Page 1

AD-63

Page 2

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Part names ........................................................................................................................................... 1-1-2

1-1-3 Machine cross section .......................................................................................................................... 1-1-3

1-1-4 Drive system ........................................................................................................................................ 1-1-4

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

1-3 Troubleshooting

1-3-1 Paper misfeed detection ...................................................................................................................... 1-3-1

(1) Paper misfeed indication............................................................................................................... 1-3-1

(2) Paper misfeed detection conditions .............................................................................................. 1-3-2

(3) Paper misfeeds ............................................................................................................................. 1-3-3

1-3-2 Electrical problems ............................................................................................................................... 1-3-4

(1) The duplex feed clutch does not operate...................................................................................... 1-3-4

1-3-3 Mechanical problems ........................................................................................................................... 1-3-5

(1) Paper jams.................................................................................................................................... 1-3-5

(2) Abnormal noise is heard. .............................................................................................................. 1-3-5

1-4 Assembly and Disassembly

1-4-1 Precautions for assembly and disassembly ......................................................................................... 1-4-1

(1) Precautions ................................................................................................................................... 1-4-1

1-4-2 Procedure for assembly and disassembly ........................................................................................... 1-4-2

(1) Adjusting the margin for printing ................................................................................................... 1-4-2

(2) Adjusting the amount of slack at the registration roller ................................................................. 1-4-3

(3) Adjusting the center line of image printing .................................................................................... 1-4-4

3CX

2-1 Mechanical construction

2-1-1 Construction of each section ................................................................................................................ 2-1-1

(1) Paper conveying operation in duplex copying .............................................................................. 2-1-2

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

2-3 Appendixes

Periodic maintenance procedures .................................................................................................................. 2-3-1

1-1-1

Page 3

1-1-1 Specifications

3CX

Type ............................................... Enclosed

Paper..............................................Plain paper: 75 – 80 g/m

2

Special paper: colored paper

1

Paper sizes ....................................A3 – A5R, folio/11" × 17" – 5

/2" × 81/2"

Power source ................................. Electrically connected to the copier

Weight............................................Approximately 4.8 kg/10.56 lbs

1-1-1

Page 4

3CX

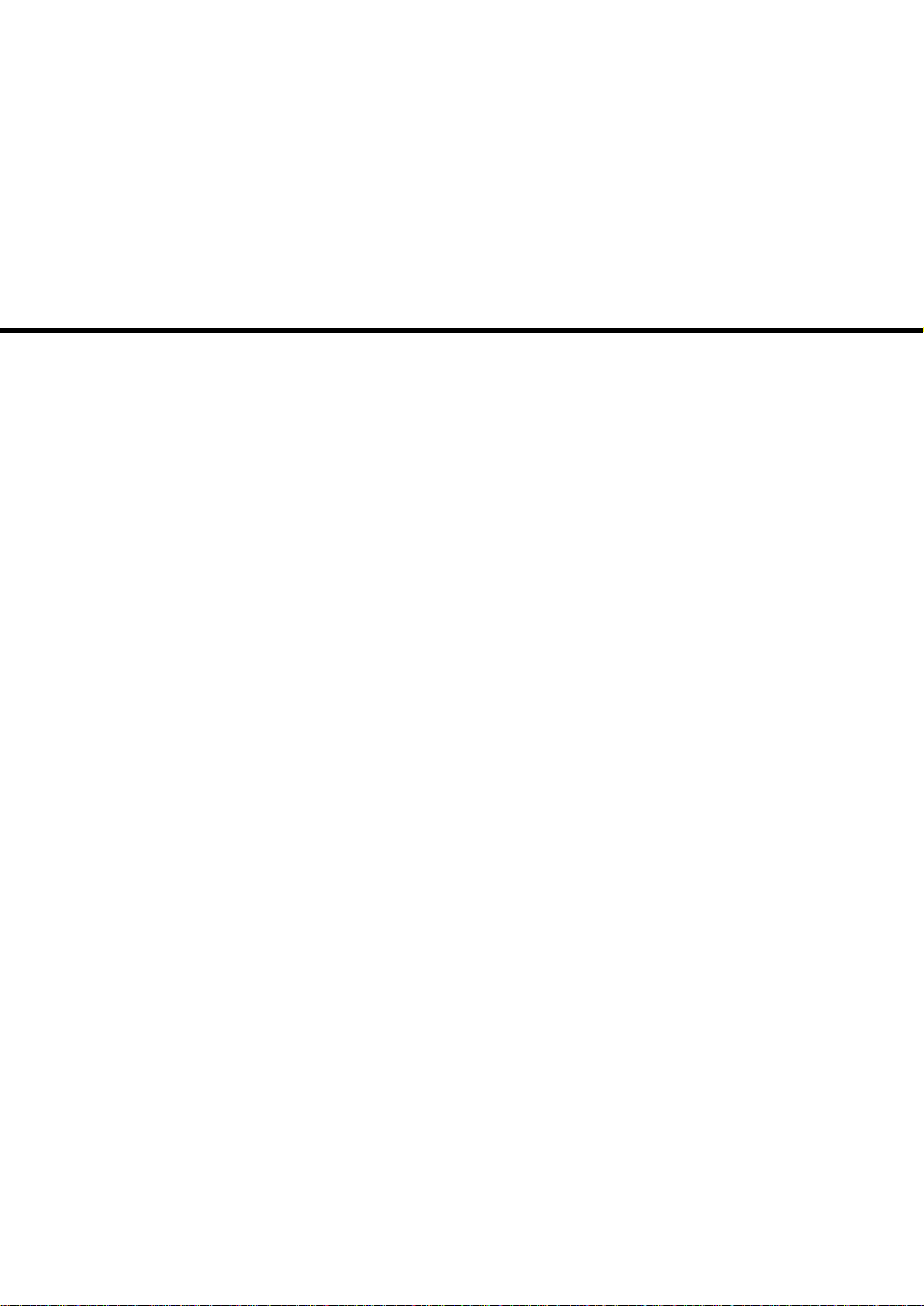

1-1-2 Part names

Duplex unit

Figure 1-1-1

1-1-2

Page 5

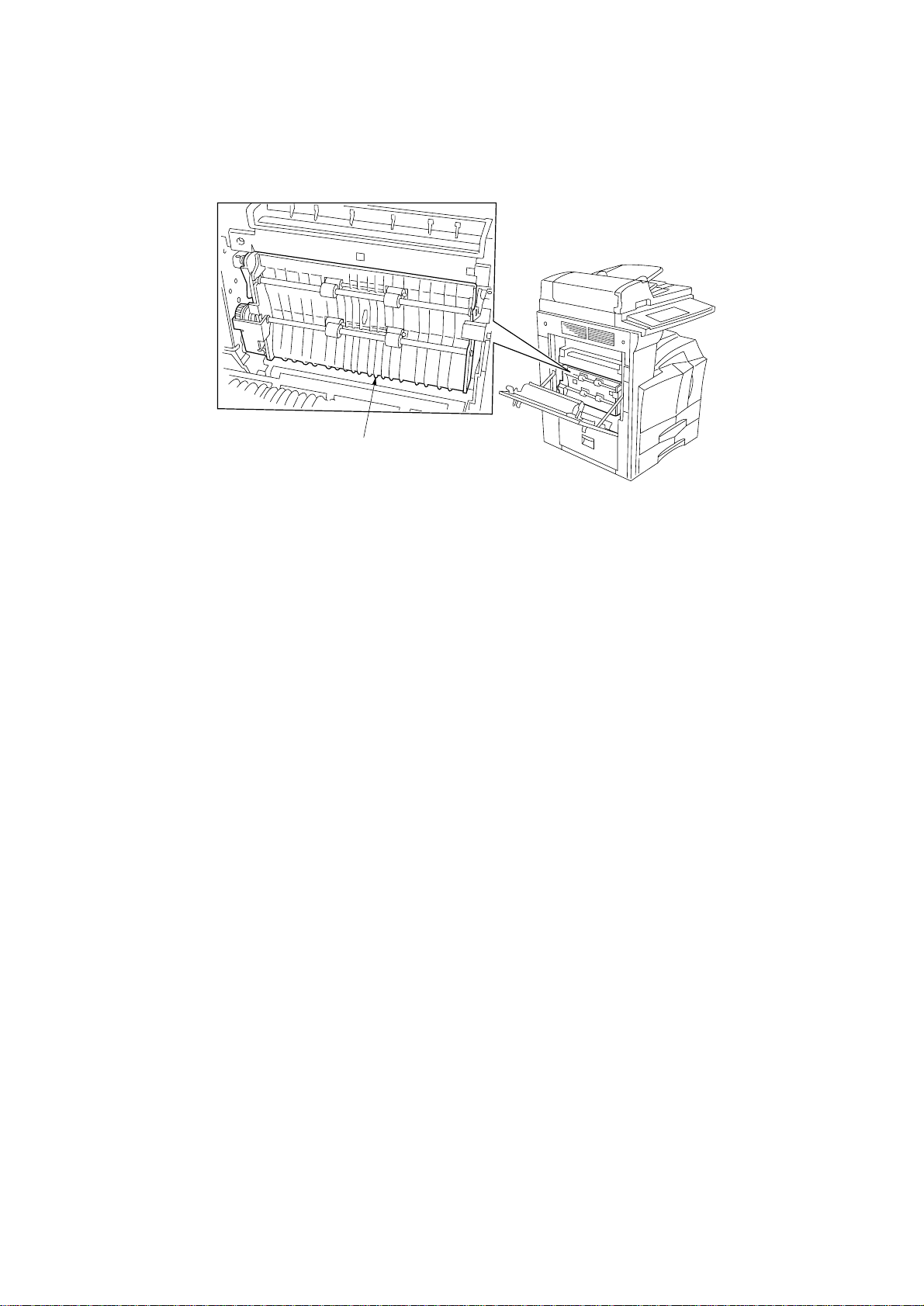

1-1-3 Machine cross section

Duplex unit

3CX

Figure 1-1-2

Paper path

1-1-3

Page 6

3CX

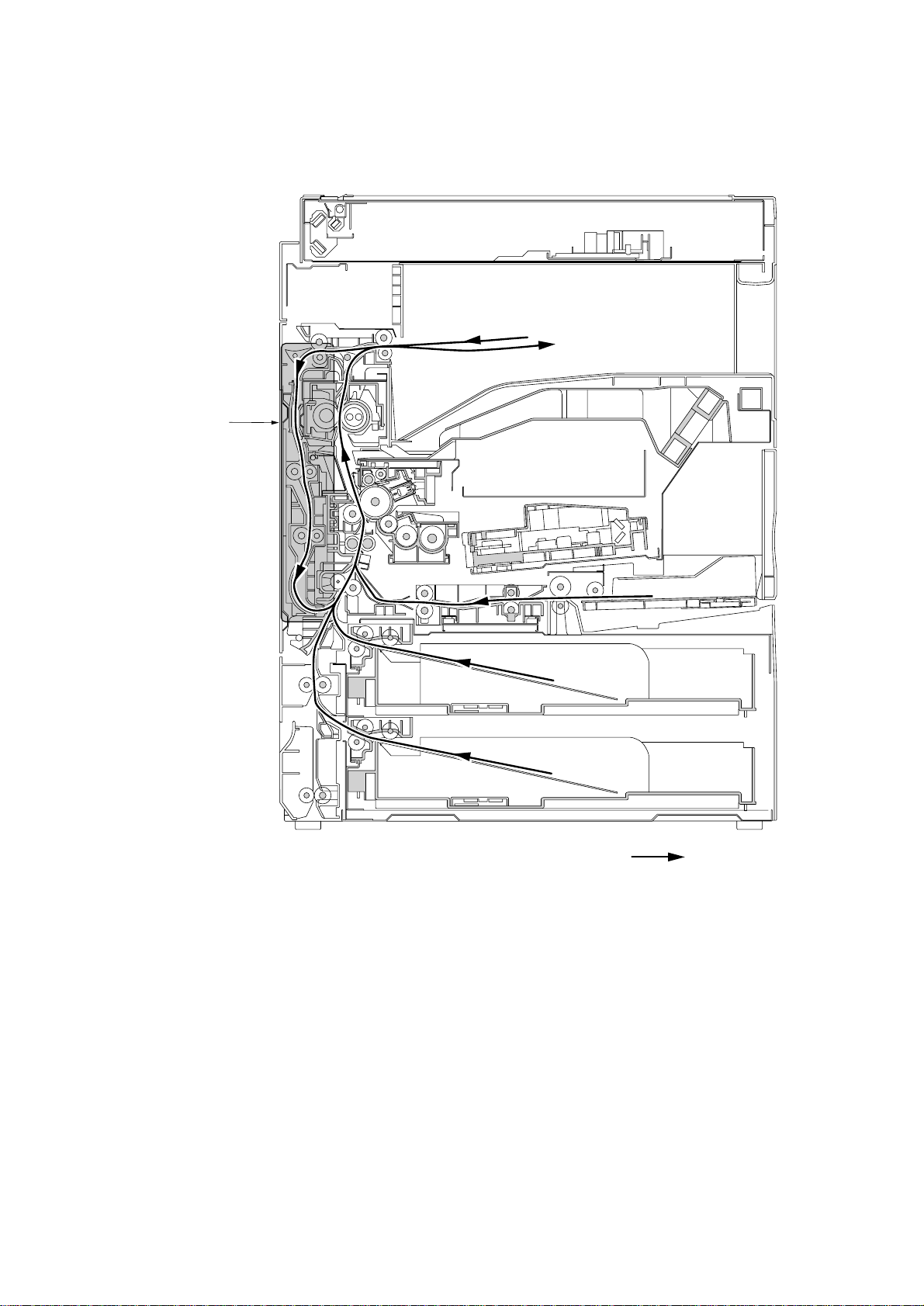

1-1-4 Drive system

Figure 1-1-3

1 Pulley T30

2 Duplex belt

3 Pulley T30

4 Duplex feed clutch gear

5 Gear 25

6 Idle gear 20

7 Gear 25

1-1-4

Page 7

1-2-1 Unpacking

3CX

Figure 1-2-1 Unpacking

1 Duplex unit

2 Nut plate

3 M3 × 10 bronze binding screws

4 Outer case

5 Bar-code label

6 Air-padded bag

7 Plastic bag

1-2-1

Page 8

3CX

1-3-1 Paper misfeed detection

(1) Paper misfeed indication

When paper jams, the machine immediately stops operation and the occurrence of a paper jam is indicated on the copier

operation panel.

To remove the jammed paper, open the conveying cover.

To reset the paper misfeed detection, open and close the conveying cover to turn safty switch 2 off and on.

FSSW

DUPPCSW

DUPFCL

FSW1

Figure 1-3-1 Paper misfeed detection

1-3-1

Page 9

3CX

(2) Paper misfeed detection condition

• Duplex paper conveying section 1 (jam code 60)

The duplex paper conveying switch (DUPPCSW) does not turn on within 1285 ms of the feedshift switch (FSSW) turning on.

FSSW

DUPPCSW

1285 ms

OFF

ON

OFF

ON

Timing chart 1-3-1

The duplex paper conve ying switch (DUPPCSW) does not turn off within 1285 ms of the feedshift s witch (FSSW) turning off.

FSSW

1285 ms

DUPPCSW

OFF

ON

OFF

ON

Timing chart 1-3-2

• Duplex paper conveying section 2 (jam code 61)

Feed switch 1 (FSW1) does not turn on within 1126 ms of the duplex paper conveying switch (DUPPCSW) turning on.

DUPPCSW

FSW1

1126 ms

OFF

ON

OFF

ON

Timing chart 1-3-3

Feed switch 1 (FSW1) does not turn off within 1126 ms of the duplex paper conveying switch (DUPPCSW) turning off.

DUPPCSW

1126 ms

FSW1

OFF

ON

OFF

ON

Timing chart 1-3-4

1-3-2

Page 10

(3) Paper misfeeds

Problem Causes Check procedures/corrective measures

(1)

Paper jams in the

duplex unit when the

main switch is turned

on.

A piece of paper torn from

copy paper is caught

around duplex paper

conveying switch.

Defective duplex paper

conveying switch.

Remove any found.

Run maintenance item U031 and turn the duplex paper

conveying switch on and off manually. Replace the switch if

indication of the corresponding switch on the operation panel is

not displayed in reverse.

3CX

(2)

Paper jams in the

duplex unit during

copying (jam in

duplex paper

conveying section 1).

(3)

Paper jams in the

duplex unit during

copying (jam in

duplex paper

conveying section 2).

Broken feedshift switch

actuator.

Defective feedshift switch.

Broken duplex paper

conveying switch actuator.

Defective duplex paper

conveying switch.

Broken duplex paper

conveying switch actuator.

Defective duplex conveying

switch.

Broken feed switch 1

actuator.

Defective feed switch 1.

Check visually and replace the feedshift switch if its actuator is

broken.

Run maintenance item U031 and turn the feedshift switch on and

off manually. Replace the switch if indication of the corresponding

switch on the operation panel is not displayed in reverse.

Check visually and replace the duplex paper conveying switch if

its actuator is broken.

Run maintenance item U031 and turn the duplex paper

conveying switch on and off manually. Replace the switch if

indication of the corresponding switch on the operation panel is

not displayed in reverse.

Check visually and replace the duplex paper conveying switch if

its actuator is broken.

Run maintenance item U031 and turn the duplex paper

conveying switch on and off manually. Replace the duplex paper

conveying switch if indication of the corresponding switch on the

operation panel is not displayed in reverse.

Check visually and replace feed switch 1 if its actuator is broken.

Run maintenance item U031 and turn feed switch 1 on and off

manually. Replace the switch if indication of the corresponding

switch on the operation panel is not displayed in reverse.

1-3-3

Page 11

3CX

1-3-2 Electrical problems

Problem Causes Check procedures/corrective measures

(1)

The duplex feed

clutch does not

operate.

Broken duplex feed clutch

coil.

Poor contact of the duplex

feed clutch connector

terminals.

Defective main PCB.

Check for continuity across the coil. If none, replace the duplex

feed clutch.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Run maintenance item U032 and check if CN10-B2 on the copier

main PCB goes low. If not, replace the main PCB.

1-3-4

Page 12

1-3-3 Mechanical problems

Problem Causes/check procedures Corrective measures

(1)

Paper jams.

Check if the duplex feed pulley, upper duplex

feed roller or lower duplex feed roller is

deformed.

3CX

Check visually and replace the pulley or

roller if deformed.

(2)

Abnormal noise is

heard.

Check if the rollers and gears operate

smoothly.

Grease the bushings and gears.

1-3-5

Page 13

1-4-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the board.

• Do not touch any PCB containing ICs with bare hands or any object prone to static charge.

• Use the following testers when measuring voltages:

Hioki 3200

Sanwa MD-180C

Sanwa YX-360TR

Beckman TECH300

Beckman DM45

Beckman 330*

Beckman 3030*

Beckman DM850*

Fluke 8060A*

Arlec DMM1050

Arlec YF1030C

* Capable of measuring RMS values.

• Prepare the following as test originals:

1. NTC (new test chart)

2. NPTC (newspaper test chart)

3CX

1-4-1

Page 14

3CX

Printer leading edge margin

for duplex copying

(second face, 3 ± 2.5 mm)

1-4-2 Procedure for assembly and disassembly

(1) Adjusting the margin for printing

Perform the following adjustment if the printer leading edge margin for duplex copying (second face) is not correct.

Procedure

Start

Enter maintenance mode.

Enter “402” using the numeric

keys.

Press the start key.

Figure 1-4-1

Select “TRAIL (DUP)”.

Press the interrupt key.

Press the start key to

output a test pattern.

Is the margin correct?

Yes

Press the stop/clear key

to exit maintenance mode.

End

Press the start key.

The new setting is stored.

No

Change the value using the

cursor up/down keys.

Setting range: –5.0 to +10.0

Reference: 4.5

Changing the value by 1 moves the margin by

0.5 mm.

Increasing the value makes the margin wider

and decreasing it makes the margin narrower.

1-4-2

Page 15

3CX

Original Copy

example 1

Copy

example 2

(2) Adjusting the amount of slack at the registration roller

Perform the f ollowing adjustment if the leading edge of the cop y image is missing or v aries randomly, or if the cop y paper is

Z-folded during duplex copying.

Procedure

Start

Enter maintenance mode.

Enter “051” using the numeric

keys.

Figure 1-4-2

Press the start key.

Select “RESIST DATA”.

Select “DUPLEX DATA”.

Press the interrupt key.

Make a test copy in duplex mode.

Is the leading

edge of the image missing

or varying randomly

(copy example 1)?

No

Is the copy paper

Z-folded (copy example 2)?

No

Press the stop/clear key

to exit maintenance mode.

End

Press the start key.

The new setting is stored.

Yes

Yes

Increase the value using the

cursor up key.

Decrease the value using the

cursor down key.

Setting range: –30 to +20

Reference: 0

Changing the value by 1

changes the amount of slack

by 0.1 mm.

Initial setting: 0

The greater the value,

the larger the amount of slack;

the smaller the value,

the smaller the amount of slack

1-4-3

Page 16

3CX

(3) Adjusting the center line of image printing

Make the following adjustment if there is a regular error between the center lines of the copy image and original when

copying using the duplex unit.

Procedure

Start

Enter maintenance mode.

Enter “034” using

the numeric keys.

Press the start key.

Select “LSU OUT (DUP)”.

Press the interrupt key. Press the start key.

The new setting is stored.

Press the start key to

output a test pattern.

For output example 1, decrease

the value using the cursor down

No

Is the image correct?

Yes

Press the stop/clear key

to exit maintenance mode.

key.

For output example 2, increase

the value using the cursor up key.

Setting range: –5.0 to +5.0

Changing the value by 1 moves the

center line by 1.0 mm.

Initial setting: 0

Center line of printing

Correct image Output

example 1

Figure 1-4-3

Output

example 2

1-4-4

End

Page 17

3CX

2-1-1 Construction of each section

The duplex unit consists of the components shown in Figure 2-1-1. In duplex mode, after copying on to the reverse face of

the paper, the paper is reversed in the switchback section and conveyed to the duplex unit. The paper is then conveyed to

the copier paper feed section by the upper and lower duplex feed rollers.

1 Feedshift guide

2 Upper duplex feed roller

3 Lower duplex feed roller

4 Duplex feed pulley

5 Duplex feed pulley

6 Duplex paper conveying switch (DUPPCSW)

Figure 2-1-1 Duplex unit

MPCB

DUPPCSW

CN10-B4

DUPFCL

CN10-B2

Figure 2-1-2 Duplex unit block diagram

2-1-1

Page 18

3CX

(1) Paper conveying operation in duplex copying

Paper of which copying onto the reverse side is complete is conveyed to the switchback section, the eject motor switches

from nomal rotation to reverse rotation to switch the eject roller to reverse rotation, and the paper conveying direction is

reversed. Paper that has been switched back is conveyed to the duplex unit via the eject roller and the switchback roller.

Paper that has been conveyed to the duplex unit is conveyed to the paper feed section again by rotation of the upper duplex

feed roller and the lower duplex feed roller and copying onto the front side is performed.

Eject roller Eject roller

Eject rollerSwitchback roller

Upper duplex

feed roller

Lower duplex

feed roller

Copying onto reverse side

(normal rotation of eject motor)

Switchback operation

(reverse rotation of eject motor)

Figure 2-1-3

Copying onto front side

(normal rotation of eject motor)

Paper path

2-1-2

Page 19

2-2-1 Electrical parts layout

1

2

3CX

Figure 2-2-1 Duplex unit

1. Duplex paper conveying switch

(DUPPCSW) ................................................ Detects a paper jam in the duplex unit.

2. Duplex paper feed clutch

(DUPFCL) .................................................... Controls the drive of the duplex feed roller.

Machine front

Machine inside

Machine rear

2-2-1

Page 20

Periodic maintenance procedures

3CX

Section

Paper Upper duplex feed roller Clean Every service Clean with alcohol or a dry cloth.

conveying

section

Maintenance

part/location

Lower duplex feed roller Clean Every service Clean with alcohol or a dry cloth.

Method Maintenance cycle Points and cautions Page

2-3-1

Loading...

Loading...