Page 1

TK 250

Signal Processing

TK 250

Digital Signal Processing System

The TK 250 digital signal processing system has been

designed for safety related applications in nuclear

measurement, e.g. radiation monitoring and neutron

ux instrumentation. It is a modular multi-micropro-

cessor system with data interface. It is optimized for

a rugged operational behaviour and high reliability.

APPLICATIONS

• Radioprotection of workers

• Operational process monitoring

○ Dose rate monitoring and activity monitoring

according to IEC 61226 cat. B and A

○ Neutron ux instrumentation and other functions

according to IEC 61226 cat. A

FEATURES

● Suitable for all types of detector signals (pulses,

DC-and AC-current)

● Up to four signal paths per rack

● Continuous self tests for hardware and software

● Remote signal generators and signal simulation

● Compatible with analogue channels

● Simple and clear operators interface

● 19” mechanical system according to IEC 60297

● Type tested according to KTA 1505 and KTA 3505

RELATED PRODUCTS

• RMS 250: radiation monitoring systems

• proTK™: neutron ux monitoring systems

radiation monitoring

systems

A Mirion Technologies Division

Featuring:

Page 2

FUNCTIONS AND

OPERATOR’S ACCESS

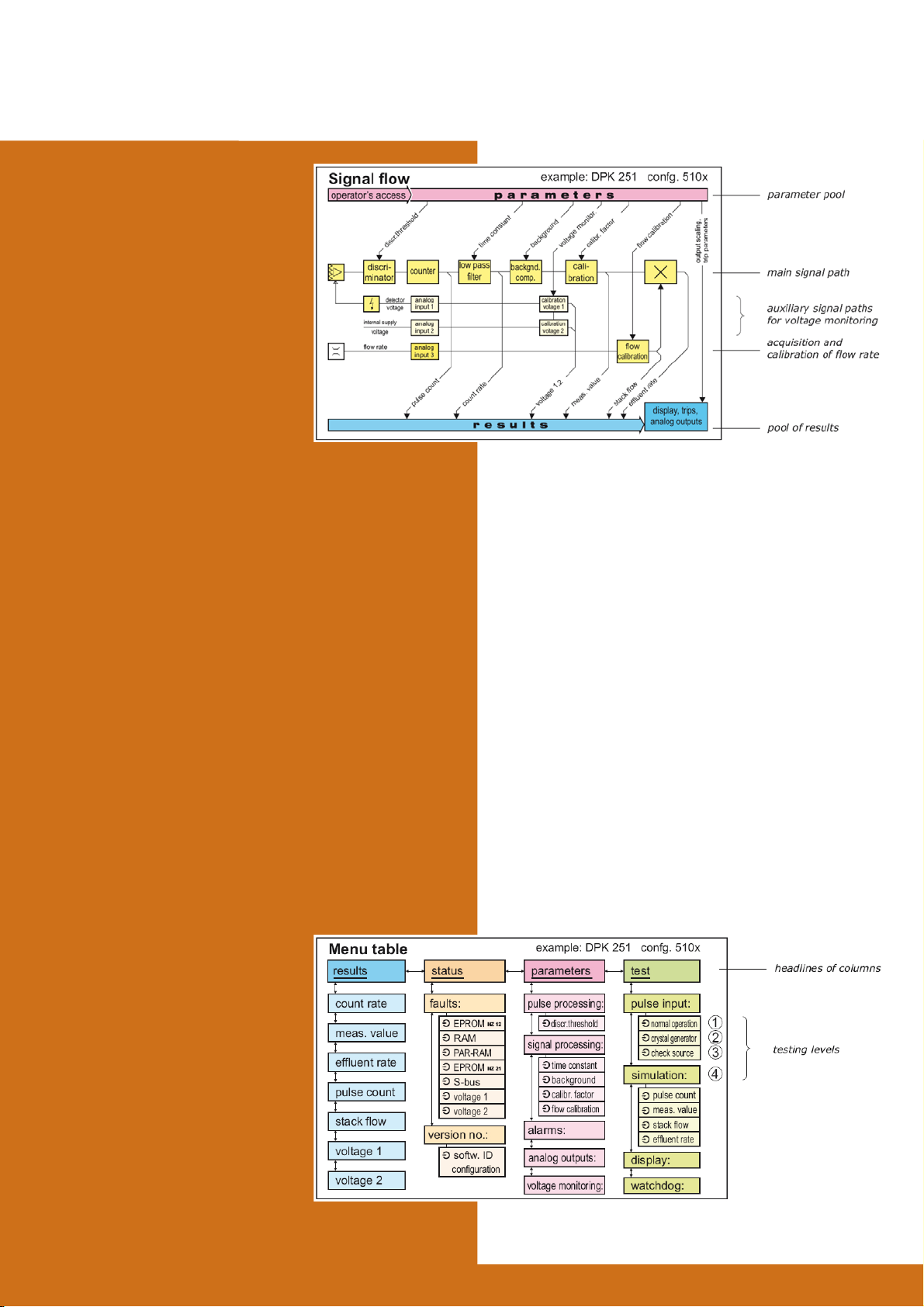

Signal processing has to be

adapted to the individual appli-

cation by adjustable parameters,

like time constant or calibration

factor. Additionally, all measur-

ing values may be monitored by

adjustable alarm thresholds, and

may be used for linear or loga-

rithmic output signals.

Measuring values and param-

eters are organized in two columns of the menu table.

There are other columns, one to activate all the test

procedures and another to show the status informa-

tions of the channel. The 2-line LCD and the keys of

the main processor board NZ 12 enables the access

to all positions of the menu table.

The operator has two different possiblities for the

access to system TK 250 signal processing channels,

either manual via display and function keys on the

front panel of the main processor board NZ 12 or via

the data interface with an external PC. Also during an

operator’s dialog the continuous signal processing

functions are not interrupted. Thus, without external

tools, reading of all measuring values, parameters

and status informations is possible in parallel to the

normal signal processing. Modi cations of para-

meters and activation of test procedures also may

be done on the menu table using the keys, but these

functions are locked and can be

enabled the key switches on the

board NS 01.

TK 250

Signal Processing

TEST PROCEDURES

Functional tests of TK 250 measuring channels in

connection with detectors and output periphery may

be performed on different levels with automatic or

remote operated procedures.

On the base level (1) there is a number of continu-

ous self checks of hardware and software in the

measuring channel. The goal is detecting drifts and

faults very early and verfying the original status of the

software originally type tested. The internal supply

voltage and the detector supply voltage, the detector

signal, the memory for data, parameters and pro-

gram, the data transfers on the internal S-bus, the

execution to the program and some other features

are subject of the continuous self checks. Faults will

cause an alarm status signal and the reason can be

checked in the status column of the menu table.

Page 3

The next level (2) is the check of the complete signal

path beginning at the detector up to the interface to the

external periphery performed with remote check sources

or with ionization chambers with internal check volume.

The third level (3) is testing with electrical signal genera-

tors. Preampli ers and signal input boards have remote

operated pulse or current sources to generate precise

test signals for the input converters.

Finally (4), analog and binary output signals and the

concerning periphery like indicators, recorders or alarm

devices can be activated by numerical signal simulation,

thus the whole range of output signals is covered, fast

and precise. The test mode generates status signal of a

binary output (relay contact).

TK 250

Signal Processing

ELECTRONIC MODULES

The measuring channels of the systems TK 250 are

constructed with 19” modules. Pre-ampli ers and signal

converters for very sensitive detector signals are moun-

ted in separate boxes. There is a variety of input boards

for the pre-processing of the detector signals, e.g. pulse

discriminator NI 21... and ampli er boards NA 31... for

neutron detectors. On the output side there are isolated

buffer ampli ers NT 31 and NT 61 for analog signals and

relay bords for binary signals, e.g. NB 21. The modules

interface, supply and auxiliary functions are assembled

all around the microprocessor boards for signal acquisi-

tion NZ 21 and for signal processing NZ 12.

Page 4

Signal Processing

LIST OF MODULES

Type Designation Function Used For Supply Voltage Width

NA 04/06

NA 07.21

NA 31

NA 32

NA 33

NA 34

NA 36

NB 21

NB 22

NB 28

NE 31

NE 32

NH 32

NH 33

NH 34

NH 36

NH 42

NI 11

NI 21

NI 22.2

NK 21.2

NN 01

NN 41

NN 43

NN 51

NN 53

NN 54

NP 31

NR 17

NR 31

NS 01

NT 31

NT 61

NZ 12

NZ 21

NV 101

NV 102

NV 320

TKV 23

Indicator unit

Pump control unit

Current input unit

Fission chamber unit

RMS input unit

Average value ampli er

SPND input unit

Binary I/O-board

Decoder board

Binary output board

Pulse outputs

Pulse shaper

High voltage supply

High voltage supply

High voltage supply

High voltage supply

High voltage supply

Standard pulse input

Pulse discriminator

Double window discriminator

Serial interface

DC supply network

24 VDC power supply

24 VDC power supply

230 VAC power supply

230 VAC power supply

230 VAC power supply

Test generator

Relay board

Relay board

Key switch board

Isolated buffer ampli er

Isolated buffer ampli er

Main processor board

I/O processor board

c/f converter

c/f converter

Pulse pre-ampli er

Wide range pre-ampli er

1 or 2 analog indicators 24 × 96 mm

Switches and operating hours counter

c/v-converter 0 ... 10/25/50 μA

Detector voltage and c/f-converter

Main ampli er and RMS-correlator

c/v-converter 0 ... 2.5/5 mA

Differential ampli er

DEK 251

DGK 250

DSK 250

DWK 250

DMK 250

DLK 250

4 inputs, 8 relays outputs 60 V/0,5 A

4 bit to 1v16, with level shifter

DAK, DWK

8 relays outputs 125V/1A

2 insulated 50 Ω pulse buffers

Pulse ampli er, e.g. for iodine monitors DEK 251

0 ... 1 kV, 2 mA max.

0 ... 2 kV, 1 mA max.

0 ... 4 kV, 0,5 mA max.

0 ... 500 V, 4 mA max.

0 ... 800 V, 30 mA max. DWK 250

2 insulated inputs

2 integral discriminators

2 single channel discriminators

DEK 251

RS 232 or RS 485, insulated

Redundant supply & battery inputs

Output voltages: 5 V, ±15V

Output voltages: 5 V, ±15V

Output voltages: 5 V, ±15V

Output voltages: 5 V, ±15V

Output voltages: 24 VDC or 28 VDC

Test signal 0 ... 10 V/20 mA adjustable

DMK 250 ±15 V

6 relays, 2 change overs each

16 relays, 2 contacts each

2 key switches, test plugs

1 ... 4 × 0 ... 10V/0 ... 20mA

Various input/output combinations

With display and keys

2 counters, 4 analog I/Os each

0.1 pA … 0.3 μA, 800 V detector supply

0.1 pA … 1mA, various detector voltages

For neutron detectors

For wide range ssion chambers

DAK 250

DWK 250

24 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±15 V

±24 V

5 V, ±15 V

5 V

5 V, ±15 V

5 V

35 VDC max.

18 ... 32 VDC

18 ... 32 VDC

195 ... 255 VAC

195 ... 255 VAC

195 ... 255 VAC

15 or 24V

15 V

5 V

±15 V

24 ... 230 VAC/DC

5 V

5 V, ±15 V

15 ... 32 VDC

15 ... 32 VDC

±15 V

±15 V

8/12 T

8 T

4 T

4 T

4 T

4 T

4 T

4 T

4 T

4 T

4 T

4 T

8 T

8 T

8 T

8 T

14 T

4 T

0/4 T *

0/4 T *

4 T

4 T

4 T

8 T

4 T

8 T

8 T

4 T

4 T

4 T

4 T

4 T

4 T

20 T

0/4 T *

Box

Box

Box

Box

TK 250

notice: T = 2/10” = 5.08 mm

Mirion Technologies (MGPI) SA

Route d’Eyguières

FR-13113 Lamanon

France

T +33 (0) 4 90 59 59 59

F +33 (0) 4 90 59 55 18

Since norms, speci cations and designs are subject to occasional change, please ask for con rmation of the information given in this publication.

Mirion Technologies (MGPI) Inc

5000 Highlands Parkway

Suite 150

Smyrna, GA 30082

USA

T +1 770 432 2744

F +1 770 432 9179

* without front panel, arranged behind NZ 12

Mirion Technologies (MGPI H&B) GmbH

Landsberger Strasse 328a

DE-80687 Munich

Germany

T +49 (0) 89515 13-0

F +49 (0) 89515 13 169

www.mirion.com

144879EN-C

Mirion Commercial (Beijing) Co., Ltd.

Shanghai Jiangchang Commercial Branch

Room 801, 78 Jiangchang SanLu

Zhabei District, Shanghai 200436

PR of China

T +86 21 6180 6920

F +86 21 6180 6924

Loading...

Loading...