Page 1

FEATURES

● Simple and compact installation

● Immunity to liquid disturbances

● Easy operation and maintenance

● All-digital processing

● Automatic calibration

ULMS

Nuclear Island Measurement Systems

ULMS

Ultrasonic Water Level Measuring System

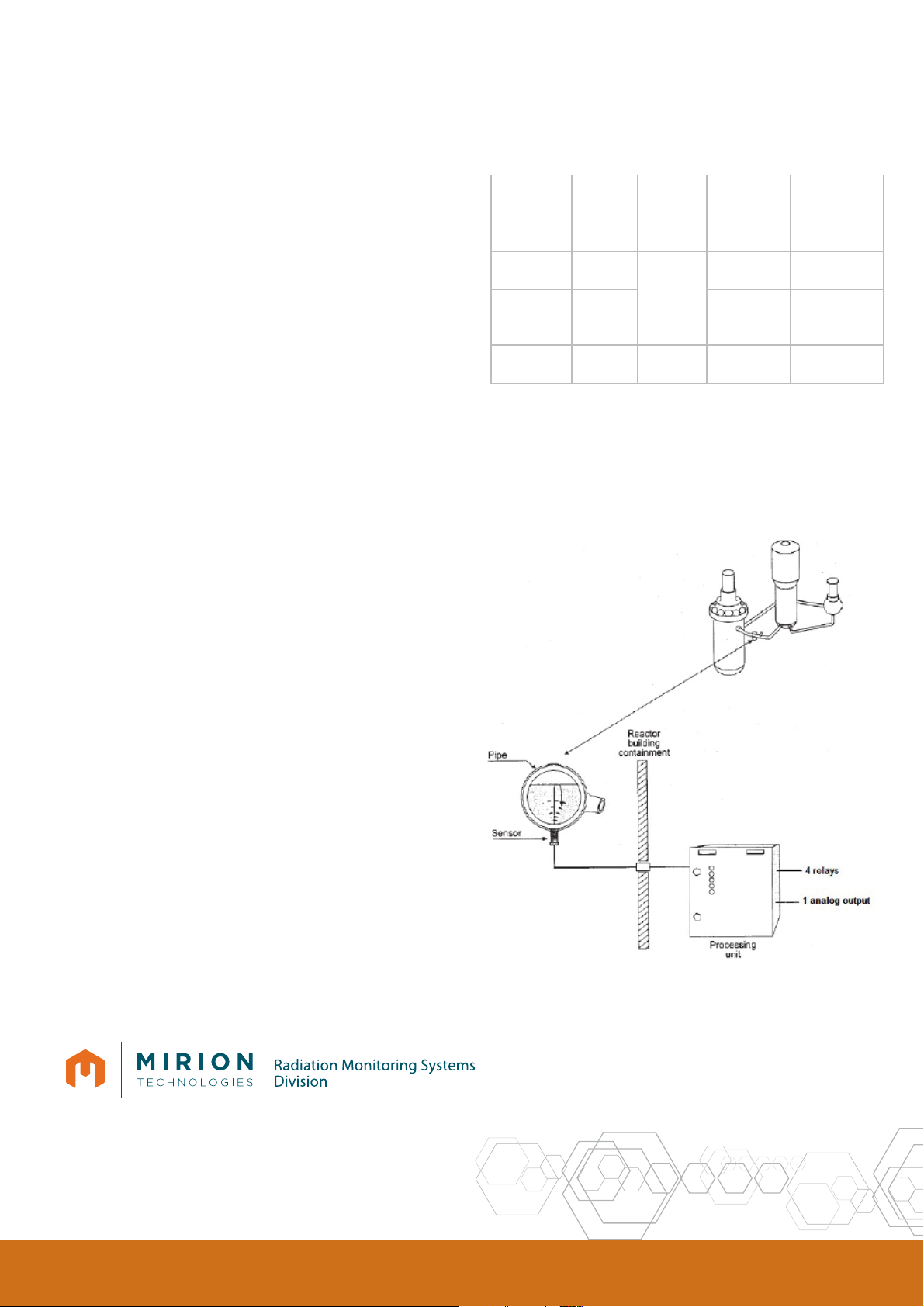

The ultrasonic level measurement channel forms part

of the NIMSYS product line. It is used during the

nuclear power plant outage to monitor the real level

of water in the reactor via the primary pipe.

The main application is to avoid the vortex cavitation

of the pump, and to optimize duration time for main-

tenance of the steam generator for example.

Its design makes it easy to install and limit the instal-

lation time in the reactor building.

Its design is based on the round-trip time of an ultra-

sonic wave which is re ected from the surface of the

liquid. It can be easily and quickly installed without

any modi cation of the plant. The high performance

of the ultrasonic measurement channel is ensured

by the measurement stability and immunity to distur-

bances of the liquid surface.

APPLICATIONS

• Operational process monitoring

VERSIONS

• 500 kHz for casted pipe

• 1 MHz for forged or extruded pipe

radiation monitoring

systems

A Mirion Technologies Division

Featuring:

Page 2

ULMS

Nuclear Island Measurement Systems

PHYSICAL CHARACTERISTICS

● Pipe inside diameter: 0.5 to 1.3 m (1.6 to 4.2 ft)

● Detector: piezoelectric sensor

● Measurement range:

○ Version 500 kHz: 20% to 100% of water level

○ Version 1 MHz: 35% to 100% of water level

● Response time: real time measurement (1 s)

● Accuracy:

○ ± 0.5% at constant temperature

○ ± 2.5% between +10°C and +70°C (+50°F and

+158°F), including the variations of the speed of

sound versus temperature

PROCESSING CHARACTERISTICS

● Supplied in casing

● Indications:

○ Illuminated indicators (LED) on the door

○ Liquid-crystal alphanumeric display

○ Level measurement values displayed:

- Absolute level with respect to a reference (in meters)

- Relative level (in % of the full pipe)

- Round-trip time of the ultrasonic wave (in μs)

● Outputs:

○ Analog output (0/4-20 mA)

○ 4 output relays (SPDT):

- Operate

- Correct coupling

- 2 programmable level thresholds (high and low level)

● Operating temperature range: +10°C to +35°C (+50°F

to +95°F)

MECHANICAL CHARACTERISTICS

Dimensions Support Sensor Processing

Unit

Heignt 120 mm

(4.72 in)

Width 210 mm

(8.26 in)

Depth 145 mm

(5.70 in)

Weight 8 kg

(17.6 lb)

314 mm

(12.36 in)

Diameter:

110 mm

(4.33 in)

5 kg

(11 lb)

525 mm

(20.66 in)

570 mm

(22.44 in)

286 mm

(11.26 in)

20 kg

(44 lb)

OPTIONS

● RS232 link toward computer, and/or printer

Belt

Adjustable to

the pipe

242 mm

(9.52 in)

Thickness:

60 mm

(2.36 in)

22 kg

48.5 lb)

ELECTRICAL CHARACTERISTICS

● Power supply: 230 Vac – 50 Hz or 120 Vac – 60 Hz

● Immunity to industrial interference: CE marking

Mirion Technologies (MGPI) SA

Route d’Eyguières

FR-13113 Lamanon

France

Mirion Technologies (MGPI) Inc

5000 Highlands Parkway

Suite 150

Smyrna, GA 30082

USA

T +33 (0) 4 90 59 59 59

F +33 (0) 4 90 59 55 18

Since norms, speci cations and designs are subject to occasional change, please ask for con rmation of the information given in this publication.

T +1 770 432 2744

F +1 770 432 9179

Mirion Technologies (MGPI H&B) GmbH

Landsberger Strasse 328a

DE-80687 Munich

Germany

T +49 (0) 89515 13-0

F +49 (0) 89515 13 169

www.mirion.com

145030EN-A

Mirion Commercial (Beijing) Co., Ltd.

Shanghai Jiangchang Commercial Branch

Room 801, 78 Jiangchang SanLu

Zhabei District, Shanghai 200436

PR of China

T +86 21 6180 6920

F +86 21 6180 6924

Loading...

Loading...