Page 1

PRO-2000 Series

Addressable Fire Detection and Control System

SYSTEM DISP LAY

DEF

ABC

GHI

1 2 3

MNOJKL

4 5 6

VWXSTU YZ

7 8 9

* 0 #

CONTINUE

MENU

EXIT

PQR

ENTER

HELP

SUPERVISORY

CONTROLS

ENABLED

ALARM

SUPER-

TROUBLE

ALARM

VISORY

FIRST

PREV

LAMP

MORE

TEST

NEXT

PANEL

POWER ON

FAILED

LAST

ISOLATE

STATUS

SERVICE

Installation and Operation Manual

LT-1012 Rev 4.1

Feburary 2016

Page 2

Page 3

PRO-2000 Installation and Operation Manual

Table of Contents

List of Figures .......................................................................................................................... iii

List of Tables............................................................................................................................ iv

PRO-2000 Series ...................................................................................................................... 1

The User Interface................................................................................................................ 2

Features Table...................................................................................................................... 3

PRO-2000, X2 SERIES - S/E/M ................................................................................................ 4

PRO-2000 X2S (Standard)................................................................................................... 4

PRO-2000 X2E (Expanded) ................................................................................................. 4

PRO-2000 X2M (Mimic)........................................................................................................ 4

PRO-2000 X2, Common Features........................................................................................ 4

General Installation Guidelines............................................................................................. 5

Special Handling................................................................................................................... 5

Enabling the Onboard Lithium Battery Backup..................................................................... 6

Cable Entry and Internal Routing.......................................................................................... 6

Grounding and Bonding........................................................................................................ 7

Enclosure Installation. ... ........................................................................................................ 7

Hookup of AC Power and Batteries...................................................................................... 11

Alarm Supply ........................................................................................................................ 11

AC Power Connection .......................................................................................................... 11

Installing Batteries in the Enclosure...................................................................................... 12

PRO-2000, X6 SERIES - S/B/E/M............................................................................................. 14

PRO-2000 X6S (standard).................................................................................................... 14

PRO-2000 X6B (blank)......................................................................................................... 14

PRO-2000 X6E (expanded).................................................................................................. 14

PRO-2000 X6M (MIMIC) ...................................................................................................... 14

PRO-2000 X6 Common Features......................................................................................... 15

General Installation Guidelines............................................................................................. 15

Special Handling................................................................................................................... 15

Enabling the Onboard Lithium Battery Backup..................................................................... 15

Cable Entry and Internal Routing.......................................................................................... 15

Grounding and Bonding........................................................................................................ 16

Enclosure Installation. ... ........................................................................................................ 16

Hookup of AC Power and Batteries...................................................................................... 21

Alarm Supply ........................................................................................................................ 21

Installing Batteries in the Enclosure...................................................................................... 21

PRO-2000 X0 Series - S/E/M.................................................................................................... 23

General Installation Guidelines............................................................................................. 23

Special Handling................................................................................................................... 24

Cable Entry and Internal Routing.......................................................................................... 24

Grounding and Bonding........................................................................................................ 24

Enclosure Installation. ... ........................................................................................................ 24

PRO-2000 Multi-Panel Systems.............................................................................................. 31

MAIN PROCESSING CARDS................................................................................................... 34

MPU - Main Processing Unit card......................................................................................... 34

LCD - Liquid Crystal Display card......................................................................................... 38

X6 and X0 series .................................................................................................................. 39

EXPANSION CARDS ........................................................................................................... 43

Communication Card............................................................................................................ 44

APS-14127-00 Auxiliary Power Supply ................................................................................ 46

12 Zone Supervised OUTPUT Card..................................................................................... 49

24/32 Zone Supervised Input Card....................................................................................... 52

ADI - Addressable Device Interface card................................... .... ...................................... . 55

MIMIC Driver Module.............. ... ... ... .... ... ... ... ... .... ... ... ... ........................................................ 59

i

Page 4

Table of Contents

LCD Expander Card............................................................................................................. 60

External Devices.................................................................................................................. 61

OPERATING INSTRUCTIONS................................................................................................. 71

The LCD Panel..................................................................................................................... 71

DISPLAY.............................................................................................................................. 73

Operating Conditions.............................................................................................................. 74

Appendix A - Battery Calculations ........................................................................................ 93

Appendix B - Compatible Devices......................................................................................... 101

Warranty & Warning Information........................................................................................... 116

ii

Page 5

PRO-2000 Installation and Operation Manual

List of Figures

Figure 1: LCD Display ................................................................................................................................... 2

Figure 2: X2, Synoptic sketch of the PRO-2000, X2 series........................................................................... 5

Figure 3: Lithium Battery Jumper .................................................................................................................. 6

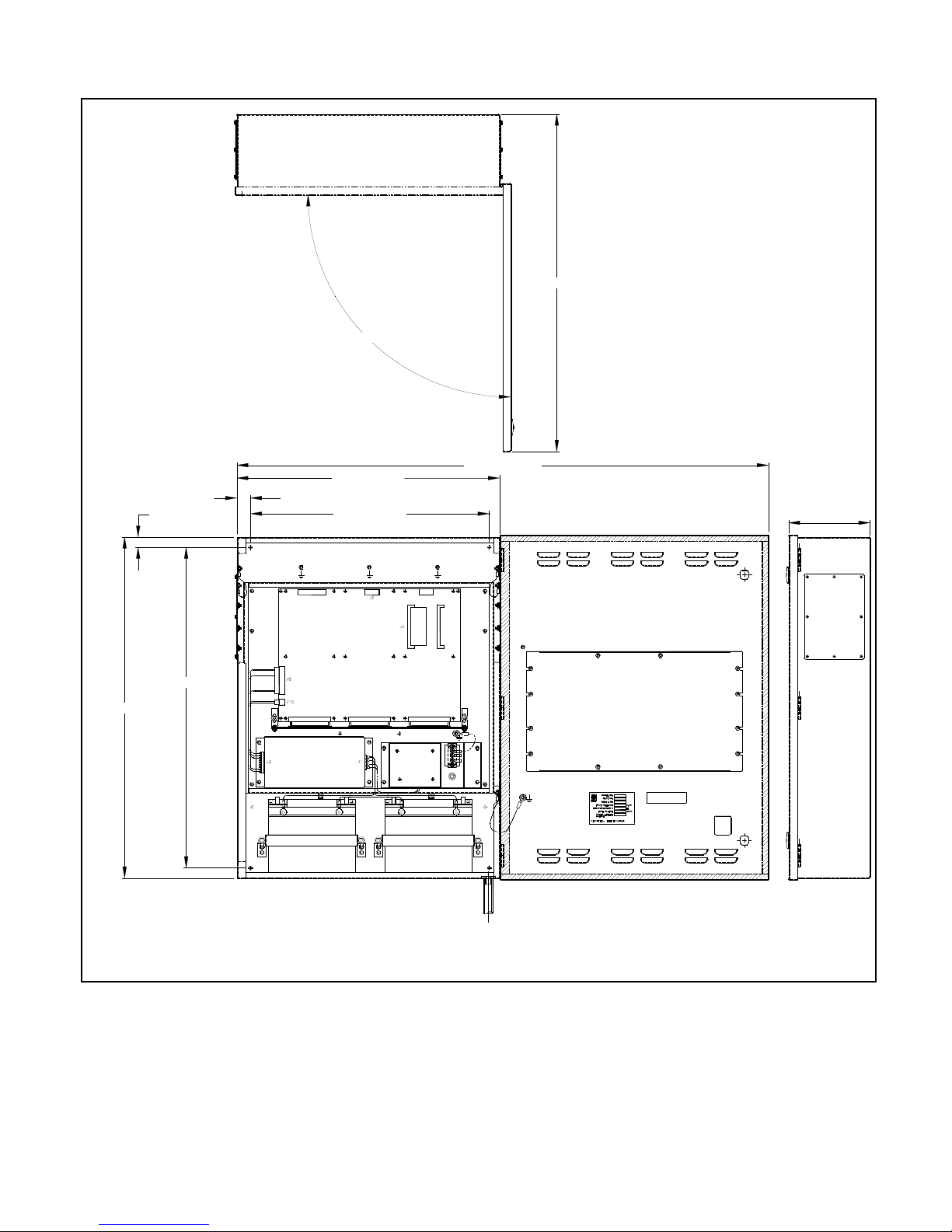

Figure 4: X2S, Installation Layout.................................................................................................................. 8

Figure 5: X2E, Installation Layout.................................................................................................................. 9

Figure 6: X2M, Installation Layout................................................................................................................. 10

Figure 7: Terminal Connections .................................................................................................................... 12

Figure 8: Battery Hookup............................................................................................................................... 13

Figure 9: Synoptic Sketch of the PR0-2000, X6 Series................................................................................. 14

Figure 10: Micro-processor (MPU)..... ... ... .... ... .............................................................................................. 15

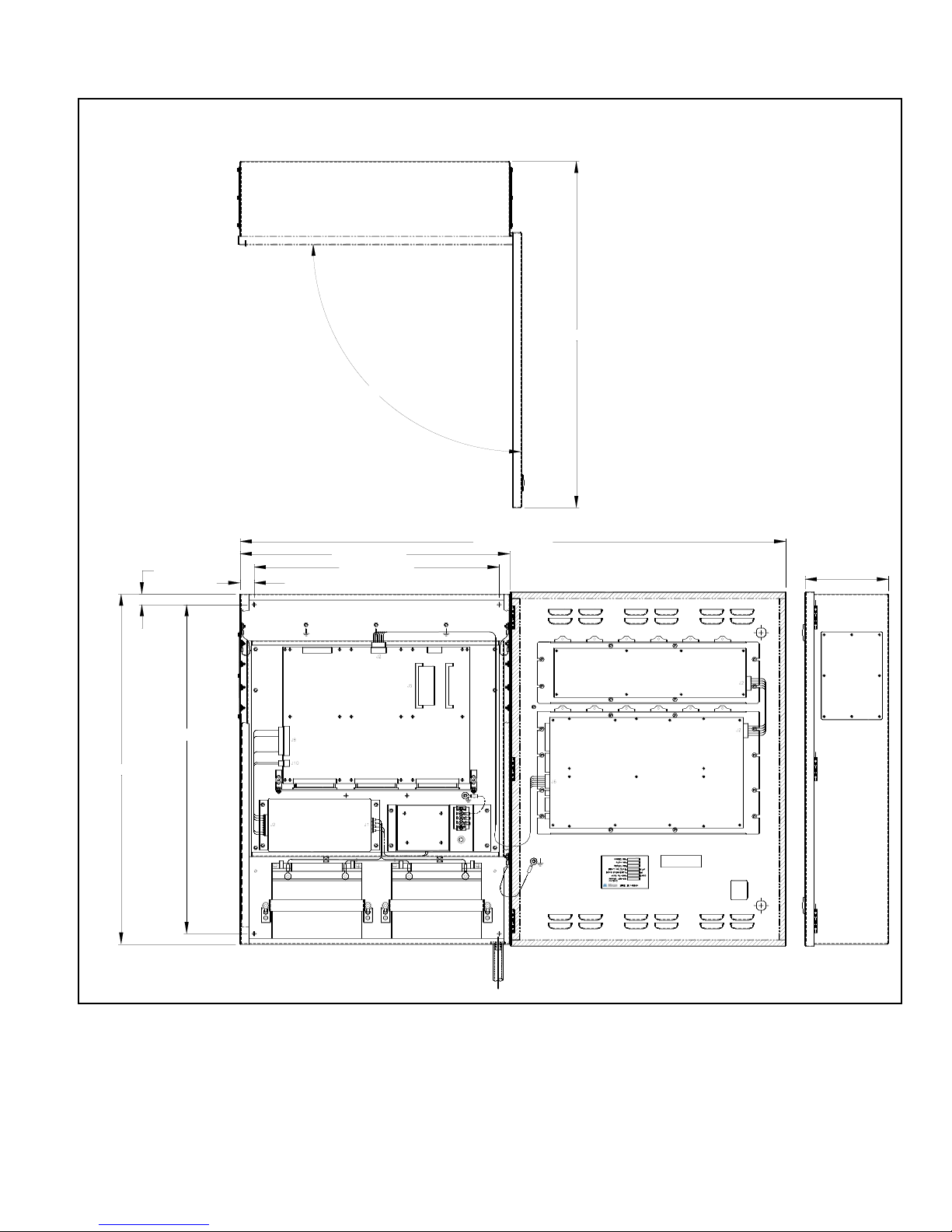

Figure 11: X6S, Installation Layout................................................................................................................ 17

Figure 12: X6B, Installation Layout................................................................................................................ 18

Figure 13: X6E, Installation Layout................................................................................................................ 19

Figure 14: X6M, Installation Layout.................................... ... .......................................... .... ... ... .................... 20

Figure 15: Battery Hookup..................... ... .... ... ... ... ... .... ... ... ... ........................................................................ 21

Figure 16: Synoptic Sketch of the PRO-2000, X0 Series.............................................................................. 23

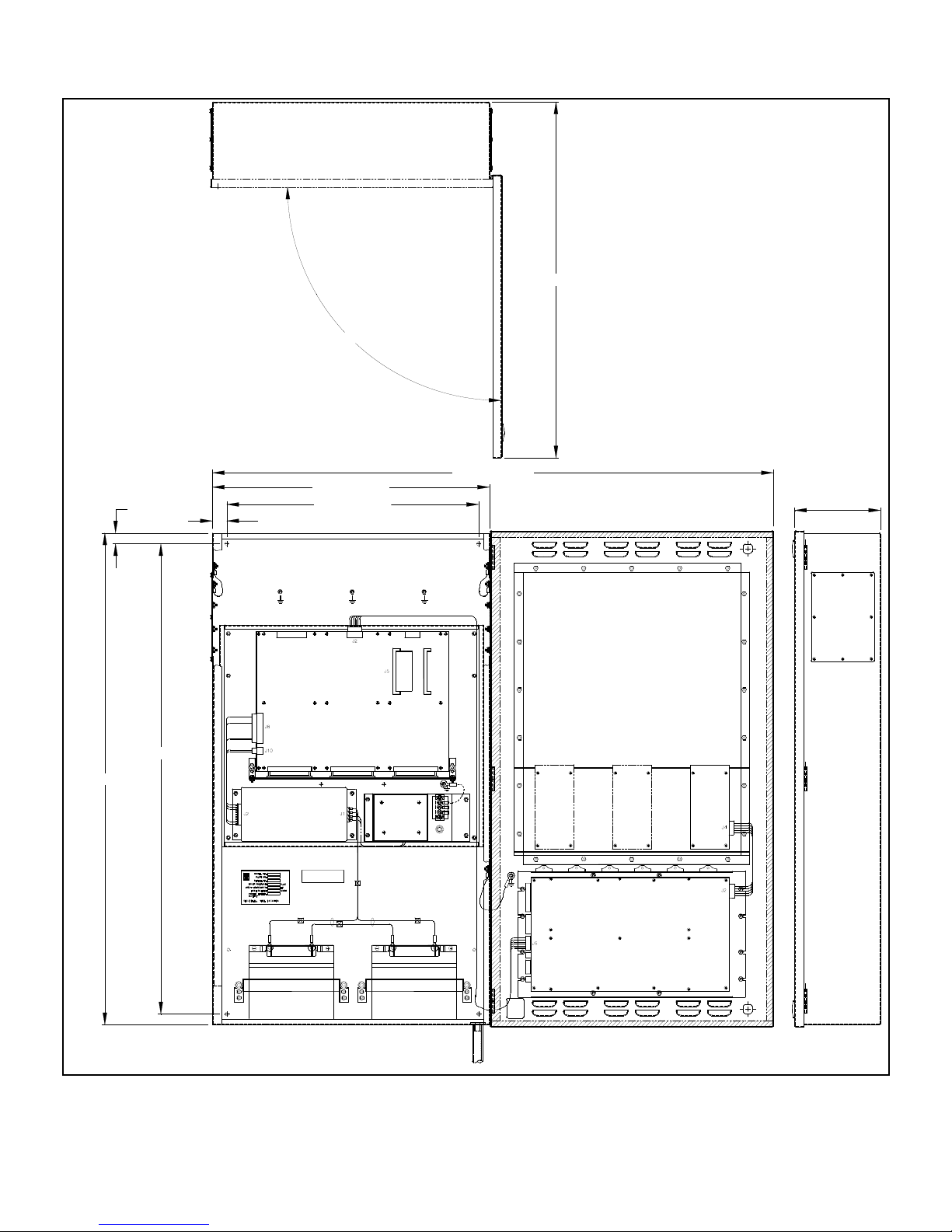

Figure 17: X0S, Installation Layout................................................................................................................ 25

Figure 18: X0E, Installation layout................................ ... ... ... .... ... .......................................... ....................... 26

Figure 19: X0M, Installation Layout.................................... ... .......................................... .... ... ... .................... 27

Figure 20: X0S, Installation Layout with Power Supply and Batteries........................................................... 28

Figure 21: X0E, Installation Layout with Power Supply and Batteries........................................................... 29

Figure 22: X0M Installation Layout with Power Supply and Batteries........................................................... 30

Figure 23: PRO-2000 Networked Panels..... ... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ....................... 31

Figure 24: X2 and X6 Network Wiring to a Repeater, X0.............................................................................. 32

Figure 25: Networking The X2 and X6 Using The Communication Card ...................................................... 33

Figure 26: MPU (Main Processing Unit) Card............................................................................................... 34

Figure 27: MPU Backplane Connectors........................................................................................................ 35

Figure 28: LCD Card ....................................................... ... ... .... ... ... ... .... ... ... ................................................. 38

Figure 29: LCD Backplane Connectors........ ... ... ........................................................................................... 38

Figure 30: Expansion Card and LCD Backplane........................................................................................... 40

Figure 31: Communication Card Connections............................................................................................... 44

Figure 32: Communication Card Wiring - Loop/Stub Mode........................................................................... 45

Figure 33: APS-14127-00 Auxiliary Power Supply....... ................................................................................. 46

Figure 34: APS-14127-00 Auxiliary Power Supply Connector ...................................................................... 47

Figure 35: APS-14127-00 Auxiliary Power Supply Typical Connection ........................................................ 47

Figure 36: APS-14127-00 Auxiliary Power Supply LED Indicators ............................................................... 48

Figure 37: 12 Zone Supervised Output Card................................................................................................. 49

Figure 38: Supervised Output Wiring ................. ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... ........................................... 51

Figure 39:

Figure 40: Supervised Input Wiring.... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... .......................... 54

Figure 41: ADI - Addressable Device Interface Card and Connections ........................................................ 55

Figure 42: ADI Driver Module........................................................................................................................ 55

Figure 43: ADI Card Wiring - Stub and Loop Mode....................................................................................... 57

Figure 44: ADI Card Wiring - Supervised Relay Outputs .............................................................................. 58

Figure 45: MIMIC Driver Module and Connections ............ ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ....... 59

Figure 46: LCD Expander Card and Connections........................................ ... ... .... ....................................... 60

Figure 47: 2 Wire Class B Initiating Circuit Configuration of Monitor Module................................................ 62

Figure 48: 2 Wire Style B Initiating Circuit Configuration of Monitor Module................................................. 63

Figure 49: Class B Indicating Circuit Wiring of Control Module..................................................................... 64

Figure 50: Typical Isolator Module Wiring - Using EOL Relay for Line Supervision...................................... 65

Figure 51: ADI CARD - Typical Wiring Diagram Number 1 for Control Module In Release Configuration.... 67

Figure 52: ADI CARD - Typical Wiring Diagram Number 2 for Control Module In Release Configuration.... 68

Figure 53: SI Card Typical Wiring Diagram for Releasing Circuit.................................................................. 69

Figure 54: SO Card Typical Wiring Diagram for Releasing Circuit................................................................ 70

Figure 55: LCD Panel.. ....................................... ... ... .... ... ... ... .... ... ....................................... .......................... 71

24/32 Zone Supervised Input Card.................................................................................... 52

iii

Page 6

PRO-2000 Installation and Operation Manual

List of Tables

Table 1: Table of features .................................................................................................................... 3

Table 2: MPU Pinouts .......................................................................................................................... 36

Table 3: MPU Relays ........................................................................................................................... 36

Table 4: MPU Switches ........................................................................................................................ 36

Table 5: MPU Jumpers ........................................ ... .... ... ... ... .... ...................................... .... ................... 37

Table 6: MPU LEDs .......................................................................... .... ... ... ... ... .................................... 37

Table 7: LCD Pinouts ........................................................................................................................... 41

Table 8: LCD Relays ............................................................................................................................ 41

Table 9: LCD Switches ......................................................................................................................... 41

Table 10: LCD Jumpers .............................. ... ... ... ... .... ... ... ... .... ...................................... .... ... ................ 42

Table 11: LCD LEDs ...................................................................... ... .... ... ... ... ... .... ... ............................. 42

Table 12: Communication card Pin outs ............................................................................................... 44

Table 13: Communication Card LEDs.......... ... ... ... ................................................................................. 44

Table 14: 12 Zone Supervised OUTPUT Card Pin outs - Screw Termination ....................................... 49

Table 15: 12 Zone Supervised OUTPUT Card Pin outs - DSUB Termination ....................................... 50

Table 16: External Power Supply Connections ..................................................................................... 50

Table 17: 12 Zone Supervised OUTPUT Card Jum pers ....................................................................... 50

Table 18: 12 Zone Supervised OUTPUT Card LEDs .. ... ... ... .... ... .......................................................... 50

Table 19: 24 Zone Supervised Input Card Pin outs .............................. ... ... ... ... .................................... 52

Table 20: 32 Zone Supervised Input Card Pin outs .............................. ... ... ... ... .................................... 53

Table 21: Supervised Input Card LEDs ................................................................................................. 53

Table 22: ADI Card Pin outs ........................................... ... ... .... ... ... ... .... ... ... ... ... .... ................................ 56

Table 23: ADI Card Jumpers .......... ... .................................................................................................... 56

Table 24: ADI Card LEDs ........... .... ... ... ................................................................................................. 56

Table 25: MIMIC Driver Module LEDs ............................... ... .... ... ... ... .... ... ... ... ....................................... 59

Table 26: MIMIC Driver Module LEDs............................. ... ... .... ... ... ... .... ... ............................................. 60

Table 27: LCD Expander LEDs.......... ... ... .... ... ... ... ... .... ... ... ... ................................................................. 60

Table 28: System Status ...................... ....................................... ... ... .... ... ... ... ... .... ................................ 72

Table 29: Indicators and Push buttons from Display Panel ................................................................... 73

Table 30: PRO-2000 - Device ID .......................................... .......................................... .... ... ... ............. 76

Table 31: MIMIC Driver Module LEDs ............................... ... .... ... ... ... .... ... ... ... ....................................... 86

Table 32a: Device Trouble ...................... .... ... ... ... ... .... ... ... ... ................................................................. 88

Table 32b: Device Trouble (continuation) ............................................................................................. 89

Table 33a: Card Trouble ...................................... ... .... ... ... ... ................................................................. 90

Table 33b: Card Trouble (continuation) ............................................. .... ... ... ... ... .... ................................ 91

Table 33c: Card Trouble (continuation) ................................................................................................. 92

Table 34: Battery Capacity - Panel Specific Configuration ............................. ....... ...... ....... ...... ...... ....... 93

Table 35: X2 Panel Standby Current Consumption - Main Power Supply ............................ ... ... ... .... ... 94

Table 36: X2 Panel Standby Current Consumption - Battery back-up .................................................. 95

Table 37: X2 Panel Alarm Current Consumption - Battery back-up ...................................... ................ 96

Table 38: X6 Panel Standby Current Consumption - Main Power Supply ............................ ... ... ... .... ... 97

Table 39: X6 Panel Standby Current Consumption - Battery back-up .................................................. 98

Table 40: X6 Panel Alarm Current Consumption - Battery back-up ...................................... ................ 99

Table 41: System Components Current Consumption - External Power Supply .................................. 100

iv

Page 7

PRO-2000 Installation and Operation Manual

PRO-2000 Series

The PRO-2000 is a sophisticated micro-processor-based, fire detection, monitoring and control series of panels.

The panels are fully on-site configurable.

The number and type of PRO-2000 panels depend on your application. They come in different versions-a n X2,

X6, and X0-allowing system scalability. The X2 and X6 versions are the main building blocks of the PRO-2000

series, with the X0 version acting as remote annunciators.

The connected detection, monitoring, and control devices can be configured in loop or stub configurations. The

status of the devices can be displayed by a single panel or by multiple p anels in a network. In a network

configuration, one panel is programmed as a Master, with all other panels configured as Slaves-reporting alarms

and device states to the Master panel.

The panels are designed to operate as a stand-alone fire detection and control panels, or as part of a network,

comprising several PRO-2000 panels, with a total capacity of 10,000 I/O points. The PRO-2000 panel performs

trend analyses of the measured values obtained from monitored sensors and adjusts individual alarm thresholds

to compensate for detector contamination or slow-changing environmental influences. These analyses ensure

reliable determination of the status (alarm, fault, or normal).

The basic configuration of a PRO-2000 panel comprises three main elements:

• An Enclosure containing the electronics necessary to run the system.

• A PRO-2000 panel may contain a combination of up to two expansion cards for the X2 series, and six

expansion cards for the X6. For example, Addressable Devices Interface (ADI), Communication, Supervised

Input, and Supervised OUTPUT cards. The enclosure size and contents depend on the configuration of your

protected installation.

• A Power Supply connecting to an external power source as well as Battery charger/Battery backup capability.

• A user interface between the system and the operator equipped with LED indica to rs, push button s, a Contr ol

Key Switch, and a Liquid Crystal Display (LCD).

• All PRO-2000 panels provide a 2 x 40 character, backlit, LCD display indicating the status (alarm, fault, or

normal) of each of the devices. The Expanded versions, X6E, X2E, and X0E pan els provide additional control

and display capabilities with the addition of 24 push buttons and 48 LEDs.

The panels can act as releasing units for applications where different extinguishing agents are used. A typical

releasing configuration comprises heat or smoke detectors, a pull station, an abort station, a set of extinguishant

cylinders, and audible/visual signaling devices. The p anel is factory programmed to meet the necessary

requirements for each zone.

Applicable Standards: NFPA 11, 12, 12A, 12B, 13, 15, 16, 17, 17A, 70, 72, 750, 2001

UL 864 Rev. 9, ULC S524, ULC S527-99

1

Page 8

PRO-2000 Series

ALARM

VWXSTU YZ

EXIT HELP

8

0

CONTINUE

#

MENU

7

ENTER

*

9

DEF

MNO

5

2

JKL

4

ABC

1

PQR

6

GHI

3

SYSTEM

SUPERVISORY

ENABLED

CONTROLS

RESET

SERVICESTATUS ISOLATE

POWER ON

FAILED

PAN EL

ACKNOWLEDGE

NEXT

LAST

PREV

FIRST

TEST

LAMP

MORE

VISORY

SUPER-

ALARM TROUBLE

DISPLAY

USER DEFINED SECTION

LCD DISPLAY - USER DEFINED MESSAGES

SYSTEM KEY PAD

CONTROL KEY SWITCH

USER CONTROL SECTION

DYSPLAY KEY PADBUZZER

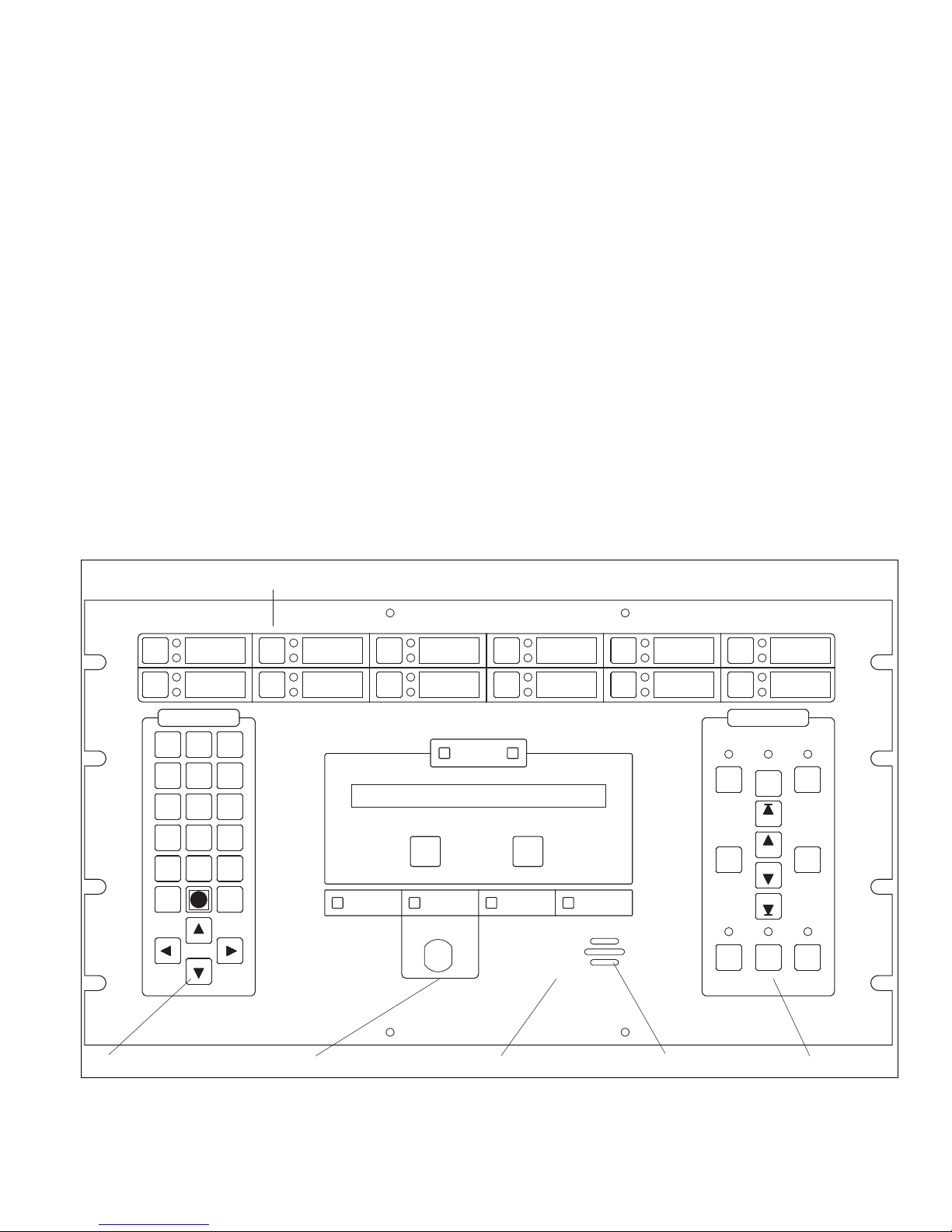

The User Interface

Mounted on the enclosure door, the LCD Display provides the user interface for the PRO-2000. The LCD Display

comprises an LCD card, a display/control escutche on with configu rable LEDs and push buttons, control key switch,

and a buzzer.

The built-in buzzer draws attention to the pane l on occurrence of any detected event. The buzzer sounds

intermittently at two different rates: fast for alarms and slow for all other conditions.

The display/control escutcheon interfaces between the operator and the panel. There are 4 sections:

•The Display section provides selectable display lists of the events you want to access. By selecting a Mode,

Alarm, Supervisory, Trouble, Status, Service or Isolate, the appropriate list appears in the LCD.

•The System section provides selections for system maintenance. For example, enable/disable printing, print

the event log, place/remove devices into/from service or isolate mode.

•The User Defined section contains 12 configurable push butto ns and 2 4 status LEDs-one red and one yellow

for each push button.

•The User Control section displays events and provides acknowledge and reset features.

Membrane push button controls acknowledge and silence alarms, reset the detection circuits, and test the panel

display. These controls also enable authorized service personnel to perform service functions. Using the System

keypad, the operator can select different maintena nce functions such as the event log, backlighting intensity, and

other maintenance related features.

The LCD Display features a 2 line by 40 character Liquid Crystal Display (LCD) indicating the status of the panel

and all connected input and OUTPUT devices. When an off-normal condition occurs, the first line displays event

occurrence and time, the second line provides a plain language description of the off-normal condition. The text

description for the zone or device is user-defined.

2

Figure 1: LCD Display

Page 9

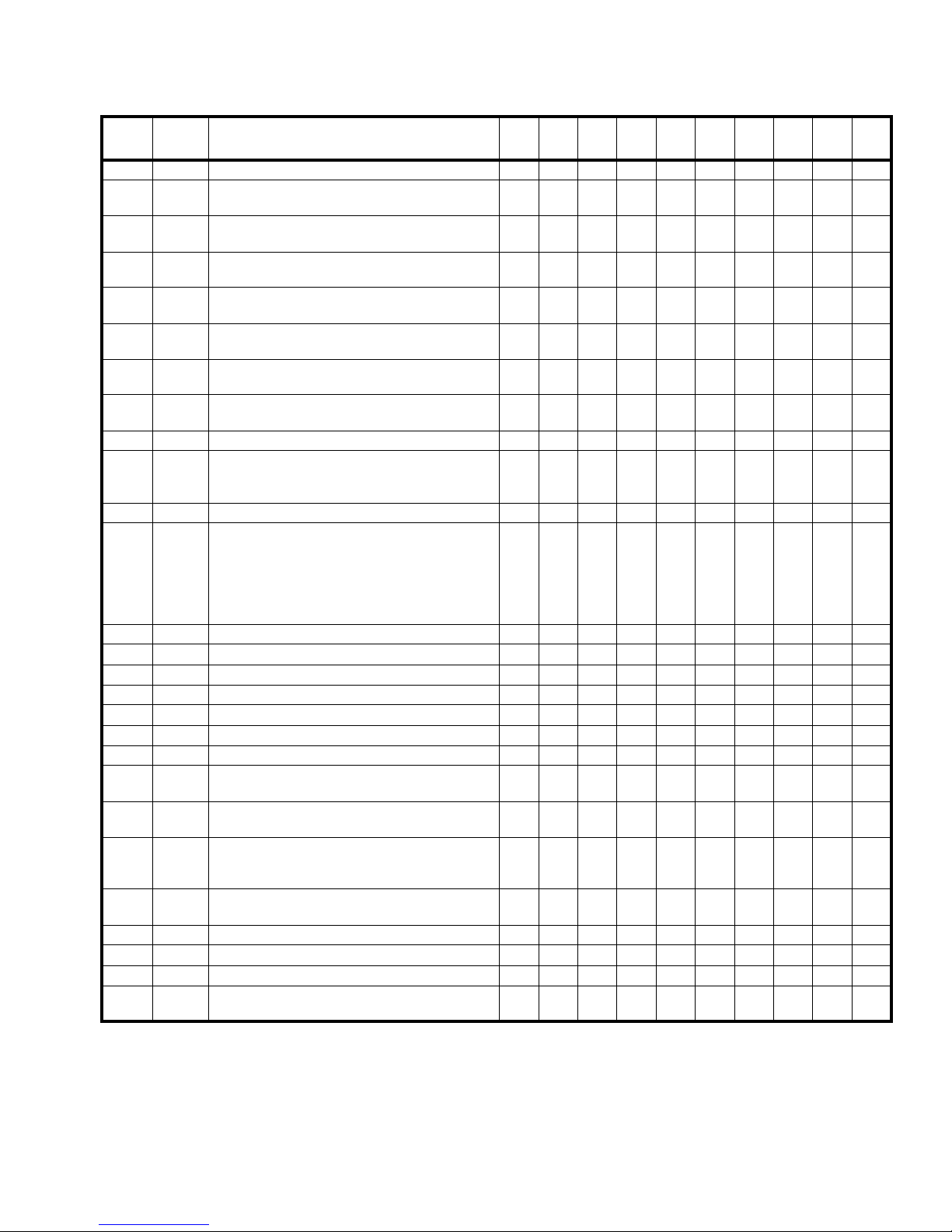

Features Table

PRO-2000 Installation and Operation Manual

USCG

UL/

ULC

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

Feature X2S X2E X2M X6S X6E X6M X6B X0S X0E X0M

Listing XXXXXXXXXX

Up to 1200 local detection/control devic es/zones

per panel

Up to 3600 local detection/control devic es/zones

per panel

Up to 5000 networked detection/control zones

per panel

Up to 10000 networked detection/control zones

per panel

Support for addressable devices (detectors,

monitor modules, control modules)

Support for conventional 2-wire initi ating devices

(shouting and non-shorting devices)

Support for notification circuits (dry conta cts and

supervised outputs)

Support for panel networking RS-422 loop/stub XXXXXXXXXX

Support for Printer, MODBUS interface,

diagnostic port RS-232 with or without

handshake

Support for repeater panels XXXXXX

User interfaces:

- 2 lines x 40 characters backlit LCD display,

- 24 programmable local LED indicators,

- 12 programmable local push buttons,

- Easy one key access to display lists, Alarm,

Supervisory, Trouble, Status, Service, Isolate

Adjustable panel brightness XXXXXX XXX

One person walk test XXXXXX XXX

Service and isolate modes XXXXXX XXX

Battery back-up real time clock and event log XXXXXX XXX

110 to 120VAC or 220 to 240VAC operation XXXXXXXXXX

Battery charger XXXXXXXXXX

Master Alarm and Trouble Relays XXXXXXX

All field wiring connected through removable

connectors with screw terminators

Isolated power supplies on each interface card

for exceptional noise immunity

Independent Ground fault detection circuits on

each interface card for easy Ground fault

tracking

Transient protection on all f ield con nect ions and

chassis

Wall mount enclosure XXXXXXXXXX

48 additional programmable local indicators X X X

24 additional programmable local push buttons X X X

Geographic mimic display containing up to 144

indicators (LED) and 72 push buttons

Table 1: Table of features

XXX

XXXX

XXX

XXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXX XXX

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

XXXXXXXXXX

XX X

3

Page 10

PRO-2000, X2 SERIES - S/E/M

PRO-2000, X2 SERIES - S/E/M

The PRO-2000 X2 Series are fire alarm monitoring and control units suitable for small to medium applications.

Large applications can be covered with networked panels.

The PRO-2000 X2 Series consists of three types of panels: the X2S, the X2E, and the X2M.

PRO-2000 X2S (Standard)

The X2S is the standard panel housed in a 23” x 24” (584 mm x 610 mm) enclosure. The X2S consists of a

processing and display unit which processes all field data and displays all event. It has the standard 2 lines by 40

character display with the associated display list controls and indicators and the standard 24 configurable indicators

(LEDs) and 12 configurable push buttons.

PRO-2000 X2E (Expanded)

The X2E is the expanded version housed in a 24” x 30” (610 mm x 76 2 mm) enclosur e. It has th e same fe atures as

the X2S plus an additional 48 configurable indicators (LEDs) and an additional 24 configurable push buttons.

PRO-2000 X2M (Mimic)

The X2M is the mimic version housed in a 24” x 41” (610 mm x 1041 mm) enclosure. It has the same features as

the X2S plus a geographic mimic providing a graphical representation of the protected area. The mimic contains up

to 144 indicators (LEDs) to provide visual feedback and 72 programmable push buttons.

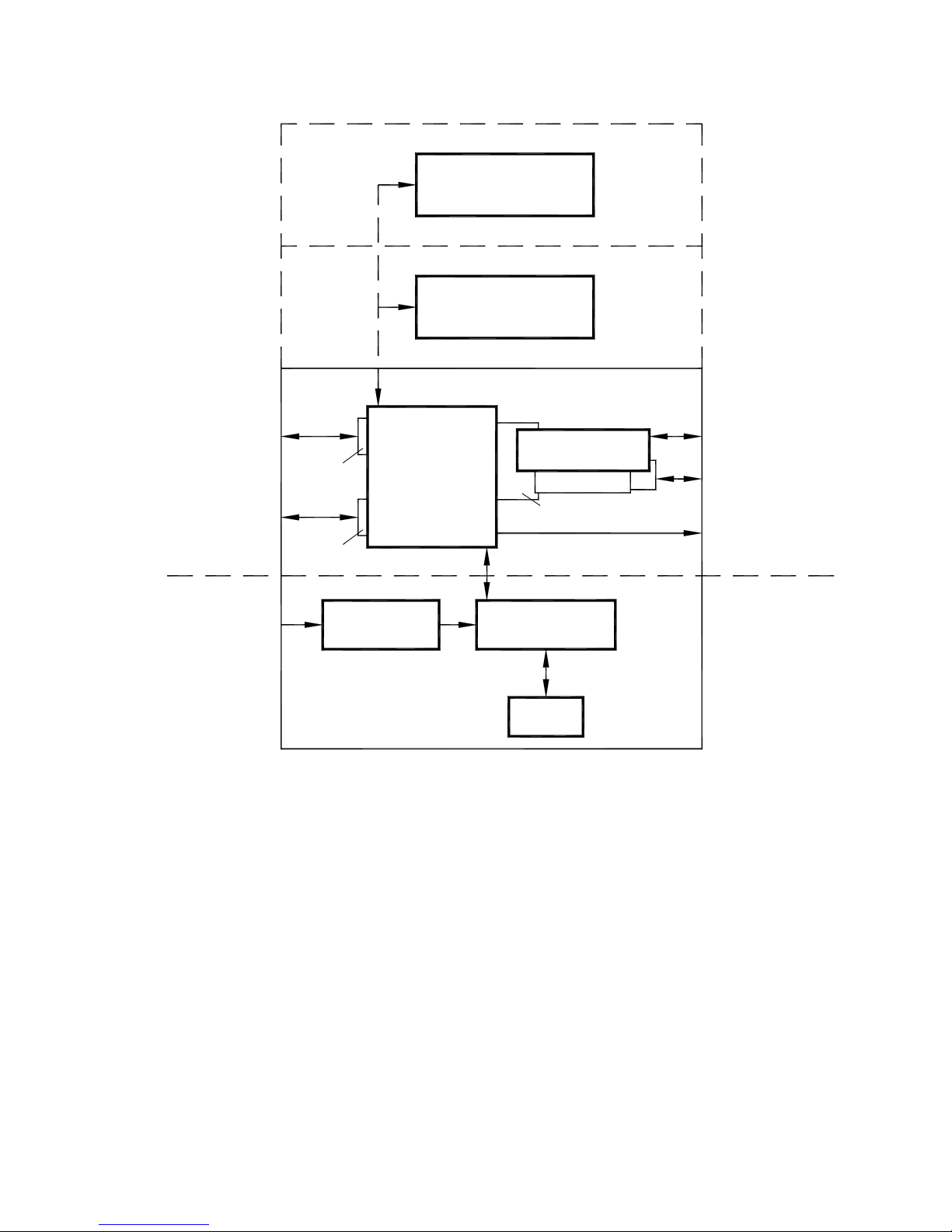

PRO-2000 X2, Common Features

The X2 Series supports communication and n etworking functions. The X2 panels can operate as standalone panels

or they can be networked in a master/slave configuration. The master can be programmed to monitor and control

the slave panels as well as monitor its own devices.

By adding an RS-232 communication module to the LCD card, the X2 panels can communicate with external

devices, such as printers or computers, via a standard modular phone jack. The RS-232 communication module

supports one channel. By adding an RS-422 communication module, the X2 panels can be networked to other

PRO-2000 panels. The RS-422 communication module supports 2 channels. The communication capabilities of the

X2 Series can be further expanded by the addition of Communication cards.

The printer used must be UL ITE Listed. ITE stands for Information Technology Equipment as per UL requirement.

The X2 panels can be expanded using up to 2 of the following expansion cards:

• Addressable Detector Interface (ADI) card - smoke/heat detectors, monitor modules, control m odules, and 4 on

board supervised/unsupervised outputs

• 24/32 Zone Supervised Input (SI) card - conventional detectors, shorting and non-shorting devices

• 12 Zone Supervised OUTPUT (SO) card - supervised outputs and dry contacts

• Communication Card - networked configurations

4

Page 11

PRO-2000 Installation and Operation Manual

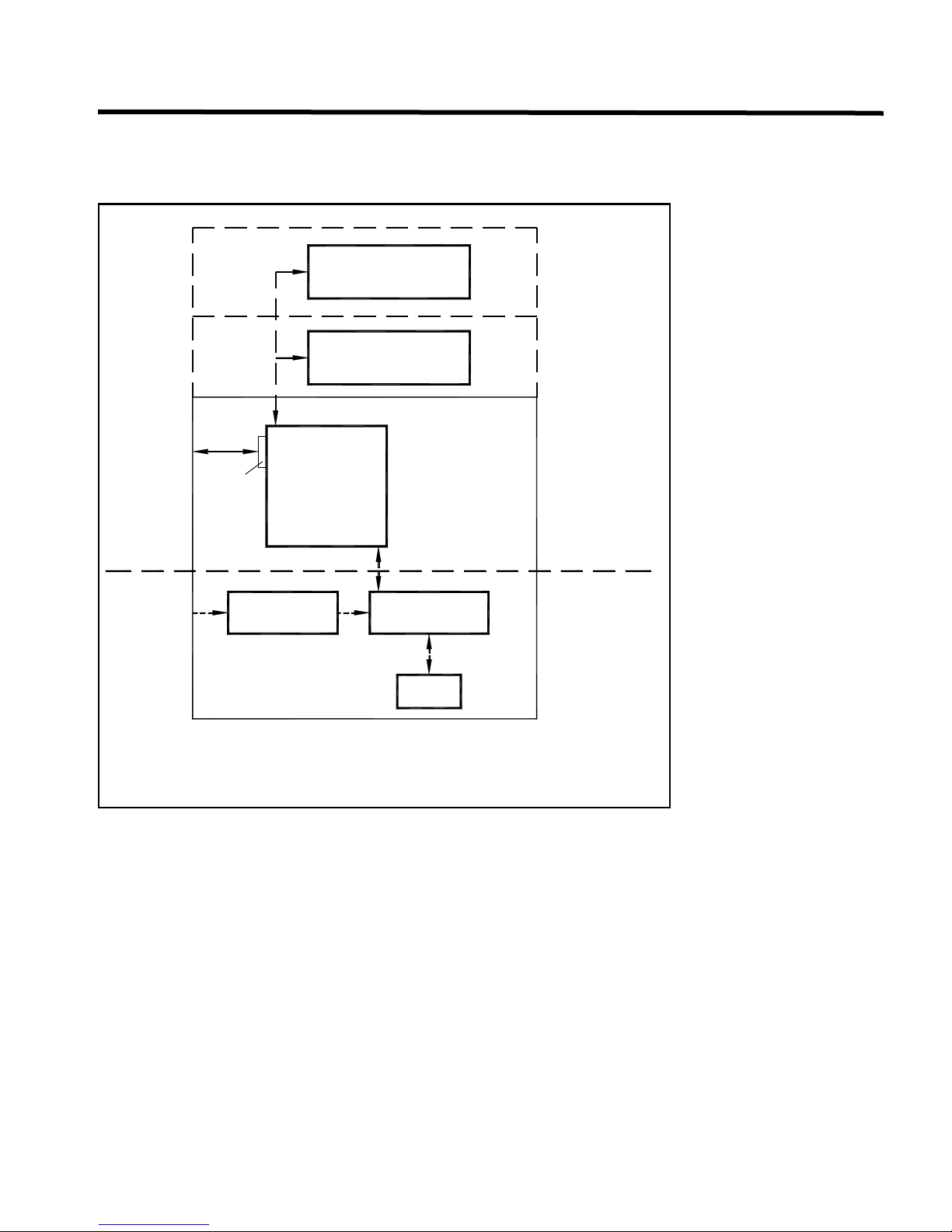

Geographic MIMIC

(MIMIC driver)

LCD expander

Processing and

Display Unit

(LCD)

Expansion cards

(Up to 2)

Transformer

115 or 220 VAC

Power supply

and

battery charger

Batteries

X2M

X2E

X2S

Power-Limited

Circuit

Detection and

Signaling

Communications

Master Alarm and

Fault Relays

Non Power-Limited

Circuit

Backplane

Networking

(RS-422)

Printer (RS-232)

AC Power

RS-422

Module

Module

RS-232

Circuits

General Installation Guidelines

X2 panels should be installed in a dry, clean, well lit secured area. No combustible or hazardous material should

be stored in the vicinity of the installed unit. The installation must comply with all local and/or national regulations

and codes of practice governing fire alarm system installation, electrical wiring, life safety, etc.

Special Handling

Circuit cards are to be stored in anti-static packaging and kept away from the sun and from direct sources of

intense UV light. The circuit card may be subject to degradation due to electrostatic discharge; therefore

grounding straps must be worn when handling the cards.

Figure 2: X2, Synoptic sketch of the PRO-2000, X2 series

5

Page 12

PRO-2000, X2 SERIES - S/E/M

LCD

JUMPER

LITHIUM BATTERY

Enabling the Onboard Lithium Battery Backup

The X2 panels are shipped with the jumper for the lithium battery disconnected. You must insert the jumper to

activate the battery backup for the real time clock and the RAM memory used for the event log. Jumper is located

on the LCD (JP6).

Cable Entry and Internal Routing

On the enclosure there are two removable cable entry plates. These plates are to be remove d, punched and reinstalled. If additional entry holes are required outside the cable entry plates, before punching cable entry holes:

1. Disconnect the wiring harness from the power supply to the LCD card.

2. Disconnect the door ground strap and remove the enclosure door with attached electronics.

3. Remove the mounting plate with attached power supply from the enclosure base.

Cable entry holes must be punched in accordance with the following criteria:

• Separate holes are required for the entry of Power-Limited and Non -Power-Limited circuit cables.

6

Figure 3: Lithium Battery Jumper

Page 13

PRO-2000 Installation and Operation Manual

• Centre-to-centre spacing between an entry hole for Power-Limited circuit cables and an entry hole for NonPower-Limited circuit cables must not be less than two (2) times the diameter of the larger entry hole.

• Sufficient clearance must be provided around each hole to allow for any required conduit fittings, cableclamps, lock nuts, washers or other hardware.

• Exclusive entry holes must be provided for the Primar y AC Supply cab le and for the External Standby Supply

(battery backup) cable.

• At no point inside the enclosure must the spacing between power-limited and non-power-limited circuit

conductors be less than 6.4mm (114 inch).

Wire length inside the enclosure should be kept to a minimum.

Cables must not interfere with, or touch any circuit card components other than the intended co nnector terminals.

Grounding and Bonding

All supply and device wiring must be grounded and bonded in accordance with applicable local regulations governing the wiring of

Fire Alarm Systems.

Enclosure Installation

All cable entry holes should be punched out prior to installation of base.

Ensure wall or structure to which the enclosure base is being mounted is capable of su pporting a fully loa ded unit.

Sufficient clearance must be provided around the unit to allow the enclosure cover door to be fu lly opened (180° )

without impediment. The enclosure box may be semi-flush mounted provided no less than 5 cm (2 inches) of the

box frame protrudes from the wall surface.

The top of the enclosure should be no more than 2.0 meters (6.7 feet) above the finished floor.

Recommended mounting hardware: four 1/4” pan head screws (if bolts are used, four suitable flat washers are

required).

1. Remove the ground strap (14 gauge, green) between the enclosure base and door by loosening and removing

the ground stud nut and star washer.

2. Disconnect the power harness connectors at J5 and J7 on the LCD card.

3. Remove the enclosure door from th e slip hin g es .

4. Remove the mounting plate, with attached power supply, from the enclosure base.

5. Secure the enclosure to wall using the for ¼“ panhead screws.

6. Align the mounting plate, with attached power supply, to the enclosure base threaded studs and secure with

attaching nut and washer.

7. Re-install the door and ground strap between the door and the enclosure base.

8. Reconnect the power harness connectors at J5 and J7 on the LCD card.

7

Page 14

PRO-2000, X2 SERIES - S/E/M

J2 J1

J11J10

J12

1

2

E

S

F

U

F

.

E

S

U

F

.

E

F

.

U

23.10" [586.74mm]

24.00" [609.60mm]

7.16" [181.94mm]

21.00" [533.40mm]

22.20" [563.88mm]

1.20" [30.48mm]

46.76" [1187.60mm]

90°

29.68" [753.92mm]

+-

-

+

0.90" [22.86mm]

Figure 4: X2S, Installation Layout

8

Page 15

PRO-2000 Installation and Operation Manual

7.16" [181.97mm]

J2

J2

INPUT FREQUENCY:

INPUT VOLTAGE:

POWER LIMITED:

FUSE RATING:

OUTPUT

AMPS

V.AC

HZ

PART NO:

SERIAL NO:

MODEL NO:

J1J2

J7

J5

21.00" [533.40mm]

1.20" [30.48mm]

23.10" [586.74mm]

46.76" [1187.60mm]

28.20" [716.28mm]

0.90" [22.86mm]

30.00" [762.00mm]

90.00°

29.68" [753.92mm]

E

F

U

F

.

F

.

U

S

E

.

F

U

S

E

Figure 5: X2E, Installation Layout

9

Page 16

PRO-2000, X2 SERIES - S/E/M

7.16" [181.97mm]

90.00°

29.68" [753.92mm]

0.90" [22.86mm]

39.20" [995.68mm]

41.00" [1041.40mm]

1.20" [30.48mm]

23.10" [586.74mm]

46.76" [1187.60mm]

21.00" [533.40mm]

Figure 6: X2M, Installation Layout

10

Page 17

PRO-2000 Installation and Operation Manual

Hookup of AC Power and Batteries

The Power Supply provides a regulated 28 VDC to the PRO-2000 series and provides charge current to the

optional backup batteries. As the batteries are kept permanently charged, power is continuously provided

(Uninterruptible Power Supply or UPS). The power supply AC rat ing s ar e as fo llow s:

120 V version: V = 120 VAC nominal, I = 1.5 A, frequency 60 Hz

220 V version: V = 220 VAC nominal, I = 0.8 A, frequency 50 Hz

LEDs are visible on the Power Supply indicating the functional status of the unit. As the Power Supply is

convection cooled, no fans or blowers are required. The transformer and power supply mount directly on the

mounting plate.

A built-in battery charger maintains the batteries at full capacity. After extended power outages, the charger

restores the batteries to full capacity. Short circuit, over-voltage, and brownout monitoring circuits protect all

powered components by switching to the batteries whenever a tr ouble condition exists in the power supply.

Alarm Supply

Power to the alarm devices in a system must be supplied from a separate battery backed-up Power Supply which

is "UL listed (ULC listed in Canada)" for fire protective signal system use.

AC Power Connection

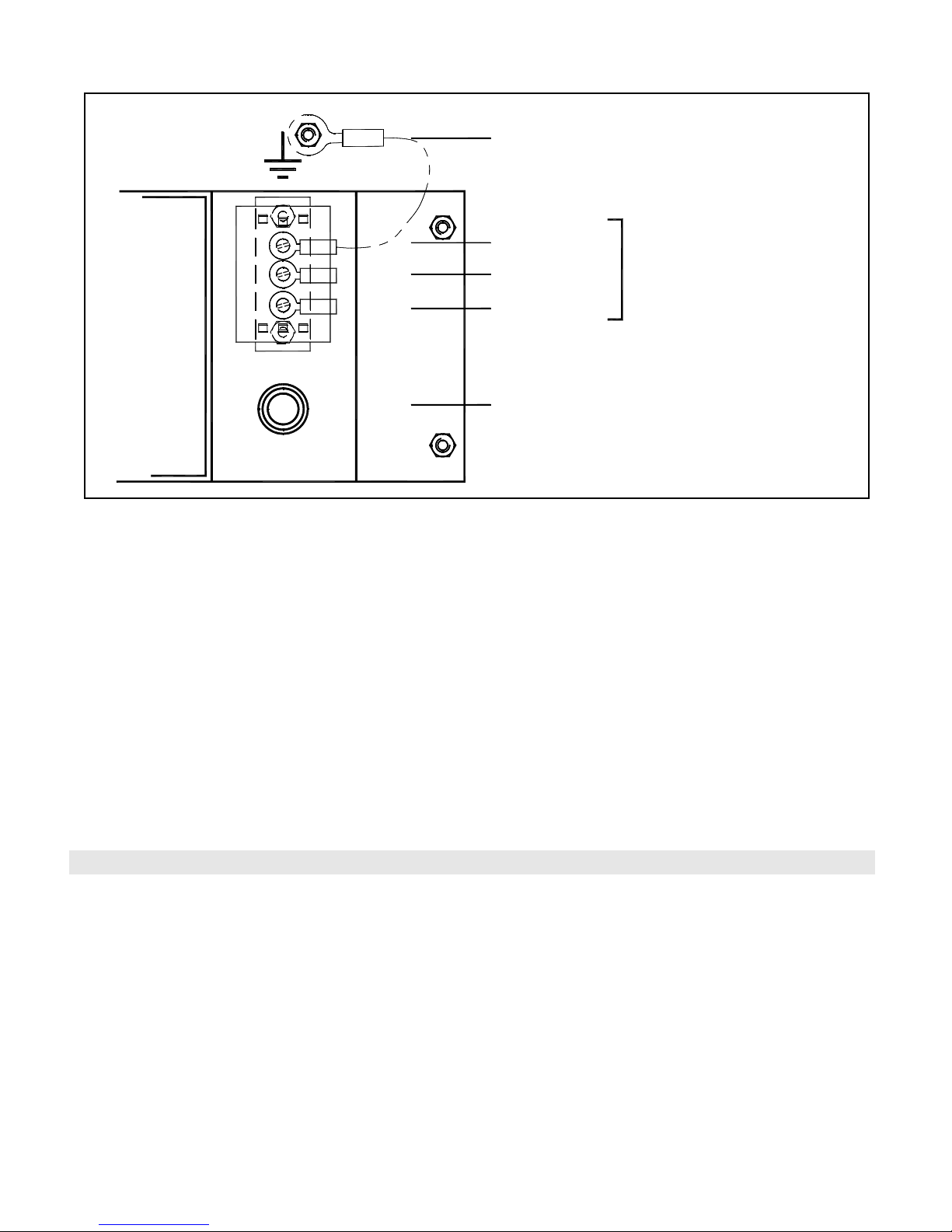

CAUTION: Ensure all voltage sources are disconnected from the panels before installing or removing cards.

1. Remove terminal cover from terminal block, TB1, located on the transformer bracket.

2. Connect Primary supply Ground wire (green) to Ground stud.

3. Connect Primary supply Neutral wire (white) to TB1 NEUTRAL terminal.

4. Connect Primary supply Line wire (black) to TB1 LINE terminal.

5. Replace and secure terminal cover on TB1.

6. Maximum 150 VAC to Ground.

11

Page 18

PRO-2000, X2 SERIES - S/E/M

S

.

F

E

.

F

U

F

E

U

E

.

F

U

S

GROUND

NEUTRAL

LINE

GROUND STUD

FUSE

NON POWER

LIMITED CIRCUIT

Figure 7: Terminal Connections

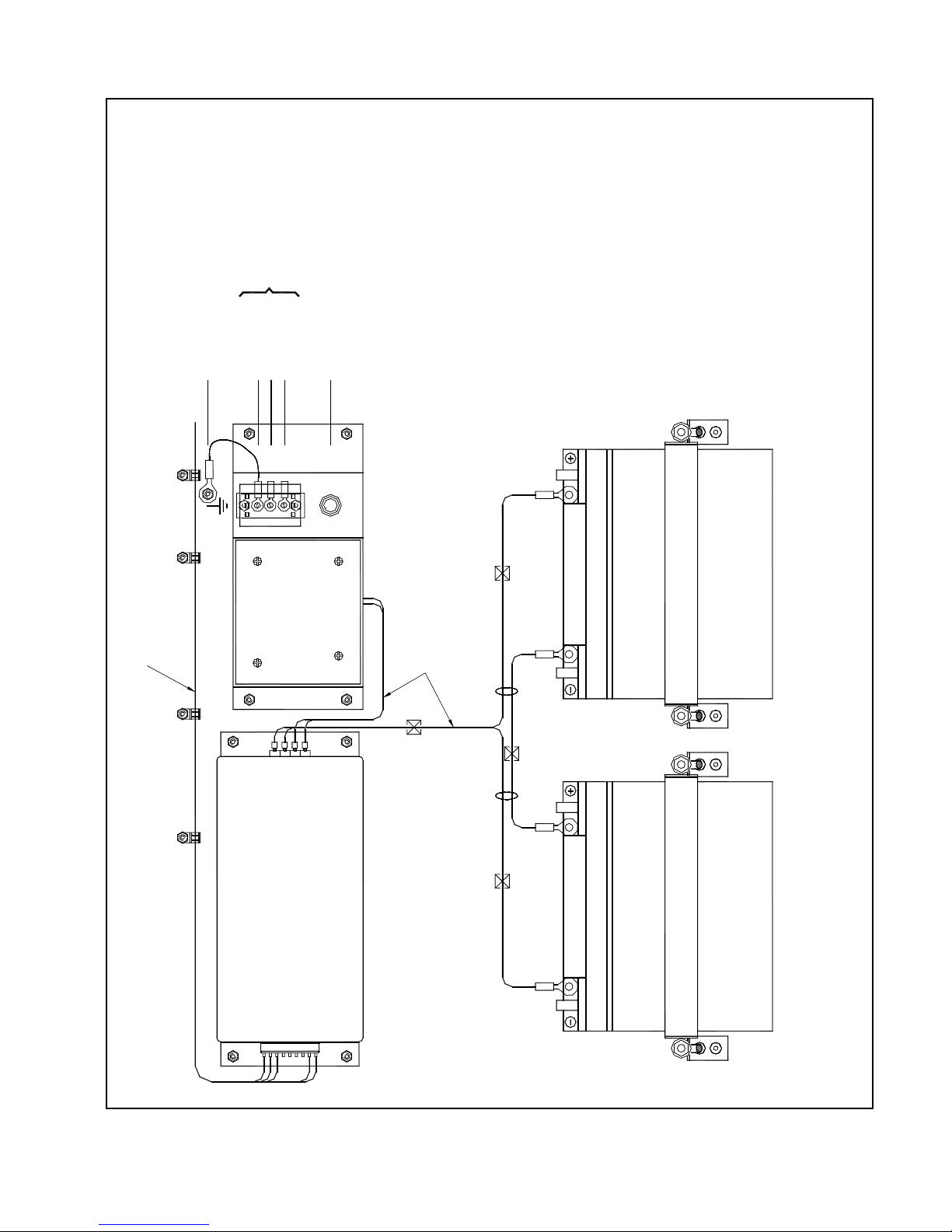

Installing Batteries in the Enclosure

The following instructions apply only to systems requiring 42 Amp-Hours or less of battery back-up capacity.

1. Remove battery retaining hardware.

2. Place two new fully charged 12V batteries on the bottom of the enclosure. Use 12V sealed lead-acid batteries.

3. Connect jumper between the batteries 'A' and 'B' poles (see Figure 8).

4. Connect black wire terminal to battery 'A'.

5. Connect red wire terminal to battery 'B' (+).

6. Replace battery and secure with retaining hardware.

For the Calculation of Battery Requirements, refer to Appendix A.

12

Page 19

C

I

R

C

U

I

T

S

N

O

N

P

O

W

E

R

-

L

I

M

I

T

E

D

C

I

R

C

U

I

T

S

N

O

N

P

O

W

E

R

-

L

I

M

I

T

E

D

B

F

U

S

E

(

F

1

)

L

I

N

E

N

E

U

T

R

A

L

G

R

O

U

N

D

S

T

U

D

G

R

O

U

N

D

A

J

U

M

P

E

R

P

O

W

E

R

-

L

I

M

I

T

E

D

C

I

R

C

U

I

T

R

E

D

B

L

A

C

K

U

F

E

.

F

U

S

E

.

F

U

F

S

E

J

1

J

2

Figure 8: Battery Hookup

PRO-2000 Installation and Operation Manual

13

Page 20

PRO-2000, X6 SERIES - S/B/E/M

Addressable Fire Detection and Control System

AL

ARM

SY

STEM DISPLAY

123

456

789

*0#

EXIT

HELP

CONTINUE

MENU

ENTER

SUPERVISORY

ENABLED

CONTROLS

POWER ON

FAILED

PANEL

NEXT

LAST

PREV

FIRST

TEST

LAMP

MORE

VISORY

SUPER-

ALARM

TROUBLE

SERVICE

STATUS

ISOLATE

VWXSTU YZ

DEF

MNOJKL

ABC

PQR

GHI

PRO-2000, X6 SERIES - S/B/E/M

The PRO-2000 X6 panels are fire alarm monitoring and con trol unit s suit able for medi um to large application s. Very

large applications can be covered with networked panels.

The PRO-2000 X6 Series consist of four types of panels: the X6B, the X6E, the X6M and the X6S.

PRO-2000 X6S (standard)

The X6S is the standard panel housed in a 24" x 30" (610 mm x 762 mm) enclosure. The X6S consists of a

processing unit (MPU to process all field data and a display unit (LCD) to display all events. The LCD has a

standard 2 line x 40 character display with the associated display list controls and indicators and the standard 24

configurable indicators (LEDS) and 12 configurable push buttons.

PRO-2000 X6B (blank)

The X6B is the blank panel housed in a 24" x 30" (610 mm x 762 mm) enclosure. It has the same features as the

X6S, but without a display unit (LCD).

PRO-2000 X6E (expanded)

The X6E is the expanded version housed in a 24" x 30" (61 0 mm x 762 mm) enclosure. It has the same features as

the X6S plus an additional 48 configurable indicators (LEDs) and an additional 24 configurable push buttons.

PRO-2000 X6M (MIMIC)

The X6M is the mimic version housed in a 24" x 41" (610 mm x 1041 mm) enclosure. It has the same features as the X6S plus a

geographic mimic providing a graphical representation of th e protected area. The mimic contains up to 144 indicators (LEDs) to

provide visual feedback and 72 programmable push buttons.

Figure 9: Synoptic Sketch of the PR0-2000, X6 Series

14

Page 21

PRO-2000 Installation and Operation Manual

MPU CCA

LITHIUM

MPU BACKPLANE

JUMPER

BATTERY

PRO-2000 X6 Common Features

The X6 Series supports communica tion and networking functions. The X6 can operate as a stand-alone panel or

it can be networked in a master/slave configuration. The master can be configured to monitor and control the

slave panels as well as monitor its own devices.

The X6 panels can support communication to one RS-232 and one repeater network using small communication

modules. By adding an RS-232 communication module to the MPU card, the X6 panels can communicate with

external devices, such as printers or computers, via a standard modular pho ne j ack. The RS- 23 2 communicatio n

module supports one channel. The built-in RS-422 commun ication module enables X6 panels to support a

maximum of two Repeater networks. The RS-422 communication module supports 2 channels. For enhanced

networking capabilities, Communication interface cards can be added to the panel.

The printer used must be UL Listed (ULC Listed in Canada).

The X6 panels can accept up to 6 of the following expansion cards:

• Addressable Detector Interface (ADI) card - smoke/heat detectors, monitor modules, control modules, and 4

onboard supervised/unsupervised outputs

• 24/32 Zone Supervised Input (S1) card - conventional detectors, shorting and non-shorting devices

• 12 Zone Supervised OUTPUT (SO) card - supervised outputs and dry contacts

• Communication Card - networked configurations

General Installation Guidelines

The panel should be installed in a dry, clean, well lit and secured area. No combustible or hazardous material

should be stored in the vicinity of the installed unit. The installation must comply with all local and/or national

regulations and codes of practice governing fire alarm system installation, electrical wiring, life safety, etc.

Special Handling

Circuit cards are to be stored in anti-static packaging and kept away from the sun and from direct sources of

intense UV light. The circuit card may be subject to degradation due to electrostatic discharge; therefore

grounding straps must be worn when handling the cards.

Enabling the Onboard Lithium

Battery Backup

The X6 panels are shipped with the jumper for the

lithium battery disconnected. You must insert the

jumper to activate the battery backup for the real

time clock and the RAM memory used for the

event log. Jumper is located on the MPU (JP3).

Cable Entry and Internal

Routing

On the enclosure there are two removable cable

entry plates. These plates are to be removed,

punched, and re-installed. For additional entry

holes, outside the cable entry plates:

1. Disconnect the wiring harness from the

MPU to the LCD card.

2. Disconnect the door ground strap and

remove the enclosure door with

attached electronics from the enclosure

base.

3. Remove the mounting plate with the

attached electronics from the enclosure base.

Figure 10: Micro-processor (MPU)

15

Page 22

PRO-2000, X6 SERIES - S/B/E/M

Cable entry holes must be punched in accordance with the following criteria:

• Separate holes are required for the entry of Power-Limited and Non -Power-Limited circuit cables.

• Centre-to-centre spacing between an entry hole for Power-Limited circuit cables and an entry hole for NonPower-Limited circuit cables must not be less than two (2) times the diameter of the larger entry hole.

• Sufficient clearance must be provided around each hole to allow for any required cond uit fittings, cable-clamp s,

lock nuts, washers or other hardware.

• Exclusive entry holes must be provided for the Primary AC Supply cable and for the External Standby Supply

(battery backup) cable if required.

• At no point inside the enclosure must the spacing between power-limited and non-power-limited circuit

conductors be less than 6.4mm (¼ inch).

Wire lengths inside the enclosure should be kept to a minimum.

Cables must not interfere with, or touch any circuit card components other than the intended co nnector terminals.

Grounding and Bonding

All supply and device wiring must be grounded and bonded in accordance with applicable local regulations

governing the wiring of Fire Alarm Systems.

Enclosure Installation

All cable entry holes should be punched out prior to installation of enclosure base.

Ensure wall or structure to which the enclosure base is being mounted is capable of supporting a fully loaded unit.

Sufficient clearance must be provided around the unit to allow the enclosure door to be fully opened (180°) without

impediment. The enclosure box may be semi-flush mounted pro vided no less than 5 cm (2 inches) of th e box frame

protrudes from the wall surface.

The top of the enclosure should be no more than 2.0 meters (6.7 feet) above the finished floor.

Recommended mounting hardware: four ¼" pan head screws (If bolts are used, four suitable flat washers are

required).

1. Remove the ground strap (14 Gauge, green) between the enclosu re base an d door by loosening and removing the

ground stud nut and star washer.

2. Remove the MPU-LCD harness connector from J6 on the LCD card.

3. Remove the enclosure door from th e slip hin g es.

4. Remove the mounting plate, with attached electronics and power supply, fro m the enclosure base.

5. Secure the enclosure base to the wall using the four ¼” panhead screws.

6. Align the mounting plate, with attached electronics and power supply, to the enclosure base threaded studs and

secure with attaching nut and washer.

7. Re-install the door and ground strap between door and enclosure base.

8. Reconnect the MPU-LCD harness connector at J6 on the LCD card.

16

Page 23

PRO-2000 Installation and Operation Manual

7.16" [181.97mm]

90°

29.68" [753.92mm]

46.76" [1187.60mm]

23.10" [586.74mm]

1.20" [30.48mm] 21.00" [533.40mm]

0.90" [22.86mm]

28.20" [716.28mm]

30.00" [762.00mm]

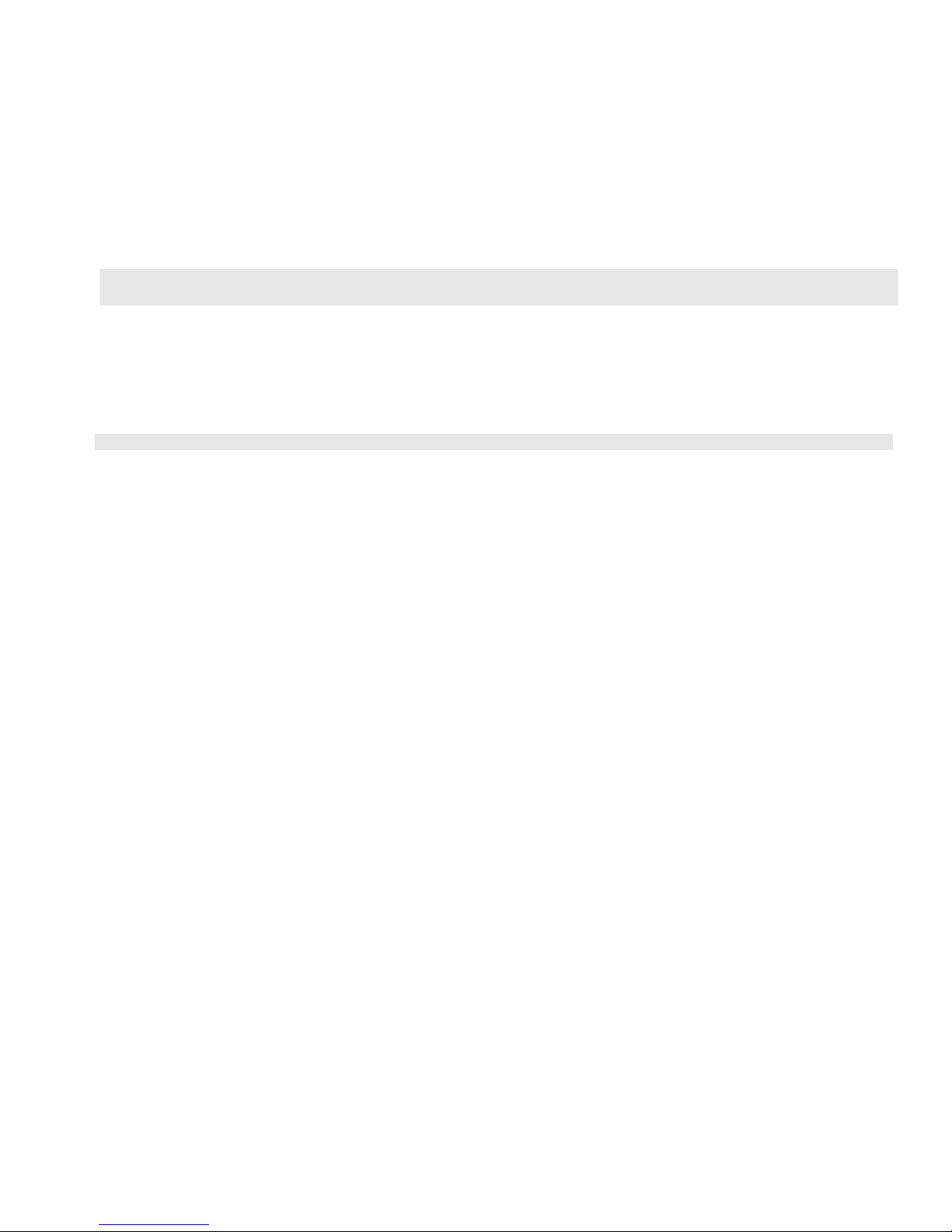

Figure 11: X6S, Installation Layout

17

Page 24

PRO-2000, X6 SERIES - S/B/E/M

7.16" [181.97mm]

90°

29.68" [753.92mm]

46.76" [1187.60mm]

23.10" [586.74mm]

1.20" [30.48mm]

21.00" [533.40mm]

0.90" [22.86mm]

28.20" [716.28mm]

30.00" [762.00mm]

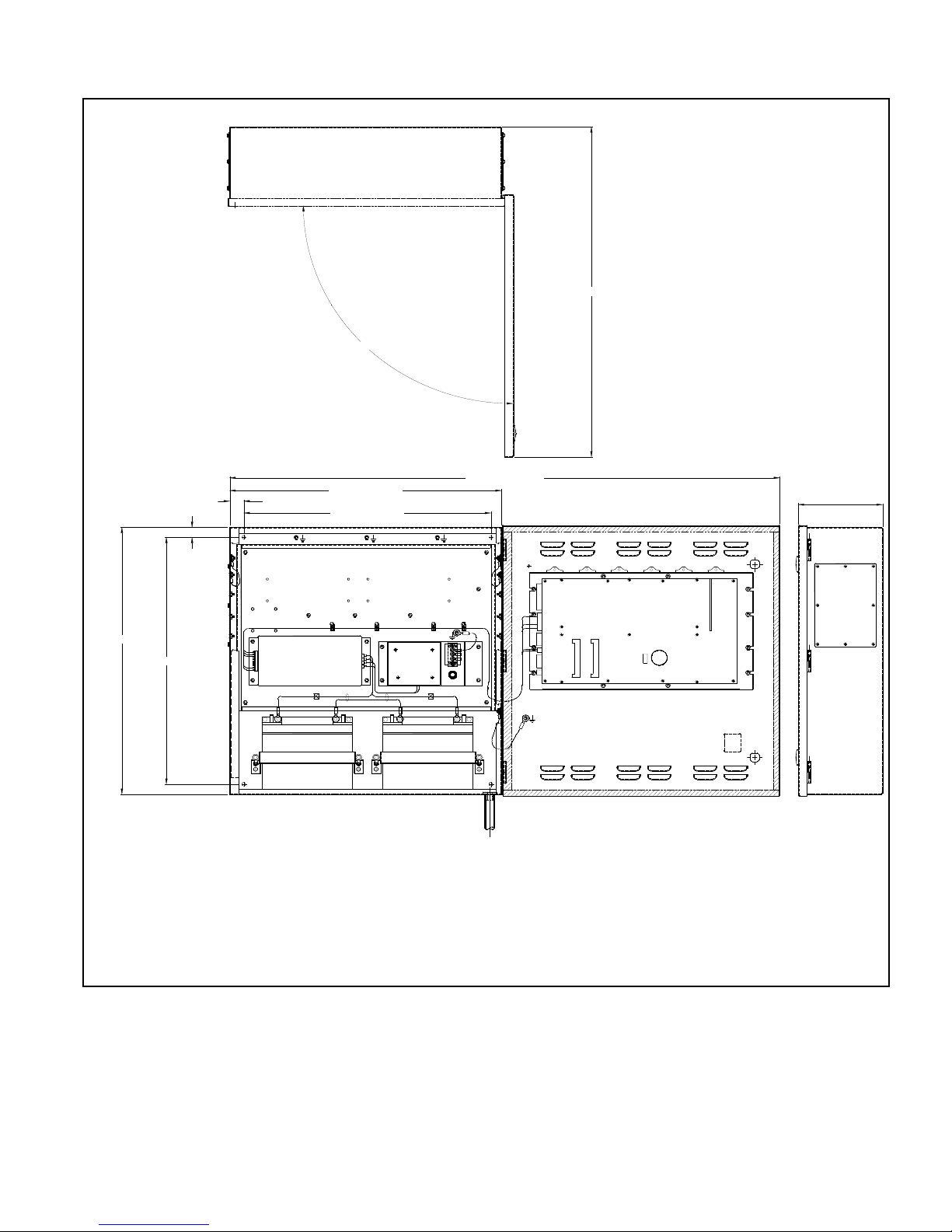

Figure 12: X6B, Installation Layout

18

Page 25

PRO-2000 Installation and Operation Manual

7.16" [181.97mm]

90°

29.68" [753.92mm]

46.76" [1187.60mm]

23.10" [586.74mm]

1.20" [30.48mm]

21.00" [533.40mm]

0.90" [22.86mm]

28.20" [716.28mm]

30.00" [762.00mm]

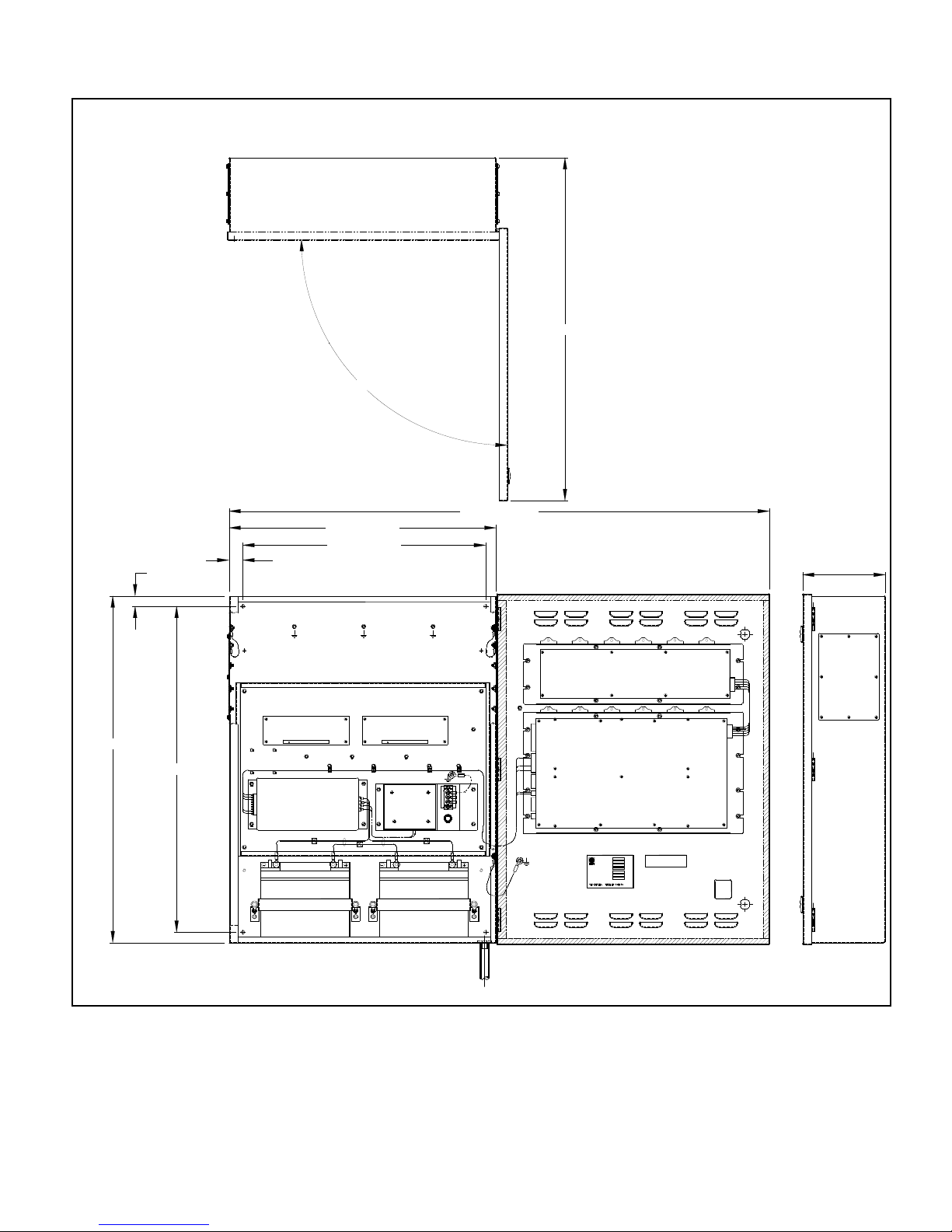

Figure 13: X6E, Installation Layout

19

Page 26

PRO-2000, X6 SERIES - S/B/E/M

7.16" [181.97mm]

90°

29.68" [753.92mm]

46.76" [1187.60mm]

23.10" [586.74mm]

1.20" [30.48mm]

21.00" [533.40mm]

41.00" [1041.40mm]

39.20" [995.68mm]

0.90" [22.86mm]

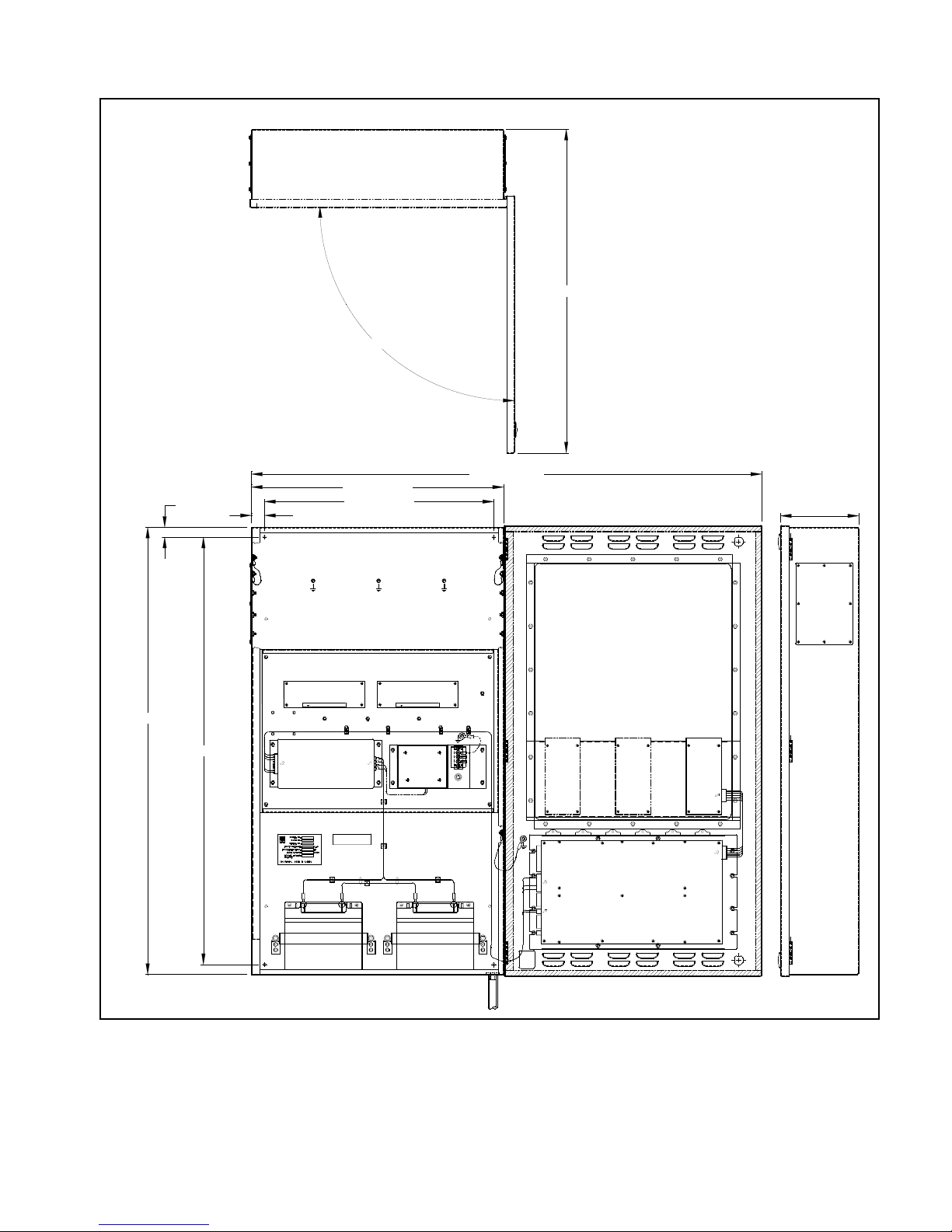

Figure 14: X6M, Installation Layout

20

Page 27

PRO-2000 Installation and Operation Manual

Hookup of AC Power and Batteries

The Power Supply provides a regulated 28 VDC to the PRO-2000 series and provides charge current to the optional

backup batteries. As the batteries are kept permanently charged, power is continuously provided (Uninterruptible Power

Supply or UPS). The power supply AC ratings are as follows:

120 VAC Version: V = 120 VAC nominal, 1 =1.5 A, Frequency 60Hz

220 VAC Version: V = 220 VAC nominal, 1 =0.8 A, Frequency 50Hz

LEDs are visible on the Power Supply indicating the functional status of the unit. As the Power Supply is convection

cooled, no fans or blowers are required. The transformer and power supply mount directly on the mounting plate.

A built-in battery charger maintains the batteries at full capa city. After extended power outages, the charger restores the

batteries to full capacity. Short circuit, over-voltage and brownout monitoring circuits protect all powered components by

switching to the batteries whenever a trouble condition exists in the power supply.

Alarm Supply

Power to the alarm devices in a system must be supplied from a separate battery backed-up Power Supply which is "UL

listed (ULC listed in Canada)” for fire protective signal system use.

AC Power Connection

CAUTION: Ensure all voltage sources are disconnected from the panels before installing or removing cards.

1. Remove terminal cover from terminal block, TB1, located on the transformer bracket.

2. Connect Primary supply Ground wire (green) to Ground stud.

3. Connect Primary supply Neutral wire (white) to TB1 NEUTRAL terminal.

4. Connect Primary supply Line wire (black) to TB1 LINE terminal.

5. Replace and secure terminal cover on TB1.

6. Maximum 150 V AC to Ground.

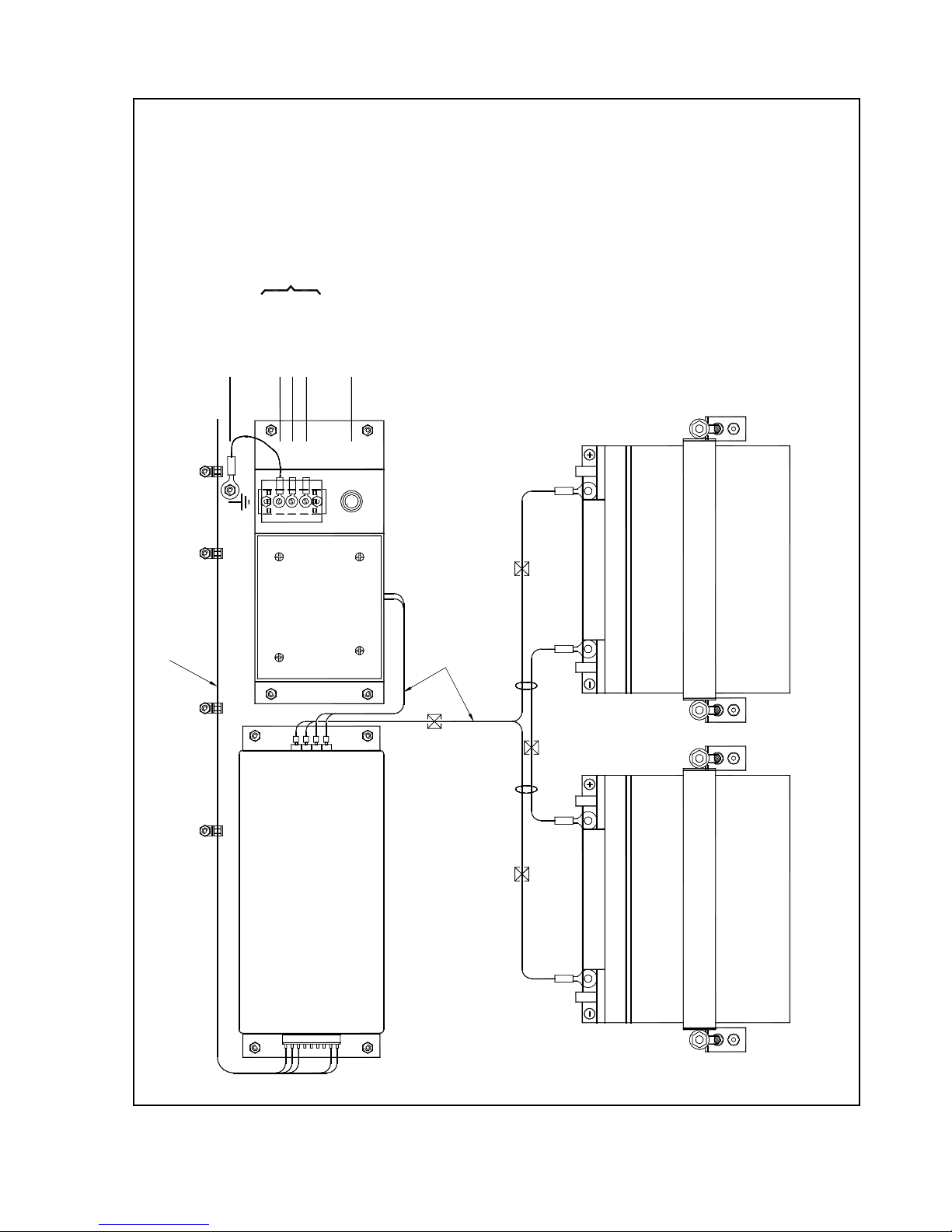

Installing Batteries in the Enclosure

The following instructions apply to stems requiring 42 Amp-Hours or less of battery back-up capacity.

1. Remove battery retaining hardwa re.

2. Place two new fully charged 12V batteries on the bottom of the enclosure. Use 12V sealed lead-acid batteries.

3. Connect jumper between the batteries ‘A’ (+) and ‘B' (-) poles (see Figure 15).

4. Connect black wire terminal to battery 'A'.

5. Connect red wire terminal to battery 'B' (+).

6. Replace battery and secure with retaining hardware.

For Calculation of Battery Requirements refer to Appendix A.

21

Page 28

PRO-2000, X6 SERIES - S/B/E/M

J

2

J

1

E

S

F

U

F

.

E

S

U

F

.

E

F

U

B

L

A

C

K

R

E

D

P

O

W

E

R

-

L

I

M

I

T

E

D

C

I

R

C

U

I

T

J

U

M

P

E

R

A

G

R

O

U

N

D

S

T

U

D

G

R

O

U

N

D

N

E

U

T

R

A

L

L

I

N

E

F

U

S

E

(

F

1

)

B

N

O

N

P

O

W

E

R

-

L

I

M

I

T

E

D

C

I

R

C

U

I

T

S

N

O

N

P

O

W

E

R

-

L

I

M

I

T

E

D

C

I

R

C

U

I

T

S

Figure 15: Battery Hookup

22

Page 29

PRO-2000 Installation and Operation Manual

Geographic MIMIC

(MIMIC driver)

LCD expander

Display unit

(LCD)

Transformer

115 or 220 VAC

Power Supply

and battery

charger

Batteries

X0M

X0E

X0S

Power-limited circuits

Non power-limited

circuit

To host panel

(RS-422)

AC power

RS-422

Module

Figure 16: Synoptic Sketch of the PRO-2000, X0 Series

PRO-2000 X0 Series - S/E/M

The PRO-2000 X0 Series are remote annunciator panels for the X2 and X6 Series.

The PRO-2000 X0 Series consist of three types of panels: the X0S, the X0E, and the X0M.

PRO-2000 X0S (Standard)

The X0S is the standard panel

housed in a 23" x 24" (584 mm x

610 mm) enclosure. The X0S

consists of a display unit which

repeats all events report ed by the

X2 or X6 host panel. It has the

standard 2 lines x 40 character

display with the associated

display list controls and indicators

and the standard 24 configurable

indicators(LEDs) and 12

configurable push buttons.

PRO-2000 X0E (Expanded)

The X0E is the expanded version

housed in a 24" x 30" (610 mm x

762 mm) enclosure. It has the

same features as the X0S plus an

additional 48 configurable

indicators (LEDs) and an

additional 24 configurable push

buttons.

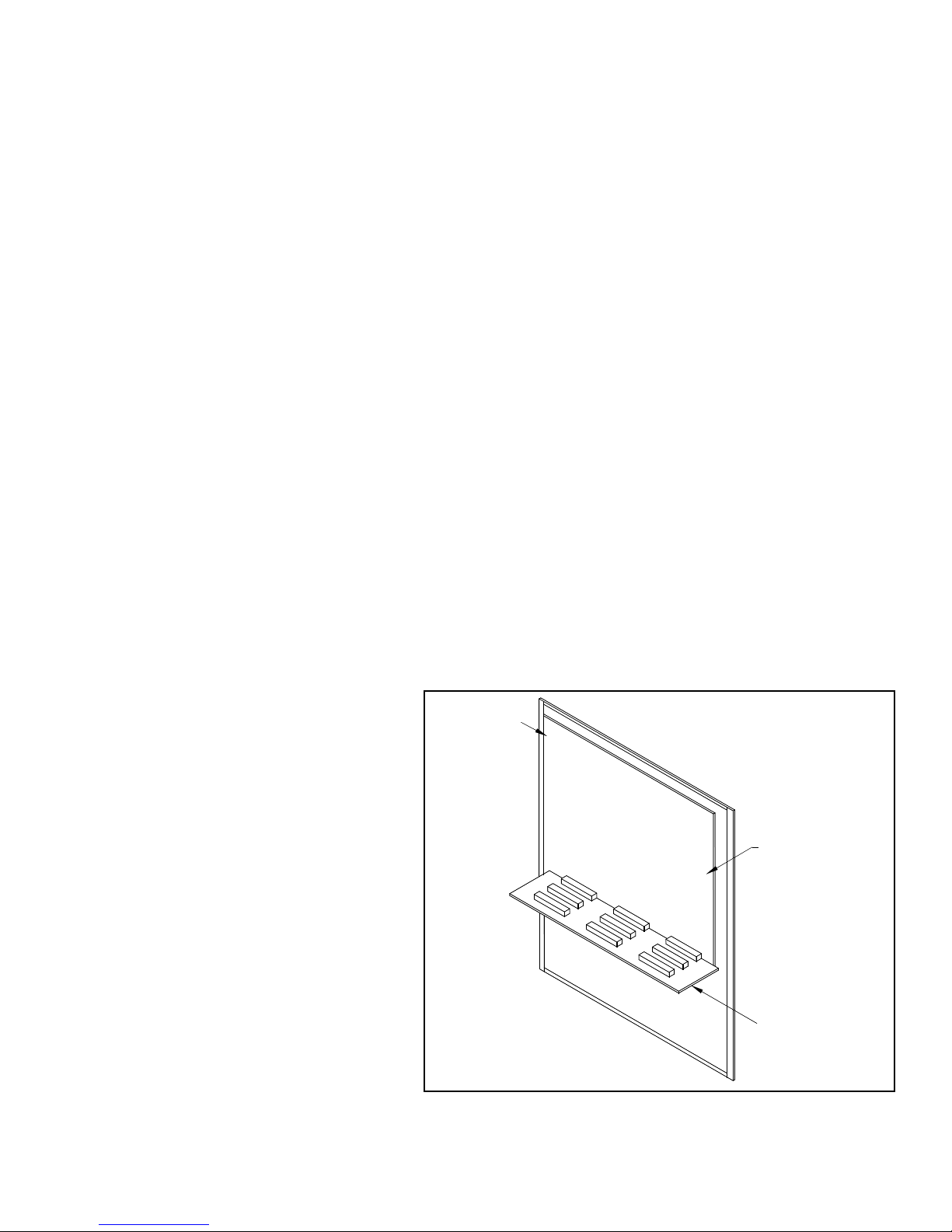

PRO-2000 X0M (Mimic)

The X0M is the mimic version

housed in a 24" x 41" (610 mm x

1041 mm) enclosure. It has the

same features as the X0S plus a

geographic mimic providing a

graphical representation of the

protected area. The mimic

contains up to 144 indicators

(LEDs) to provide visual feedback

and 72 programmable push

buttons.

PRO-2000 X0, Common Features

The X0 panels operate as repeater panels. All the user interface functionality available on the host (X2 or X6) is

also available on the repeater panel. This includes all display lists (alarm, supervisory, trouble, etc.),

acknowledgement and reset functions, as well as System Maintenance accessibility.

The built-in RS-422 communication module allows the X0 Series to be connected to a host. Other than the RS422 communication module, there are no expansion cards available with this unit.

General Installation Guidelines

X0 panels should be installed in a dry, clean, well lit and secured area. No combustible or hazardous material

should be stored in the vicinity of the installed unit. The installation must comply with all local and/or national

regulations and codes of practice governing fire alarm system installation, electrical wiring, life safety, etc.

23

Page 30

PRO-2000 X0 Series - S/E/M

Special Handling

Circuit cards are to be stored in anti-static packaging and k ept away from the sun and from direct source s of intense

UV light. The circuit card may be subject to degradation due to electrostatic discharge; therefore grounding straps

must be worn when handling the cards.

Cable Entry and Internal Routing

On the enclosure there are two removable cable entry plates. These plates are to be removed, punched, and reinstalled. If additional entry holes are required outside the cable entry plates, before punching cable entry holes,

disconnect the door ground strap and remove the enclosure door with attached electronics.

Cable entry holes must be punched in accordance with the following criteria:

• Separate holes are required for the entry of Power-Limited and Non -Power-Limited circuit cables.

• Centre-to-centre spacing between an entry hole for Power-Limited circuit cables and an entry hole for NonPower-Limited circuit cables must not be less than two (2) times the diameter of the larger entry hole.

• Sufficient clearance must be provided around each hole to allow for any required cond uit fittings, cable-clamp s,

lock nuts, washers or other hardware.

• At no point inside the enclosure must the spacing between power-limited and non-power-limited circuit

conductors be less than 6,4mm (¼ po).

Wire lengths inside the enclosure should be kept to a minimum.

Cables must not interfere with, or touch any circuit card components other than the intended co nnector terminals.

Grounding and Bonding

All supply and device wiring must be grounded and bonded in accordance with applicable local regulations

governing the wiring of Fire Alarm Systems. The enclosure must be connected to earth Ground.

Enclosure Installation

All cable entry holes should be punched out prior to installation of base.

Ensure wall or structure to which the enclosure base is being mounted is capable of supporting a fully loaded unit.

Sufficient clearance must be provided around the unit to allow the enclosure cover door to be fully opened (180°)

without impediment. The enclosure box may be semi-flush mounted provided no less than 5 cm (2 inches) of the

box frame protrudes from the wall surface.

The top of the enclosure should be no more than 2 meters (6.7 feet) above the finished floor.

Recommended mounting hardware: four ¼ “ pan head screws (if bolts are used, four suitable flat washers are

required).

1. Remove the ground strap (14 Gauge, green) between the enclosu re base an d door by loosening and removing the

ground stud nut and star washer.

2. Remove the enclosure door from th e slip hin g es.

3. Secure the enclosure to wall using the four ¼” pan head screws.

4. Reinstall the door and ground strap between the door and the enclosure base.

24

Page 31

PRO-2000 Installation and Operation Manual

7.16" [181.97mm]

90°

29.68" [753.92mm]

46.76" [1187.60mm]

21.00" [533.40mm]

23.10" [586.74mm]

1.20" [30.48mm]

22.20" [563.88mm]

24.00" [609.60mm]

0.90" [22.86mm]

Figure 17: X0S, Installation Layout

25

Page 32

PRO-2000 X0 Series - S/E/M

29.68" [753.92mm]

46.76" [1187.60mm]

1.20" [30.48mm]

23.10" [586.74mm]

21.00" [533.40mm]

28.20" [716.28mm]

0.90" [22.86mm]

30.00" [762.00mm]

7.16" [181.97mm]

90°

Figure 18: X0E, Installation layout

26

Page 33

7.16" [181.97mm]

90°

29.68" [753.92mm]

46.76" [1187.60mm]

1.20" [30.48mm]

23.10" [586.74mm]

21.00" [533.40mm]

39.20" [995.68mm]

41.00" [1041.40mm]

0.90" [22.86mm]

PRO-2000 Installation and Operation Manual

Figure 19: X0M, Installation Layout

27

Page 34

PRO-2000 X0 Series - S/E/M

23.10" [586.74mm]

24.00" [609.60mm]

7.16" [181.94mm]

21.00" [533.40mm]

22.20" [563.88mm]

1.20" [30.48mm]

46.76" [1187.60mm]

90°

29.68" [753.92mm]

0.90" [22.86mm]

Figure 20: X0S, Installation Layout with Power Supply and Batteries

28

Page 35

PRO-2000 Installation and Operation Manual

7.16" [181.97mm]

21.00" [533.40mm]

1.20" [30.48mm]

23.10" [586.74mm]

46.76" [1187.60mm]

28.20" [716.28mm]

0.90" [22.86mm]

30.00" [762.00mm]

90.00°

29.68" [753.92mm]

Figure 21: X0E, Installation Layout with Power Supply and Batteries

29

Page 36

PRO-2000 X0 Series - S/E/M

7.16" [181.97mm]

90.00°

29.68" [753.92mm]

0.90" [22.86mm]

39.20" [995.68mm]

41.00" [1041.40mm]

1.20" [30.48mm]

23.10" [586.74mm]

46.76" [1187.60mm]

21.00" [533.40mm]

Figure 22: X0M Installation Layout with Power Supply and Batteries

30

Page 37

PRO-2000 Installation and Operation Manual

X2M

MASTER REPEATER

X0M

SLAVE #1

X2S

Addressable devices

stub/loop

Conventional notification or

initiating device stub

X6E

Conventional initiating

device stub

Conventional notification

device stub

SLAVE #2

PRINTER

PRO-2000

network

(stub or loop)

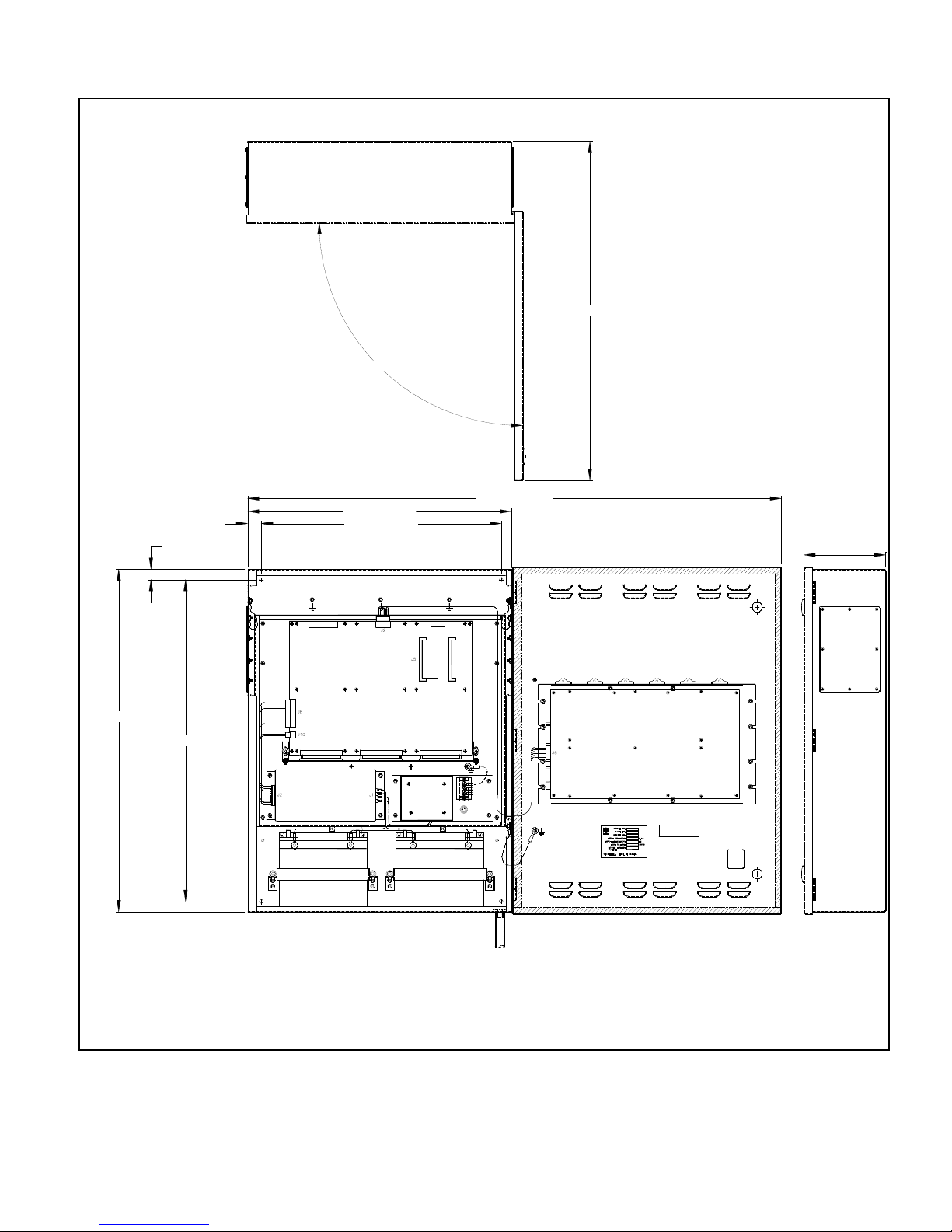

PRO-2000 Multi-Panel Systems

PRO-2000 panels can be programmed to act as Master or Slave panels. A Master panel monitors and controls a

system comprising several Slave panels.

Up to 32 PRO-2000 Slave panels can be con nected, in an ope n o r closed loo p config uration, to the ma ster panel

by means of a 4-conductor, full duplex, serial communication data link.

Should a communication fault occur, isolating one or more Slave panels from the Master panel, the isolated

panels revert to the stand-alone mode. In this mode, fire alarms are annunciated locally.

One or all of the networked panels can have a push button as a General Alarm. The General Alarm functiona lity is

configurable. Activating a General Alarm, either through devices or through the GA ON/OFF push button,

broadcasts the alarm to all the panels. Silencing the General Alarm at any panel silences all the 'General Alarm'

devices. Any new alarm, anywhere in the system, reactivates all the 'General Alarm' devices.

Figure 23: PRO-2000 Networked Panels

31

Page 38

PRO-2000 Multi-Panel Systems

LCD

TX1+

4

1

2

3

J6

X2 PANEL

5

6

TX1-

28V

GND

RX1+

RX1-

RX2-

RX2+

GND

28V

TX2-

TX2+

6

2

5

4

3

J8

1

GND

28V

6

J9

5

RX2-

RX2+

TX2-

TX2+

28V

GND

RX1-

LCD

X0 PANEL (REPEATER)

RX1+

GND

28V

TX1-

TX1+

6

2

5

4

3

J8

1

6

2

5

4

3

J6

1

TX1+

28V

TX1-

GND

RX1-

RX1+

X0 PANEL (REPEATER)

TX2+

28V

TX2-

GND

RX2+

RX2-6

5

4

J8

3

2

1

6

5

4

J6

2

3

1

LCD

Omit these wires

for stub operation

Note 2

Note 1

RX1- 6

X6 PANEL

28V

RX1+

GND

TX1+

TX1-

RX2-

RX2+

28V

GND

TX2-

MPU

TX2+

3

4

5

1

J2

2

6

5

2

4

3

1

J3

3

4

5

2

6

3

4

5

6

1

J8

RX1+

RX1-

GND

TX1+

TX1-

28V

RX2-

RX2+

GND

28V

2

X0 PANEL (REPEATER)

1

J6

TX2+

TX2-

LCD

Wires to be omitted

for stub operation

RX2- 6

RX2+

RX1-

RX1+

28V

GND

TX2-

TX2+

TX1-

28V

GND

3

4

5

J8

1

2

6

5

2

4

3

TX1+

LOCAL LCD

J6

1

Note 3

Note 2

Note 1

ALL CIRCUITS ARE POWER-LIMITTED AND SUPERVISED

ALL CIRCUITS ARE POWER-LIMITED AND SUPERVISED

X2 SERIES Max. 28 V supply cable length depends on configuration.

Must run in conduit separate from Tx and Rx cables.

Maximum current (short circuit: 4.5 Amp).

Maximum current (short circuit: 1 Amp).

X6 SERIES Max. 28 V supply cable length depends on configuration.

Must run in conduit separate from Tx and Rx cables.

NOTES

1.

Number of Repeaters limited by the configuration of the Host panel.

An external power supply can be used to extend the number of Repeaters.

Use only UL Listed for Fire Protective Signaling Systems (ULC Listed in Canada)

regulated, isolated 24VDC power supply (supervised and power limited).

3.

Use shielded, twisted pair cables, one pair for Tx lines, one pair for Rx lines.

No branches

or T-Taps allowed. Shields to be connected according to specific

system Wiring Diagrams.

Maximum cable length for communication: 1 Km between panels.

Maximum cable resistance (per pair): 40 Ohms.

Maximum loop current (short circuit): 150 mA.

Figure 24: X2 and X6 Network Wiring to a Repeater, X0

Minimum detected ground fault impedance is 10K ohms.

32

Page 39

LCD

TX1+

4

1

2

3

J6

X2 PANEL

5

6

TX128V

GND

RX1+

RX1-

RX2-

RX2+

GND

28V

TX2-

TX2+

6

2

5

4

3

J8

1

RX2+

COMM CARD

X6/X2 PANEL

RX2-

TX1+

TX1-

RX1+

RX1-

3

7

4

5

6

J1

8

TX1+

28V

TX1-

GND

RX1-

RX1+

X2 PANEL

TX2+

28V

TX2-

GND

RX2+

RX2-

6

5

4

J8

3

2

1

6

5

4

J6

2

3

1

LCD

Omit these wires

for stub operation

ALL CIRCUITS ARE POWER-LIMITED AND SUPERVISED

MASTER PANEL

SLAVE PANEL #1

SLAVE PANEL #2

2

1

TX2TX2+

USE SHIELDED TWISTED PAIR CABLE.

NO BRANCHES OR T-TAPS ALLOWED.

MAXIMUM DISTANCE BETWEEN CONTROL UNITS: 1 Km.

MAXIMUM CABLE RESISTANCE BETWEEN CONTROL UNITS: 40 Ohms.

MAXIMUM LOOP CURRENT (SHORT CIRCUIT): 150 mA.

MAXIMUM VOLTAGE: 7.0 VDC.

SHIELDS TO BE CONNECTED ACCORDING TO SPECIFIC SYSTEM

WIRING DIAGRAMS.

NOTES:

1.

2.

3.

4.

5.

6.

7. MINIMUM DETECTED GROUND FAULT IMPEDANCE IS 10K OHMS.

PRO-2000 Installation and Operation Manual

Figure 25: Networking The X2 and X6 Using The Communication Card

33

Page 40

MAIN PROCESSING CARDS

MAIN PROCESSING CARDS

There are two main processing cards, the MPU and the LCD. These cards form the basis for the PRO-2000 Pane ls'

electronics.

In the X6 panels, the MPU card with the MPU Backplane, expansion cards (optional), Power Supply and

Transformer are mounted to a removable mounting plate in the enclosure base. The LCD card is mounted directly

on the enclosure door.

In the X2 Series the power supply and transformer are mounted to a removable mounting plate in the enclosure

base. The LCD with the LCD Backplane and optional expansion cards are mounted on the enclosure door.

MPU - Main Processing Unit card

The Main Processing Unit (MPU) provides

processing and communication circuitry for the

X6 series panels. It provides two RS-422 fullduplex, 4-conductor serial links used for

communications with the local LCD panel.

The MPU is shipped pre-installed on the

enclosure backplate with an MPU Backplane

attached and an, RS-422 communication module

installed. The MPU Backplane enables the MPU

to have up to 6 expansion cards installed, for

example, the ADI, Supervised output, or

Supervised Input cards. The MPU Backplane has

a side connector to plug into the MPU expansion

slot providing connectivity between the MPU and

the expansion cards.

The MPU provides monitoring of the power

supply for AC/DC fault detection. The card

provides the following visual indicators and

controls:

• Various status LEDs provide a visual indication of the card's health. There are Red LEDs for error codes,

blinking LEDs (Running) indicating the board is working; Green Power LEDs, and Communication LEDs.

• Reset push button to hard reset the MPU card.

• DIP switch providing software options. Factory set only.

• Rotary switch allowing the selection of different configuration modes. Factory set only.

• Three jumpers, two for the watchdog and one for battery. These jumpers must be connected at all times. A

watchdog circuit, monitoring microprocessor, halts system operation if a hardware or sof tware failure occurs.

The lithium battery provides the backup for the real-time clock and the RAM memory used for event logging.

The real-time clock provides time and date for event recording.

Figure 26: MPU (Main Processing Unit) Card

34

Page 41

PRO-2000 Installation and Operation Manual

RS-422

J3

RS-232

Phone Jack

LCD Display

RS-422 LinkRS-422 Link

LCD Display

J2

RS-232

JP1

JP3

Jumpers

Rotary Switch

DIP Switches

Reset Button

Reset

Status

Error code

Indicators

Communication

Indicators

Power/Status

Indicators

Monitor Power

AC/DC Fault

Power

Connector

Running

J10

J8

LD25

LD20

LD12

LD19

LD11

LD1

SW3

SW1

SW2

1

J1

Master Alarm

and Trouble

Relays

Lithium

Battery

RAM

Program Device

Configuration

Communication

module sockets

Position for Expansion

cards with screw

termination to field devices

Connectors for MPU Backplane

JP4

Figure 27: MPU Backplane Connectors

35

Page 42

MAIN PROCESSING CARDS

When a system is first delivered the MPU card has its internal battery jumper, JP3, disabled. Prior to installation,

move the jumper shunt (located above the board mounted battery) into position over both pins. If the jumper is

missing, the panel will annunciate a "Clock Battery Fault “ at power up. If the jumper is in, you can remove power

and the event log and the clock remain powered.

The MPU has two sockets for adding communication modules. Depending on your configuration, these could be

either the RS-232 or RS-422 communication modules. Installing an RS-232 module activates the phone jack

allowing MPU software configuration through an external PC or communication with a printer (depending on

position of SW1, see Table 4 below).

Installing an RS-422 module activates the two connectors to the LCD. The two connectors provide power to the

LCD. This available power is current limited to 1 amp. Note-the MPU ships with a pre-installed RS-422 module.

The MPU has built-in Common Alarm and Fault Relay-2 For m-C contact s for each relay. The Common Alarm Relay

activates whenever an alarm is present on the system. The Common Fault Relay activates whenever a fault is

present on the system. The rating for Common Alarm and Fault Relay is 2A at 30VDC.

COMM Loop (S1 (J2) X) COMM Loop (S2 (J3) Y)

Signal Pin Signal Pin Signal Pin

TX1+ (out) 1 TX2+ (out) 1 TX (out) 5

TX1- (out) 2 TX2- (out) 2 RX (in) 2

24V 3 24V 3 RTS* (out) 3

GND4GND4CTS* (out)6

RX1+ (in) 5 RX2+ (in) 5 CD* (in) 1

RX1- (in) 6 RX2- (in) 6 GND 4

Table 2: MPU Pinouts

RS-232 Modular Phone

Jack (J4)

Common Alarm and

Trouble Relays (J1)

2A max @ 30V DC

Pin

Resistive

C1 1

NC1 2

Trouble

Alarm