MistAway GEN III Operation Manual

MistAway® Tankless Misting Unit – Gen III

Operations Manual

Important Safety Instructions

Functionality and Components

Operating Instructions

Assembly and Installation Instructions

Maintenance and Winterization Instructions

Frequently Asked Questions

Troubleshooting

Warranty

Section

1

2

3

4

5

6

7

8

Copyright © 2007 by MistAway® Systems, Inc.

Visit us on the web at

www.mistaway.com

Section 1

Important Safety Instructions

Using the Unit

• Do not allow the unit to mist in the presence of people, pets or

food.

• Unit must be configured, installed and operated so that any

insecticide application complies with all label directions,

including application rate and prohibitions against offsite drift.

• The unit should be locked.

• Unit and remote transmitter should be secured against access

by children.

• DIP Switches on remote transmitter should be repositioned

(from factory setting) to ensure that another transmitter will not

activate unit.

• If a leak or siphon in nozzle circuit is suspected, disconnect

nozzle circuit from unit and discontinue use of unit until it is

repaired.

• Unit must never be used for cooling.

Permitted Insecticides and Handling

• Use only insecticides that are labeled for use in automated

misting systems, and use only as described in the label.

• Insecticides that state “Not for use in outdoor residential misting

systems” may not be used under any circumstances.

• Insecticide label should be securely attached to the cartridge

inserted in the unit.

• Strictly follow label instructions regarding storage and disposal of

insecticide and container.

Nozzle Circuit Installation:

• The nozzle circuit must be configured and installed so that

insecticide does not drift off the property.

• Nozzles must be directed to spray towards the target area and

away from swimming pools, water bodies, or eating and cooking

areas.

To Protect Against Accidental Exposure to Insecticide

Section 1

Important Safety Instructions

To Protect Against Fire or Electric Shock

• Ensure unit is positioned where it is free from flooding or

exposure to irrigation system spray.

• Unit must be plugged into electrical outlet with ground fault

interrupt protection. (GFI/GFCI)

• Extension cord must not be used.

• Disconnect unit from power source if replacing components.

• Replace fuses only with those of equivalent value.

Section 2

Functionality and Components

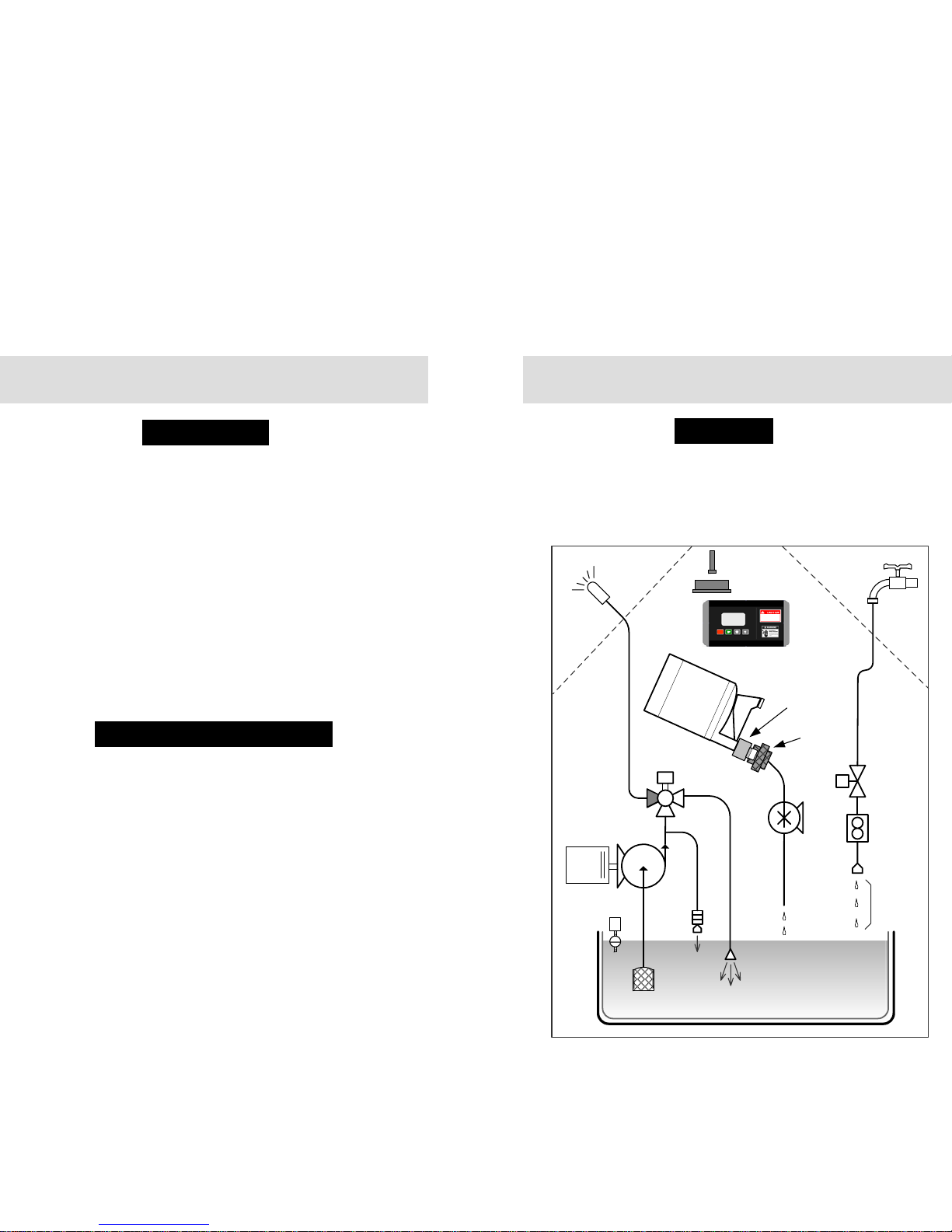

• MistAway’s Tankless Misting Unit, Gen III, is a batch processing

unit that precisely mixes water from a faucet and concentrated

botanical insecticide from a cartridge in a batch tank and then

atomizes it through an installed nozzle circuit to control

mosquitoes and other annoying insects.

• The capacity of the unit is dependent on the configuration of the

nozzle circuit. A practical field maximum is around 60 – 75

nozzles (some in parallel) connected by 900 feet of tubing.

• The unit may be programmed to mist up to 12 times daily, with

each mist cycle having its own independent duration. A typical

program would consist of 2 to 3 mist cycles per day, each with a

45 – 60 second duration, for a daily total of 90 – 180 seconds.

• The unit will also mist in response to a signal from a handheld

remote transmitter for a duration programmed by the user.

Base Functionality

Optional Equipment and Functionality

• Wind Sensor: Sensor input will inhibit a programmed mist if the

wind speed is higher than a user-defined limit for a 5 minute

period following the scheduled mist.

• Zone Kit: Kit will enable the unit to effectively double the

number of nozzles and protected area that it would otherwise

support. A single schedule drives misting in both zones.

Section 2

Functionality and Components

The operations of the Gen III are managed by a digital controller

and a number of electro-mechanical components. The controller

gets information about dosing and agitating the insecticide from

an electronic tag that is embedded in the Smart Cap on the

insecticide cartridge.

Batch Control

Pump Intake

& Filter

Water

source

Nozzle

Circuit

Motor

Pump

Agitate Line

Discharge

Auto

Drain

Valve

Float

Switch

Supply

Valve

Flow

Meter

Flow

Regulator

2" Air

Gap

Insecticide

Cartridge

Smart

Cap

Smart

Coupler

Agitation

Valve

Dosing

Pump

Batch Tank

Digital Controller

Remote Receiver

Antenna

Section 2

Functionality and Components

Section 2

Functionality and Components

• Digital Controller – accepts user input, displays unit operating

mode and status, controls electromechanical components.

• Remote Receiver & Antenna – receives signal from handheld

remote transmitter. Receiver located on underside of enclosure

lid.

• LED warning light – annunciates unit status – warning, misting,

suspended due to error or empty cartridge. Located on top of

enclosure lid.

Components – Interface and Controls

• Supply Valve – opens to allow water to flow from faucet into

batch tank.

• Flow Meter – on inlet water line, measures flow into the batch

tank. Used to control insecticide dosing and error condition

calculations.

• Float Switch – closes supply valve when batch tank is full.

• Flow Regulator – ensures smooth flow of water into batch tank.

Positioned to ensure 2” air gap between water supply and batch

tank contents.

Components – Fresh Water Flow Control

• Remote Transmitter – 3-button remote enables the user to start

a mist, stop a mist and skip the next scheduled mist.

• Key – for lock that is located on top front wall of enclosure.

Other Components

• Insecticide Cartridge –vented two-chamber bottle containing

one of a number of botanical insecticides.

• Smart Cap – embedded RFID (radio frequency identification)

tag programmed with information to control dosing, agitation,

cartridge volume display and misting limits.

• Smart Coupler – accepts snap-in Smart Cap, reads the

information stored on it and passes it to the controller.

• Dosing Pump – precisely meters insecticide concentrate from

the cartridge into the batch tank.

Components – Insecticide Flow Control

Components – Agitation and Atomization

• Batch Tank – 2 gallon plastic tank with enough capacity to

enable a 60 nozzle circuit to mist for 120 seconds.

• Pump & Motor – atomizes batch tank contents through nozzle

circuit. Pump pressure typically set to 240 psi.

• Agitation Valve – One path through the valve routes fluid to the

nozzle circuit. The other path recirculates fluid in the batch tank

through the agitation line. Each mist (including REMOTE

MISTs) will be preceded by an agitation cycle that will ensure

thorough mixing of the batch tank contents prior to misting. In

addition, there is a once daily agitation that is independent of any

AUTO or REMOTE MIST. The agitating valve also eliminates

the possibility of a siphon emptying the batch tank contents.

• Pump Intake Line and Filter – Pump intake positioned near

bottom of batch tank. Filter ensures debris is not drawn into

pump and nozzle circuit.

• Agitation Line – during agitation, batch tank contents are

recirculated to ensure thorough mixing prior to misting.

• Auto-Drain Valve – ensures rapid increase in nozzle circuit

pressure on pump startup and rapid decrease on shutdown.

• Enclosure and Lid – sturdy powder-coated galvanealed metal

walls, locking lid, and aluminum chassis and feet.

• Shroud – black plastic inner shelf with well for snap-in

insecticide cartridge. Supports recessed controller and pressure

gauge.

Components - Structural

Section 3

Operating Instructions

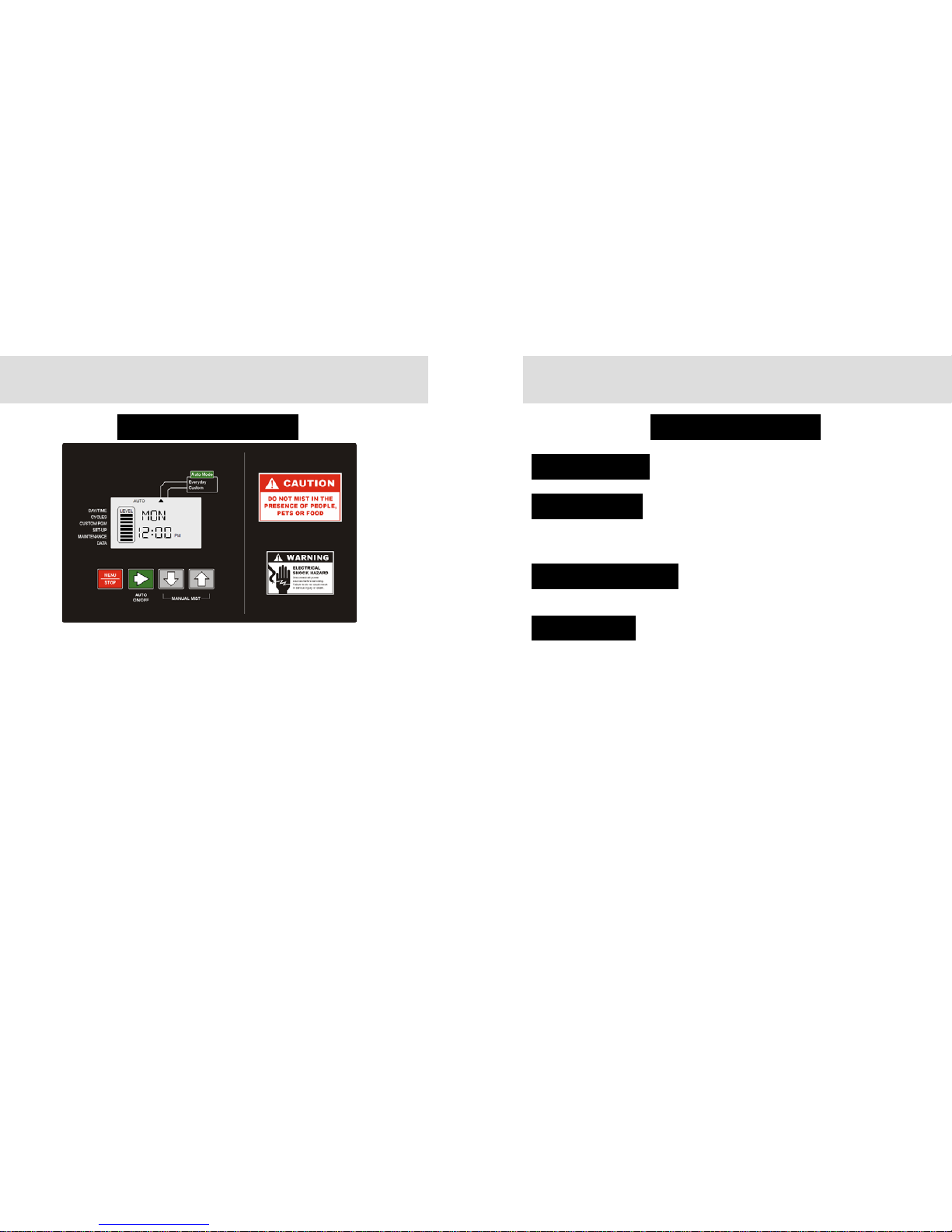

• When the unit is powered up and idle, the controller display

indicates four pieces of information:

1.Day of the week

2.Time of day

3.System mode (Off, On, Auto-Everyday, Auto-Custom)

4.Cartridge Level (each bar indicating cartridge 1/8

th

full)

• Pressing Green ► button will cycle through each of four System

Modes. Active mode indicated at top of display.

1.OFF – Unit will perform a daily agitation cycle and otherwise

sit idle.

2.ON – Unit will allow Remote and MANUAL MISTs, but no

AUTO MISTs.

3.AUTO-EVERYDAY – Misting program runs daily.

4.AUTO-CUSTOM – Misting program runs on days set in

CUSTOM PGM menu.

• Pressing Red MENU/STOP button displays triangular cursor by

DAY/TIME position on left side of display. Use ▲ or ▼ buttons to

cycle through menu structure. Use Green ►button to select menu

item and view or change data element within that item.

• Within a menu item, the convention is that the flashing data

element can be changed with the ▲ or ▼ buttons. Move to the

next data element with the Green ► button.

• Exit the menu item by pressing the MENU button. The unit will

revert to previous System Mode in 3 minutes if the MENU button is

not pressed.

Programming the Controller

Section 3

Operating Instructions

Set the Day of the Week and the Time of Day.

DAY/TIME Menu

Configure the mist time and duration of each of

the twelve possible AUTO MIST Cycles (Each

with unique duration and time of day.)

CYCLES Menu

Configures the days of the week for AUTO

MISTing in the AUTO-CUSTOM PGM

mode. (Turn each day OFF or ON.)

CUSTOM PGM Menu

DST Turn daylight savings time switch ON or OFF.

REM Set the duration for mists triggered by the remote

transmitter. (Values from OFF to 120 seconds)

LRN Program unit to recognize a specific remote transmitter.

Hold down Green ► button for 5 seconds and wait for

countdown to begin. Press and hold any button on the

remote transmitter. When DONE flashes in the display,

the transmitter is programmed.

MAN Set the duration for mists triggered by a MANUAL MIST

(pressing ▲ and ▼ buttons simultaneously for 2 seconds.)

NOZ Set the Number of nozzles in the circuit attached to the

unit. If Zone Kit installed, there are separate displays for

NZ1 and NZ2.

SEN Turn (optional) wind sensor ON or OFF

WND Set max wind speed (above which wind sensor reading

inhibits mist.)

AGT Set time of once daily off-cycle agitation. (Note: Agitation

duration preceding AUTO MIST is read from cap.)

ZN1/ZN2 Enable or disable misting in Zone 1 and (optional) Zone 2.

SET-UP Menu

Controller Menu Structure

Loading...

Loading...