Page 1

RADOS Mobile Change Unit

Mobile Contamination Monitoring Suite

RADOS Mobile Change Unit

Mobile Contamination Monitoring Suite

The use of radioactive materials can cause radioactive

contamination spots in buildings and working areas.

An important task of Health Physics is to prevent

spread of contamination to other work areas, in

particular out of controlled areas.

Change rooms are an integral part of designated areas

set up for the control of contamination (controlled

areas). However, it is often necessary to set up

temporary controlled areas and related facilities, in

particular in decommissioning related activities.

FEATURES

•1 container: transportable in two units

by crane / fork lift truck

•2 RADOS CheckPoint:Body™

contamination monitors

•1 RADOS CheckPoint:Waste™

clearance measurement chamber

•3 washing stations incl. sinks with auto-stop

water taps, soap dispensers and air dryers

•interfaces to external electricity and water supply

as well as drainage

•air conditioning and heating installations

•assembly in less than 8 hours (by two people)

not including local support and transport tools

Mirion Technologies (RADOS) GmbH and its partners

in nuclear industry have developed a Mobile

Contamination Monitoring Suite to support these

requirements. The RADOS Mobile Change Unit is a

container module combining the well-known RADOS

body contamination monitors and a clearance monitor

with washing facilities.

These monitors have been used in many nuclear

installations worldwide and meet the most demanding

specications of the nuclear regulators both in terms

of radiometric performance as well as the criteria of

usage under nuclear industrial conditions.

health physics

A Mirion Technologies Division

Featuring:

Page 2

INTRODUCING THE RADOS MOBILE CHANGE UNIT

The RADOS Mobile Change Unit combines the advances

in Fibre™ - and plastic-detector technology with

conventional change room installations in a modular

solution designed to t the fast changing conditions

of projects typical for nuclear decommissioning or

emergency response.

CheckPoint:Body™

feat. RADOS TwoStep™-Exit II

Designed to check for beta and optional gamma

contamination on personnel leaving the controlled

areas of nuclear facilities. The gas-less TwoStep™-

Exit II is product development at the cutting edge of

technology, based on years of experience in building

body monitors. It utilizes advances in BetaFibre™

and GammaFibre™ detector technology paired with

a radical redesign of monitor geometry. A monitor

setting new standards using unique technology.

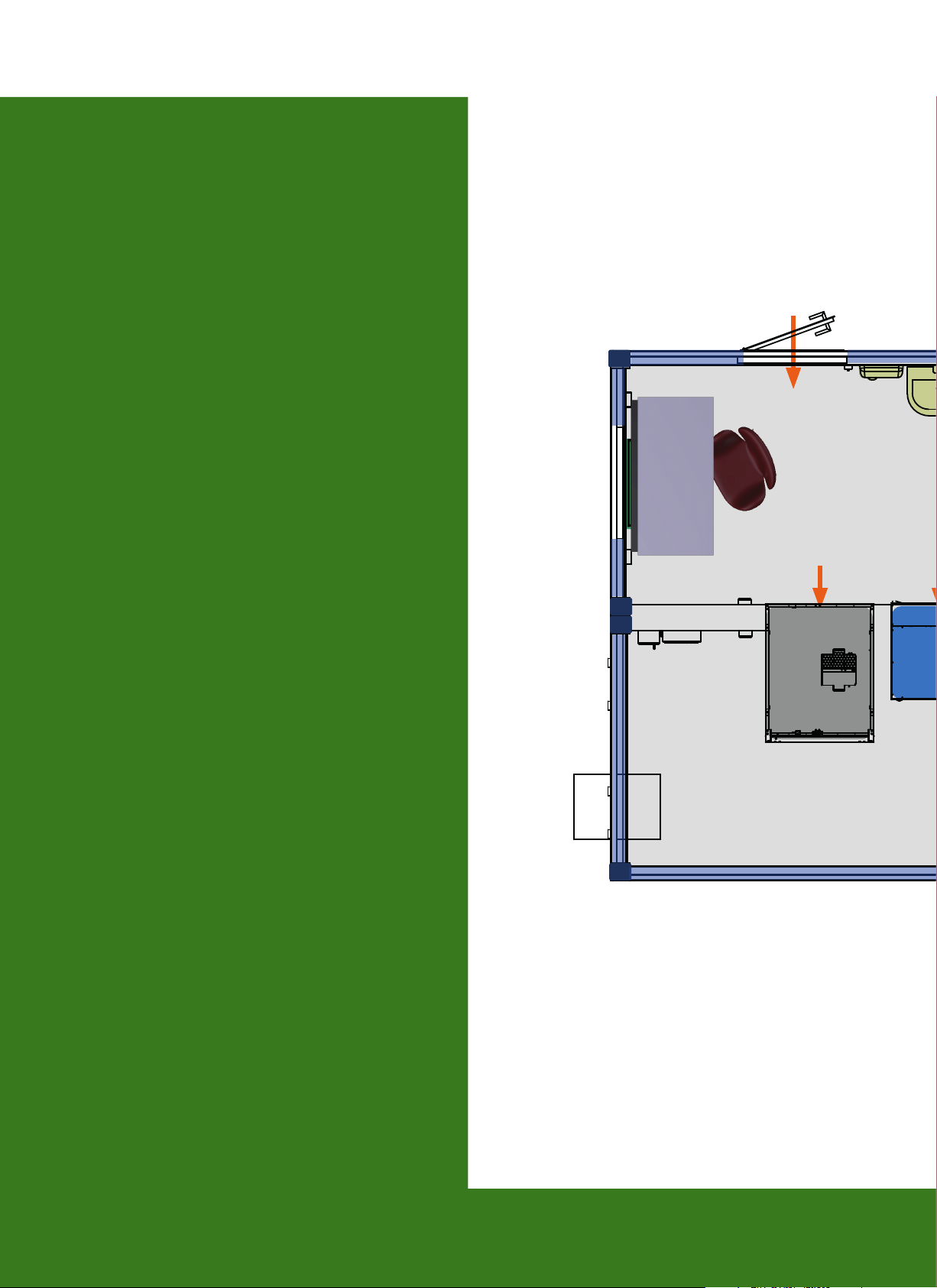

Walking through the RADOS Mobile Change Unit is

as simple as through any controlled area exit .

In fact there is no difference.

Entry

Desk

CheckPoint:Waste™

feat. RADOS RTM661/300

One of the main members of the compact and

stand alone clearance monitor family with integrated

electronics for the measurement of contamination on

small items and other parts. It features a front door

for the loading/unloading and an additional back

door with an interlocking front and back door system.

The interlock mechanism is designed to prevent the

export of items above a pre-set activity limit from the

controlled area.

The value in the RADOS Mobile Change Unit is in the

modular nature of the unit, which can be transported

from site to site with minimal effort. Two containers,

which are used for the Mobile Change Unit, can be

moved by crane or fork lift truck. Installation consists

of lining up the containers on the previously prepared

foundations, fastening the linkage, sealing the gaps,

connecting the supplies and taking the monitors into

operation. Two people can easily do these works in a

single shift.

RTM661/300

TwoStep™-Exit II

Mobile Change Room features

•2 off CheckPoint:Body™ (eg TwoStep™-Exit II)

•1 off CheckPoint:Waste™ (eg RTM661/300)

•Air conditioning and heating system

•Water saving taps, soap dispensers and hand dryers

•Health Physics desk + optional telecommunication

equipment

Page 3

Washing Facilities

Enter the Mobile Change Unit

The rst container holds the washing

stations for cleaning hands. It is

including washing facilities and hand

dryers as well as air conditioning and

heating systems.

Cleaning Hands & Tools

After cleaning hands, tools and other

small items can be deposited in the

compact chamber of the clearance

monitor. Successful clearance of

the small items should be awaited

before proceeding to the body

contamination monitor.

TwoStep™-Exit II

Exit

Enter the Body Contamination Monitor

Passing through the body contamination

monitor is voice guided throughout.

All measurement information is also

displayed on the display at the front of

the monitor.

Exit after completed measurement

If no contamination is found, the body

contamination monitor can be left via exit

and small items can be removed from the

clearance monitor.

In case of contamination information on the

contaminated body parts are displayed to

guide the cleaning.

Measurement Sequence

Page 4

Health Physics

Division

RADOS Mobile Change Unit

Mobile Contamination Monitoring Suite

Technical Specifications Mobile Change Unit (MCU)

CheckPoint:Family™ CheckPoint:Body™ CheckPoint:Waste™

Family member e.g. TwoStep™-Exit e.g. RTM661/300

Electronics Industrial PC, Hard disc, CD-RW Disc drive, LC Display, IR Keyboard with mouse,

Printer interface, USB device, Speech processor

Facility All facility installations will be built to order. Standard installations:

3 hand basin, 3 water tap with autostop, 3 soap dispenser, 3 hand dryer (fan), water heater,

electrical heating, air conditioning, operator chair and table

Option: telecoms equipment

Power requirements 240/400 V 63.0 A 50 Hz

Dimensions

(see also gure)

Transport features Both containers of the Mobile Change Unit have to be transported separately. Each container can be moved by

Entrance container

Exit container

Overall weight

6058 x 2438 x 2896 mm

6058 x 2438 x 2896 mm

approx. 11,100 kg (4,100 kg + 7,000 kg)

an adequate crane or fork lift truck.

Each container provides 4 lifting accessories at the upper vertices for lifting via crane and 2 forklift tubes for lifting via fork lift truck. On nal destination of Mobile Change Unit a foundation has to be provided.

Foundation requirements A concrete foundation of a planar surface of minimum foot print of approx. 5.4 m x 6.6 m has to be prepared. It

should withstand a surface pressure of approx. 200 kN/m

2

. Alternatively the foundations can consist of 6 level

concrete cubes.

Water connections Required connections:

Cold water supply (please specify interface dimension requirements)

Waste water to active drainage (please specify interface requirements)

6058 cm

2400 cm

4876 cm

www.mirion.com

7NUC_MCU_Y015-070E_2_PDB

Mirion Technologies (MGPI) Inc

5000 Highlands Parkway

Suite 150

Smyrna Georgia 30082

USA

T +1.770.432.2744

F +1.770.432.9179

Since norms, specications and designs are subject to occasional change, please ask for conrmation of the information given in this publication.

© Copyright 2012, All rights reserved. For trademark and registered trademark information. The copyright in this work is the exclusive property of Mirion Technologies

(RADOS) GmbH and is protected under the laws of Germany and other countries worldwide.

Mirion Technologies (MGPI) SA

Lieu-Dit Calès

Route d‘Eyguières

F-13113 Lamanon

France

T +33 (0) 4 90 59 59 59

F +33 (0) 4 90 59 55 18

Mirion Technologies

(RADOS) Oy

P.O. Box 506

FIN-20101 Turku

Finland

T +358 2 4684 600

F +358 2 4684 601

Mirion Technologies

(RADOS) GmbH

Ruhrstrasse 49

D-22761 Hamburg

Germany

T +49 40 85193 0

F +49 40 85193 256

Mirion Technologies Shanghai Branch

Room 801, 78 Jiangchang

San Lu, Zhabei District

Shanghai 200436

China

T +86 21 6180 6920

F +86 21 6180 6924

Loading...

Loading...