Stepping Motor Controller

MSCTL102 Series/MSCTL112 Series Operation Manual

Ver 1.01 (02.13.2015)

Remarks

MSCTL102/112 Series(MISUMI products) are same as DS102/112 Series that are made by Suruga Seiki.

All of DS102/112 series that are mentioned in the operation manual indicate MSCTL102/112.

MISUMI CO., LTD.

SURUGA SEIKI CO., LTD.

2

Index

1.INTRODUCTION ................................................................................................................................................................................. 5

1.1 FOR YOUR SAFETY .............................................................................................................................................................................. 5

1.2 PRODUCT OUTLINE / FEATURES ................................................................................................................................................... 7

1.3 SYSTEM CONFIGURATION EXAMPLE .............................................................................................................................................. 9

1.3.1 CONTROL WITH PLC................................................................................................................................................................. 9

1.3.2 CONTROLLED BY PC ............................................................................................................................................................. 10

1.4 ACCESSORIES .................................................................................................................................................................................... 11

2.SET-UP AND EXAMPLE OF USE ................................................................................................................................ 11

2.1 SET UP BEFORE USE ....................................................................................................................................................................... 11

2.1.1 CONNECTING ............................................................................................................................................................................ 12

2.1.2 USB DRIVER INSTALL ......................................................................................................................................................... 15

2.1.3 INSTALLATION FOR CONTROL SOFTWARE DS102/112(DSCONTROL-WIN) ..................................... 19

2.1.4 ADJUSTMENT SYSTEM PARAMETER ............................................................................................................................... 23

2.1.5 OPERATION CHECK ................................................................................................................................................................ 25

2.2 SYSTEM ARCHITECTURE ............................................................................................................................................................... 27

2.2.1 MOVEMENT BETWEEN EACH TEACHING POSITION..................................................................................................... 27

2.2.2 EASY RETURN TO ORIGIN POSITION .................................................................................................................................. 34

2.2.3 CONTROL BY EXTERNAL SIGNAL ...................................................................................................................................... 43

2.2.4 EXTERNAL DEVICE CONTROL WITH GENERALI/O. ................................................................................................. 54

2.2.5 MOVE TO ARBITRARY COORDINATE ................................................................................................................................ 56

2.2.6 CONTROLLED OVER 3 AXES .............................................................................................................................................. 58

3.SPEC AND FUNCTION........................................................................................................................................................... 59

3.1 BASIC SPEC ...................................................................................................................................................................................... 59

3.2 PART NAME AND FUNCTIONS ..................................................................................................................................................... 60

3.3 SETTING .................................................................................................................................................................................................. 63

3.4 EXTERNAL INTERFACE ...................................................................................................................................................................... 64

3.4.1 LINK CONNECTION(LINK) ................................................................................................................................................... 64

3.4.2 CONTROL INPUT/OUTPUT(CNT-I/O) ........................................................................................................................ 65

3.4.3 GENERAL I/O(I/O)( OPTION) ........................................................................................................................................ 68

3.4.4 EMERGENCY STOP INPUT(EMS) .................................................................................................................................... 70

3.4.5 STAGE INTERFACE ..................................................................................................................................................................... 70

3.5 DRIVER DIVISION NUMBER SETTING .............................................................................................................................................. 71

3.5.1 OPEN AND SHUT ........................................................................................................................................................................ 71

3.5.2 SETTING DIVISION NUMBER ..................................................................................................................................................... 71

3.6 SMOOTH DRIVE FUNCTION(ONLY MS TYPE) ...................................................................................................................... 72

3.7 UNITS SETTING FUNCTION ............................................................................................................................................................... 73

3.8 SPEED SETTING(SPEED TABLE) .............................................................................................................................................. 74

3.9 FUNCTION OF ORIGIN RETURN ........................................................................................................................................................ 77

3.10 LINEAR INTERPOLATING FUNCTION ........................................................................................................................................... 83

3.10.1 LINEAR INTERPOLATING(RELATIVE VALUE) ........................................................................................................... 83

3.10.2 LINEAR INTERPOLATING(ABSOLUTE VALUE) ........................................................................................................ 83

3.11 TEACHING FUNCTION ..................................................................................................................................................................... 84

3.12 PROGRAM FUNCTION ..................................................................................................................................................................... 84

3

4.OPERATION AND CONTROL METHOD .................................................................................................................. 85

4.1 OPERATION BY THE HANDY TERMINAL ...................................................................................................................................... 85

4.1.1 INITIAL SCREEN ............................................................................................................................................................................ 85

4.1.2 TRANSITION MODE ..................................................................................................................................................................... 86

4.1.3 DRIVING MODE SELECT(JOG KEY) ............................................................................................................................. 87

4.1.3.1 CONTINUOUS DRIVING MODE(CNT:CONTINUE MODE) ............................................................................ 87

4.1.3.2 UNIFORM PULSE DRIVING MODE(STP: STEP MODE) ................................................................................ 87

4.1.3.3 ABSOLUTE VALUE DRIVING MODE(ABS: ABSOLUTE MODE) ............................................................... 88

4.1.3.4 ORIGIN RETURN MODE(ORG: ORIGIN MODE) ............................................................................................... 88

4.1.3.5 HOME POSITION RETURN MODE(HOM:HOME) .......................................................................................... 88

4.1.4 MENU SELECT(MENU KEY) .............................................................................................................................................. 89

4.1.4.1 PARAMETER MODE(PRM) ....................................................................................................................................... 89

4.1.4.2 PROGRAM DRIVING MODE(PRG) ......................................................................................................................... 98

4.1.4.3 TEACHING MODE (TCH) ......................................................................................................................................... 99

4.1.4.4 GENERAL MONITOR(IN) ....................................................................................................................................... 102

4.1.4.5 GENERAL OUTPUT CONTROL(OUT) .............................................................................................................. 102

4.1.5 OTHER FUNCTION .................................................................................................................................................................. 103

4.1.5.1 CHANGE THE SPEED TABLE(SPD KEY)....................................................................................................... 103

4.1.5.2 CHANGE THE AXIS(LINK KEY) ............................................................................................................................ 103

4.1.5.3 CHANGES CURRENT POSITION(POS KEY) ................................................................................................... 103

4.1.5.4 VERSION CONFIRMATION, PARAMETER RESET .................................................................................................. 104

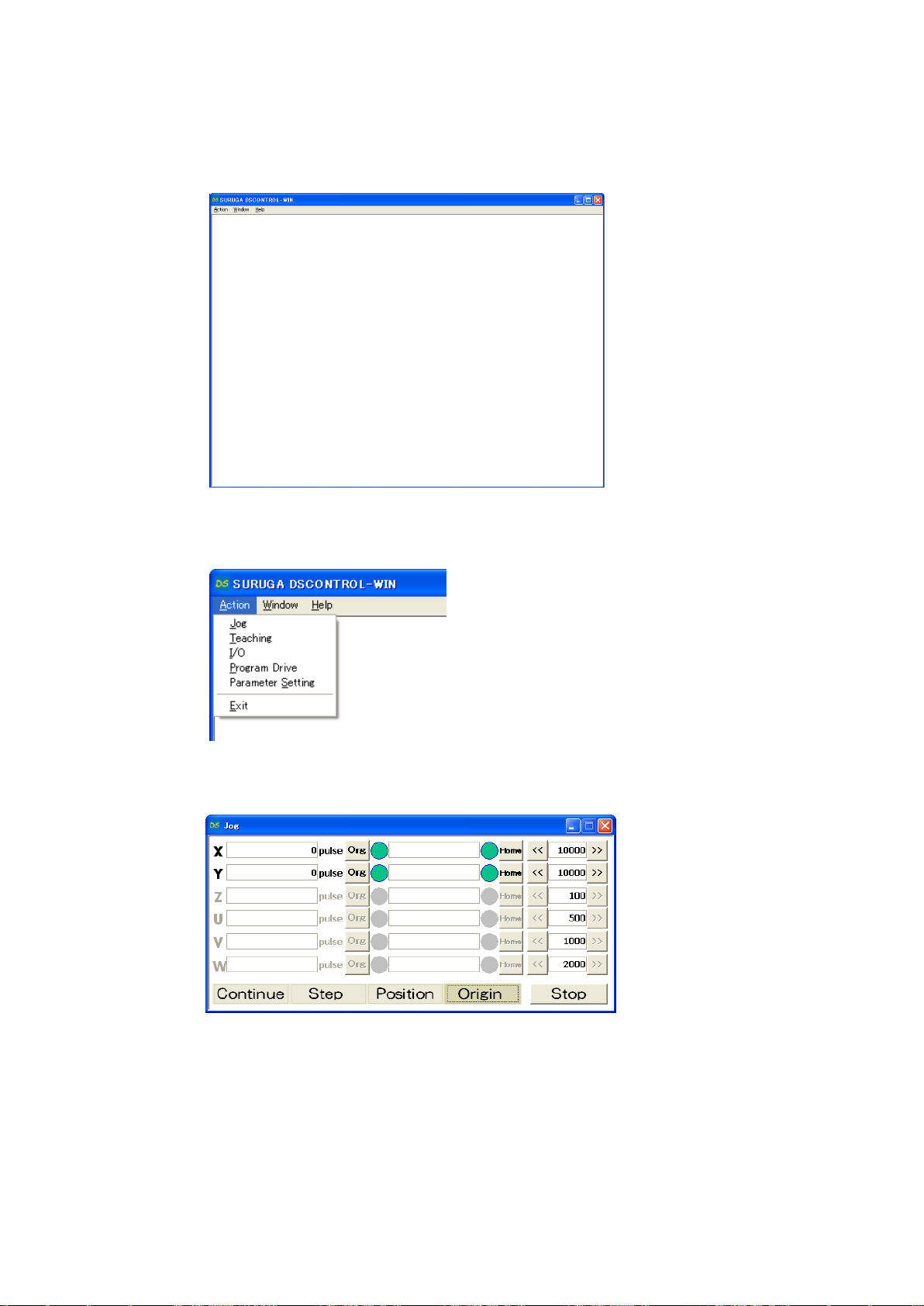

4.2 DS102/112 CONTROLLED SOFTWARE(DSCONTROL-WIN) ...................................................................... 105

4.2.1 DSCONTROL-WIN START-UP ................................................................................................................................... 105

4.2.2 PARAMETER SET-UP ............................................................................................................................................................ 105

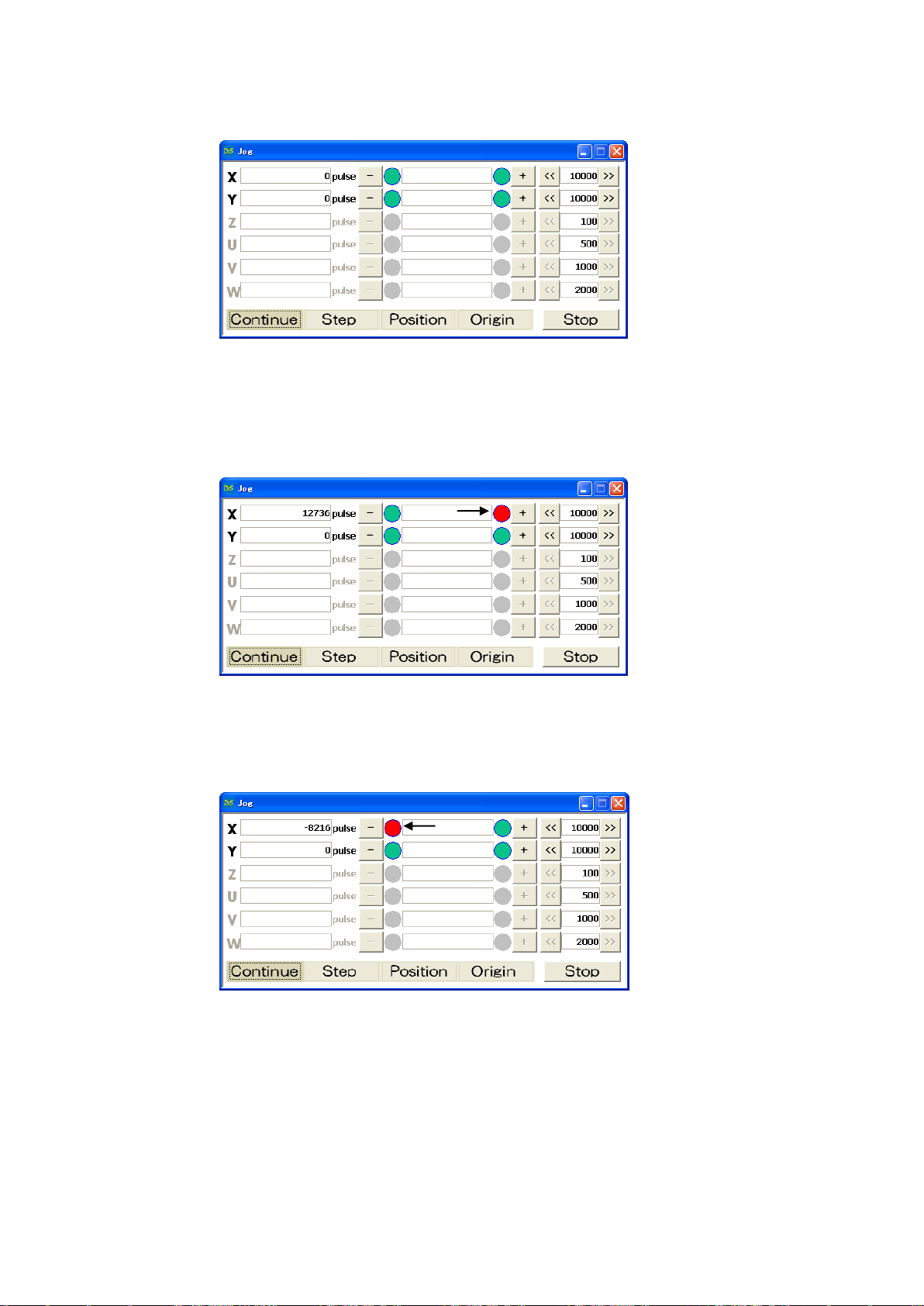

4.2.3 JOG DRIVING ............................................................................................................................................................................. 107

4.2.4 TEACHING ................................................................................................................................................................................. 110

4.2.5 DRIVING PROGRAM ................................................................................................................................................................ 112

4.2.6 I/O MONITOR ..................................................................................................................................................................... 118

4.3 USER PROGRAM PROCESSING ................................................................................................................................................... 119

4.3.1 RS232C ................................................................................................................................................................................ 119

4.3.2 USB ........................................................................................................................................................................................... 120

4.3.3 DELIMITER .................................................................................................................................................................................. 122

4.3.4 TYPES OF COMMUNICATION COMMAND ........................................................................................................................ 123

4.3.5 DETAILS OF COMMUNICATION COMMAND .................................................................................................................. 135

4.3.5.1 AXIS SPECIFICATION COMMAND .............................................................................................................................. 135

4.3.5.2 PARAMETER SETTING COMMAND ........................................................................................................................... 135

4.3.5.3 MEMORY SW SETTING COMMAND........................................................................................................................ 139

4.3.5.4 SPEED TABLE SETTING COMMAND ...................................................................................................................... 140

4.3.5.5 WRITE COMMAND ......................................................................................................................................................... 141

4.3.5.6 DRIVING COMMAND ...................................................................................................................................................... 141

4.3.5.7 STOP COMMAND ........................................................................................................................................................... 142

4.3.5.8 PARAMETER SETTING REQUEST COMMAND .................................................................................................... 143

4.3.5.9 MEMORY SW SETTING REQUEST COMMAND .................................................................................................. 145

4.3.5.10 SPEED TABLE SETTING REQUEST COMMAND .............................................................................................. 147

4.3.5.11 STATUS REQUEST COMMAND............................................................................................................................. 147

4.3.5.12 GENERAL I/O COMMAND ....................................................................................................................................... 152

4.3.6 PROGRAM DRIVING DEDICATED COMMAND ............................................................................................................... 153

4.3.7 ERROR CODE ........................................................................................................................................................................... 156

4

5.CHECKOUT ..................................................................................................................................................................................... 157

6.FAULT DIAGNOSIS AND SOLUTION ...................................................................................................................... 157

7.WARRANTY & CUSTOMER SERVICE.................................................................................................................... 158

● APPENDIX ............................................................................................................................................................................................... 159

■ DIP SWITCH SET ............................................................................................................................................................................................. 159

■ DS102 EXTERNALS .................................................................................................................................................................................... 160

■ DS112 EXTERNALS .................................................................................................................................................................................... 161

■ CONTROL I/O CABLE(MODEL:DS100-CNT-2) ............................................................................................................... 162

■ GENERAL I/O CABLE(MODEL:DS100-IO-2) ................................................................................................................... 163

■ SELECTION OF A PROGRAM NUMBER BY CNT-IO ........................................................................................................................ 164

■ SELECTION OF A TEACHING NUMBER BY CNT-IO ........................................................................................................................ 164

5

Cautions

!

1.INTRODUCTION

Thank you for purchasing this series Stepping Motor Controller.

1.1 For Your Safety

For Proper use, please read this operation manual thoroughly prior to using this product.

means the PROHIBITATION.

Please look after instructions shown here by all means.

Failure to use controller, may be hurt or suffer material damage.

・Basic cautions

・ Connect a power cable to a power outlet which comes with protective earth terminal, In case of

using an extension cable without protective earth terminal, protective earth will be of no effect.

・Cable

・When you unplug a power cable, turn off a power switch.

・When it supplies DS112 Series with a power supply, please be careful not to make a mistake in

polarity.

・Operating Environment

・To avoid as follows.:

-Areas that have much dust or metallic particles

-Directly under sunlight

-Near fire

-Much vibration

-Watery or oily place

-Wonky place

-Place with Corrosive Gas and Flammable Gas

・Storage

Please unplug a power from the outlet when

It doesn’t use for a long time, and you move this product..

A fire and the accident of the electric shock etc. are prevented.

6

Caution

!

・Power Source

・Please DO NOT connect the DS102 series besides the power supply outlet of interchange 100~

240V (AC100~240V 50/60Hz)

・Please supply direct 24V(DC24V±10%)power supply for DS112 series.

In order to avoid damage to controller, DO NOT use any input voltage or frequency over

the specifications.

・Resolution of the product/Remodeling

・ Please DO NOT perform the resolution of the product, remodeling, the

unfair repair.

・ Please contact us for correct information if needed.

・Repair Service

・ In the case of the following, please disconnect the plug promptly and then

contact your supplier.

-When there are some strange sound, smelling and smoke.

-When a power supply cable damaged.

-When spilled water on the equipment and foreign materials entered

inside.

-When dropped the equipment and was damaged with a cabinet.

7

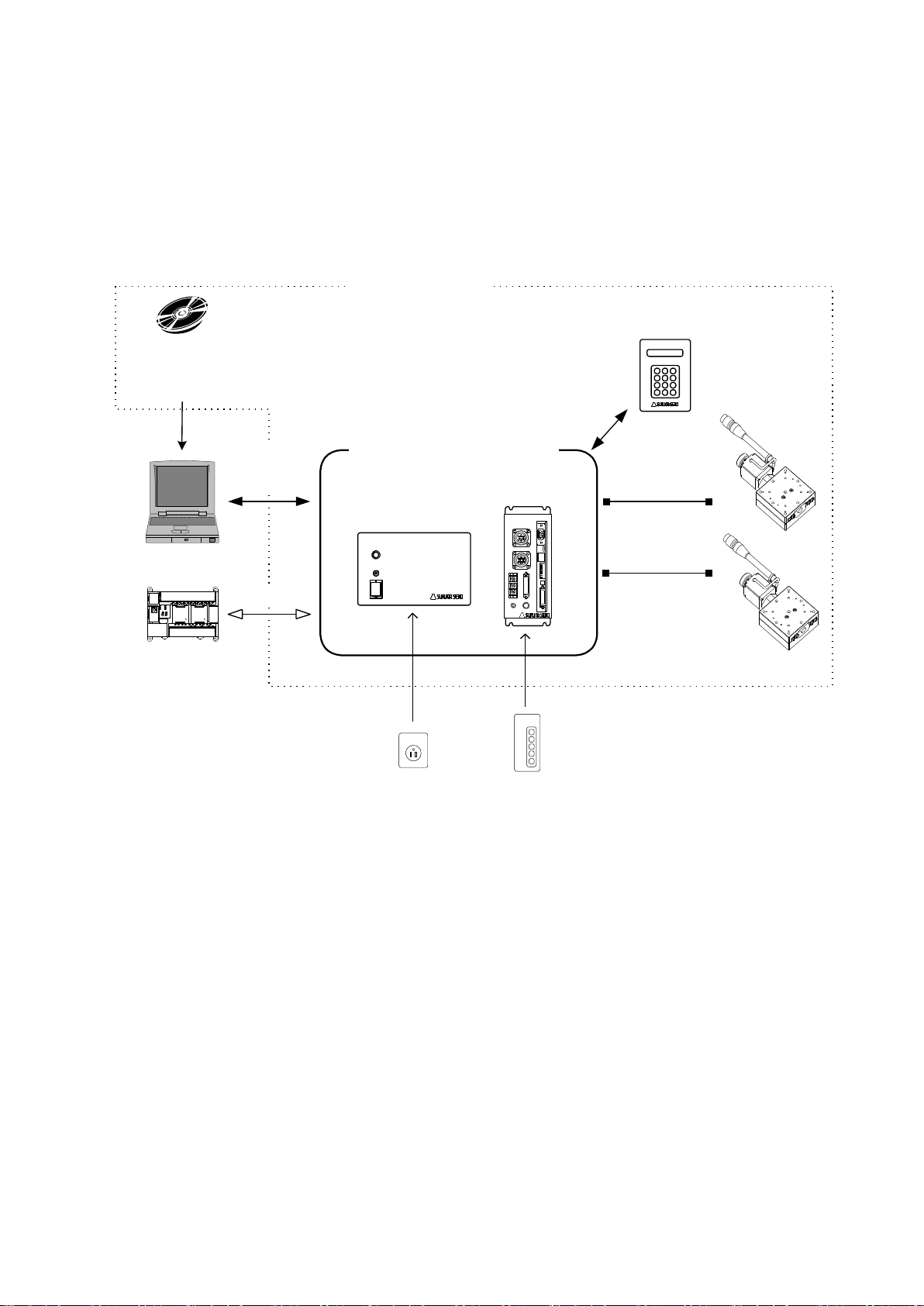

1.2 Product Outline / Features

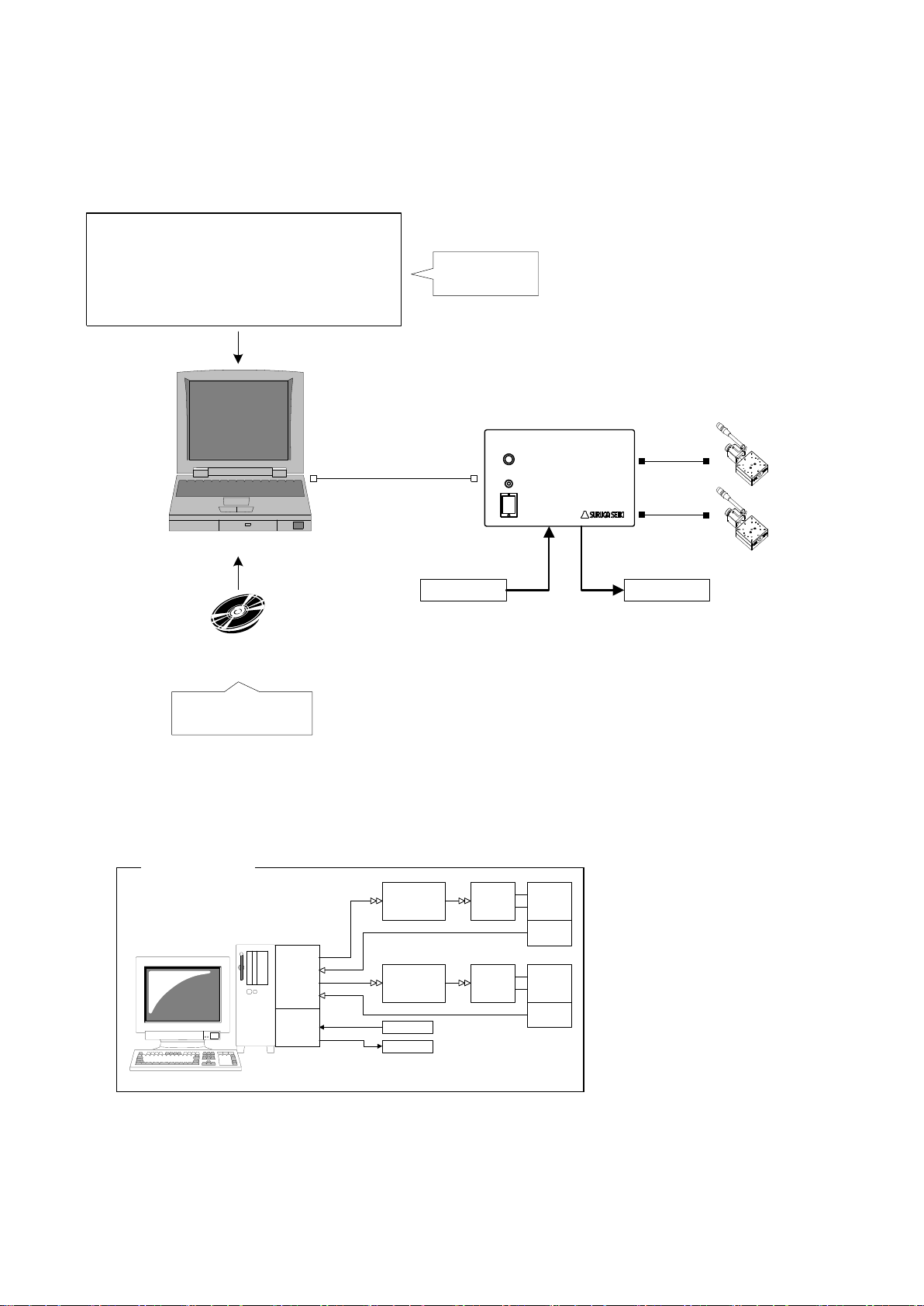

Computer

PLC

DC24V

AC100V

XY

DS112

Stepping Motor Controller

DS112

Stepping Motor Controller

DS102/DS112 series

AC100~240V

DC24V

Motorized stage

DS102/112

Controlled software:

DSCONTROL-WIN

DS102

Stepping Motor

Controller

DS102

Suruga Seiki

Standard

DT100

Handyterminal

DT100

I/O for

controlled

USB

or

RS232C

DS102/DS112 series is stepping motor controller with 2 axes for not only R&D but also units and

manufacturing you can use what you want.

Product Outline

8

Features

SURUGA Type

MISUMI Type

Input PS

Type of Drive

General I/O

DS102NR

MSCTL102

AC100~240V

±10%

50/60Hz

Normal (FULL/HALF)

-

DS102NR-IO

MSCTL102-IO

Input16, Output12

DS102MS

MCSTL102-MS

Microstep (16levels)

-

DS102MS-IO

MSCTL102-IO-MS

Input16, Output12

DS112NR

MSCTL112

DC24V ±10%

Normal (FULL/HALF)

-

DS112NR-IO

MSCTL112-IO

Input16, Output12

DS112MS

MCSTL112-MS

Microstep (16levels)

-

DS112MS-IO

MSCTL112-IO-MS

Input16, Output12

SURUGA Type

MISUMI Type

Cable length

Recital

DS100-LINK2-0.5

MSLINK2-0.5

0.5m

For 2 links

DS100-LINK3-0.5

MSLINK3-0.5

0.5m

For 3 links

DS100-CNT-2

MSCNT2

2m

For control I/O(one end loose)

DS100-IO-2

MSGP2

2m

For general I/O(one end loose)

D100-R9-2

MSRS232C

2m

RS232C cable

DS100-USB-1.8

MSUSB1.8

1.8m

USB Cable

SURUGA Type

MISUMI Type

Article name

DT100

HDT100

Handy Terminal

DSCONTROL-WIN

MSSOFT

DS102/112 controlled software

1. Controlled

・ 5 phase stepping motor is controlled by 2 axes

・ Linear interpolation of 2 axes

・ 2 types motor driver with normal(FULL/HALF) and micro-step(16 levels)

As a microstep type, it is possible to highly positioning control and low vibration with

Smooth drive function.

・ It is possible to control 6 axes with link function.

Up to 24 axes can be controlled with USB Hub.

2. Drive

・ Teaching point movement

・ Program Drive

・ Jog Drive

・ It is possible to memorize teaching point 64 points and 8 of programs.

3. Interface

・ Connected USB、RS232C

・ DS102/112 controlled software:DSCONTROL-WIN

・ Handy terminal:DT100

・ I/O for controlled

・ General I/O:Input16points、output12points (Option)

・ 2 types of PS/V AC100~240V、DC24V

【Line up products】

【Option Cable】

【Other Option】

9

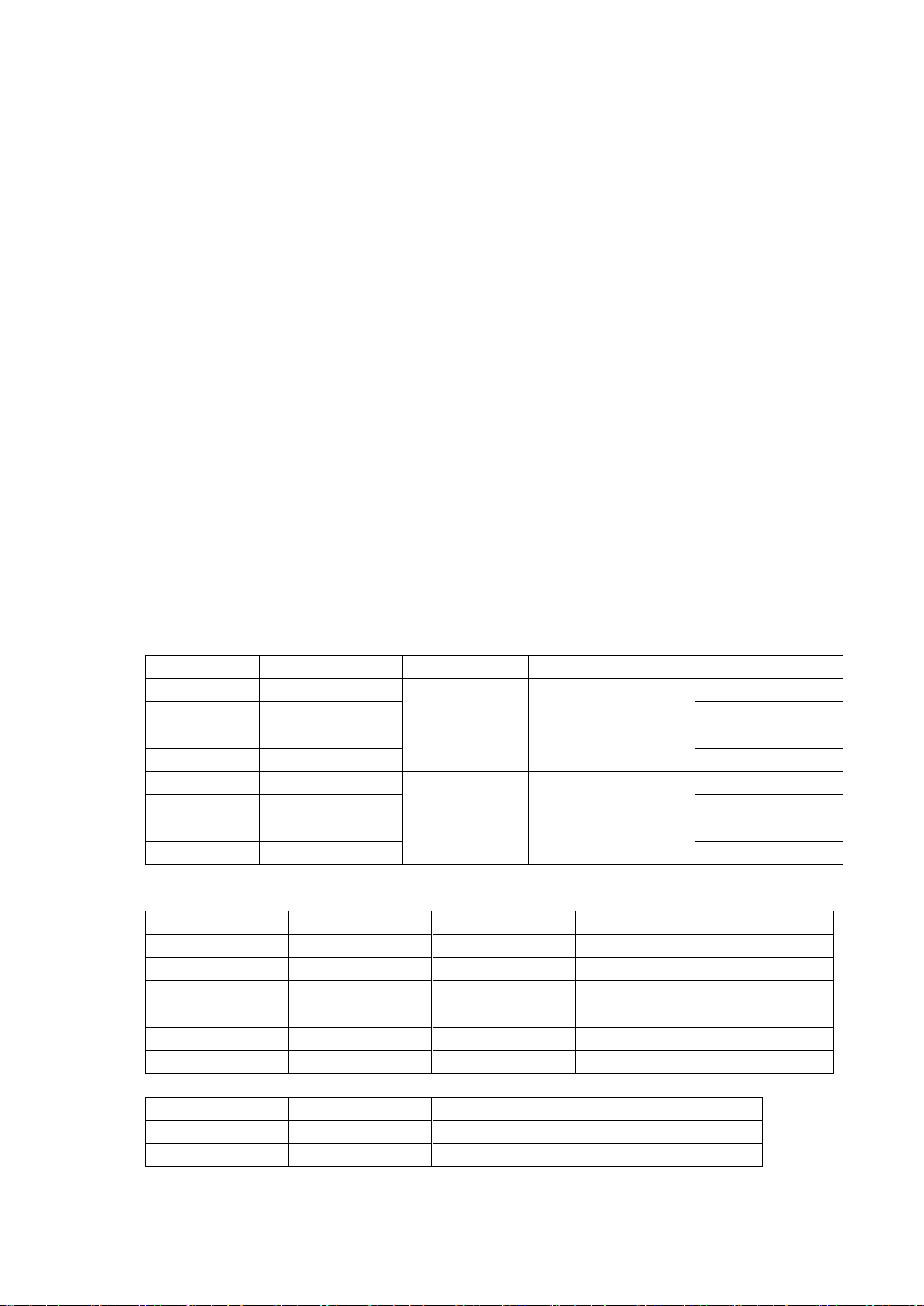

1.3 System configuration example

X axis

Motor driver

X axis motor

Guide ball

screw

Limit

Switch

Y axis

Motor driver

Y axis motor

Guide ball

screw

Limit

Switch

Position Control

Unit

CPU Unit

I/O Unit Sensor

Actuator

PLC

Former System

CPU Unit

I/O Unit

X Axis Stage

Y Axis Stage

PLC

XY

DS112

Stepping Motor Controller

DS112NR

Move the teaching point/Switch the program

drive

Teaching point number selected

Program number selected

Start/Stop

DS102/112

Controlled SoftWare:

DSCONTROL-WIN

・Move the teaching point/Switch the program drive.

・Teaching Point Number Selected.

・Program Number Selected

・Start

・Stop

・Set up the system parametor

・Memorized teaching points

・Programming and editing

・Operation check

・Back up data

PC

DT100

Handy Terminal

DT100

・Set up the system parametor

・Memorized teaching points

・Operation check

USB or RS232C

1.3.1 Control with PLC

Stages can be controlled with I/O units of PLC.

No need positioning units.

10

1.3.2 Controlled by PC

Motion

Control

Board

X Axis

Motor driver

X Axis

Motor

Guide

ball screw

Limit

Switch

Y Axis

Motor Driver

Y Axies

Motor

Guide

ball screw

Limit

Switch

I/O

Board

Sensor

Actuator

PC

Former set-up

Sensor Actuator

USB

or

RS-232C

X axis stage

Y axis stage

PC

General Input:

16points

General Output:

12points

DS102

Stepping Motor

Controller

DS102NR-IO

Use virtual COM port (Ex.:VB)

RS-232C communication application

MSComm1.Settings = "9600,N,8,1" ' Set up the port

MSComm1.CommPort = 1 ' Set up the port add.

MSComm1.PortOpen = True ' Open the port

' Move to 100 X axies

MSComm1.Output = "Axis1:Selsp 0:Goabs 100"

Original software

・Set up the system

parametor

・Operation check

・Cotrolled stage

・ControlI I/O

DS102/112

Control Software:

DSCONTROL-WIN

Easily controlled external machine by software.

No need motion control board and I/O board.

11

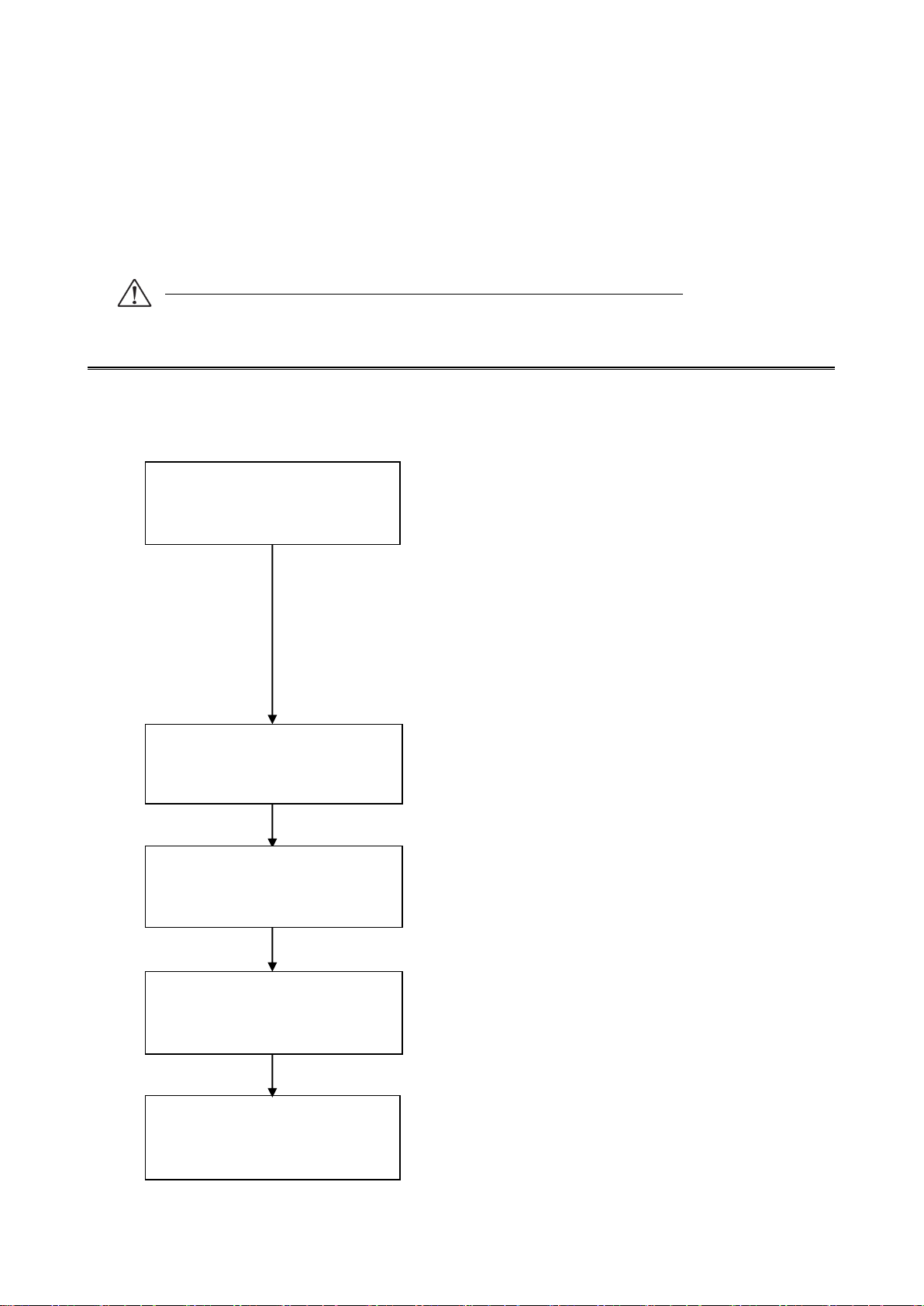

1.4 Accessories

Operation check

・DS102 or DS112

・X axis stage ・Y axis stage

・Motor cable

・RS232C cable:DS100-R9-2

・USB cable:DS100-USB-1.8

・Power cable

・PC

※You must have another power supply

and power cable if you use DS112.

・USB driver CD-R

・DSCONTROL-WIN CD-R (Option)

Conecting

Install USB driver

Set up the system parametor

DS102/112 Control soft ware:

Install DSCONTROL-WIN

This included following goods. Please check when you open. If some parts missing, please let us

know.

・ DS102/DS112:1 PCS

・ Power cable(2m) :1 PCS(Only case of DS102)

・ CD-R(data of this Manual , USB Device driver) :1PCS

・ Manual(this documents) :1PCS

The power cable of DS102 attachment is exclusively for this machine.

2.Set-up and example of use

2.1 Set up before use

Shows flow before use DS102/DS112.(MISUMI Type: MSCTL102/MSCTL112)

12

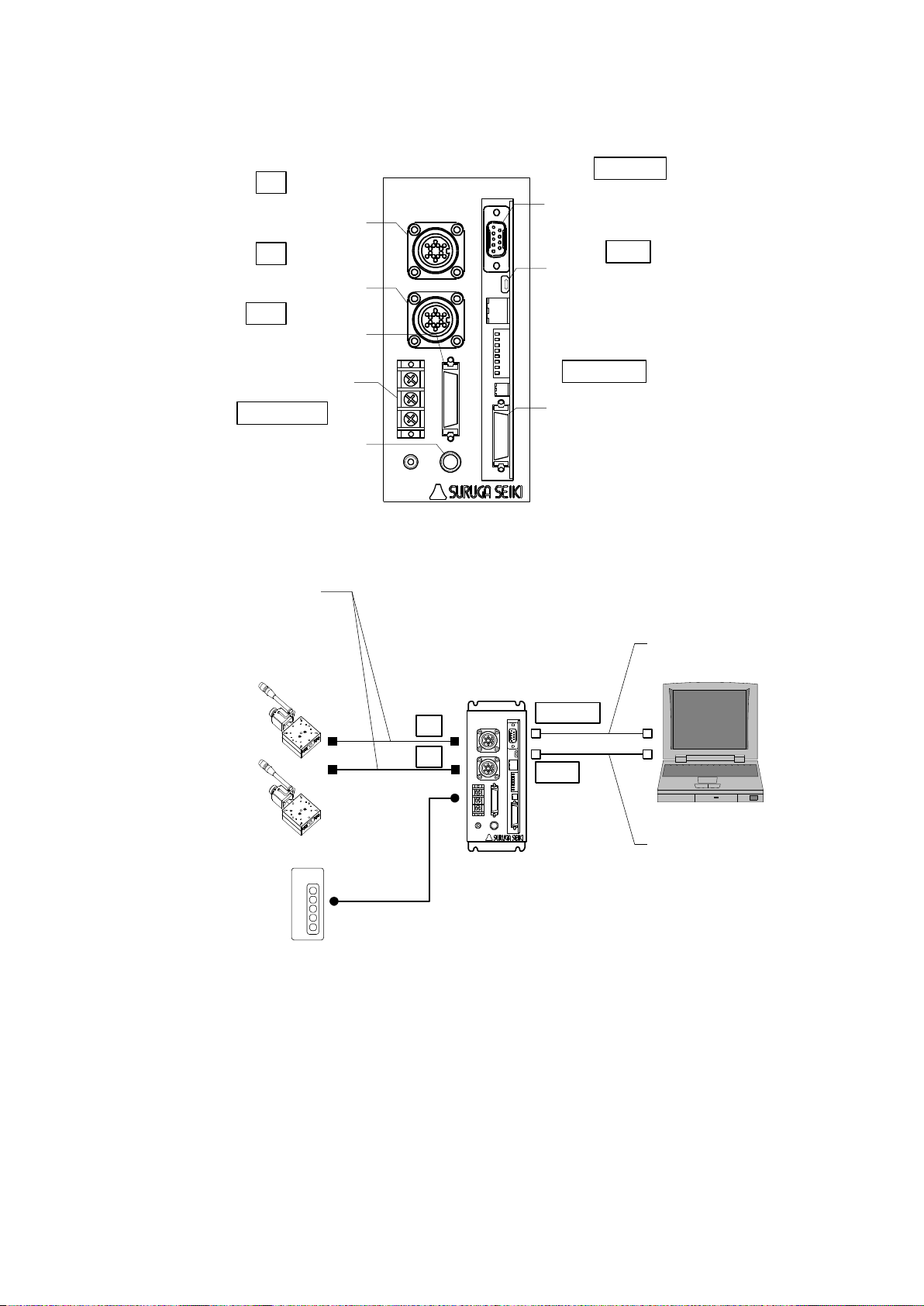

2.1.1 Connecting

I/O connector for

control

RS232C

X axis stage connector

General I/O

Connector

X Y

I/O

CNT-I/O EMS SW1 LINK USB RS232C

USB Connector

AC Inlet

Y axis stage connector

I/O

CNT-I/O

USB

RS232C

X

Y

TERMINAL

DS102

Stepping Motor Controller

Power

Connector for

Handy terminal

TERMINAL

Shows how to connect DS102/DS112

DS102

13

DS102

Stepping Motor

Controller

X axis stageY axis stage

AC100V

AC100

~240V

USB Cable:

DS100-USB-1.8

USBRS232C

RS232C Cable:

D100-R9-2

or

XY

Motor Cable

16 pins series stages:

D214-1-□E,D214-1-□R

(MISUMI:SRCB□,SRCB□-R)

12 pins series stages:

D214-2-□E,D214-2-□R

(MISUMI:MSCB□,MSCB□-R)

D214-2-□EA,D214-2-□RA

(MISUMI:MS4CB□,MS4CB□-R)

Attached

Power Cable

① Connect X axis motor connector to X axis stage.

② Connect Y axis motor connector to Y axis stage.

③ Connect AC inlet and AC100~240V.

④ Connect USB connector to USB port of PC.

(Connect RS232C connector to PC if use RS232C)

14

Use DS112

XY

TERMINAL

POWER

+24V

CNT-I/O EMS SW1 LINK USB RS232C

DS112

GNDFG

I/O

Y axis motor

connector

Terminal block for

power

General I/O

connector

Handy terminal

for connector

RS232C

connector

USB

connector

I/O connector for

control

Stepping Motor Controller

I/O

CNT-I/O

USB

RS232C

X

Y

TERMINAL

X axis motor

connector

X axis stage

Y axis stage

XY

DS112

Stepping Motor Controller

X

Y

USB cable:

DS100-USB-1.8

USB

RS232C

RS232C cable:

D100-R9-2

or

Motor cable

16pin series stage:

D214-1-□E,D214-1-□R

12pin series stage:

D214-2-□E,D214-2-□R

DC24V

DC24V

① Connect X axis motor connector to X axis stage.

② Connect Y axis motor connector to Y axis stage.

③ Connect terminal for power of DC24V to power supply(DC24V)

※ Must have DC24V power supply and cable

④ Connect USB connector to PC USB port.

(Connect RS232C connector to PC if use RS232C )

15

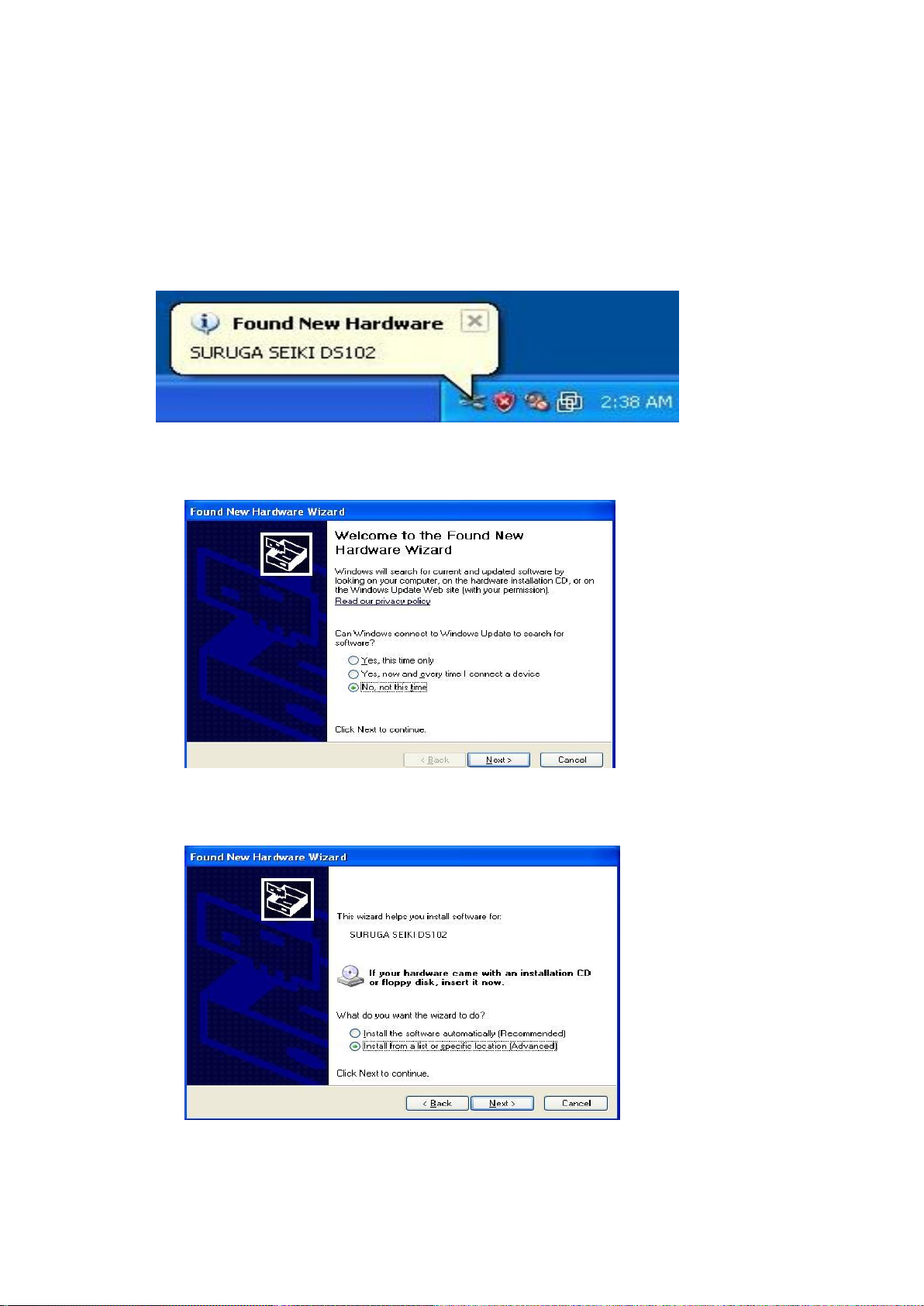

2.1.2 USB Driver Install

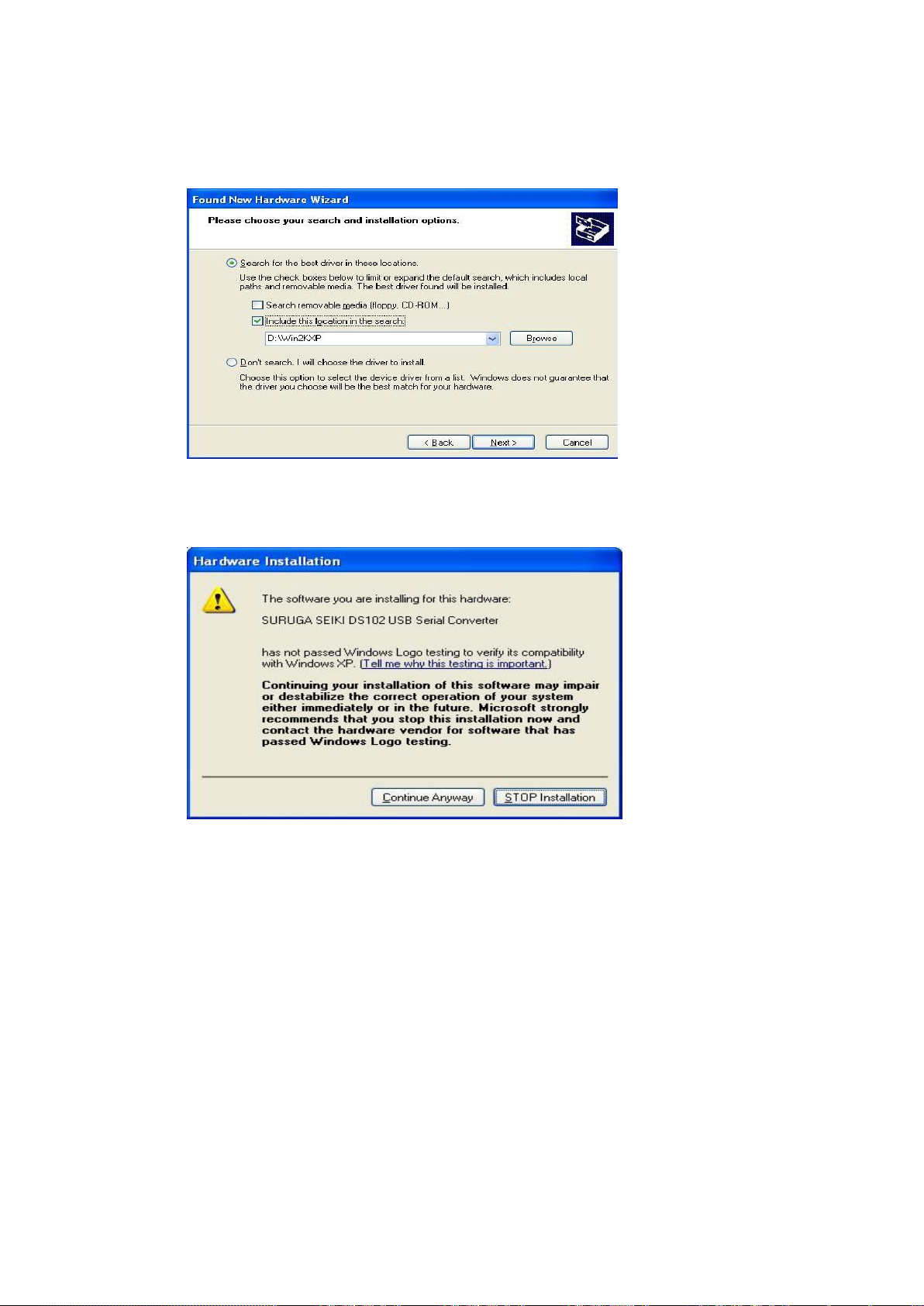

Shows how to install USB driver to PC(for XP).

① Switch on a computer and start Windows.

② Set up DS102/112 USB driver CD-ROM to computer drive.

③ Switch on DS102/112 and wait 5 seconds.

④ Connect computer USB port and DS102/112 USB connector.

When computer recognize to connect DS102/112, shows following messages.

⑤ At the detecting wizard of new hardware, choose [No, not this time]

and click [Next].

⑥ Select [Install from list or specific location (Advanced)] and click [Next].

16

⑦ Check the [included this location in the search], push [Browse] and select [Win2KXP] then,

click [next].

Start the driver install.

⑧ Click the [Continue Anyway] when displays Hardware Installation.

17

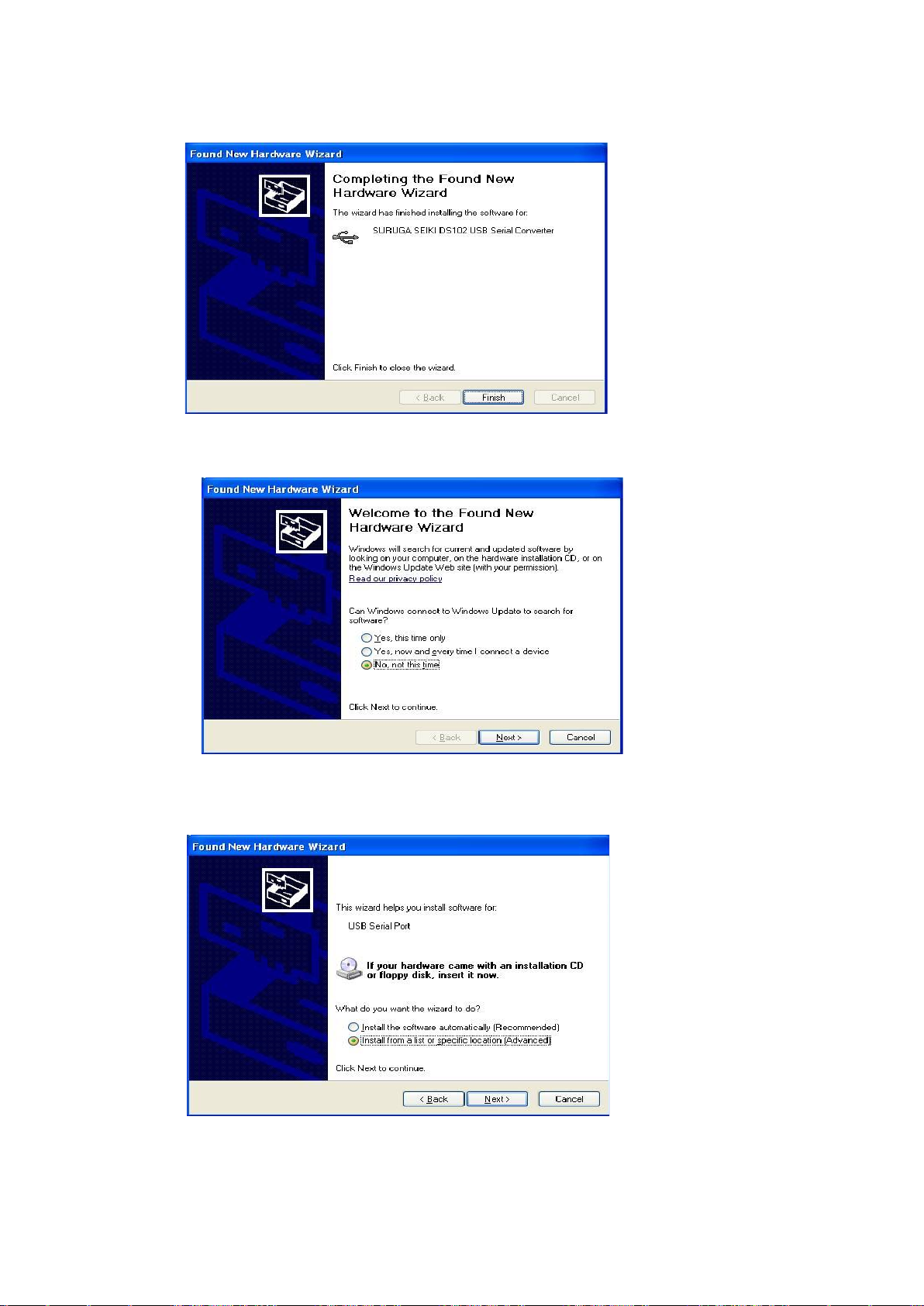

⑨ Click [finish]

Display the found new hardware wizard.

⑩ Select [No, not this time] and click [Next].

⑪ Select [Install from a list or specific location (advanced)] and click [Next].

18

⑫ Check the [included this location in the search], push [Browse] and select [Win2KXP] then,

click [next].

Start the driver install.

⑬ Click the [Continue Anyway] when displays Hardware Installation.

19

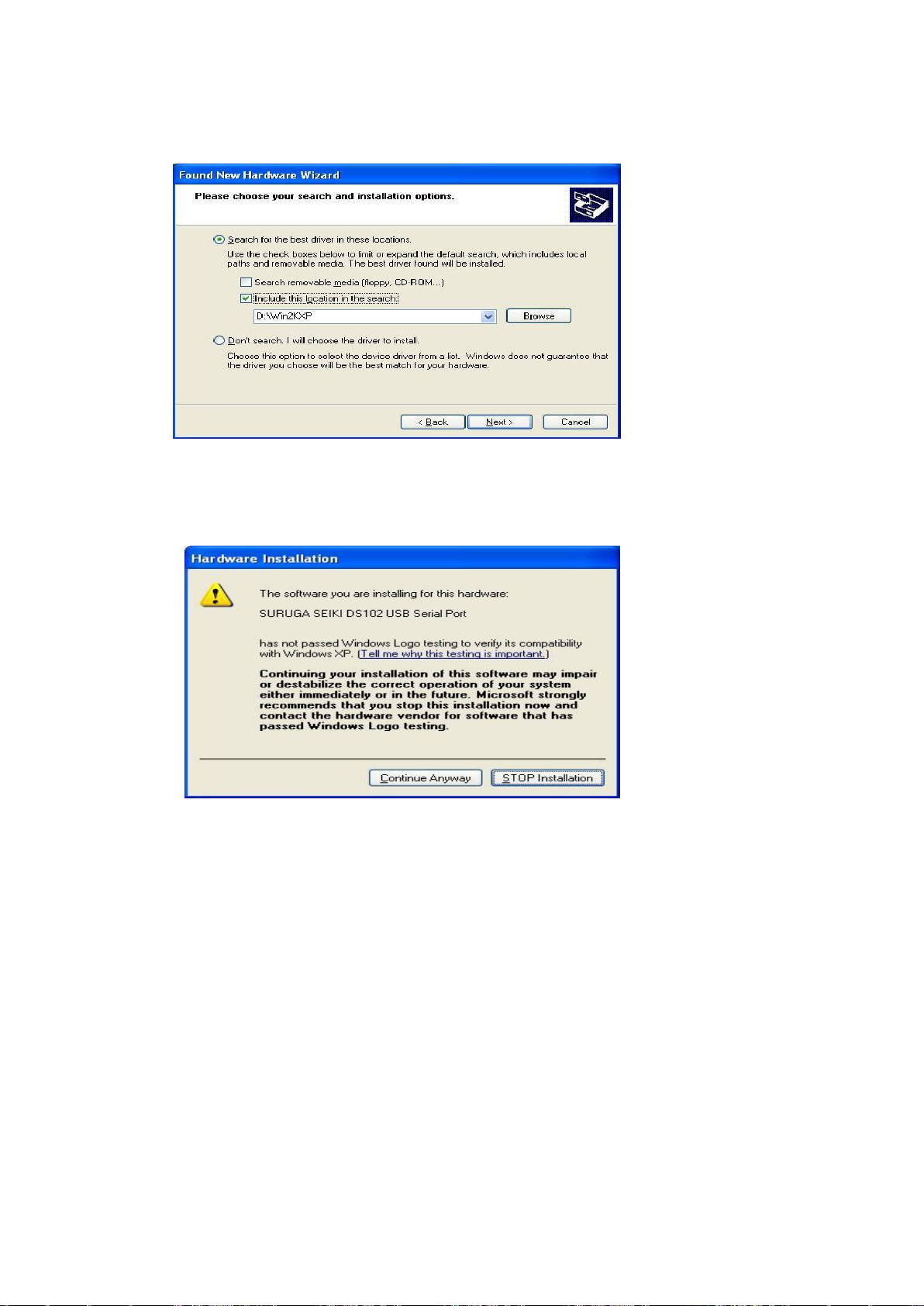

⑭ Click [finish]

Display the found new hardware wizard.

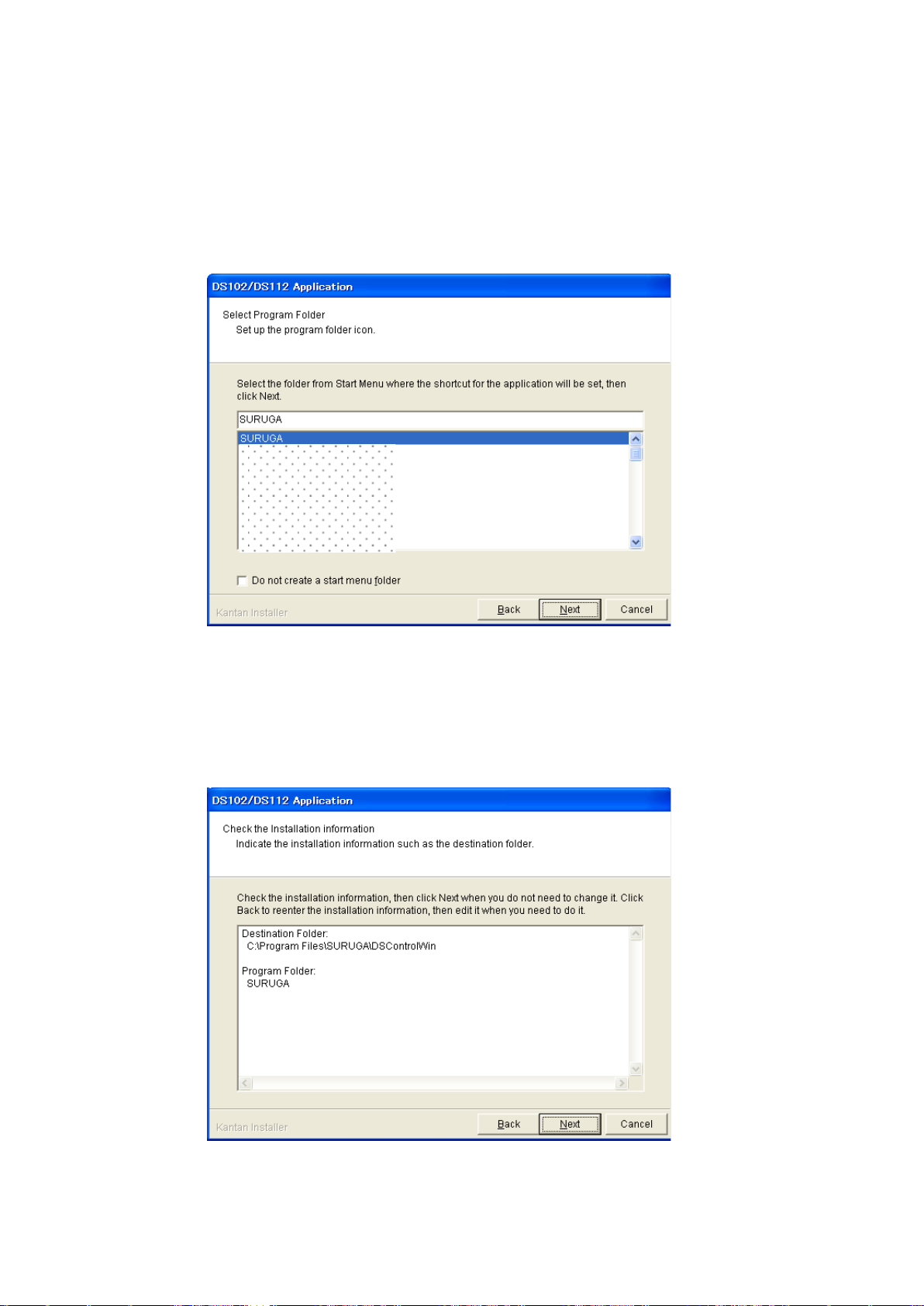

2.1.3 Installation for control software DS102/112(DSCONTROL-WIN)

Show how to install software (DS CONTROL-WIN) to control DS102/112 by PC.

① Insert CD-ROM of DSCONTROL-WIN inside PC drive.

② Double click on setup.exe in CD-ROM.

DSCONTROL-WIN installer start.s.

③ Click [next]

The screen below appears on PC.

20

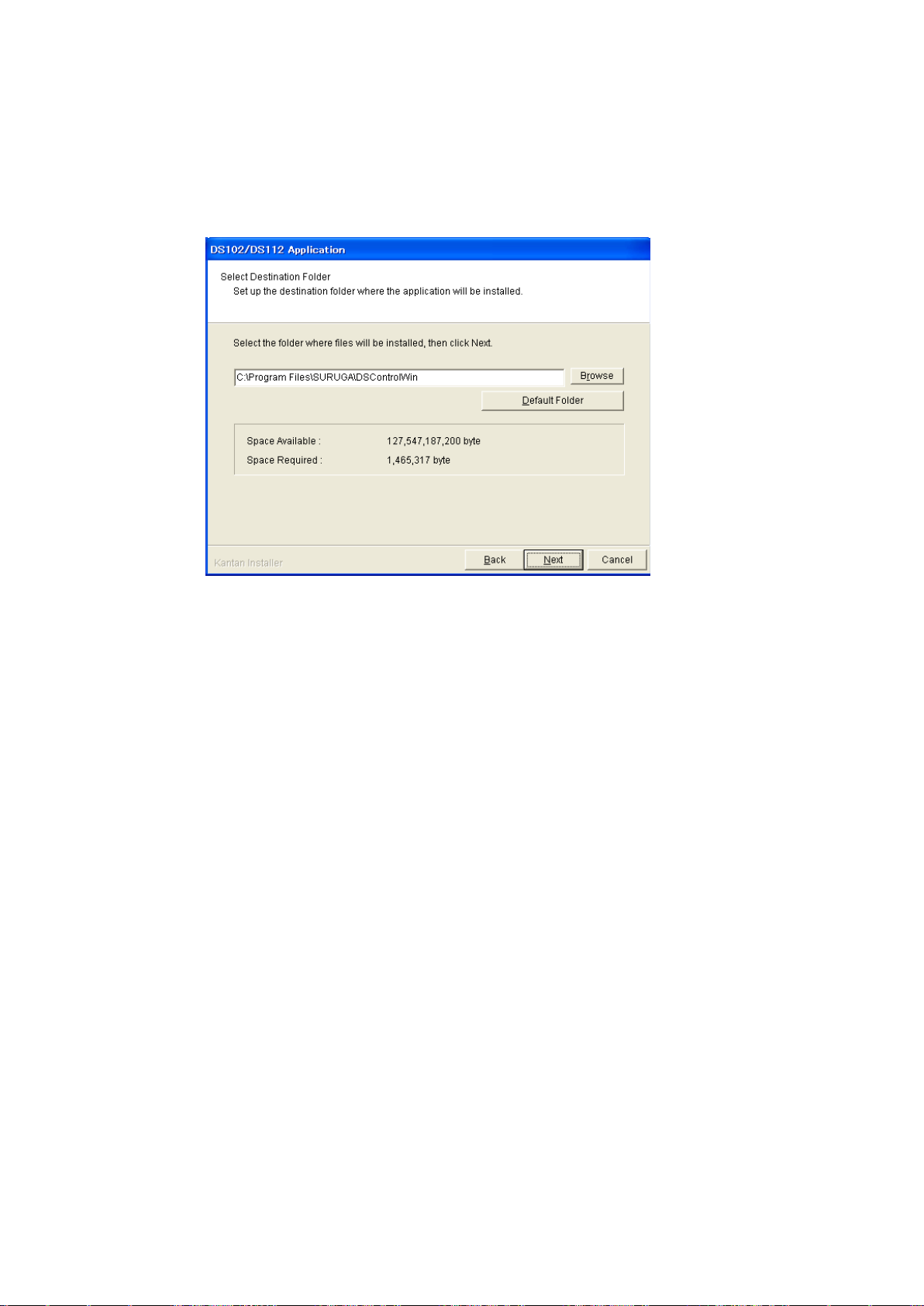

④ Select folder of installation then click {Next}

The screen shows folder selection

※On initial setting, installation folder is:\Program Files\SURUGA\DSControlWin.

Click [Next] in case of no required folder

21

⑤ To prepared Program Shortcut, you need to select folder from list on START MENU then click

[Next]

The drawing below appears on PC screen

※On initial setting, Startmenu folder is DSControlWin.

Click [Next] in case of no required folder

⑥ Click [Next] after you confim installed contents

The screes scomes to [Information]

22

⑦ Click [YES]

※ No pop-up message appears if you already select folder

Installation begins

Installation complete.

⑧ Click [Finish]

Installing DSCONTROL-WIN completed.

23

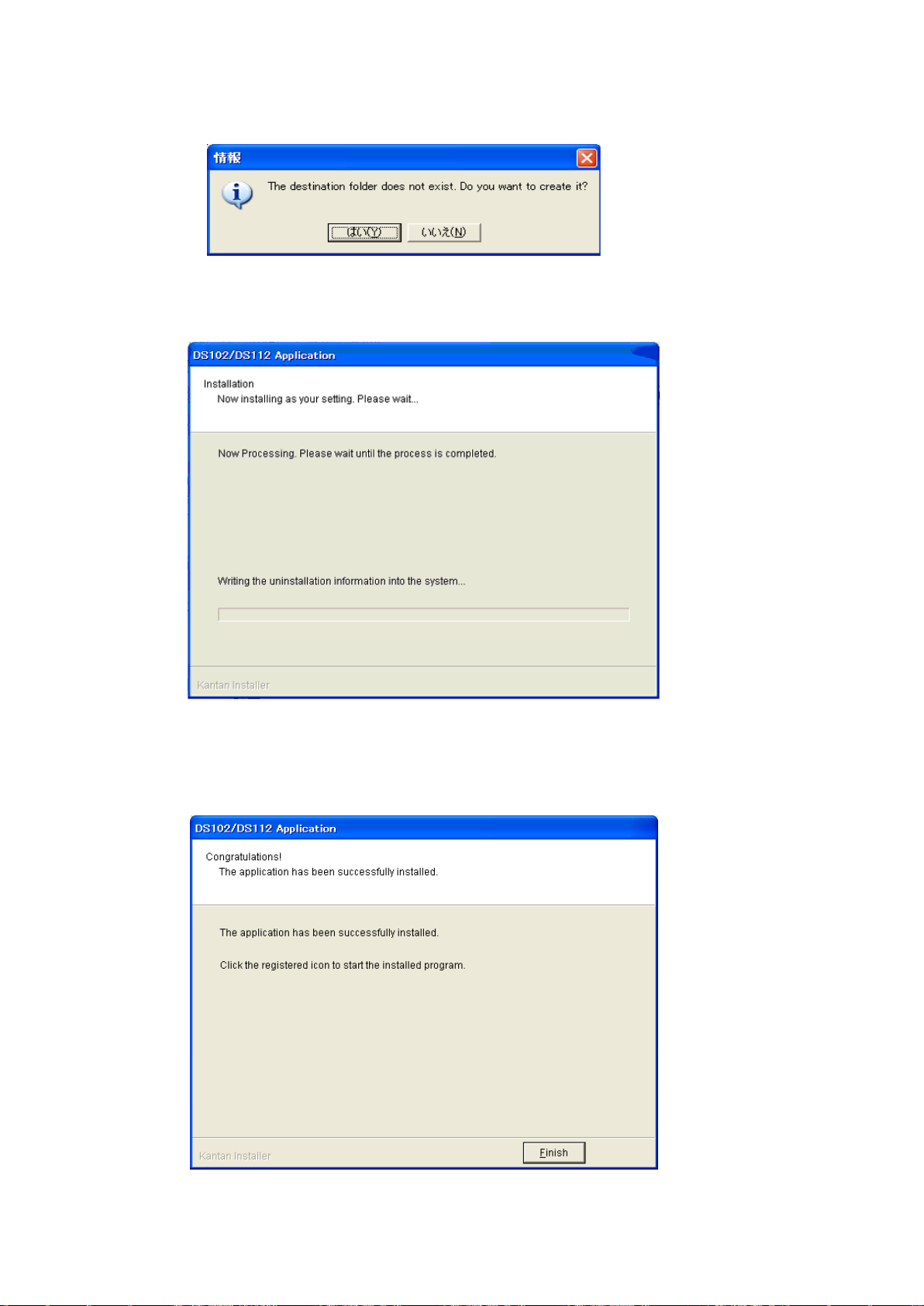

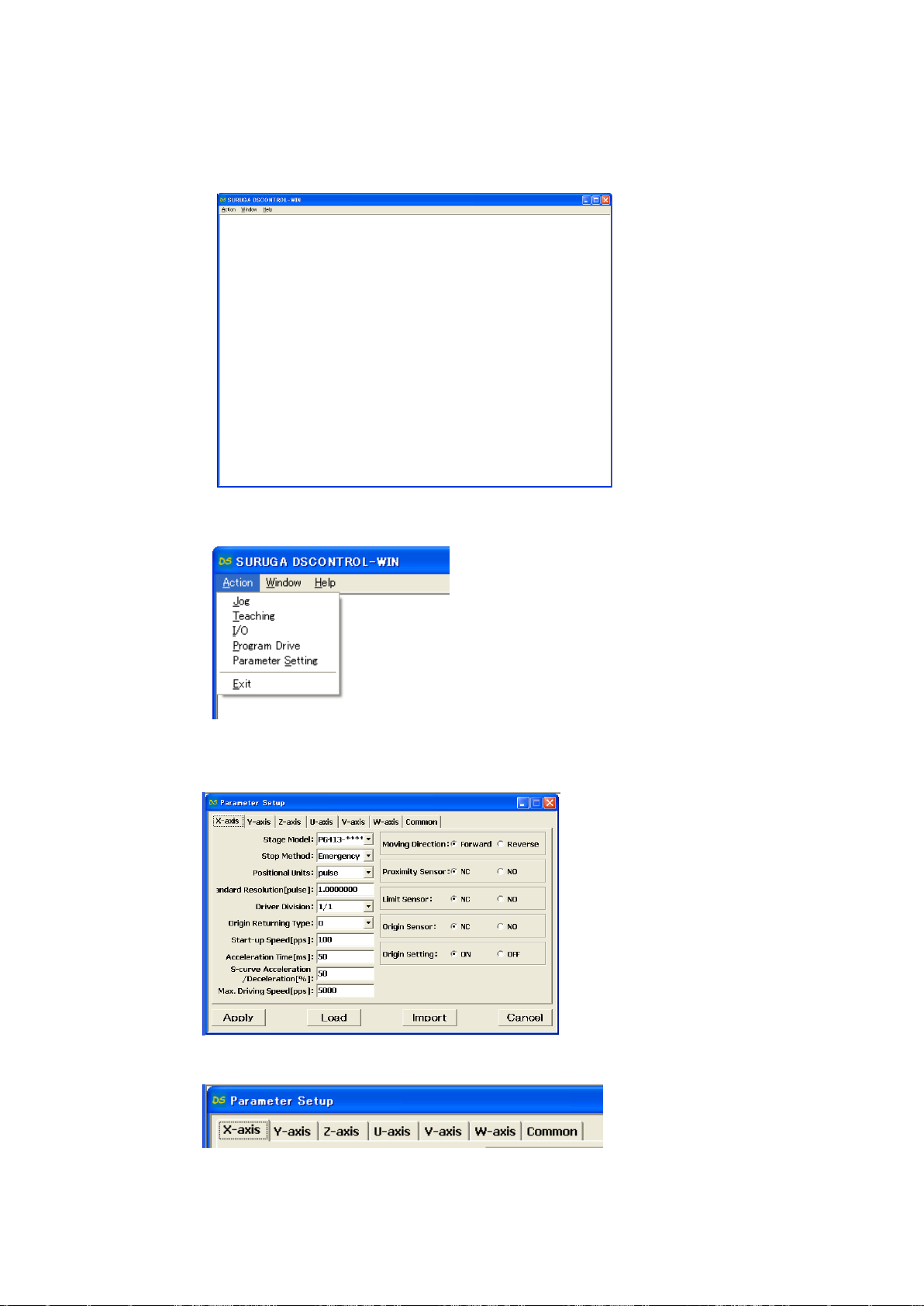

2.1.4 Adjustment system parameter

Shows how to set up system parameter by DSCONTROL-WIN

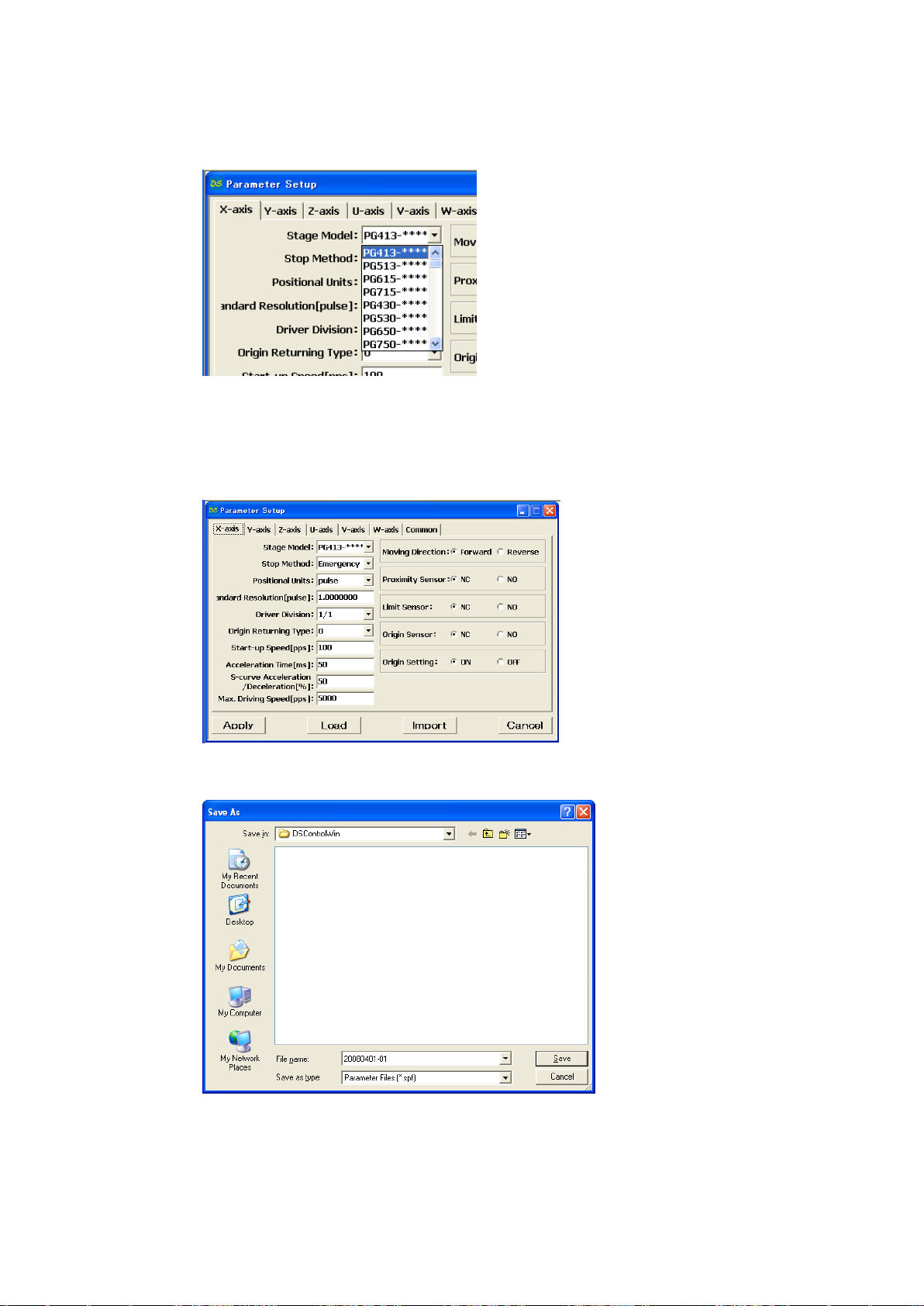

① Starts DSCONTROL-WIN

② Select [Parameter setting] in [Action]

Parameter setting appears on screen

③ Click on Tab you sellect

24

④ Select stage model you use from [Stage Model]

Initial value appears when you select stage model.

※ input direct value if we want to change initial value.

⑤ Select axis parameter by repeating ③~④ again.

⑥ Click [Apply].

Screen shows folder storing parameter.

⑦ Select folder and input file name then click [Save].

Parameter values are saved PC then forward values toward DS102/112.

※ Spf is automatically added.

25

2.1.5 Operation check

Shows how to check operation.

① Starts DSCONTROL-WIN.

② Click [JOG] in [Action] on main menu

JOG dialog appears on screen.

③ Click [Origin]

[Org],[Home] appears.

④ Click [Org] on X axis

X stage return origin position.

Make sure X stage moves origin position.

⑤ Repeat ③~④ again Y axis return to origin position.

26

⑥ Click [Contiue]

[+],[-]appear on screen.

⑦ Keep clicking [+] on X axis

X stage moves toward CW direction.

Stage stops when it reachs to CWLS then indicator leftside [+] becomes RED.

⑧ Keep clicking [-] on X axis

X stage moves toward CCW direction.

Stage stops when it reachs to CCWLS then indicator rightside [-] becomes RED.

⑨ Repeat ⑦~⑧ on Y axis.

27

2.2 System architecture

Waiting posi

(50,100)

Working posi

(1000,1500)

Exporting Posi

(2000,3000)

X axis stage

CPU unit

I/O unit

Y axis stage

PLC

XY

DS112

Stepping Motor Controller

DS112

T_BIT0~5

P/T_START

STOP

PRG/TCH

CNT-I/O

I/O cable

DS100-CNT-2

PC

DT100

Handy Terminal

DT100

USB

TERMINAL

X

Y

RS232C or

STEP1 : Moving to waiting position (50,100)

STEP2 : Moving to working position (1000,1500)

STEP3 : Processing on target

STEP4 : Moving to exporting position (2000,3000)

STEP5 : Exporting processig

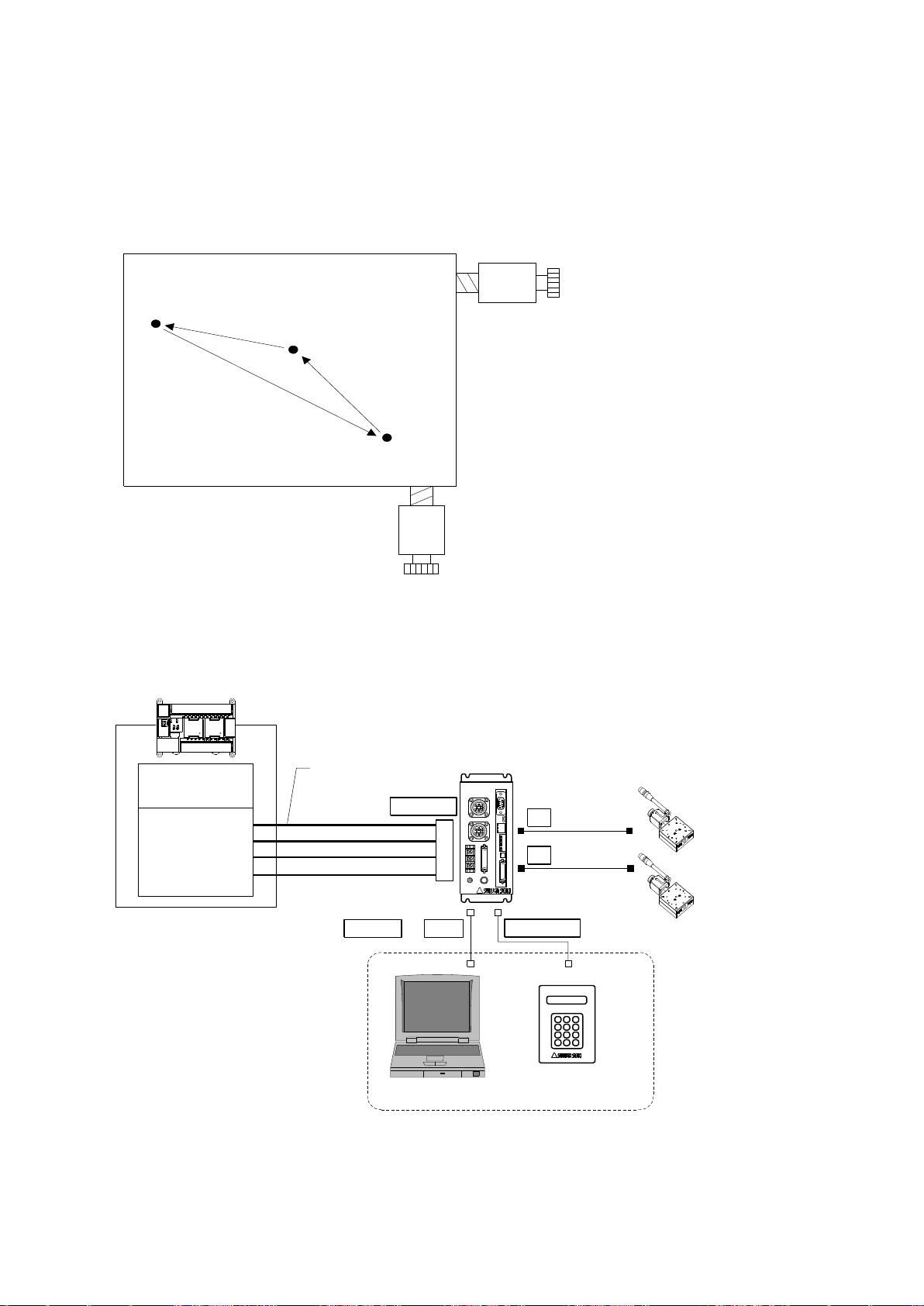

2.2.1 Movement between each teaching position

Show how to set up position inside memory of DS112 (MISUIMI Type: MSCTL112)and move its

position by PLC.

1) Configuration

※ CNT-I/O shows following signal. READY means Waiting condition of DS112 and X_DRIVE and

Y_DRIVE means both working condition. P/T_RUN means Teaching working and Program

working.

28

2) Movement summary

Waiting, working and exporting position memorized inside DS112 as teaching points, 00, 01, 02,

PLC appoints each points then make state move to each points.

① Set up 00 among T_BIT0~5, press P/T_START <STEP1>

② Set up 01 among T_BIT0~5, press P/T_START <STEP2>

③ Wait unitl woring on target is done <STEP3>

④ Set up 02 among T_BIT0~5, press P/T_START <STEP4>

⑤ Wait until exporting is done <STEP5>

3) Connect

Connect to DS112

PC is used when setting or editing teaching point

① Connect USB to PC USB port

(Connect RS232C to PC when using RS232C)

② Connect handy terminal to DS112

③ Connect X axis motor connector to X stage

④ Connect Y axia motor connector to Y stage

⑤ Connect control I/O connector to PLC I/O unit

On control I/O,

T_BIT0~5:Appoint teaching point

P/T_START:Signal to move to teaching point

STOP:Stop signal for all axes

PRG/TCH:program mode / teaching point mode

※ T_BIT0~2:combined use for program selection

29

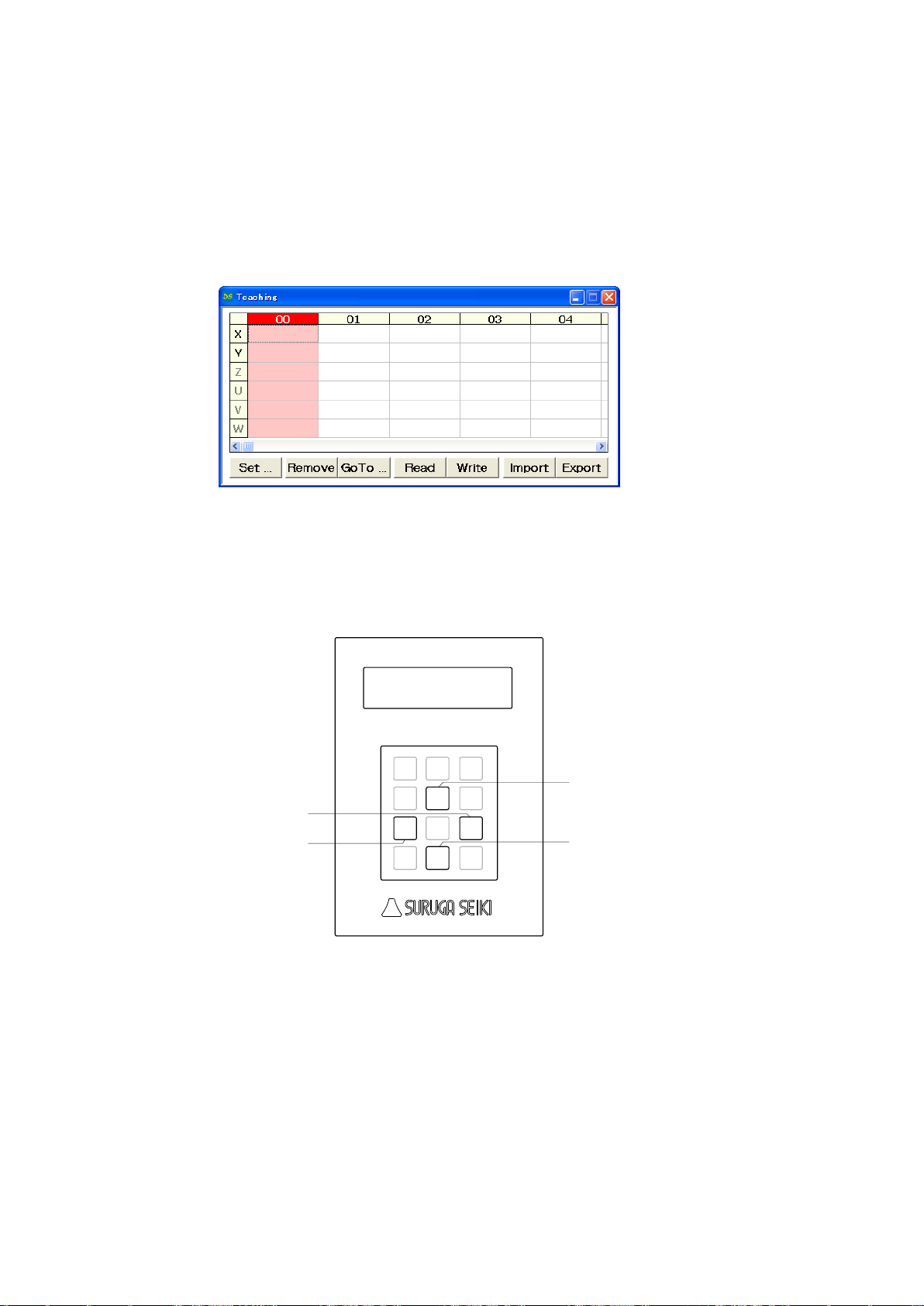

4) Memory of teaching point

Jog

7

Menu8Set

9

SPD

4

↑

5

POS

6

←1Link

2

→

3

Stop

0

/ESC

DT100

Handy Terminal

↓

.-

Enter

X stage CCW direction

X stage CW direction

Y stage CCW direction

Y stage CW direction

Memorizing teaching point inside DS112

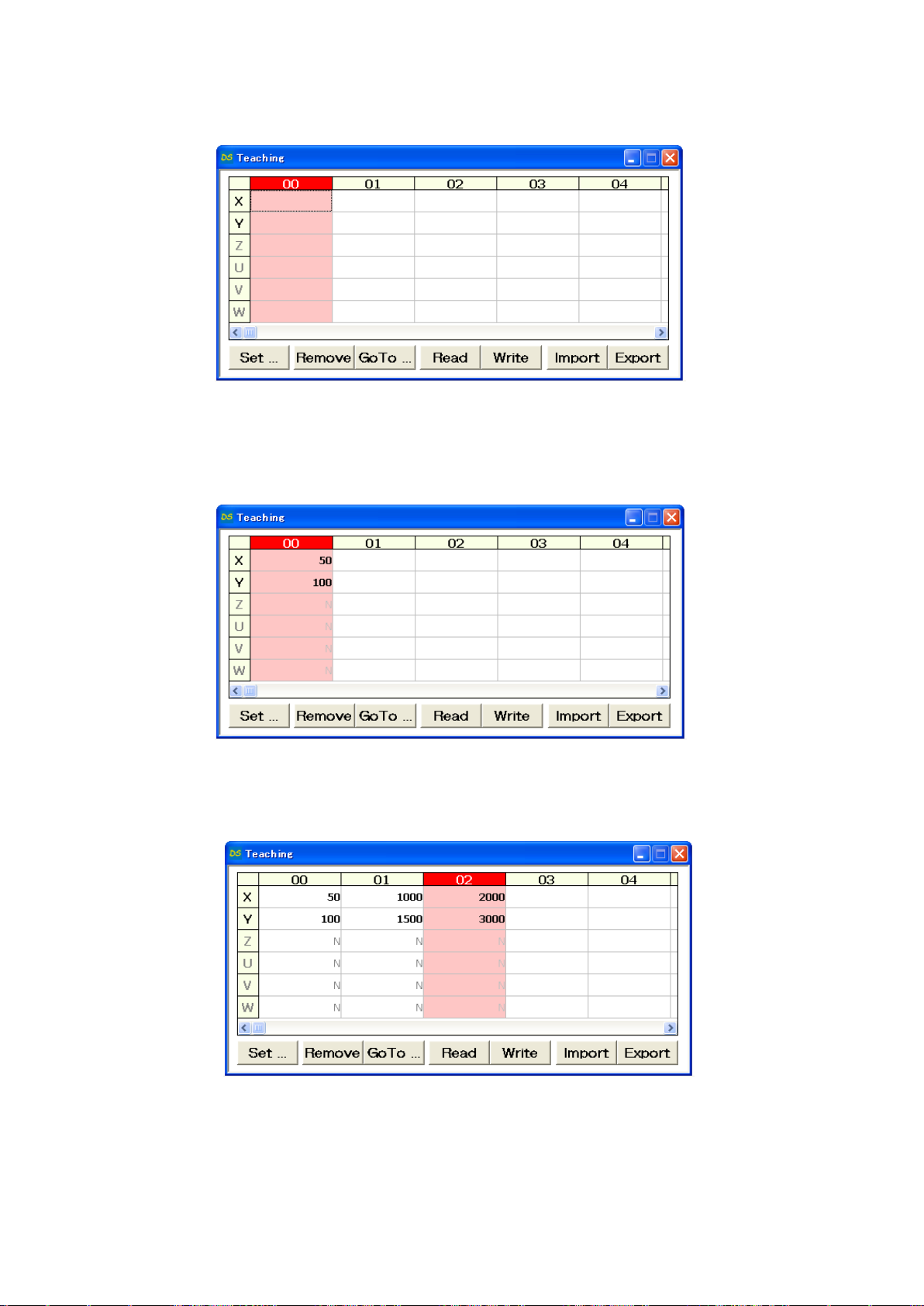

① Start DSCONTROL-WIN

② Select [Teaching] on main menu in DSCONTROL-WIN.

Screen below appears.

③ Push direction key on handy terminal unitl stage moves to specific positon.

30

④ Click [00] CELL on the teacing screen

00 CELL gets to be Red.

⑤ Click [Set]

Current stage position as 00 is memorized to DS112.

⑥ Repeat ③~⑤ so memorize 01 as working position and 02 as exporting position to DS112.

31

5) Save teaching file

Teaching points memorized are saved as teaching file in PC.

① Click [Save]

Save As appears on screen.

② Clcik [Save] after you determine [Save location] and [File name]

Teaching file is saved in PC.

※ tdf is added to your file name as extension.

32

6) Operation check

Checking movememt to the memorized position.

① No interference affects stage movement.

② Click [00] CELL on teaching screen.

00 CELL gets to be Red.

③ Click [Go to].

Stage moves to teaching point [00] (Waiting point).

④ Repeat ②~③ and check same operation at teaching point [01] working position as well as

[02] exporting position.

33

7) Execution of movement

Timing chart

PRG/TCH

T_BIT5-0

P/T_START

Function

00 01 02

Move to wait posi Move to Target Working Move to expt posi Working

P/T_RUN

READY

X_DRIVE

Y_DRIVE

Execute movement to teaching position by PLC.

※ All stages stop when making signal [STOP] [ON]

34

2.2.2 Easy return to origin position

CPU unit

I/O unit

X axis stage

Y axis stage

PLC

XY

DS112

Stepping Motor Controller

DS112

P_BIT0~2

P/T_START

STOP

PRG/TCH

CNT-I/O

I/O cable

DS100-CNT-2

X

Y

PC

USBRS232C or

Program #0

① Speed adjustment on X axis origin return movement

② [Origin] return on X axis

③ Speed adjustment on Y axis origin return movement

④ [Origin] return on Y axis

⑤ Speed adjustment on X axis movement

⑥ Speed adjustment on Y axis movement

Shows how to set [Origin] program in DS112 and execute [Origin return] by PLC.

1) Configuration

※ CNT-I/O continuously output READY is stand-by condition of DS112, X_DRIVE is X axis

working condition, Y_DRIVE is Y axis working condition and P/T_RUN means teaching point and

program are in action.

2) Movement summary

Setting up [Origin] program at program #0 in DS112 and [Origin] program starts by using PLC.

① Set 0 among P_BIT0~2 and make P/T_START ON (Program #0 starts).

35

3) Connection

Connection of DS112

PC (DSCONTROL-WIN) is connected only when creating or editing program.

① Connect USB connector to USB port in PC

(Connect RS232C to PC when using RS232C)

② Connect X axis stage connector to X axis stage

③ Connect Y axis stage connector to Y axis stage

④ Connect control I/O connector to I/O unit in PLC

On control I/O,

P_BIT0~2:Select program #

P/T_START:Signal of movement to teaching point

STOP:Stop signal for all axes

PRG/TCH:Select mode (Start program / movement to teaching point)

※ P_BIT0~2: combined use for teaching point selection

4) Creating program

Creating [Origin return] of two axes.

① Start DSCONTROL-WIN

② Click [Action]→[Program drive] on main menu.

36

③ Click [Add]

The display below appears on display.

④ Click [Speed] on command menu

“Speed Setup” appears on display.

⑤ Check axis X and input speed value then click [OK].

Command appears on the program drive screen.

⑥ Click [Add] on Program drive

Drive menu appears on display.

37

⑦ Click [Single Axis Drive]

Single Axis Drive appears on display.

⑧ Single Axis Drive display

[Mode] = “ORG”

[Axis] = “X”

[Wait until finish] = “Enable”

Click [OK]

[Origin] of X axis command appears on the first line.

⑨ Repeat ③~⑧ for Y axis

⑩ Click [Add]

Drive command menu appears on display.

38

⑪ Click [Speed]

Speed Setup display appears display.

⑫ Check [Axis] X and input drive speed value then click [OK].

Speed command appears on the fourth line.

⑬ Repeat ⑩~⑫ to set up Y axis speed.

39

5) Writing program

Writing program to DS112

① Click [Write]

Write Program appears on display.

② Select [0] then click [Transfer]

Program is forwarded to Program#0.

40

6) Save program

Save program at PC program drive file.

① Click [Save] on program drive display

The display below appears on display.

② Select [location] and [file name] then click [Save].

Program is saved as Program drive file.

※ prg is automatically added as extension.

41

7) Operation check

Checking movement to origin return.

① No interference affects stage movement.

② Click [Start]

Start Program appears on display.

③ Select program [0] then click [Start].

42

8) Practice of movement

Timing chart

PRG/TCH

P_BIT2-0

P/T_START

動作

0

X axis origin

return

Y axis origin

return

P/T_RUN

READY

X_DRIVE

Y_DRIVE

Function

Movement to [Origin] position by PLC.

※ All stages stop when [STOP] button

43

2.2.3 Control by external signal

CPU unit

I/O unit

X guide

Y guide

PLC

XY

DS112

Stepping Motor Controller

DS112

P_BIT0~2

P/T_START

STOP

PRG/TCH

CNT-I/O

CNT-I/O cable

DS100-CNT-2

I/O

X sensor

Y sensor

In00

In01

General I/O cable

DS100-IO-2

USBRS232C or

X

Y

STEP1 : Set both X and Y stages at starting position (50,100)

STEP2 : Move X stage by 10pulses then stop X stage when target reach X sensor

STEP3 : Move Y stage by 10pulses then stop Y stage when target reach Y sensor

X motor

Y motor

workwork

work

X sensor Y sensor X guide

Y guide

Shows how to stop stage by external signal that DS112 outputs.

1) Configuration

※CNT-I/O continuously output READY is stand-by condition of DS112, X_DRIVE is X axis working

condition, Y_DRIVE is Y axis working condition and P/T_RUN means teaching point and program are in

action.

44

2) Operation summary

Program #1

① Setting up address speed on both X and Y axes

② Movement of X and Y axes to work starting point <STEP1>

③ Move X axis to CW direction by 10 pulse

④ Repeat ③~④ until target reaches X sensor <STEP2>

⑤ Move Y axis to CW direction by 10 pulse

⑥ Repeat ⑤~⑥ until target reaches Y sensor <STEP3>

Setting up [Detecting sensor program] at program #1 in DS112 then executing movement by

PLC addressing program #1.

① Settting up 1 among P_BIT0~2 then press [ON] on P/T_START (Executing program #1).

3) Connection

Connection of DS112.

PC (DSCONTROL-WIN) is connected only when creating or editing program.

① Connect USB connector to USB port in PC

(Connect RS232C to PC when using RS232C)

② Connect X axis stage connector to X axis stage

③ Connect Y axis stage connector to Y axis stage

④ Connect control I/Oconnector to I/O unit in PLC

On control I/O,

P_BIT0~2:Select program #

P/T_START:Signal of movement to program

STOP:Stop signal for all axes

PRG/TCH:Select mode (Start program / movement to teaching point)

⑤ Connect X sensor and Y sensor to general I/O.

Assign X axis sensor output to In00, and Y axis sensor output to In01.

45

4) Creating program

Creating the program that stopping axis in response to external sensor.

① Starts DSCONTROL-WIN.

② Click [Action]→[Program drive] on main menu.

③ Click [Add]

Command menu appears on display.

46

④ Click [Speed] on command menu.

⑤ Check Axis X and input speed value then click.

Drive speed value appears on the line [0] on program drive display.

⑥ Click [Add] on.

Command menu appears on display.

47

⑦ Click [Single Axis]

Single Axis Drive appears on display..

⑧ Single-Axis Drive.

[Mode] = “POS”

[Axis] = “X”

[Destination] = “50”

[Waiiting until finish] = “Enable”

Click [OK]

Movement command on X axis appears.

⑨ Repeat ③~⑧ then input speed drive and movement command on Y axis.

⑩ Click [Add] on Drive command menu.

Drive command menu appears.

48

⑪ Click [Single Axis].

Single-Axis Drive appears on screen.

⑫ Single-Axis Drive

[Mode] = “STEP”

[Axis] = “X”

[Diistance] = “10”

[Direction] = “CW”

[Wait until finish] = “Enable”

Click [OK].

Program command on X axis appears on fourth line.

⑬ Click [Add] on Program drive

Drive command menu appears.

⑭ Click [Conditional Jump] on Drive command menu

Conditional Jump appears.

49

⑮ Input [0] at Input Port No, [OFF] at State and [4] at jump to Line then click [OK].

Repeat Command on fourth line while State of input0 is [OFF] .

Conditional Jump command appears on fifth line on Program Command display.

※ On Conditional jump is set up, Command on fourth line is repeated while State of input0 is

[OFF].

⑯ Repeat ⑩~⑮ to input movement command and conditional jump command to Y axis.

50

5) Writing Program

Writing program in DS112.

① Click [Write] on Program Drive.

Write Program appears on display.

② Select Program #1 then click [Transfer].

Program is forwarded to Program #1.

51

6) Save Program

Save Program in Program drive file.

① Click [Save] on Program drive display.

Saving display of Program drive appears.

② Confirm save location and its name then click [Save].

Program is saved in Program drive.

※ .prg is automatically added as extension.

52

7) Operation check

Checking stage movement by external signal.

① No interference affects stage movement.

② Click [Start].

Start Program appears on display.

③ Select 1 at Program No.: then click [Start].

53

8) Operating

Timing chart

Move to the

start position

Move 10pulse

to X axis CW

X axis

sensor

Output

detector

Move 10pulse

to Y axis CW

Y axis

sensor

state

detection

PRG/TCH

P_BIT2-0

P/T_START

Operating

1

P/T_RUN

READY

X_DRIVE

Stop the axes due to input external signal.

※ All stages will be stopped when input the “STOP” signal.

54

2.2.4 External device control with generalI/O.

Waiting

position

(50,100)

Action point

(1000,1500)

Actuator

Input the signal to start

pressure operating.

Completed pressure operating,

output the completed pressure

operating signal .

Pressure

operating

Out00In00

Press-in

operating

Start signal

Press-in

operating

Completed

signal

X axis stage

Y axis stage

I/O

Actuator

Out00

In00

General I/O cable

DS100-IO-2

Computer

DS102

Stepping Motor

Controller

DS102 X

Y

USB

RS232C

or

STEP1 : Move to Action point(1000,1500)

STEP2 : Send to actuator the press-in start signal, then start the press-in.

STEP3 : Detect the completed press-in operating from actuator.

STEP4 : Move to waiting position(50,100)

Shows to make a program that means to control general I/O and to control the external device.

1) Configuration

55

2) Operation outline

MSComm1.Output = “AXI1:SELSP 0:F0 1000” ’X stage set up speed

MSComm1.Output = “AXI2:SELSP 1:F1 1000” ’Y stage set up speed

MSComm1.Output = “AXI1:GOABS 1000” ’X stage move to operation point

MSComm1.Output = “AXI2:GOABS 1500” ’Y stage move to operation point

MSComm1.Output = “Out00 1” ’Turn on the start operation signal to the actuator

Do

MSComm1.Output = “In00?” ’Pick the operation completed signal to the

actuator

intSens = MSComm1.Input

Loop Until [intSens = 1]

MSComm1.Output = “AXI1:GOABS 100” ’X stage move to waiting point

MSComm1.Output = “AXI2:GOABS 200” ’Y stage move to waiting point

MSComm1.Output = “Out00 0” ’Turn off the start operation signal to the actuator

Programming

① Set up driving speed of X, Y stages.

② Move X, Y stages to operation position. <STEP1>

③ Start actuator operation. <STEP2>

④ Pick up operation completed signal of actuator.

<STEP3>

⑤ Move X,Y stages to waiting position. <STEP4>

① Execute the computer program.

3) Connecting

DS102 connection

① Plug the USB connector into the computer USB port.

(In case of using RS232C, plug the connector into the computer)

② Connect X axis stage connector to X axis stage.

③ Connect Y axis stage connector to Y axis stage.

④ Connect general I/O connector to actuator.

4) Make and execute the program

56

2.2.5 Move to arbitrary coordinate

Waiting point

Shooting point

(2000,3000)

Camera Unit

X,Y direction

positioning

correction

Xrv,Yrv

1

Xrv

Yrv

X axis stage

Y axis stage

DS102

Stepping Motor

Controller

DS102

Computer

Camera

X

Y

USB

RS232C

or

STEP1 : Shooting position move to(2000,3000)

STEP2 : Obtained positioning correction by camera unit

STEP3 : Move subject to the center based on positioning correction

Camera Unit

Output positioning correction of X,Y

direction from shooting center to subject

Shows how to move the stage base on data, which is downloaded, from external.

1) Configuration

57

2) Operation Outline

MSComm1.Output = “AXI1:SELSP 0:F0 1000” ’X stage set up speed

MSComm1.Output = “AXI2:SELSP 1:F1 1000” ’Y stage set up speed

MSComm1.Output = “AXI1:GOABS 2000” ’X stage move to shooting point

MSComm1.Output = “AXI2:GOABS 3000” ’Y stage move to shooting point

intXrv = Obtain X direction correction position ( )

intYrv = Obtain Y direction correction position ( )

MSComm1.Output = “AXI1:PULS intXrv:GO CW” ’X stage move to correction position

MSComm1.Output = “AXI2:PULS intYrv:GO CW” ’Y stage move to correction position

Program contents

① Set up operation speed of X stage, Y stage.

② Move X stage, Y stage to shooting point. <STEP1>

③ Get positioning correction from camera units. <STEP2>

④ Move X stage, Y stage to correction point. <STEP3>

Program for stage is moved to arbitrary position to DS102 with the computer.

① Run the program from the computer.

3) Connection

Connect DS102

① Plug computer USB port into USB connector.

(In case of using RS232C, connect RS232C and computer)

② Connect X axis motor connector and X axis stage.

③ Connect Y axis motor connector and Y axis stage.

4) Programming

58

Controlled max. 24 axes

Using USB hub

Controlled max.6 axes

Using link cable

DS102

Stepping Motor

Controller

DS102

1axis

2axis

Computer

PLC

or

DS102

Stepping Motor

Controller

DS102

1axis

2axis

DS102

Stepping Motor

Controller

DS102

3axis

4axis

DS102

Stepping Motor

Controller

DS102

5axis

6axis

Computer

PLC

or

A

C

USBハブ

Computer

1set

Can be connected

max. 4sets

1axis

2axis

DS102

DS102

3axis

4axis

DS102

DS102

5axis

6axis

DS102

DS102

USB hub

19axis

20axis

DS102

DS102

21axis

22axis

DS102

DS102

23axis

24axis

DS102

DS102

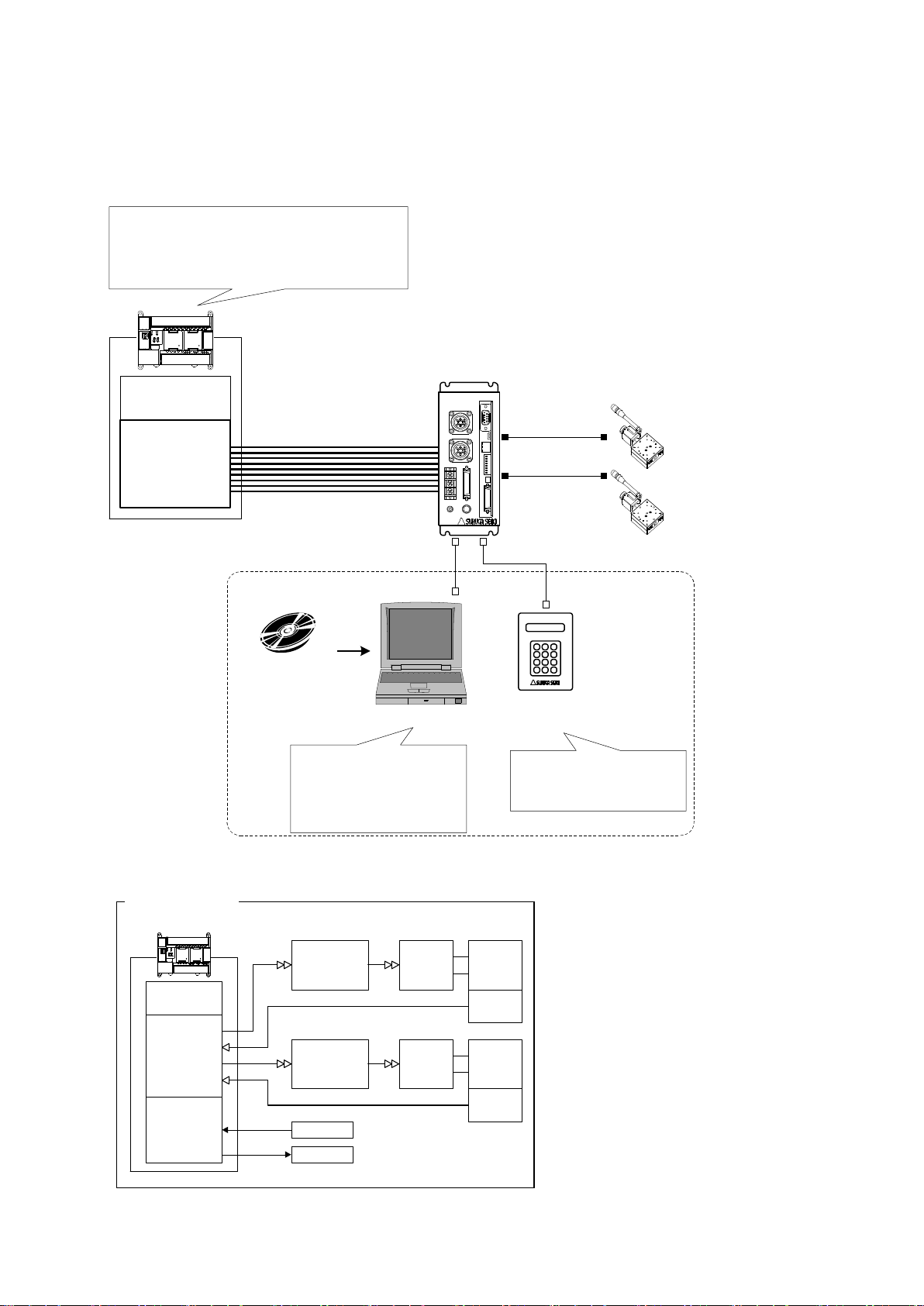

2.2.6 Controlled over 3 axes

Can be controlled max.6 axes using link cable, and max.24 axes using USB hub.

59

Type

DS102□□

DS102□□-IO

DS112□□

DS112□□-IO

Dimension

(Projection such as connector no included)

140(W)×300(D)×90(H)mm

70(W)×165(D)×155(H)mm

Weight

2.2kg

1.2kg

Usage environment

0~40℃ 20~80%RH(No condensation)

Storage environment

-20~60℃ 20~80%RH(No condensation)

Power supply input

AC100-240V ±10% 50/60Hz

DC24V±10% (3.5A 以上)

Maximum power consumption

Below 70W

Below 2.5A

Driver type

DS102NR/DS112NR :Normal (FULL/HALF)

DS102MS/DS112MS :Microstep(1/1~1/250)

Driver current rating

0.75A

Drive system

Bipolar Galvan static chopper pentagon drive system

Excitation system

DS102NR/DS112NR : 4-5 excitation(FULL/HALF)

DS102MS/DS112MS : 4 excitation(1/1~1/250)

Number of controlled axis

2 axes

Coordinate setting range

±99,999,999pulse

Driving speed setting range

1~999,999pps

Rate of rise speed setting range

1~9,999pps

Addition-subtraction speed setting

Range

1~9,999ms

S additional-subtraction speed rate

Setting range

0~100%

Machine limit

2 places for each axis to CW,CCW(Possible logic change)

Detected proximity origin

1 place for each axis(Possible logic change)

Detected origin

1 place for each axis(Possible logic change)

How to detect origin

12style

Home position

1 place for each axis(Can be set up in effective area arbitrarily)

External COM

Interface

RS232C:4,800~38,400bps(Dsub9pin male)

USB2.0:Full/Low Speed only(USB mini B terminal)

Controlled I/O(CNT-I/O):Input9points(24Vphoto coupler)、 Output11points(Open collector)

Link function

RS485(Can be connected link max. 3 controller 6 axes with DG chain )

Program function

8Programs(100steps/1program)

Can be controlled program number choice, start, stop with controlled I/O

Teaching function

64 points(Can be controlled intended point, move, stop with controlled I/O)

Interpolation function

6 axes linear interpolation(Easy linear interpolation on the link)

Controlled I/O (CNT-I/O)

Input 9points(P/T START,STOP)( 24V photo coupler)

Output 12points(X DRIVE,XCWLS)( Open collector)

General I/O (I/O)

(Option)

-

Input16 points

(24Vphoto coupler)

Output12 points

(Open collector)

-

Input16 points

(24Vphoto coupler)

Output12 points

(Open collector)

Item

SPEC

Remarks

Display

16 figures×2 lines

No backlight

Input

DC24V

Supply from DS102/DS112

Number of key

12keys

Click emboss12 keys

Cable length

1.5m

Can be extended till Max10m (Option)

Operation

Mode

11mode

Continue/Step/Absolute/Origin/Home/

Parameter/Program/Teaching/Input/Output/Remote

(Display time which receive a command from external controlled)

Outline

73(W)×130(D)×27(H)mm

Not included the screw and cable

Weight

280g

1.5m cable included

3.SPEC and FUNCTION

3.1 Basic SPEC

【Motor Controller DS102/DS112 (MISUMI Type: MSCTL102/MSCTL112)】

【Handy terminal DT100】

60

3.2 Part name and functions

TERMINAL

DS102

Stepping Motor Controller

1

2

3

X Y

I/O

FUSE(250V 4A)

Normal Blow

5.2×20.0mm

Voltage

AC100-240V

Wattage

max 70W

Frequency

50/60Hz

CNT-I/O EMS SW1 LINK USB RS232C

9

8

7

6

5 4

11

12 13

10

【DS102 (MISUMI Type: MSCTL102) Front panel】

【DS102 Rear panel】

① Power :Power switch

② LED :LED lights up when switch on

③ TERMINAL :Connector for handy terminal(DT100)

④ RS232C Connector :Connector for RS232C communication(Dsub9P male)

⑤ USB Connector :Connector for USB communication(Mini Btype)

⑥ Link Connector :Connector for connecting Link to DS102(Max 3 units)

⑦ Dip Switch(8bit) :RS232C Baud rate(2bit)、Link Number(2bit)、USB ID(2bit)、

Command response (1bit) setting up

⑧ EMS Connector :Connector for emergency stop input(Software interlock,B point)

(Included connector for EMS cancel)

⑨ CNT-I/O Connector :Check the each axis status, Select program operating number・Start・

Stop, Select teaching position number・Start・Stop I/O connector

(Bellows 26pin half pitch)

⑩ I/O Connector :General I/O(In 16points,Out12 points)connector

(Option) (Bellows 36pin half pitch)

⑪ Stage connector :Connector for Motorized stage(X axis,Y axis)

⑫ Fuse holder :Use 250V、4A Nomal blow glass fuse

⑬ AC inlet :Input AC100~240V 50/60Hz

(Connector type:09-0054-00-14(Binder products))。

Incase of AC100~120V, use attached electric cable

In case of AC200V, use with the proper cable

61

【DS112 (MISUMI Type: MSCTL112) Front panel】

XY

TERMINAL

POWER

+24V

CNT-I/O EMS SW1 LINK USB RS232C

DS112

Stepping Motor Controller

GNDFG

I/O

11

1

10

2

3

4

5

6

7

8

9

① Terminal block for power :For input(DC24V、M3 screw)

② POWER LED :LED lights up when power on

③ TERMINAL :Connector for handy terminal DT100

④ RS232C Connector :Connector for RS232C communications(Dsub9P male)

⑤ USB Connector :Connector for USB communications(Mini B type)。

⑥ Link Connector :Connector for link connection DS112(Max 3 units)

⑦ Dip SW(8bit) :Connector for RS232C baud rate(2bit),Link number(2bit),USB ID(2bit),

Command response (1bit) setting up

⑧ EMS Connector :Connector for emergency stop(Normal close)

(Included connector for EMS cancel)

⑨ CNT-I/O Connector :Check status each axis, select program operating number・Start・Stop

select the number of teaching position・Start・for stopI/O connector

(Bellows 26pin half pitch)

⑩ I/O connector :General I/O(In 16points,Out 12points)connector

(Option) (Bellows 36pin half pitch)

⑪ Stage connector :Motorized stage(Xaxis,Yaxis)for connecting

(Connector model:09-0054-00-14(Binder products))

62

【DT100 (MISUMI Type: HDT100)】

Key name

Function

Jog/7

Operation mode(CNT/STP/ABS/ORG/HOM)transit to selection screen/7-key

Menu/8

Menu(PRM/PRG/TCH/IN/OUT)transit to selection screen /8-key

Set/9

Jump to setting value switchable screen for each operation mode(STP/ABS/ORG/HOM)、

Use at the teaching position registration /9-key

←/1

X axis to Cooperation, Select setting item /1-key

→/3

X axis to Cw operation, Select setting item /3-key

↑/5

Y axis to CW operation, Select setting item/5-key

↓/. -

Y axis to CCW operation, Select setting item/key .( decimal) -(negative)

SPD/4

Select speed table number /4-key

POS/6

Set current position /6-key

Link/2

Controller(axes)switching(at the link connecting)/2-key

STOP/ESC/0

Stop operating axes, stop program operating、return to previous screen /0-key

Enter

Decision

DT100

Handy Terminal

Stop

/ESC

0

Enter

. -

Jog7Menu8Set

9

SPD

4

POS

6

Link

2 31

5

DS102/DS112

1.5m

LCD:16 digit X 2 lines

Click emboss 12 keys

63

3.3 Setting

TERMINAL

DS102

Stepping Motor Controller

TERMINAL

DS102

Stepping Motor Controller

TERMINAL

DS102

Stepping Motor Controller

Over 20mm

155

70

X

Y

TERMINAL

POWER

+24V

CNT-I/O EMS SW1 LINK USB RS232C

DS112

Stepping Motor Controller

GNDFG

I/O

177.4

11.3

1.6

3.7

170

10

4.5 4.5

50

66

X

Y

TERMINAL

POWER

+24V

CNT-I/O EMS SW1 LINK USB RS232C

DS112

Stepping Motor Controller

GNDFG

I/O

Over 20mm

X

Y

TERMINAL

POWER

+24V

CNT-I/O EMS SW1 LINK USB RS232C

DS112

Stepping Motor Controller

GNDFG

I/O

Over 20mm

Over 20mm

Over 20mm

【DS102 (MISUMI Type: MSCTL102)series】

Please set DS102 on the level and vibration-free, and open the space over 20mm because of

eradiation on top of this unit.

No need to open the space in between controllers when line up the few units in one row

sideways.

If cover the upper radiation space, it is to be a cause of a fire and damage because of heat

up inside.

【DS112 (MISUMI Type: MSCTL112)series】

Should set up DS112 on the level with 4 mounted holes. In case of set up on the level, radiation

hole should be comes to upper or left side of units, please open over 20mm spaces.

If cover the upper radiation space, it is to be a cause of a fire and damage because of heat

up inside.

64

3.4 External Interface

Pin No.

Signal

I/O

Function

1

T (+)

I/O

Transmitted and received data (+)

2

T (-)

I/O

Transmitted and received data (-)

3

GND

-

Ground 4 NC

-

Non connected

5

T (+)

I/O

Transmitted and received data (+)

6

T (-)

I/O

Transmitted and received data (-)

7

GND

-

Ground 8 NC

-

Non connected

9

GND

-

Ground

10

FG

-

Frame ground

3

4

Link number

OFF

OFF

0(Default)

ON

OFF

1

OFF

ON 2 ON

ON

1 2 3 4 5 6

ON

7

8

SW1

3.4.1 Link connection(Link)

In case of controlled over 3 axes, can be operated max.6 axes operations connected with original

link cable (DS100-LINK2-0.5 (MISUMI Type: MSLINK2-0.5) or DS100-LINK3-0.5 (MISUMI Type:

MSLINK3-0.5) between 2 units or 3 units of DS102/DS112. (MISUMI Type:

MSCTL102/MSCTL112)

【Link connector】

Connector type : S10B-PADSS-1(LF)(SN) (JST)

Matched plug : PADP-10V-1-S(LF)(SN) (JST)

Conformance contact : SPH-002T-P0.5L (JST)

※If use link function, need to set the ID number with DIP switch.

【Set the DIP switch】

Set third bit and forth bit of SW1

● Set link number

※Factory-setting is OFF.

※ Please power on in the order Link number 2,→1→0

In case of can’t be powered on in turn because of included system, please power on 3 units

at the same time.

65

3.4.2 Control Input/Output(CNT-I/O)

Pin

number

Name of

signal

I/O

Function

1

X_DRIVE

O

X axis now driving

2

X_CWLS

O

X axis CWLS now detecting

3

X_CCWLS

O

X axis CCWLS now detecting

4

X_ORG

O

X axis ORG now detecting

5

Y_DRIVE

O

Y axis now operating

6

Y_CWLS

O

Y axis CWLS now detecting

7

Y_CCWLS

O

Y axis CCWLS now detecting

8

Y_ORG

O

Y axis ORG now detecting

9

READY

O

Ready output

10

NC

-

Non-connected(System reserved)

11

EMS

O

EMS now detecting (OFF for EMS detecting / On for EMS non detecting)

12

P/T_RUN

O

Program now driving or teaching point now moving

13

-COM1

-

Common for output signal

14

P/T_BIT0

I

Select program numberBIT0 or teaching point specification BITO

15

P/T_BIT1

I

Select program numberBIT1 or teaching point specification BIT1

16

P/T_BIT2

I

Select program numberBIT2 or teaching point specification BIT2

17

T_BIT3

I

Teaching point specification BIT3

18

T_BIT4

I

Teaching point specification BIT4

19

T_BIT5

I

Teaching point specification BIT5

20

P/T_START

I

Program driving start signal / Teaching point moving start signal

21

STOP

I

Program stop (All axes will be stopped)

22

PRG/TCH

I

Program driving mode/Switching teaching point moving signal

(When OFF、program driving mode/When ON、teaching point

moving mode)

23

-COM0

-

Common for input signal

24

NC

-

Non connected

25

DC+24V

O

Service power (DC24V,max 250mA)

26

0V

O

Output the status of motorized stages that connected DS102/DS112. Also can operated

teaching point number, specify program number, move teaching point, program operation start and

stop.

By connecting I/O of PLC and CNT-I/O, can be controlled the motorized stages easily.

【CNT-I/O connector】

Connector type : 10226-52A2PL (3M)

Matched connector(ex.): 10126-3000PE (3M)

【Option cable(2m)】

type : DS100-CNT-2 (MISUMI Type: MSCNT2)

【CNT-I/O pin assign】

Driving current of output circuit is 20mA/points, ON current of input circuit is

5mA/points.

-COM0 and -COM1 are insulated.

66

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

CNT-I/O

X_DRIVE

Y_CCWLS

T_BIT3

P/T_BIT2

P/T_BIT1

P/T_BIT0

EMS

(Reserved)

READY

Y_ORG

Y_CWLS

Y_DRIVE

X_ORG

X_CCWLS

X_CWLS

T_BIT4

PRG/TCH

DC+24V

N.C.

-COM0

STOP

P/T_START

-COM1

P/T_RUN

T_BIT5

0V

EMS

EMS-

EMS+

1

2

E

24V+

0V

PS2801-4

PS2801-4

PS2801-4

PS2801-4

PS2801-4

PS2801-4

4.7k

4.7k

4.7k

4.7k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

4.7k

4.7k

4.7k

4.7k

4.7k

4.7k

【CNT-I/O Circuit】

67

【Timing Chart】

PRG/TCH

P/T_START

P/T_RUN

P/T_BIT0

P/T_BIT1

P/T_BIT2

READY

T_BIT3

T_BIT4

T_BIT5

↑Start

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

Operating

Stop

↑PowerON

>5s

4s

>30ms

IN

OUT

STOP

On

Off

>30ms

↑Start

①Normal operation ②Suspend

PRG/TCH

P/T_START

P/T_RUN

P/T_BIT0

P/T_BIT1

P/T_BIT2

READY

T_BIT3

T_BIT4

T_BIT5

Teachingposition moving

↑Start

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

駆動中

停止

↑PowerON

>5s

4s

>30ms

IN

OUT

STOP

On

Off

>30ms

↑Start

①Nomal operation ②Suspend

①Program operated by CNT-I/O(Ex.:Program No.5)

※Documentation, transfer and delete of program (No.0~7) is started from computer.

②Teaching position moved by CNT-I/O(Ex.:Teaching No.21)

※ Registration of teaching position is started from computer or handy terminal DT100.

68

3.4.3 General I/O(I/O)( Option)

Pin No.

Signal name

I/O

Function

1

In_00

I

General input00

2

In_01

I

General input01

3

In_02

I

General input02

4

In_03

I

General input03

5

In_04

I

General input04

6

In_05

I

General input05

7

In_06

I

General input06

8

In_07

I

General input07

9

In_08

I

General input08

10

In_09

I

General input09

11

In_10

I

General input10

12

In_11

I

General input11

13

In_12

I

General input12

14

In_13

I

General input13

15

In_14

I

General input14

16

In_15

I

General input15

17

+COM2

I

In_00~In_15 for insulation power on

18

+COM3

I

OUT_00~OUT_11 for insulation power on

19

Out_00

O

General output00

20

Out_01

O

General output01

21

Out_02

O

General output02

22

Out_03

O

General output03

23

Out_04

O

General output04

24

Out_05

O

General output05

25

Out_06

O

General output06

26

Out_07

O

General output07

27

Out_08

O

General output08

28

Out_09

O

General output09

29

Out_10

O

General output10

30

Out_11

O

General output11

31

-COM3

-

Out_00~Out_11 for insulation power ground

32

-COM3

-

Out_00~Out_11 for insulation power ground

33

DC+24V

O

Service power (DC24V,max 400mA)

34

0V

O

35

NC

-

Non-connected

36

NC

-

Non-connected

There’s option for general I/O that is input 16 points and output 12 points due to control each

sensors, switches, magnet valves and indicator lights.

【I/O connector】 General I/O(I/O)( Option)

Connector type : 10236-0200 (3M)

Adaptive connector(Ex.) : 10136-3000PE (3M)

【Option cable(2m)】

Type : DS100-IO-2 (MISUMI Type: MSGP2)

【I/O pin assign】

Input ON current is 5mA/point、Output drive current is 60mA/point(Total

under 500mA)

DC+24V power, COM2 and COM are each insulated.

69

【I/O Circuit】

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

I/O

IN_00

IN_06

+COM2

IN_15

IN_14

IN_13

IN_10

IN_09

IN_08

IN_07

IN_05

IN_04

IN_03

IN_02

IN_01

+COM3

OUT_03

OUT_06

OUT_05

OUT_04

OUT_02

OUT_01

IN_12

IN_11

OUT_00

OUT_07

24V+

0V

TLP281-4

TLP281-4

TLP281-4

TLP281-4

TLP281-4

TLP281-4

4.7k

4.7k

4.7k

4.7k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

1.5k

4.7k

4.7k

4.7k

4.7k

4.7k

4.7k

27

28

29

30

31

32

33

34

35

36

OUT_10

OUT_09

OUT_08

OUT_11

0V

N.C.

DC+24V

-COM3

-COM3

N.C.

TLP281-4

1.5k

1.5k

4.7k

4.7k

1.5k

1.5k

4.7k

4.7k

1.5k

1.5k

4.7k

4.7k

TD62084AFG

TD62084AFG

70

3.4.4 Emergency stop input(EMS)

Pin No.

Signal name

I/O

Function

1

EMS (+)

I

Input emergency stop signal (Normal close)

DC24V 5mA

2

EMS (-)

-

Common

Pin No.

I/O

Terminal function

A

O

Motor lead (Blue)

C

O

Motor lead (Red)

E

O

Motor lead (Orange)

G

O

Motor lead (Green)

J

O

Motor lead (Black)

L

I

CWLS input

M

I

CCWLS input

N

I

Near origin sensor input

O

I

Origin sensor input

P

O

Sensor power (DC5V(+))

R

O

Sensor power (DC5V(-))

S

-

N.C. T -

N.C. U -

Frame ground

A

P

O

N

M

L

R

J

T

S

GE

C

U

Can be emergency stopped all axes operating to open 1 pin and 2 pin of EMS connector.

(At the link connected, 3~6 axes that connected to Link No.1,2 is emergency stopped to open EMS

signal of Link No.0)

※ In case of no use EMS signal, please attached release-connector always on.

【EMS connector】

Connector type : S02B-PASK-2(LF)(SN) (JST)

Mattched plug : PAP-02V-S(LF)(SN) (JST)

Mattched contact : SPHD-001T-P0.5 (JST)

As software’s interlock function, please do not use as the last protect function of systems.

3.4.5 Stage interface

Connect the motorized stage connected cable to motor connector.

【Motorized stage connector】

Connector type : 09-0054-00-14 (Product of Binder: female)

Matched plug : 09-0341-02-14 (Product of Binder)

71

3.5 Driver division number setting

Driver type

Division number setting

Normal driver

Can be switched FULL/Half from handy terminal(DT100),control

software (DSCONTROL-WIN), communication command.

Micro step driver

Need to open the cover and set the rotary switch of micro-step driver.

Y axis

X axis

X axis

Y axis

Division number changing-over switch

Different how to set the division number normal type and micro-step type.

3.5.1 Open and shut

①In case of DS102, take out 10 screws from side of cover, in case of DS112, take out 6 screws

from side of cover with cross screwdriver.

②See following picture, set the marked point with precision screwdriver.

<DS102MS> <DS112MS>

・ Please power off during the open and shut, cause fire, injury and device breakage.

・ Please do not set up the driver with charged hands, cause breakage by static

electricity.

3.5.2 Setting division number

When set division number, please check driver’s division changing-over switch to [R1].

Default setting:R1

72

There are 2 division number setting switch [DATA1][DATA2], use [DATA1]here.

R1

DATA1

(DATA2)

Division number

Motor step angle

0

1/1

0.72°

1

1/2

0.36°

2

1/2.5

0.288°

3

1/4

0.18°

4

1/5

0.144°

5

1/8

0.09°

6

1/10

0.072°

7

1/20

0.036°

8

1/25

0.0288°

9

1/40

0.018°

A

1/50

0.0144°

B

1/80

0.009°

C

1/100

0.0072°

D

1/125

0.00576°

E

1/200

0.0036°

F

1/250

0.00288°

Can be used [DATA2] at the only use communication command. Please refer to 4, 3, 5, 2

paragraph.

In case of change the division number, change [DATA1].

Default setting: [DATA1 : 0]

[DATA2:0]

Following chart shows basic step angle 0.72°/STEP.

Resolution = Basic step angle × Division number

Please set “PULSE” as unit setting, in case of using both DATA1 and DATA2.

Division number are theoretical figure.

Please do not change the division number switch during operation, motor might be

stopped.

3.6 Smooth drive function(only MS type)

This function can get low vibration and low noise during slow operating without any change the

division number setting. It divides automatically into 1/16 pulse signal.

No need pulse changing(speed and pulse) of upper controller side. Smooth drive function must

be operated case of division number [R1],[DATA:0]~[DATA:6]([R2]cannot be set)

([DATA]numeric shows 3.5.2 paragraph division number switch [DATA1])

73

Smooth drive changing-over switch

Default setting:[SD:Operate smooth drive]

• When operate smooth drive function、set [SD]side.(Initialization)

• When no operate smooth drive function, set [OFF]side.

・Smooth drive function will not work when set over 10 divide division number.

Might be ignored to set[SD].(Same as[OFF]operation)

3.7 Units setting function

No need difficulty change from pulse to actual displacement.

Units setting must be first for each setting parameter. Follow the below.

① Units setting(pulse, μm, mm, deg, mrad)

② Set 1 pulse displacement at the full step(Basic resolution)set.

③ Set the division number(1/1~1/250)