Page 1

FX-3500

Fire Alarm Control Panel

LT-1083 Rev.2.1

December 2013

Installation and Operation Manual

For the latest compatability information visit www.mircom.com/deviceguide

Page 2

Page 3

Table of Contents

Table of Contents

1.0 Industry Canada and FCC Notice 9

1.1 Notice for all FX-3500 Series Built-In UDACTs Sold in Canada .................................... 9

1.2 Industry Canada Notice ................................................................................................. 9

1.3 Notice for all FX-3500 Series Built-in UDACTs Sold in the U.S.A. ................................ 9

1.4 FCC Notice .................................................................................................................... 10

2.0 Introduction 11

2.1 The FX-3500 Addressable Fire Alarm Control Panel ....................... ... ... .... ... ... ... ... ........ 11

2.1.1 Optional Items ................................................................................................................ 11

2.2 General Notes ................................................................................................................ 12

2.3 Contact Us ..................................................................................................................... 13

2.3.1 General Inquiries ............................................................................................................ 13

2.3.2 Customer Service ......................................................................... ... ... ........................... 13

2.3.3 Technical Support .. ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... .... ... ... ... ... ........ 13

2.3.4 Website ............................... ................................................................... ........................ 13

3.0 FX-3500 Overview 14

3.1 FX-3500 Fire Alarm Control Panel Models .................................................................... 14

3.2 FX-3500 System Components ............................ ....................................... .................... 15

3.2.1 Devices .......................................................................................................................... 20

4.0 Installation 23

4.1 BBX-1024DS and BBX-1024DSR Mechanical Installation ............................................ 23

4.2 Installation Tips .............................................................................................................. 24

4.3 Installing Adder Modules ................................................................................................ 24

4.3.1 Installing the PR-300 Polarity Reversal and City Tie Module ........................................ 28

4.4 Installing the ALC-636 Dual Loop Adder ........................................................................ 28

4.4.1 Installing the RAX-1048TZDS Display Adder Module .................................................... 30

5.0 Operation 31

5.1 Addressable/Analog Devices ......................................................................................... 31

5.1.1 Supervision of Devices .................................................................................................. 32

5.1.2 Device LEDs .................................................................................................................. 32

5.1.3 Alarm Conditions ....................... ... ... .... ... ... ... .... ... ... ....................................... ... ... ... .... .... 32

5.1.4 Drift Compensation ........................................................................................................ 33

5.1.5 Auto Test ........................................................................................................................ 33

5.2 Configurable Input Types ............................................................................................... 33

3

Page 4

Table of Contents

5.2.1 Alarm Input (Non-Verified) ............................................................................................. 34

5.2.2 Supervisory Inputs ................ .... ... ... ... ... .... ... ....................................... ... ... ... .................. 34

5.2.3 Building/Property Safety Input ............... .... ... ... ... .... ...................................... .... ... ... ... ... .. 35

5.2.4 Priority Alarm .................................................................................................................. 35

5.2.5 Trouble-Only Input ......................................................................................................... 35

5.2.6 Waterflow Alarm Input ............................... ... ... ... .... ... ... ....................................... ... ... ... .. 36

5.2.7 System Status Correlations ....................... ... ... ... .... ... ..................................................... 36

5.2.8 Audible Walktest ....................... ... ... ... ....................................... ... ... .... ... ... ... .................. 36

5.2.9 Silent Test .......................................... ... ....................................... ... ............................... 36

5.2.10 Manual Day/Night ........................................................................................................... 37

5.2.11 Auto Day/Night ............................................................................................................... 37

5.2.12 Verified Alarm Input ........................................................................................................ 37

5.3 Output Types .................................................................................................................. 37

5.3.1 Signal Output ................................................................................................................. 38

5.3.2 Strobe Type Settings ...................................................................................................... 38

5.3.3 Relay Output .................................................................................................................. 39

5.4 NAC Circuit Operation ........................ ... .... ... ... ... .... ... ... ....................................... ... ... ... .. 39

5.5 Single Stage Operation .................................................................................................. 40

5.6 Two-Stage Operation ......................................... .... ... ... ... .... ...................................... ... .. 40

5.7 Evacuation Codes .......................................................................................................... 42

5.7.1 Two Stage Alert Code .................................................................................................... 42

5.8 Positive Alarm Sequence ............................................................................................... 42

5.8.1 Enabling or Disabling the Positive Alarm Sequence ...................................................... 43

5.9 Remote Annunciator Operation ....................................... ............. ............. ............. ........ 44

5.9.1 Supervision of annunciators ........................................................................................... 44

5.9.2 RAX-LCD-LITE Shared Display Annunciator ................................................................. 44

5.9.3 RAM-3500-LCD Shared Display Annunciator ........................... ... ... .... ... ... ... .... ... ... ... ... .. 44

5.9.4 Conventional Annunciators ............................................................................................ 45

5.9.5 SRM-312 Smart Relay Module ...................................................................................... 45

5.10 Dialer Operation ............................................................................................................. 45

5.10.1 Event Reporting ............................................................................................................. 45

5.10.2 Telephone line supervision ............................................................................................ 45

5.11 Using the Operation Menu from the Control Panel ........................................................ 47

5.11.1 Setting the Time ........... ... ... ... .... ... ... ... ............................................................................ 48

5.11.2 Setting the Password ..................................................................................................... 48

5.11.3 Reports ........................................................................................................................... 49

5.11.4 Clear Logs ...................................................................................................................... 52

5.11.5 Walk Test ....................................................................................................................... 52

5.11.6 Bypass ........................................................................................................................... 53

5.11.7 Auxiliary Disconnect ....................................................................................................... 57

5.11.8 Test Dialer ...................................................................................................................... 57

5.11.9 After Hours ..................................................................................................................... 57

5.11.10 Clear Verify Count .......................................................................................................... 58

5.11.11 Ground Fault Test - Factory Use Only ........................................................................... 58

5.11.12 Positive Alarm Sequence ............................................................................................... 58

4

Page 5

Table of Contents

5.11.13 Exit .................................. .................................................................... ........................... 59

6.0 Indication & Controls 60

6.1 Indication and Controls ............. ... ... .... ... ... ... .... ... ....................................... ... ... ... ... .... ... . 60

6.2 LCD Display ................................................................................................................... 60

6.2.1 Numeric Keypad and Cursor Buttons ............................................................................ 61

6.3 Common LED Indicators and Control Buttons ............................................................... 62

6.3.1 Flash Rates .................................................................................................................... 65

7.0 Wiring 66

7.1 Wiring Tables ............................................................................ .... ... ... ........................... 66

7.1.1 Addressable Loop Wiring Maximums ............................................................................ 66

7.1.2 RS-485 Wiring to Annunciators and other Devices ........................................................ 66

7.1.3 NAC and Auxiliary Power Supply Circuits ...................................................................... 66

7.1.4 Input Circuits .................................................................................................................. 67

7.2 Wire Routing .................................................................................................................. 68

7.3 Addressable Loop Wiring ............................................................................................... 69

7.3.1 Addressable Loop Wiring - Class B or Style 4 ....... ....................................... ................. 69

7.3.2 Addressable Loop Wiring - Class A or Style 6 ....... ....................................... ................. 69

7.3.3 Addressable Loop Wiring - Class A or Style 7 ....... ....................................... ................. 70

7.4 NAC Circuit Wiring ......................................................................................................... 70

7.4.1 NAC Circuit – Class B or Style Y Wiring ............................................. ... .... ... ... .............. 71

7.4.2 NAC Circuit – Class A or Style Z Wiring ............. ... ... .... ... ... ... ... .... ................................. 71

7.4.3 UL 864 Rev. 9 Addressable Supervised Output Module Wiring ......... ... ....... ... ... ... .... ... . 72

7.4.4 RTI-1 Common Remote Trouble Indicator Wiring ......................... ............. ............ ........ 72

7.5 Module and Devices Wiring ........................................................................................... 73

7.5.1 Dialer Wiring ............................. ... ... .... ... ... ... .... ... ... ....................................... ... ... ... ........ 73

7.5.2 Connecting to a DCS SurGuard Receiver ..................................................................... 74

7.5.3 PR-300 Polarity Reversal and City Tie Module Wiring .................................................. 75

7.6 Power Supply Wiring ...................................................................................................... 76

7.6.1 Main Power Supply ... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... ... ... ... .... .... 76

7.6.2 Supervision of Auxiliary Supplies ................................................................................... 77

7.7 System Checkout ........................................................................................................... 79

7.7.1 Before Turning The Power ON ...................................................................................... 79

7.7.2 Power-up Procedure .... ................................................................................. ................. 79

7.8 Troubleshooting ............................................................................................................. 79

7.8.1 Circuit Trouble ........................... ... ....................................... ... ... .... ... ... ... ........................ 79

7.8.2 Ground Fault .................................................................................................................. 79

7.8.3 Battery Trouble .............................................................................................................. 79

7.8.4 Common Trouble ........................................................................................................... 79

5

Page 6

Table of Contents

8.0 Appendix A - Compatible Receivers 80

9.0 Appendix B - FX-3500 Series Compatible Devices 81

9.1 FX-3500 Series ULI Listed Compatible Devices ............................................................ 81

9.1.1 ULI Listed Compatible Addressable Devices ................................................................. 81

9.1.2 ULI Listed Compatible Two-Wire Smoke Detectors ............... ........................................ 84

9.2 FX-3500 Compatible Horn/Strobes ................................................................................ 86

9.3 FX-3500 Series ULC Listed Compatible Devices .......................................................... 87

9.3.1 ULC Listed Compatible Addressable Devices ............................................................... 87

9.3.2 ULC Listed Two-Wire Smoke Detectors ........................................................................ 90

9.3.3 UL and ULC Listed Supported Non-Synchronous Horn/Strobes ................................... 90

10.0 Appendix C - Manual Panel Configuration 91

10.0 COMMAND MENU ......................................................................................................... 91

10.0 COMMAND MENU/ 1. CONFIGURATION MENU ......................................................... 91

10.0 CONFIGURATION MENU/1. PANEL CONFIGURATION ............................................. 91

10.0 PANEL CONFIGURATION/1. FEATURES .................................................................... 91

Note: PANEL CONFIGURATION/2. ADDRESS CFG. ............................................................ 94

Note: PANEL CONFIGURATION/3. DEVICE LABEL .............................................................. 94

Note: PANEL CONFIGURATION/4. USER MESSAGE .......................................................... 95

Note: PANEL CONFIGURATION/5. LANGUAGE ................................................................... 95

11.0 Appendix D - Reporting 96

11.1 Ademco Contact-ID FX-3500 Series Event Codes ....................................................... 96

11.2 Security Industries Association SIA Format Protocol FX-3500 Series Event Codes ..... 97

12.0 Appendix E - Specifications And Features 98

12.1 FX-3500 Fire Alarm Control Panel ................................................................................. 98

12.2 FX-3500 System Module and Annunciator Specifications ........................................... .. 99

13.0 Appendix F - Battery Calculations 100

14.0 Warranty and Warning Information 102

6

Page 7

List of Figures

List of Figures

Figure 1 FX-3500 with DOX-1024DSR ............. ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... .............. 14

Figure 2 BBX-1024DS and BBX-1024DSR Installation Instructions and Dimensions ................. 23

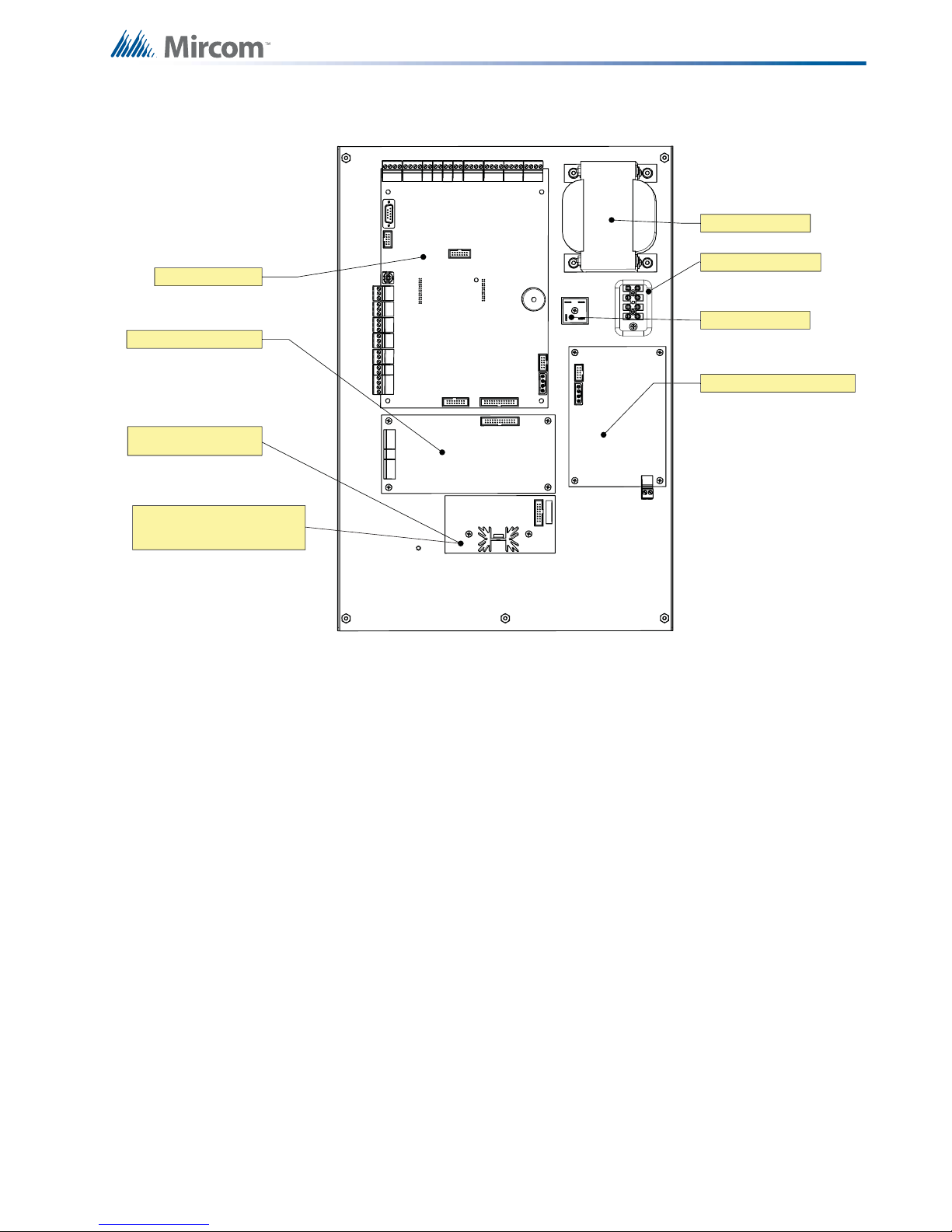

Figure 3 Main Board with all Adder Modules Installed ......................... ... .... ... ... ... .... ... ... ... ... ........ 25

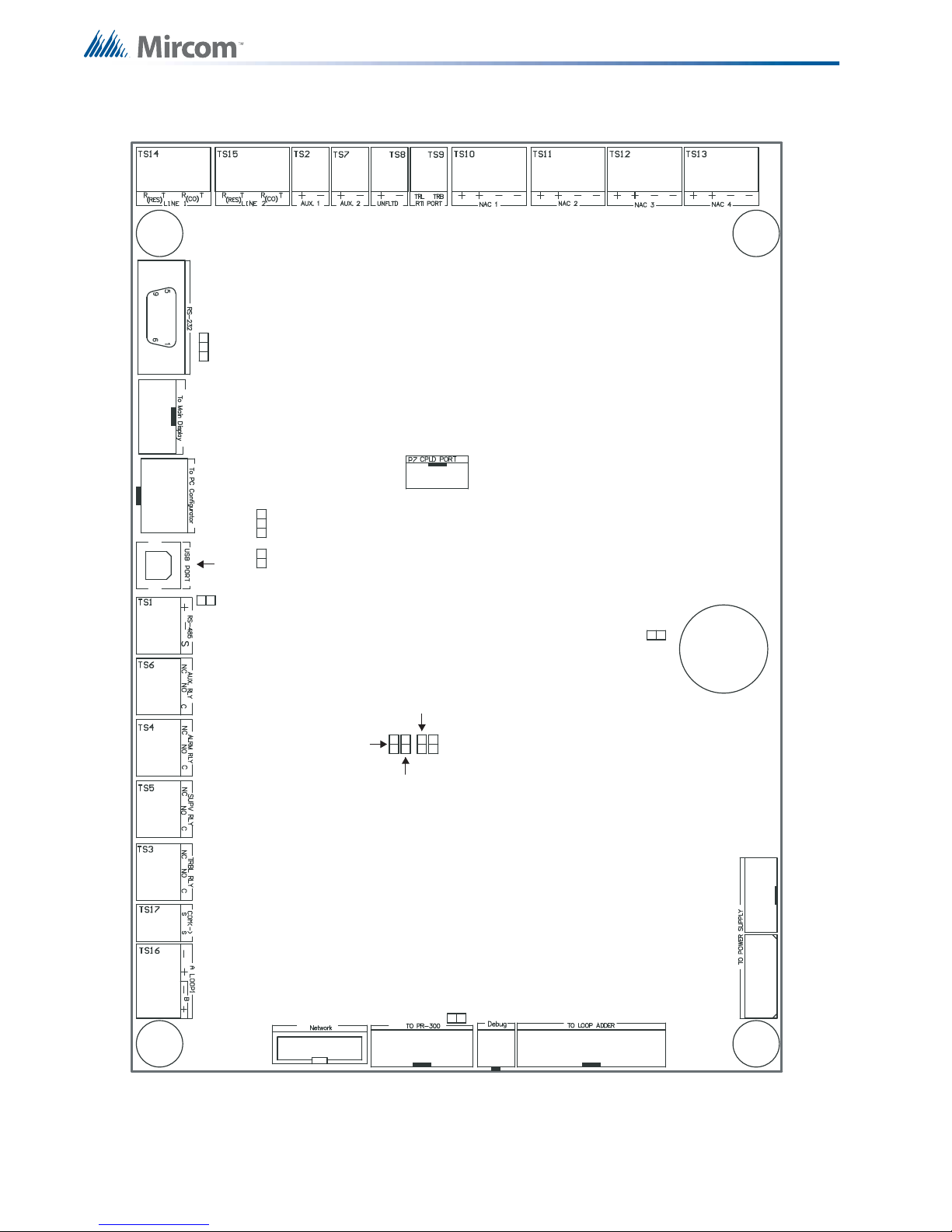

Figure 4 Port and Jumper Locations on Main Board .................................................................... 26

Figure 5 Installing the PR-300 Polarity Reversal and City Tie Module ........................................ 28

Figure 6 Installing the ALC-636 Dual Loop Adder ........................................................................ 29

Figure 7 FX-3500 Configurator Date and Time Settings ...................................... .... ... ... ... ... .... ... . 32

Figure 8 Enabling the Positive Alarm Sequence .. ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... . 43

Figure 9 Operation Menu ............................................................................................................ 47

Figure 10 LED Indicators and Control Buttons .............................. ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... . 60

Figure 11 Numeric Keypad ............................. .... ... ... ... .... ... ........................................................... 61

Figure 12 Wire Routing ................ ....................................... ... ... .... ... ... ... ... .... ... ... ... ........................ 68

Figure 13 Addressable Loop Wiring - Class B or Style 4 .............................. ... ... ... ........................ 69

Figure 14 Addressable Loop Wiring - Class A or Style 6 .............................. ... ... ... ........................ 69

Figure 15 Addressable Loop Wiring - Class A or Style 7 .............................. ... ... ... ........................ 70

Figure 16 NAC Circuit – Class B or Style Y Wiring .......................................... ... ... .... ... ... ... ... .... ... . 71

Figure 17 NAC Circuit – Class A or Style Z Wiring .......... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... . 71

Figure 18 RTI-1 Common Remote Trouble Indicator Wiring .......................................................... 72

Figure 19 Wiring the Dialer ............................ ....................................... ... .... ... ... ... .... ... ................. 73

Figure 20 Connecting an FX-3500 FACP to a DCS Surguard System Receiver ............. .............. 74

Figure 21 Wiring the PR-300 Polarity Reversal and City Tie Module ............................................ 75

Figure 22 Main Power Supply Wiring and Connections ...... ... ... .... ... ... ...... .... ... ... ... .... ... ... ... ... .... ... . 77

Figure 23 Supervision of Auxiliary Supplies ................................................................................... 78

7

Page 8

List of Tables

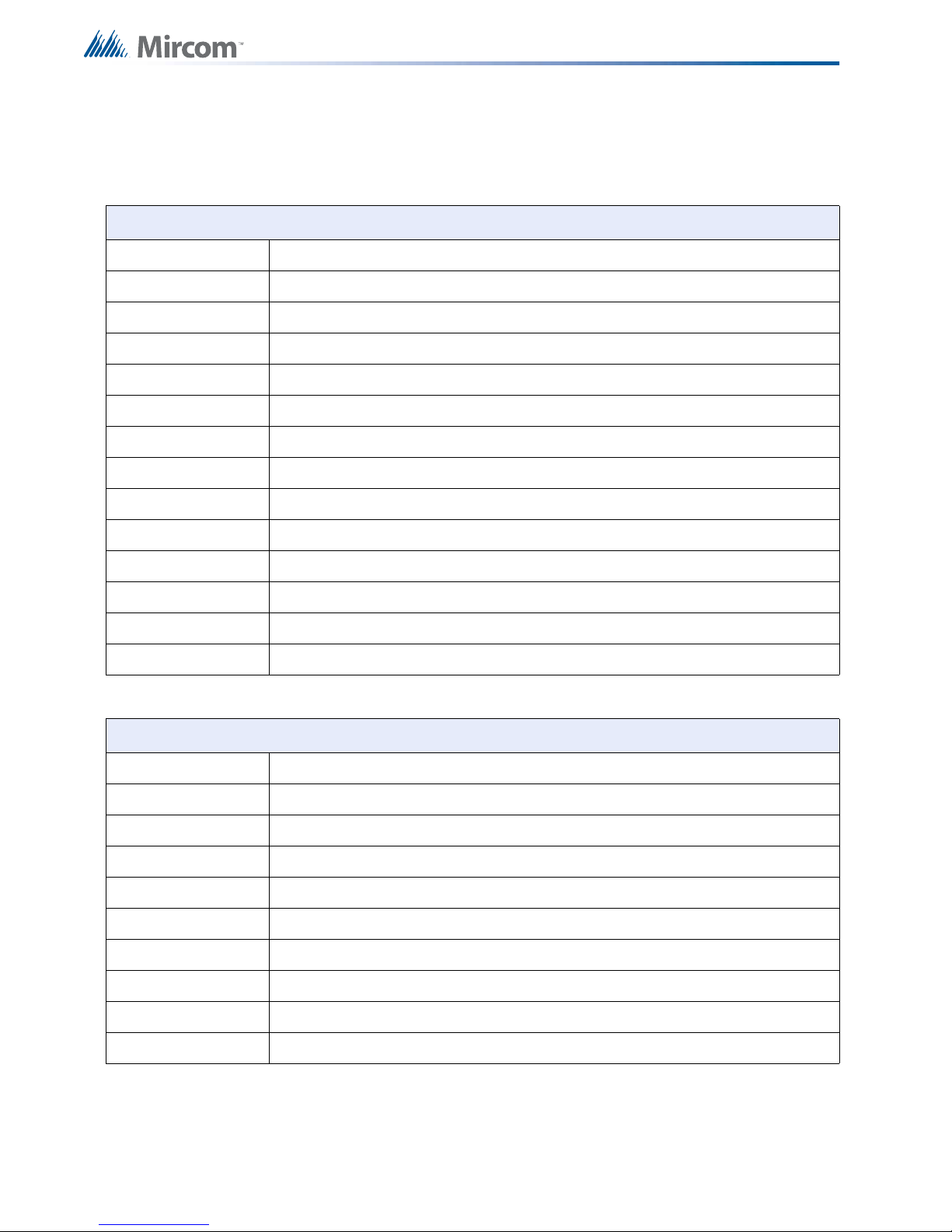

Table 1 FX-3500 System Components .. ... ... ... ... .... ... ... ... .... ... ... .......................................... ... ... .. 15

Table 2 Advanced Protocol Detectors ......................................................................................... 20

Table 3 Advanced Protocol Intelligent Modules .......................................................................... 20

Table 4 Advanced Protocol Manual Stations .............................................................................. 21

Table 5 Ancillary Modules ......... ... ... ... .... ... ....................................... ... ... ... ... .... ... ... ... .... ... ........... 21

Table 6 Bases .............. ... ... ... ....................................... ... .... ... ....................................... .............. 21

Table 7 CLIP Detectors ............................. ... ... ... .... ... ... ... .... ... ....................................... ... ... ........ 22

Table 8 CLIP Modules ................................................................................................................. 22

Table 9 Main Board Connectors and Jumper ............................................................................. 27

Table 10 PR-300 Polarity Reversal and City Tie Module Connectors and Jumpers ..................... 28

Table 11 ALC-636 Dual Loop Adder Connectors and Jumpers .................................................... 29

Table 12 UL864 90.23 Table ......................................................................................................... 31

Table 13 Configurable Input Types ............................................................................................... 33

Table 14 Configurable Output Types ............................................................................................ 38

Table 15 Annunciator Address DIP Switch Settings ..................................................................... 44

Table 16 List Bypass Special Characters ..................................................................................... 55

Table 17 Keypad and Cursor buttons descriptions ....................................................................... 61

Table 18 LED Indicators and Control Buttons ............................................................................... 62

Table 19 Advanced Protocol and CLIP Devices Addressable Loop Wiring Table ........................ 66

Table 20 NAC and Auxiliary Power Circuits Wiring Table ........................................ ................ ..... 66

Table 21 MIX-502MAP(A) Conventional Zone Module Input Circuit Wiring Table ........................ 67

Table 22 Power Supply Electrical Ratings .................................................................................... 76

Table 23 Compatible DACR Receivers .................................... ............................................. ........ 80

Table 24 ULI Advanced Protocol Detectors .................................................................................. 81

Table 25 ULI Advanced Protocol Intelligent Modules ................................................................... 81

Table 26 ULI Advanced Protocol Manual Stations ........................................................................ 81

Table 27 ULI Ancillary Modules .................................................................................................... 82

Table 28 ULI Bases .................................. ... ... ... ... ....................................... ... .... ... ... ... .... .............. 82

Table 29 ULI Intelligent Detectors ................................................................................................. 82

Table 30 ULI Intelligent Modules ................................................................................................... 83

Table 31 ULI Two-Wire Smoke Detectors ..................................................................................... 84

Table 32 FX-3500 Compatible Horn/Strobes ..................................... ........................................... 86

Table 33 ULC Advanced Protocol Detectors ................................................................................ 87

Table 34 ULC Advanced Protocol Intelligent Modules ................... .... ... ... .....................................

Table 35 ULC Advanced Protocol Manual Stations ...................................................................... 87

Table 36 ULC Ancillary Modules ................................................................................................... 88

Table 37 ULC Bases ......... ... ... .... ... ... ....................................... ... ... .... ... ... ... ... .... ... ... ..................... 88

Table 38 ULC Intelligent Detectors ...... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... ... ... ..... 88

Table 39 ULC Intelligent Modules ..... ... .... ... ... ............................................................................... 88

Table 40 ULC Two-Wire Smoke Detectors .......... ......................................................................... 90

Table 41 Contact-ID Event Codes ................................................................................................ 96

Table 42 SIA-DCS Event Codes . ... ... ... .... ... ... .......................................... ..................................... 97

Table 43 FX-3500 Specifications ................ ... ............................................................................... 98

Table 44 FX-3500 System Modules and Annunciator Specifications ................... ... ... .... ... ... ... ... .. 99

Table 45 Recommended Batteries ................................................................................................ 101

87

8

Page 9

Industry Canada and FCC Notice

!

i

1.0 Industry Canada and FCC Notice

1.1 Notice for all FX-3500 Series Built-In UDACTs Sold in Canada

Mircom's FX-3500 SERIES BUILT-IN UDACT Communicator described in this manual is listed

by Underwriters Laboratories Canada (ULC) for use in slave application under Standard ULCS527 (Standard for Control Units for Fire Alarm Systems) and ULC-S559 (Equipment for Fire

Signal Receiving Centres and Systems). These Communicators should be installed in

accordance with this manual; the Canadian / Provincial / Local Electrical Code; and/or the

local Authority Having Jurisdiction (AHJ).

1.2 Industry Canada Notice

Repairs to certified equipment should be made by an authorized Canadian maintenance

facility designated by the supplier. Any repairs or alteration made by the user to this

equipment, or equipment malfunctions, may give the telecommunications company cause to

request the user to disconnect the equipment. Users should ensure for their own protection

that the Earth Ground connections of the power utility, telephone lines and internal metallic

water pipe system, if present, are connected together. This is necessary both for proper

operation and for protection.

Attention: Users should not attempt to make such connections themselves, but

should contact the appropriate electric inspection authority, or

electrician, as appropriate.

Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate

1.3 Notice for all FX-3500 Series Built-in UDACTs Sold in the

U.S.A.

Notes: The Ringer Equivalence Number (REN) assigned to each terminal device

provides an indication.

The termination on an interface may consist of any combination of devices

subject only to the requirement that the sum of the Ringer Equivalence Numbers

of all the devices does not exceed 5.

The Label Identification Number for this product is xxx. The zzz represents the REN without a

decimal point (e.g., zzz is a REN of z.zz). For earlier products, the REN is separately shown

on the label.

Mircom's FX-3500 SERIES BUILT-IN UDACT Digital Communicator described in this manual

is listed by Underwriters Laboratories Inc.

(ULI) for use in slave application in conjunction with a Listed Fire Alarm Control Panel under

Standard 864 (Control Units for Fire Protective Signalling Systems). These Communicators

comply with the National Fire Protection Association (NFPA) performance requirements for

UDACTs and should be installed in accordance with NFPA 72 Chapter 4 (Supervising Station

Fire Alarm System). These Communicators should be installed in accordance with this

9

Page 10

manual; the National Electrical Code (NFPA 70); and/or the local Authority Having Jurisdiction

(AHJ).

1.4 FCC Notice

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the

ACTA. On the telco transformer of this equipment is a label that contains, among other

information, a product identifier in th e format US:XXXXXXXX. If requested, this number must

be provided to the telephone company. This equipment is capable of seizing the line. This

capability is provided in the hardware.

Type of Service

The Communicator is designed to be used on standard device telephone lines. It connects to

the telephone line by means of a standard jack called the USOC RJ-11C (or USOC FJ45S).

Connection to telephone company provided coin service (central office implemented systems)

is prohibited. Connection to party lines service is subject to state tariffs.

Telephone Company Procedures

The goal of the telephone company is to provide you with the best serv ice it can. In orde r to do

this, it may occasionally be necessary for them to make changes in their equipment,

operations or procedures. If these changes might affect your service or the operation of your

equipment, the telephone company will give you notice, in writing, to allow you to make any

changes necessary to maintain uninterrupted service. In certain circumstances, it may be

necessary for the telephone company to request information from you concerning the

equipment which you have connected to your telephone line. Upon request of the telephone

company, provide the FCC registration number and the ringer equivalence number (REN);

both of these items are listed on the equipment label. The sum of all of the REN’s on your

telephone lines should be less than five in order to assure proper service from the telephone

company. In some cases, a sum of five may not be usable on a given line.

Industry Canada and FCC Notice

If Problems Arise

If any of your telephone equipment is not operating pr operly, you should immediately remove it

from your telephone line, as it may cause harm to the telephone network. If the telephone

company notes a problem, they may temporarily discontinue service. When practical, they will

notify you in advance of this disconnection. If advance notice is not feasible, you will be

notified as soon as possible. When you are notified, you will be given the opportunity to correct

the problem and informed of your right to file a complaint with the FCC. Contact your

telephone company if you have any questions about your phone line. In the event repairs are

ever needed on the Communicator, they should be performed by Mircom Technologies Ltd. or

an authorized representative of Mircom Technologies Ltd. For information contact Mircom

Technologies Ltd. at the address and phone numbers shown on the back page of this

document.

10

Page 11

2.0 Introduction

i

This document provides information for the successful installation and operation of the FX-

3500.

2.1 The FX-3500 Addressable Fire Alarm Control Panel

Mircom’s FX-3500 Addressable Fire Alarm Control Panel provides the following:

• Advanced Protocol mode with one or three loops with 159 addre ssable sensors and 159

addressable modules per loop.

• CLIP Device compatible.

• Four Power Limited Class B (Style 4) or Class A (Style 6 or 7) NAC circuits.

• NAC circuits may be configured as silenceable signal, non-silenceable signal,

silenceable strobes, non-silenceable strobes, or relay outp ut. The audible signal may be

Steady, Temporal Code, California Code, or March Time.

• Supports sync strobe protocols from major manufacturers.

• Software configuration.

• Two-stage, alarm verification, waterflow retard and positive alarm sequence operations.

• Configurable Signal Silence Inhibit, Auto Signal Silence, Two-Stage Operation, and

One-Man Walk Test.

• Subsequent Alarm, Supervisory, Monitor and Trouble operation.

• Relay Contacts for Common Alarm, Common Supervisory and Common Tr ouble all

non-disconnectable and Auxiliary Alarm Relay (disconnectable).

• Built-in Dialer Module.

Introduction

2.1.1 Optional Items

• Supports up to 2 RAX-1048TZDS Display Adder Modules.

• Semi-flush or surface mountable enclosures for retrofits and new installations.

Note: Installation of the FX-3500 Series Fire Alarm Control panel should be in

accordance with Canadian Electrical Code Part 1, ULC-S524 installation of Fire

Alarm System; or National Electrical Code NFPA 70 and NFPA 72. Final

acceptance subject to the Local Authority Having Jurisdiction (AHJ).

11

Page 12

2.2 General Notes

Circuits

Refers to a physical electrical interface for the analog loop, indicating signals or relays, and

common alarm, supervisory, and trouble relay outputs.

Zone/Group

Is a logical concept for a Fire Alarm Protected Area, and will consist of at least one Circuit. The

FX-3500 uses Groups extensively to facilitate annunciation of multiple input and output points

on the 30 (up to 64) LED display and to facilitate the bypassing of inputs and outputs.

Display Points

The FX-3500 LCD display annunciates the status of the system and connected devices. There

are up to two (2) RAX-1048TZDS Display Adder Module Display point s that may be co nfigured

to assign LEDs to groups of input s or ou tputs. There are two LEDs for every display point; one

single color (yellow) and one dual color (red/yellow).

Wiring Styles

The analog loop can be connected in Class B (Style 4) or Class A (Style 6 or 7) configurations.

Introduction

12

Page 13

2.3 Contact Us

For General Inquiries, Customer Service and Technical Support you can contact us Monday to

Friday 8:00 A.M. to 5:00 P.M. E.S.T.

2.3.1 General Inquiries

To ll Free 1-888-660-4655 (North America Only)

Introduction

Local 905-660-4655

Email mail@mircom.com

2.3.2 Customer Service

To ll Free 1-888-MIRCOM5 (North America Only)

Local 905-695-3535

Toll Free Fax 1-888-660-4113 (North America Only)

Local Fax 905-660-4113

Email salessupport@mircom.com

2.3.3 Technical Support

To ll Free 1-888-MIRCOM5 (North America Only)

Local 905-695-3535

Email techsupport@mircom.com

2.3.4 Website

www.mircom.com

13

Page 14

3.0 FX-3500 Overview

This chapter lists all the possible components of an FX-3500 system .

3.1 FX-3500 Fire Alarm Control Panel Models

All FX-3500 Fire Alarm Control Panels have the following features:

• Main Board, Power Supply and Backbox.

• Multi-zone fire alarm control panel

• MAM-3500 Main Display with 4 x 20 LCD display.

• Class A (Style 6 or 7) or Class B (Style 4) analog loop(s).

• Four Power Limited Class B (Style 4) or Class A (Style 6 or 7) NAC circ uits (max 1.5

Amps each - 6.0 Amps total).

• Dedicated common alarm, supervisory, trouble, and auxiliary alarm relays.

• Additiona l RAX-1048TZDS Display Adder Module can be added to provide 96

annunciation points per Adder.

• Additional outputs include connections for a RTI remote trouble indicator, PR-300

Reverse Polarity Module, an RS-485 bus for connection of up to seven RAX-LCD-LITE,

RAM-3500-LCDs, SRM-312s and RA-1000 Series annunciators.

• Auxiliary power is available in the form of 24V FWR unfiltered and unsupervised, 24VDC

filtered and regulated, and resettable auxiliary power supply.

FX-3500 Overview

Figure 1 FX-3500 with DOX-1024DSR

14

Page 15

3.2 FX-3500 System Components

The following table describes the components of the FX-3500.

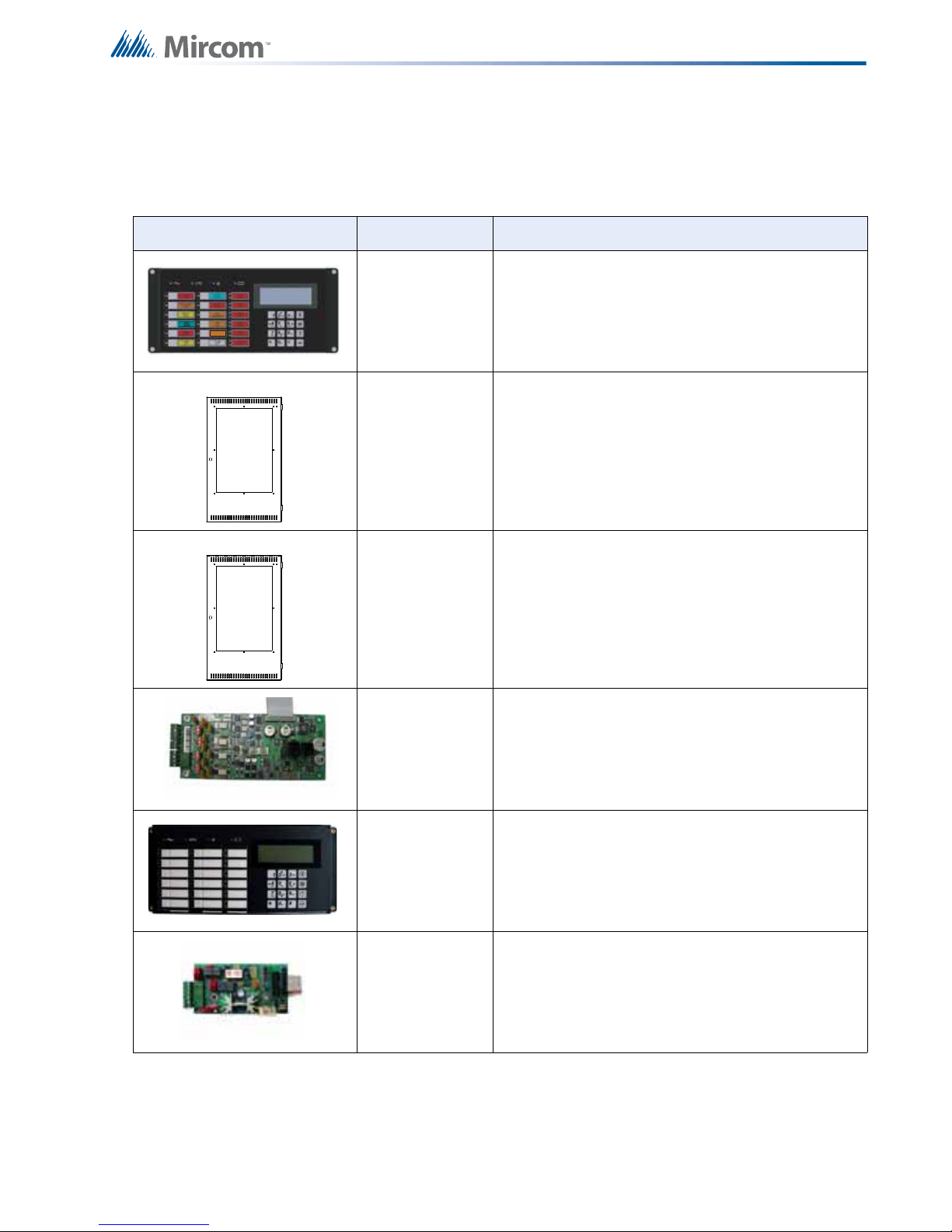

Table 1 FX-3500 System Components

Model Description

MAM-3500 Main Display

Visual

Indicator Test

DOX-1024DS White enclosure door

FX-3500 Overview

DOX-1024DSR Red enclosure door

ALC-636 636 Point Dual Loop Adder.

RAM-3500-LCD Remote Annunciator with 4-line LCD Display.

PR-300 Polarity Reversal and City Tie Module.

15

Page 16

Table 1 FX-3500 System Components (Continued)

FA-300 SERIES

REMOTE RELAY

Model Description

FX-3500 Overview

PCS-100

SRM-312W

SRM-312R

Power Supply Interface Board use for powering

GS3060 Universal Wireless Alarm Communicator.

Smart Relay Module with White Enclosure.

Can support up to 12 relays.

Smart Relay Module with Red Enclosure.

Can support up to 12 relays.

RAM-1016TZDS

16 Point Annunciator Chassis with 16 Trouble

LEDs.

RAM-1032TZDS 32 point Remote Annunciator with 32 Tr ouble LEDs.

RAX-1048TZDS

48 Point adder annunciator display with 48 Trouble

LEDs.

16

Page 17

Table 1 FX-3500 System Components (Continued)

Model Description

JW

JW1

JW5

2 3 4 9 10 11

P2

P3

MGD-32 Graphic Annunciator.

FX-3500 Overview

P1

P4

JW

JW15

8 7 6 14 13 12

RAX-LCD-LITE Remote Annunciator with 4-line LCD Display.

JW

JW1

JW5

2 3 4 9 10 11

P2

P3

AGD-048 Graphic Annunciator Adder Driver Board.

P1

P4

JW

JW15

8 7 6 14 13 12

RTI-1

Common Remote Trouble Indicator, Buzzer and

LED.

BB-1001 White Enclosure for one annunciator.

BB-1001R Red Enclosure for one annunciator.

BB-1002 Enclosure for two annunciators.

17

Page 18

Table 1 FX-3500 System Components (Continued)

Model Description

BB-1002R Red Enclosure for two annunciators.

BB-1003 White Enclosure for three annunciators.

FX-3500 Overview

BB-1003R Red Enclosure for three annunciators.

BB-1008 Enclosure for eight annunciators.

BB-1008R Red Enclosure for eight annunciators.

BB-1012 Enclosure for twelve annunciators.

18

Page 19

Table 1 FX-3500 System Components (Continued)

Model Description

BB-1012R Red Enclosure for twelve annunciators.

MP-300 End of line resistor plate. 3K9.

FX-3500 Overview

BC-160 External Battery Cabinet.

INX-10A Intelligent NAC Expander Panel.

19

Page 20

3.2.1 Devices

The following tables lists all the devices available for the FX-3500.

Table 2 Advanced Protocol Detectors

Advanced Protocol Detectors

MIX-1251AP Advanced Protocol Ion Smoke Detector

MIX-1251APA Advanced Protocol Ion Smoke Detector ULC

MIX-2251AP Advanced Protocol Photo Smoke Detector

MIX-2251APA Advanced Protocol Photo Smoke Detector ULC

MIX-2251TAP Advanced Protocol Photo Heat Detector

MIX-2251TAPA Advanced Protocol Photo Heat Detector ULC

MIX-2251TMAP Advanced Protocol Acclimate Detector

MIX-2251TMAPA Advanced Protocol Acclimate Detector ULC

FX-3500 Overview

MIX-5251AP Advanced Protocol Heat Detector

MIX-5251APA Advanced Protocol Heat Detector ULC

MIX-5251HAP Advanced Protocol High Temperature Heat Detector

MIX-5251HAPA Advanced Protocol High Temperature Heat Detector ULC

MIX-5251RAP Advanced Protocol Rate of Rise Heat Detector

MIX-5251RAPA Advanced Protocol Rate of Rise Heat Detector ULC

Table 3 Advanced Protocol Intelligent Modules

Advanced Protocol Intelligent Modules

MIX-M500MAP Advanced Protocol Monitor Module

MIX-M500MAPA Advanced Protocol Monitor Module ULC

MIX-M500RAP Advanced Protocol Relay Control Module

MIX-M500RAPA Advanced Protocol Relay Control Module ULC

MIX-M500SAP Advanced Protocol Supervised Control Module

MIX-M500SAPA Advanced Protocol Supervised Control Module ULC

MIX-M501MAP Advanced Protocol Mini Monitor Module

MIX-M501MAPA Advanced Protocol Mini Monitor Module ULC

MIX-M502MAP Advanced Protocol Conventional Zone Module

MIX-M502MAPA Advanced Protocol Conventional Zone Module ULC

20

Page 21

Table 4 Advanced Protocol Manual Stations

Advanced Protocol Manual Stations

MS-401AP Addressable Single Stage Manual Station ULC

MS-402AP Addressable Two Stage Manual Station ULC

MS-701AP Addressable Single Stage Single Action Station ULC

MS-701APU Addressable Single Stage Single Action Station

MS-702AP Addressable Two St age Single Action Station ULC

MS-702APU Addressable Two St age Single Action Station

MS-710AP Addressable Single Stage Dual Action Station ULC

MS-710APU Addressable Single Stage Dual Action Station

Table 5 Ancillary Modules

Ancillary Modules

FX-3500 Overview

CR-6 Six Relay Control Module

CZ-6 Six Conventional Zone Interface Module

IM-10 Ten Input Monitor Module

MIX-M500X Fault Isolator Module

MIX-M500XA Fault Isolator Module ULC

SC-6 Six Supervised Control Module

Table 6 Bases

Bases

B210LP Intelligent Flanged Mounting Base

B210LPA Intelligent Flanged Mounting Base ULC

B224BI Intelligent Isolator Base

B224BIA Intelligent Isolator Base ULC

B224RB Intelligent Relay Base

B224RBA Intelligent Relay Base ULC

B501 Intelligent Flangeless Mounting Base

B501A Intelligent Flangeless Mounting Base ULC

DNR Intelligent non-relay photoelectric low-flow duct smoke detector housing

DNRW

DNRA Intelligent Non-relay Photoelectric Low-flow Duct Smoke Detector Housing ULC

Watertight Intelligent Non-relay Photoelectric Low-flow Duct Smoke Detector

Housing

21

Page 22

Table 7 CLIP Detectors

Intelligent Detectors

MIX-1251B Intelligent Low Profile Ionization Smoke Sensor

MIX-1251BA Intelligent Low Profile Ionization Smoke Sensor ULC

MIX-2251B Intelligent Low Profile Photoelectronic Smoke Sensor

MIX-2251BA Intelligent Low Profile Photoelectronic Smoke Sensor ULC

FX-3500 Overview

MIX-2251TB

MIX-2251TBA

Intelligent Low Profile Photoelectronic Smoke Sensor c/w 135°F Fixed Temp.

Thermal Sensor

Intelligent Low Profile Photoelectronic Smoke Sensor c/w 135°F Fixed Temp.

Thermal Sensor ULC

MIX-2251TMB Intelligent Low Profile Multi-Criteria Sensor

MIX-2251TMBA Intelligent Low Profile Multi-Criteria Sensor ULC

MIX-5251B Intelligent Low Profile Fixed Temp. Thermal Sensor 135°F

MIX-5251BA Intelligent Low Profile Fixed Temp. Thermal Sensor 135°F ULC

MIX-5251H Intelligent Low Profile High Temperature Thermal Sensor 190°F

MIX-5251HA Intelligent Low Profile High Temperature Thermal Sensor 190°F ULC

MIX-5251RB Intelligent Low Profile Fixed Temp. and Rate of Rise Thermal Sensor 135°F

MIX-5251RBA Intelligent Low Profile Fixed Temp. and Rate of Rise Thermal Sensor 135°F ULC

MIX-7251B Intelligent Low Profile Laser Smoke Detector

MIX-7251BA Intelligent Low Profile Laser Smoke Detector ULC

Table 8 CLIP Modules

Intelligent Modules

MIX-500DM Intelligent Dual Monitor Module

MIX-500DMA Intelligent Dual Monitor Module ULC

MIX-M500M Intelligent Addressable Monitor Module

MIX-M500MA Intelligent Addressable Monitor Module ULC

MIX-M500R Intelligent Addressable Relay Module

MIX-M500RA Intelligent Addressable Relay Module ULC

MIX-M500S Intelligent Addressable Supervised Control Module

MIX-M500SA Intelligent Addressable Supervised Control Module ULC

MIX-M501M Intelligent Addressable Mini-Monitor Module

MIX-M501MA Intelligent Addressable Mini-Monitor Module ULC

MIX-M502M Intelligent Addressable Interface Module

MIX-M502MA Intelligent Addressable Interface Module ULC

22

Page 23

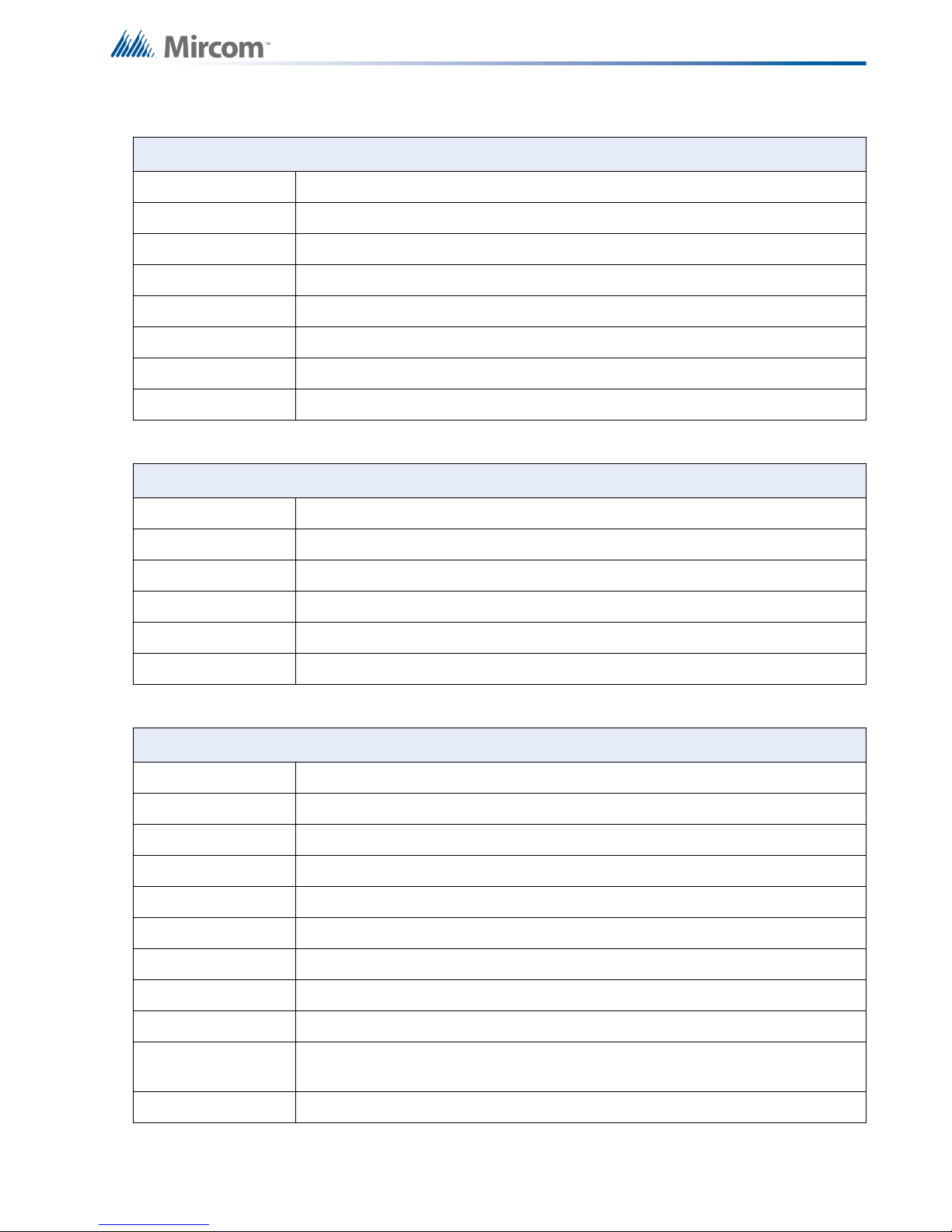

4.0 Installation

26.0 "

14.5 "

4.2 "

External Dimensions

This chapter describes the installation of the FX-3500.

4.1 BBX-1024DS and BBX-1024DSR Mechanical Installation

The BBX-1024DS and BBX-1024DSR are suitable for flush or surface mounting, and have a

built-in trim ring.

Dimensions of Enclosure (minus built in trim ring) 14.5” x 4.2” x 26”

Distance between horizontal mounting screws 12”

Distance between vertical mounting screws 23.5”

Complete Dimensions of Enclosures 16.3” x 5.5” x 27.5”

Installation

Mounting Dimensions

12.0 "

1.3 "

Side View

23.5 "

2.1 "

6.0 "

9.5 "

1.3 "

1.7 "

2.0 "

Top View

Figure 2 BBX-1024DS and BBX-1024DSR Installation Instructions and Dimensions

23

Page 24

4.2 Installation Tips

!

1. Group the incoming wires through the top of the enclosure. For easy identification and

neatness use a wire tie to group wires.

2. Be sure to connect a solid Earth Ground (from building system ground / to a cold water

pipe) to the Chassis Earth Ground Mounting Lug, and to co nnect the Ear th Gro und Wire

Lugs from the Main Chassis to the ground screw on the Backbox.

Attention: DO NOT install cable through bottom of the box. This space is reserved

for Batteries.

4.3 Installing Adder Modules

The FX-3500 Series Fire Alarm panels are shipped pre-assembled with all main components

and boards. Adder modules are not preinstalled.

The following items can be installed in the field:

Installation

• ALC-636 Dual Loop Adder

• PR-300 Polarity Reversal And City Tie Module

• PCS-100 Power Supply Interface Board

See the following diagrams for adder module installation locations. For Jumper or DIP Switch

settings refer to Table 9 and for Wiring Specifications see 7.1 Wiring Tables.

24

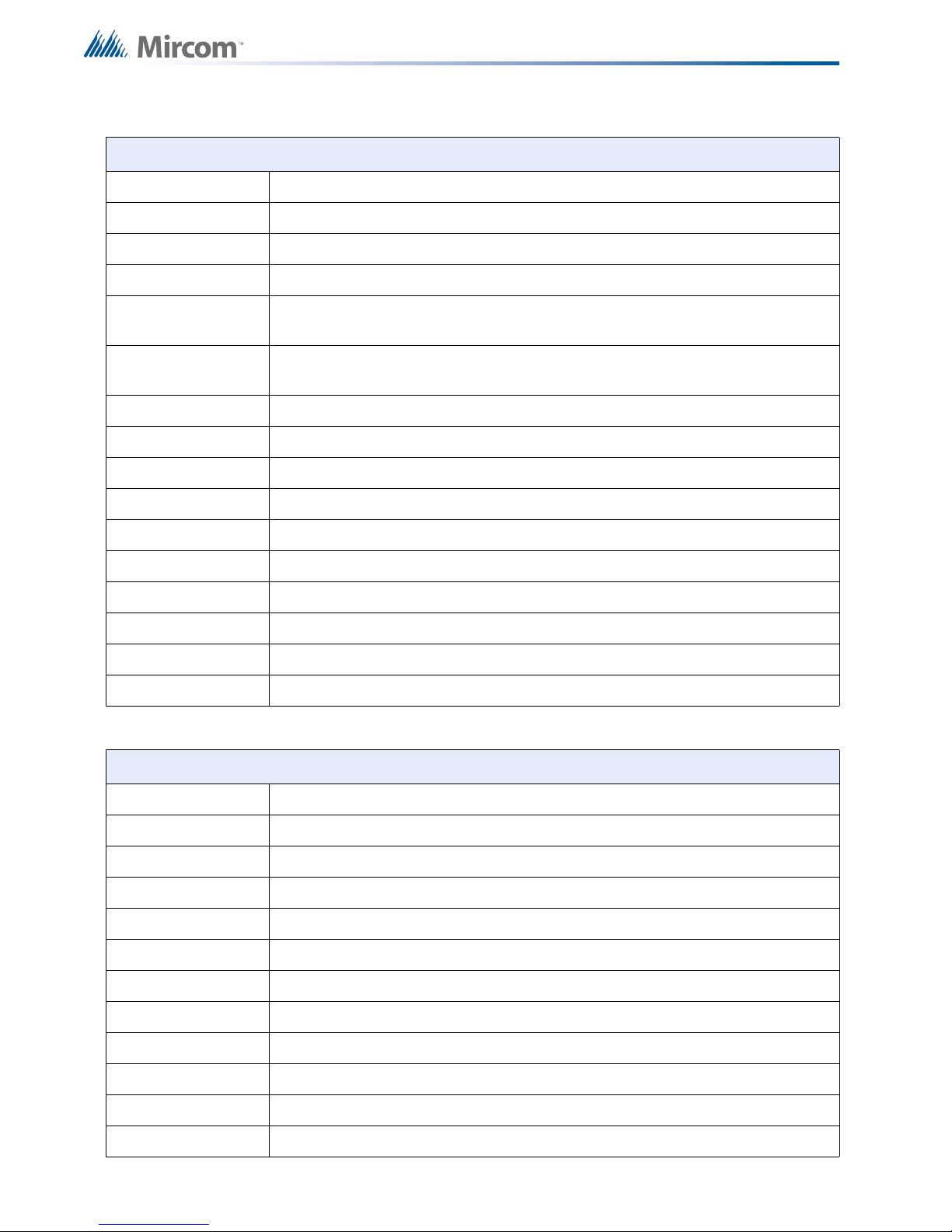

Page 25

Installation

Rectifier Bridge

MD-1011 Power Supply Board

ALC-636 Dual Loop Adder

PR-300 Polarity Reversal

And City Tie Module

FX-3500 Main Board

TR-063A Transformer

Barrier Terminal Block

Note:

The PCS-100 mounts in the same

position as the PR-300.

Figure 3 Main Board with all Adder Modules Installed

25

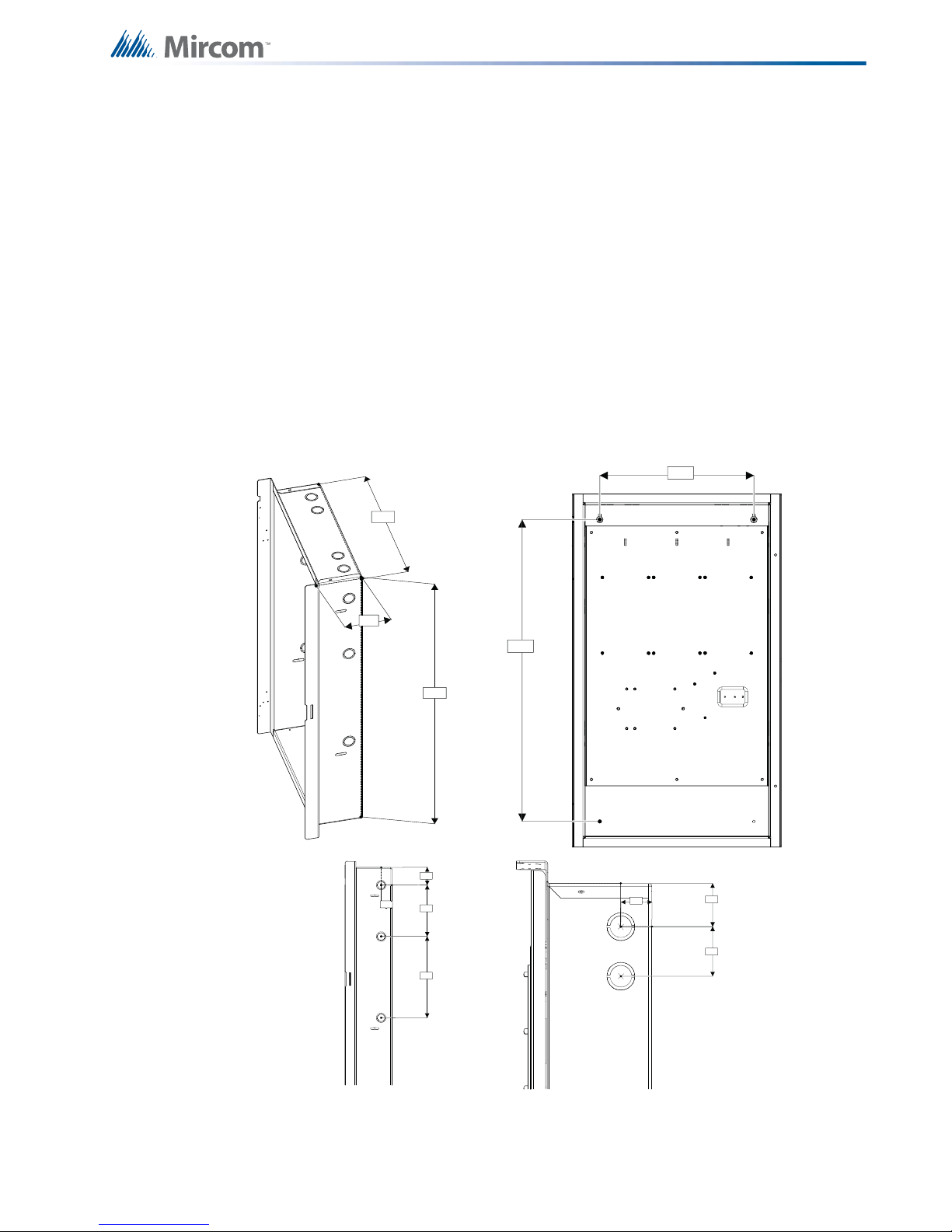

Page 26

P2

P3

P4

P5

P8

P9

P13

P10P11P14

JW1

JW2

JW5

JW6

JW10

JW7

Buzzer

JW11

JW12

3

2

1

3

2

1

Installation

Figure 4 Port and Jumper Locations on Main Board

26

Page 27

Table 9 Main Board Connectors and Jumper

!

Installation

Connector/

Description

Jumper

P2 To Power Supply

P3 To Power Supply

P4 Ribbon Cable connects to P4 of MAM-3500

P5 To PC Configurator

P8 To PR-300

P9 To Printer

P10 To ALC-636 Loop Adder

P11 Factory Use Only

P13 USB Port

P14 Future Use

JW1 Must be ON - Allows Configuratio n Connection

JW2 Must be ON - Annunciator End of Line

JW5 Normally open. Place jumper here and power down (AC and batteries) and power

back to restore Master Password. After reset, remove jumper and leave normally

open.

JW6 Normally open to BLOCK remote configuration via modem. Place jumper here to

ALLOW for remote configuration. When jumper is set panel will indicate a trouble.

JW7 On the Main Fire Alarm Module, this jumper must be removed if a PR-300 Polarity

Reversal and City Tie Module is installed.

JW10 Must be in the 1-2 Position (Bottom 2 Pins) - Allows PC Connection through serial port

JW11 Place in the 1-2 Position (Bottom 2 Pins) for Serial Port or Place in the 2-3 Positio n

(Top 2 Pins) for Keltron Dialer

JW12 If set will output debug trace in the RS-232 port. Normally should not be used.

Attention: ADVANCED INSTALLER NOTE

Setting JW5 and JW6 at start-up will revert the panel to the default

configuration.

27

Page 28

4.3.1 Installing the PR-300 Polarity Reversal and City Tie Module

i

Mount the PR-300 as shown in Figure 5.

The Alarm Transmit signal to the PR-300 can be prog rammed to tur n OFF when signal silenc e

is active. This allows the City Tie Box to be manually reset. On subsequent alarms the

silenceable signals will resound and the City Tie Box will be retriggered.

The Trouble Transmit signal to the PR-300 can be programmed to delay AC power fail 0, 1, 2,

or 3 hours if this is the only system trouble.

JW4

Installation

SUPV

POLARITY

REVERSAL

ALARM

POLARITY

REVERSAL

TIE

CITY

+ | - + | - + | -

Mounting hole for

#6-32 screws

Mounting hole for

#6-32 screws

Reverse pola rity and city

tie module PR-300.

Mounted on hex spacer

with two screws provided

P1 P2

PR-300

Figure 5 Installing the PR-300 Polarity Reversal and City Tie Module

Table 10 PR-300 Polarity Reversal and City Tie Module Connectors and Jumpers

Item Setting

P1 Connect cable to P8 on th e Main Bo ar d of th e FX-3500

JW4 Not used. Keep jumper intact.

Note: If using a PR-300 remember to remove JW7 on the main board. For the location

of JW7 on the main board see Figure 3.

4.4 Installing the ALC-636 Dual Loop Adder

Mount the ALC-636 Dual Loop Adder as shown in Figure 5.

The panel can provide up to 350mA of alarm current to the devices on the loop. For device

currents see Appendix F - Battery Calculations on page 100.

28

Page 29

Installation

Mounted on hex spacer

with four screws provided

ALC-636

A LOOP1

B

+

-

+

-

Figure 6 Installing the ALC-636 Dual Loop Adder

Table 11 ALC-636 Dual Loop Adder Connectors and Jumpers

Item Setting

P1 Connect cable to P10 on the Main Board of the FX-3500.

29

Page 30

4.4.1 Installing the RAX-1048TZDS Display Adder Module

The FX-3500 can add a maximum of two RAX-1048TZDS Display Adder Module. No jumpers

or other physical configuration steps are required to install the RAX-1048TZDS Display Adder

Modules.

To Install the RAX-1048TZDS Display Adder Module

1. Remove the blank cover plate from the front door and install the RAX-1048TZDS with

the clear cover in the opening with the hardware provided.

2. Disconnect main and standby power and connect the cable of the second RAX1048TZDS into the open, remaining header of the existing RAX-1048TZDS. The

additional LEDs will be available for configuration as LEDs 49 to 96, when the system

power is restored.

Installation

30

Page 31

5.0 Operation

i

This chapter describes the operational capabilities of the FX-3500.

Table 12 UL864 90.23 Table

NOTICE TO USERS, INSTALLERS, AUTHORITIES HAVING JURISDICTION, AND OTHER INVOLVED PARTIES

This product incorporates field-programmable software. In order for the product to comply with the requirements in the Standard for

Control Units and Accessories for Fire Alarm Systems, UL 864, certain programming features or options must be limited to specific

values or not used at all as indicated below.

Operation

Program feature or option Permitted in UL 864? (Y/N) Possible settings

5.1 Addressable/Analog Devices

The FX-3500 System supports up to 3 loops of Advanced Protocol and CLIP compatible

devices.

Using the Advanced Protocol the FX- 3 50 0 su pp o rts up to:

• 159 addressabl e sensors per loop.

• 159 addressable modules per loop.

Using the CLIP protocol the FX-3500 supp orts up to:

• 99 analog sensors per loop.

• 99 analog modules per loop.

Configuration is done via the software configurator.

Settings permitted in UL

864

Note: When mixing modes every address assigned to CLIP removes the equal amount

of addresses from the Advanced Protocol addressable sensor and addressable

module range.

Additional Information

• The addressable loop can be configured for Class A or Class B operation.

• T-tapping is not recommended.

• Unshielded twisted pair (UTP) is recommended.

• Conventional de vices can be used in a semi addressa ble application in conjunction with

MIX-M502M, MIX-M502MA, MIX-M502MAP, or MIX-M502MAPA Intelligent Addressable

Interface Modules.

• A short or open on the loop will activate the common trouble sequence with a latching

trouble. (Class A only)

• DO NOT connect more than 25 devices to a single isolator or betwee n isolators.

• The FX-3500 FACP will test the sensitivity of a single sensor address every 4 minutes.

Each address will be tested once in approximately every 11 hours.

31

Page 32

5.1.1 Supervision of Devices

The loop interface software continuously supervises the devices on its loop against those

found during configuration for the following conditions:

• Device missing.

• Unconfigured device responding.

• Two or more devices responding to the same address.

• Wrong device type.

A communication or addressing error on a device is reported as a trouble on the associated

zone LED as configured. The detectors may be configured as non-verified or verified alarm

inputs.

5.1.2 Device LEDs

• Polling the devices on the loop causes the LED to flash normally.

• All device LEDs can be suppressed via the configurator. Suppressing the device LED’s

causes sounder or relay bases to not operate. AP devices do not support sounder or

relay bases.

• Activating devices on the loop (alarm for an input device, active for an output device)

illuminates the LED steady.

• The maximum number of active Advanced Protocol and/or CLIP devices with their LED

illuminated steady is fifty (50) per loop.

Operation

5.1.3 Alarm Conditions

Alarm conditions are determined by the system continually polling the analog devices and

comparing the reported value against stor ed thresholds for p re-alarm and alarm conditions. An

agency approved range of thresholds is provided for each type of analog device (except for

contact devices).

Devices can be individually configur ed with 2 separate thresholds, “day time” and one “night

time” or after hours operation; i.e. a device may be config ured to a low sensitivity for “day time”

and high sensitivity at “night time”. The day time threshold will be used unless the after hours

operation is active. To configure threshold settings, Enable Auto After Hours must be selected

in the configurator.

Figure 7 FX-3500 Configurator Date and Time Settings

The panel can provide up to 280mA of current to the devices on the loop at normal standby.

For device currents see Appendix F - Battery Calculations on page 100.

32

Page 33

For further information refer to the device Installation Instructions and other documentation

provided with the addressable devices, bases, and isolators.

5.1.4 Drift Compensation

Drift Compensation is built into AP devices and CLIP devices Models MIX-2251TMB and MIX7251B, and is not performed by the panel. Drift Compensation is not provided for other CLIP

devices.

Drift compensation automatically adjusts for gradually increasing effects of dust and other

accumulations of dirt in the detectors. It will adjust the thresholds to compensate for a detector

going dirty according to the gradual change in the normal clean air value receive d. When it can

no longer compensate for an increasingly dirty detector, a dirty detector trouble is indicated for

that device.

5.1.5 Auto Test

Periodically each detector is commanded to return an alarm value to test its ability to alarm. If

the device fails the test, a trouble is indicated on that device. This trouble is latched until

system reset.

5.2 Configurable Input Types

Operation

Input devices and modules m ay be configured as one of many possible inpu t types. Table 13

identifies the device types assignable to each input type. For device type descriptions see

sections 5.2.1 to 5.2.12.

Table 13 Configurable Input Types

Device Types

Description

As listed in

Input Type

Alarm Input Alarm Input 5.2.1 XX

Latched Supervisory Latched Supv 5.2.2 XX

Building/Property Safety

Input

Non-Latching

Supervisory

Priority Alarm Priority Alm 5.2.4 XX

Trouble Input Trouble Input 5.2.5 XX

Waterflow Alarm Input Waterflow 5.2.6 X

System Reset Sys Reset 5.2.7 X

Configurator

Building 5.2.3 XX

Non-Latch Supv 5.2.2 XX

located in

Section number

Detectors

Dual Mini Modules

Zone Module

Mini Monitor Module

Monitor Module

Fire Drill Fire Drill 5.2.7 X

Acknowledge Ack 5.2.7 X

Total Evacuation Total Evac 5.2.7 X

Auxiliary Disconnect Aux Disc 5.2.7 X

Buzzer Silence Buzz Sil 5.2.7 X

Signal Silence Signal Silence 5.2.7 X

33

Page 34

Input Type

!

Table 13 Configurable Input Types (Continued)

Description

As listed in

Configurator

located in

Section number

Device Types

Detectors

Dual Mini Modules

Zone Module

Operation

Mini Monitor Module

Monitor Module

Acknowledge General

Alarm

Audible Walktest Audible Walktest 5.2.8 X

Silent Test Silent Test 5.2.9 X

Manual Day/Night Manual Day/Night X

Auto Day/Night Auto Day/Night X

Auxiliary Reset Auxiliary Reset 5.2.7 X

Verified Alarm Verified Alm 5.2.12 X

Ack GA 5.2.7 X

5.2.1 Alarm Input (Non-Verified)

An un-bypassed, non-verified alarm input entering into alarm activates the common alarm

sequence.

Common Alarm Sequence

• Updates un-byp assed relay, signal, and strobe outputs based upon the ir configuration.

• Activates Alarm zone status indicators associated with the input.

• Alarm input activations d isplay first and as the highest priority on the shared display in

the common queue.

• Devices configured as alarm inputs display a pre-alarm condition on the shared display

and on the alarm zone status indicator.

• Restoring the pre-alarm condition clears the status. If the input goes from pre-alarm to

alarm, the pre-alarm status will be replaced with the alarm status for the input.

• Devices configured as alarm inputs display an alarm condition on the shared display

and on the alarm zone status indicator.

• Once an alarm input is in alarm the alarm condition is latched until system reset

(changes in status from alarm to pre-alarm or to normal are ignored).

5.2.2 Supervisory Input s

Attention: Non-latching supervisory inputs are not permitted in Canada unless

done so by the AHJ as per ULC-S527-11 4.6.3.

Devices can be configured as latching or non-latching supervisory inputs. Any un-bypassed

supervisory input entering alarm activates the common supervisory sequence.

Common Supervisory Sequence

• Updates un-byp assed relay, signal, and strobe outputs based upon the ir configuration.

• Activates Supervisory zone status indicators associated with the input.

• Supervisory input activations display as the second highest priority on the shared

display in the common queue.

• Devices configured as supervisory inputs display as supervisory conditions on the

shared display and on the supervisory zone status indicator.

34

Page 35

• Restoring the non-latching supervisory input returns all outputs correlated to the input,

!

i

that are not correlated to another active input, to normal.

• Zone display indicators update announcing the input is no longer active and removes

the message from the shared display common queue.

• If there are no other active supervisory inputs the common supervisory condition will be

restored.

Latched supervisory inputs operate the same as non-latched supervisory inputs with one

exception:

• A normal to off-normal status change indication shall be latched and only manually

resettable at the control unit or display and control centre.

5.2.3 Building/Property Safety Input

Building/Property Safety Inputs may include but are not limited to: fan status, dampers,

motors, elevators, telephones, etc.

Building/Property Safety Inputs may be programmed to LED Indicators. The input status will

activate the LED as configured.

• Building input activations display as the thir d highest priority on the shared di splay in the

common queue. They are lower than supervisory and higher than troubles.

• May also be programmed to relay, signal, and strobe outputs.

Operation

Caution: Correlating signal and strobe devices to building/property safety inputs

requires the approval of the AHJ and are not to be used for fire events.

• When an un-bypassed building circuit activates, the status display and programmed

outputs are activated.

• Restoring the building status returns all outputs correlated to the inp ut, that are not

correlated to another active input, to normal.

Note: Devices used for building inputs are to be isolated from fire operation. It is

required that these devices are placed on a separate SLC loop if Class B wiring

is used, otherwise wire the devices according to Class A (Style 7) to accomplish

isolation.

5.2.4 Priority Alarm

Increases the polling frequency and optimizes the transmission of data from the device.

5.2.5 Trouble-Only Input

An active condition on an un-bypassed trouble-only input initiates the common trouble

sequence as a non-latching trouble.

• Activates Trouble zone status indicators associated with the input.

• Trouble input activations display as the lowest priority on the shared display in the

common queue.

35

Page 36

• May also be programmed to relay, signal, and strobe outputs.

i

i

!

Note: Trouble conditions initiated as a result of a trouble-only input activating is

separate from the circuit or device supervision trouble.

5.2.6 Waterflow Alarm Input

Waterflow inputs are sampled every second. 10 samples in alarm in any given 15 second

period confirms the alarm condition. Therefore from a continuous input activation the alarm will

be processed within 10s.

LED Indication

The Alarm Zone LED indicator flashes when one sample indicates an alarm condition. If the

alarm is confirmed the LED indicator will illuminate steady. If 15 seconds elapses without any

samples in the alarm condition the LED Indicator will turn OFF. The waterflow retard operation

operates regardless of whether or not the system is in alarm.

Operation

Note: Do not use the retard operation with any external retarding device.

5.2.7 System Status Correlations

The following System Status processes can be correlated to configured (mini) monitor

modules:

• System Reset

• Fire Drill

• Acknowledge

• Total Evacuation

• Buzzer Silence

• Signal Silence

• Acknowledge Genera l Alarm

• Auxiliary Disconnect

Attention: Devices correlated with any of the above System Statuses need to be

contained within a secured enclosure accessibly only to those with the

proper authority.

5.2.8 Audible Walktest

Configures (mini) monitor modules as audible when conducting a walktest. For more

information on performing a walktest see 5.11.5 Walk Test.

5.2.9 Silent Test

Configures (mini) monitor modules as silent when conducting a walktest. For more information

on performing a walktest see 5.11.5 Walk Test.

36

Page 37

5.2.10 Manual Day/Night

i

Configures (mini) monitor modules for manual day/night alarm thresholds. For more

information on alarm thresholds see 5.1.3 Alarm Conditions.

5.2.11 Auto Day/Night

Configures (mini) monitor modules for auto day/night alarm thresholds. For more information

on alarm thresholds see 5.1.3 Alarm Conditions.

5.2.12 V erified Alarm Input

Un-bypassed verified alarm inputs entering into alarm are verified over a period of time to

determine if the alarm condition is valid.

Addressable / Analog Device Verification Process

If the system is not already in alarm:

1. A device entering into alarm initiates a 30 second delay timer.

2. When the 30 second delay times out the device is monitored for the next 60 seconds.

3. If the same device enters into alarm again during this time the alarm is confirmed. The

following will also confirm the alarm:

Operation

• Any additional Alarm Input activating aborts the verification process and confirms

the alarm.

• Any trouble detected on the circuit being verified aborts the verification process

and confirms the alarm.

LED Indication

The Alarm Zone LED indicator flashes for the duration of the verification process. If the alarm

is not confirmed the LED turns off. If the alarm is confirmed the LED illuminates steady.

Note: Conventional smoke detectors cannot utilize alarm verification with M502(AP)

zone modules.

5.3 Output Types

Output devices and modules may be configured as one of many possible output types. Table

14 identifies the device types assignable to each output type. For device type descriptions see

sections 5.3.1 to 5.3.3

Output modules on the addressable/analog loop may be configured as any of the following

output types:

• Signals

• Strobes

• Relay outputs

37

Page 38

Table 14 Configurable Output Types

i

Operation

Description

As listed in

Output Type

Relay Relay 5.3.3 XX

Signal Signal 5.3.1 XX

Strobe Strobe 5.3.2 XX

Configurator

Additional Operation Features

• When using CLIP devices once the FACP activates the sensor LED, an attached Relay/

Sounder base and any Remote Devices wired to the base are also activated.

Suppressing the device LED via the NF flag in the configurator means the Relay/

Sounder base and any Remote devices wired to the base will not activate.

• When using AP devices the FACP activates the sensor LED and the Remote Device

output separately. Suppressing the device LED via the NF flag in the configurator still

allows the activation of any remote device wired to th e base . Th e AP pro to co l does not

support Relay/Sounder Bases at this time+.

• The panel can synchronize strobes directly without the use of the synchro n ou s mo du le .

• Depending on the device, the system can detect open and short troubles and rep ort it as

an output circuit trouble.

located in

Section number

Relay Output

Device Types

Module

Supv Output

Module

5.3.1 Signal Output

For audible devices such as bells and piezo mini-horns. Signals operate in alert (two stage)

and/or evacuation rate.

5.3.2 Strobe Type Settings

Normal (non-synchronized)

• Strobe circuits operate similar to signals except that they are always turned ON

continuously (they are not affected by the alert or evacuation rates) if configured as

Normal.

• Configuring strobes as Normal does not use a sync protocol for the output circuit.

• Silenceable or non-silenceable.

Synchronized

Output circuits can be configured with various synchronization protocols.

When the output circuit is configured as strobe and also configured as non-silenceable and the

device used on the output is a combination of horn and strobe, then if the signal silence is

activated while the circuit is active the hor n(s) are silenced while the strobe keep s on flashin g.

Synchronized strobes and strobe/horn models of the following manufacturers are supported:

System Sensor, Wheelock, Secutron, and Mircom.

Note: Sile ncing of the h or n depen ds on th e feat u re pr ovided by the manu fa ctu rer of the

horn/strobe combination. Some models of the horn/strobe combination may not

have this feature and will not work as described above.

38

Page 39

5.3.3 Relay Output

Un-bypassed relay outputs are activated if any un-bypassed input circuit or common system

status which has been programmed to it is active. If the relay is configured as silenceable it is

inhibited when common auxiliary disconnect is active. Relays also turned off if they are

bypassed or if all inputs and system status correlated to the Relay Output are restored or

bypassed.

5.4 NAC Circuit Operation

NAC Circuits can be configured as

• Signal Output

• Strobe Output

• Relay Output

For more information on Outputs see 5.3 Output Types.

Powered output circuits are supervised while they are not active for both open circuits and

shorts.

Operation

The circuit will not be activated if there is a short trouble on the circuit. It will be activated if an

open trouble is indicated. A circuit trouble activates the common trouble sequence as a nonlatching trouble. Since open circuit supervision does not operate while the circuit is in alarm, if

the circuit was in trouble before it was activated, it will still indicate trouble while active. The

trouble condition will be re-evaluated when supervision resumes.

Output circuits configured as strobes can have sync protocol for synchronization if configured.

Certain strobe and strobe/horns models of the following brands are supported:

• Mircom

• Secutron

• System Sensor

• Wheelock

For a complete list of compatible Horn/Strobes see 9.2 FX-3500 Compatible Horn/Strobes.

When configured as normal, the output circuit is ON continuously when activated and does not

use any sync protocol. When configured as non-silenceable strobes, the strobes cannot be

silenced, but the horn can be silenced by pressing the 'signal silence' button.

If the strobe is configured as silenceable strobe both the horn and the strobe are silenced

(stopped) by pressing the 'signal silence' button.

39

Page 40

5.5 Single Stage Operation

In a single stage system, all alarm inputs are treated in a similar manner. Alarm inputs include

any of the following:

• Non-verified alarm

• Verified alarm

• Waterflow alarm

• Sprinkler alarm

Any of the above alarm inputs activating when the panel is not already in alarm cause the

following:

• The buzzer sounds steady.

• Cancels active fire drill.

• Common Alarm LED turns ON.

• Common Alarm relay activates if Aux disconnect is not active.

• The Auto Signal Silence timer activates (if configured).

• The Signal Silence Inhibit timer activates (if configured).

• If Aux disconnect is not active, activates all non-disconnected indicating circuits

programmed to the input.

• Activates non-disconnected strobes associated with the input.

• Activates non-disconnected signals associated with the input at the evacuation rate.

Operation

Subsequent alarms when the panel is already in alarm, cause the following:

• The alert buzzer sounds steady.

• Resounds silenced signals, turns off the Signal Silence LED, and restarts the Auto

Signal Silence timer (if configured).

• Activates continuously any additional non-disconnected strobes associated with the

input.

• Activates at the evacua tion rate any additional non-disconnected signals associated

with the new input.

5.6 Two-Stage Operation

In a two stage system, alarm inputs are either first stage (alert) inputs or second stage

(general alarm) inputs. First stage inputs include inputs from the following types of circuits:

• Non-verified alarm

• Verified alarm

• Sprinkler alarm

• Water-flow alarm

Second stage inputs include the following:

• Alarms on the general alarm inputs.

• Activation of the General Alarm button.

• Expiration of the Auto General Alarm timer.

Any of the above alarm inputs activating when the panel is not already in alarm cause the

following:

• The buzzer sounds steady.

40

Page 41

• Cancels active fire drill.

i

• Common Alarm LED turns ON.

• Common Alarm relay activates if Aux disconnect is not active.

• The Auto Signal Silence timer activates (if configured).

• The Signal Silence Inhibit timer activates (if configured).

• If Aux disconnect is not active, activates all non-disconnected indicating circuits

programmed to the input.

If the alarm is a Second S tage alarm, the following occurs:

• Activates non-disconnected strobes associated with the input.

• Activates non-disconnected signals associated with the input at the evacuation rate.

• General Alarm LED illuminates steady.

If the alarm is a First Stage alarm, the following occurs:

• Activates continuously non-disconnected strobe circuits programmed to that circuit.

• Activates with the alert code non-disconnected signal circuits programmed to that

circuit.

• Activates the Auto General Alarm timer (if configured).

• Acknowledge LED flashes.

Operation

Subsequent First Stage alarms when the panel is already in alarm, cause the following:

• The buzzer sounds steady.

• Resounds silenced signals, turns off the Signal Silence LED, and restarts the Auto

Signal Silence timer (if configured).

• If the panel is not already in General Alarm, activates additional non-disconnected

signals programmed to the new input with the Alert Code (see 5.3 Output Types on

page 37).

• If the panel is not already in General Alarm and the Acknowledge LED is ON steady

indicating that the Auto General Alarm timer has been acknowledge d, restarts the timer

and extinguishes the Acknowledge LED.

A second stage alarm (general alarm) when the p anel is alread y in alarm causes the fo llowing:

• The buzzer sounds steady.

• Activates all non-disconnected signals at the evacuation rate.

• If the Signal Silence LED is ON, it turns OFF and restarts the Auto Signal Silence timer

(if configured).

• If the Acknowledge LED is ON, turns the LED OFF.

• The General Alarm LED illuminates steady.

Alarm inputs are latching, they remain active until system reset.

Note: All circuits with process type designated as “signal or strobe” are automatically

correlated to the “fire drill” and “general alarm” status.

41

Page 42

5.7 Evacuation Codes

The following Evacuation codes can be configured for the FX-3500 FACP.

Continuous On 100% of the time.

Temporal Code 0.5 second on and 0.5 seco nd off repeate d 3 time s 1. 5s pause

March Code 0.5 second on 0.5 second off.

California Code 5 seconds on 10 seconds off.

5.7.1 Two Stage Alert Code

When configured for Two Stage operation, the FX-3500 FACP uses a pre-configured Alert

code that sounds prior to the evacuation code.

Alert Code 0.5 second on, 2.5 seconds off.

5.8 Positive Alarm Sequence

In a Positive Alarm Sequence (PAS) system, on ly smoke detectors can be dedicated as PAS

inputs. PAS Inputs can only be from the following process types:

Operation

• Non-verified alarm

• Verified alarm

Any of these alarm inputs activating when the panel is not already in alarm causes the

following:

• Buzzer sounds steady.

• Cancels active fire drill.

• Common Alarm LED turns ON.

• Individual zone LED (if programmed) turns ON.