Page 1

F-2205/AD-62

Page 2

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Part names and their functions ............................................................................................................ 1-1-2

(1) Finisher ......................................................................................................................................... 1-1-2

(2) Duplex unit .................................................................................................................................... 1-1-3

1-1-3 Machine cross section .......................................................................................................................... 1-1-4

(1) Finisher ......................................................................................................................................... 1-1-4

(2) Duplex unit .................................................................................................................................... 1-1-5

1-1-4 Drive system ........................................................................................................................................ 1-1-6

(1) Finisher ......................................................................................................................................... 1-1-6

(2) Duplex unit .................................................................................................................................... 1-1-7

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

1-3 Troubleshooting

1-3-1 Paper misfeed detection ...................................................................................................................... 1-3-1

(1) Paper misfeed indication ............................................................................................................... 1-3-1

(2) Paper misfeed detection condition ................................................................................................ 1-3-2

(2-1) Finisher ................................................................................................................................. 1-3-2

(2-2) Duplex unit ........................................................................................................................... 1-3-3

(3) Paper misfeeds ............................................................................................................................. 1-3-4

(3-1) Finisher ................................................................................................................................. 1-3-4

(1) Paper jams in the finisher when the main switch is turned on. ..................................... 1-3-4

(2) Paper jams in the finisher during copying (jam during paper conveying for

batch ejection 1). ........................................................................................................... 1-3-4

(3) Paper jams in the finisher during copying (jam during paper conveying for

batch ejection 2). ........................................................................................................... 1-3-4

(3-2) Duplex unit ........................................................................................................................... 1-3-5

(1) Paper jams in the duplex unit when the main switch is turned on. ............................... 1-3-5

(2) Paper jams in the feedshift section during copying (jam in feedshift section). .............. 1-3-5

(3) Paper jams in the duplex unit during copying (jam in duplex paper

conveying section 1). .................................................................................................... 1-3-5

(4) Paper jams in the duplex unit during copying (jam in duplex paper

conveying section 2). .................................................................................................... 1-3-5

1-3-2 Self-diagnosis ....................................................................................................................................... 1-3-6

(1) Self-diagnostic function ................................................................................................................. 1-3-6

(2) Self-diagnostic codes .................................................................................................................... 1-3-7

1-3-3 Electrical problems ............................................................................................................................... 1-3-9

(1) Finisher ......................................................................................................................................... 1-3-9

(1) The paper conveying motor does not operate. ...................................................................... 1-3-9

(2) The feedshift solenoid does not operate. .............................................................................. 1-3-9

(3) The switchback solenoid does not operate. .......................................................................... 1-3-9

(4) The pickup solenoid does not operate. .................................................................................. 1-3-9

(5) The front side registration motor does not operate. ............................................................... 1-3-9

(6) Rear side registration motor does not operate. ..................................................................... 1-3-9

(7) Trailing edge registration motor does not operate. .............................................................. 1-3-10

(2) Duplex unit .................................................................................................................................. 1-3-11

(1) The duplex feedshift solenoid does not operate. ................................................................. 1-3-11

1-3-4 Mechanical problems ......................................................................................................................... 1-3-12

(1) Finisher ....................................................................................................................................... 1-3-12

(1) Paper jams. ......................................................................................................................... 1-3-12

(2) Abnormal noise is heard. ..................................................................................................... 1-3-12

(2) Duplex unit .................................................................................................................................. 1-3-13

(1) Paper jams. ......................................................................................................................... 1-3-13

(2) Abnormal noise is heard. ..................................................................................................... 1-3-13

1-1-1

3BN/3A4

Page 3

3BN/3A4

1-4 Assembly and Disassembly

1-4-1 Precautions for assembly and disassembly ......................................................................................... 1-4-1

(1) Precautions ................................................................................................................................... 1-4-1

1-4-2 Finisher ................................................................................................................................................ 1-4-2

(1) Adjusting the positions of the front side registration cursor, rear side registration cursor

and trailing edge registration cursor (reference) ........................................................................... 1-4-2

(2) Cleaning the stapler ...................................................................................................................... 1-4-3

(3) Adjusting the tension of the front and rear side registration belts ................................................. 1-4-4

1-4-3 Duplex unit ........................................................................................................................................... 1-4-5

(1) Adjusting the margin for printing ................................................................................................... 1-4-5

(2) Adjusting the amount of slack at the registration roller ................................................................. 1-4-6

(3) Adjusting the center line of image printing .................................................................................... 1-4-7

2-1 Mechanical construction

2-1-1 Feedshift section .................................................................................................................................. 2-1-1

(1) Paper conveying operation in sort mode ...................................................................................... 2-1-2

(2) Switchback operation in duplex mode .......................................................................................... 2-1-3

2-1-2 Intermediate tray section ...................................................................................................................... 2-1-4

(1) Paper registration on the intermediate tray ................................................................................... 2-1-5

2-1-3 Eject section ......................................................................................................................................... 2-1-6

2-1-4 Stapler section ..................................................................................................................................... 2-1-7

2-1-5 Duplex unit ........................................................................................................................................... 2-1-8

(1) Switching the paper path in the duplex unit .................................................................................. 2-1-9

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

(1) Finisher ......................................................................................................................................... 2-2-1

(2) Duplex unit .................................................................................................................................... 2-2-4

2-3 Operation of the PCBs

2-3-1 Main PCB ............................................................................................................................................. 2-3-1

2-4 Appendixes

Timing chart No. 1 ........................................................................................................................................... 2-4-1

Timing chart No. 2 ........................................................................................................................................... 2-4-2

Timing chart No. 3 ........................................................................................................................................... 2-4-3

Timing chart No. 4 ........................................................................................................................................... 2-4-4

Periodic maintenance procedure .................................................................................................................... 2-4-5

Wiring diagram ................................................................................................................................................ 2-4-6

1-1-2

Page 4

1-1-1 Specifications

3BN/3A4

Finisher

Type ............................................... Built-in

Number of trays.............................. 1 (intermediate tray)

1

Stapling limit ................................... A4/11" × 8

/2" or smaller: 30 sheets

Other sizes than above: 20 sheets

Power source ................................. Electrically connected to the copier

Dimensions .................................... 696 (W) × 618 (D) × 281 (H) mm

273/8" (W) × 245/16" (D) × 111/16" (H)

Weight ............................................ Approximately 11 kg/24.2 lbs

Duplex unit

Type ............................................... Outboard

Paper ..............................................Plain paper: 75 – 80 g/m

2

Special paper: colored paper

1

Paper sizes .................................... A3 – A5R, folio/11" × 17" – 5

/2" × 81/2"

Power source ................................. Electrically connected to the copier

Dimensions .................................... 48 (W) × 450 (D) × 397 (H) mm

1

/8" (W) × 1711/16" (D) × 155/8" (H)

1

Weight ............................................Approximately 3.3 kg/7.26 lbs

1-1

1-1-1

Page 5

3BN/3A4

1-1-2 Part names and their functions

1-1

(1) Finisher

4

3

2

1

Figure 1-1-1

1 Intermediate tray

2 JAM release lever

3 Stapler

4 Eject tray

1-1-2

Page 6

(2) Duplex unit

3BN/3A4

1-1

2

1

Figure 1-1-2

1 Duplex lever

2 Open/close guide

1-1-3

Page 7

3BN/3A4

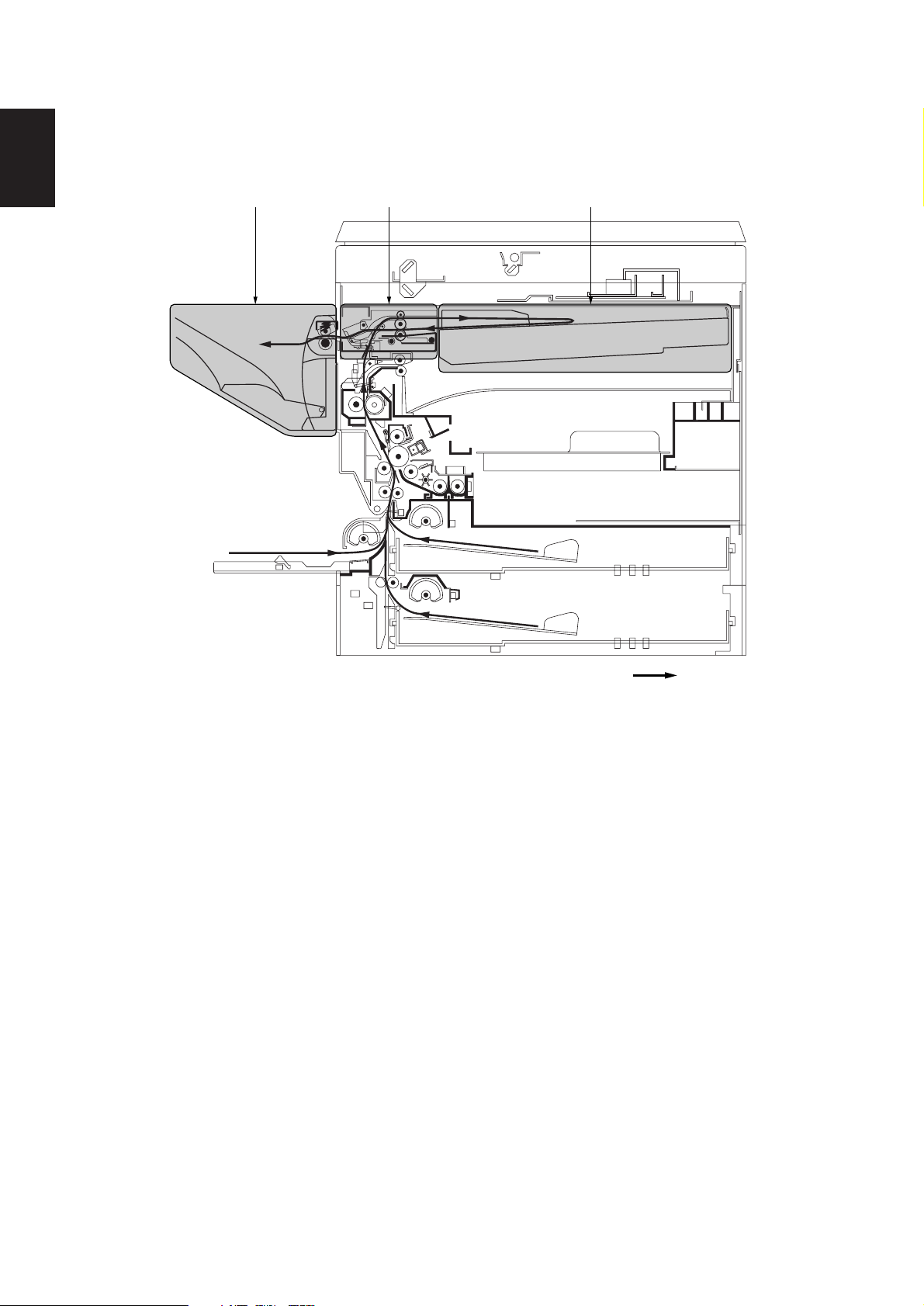

1-1-3 Machine cross section

1-1

(1) Finisher

31 2

Figure 1-1-3 Machine cross section (finisher)

1 Feedshift section

2 Intermediate tray section

3 Eject section

Paper path

1-1-4

Page 8

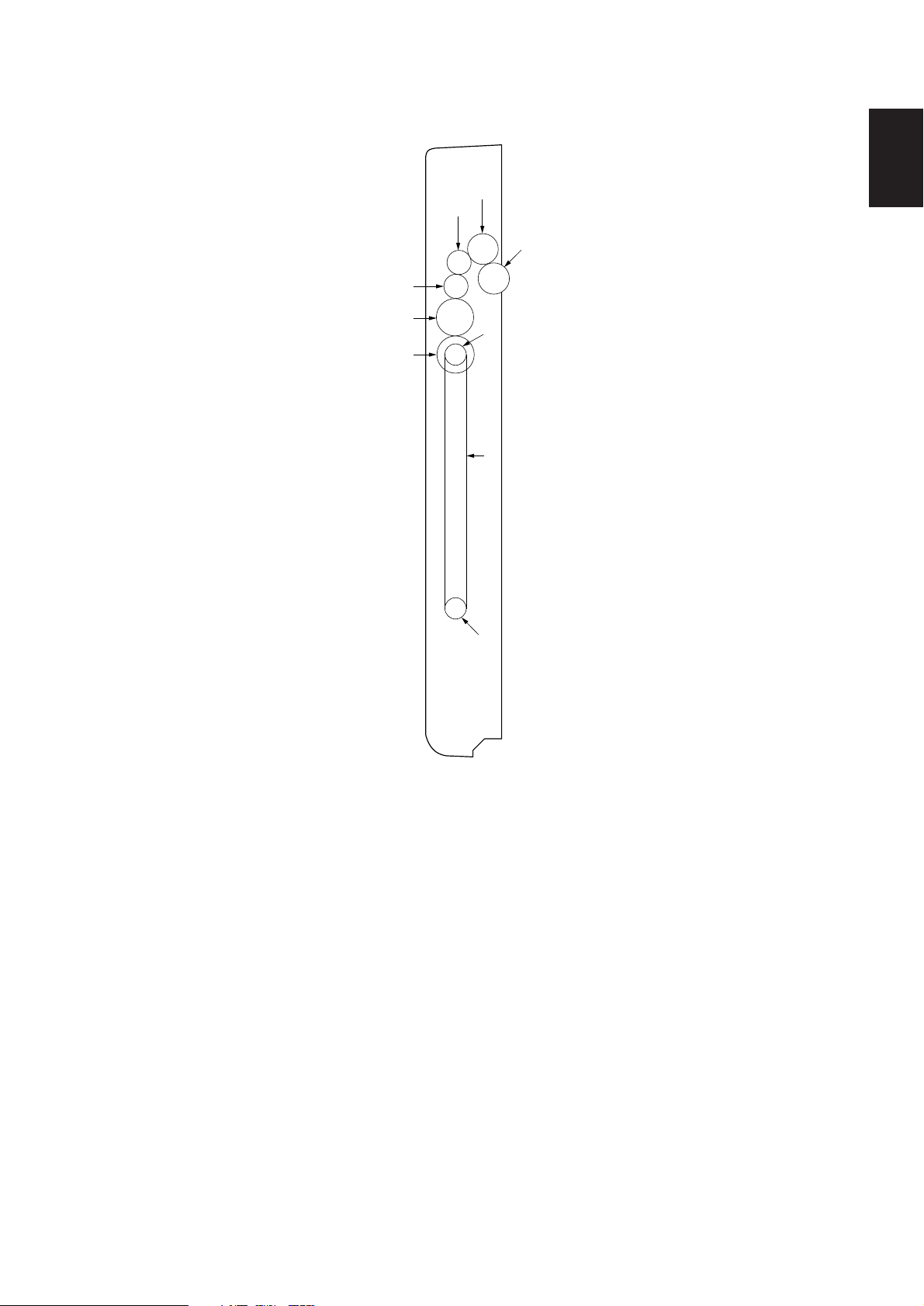

(2) Duplex unit

3BN/3A4

1-1

Figure 1-1-4 Machine cross section (duplex unit)

Paper path

1-1-5

Page 9

3BN/3A4

1-1-4 Drive system

1-1

(1) Finisher

(

*

%$# 43 67 8

^

5

9

&2 @1!0

Figure 1-1-5

1 Paper conveying motor gear

2 Gear 18/38

3 Gear 18

4 Central gear

5 Gear 15

6 Central gear (front)

7 Gear 21 (rear)

8 Lift clutch gear

9 Clutch cam

0 Stopper gear

! Gear 32

@ Stopper gear 26

# One-way gear 18 (rear)

$ Gear 21 (front)

% Central gear (middle)

^ Gear 25

& Gear 18

* Gear 16

( Gear 25

1-1-6

Page 10

(2) Duplex unit

3BN/3A4

1-1

2

3

1

4

5

6

7

8

9

1 Gear 20

2 Gear 20

3 Gear 16

4 Gear 16

5 Gear 25

Figure 1-1-5

6 Gear 25

7 Pulley 20

8 Duplex belt

9 Pulley 20

1-1-7

Page 11

1-2-1 Unpacking

„

¤

2

3BN/3A4

%

‹

6

fi

^

&

⁄

1

(

*

›

fl

‡

3

‚

@

7

8

$

9

·

4

Œ

)

#

5

1-2

0

!

°

›

Figure 1-2-1 Unpacking (finisher)

1 Intermediate tray unit

2 Feedshift unit

3 Eject unit

4 Eject tray unit

5 Stapler cover

6 Staple cartridge

7 Upper paper conveying cover F

8 Upper eject cover F

9 Upper eject cover D

0 Two (2) cross-head bronze binding screws BVM3 × 05

! Two (2) cross-head chrome TP-A screws M3 × 05

@ Installation manual

# Instruction handbook

$ Plastic bag

% Unit spacer

^ Cursor spacer

& Outer case

* Eject tray spacer

( Spacer B

) Spacer C

⁄ Intermediate tray pad

¤ Stapler pad

‹ Cover pad

› Bar-code labels

fi Plastic sheet

fl Product cover

‡ Air-padded bag

— Plastic bag

· Air-padded bag

‚ Plastic bag

ΠPlastic bag

„ Plastic bag

1-2-1

Page 12

3BN/3A4

^

1-2

7

(

⁄

¤

2

(

%

)

&

$

%

90!

@#*

‹

4

1

¤

$

6

35

8

Figure 1-2-2 Unpacking (duplex unit)

1 Duplex unit

2 Duplex joint

3 Front duplex fulcrum plate

4 Rear duplex fulcrum plate

5 Front fulcrum hook

6 Duplex stopper

7 Left cover

8 Entry guide

9 Two (2) stoppers 5

0 Seven (7) cross-head chrome binding screws

M3 × 14

! One (1) cross-head chrome TP-A screw M3 × 05

@ One (1) cross-head tap-tight P chrome TP-A screw

M3 × 08

# One (1) cross-head tap-tight P chrome TP-A screw

M4 × 12

$ Bottom pads

% Spacers

^ Upper pad

& Outer case

* Plastic bag

( Plastic bag

) Product cover

⁄ Air-padded bag

¤ Bar-code label

‹ Air-padded bag

1-2-2

Page 13

3BN/3A4

1-3-1 Paper misfeed detection

(1) Paper misfeed indication

When paper jams, the machine immediately stops operation and the occurrence of a paper jam is indicated on the copier

operation panel.

To remove the jammed paper, lower the intermediate tray or open the duplex unit.

To reset the paper misfeed detection, detach and refit the intermediate tray to turn the tray open/close switch off and on or

open and close the duplex unit to turn the duplex open/close switch off and on.

DUPPCSW1

PCSW

1-3

DUPPCSW2

RSW

Figure 1-3-1 Paper misfeed detection

1-3-1

Page 14

1-3

3BN/3A4

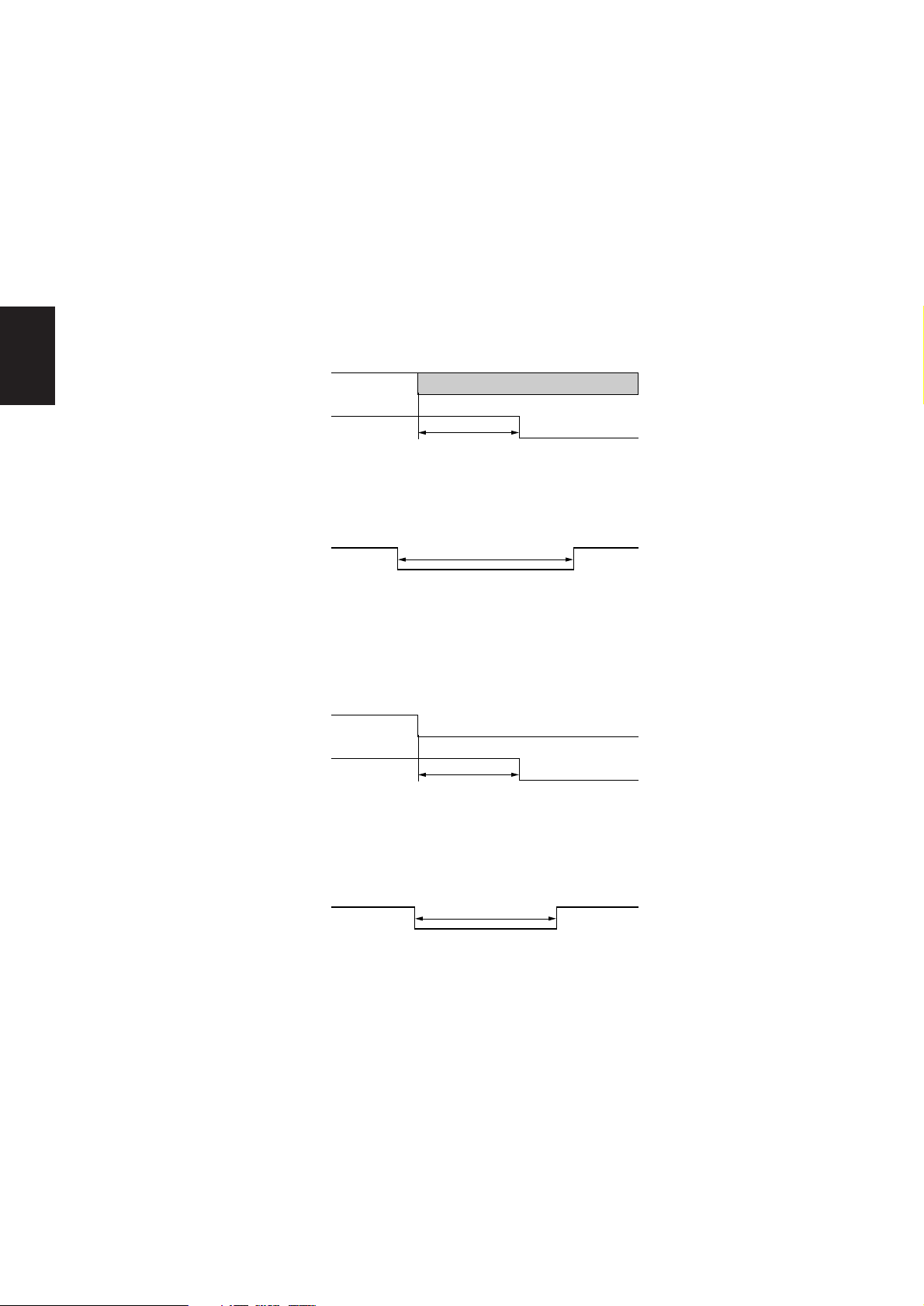

(2) Paper misfeed detection condition

(2-1) Finisher

• Jam between the finisher and copier (jam code 80)

No signal indicating the completion of paper ejection is output from the finisher within 15 s of the paper conveying switch

(PCSW) turning off.

• Jam during batch ejection standby (jam code 81)

No signal requesting batch ejection is output from the finisher within 15 s of the ejection of the last sheet to the

intermediate tray.

• Jam during paper conveying for batch ejection 1 (jam code 82)

When ejecting a stack of paper, the paper conveying switch (PCSW) does not turn on within 1250 ms of the start of forward

rotation of the paper conveying motor (PCM).

PCM

PCSW

Fwd. rotation

1250 ms

Off

On

Off

On

Timing chart 1-3-1

When ejecting a stack of paper, the paper conveying switch (PCSW) does not turn off within 6320 ms of turning on.

PCSW

6320 ms

Off

On

Timing chart 1-3-2

• Jam during paper conveying for batch ejection 2 (jam code 83)

When ejecting a stack of paper, duplex paper conveying switch 1 (DUPPCSW1) does not turn on within 1250 ms of the

paper conveying switch (PCSW) turning on.

PCSW

DUPPCSW1

1250 ms

Off

On

Off

On

Timing chart 1-3-3

When ejecting a stack of paper, duplex paper conveying switch 1 (DUPPCSW1) does not turn off within 1640 ms of turning

on.

DUPPCSW1

1640 ms

Off

On

Timing chart 1-3-4

1-3-2

Page 15

3BN/3A4

(2-2) Duplex unit

• Jam in feedshift section (jam code 51)

Duplex paper conveying switch 1 (DUPPCSW1) does not turn on within 1640 ms of the start of reverse rotation of the

paper conveying motor (PCM).

PCM

DUPPCSW1

Rev. rotation

1640 ms

Off

On

Off

On

Timing chart 1-3-5

• Jam in duplex paper conveying section 1 (jam code 60)

Duplex paper conveying switch 2 (DUPPCSW2) does not turn on within 3360 ms of duplex paper conveying switch 1

(DUPPCSW1) turning on.

DUPPCSW1

DUPPCSW2

3360 ms

Off

On

Off

On

Timing chart 1-3-6

• Jam in duplex paper conveying section 2 (jam code 61)

Duplex paper conveying switch 2 (DUPPCSW2) does not turn off within 3360 ms of duplex paper conveying switch 1

(DUPPCSW1) turning off.

DUPPCSW1

DUPPCSW2

3360 ms

Off

On

Off

On

1-3

Timing chart 1-3-7

The registration switch (RSW) of the copier does not turn on within 3300 ms of duplex paper conveying switch 2

(DUPPCSW2) turning on.

DUPPCSW2

RSW (copier)

3300 ms

Off

On

Off

On

Timing chart 1-3-8

1-3-3

Page 16

1-3

3BN/3A4

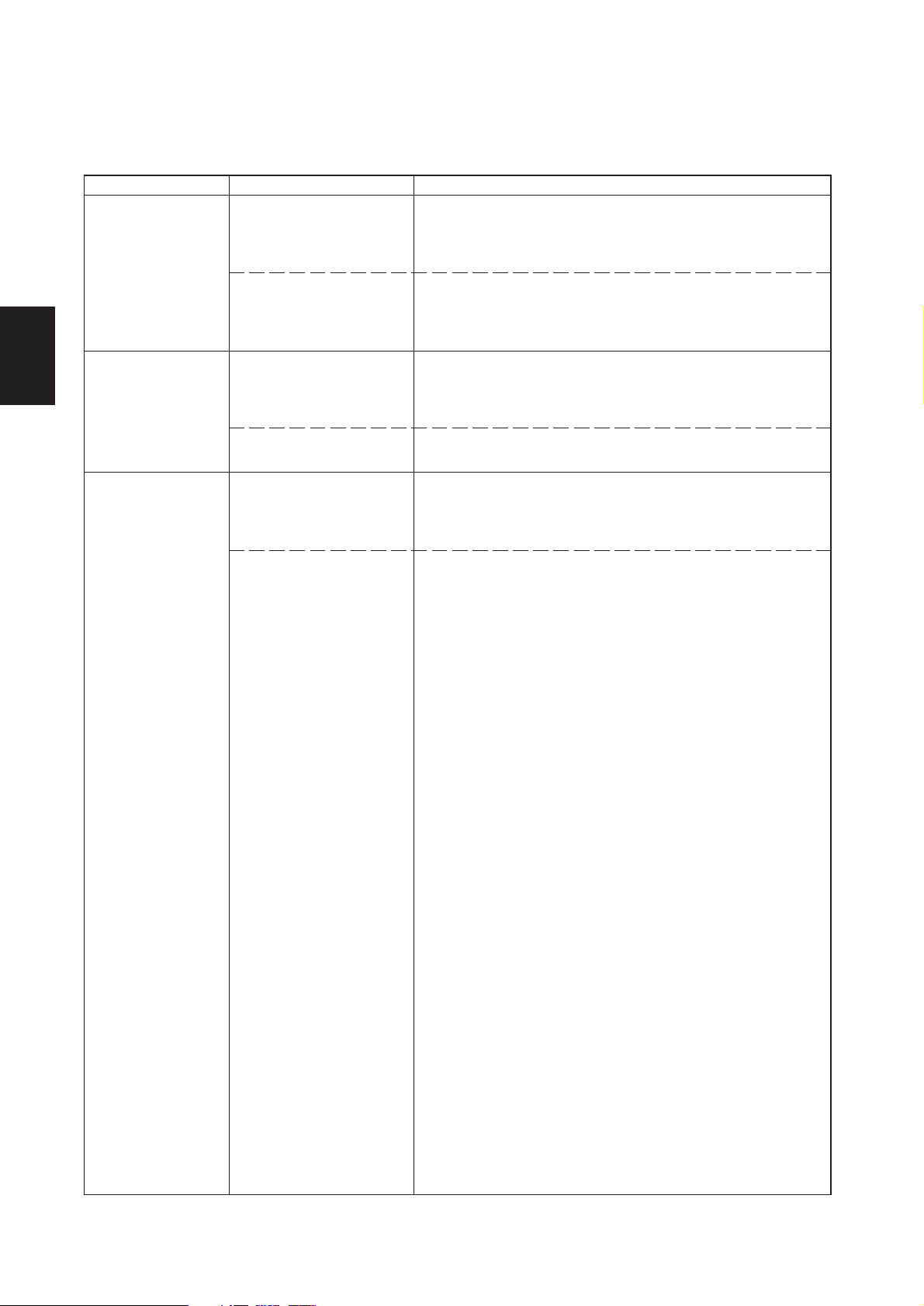

(3) Paper misfeeds

(3-1) Finisher

Problem Causes Check procedures/corrective measures

(1)

Paper jams in the

finisher when the

main switch is turned

on.

(2)

Paper jams in the

finisher during

copying (jam during

paper conveying for

batch ejection 1).

(3)

Paper jams in the

finisher during

copying (jam during

paper conveying for

batch ejection 2).

A piece of paper torn from

copy paper is caught

around the paper

conveying switch.

Defective paper conveying

switch.

Defective paper conveying

switch.

Check if the feedshift roller

or press roller is deformed.

Defective duplex paper

conveying switch 1 in the

duplex unit.

Check if the eject pulley or

eject roller is deformed.

Remove any found.

With 5 V DC present at CN4-9 on the main PCB, check if CN4-10

on the main PCB remains low when the paper conveying switch

is turned on and off. If it does, replace the paper conveying

switch.

With 5 V DC present at CN4-9 on the main PCB, check if CN4-10

on the main PCB remains high or low when the paper conveying

switch is turned on and off. If it does, replace the paper

conveying switch.

Check visually and replace the pulley or roller if deformed.

With 5 V DC present at CN5-11 on the copier main PCB, check if

CN5-10 on the copier main PCB remains high or low when

duplex paper conveying switch 1 is turned on and off. If it does,

replace duplex paper conveying switch 1.

Check visually and replace the pulley or roller if deformed.

1-3-4

Page 17

(3-2) Duplex unit

Problem Causes Check procedures/corrective measures

(1)

Paper jams in the

duplex unit when the

main switch is turned

on.

A piece of paper torn from

copy paper is caught

around duplex paper

conveying switch 1 or 2.

Defective duplex paper

conveying switch 1.

Remove any found.

With 5 V DC present at CN5-11 on the copier main PCB, check if

CN5-10 on the main PCB remains low when duplex paper

conveying switch 1 is turned on and off. If it does, replace duplex

paper conveying switch 1.

3BN/3A4

(2)

Paper jams in the

feedshift section

during copying (jam

in feedshift section).

(3)

Paper jams in the

duplex unit during

copying (jam in

duplex paper

conveying section 1).

(4)

Paper jams in the

duplex unit during

copying (jam in

duplex paper

conveying section 2).

Defective duplex paper

conveying switch 2.

Defective duplex paper

conveying switch 1.

Check if the feedshift pulley

or feedshift roller is

deformed.

Defective duplex paper

conveying switch 2.

Check if the duplex roller or

upper duplex roller is

deformed.

Defective duplex paper

conveying switch 2.

Defective copier

registration switch.

Check if the duplex pulley

or lower duplex roller is

deformed.

With 5 V DC present at CN5-8 on the copier main PCB, check if

CN5-7 on the main PCB remains low when duplex paper

conveying switch 2 is turned on and off. If it does, replace duplex

paper conveying switch 2.

With 5 V DC present at CN5-11 on the copier main PCB, check if

CN5-10 on the main PCB remains high when duplex paper

conveying switch 1 is turned on and off. If it does, replace duplex

paper conveying switch 1.

Check visually and replace the pulley or roller if deformed.

With 5 V DC present at CN5-8 on the copier main PCB, check if

CN5-7 on the main PCB remains high when duplex paper

conveying switch 2 is turned on and off. If it does, replace duplex

paper conveying switch 2.

Check visually and replace the pulley or roller if deformed.

With 5 V DC present at CN5-8 on the copier main PCB, check if

CN5-7 on the main PCB remains low when duplex paper

conveying switch 2 is turned on and off. If it does, replace duplex

paper conveying switch 2.

With 5 V DC present at CN3-6 on the copier main PCB, check if

CN3-7 on the main PCB remains high when the registration

switch is turned on and off. If it does, replace the registration

switch.

Check visually and replace the pulley or roller if deformed.

1-3

1-3-5

Page 18

1-3

3BN/3A4

1-3-2 Self-diagnosis

(1) Self-diagnostic function

This unit is equipped with a self-diagnostic function. When a problem is detected, copying is disabled and the problem

displayed as a code consisting of “C” followed by a number between 034 and 821, indicating the nature of the problem.

A message is also displayed requesting the user to call for service.

After removing the problem, the self-diagnostic function can be reset by turning the tray open/close switch or copier safety

switch 1, 2 or 3 off and back on.

1-3-6

Page 19

(2) Self-diagnostic codes

3BN/3A4

Code Contents

C034 Finisher communication problem

During the serial communication

between the copier and finisher, when

there is no reply to the command from

the copier from the finisher, serial

communication does not recover after

5 retries.

C817 Front side registration motor problem

When the side registration front home

position sensor is on during initialization,

the sensor does not turn off within

570 ms of the start of initialization.

When the side registration front home

position sensor is off during initialization,

the sensor does not turn on within

3180 ms of the start of initialization.

Remarks

Causes Check procedure/corrective measures

The connector

makes poor

contact.

Defective copier

main PCB.

Defective finisher

main PCB.

The front side

registration motor

connector makes

poor contact.

Defective front

side registration

motor.

The side registration front home

position sensor

connector makes

poor contact.

Defective side

registration front

home position

sensor.

Check the connection of connector CN27

on the copier main PCB and CN1 on the

finisher main PCB, and the continuity

across the connector terminals. Remedy or

replace if necessary.

Replace the copier main PCB and check for

correct operation.

Replace the finisher main PCB and check

for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the front side registration motor

and check for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the side registration front home

position sensor and check for correct

operation.

1-3

C818 Rear side registration motor problem

When the side registration rear home

position sensor is on during initialization,

the sensor does not turn off within

570 ms of the start of initialization.

When the side registration rear home

position sensor is off during initialization,

the sensor does not turn on within

2880 ms of the start of initialization.

Defective finisher

main PCB.

The rear side

registration motor

connector makes

poor contact.

Defective rear side

registration motor.

The side registration rear home

position sensor

connector makes

poor contact.

Defective side

registration rear

home position

sensor.

Defective finisher

main PCB.

Replace the finisher main PCB and check

for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the rear side registration motor and

check for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the side registration rear home

position sensor and check for correct

operation.

Replace the finisher main PCB and check

for correct operation.

1-3-7

Page 20

3BN/3A4

1-3

Code Contents

C819 Trailing edge registration motor

problem

When the trailing edge registration

home position sensor is on during

initialization, the sensor does not turn off

within 570 ms of the start of initialization.

When the trailing edge registration

home position sensor is off during

initialization, the sensor does not turn on

within 4550 ms of the start of

initialization.

C821 Stapler motor problem

When the stapler home position sensor

is off during stapler initialization, the

sensor does not turn on within 600 ms

of the start of the stapler motor forward

rotation and then it fails to turn on again

within 600 ms of the start of the stapler

motor reverse rotation.

The stapler home position sensor does

not turn off within 200 ms of the start of

stapling.

During stapling, the stapler home

position sensor does not turn on within

600 ms of turning off.

The stapler home position sensor does

not turn off within 200 ms of the start of

self-priming.

During self-priming, the stapler home

position sensor does not turn on within

600 ms of turning off.

Remarks

Causes Check procedure/corrective measures

The trailing edge

registration motor

connector makes

poor contact.

Defective trailing

edge registration

motor.

The trailing edge

registration home

position sensor

connector makes

poor contact.

Defective trailing

edge registration

home position

sensor.

Defective finisher

main PCB.

The stapler motor

connector makes

poor contact.

The stapler

malfunctions.

a) The stapler is

blocked with a

staple.

b) The stapler is

broken.

Defective finisher

main PCB.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the trailing edge registration motor

and check for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the trailing edge registration home

position sensor and check for correct

operation.

Replace the finisher main PCB and check

for correct operation.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

a) Remove the staple cartridge and check

the cartridge and the stapling section of

the stapler.

b) Replace the stapler and check for correct

operation.

Replace the finisher main PCB and check

for correct operation.

1-3-8

Page 21

1-3-3 Electrical problems

(1) Finisher

Problem Causes Check procedures/corrective measures

(1)

The paper conveying

motor does not

operate.

Broken paper conveying

motor coil.

Poor contact of the paper

conveying motor connector

terminals.

Check for continuity across the coil. If none, replace the paper

conveying motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

3BN/3A4

(2)

The feedshift

solenoid does not

operate.

(3)

The switchback

solenoid does not

operate.

(4)

The pickup solenoid

does not operate.

Defective finisher main

PCB.

Broken feedshift solenoid

coil.

Poor contact of the

feedshift solenoid

connector terminals.

Defective finisher main

PCB.

Broken switchback

solenoid coil.

Poor contact of the

switchback solenoid

connector terminals.

Defective finisher main

PCB.

Broken pickup solenoid

coil.

Poor contact of the pickup

solenoid connector

terminals.

Defective finisher main

PCB.

Check if a motor drive coil energization signal is output at CN9-9,

CN9-10, CN9-11 and CN9-12 on the finisher main PCB. If not,

replace the finisher main PCB.

Check for continuity across the coil. If none, replace the feedshift

solenoid.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check if CN4-2 and CN4-4 on the finisher main PCB go low. If

not, replace the finisher main PCB.

Check for continuity across the coil. If none, replace the

switchback solenoid.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check if CN4-6 and CN4-8 on the finisher main PCB go low. If

not, replace the finisher main PCB.

Check for continuity across the coil. If none, replace the pickup

solenoid.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check if CN4-7 on the finisher main PCB goes low. If not, replace

the finisher main PCB.

1-3

(5)

The front side

registration motor

does not operate.

(6)

Rear side

registration motor

does not operate.

Broken front side

registration motor coil.

Poor contact of the front

side registration motor

connector terminals.

Defective finisher main

PCB.

Broken rear side

registration motor coil.

Poor contact of the rear

side registration motor

connector terminals.

Defective finisher main

PCB.

Check for continuity across the coil. If none, replace the front side

registration motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check if a motor drive coil energization signal is output at CN5-1,

CN5-3, CN5-4 and CN5-5 on the finisher main PCB. If not,

replace the finisher main PCB.

Check for continuity across the coil. If none, replace the rear side

registration motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

Check if a motor drive coil energization signal is output at CN5-6,

CN5-8, CN5-9 and CN5-10 on the finisher main PCB. If not,

replace the finisher main PCB.

1-3-9

Page 22

3BN/3A4

Problem Causes Check procedures/corrective measures

(7)

Trailing edge

registration motor

does not operate.

Broken trailing edge

registration motor coil.

Poor contact of the trailing

edge registration motor

connector terminals.

Check for continuity across the coil. If none, replace the trailing

edge registration motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

1-3

Defective finisher main

PCB.

Check if a motor drive coil energization signal is output at CN6-1,

CN6-2, CN6-3 and CN6-4 on the finisher main PCB. If not,

replace the finisher main PCB.

1-3-10

Page 23

(2) Duplex unit

Problem Causes Check procedures/corrective measures

(1)

The duplex feedshift

solenoid does not

operate.

Broken duplex feedshift

solenoid coil.

Poor contact of the duplex

feedshift solenoid

connector terminals.

Check for continuity across the coil. If none, replace the duplex

feedshift solenoid.

Reinsert the connector. Also check for continuity within the

connector cable. If none, remedy or replace the cable.

3BN/3A4

Defective copier main PCB.

Run maintenance item U033 and check if CN5-3 and CN5-4 on

the copier main PCB go low. If not, replace the main PCB.

1-3

1-3-11

Page 24

3BN/3A4

1-3-4 Mechanical problems

(1) Finisher

Problem Causes/check procedures Corrective measures

(1)

Paper jams.

Check if the contact between the feedshift

pulley and feedshift roller is correct.

Check and remedy.

1-3

(2)

Abnormal noise is

heard.

Check if the contact between the feedshift

roller and press roller is correct.

Check if the rollers and gears operate

smoothly.

Check and remedy.

Grease the bushings and gears.

1-3-12

Page 25

(2) Duplex unit

Problem Causes/check procedures Corrective measures

(1)

Paper jams.

Check if the duplex pulley, upper duplex roller

or lower duplex roller is deformed.

3BN/3A4

Check visually and replace the pulley or

roller if deformed.

(2)

Abnormal noise is

heard.

Check if rollers and gears operate smoothly.

Apply grease to the bushings and gears.

1-3

1-3-13

Page 26

1-4-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the board.

• Do not touch any PCB containing ICs with bare hands or any object prone to static charge.

• Use the following testers when measuring voltages:

Hioki 3200

Sanwa MD-180C

Sanwa YX-360TR

Beckman TECH300

Beckman DM45

Beckman 330*

Beckman 3030*

Beckman DM850*

Fluke 8060A*

Arlec DMM1050

Arlec YF1030C

* Capable of measuring RMS values.

• Prepare the following as test originals:

1. NTC (new test chart)

2. NPTC (newspaper test chart)

3BN/3A4

1-4

1-4-1

Page 27

3BN/3A4

Stapler

5 ± 2.5 mm

5 ± 2.5 mm

1-4-2 Finisher

(1) Adjusting the positions of the front side registration cursor, rear side registration cursor and trailing edge

registration cursor (reference)

Perform the following adjustment if paper registration is poor or stapling is made outside the specified area.

Procedure

Start

Make a test copy

in staple-sort mode.

1-4

Is the paper registration

good?

Yes

Is the stapling

position correct?

See Figure 1-4-1.

Yes

End

No

No

Enter maintenance mode.

Enter 246 using the numeric

keys.

Press the start key.

Select the item to be adjusted

using the cursor up/down keys.

Change the setting using the

cursor left/right keys.

Press the start key.

The new setting

is stored.

Press the stop/clear key.

Figure 1-4-1 Stapling position

ADJUST FRONT JOGGER: Stop position of the

front side registration cursor

ADJUST REAR JOGGER: Stop position of the rear

side registration cursor

ADJUST END JOGGER: Stop position of the

trailing edge registration cursor

Setting range: 0 to 8

Reference: 4

Increasing the value moves the front or rear side

registration cursor or trailing edge registration

cursor outward (a); decreasing the value moves

each cursor inward (e). See Figure 1-4-2.

1-4-2

Exit maintenance mode.

Rear side registration cursor

Trailing edge

registration cursor

Front side

registration cursor

Figure 1-4-2

Page 28

(2) Cleaning the stapler

During periodic maintenance, remove all the staples remaining inside the machine due to failure of stapling.

Procedure

1. Open the front cover of the copier.

2. Remove the staple cartridge.

3. Remove the screw securing the stapler cover

and then the cover.

4. Remove the staples attracted to the magnet on

the inside of the stapler cover.

5. Refit all the removed parts.

Magnet

Staple

3BN/3A4

1-4

Stapler cover

Staple cartridge

Figure 1-4-3

1-4-3

Page 29

1-4

3BN/3A4

(3) Adjusting the tension of the front and rear side registration belts

Adjust the tension of each belt during periodic maintenance.

Procedure

1. Remove the intermediate tray unit from the

copier.

2. Loosen the tension adjustment screws for the

front and rear side registration belts. The

tension of the tension spring will be applied to

the belts.

3. Retighten the screws. Each belt will be

secured with the tension applied.

For adjusting the tension of

the rear side registration belt

Intermediate tray unit

For adjusting the tension

of the front side

registration belt

Figure 1-4-4

1-4-4

Page 30

3BN/3A4

Printer leading edge margin

for duplex copying

(second face, 3 ± 2.5 mm)

1-4-3 Duplex unit

(1) Adjusting the margin for printing

Perform the following adjustment if the printer leading edge margin for duplex copying (second face) is not correct.

Procedure

Start

Enter maintenance mode.

Enter “402” using the numeric

keys.

Press the start key.

Figure 1-4-5

Select “TRAIL 2” using the

cursor up/down keys.

1-4

Press the interrupt key.

Press the start key to

output a test pattern.

Is the margin correct?

Yes

Press the stop/clear key.

Exit maintenance mode.

End

Press the start key.

The new setting is stored.

No

Change the value using the

cursor left/right keys.

Setting range: –5.0 to +10.0

Reference: 4.5

Changing the value by 1 moves the margin by

0.5 mm.

Increasing the value makes the margin wider

and decreasing it makes the margin narrower.

1-4-5

Page 31

3BN/3A4

(2) Adjusting the amount of slack at the registration roller

Perform the following adjustment if the leading edge of the copy image is missing or varies randomly, or if the copy paper is

Z-folded during duplex copying.

Procedure

Start

Enter maintenance mode.

1-4

Enter “051” using the numeric

keys.

Press the start key.

Select “DUPLEX” using the

cursor up/down keys.

Press the interrupt key.

Make a test copy in duplex mode.

Is the leading

edge of the image missing

or varying randomly

(copy example 1)?

No

Is the copy paper

Z-folded (copy example 2)?

Yes

Yes

Press the start key.

The new setting is stored.

Increase the value using the

cursor right key.

Decrease the value using the

cursor left key.

Original Copy

example 1

Figure 1-4-6

Copy

example 2

No

Press the stop/clear key.

Exit maintenance mode.

End

Setting range: –50 to +50

Reference: 0

Changing the value by 1

changes the amount of slack

by 0.1 mm.

Initial setting: 0

The greater the value,

the larger the amount of slack;

the smaller the value,

the smaller the amount of slack

1-4-6

Page 32

3BN/3A4

(3) Adjusting the center line of image printing

Make the following adjustment if there is a regular error between the center lines of the copy image and original when

copying using the duplex unit.

Procedure

Start

Enter maintenance mode.

Enter “034” using

the numeric keys.

Press the start key.

Select “ADJ. LSU OUT TIMING”

using the cursor up/down keys

and press the start key.

Select “LSU DUP” using

the cursor up/down keys.

Press the interrupt key.

Press the start key to

output a test pattern.

Correct image Output

Press the start key.

The new setting is stored.

Center line of printing

example 1

Figure 1-4-7

Output

example 2

1-4

Is the image correct?

Yes

Press the stop/clear key

to exit maintenance mode.

End

For output example 1, decrease

the value using the cursor left key.

No

For output example 2, increase

the value using the cursor right

key.

Setting range: –5.0 to +5.0

Changing the value by 1 moves the

center line by 0.1 mm.

Initial setting: 0

1-4-7

Page 33

3BN/3A4

2-1-1 Feedshift section

The feedshift section consists of the components shown in Figure 2-1-1. It switches the path for the paper conveyed from

the copier in sort and duplex modes.

1

6

2

3

5

7

Figure 2-1-1 Feedshift section

1 Feedshift pulley

2 Feedshift roller

3 Press roller

4 Press roller lift

PCM

4

5 Stopper

6 Feedshift claw

7 Paper conveying switch (PCSW)

SBSOL

PCSW

FSSOL

2-1

PUSOL

CN6-7 –

CN6-12

CN4-10

CN4-2, 4

CN4-6, 8

MPCB

Figure 2-1-2 Feedshift section block diagram

CN4-7

2-1-1

Page 34

3BN/3A4

(1) Paper conveying operation in sort mode

When a copy is made in the sort mode, the feedshift solenoid (FSSOL) turns on and the feedshift guide of the copier

operates to switch the paper path to the feedshift section. The switchback solenoid (SBSOL) then turns on to lower the

separation claw and the paper is conveyed to the intermediate tray by the feedshift roller. When the trailing edge registration

cursor of the intermediate tray shifts the paper stocked in the intermediate tray to the stopper, the pickup solenoid (PUSOL)

turns on to lift the press roller and release the stopper, and the switchback solenoid (SBSOL) turns off to lift the feedshift

claw. The stack of paper on the intermediate tray is then ejected to the eject tray by the feedshift roller.

2-1

Feedshift claw

(SBSOL: ON)

Feedshift guide

(FSSOL: ON)

Feedshift claw

(SBSOL: OFF)

Feedshift pulley

To intermediate tray

Feedshift roller

Stocked paper

Press roller

Stopper (PUSOL: OFF)

Feedshift pulley

2-1-2

Feedshift roller

Press roller

Stopper (PUSOL: ON)

Figure 2-1-3

Page 35

3BN/3A4

(2) Switchback operation in duplex mode

In duplex mode, when the rear face of the paper is copied, the paper is conveyed to the feedshift section in the same

manner as in sort mode. When the trailing edge of the paper passes the paper conveying switch (PCSW), the paper

conveying motor (PCM) reverses, rotating the feedshift roller in the reverse direction to switch back the paper into the

duplex unit.

Feedshift roller

(PCM: Fwd. rotation)

PCSW: ON

PCSW: OFF

2-1

Feedshift roller

(PCM: Rev. rotation)

Figure 2-1-4

2-1-3

Page 36

3BN/3A4

2-1-2 Intermediate tray section

The intermediate tray section consists of the components shown in Figure 2-1-5. It stores and evens up the paper conveyed

from the feedshift section and returns the stack of paper to the feedshift section.

23

4

1

Figure 2-1-5 Intermediate tray section

2-1

1 Intermediate tray

2 Front side registration cursor

SRFHPS

FSRM

CN4-12

CN5-1 –

CN5-5

RSRM

CN5-6 –

Figure 2-1-6 Intermediate tray section block diagram

CN5-10

3 Rear side registration cursor

4 Trailing edge registration cursor

SRRHPS TERHPS

TERM

CN4-14

CN4-26

CN6-1 –

MPCB

CN6-4

2-1-4

Page 37

3BN/3A4

(1) Paper registration on the intermediate tray

In sort mode, the front and rear side registration cursors move to the size of the paper used to even up the sides of the stack

of paper and the trailing edge registration cursor shifts the paper to the feedshift section.

In staple-sort mode, the front and rear side registration cursors even up the sides of the stack of paper and shift the stack

toward the machine front, and then the trailing edge registration cursor shifts the stack to the stapling position.

Home positions

Rear side registration cursor

Trailing edge registration cursor

Front side

registration cursor

Paper registration

Shifting the paper to

the stapling position

2-1

Figure 2-1-7

2-1-5

Page 38

3BN/3A4

2-1-3 Eject section

The eject section consists of the components shown in Figure 2-1-8. It ejects paper to the eject tray.

2

2-1

1

3

Figure 2-1-8 Eject section

1 Eject tray

2 Eject pulley

4

3 Eject roller

4 Lower eject guide

2-1-6

Page 39

2-1-4 Stapler section

In staple-sort mode, paper stocked on the intermediate tray is stapled by the stapler.

The stapler motor (STM) drives the stapler cam via the stapler drive gear to staple paper.

3BN/3A4

Stapler self-priming

sensor

Figure 2-1-9 Stapler section

Stapler drive gear

Stapler cam

Stapler motor

Stapler cam

2-1

STES STCS

STHPS

STM

STSPS

Figure 2-1-10 Stapler section block diagram

CN4-20

CN4-22

CN4-16

CN6-13 –

CN6-16

CN4-24

MPCB

2-1-7

Page 40

2-1

3BN/3A4

2-1-5 Duplex unit

The duplex unit consists of the components shown in Figure 2-1-11. In duplex mode, it refeeds paper switched back in the

feedshift section to the copier paper feed section.

7

1

2

4

5

8

3

4

6

1 Duplex feedshift guide

2 Upper duplex roller

3 Lower duplex roller

4 Duplex pulley

Figure 2-1-12 Duplex unit block diagram

Figure 2-1-11 Duplex unit

5 Open/close guide

6 Entry guide

7 Duplex paper conveying switch 1 (DUPPCSW1)

8 Duplex paper conveying switch 2 (DUPPCSW2)

DUPPCSW1

CN5-10

DUPFSSOL

CN5-3, 4

DUPPCSW2

CN5-7

MPCB

(copier)

2-1-8

Page 41

3BN/3A4

(1) Switching the paper path in the duplex unit

In duplex mode, when the reverse face of the paper is copied, the paper is switched back in the feedshift section and

conveyed to the duplex unit. The paper is then conveyed to the paper conveying section of the copier by the upper and

lower duplex rollers.

When ejecting paper to the eject tray, the duplex feedshift solenoid (DUPFSSOL) turns on to operate the duplex feedshift

guide to switch the paper path to the eject tray.

Duplex feedshift guide

Eject tray

2-1

Figure 2-1-13

2-1-9

Page 42

2-2-1 Electrical parts layout

(1) Finisher

3BN/3A4

3

56

1

Machine front

2

Machine inside

4

Machine rear

Figure 2-2-1 Feedshift section

1. Left cover switch (LCSW) ............................ Detects if the copier left cover is opened or closed.

2. Paper conveying switch (PCSW) ................. Detects a paper jam in the finisher.

3. Paper conveying motor (PCM) .................... Drives the feedshift section.

4. Feedshift solenoid (FSSOL) ........................ Operates the feedshift guide of the copier.

5. Switchback solenoid (SBSOL) ..................... Operates the feedshift claw.

6. Pickup solenoid (PUSOL) ............................ Operates the press roller.

2-2

2-2-1

Page 43

3BN/3A4

6

2

8

7

5

4

3

1

9

2-2

Machine front Machine inside

Machine rear

Figure 2-2-2 Intermediate tray section

1. Main PCB (MPCB) ....................................... Controls electrical components.

2. Tray open/close switch (TOCSW) ................ Detects if the intermediate tray is opened or closed.

3. Intermediate tray sensor (ITS) ..................... Detects the presence of paper on the intermediate tray.

4. Side registration front home position

sensor (SRFHPS) ........................................ Detects the front side registration cursor in the home position.

5. Side registration rear home position

sensor (SRRHPS) ........................................ Detects the rear side registration cursor in the home position.

6. Trailing edge registration home position

sensor (TERHPS) ........................................ Detects the trailing edge registration cursor in the home position.

7. Front side registration motor (FSRM) .......... Drives the front side registration cursor.

8. Rear side registration motor (RSRM) .......... Drives the rear side registration cursor.

9. Trailing edge registration motor (TERM) ...... Drives the trailing edge registration cursor.

2-2-2

Page 44

3BN/3A4

2

1

3

5

4

Machine front Machine inside

Machine rear

Figure 2-2-3 Stapler section

1. Stapler empty sensor (STES) ...................... Detects the presence of staples.

2. Staple cartridge sensor (STCS) ................... Detects the presence of the staple cartridge.

3. Stapler home position sensor (STHPS) ....... Detects the stapler in the home position.

4. Stapler self-priming sensor (STSPS) ........... Detects the pre-stapling state of the stapler.

5. Stapler motor (STM) .................................... Drives the stapler.

2-2

2-2-3

Page 45

3BN/3A4

(2) Duplex unit

2

1

3

2-2

Machine front

Machine inside

Machine rear

Figure 2-2-4 Duplex unit

1. Duplex feedshift solenoid (DUPFSSOL) ...... Operates the duplex feedshift guide.

2. Duplex paper conveying switch 1

(DUPPCSW1) .............................................. Detects a paper jam in the duplex unit.

3. Duplex paper conveying switch 2

(DUPPCSW2) .............................................. Detects a paper jam in the duplex unit.

2-2-4

Page 46

2-3-1 Main PCB

Paper conveying

motor,

feedshift solenoid,

switchback

solenoid

3BN/3A4

Solenoids

Main PCB

CPU (IC5)

Buffer IC12,

IC13, IC14

TXD

Copier

Driver drive

circuit

RXD

Figure 2-3-1 Main PCB block diagram

Motors

Switches

and

sensors

2-3

The main PCB (MPCB) consists mainly of the CPU IC5 and driver drive circuit.

The CPU IC5 detects the condition of the switches and sensors and controls the motors and solenoids by serially

communicating with the copier. The paper conveying motor (PCM), switchback solenoid (SBSOL) and feedshift solenoid

(FSSOL) operate with the control signals from the copier.

2-3-1

Page 47

3BN/3A4

18CN8

IC1

1

R1

CN5

110

32

1

1

131

2

11 1

C1

1

R8 R9

C11

IC9

IC10

CN4

CN3

C12

IC4

IC11

D1

9

9

Figure 2-3-2 Main PCB silk-screen diagram

R2

IC13

1

ZD1

C13

IC8

1

1

TR4

TR5

5

C9

16

IC2

TR6

C14

R7

C8

CN6

C10

1

16 2

15 1

8

IC20

12 1

IC5

TP1

TP2

TP4

8

8

L3F1

C2

100

IC12

TP5

81

C3

CN2

80

C4

1

IC6

1

IC14

1

12

D3

1

CN1

18

JP1

IC3

18

1

D2

JP2

1

51

50

R3

R4

31

30

TP3

IC7

8

IC15

TR1

1

8

10

1

1

D4

IC16

8

IC17

TR2

TR3

C6

C5 C7

L1

X1

R5 R6

18

8

IC18

CN7

8

7

L2

IC19

1

2

2-3

2-3-2

Page 48

Terminals (CN) Voltage Remarks

1-2 1-7 0/5 V DC PCM control signal (MODE), input

1-3 1-9 5/0 V DC TOCSW on/off, output

1-4 1-7 0/5 V DC PCM on/off, input

1-5 1-7 0/5 V DC PCM control signal CWB, input

1-6 1-7 0/5 V DC (pulse) PCM clock signal, input

1-8 1-7 5 V DC 5 V DC supply, input

2-1 2-3 0/5 V DC RESET signal, input

2-4 2-5 0/5 V DC (pulse) Serial signal TXD, input

2-6 2-7 0/5 V DC (pulse) Serial signal RXD, output

2-8 2-7 5 V DC 5 V DC supply, input

2-11 2-9 24 V DC 24 V DC supply, input

2-12 2-10 24 V DC 24 V DC supply, input

3-1 3-4 0/24 V DC SBSOL release signal, input

3-2 3-4 0/24 V DC SBSOL latch-on signal, input

3-3 3-4 24 V DC 24 V DC supply for SBSOL, input

3-5 3-4 0/5 V DC PCSW on/off, output

3-6 3-4 5 V DC 5 V DC supply for PCSW, input

3-7 3-4 0/24 V DC FSSOL release signal, input

3-8 3-4 0/24 V DC FSSOL latch-on signal, input

3-9 3-4 24 V DC 24 V DC supply for FSSOL, input

4-1 4-29 24 V DC 24 V DC supply for FSSOL, output

4-2 4-29 0/24 V DC FSSOL latch-on signal, output

4-3 4-29 24 V DC 24 V DC supply for SBSOL, output

4-4 4-29 0/24 V DC FSSOL release signal, output

4-5 4-29 24 V DC 24 V DC supply for PUSOL, output

4-6 4-29 0/24 V DC SBSOL latch-on signal, output

4-7 4-29 0/24 V DC PUSOL on/off, output

4-8 4-29 0/24 V DC SBSOL release signal, output

4-9 4-29 5 V DC 5 V DC supply for PCSW, output

4-10 4-29 0/5 V DC PCSW on/off, input

4-11 4-23 5 V DC 5 V DC supply for SRFHPS, output

4-12 4-23 0/5 V DC SRFHPS on/off, input

4-13 4-25 5 V DC 5 V DC supply for SRRHPS, output

4-14 4-25 0/5 V DC SRRHPS on/off, input

4-15 4-27 5 V DC 5 V DC supply for stapler, output

4-16 4-27 0/5 V DC STHPS on/off, input

4-17 4-21 5 V DC 5 V DC supply for ITS, output

4-18 4-21 0/5 V DC ITS on/off, input

4-19 4-28 5 V DC 5 V DC supply for TERHPS, output

4-20 4-27 0/5 V DC STCS on/off, input

4-22 4-27 0/5 V DC STES on/off, input

4-24 4-27 0/5 V DC STSPS on/off, input

4-26 4-28 0/5 V DC TERHPS on/off, input

5-1 3-4 0/24 V DC (pulse) FSRM motor coil energization pulse, output (A)

5-2 3-4 24 V DC 24 V DC supply for FSRM, output

5-3 3-4 0/24 V DC (pulse) FSRM motor coil energization pulse, output (B)

5-4 3-4 0/24 V DC (pulse) FSRM motor coil energization pulse, output (B)

5-5 3-4 0/24 V DC (pulse) FSRM motor coil energization pulse, output (A)

5-6 3-4 0/24 V DC (pulse) RSRM motor coil energization pulse, output (A)

5-7 3-4 24 V DC 24 V DC supply for RSRM, output

5-8 3-4 0/24 V DC (pulse) RSRM motor coil energization pulse, output (B)

5-9 3-4 0/24 V DC (pulse) RSRM motor coil energization pulse, output (B)

5-10 3-4 0/24 V DC (pulse) RSRM motor coil energization pulse, output (A)

6-1 3-4 0/24 V DC (pulse) TERM motor coil energization pulse, output (A)

6-2 3-4 0/24 V DC (pulse) TERM motor coil energization pulse, output (B)

6-3 3-4 0/24 V DC (pulse) TERM motor coil energization pulse, output (B)

3BN/3A4

2-3

2-3-3

Page 49

3BN/3A4

Terminals (CN) Voltage Remarks

6-4 3-4 0/24 V DC (pulse) TERM motor coil energization pulse, output (A)

6-5 3-4 24 V DC 24 V DC supply for TERM, output

6-7 3-4 24 V DC 24 V DC supply for PCM, output

6-8 3-4 24 V DC 24 V DC supply for PCM, output

6-9 3-4 0/24 V DC (pulse) PCM motor coil energization pulse, output (A)

6-10 3-4 0/24 V DC (pulse) PCM motor coil energization pulse, output (A)

6-11 3-4 0/24 V DC (pulse) PCM motor coil energization pulse, output (B)

6-12 3-4 0/24 V DC (pulse) PCM motor coil energization pulse, output (B)

6-13 3-4 0/24 V DC STM forward rotation drive signal (F), output

6-14 3-4 0/24 V DC STM forward rotation drive signal (F), output

6-15 3-4 0/24 V DC STM reverse rotation drive signal (R), output

6-16 3-4 0/24 V DC STM reverse rotation drive signal (R), output

7-3 3-4 24/0 V DC TOCSW on/off, input

7-6 3-4 24/0 V DC LCSW on/off, output

7-7 3-4 24 V DC 24 V DC supply for LCSW, output

7-8 3-4 24/0 V DC LCSW on/off, input

2-3

2-3-4

Page 50

PCM CN6-9, 10, 11, 12

SRFHPS CN4-12

FSRM CN5-1, 2, 3, 5

SRRHPS CN4-14

RSRM CN5-6, 8, 9, 10

TERHPS CN4-26

TERM CN6-1, 2, 3, 4

PCSW CN4-10

P1

P2

P3

Initialization start

Sort endStandby for paper entry

Paper entry

Positioning for side registration

300 ms 300 ms100 ms

T1 T1

100 ms

1000 mm/s

55 P

35 P

1 Operation start

Finisher operation sequence

Simplex copying

Sort mode: 1 → 3 or 4 → 5 or 6

Staple-sort mode:

1 → 2 → 5 or 6

Duplex copying

Sort mode: 1 → 3 or 4 → 7 or 8

Staple-sort mode:

1 → 2 → 7 or 8

Pulse Paper sizes

No. of

pulses

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

P1

367

438

521

398

510

Pulse Paper sizes

No. of

pulses

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

P2

0

71

154

31

143

Pulse Paper sizes

No. of

pulses

A3

B4

A4R

A4

B5

11" × 17"

8

1

/

2

" × 14"

8

1

/

2

" × 11"

11" × 8

1

/

2

"

P3

42

240

476

784

883

0

269

539

763

Timer Paper sizes

Timer

value

A4, B5, 11" × 8

1

/

2

"

B4, A4R, 8

1

/

2

" × 11", 8

1

/

2

" × 14"

A3, 11" × 17"

Other sizes

T1

850 ms

950 ms

1050 ms

550 ms

3BN/3A4

2-4

Timing chart No. 1

2-4-1

Page 51

SRFHPS CN4-12

FSRM CN5-1,

2, 3, 5

SRRHPS CN4-14

RSRM CN5-6,

8, 9, 10

TERHPS CN4-26

TERM CN6-1,

2, 3, 4

STM CN6-13,

14, 15, 16

STHPS CN4-16

SRFHPS CN4-12

FSRM CN5-1,

2, 3, 5

SRRHPS CN4-14

RSRM CN5-6,

8, 9, 10

TERHPS CN4-26

TERM CN6-1,

2, 3, 4

SRFHPS CN4-12

FSRM CN5-1,

2, 3, 5

SRRHPS CN4-14

RSRM CN5-6,

8, 9, 10

TERHPS CN4-26

TERM CN6-1,

2, 3, 4

Sort end

Moving to stapling position

Stapling

Moving to

shift-eject

position

To batch

ejection

Sort end To batch

ejection

150 ms 150 ms

150 ms

P4 P5

P4 P5

P6

P6

P7

P7

Moving to

shift-eject

position

Sort end To batch

ejection

Moving to

shift-eject

position

2 Stapling operation 3 Non-stapling operation (for front-shift ejection) 4 Non-stapling operation (for rear-shift ejection)

300 ms

Pulse Paper sizes

No. of

pulses

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

P4

367

438

521

398

510

Pulse

Paper sizes No. of pulses

Paper sizes

Front-shift ejection Rear-shift ejection

No. of pulses

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

P5

292

415

498

323

488

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

380

521

604

411

594

Pulse Paper sizes

No. of

pulses

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

P6

53

18

18

53

18

Pulse Paper sizes

No. of

pulses

A3, A4

B4, B5

A4R

11" × 17", 11" × 8

1

/

2

"

8

1

/

2

" × 14", 8

1

/

2

" × 11"

P7

18

88

88

18

88

3BN/3A4

2-4

Timing chart No. 2

2-4-2

Page 52

SRFHPS CN4-12

FSRM CN5-1,

2, 3, 5

SRRHPS CN4-14

RSRM CN5-6,

8, 9, 10

TERHPS CN4-26

TERM CN6-1,

2, 3, 4

PCSW CN4-10

PCM CN6-9,

10, 11, 12

PUSOL CN4-7

500 ms

100 mm/s 100 mm/s

2 s

300 mm/s

200 mm/s

Batch ejection start

SRFHPS CN4-12

FSRM CN5-1,

2, 3, 5

SRRHPS CN4-14

RSRM CN5-6,

8, 9, 10

TERHPS CN4-26

TERM CN6-1,

2, 3, 4

PCSW CN4-10

PCM CN6-9,

10, 11, 12

PUSOL CN4-7

500 ms

100 mm/s 100 mm/s

2 s

300 mm/s

200 mm/s

Batch ejection start

330 ms

5 Batch ejection 1 (simplex copying onto large paper)

Small paper: A4, B5, 11"

× 8

1

/

2

" Large paper: others

6 Batch ejection 2 (simplex copying onto small paper)

3BN/3A4

2-4

Timing chart No. 3

2-4-3

Page 53

3BN/3A4

SRFHPS CN4-12

FSRM CN5-1, 2,

3, 5

SRRHPS CN4-14

RSRM CN5-6, 8,

9, 10

TERHPS CN4-26

TERM CN6-1, 2,

3, 4

PCSW CN4-10

PCM CN6-9, 10,

11, 12

PUSOL CN4-7

500 ms

100 mm/s 100 mm/s

2 s

300 mm/s

200 mm/s

Batch ejection start

SRFHPS CN4-12

FSRM CN5-1, 2,

3, 5

SRRHPS CN4-14

RSRM CN5-6, 8,

9, 10

TERHPS CN4-26

TERM CN6-1, 2,

3, 4

PCSW CN4-10

DUPPCSW1 CN5-10 DUPPCSW1 CN5-10

PCM CN6-9, 10,

11, 12

PUSOL CN4-7

500 ms

100 mm/s 100 mm/s

300 mm/s

200 mm/s

Batch ejection start

330 ms

2 s

7 Batch ejection 3 (duplex copying onto large paper) 8 Batch ejection 4 (duplex copying onto small paper)

Small paper: A4, B5, 11"

× 8

1

/

2

" Large paper: others

2-4

Timing chart No. 4

2-4-4

Page 54

3BN/3A4

Periodic maintenance procedures

• Finisher

Section

Stapler section Magnet Clean Every service Remove the staples attracted to 1-4-3

• Duplex unit

Section

Paper Upper duplex roller Clean Every service Clean with alcohol or a dry cloth.

conveying

section

Maintenance

part/location

Maintenance

part/location

Lower duplex roller Clean Every service Clean with alcohol or a dry cloth.

Method Maintenance cycle Points and cautions Page

the magnet inside the stapler

cover.

Method Maintenance cycle Points and cautions Page

2-4-5

2-4

Page 55

3BN/3A4

ABCDEFGH I J

ABCDEFGH I J

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

3

2

1

2

3

1

3

2

1

1

3

2

3

2

1

3

2

SET

N.C

SET

N.C

2

RD C201-32

RD C201-31

YW C201-19

OE C201-20

BE C201-22

BE C201-28

OE C201-21

YW C201-25

YW C201-24

YW C201-26

YW C201-23

RD C201-15

RD C201-16

BE C201-17

BE C201-18

GY C201-11

GY C201-14

GY C201-13

RD C205-1

RD C205-3

BE C206-11

BE C204-3

YW C206-13

YW C206-8

YW C206-7

YW C206-9

YW C204-2

OE C206-12

OE C204-1

BE C206-2

BE C206-1

RD C206-5

RD C206-4

GY C202-1

GY C202-3

GY C202-6

GY C202-4

RD C202-5

RD C202-2

GY C203-3

GY C208-3

GY C208-2

GY C207-3

GY C207-2

RD C203-1

RD C208-1

RD C207-1

RD C007-8

RD C007-7

BE C004-27

BE C004-29

YW C004-24

YW C004-22

YW C004-20

YW C004-16

YW C004-10

OE C004-15

OE C004-9

BE C006-16

BE C006-15

RD C006-14

RD C006-13

GY C006-12

GY C006-11

GY C006-10

GY C006-9

RD C006-8

RD C006-7

GY C004-7

GY C004-8

GY C004-6

GY C004-4

GY C004-2

RD C004-5

RD C004-3

RD C004-1

RD C007-6

RD C007-3

RD C006-5

GY C006-4

GY C006-3

GY C006-2

GY C006-1

GY C005-10

GY C005-9

GY C005-8

GY C005-6

GY C005-5

GY C005-4

GY C005-3

RD C005-7

RD C005-2

GY C005-1

YW C112-2

YW C110-2

YW C109-2

YW C107-2

BE C112-3

BE C110-3

BE C109-1

BE C107-1

OE C112-1

OE C110-1

OE C107-3

OE C109-3

GY C111-5

GY C111-4

GY C111-3

GY C111-1

RD C111-2

RD C105-1

RD C105-3

GY C106-5

GY C106-4

GY C106-3

GY C106-1

RD C106-2

RD C108-2

GY C108-5

GY C108-4

GY C108-3

GY C108-1

BE C104-18

BE C104-17

RD C104-16

RD C104-15

GY C104-14

GY C104-13

GY C104-12

GY C104-11

RD C104-32

RD C104-31

RD

RD

RD C104-10

RD C104-9

BE C104-27

BE C104-21

YW C104-26

YW C104-25

YW C104-24

YW C104-23

OE C104-22

YW C104-20

OE C104-19

GY C104-6

GY C104-8

GY C104-5

RD C104-7

RD C104-4

GY C104-3

GY C104-2

RD C104-1

GY C103-1

GY C103-2

GY C003-11

GY C003-10

GY C103-3

GY C103-4

GY C103-5

GY C103-6

GY C103-7

GY C103-8

GY C103-9

GY C103-10

GY C103-11

GY C003-1

GY C003-2

GY C003-3

GY C003-4

GY C003-5

GY C003-6

GY C003-7

GY C003-8

GY C003-9

GY C102-1

GY C102-2

GY C102-3

GY C102-4

GY C102-5

GY C102-6

GY C102-7

GY C102-8

GY C102-9

GY C102-10

GY C102-11

GY C102-12

GY C002-1

GY C002-2

GY C002-3

GY C002-4

GY C002-5

GY C002-6

GY C002-7

GY C002-8

GY C002-9

GY C002-10

GY C002-11

GY C002-12

GY C101-2

GY C101-3

GY C101-4

GY C101-5

GY C101-6

GY C101-7

GY C101-8

GY C101-9

GY C101-10

GY C001-9

GY C001-8

GY C001-7

GY C001-6

GY C001-5

GY C001-4

GY C001-3

GY C001-2

GY C001-1

N.C

N.C

LCSW

LCSW 24V

TOCSW 24V

TOCSW

RSRM A

RSRM B

RSRM B

24V

RSRM A

FSRM A

FSRM B

FSRM B

24V

FSRM A

STM R

STM R

STM F

STM F

PCM B

PCM B

PCM A

PCM A

24V

24V

N.C

24V

TERM B

TERM A

TERM B

TERM A

N.C

TERHPS SG

ST SG

TERHPS

SRRHPS SG

STSPS

STES

ITS SG

STCS

TERHPS 5V

ITS

ITS 5V

STHPS

ST 5V

SRRHPS

SRRHPS 5V

3

2

1

1

2

3

TERM RSRM FSRM

TOCSW

TERHPS SRRHPS SRFHPS

ITS

PCSW

LCSW

PUSOLPCM

FSRM B

FSRM A

FSRM B

R24V

FSRM A

RSRM B

RSRM A

RSRM B

R24V

RSRM A

PUSOL

Stapler

5V

STSPS

FSSOL

SBSOL

SRFHPS SG

SRFHPS

SRFHPS 5V

PCSW SG

PCSW

PCSW 5V

PUSOL

PUSOL 24V

SBSOL R

SBSOL A

SBSOL 24V

FSSOL R

FSSOL A

FSSOL 24V

5V

PCSW

SG3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

STM F

STCS

STHPS

SG

STHPS

STM F

STM R

STM R

TOCSW

TOCSW 24V

1

LCSW

LCSW 24V

RD C201-7

YW C004-18

OE C004-17

BE C004-21

5V

ITS

SG

3

2

1

YW C004-12

OE C004-11

BE C004-23

5V

SRFHPS

SG

3

2

1

5

4

3

2

1

5

4

3

2

1

GY C201-5

GY C201-6

RD C201-3

GY C201-4

GY C201-1

RD C201-2

RD C201-8

FSSOL A

FSSOL R

SBSOL R

SBSOL A

R24V

R24V

R24V

3

2

1

3

1

3

2

1

YW C004-14

YW C004-26

OE C004-13

OE C004-19

BE C004-25

BE C004-28

RD C201-9

GY C201-12

RD C201-10

5V

SRRHPS

SG

5V

TERHPS

SG

5

4

3

2

1

TERM B

TERM A

TERM B

R24V

TERM A

6

5

4

3

2

1

3

2

1

3

2

1

PCM B

PCM B

PCM A

PCM A

R24V

R24V

30 29 28 27

26 25 24 23 22 21

2019181716151413121110987654321

302928272625242322212019181716151413121110987654321

11

12

11

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

PCSW

FSSOL 24V

SG

SBSOL A

SBSOL R

PCSW 5V

SBSOL 24V

FSSOL R

FSSOL A

24V

24V

SET

SG

RXD

TXD

SG

5V

PG

PG

RESET

SG

1

2

3

4

5

6

7

8

9

10

SG

SET

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

PCM MODE

PCM CWB

10

TOCSW

PCM

PCM CLOCK

5V

PG

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

11

10

9

PCSW

FSSOL R

FSSOL A

8

7

6

5

4

3

2

1

PG

PG

24V

24V

12

11

10

9

PG

PCM CLOCK

10

RESET

SG

RXD

SG

TXD

SG

5V

5V

SG