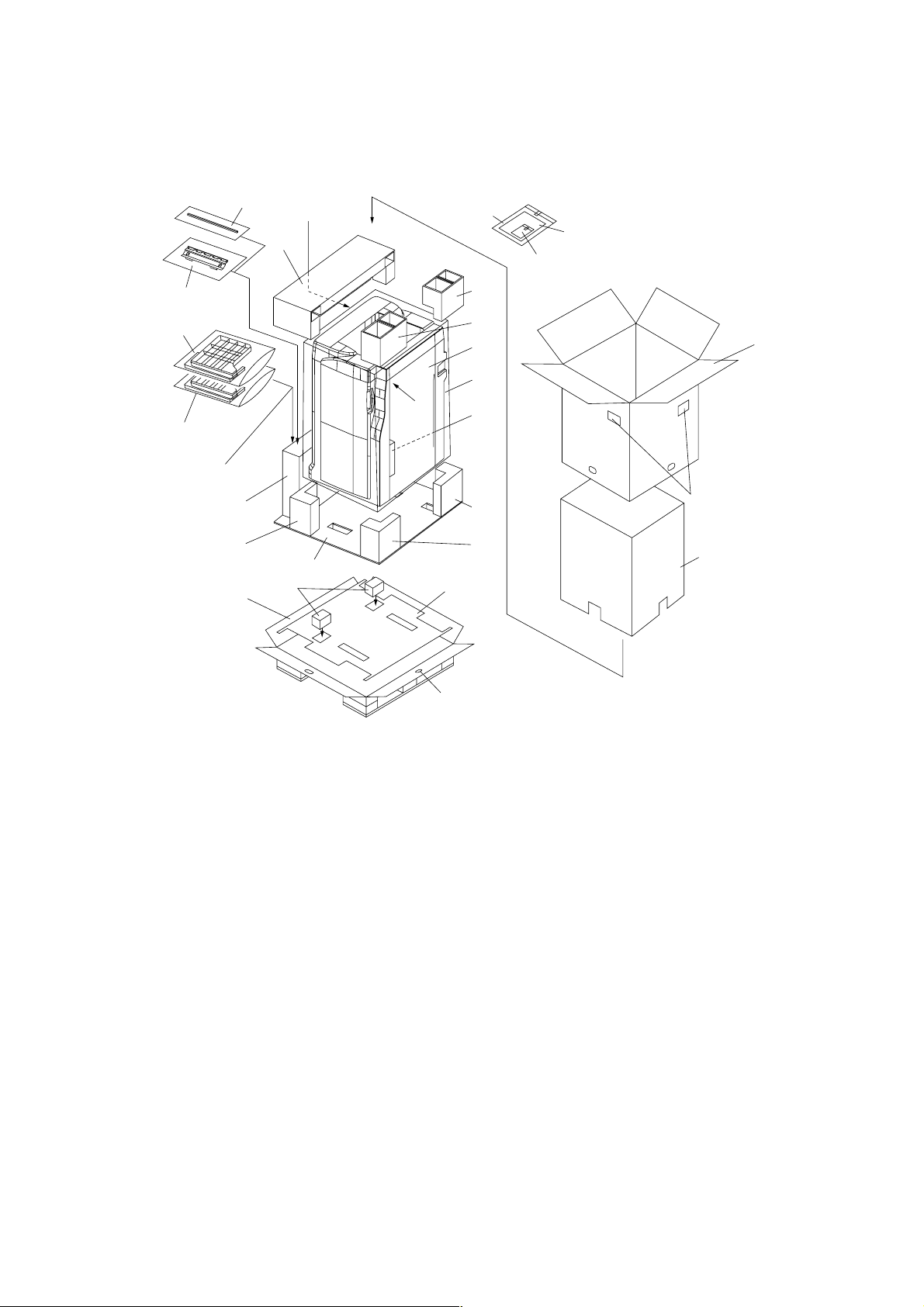

1-2-1 Unpacking and installing the machines

(1) Finisher

3B8/9

fl@

·2

·3

fl—4

5

ˇ#

›

&

%

⁄

Œ

Ø

^

∏

„

‹

¤

1

fi

*

)

(

Á

0!¨ˆ

´6789

$

‡

‚

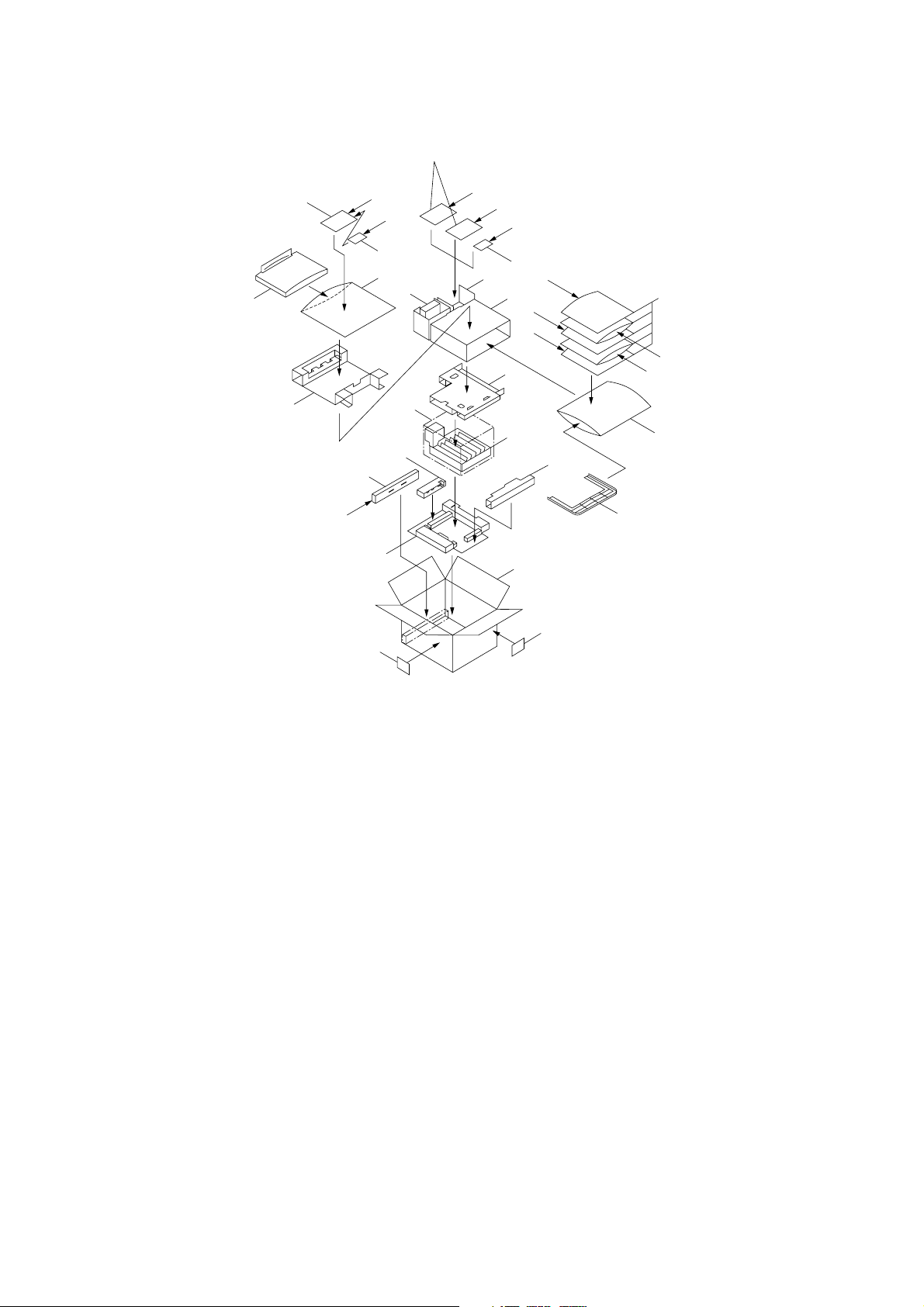

1 Finisher

2 Main tray

3 Sub tray*

4 Finisher connecting plate

5 Stapler cartridge

6 Pins

7 Hexagonal nuts

8 M4 × 10 tap-tight binding screws

9 BVM4 × 12 binding screws

0 Label A

! Label B*

@ Paper insertion aid guide plate

# Connecting sponge

$ Outer case

‰

Figure 1-2-1 Finisher package

% Skid

^ Bottom cushion sheet

& Front lower left pad

* Rear lower left pad

( Front lower right pad

) Rear lower right pad

⁄ Upper left pad

¤ Front upper right pad

‹ Rear upper right pad

› Accessory case

fi Dust cover

fl Air cap bags

‡ Barcode labels

° Air cap bag

· Air cap bags

‚ Inner case

ΠBottom pads

„ Bottom board

´ Vinyl bag

‰ Hinge joint

ˇ Polyethylene bag

Á Polyethylene bag

¨ Instruction handbook

ˆ Installation guide

Ø Spacer

∏ Spacer

* For multi finisher only.

1-2-1

Page 18

3B8/9

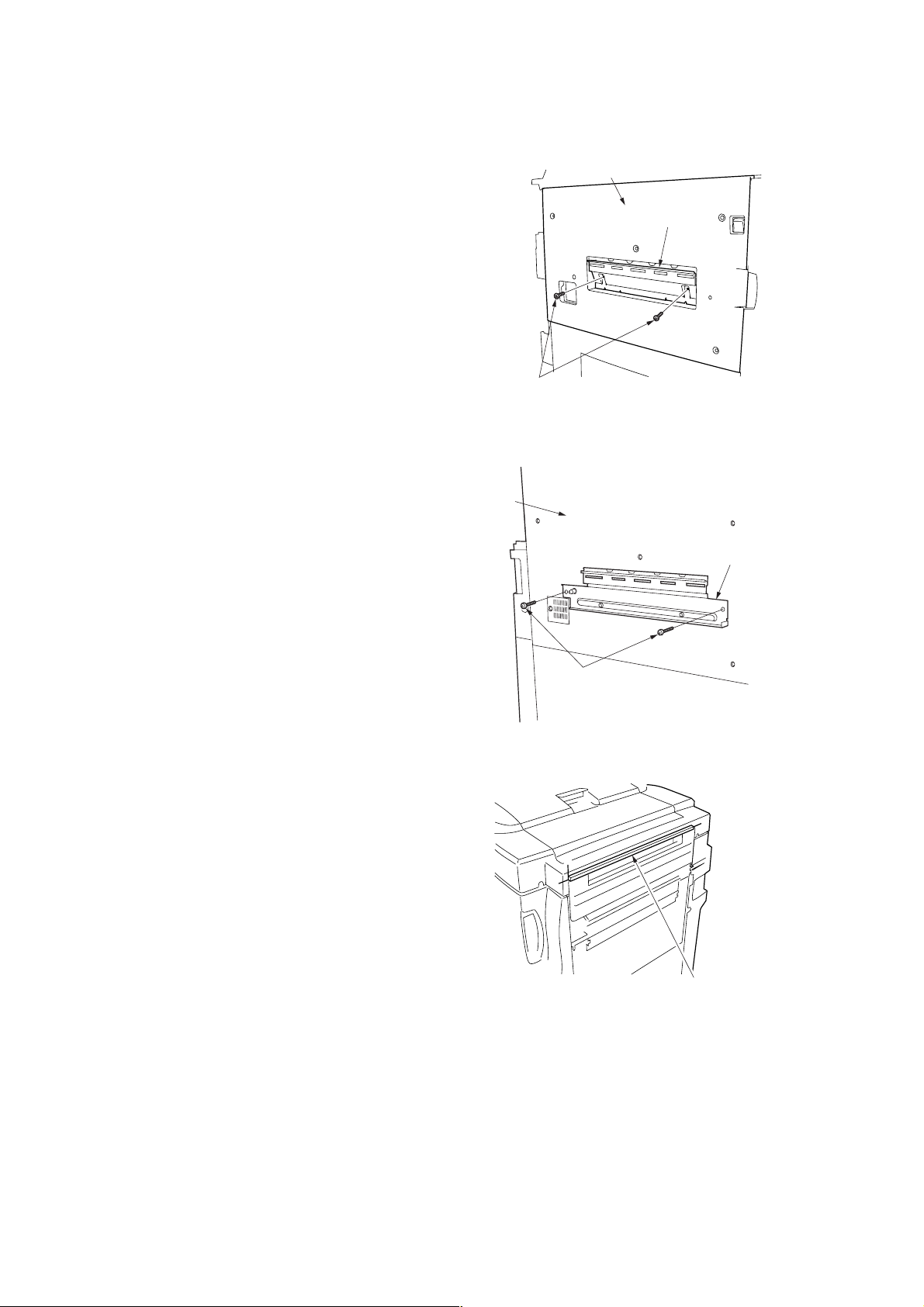

Installation procedure

Before installing the finisher, turn the copier off from the main switch and unplug the power cable from the wall outlet.

1. Attach the paper insertion aid guide plate to

the eject cover of the copier and lock down

with the two M4 × 10 tap-tight binding screws.

2. Attach the finisher connecting plate to the

copier eject cover and then hold them together

with the two BVM4 × 12 binding screws.

Eject cover

Paper insertion

aid guide plate

M4 × 10 tap-tight

binding screws

Figure 1-2-2

Eject cover

Finisher connecting plate

3. Attach the connecting sponge to the finisher by

aligning the sponge to the upper end “a” and

front end “b” of the paper port of the finisher.

BVM4 × 12 binding screws

Figure 1-2-3

a

b

a

Connecting sponge

Figure 1-2-4

1-2-2

Page 19

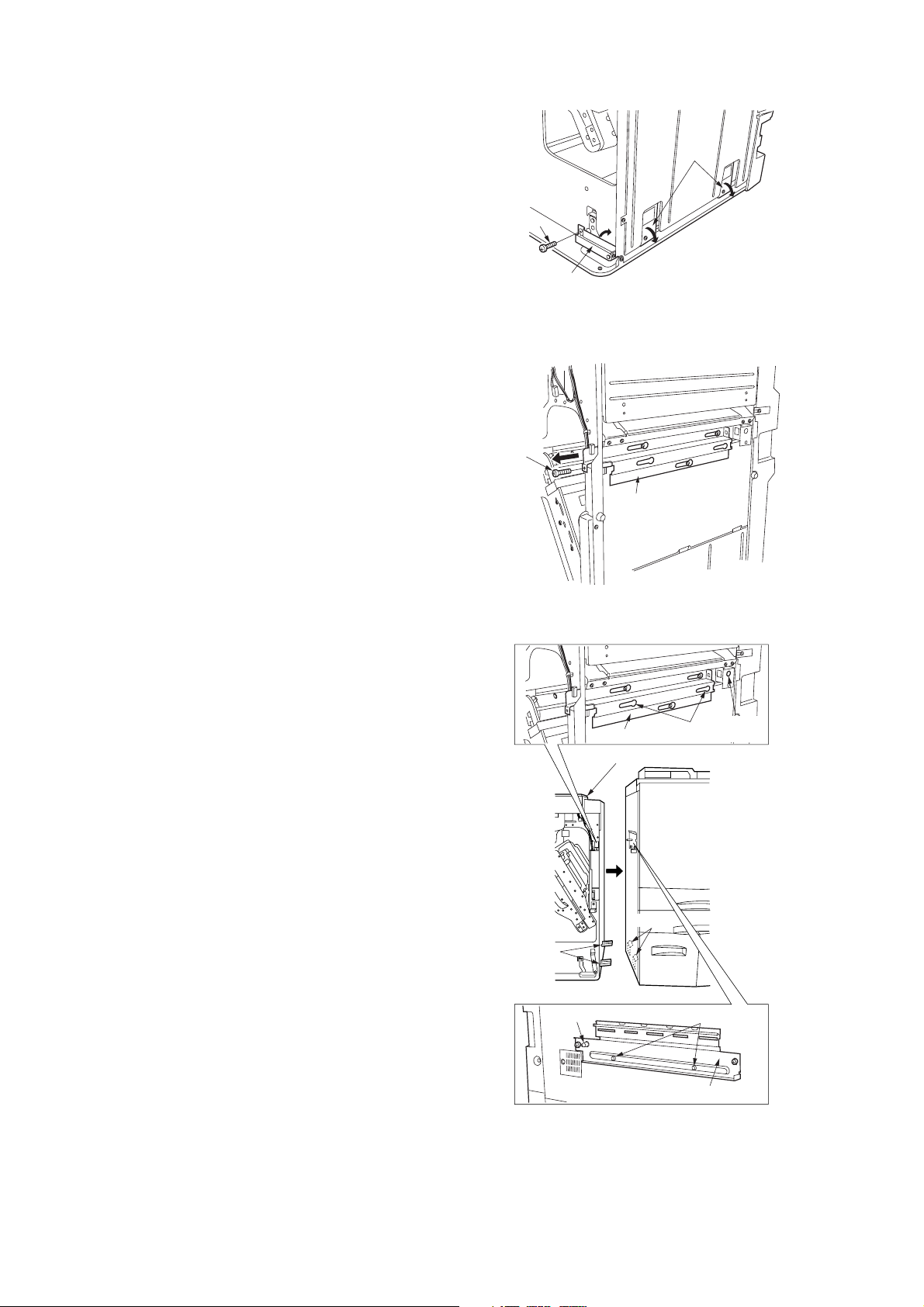

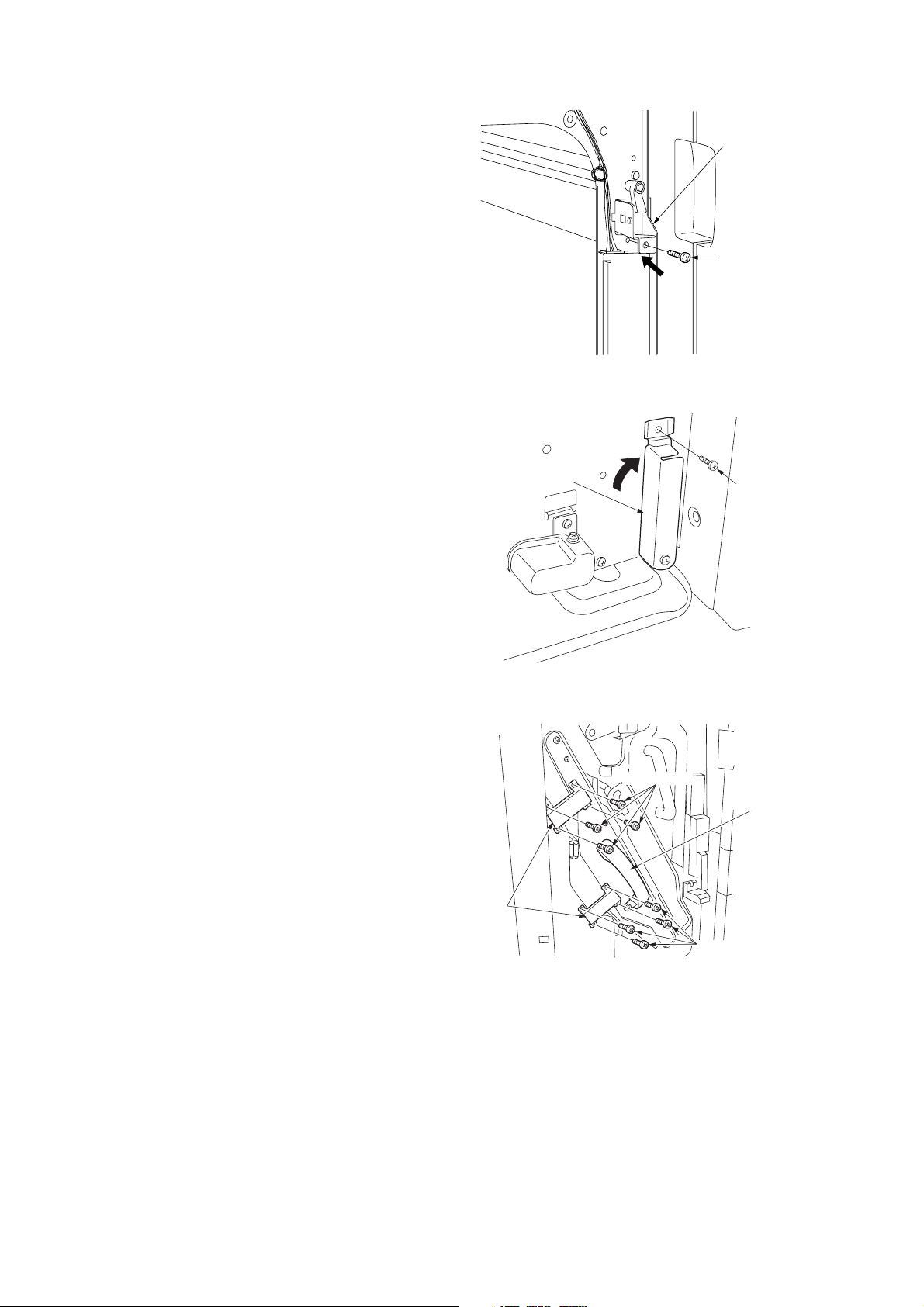

4. Open the front cover.

5. Remove the screw and raise the connecting

lever at the bottom of the finisher. Raising the

lever lowers the hooks.

6. Remove the screw and pull out the connecting

rail at the upper part of the finisher.

3B8/9

Hooks

Screw

Connecting

lever

Figure 1-2-5

Screw

Connecting rail

7. Join the finisher and the copier by hanging the

hooks onto the fittings inside the copier.

8. Join the finisher and the copier so that the long

pin of the finisher connecting plate is inserted

into the hole at the rear of the finisher and the

two short pins into the holes on the connecting

rail.

Hooks

Long pin

Figure 1-2-6

Connecting rail

Finisher

Fittings

Holes

Short pins

Hole at

the rear

Finisher connecting plate

Figure 1-2-7

1-2-3

Page 20

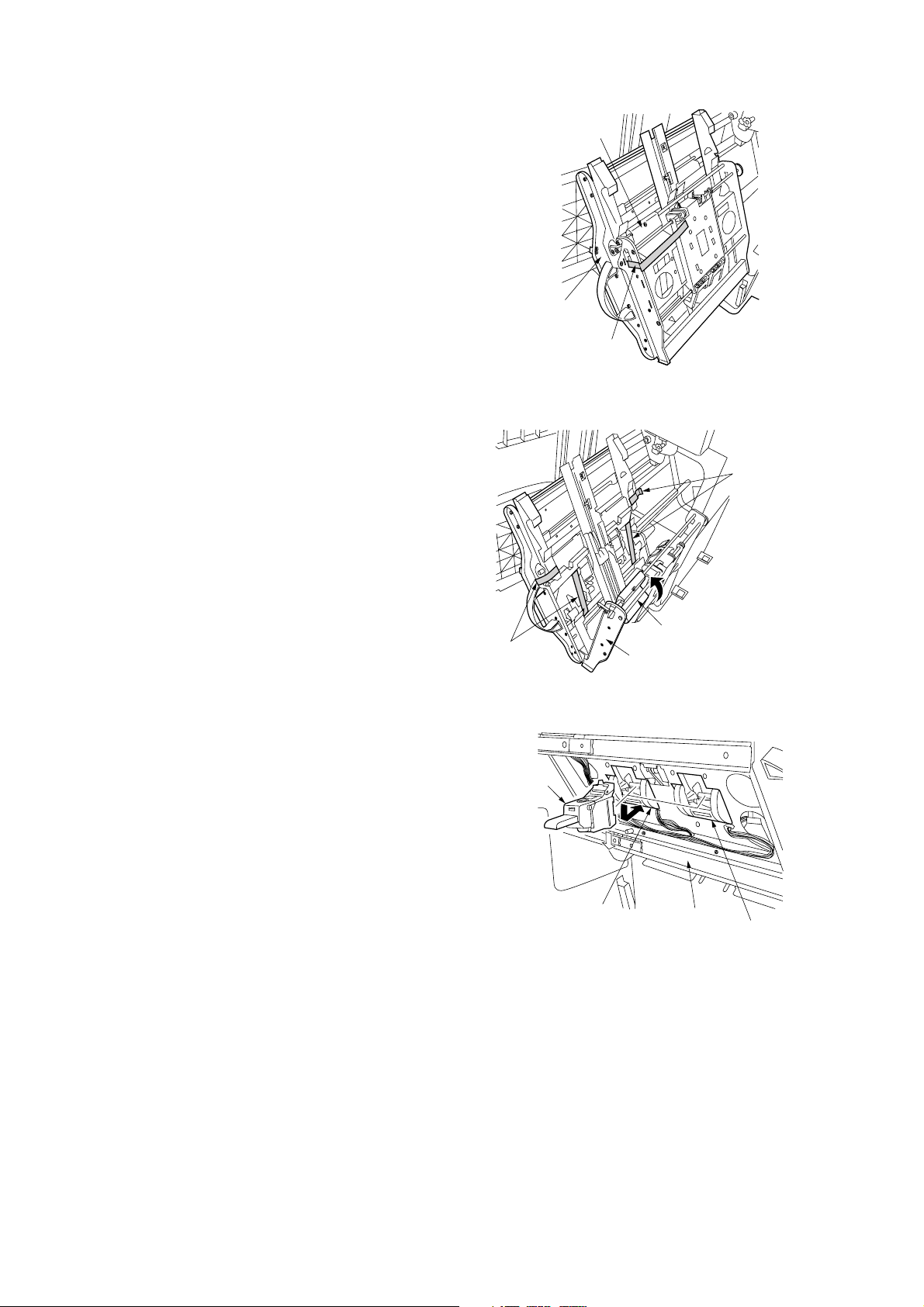

3B8/9

9. Make sure that the finisher is securely joined

with the copier. Then, push the connecting rail

in and lock back down with the screw.

10. Slide the connecting lever rightward and lock

down with the screw removed in step 5.

Connecting rail

Screw

Figure 1-2-8

11. Remove the four blue screws locking each of

the two separate retainers to the intermediate

tray and detach both retainers.

Retainers

Connecting lever

Figure 1-2-9

Blue screws

Screw

Intermediate

tray

1-2-4

Blue

screws

Figure 1-2-10

Page 21

3B8/9

p

12. Pull out the intermediate tray.

13. Remove the strip of fixing tape from the

release lever.

14. Raise the release lever to open the intermediate tray, and then remove the four strips

of fixing tape.

Release lever

Intermediate

tray

Fixing tape

stri

Figure 1-2-11

Fixing tape

strips

15. Insert a stapler cartridge into each of the

staplers of the intermediate tray. Press on the

cartridges until they are securely locked.

Note: With the simple finisher, attach just one

stapler cartridge to the stapler at the rear side.

Fixing tape

strips

Stapler

cartridge

Intermediate tray

Figure 1-2-12

Stapler

Figure 1-2-13

Release lever

Intermediate

tray

Stapler

1-2-5

Page 22

3B8/9

16. Fit the main tray with two hexagonal nuts.

17. Secure the main tray with two pins.

For the multi finisher only

18. Attach the sub tray to the finisher by inserting

the projections at the front and back of the sub

tray into the holes of the finisher.

Main tray

Hexagonal nuts

Pins

Figure 1-2-14

Sub tray

Projection

Hole

Projection

Hole

Figure 1-2-15

1-2-6

Page 23

19. Affix label A to the recessed portion on the side

of the main tray.

For multi finisher only

20. Affix label B to the recessed portion on the side

of the sub tray.

21. Connect the signal cable of the finisher to the

connector of the copier.

22. Plug the copier’s power cable into a wall outlet

and turn the copier on from the main switch.

3B8/9

Sub tray

Label B

Main tray

Label A

Figure 1-2-16

Signal cable

Adjustment

After installing the multi/simple finisher, perform the following adjustment.

• Correcting paper curling

See page 1-5-1.

• Correcting centerfold-stapling (for multi finisher only)

See page 1-5-2.

Figure 1-2-17

1-2-7

Page 24

3B8/9

(2) Multi job tray

‰

6

´

‡

———

234

$%Œ

*

^

‚

00

„„

‹

)

fi

·

8

fl

9

!@#

„

(

5

&

1

⁄

5

¤

5

5

5

‹

›

7

‚

Figure 1-2-18 Multi job tray package

1 Multi job tray

2 Bin front guide plate

3 Bin rear guide plate

4 Bin guide plate retainer

5 Job trays

6 Right cover

7 Left cover

8 Tray detection plate A

9 Motor front cover

0 Job tray switches

! BVM3 × 5 binding screws

@ BVM4 × 6 binding screws

# M4 × 8 TP screws

$ Sheet of tray No. labels

% Sheet of name labels

^ Bottom pad

& Top pad

* Rail case

( Tray spacer

) Spacer

⁄ Outer case

¤ Air cap bags

‹ Air cap bags

› Front bottom spacer

fi Rear bottom spacer

fl Retaining spacer

‡ Top spacer

° Polyethylene bags

· Dust cover

‚ Barcode labels

ΠInstallation guide

„ Vinyl bags

´ Polyethylene bag

‰ Vinyl bags

1-2-8

Page 25

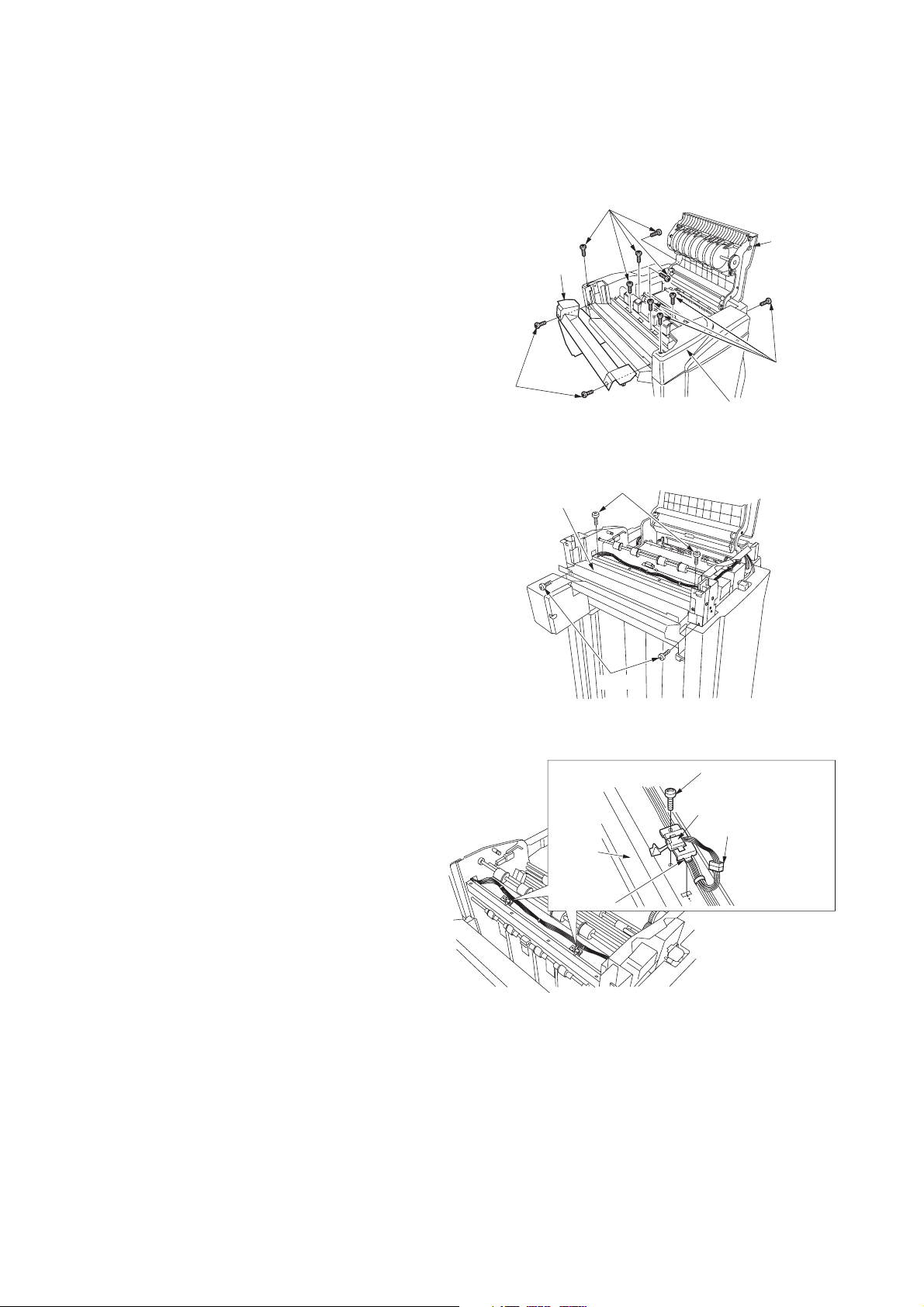

3B8/9

Installation procedure

Before installing the multi job tray, turn the copier off from the main switch and unplug the power cable from the wall outlet.

Install the multi job tray after attaching the finisher main tray.

When installing the multi job tray and centerfold unit as a set, first install the centerfold unit and then the multi job tray.

1. Remove the two screws locking down the top

cover lid followed by the lid.

2. Open the upper cover and remove the nine

screws locking down the top cover followed by

the top cover.

3. Remove the four screws locking down the top

cover lid guide followed by the guide.

Screws

Top cover lid

Top cover

lid guide

Screws

Upper

cover

Screws

Top cover

Figure 1-2-19

Screws

4. Attach the two multi job tray switches to the

eject stay by inserting the tabs, and lock in

place with one BVM3 × 5 binding screw each.

5. Connect the 3-pin connector of the size

detection switch to the connector of the

finisher.

Screws

Figure 1-2-20

BVM3 × 5

binding screw

Multi job tray switch

3-pin connector

Eject

stay

Ta b

Figure 1-2-21

1-2-9

Page 26

3B8/9

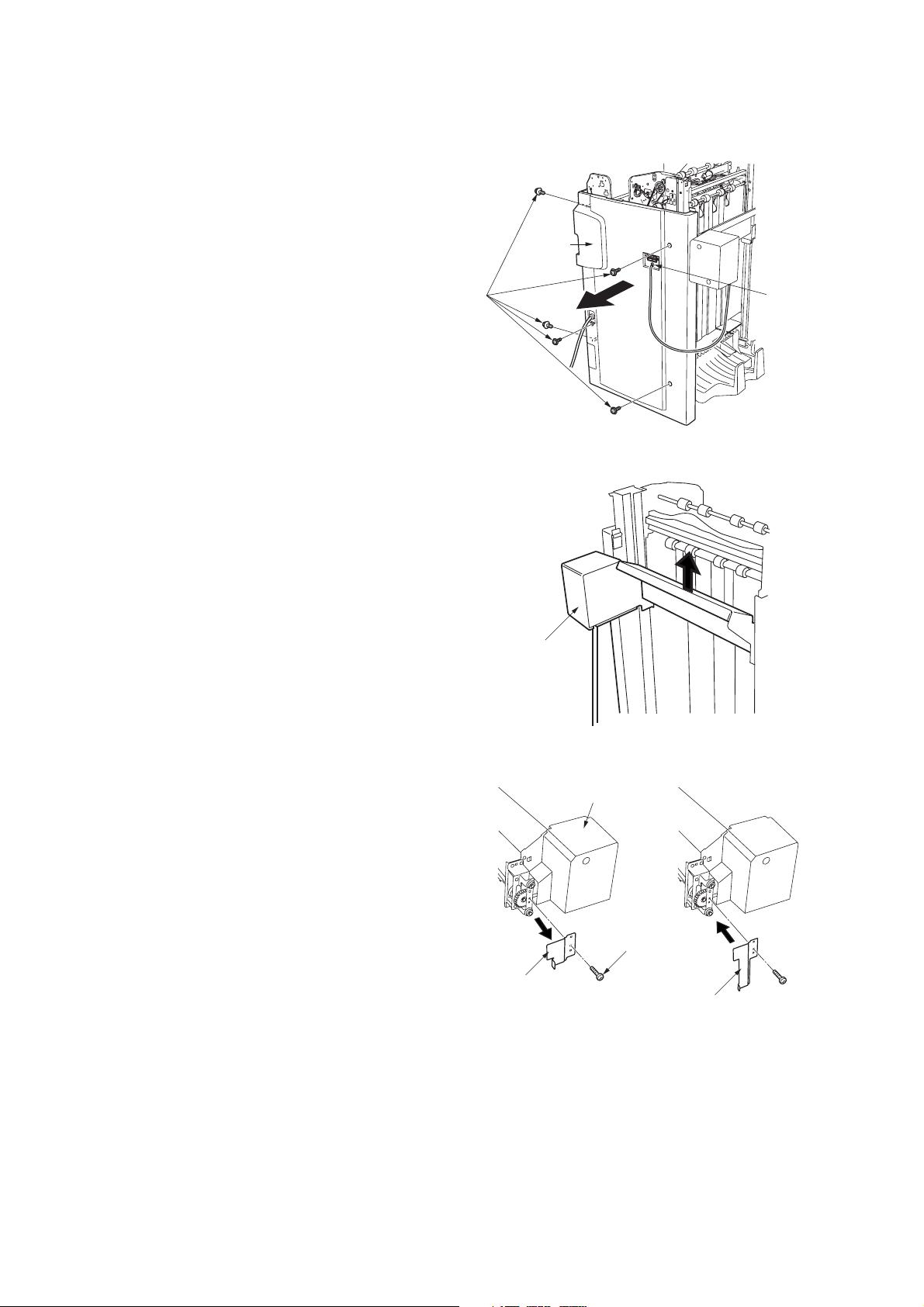

When installing the multi job tray and centerfold unit as a set, follow steps 6 to 18. When installing the multi job tray only, skip

to step 19.

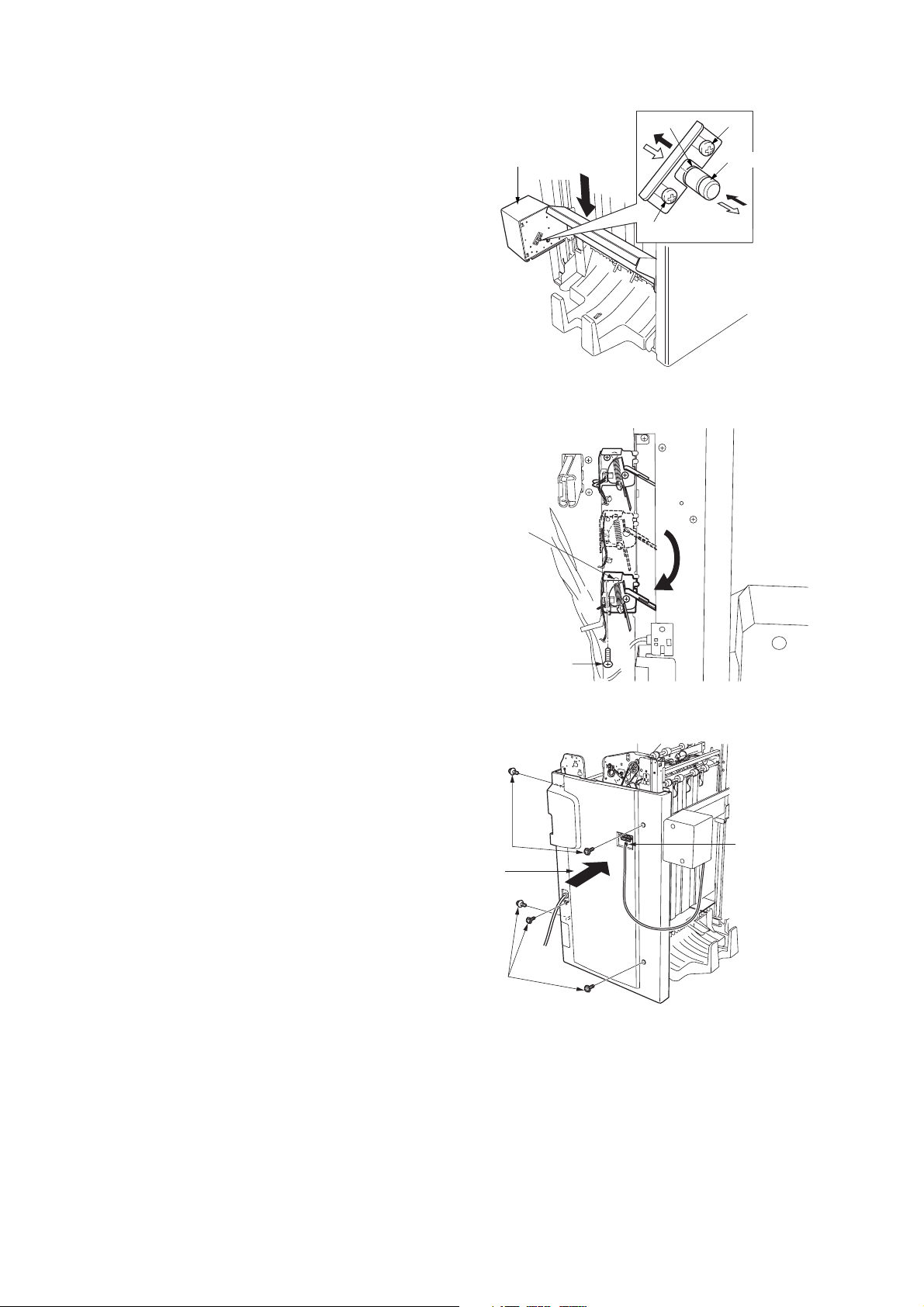

6. Disconnect the 2-pin connector of the main

tray unit.

7. Remove the five screws locking down the

finisher rear cover followed by the cover.

Rear

cover

8. Raise the main tray unit by hand and detach

from the finisher.

Screws

2-pin

connector

Figure 1-2-22

Main tray unit

9. Remove the screw locking the tray detection

plate to the main tray unit. Replace the tray

detection plate with tray detection plate A

included in the package.

Figure 1-2-23

Main tray unit

Screw

Tray detection plate

Tray detection plate A

Figure 1-2-24

1-2-10

Page 27

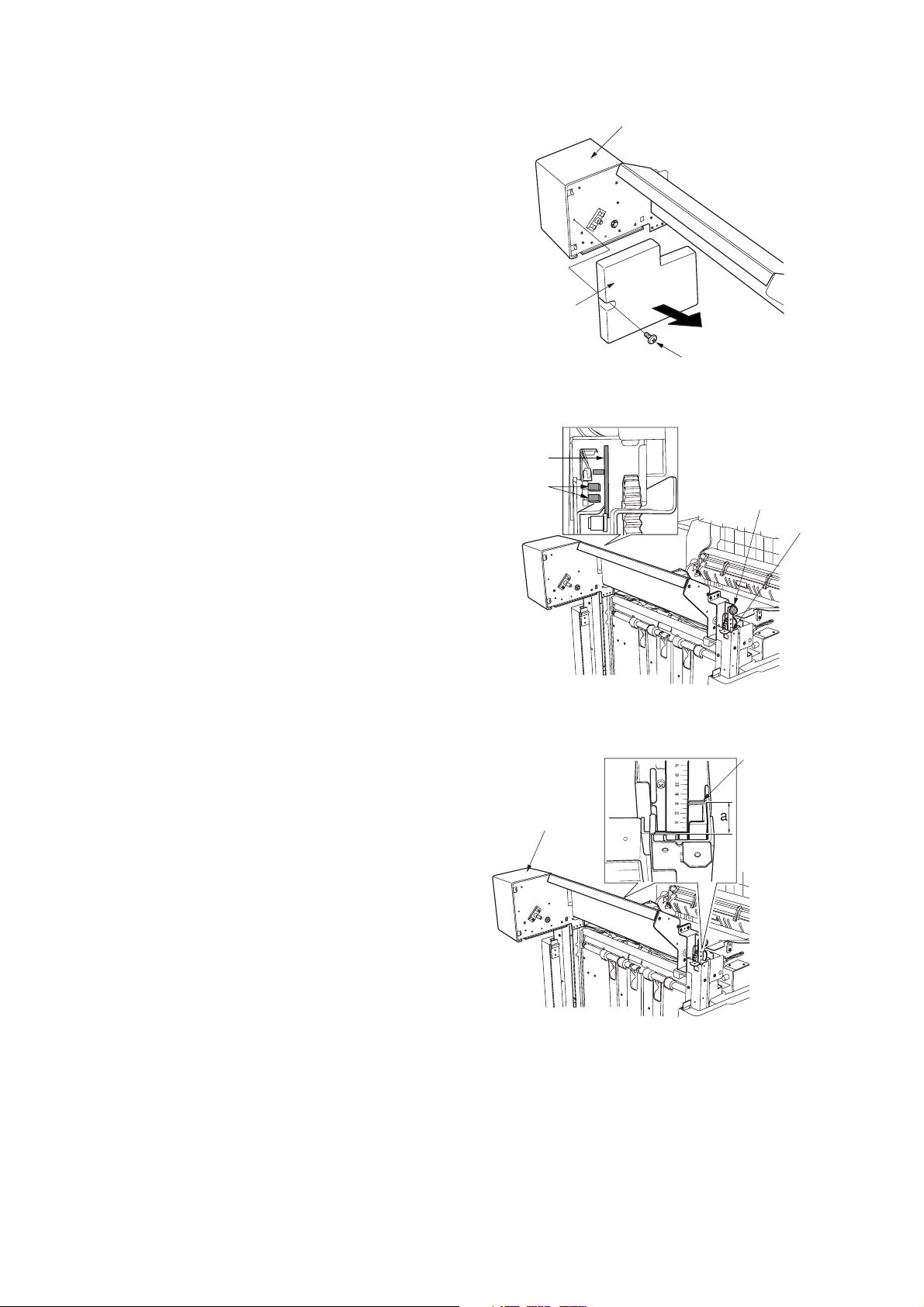

3B8/9

10. Remove the screw locking the motor front

cover to the main tray unit followed by the

cover.

11. Attach the main tray unit to the finisher by

inserting the main tray pulleys at the unit front

and rear into the rails on the finisher.

Note: Be sure that tray detection plate A does

not make contact with the sensors.

Main tray unit

Motor front cover

Screw

Figure 1-2-25

Tray detection

plate A

Sensors

Main tray pulley

Rail

12. Measure the gaps “a” between the main tray

unit and finisher rail ends against the scale to

make sure that “a” is same at the front and

rear.

Note: If gap “a” is not the same at the unit front

and rear, install the main tray unit again so that

it becomes the same.

Figure 1-2-26

Rail end

Main tray unit

Figure 1-2-27

1-2-11

Page 28

3B8/9

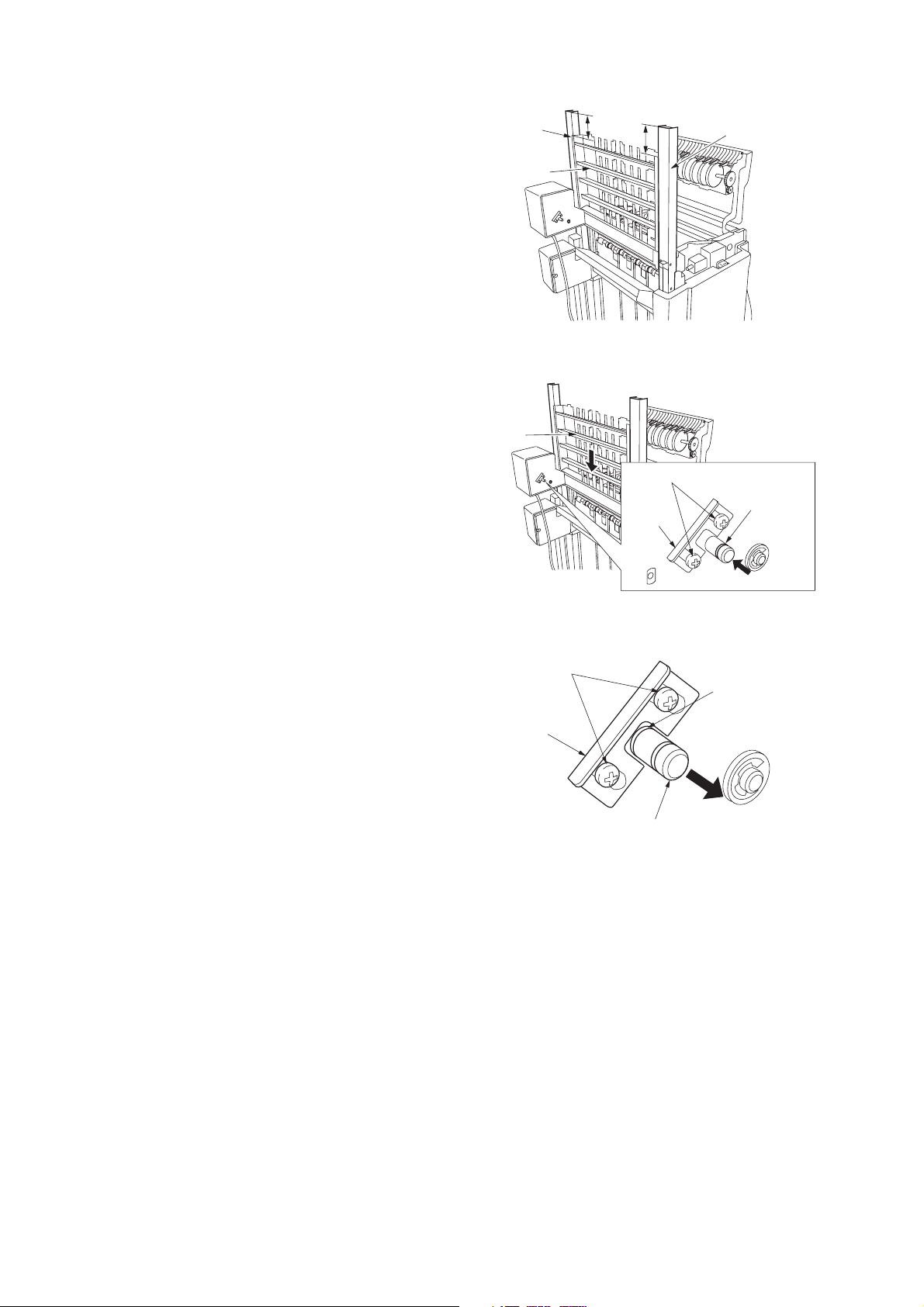

13. Loosen the two screws locking down the

retainer. With the retainer slid upward, push in

the gear shaft while holding the bottom of the

main tray unit. Then, lower the main tray unit to

its lowest position.

14. Pull out the gear shaft, slide the retainer to its

original position and retighten the two screws.

Note: Make sure the gear shaft is positioned

so that the retainer will be engaged in groove

“b” on the shaft.

15. Insert the two pegs of the motor front cover of

the main tray unit into the square holes and

lock down with the screw.

16. Remove the screw locking the mid-point

detection sensor to the finisher rear panel.

Lower the sensor and lock it down again.

Main tray unit

Mid-point

detection sensor

Screw

Figure 1-2-28

b

Screw

Gear shaft

17. Reattach the finisher rear cover with the five

screws.

18. Connect the 2-pin connector of the main tray

unit.

Screws

Rear cover

Screws

Screw

Figure 1-2-29

2-pin connector

Figure 1-2-30

1-2-12

Page 29

3B8/9

19. Remove the three blue screws locking the

base retainer to the multi job tray followed by

the retainer.

20. Attach the bin front guide plate and bin rear

guide plate to the finisher by inserting the

claws on plates into the finisher frame and lock

in place with three BVM4 × 6 binding screws

each.

Base retainer

Bin rear

guide plate

BVM4 × 6

binding screws

Multi job tray

Blue screws

Figure 1-2-31

Bin front guide plate

21. Attach the multi job tray to the bin front guide

plate and bin rear guide plate by inserting the

six pulleys at the tray front and rear into the

plates.

Note: Make sure that the shading plate at the

rear of the multi job tray does not make contact

with the sensor.

BVM4 × 6

binding screws

Multi job tray

BVM4 × 6

binding screws

Figure 1-2-32

Shading

plate

Sensor

Bin front guide plate

Pulleys

Bin rear

guide plate

Pulleys

Figure 1-2-33

1-2-13

Page 30

3B8/9

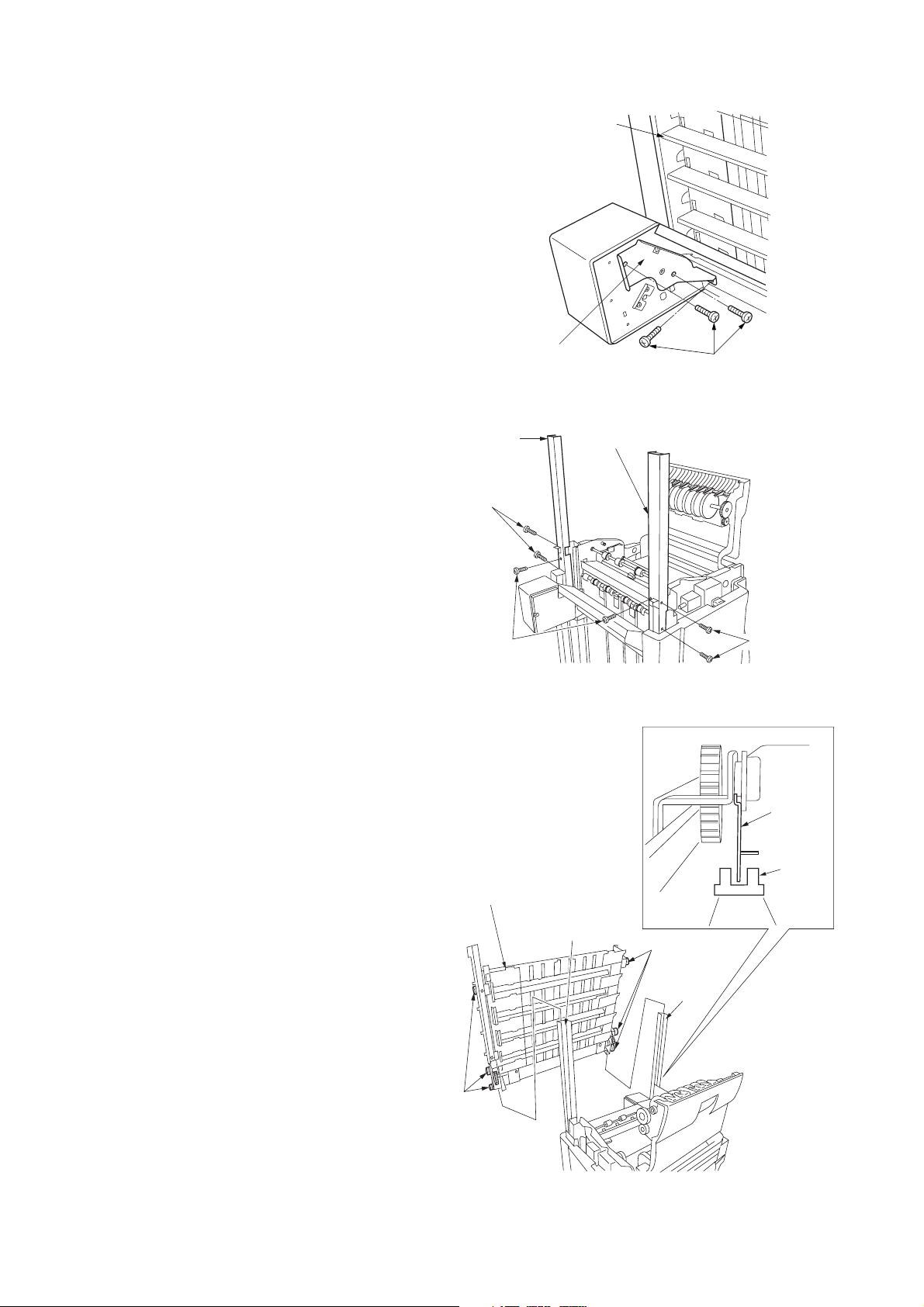

22. Measure the height “a” against the scale to

make sure that the multi job tray is positioned

properly to stay level from front to rear.

If the height “a” is not the same at the front and

rear, the multi job tray may not be positioned

on a level plane. Install the tray again.

23. Loosen the two screws.

24. With the retainer slid upward, push in the gear

shaft while holding the bottom of the multi job

tray. Then, lower the multi job tray by about

30 mm.

Bin rear

guide plate

Multi job tray

Multi job tray

a

a

Figure 1-2-34

Screws

Retainer

Bin front

guide plate

Gear shaft

25. Pull out the gear shaft, slide the retainer to its

original position and retighten the two screws.

Note: Make sure the gear shaft is positioned

so that the retainer will be engaged in groove

“b” on the shaft.

Figure 1-2-35

Screws

b

Retainer

Gear shaft

Figure 1-2-36

1-2-14

Page 31

3B8/9

26. Attach the bin guide plate retainer with two

BVM4 × 6 binding screws.

27. Reattach the top cover with the nine screws

removed in step 2, keeping the upper cover

open halfway to enable proper attaching.

28. Attach the right cover with four M4 × 8 TP

screws.

BVM4 × 6 binding screws

Bin guide

plate retainer

Figure 1-2-37

Right cover

M4 × 8 TP

screws

M4 × 8

TP screws

29. Attach the left cover by inserting the two pegs

into the square holes, and lock in place with

two M4 × 8 TP screws.

Figure 1-2-38

M4 × 8 TP screws

Left cover

Peg

Peg

Figure 1-2-39

1-2-15

Page 32

3B8/9

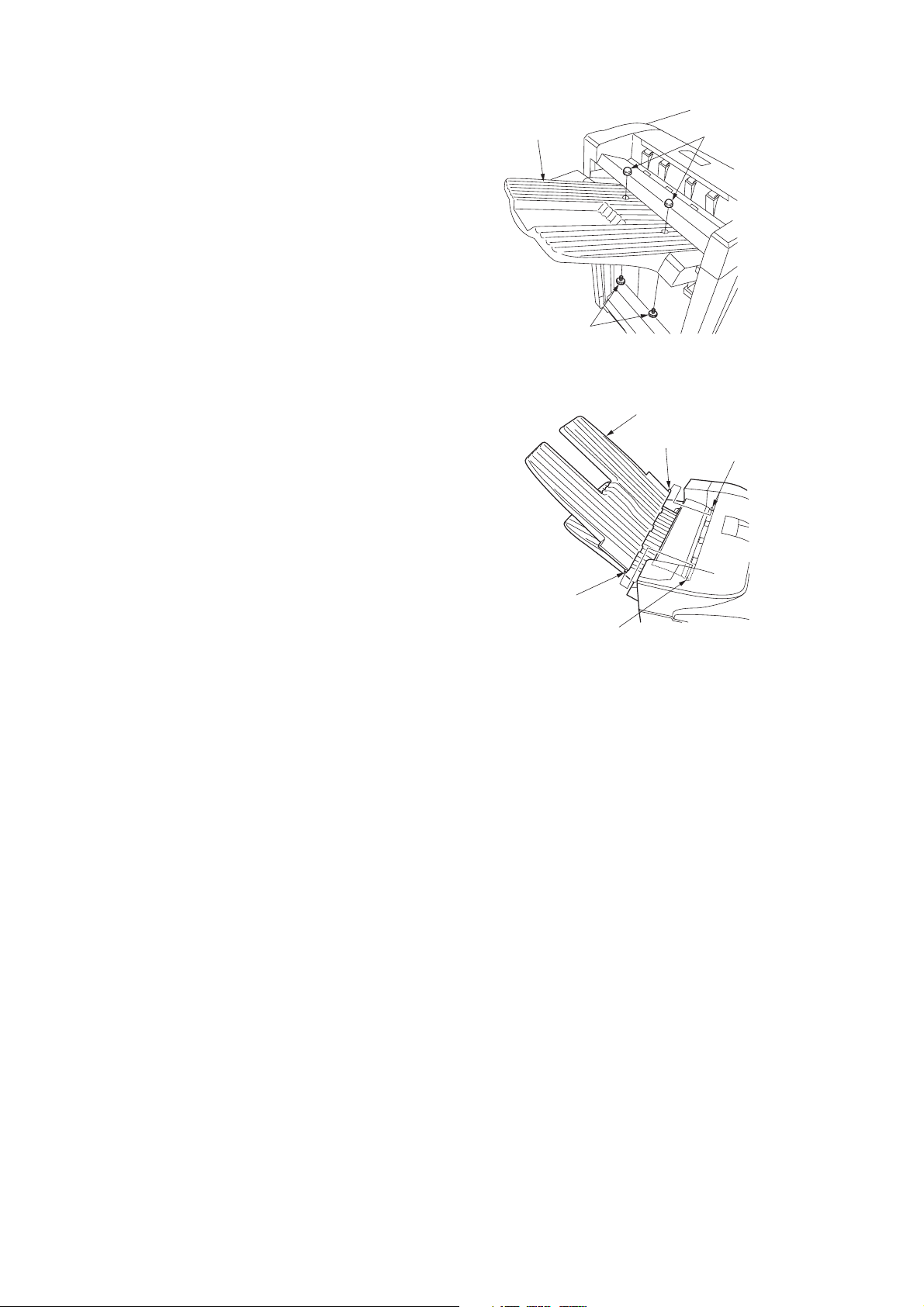

30. Affix a tray No. label to each of the five job

trays.

31. Attach the job tray with the label No.1 affixed at

the uppermost shelf of the multi job tray by

inserting the three claws into the square holes.

Job tray

Tray No. label

Figure 1-2-40

Claws

Job tray

Figure 1-2-41

32. Connect the 3-pin connector at the back side

of the job tray.

33. Fit the cable of the 3-pin connector to the

inside of the job tray and lock down with the

cable retainer.

34. Slide the job tray lid into position and lock in

place by inserting the two pegs into the square

holes.

Note: Make sure that the cable is tidily fitted

and not caught in the job tray lid.

35. Repeat steps 31 to 34 to attach the other four

job trays.

Note: Attach the job trays in the order of the

tray No. labels so that the tray with the label

No.1 is at the uppermost shelf, No.2 at the

second and so forth.

Peg

3-pin connector

Job tray

Job tray lid

Peg

Cable

Cable retainer

1-2-16

Figure 1-2-42

Page 33

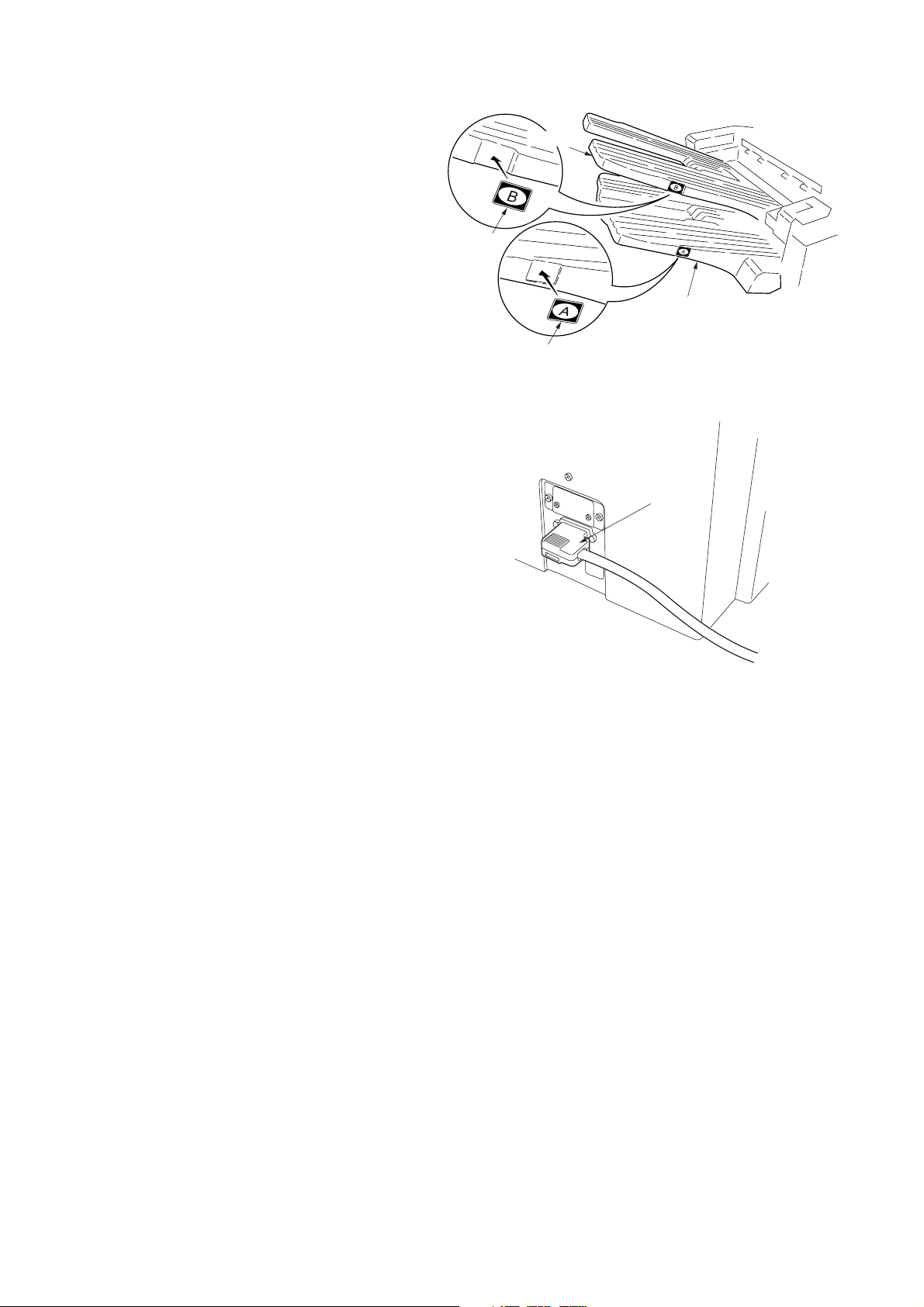

36. Attach the motor front cover by inserting the

two pegs into the square holes, and lock in

place by the M4 × 8 TP screw.

3B8/9

Pegs

37. Connect the signal cable of the multi job tray to

the finisher connector.

38. Plug the copier’s power cable into a wall outlet

and turn the copier on from the main switch.

39. Make a test print and check the multi job tray

performs properly.

Motor front cover

M4 × 8 TP screw

Figure 1-2-43

Signal cable

Figure 1-2-44

1-2-17

Page 34

3B8/9

(3) Centerfold unit

Á

ˇ

Ç

&

^

%

#

ı

‰

´

„

8

@

0

9

Œ

‚

·

°

‡

fl

Ø

*

◊

ˆ

ı

6

5

$

4

7

Â

!

˝

Ô

ı

˜

Ú

Ò

Ï

˝

¸

Í

Ó

˜

(

‹

˛

)

›

1

∏

⁄

fi

¤

Î

Å

1 Centerfold unit

2 Release pole assembly

3 Release stopper pole assembly

4 Storage cover

5 Right cover

6 Left cover

7 Release handle

8 Sliders

9 Release lever

0 Release pole retainer

! Release lever actuating plate

@ Backstop

# Detection PI douser

$ Unit transport handle

% Unit lock hook

^ Unit lock rod

& Tray stopper

* Eject guide upper spacer

( Unit insertion label

¸

2

3

Figure 1-2-45 Centerfold unit package

) Jam correction label

⁄ Jam correction label (Japan)

¤ Jam correction label (export)

‹ Operation label 1

› Operation label 2

fi Operation label 3

fl Large stop rings

‡ Medium stop ring

° Small stop ring

· Pins

‚ Small springs

ΠLarge spring

„ BVM4 × 6 bronze binding screws

´ M4 × 6 TP-A bronze screws

‰ M4 × 10 TP-A bronze screw

ˇ BVM3 × 5 bronze binding screw

Á M3 × 10 tapping screws

¨ Outer case

ˆ Accessory case

¨

Ø Air cap bags

∏ Unit bottom pad

Å Unit left spacer

Í Unit rear spacer

Î Unit front spacer

Ï Unit case

˝ Top and bottom pads

Ó Left spacer

Ô Right spacer

Arm spacer

Ò Centerfold blade spacers

Ú Installation guide

¸ Barcode labels

˛ Dust cover

Ç Vinyl bag

◊ Polyethylene bag

ı Vinyl bags

˜ Polyethylene bags

Air cap bag

1-2-18

Page 35

3B8/9

Installation procedure

Before installing the centerfold unit, turn the copier

off from the main switch and unplug the power

cable from the wall outlet.

When unpacking or installing, hold the centerfold

unit by “a” indicated in the illustration. Do not hold it

by “b” at the center of the unit.

When installing the multi job tray and centerfold

unit as a set, first install the centerfold unit and

then the multi job tray.

1. Disconnect the 2-pin connector of the main

tray unit.

2. Remove the five screws locking down the

finisher rear cover followed by the cover.

Screws

b

a

a

Figure 1-2-46

Rear

cover

2-pin

connector

3. Disconnect the 3-pin connector of the sensor.

Figure 1-2-47

3-pin connector

Figure 1-2-48

1-2-19

Page 36

3B8/9

4. Remove the screw from the rear of the

reinforcing plate.

5. Insert the tray stopper and lock it down with the

screw removed in step 4 and the BVM4 × 6

bronze binding screw.

Note: When inserting the tray stopper, take

care not to damage the sensors.

6. Reconnect the 3-pin connector that was

disconnected in step 3.

7. Reattach the finisher rear cover with five

screws.

8. Connect the 2-pin connector of the main tray

unit.

Tray stopper

BVM4 × 6

bronze binding

screw

Screw

Figure 1-2-49

9. Remove the four screws locking down the

guide plate followed by the plate.

10. Remove the left lower shaft from the finisher

side plate.

Screws

Rear cover

Screws

2-pin connector

Figure 1-2-50

Guide plate

Screws

Left lower shaft

Figure 1-2-51

1-2-20

Page 37

3B8/9

11. Open the front cover. Remove the screw

locking down the retainer followed by the

retainer.

12. While keeping the front cover perpendicular to

the copier, detach the cover by raising it

vertically in the direction of the arrow.

13. Hang the backstop over the claw on the side

plate and fit with two pins.

14. Attach one end of the small spring to the

backstop and hang the other end over the

hook inside the machine.

Front cover

Figure 1-2-52

Backstop

Screw

Retainer

Hook

Claw

Pins

15. Insert the rear end of the release stopper pole

assembly into the bypass hole and the front

end into the mounting hole.

Note: When attaching the assembly, make

sure the release stopper is orientated

correctly.

16. Insert the rear end of the release stopper pole

assembly already inserted through the bypass

hole into the mounting hole on the opposite

side.

Hook

Backstop

Small

spring

Figure 1-2-53

Mounting hole

Front end

Bypass hole

Release

stopper

Mounting hole

Figure 1-2-54

Release stopper

pole assembly

Front end

1-2-21

Page 38

3B8/9

p

y

17. Fit the small stop ring into the groove on the

left side of the release stopper pole assembly.

Push the release stopper pole assembly in the

direction of the arrow.

18. Attach the release lever to the release stopper

pole assembly with the BVM3 × 5 bronze

binding screw.

Small stop ring

Groove

Release stopper

ole assembl

Figure 1-2-55

BVM3 × 5 bronze

binding screw

Release lever

Release stopper

pole assembly

19. Loosely attach the release pole retainer with

an BVM4 × 6 bronze binding screw.

Figure 1-2-56

Release pole

retainer

BVM4 × 6 bronze binding screw

Figure 1-2-57

1-2-22

Page 39

20. Insert the release lever actuating plate through

the hole to the inside of the machine and fit

with two pins. Then, make sure that the

release lever actuating plate slides leftward

and rightward.

3B8/9

Release

lever

actuating

plate

21. Attach one end of the small spring to the

release lever actuating plate and hang the

other end over the hook on the side plate.

22. Coat the release lever actuating plate with

TEMP1 or the similar grease in the indicated

area “a”.

Pin

Release lever

actuating plate

Hole

Release lever

actuating plate

Pin

Figure 1-2-58

Release lever

actuating plate

Hook

Small spring

Figure 1-2-59

a

1-2-23

Page 40

3B8/9

23. Insert one end of the release pole assembly

into the square bypass hole and the other end

into the hole with the projection, with the D-cut

of the release pole assembly aligned with the

projection.

24. Insert the end of the release pole assembly

already inserted through the square bypass

hole into the mounting hole.

Mounting hole

Bypass

hole

Release pole

assembly

Bypass hole

Mounting hole

Hole

D-cut

25. Fit the medium stop ring onto the release pole

assembly. Then, make sure the release pole

assembly can rotate slightly.

26. Attach the release handle to the release pole

assembly at the machine front side with an

M4 × 10 TP-A bronze screw.

Release pole assembly

Figure 1-2-60

Medium stop ring

Release pole

assembly

Figure 1-2-61

Front end

Release

handle

1-2-24

M4 × 10 TP-A

bronze screw

Figure 1-2-62

Page 41

3B8/9

27. Place the slider on the projections on the

finisher rear side-plate and lock down with

three BVM4 × 6 bronze binding screws.

Note: Insert the screws from the round holes

on the eject side of the finisher.

28. Place the slider on the projections on the

finisher front side-plate and lock down with

three BVM4 × 6 bronze binding screws.

Note: Insert the screws from the round holes

on the eject side of the finisher.

29. Pull out the intermediate tray.

30. Fit the large stop ring onto the unit lock rod.

31. Attach the unit lock hook to the guide stay with

the unit lock rod.

Projections

BVM4 × 6 bronze

binding screws

Unit

lock rod

Slider

Large stop

ring

BVM4 × 6 bronze

binding screws

Projections

Sliders

Figure 1-2-63

Guide stay

Guide stay

Unit lock hook

Unit lock hook

Intermediate tray

Figure 1-2-64

1-2-25

Page 42

3B8/9

32. Fit the large stop ring onto the lower part of the

unit lock rod.

33. Hang one end of the large spring over the hook

on the unit lock hook and the other end over

the hook on the guide stay.

34. Remove the eight strips of fixing tape and the

cushioning material from the centerfold unit.

Hook

Large spring

Fixing tape strip

Guide stay

Unit lock rod

Large stop ring

Unit lock hook

Hook

Figure 1-2-65

Fixing tape strip

35. Pull the left and right sliders out until they stop.

Attach the centerfold unit on the pins of the

sliders.

Note: Hold the centerfold unit by “a” indicated

in the illustration. Do not hold it by “b” at the

center of the unit.

Fixing tape strip

Cushioning material

Fixing tape strips

Fixing tape

strips

Sliders

Figure 1-2-66

b

a

Fixing tape strip

Centerfold

a

unit

Pins

Fixing tape strip

1-2-26

Figure 1-2-67

Page 43

36. Slide the centerfold unit in the direction of the

pp

arrow.

37. Loosen the two screws and push the retainer

in the direction of the arrow and retighten the

screws.

Screw

Retainer

3B8/9

Screw

Retainer

38. Attach the left and right covers by inserting the

catches of the left and right covers into the

square holes on the front and rear side-plates,

respectively, of the centerfold unit with one

M4 × 6 TP-A bronze screw each.

Screw

M4 × 6 TP-A

bronze screw

Left cover

Screw

Centerfold unit

Figure 1-2-68

M4 × 6 TP-A

bronze screw

Right cover

Centerfold unit

39. Attach the eject guide upper spacer with the

three M3 × 10 tapping screws.

Figure 1-2-69

M3 × 10 tapping screws

Eject guide

u

Figure 1-2-70

er spacer

1-2-27

Page 44

3B8/9

40. Attach the storage cover to the centerfold unit

by inserting the projection of the tray into the

hole inside the unit.

41. Engage the projection of the detection PI

douser with the cutout on the centerfold unit

rear panel and lock down the douser with the

BVM4 × 6 bronze binding screw.

Note: When inserting the centerfold unit, make

sure that the detection PI douser does not

make contact with the finisher’s centerfold unit

set switch. If it does, bend the douser with your

hand as much as needed so that the contact is

avoided.

Centerfold unit

Hole

Projection

Storage cover

Figure 1-2-71

42. Pull the release lever in the direction of the

arrow and push in the centerfold unit.

Detection PI douser

BVM4 × 6 bronze

binding screw

Figure 1-2-72

Release lever

Centerfold unit

Figure 1-2-73

1-2-28

Page 45

43. Push the release lever actuating plate.

44. Push in the centerfold unit until it stops.

3B8/9

Release lever actuating plate

Centerfold unit

Figure 1-2-74

45. Push the release stopper pole assembly in the

direction of the arrow and tighten the BVM4 × 6

bronze binding screw that loosely attached the

release pole retainer.

46. Attach the unit transport handle with an

BVM4 × 6 bronze binding screw.

Release pole retainer

Release stopper pole assembly

BVM4 × 6 bronze binding screw

Figure 1-2-75

Unit transport

handle

BVM4 × 6 bronze

binding screw

Figure 1-2-76

1-2-29

Page 46

3B8/9

47. Affix the jam correction label on the rating plate

of the finisher front side-plate, in a point 15 mm

from each “a” and “b”.

Jam correction label

Rating plate

Figure 1-2-77

b

15 mm

a

15 mm

48. Reattach the front cover.

49. Affix the unit insertion label to the right cover

aligning the label with the left end and bottom

of the cover.

50. Affix operation labels 1 and 2 to the finisher

front panel as shown in the illustration.

Unit insertion

label

Operation label 1

Right cover

Figure 1-2-78

15 mm

5 mm

Operation

label 2

1-2-30

Figure 1-2-79

Page 47

51. Affix operation label 3 to the finisher’s

intermediate tray handle as shown in the

illustration.

52. Affix the jam correction label (export) over the

existing label on the inside of the finisher front

cover, as shown in the illustration.

3B8/9

15 mm

Operation label 3

Figure 1-2-80

53. Plug the copier’s power cable into a wall outlet

and turn the copier on from the main switch.

54. Make a test copy to check that the centerfold

unit operates correctly.

Adjustment

After installing the centerfold unit, perform the following adjustment.

• Adjusting the paper folding position

See page 1-5-5.

Jam correction

label (export)

Figure 1-2-81

1-2-31

Page 48

3B8/9

(4) Punch Unit

2

#

(

$

0

!

&

3

5

%

@

#

1

9

6

Figure 1-2-82 Punch unit package

1 Punch unit

2 Paper conveying unit

3 Punch waste box

4 Paper conveying unit upper guide

5 M4 × 6 TP screws

6 Outer case

7 Bottom pad A

8 Bottom pad B

9 Upper left pad

0 Upper right pad

*

#

8

7

4

^

! Right pad

@ Spacer

# Polyethylene bags

$ Installation guide

% Vinyl bag

^ Bar code labels

& Polyethylene bag

* Rust-proofing sheet

( Supply parts check list

1-2-32

Page 49

3B8/9

Procedure

Before installing the punch unit, turn the copier off from the main switch and unplug the power cable from the wall outlet.

1. Remove the two screws locking down the top

cover lid followed by the lid.

2. Open the upper cover and remove the nine

screws locking down the top cover followed by

the top cover.

3. Open the front cover.

4. Remove the three screws locking down the

right inner cover followed by the cover.

Top cover lid

Screws

Screws

Upper cover

Screw

Screws

Top cover

Figure 1-2-83

Right inner cover

Screws

5. Remove the bushing from the side plate.

6. Disconnect the 7-pin connector and pass it

through the hole where the bushing was fit, to

the inside of the side plate.

Bushing

Figure 1-2-84

Side plate

7-pin connector

Figure 1-2-85

1-2-33

Page 50

3B8/9

7. Detach the cables of the 2-pin connector and

9-pin connector on the finisher rear from the

wire saddle.

8. Remove the four screws locking down the

guide plate followed by the plate.

2-pin

connector

9-pin connector

Screws

Wire saddle

2-pin connector

9-pin

connector

Wire saddle

Figure 1-2-86

Screws

9. Set the paper conveying unit on the two

projections and lock down with the four screws

removed in step 8.

Guide plate

Screws

Figure 1-2-87

Paper conveying unit

Projection

Figure 1-2-88

Projection

Screws

1-2-34

Page 51

3B8/9

p

10. Fit the 7-pin connector and 3-pin connector of

the paper conveying unit to the outside of the

side plate, and connect them to the finisher

cable.

11. Reattach the bushing to the side plate.

12. Attach the paper conveying unit upper guide to

the paper conveying unit with two M4 × 6 TP

screws.

Bushing

7-pin connector

3-pin connector

Side plate

Figure 1-2-89

M4 × 6 TP screws

13. Attach the punch unit to the paper conveying

unit with two M4 × 6 TP screws.

Note: Align the center of the markings on the

front side with the center of the slot.

Paper conveying

unit

Pa

M4 × 6

TP screw

er conveying unit upper guide

Figure 1-2-90

M4 × 6

TP screw

Slot

Punch unit

Figure 1-2-91

1-2-35

Page 52

3B8/9

p

14. Connect the cable of the 2-pin connector to the

2-pin connector of the clutch.

15. Bind the cable of the 9-pin connector at the

finisher rear with the wire saddle and connect

the connector to CN1 on the motor PCB.

16. Connect the 3-pin connector at the front side of

the finisher to the 3-pin connector of the

solenoid.

Motor PCB

Wire saddle

Solenoid

2-pin connectors

Figure 1-2-92

Wire saddle

9-

in connector

Cable

CN1

3-pin

connector

17. Attach the punch waste box to the rails.

18. Reattach the right inner cover, top cover and

top cover lid.

19. Plug the copier’s power cable into a wall outlet

and turn the copier on from the main switch.

Adjustment

After installing the punch unit, perform the following adjustment.

• Centering punch-holes

See page 1-5-6.

• Setting margin from leading edge to punch-holes

See page 1-5-7.

3-pin

connector

Figure 1-2-93

Punch waste box

Rails

Figure 1-2-94

1-2-36

Page 53

1-3-1 Maintenance mode

(1) Executing a maintenance item

3B8/9

Start

Use the numeric keys

to enter “10871087”.

Use the numeric keys or the cursor

up/down keys to enter the number of

the maintenance item to be executed.

Press the start key.

That maintenance item will be run.

Press the stop/clear key.

Yes

Run that item again?

- - - - - Entering the maintenance mode

- - - - - Selecting the maintenance item

No

Yes

Use the numeric keys or the cursor

up/down keys to enter “001”, and then

press the start key.

Run another

maintenance item?

No

End

- - - - - Exiting the maintenance mode

1-3-1

Page 54

3B8/9

(2) Contents of maintenance mode items

Maintenance

item No.

U019 Displaying the ROM version

Description

Displays the part number of the ROM fitted to each PCB.

Purpose

To check the part number or to decide if the ROM version is new from the last digit of the number.

Method

Press the start key. The last eight digits of the part number indicating the ROM version are displayed.

Display Description

MAIN* Main ROM IC

MMI* Operation ROM IC

LANGUAGE(Stand.)* Standard language ROM IC

LANGUAGE(Option)* Optional language ROM IC

MAIN BOOT* Boot of main ROM IC

MMI BOOT* Boot of operation ROM IC

NETWORK SCANNER* Network scanner ROM IC

FINISHER Finisher ROM IC

FINISHER Boot of finisher ROM IC

* For the copier.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Description

1-3-2

Page 55

3B8/9

Maintenance

item No.

U240 Checking the operation of the finisher

Description

Turns each motor, clutch and solenoid of the document finisher ON.

Purpose

Used to check the operation of each motor, clutch and solenoid of the document finisher.

Method

1. Press the start key. The screen for selecting an item will be displayed.

2. Use the cursor up/down keys to select the clutch or solenoid that you want to check the operation for.

The display for the selected motor, clutch or solenoid will be highlighted, and the operation will start.

Display Motors, clutches and solenoids

CONV MOTOR Paper conveying motor (PCM)

PUNCH MOTOR Punch motor (PUNM)

WID T MOTOR Font/Rear upper side-registration guide motors

WID U MOTPR Lower side-registration guide motor (SRGM-L)

MTRAY MOTOR Main tray elevation motor (MTEM)

JTRAY MOTOR Multi job tray elevation motor (MJTEM)

BRA A SOL Feedshift solenoid A (FSSOLA)

BRA B SOL Feedshift solenoid B (FSSOLB)

BRA C SOL Feedshift solenoid C (FSSOLC)

PUNCH P SOL Punch solenoid (PUNSOL)

MTRAY SOL Paper holder solenoid (PHSOL)

EJEC SOL Eject guide solenoid (EGSOL)

PUNCH I SOL Paper entry guide solenoid (PEGSOL)

MIDDLE SOL Movable guide solenoid (MGSOL)

DRAM CL Siding drum clutch (SDCL)

FEED IN CL Paper conveying clutch (PCCL)

PUNCH CL Punch clutch (PUNCL)

SADDLE ROL1 Main motor (MM)

SADDLE ROL2 Main motor (MM)

SADDLE BLD Centerfold blade motor (CBLM)

SADDLE INI1 Centering plate motor (CPM)

SADDLE INI2 Side-registration guide motor (SRGM)

SADDLE SOL Pressure release solenoid (PRSOL)

3. To turn ON a clutch or solenoid with the motor driving, press the interrupt key before selecting the clutch or

solenoid.

* The driving motor will start operation, and the selected clutch or the solenoid will remain ON until the

interrupt key is pressed again.

4. To stop motor driving, press the interrupt key again.

5. To return to the screen for selecting an item, press the stop/clear key with the motor stopped.

Completion

Press the stop/clear key with the operation stopped. The screen for selecting a maintenance item No. is

displayed.

Description

(SRGM-FU/SRGM-RU)

1-3-3

Page 56

3B8/9

Maintenance

item No.

U241 Checking the operation of the switches of the finisher

Description

Displays the status of each switch of the document finisher.

Purpose

Used to check the operation of each switch of the document finisher.

Method

1. Press the start key to run the maintenance item.

2. Turn each switch ON manually.

* When a switch is detected to be in the ON position, the display for that switch will be highlighted.

Display Switches

CONV Paper entry sensor (PES)

EJECT SUB Paper ejection sensor (PEJS)

CONV TRAY Intermediate tray paper conveying sensor (ITPCS)

EJECT MAIN Sub tray paper ejection sensor (STPES)

TRAY U PAP Upper paper sensor (PS-U)

TRAY L PAP Lower paper sensor (PS-L)

MTRAY U LMT Main tray upper limit detection sensor (MTULDS)

MTRAY L LMT Main tray lower limit detection sensor (MTLLDS)

MTRAY POS Main tray paper upper surface detection light

emitting/intercepting sensors (MTPUSDLES/MTPUSDLIS)

MTRAY PUSH Paper holder detection sensor (PHDS)

MTRAY OVER1 Main tray load 1000 detection sensor (MTLDS-10)

MTRAY OVER2 Main tray load 1500 detection sensor (MTLDS-15)

MTRAY OVER3 Main tray load 3000/2000 detection sensors

(MTLDS-30/MTLDS-20)

JOB U LMT Multi job tray upper limit detection sensor (MJTULDS)

JOB L LMT Multi job tray lower limit detection sensor (MJTLLDS)

JOB SAFETY Multi job tray front/rear switches (MJTSW-F/MJTSW-R)

JOB POS Multi job tray position sensor (MJTPS)

JOB OVER Multi job tray paper upper surface detection light

emitting/intercepting sensors (MJTPUSDLES/MJTPUSDLIS)

JOB PAP1 Paper detection switch 1 (PDSW1)

JOB PAP2 Paper detection switch 2 (PDSW2)

JOB PAP3 Paper detection switch 3 (PDSW3)

JOB PAP4 Paper detection switch 4 (PDSW4)

JOB PAP5 Paper detection switch 5 (PDSW5)

SDL CONV Centerfold unit paper entry sensor (CUPES)

SDL EJECT Eject switch (ESW)

SDL PAP Eject tray paper detection switch (ETPDSW)

SDL BIN PAP Inside tray detection sensor (ITDS)

Description

1-3-4

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Page 57

3B8/9

Maintenance

item No.

U248 Setting the paper eject device

Description

Adjusts the amount of slack in the paper for finisher punch mode, the booklet stapling position, and the center

folding position for the copier.

Purpose

• Adjustment of the amount of slack in the paper in punch mode

Adjusts the amount of slack in the paper while in the punch section if, in punch mode, paper jams or is

Z-folded frequently due to too much slack in the paper, or, the position of punch holes varies due to too little

slack in the paper.

• Adjustment of booklet stapling position

Adjusts the booklet stapling position in the stitching mode if the position is not proper.

• Adjustment of center folding position

Adjusts the center folding position in the stitching mode if the position is not proper.

Start

Press the start key. The screen for selecting an item is displayed.

Display Operation

PUNCH TIMING Adjustment of the amount of slack in the paper in punch mode

SADDLE STAPLE ADJUST Booklet stapling position adjustment

SADDLE ADJUST Adjustment of center folding position

Setting the amount of slack in the paper

1. Select PUNCH TIMING on the screen for selecting an item.

2. Change the setting using the cursor up/down keys.

Description

Description Setting range Initial setting

Amount of slack in the paper –15 to +15 0

If the position of punch holes varies, increase the setting to make the amount of slack larger.

If paper jams or is Z-folded frequently, decrease the setting to make the amount of slack smaller.

Changing the value by 1 changes the amount of slack by 1.25 mm.

3. Press the start key. The value is set.

4. To return to the screen for selecting an item, press the stop/clear key.

Setting the booklet stapling position

1. Select SADDLE STAPLE ADJUST on the screen for selecting an item.

2. Select the size to be set.

3. Change the setting using the cursor up/down keys.

Display Description Setting range Initial setting

A4R Adjustment of booklet stapling position for A4R size –125 to +125 0

B4R Adjustment of booklet stapling position for B4R size –125 to +125 0

A3R Adjustment of booklet stapling position for A3R size –125 to +125 0

LTR Adjustment of booklet stapling position for LTR size –125 to +125 0

LDR Adjustment of booklet stapling position for LDR size –125 to +125 0

Change in value per step: 0.25 mm

1-3-5

Page 58

3B8/9

Maintenance

item No.

U248

4. Press the start key. The value is set.

5. To return to the screen for selecting an item, press the stop/clear key.

Setting the center folding position

1. Select SADDLE ADJUST on the screen for selecting an item.

2. Select the size to be set.

3. Change the setting using the cursor up/down keys.

Description

Left stapling Right stapling Adjustment method

Proper

Decrease the

preset value.

Upper side is longer. Lower side is longer.

Increase the

preset value.

Lower side is longer. Upper side is longer.

Display Description Setting range Initial setting

A4R Adjustment of center folding position for A4R size –4 to +3 0

B4R Adjustment of center folding position for B4R size –4 to +3 0

A3R Adjustment of center folding position for A3R size –4 to +3 0

LTR Adjustment of center folding position for LTR size –4 to +3 0

LDR Adjustment of center folding position for LDR size –4 to +3 0

Change in value per step: 0.56 mm

4. Press the start key. The value is set.

5. To return to the screen for selecting an item, press the stop/clear key.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key. The screen for

selecting a maintenance item No. is displayed.

1-3-6

Page 59

3B8/9

Maintenance

item No.

U905 Checking/clearing counts by optional devices

Description

Displays or clears the counts of the DF or finisher.

Purpose