Page 1

TECHNICAL SUPPORT

North America

Tel: (888) Mircom5

(888) 647-2665

International

Tel: (905) 647-2665

Canada - Head Ofce

25 Interchange Way, Vaughan, Ontario, L4K 5W3

Tel: (905) 660-4655, Fax: (905) 660-4113

USA

4575 Witmer Industrial Estates, Niagara Falls, NY 14305

Tel Toll Free: (888) 660-4655, Fax Toll Free: (888) 660-4113

Website: www.mircom.com

4

1

MIR-65 Series Smoke & Heat Detectors

Installation Instructions

General

These ins tructions apply to the 6” E-Z Fit base, part no MSB -65B, for installing

MIR-65 Series smoke and heat detectors.

Installation

These pr oducts must be installed in accor dance with the applicable NFPA standards,

local codes and jurisdictional authorities. Failure to follow these instructions

may result in failure of the detectors to report an alarm condition. Mircom is not

responsible for dete ctors which are improperly installed, maintained and teste d.

Before in stalling the se produc ts chec k the continuity, polarity and insulation

resist ance of all wiring. Check that siting is in accor dance with the r e system

drawings and conforms to all applicable loc al codes such as NFPA 72.

Use 3” oct agonal box for dir ect connection to the base. 4” oct agonal and 4” square

boxes may be used with proper UL listed mounting brackets. When mounting on

a wall, install 4” to 12” from the ceiling. Use 3M Weatherban 606 Non-Flammable

sealing compound (or equivalent) to seal eld wiring conduit opening in the ele ctric al

box, this will reduce the stac king effect. Secure the bas e to the elec trical box with

appropriate screws. Do not overtighten the screws. The raise d mark on the side of

the base indic ates the direction of the detector LED when t ted. Connec t the shield, if

required, to the SHIELD terminal on the base.

LT-949 Rev.2

September 2010

39214-244/Issue 1

Page 2

2

3

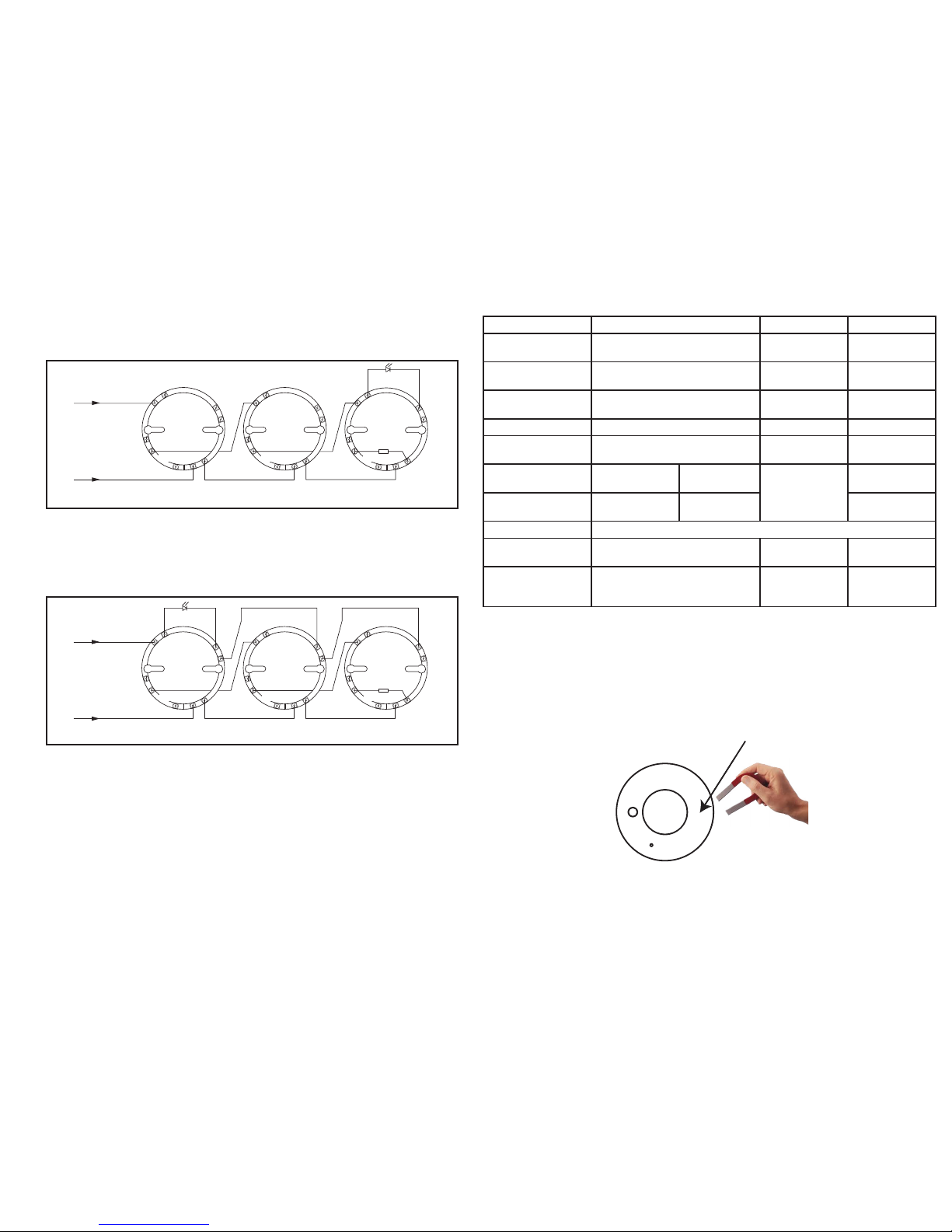

Fig 1. Wiring diagram of MIR-65 Series zone

Fig 2. Wiring diagr am of MIR-65 Series zone with co mmon remote indic ator

Fr

om control panel

L2

L

1

IN

–R

L1OUT

L2

L

1

IN

–R

L1OUT

L2

L

1

IN

–R

L1OUT

End-of-line

device

Remote LED

+

–

SHIELD SHIELD SHIELD

L

1

IN

–R

L1OUT

L2

L

1

IN

–R

L1OUT

L2

L

1

IN

–R

L1OUT

End-of-line

device

From control panel

L2

+

–

SHIELD SHIELD SHIELD

Remote LED

Warning

CAU TIO N: Do not use looped wire under terminal L2. Break wir e run to provide

supervision of conne ctions.

The above instructions cover the following base model:

MSB-65B 6” E-Z Fit base

Technical Data

Detector model # MHD-65-135, MHD-65-200 MID-65I MPD-65P

Detector type Heat Rate-of-Rise/Fixed

Temperature

Ionization Photoelectric

Working voltage 9–33V dc 9–33V dc 9–33V dc

Maximum alarm

current

17mA at 9V, 52mA at 24V 17mA at 9V,

52mA at 24V

17mA at 9V,

52mA at 24V

Surge current 0mA 0mA 0mA

Supervisory

current

40–50μA at 9V, 45–55μA at 24V 40–50μA at 9V,

45–55μA at 24V

40–50μA at 9V,

45–55μA at 24V

Heat element

rating

MHD-65-135 Ordinary

(135º F/57 ºC)

N/A N/A

MHD-65-200 Intermediate

(200ºF/93ºC)

Control panel UL/ULC L isted Compatible Contr ol Panel

Test method Magnet or hair dryer Magnet or

Gemini 501

Magnet or

Gemini 501

Installation

temperature

Minimum 32ºF (0ºC) Maximum

at least 20ºF (11ºC) below

rating

Minimum 32ºF

(0ºC) Maximum

158ºF (70ºC)

Minimum 32ºF

(0ºC) Maximum

140ºF (60ºC)

Control Panel Compatibility

For details of compatible control panels, please contact Mircom directly.

Performing the Magnet Test

Place the magnet near the detector on the OPPOSITE side of the LED.

Fig 3. Performing a magnet test o n the MIR-65 series detec tors.

LED

PLACE MAGNET HERE

Loading...

Loading...