Page 1

FX-2000

Intelligent Analog Fire Alarm Control Panel

Installation and Operation Manual

For the latest compatability information visit www.mircom.com/deviceguide

LT-657 Rev 15

December 2016

Page 2

Table of Contents

1.0 Introduction 1

2.0 Document Conventions 3

3.0 System Components 4

4.0 Mechanical and Chassis Installation 12

5.0 Module Mounting Locations 23

6.0 Display and Adder Modules Mounting Locations 25

6.1 FX-2003-6DS/FX-2003-12DS/FX-2003-6DS-16LED Compact Main Chassis ............... 25

6.2 FX-2017(S)-12DS Mid-size Main Chassis ...................................................................... 25

6.3 FX-2009(S)-12DS Large Main Chassis .......................................................................... 26

6.4 ECX-0012 Expander Chassis for FX-2009-12DS ........................................................... 26

7.0 Module Settings 29

7.1 Main Fire Alarm Modules (MD-764 Part of Main Chassis) ............................................. 29

7.2 Main Fire Alarm Super Module (MD-757 Part of “S” Version Main Chassis) ................. 30

7.3 RAX-1048TZDS Zone Display Module ........................................................................... 32

7.4 IPS-2424DS Programmable Input Switches Module ...................................................... 32

7.5 Fan Damper Control Display Module (FDX-008W/WKI) ................................................ 33

7.6 DM-1008A Hardwire Detection Adder Module ............................................................... 36

7.7 SGM-1004A Hardwire NAC Signal Adder Module ......................................................... 37

7.8 RM-1008A Hardwire Relay Adder Module ..................................................................... 39

7.9 Polarity Reversal and City Tie Module (Model PR-300) ................................................ 40

7.10 UDACT-300A Main Board .............................................................................................. 41

7.13 ALC-H16 Hardwire Loop Controller Module ................................................................... 47

8.0 Field Wiring 49

8.1 Main Fire Alarm Module Terminal Connections ............................................................. 49

8.2 Analog Loop Wiring ........................................................................................................ 51

8.3 NAC Signal Module (SGM-1004A) Terminal Connections ............................................. 58

8.6 UDACT-300A Main Board Terminal Connections .......................................................... 61

8.8 Wiring Tables and Information ........................................................................................ 63

9.0 System Checkout 65

i

Page 3

10.0 Indicators and Controls 66

11.0 Operation 72

11.1 Single Stage Operation .................................................................................................. 72

11.2 Two Stage Operation ..................................................................................................... 73

11.3 Pre-Signal Operation ...................................................................................................... 74

11.4 UUKL feature ................................................................................................................. 74

11.5 Output Circuit Delay Operation ...................................................................................... 74

11.6 Circuit Types .................................................................................................................. 75

12.0 Appendix A: Specifications 79

13.0 Appendix B: Compatible Devices 85

13.1 FX-2000 Series Compatible Addressable Loop Devices (UL) ....................................... 85

13.2 FX-2000 Series Compatible Two-Wire Smoke Detectors (UL) ...................................... 86

13.3 FX-2000 Series Compatible Four-Wire Smoke Detectors (UL Listed) ........................... 88

13.4 FX-2000 Series Compatible Signalling Devices (UL Listed) .......................................... 88

13.5 FX-2000 Series Compatible Addressable Loop Devices (ULC) ..................................... 89

13.6 FX-2000 Series Compatible Hardwire Smoke Detectors (ULC) .................................... 90

13.7 FX-2000 Series Compatible Synchronized Modules and Strobes ................................. 91

14.0 Appendix C: Power Supply and Battery Calculations 92

15.0 Appendix D: Remote Annunciator Panels 94

16.0 Appendix E: DIP Switch Settings Summary 96

17.0 Appendix F: Alarm Verification Timing 98

18.0 Appendix G: Wiring For Supervised Output Module 99

19.0 Appendix H: Label Requirements for Zone Identification 100

ii

Page 4

1.0 Introduction

1.1 About the FX-2000

Mircom's cost-effective FX-2000 Intelligent Analog Fire Alarm Control Panel (FACP) is a

flexible and easy-to-use analog system. The FX-2000 base panel consists of: one intelligent

analog loop controller capable of supporting 99 analog sensors and 99 addressable modules

that can be wired in Class A (Style 6 or 7) or Class B (Style 4). Analog sensors and

addressable modules consist of all compatibility listed devices including Advanced Protocol

devices. Loop adder modules are available for additional addressable (SLC) loops. The ALC198S provides one additional addressable loop, and the ALC-396S provides two addressable

loops each capable of supporting 99 analog sensors and 99 addressable modules. In addition,

the base panel supports up to 16 conventional adder modules such as the DM-1008A Initiating

Circuit Module, SGM-1004A NAC Circuit Module, and the RM-1008A Relay Circuit Module.

The base panel also includes 4 Class A/B (Style Z/Y) NAC circuits rated at 1.7 amperes each,

and either a 6- or 12-ampere power supply. The ALC-H16 adder board provides expansion for

16 additional conventional hardwire modules.

1.2 Overall Features

Introduction

• Large system capacity and modular design.

• Each Analog Loop is capable of supporting 99 analog sensors and 99 addressable

modules which can be wired as Class A (Style 6 or 7) or Class B (Style 4).

• The base system supports 16 conventional hardwire adder modules.

• 6 or 12 Ampere Power Supply.

• Four Class A/B (Style Z/Y) NAC Circuits rated at 1.7 Amperes each, which can be

configured as Audible or Visual (silenceable or non-silenceable circuits). Audibles may

be steady, Temporal Code, California Code, or March Time.

• NAC circuits may be configured to provide additional auxiliary power or resettable

auxiliary power.

• Fault isolators are present on all in panel addressable loops.

• Configurable Signal Silence Inhibit, Auto Signal Silence, Two-Stage Operation, One-

Man Walk Test.

• Outputs for 4 Wire resettable Smoke Power Supply, Auxiliary Power Supply, and an

interface to the Mircom RTI Remote Trouble Indicator.

• RS-485 Interface for Remote Multiplex Annunciators.

• Three Level Password Protection with field settable definition which enables the installer

to determine what functions are accessible for each of the three levels of pass

• Four queues for Alarm ACK, Supervisory ACK, Trouble ACK, and BLDG (Monitor) ACK,

with LED indicators and selector keys.

• Auxiliary Form-C Relay Contacts for Common Alarm, Common Supervisory, and

Common Trouble.

• RS-232 Port for remote system printer or “CRT terminal”.

• Two Event History Logs; one for Alarm related events and one for all events.

• Front Panel Auto-Configure and / or Personal Computer Configuration.

• Large 4 line by 20 character alphanumeric, back-lit LCD Display with user-friendly menu

system.

1

Page 5

Introduction

• Common controls and indicators for System Reset, Lamp Test, Fire Drill, Signal Silence,

General Alarm,

• General Alarm Cancel, AC On, Pre-Alarm, and Ground Fault.

• Two Spare configurable Keys and LED Indicators.

• 16 configurable LEDs (bi-coloured) with slide-in labels, available with the DSPL-420-

16TZDS display.

• Provides drift compensation for photoelectric smoke detectors.

• Provides Signal Coding of signal circuits for easy alarm identification (code consists of 1

to 4 digits, each digit consisting of 1-15 pulses on the signal).

• Selection for Canadian (ULC) or USA (ULI) requirements for Smoke Sensor sensitivity.

• Extensive transient protection.

• Surface Mountable Enclosures with removable doors for easy installation and service.

Flush Trims available.

• Removable Terminal Blocks for easy wiring and service.

• Loop Adder modules ALC-198S and ALC-396S for expanding addressable loops by 1

and 2 respectively.

• Adder module ALC-H16 hardwire loop interface board for expanding conventional input,

output, relay capability.

2

Page 6

2.0 Document Conventions

2.1 Circuits and Zones

The term circuits refers to an actual electrical interface, initiating (detection), NAC (signal), or

relay.

The term zone is a logical concept for a fire alarm protected area, and will consist of at least

one circuit.

Often the terms zone and circuit are used interchangeably, but in this manual the term circuit

is used.

On the FX-2000, circuits can be hardwired inputs and outputs or addressable inputs and

outputs. Both hardwired inputs and outputs, and addressable inputs and outputs may be

grouped together to form logical zones.

2.2 Wiring Styles

Document Conventions

Initiating circuits are configured by default as Class B (Style B). They may be globally (all or

none) configured as Class A (Style D) as described in the system configurator. This operation

uses odd and even pairs of two-wire Class B (Style B) circuits to make one four-wire Class A

(Style D) circuit, thus cutting in half the number of available initiating circuits.

Notification Appliance Circuits (NAC) circuits (also known as NAC circuits) may be

individually wired as Class A (Style Z) or Class B (Style Y) without affecting the number of

circuits available.

Addressable Loops may be configured system wide as Class B (Style 4) or Class A (Style 6).

With the addition of isolators, a Class A (Style 6) will become a Class A (Style 7).

3

Page 7

3.0 System Components

FX-2000 Chassis Types

System Components

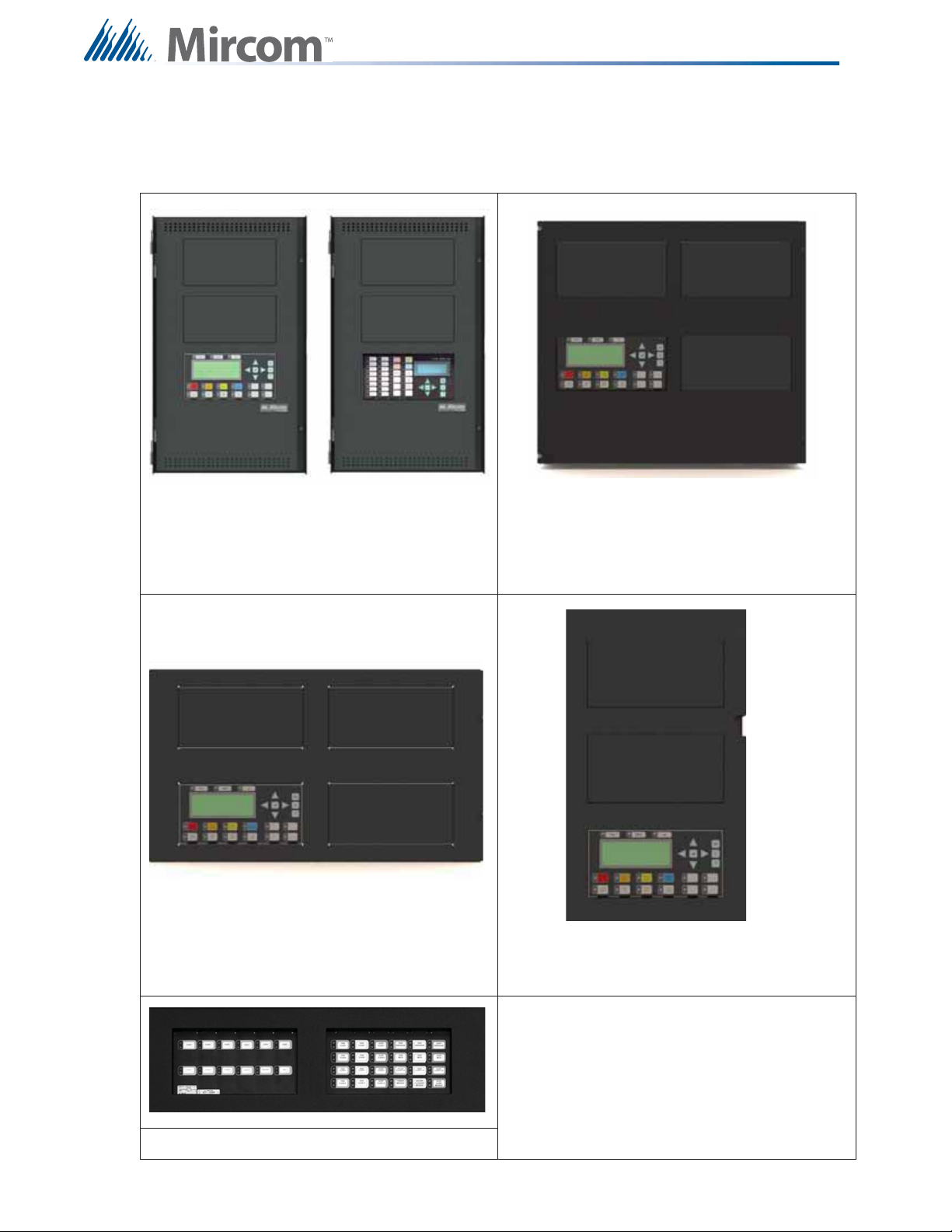

FX-2003-6DS (pictured on the left) FX-2017-12ADS

FX-2003-6DS-16LED (pictured on the right) FX-2017S-12ADS

FX-2003-12DS (pictured on the left)

FX-2009-12DS FX-2003-12XTDS

FX-2009S-12DS

ECX-0012 Expander Chassis

4

Page 8

System Components

All FX-2000 Series Panels have the following features:

• Main Chassis with one analog loop

• 4 Style Y or Z NAC Circuits

• 4 line by 20 character back-lit LCD display

Table 1 details the specifics of each chassis type. Some models may not be available in all

markets. Verify with your local distributor.

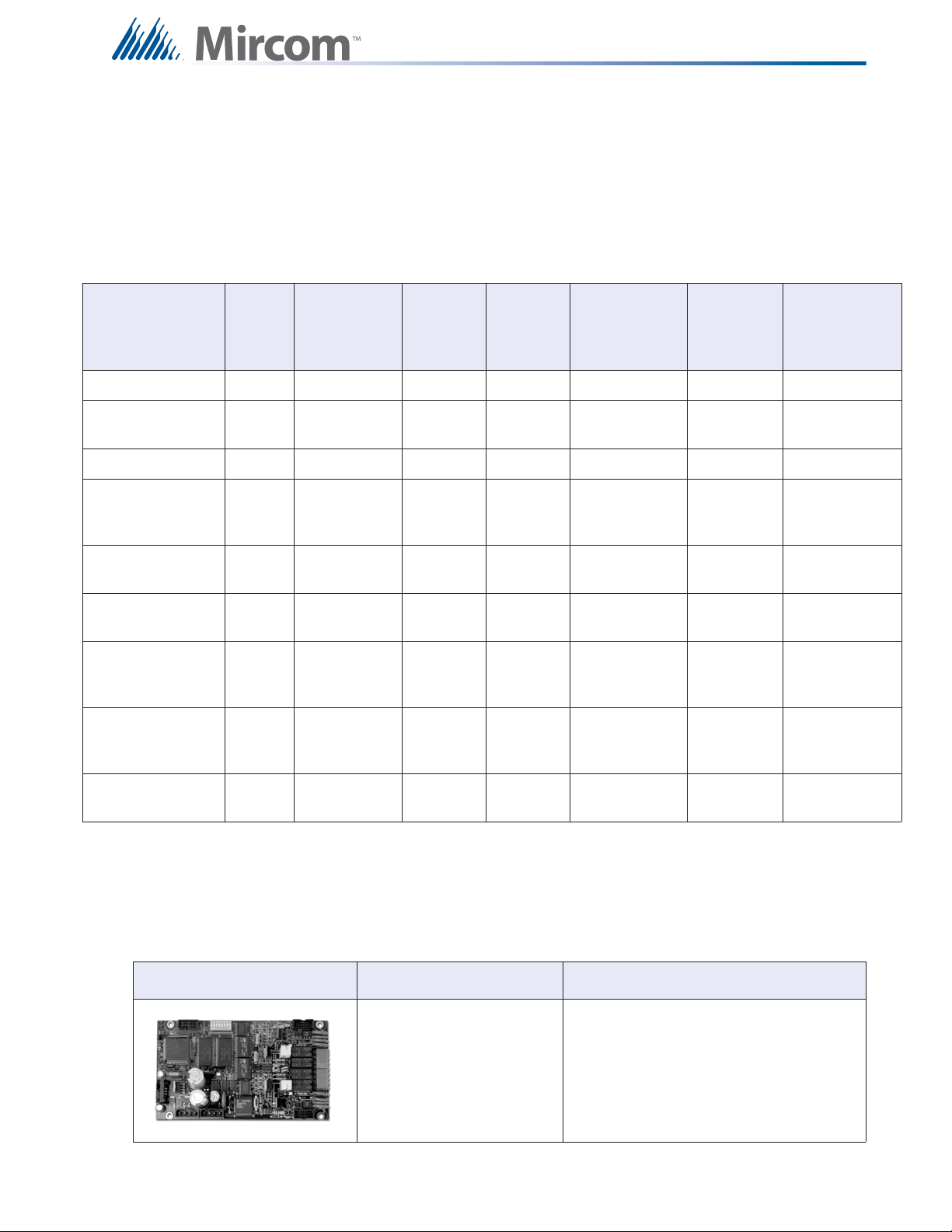

Table 1 FX-2000 Chassis Types

Model Amps

# of

Addressable

loops

# of

NACs

# of

Adder

Modules

# of

Conventional

Adder

Max # of

Display

Adders

Mounts into

Modules

FX-2003-6DS 6 1 4 3 3 2 UB-1024DS

FX-2003-6DS-

16LED

FX-2003-12DS 12 1 4 3 3 2 UB-1024DS

FX-2003-12XTDS 12 1 4 9 9 2

FX-2009-12DS 12 1 4 9 16 3

FX-2009S-12DS 12 0 4 9 16 3

FX-2017-12ADS 12 1 4 17 16 3

FX-2017S-12ADS 12 0 4 17 16 3

6 1 4 3 3 2 UB-1024DS

BBX-1024XT

or

BBX1024XTR

BB-5008 or

BB-5014

BB-5008 or

BB-5014

BBX-1072ADS

or BBX1072ARDS

BBX-1072ADS

or BBX1072ARDS

EXC-0012 12 0 0 12 0 2

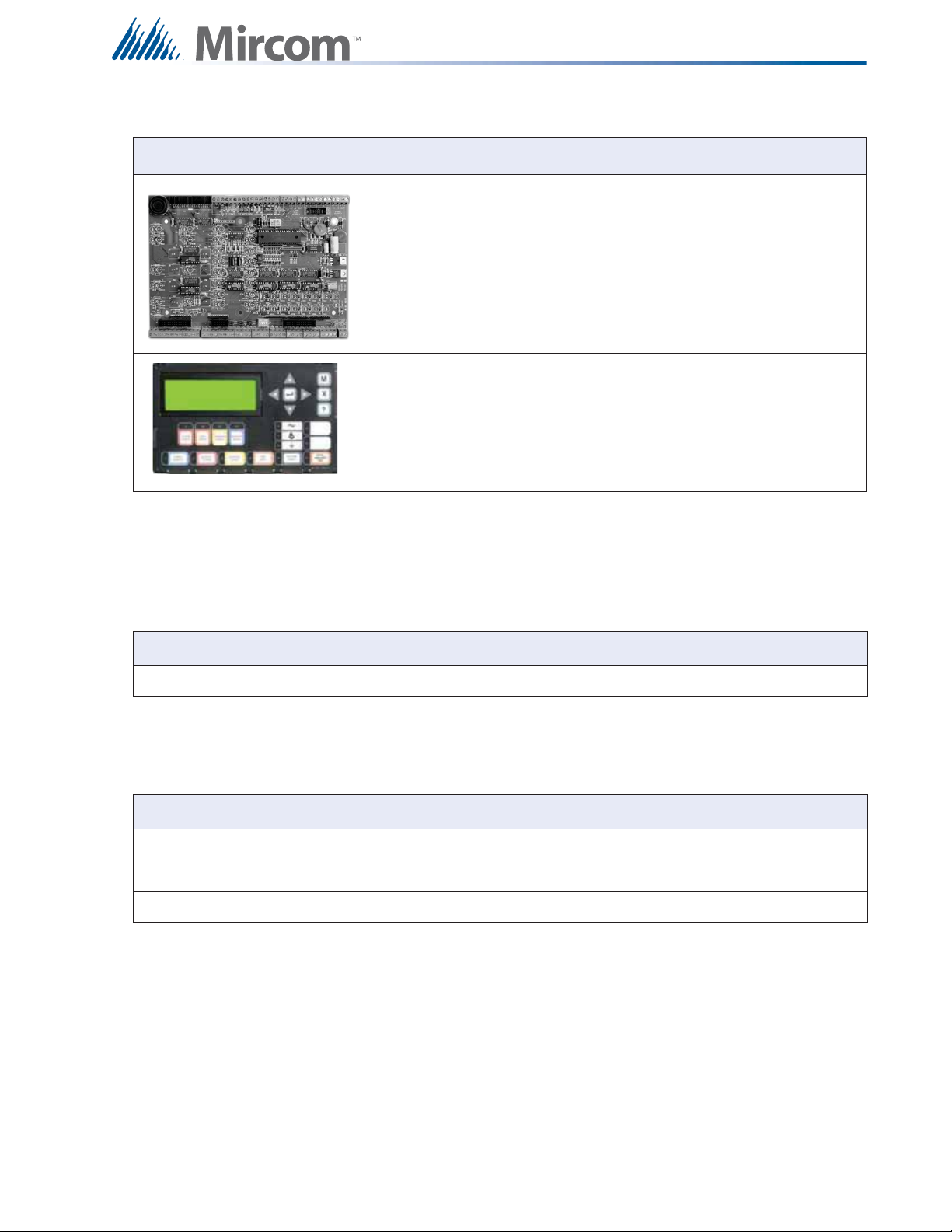

3.1 Adder Modules

The following table describes the adder modules used with the FX-2000.

Table 2 FX-2000 Adder Modules

Models Description

ALC-198S

Single Intelligent Analog Loop Controller

Module

BB-5008 or

BB-5014

5

Page 9

Table 2 FX-2000 Adder Modules

Models Description

System Components

ALC-396S

DM-1008A, SGM-1004A,

RM-1008A

DSPL-420-16TZDS

3.2 Auxiliary Modules

The following table describes the auxiliary modules used with the FX-2000.

Dual Intelligent Analog Loop Controller

Module

Conventional Circuit Adder Modules,

Detection, Signal and Relay.

Optional main display with 16

configurable bi-coloured LEDs.

This display is included in the

FX-2003-6DS-16LED chassis package.

Table 3 FX-2000 Auxiliary Modules

Model Description

PR-300 Polarity Reversal and City Tie Module

UDACT-300A Digital Communicator/Dialer Module

IPS-2424DS Programmable Input Switches Module

6

Page 10

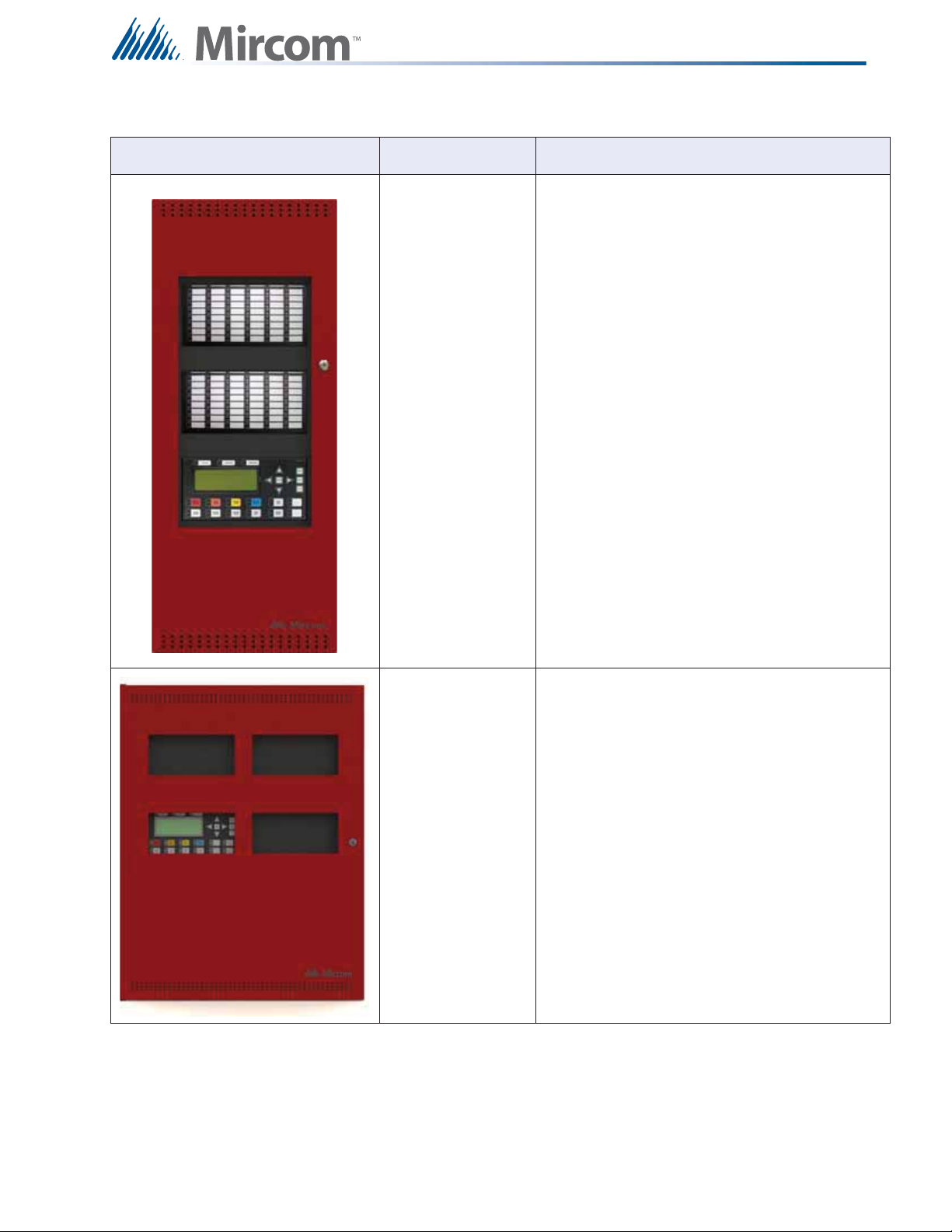

3.3 Enclosures

The following table describes the enclosures used with the FX-2000.

Table 4 FX-2000 Encl o su res

System Components

Model Description

BB-5008 Backbox 36”H x 30”W x 7”D

BB-5014 Backbox 60”H x 30”W x 7”D

7

Page 11

Table 4 FX-2000 Enclosures

Model Description

System Components

UB-1024DS

DOX-1024DS

DOX-1024DSR

FX-2003-6DS16LED

UB-1024DS Universal Backbox

26”H x 14.5”w x 4.2”D

DOX-1024DS white door for universal backbox.

DOX-1024DSR red door or universal backbox.

Complete system with DSPL-420-16TZDS

display and UB-1024DS backbox and

DOX-1024DSR door.

8

Page 12

Table 4 FX-2000 Encl o su res

Model Description

System Components

BBX-1024XT

BBX-1024XTR

BBX-1072ADS

Enclosure 35.5”H x 14.5”w x 5.25”D, white door

Enclosure 35.5”H x 14.5”w x 5.25”D, red door

Enclosure 24.8” x 32.5” x 6.4”, white door

BBX-1072ARDS

Enclosure 24.8” x 32.5” x 6.4”, red door

9

Page 13

3.4 Flush Trim Ring

The following table describes the flush trim ring used with the FX-2000.

Table 5 FX-2000 Flush Trim Ring

System Components

Model Description

FA-XT-TRB

3.5 Remote Annunciators

The following table describes the remote annunciators used with the FX-2000.

Table 6 FX-2000 Remote Annunciators

Model

RA-1000

Series

Black flush trim ring for BBX-1024XT and

BBX-1024XTR.

Description

Remote multiplex annunciator panels. For Canada,

ULC-S527 Standard requires a Common Alarm,

Common Supervisory, and a Common Ground Fault

LED indicator on the Remote Annunciators. To meet

this requirement, use the FX-2000 Configurator to

correlate one LED for Common Alarm, one LED for

Common Supervisory and one LED for Common

Ground Fault.

10

RAM-208/216

Remote multiplex annunciator panels. For Canada,

ULC-S527 Standard requires a Common Alarm,

Common Supervisory, and a Common Ground Fault

LED indicator on the Remote Annunciators. To meet

this requirement, use the FX-2000 Configurator to

correlate one LED for Common Alarm, one LED for

Common Supervisory and one LED for Common

Ground Fault.

Page 14

Table 6 FX-2000 Remote Annunciators

System Components

3.6 Batteries

The following table describes the batteries used with the FX-2000.

Model

MGD-32,

AGD-048

RAX-LCD Remote Shared Display Annunciator

Description

Remote graphic annunciator drivers. The AGD-048

must be installed in the same enclosure as the

MGD-032.

Table 7 Batteries

Model Description

Batteries 10 to 55 AH

3.7 FX-2000 Accessories

Table 8 Accessorie s

Model Description

MP-300/R/S End-of-line Resistor Plate, Beige, R for red, S for stainless steel finish

RTI-1 Remote Trouble Indicator (ULC and ULI listed)

BC-160 External Battery Cabinet (ULC and ULI listed)

11

Page 15

Mechanical and Chassis Installation

4.0 Mechanical and Chassis Installation

The following chapter describes the Mechanical and Chassis installation for all FX-2000

FAC Ps.

4.1 Mechanical Installation Diagrams

Mechanical Installation Instructions for the following enclosures:

• BB-5008

• BB-5014

• UB-1024DS and DOX-1024DS/R

• BBX-1024XT

• BBX-1024XTR

• BBX-1072ADS

• BBX-1072ARDS

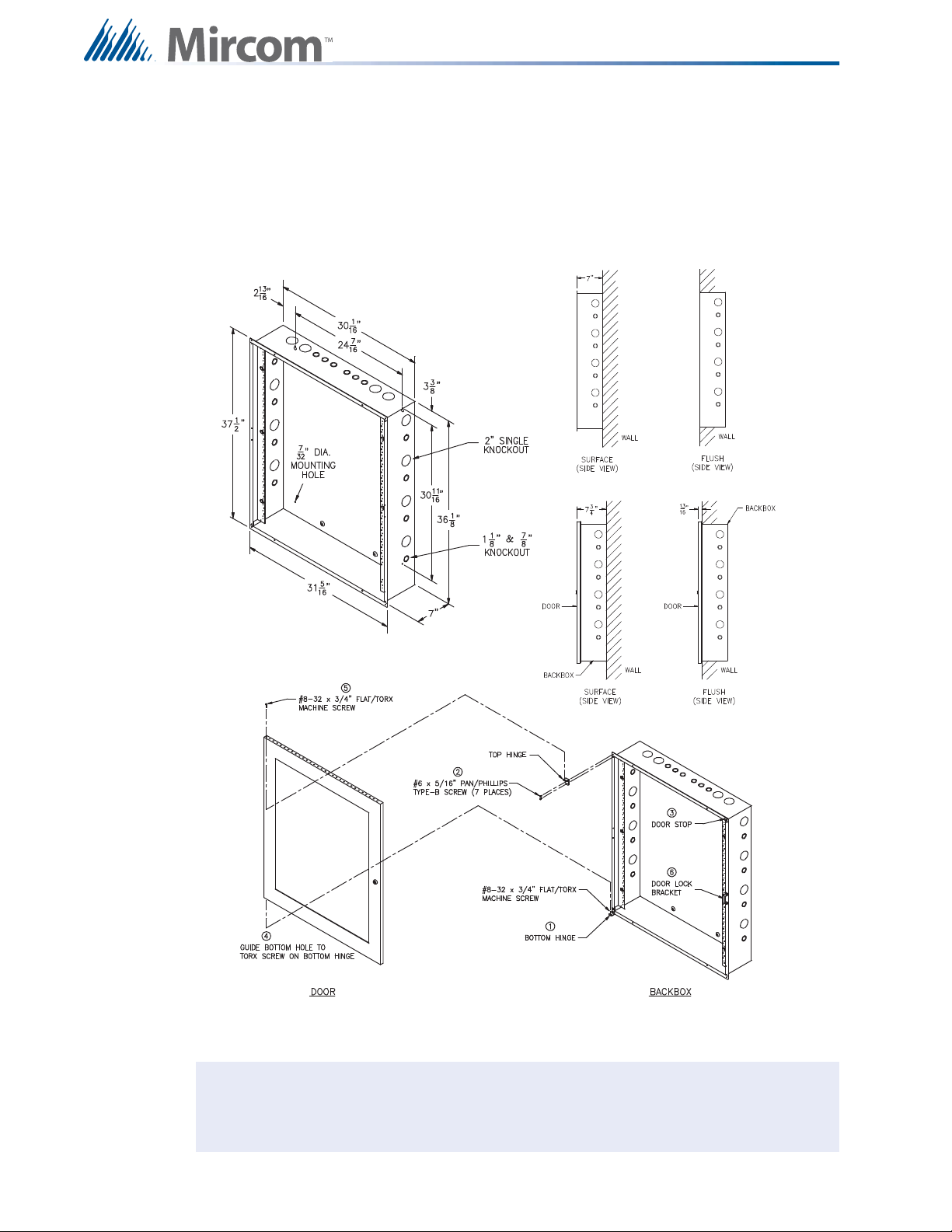

4.1.1 BBX-1072ADS and BBX-1072ARDS Mechanical Installation

Material Cold rolled steel18GA (0.048”) thick cold rolled steel

16GA (0.059”) thick for backbox

14GA (0.075”) thick for door

The BBX-1072ADS and BBX-1072ARDS are suitable for flush or surface mounting, and have

a built-in trim ring.

Dimensions of Enclosure (minus built in trim ring) 24.8” x 6.4” x 32.5”

Distance between horizontal mounting screws 16”

Distance between vertical mounting screws 23.6”

Complete Dimensions of Enclosures 26.4” x 7.7” x 34”

12

Page 16

Mechanical and Chassis Installation

i

Figure 1 BBX-1072ADS and BBX-1072ARDS Flush or Surface Enclosure Installation

and Dimensions

Note: Leave bottom of box conduit free for batteries.

13

Page 17

4.1.2 BB-5008 Mechanical Installation

Backbox

BB-5008 Backbox

DOX-5008M Metal Door

Backbox with DOX-5008M Door

i

Material Cold rolled steel18GA (0.048”) thick cold rolled steel

16GA (0.059”) thick for backbox

14GA (0.075”) thick for door

Mechanical and Chassis Installation

Figure 2 BB-5008 Enclosure Installation Instructions and Dimensions

Note: Leave bottom of box conduit free for batteries.

14

Page 18

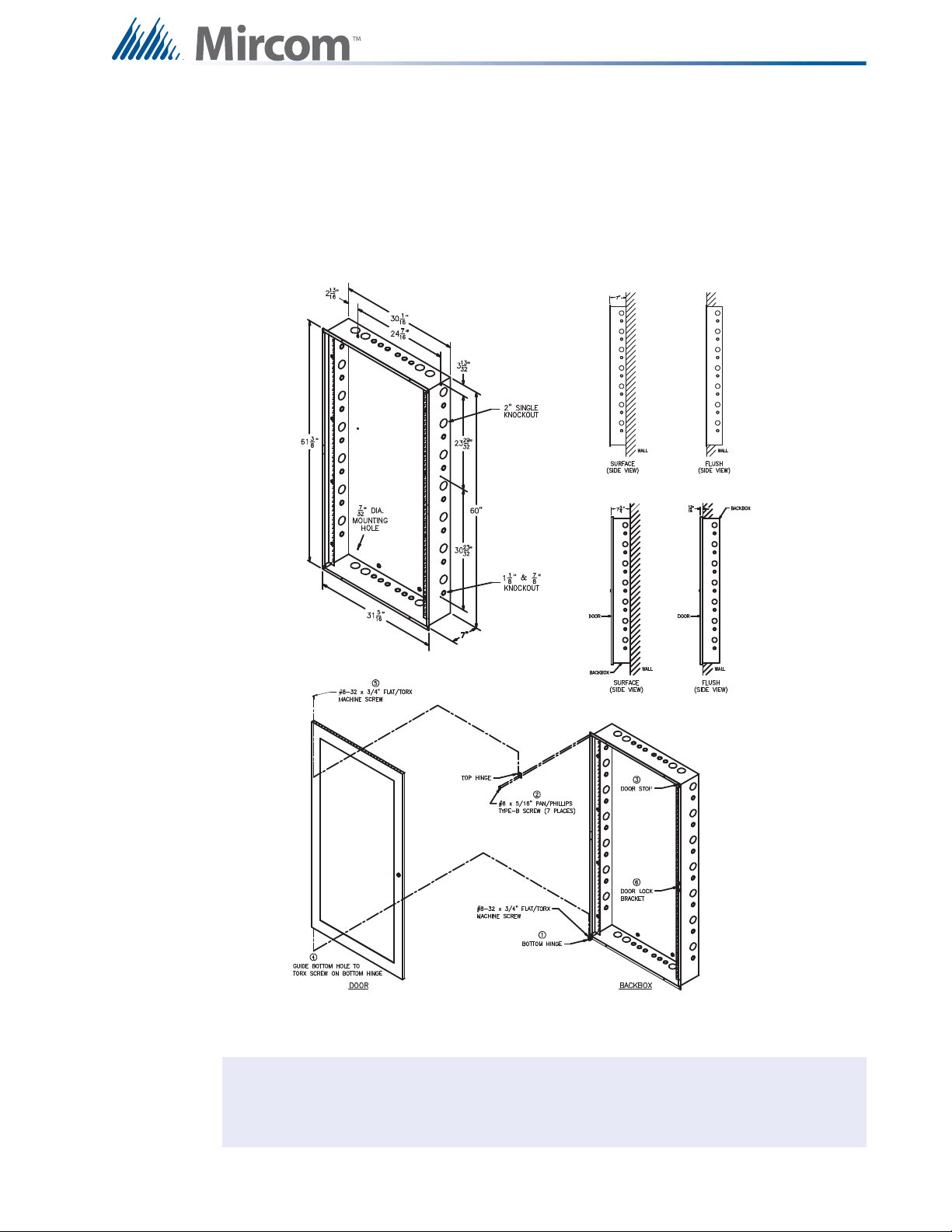

4.1.3 BB-5014 Mechanical Installation

Backbox

BB-5014 Backbox

DOX-5014M Metal Door

Backbox with DOX-5014M Door

i

Material Cold rolled steel18GA (0.048”) thick cold rolled steel

16GA (0.059”) thick for backbox

14GA (0.075”) thick for door

Finish Painted except for hinges

Mechanical and Chassis Installation

Figure 3 BB-5014 Installation Instructions and Dimensions

Note: Leave bottom of box conduit free for batteries.

15

Page 19

Mechanical and Chassis Installation

26 ”

17”

23 1/2”

14 1/2”

5 5/8”

1 3/8”

4 1/4”

12”

28 ”

26 ”

1 3/4”

1 3/4”

6”

2”

9 1/2”

1 3/4”

1 3/4”

2”

2”

TOP VIEW

SIDE VIEW

SIDE VIEW

BACKBOX

DOOR

BACKBOX FRONT VIEW

UB-1024DS UNIVERSAL BACKBOX AND DOX-1024DS/R DOOR

KNOCKOUT LOCATIONS

Dimensions of backbox (minus built-in trim ring)

Horizontal distance between mounting screws

Vertical distance between mounting screws

Complete dimensions of enclosure with door

Size of Knockouts

26”H x 14 1/2”W x 4 1/4” D

12”

1”

23 1/2”

28”H x 17”W x 5 5/8”D

4.1.4 UB-1024DS and DOX-1024DS/R Mechanical Installation

The universal enclosure is suitable for flush or surface mounting, and have a built-in trim ring.

Dimensions of backbox (minus built in trim ring) 26” x 14.5” x 4.25”

Distance between horizontal mounting screws 12”

Distance between vertical mounting screws 23.5”

Complete Dimensions of Enclosure with door 28” x 17” x 5.6”

Figure 4 UB-1024DS and DOX-1024DS/R Installation Instructions and Dimensions

16

Page 20

4.1.5 FX-2003-12XTDS Mechanical Installation

14.500

35.500

5.25

17.000

38.010

12.000

25.500

Front Door

(Inside View)

FA-XT-TRB

Trim Ring for

Flush Mounting

Backbox

Adhere trim ring to wall

surface around backbox.

Backbox

Mounting Holes

FX-2003-12XTDS is an expanded version of the FX-2003-12DS.

Dimensions 14.76” wide by 35.8” long by 5.45”

16GA (0.059”) thick for backbox

14GA (0.075”) thick for door

Finish Painted except for hinges

Mechanical and Chassis Installation

Figure 5 BBX-1024XT/R Backbox Enclosure with Trim Ring

17

Page 21

Mechanical and Chassis Installation

TRIM R ING

WALL

WOOD OR

METAL STUD

BACKBOX

4.1.6 Surface and Flush Mounting Views of the BBX-1024XT/R

5.45” 0.7”

Figure 6 BBX-1024XT/R Surface and Flush Side Views

4.1.7 BBX-1024XT Flush Mounted Box with FA-XT-TRB Trim Ring

Figure 7 Cross section view of mounted BBX-1024XT/R enclosure

18

Page 22

4.2 Chassis Installation

Chassis Installation Instructions for the following:

• FX-2003-6DS

• FX-2003-12DS

• FX-2003-12XTDS

• FX-2009-12DS

• FX-2009S-12DS

• FX-2017-12ADS

• FX-2017S-12ADS

• ECX-0012

For proper chassis installation do the following

1. Group the incoming wires through the top of the enclosure to prepare it for wiring the

modules. Do not run the wires in-between the modules since it could cause a short

circuit.

Mechanical and Chassis Installation

2. Use a wire tie to group wires for easy identification and neatness.

3. Be sure to connect a solid earth ground (from building system ground / to a cold water

pipe) to the chassis earth ground mounting lug, and to connect the earth ground wire

lugs from the main chassis to the ground screw on the backbox.

4. Mount chassis using the supplied hex nuts.

19

Page 23

Mechanical and Chassis Installation

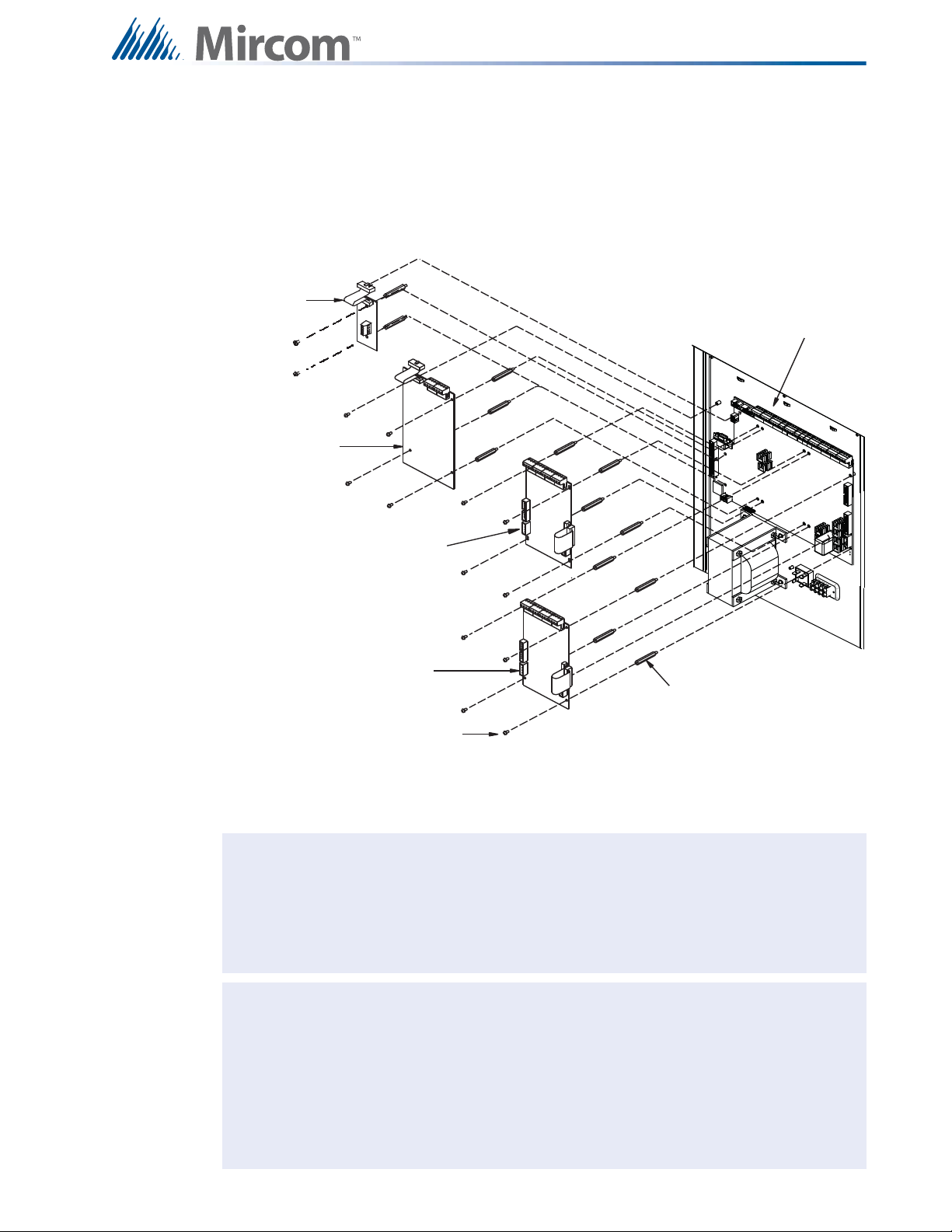

4.2.1 Mounting the Chassis into the BBX-1072ADS or BBX-1072ARDS

Enclosure

Mount chassis FX-2017-12ADS or FX-2017S-12ADS into backbox BBX-1072ADS or BBX1072ARDS using the supplied four #6 hex nuts (two at the top and two at the bottom) as

shown below. The transformer chassis is also mounted using four hex nuts.

20

8 #8 hex nuts, 4 for inner

chassis and 4 for the

transformer chassis.

Figure 8 Chassis Installation into BBX-1072ADS or BBX-1072ARDS Module Mounting

Locations

Page 24

Mechanical and Chassis Installation

4.2.2 Mounting the Chassis into the BB-5008 or BB-5014

The chassis is mounted using the four #6 hex nuts provided. Two across the top portion and

two across the bottom of the chassis. The inner door is mounted using four hex nuts on the left

side and secured with two screws on the right side.

Figure 9 Chassis Installation into backbox BB-5008 and BB-5014

21

Page 25

Mechanical and Chassis Installation

i

4.2.3 Mounting the Chassis into the UB-1024DS and DOX-1024DS/R Enclosure

The chassis is mounted using the six #8 hex nuts provided. Three across the top and three

across the bottom of the chassis. The inner door mounts over the chassis with two #8 hex

nuts.

22

Figure 10

Note: Leave bottom of box conduit free for batteries.

Chassis Installation into Universal Enclosure UB-1024DS and DOX-1024DS/R

Page 26

5.0 Module Mounting Locations

SCREWS

PROVIDED

M/F HEX SPACER

UDACT-300A

DIALER MODULE

OTHER ADDER

CIRCUIT MODULE

FX-2000

MAIN CHASSIS

OTHER ADDER

CIRCUIT MODULE

PR-300 CITY TIE MODULE

i

i

The FX-2003-6DS/12DS or FX-2017-12ADS Main Chassis come pre-assembled with a main

chassis, display components and boards. Install adder modules of different types as shown in

the diagrams on the following pages.

Module Mounting Locations

Figure 11 Module Mounting Loc ations View #1

Note: To enable communication from the main module to all of the adder modules, it is

necessary to add a continuity jumper on the last adder module in a chain (see the

appropriate module settings section to verify the location of the continuity jumper

on a particular circuit adder module). Only the last circuit adder module should

have a jumper plug on its continuity jumper; all others must be left without a

jumper plug.

Notes: Front plate is not shown. Reserved for PR-300 or UDACT-300A. Other circuit

adder modules may be:

• DM-1008A Detection Circuit Adder Module

• SGM-1004A Signal Circuit Adder Module

• RM-1008A Relay Circuit Adder Module

• ALC-198S Loop Adder Module

• ALC-396S Loop Adder Module

• ALC-H16 Hardwire Loop Controller Module

23

Page 27

Provision for PR-300 or UDACT-300A

Module Mounting Locations

Figure 12 Module Mounting Locations View #2

24

Page 28

Display and Adder Modules Mounting Locations

FX-2000 Main Board

123

Slot is reserved for

PR-300 or UDACT300A. If not

required, this slot

can be used to

mount any of the

adder modules.

1

23

45

67

89101112

1314151617

FX-2000 Main Board

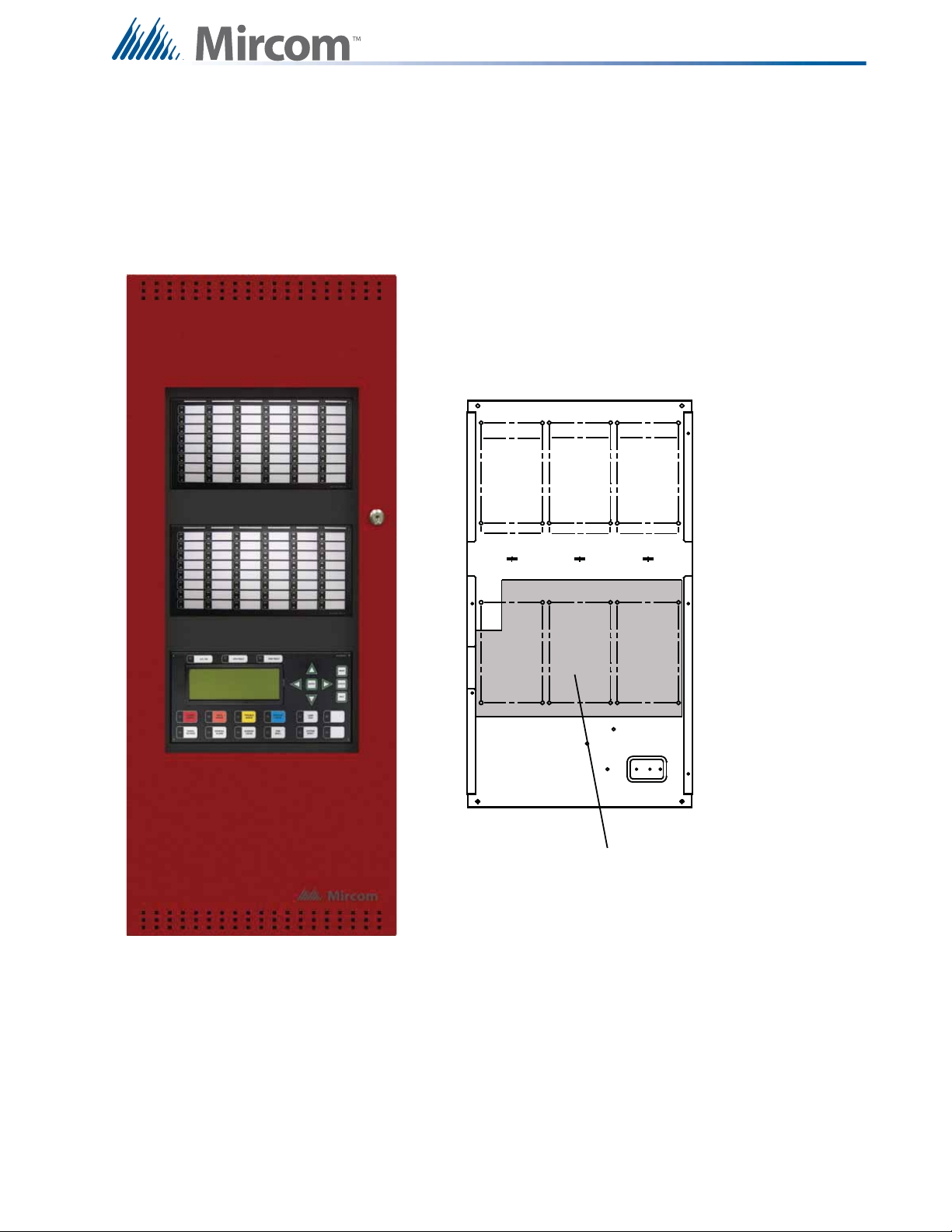

6.0 Display and Adder Modules Mounting Locations

6.1 FX-2003-6DS/FX-2003-12DS/FX-2003-6DS-16LED Compact

Main Chassis

Mounts in the UB-1024DS backbox and supports three circuit adder modules.

Exterior View Interior View

6.2 FX-2017(S)-12DS Mid-size Main Chassis

Mounts in the BBX-1072ADS or BBX-1072ARDS Enclosure, and supports three display

modules and 17 adder modules.

Exterior View Interior View

Slot is reserved for PR-300 or UDACT300A. If not required, this slot can be used

to mount any of the adder modules.

25

Page 29

Display and Adder Modules Mounting Locations

Slot is reserved for PR-300 or UDACT300A. If not required, this slot can be used

to mount any of the adder modules.

Cutout to mount

display module

Cutout to mount

display module

6.3 FX-2009(S)-12DS Large Main Chassis

Mounts and occupies four display positions in BB-5008 or BB-5014 Enclosures, and supports

two display modules and nine adder modules.

Exterior View Interior View

Cutout to mount

display module

Cutout to mount

display module

Cutout to mount

display module

231

FX-2000 Main Board

6.4 ECX-0012 Expander Chassis for FX-2009-12DS

Mounts and occupies two display positions in BB-5008 or BB-5014 Enclosures, and supports

two display and 12 adder modules.

Exterior View Interior View

56

56

34

4

789

2

1

789101112

26

Page 30

Display and Adder Modules Mounting Locations

Inside Chassis for mounting adder

modules. Three modules can be

mounted over the main re alarm

board and six above the main re

alarm board stacked three over

three.

Three adder modules

mounted over main re

alarm board.

Main Fire Alarm Board

3

4

5

6

7

8

9

2

1

6.5 Mounting the Boards to the BBX-1024XTChassis

The main board is mounted to the chassis and is shipped out this way. Mounts up to 9 adder modules

and one display module such as RAX-1048TZDS Programmable 48 Zone and Trouble LED display

module, IPS-2424DS Programmable Input Switches module and FDX-008W Fan Damper module.

Figure 13 FX-2003-12XT in a BBX-1024XT Enclosure

27

Page 31

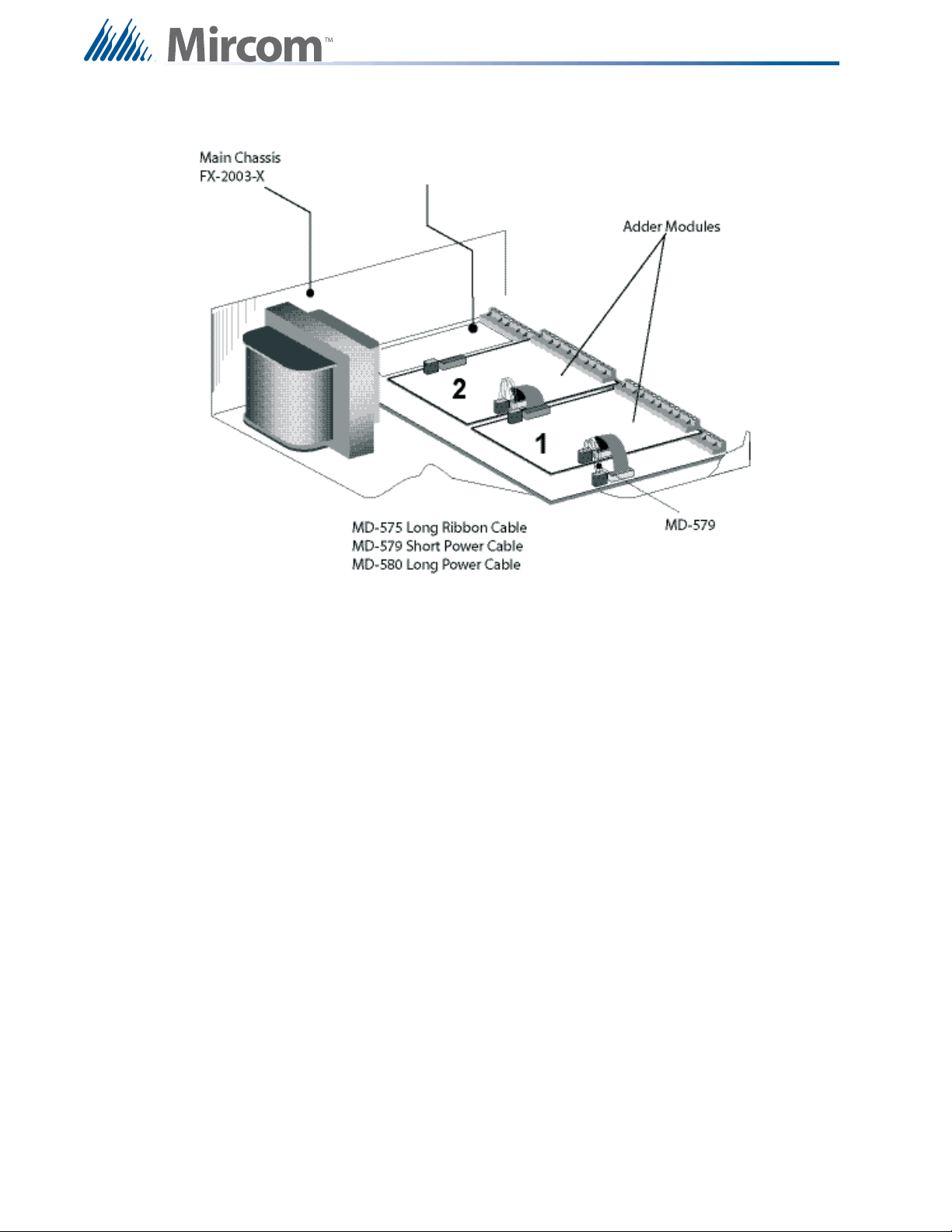

6.5.1 Adder Modules

CONNECT RIBBON

CABLE FROM P1

TO FIRE ALARM

CONTROL PANEL

POLARITY

REVERSAL

ALARM

POLARITY

REVERSAL

SUPV

CITY

TIE

+ | - + | - + | -

JW4

P1 P2

Each adder module occupies one module slot and mounts inside the following chassis:

• FX-2003-6DS/FX-2003-12DS/FX-2003-12XT/FX-2003-12XTDS Chassis

• FX-2017-12DS Mid-size Main Chassis and FX-2009-12DS Large Main Chassis

• ECX-0012 Expander Chassis for FX-2009-12DS

Display and Adder Modules Mounting Locations

ALC-198S

Single Intelligent

Analog Loop

Controller Module

SGM-1004A

Four NAC Circuit

Module

6.5.2 Display Modules

Each display module occupies one display position and mounts to the display cutouts on the

following chassis:

• FX-2003-6/FX-2003-12 Compact Main Chassis

• FX-2003-6DS/FX-2003-6DS-16LED/FX-2003-12DS Compact Main Chassis

• FX-2003-12XT/FX-2003-12XTDS Mid-size Main Chassis

• FX-2017-12DS Mid-size Main Chassis

• FX-2009-12DS Large Main Chassis

• ECX-0012 Expander Chassis for FX-2009-12

These modules can also be mounted in the standard BB-5000 cutouts (with brackets), and the

BBX-1000 enclosures (requires RAX-LCD as a driver).

ALC-396S

Dual Intelligent

Analog Loop

Controller Module

RM-1008A

Eight Relay

Circuit Module

ALC-H16

Hardwire Loop

Controller Module

UDACT-300A

Digital Alarm

Communicator

Module

DM-1008A

Eight Initiating

Circuit Module

PR-300

Polarity

Reversal/ City

Tie Module

RAX-1048TZDS

Programmable Zone LED

Annunciator Module

RAX-1048TZDS

Programmable Zone LED

IPS-2424DS

Programmable Input

Switches Module

FDX-008W

Fan Damper Module

Annunciator Module

OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE

28

Page 32

7.0 Module Settings

MAIN FIRE ALARM BOARD

FIELD WIRING TERMINALS

P9

P8

F1

P 10 P1 1 P12 P1 3

+ BDG- +BAT-

P7

JW1

P4

JW4

P14

P3

JW2

JW3

P5

P6

i

7.1 Main Fire Alarm Modules (MD-764 Part of Main Chassis)

JW1 Remove jumper if a PR-300 or UDACT-300A is installed.

JW2 to JW4 Jumpers are factory set and should not be changed.

P3 Black RS-485 Connector connects to the Adder Loop ALC-198S, ALC-396S

or ALC-H16 if used (Address Loops 3, 4, etc)

P4 Connector for PR-300 module or UDACT-300A.

P6 Connector for first eight conventional hardwire circuit adder modules (Loop 0).

P5 Connector for next eight conventional hardwire circuit adder modules (Loop1).

P7 White BDM Connector for factory use only.

P8 Power Connector for Adder Modules.

P9 RS-232C for printer or CRT monitor.

P10, P11 Factory connection to bridge rectifier.

P12, P13 Connection to 24VDC battery. Observe correct polarity

Module Settings

P14 Connector for display module.

F1 20 Amp slow blow non-replaceable fuse.

TO CONFIGURE THE FIRE ALARM PANEL USE THE RS-485 CONNECTOR P4 OF THE

LAST ADDER LOOP CONTROLLER MODULE INSTALLED.

Figure 14 Main Fire Alarm Board

Note: To enable communication from the Main Module to all of the Adder Modules, it is

necessary to add a Continuity Jumper on the last Adder Module in a chain (see

the appropriate Module Settings section to verify the location of the Continuity

Jumper on a particular Circuit Adder Module). Only the last circuit adder module

should have a jumper plug on its continuity jumper; all others must be left without

a jumper plug.

29

Page 33

Module Settings

MAIN FIRE ALARM SUPER BOARD

FIELD WIRING TERMINALS

P9

P8

F1

P 10 P1 1 P12 P1 3

+BDG- +BAT-

P7

JW1

P4

JW4

P14

P3

JW2

JW3

i

7.2 Main Fire Alarm Super Module (MD-757 Part of “S” Version

Main Chassis)

This super main board does not have any addressable loops on it. For an addressable loop,

adder boards are required.

JW1 Remove jumper if a PR-300 or UDACT-300A is installed.

JW2 to JW4 Jumpers are factory set and should not be changed.

P3 Black RS-485 Connector connects to the Adder Loop ALC-198S,

ALC-396S or ALC-H16 if used (Address Loops 3, 4, etc)

P4 Connector for PR-300 module or UDACT-300A.

NO HARDWIRE CIRCUIT ADDER MODULES ARE CONNECTED TO

THIS MAIN FIRE ALARM SUPER MODULE

P7 White BDM Connector for factory use only.

P8 Power Connector for Adder Modules.

P9 RS-232C for printer or CRT monitor.

P10, P11 Factory connection to bridge rectifier.

P12, P13 Connection to 24VDC battery. Observe correct polarity

P14 Connector for display module.

F1 20 Amp slow blow non-replaceable fuse.

TO CONFIGURE THE FIRE ALARM PANEL USE THE RS-485 CONNECTOR P4 OF THE

LAST ADDER LOOP CONTROLLER MODULE INSTALLED.

Figure 15 Main Fire Alarm Super Module (MD-757 Part of “S” Version Main Chassis)

30

Note: To enable communication from the Main Module to all of the Adder Modules, it is

necessary to add a Continuity Jumper on the last Adder Module in a chain (see

the appropriate Module Settings section to verify the location of the Continuity

Jumper on a particular Circuit Adder Module). Only the last circuit adder module

should have a jumper plug on its continuity jumper; all others must be left without

a jumper plug.

Page 34

7.2.1 DSPL-420 Main Display Module

i

i

P1 Cable connects to P14 of main fire alarm module

P2 Connection to P1 of any adder display module if used.

Figure 16 DSPL-420 Main Display Module

Module Settings

Note: The main display module comes with slide-in paper labels including both English

and French slide-ins, and laser printer-compatible blanks for zone labelling.

7.2.2 Optional DSPL-420-16TZDS Display Module

P1 Cable connects to P14 of main fire alarm module

P2 Connection to P1 of any adder display module if used.

Figure 17 DSPL-420-16TZDS Main Display Module with 16 Zone LEDs

Note: The main display module comes with slide-in paper labels including both English

and French slide-ins, and laser printer-compatible blanks for zone labelling.

31

Page 35

7.3 RAX-1048TZDS Zone Display Module

P

2

P

1

i

P1 Cable connects to P2 of previous display module.

P2 Cable connects to P1 of next display module.

Module Settings

Figure 18 Zone Display Module (RAX-1048TZDS)

7.4 IPS-2424DS Programmable Input Switches Module

P1 Cable connects to P2 of previous display module.

P2 Cable connects to P1 of next display module.

P

2

ZONE

BYPA

SS

#1

ZONE

BYPA

SS

#2

ZONE

BYPA

SS

#3

ZONE

BYPA

SS

#4

P

1

ZONE

BYPA

SS

#5

ZONE

BYPA

SS

#6

ZONE

BYPA

SS

#7

ZONE

BYPA

SS

#8

ZONE

BYPA

SS

#9

ZONE

BYPA

SS

#10

ZONE

BYPA

SS

#11

ZONE

BYPA

SS

#12

ZONE

BYPA

SS

#13

ZONE

BYPA

SS

#14

ZONE

BYPA

SS

#15

ZONE

BYPA

SS

#16

ZONE

BYPA

SS

#17

ZONE

BYPA

SS

#18

ZONE

BYPA

SS

#19

ZONE

BYPA

SS

#20

ZONE

BYPA

SS

#21

ZONE

BYPA

SS

#22

ZONE

BYPA

SS

#23

ZONE

BYPA

SS

#24

Figure 19 IPS-2424DS Programmable Input Switches Module.

Note: The zone display modules comes with laser printer-compatible slide-in paper

labels for zone labelling.

32

Page 36

7.5 Fan Damper Control Display Module (FDX-008W/WKI)

OFF AUTO ON TROUBLE

PARKING GARAGE #1,

FANS 1, 2 , 3

There are two models of the Fan Damper Control Display modules available. The FDX-008W

provides switch control and LED indication of 8 fan damper zones. The FDX-008WKI provides

switch control of 7 fan damper zones with the eighth zone activated by keyswitch. LED

indication is provided for all 8 fan damper zones on the FDX-008WKI. Both the FDX-008W

and the FDX-008WKI are used in conjunction with a FX-2000 Fire Alarm Control Panel.

Module Settings

Figure 20 Fan Damper Control Display Module (FDX-008W/WKI)

7.5.1 Fan Damper Operation

The FDX-008W Fan Damper Control Display module has eight configurable output circuits,

each with a three position switch. The FDX-008WKI operates in the same manner as the FDX008W except zone 8 is controlled by a remote keyswitch. Each switch has an ON and OFF

position, plus an AUTO position. If the switch is placed in the AUTO position, the white AUTO

LED will illuminate steady and the output will activate as programmed or configured. The

output can be manually turned ON or OFF by placing the switch in the ON or OFF position,

respectively.

Basically each switch can be configured to operate multiple fans or dampers. For each switch,

there are 3 operations provided; outputs to turn ON, same outputs to turn OFF and inputs to

bypass.

An example of the most common use of the FDX-008W or FDX-008WKI Fan Damper Control

Display module is to operate exhaust fans and confirm fan operation (via monitor modules).

See FDX-008W Block Diagram on the next page for a block diagram of fan and monitor set up.

7.5.2 Example

As shown in the figure to the right, Parking Garage #1 has 3

exhaust fans. The three position switch is configured to operate

(to turn ON) fans 1, 2 and 3 in stairwell #1. The switch is set in the

AUTO position. Upon activation (via alarm or some other

programmed trigger) with the switch in AUTO, the 3 fans (1,2, and

3) in stairwell #1 are turned ON automatically. Monitor modules in

the Parking Garage #1 detect that all 3 fans are operating,

therefore the ON LED will illuminate steadily. If one of the fans did

not turn ON (due to malfunction), the ON LED will flash. The TRBL (trouble) LED will illuminate

33

Page 37

Module Settings

OFF AUTO ON TROUBLE

FX-2000 FIRE

ALARM PANEL

FANS

OUTPUT MODULES

MONITOR MODULES

FDX-008W/WKI FAN/DAMPER CONTROL MODULE

i

i

steady amber based on feedback from the monitor module that one or more of the fans is not

working.

ON LED shows steady for all outputs operating and confirmed.

OFF LED shows steady for all outputs NOT operating and confirmed.

TRBL LED shows steady for one or more outputs NOT operating and confirmed.

Figure 21 FDX-008W Block Diagram of Fan and Monitor Setup

Note: A bypass function always has priority, so that if a circuit is bypassed by moving

the switch manually or by loop bypass (FX-2000 Fire Alarm Panel), no other

action will operate this switch other then again moving the switch manually or by

un-bypassing the loop.

Before mounting the FDX-008WKI module, if a keyswitch is to be connected, wire the

keyswitch to terminals at TS1 as shown in Figure 22 on page 35.

Note: There are also terminals located behind TS1 on the other side of the board for

the convenience of wiring the keyswitch. The last fan damper zone in the bottom

right position of the FDX-008WKI is controlled by the keyswitch.

34

Page 38

Module Settings

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE

OFF AUTO ON TROUBLE OFF AUTO ON TROUBLE

TS1

P2

TERMINALS AT TS1 ARE WIRED TO A KEYSWITCH.

NOTE: IF FAN DAMPER MODULE IS MOUNTED TO

THE DOOR USE TERMINALS LOCATED AT THE

BACK OF THIS BOARD, BEHIND TS1.

P1

KEYSWITCH

CONTROLLED

CONNECTS TO

PREVIOUS DISPLAY

MODULE P2

Mount the FDX-008W and FDX-008WKI Fan Damper Control Display modules in any position

on the front part of the FX-2000 chassis.

Figure 22 FDX-008WKI Fan Damper Control Display Module

35

Page 39

7.6 DM-1008A Hardwire Detection Adder Module

P1

P3

P4

FI ELD WIRI NG TERMINALS

P2

JW5

JW4

JW3

JW2

JW1

Data cable to P6 or P5 of

main fire alarm module or to

P12 or P13 of hardwire

loop controller module, or

previous adder module

Powe r connect or t o P8 of

main fire alarm mod ule,

or to P2 of ha rdwire lo op

controller module, or to

previou s adder module

Data connector for

next adder module

Powe r con nect or for

next adder module

i

JW1 Install jumper for Class A (Style D) operation of initiating circuits 1 and 2.

JW2 Install jumper for Class A (Style D) operation of initiating circuits 3 and 4.

JW3 Install jumper for Class A (Style D) operation of initiating circuits 5 and 6.

JW4 Install jumper for Class A (Style D) operation of initiating circuits 7 and 8.

Module Settings

JW5

Remove continuity jumper if there are any more adder modules installed.

Figure 23 Hardwire Detection Adder Module (DM-1008A)

Note: For Class A (Style D) operation the FX-2000 must be configured as Class A via

the configuration program.

36

Page 40

7.7 SGM-1004A Hardwire NAC Signal Adder Module

i

JW1 Remove continuity jumper if this is not the last adder module installed.

JW2 Jumper pins for bell cut or isolators on Zone 1.

JW3 Jumper pins for bell cut or isolators on Zone 2.

JW4 Jumper pins for bell cut or isolators on Zone 3.

JW5 Jumper pins for bell cut or isolators on Zone 4.

JW11 For basic operation do not wire these terminals.

Module Settings

J11

ZONE 4

1 2 3

JW5

ZONE 3

JW4

ZONE 2

JW3

ZONE 1

FIELD WIRING TERMINALS

JW2

GREEN SIGNAL LEDs

Figure 24 Hardwire NAC Signal Adder Module (SGM-1004A)

Data cable to P6 or P5 of

main fire alarm module

or to previous adder module

P2

Data connector for

next adder module

JW1

P1

P4

Power connector to P8 of

main fire alarm module,

or to previous adder module

Power connector for

next adder module

P3

7.7.1 SGM-1004A Components

There are four green LEDs on the board, one for each signal zone. The LED will illuminate or

flash following the NAC signal rate sent to its zone. It will be off when the system is normal and

they will illuminate when a NAC signal zone is activated. The LED does not reflect what is

happening on the NAC signal zone, just that it is receiving data to activate that NAC signal

zone.

Note: Jumpers JW2, JW3, JW4 and JW5 are positioned on pins 2 and 3 (right two pins

with board orientation as shown above) from factory.

37

Page 41

7.7.2 SGM-1004A Operation

!

!

There are three modes of operation for this module. The basic mode of operation does not

involve any bell cut relay or isolators connected to the signal zones. For this case, leave

jumpers JW2, JW3, JW4 and JW5 as they come on pins 2 and 3, and do not make any

connection to terminal block J11. The second mode provides bell cut operation which allows

the silencing of the bells. The third mode is used when isolators are to be connected to the

signal circuits. For further information on bell cut relays or isolators, please refer to the specific

fire alarm panel manual or the isolator instruction manual.

7.7.3 SGM-1004A Jumpers for the Bell Cut Mode

JW2 Place jumper over pins 1 and 2 for the ability to remotely silence the bells on

Zone 1.

JW3 Place jumper over pins 1 and 2 for the ability to remotely silence the bells on

Zone 2.

JW4 Place jumper over pins 1 and 2 for the ability to remotely silence the bells on

Zone 3.

JW5 Place jumper over pins 1 and 2 for the ability to remotely silence the bells on

Zone 4.

Module Settings

JW11 Wire these terminals to a bell cut relay (for details see QRM-1001 Bell Cut

Module Installation and Operating Instructions, LT-666).

Attention: Discard jumpers on zones that are not configured for bell cut.

7.7.4 SGM-1004A Jumpers for the Isolator Mode

JW2 Place jumper over pins 2 and 3 for the ability to connect an isolator on Zone 1.

JW3 Place jumper over pins 2 and 3 for the ability to connect an isolator on Zone 2.

JW4 Place jumper over pins 2 and 3 for the ability to connect an isolator on Zone 3.

JW5 Place jumper over pins 2 and 3 for the ability to connect an isolator on Zone 4

JW11 Wire these terminals to an alarm relay. These may be tapped if more signal

modules are used in this manner.

Attention: Discard jumpers on zones that are not configured for isolators.

38

Page 42

7.8 RM-1008A Hardwire Relay Adder Module

P1

P3

P4

FIELD WIRING TERMINALS

P2

JW1

FIELD WIRING TERMINALS

3 2 1

3 2 1

3 2 1

3 2 1

3 2 1

3 2 1

3 2 1

3 2 1

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

I1

I2

I3

I4

I5

I6

I7

I8

P2 Data cable to P6 or P5 of main fire alarm module, or to P12 or P13 of Hardwire

loop controller module, or to previous adder module.

P1 Data connector for next adder module.

P4 Power connector to P8 of main fire alarm module, or to P2 of Hardwire loop

controller or to previous adder module.

P3 Power connector for next adder module.

JW1 Remove continuity jumper if there are any more adder modules installed. If this

is the last module installed, leave JW1 on.

JP1-JP8 Move jumpers from pins 1 and 2 to 2 and 3 to connect relay commons between

two or more relays.

.

Module Settings

Figure 25 Hardwire Relay Adder Module (RM-1008A)

39

Page 43

7.9 Polarity Reversal and City Tie Module (Model PR-300)

i

Module Settings

+ | - + | - + | -

ALARM

SUPV

TIE

REVERSAL

REVERSAL

CITY

POLARITY

POLARITY

P1 P2

JW4

Mounting hole for

#6-32 screws

Mounting hole for

#6-32 screws

Figure 26 Polarity reversal and city tie module

The following hardware configuration must be performed before installing the PR-300.

P1 Cable connects to P5 on the FX-2000 Main Fire Alarm Board

P2 P2 is for connecting the UDACT-300A if both PR-300 and UDACT-300A are

installed on the FX-2000.

JW4 If the PR-300 is used this is the last module jumper. JW1 on the main board

should be removed and JW4 on the PR-300 should be set. If both PR-300

and UDACT-300A are installed, then JW1 on the main board and JW4 on

the PR-300 should be removed.

Table 9 PR-300 jumper settings

The Alarm Transmit signal to the PR-300 can be programmed to turn OFF when signal silence

is active. This allows the City Tie Box to be manually reset. On subsequent alarms the

silenceable signals will resound and the City Tie Box will be retriggered. Please refer to the

Configurator for more information.

The Trouble Transmit signal to the PR-300 can be programmed to delay AC power fail. Please

refer to the Configurator for more information.

Note: Jumper JW1 on the FX-2000 main fire alarm board must be removed if a city tie

module is installed.

40

Page 44

7.10 UDACT-300A Main Board

There are two jumpers on the UDACT-300A which are used for operation/configuration

purposes. Jumper JW1 is used to reset the default passcode. Jumper JW2 is required for

configuring

connections, pushbutton and LEDs. Table 2 following, provides a description of the user items

on the UDACT-300A.

the UDACT-300A. Refer to Figure 22 below for location of jumpers, cable

SYSTEM NORMAL

13:21 MON 2015-08-03

Module Settings

CONNECT RIBBON

CABLE FROM P1

TO MIRCOM FIRE

ALARM CONTROL

PANEL

Figure 27 UDACT-300A Board Layout

Table 10 UDACT-300A Cable Connectors and Miscellaneous

Cable Connector Function

P1 Ribbon Cable for connecting to P4 of FX-2000 FACP main board.

P2 RS-232C/RS-485 Connection for computer configuration.

U18 Connector for CFG-300 Configuration Tool

Lamp Test button Connector for CFG-300 Configuration Tool

UR1 Potentiometer This potentiometer is for adjustment of the CFG-300 LCD contrast.

41

Page 45

Module Settings

i

The following table lists all the LEDs located on the UDACT-300A board and states the

function of each LED.

Table 11 UDACT-300A List of LEDs and their Functions

Cable Connector Function

Relay Line 1 Located below Line 1 terminal block. When Line 1 relay is energized, this green

LED will illuminate

Relay Line 2 Located below Line 2 terminal block. When Line 2 relay is energized, this green

LED will illuminate.

RS-485 Status LED for communication, will flash when RS-485 communication is

active.

Common Trouble Steady amber for any troubles on the Fire Alarm panel or UDACT-300A.

CPU Fail Steady amber for any on board CPU trouble.

Telephone Line 1 Telephone status indicator LED; Red when the line is in use, Amber when there

is a line trouble.

Telephone Line 2 Telephone status indicator LED; Red when the line is in use, Amber when there

is a line trouble.

Power ON Green LED is ON steady when power is supplied to the board.

The following table lists the user jumpers available on the UDACT-300A and their functions.

The following table lists the user jumpers available on the UDACT-300A and their functions..

Table 12 UDACT-300A List of Jumpers for Operation and Configuration

Cable

Function

Connector

JW1 Normally open. Place jumper here and power down the UDACT-300A by disconnecting

P1 or power down the fire alarm panel (AC and Batteries), then power back to revert to

default passcode. After reset, remove the jumper. Leave normally open.

JW2 Normally open to BLOCK remote configuration via modem, PC with a UIMA converter

module or using the LCD and keypad at the UDACT-300A. Place jumper here to

ALLOW any type of configuration. Remove jumper once configuration is complete.

Note: Can be installed with the PR-300 City Tie but not in the same location. If using

this configuration the PR-300 must be installed on the left and it is recommended

that the UDACT-300A be installed in the middle, although it can be installed on

the right if needed.

See the UDACT-300A Installation and Operation Manual (LT-888) for more information.

42

Page 46

Module Settings

7.11 ALC-198S Single Intelligent Analog Loop Controller Module

The ALC-198S Single Intelligent Analog Loop Controller module provides a single

addressable loop. It may be mounted over the main chassis of the FX-2000 Fire Alarm Panel

or on any chassis which supports adder boards. Refer to Module Mounting Locations View

#2 on page 24. The module is mounted using four #6 screws and (if necessary) four 1 1/2"

spacers.

Power The power is supplied to the board via cable from the main chassis board

or from the previous loop controller module into the P1 Power IN connector.

The P2 Power OUT connector is connected to the next loop controller

module or other adder module. Two power cables are supplied with the

module.

RS-485 The RS-485 cable comes attached at P3 and is connected to the main

chassis board or from the previous loop controller module or other adder

board. The RS-485 OUT at P4 is connected to the next loop controller

module if used or left without connection.

DIP switches The dip switches are used to set the address of the board. The address is

binary, with the SW-1 switch as the lowest significant digit and OFF being

active. For example an address of two is SW-1 ON, SW-2 OFF, and all the

other dip switches SW-3 to SW-8 ON. Refer to Appendix E: DIP Switch

Settings Summary on page 96 for more information.

Loop 1 This is the addressable loop for all initiating devices. Wire the loop as

shown in Field Wiring on page 49.

Jumpers A jumper is provided at JW2 for normal operation. To reset the board the

jumper is left at JW2 and the pins at position JW1 are shorted momentarily.

BDM Port This connection is for factory use only.

43

Page 47

Module Settings

1

8

RS-485

CABLE

RS-485

ADDRESS

DIP

SWITCH

BDM

PORT

JW2 - A

JUMPER IS

PLACED HERE

TO ENABLE

WATCHDOG

TIMER. THIS

IS JUMPER=S

NORMAL

LOCATION.

JW1 - JUMPER IS

PLACED HERE TO

RESET HARDWARE

POWER

CABLE

(OUT)

POWER

CABLE

(IN)

LOOP A

IN

OUT

+ - + -

B

A

DIP SWITCHES ARE FOR

THIS BOARD=S ADDRESS.

SW-1 IS THE LEAST

SIGNIFICANT DIGIT (BINARY).

ACTIVE POSITION IS OFF.

JW3 - JUMPER

FROM JW2 IS

PLACED HERE TO

BYPASS

WATCHDOG FOR

FACTORY

DOWNLOADING

USING BDM

P3

P4

P5

P1

P2

SHIELD

Figure 28 ALC-198S Single Intelligent Analog Loop Controller Module

Mount the ALC-198S Single Intelligent Analog Loop Controller module as described in the

section Display and Adder Modules Mounting Locations on page 25. The module may be

mounted over the main chassis board or in any position that an adder module is mounted.

44

Page 48

Module Settings

7.12 ALC-396S Dual Intelligent Analog Loop Controller Module

The ALC-396S Dual Intelligent Analog Loop Controller module provides a two addressable

loops. It may be mounted over the main chassis of the FX-2000 Fire Alarm Panel or on any

chassis that supports adder boards. Refer to page Module Mounting Locations View #2 on

page 24 for mounting applications. The module is mounted using four #6 screws and (if

necessary) four 1 1/2" spacers.

Power The power is supplied to the board via cable from the main chassis board

or from the previous loop controller module into the P1 power in connector.

Connect the P2 power out connector to the next loop controller module or

other adder module. Two power cables are supplied with the module.

RS-485 The RS-485 cable comes attached at P3 and is either connected to the

main chassis board or connected from the previous loop controller module

or other adder board. If the next loop controller module is used, connect the

RS-485 out at P4 to the next loop controller module; if it is not used, leave

without connection.

DIP switches Use the DIP switches to set the binary address of the board. SW-1 is the

lowest significant digit and OFF is active. For example, an address of two

would be created by turning SW-1 on, SW-2 off and DIP switches SW-3 to

SW-8 on. Refer to Appendix E: DIP Switch Settings Summary on page 96

for DIP switch settings.

Loop 1 This is the addressable loop for all initiating devices. Wire the loop as

shown in Single Loop Terminal Connections - Class B on page 54 or Single

Loop Terminal Connections - Style 7 on page 55 and Single Loop Terminal

Connections - Style 6 on page 56.

Loop 2 This is the addressable loop for all initiating devices. Wire the loop as

shown in Single Loop Terminal Connections - Class B on page 54 or Single

Loop Terminal Connections - Style 7 on page 55 and Single Loop Terminal

Connections - Style 6 on page 56.

Jumpers A jumper is provided at JW2 for normal operation. To reset the board, leave

the jumper at JW2 and momentarily short the pins at position JW1.

BDM Port This connection is for factory use only.

45

Page 49

Module Settings

1

8

RS-485

CABLE

RS-485

ADDRESS

DIP

SWITCH

BDM

PORT

JW2 - THE

JUMPER IS

KEPT HERE

FOR

NORMAL

OPERATION

JW1 - PINS ARE

SHORTED

MOMENTARILY TO

RESET

HARDWARE

JW3 - JUMPER

FROM JW2 IS

PLACED HERE TO

BYPASS

WATCHDOG FOR

FACTORY

DOWNLOADING

USING BDM

POWER

CABLE

POWER

CABLE

LOOP A

DIP SWITCHES ARE FOR

THIS BOARD=S ADDRESS.

SW-1 IS THE LEAST

SIGNIFICANT DIGIT (BINARY).

ACTIVE POSITION IS OFF.

+ - + -

B

A

P3

P2

P1

P5

P4

LOOP B

+ - + -

B

A

SHIELD

i

Figure 29 ALC-396S Dual Intelligent Analog Loop Controller Module

Mount the ALC-396S Dual Intelligent Analog Loop Controller module as shown in Module

Mounting Locations View #2 on page 24. The module may be mounted over the main chassis

board or in any position that an adder module is mounted.

46

Note: There are two addressable loops present on this board (ALC-396S) that are

wired in the same manner as shown in the wiring diagrams beginning with Main

Fire Alarm Module Terminal Connections on page 49. Although these drawings

show only Loop 1, Loop 2 is wired in the same way as Loop 1 is. Note that Loop

1 and Loop 2 do not have to be wired in the same class, such as Class A or

Class B or Style 7. Therefore Loop 1 may be wired as Class A and Loop 2 may

be wired as Class B.

Page 50

7.13 ALC-H16 Hardwire Loop Controller Module

The ALC-H16 Hardwire Loop Controller module provides an interface in order to add 16

conventional adder boards. This board may be mounted over the main chassis of the FX-2000

Fire Alarm Panel or on any chassis which supports adder boards. Refer to page Module Mounting

Locations View #2 on page 24 for mounting applications. Mount the module using four #6 screws

and (if necessary) four 1 1/2" spacers.

Power The power is supplied to the board via cable from the main chassis board

or from the previous loop controller module into the P1 power in connector.

Connect the P2 power out connector to the next loop controller module or

other adder module. Two power cables are supplied with the module.

RS-485 The RS-485 cable comes attached at P3 and is either connected to the

main chassis board or connected from the previous loop controller module

or other adder board. If the next loop controller module is used, connect the

RS-485 out at P4 to the next loop controller module; if it is not used, leave

without connection.

Jumpers A jumper is provided at JW2 for normal operation. To reset the board, leave

the jumper at JW2 and momentarily short the pins at position JW1.

BDM Port This connection is for factory use only.

P13 and P12

Connectors

Connect the P13 connector (via ribbon cable included with this module) to

the first module of the first group of eight conventional adder modules.

Connect the P12 connector (via ribbon cable included with this module) to

the first module of the second group of eight conventional adder modules

Module Settings

47

Page 51

Module Settings

A

.

P12 IS USED TO CONNECT SECOND GROUP OF 8 ADDER MODULES

P13 IS USED TO CONNECT FIRST GROUP OF 8 ADDER MODULES

RS-485

P12

CAB LE

DDRESS

DIP

SWI TCH

RS- 4 8 5

P13

P4

ON

1

8

D I P SWI TCH ES ARE FO R

THIS BOARD= S ADDRESS.

SW- 1 IS TH E LEA ST

SIGNIFICANT DIGIT (BINARY).

ACTIVE POSITION IS OFF.

JW3 - JUM PER

FROM JW2 IS

PLACED HERE TO

BYPASS

WATCH DOG FOR

FA C T O R Y

DOWNLOADING

USING BDM

P3

P2

POWER

CAB LE

(OUT)

POWER

CAB LE

(IN)

BDM PORT

JW3

JW1

JW2

JW2 - THE

JUM PER IS

KEPT HERE

FOR

NORMAL

OPERATION

P1

JW1 - PINS ARE

SH ORT ED

MOMENTARILY TO

RESET

H A RD W A RE

Figure 30 ALC-H16 Hardwire Loop Controller Module

Mount the ALC-H16 Hardwire Loop Controller module as shown on Module Mounting

Locations View #2 on page 24 and ECX-0012 Expander Chassis for FX-2009-12DS on

page 26. The module may be mounted over the main chassis board or in any position that an

adder module is mounted.

There is no wiring at the ALC-H16 Hardwire Loop Controller module, but there is wiring at the

16 standard conventional adder modules. For conventional hardwire circuit wiring refer to

Hardwire Detection Module (DM-1008A) Terminal Connections on page 57, Hardwire Signal

Module Terminal Connections on page 58, and Hardwire Relay Module Terminal

Connections on page 59 for the specific module you are wiring.

48

Page 52

8.0 Field Wiring

!

i

COM

-

RS485

NO

NC

COM

TROUBLE

NO

NC

COM

SIG GND

or COM(-)

NO

NC

ALARM

USE TWISTED SHIELDED PAIR.

22 AWG UP TO 2000 FT.

20 AWG UP TO 4000 FT.

SUPV.

+

S

RS-485 INTERFACE TO

ANNUNCIATORS AND

OTHER DEVICES

(POWER LIMITED)

NOT USED

MUST BE

CONNECTED TO A

LISTED POWER

LIMITED SOURCE

OF SUPPLY

COMMON TROUBLE

CONTACTS

28 VDC, 1 AMP

RESISTIVE LOAD

AUXILIARY COMMON

SUPERVISORY

CONTACTS

28 VDC, 1 AMP

RESISTIVE LOAD

AUXILIARY COMMON

ALARM CONTACTS

28 VDC, 1 AMP

RESISTIVE LOAD

S

8.1 Main Fire Alarm Module Terminal Connections

Wire devices to terminals as shown in Figure 31 below. See Wiring Tables and Information on

page 63. See Appendix A: Specifications on page 79 and Appendix B: Compatible Devices on

page 85 for compatible devices..

Attention: Do not exceed power supply ratings:

Main Chassis FX-2003-6DS and FX-2003-6DS-16LED total current for NAC

circuits is 5A max.

Main Chassis FX-2003-12DS, FX-2003-12XTDS, FX-2017-12ADS or FX-

2017S-12ADS total current for NAC circuits is 10A max.

Main Chassis FX-2009-12DS and FX-2009S-12DS: total current for NAC

circuits is 10A max.

Notes: The terminal blocks are "depluggable" for ease of wiring.

Field Wiring

All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

8.1.1 Main Fire Alarm Module Terminal Connections.

Figure 31 Main Fire Alarm Module Terminal Connections

49

Page 53

BELL, HORN, OR

STROBE

Legend: See Appendix A for compatible devices.

3.9K 1/2W ELR LISTED S5434

MODEL MP-300 MANUFACTURED

BY MIRCOM

IND2+ (Z)

IND2- (Z)

IND2- (Y/Z)

SUPERVISED INDICATING CIRCUIT #2

INDICATION

CIRCUIT 1

(POWER

LIMITED)

IND1+ (Z)

STYLE Z

(CLASS A)

WIRING

IND1- (Y/Z)

IND1+ (Y/Z)

IND2+ (Y/Z)

IND1- (Z)

INDICATION

CIRCUIT 2

(POWER

LIMITED)

INDICATING CIRCUITS 3 & 4

ARE NOT SHOWN

STYLE Y

(CLASS B)

WIRING

SUPERVISED INDICATING CIRCUIT #1

ANALOG

LOOP 2

CONNECTIONS

(LOOP 0 AND

LOOP1 ARE

INTERNAL

ADDRESSES

FOR FIRST 8

CARDS AND

SECOND 8

CARDS

RESPECTIVELY

+

4-WIRE

POWER

SUPPLY

-

+

AUX.

POWER

-

TRB

RTI

INTERFACE

TRL

ANALOG LOOP FIELD WIRING

(CLASS A OR B)

SEE ANALOG LOOP WIRING SECTION

CONNECTION TO MIRCOM RTI

REMOTE TROUBLE INDICATOR

(SEE RTI INSTALLATION

INSTRUCTION) BLK TOTRB+ BLU

TO TRL-RED & WHT TO AUX.

POWER COM+

END OF LINE RELAY

LISTED S3403

MODEL A77-716B

MANUFACTURED BY

SYSTEM SENSOR

2

3

41

6

5

+

-

+

-

TO

INITIATING

CIRCUIT

+

-

+

-

POWER

+

-

DETECTION

4-WIRE

DETECTION

DEVICE

AUXILIARY POWER

FOR REMOTE ANNUNCIATORS

24 VDC UNFILTERED

1.7 AMPS MAXIMUM

RTI

BLK

BLU

RED & WHT

LOOP 2

B

A

+

+

-

+

-

-

+

+

+

-

-

i

i

Field Wiring

NAC

NAC

Figure 32 Main Fire Alarm Module Terminal Connections (continued)

Notes: The terminal blocks are "depluggable" for ease of wiring.

All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

50

Notes: All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Indicating (NAC) circuits are fully supervised and rated for 24 VDC unfiltered

1.7A max. Use wire size as stated in Table 15 NAC Circuit Wiring Table on

page 63.

Page 54

8.2 Analog Loop Wiring

i

8.2.1 Loop Terminal Connections - Class B

Field Wiring

FX-2000

MAIN FIRE ALARM BOARD

ANALOG

LOOP

CONNECTIONS

COM ( - )

LOOP 2

B

A

+

+

-

NAC

INDICATING

CI RCUI TS

4-WIRE

RESET TA B L E

SUPPLY

+

-

IND1 + (Y/Z)

IND1 + (Z)

IND1 - (Z)

IND1 - (Y/Z)

S

S

TWO WIRES

S

SO

F

M

C

M

2 Pair

s

C

s

Conventional Heat Sensors

and Manual Pull Stations

C

C

s

s

TWO WIRES

H

F

H

H

S

F

LEGEND

Addr essabl e Smo ke Detect or

S

wi th St andar d An alog Base

Addr essable Thermal Sensor

H

wi th St andar d An alog Base

Convent ional Smo ke Sensor

C

s

Addressable Manual

F

Pull Station

End -Of -Li n e- Resist o r

Combination

Horn /St robe

Addressable

Monit or Module

M

Addressable Supvr.

SO

Out pu t M odu le

Figure 33 Loop Terminal Connections - Class B

Notes: Terminal blocks are “depluggable” for ease of wiring.

All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Loop wiring: maximum loop resistance is 40 ohms total. These lines are fully

supervised.

Observe in and out polarity when using module and base isolators.

51

Page 55

8.2.2 Loop Terminal Connections - Style 7

i

Field Wiring

TWO WIRES

FX-2000

MAIN FIRE ALARM BOARD

COM(-)

+

LOOP 2

ANALOG

LOOP

CONNECTIONS

4-WIRE

RESETTABLE

SUPPLY

AUXILIARY

POWER

SUPPLY

B

-

A

+

-

+

+

-

I

F

I

ADDRESSABLE

SMOKE DETECTOR

WITH ISOLATOR BASE

S

I

I

F

I

TWO WIRES

TWO WIRES

I

Conventional Heat Sensors

and Manual Pull Stations

M

C

I

s

I

H

ADDRESSABLE

THERMAL

SENSOR

WITH

ISOLATOR

BASE

STYLE 7: For Style 7 operation use isolator

bases for the detectors and use isolator modules

(front and back as shown in this diagram) for the

addressable pull stations, monitor modules, and

control modules

LEGEND

Addressable Smoke Detector

S

with Isolator Base

Addressable Thermal Sensor

H

with Isolator Base

52

Conventional Smoke Sensor

C

s

Addressable Manual Pull Station

F

Fault Isolator Module

I

Addressable Monitor Module

M

Figure 34 Loop Terminal Connections - Style 7

Notes: All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Isolators need to be close nipple connected to the device being protected.

Loop wiring: maximum loop resistance is 40 ohms total. These lines are fully

supervised.

Page 56

8.2.3 Loop Terminal Connections - Style 6 (Formerly Class A)

F

4-WIRE

RESETTABLE

SUPPLY

+

-

AUXILIARY

POWER

SUPPLY

+

-

ADDRESSABLE

THERMAL SENSOR

ADDRESSABLE

SMOKE DETECTORS

FX-2000

ANALOG

LOOP

CONNECTIONS

F

LEGEND

Addressable Smoke Detector

Addressable Thermal Sensor

Addressable Manual Pull Station

F

Addressable Monitor Module

RO

TWO WIRES

TWO WIRES

B

A

+

-

+

-

LOOP 2

S

H

S

S

H

Addressable

Relay Output Module

M

M

M

RO

COM(-)

MAIN FIRE ALARM BOARD

Conventional 4-Wire Smoke

Detectors, Heat Sensors

and Manual Pull Stations

Field Wiring

Figure 35 Loop Terminal Connections - Style 6 (Formerly Class A)

53

Page 57

8.2.4 Single Loop Terminal Connections - Class B

Conventional Heat Sensors

and Manual Pull Stations

2 Pair

4-WIRE

RESETTABLE

SUPPLY

+

-

IND1 + (Y/Z)

IND1 + (Z)

IND1 - (Z)

IND1 - (Y/Z)

F

LEGEND

Addressable Smoke Sensor

with Standard Analog Base

Addressable Thermal Sensor

with Standard Analog Base

Conventional Smoke

Sensor

Addressable Manual

Pull Station

Combination

Horn/Strobe

Addressable

Monitor Module

Addressable Supvr.

Output Module

End-Of-Line-Resistor

TWO WIRES

TWO WIRES

S

H

S

C

s

C

s

C

s

F

F

H H

S

S

H

C

s

C

s

F

M

SO

M

TWO WIRES

M

SO

B

A

ANALOG

LOOP A

+

-

+

-

SHIELD

FX-2000

MAIN FIRE ALARM BOARD

ALC-198S SINGLE

LOOP MODULE

i

Field Wiring

54

Figure 36 Single Loop Terminal Connections - Class B

Notes: All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Loop wiring: maximum loop resistance is 40 ohms total. These lines are fully

supervised.

Page 58

8.2.5 Single Loop Terminal Connections - Style 7

LEGEND

Ad dr essabl e Smo ke

Sensor with Isolator Base

Addressable Thermal

Sensor with Isolator Base

Conventional Smoke Sensor

Addressable Manual Pull Station

Fault Isolator Module

Conventional Heat Sensors

and Manu al Pull St ati on s

F

C

s

F

ADDRESSABLE

THERMAL SENSOR

WITH ISOLATOR

BASE

ADDRESSABLE

SMOKE DETECTOR

WITH ISOLATOR

BASE

F

C

s

Addressable Monit or Module

H

S

S

H

TWO WIRES

TWO WIRES

TWO WIRES

TWO WIRES

I

I

I

I

I

I

I

I

M

M

I

B

A

ANALOG

LOOP A

+

-

+

-

ALC-198S SINGLE

LOOP MODULE

STYLE 7: For Style 7 operation use isolator

bases for the detectors and use isolator modules

(front and back as shown in this diagram) for the

addressable pull stations, monitor modules, and

control modules

i

Field Wiring

Figure 37 Single Loop Terminal Connections - Style 7

Notes: All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Isolators need to be close nipple connected to the device being protected.

Loop wiring: maximum loop resistance is 40 ohms total. These lines are fully

supervised.

55

Page 59

8.2.6 Single Loop Terminal Connections - Style 6

F

ADDRESSABLE

THERMAL SENSOR

ADDRESSABLE

SMOKE DETECTORS

F

LEGEND

Addr essabl e Smo ke Sensor

Addressable Thermal Sensor

Addressable Manual Pull Station

F

Addressable Monitor Module

TWO WIRES

S

S

H

Addressable Relay Output Module

S

H

M

M

RO

M

RO

B

A

+

-

+

-

ANALOG

LOOP A

ALC-198S SINGLE

LOOP MODULE

Conventional 4-Wire Smoke

Detectors, Heat Sensors

and Manual Pull Stations

i

Field Wiring

Figure 38 Single Loop Terminal Connections - Style 6

Notes: All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Loop wiring: maximum loop resistance is 40 ohms total. These lines are fully

supervised.

56

Page 60

8.2.7 Detection Module (DM-1008A) Terminal Connections

SUPERVISORY OR

WATERFLO W

SWI TCH (N O)

HEAT DETECTOR

Legend: See Appendix B for compatible devices.

SMOKE DETECTOR

3.9K 1/ 2W ELR LISTED S5434

MODEL MP-300

MANUFACTURED BY MIRCOM

INI1+

INI1-

INI2+

INI2-

INI3+

INI3-

INI4+

INI4-

STY LE B/ D

INI2

STY LE B/ D

INI1

PULL STATION

STY LE B

( CLA SS B)

WIRING

STY LE B

( CLA SS B)

WIRING

STY LE D

( CLA SS A)

WIRING

SUPERVISED INITIATING CIRCUIT #2

(SUPERVISORY OR WATERFLOW ZONE)

(POWER LIMITED)

SUPERVISED INITIATING CIRCUIT #1

(ALARM ZONE) (POWER LIMITED)

SUPERVISED INITIATING CIRCUIT #3

( AL ARM ZO NE) SEE STYL E D N OTE ( PO WER LI M IT ED)

INI5+

INI5-

INI6+

INI6-

INI7+

INI7-

INI8+

INI8-

STY LE B/ D

INI4

STY LE B/ D

INI3

Style D Note: Initiating circuits in a series

FX-2000 must be either all Style B (Class B)

or Style D (Class A). If Style D is selected, the

number of circuits is cut in half.

i

Wire devices to terminals as shown in Figure 39. For further wiring information 8.8 Wiring

Tables and Information. For specifications 12.0 Appendix A: Specifications. For compatible

devices 13.0 Appendix B: Compatible Devices. Jumpers are required for Class A operation.

Field Wiring

Figure 39 Hardwire Detection Module (DM-1008A) Terminal Connections

Notes: Terminal blocks are “depluggable” for ease of wiring.

All power limited circuits must use type FPL, FPLR, or FPLP power limited cable.

Initiating circuits are fully supervised and rated for 22 VDC, 3 mA standby, 5 mV

ripple, 50 mA max alarm. They may be configured as required. The alarm

threshold is 21 mA. Maximum loop resistance is 100 ohms, 50 ohms per side.

All conventional hardwire initiating circuits are Compatibility ID "A".

57

Page 61

8.3 NAC Signal Module (SGM-1004A) Terminal Connections

IND2+ (Z)

IND2- (Z)

IND2- (Y/Z)

SUPERVISED INDICATING CIRCUIT #2

INDICATION

CIRCU IT 1

(POWER

LIMI TED)

IND1+ (Z)

STY LE Z

( CLA SS A)

WIRING

IND1- (Y/Z)

IND1+ (Y/Z)

IND2+ (Y/Z)

IND1- (Z)

INDICATION

CIRCU IT 2

(POWER

LIMI TED)

STY LE Y

( CLA SS B)

WIRING

SUPERVISED INDICATING CIRCUIT #1

IND4+ (Z)

IND4- (Z)

IND4- (Y/Z)

SUPERVISED INDICATING CIRCUIT #4

INDICATION

CIRCU IT 3

(POWER

LIMI TED)

IND3+ (Z)

STY LE Z

( CLA SS A)

WIRING

IND3- (Y/Z)

IND3+ (Y/Z)

IND4+ (Y/Z)

IND3- (Z)

INDICATION

CIRCU IT 4

(POWER

LIMI TED)

STY LE Y

( CLA SS B)

WIRING

SUPERVISED INDICATING CIRCUIT #3

Legend: See Appendix B for compatible devices.

SMOKE DETECTOR

3.9K 1/2W ELR LISTED S5434

MODEL MP-300

MANUFACTURED BY MIRCOM

i

Wire devices to terminals as shown in Figure 40. For further wiring information 8.8 Wiring

Tables and Information. For specifications 12.0 Appendix A: Specifications. For compatible

devices 13.0 Appendix B: Compatible Devices.

Field Wiring

58

Figure 40 Hardwire Signal Module Terminal Connections

Notes: The terminal blocks are “depluggable” for ease of wiring.