Mircom OpenBAS-HV-NX10, OpenBAS-HV-NX10D, OpenBAS-HV-NX10L, OpenBAS-HV-NX10P Installation Manual

Page 1

OpenBAS-HV-NX10 Series

Building Automation Controller and HVAC

Automation Solution

Installation Manual

LT-2201 Rev. 4.4

October 2017

Page 2

Page 3

Table of Contents

1.0 Introduction 7

1.1 OpenBAS-HV-NX10 Series Building Automation Controller .......................................... 7

1.2 Features ......................................................................................................................... 7

2.0 Overview 8

2.1 OpenBAS-HV-NX10 Series Components ...................................................................... 8

3.0 Installation 10

3.1 Parts of the Enclosure .................................................................................................... 10

3.2 Controller Board Connections ........................................................................................ 13

3.3 Installing Accessories .................................................................................................... 13

3.4 Ethernet Controllers (OpenBAS-NWK-ETH3) ................................................................ 17

3.5 DIP Switches .................................................................................................................. 17

3.6 USB ................................................................................................................................ 18

3.7 Reset and Download Buttons ........................................................................................ 18

3.8 Battery ............................................................................................................................ 18

3.9 Enclosure Dimensions ................................................................................................... 19

3.10 Assembly ....................................................................................................................... 20

3.11 Mounting the Enclosure ................................................................................................. 21

4.0 Field Wiring 22

4.1 Wiring the Terminals ...................................................................................................... 22

4.2 Power Supply Connection .............................................................................................. 22

4.3 Universal Inputs ............................................................................................................. 23

4.4 Analog Outputs .............................................................................................................. 31

4.5 Digital Relay Outputs ..................................................................................................... 33

4.6 Field Bus Connections and OpenBAS-ACC-DB9 .......................................................... 36

4.7 Networking ..................................................................................................................... 37

4.8 Connections and LEDs on OpenBAS-HV-HX10D ......................................................... 38

4.9 Circuit Board LEDs ........................................................................................................ 39

5.0 Specifications 40

6.0 Warranty and Warning Information 42

3 (45)

Page 4

List of Figures

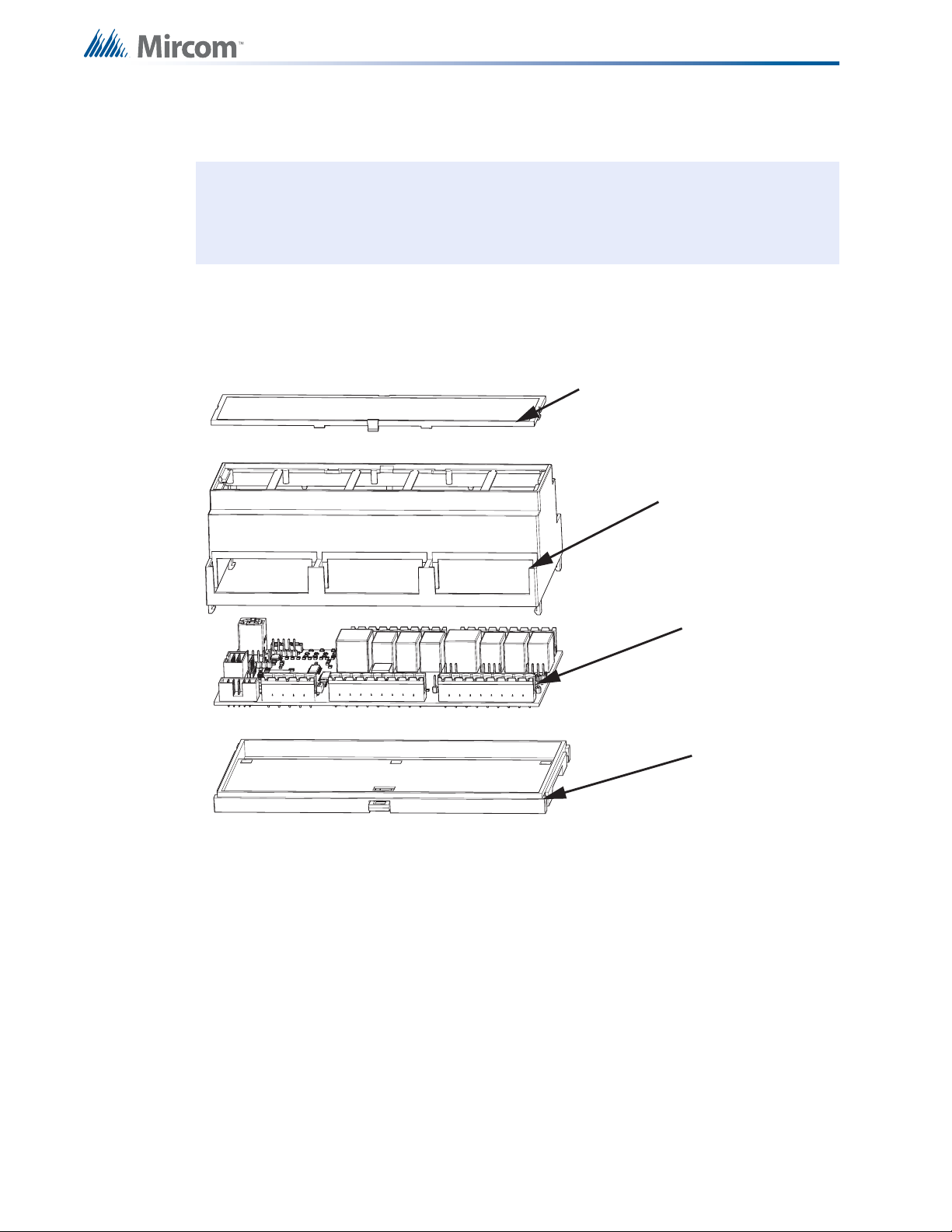

Figure 1 Parts of the enclosure .................................................................................................... 10

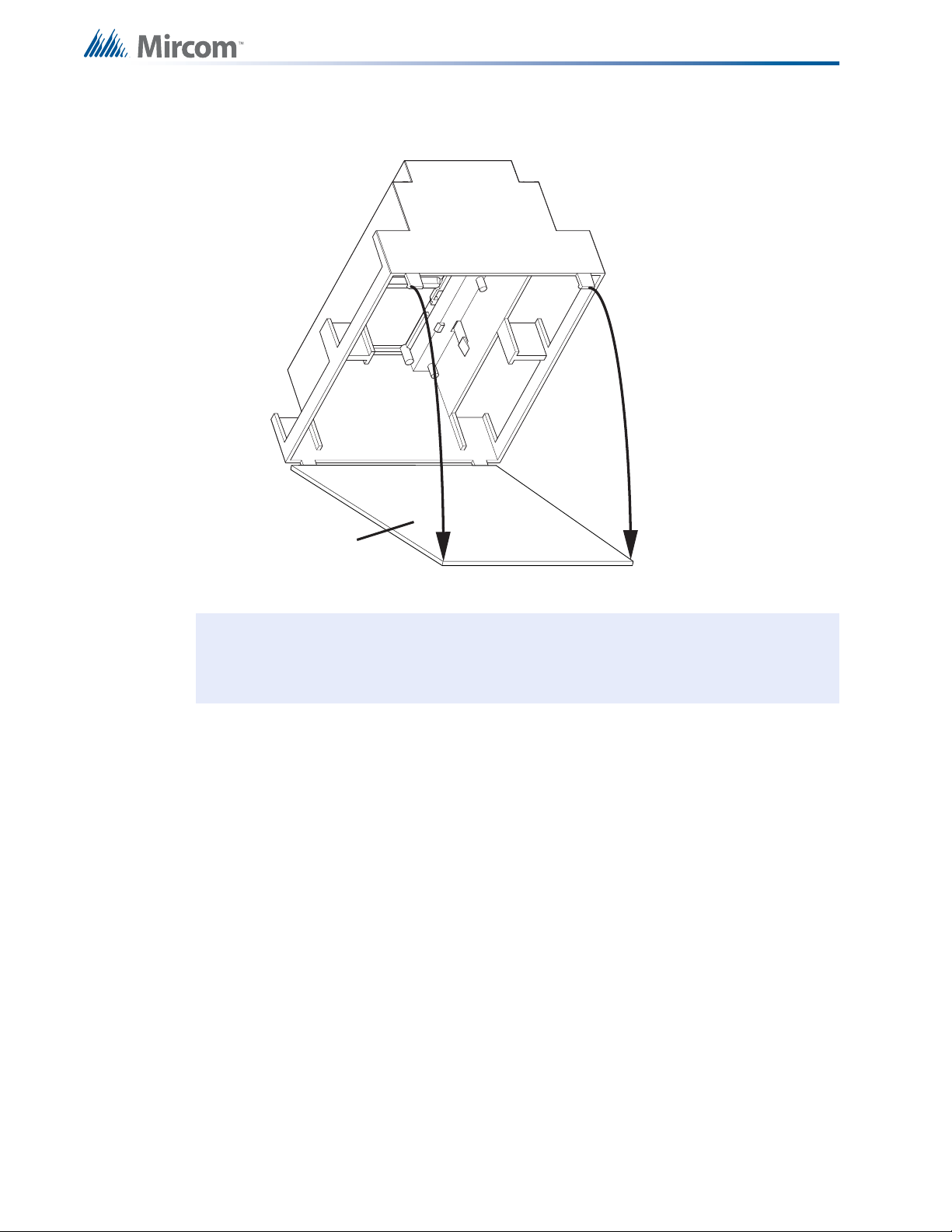

Figure 2 Tabs on enclosure .......................................................................................................... 11

Figure 3 Lift tabs and remove circuit board .................................................................................. 12

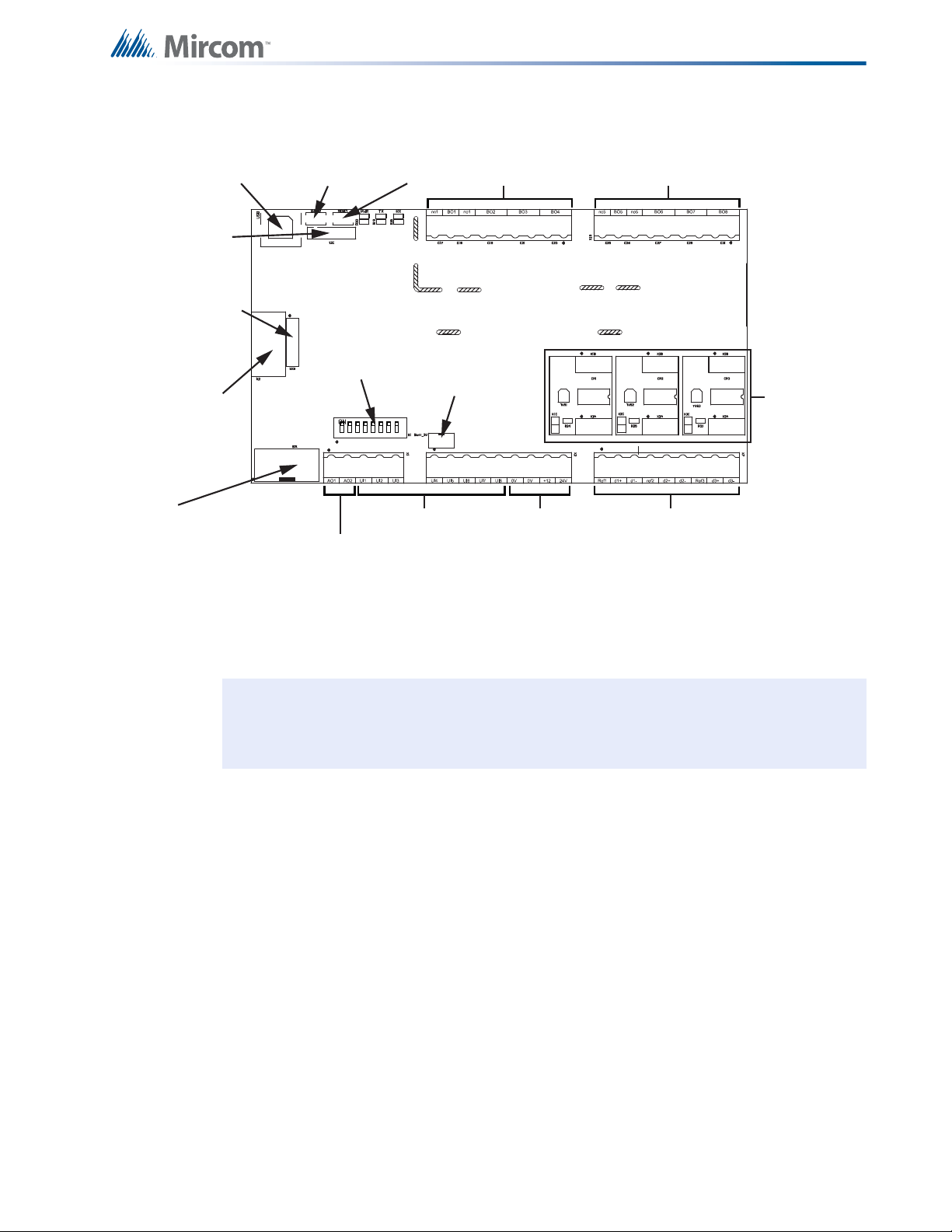

Figure 4 Board connections ......................................................................................................... 13

Figure 5 COM ports ...................................................................................................................... 14

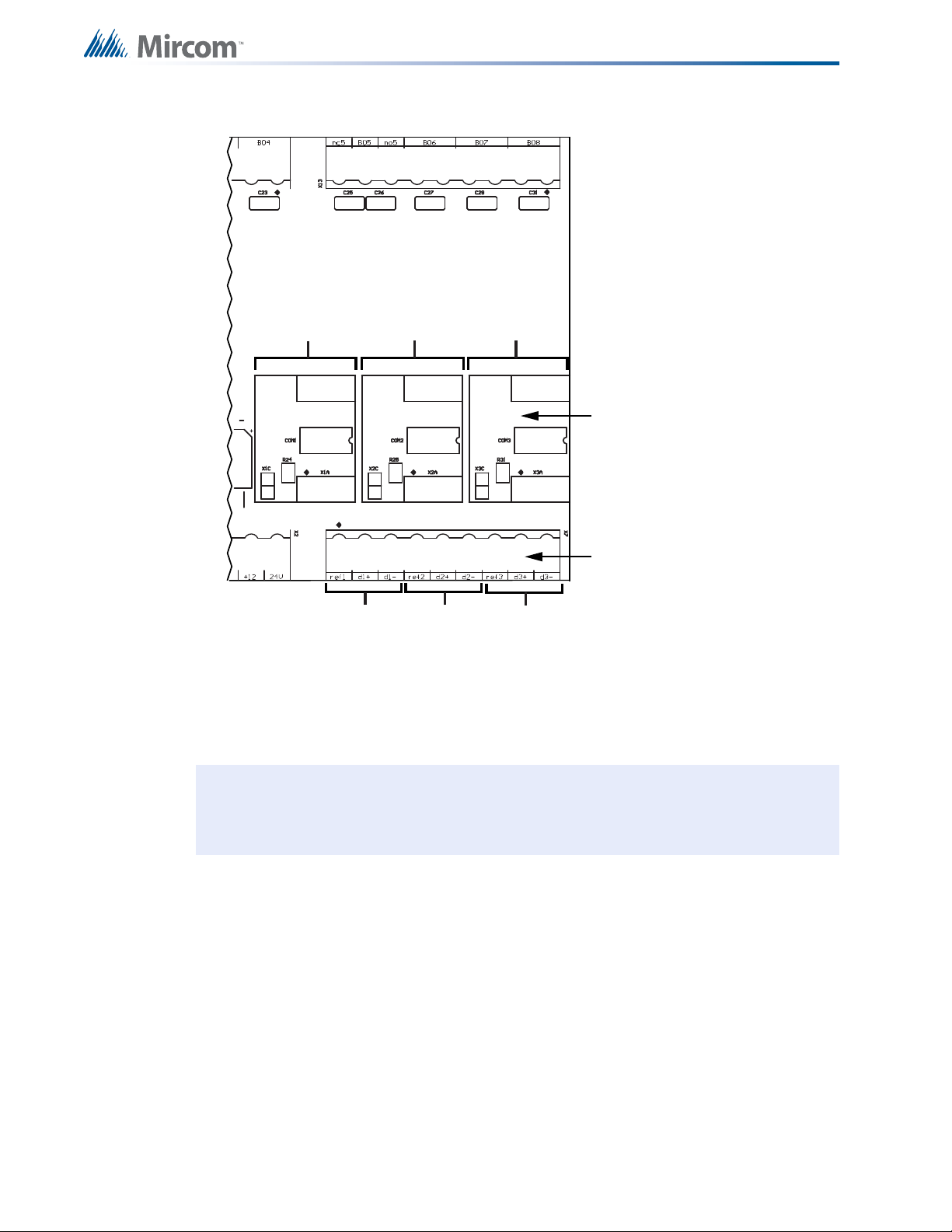

Figure 6 Location of factory-installed modules and jumpers ........................................................ 15

Figure 7 The jumper and RS-485 module are removed from P1 ................................................. 15

Figure 8 OpenBAS-ACC-RS232 is installed in P1 ....................................................................... 16

Figure 9 I2C, I2CB, N2, and SPI connections .............................................................................. 17

Figure 10 DIP switches .................................................................................................................. 18

Figure 11 Enclosure (back view) .................................................................................................... 19

Figure 12 Fit the circuit board in enclosure .................................................................................... 20

Figure 13 Enclosure mounted on DIN rail (circuit board not shown) .............................................. 21

Figure 14 Enclosure mounted on DIN rail (back view) ................................................................... 21

Figure 15 Power supply - 24 VAC or 24 VDC ................................................................................ 23

Figure 16 Power supply - 12 VDC .................................................................................................. 23

Figure 17 Universal Inputs ............................................................................................................. 23

Figure 18 Measuring VDC .............................................................................................................. 29

Figure 19 Digital input voltage range .............................................................................................. 30

Figure 20 Analog outputs ............................................................................................................... 32

Figure 21 Relay outputs ................................................................................................................. 33

Figure 22 Field bus connections .................................................................................................... 36

Figure 23 Networking with OpenBAS-NWK-ETH3 with the included cable ................................... 37

Figure 24 Networking with OpenBAS-NWK-ETH3 over RS-458 .................................................... 37

Figure 25 Networking with RS-485 ................................................................................................. 38

Figure 26 Connections and LEDs on the OpenBAS-HV-NX10D ................................................... 38

Figure 27 LEDs .............................................................................................................................. 39

4 (45)

Page 5

List of Tables

Table 1 OpenBAS-HV-NX10 Series Controllers ......................................................................... 8

Table 2 OpenBAS-HV-NX10 Series Accessories ....................................................................... 8

Table 3 OpenBAS-HV-NX10 Series Compatible Modules .......................................................... 9

Table 4 Analog Input Wiring ........................................................................................................ 25

Table 5 Wiring a 1000 Ω temperature sensor ............................................................................. 29

Table 6 Digital Input Wiring ......................................................................................................... 31

Table 7 Analog Output Wiring ..................................................................................................... 32

Table 8 Surge Protection on Relay Outputs ............................................................................... 34

Table 9 Field Bus Ports ............................................................................................................... 36

5 (45)

Page 6

List of Tables

6 (45)

Page 7

1.0 Introduction

This document provides information on installing the OpenBAS-HV-NX10 series Building

Automation Controller.

1.1 OpenBAS-HV-NX10 Series Building Automation Controller

Mircom’s OpenBAS-HV-NX10 Series building automation controller is an HVAC controller with

an integrated PLC (programmable logic controller) and scheduler. It includes 18 hardware

input/output points, 2 RS-485 field bus connections, USB, SPI, and I

HV-NX10L and OpenBAS-HV-NX10D models have an operator interface with LCD display

and keyboard.

1.2 Features

Mircom’s OpenBAS-HV-NX10 series Building Automation Controller integrates into Mircom’s

unified platform for automating HVAC and mechanical rooms as well as incorporating energy

management features and lighting control to offer building owners and managers a seamless

operation with the following features:

• Modular design to cover any small, medium or large project.

• Industry standard field bus protocols to integrate into any existing BAS system, such as

BACnet, Modbus, Optomux, N2-Open, and ASCII.

2

C buses. The OpenBAS-

• Advanced Networking to integrate into IP networks and use the most advanced features

and protocols such as distributed computing, USB and Cloud storage, HTML5,

JavaScript, XML, Ajax, SMS, and GSM.

• Universal inputs to connect any industry standard sensors.

• Modular add-ons for every Building Automation System solution.

• The OpenBAS software which provides owners and managers a single solution for

managing all their building’s automation needs.

7 (45)

Page 8

2.0 Overview

2.1 OpenBAS-HV-NX10 Series Components

2.1.1 Controllers

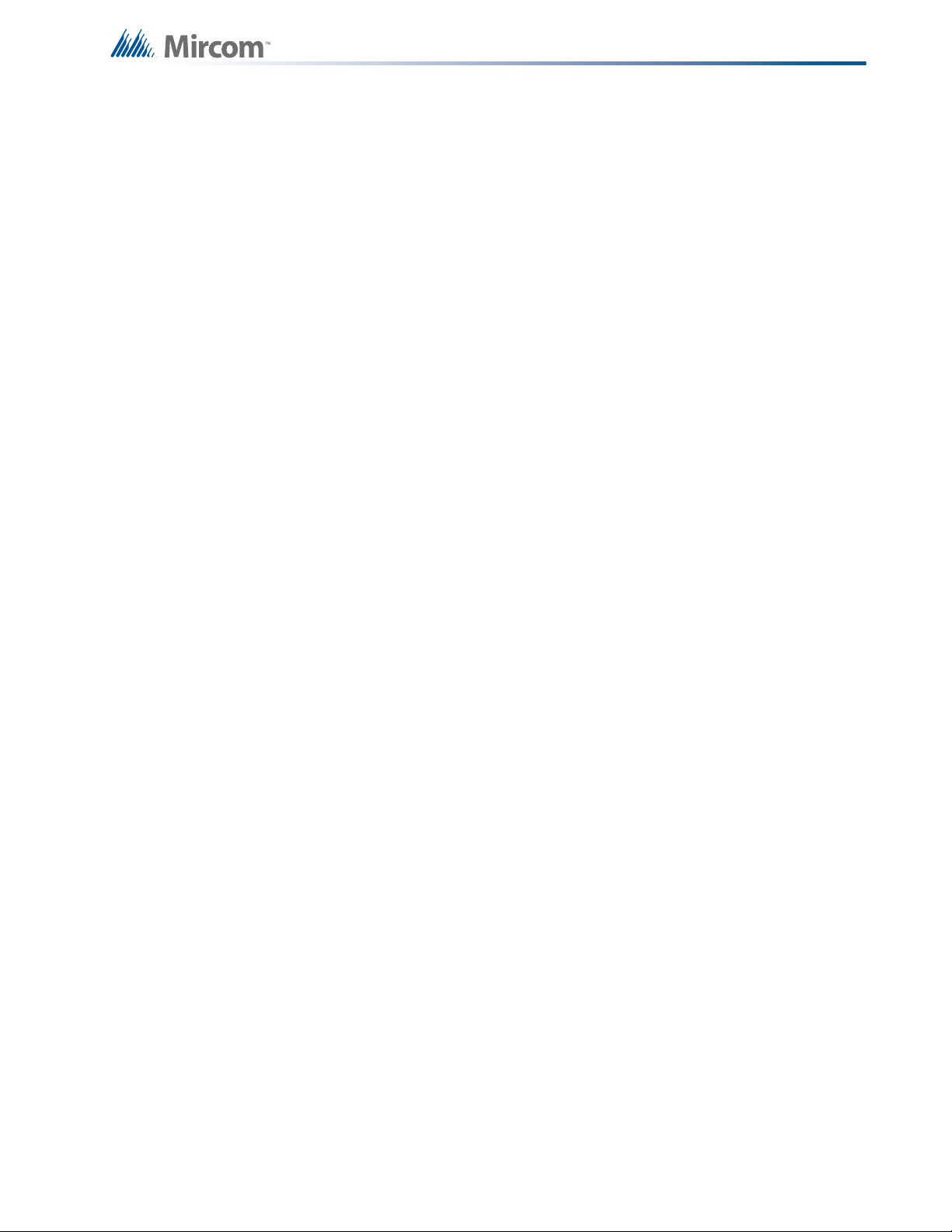

Table 1 OpenBAS-HV-NX10 Series Controllers

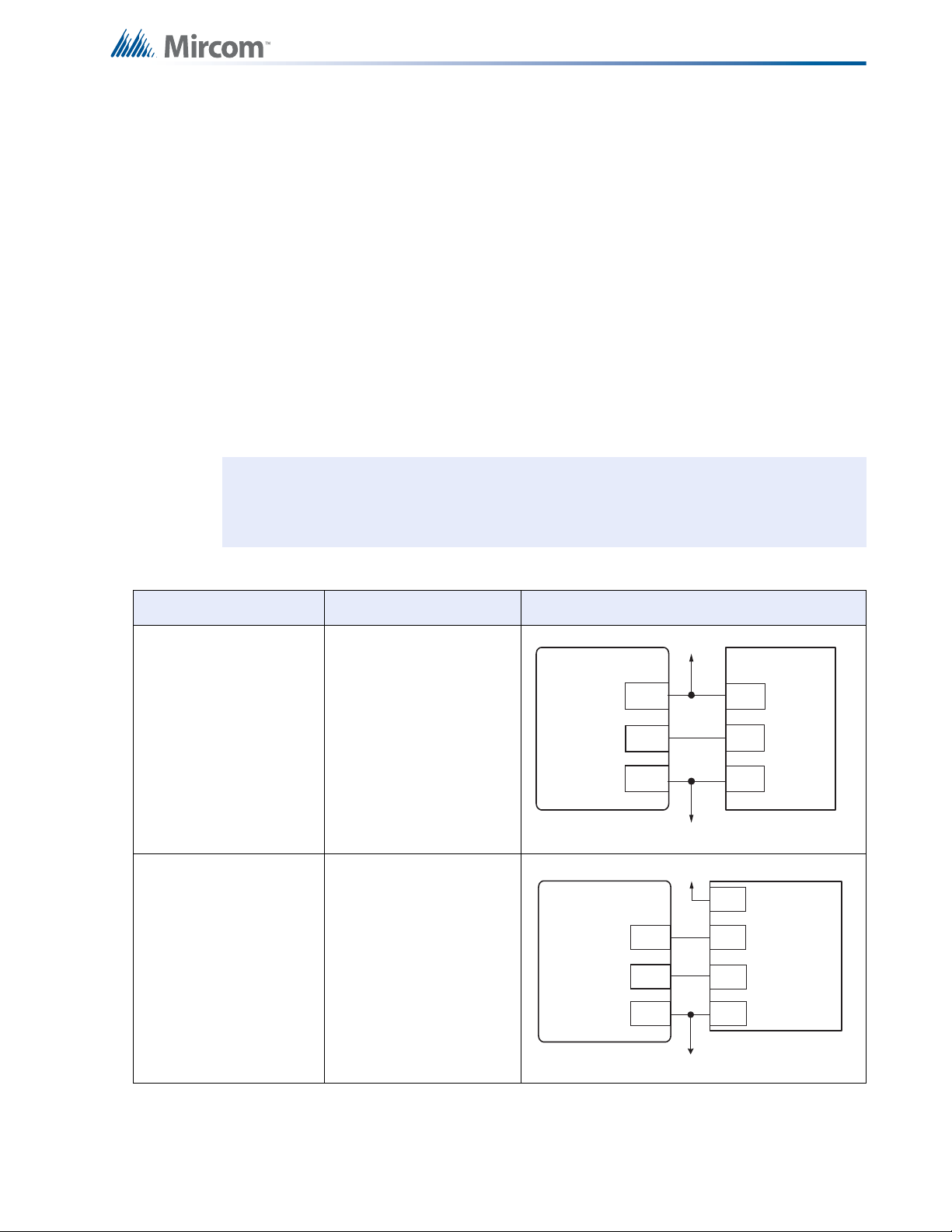

Picture Model Description

HVAC controller

• Integrated programmable logic

OpenBAS-HV-NX10P

OpenBAS-HV-NX10L

controller and scheduler

• 18 hardware input/output points

• 2 RS-485 field bus connections

• USB, SPI and 1²C buses

HVAC controller plus the OpenBASHV-LCD display

• Integrated programmable logic

controller and scheduler

• 18 hardware input/output points

• 2 RS-485 field bus connections

• USB, SPI and 1²C buses

• Operator interface with LCD and

keyboard

HVAC controller plus the OpenBASHV-CORE2 display

• 32 bit dual core processor

• Scheduler and 3 integrated

programmable logic controllers

OpenBAS-HV-NX10D

• 18 hardware input/output points

• 3 RS-485 field bus connections,

• USB, SPI and 1²C buses

• Operator interface with graphical

LCD, keyboard, and secondary

USB for data storage

2.1.2 Accessories

Accessories are powered from the controller.

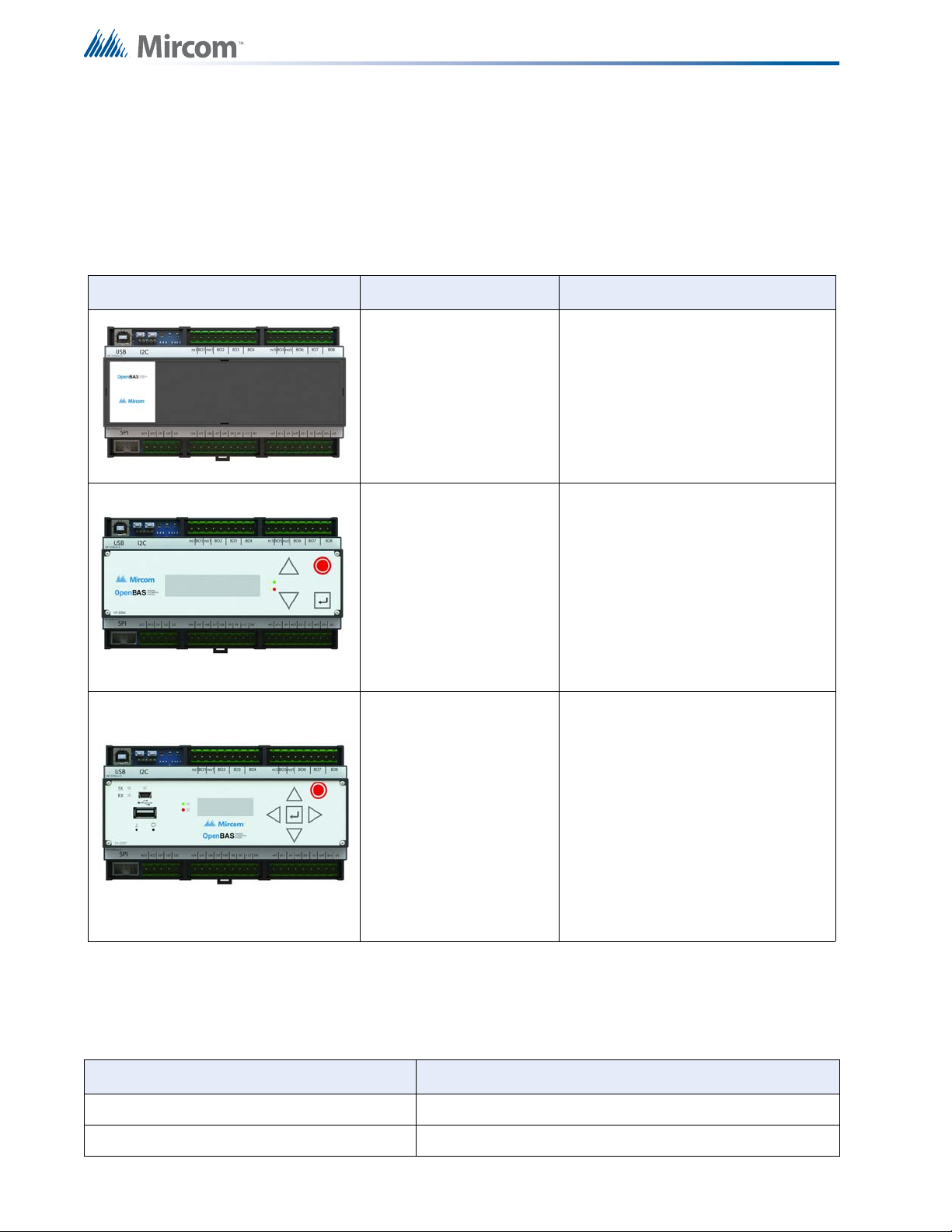

Table 2 OpenBAS-HV-NX10 Series Accessories

Model Description

OpenBAS-ACC-RS485 Optically isolated RS-485 converter

OpenBAS-ACC-RS232 RS-232 converter

8 (45)

Page 9

Table 2 OpenBAS-HV-NX10 Series Accessories (Continued)

Model Description

OpenBAS-ACC-DB9 DB9 adapter

OBS-ACC-32K128 128 KB plus 32 KB memory expansion

OpenBAS-ACC-TE1K 1000 Ω resistive silicon temperature sensor

2.1.3 Compatible Modules

Compatible modules are mounted separately from the controller.

Table 3 OpenBAS-HV-NX10 Series Compatible Modules

Model Description

Wireless 433 MHz RF receiver that integrates up to 10

OpenBAS-HV-RF433R

wireless transmitters and thermostats into OpenBAS-HVNX10 series controllers

Mounts in a DIN rail-mounted box

Overview

OpenBAS-NWK-ETH3

Ethernet controller with support for multiple protocols

• 2 field bus connections

2

• 1 I

C connection

• Mounts in a DIN rail-mounted box

• Powered separately

9 (45)

Page 10

3.0 Installation

i

Circuit board

Base with

mounting clip

Enclosure

Cover (OpenBAS-HV-NX10P)

or display

(OpenBAS-HV-NX10L and

HV-NX10D)

Note: Installation of OpenBAS-HV-NX10 series automation controllers should be in

accordance with the Canadian Electrical Code or the National Electrical Code,

and comply with all local regulations. Final acceptance is subject to the Local

Authority Having Jurisdiction (AHJ).

3.1 Parts of the Enclosure

10 (45)

Figure 1 Parts of the enclosure

Page 11

Installation

!

To remove the circuit board from the enclosure

Caution: Risk of Electric Shock. Disconnect the mains power and disconnect the

controller from all wiring before opening the enclosure.

Attention: Always hold circuit boards by the edges to prevent damage from static

electricity. Always wear an anti-static bracelet when handling circuit

boards.

1. On OpenBAS-HV-NX10P, remove the cover. On OpenBAS-HV-NX10L and OpenBASHV-NX10D, remove the 4 screws and then remove the display.

2. Insert a flathead screwdriver under the tabs on the enclosure, shown in Figure 2, in order

to lift the tabs and remove the base.

Figure 2 Tabs on enclosure

11 (45)

Page 12

Installation

circuit board

!

3. Hold the circuit board with one hand, and with the other hand lift the tabs so that you can

remove the circuit board from the enclosure. See Figure 3.

Lift tabs and remove

Circuit board

Figure 3 Lift tabs and remove circuit board

Attention: Be careful not to break the tabs. Do not apply excessive force.

12 (45)

Page 13

3.2 Controller Board Connections

COM1, COM2, COM3

Universal

inputs 1-8

Power

Analog

outputs 5-8

outputs 1-4

Connections for

communication

converters

connection

DIP switches

button

button

Battery

connection

!

Installation

USB

Connection for

memory expansion

or wireless receiver

Connection for

memory expansion or

OpenBAS-HV-LCD

(OpenBAS-HV-NX10L

only)

Connection for

OpenBAS- HV-CORE2

display

(OpenBAS-HV-NX10D

only)

SPI port for

Ethernet controller

Download

outputs 1-2

Figure 4 Board connections

Reset

Relay

Relay

3.3 Installing Accessories

Attention: This job must be performed only by a certified technician as dangerous

voltages might be present inside of the enclosure.

Always disconnect the power before installing accessories.

3.3.1 Communication Converters (OpenBAS-ACC-RS485, OpenBAS-ACCRS232)

By default, the field bus ports (labeled COM1, COM2 and COM3) are configured as RS-485

through factory-installed modules. They can be changed to RS-232 or optically isolated RS485 by installing the OpenBAS-ACC-RS232 or OpenBAS-ACC-RS485 converters.

The communication converters OpenBAS-ACC-RS485 and OpenBAS-ACC-RS232 attach to

the connections labeled P1, P2, and P3 in Figure 5 below. Figure 5 also shows the relationship

between the 3 converters and the field bus connections (labeled COM1, COM2, and COM3).

P1 controls COM1, P2 controls COM2, and P3 controls COM3.

13 (45)

Page 14

Installation

P1 P2 P3

COM1 COM2

COM3

Field bus

connections and

connection for

OpenBAS-ACC-DB9

Connections for

OpenBAS-ACC-RS485

and

OpenBAS-ACC-RS232

i

Figure 5 COM ports

For example, if OpenBAS-ACC-RS485 is installed in P1 and OpenBAS-ACC-RS232 is

installed in P2, then COM1 functions as optically isolated RS-485, and COM2 functions as RS-

232.

Note: P3 and COM3 are functional only on OpenBAS-HV-NX10D.

14 (45)

Page 15

Installation

Jumpers

Factory-installed

RS-485 modules

Jumper

open

Factory-installed RS-485

module removed

Figure 6 Location of factory-installed modules and jumpers

To install a communication converter

1. Open the jumper.

2. Remove the factory-installed RS-485 module.

Figure 7 The jumper and RS-485 module are removed from P1

15 (45)

Page 16

Installation

OpenBAS-ACC-RS232

i

3. Install the communication converter.

Figure 8 OpenBAS-ACC-RS232 is installed in P1

3.3.2 Memory Expansion Card (OBS-ACC-32K128) and Wireless Receiver (OpenBAS-HV-RF433R)

Connect the memory expansion cards to either one of the two terminals shown in Figure 9.

They are labeled I2C and I2CB.

Note: When connecting the I2C ports on 2 devices, make sure to connect pin 1 on the

first device to pin 1 on the second device. Pin 1 is marked by a dot or a “1”.

16 (45)

Page 17

Installation

Connection for

wireless receiver

or memory

expansion card

Connection for

OpenBAS-HV-LCD

or memory

expansion card

Connection for

OpenBAS-HV-CORE2

I2C

I2CB

N2

SPI port for

Ethernet controller

Connect the OpenBAS-HV-RF433R wireless receiver to the port labeled I2C, so that it is

accessible when the board is in the enclosure.

Figure 9 I2C, I2CB, N2, and SPI connections

3.3.3 Displays (OpenBAS-HV-LCD and OpenBAS-HV-CORE2)

The OpenBAS-HV-LCD display connects to I2CB, and the OpenBAS-HV-CORE2 display

connects to N2 as shown in Figure 9.

3.4 Ethernet Controllers (OpenBAS-NWK-ETH3)

Connect an Ethernet controller to the terminal labeled SPI (shown in Figure 9) with the cable

included with the Ethernet controller. See section 4.7 on page 37 for information on

networking.

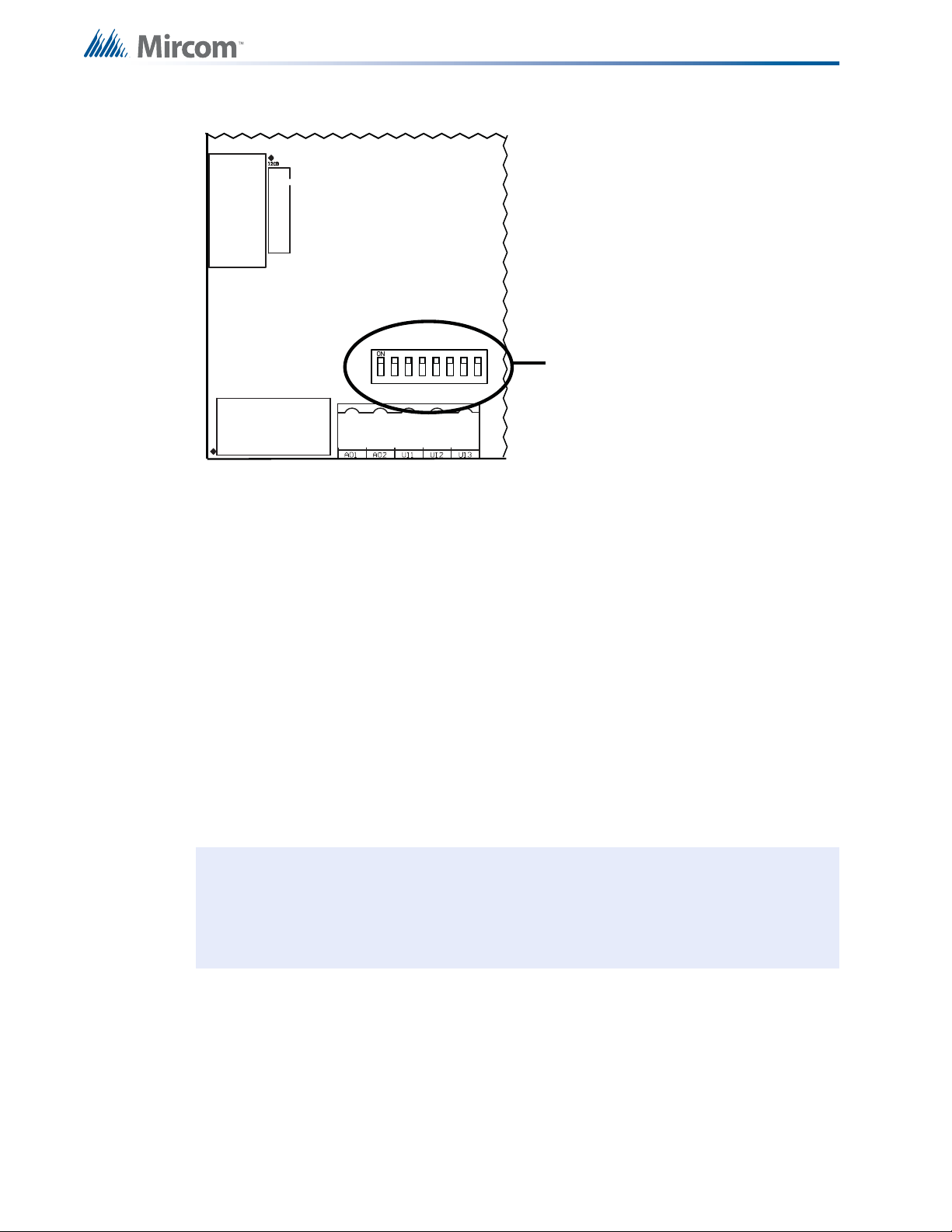

3.5 DIP Switches

The 8 DIP switches (shown in Figure 10) are used with the 8 universal inputs ONLY when the

inputs are connected to resistive 1000 Ω temperature sensors.

In all other cases, make sure that the DIP switches are off.

For example, if you are going to connect universal input 1 to a resistive 1000 Ω temperature

sensor, turn on DIP switch 1.

The DIP switches are set at the factory in the off position.

17 (45)

Page 18

Figure 10 DIP switches

DIP switches

12

3

456

78

!

Installation

3.6 USB

The full speed USB 2.0 connection is shown in Figure 4. Connect a computer to this port in

order to configure the controller.

3.7 Reset and Download Buttons

Press the RESET button to restart the controller.

The DWNLD button is used for loading firmware on to the controller.

Refer to the OpenBAS Programming Manual for information on upgrading controllers.

3.8 Battery

Attention: Caution – The battery used in this device may present a risk of fire or

chemical burn if mistreated. Do no disassemble, heat above 60°C

(140°F), or incinerate. Replace battery with FDK Corporation ML2430

batteries only. Use of another battery may present a risk of fire or

explosion.

18 (45)

The battery is used only during power outages for real time clock and data retention. The

Mircom part number for the battery is BT-025.

Install the battery before mounting the controller.

Page 19

To install or replace the battery

3 35/64” (90 mm)

6 9/32”

(160 mm)

Mounting

clip

Hooks

1. Disconnect the mains power and open the mains breaker.

2. Disconnect all wiring from the unit.

3. Remove the top cover as described on page 21.

4. Disconnect the old battery.

5. Dispose of the used battery promptly. Keep away from children. Do not disassemble and

do not dispose of in fire.

6. Connect the new battery to the connection shown in Figure 4. The battery wire can be

connected only one way.

3.9 Enclosure Dimensions

Installation

Figure 11 Enclosure (back view)

19 (45)

Page 20

3.10 Assembly

i

Circuit board

!

To put the circuit board in the enclosure

1. Hold the circuit board with one hand, and with the other hand lift the tabs so that you can

fit the circuit board into the enclosure as shown below.

Note: Make sure that the board is the right way up: the terminal labels on the enclosure

must match the terminal labels on the circuit board.

Installation

20 (45)

Figure 12 Fit the circuit board in enclosure

2. Snap the base onto the enclosure. Make sure that the mounting clip is on the bottom.

3. On OpenBAS-HV-NX10P, snap the cover in place.

On OpenBAS-HV-NX10L, connect the OpenBAS-HV-LCD display to the connection

labeled I2CB.

On OpenBAS-HV-NX10D, connect the OpenBAS-HV-CORE2 display to the connection

labeled N2.

Make sure that the Mircom logo is the right way up.

4. Secure the display with the 4 screws.

Attention: Always hold circuit boards by the edges to prevent damage from static

electricity. Always wear an anti-static bracelet when handling circuit

boards.

Page 21

3.11 Mounting the Enclosure

!

Mount with

mounting clip on bottom

Attention: Mount the enclosure on a DIN rail in a UL-compliant metal box. Do not

drill holes in the enclosure or modify the enclosure in any way.

To mount the enclosure on a DIN rail

Mount the enclosure with terminal labels the right way up and the mounting clip on the bottom.

1. Mount a section of DIN rail so that there is enough space for the enclosure to be

mounted.

2. Slide the hooks under the rail and push the enclosure to secure it on the DIN rail. The

mounting clip locks it in place.

Installation

Figure 13 Enclosure mounted on DIN rail (circuit board not shown)

Figure 14 Enclosure mounted on DIN rail (back view)

To remove the enclosure from the DIN rail

• With your hands or with a small flathead screwdriver, pull the mounting clip to release

the enclosure from the DIN rail, and carefully pull the enclosure off the DIN rail.

21 (45)

Page 22

4.0 Field Wiring

i

Note: Installation of OpenBAS-HV-NX10 series automation controllers must be in

accordance with the Canadian Electrical Code or the National Electrical Code,

and comply with all local regulations. Final acceptance is subject to the Local

Authority Having Jurisdiction (AHJ).

4.1 Wiring the Terminals

Figure 4 on page 13 shows the location of the terminals. The terminals are depluggable for

ease of wiring.

4.1.1 Required Tools

Tools needed:

• Precision or jeweler's screwdriver set

• Wire cutter

• Wire stripper

4.1.2 Installation Tips

• Perform visual inspection of circuit board and parts for obvious issues.

• Use a wire tie to group wires for easy identification and neatness.

4.2 Power Supply Connection

The OpenBAS-HV-NX10 series controller can be powered 3 ways.

• 12 Vdc, 360 mA max.

• 24 Vdc, 450 mA max.

• 24 Vac 50/60 Hz, 500 mA max.

Notes:

• Use either of the terminals labeled 0V to connect the negative side of the power supply.

• Use the +12 or 24V terminals to daisy chain a shared supply between more than one

controller.

22 (45)

Page 23

4.2.1 24 VDC or 24 VAC

24 VAC/VDC

0 V

24V0V +120V

12 VDC

0 V

24V0V +120V

!

Universal inputs 1-8

UI2 UI3UI1 UI5 UI6UI4 UI8UI7 0V0V

UI1

UI2

UI3

UI4

UI5

UI6

UI7

UI8

When the controller is powered from the 24V terminal, it can provide 12 VDC power to field

devices through the +12 terminal. In this case, the +12 terminal can provide up to 250 mA.

Figure 15 Power supply - 24 VAC or 24 VDC

4.2.2 12 VDC

Field Wiring

Figure 16 Power supply - 12 VDC

Caution: An appropriate UL listed class 2 power supply or transformer with

necessary protection devices such as fuses or breakers should be used

to limit the risk of fire. All local codes and regulations for installation

must be observed.

4.3 Universal Inputs

Figure 17 Universal Inputs

The controller has 8 universal inputs. Depending on the application, the universal inputs can

be used the following ways:

• Analog Inputs (section 4.3.2 on page 24) 0-10 VDC

0-5 VDC

23 (45)

Page 24

• Input for a resistive 1000 Ω temperature sensor (section 4.3.3 on page 29)

• Measuring 24 VDC (section 4.3.4 on page 29)

• Digital (binary) inputs (section 4.3.5 on page 29) for dry contacts being fed by

• Pulse counters (section 4.3.5 on page 29) active PNP 12 VDC

4.3.1 Tips for Universal Inputs

• Use 18 AWG stranded wire.

• The absolute maximum voltage is 15 VDC.

• Fit the end of the wire with terminal connectors to provide a solid connection that can

withstand temperature changes and vibration without becoming loose.

• Connect the common wires of sensors to either of the 0V terminals.

• Turn the corresponding DIP switch on ONLY when using resistive 1000 Ω temperature

sensors. See section 3.5 on page 17.

Field Wiring

0.5-4.5 VDC ratiometric

0-20 mA

4-20 mA

Thermocouple input with

x200 amplifiers

12 VDC

for dry contacts being fed by

12 VDC

• When using 2 or more external power supplies, connect the negatives or commons of

both power supplies to the 0V terminal of the controller.

To ensure that the universal inputs operate correctly, follow these guidelines:

• Limit the distance between the analog sensor and the controller to 10 m (30 ft). Mircom

recommends shielded wire for noisy environments.

• If this distance is not possible, longer wire runs with shielded wire are allowed up to 30 m

(100 ft). Connect the shield to any 0V terminal on the controller, making sure to isolate

the shield on the other end. Failing to do so creates ground loops.

• When possible, route the wiring inside metal piping and ground the piping for better

results.

• Avoid running any analog signals near sources of electric noise such as: motors,

ballasts, fluorescent lamps, variable frequency drives, high energy contacts, RF (radio

frequency) transmitters, microwave ovens, and any other equipment that generates

electromagnetic interference.

• Keep a minimum distance of 30 cm (1 ft) between analog input wiring and any conductor

carrying more than 24 VAC.

• Follow good wiring and installation practices, and follow all local regulations and

electrical codes.

4.3.2 Analog Inputs

24 (45)

Connect any sensor or transducer that outputs 0-5 V, 0.5-4.5 V ratiometric, or 0-10 V directly

to the universal inputs when they are configured as analog inputs.

Page 25

Field Wiring

!

UI#

12 VDC

0 V

Field Device

+

Signal

-

+12

0V

Controller

UI#

0V

24 V

0 V

Field Device

+

Signal

-

+12

24 V

Controller

To use the universal inputs as analog inputs

1. Connect the appropriate analog signal to the universal input according to the diagrams

below.

2. Configure the analog input type and then calibrate using the OpenBAS software.

Terminal Labeling on Field Devices

The positive terminal on field devices might be labeled one of the following:

+ +24 +PWR 24 +DC AC PWR

The negative terminal on field devices might be labeled one of the following:

-0VGNDNegCOM

Table 4 shows how to connect different devices to the analog inputs.

Attention: When using 2 or more external power supplies, connect the negatives

or commons of both power supplies to the 0V terminal of the controller.

Table 4 Analog Input Wiring

Type of field device Power source Wiring diagram

12 VDC powered

transducer with 1-10

VDC output

12 VDC powered

transducer with 1-10

VDC output

12 VDC power supply

common to field device

and controller.

24 VAC or VDC power

supply common to field

device and controller.

The controller provides

the 12 VDC to the field

device.

25 (45)

Page 26

Table 4 Analog Input Wiring (Continued)

UI#

0 V

24V

Signal

0V

24V

0V

24 V

Field Device Controller

UI#

+

Signal

-

+12

0V

Field Device Controller

Power Supply

+

-

12VDC

Power Supply

+

-

UI#

+

Signal

-

24V

0V

Field Device Controller

Power Supply

+

-

24VAC or VDC

Power Supply

+

-

UI#

0 V

+

-

+12

0V

12VDC

ȍ

Field Device Controller

Type of field device Power source Wiring diagram

24 V external power

24 V powered

transducer with 1-10

VDC output

Transducer with 1-10

VDC output

supply common to field

device and controller.

Power can be 24 VDC or

VAC as required by the

field device.

External power supply for

field device (depends on

field device requirements)

and 12 VDC external

power supply for

controller.

Connect the negative or

common of both power

supplies to the 0V

terminal of the controller.

Field Wiring

Transducer with 1-10

VDC output

2-wire transducer with 420 mA or 0-20 mA output

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

External power supply for

field device (depends on

field device requirements)

and 24 V external power

supply for controller.

Connect the negative or

common of both power

supplies to the 0V

terminal of the controller.

12 VDC power supply

common to field device

and controller.

26 (45)

Page 27

Table 4 Analog Input Wiring (Continued)

UI#

Field Device

+

-

24V

0V

24 VDC

ȍ

Controller

24V

0V

UI1

ȍ

Controller

Power Supply

+

-

24 VAC or VDC

Power Supply

+

-

+

-

Field Device

+12

0V

UI1

ȍ

Controller

Power Supply

+

-

12 VDC

Power Supply

+

-

+

-

Field Device

UI#

0 V

+

Signal

24V

0V

24 VAC

ȍ

-

Field Device Controller

Type of field device Power source Wiring diagram

2-wire transducer with 420 mA or 0-20 mA output

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

24 VDC power supply

common to field device

and controller.

Field Wiring

0 V

2-wire transducer with 420 mA or 0-20 mA output

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

2-wire transducer with 420 mA or 0-20 mA output

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

3-wire transducer with 420 mA or 0-20 mA output

External power supply for

field device (depends on

field device requirements)

and 24 V external power

supply for controller.

Connect the negative or

common of both power

supplies to the 0V

terminal of the controller.

External power supply for

field device (depends on

field device requirements)

and 12 VDC external

power supply for

controller.

Connect the negative or

common of both power

supplies to the 0V

terminal of the controller.

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

24 VAC power supply

common to field device

and controller.

27 (45)

Page 28

Table 4 Analog Input Wiring (Continued)

24V

0V

UI1

ȍ

Controller

Power Supply

+

-

24 VAC or VDC

Power Supply

+

-

+

Signal

-

Field Device

+12

0V

UI1

ȍ

Controller

Power Supply

+

-

12VDC

Power Supply

+

-

+

Signal

-

Field Device

+12

Signal

0V

J or K

thermocouple

+

-

+

-

x200

instrumentation

amplier

UI#

0V

24 V

0 V

+12

24 V

Controller

+12

Signal

0V

J or K

thermocouple

+

-

+

-

x200

instrumentation

amplier

12

VDC

UI#

+12

0V

Controller

Type of field device Power source Wiring diagram

Field Wiring

3 wire transducer with 420 mA or 0-20 mA output

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

3 wire transducer with 420 mA or 0-20 mA output

Connect an external 250

Ω ½ Watt 1% load

resistor in parallel

between the universal

input terminal and 0V to

provide a return path for

the transducer signal

current.

J or K Thermocouples

When using J or K

thermocouples, install a

x200 low offset amplifier.

External power supply for

field device (depends on

field device requirements)

and 24 V external power

supply for controller.

Connect the negatives or

commons of both power

supplies to the 0V

terminal of the controller.

External power supply for

field device (depends on

field device requirements)

and 12 VDC external

power supply for

controller.

Connect the negatives or

commons of both power

supplies to the 0V

terminal of the controller.

24 VAC or VDC power

supply to controller.

The controller provides

the 12 VDC and a

maximum current of

250 mA to the field

device.

J or K Thermocouples

When using J or K

thermocouples, install a

x200 low offset amplifier.

28 (45)

12 VDC power supply

common to field device

and controller.

0 V

Page 29

4.3.3 Resistive 1000 Ω Temperature Sensor

UI#

1

2

0V

1000 Ω

resistive

temperature

sensor

Controller

0V

UI#

Nȍ

Field Device

+

-

1-30 VDC

Controller

!

For resistive temperature sensors, the corresponding DIP switch must be ON. See section

3.5 on page 17. For all other devices, the DIP switch must be OFF.

Table 5 Wiring a 1000 Ω temperature sensor

Type of field device Power source Wiring diagram

1000 Ω nickel or silicon

resistive temperature

sensor, for instance

OpenBAS-ACC-TE1K or

any PTC (positive

temperature coefficient)

thermistors

4.3.4 Measuring 24 VDC with Analog Inputs

N/A

Field Wiring

If you want to measure 24 VDC voltages, add a 15 kΩ ½ Watt 1% resistor in series with the

higher voltage to be measured. See Figure 18.

Figure 18 Measuring VDC

Caution: You can measure up to 30 VDC. A higher voltage will damage the

controller.

Only DC voltages can be input to the universal inputs. Applying AC

voltages or inverting the polarity will provide incorrect readings, and

can eventually damage the inputs.

4.3.5 Digital Inputs

The 8 universal inputs can receive digital signals. These are signals that represent only two

states.

The digital inputs have the following ranges:

• ZERO (0) is valid for an input voltage between 0 to 4 VDC

• ONE (1) is valid for an input voltage between 8 to12 VDC

29 (45)

Page 30

Field Wiring

Voltage

0V

2V

4V

6V

8V

10V

+12V

Valid

ZERO

region

Valid

ONE

region

Uncertain

region

Any voltage that lies between 4.1 to 7.9 V can give ambiguous results and must be avoided.

See Figure 19.

Input

Figure 19 Digital input voltage range

The digital inputs can be used as frequency or pulse counters with these specifications:

• Digital inputs 1-2 can measure square wave or pulsed signals

. The maximum

measurable frequency is 250 Hz (15,000 pulses per minute). The minimum pulse width

detectable is 2 milliseconds.

• Digital inputs 3-8 can measure frequencies up to 10 Hz (600 pulses per minute). The

minimum pulse width detectable is 50 milliseconds.

Dry contact, push buttons, magnetic reed switches or PNP transistors must supply voltage to

the digital input for correct operation.

To use the universal inputs as digital inputs

1. Connect the appropriate digital signal to the universal input according to the diagrams in

Ta bl e 6 .

2. Configure the digital input type using the OpenBAS software.

Table 6 shows how to connect different devices to the digital inputs.

30 (45)

Page 31

Table 6 Digital Input Wiring

UI#

+12

Field Device

Controller

0V

12VDC

OR

UI#

24V

+12

Field Device

Controller

0V

OR

UI#

Nȍ

24V

Field Device

24VDC

Controller

0V

0V

OR

!

Type of field device Power source Wiring diagram

Dry contact switch or

high switched PNP

transistor

Note: If you use a PNP

transistor, the voltage

must be DC.

Dry contact switch or

high switched PNP

transistor

Note: If you use a PNP

transistor, the voltage

must be DC.

External 12 VDC power supply

to feed the dry contact switches

12 VDC generated by the

controller

Field Wiring

0V

24V

Dry contact switch or

high switched PNP

transistor

4.4 Analog Outputs

The two analog outputs have short-circuit and thermal protection. They provide 10 mA with a

maximum voltage of 10 VDC to control the speed of a motor, the position of a valve or damper,

or light intensity using electronic ballasts with 0-10 V inputs.

Caution: Applying any external voltage less than 0 V or greater than 10 V will

damage the analog outputs.

0V

24 VDC power supply to feed

the dry contact switches

To ensure that analog outputs operate correctly, follow these guidelines:

• Use 18 AWG stranded wire.

• Limit the distance between the field device and the controller to 10 m (30 ft). Mircom

recommends shielded wire for noisy environments.

31 (45)

Page 32

Field Wiring

Analog

output 1

AO2AO1

Analog

AO#

+

-

0V

Field Device Controller

• If this distance is not possible, longer wire runs with shielded wire are allowed up to 30 m

(100 ft). Connect the shield to any 0V terminal on the controller, making sure to isolate

the shield on the other end. Failing to do so creates ground loops.

• When possible, route the wiring inside metal piping and ground the piping for better

results.

• Avoid running any analog signals near sources of electric noise such as: motors,

ballasts, fluorescent lamps, variable frequency drives, high energy contacts, RF (radio

frequency) transmitters, microwave ovens, and any other equipment that generates

electromagnetic interference.

• Keep a minimum distance of 30 cm (1 ft) between analog output wiring and any

conductor carrying more than 24 VAC.

• Follow good wiring and installation practices, and follow all local regulations and

electrical codes.

• Use either of the terminals labeled 0V to connect the return signal or common.

output 2

Figure 20 Analog outputs

Table 7 shows how to connect devices to the analog outputs.

Table 7 Analog Output Wiring

Type of field device Wiring diagram

Variable-frequency drive

with 1-10 VDC input for

speed control

Or

Dimmable ballast with 010 VDC control input

32 (45)

Page 33

Table 7 Analog Output Wiring (Continued)

AO#

+

Signal

-

24V

0V

Field Device

0V

Controller

24 V

!

BO2

BO1

no1

nc1

Relay

output 1

BO3 BO4 BO6

BO5

no5nc5

BO7

BO8

Relay

output 2

Relay

output 3

Relay

output 4

Relay

output 5

Relay

output 6

Relay

output 7

Relay

output 8

Type of field device Wiring diagram

24 VAC or VDC valve or

damper with 1-10 VDC

control input

4.5 Digital Relay Outputs

Field Wiring

Outputs 1 and 5 have common (labeled BO), normally open (labeled no), and normally closed

(labeled nc) contacts.

Outputs 2-4 and 6-8 have 2 contacts and can be configured in the software as normally open

or normally closed. By default they are normally open.

Attention: If DC voltage with anything other than purely resistive load is used on

the digital outputs, then the appropriate protective devices must be

installed.

Figure 21 Relay outputs

33 (45)

Page 34

Note: Installation of OpenBAS-HV-NX10 series automation controllers must be in

i

!

Single Phase

Motor

NO

NC

C

120 VAC

Controller

120 V lamp

120 VAC

Neutral

NO

NC

C

Controller

accordance with the Canadian Electrical Code or the National Electrical Code,

and comply with all local regulations. Final acceptance is subject to the Local

Authority Having Jurisdiction (AHJ).

Relay output connections can contain hazardous voltages that present the risk of

electric shock. Caution must be exercised when handling these terminals. Only

certified technicians should handle these terminals.

4.5.1 Surge Protection

The provisions shown in Table 8 should help to reduce electrical noise that could affect nearby

equipment.

Attention: Always install safety breakers and fuses according to the load and

voltage, and in accordance with Canadian Electrical Code or National

Electric Code. Follow all local regulations.

Field Wiring

Table 8 Surge Protection on Relay Outputs

Type of field

device

Single phase motor

120 V lamp with

ballast

Notes Wiring diagram

Install a 120 V MOV surge

protector in parallel with motor

to suppress noise.

Neutral

Install a 120 V MOV surge

protector in parallel with

solenoid coil to suppress

noise.

Note: Only lamps with ballast

require surge protection.

Incandescent, LED, and

halogen lamps do not require

surge protection.

34 (45)

Page 35

Table 8 Surge Protection on Relay Outputs (Continued)

120 VAC LED

120 VAC

Neutral

NO

NC

C

Controller

Nȍ

120 VAC coil

120 VAC

NO

NC

C

Controller

24 VDC coil

C

24 VDC

0 V

NO

NC

Controller

24 VDC lamp

24 VDC

0 V

C

NO

NC

Controller

Field Wiring

Type of field

device

120 VAC LED lamp

120 VAC coil

Notes Wiring diagram

High impedance lamps such

as LED lamps require a 15 kΩ

1W 5% resistor in parallel to

the lamp to prevent current

leakage.

Install a 120 V MOV surge

protector in parallel with

solenoid coil to suppress

noise.

Install a 1N4007 reverse

24 VDC coil

polarizing diode in parallel

with DC solenoid coil to

suppress flyback voltage.

24 VDC lamp N/A

Neutral

35 (45)

Page 36

Table 8 Surge Protection on Relay Outputs (Continued)

24 VAC coil

24 VAC

0 V

C

NO

NC

Controller

COM1

ref1

d1+ d1- ref2d2+ d2- ref3 d3+ d3-

COM2 COM3

Field Wiring

Type of field

Notes Wiring diagram

device

Install a 36 V MOV surge

24 VAC coil

protector in parallel with coil of

solenoid to suppress noise.

4.6 Field Bus Connections and OpenBAS-ACC-DB9

Figure 22 Field bus connections

Table 9 Field Bus Ports

Port Driver Module Functional Optional Driver Comments

COM1 RS-485 Yes Yes

COM2 RS-485 Yes Yes

COM3 RS-485

Note 1: P3 and COM3 are functional only on OpenBAS-HV-NX10D.

Note 2: Each of the three P ports allow the field replacement of the RS-485 modules with the

OpenBAS-ACC-RS485 optically isolated RS-485 module or OpenBAS-ACC-RS232

conversion module. See section 3.3.1 on page 13.

Note 3: To avoid intermittent communication blackouts, the isolation provided by the

OpenBAS-ACC-RS485 module is highly recommended for noisy environments, and to prevent

damage to the boards in extreme cases, especially if the OpenBAS-HV-NX10 series controller

is inside an enclosure containing high voltage wiring.

OpenBAS-HVNX10D only

OpenBAS-HVNX10D only

See notes 1, 2 and 3

4.6.1 OpenBAS-ACC-DB9

OpenBAS-ACC-DB9 is a DB9 adapter which is installed in one of the field bus ports.

36 (45)

Page 37

4.7 Networking

OpenBAS-NWK-ETH3

Cat 5 cable

RS-485

RS-485

Maximum 50 cm (20”)

OpenBAS-HV-NX10 Series

OpenBAS-NWK-ETH3

Cat 5 cable

RS-485

RS-485

OpenBAS-HV-NX10 Series

Figures 23 and 24 show how to add a controller to a network with OpenBAS-NWK-ETH3.

Each OpenBAS device must be powered separately.

Connect the SPI port on OpenBAS-NWK-ETH3 to the SPI port on the OpenBAS-HV-NX10

series controller with the included cable, as shown in Figure 23. See section 3.4 on page 17

for information about the SPI port.

Field Wiring

4.7.1 RS-485 Details

Figure 23 Networking with OpenBAS-NWK-ETH3 with the included cable

OpenBAS-NWK-ETH3 can also connect to one of the RS-485 connections on the OpenBASHV-NX10 series controller, as shown in Figures 24 and 25. See section 4.7.1 on page 37 for

information on the RS-485 ports.

Figure 24 Networking with OpenBAS-NWK-ETH3 over RS-458

Figure 25 shows 3 controllers networked with RS-485. The list of supported protocols is in

chapter 5.

• 22 AWG twisted pair

• Maximum length: 1219.2 m (4000 feet)

• Mircom recommends shielded cable

37 (45)

Page 38

Field Wiring

First controller

on network

Last controller

on network

Second

controller on

network

Connect shield to

chassis ground on

one metal enclosure

only

Send and

receive on P3

Reset button

Download

button

USB connection

for programming

USB connection

for backup

38 (45)

Figure 25 Networking with RS-485

4.8 Connections and LEDs on OpenBAS-HV-HX10D

Figure 26 Connections and LEDs on the OpenBAS-HV-NX10D

• USB connection for programming and updating firmware: Connect a computer to this

port in order to configure the display.

• USB connection for backup: Connect a USB stick to this port in order to create backups

for data trending.

• TX and RX: These LEDs flash to indicate communication through the P3 port (see

section 4.6 on page 36).

• Reset button: Press this button to restart the display.

• Download button: Press this button to load firmware on to the controller. Refer to the

OpenBAS Programming Manual for information on upgrading controllers.

Page 39

4.9 Circuit Board LEDs

PWR

TX

RX

• PWR: Is red when the unit is powered

• TX and RX: Flash green to indicate communication through ports COM1 and COM2

Figure 27 LEDs

Field Wiring

39 (45)

Page 40

5.0 Specifications

Standards: UL 60730-1

Input: 12 Vdc, 360 mA max., or 24 Vdc, 450 mA max.,

or 24 Vac 50/60 Hz, 500 mA max.

Output: 12 Vdc, 250 mA max. (when 24V powered)

Power Supply Protection: Resettable Fuse 1.1 A

Battery: FDK Corporation ML2430

Type: lithium

Nominal capacity: 100 mAh

Nominal voltage: 3 V

Mircom part number: BT-025

Relay Outputs 1 and 5: Voltage, current Load Form

125 VAC, 5 A General Use NO/NC

28 VDC, 5 A Resistive NO/NC

Relay Outputs 2, 3, 4, 6, 7, 8: Voltage, current Load Form

125 VAC, 5 A Resistive NO

125 VAC, 3 A General Use NO

2 Analog Outputs: Analog Output Voltage:

• 0-10 VDC

• 2-10 VDC

• 0-5 VDC

8 Universal Inputs: Analog Inputs:

• 0-10 VDC

• 0-5 VDC

• 0.5-4.5 VDC ratiometric

• 0-20 mA

• 4-20 mA

• 1000 Ω temperature sensor

• Thermocouple input with x200 amplifiers

Digital (binary) inputs:

• For dry contacts being fed by 12 VDC

Pulse counters:

• Active PNP 12 VDC

• For dry contacts being fed by 12 VDC

40 (45)

Page 41

Specifications

Communication Ports: 2 RS-485 ports (3 RS-485 ports on OpenBAS-HV-NX10D) supporting

the following protocols:

• COM1

• BACnet/MSTP

• Modbus/RTU-Slave

• Modbus/RTU-Master

• N2-Open

• Optomux

• COM2

• N2-Open

• Optomux

• N2/O22-master

• ASCII

• ECM

• COM3 (OpenBAS-HV-NX10D only)

• Modbus/RTU-Slave

• N2-Open

• Optomux

• N2/O22-master

• ASCII

RS-485 ports can be configured as RS-232 or optically isolated RS-485

1 USB 2.0 port supporting the following protocols:

• Optomux

• ASCII

2

2 I

C ports for memory expansion, LCD display, and OpenBAS-HV-

RF433R

1 SPI port

1 port for OpenBAS-HV-CORE2 display

Physical Characteristics: Weight: 360 g (12.8 oz)

Enclosure dimensions: 6 9/32” x 3 35/64” x 2 17/64” (160 mm x 90 mm x

58 mm)

Ambient Conditions: Operating Temperature: 0° to 40°C (32° to 104°F), 10% to 90% RH

noncondensing

Indoor Use Only

Purpose of Control: Operating Control

Construction of Control: Independently Mounted, for Panel Mount

Action Type and additional

Type 1.C

features:

Pollution Degree: 2

Software Class: Class A

Rated Impulse Voltage: 120V circuits: 2500V

24V circuits: 330V

41 (45)

Page 42

6.0 Warranty and Warning Information

WARNING!

Please read this document CAREFULLY, as it contains important warnings, life-safety, and

practical information about all products manufactured by the Mircom Group of Companies,

including Mircom and Secutron branded products, which shall include without limitation all fire

alarm, nurse call, building automation and access control and card access products

(hereinafter individually or collectively, as applicable, referred to as “Mircom System”).

NOTE TO ALL READERS:

1. Nature of Warnings. The within warnings are communicated to the reader out of an

abundance of caution and create no legal obligation for Mircom Group of Companies,

whatsoever. Without limiting the generality of the foregoing, this document shall NOT be

construed as in any way altering the rights and obligations of the parties, governed by the legal

documents that apply in any given circumstance.

2. Application. The warnings contained in this document apply to all Mircom System and shall

be read in conjunction with:

a. the product manual for the specific Mircom System that applies in given circumstances;

b. legal documents that apply to the purchase and sale of a Mircom System, which may

include the company’s standard terms and conditions and warranty statements;

c. other information about the Mircom System or the parties’ rights and obligations as may

be application to a given circumstance.

3. Security and Insurance. Regardless of its capabilities, no Mircom System is a substitute for

property or life insurance. Nor is the system a substitute for property owners, renters, or other

occupants to act prudently to prevent or minimize the harmful effects of an emergency

situation. Building automation systems produced by the Mircom Group of Companies are not

to be used as a fire, alarm, or life-safety system.

NOTE TO INSTALLERS:

All Mircom Systems have been carefully designed to be as effective as possible. However,

there are circumstances where they may not provide protection. Some reasons for system

failure include the following. As the only individual in contact with system users, please bring

each item in this warning to the attention of the users of this Mircom System. Failure to

properly inform system end-users of the circumstances in which the system might fail may

result in over-reliance upon the system. As a result, it is imperative that you properly inform

each customer for whom you install the system of the possible forms of failure:

4. Inadequate Installation. All Mircom Systems must be installed in accordance with all the

applicable codes and standards in order to provide adequate protection. National standards

require an inspection and approval to be conducted by the local authority having jurisdiction

following the initial installation of the system and following any changes to the system. Such

inspections ensure installation has been carried out properly.

42 (45)

5. Inadequate Testing. Most problems that would prevent an alarm a Mircom System from

operating as intended can be discovered by regular testing and maintenance. The complete

system should be tested by the local authority having jurisdiction immediately after a fire,

storm, earthquake, accident, or any kind of construction activity inside or outside the premises.

Page 43

The testing should include all sensing devices, keypads, consoles, alarm indicating devices

and any other operational devices that are part of the system.

NOTE TO USERS:

All Mircom Systems have been carefully designed to be as effective as possible. However,

there are circumstances where they may not provide protection. Some reasons for system

failure include the following. The end user can minimize the occurrence of any of the following

by proper training, testing and maintenance of the Mircom Systems:

6. Inadequate Testing and Maintenance. It is imperative that the systems be periodically

tested and subjected to preventative maintenance. Best practices and local authority having

jurisdiction determine the frequency and type of testing that is required at a minimum. Mircom

System may not function properly, and the occurrence of other system failures identified below

may not be minimized, if the periodic testing and maintenance of Mircom Systems is not

completed with diligence and as required.

7. Improper Operation. It is important that all system users be trained in the correct operation

of the alarm system and that they know how to respond when the system indicates an alarm.

A Mircom System may not function as intended during an emergency situation where the user

is unable to operate a panic or emergency switch by reason of permanent or temporary

physical disability, inability to reach the device in time, unfamiliarity with the correct operation,

or related circumstances.

Warranty and Warning Information

8. Insufficient Time. There may be circumstances when a Mircom System will operate as

intended, yet the occupants will not be protected from the emergency due to their inability to

respond to the warnings in a timely manner. If the system is monitored, the response may not

occur in time enough to protect the occupants or their belongings.

9. Carelessness or Safety Hazards. Moreover, smoke detectors may not provide timely

warning of fires caused by carelessness or safety hazards such as smoking in bed, violent

explosions, escaping gas, improper storage of flammable materials, overloaded electrical

circuits or children playing with matches or arson.

10. Power Failure. Some Mircom System components require adequate electrical power supply

to operate. Examples include: smoke detectors, beacons, HVAC, and lighting controllers. If a

device operates only by AC power, any interruption, however brief, will render that device

inoperative while it does not have power. Power interruptions of any length are often

accompanied by voltage fluctuations which may damage Mircom Systems or other electronic

equipment. After a power interruption has occurred, immediately conduct a complete system

test to ensure that the system operates as intended.

11. Battery Failure. If the Mircom System or any device connected to the system operates from

batteries it is possible for the batteries to fail. Even if the batteries have not failed, they must be

fully charged, in good condition, and installed correctly. Some Mircom Systems use

replaceable batteries, which have a limited life-span. The expected battery life is variable and

in part dependent on the device environment, usage and type. Ambient conditions such as

high humidity, high or low temperatures, or large temperature fluctuations may reduce the

expected battery life. Moreover, some Mircom Systems do not have a battery monitor that

would alert the user in the event that the battery is nearing its end of life. Regular testing and

replacements are vital for ensuring that the batteries function as expected, whether or not a

device has a low-battery monitor.

12. Physical Obstructions. Motion sensors that are part of a Mircom System must be kept clear

of any obstacles which impede the sensors’ ability to detect movement. Signals being

communicated by a Mircom System may not reach the receiver if an item (such as metal,

water, or concrete) is placed on or near the radio path. Deliberate jamming or other

inadvertent radio signal interference can also negatively affect system operation.

43 (45)

Page 44

Warranty and Warning Information

13. Wireless Devices Placement Proximity. Moreover all wireless devices must be a minimum

and maximum distance away from large metal objects, such as refrigerators. You are required

to consult the specific Mircom System manual and application guide for any maximum

distances required between devices and suggested placement of wireless devices for optimal

functioning.

14. Failure to Trigger Sensors. Moreover, Mircom Systems may fail to operate as intended if

motion, heat, or smoke sensors are not triggered.

a. Sensors in a fire system may fail to be triggered when the fire is in a chimney, walls, roof,

or on the other side of closed doors. Smoke and heat detectors may not detect smoke

or heat from fires on another level of the residence or building. In this situation the

control panel may not alert occupants of a fire.

b. Sensors in a nurse call system may fail to be triggered when movement is occurring

outside of the motion sensors’ range. For example, if movement is occurring on the other

side of closed doors or on another level of the residence or building the motion detector

may not be triggered. In this situation the central controller may not register an alarm

signal.

15. Interference with Audible Notification Appliances. Audible notification appliances may be

interfered with by other noise sources such as stereos, radios, televisions, air conditioners,

appliances, or passing traffic. Audible notification appliances, however loud, may not be heard

by a hearing-impaired person.

16. Other Impairments. Alarm notification appliances such as sirens, bells, horns, or strobes

may not warn or waken a sleeping occupant if there is an intervening wall or door. It is less

likely that the occupants will be alerted or awakened when notification appliances are located

on a different level of the residence or premise.

17. Software Malfunction. Most Mircom Systems contain software. No warranties are provided

as to the software components of any products or stand-alone software products within a

Mircom System. For a full statement of the warranties and exclusions and limitations of

liability please refer to the company’s standard Terms and Conditions and Warranties.

18. Telephone Lines Malfunction. Telephone service can cause system failure where telephone

lines are relied upon by a Mircom System. Alarms and information coming from a Mircom

System may not be transmitted if a phone line is out of service or busy for a certain period of

time. Alarms and information may not be transmitted where telephone lines have been

compromised by criminal tampering, local construction, storms or earthquakes.

19. Component Failure. Although every effort has been made to make this Mircom System as

reliable as possible, the system may fail to function as intended due to the failure of a

component.

20. Integrated Products. Mircom System might not function as intended if it is connected to a

non-Mircom product or to a Mircom product that is deemed non-compatible with a particular

Mircom System. A list of compatible products can be requested and obtained.

Warranty

44 (45)

Purchase of all Mircom products is governed by:

https://www.mircom.com/product-warranty

https://www.mircom.com/purchase-terms-and-conditions

https://www.mircom.com/software-license-terms-and-conditions

Page 45

45

CANADA - Main Office

25 Interchange Way

Vaughan, ON L4K 5W3

Tel: (905) 660-4655

(888) 660-4655

Fax: (905) 660-4113

U.S.A

4575 Witmer Industrial Estates

Niagara Falls, NY 14305

Tel: (905) 660-4655

(888) 660-4655

Fax: (905) 660-4113

© Mircom 2017

Printed in Canada

Subject to change without prior notice

www.mircomgroup.com

Loading...

Loading...