Mirrow Moovo LN4, Moovo LN432e Instructions Manual

English – 3

English

GENERAL SAFETY WARNINGS AND

PRECAUTIONS

STEP 1

– Working in safety! 4

– Installation warnings 4

KNOWLEDGE OF THE PRODUCT AND PREPARATION

FOR INSTALLATIONE

STEP 2

2.1 - Product description and intended use 5

2.2 - Components used to set up a complete system 5

STEP 3

Preliminary checks for installation 6

3.1 - Checking suitability of the environment and gate to be automated 6

3.2 - Checking product application limits 6

STEP 4

4.1 - Preliminary set-up work 7

- 4.1.1 - Typical reference system 7

- 4.1.2 - Establishing positions of components 7

- 4.1.3 - Establishing the positions of the gearmotor 7

- 4.1.4 - Establishing the device connection layout 7

- 4.1.5 - Checking the tools required for the work 8

- 4.1.6 - Completing the set-up work 8

4.2 - Preparing the electrical cables 8

INSTALLATION: COMPONENT ASSEMBLY AND

CONNECTIONS

STEP 5

– Installing the automation components 9

STEP 6

– System device installation and connection 11

6.1 - Selection the gearmotor position with respect to the gate, on the

control unit 12

6.2 - Installing and connecting flashing light mod. MF 12

6.3 - Installing and connecting photocells mod. MP 14

– Selecting the photocell pair operating mode 15

6.4 - Installing and connecting keypad mod. MK 16

6.5 - Installing buffer battery mod. MB 17

POWER SUPPLY CONNECTION

STEP 7 18

INITIAL START-UP AND ELECTRICAL CONNECTION

CHECK

STEP 8 18

PROGRAMMING THE AUTOMATION

STEP 9

9.1 - Memorising the devices connected by means of “Bus” cable and the leaf

“Closing” and “Opening” limit positions 19

9.2 - Memorisation of transmitter mod. MT4 20

9.3 - Programming keypad mod. MK 20

ADJUSTMENTS AND OTHER OPTIONAL FUNCTIONS

10 - Automation operation adjustment 21

11 - Memorisation of a new transmitter with control unit “in the vicinity” 21

12 - Deleting data from the control unit memory 22

13 - Automation testing and commissioning 22

14 - Installing and connecting a buffer battery 22

WHAT TO DO IF ... (troubleshooting guide) 23

TASKS RESERVED FOR QUALIFIED TECHNICIANS

– Connecting the automation to the electrical mains with a cable other than

that supplied 24

– Automation testing and commissioning 25

– Product disposal 25

TECHNICAL SPECIFICATIONS OF PRODUCT

COMPONENTS 26

Enclosures: “TECHNICAL DOCUMENTATION” I - VII

CONTENTS

4 – English

English

GENERAL SAFETY WARNINGS AND PRECAUTIONS

Considering the risk situations that may arise during installation

phases and use of the product, the automation must be installed in

observance of the following warnings:

– never make any modifications to part of the automation other than those

specified in this manual. Operations of this type will lead to malfunctions.

The manufacturer declines all liability for damage caused by makeshift

modifications to the product.

– ensure that parts of the automation cannot come into contact with

water or other liquids. During installation ensure that no liquids penetrate

the gearmotors or other devices present.

– Should this occur, disconnect the power supply immediately and contact a Moovo service centre. Use of the automation in these conditions

constitutes a hazard.

– never place automation components near to sources of heat and never

expose to naked flames. This may damage system components and

cause malfunctions, fire or hazardous situations.

– all operations requiring opening of the protection housings of various

automation components must be performed with the control unit disconnected from the power supply. If the disconnect device is not in a

visible location, affix a notice stating: “WARNING! MAINTENANCE IN

PROGRESS”.

– the product may not be considered an efficient system of protection

against intrusion. If an efficient protection system is required, the automation must be integrated with other devices.

– Connect the control unit to an electric power line equipped with an

earthing system.

– the product may only be used after completing the automation “commissioning” procedure as specified in paragraph “Automation testing

and commissioning” provided in the section “Tasks reserved for qualified

technicians”.

– The automation component packaging material must be disposed of in

full observance of current local legislation governing waste disposal.

STEP 1

WORKING IN SAFETY!

Warning – for personal safety it is important to observe

these instructions.

Warning – Important safety instructions: Keep these

instructions in a safe place.

The design and manufacture of the devices making up the product

and the information in this manual fully comply with current standards governing safety. However, incorrect installation or programming may cause serious physical injury to those working on or using

the system. For this reason, during installation, always strictly

observe all instructions in this manual.

If in any doubt regarding installation, do not proceed and contact the

Moovo Technical Assistance for clarifications.

If this is the first time you are setting up an automation for sliding gates,

we recommend that you read this entire manual with care. This is preferable before any work, without any hurry to start practical tasks.

Also keep product devices on hand while consulting the manual to enable

testing and checking (excluding any programming phases) with the information provided in the manual.

While reading this manual, take care to observe all instructions

marked with the following symbol:

These symbols indicate subjects that may be the source of potential

hazards and therefore the prescribed operations must be performed

exclusively by qualified and skilled personnel, in observance of

these instructions current safety standards.

INSTALLATION WARNINGS

According to the most recent legislation, the installation of an automatic gate or door must be in full observance of the standards envisaged by European Directive 98/37/EC (Machinery Directive) and in

particular standards EN 12445, EN 12453 EN 12635 and EN 13241-1,

which enable declaration of presumed conformity of the automation.

In consideration of the above,

The final connection of the automation to the electrical mains, system testing, commissioning and periodic maintenance must be performed by skilled and qualified personnel, in observance of the

instructions in the section “Tasks reserved for qualified technicians”.

These personnel are also responsible for the tests required according to the risks present, and for ensuring observance of all legal provisions, standards and regulations: and in particular all requirements

of the standard EN 12445, which establishes the test methods for

checking automations for gates.

However, all preliminary set-up, installation and programming operations may be performed by personnel with standard skills, provided

that all instructions and the relative sequences in this manual are

strictly observed, with special reference to the warnings in STEP 1

Before starting installation, perform the following checks and

assessments:

– ensure that each device used to set up the automation is suited to the

intended system. For this purpose, pay special attention to the data provided in the paragraph “Technical specifications”. Do not proceed with

installation if any one of these devices does not correspond to specifications.

– ensure that the devices in the kit are sufficient to guarantee system safety and functionality.

– an assessment of the associated risks must be made, including a list of

the essential safety requirements as envisaged in Appendix I of the

Machinery Directive, specifying the relative solutions adopted. Note that

the risk assessment is one of the documents included in the automation

Technical documentation. This must be compiled by a professional

installer.

English – 5

English

STEP 2

2.1 – PRODUCT DESCRIPTION AND INTENDED USE

In general, the series of devices that make up this product serve to automate a sliding gate for residential applications (fig. 1).

Any other use than as specified herein or in environmental conditions other than as stated in STEP 3 is to be considered improper

and is strictly prohibited!

The gearmotor comprises a 12 V dc motor, a pinion and a control unit.

The control unit powers all devices present in the system and manages all

relative functions. It is made up of a board and incorporated radio receiver which receives the commands sent by a transmitter. It may also be

controlled via a wall-mounted keypad or a pair of photocells set with the

single opening command.

The control unit can control different types of manoeuvres, each programmable and usable according to specific requirements.

Special functions are also available to enable personalisation of automation use.

The automation enables the installation of various accessories which

enhance functionality and guarantee optimal safety. In particular, the control unit can memorise up to 150 keys of MT4 transmitters; up to 4 MK

control keypads or alternatively up to 4 pairs of MP photocells, set for the

opening command only.

Connections of the various devices are by means of a “Bus” cable. This

reduces complexity of the connection, as the “Bus” envisages the use of

a single cable between one device and another.

The product is mains-powered, and, in the event of a power failure

enables manual release of the gearmotor for manual movement of the

gate leafs.

In this situation, the gate can also be opened using the buffer battery (MB

model) if fitted on the system.

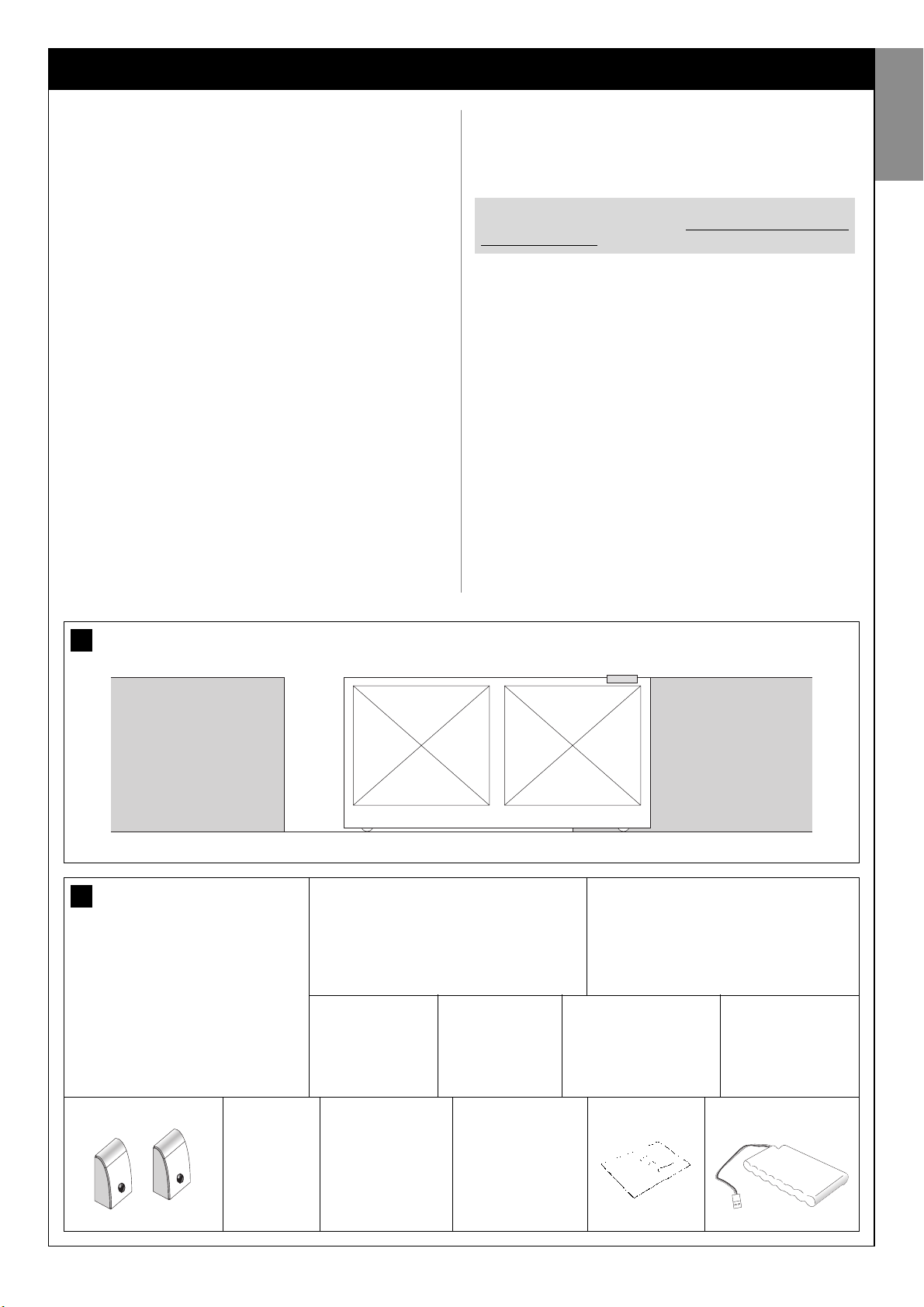

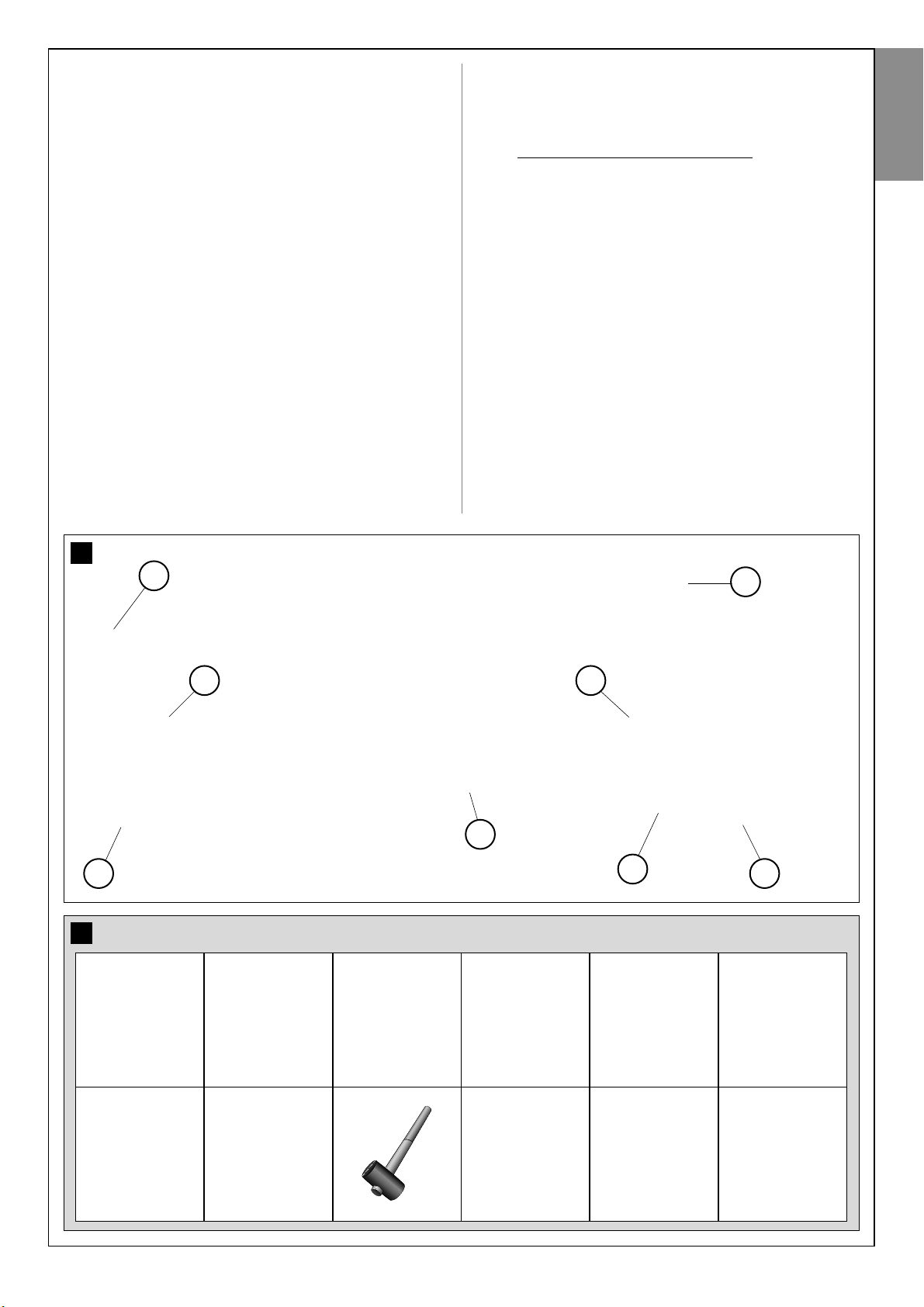

2.2 – COMPONENTS USED TO SET UP A

COMPLETE SYSTEM

fig. 2 illustrates all components used to set up a complete system, such

as that shown in fig. 5.

List of components:

[a] - electromechanical gearmotor

[b] - foundation plate

[c] - rack

[d] - rack fixing brackets

[e] - anchor bolts

[f] - reinforcement plates

[g] - keys for manual release of gearmotor

[h] - pair of photocells mod. MP (wall-mounted)

[i] - control keypad mod. MK (wall-mounted)

[l] - portable transmitter mod. MT4

[m]- flashing light mod. MF

[n] - metal hardware (screws, washers, etc.)

[o] - buffer battery mod. MB

WARNING!

Some components shown in fig. 2 are optional and may not be

supplied in the pack.

KNOWLEDGE OF THE PRODUCT AND PREPARATION FOR INSTALLATION

1

a b

i m n oh

l

2

c

ef gd

6 – English

English

4

A

A

B

B

3

264 mm

78 mm

288 mm 176 mm

STEP 3

PRELIMINARY INSTALLATION WORK

Before proceeding with installation, check the condition of the product

components, suitability of the selected model and conditions of the

intended installation environment.

IMPORTANT – The gearmotor cannot be used to power a manual

gate that does not have a fully efficient and safe mechanical structure. Neither can it solve defects caused by poor installation or insufficient maintenance of the door itself.

3.1 – CHECKING SUITABILITY OF THE ENVIRONMENT

AND THE GATE TO BE AUTOMATED

• Ensure that the mechanical structure of the gate complies with current

national standards and that it is suitable for automation. (If present, refer

to the information specified on the gate dataplate).

• Move the gate leaf manually to open and close, checking that move-

ment has the same degree of friction throughout all points of travel (no

increase in friction must occur).

• Manually move the leafs to any position and leave stationary, ensuring

that they do not move from this position.

• Ensure that the space around the gearmotor enables safe and easy

manual gate release. (see chapter “Manually releasing or locking the

gearmotor” in the “Operation manual”).

• Ensure that the selected surfaces for installation of the various devices

are solid and guarantee a stable fixture.

• Ensure that all devices to be installed are in a sheltered location and pro-

tected against the risk of accidental impact.

• Ensure that the selected surfaces for fixing the photocells are flat and

enable correct alignment between photocells.

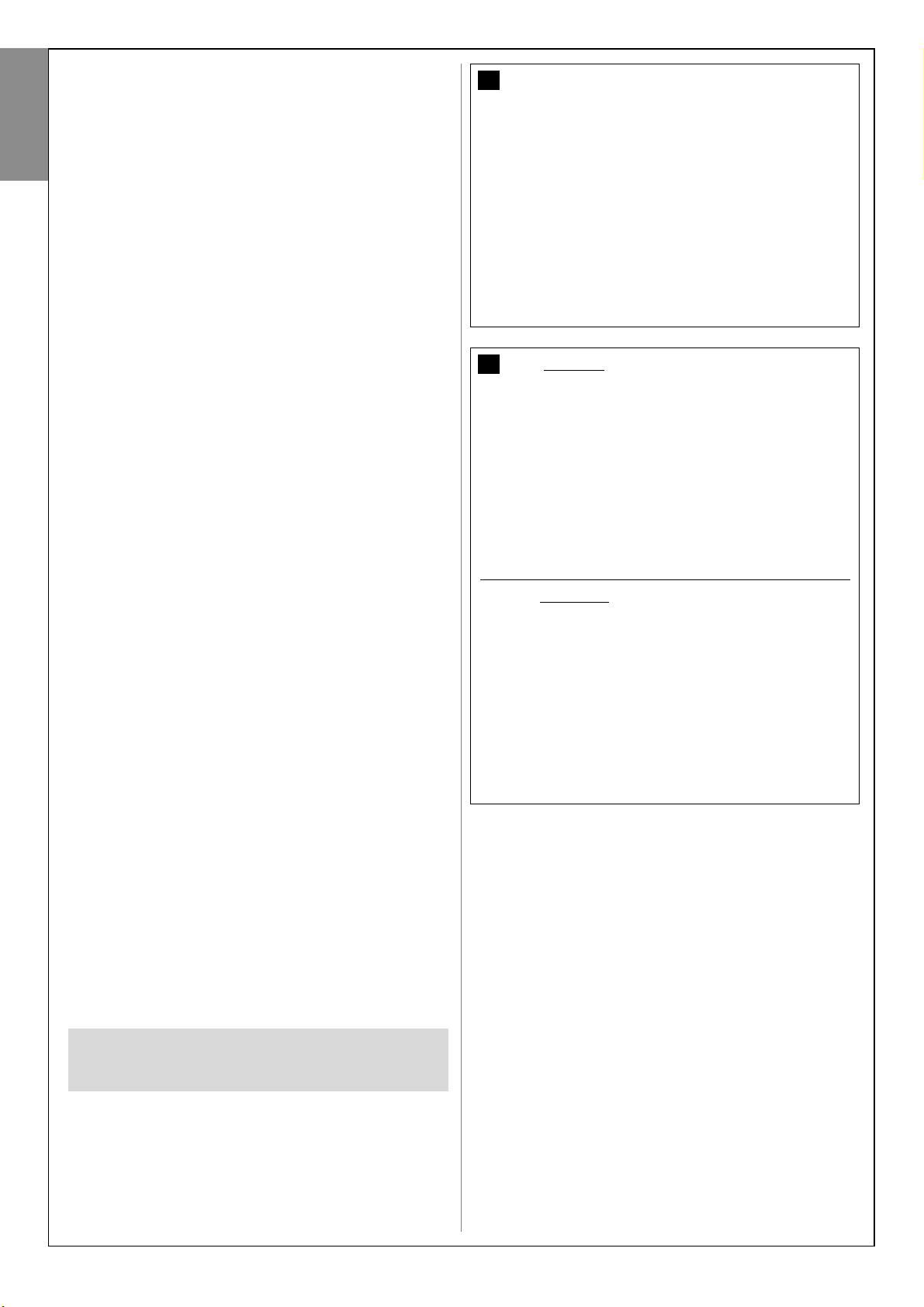

3.2 – CHECKING PRODUCT APPLICATION LIMITS

To ascertain suitability of the product with respect to the specific features

of the gate and area to be automated, the following checks should be performed as well as a check for compliance of the technical data in this

paragraph and the chapter “Product technical specifications”.

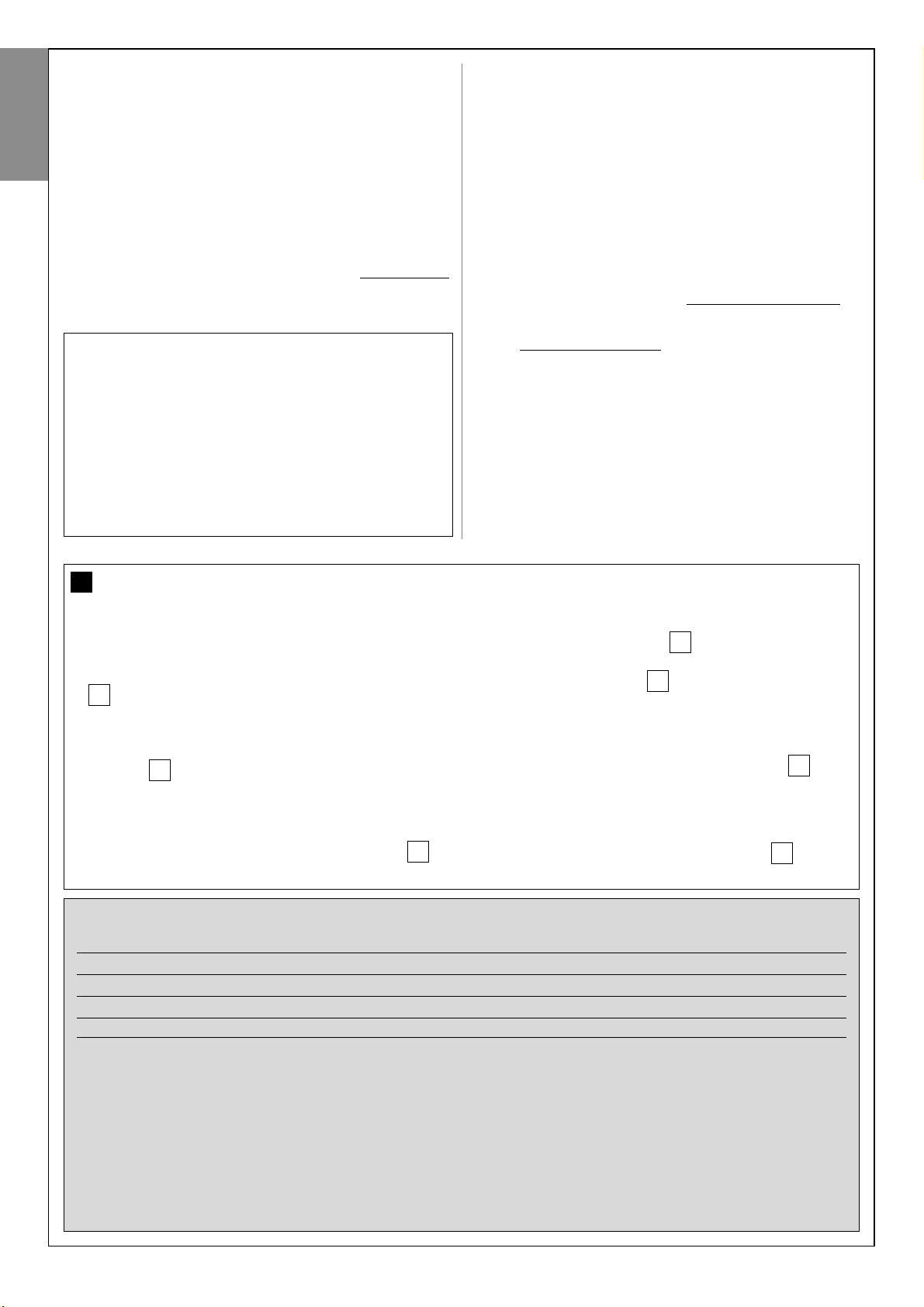

IMPORTANT – For the checks below, refer also to fig. 3 and 4:

– Fig. 3: indicates the overall dimensions of the gearmotor.

– Fig. 4: indicates values A and B, i.e. the minimum and maximum meas-

urements to observe when locating the position for the foundation plate.

Note – These measurements also serve as a reference to calculate the

space occupied by the foundation pit for routing the electrical cable ducting.

• Ensure that the dimensions and weight of the gate are within the follow-

ing limits of use.

- maximum length 5 m (

*

);

- maximum weight 300 kg.

(

*

) Note – The e rack supplied with this product is suitable for automation

of a gate with leafs of a maximum length of 4 m. If necessary, this may be

extended to a maximum length of 5 m using rack mod. MR1 (2 sections of

50 cm).

• Ensure that the dimensions of the selected area for mounting the gear-

motor is compatible with the overall dimensions.

• On the gate leaf, ensure that the surface for mounting the rack is suit-

able and solid.

CAUTION! – If the results of these checks do not conform to

specifications, this model cannot be used for automation of

your gate.

30 mm

30 mm

40 mm

40 mm

Left-hand

positioning of the gearmotor

Right-hand

positioning of the gearmotor

English – 7

English

CAUTION! - If forced to install the gearmotor on the left-hand side of

the gate, refer to the instructions in STEP 6.1.

4.1.4 – Establishing the device connection layout

The product envisages a “Bus” type connection between all system

devices, using a single cable with two electrical wires. In this type of connection, data communication between devices is via cable, using the specific protocol named “Bus-Moovo”.

CAUTION! – on the Bus system, only devices compatible with this protocol may be installed in the system.

On a “Bus” network, devices can be connected using various connection

configurations, and in each one, each device becomes a node of this network. The possible connection layouts are the following:

– “star”: In this configuration, each device is autonomous as it is connected directly to the two Bus terminals on the control unit.

– “chain”: In this configuration one device is connected to another and

the latter to another and so on, like links of a chain. Therefore only the first

device in the chain is connected to the two Bus terminals on the control

unit.

– “mixed”: this configuration is a combination of the two configurations

described above.

To select the most suitable connection configuration for the connection of

all system devices, refer to the example shown in fig. 7 / fig. 17. In gener-

al, it is recommended to connect the flashing light as the first device connected to the control unit.

STEP 4

4.1 – PRELIMINARY SET-UP WORK

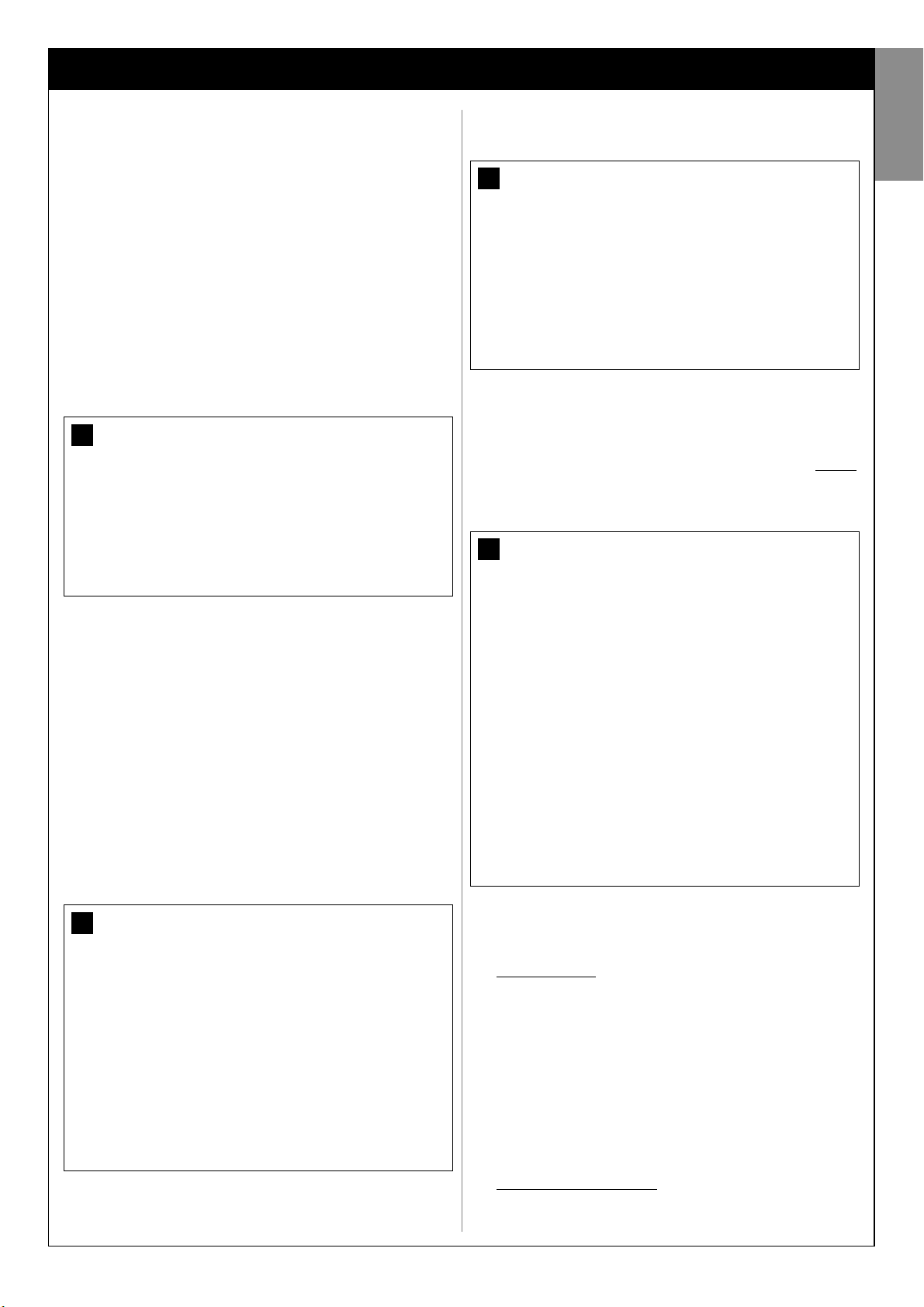

4.1.1 – Typical reference system

Fig. 5, shows an example of an automation system set up with Moovo

components. These parts are positioned according to a typical standard

layout. The following components are used:

a - Electromechanical gearmotor

b - Rack

c - Pair of photocells (wall-mounted)

d - Flashing light

e - Control keypad (wall-mounted)

f - Pair of photocells (on posts)

4.1.2 – Establishing positions of components

With reference to fig. 5, locate the approximate position for installation of

each component envisaged in the system. In particular, to establish the

position of the flashing light, refer also to fig. 20.

Warning – The “fixed” control devices must be visible from the gate but

positioned far from moving parts.

4.1.3 – Establishing the positions of the gearmotor

The gearmotor is factory set to be installed on the right-hand side of the

gate.

5

cc

d

e

f f

b

a

6

8 – English

English

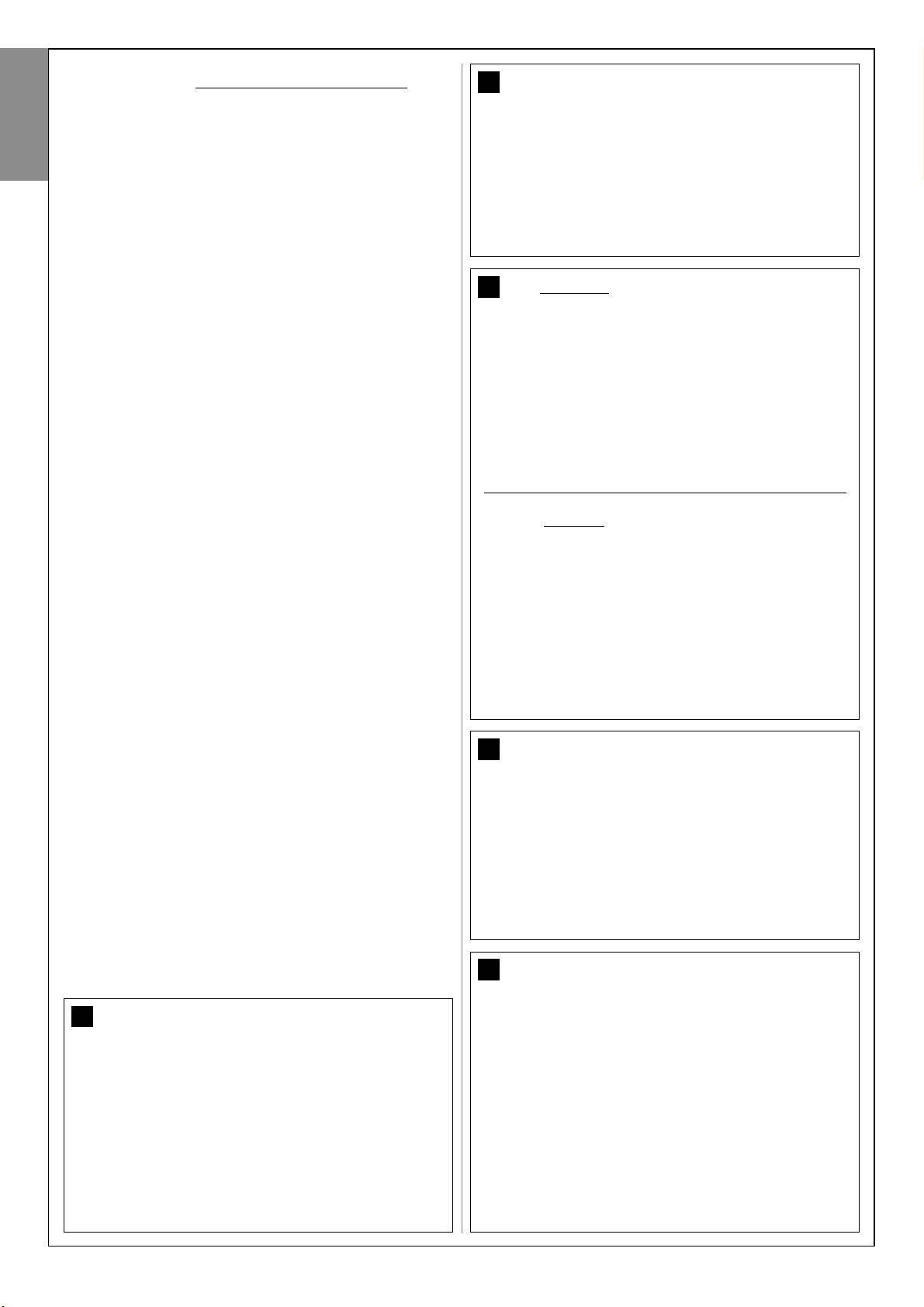

TABLE 1 – Technical specifications of electric cables (see also paragraph 4.2)

Connection Cable type Maximum admissible len

A - FLASHING LIGHT cable Cable 2 x 1.0 mm

2

10 m (note 2)

B - POWER SUPPLY cable Cable 3 x 1.5 mm2(note 1) 30 m

D - BUS cable Cable 2 x 0.5 mm

2

20 m (note 3)

Note – The cables required for the set-up of the system (not included in the pack) may vary according to the quantity and type of

components envisaged for the system.

Note 1 – If the power cable supplied is not long enough, replace with a cable of this type. This task must be performed by skilled

and qualified personnel: Refer to the section “Tasks reserved for qualified technicians”.

Note 2 – If a greater length is required use a cable with diameter 2 x 1.5 mm

2

.

Note 3 – If a greater length is required use a cable with diameter 2 x 1.0 mm

2

.

CAUTION! – The cables used must be suited to the installation environment; for example a cable type H07RN-F for outdoor environments is recommended.

4.1.5 – Checking the tools required for work

Before starting installation, ensure that there is all equipment and materials required for the work concerned (see example in fig. 6); also ensure

that all items are in good condition and comply with local safety standards.

4.1.6 – Preliminary set-up work

Dig the routes for the ducting used for electrical cables, or alternatively

external ducting can be laid, after which the pipelines can be embedded

in concrete and other preparation work for the installation can be completed to finalise the site ready for subsequent installation operations.

In particular, for digging the pit for anchoring the gearmotor to the

ground, proceed as follows:

01. Dig the foundation pit in the gearmotor fixture point: refer to STEP

3.2.

Note – The dimensions of the pit must be the same or greater than

those of the foundation plate.

02. Lay the ducting used for electrical cables as shown in the figure

below.

CAUTION! – In general, position the ends of the ducting used for

electrical cables in the vicinity of the points envisaged for fixture of

the various components.

Note: The ducting serves to protect electrical cables and prevent accidental damage in the event of impact.

4.2 – PREPARING THE ELECTRICAL CABLES

When preparing the electrical cables required for your system, please

refer to fig. 7 and “Table 1 – Technical characteristics of the electric

cables”. In addition to this, you should always remember the following:

– In the “star” configuration, NONE of the individual cables linking up

any of the devices to the Control Unit may exceed 20 m in length

.

– In the “chain” configuration”, the sum of the lengths of each cable

used to connect one device to the other and, last of all, to the Control Unit MUST NOT exceed 20 m

.

– If connecting other devices between the Control Unit and the flashing lamp, use the same cable for these devices as was used for the

flashing lamp.

– All operations to lay the electric cables and connect them to the

various devices must be carried out during installation of the components.

7

A

B

C

C

C

C

C

English – 9

English

STEP 5

INSTALLING THE AUTOMATION COMPONENTS

WARNINGS

• Incorrect installation may cause serious physical injury to those

working on or using the system.

• Before starting automation assembly, make the preliminary checks

as described in STEP 3.

The following assembly phases illustrate the “physical” illustration of the

gearmotor.

01. After digging the pit for fixture of the gearmotor (see STEP 4.1.7),

secure the anchor bolts to the plate as follows (fig. 8):

a) Tighten a standard nut (NOT locknut) fully down on each anchor

bolt.

b) Insert the anchor bolts so that the threaded section protrudes by

30 mm from the side of the plate bearing the pinion image.

c) Then temporarily tighten a standard nut (NOT locknut) onto the

ends of the anchor bolts. Note – In the next steps, the two upper

nuts will be removed and replaced with two locknuts.

02. Cast concrete into the pit, filling it to the edge and ensuring that the

ducting tube for electric cables come out of the surface.

03. While the concrete is still liquid, carefully place the foundation plate

on top, immersing the anchor bolts in the mix: shake the plate to

ensure that all air escapes from underneath and no bubbles form.

Take care to observe the following warnings (fig. 9):

– the side of the plate bearing the image of the pinion must be facing

the gate (see fig. 4);

– the ducting tube for routing the electric cables must pass through

the relative hole in the plate;

– observe the distances specified in fig. 4 to correctly position the

plate with respect to the gate leaf and wall.

– ensure that the plate is parallel to the gate and perfectly level (use a

spirit level).

04. When the concrete is solid (after a few days), loosen and remove the

upper nuts of the plate, which are no longer required.

05. Remove the gearmotor cover using a screwdriver to loosen the 4 lat-

eral screws (fig. 10). Note – Leave the gearmotor without the cover

until the installation and programming phases have been completed

06. Fig. 11:

a) Pass the electric cables through the relative holes and cable

clamps.

b) Gently place the gearmotor on the protruding section of the

anchor bolts so that they are inserted in the lateral holes of the gearmotor. Lock the assembly with the serrated washer and locknut

.

Note – Do not tighten the nuts fully down, as the gearmotor must

subsequently be moved forwards and backwards during rack

assembly.

07. Assemble and secure the rack:

To facilitate this operation, the rack assembly should be put together

separately, including brackets, to then be mounted onto the gate leaf.

Assemble the rack

:

a) - establish the total length of the rack, which should be the same

length as the gate leaf. Then calculate the number of parts required

(sections of 50 cm) and if necessary cut one section to reach the

total required length.

b) - using a rubber mallet, join the two sections of the rack and insert

a fixing bracket in the joining point. Then secure the bracket by

means of a screw (fig. 12).

– To improve fixture of the rack to the gate leaf, fix a bracket also at

the centre of each section.

c) - assemble the other parts of the rack (fig. 13) proceeding as

described in point “b”. Lastly, fit a fixing bracket on each end of the

rack: this must be positioned between the 6th and 8th tooth of the

rack, starting from the end.

Fixing the rack to the gate leaf

:

d) - close the gate leaf completely.

INSTALLATION: COMPONENT ASSEMBLY AND CONNECTIONS

8

9

10

11

30 mm

10 – English

English

e) - position one end of the rack above the gearmotor pinion, taking

care to align the first fixing bracket with the centre of the pinion (fig. 14).

f) - using a spirit level, level the first section of the rack in the pinion

area and temporarily secure to the gate leaf by means of adhesive

tape.

Then repeat the same operations on the next section and so on

through the entire length of the rack, taking care to position each

section horizontally and perfectly aligned with the end placed on the

pinion.

g) - Tighten the fixing brackets fully down on the gate leaf as follows

(fig. 15): first secure the two brackets in the vicinity of the gear-

motor by means of screws and washers (with the gate completely closed). Then move the gate to bring the next bracket in

alignment with the pinion and secure it to the leaf.

Repeat the same operation for the next bracket and so on until all

brackets on the rack are secured.

Note – The screws required to fix the rack on the gate leaf are not

included in the pack as their type depends on the material and thickness of the leaf on which they are inserted.

h) - before securing the last section of the rack, completely open the

gate and check that the bracket on the end is aligned with the centre

of the pinion. If this is not so, move the bracket to this position and, if

necessary, use a hacksaw to cut off the excess section of the rack,

leaving a free section of approx. 5 cm. IMPORTANT - the rack must

not protrude from the gate leaf.

Caution – At the end of this work, check that the rack is perfectly level; the slots on the brackets enable corrections of small

differences in alignment during fixture.

08. Then secure the gearmotor onto the foundation plate, tightening the

two locknuts fully down: the pinion must be perfectly aligned with the

rack; if necessary slide the gearmotor forwards or backwards to

adjust.

09. Release the gearmotor by means of the special release key (see

chapter “Manually releasing or locking the gearmotor” in the

“Operation manual”) and move the gate leaf to mid-travel.

10. Make a number of complete manual gate opening and closing

manoeuvres to enable self-adjustment of the mechanical limit

switches. Important – During this manoeuvre, ensure that the rack

slides in alignment with the pinion.

11. Then move the gate leaf to mid-travel and lock the gearmotor

by means of the special key (see chapter “Manually releasing or

locking the gearmotor” in the “Operation manual”).

Note – The 4 stud bolts supplied in the pack must be used exclusively to

adjust the gearmotor height, when deciding to assembly the rack before

the gearmotor (fig. 16).

15

12

13

16

14

80 mm

Right-hand

positioning of the gearmotor

“Closing” position

C

80 mm

Left-hand

positioning of the gearmotor

“Closing” position

C

Loading...

Loading...