Mirror Models Ford F15A Assembly Instructions Manual

Go through assembly guide before you start your work. Some gates are larger, because we don´t want

any ejector marks on parts, and also very thin true-to scale parts require larger gates to avoid filling

issues, you need to use a little razor blade and sharp scalpel to remove these parts carefully.

Images in rows one by one show usually one small assembly step

Heat up PE parts with lighter before use, brass will soften and become easy to bend and work with.

Gunze Mr. Cement or Tamiya Super Thin Glue recommended for plastic parts, let the glue work for a few

seconds, then push parts together, melted plastic will fill the gaps between parts. You can also melt

sprue frame and use it as an amazing filler for small works, or use this glue to wash out tiny seam lines

on little parts or make texture on some parts etc.

The Canadian Military Pattern truck was a class of military trucks made in large numbers in Canada during World War II

to British Army specifications for use in the armies of the British Commonwealth allies. Standard designs were drawn up just

before the beginning of the war. CMP trucks were also sent to the Soviet Union following the Nazi invasion of Russia, as part

of Canada's lend-lease program to the Allies. During the War CMP trucks saw service around the world in the North African

Campaign, the Allied invasion of Sicily, the Italian Campaign, the Russian Front, the Burma Campaign, the Battle of the

Philippines (1941-42), the liberation of Northwest Europe, and the Western Allied invasion of Germany. CMP trucks also saw

service in post-war conflicts in Indonesia, French Indochina, and the Portuguese colonies in Africa. Most CMP trucks were

manufactured by the Chevrolet division of General Motors of Canada Ltd and by the Ford Motor Company of Canada. Just over

400,000 CMP trucks were manufactured in Canada, accounting for roughly half of the 815,729 military vehicles made in Canada

during World War II. The Ford-built CMP trucks had a 239 cu in (3.9 L), 95 bhp (70.8 kW) V8 engine. Cab design changed twice,

first designed at Ford, second and third cab designs - called No. 11, 12 and 13. First two type were similar, the main difference

being a two-part radiator grille in No.12 cab, its upper part was opened with a bonnet, which was known as the "Alligator cab".

The production of CMP truck bodies in Canada was subcontracted out to smaller companies in Ontario and Manitoba, organized

into the wartime Steel Body Manufacturers Association by the Department of Munitions and Supply. The wide variety of truck

body designs included general service, water tanker, fuel tanker, vehicle recovery, dental clinic, mobile laundry, wireless house,

machinery, folding boat transport, and anti-tank gun portee. F15 Ford was often seen in desert service with top of the cab removed

Ford F15A assembly instructions

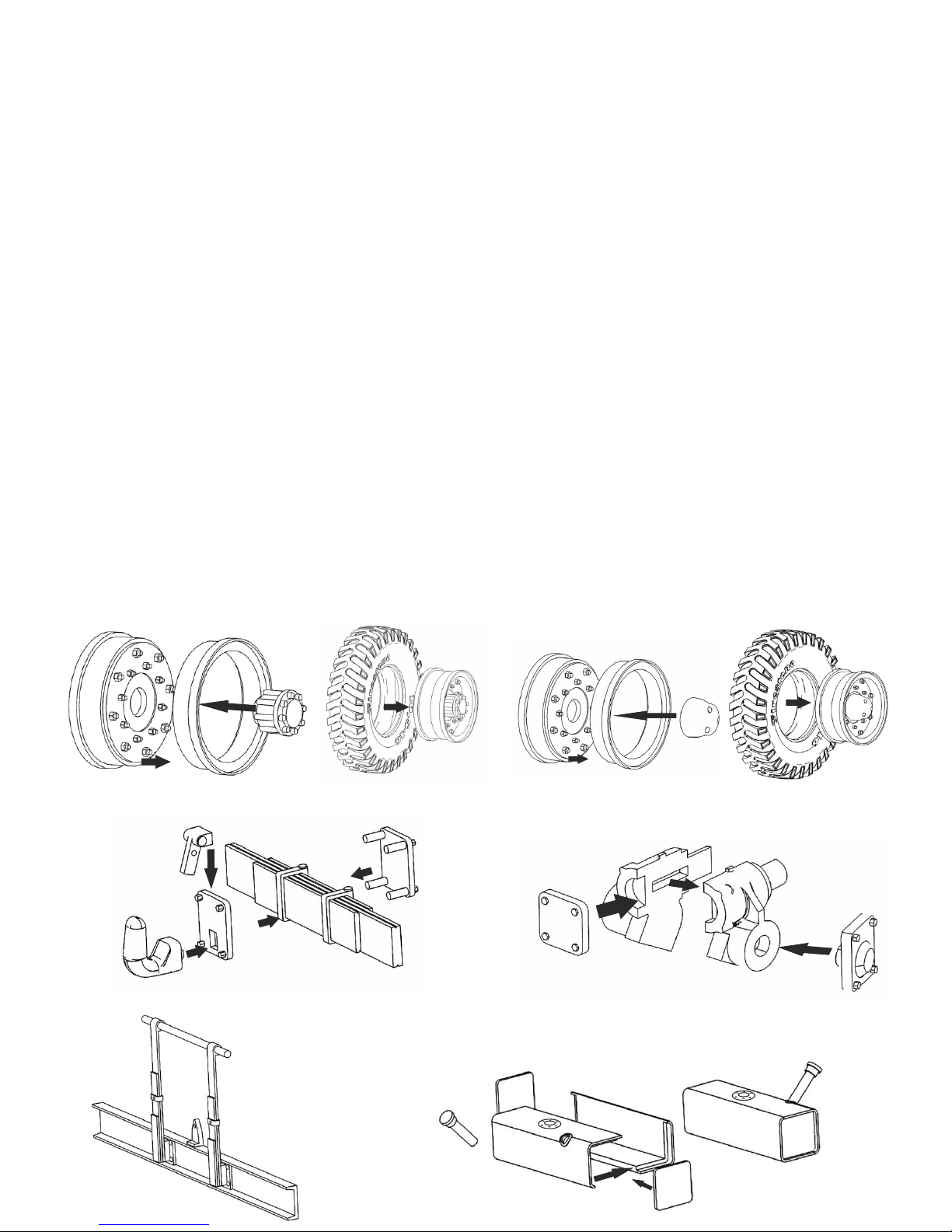

Prepare subassemblies:

Rear wheel assembly

Front wheel assembly

“AA”

“BB”

“CC”

“DD”

S2

S1

S4

S2

(S5 for spare wheel)

S1

S3

E9

E8

E10

E11

E12

E21

E24

E22

E23

E3

E15

E14

E16

W35

W35

W37 (W36)

W38

W30

PE1

1

PE1

Make two, left and right ones

“EE”

“FF”

“GG”

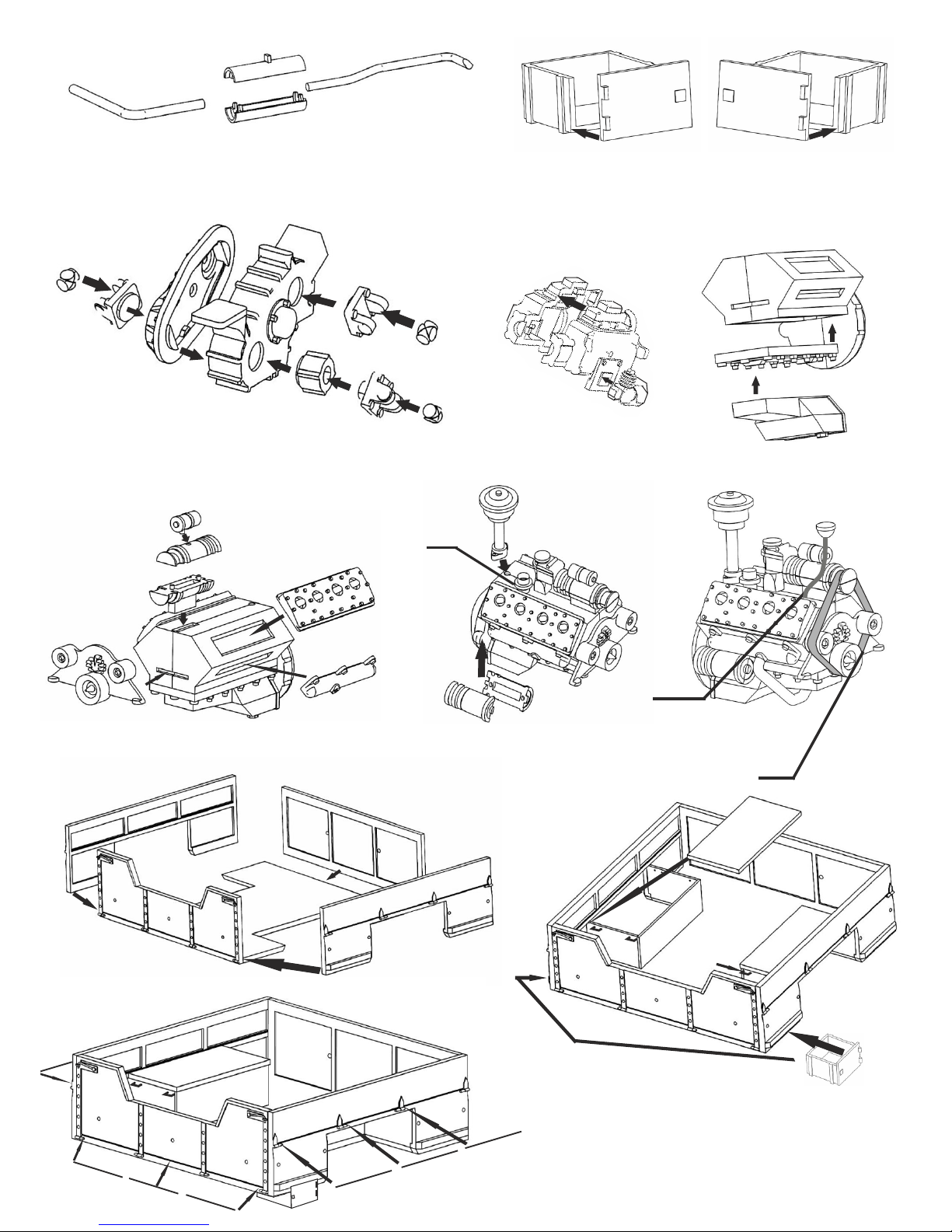

engine

Z25

E17

E18

A16

F2

F1

E19

E20

F11

F18_2

F18

W33

W33

W33

F11

A11

A12

A9

A10

A2

A7

A8 (A7)

A15

A3

A4

A13 (A14)

Z3

Z2

A1

A5

A6

0,6mm

wire

strip of tape

used for belt

0,3mm wire lengths

use lengths of 0,3mm wire to connect hinges and create true

looking appearance of folding down body walls

0,3 wire

for handles

Body

“GG”

G1

G4

G5

G2

G3

G6

G7

G8

W3

W1

W2

“HH”

A17

2

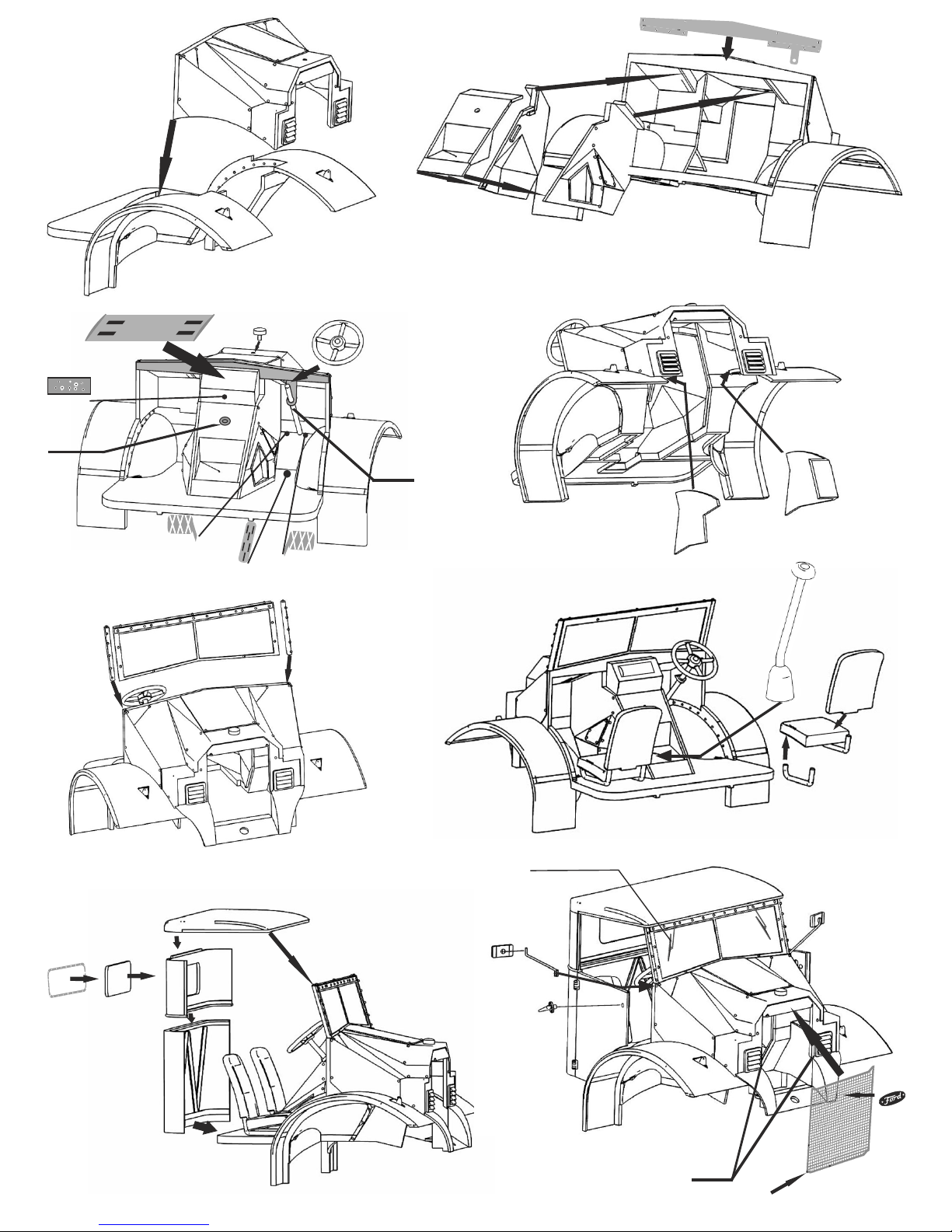

Cab 11

E33

E31

E30

E32

H1

H9

H11

H10

H20

H23

E27

PE5

PE6

push all rivets

from back

PE7

PE8

PE9

H4

H3

H22

H21

C1

PE10

PE11

H5

H6

H7

(PE12)

E13

Z22

Z23

Z24

H18

H19

H8

C2

F17

F17

F9

E7

E6

H17

H16

3

PE19

PE20

F17

PE36+PE37

Loading...

Loading...