MISUMI DS102MS, MSCTL102, MCSTL102-MS, MSCTL102-IO-MS, DS102MS-IO Operation Manual

...

Stepping Motor Controller

MSCTL102 Series/MSCTL112 Series Operation Manual

Ver 1.01 (02.13.2015)

Remarks

MSCTL102/112 Series(MISUMI products) are same as DS102/112 Series that are made by Suruga Seiki.

All of DS102/112 series that are mentioned in the operation manual indicate MSCTL102/112.

MISUMI CO., LTD.

SURUGA SEIKI CO., LTD.

2

Index

1.INTRODUCTION ................................................................................................................................................................................. 5

1.1 FOR YOUR SAFETY .............................................................................................................................................................................. 5

1.2 PRODUCT OUTLINE / FEATURES ................................................................................................................................................... 7

1.3 SYSTEM CONFIGURATION EXAMPLE .............................................................................................................................................. 9

1.3.1 CONTROL WITH PLC................................................................................................................................................................. 9

1.3.2 CONTROLLED BY PC ............................................................................................................................................................. 10

1.4 ACCESSORIES .................................................................................................................................................................................... 11

2.SET-UP AND EXAMPLE OF USE ................................................................................................................................ 11

2.1 SET UP BEFORE USE ....................................................................................................................................................................... 11

2.1.1 CONNECTING ............................................................................................................................................................................ 12

2.1.2 USB DRIVER INSTALL ......................................................................................................................................................... 15

2.1.3 INSTALLATION FOR CONTROL SOFTWARE DS102/112(DSCONTROL-WIN) ..................................... 19

2.1.4 ADJUSTMENT SYSTEM PARAMETER ............................................................................................................................... 23

2.1.5 OPERATION CHECK ................................................................................................................................................................ 25

2.2 SYSTEM ARCHITECTURE ............................................................................................................................................................... 27

2.2.1 MOVEMENT BETWEEN EACH TEACHING POSITION..................................................................................................... 27

2.2.2 EASY RETURN TO ORIGIN POSITION .................................................................................................................................. 34

2.2.3 CONTROL BY EXTERNAL SIGNAL ...................................................................................................................................... 43

2.2.4 EXTERNAL DEVICE CONTROL WITH GENERALI/O. ................................................................................................. 54

2.2.5 MOVE TO ARBITRARY COORDINATE ................................................................................................................................ 56

2.2.6 CONTROLLED OVER 3 AXES .............................................................................................................................................. 58

3.SPEC AND FUNCTION........................................................................................................................................................... 59

3.1 BASIC SPEC ...................................................................................................................................................................................... 59

3.2 PART NAME AND FUNCTIONS ..................................................................................................................................................... 60

3.3 SETTING .................................................................................................................................................................................................. 63

3.4 EXTERNAL INTERFACE ...................................................................................................................................................................... 64

3.4.1 LINK CONNECTION(LINK) ................................................................................................................................................... 64

3.4.2 CONTROL INPUT/OUTPUT(CNT-I/O) ........................................................................................................................ 65

3.4.3 GENERAL I/O(I/O)( OPTION) ........................................................................................................................................ 68

3.4.4 EMERGENCY STOP INPUT(EMS) .................................................................................................................................... 70

3.4.5 STAGE INTERFACE ..................................................................................................................................................................... 70

3.5 DRIVER DIVISION NUMBER SETTING .............................................................................................................................................. 71

3.5.1 OPEN AND SHUT ........................................................................................................................................................................ 71

3.5.2 SETTING DIVISION NUMBER ..................................................................................................................................................... 71

3.6 SMOOTH DRIVE FUNCTION(ONLY MS TYPE) ...................................................................................................................... 72

3.7 UNITS SETTING FUNCTION ............................................................................................................................................................... 73

3.8 SPEED SETTING(SPEED TABLE) .............................................................................................................................................. 74

3.9 FUNCTION OF ORIGIN RETURN ........................................................................................................................................................ 77

3.10 LINEAR INTERPOLATING FUNCTION ........................................................................................................................................... 83

3.10.1 LINEAR INTERPOLATING(RELATIVE VALUE) ........................................................................................................... 83

3.10.2 LINEAR INTERPOLATING(ABSOLUTE VALUE) ........................................................................................................ 83

3.11 TEACHING FUNCTION ..................................................................................................................................................................... 84

3.12 PROGRAM FUNCTION ..................................................................................................................................................................... 84

3

4.OPERATION AND CONTROL METHOD .................................................................................................................. 85

4.1 OPERATION BY THE HANDY TERMINAL ...................................................................................................................................... 85

4.1.1 INITIAL SCREEN ............................................................................................................................................................................ 85

4.1.2 TRANSITION MODE ..................................................................................................................................................................... 86

4.1.3 DRIVING MODE SELECT(JOG KEY) ............................................................................................................................. 87

4.1.3.1 CONTINUOUS DRIVING MODE(CNT:CONTINUE MODE) ............................................................................ 87

4.1.3.2 UNIFORM PULSE DRIVING MODE(STP: STEP MODE) ................................................................................ 87

4.1.3.3 ABSOLUTE VALUE DRIVING MODE(ABS: ABSOLUTE MODE) ............................................................... 88

4.1.3.4 ORIGIN RETURN MODE(ORG: ORIGIN MODE) ............................................................................................... 88

4.1.3.5 HOME POSITION RETURN MODE(HOM:HOME) .......................................................................................... 88

4.1.4 MENU SELECT(MENU KEY) .............................................................................................................................................. 89

4.1.4.1 PARAMETER MODE(PRM) ....................................................................................................................................... 89

4.1.4.2 PROGRAM DRIVING MODE(PRG) ......................................................................................................................... 98

4.1.4.3 TEACHING MODE (TCH) ......................................................................................................................................... 99

4.1.4.4 GENERAL MONITOR(IN) ....................................................................................................................................... 102

4.1.4.5 GENERAL OUTPUT CONTROL(OUT) .............................................................................................................. 102

4.1.5 OTHER FUNCTION .................................................................................................................................................................. 103

4.1.5.1 CHANGE THE SPEED TABLE(SPD KEY)....................................................................................................... 103

4.1.5.2 CHANGE THE AXIS(LINK KEY) ............................................................................................................................ 103

4.1.5.3 CHANGES CURRENT POSITION(POS KEY) ................................................................................................... 103

4.1.5.4 VERSION CONFIRMATION, PARAMETER RESET .................................................................................................. 104

4.2 DS102/112 CONTROLLED SOFTWARE(DSCONTROL-WIN) ...................................................................... 105

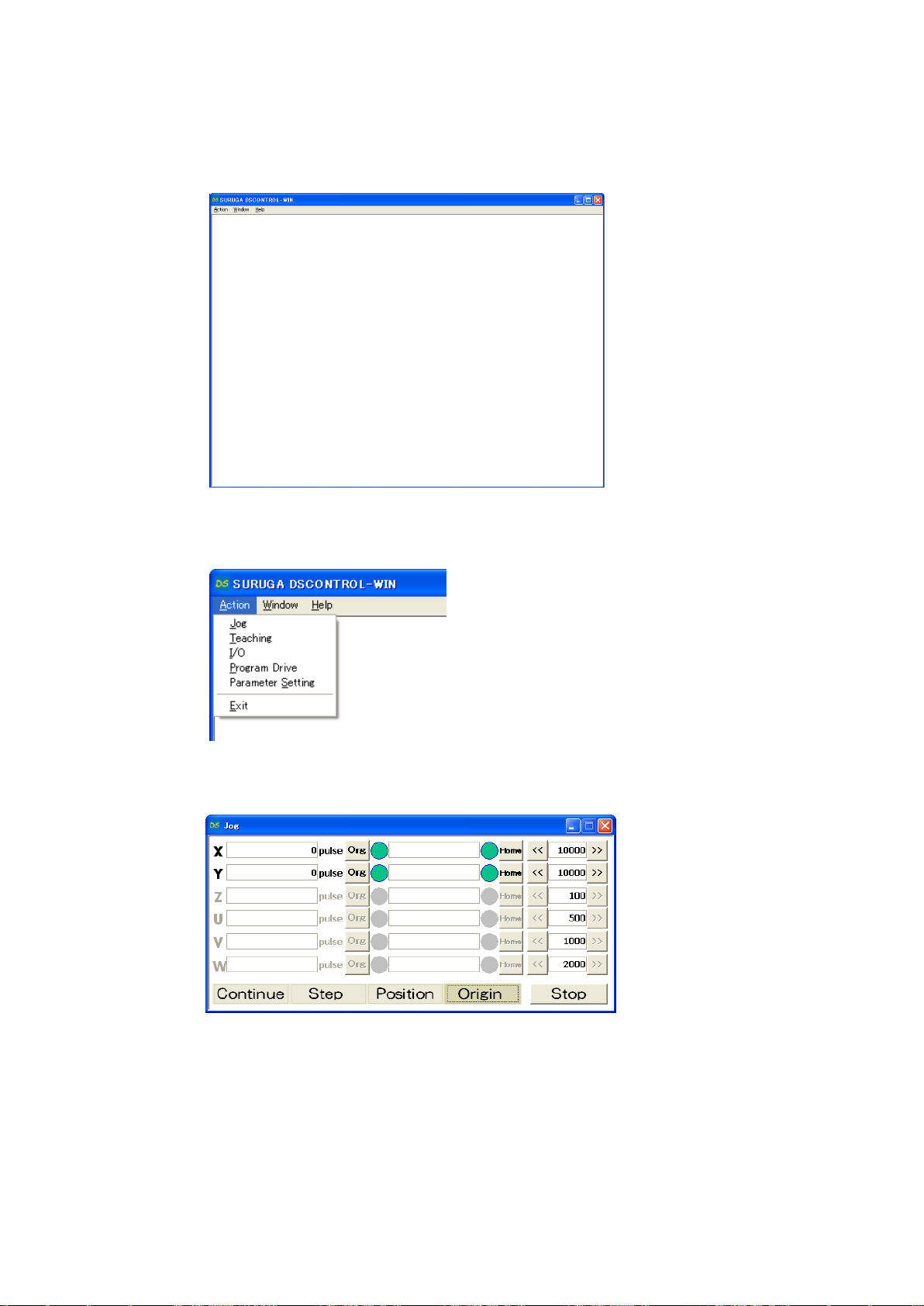

4.2.1 DSCONTROL-WIN START-UP ................................................................................................................................... 105

4.2.2 PARAMETER SET-UP ............................................................................................................................................................ 105

4.2.3 JOG DRIVING ............................................................................................................................................................................. 107

4.2.4 TEACHING ................................................................................................................................................................................. 110

4.2.5 DRIVING PROGRAM ................................................................................................................................................................ 112

4.2.6 I/O MONITOR ..................................................................................................................................................................... 118

4.3 USER PROGRAM PROCESSING ................................................................................................................................................... 119

4.3.1 RS232C ................................................................................................................................................................................ 119

4.3.2 USB ........................................................................................................................................................................................... 120

4.3.3 DELIMITER .................................................................................................................................................................................. 122

4.3.4 TYPES OF COMMUNICATION COMMAND ........................................................................................................................ 123

4.3.5 DETAILS OF COMMUNICATION COMMAND .................................................................................................................. 135

4.3.5.1 AXIS SPECIFICATION COMMAND .............................................................................................................................. 135

4.3.5.2 PARAMETER SETTING COMMAND ........................................................................................................................... 135

4.3.5.3 MEMORY SW SETTING COMMAND........................................................................................................................ 139

4.3.5.4 SPEED TABLE SETTING COMMAND ...................................................................................................................... 140

4.3.5.5 WRITE COMMAND ......................................................................................................................................................... 141

4.3.5.6 DRIVING COMMAND ...................................................................................................................................................... 141

4.3.5.7 STOP COMMAND ........................................................................................................................................................... 142

4.3.5.8 PARAMETER SETTING REQUEST COMMAND .................................................................................................... 143

4.3.5.9 MEMORY SW SETTING REQUEST COMMAND .................................................................................................. 145

4.3.5.10 SPEED TABLE SETTING REQUEST COMMAND .............................................................................................. 147

4.3.5.11 STATUS REQUEST COMMAND............................................................................................................................. 147

4.3.5.12 GENERAL I/O COMMAND ....................................................................................................................................... 152

4.3.6 PROGRAM DRIVING DEDICATED COMMAND ............................................................................................................... 153

4.3.7 ERROR CODE ........................................................................................................................................................................... 156

4

5.CHECKOUT ..................................................................................................................................................................................... 157

6.FAULT DIAGNOSIS AND SOLUTION ...................................................................................................................... 157

7.WARRANTY & CUSTOMER SERVICE.................................................................................................................... 158

● APPENDIX ............................................................................................................................................................................................... 159

■ DIP SWITCH SET ............................................................................................................................................................................................. 159

■ DS102 EXTERNALS .................................................................................................................................................................................... 160

■ DS112 EXTERNALS .................................................................................................................................................................................... 161

■ CONTROL I/O CABLE(MODEL:DS100-CNT-2) ............................................................................................................... 162

■ GENERAL I/O CABLE(MODEL:DS100-IO-2) ................................................................................................................... 163

■ SELECTION OF A PROGRAM NUMBER BY CNT-IO ........................................................................................................................ 164

■ SELECTION OF A TEACHING NUMBER BY CNT-IO ........................................................................................................................ 164

5

Cautions

!

1.INTRODUCTION

Thank you for purchasing this series Stepping Motor Controller.

1.1 For Your Safety

For Proper use, please read this operation manual thoroughly prior to using this product.

means the PROHIBITATION.

Please look after instructions shown here by all means.

Failure to use controller, may be hurt or suffer material damage.

・Basic cautions

・ Connect a power cable to a power outlet which comes with protective earth terminal, In case of

using an extension cable without protective earth terminal, protective earth will be of no effect.

・Cable

・When you unplug a power cable, turn off a power switch.

・When it supplies DS112 Series with a power supply, please be careful not to make a mistake in

polarity.

・Operating Environment

・To avoid as follows.:

-Areas that have much dust or metallic particles

-Directly under sunlight

-Near fire

-Much vibration

-Watery or oily place

-Wonky place

-Place with Corrosive Gas and Flammable Gas

・Storage

Please unplug a power from the outlet when

It doesn’t use for a long time, and you move this product..

A fire and the accident of the electric shock etc. are prevented.

6

Caution

!

・Power Source

・Please DO NOT connect the DS102 series besides the power supply outlet of interchange 100~

240V (AC100~240V 50/60Hz)

・Please supply direct 24V(DC24V±10%)power supply for DS112 series.

In order to avoid damage to controller, DO NOT use any input voltage or frequency over

the specifications.

・Resolution of the product/Remodeling

・ Please DO NOT perform the resolution of the product, remodeling, the

unfair repair.

・ Please contact us for correct information if needed.

・Repair Service

・ In the case of the following, please disconnect the plug promptly and then

contact your supplier.

-When there are some strange sound, smelling and smoke.

-When a power supply cable damaged.

-When spilled water on the equipment and foreign materials entered

inside.

-When dropped the equipment and was damaged with a cabinet.

7

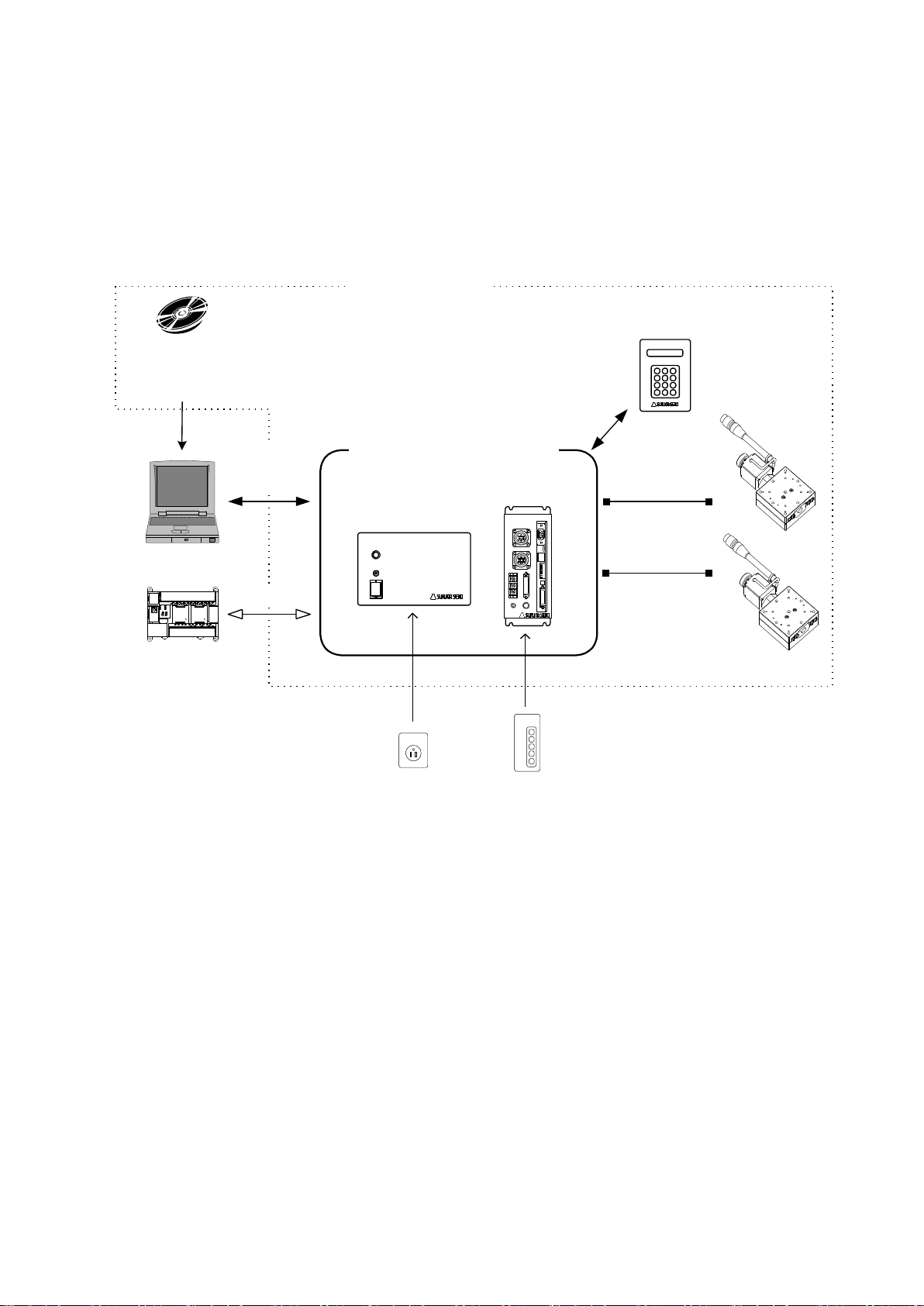

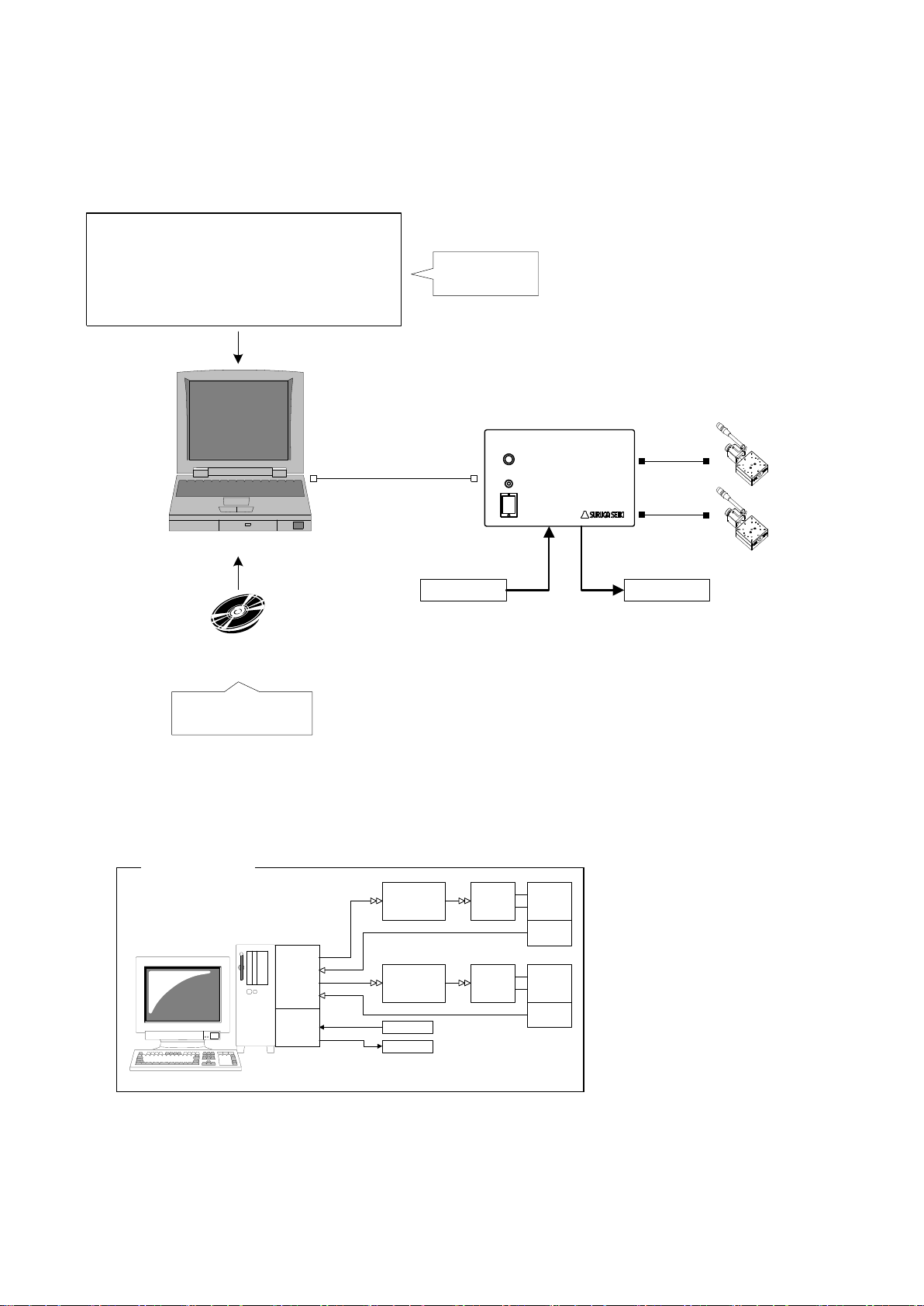

1.2 Product Outline / Features

Computer

PLC

DC24V

AC100V

XY

DS112

Stepping Motor Controller

DS112

Stepping Motor Controller

DS102/DS112 series

AC100~240V

DC24V

Motorized stage

DS102/112

Controlled software:

DSCONTROL-WIN

DS102

Stepping Motor

Controller

DS102

Suruga Seiki

Standard

DT100

Handyterminal

DT100

I/O for

controlled

USB

or

RS232C

DS102/DS112 series is stepping motor controller with 2 axes for not only R&D but also units and

manufacturing you can use what you want.

Product Outline

8

Features

SURUGA Type

MISUMI Type

Input PS

Type of Drive

General I/O

DS102NR

MSCTL102

AC100~240V

±10%

50/60Hz

Normal (FULL/HALF)

-

DS102NR-IO

MSCTL102-IO

Input16, Output12

DS102MS

MCSTL102-MS

Microstep (16levels)

-

DS102MS-IO

MSCTL102-IO-MS

Input16, Output12

DS112NR

MSCTL112

DC24V ±10%

Normal (FULL/HALF)

-

DS112NR-IO

MSCTL112-IO

Input16, Output12

DS112MS

MCSTL112-MS

Microstep (16levels)

-

DS112MS-IO

MSCTL112-IO-MS

Input16, Output12

SURUGA Type

MISUMI Type

Cable length

Recital

DS100-LINK2-0.5

MSLINK2-0.5

0.5m

For 2 links

DS100-LINK3-0.5

MSLINK3-0.5

0.5m

For 3 links

DS100-CNT-2

MSCNT2

2m

For control I/O(one end loose)

DS100-IO-2

MSGP2

2m

For general I/O(one end loose)

D100-R9-2

MSRS232C

2m

RS232C cable

DS100-USB-1.8

MSUSB1.8

1.8m

USB Cable

SURUGA Type

MISUMI Type

Article name

DT100

HDT100

Handy Terminal

DSCONTROL-WIN

MSSOFT

DS102/112 controlled software

1. Controlled

・ 5 phase stepping motor is controlled by 2 axes

・ Linear interpolation of 2 axes

・ 2 types motor driver with normal(FULL/HALF) and micro-step(16 levels)

As a microstep type, it is possible to highly positioning control and low vibration with

Smooth drive function.

・ It is possible to control 6 axes with link function.

Up to 24 axes can be controlled with USB Hub.

2. Drive

・ Teaching point movement

・ Program Drive

・ Jog Drive

・ It is possible to memorize teaching point 64 points and 8 of programs.

3. Interface

・ Connected USB、RS232C

・ DS102/112 controlled software:DSCONTROL-WIN

・ Handy terminal:DT100

・ I/O for controlled

・ General I/O:Input16points、output12points (Option)

・ 2 types of PS/V AC100~240V、DC24V

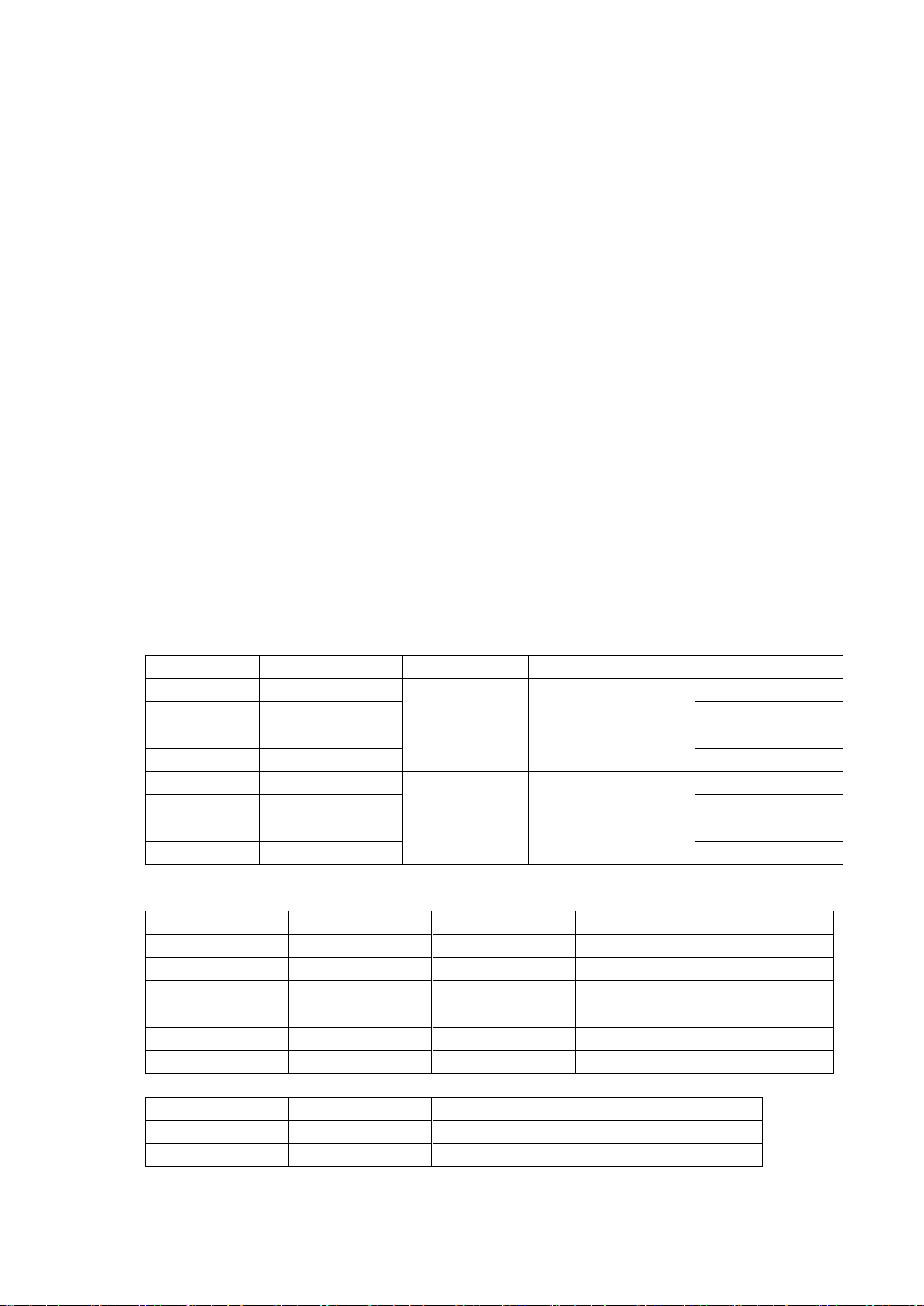

【Line up products】

【Option Cable】

【Other Option】

9

1.3 System configuration example

X axis

Motor driver

X axis motor

Guide ball

screw

Limit

Switch

Y axis

Motor driver

Y axis motor

Guide ball

screw

Limit

Switch

Position Control

Unit

CPU Unit

I/O Unit Sensor

Actuator

PLC

Former System

CPU Unit

I/O Unit

X Axis Stage

Y Axis Stage

PLC

XY

DS112

Stepping Motor Controller

DS112NR

Move the teaching point/Switch the program

drive

Teaching point number selected

Program number selected

Start/Stop

DS102/112

Controlled SoftWare:

DSCONTROL-WIN

・Move the teaching point/Switch the program drive.

・Teaching Point Number Selected.

・Program Number Selected

・Start

・Stop

・Set up the system parametor

・Memorized teaching points

・Programming and editing

・Operation check

・Back up data

PC

DT100

Handy Terminal

DT100

・Set up the system parametor

・Memorized teaching points

・Operation check

USB or RS232C

1.3.1 Control with PLC

Stages can be controlled with I/O units of PLC.

No need positioning units.

10

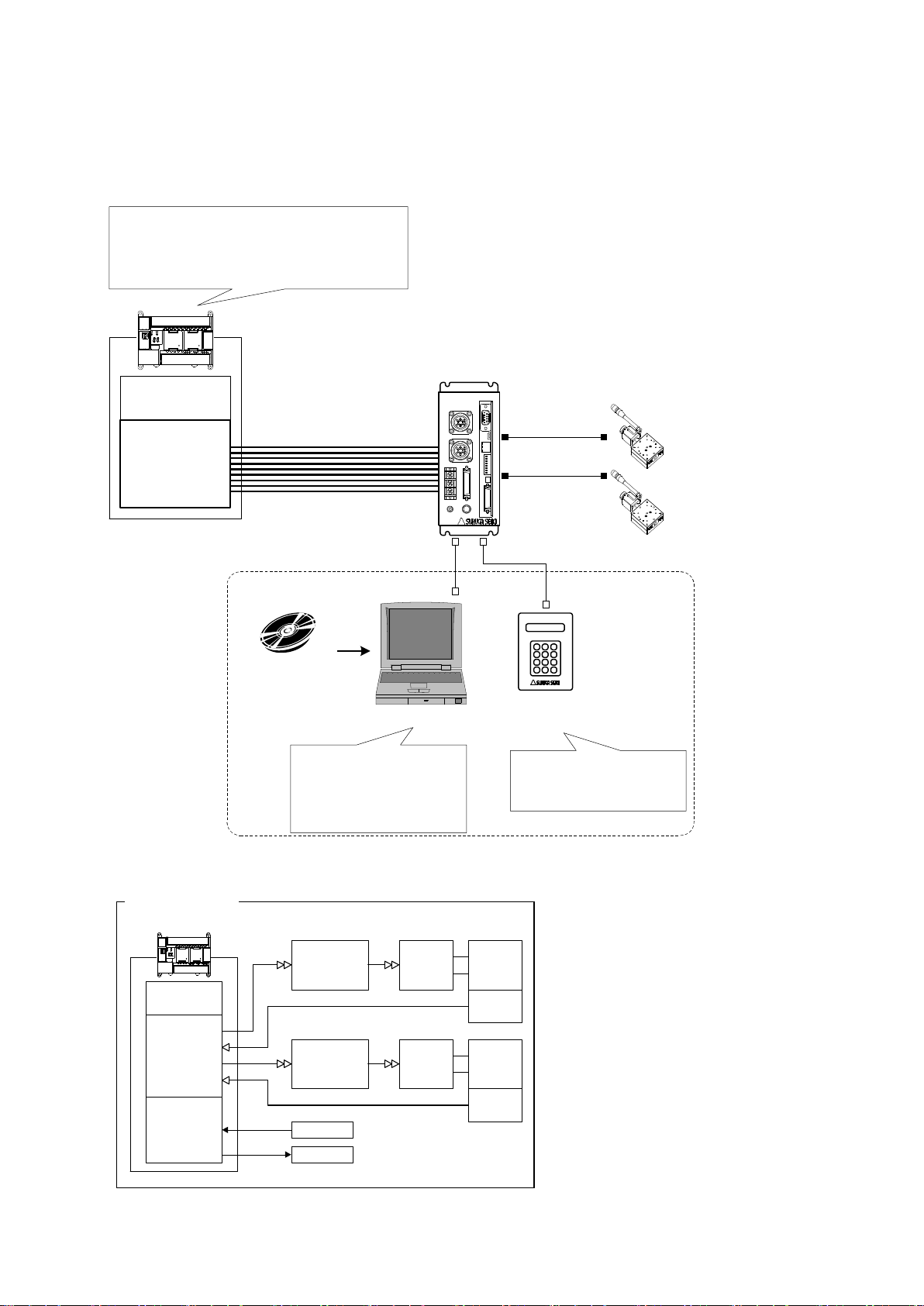

1.3.2 Controlled by PC

Motion

Control

Board

X Axis

Motor driver

X Axis

Motor

Guide

ball screw

Limit

Switch

Y Axis

Motor Driver

Y Axies

Motor

Guide

ball screw

Limit

Switch

I/O

Board

Sensor

Actuator

PC

Former set-up

Sensor Actuator

USB

or

RS-232C

X axis stage

Y axis stage

PC

General Input:

16points

General Output:

12points

DS102

Stepping Motor

Controller

DS102NR-IO

Use virtual COM port (Ex.:VB)

RS-232C communication application

MSComm1.Settings = "9600,N,8,1" ' Set up the port

MSComm1.CommPort = 1 ' Set up the port add.

MSComm1.PortOpen = True ' Open the port

' Move to 100 X axies

MSComm1.Output = "Axis1:Selsp 0:Goabs 100"

Original software

・Set up the system

parametor

・Operation check

・Cotrolled stage

・ControlI I/O

DS102/112

Control Software:

DSCONTROL-WIN

Easily controlled external machine by software.

No need motion control board and I/O board.

11

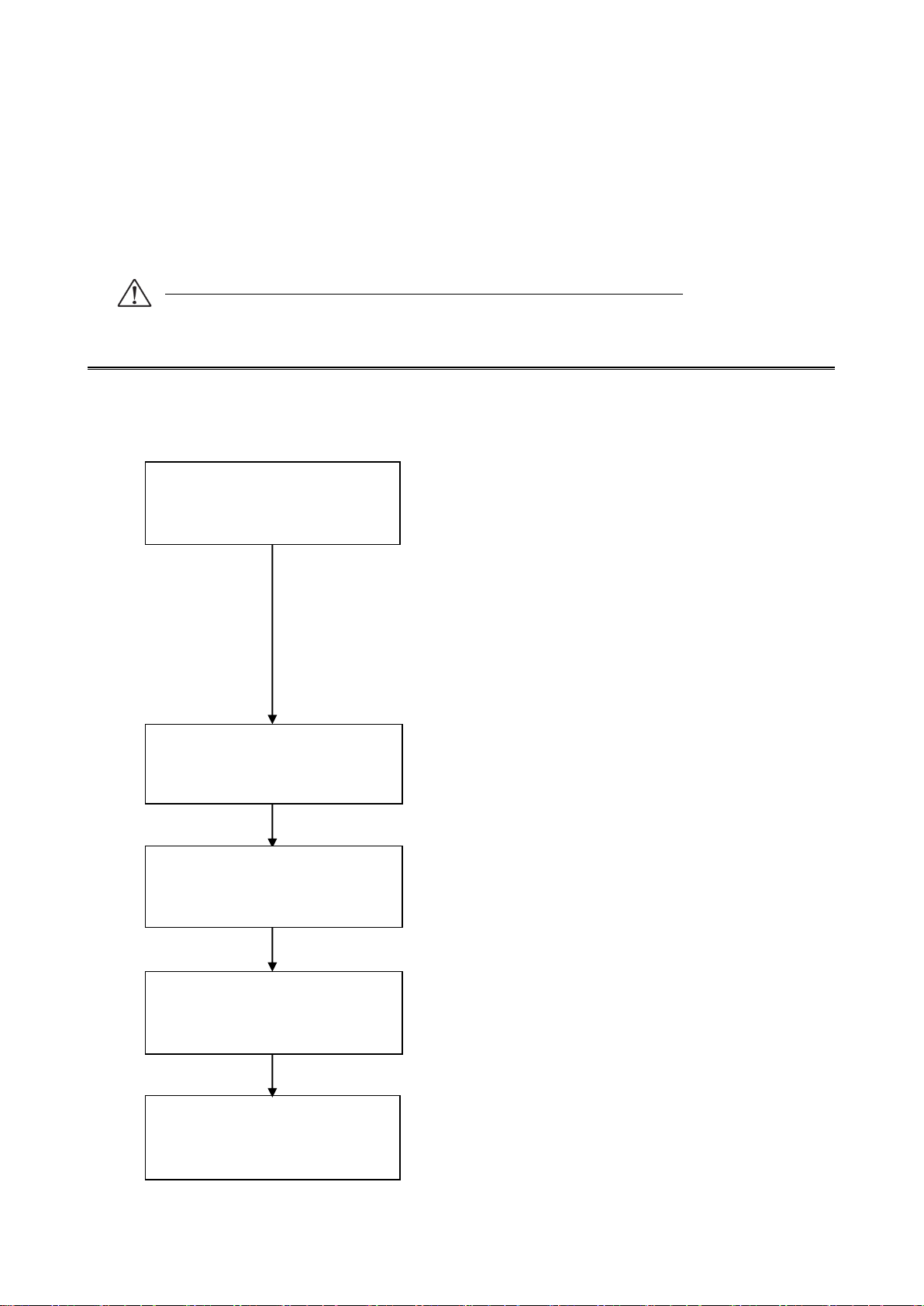

1.4 Accessories

Operation check

・DS102 or DS112

・X axis stage ・Y axis stage

・Motor cable

・RS232C cable:DS100-R9-2

・USB cable:DS100-USB-1.8

・Power cable

・PC

※You must have another power supply

and power cable if you use DS112.

・USB driver CD-R

・DSCONTROL-WIN CD-R (Option)

Conecting

Install USB driver

Set up the system parametor

DS102/112 Control soft ware:

Install DSCONTROL-WIN

This included following goods. Please check when you open. If some parts missing, please let us

know.

・ DS102/DS112:1 PCS

・ Power cable(2m) :1 PCS(Only case of DS102)

・ CD-R(data of this Manual , USB Device driver) :1PCS

・ Manual(this documents) :1PCS

The power cable of DS102 attachment is exclusively for this machine.

2.Set-up and example of use

2.1 Set up before use

Shows flow before use DS102/DS112.(MISUMI Type: MSCTL102/MSCTL112)

12

2.1.1 Connecting

I/O connector for

control

RS232C

X axis stage connector

General I/O

Connector

X Y

I/O

CNT-I/O EMS SW1 LINK USB RS232C

USB Connector

AC Inlet

Y axis stage connector

I/O

CNT-I/O

USB

RS232C

X

Y

TERMINAL

DS102

Stepping Motor Controller

Power

Connector for

Handy terminal

TERMINAL

Shows how to connect DS102/DS112

DS102

13

DS102

Stepping Motor

Controller

X axis stageY axis stage

AC100V

AC100

~240V

USB Cable:

DS100-USB-1.8

USBRS232C

RS232C Cable:

D100-R9-2

or

XY

Motor Cable

16 pins series stages:

D214-1-□E,D214-1-□R

(MISUMI:SRCB□,SRCB□-R)

12 pins series stages:

D214-2-□E,D214-2-□R

(MISUMI:MSCB□,MSCB□-R)

D214-2-□EA,D214-2-□RA

(MISUMI:MS4CB□,MS4CB□-R)

Attached

Power Cable

① Connect X axis motor connector to X axis stage.

② Connect Y axis motor connector to Y axis stage.

③ Connect AC inlet and AC100~240V.

④ Connect USB connector to USB port of PC.

(Connect RS232C connector to PC if use RS232C)

14

Use DS112

XY

TERMINAL

POWER

+24V

CNT-I/O EMS SW1 LINK USB RS232C

DS112

GNDFG

I/O

Y axis motor

connector

Terminal block for

power

General I/O

connector

Handy terminal

for connector

RS232C

connector

USB

connector

I/O connector for

control

Stepping Motor Controller

I/O

CNT-I/O

USB

RS232C

X

Y

TERMINAL

X axis motor

connector

X axis stage

Y axis stage

XY

DS112

Stepping Motor Controller

X

Y

USB cable:

DS100-USB-1.8

USB

RS232C

RS232C cable:

D100-R9-2

or

Motor cable

16pin series stage:

D214-1-□E,D214-1-□R

12pin series stage:

D214-2-□E,D214-2-□R

DC24V

DC24V

① Connect X axis motor connector to X axis stage.

② Connect Y axis motor connector to Y axis stage.

③ Connect terminal for power of DC24V to power supply(DC24V)

※ Must have DC24V power supply and cable

④ Connect USB connector to PC USB port.

(Connect RS232C connector to PC if use RS232C )

15

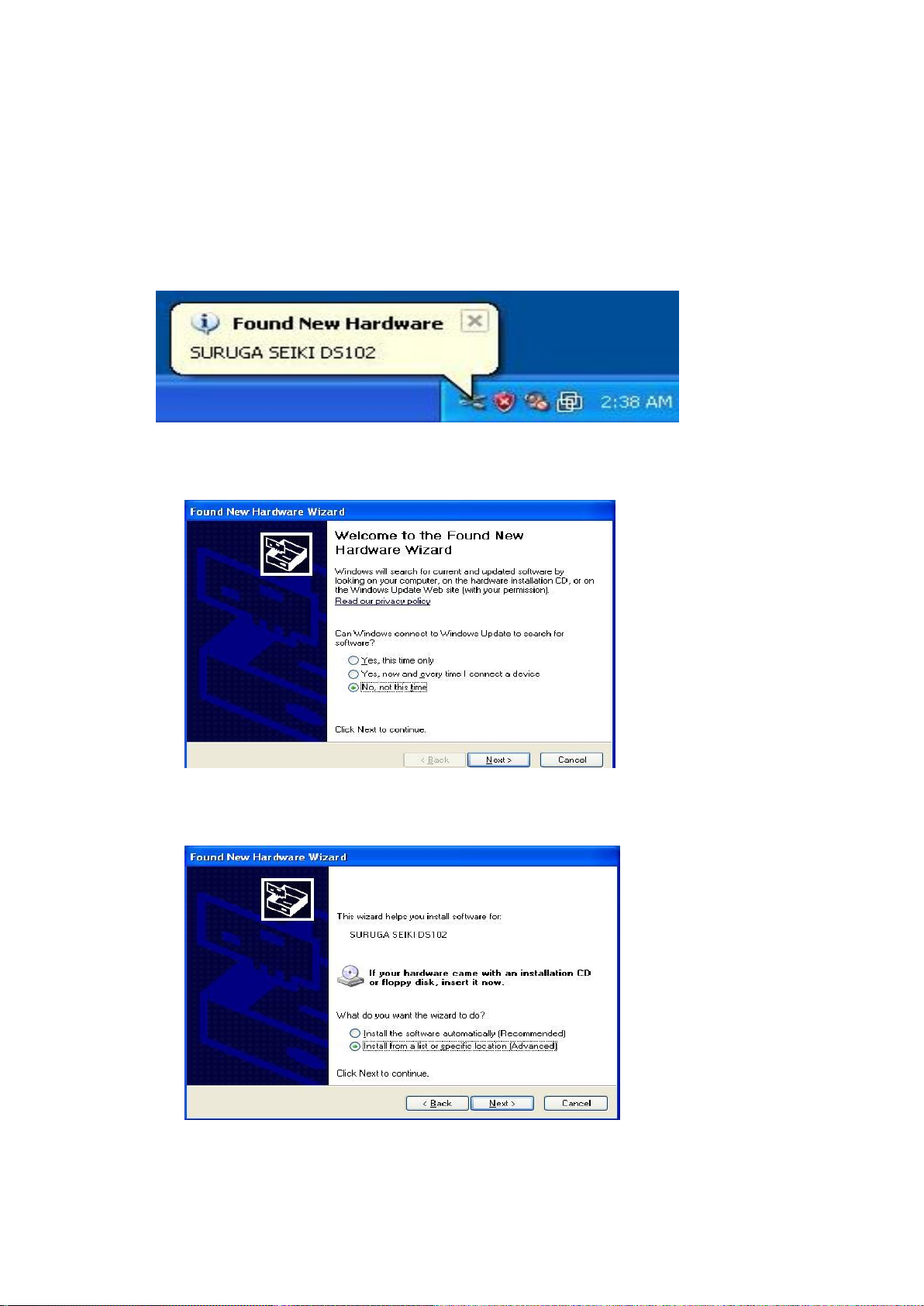

2.1.2 USB Driver Install

Shows how to install USB driver to PC(for XP).

① Switch on a computer and start Windows.

② Set up DS102/112 USB driver CD-ROM to computer drive.

③ Switch on DS102/112 and wait 5 seconds.

④ Connect computer USB port and DS102/112 USB connector.

When computer recognize to connect DS102/112, shows following messages.

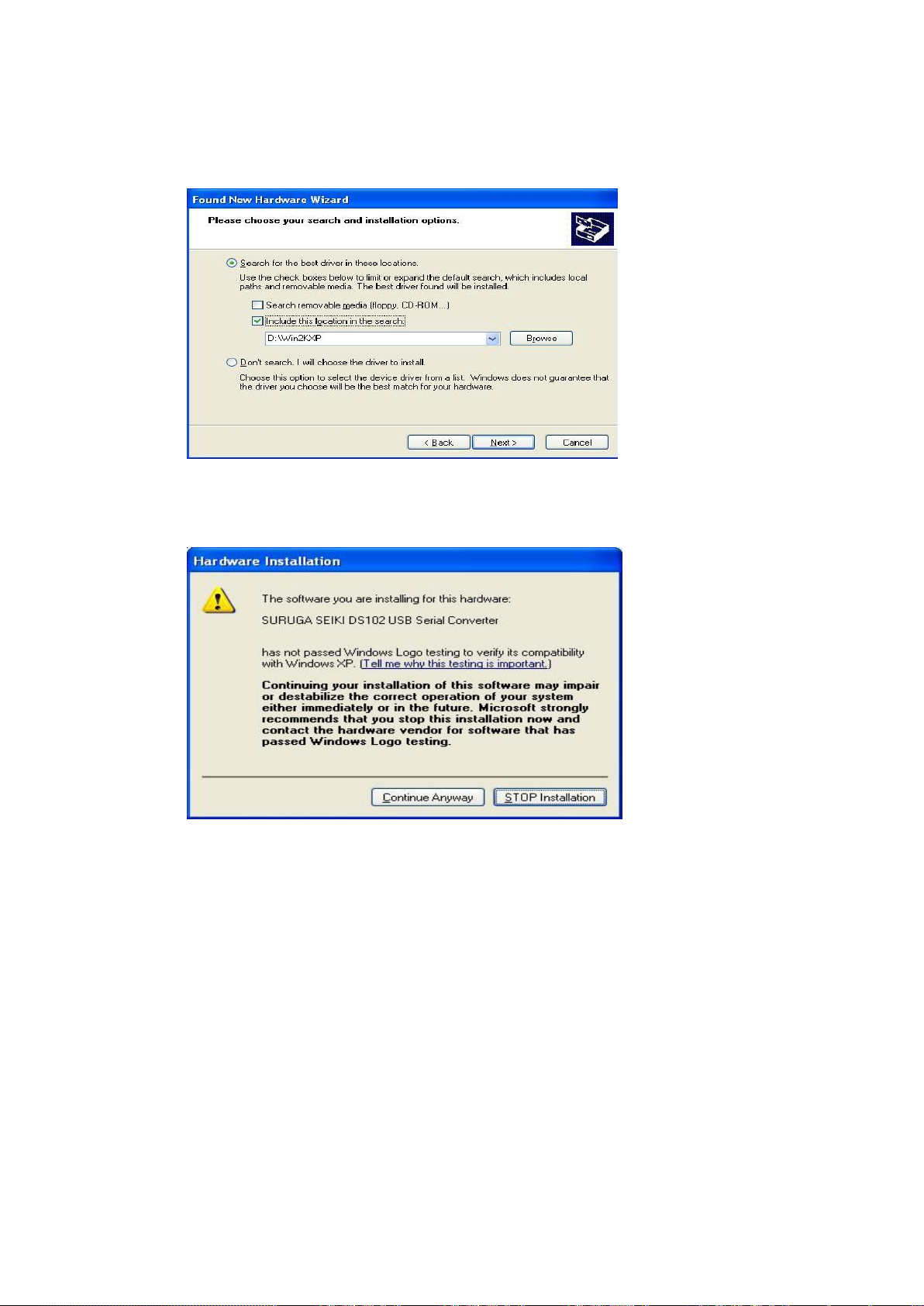

⑤ At the detecting wizard of new hardware, choose [No, not this time]

and click [Next].

⑥ Select [Install from list or specific location (Advanced)] and click [Next].

16

⑦ Check the [included this location in the search], push [Browse] and select [Win2KXP] then,

click [next].

Start the driver install.

⑧ Click the [Continue Anyway] when displays Hardware Installation.

17

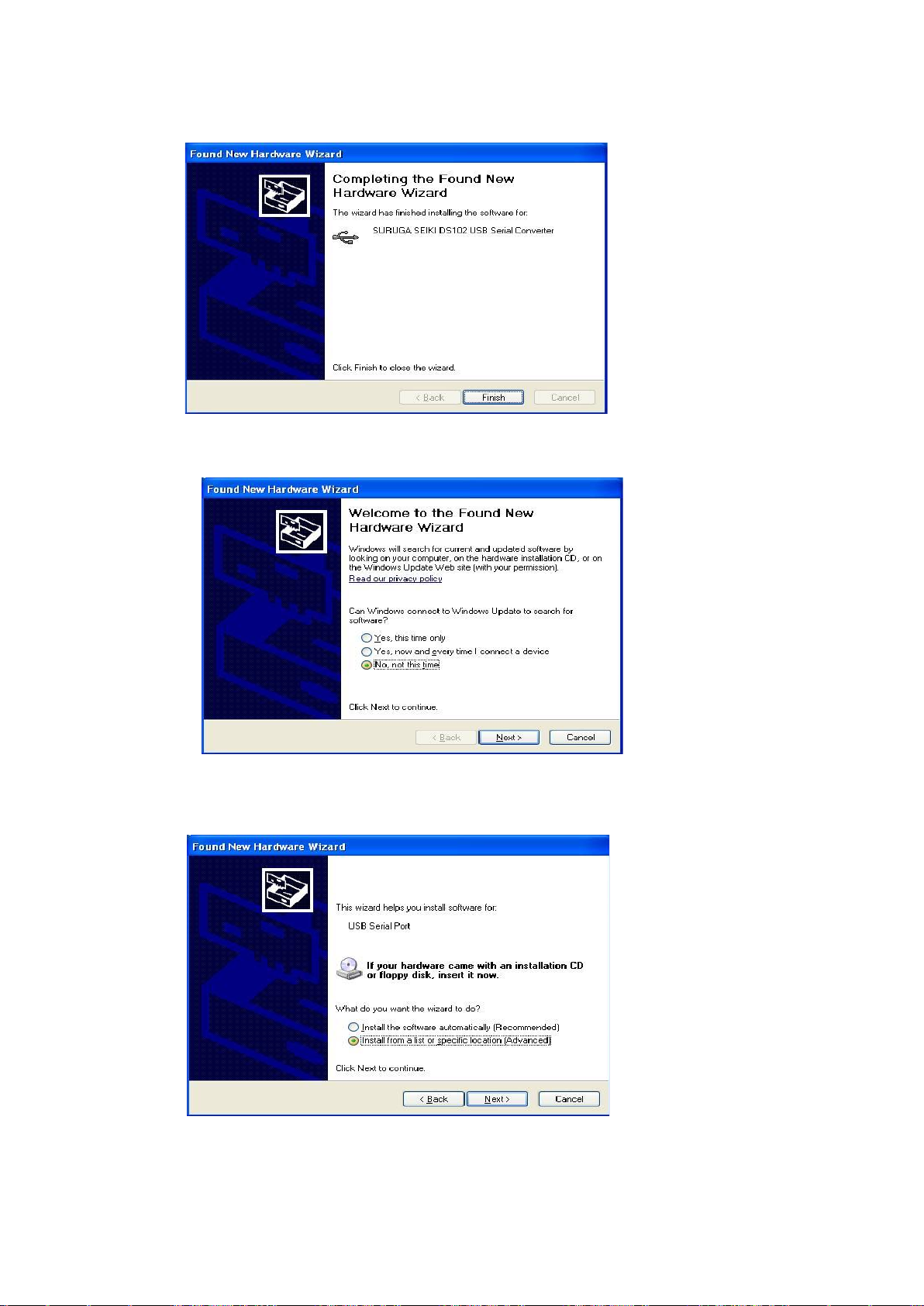

⑨ Click [finish]

Display the found new hardware wizard.

⑩ Select [No, not this time] and click [Next].

⑪ Select [Install from a list or specific location (advanced)] and click [Next].

18

⑫ Check the [included this location in the search], push [Browse] and select [Win2KXP] then,

click [next].

Start the driver install.

⑬ Click the [Continue Anyway] when displays Hardware Installation.

19

⑭ Click [finish]

Display the found new hardware wizard.

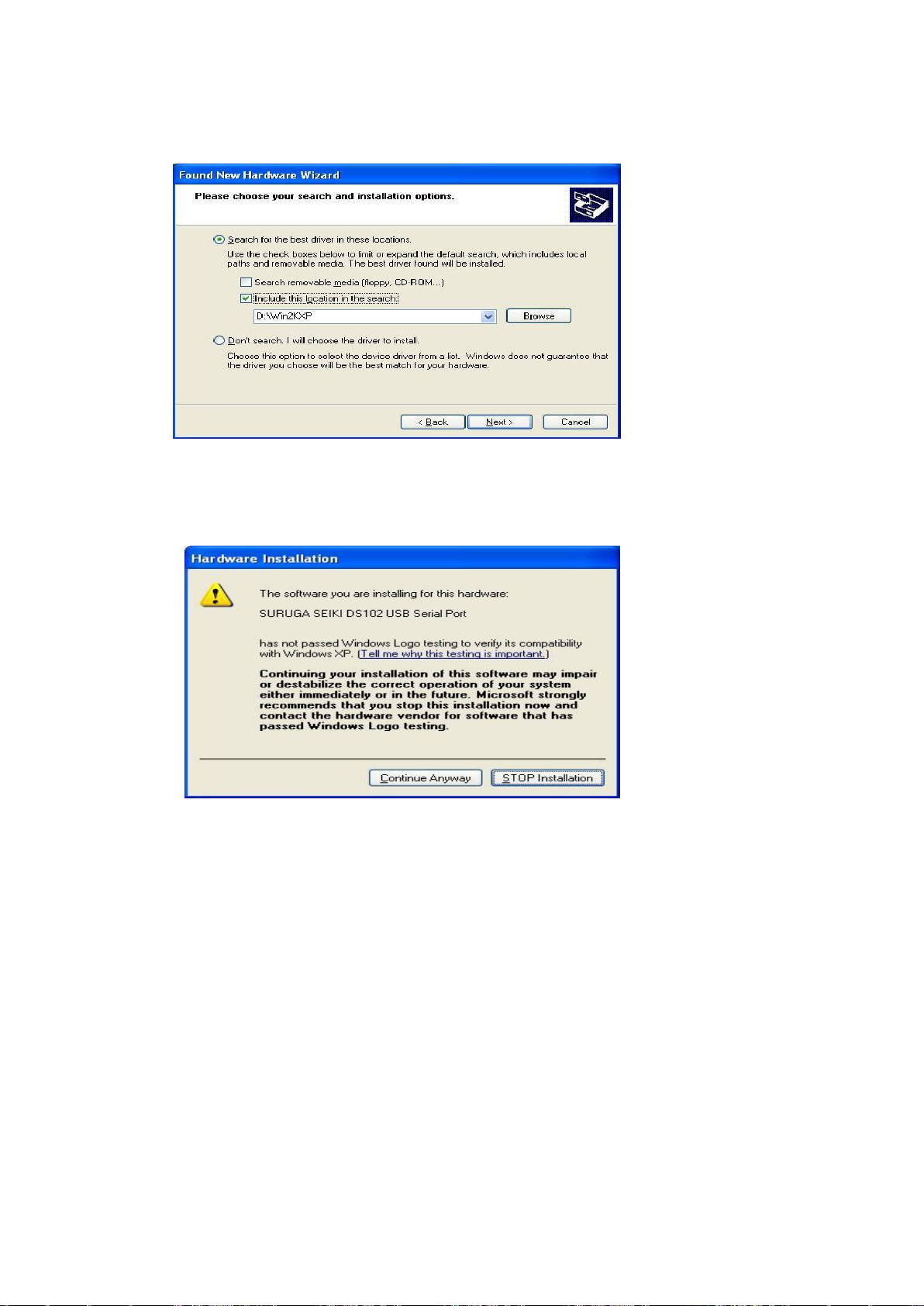

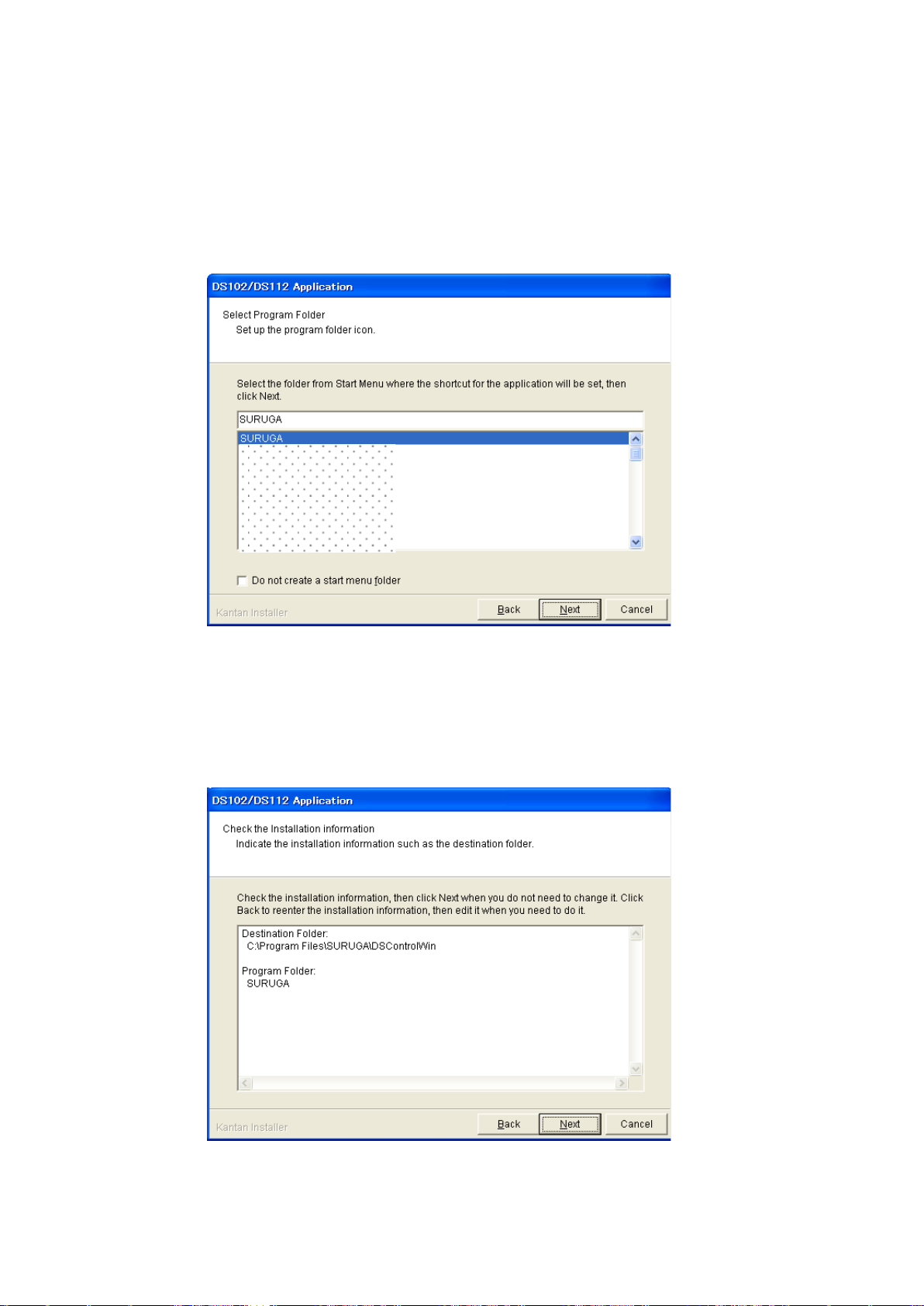

2.1.3 Installation for control software DS102/112(DSCONTROL-WIN)

Show how to install software (DS CONTROL-WIN) to control DS102/112 by PC.

① Insert CD-ROM of DSCONTROL-WIN inside PC drive.

② Double click on setup.exe in CD-ROM.

DSCONTROL-WIN installer start.s.

③ Click [next]

The screen below appears on PC.

20

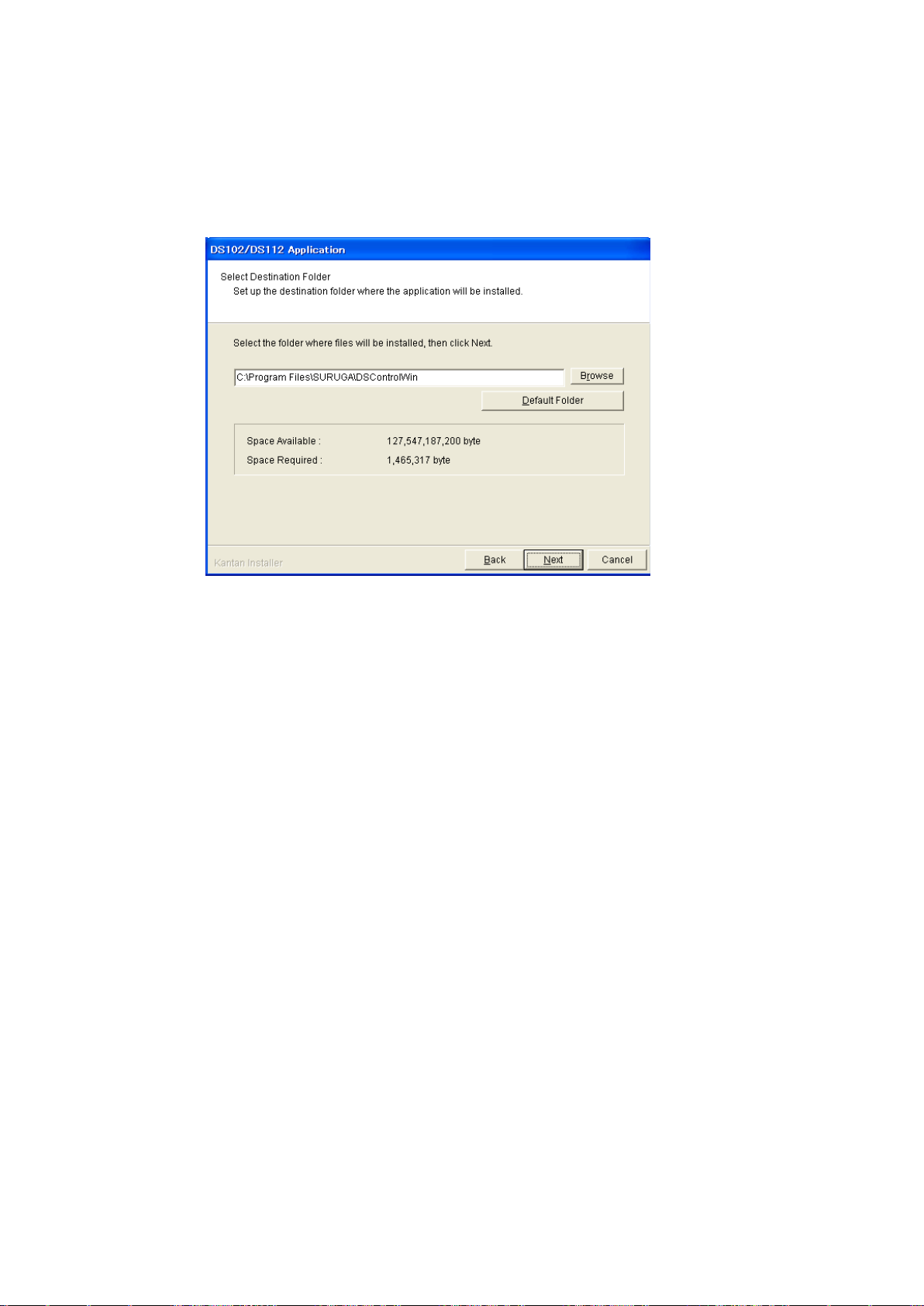

④ Select folder of installation then click {Next}

The screen shows folder selection

※On initial setting, installation folder is:\Program Files\SURUGA\DSControlWin.

Click [Next] in case of no required folder

21

⑤ To prepared Program Shortcut, you need to select folder from list on START MENU then click

[Next]

The drawing below appears on PC screen

※On initial setting, Startmenu folder is DSControlWin.

Click [Next] in case of no required folder

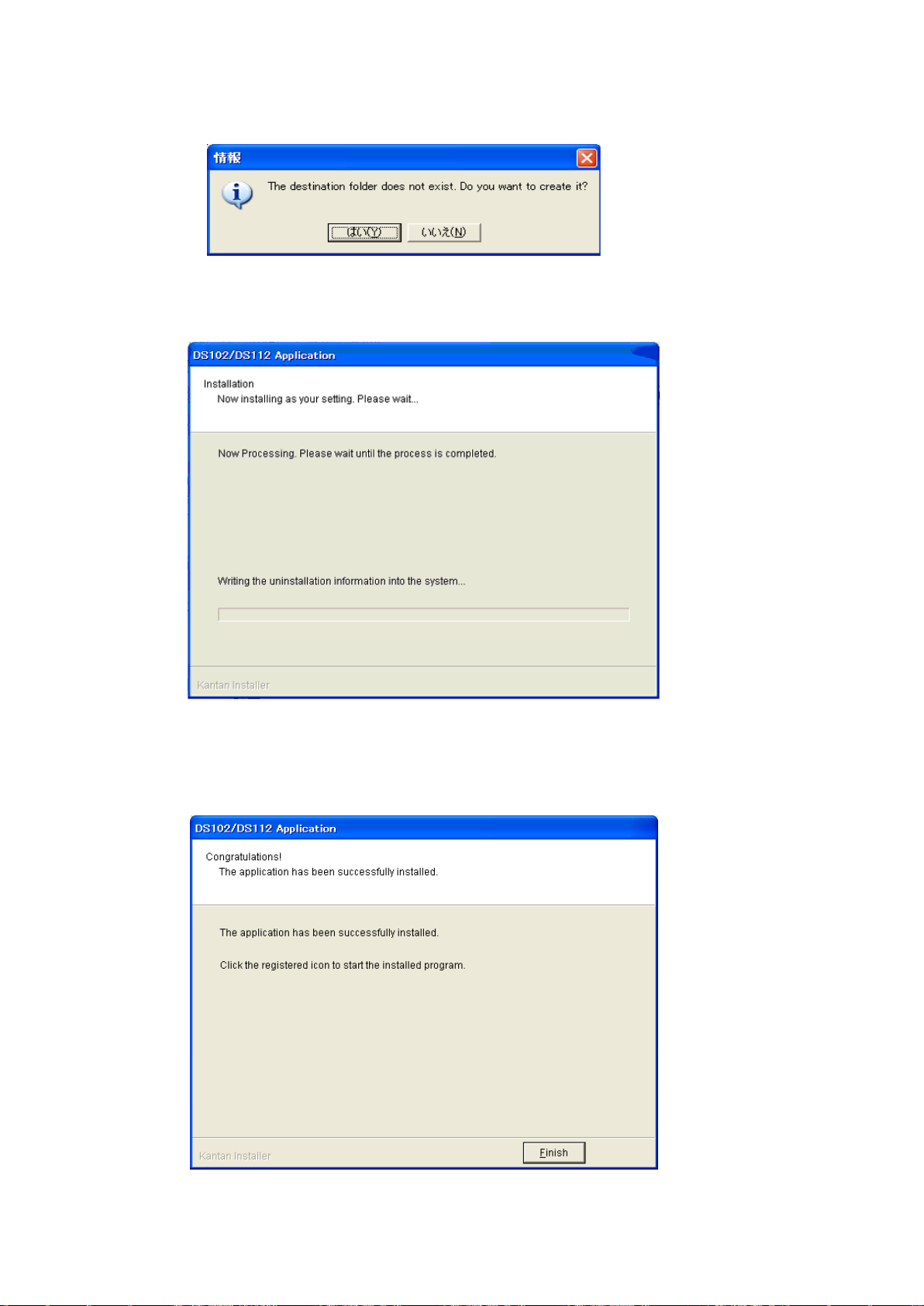

⑥ Click [Next] after you confim installed contents

The screes scomes to [Information]

22

⑦ Click [YES]

※ No pop-up message appears if you already select folder

Installation begins

Installation complete.

⑧ Click [Finish]

Installing DSCONTROL-WIN completed.

23

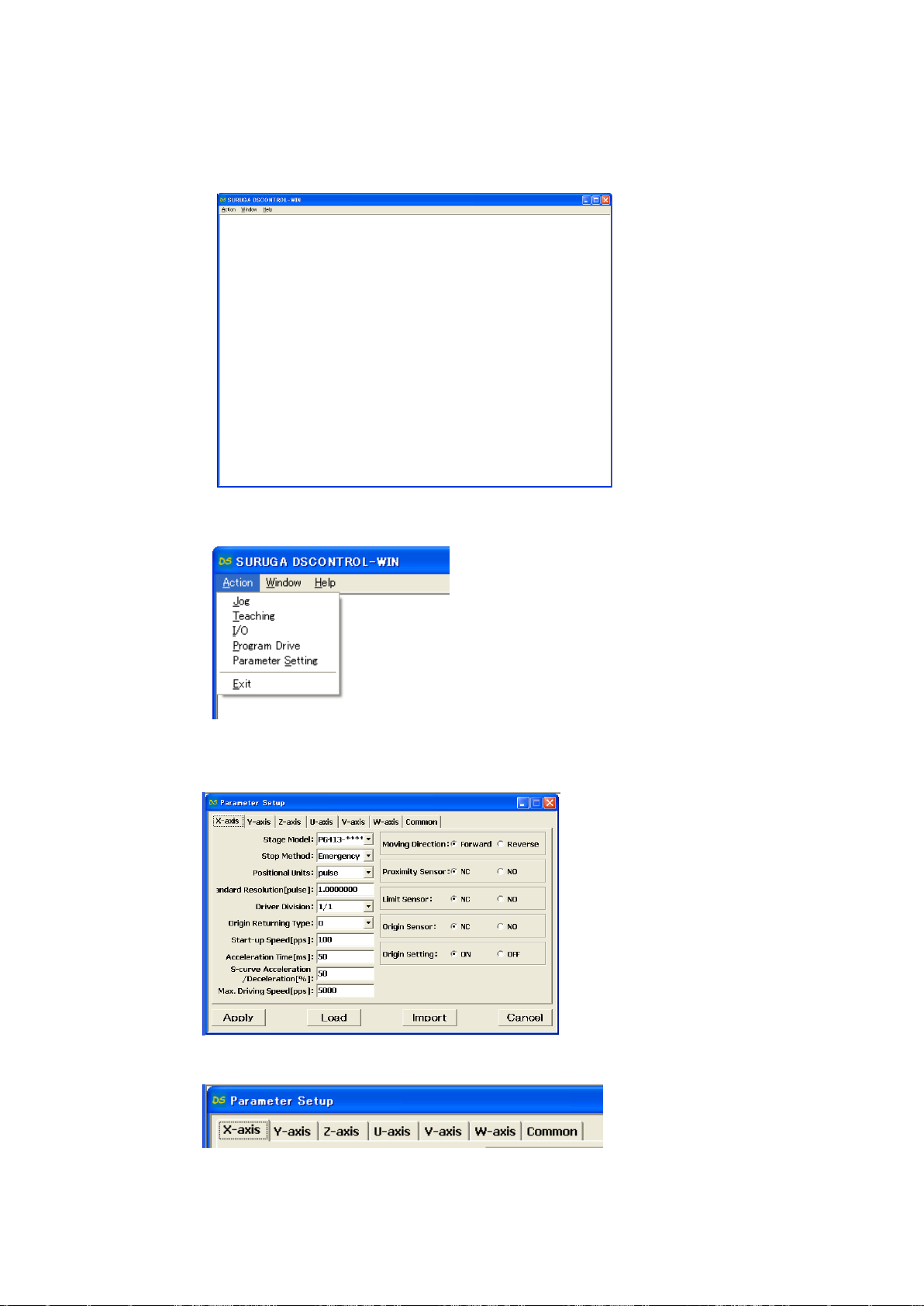

2.1.4 Adjustment system parameter

Shows how to set up system parameter by DSCONTROL-WIN

① Starts DSCONTROL-WIN

② Select [Parameter setting] in [Action]

Parameter setting appears on screen

③ Click on Tab you sellect

24

④ Select stage model you use from [Stage Model]

Initial value appears when you select stage model.

※ input direct value if we want to change initial value.

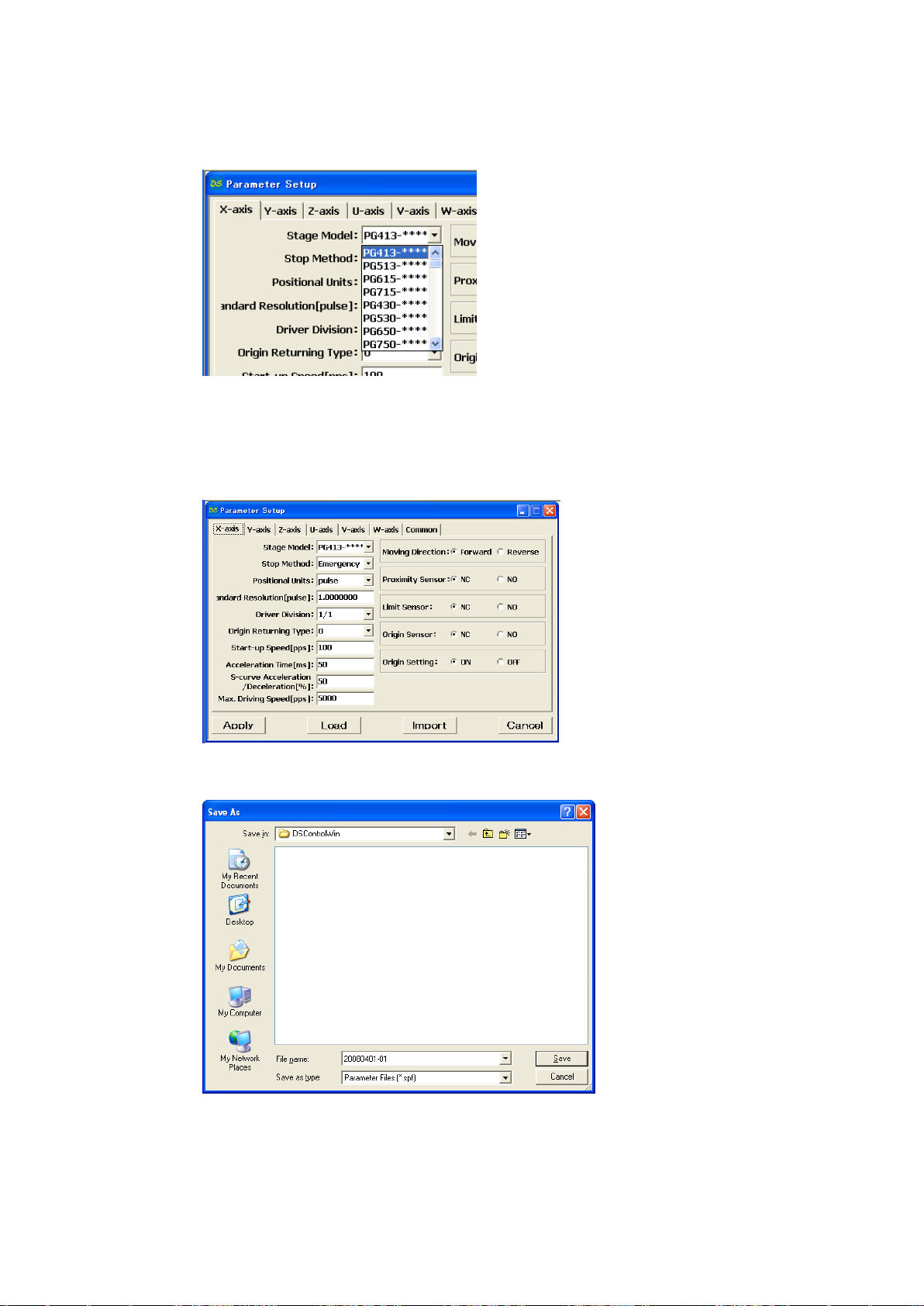

⑤ Select axis parameter by repeating ③~④ again.

⑥ Click [Apply].

Screen shows folder storing parameter.

⑦ Select folder and input file name then click [Save].

Parameter values are saved PC then forward values toward DS102/112.

※ Spf is automatically added.

25

2.1.5 Operation check

Shows how to check operation.

① Starts DSCONTROL-WIN.

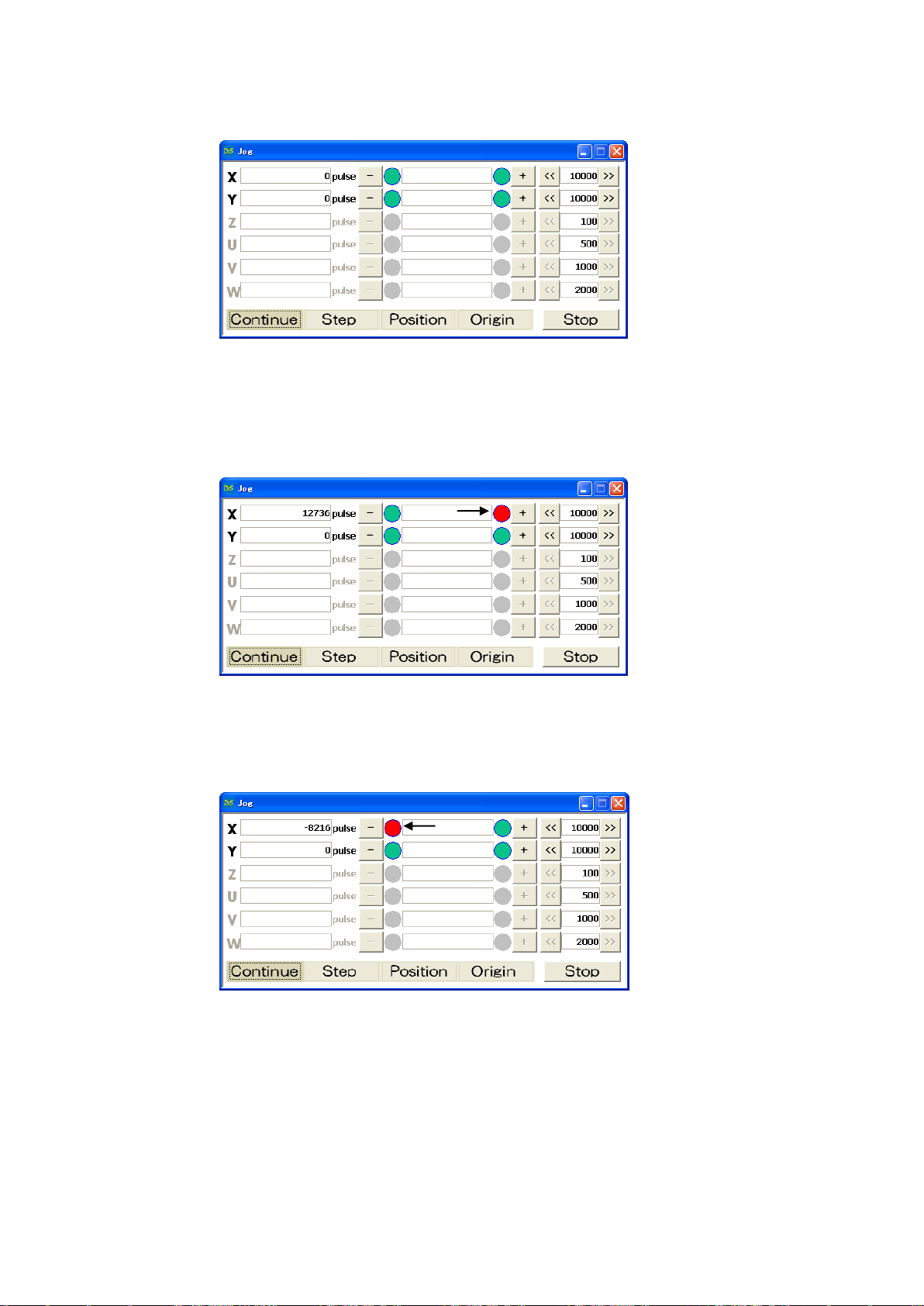

② Click [JOG] in [Action] on main menu

JOG dialog appears on screen.

③ Click [Origin]

[Org],[Home] appears.

④ Click [Org] on X axis

X stage return origin position.

Make sure X stage moves origin position.

⑤ Repeat ③~④ again Y axis return to origin position.

26

⑥ Click [Contiue]

[+],[-]appear on screen.

⑦ Keep clicking [+] on X axis

X stage moves toward CW direction.

Stage stops when it reachs to CWLS then indicator leftside [+] becomes RED.

⑧ Keep clicking [-] on X axis

X stage moves toward CCW direction.

Stage stops when it reachs to CCWLS then indicator rightside [-] becomes RED.

⑨ Repeat ⑦~⑧ on Y axis.

27

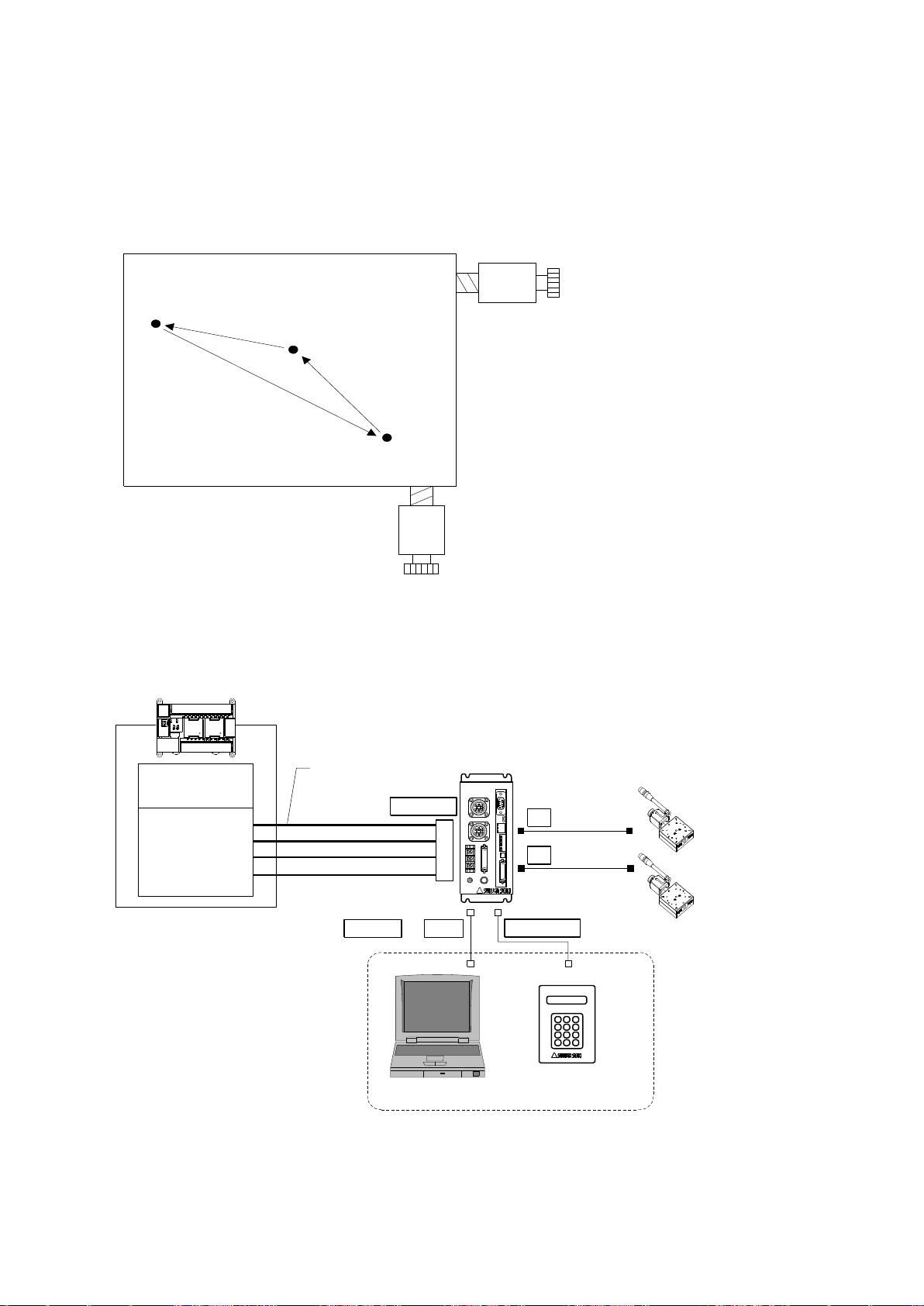

2.2 System architecture

Waiting posi

(50,100)

Working posi

(1000,1500)

Exporting Posi

(2000,3000)

X axis stage

CPU unit

I/O unit

Y axis stage

PLC

XY

DS112

Stepping Motor Controller

DS112

T_BIT0~5

P/T_START

STOP

PRG/TCH

CNT-I/O

I/O cable

DS100-CNT-2

PC

DT100

Handy Terminal

DT100

USB

TERMINAL

X

Y

RS232C or

STEP1 : Moving to waiting position (50,100)

STEP2 : Moving to working position (1000,1500)

STEP3 : Processing on target

STEP4 : Moving to exporting position (2000,3000)

STEP5 : Exporting processig

2.2.1 Movement between each teaching position

Show how to set up position inside memory of DS112 (MISUIMI Type: MSCTL112)and move its

position by PLC.

1) Configuration

※ CNT-I/O shows following signal. READY means Waiting condition of DS112 and X_DRIVE and

Y_DRIVE means both working condition. P/T_RUN means Teaching working and Program

working.

28

2) Movement summary

Waiting, working and exporting position memorized inside DS112 as teaching points, 00, 01, 02,

PLC appoints each points then make state move to each points.

① Set up 00 among T_BIT0~5, press P/T_START <STEP1>

② Set up 01 among T_BIT0~5, press P/T_START <STEP2>

③ Wait unitl woring on target is done <STEP3>

④ Set up 02 among T_BIT0~5, press P/T_START <STEP4>

⑤ Wait until exporting is done <STEP5>

3) Connect

Connect to DS112

PC is used when setting or editing teaching point

① Connect USB to PC USB port

(Connect RS232C to PC when using RS232C)

② Connect handy terminal to DS112

③ Connect X axis motor connector to X stage

④ Connect Y axia motor connector to Y stage

⑤ Connect control I/O connector to PLC I/O unit

On control I/O,

T_BIT0~5:Appoint teaching point

P/T_START:Signal to move to teaching point

STOP:Stop signal for all axes

PRG/TCH:program mode / teaching point mode

※ T_BIT0~2:combined use for program selection

29

4) Memory of teaching point

Jog

7

Menu8Set

9

SPD

4

↑

5

POS

6

←1Link

2

→

3

Stop

0

/ESC

DT100

Handy Terminal

↓

.-

Enter

X stage CCW direction

X stage CW direction

Y stage CCW direction

Y stage CW direction

Memorizing teaching point inside DS112

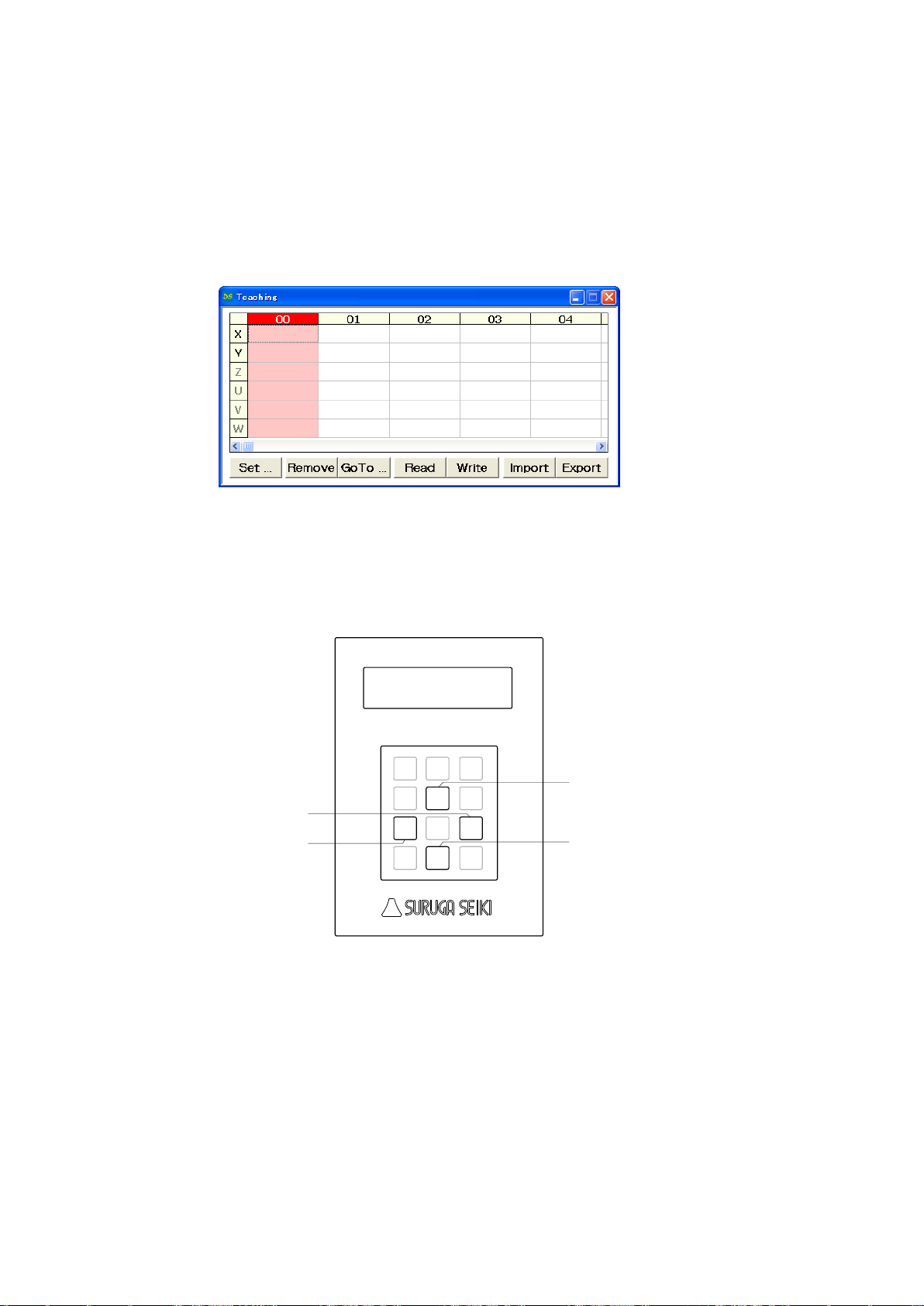

① Start DSCONTROL-WIN

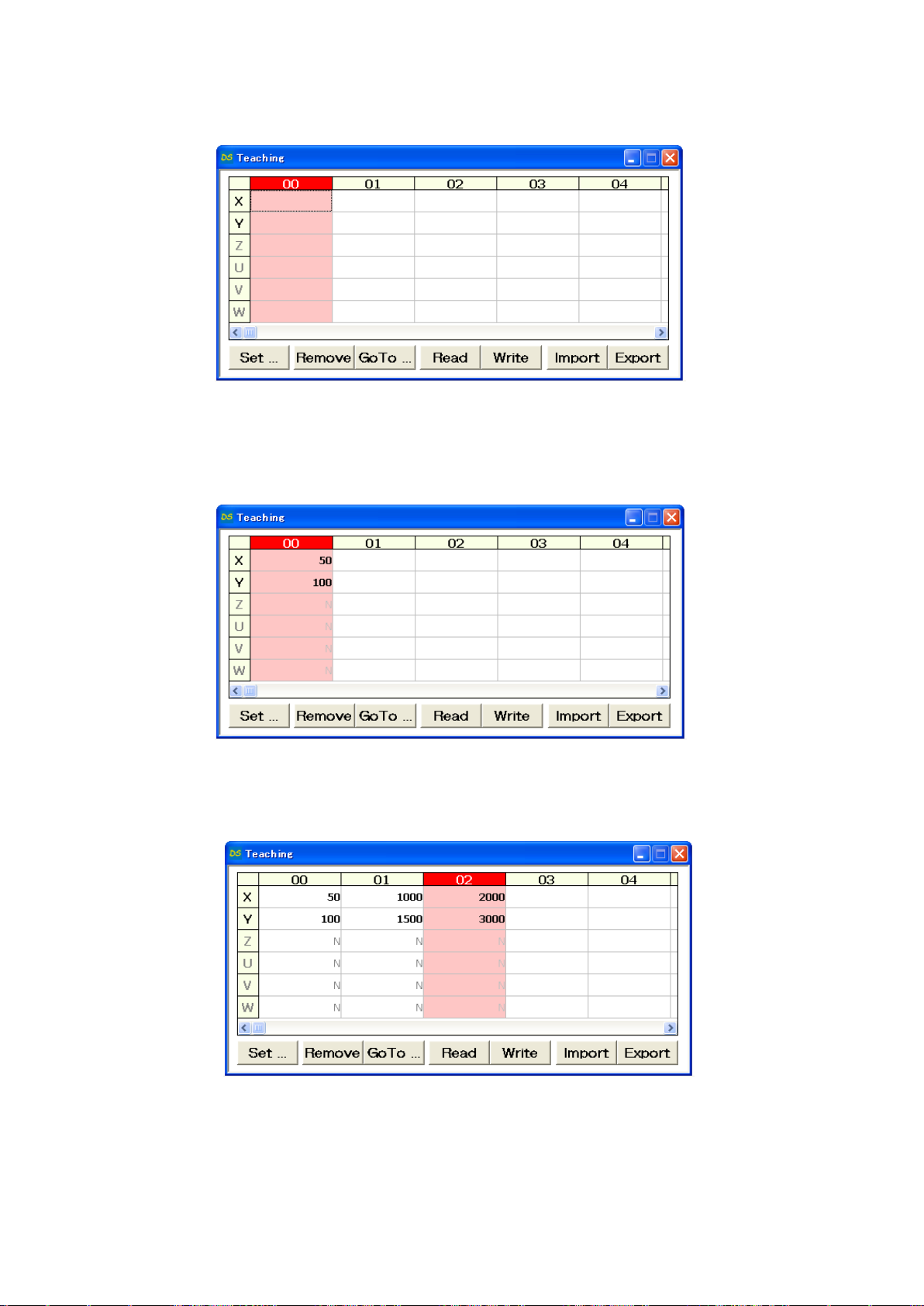

② Select [Teaching] on main menu in DSCONTROL-WIN.

Screen below appears.

③ Push direction key on handy terminal unitl stage moves to specific positon.

30

④ Click [00] CELL on the teacing screen

00 CELL gets to be Red.

⑤ Click [Set]

Current stage position as 00 is memorized to DS112.

⑥ Repeat ③~⑤ so memorize 01 as working position and 02 as exporting position to DS112.

Loading...

Loading...