Page 1

OPERATING MANUAL

MBD-2 (IM-278/U)

Personal Dosimeter

Document # 15-00167

Revision 1

December 2018

Page 2

Table of Contents

1. Preparation for Storage or Shipment .................................................................................................... 5

2. Introduction ............................................................................................................................................ 6

3. Description ............................................................................................................................................ 6

3.1 Physical Desc r iption .......................................................................................................................... 6

4. Operation ............................................................................................................................................... 8

4.1 Principle of Operation ........................................................................................................................ 8

4.2 Installing the Wrist Strap ................................................................................................................... 9

4.3 Batteries .......................................................................................................................................... 11

4.3.1 Removal/Replacement of the Main Battery ................................................................................ 11

4.3.1.1 Main Battery Replacement ...................................................................................................... 11

4.3.1.2 Battery Display Indications: ..................................................................................................... 13

4.4 Start-up and Diagnostics ................................................................................................................. 15

4.4.1 Start-up ........................................................................................................................................ 15

4.4.2 Diagnostics .................................................................................................................................. 15

4.4.3 Operation ..................................................................................................................................... 16

4.4.4 Display Messages ....................................................................................................................... 16

5. Reading Data from the MBD-2 ............................................................................................................ 17

6. Maintenance ........................................................................................................................................ 17

6.1 O-Ring ............................................................................................................................................. 17

6.1.1. Inspection and Replacement....................................................................................................... 17

6.2 Internal Battery (Detector & RTC) Replacement ............................................................................. 18

6.3 C-Rings ........................................................................................................................................... 20

7 Troubleshooting .................................................................................................................................. 22

7.1 Display Messages ........................................................................................................................... 22

7.1.1 Display Messages: Problems and Resolutions ........................................................................... 22

7.1.2 Parameter Error Codes: Problem and Resolution ...................................................................... 23

8. Technical Specifications ...................................................................................................................... 27

8.1 Radiological Characteristics ............................................................................................................ 27

8.2 Physical Characteristics .................................................................................................................. 27

8.3 Environmental Characteristics ........................................................................................................ 27

8.4 Electrical Characteristics ................................................................................................................. 27

9. Parts .................................................................................................................................................... 28

10. Dimensional Drawing ...................................................................................................................... 29

MBD-2 Operating Manual 2

15-00167, Rev 1

Page 3

List of Figures

Figure 1: MBD-2 Personal Dos imeter System .............................................................................................. 7

Figure 2: MBD-2 Physical Features .............................................................................................................. 7

Figure 3: MBD-2 Board with Detector Placement (relative to case) ............................................................. 7

Figure 4: MBD-2 Wrist Strap ......................................................................................................................... 9

Figure 5: Wrist Strap Orientation & Assembly .............................................................................................. 9

Figure 6: Preparing the Wrist Strap ............................................................................................................ 10

Figure 7: Donning the MBD-2 and Securing the Wrist Strap ...................................................................... 10

Figure 8: MBD-2 Battery Cover Removal ................................................................................................... 11

Figure 9: O-Ring Location ........................................................................................................................... 11

Figure 10: MBD-2 Battery Compartment and Markings .............................................................................. 12

Figure 11: MBD-2 Correctly Installed Battery Position ............................................................................... 12

Figure 12: MBD-2 and Main Battery Cover Thread Stops .......................................................................... 13

Figure 13: Battery Power Icon .................................................................................................................... 13

Figure 14: MBD-2 with Active Displa y ......................................................................................................... 16

Figure 15: MBD-2 with O-Ring Removed ................................................................................................... 18

Figure 16: MBD-2 without O-Ring and Inspection ...................................................................................... 18

Figure 17: MBD-2 with Installed O-Ring ..................................................................................................... 18

Figure 18: Internal Battery Cover and Compartment .................................................................................. 19

Figure 19: Installing the Internal Battery Cover........................................................................................... 20

Figure 20: C-Ring Removal......................................................................................................................... 21

Figure 21: C-Ring Replacement ................................................................................................................ 21

Figure 22: MBD-2 Replacement Parts ........................................................................................................ 28

List of Tables

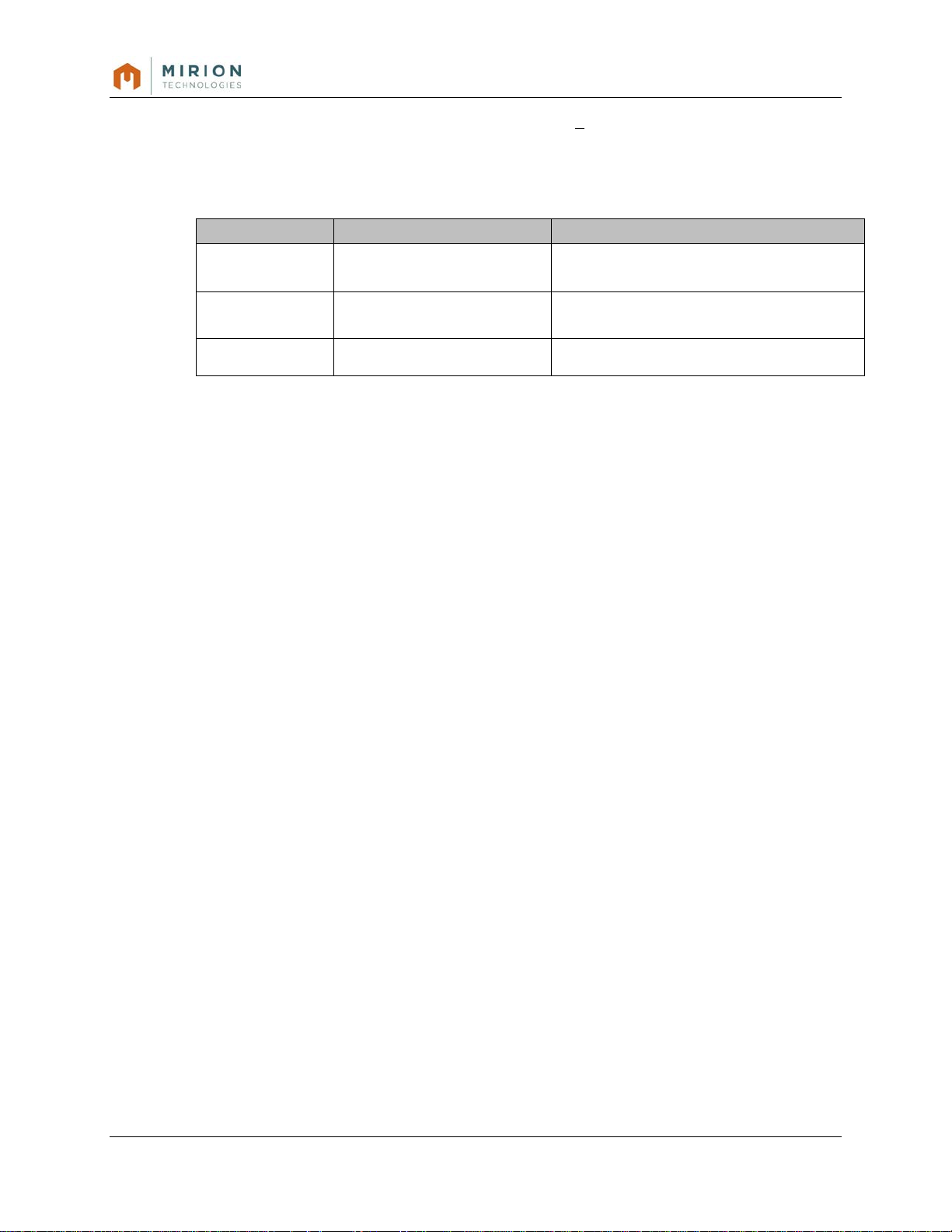

Table 1: MBD-2 Detector and Range Table .................................................................................................. 8

Table 2: MBD-2 Battery Icon Segments ..................................................................................................... 13

Table 3: MBD-2 Battery Display Messages ................................................................................................ 14

Table 4: MBD-2 Start-up & Diagnostics ...................................................................................................... 15

Table 5: MBD-2 Display Messages ............................................................................................................. 16

Table 7: Display Message Table ................................................................................................................. 22

Table 8: Parameter Error Code Table ......................................................................................................... 23

MBD-2 Operating Manual 3

15-00167, Rev 1

Page 4

FCC Compliance S t atement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired

operation.

Modifications: Any modifications made to this device that are not approved by Mirion Technologies Oy

may void the authority granted to the user by the FCC to operate this equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and us ed in acc or dance w ith the instr uct ions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/television technician for help.

Precautions concerning the use of 3V Lithium

Batteries

• Do not attempt to recharge or reenergize batteries.

• Exhausted batteries immediately shall be removed as soon as practical to prevent damage from

leaking batteries

o If batteries have leaked (dry or wet white residue), use personnel protective equipment such as

hand and eye protection to remove and clean.

• Do not dispose of batteries in fire.

• Do not dismantle batteries.

MBD-2 Operating Manual 4

15-00167, Rev 1

Page 5

1. Preparation for Storage or

Shipment

The following procedure is to be used if your MBD-2 must be stored or shipped for any

reason. First, remove the main battery (Section 3.2.1.1). Pack the complete MBD-2 along

with the proper maintenance documentation and turn it in to your Property Book Officer

(PBO) for shipment. PBO confirms the MBD-2 is packed properly.

1.1 Preparation for Long Term Storage

In hot, humid climates, the MBD-2 should be caref ul l y clean ed with a small amount of

isopropyl alcohol on a clean cloth to remove any skin oils that could support fungal growth.

Wipe down all visible surfaces.

MBD-2 Operating Manual 5

15-00167, Rev 1

Page 6

2. Introduction

The MBD-2 Personal Dosimeter is a device which incorporates the benefits of passive

radiation detection with active, self-reading and recording functionality. The MBD-2 has no

pushbuttons, switches, speaker, or LED and requires no user intervention for operation. The

MBD-2 is pre-configured for rapid issue from storage. The battery powered device includes

on-board digital processing to provide a self-reading, accurate and reliable dose

measurement on an integrated, non-reflective LCD display. Battery power level is reported on

the display using an interactive icon found in commercial electronics. Radiation

measurement data is recorded in device memory every 12 hours.

The MBD-2 provides radiation dose information to the wearer in the field. The MBD-2

displays the total deep absorbed dose D(10) (sum of deep gamma and deep neutron) and is

displayed in measurement units of cGy and Gy.

The MBD-2 uses Direct Ion Storage (DIS), Pin Diode and MOSFET detector technology

passive detectors. The passive DIS radiation detectors are continuously responsive to

radiation, with or without the field-replaceable main battery. The internal electronics provide

self-reading measurement display, digital memory, data logging, on-board diagnostic testing

during startup and NFC (Near Field Communication) read-only wireless communication. All

data resides in non-volatile memory for dose-of-record processing so there is no any danger

of losing stored data or configuration settings on main battery failure. The diagnostics

measure and display battery conditions and fault conditions of the device.

The MBD-2 is a sealed device for durability and hardness. There are no serviceable internal

parts. Maintenance parts are accessible and replaceable.

3. Description

3.1 Physical Descri ption

The MBD-2 personal dosimeter system is designed to be worn on the wrist w ith a 15- inch

hook and loop wrist strap. The MBD-2 can also be worn on the trunk of body (clipped to

lanyard, pocket, etc.). In this use case, the proper MBD-2 orientation is the display facing

away from the body.

The MBD-2 features a non-backlit LC D dis play, wireless (NFC read-only) communication,

adjustable wristband, and replaceable batteries.

The main battery compartment is accessible through a removable, self-securing battery cover

located on the back of the device. A sealed compartment below the main battery contains

additional batteries used to provide power to the DIS detectors and real-time clock (RTC).

The main battery compartment incorporates an O-ring seal to secure the battery from the

external environment.

MBD-2 Operating Manual 6

15-00167, Rev 1

Page 7

1. LCD Display

3. C-Ring (2) for Wrist strap

2. Screen Protector and Label

4. Battery Compartment Cover

Figure 1: MBD-2 Personal Dosimeter System

Figure 2: MBD-2 Physical Features

MBD-2 Operating Manual 7

15-00167, Rev 1

Figure 3: MBD-2 Board with Detector Placement (relative to case)

Page 8

Detector Type

Detector Code

Range

Deep

Gamma

DIS High Range

DH

0.1 cGy – 600 cGy

Deep

Neutron

ɣ+ n DIS

NL

0.001 cGy – 60 cGy

ɣ DIS

NG

0.001 cGy – 60 cGy

0.01 cGy – 14 cGy Cf-252 Moderated

0.01 cGy – 36 cGy Cf-252 Unmoderated

Tactical Pin Diode

NA

0.001 – 1250 cGy

The MBD-2 includes six separate detector elements:

• Three (3) elements for gamma measurements,

• Three (3) elements for neutron measurements.

Each detector element is listed below in Table 1, MBD-2 Detector and Range Table.

Displayed results including gamma (DA) or neutron (NA) accident detector elements are

provided in centigray (cGy) measurement units.

Table 1: MBD-2 Detector and Range Table

DIS Low Range DL 0.001 cGy – 60 cGy

–

Tactical MOSFET DA 1 cGy – 2500 cGy

–

Calculational Neutron Dose NG/NL

4. Operation

4.1 Principle of Operation

When the main battery is installed, the MBD-2 will power on, activate the LCD display,

initialize and perform diagnostics and operate according to its configurati on. See Section

4.4.2.

During operation, the MBD-2 continuously displays total absorbed dose (as measured),

battery status and periodic self-diagnostic checks. In the event of a device malfunc tion, an

error message will be displayed on the LCD as shown in Section 4.4.4, Common Display

Messages.

The MBD-2 will alert the wearer to the status of battery life by display battery icon and message, as shown in Section 4.3.1.3, Battery Display Indication.

When the main battery is depleted or removed, the MBD-2 detector elements continue to

respond to a radiation field. The detector elements remain active as they are powered by two

internal batteries. When restoring the main battery power, the MBD-2 will display the dose

measurement(s) including any exposure received during the time it was without main battery

power, however, the internal history will not account for the date and time of the

measurements while the main battery power was off.

MBD-2 Operating Manual 8

15-00167, Rev 1

Page 9

4.2 Installing the Wrist Strap

The Wrist Strap is a simple, durable accessory for affixing the MBD-2 to a wrist. The Wrist

Strap uses hook and loop material with a C-shaped ring to facilitate eas y donning and

securing to an outer garment sleeve.

a. Inspect the Wrist Strap seams for visibly loose stitching and frayed edges. Set aside any

Wrist Strap that app ears wor n.

Figure 4: MBD-2 Wrist Strap

b. Install the Wrist Strap by feeding the coarse “Hook” end through the bottom (6 o’clock

position) C-ring.

c. Loop the Wrist Strap through C Rings in the orientation as shown below – smooth side

facing away from the back case as shown in Figure 5: Wrist Strap Orientation and

Assembly.

Figure 5: Wrist Strap Orientation and Assembly

MBD-2 Operating Manual 9

15-00167, Rev 1

Page 10

E

F

d. Feed the Wrist Strap through its own ring to form a loop as shown below.

e. Pull the strap all the way through until it stops at the black metal loop. Feed the course

hook end back though the metal loop as shown below in Figure 6, Preparing the Wrist

Strap.

Figure 6: Preparing the Wrist Strap

f. Insert hand through the loop, pull the strap around itself and securely fasten as shown

below in Figure 7, Donning the MBD-2 and Securing the Wrist Strap

Figure 7: Donning the MBD-2 and Securing the Wrist Strap

MBD-2 Operating Manual 10

15-00167, Rev 1

Page 11

4.3 Batteries

4.3.1 Removal/Replacement of the Main Battery

4.3.1.1 Main Battery Replacement

a. Prior to replacing the battery, remove the wristband from at least one C-Ring so that the

battery cover is accessible.

NOTE: Battery change should not take place under direct rain-like conditions as water inside the battery compartment may cause premature battery discharge.

b. Turn the battery cover counter-clockwise to remove.

Figure 8: MBD-2 Battery Cover Removed

c. Verify the presenc e of the O-Ring. Inspect for integrity. See Section 6, Maintenance, for

additional O-Ring information.

Figure 9: O-Ring Location

d. Remove the main battery

e. Dispose the used battery in accordance with site requirements.

MBD-2 Operating Manual 11

15-00167, Rev 1

Page 12

Battery Orientation:

Positive (+) Side Up

Battery Model: CR2450N

(Renata brand recommended)

Figure 10: MBD-2 Battery Compartment and Markings

f. The battery compartment features imprints of battery orientation and model number.

g. Insert a new battery (Model CR2450, Renata brand preferred) into the compartment,

positive (+) side facing up, as shown below in Figure 11, MBD-2 Correctly Installed

Battery Position.

h. Confirm the presence of the O-ring prior to installing the battery cover. Ensure the O-Ring

is not twisted, warped or worn and that it lays flush on the surface flange. Refer to

Section 6.1, O-Ring for guidance.

i. Install the battery cover by turning clockwise.

The MBD-2 case and battery cover are designed with thread stops, as shown below in

Figure 12, MBD-2 and Main Battery Cover Thread Stop, to prevent wear and stripping

of the threads and also ensure a secure fit.

When installed and turned clockwise, the battery cover will stop in place when the threadstop is engaged.

MBD-2 Operating Manual 12

15-00167, Rev 1

Figure 11: MBD-2 Correctly Installed Battery Position

Page 13

Segments

Status

Voltage

Figure 12: MBD-2 and Main Battery Cover Thread Stops

4.3.1.2 Battery Display Indications:

The MBD-2 reports Main Battery power status with a standard battery icon:

Figure 13: Battery Power Icon

The icon segments, as shown below in Table 2, MBD-2 Battery Icon Segments, represent

the following power status:

Table 2: MBD-2 Battery Icon Segments

100% to 51% range Max to 2601 mV

51% to 26% range 2600 to 2401 mV

25% to 1% range 2400 to 2201 mV

MBD-2 Operating Manual 13

15-00167, Rev 1

Page 14

When the battery voltage is below 25% (approximately < 2400 mV), the MBD-2 will report

battery low power status on the display in the following conventions as shown below in Table

3: MBD-2 Battery Display Messages:

Table 3: MBD-2 Battery Display Messages

Battery Display Message Condition

Main PbAt permanent on display

Detector

Real-Time Clock

Note: there is no Low Battery message for the Main Battery. The battery icon provides visual

status.

Main Battery exhausted, replace

dbAt cycles display screen

dbAt permanent on display

No message Change with Detector Batte r ies

Detector Batteries are critically low (<25%)

Detector Batteries are exhausted, replace

MBD-2 Operating Manual 14

15-00167, Rev 1

Page 15

4.4 Start-up and Diagnostics

4.4.1 Start-up

When the battery is installed, the MBD-2 powers on. There are no switches to power on or off

the MBD-2.

4.4.2 Diagnostics

During start-up, the MBD-2 performs diagnostics and then becomes active with a live display.

Table 4 below describes the visual start-up operation:

Table 4: MBD-2 Start-up & Diagnostics

Start-up Operation and Effect LCD Display Indication

All LCD Segments illuminate for 3 seconds

Installed Firmware version (example)

Diagnostics Check OPEr (Operating Mode)

no.Er message indicates no errors have been identified.

If the MBD-2 becomes operational following an Error

during start-up, the PA.Er message will appear on the

Display, indicating an Error was recorded.

Initialization init

Measurement display: Dose Value (measurement value).

The Deep Total value displayed is a sum of the Gamma

and Neutron dose measurements.

NOTE: The MBD-2 may be stored with or without a main battery. When storing with a battery,

background radiation will accumulate dose to the detectors and record data to memory.

MBD-2 Operating Manual 15

15-00167, Rev 1

Page 16

OF:t

OF:n

4.4.3 Operation

The default LCD configuration displays Total Deep Dose (sum of Gamma and Neutron) and

cGy measurement units.

Figure 14: MBD-2 with Active Display

4.4.4 Display Messages

The MBD-2 may display messages or characters on the LCD under certain conditions of

operation:

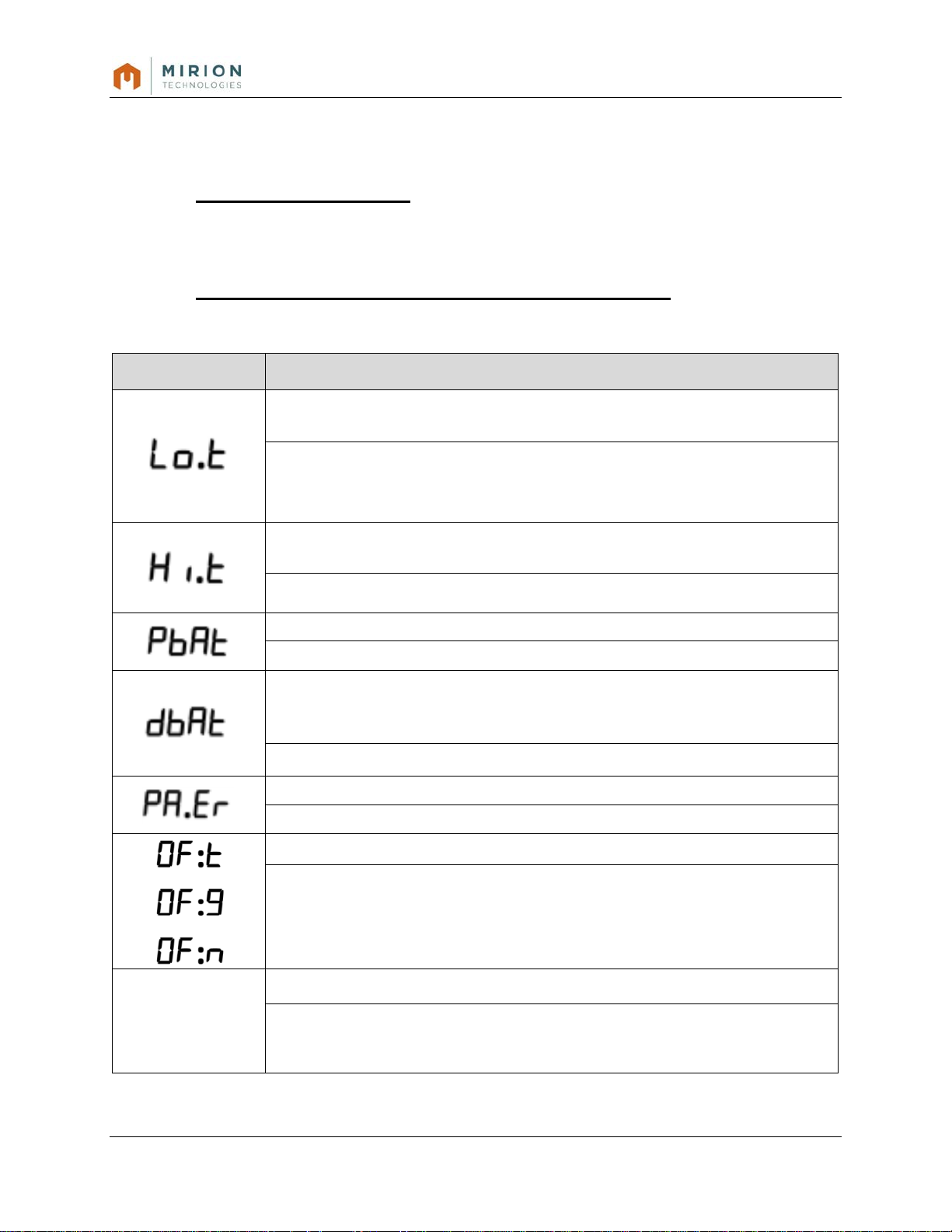

Table 5: MBD-2 Display Messages

Message Condition

Lo.t

Hi.t

PbAt

dbAt

PA.Er

OF:G

Operating temperature is below the lower temperature threshold (-10°C)

Operating temperature is above the upper temperature threshold (+50°C)

The Main Battery voltage is exhausted

The Detector Batteries voltage is low or exhausted

A parameter error has been detected.

One or more detectors is over-range or has been saturated

See Section 7, Troubleshooting for Display Message information.

MBD-2 Operating Manual 16

15-00167, Rev 1

Page 17

5. Reading Data from the MBD-2

The MBD-2 is a read-only device. Measurement data that is recorded and stored in the

MBD-2 memory can be transferred using a “smart” reader device (i.e.; smartphone with

software application [“App”]).

Measurement data is saved in MBD-2 resident memory and the newest values over period of

15 days is maintained in the NFC chip memory. The MBD-2 is configured to perform two daily

“reads”, where a dose or measurement record is saved to memory including a date and time

stamp. These records are maintained on the MBD memory and the NFC memory chip until

the space allotment is filled. Once the data is transferred, new data records are recorded into

the available space (i.e.; cyclic memory).

“Instant” data can be transferred from the MBD-2. When a reader device communicates with

the MBD-2 NFC chip, an instant read is initiated and the most current log data recorded will

be transferred with current total dose measurement. This can take place only when there is

dose value given on the display. So during ‘init’ phase or if the main battery is removed /

exhausted, no current dose value is available.

When an external NFC reader device is used, the data is transferred from the dosimeter over

the air in binary format. Using Mirion standard reader application, the results can be sent as

text files and transferred from the Smartphone to a computer for further action.

Data formats and NFC protocol information is available in external documentation.

6. Maintenance

6.1 O-Ring

The O-Ring provides the battery compartment a barrier and protection from moisture and dust intrusion. The O-Ring should be:

a. Confirmed to be in place whenever the main battery cover is opened

b. Inspected for condition when replacing the main battery.

6.1.1. Inspection and Replacement

a. Remove and inspect the O-Ring for indications of wear and degradation, to include, cuts,

shedding, twisting, or uneven placement.

MBD-2 Operating Manual 17

15-00167, Rev 1

Page 18

Figure 15: MBD-2 with O-Ring Removed

b. Ensure surface area for the O-Ring is clean.

Figure 16: MBD-2 without O-Ring and Inspection

c. Install the O-Ring on the flange. Run a fingertip around the top of the O-Ring to ensure it

is seated properly as shown in Figure 17, MBD-2 with Installed O-Ring below.

Figure 17: MBD-2 with Installed O-Ring

6.2 Internal Battery (Detector & RTC) Replacement

The internal battery cover should be opened onl y unde r a controlled environment.

Careful maintenance shall be ensured to prevent:

• misplacement of parts (screws securing the internal battery cover)

• contamination of the battery contact springs, which have direct access to the internal

electronics.

a. Remove the main battery cover and main batt ery in accordance with Step 3.2.1.1.

b. The Internal battery cover has three “Torx” pattern, size T6 screws.

MBD-2 Operating Manual 18

15-00167, Rev 1

Page 19

1

Internal Battery Cover

4 Detector Battery CR1025, 2 each

2

Torx (T6) screw 3each

5 Real Time Clock (RTC) Battery, 1 each

3

Main Battery Compartment

6 Battery Orientation Markings

WARNING

1

2

4 5 3

6

c. Remove the screws and set the cover aside on a clean surface.

NOTE: the screws can be withdrawn without removal where the elastomer gasket material on

the battery cover will hold the screw in place permitting removal, thus minimizing the risk of

screw misplacement.

Figure 18: Internal Battery Cover and Compartment

d. Replace two detector batteries and one RTC battery using Model CR1025, Renata

preferred. Ensure battery orientation is Positive (+) side up. The internal battery case

features imprints for battery orientation and model number.

If the batteries appear to have leaked, i.e.; there is white residue on the battery

and/or internal battery compartment surfaces; use personnel protective

equipment (i.e.; gloves, safety glasses, etc.) as applicable.

e. Dispose the used batteries in accordance with site requirements.

Note: the detector and real-time clock batteries shall be replaced together during scheduled

maintenance.

MBD-2 Operating Manual 19

15-00167, Rev 1

Page 20

WARNING

Both detector batteries must be replaced.

f. Prior to installing the battery cover:

• Inspect the battery cover for cracks.

• Inspect the gasket for wear or missing segments.

WARNING

The internal battery cover must be replaced if there is evidence of damage

and/wear that would preclude protection of the internal batteries.

g. Install the internal battery cover by positioning over the compartment and installing the

three Torx head screws. The screws are secure when the battery cover is seated and

flush with the case surface as shown below in Figure 19, Installing the Internal Battery

Cover

Figure 19: Installing the Intern al Battery Cover

WARNING

• Do not overtighten the screws as damage can occur to the battery cover and

case threads.

• Use only the prescribed Torx T6 screw, use of screw types will damage the

h. Install the main battery in accordance with 3.2.1.1, steps f-h.

threads.

• Never use power tools to install the screws.

6.3 C-Rings

The C-Ring is 1.9mm thick stainless steel ‘C” shaped loop which is affixed to the MBD-2 by

two insertion holes on opposite ends of the device case. The C-Rings are used for attaching

a wrist strap or other accessory. To remove and/or replace the C-Ring:

MBD-2 Operating Manual 20

15-00167, Rev 1

Page 21

a. Obtain a Snap-Ring plier or similar tool that will facilitate easy removal of the C-Ring. The

adjustable tines on the Snap-Ring plier tool should be extended to allow expansion, when

squeezed, so that it will be slightly wider than the width of the C-Ring.

b. Lift one end of the ring from the insertion hole and angle away to remove the C-Ring as

shown in Figure 3-3: MBD C-Ring Rem oval.

Figure 20: C-Ring Removal

c. To replace the C-Ring, grip the loose C-Ring with the Snap-Ring plier tool. Ensure that

when squeezing the Snap-Ring plier tool, the width of the C-Ring will be slig htly wider than

the case to facilitate easy replacement as shown in Figure 21: C Ring Replacement.

d. Position one side of the C-Ring into the insertion hole, then the other side.

e. Release the Plier tool so that the C-Ring is now secure.

f. Swivel the C -Ring to ensure fit.

Figure 21: C-Ring Replacement

MBD-2 Operating Manual 21

15-00167, Rev 1

Page 22

7 Troubleshooting

7.1 Display Messages

The MBD-2 will display messages or characters on the LCD display during certain conditions. This section describes the displayed messages, their meaning and how to correct:

7.1.1 Display Messages: Problems and Resoluti ons

Table 6: Display Message Table

Display Message Problem / Resolution

Problem: Operating temperature is below the lower temperature threshold of

-10°C. During this condition, the read-out process is not performed.

Resolution: Move device to a warmer environment. This can be within a pocket,

inside layers of a garment. Once the temperature is stabilized, the Lo.t message

is removed.

Problem: Operat ing temperature is above the upper temper ature thres hold of

+50°C. During this condition, the read-out process is not performed.

- - - -

(four dashes)

Resolution: Move the device to a cooler environment

Problem: If PbAt permanent on display, battery exhausted

Resolution: Replace with a new CR2450 battery, Section 3.2 Batteries

Problem:

• If dbAt cycling on the display, less 25% life remains

• If dbAt permanent on display, battery exhausted

Resolution: Replace with 3 new CR1025 battery, Section 3.2 Batteries

Problem: A Parameter Error has been detected, Section 6.1.2 Error Code Table

Resolution: Remove device from service. Return for Warranty Repair

Problem: One or more detectors has reached saturation

Resolution:

• OF:t Overflow Total Dose: the total dose has reached/exceeded 3,750 cGy

• OF:G Overflow Gamma: the gamma dose has reached/exceeded 2,500 cGy

• OF:n Overflow Neutron: the neutron dose has reached/exceeded 1,250 cGy

Problem: One or more detectors cannot report a measurement value(s)

Resolution: Remove device from service. Remove and replace battery and

observe display. If the problem persists, return device for Warranty Repair

MBD-2 Operating Manual 22

15-00167, Rev 1

Page 23

Parameter Error Code

Problem / Resolution

7.1.2 Parameter Error Codes: Problem and Resolution

Table 7: Parameter Error Code Table

Problem: After a system reset, result memory is found to be

inaccessible and the device resets itself. If no element

1

2 Battery i s Exhausted

3 REG UP Timeout

Result memory access failed

measurement has been successful before three self-resets (see

exception 7), the reset operation is disabled and the message

‘Err’ is displayed continuously.

Resolution: Remove device from service.

Problem: The Main Battery voltage is too low (<2200 mV volts).

No segment batter y icon and PbAt display message permanently

displayed.

Resolution: Replace the Main Battery with model CR2450

Problem: The time allowed for the read-out voltage to reach the

target value has expired. The condition can be caused by a

combination of sub-freezing temperature, low batter y capacity

and high internal resistance.

4

5

6

7 Device is resetting itself

AD Converter timeout

has occurred

ADC Failure has

occurred

Device is starting after

reset

Resolution: Restart device by removing and re-inserting batter y.

If error message repeats, remove device from service.

Problem: The device has reported an error due to the AD

converter not completing internal readout conversion

Resolution: Remove device from service for analysis. If error

occurs only in cold environments, the condition should be

reported so that device configuration can be modified to the

environment and prevent recurrence.

Problem: The device has reported an error when the AD

converter has detected maximum voltage in the input line.

Resolution: Remove device from service.

Problem: When the battery is replaced, the device has

performed an intentional hard reset from either: Watchdog Circuit

has reset the micro controller, or; external flash gamma pulse has

reset the device.

Resolution: Information message, error message disappears

after reset. If error message repeats, remove device from service

Message: If following Error #6, indication of an intentional hard

reset due to corruption of: parameter, data structure, calibration,

DAC, element, BLE reset, watchdog, RTC, NFC and others,

MBD-2 Operating Manual 23

15-00167, Rev 1

Resolution: Informational message, no action.

Page 24

8

Problem: Recombination has occurred in an ionization chamber

element a gamma flash or neutron burst event.,

Resolution: If display indicates corrupt or erratic segments,

from service.

Detector Element has

Overflown

Problem: The device has reported that one of more detector

elements has exceeded maximum dose.

Resolution: Requires a reset of the device. Remove device

from service.

9

A

B Display access failed

C

Recombination has

Occurred

DA Element has been

Disabled

DAC value is out of

bounds

Resolution: Requires a reset of the device. Remove device

from service.

Problem: Device restarts from reset after a battery change.

Resolution: If internal data memory is found to be corrupt,

device will perform a self-hard reset to clean memory with clean

data from flash memory. If error message occurs under normal

use (no high dose or neutron exposure), remove device from

service.

Problem: A The device has reported an error when attempting a

display update

physical damage has occurred to the LCD. If there is no visual

damage to the LCD, a possible corruption to the histogram data

exists.

If the problem is repeated without visual LCD damage, remove

Problem: the RAM memory has been corrupted

Resolution:

Problem: The device temperature is below the factory-set low

Device temperature is

D

E

F

MBD-2 Operating Manual 24

15-00167, Rev 1

too low

Device temperature is

too high

NFC chip is not

responding

limit of -10C. The read-out process is halted until the temperature

increases

Resolution: Move the device to a warmer environment and

stabilize. The Lo-T message disappears.

Problem: The device temperature is above the factory-set high

limit of C. The read-out process is halted until the temperature

decreases.

Resolution: Move the device to a cooler environment and

stabilize. The Hi-T message disappears.

Problem: The NFC chip is not responding due to an electronics

failure.

Resolution: Read-out is not possible. Remove device from

service.

Page 25

10

Problem: There is a failure in electronics or processor SPI

peripheral and reporting an error.

Shift register data

transfer has failed

Resolution: Restart device by removing and re-inserting

battery. If error message repeats, remove device from service.

11

12 Dose battery is too low

13

14

Dose battery is

exhausted

Incorrect result record

type

Incorrect result reading

position

Problem:

has decreased below the low limit. The default limit is 5500 mV.

dbAt display message permanently displayed.

Resolution: Replace internal dose batteries (3) with model

CR1025.

Problem: The Dose battery (Internal Detector Batteries) is

reporting <25% above the voltage low limit (5500). dbAt display

message alternates with dose value.

Resolution: No action required until 11 above message, or,

replace internal dose batteries (3) with model CR1025.

Problem: An invalid type has been identified during a memory

scan, indicating a failure or corruption in flash memory.

Resolution: Restart device by removing and re-inserting

battery. If error message repeats, remove device from service.

Problem: The device could not determine the reading result

position in the flash memory, due to a failure in flash memory

access or corruption of memory contents

Resolution: Restart device by removing and re-inserting

battery. If error message repeats, remove device from service.

The Dose battery (Internal Detector Batteries) voltage

Problem: The measurement result reading failed due to

15

16 (RESERVED)

17

18 (RESERVED)

MBD-2 Operating Manual 25

15-00167, Rev 1

Result record reading

failed

NFC device address has

been invalid

corruption of the result memory.

Resolution: Restart device by removing and re-inserting

battery. If error message repeats, remove device from service.

Problem: The I2C address of the NFC chip has been invalid at

device start-up. The chip has not been properly initialized by the

manufactured.

Resolution: The problem is resolved by the NFC device

firmware.

Page 26

19 Too early REG_UP

1B

Factory parameters

applied

Problem: The REG_UP I/O line signal was detected too early

due to a failure in the voltage block regulator.

Resolution: Restart device by removing and re-inserting

battery. If error message repeats, remove device from service.

Problem: The measurement result memory does not contain a

valid measurement result record due to empty or corrupt flash

memory

Resolution: Restart device by removing and re-inserting

battery. If error message repeats, remove device from service.

MBD-2 Operating Manual 26

15-00167, Rev 1

Page 27

Detector

Type

Designation

Range

DIS Low Range

Deep Gamma

DL

0.001 cGy – 60 cGy

DIS High Range

Deep Gamma

DH

0.1 cGy – 600 cGy

Tactical MOSFET

Deep Gamma

DA

1cGy - 2500 cGy

DIS

n

Deep Neutron

NL

0.001 cGy – 60 cGy

DIS γ

Deep Neutron

NG

0.001 cGy – 60 cGy

Calculational

NG/NL

0.01 cGy – 14 cGy Cf-252

Unmoderated

Pin Diode

Deep Neutron

NA

0.001 – 1250 cGy

Energy Range

Photon Effective

60 keV to 3 MeV (+20%)

IAW NVLAP Cat IA, II B, C

Neutron Effective:

550V to 2.13 MeV (+20%)

Dimensions:

2.08” x 2.2” x .91” (52.8 x 55.8 x 23.2 mm)

Weight:

2.0 oz. (57 gm) with batteries

Operating Temperature range:

-32°C to +52°C (dose accum ulation)

Storage Temperature range:

-54°C to +71°C

Humidity:

Relative humidity of 95% at +60°C

Water Resistance:

IP-67

Drop Test:

1 m height on hard surface in case

RF-RI-EMI Emission:

RS101, RS103, RS105, RE102 compliant

Vibration/Sand/Dust, Salt Fog & Fungus:

Compliant IAW MIL-STD 810G

Main Battery (Field Replaceable):

(1) Renata CR2450, 3.6 volt, lithium coin cell

Autonomy:

800-1000 hours

Internal (Controlled replaceable):

(2) Renata CR1025 6 volt, lithium coin cell

Autonomy:

> 6years

8. Technical Specifications

8.1 Radiological Characteristics

γ +

Neutron Dose

Moderated

0.01 cGy – 36 cGy Cf-252

8.2 Physical Characteristics

8.3 Environm ental Characteristics

8.4 Electrical Characteristics

MBD-2 Operating Manual 27

15-00167, Rev 1

Page 28

Item

Description

Part Number

1

MBD-2 Personal Dosimeter

MBD-2, complete unit only

RAF 1237 058

2

C-Ring (2)

C-Ring retainer for wrist band (each)

MBD-1003

3

Internal Batteries: Real-TimeClock (1), Detector (2)

Renata CR1025N Lithium Coin Cell

MBD-2000

4

Main Battery

Renata CR2450N Lithium Coin Cell

D20-2000

5

Internal Battery Cover

Internal Battery cover with integrat ed gas ket

2036 6808

6

Screws (3)

Screws, Torx, T6, Countersink head

2127 6039

7

O-Ring

O-ring for the Main Battery Compartment

2139 0079

8

Main Battery Cover

Battery Cover

2036 6807

9

Wrist Strap

Wrist Strap, hook & loop material

MBD-1004

9. Parts

Replacement parts for the MBD-2 can be identified in Figure 22, MBD-2 Replacement Parts below

Figure 22: MBD-2 Replacement Parts

MBD-2 Operating Manual 28

15-00167, Rev 1

Page 29

10. Dimensiona l Drawing

MBD-2 Operating Manual 29

15-00167, Rev 1

Loading...

Loading...