Page 1

FR-320 Series

Pre-Action/Deluge and Agent Release Control Panel

Installation and Operation Manual

LT-951 Rev. 12.1

Jan. 2017

Page 2

Page 3

Table of Contents

1.0 FCC Notice 11

1.0.1 Notice for all FR-320 Series Built-in UDACTs Sold in the U.S.A. .................................. 11

1.0.2 FCC Notice .................................................................................................................... 11

2.0 Introduction 13

2.1 Panel Type ................................ ....................................... ... ... ... .... ................................. 13

2.1.1 Deluge sprinkler system ................................................................................................. 13

2.1.2 Pre-action sprinkler system ............................................................................................ 13

2.1.3 Agent release system .................................................................................................... 13

2.2 Overall Features ............................................................................................................ 13

3.0 Conventions 15

3.1 Circuits ............................ ....................................................................... ........................ 15

3.2 Zone .................................... ...................................... ....................................... .............. 15

3.3 Display Points ..................................................................... ... ... .... ... ... ... .... ... ... ... ........... 15

3.4 Wiring Styles ....................................... ... ... ... .... ... ... ... ....................................... ... ... ........ 15

4.0 System Components 16

4.1 Main Pre-Action/Deluge and Agent Release Control Panel ........................................... 16

4.2 Relay Modules: Six Relays .................................................................... .... ... ... ... ... .... .... 17

4.3 Polarity Reversal/City Tie ............................................................................................... 17

4.4 Smart Relay Module ...................................................................................................... 17

4.5 Input Class A Converter: Six Circuits ............................................................................. 17

4.6 Output Class A Converter: Two Circuits ........................................................................ 18

4.7 RAM-216 Ancillary Annunciator ....................... .............................................................. 18

4.8 Active end-of-line ........................................................................................................... 18

4.9 Additional System Accessories ...................................................................................... 18

5.0 Mechanical Installation 19

5.1 Installing the Enclosure .................................................................................................. 19

5.2 BBX-1024DS and BBX-1024DSR Mechanical Installation ............................................ 20

5.3 Installing the Adder Modules .......................................................................................... 22

3

Page 4

Table of Contents

6.0 Cable and Jumper Connections for Main Board, Core

Board and Adder Modules 23

6.1 Main Pre-Action/Deluge and Agent Release Control Board .......................................... 23

6.1.1 Connectors and Jumpers on the Main Fire Alarm Board ............................................... 24

6.1.2 Connectors and Jumpers on the Core Board ................................................................. 24

6.2 ICAC-306 Input Class-A Converter Adder Module ......................................................... 24

6.3 OCAC-302 Output Class-A Converter Adder Module .................................................... 25

6.4 RM-306 Relay Adder Module ....................................... ... .......................................... ... .. 25

6.4.1 RM-306 Jumpers ................... .... ... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... .. 26

6.4.2 RM-306 Correlations ....................................... ... .... ... ... ... ....................................... ... ... .. 26

6.5 Polarity Reversal and City Tie Module (Model PR-300) ................................................ 26

6.5.1 PR-300 jumper settings .................................................................................................. 26

7.0 Field Wiring 27

7.1 Main Board Field Wiring ................................................................................................. 27

7.1.1 Initiating Circuit Wiring .................................................................... .... ... ... ... .... ... ... ... ..... 27

7.2 Abort and Manual Release Switch Wiring ...................................................................... 28

7.3 Indicating Circuit Wiring ................................................................................................. 30

7.3.1 Releasing Circuit Wiring ................................................................................................. 31

7.4 Dialer Wiring (US only) ................................................................................................... 31

7.5 Four-Wire Smoke Detector Wiring ................................................................................. 32

7.6 Relay Adder Module Wiring ........................................................................................... 32

7.7 Polarity Reversal and City Tie Module (PR-300) Wiring ................................................ 33

7.7.1 Power Supply Connection .............................................................................................. 34

7.8 Wiring Tables and Information ....................................................................................... 35

7.9 Four-Wire Smoke Power (regulated) ............................................................................. 35

7.10 Supervised Auxiliary Power (regulated) ......................................................................... 36

7.11 Unfiltered Supply (full wave rectified) ..................... .......................................... .............. 36

8.0 System Checkout 37

8.1 Before turning the power “ON” ....................................................................................... 37

8.2 Power-up procedure ....................................................................................................... 37

8.3 Troubleshooting ............................................................................................................. 38

9.0 Indicators, Controls and Operations 39

9.1 Common LED Indicators ........................................... ... ... .... ... ... ... ... .... ... ... ..................... 40

9.1.1 AC On ................................... .... ... ... ... ... ....................................... ... .... ........................... 40

9.1.2 Common Alarm ............ ... ....................................... ... ... ... .... ... ... ... ... ............................... 40

9.1.3 Common Trouble ...................................... ... ... ... .... ...................................... .... ... ... ... ... .. 40

9.1.4 Battery Trouble ............................................................................................................... 40

4

Page 5

Table of Contents

9.1.5 Remote Trouble ............................................................................................................. 40

9.1.6 Ground Fault .................................................................................................................. 40

9.1.7 CPU Fail ......................................................................................................................... 40

9.1.8 Abort .............................................................................................................................. 40

9.1.9 Released ................................... ....................................... ...................................... ........ 40

9.1.10 System Reset ................................................................................................................. 40

9.1.11 Signal Silence ................. .... ... ....................................... ... ... ... ... .... ... ... ... .... ... ... ... ... ........ 40

9.1.12 Auxiliary Disconnect ....................................................................................................... 40

9.1.13 Lamp Test ...................................................................................................................... 40

9.1.14 ALM/SUP/TBL/BLDG AUDIBLE SIL (Buzzer Silence) ................................................... 41

9.1.15 Pre Release ................................................................................................................... 41

9.2 Menu Buttons ................................................................................................................. 41

9.3 Switches and Common Indicators ................................................................................. 41

9.3.1 Zone 1 to Zone 4 ............................................................................................................ 41

9.3.2 Zone 5 and Zone 6 ......................................................................................................... 41

9.3.3 Out1 and Out2 (NAC circuits) ........................................................................................ 42

9.3.4 Out3 and Out4 (Releasing circuits) ................................................................................ 42

9.3.5 Input Circuits Bypass Switch .......................................................................................... 42

9.3.6 Output Circuits Bypass Switch ....................................................................................... 42

9.4 Common Controls .......................................................................................................... 42

9.4.1 System Reset Button ..................................................................................................... 42

9.4.2 Signal Silence Button ................................... .... ... ... ... .... ... ... ... ... .... ... .............................. 42

9.4.3 Auxiliary Disconnect Button ........................................................................................... 42

9.4.4 Lamp Test Button ........................................................................................................... 43

9.4.5 ALM/SUP/TBL/BLDG AUDIBLE SIL Button (Buzzer Silence) ....................................... 43

9.5 Circuit (zone) disconnect buttons .................................. ... ... ... ... .... ................................. 43

9.6 Common Relays ............................................................................................................ 44

9.7 Circuit Types .......................................... ... ... .... ...................................... .... ... ... ... ........... 44

9.7.1 Initiating (Detection) Circuit Types ................................................................................. 44

9.7.2 Non-Verified Alarm ......................................................................................................... 44

9.7.3 Water Flow Alarm (Water flow Sensors) ....................................................................... 44

9.7.4 Non-Latching Supervisory (For Supervisory Circuits) ................................................... 44

9.7.5 Latching Supervisory (For Supervisory Devices) ........................................................... 45

9.7.6 Abort Switch ................................................................................................................... 45

9.7.7 Manual Release Switch ................................................................................................. 45

9.7.8 Indicating (Signal) Circuits Types .................................................................................. 45

9.7.9 Silenceable Signal ....................................... .... ... ... ... .... ... ...................................... .... .... 45

9.7.10 Non-Silenceable Signal .......................... ... ... .... .......................................... ... ... .............. 45

9.7.11 Silenceable Strobe ................................. ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ........................

9.7.12 Non-Silenceable Strobes ............. ... .... ... ... ... .......................................... .... ... ................. 45

9.8 Evacuation codes ........................................................................................................... 46

45

10.0 Configuration 47

10.1 Using the CFG-300 Tool ........................................... ....................................... ... ... .... ... . 48

5

Page 6

Table of Contents

10.2 Entering the Passcode . ... ............................................................................................... 48

10.3 How to Use the Keypad to Program the FR-320 .................................... ............. ........... 49

10.4 Command Menu ............................................................................................................. 50

10.5 1. Panel Config (Command-Menu) ................................................................................ 51

10.5.1 Command Menu-->Panel Config-->Choose a mode ....................... .... ... ... ... .... ... ... ... ... .. 51

10.5.2 Command Menu-->Panel Config-->Hazard Config ........................................................ 52

10.6 2. Set Time (Command-Menu) ....................................................................................... 56

10.5.3 Command Menu-->Panel Config-->Default Config ........................................................ 56

10.7 4. View Event Log (Command-Menu) ............................................................................ 58

10.8 5. Print Event Log ........................................................................................................... 58

10.9 6. Clear Event Log (Command-Menu) ........................................................................... 59

10.10 7. Dialer Config (Command-Menu) ................................................................................ 59

10.10.1 Account Info ................................................................................................................... 60

10.10.2 Telephone Line .............................................................................................................. 61

10.10.3 Report Options ............................................................................................................... 62

10.10.4 Time Parameters ............................................................................................................ 63

10.10.5 Dialer Enable/Disable ..................................................................................................... 64

10.11 8. Test Dialer (Command-Menu) .................................................................................... 65

10.11.1 Dialer Test Messages .................................................................................................... 65

10.12 9. Exit (Command-Menu) ............................................................................................... 66

11.0 Operating the Panel 67

11.1 Panel Operation During Various Hazard States ........................ ............. ............. ........... 67

11.1.1 Hazard Idle ................................ ...................................... ............................................... 67

11.1.2 Hazard Alert (or equivalently first Alarm in Cross-zoned Application) .......... ................ .. 67

11.1.3 Hazard Alarm (pre-discharge, or equivalently second Alarm in Cross-zoned

Application) .................................................................................................................... 67

11.1.4 Hazard Release ............................................................................................................. 68

11.2 General Panel Operation .......................................... ... ... .... ... ........................................ 68

12.0 Pre-Programm ed Modes 69

12.1 Mode 1: Agent Release, Single Hazard, Cross-zoned, Combined Release .................. 69

12.1.1 Zone Configuration ....................... ... ... ... ....................................... ... .... ... ... ... .... ... ........... 69

12.1.2 Hazard Configuration ..................................................................................................... 69

12.1.3 NAC Configuration .......... ... ... .... ... ... ... ... ......................................................................... 69

12.1.4 How the Panel Works in Mode 1 .................................................................................... 70

12.2 Mode 2: Agent Release, Single Hazard, Not Cross-zoned, Combined Release ........... 71

12.2.1 Zone Configuration ....................... ... ... ... ....................................... ... .... ... ... ... .... ... ........... 71

12.2.2 Hazard Configuration ..................................................................................................... 71

12.2.3 NAC Configuration .......... ... ... .... ... ... ... ... ......................................................................... 71

12.2.4 How the Panel Works in Mode 2 .................................................................................... 72

12.3 Mode 3: Agent Release, Dual Hazard, Cross-zoned, Split Release .............................. 73

12.3.1 Zone Configuration ....................... ... ... ... ....................................... ... .... ... ... ... .... ... ........... 73

6

Page 7

Table of Contents

12.3.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 73

12.3.3 NAC Configuration ......................................................................................................... 73

12.3.4 How the Panel Works in Mode 3 .................................................................................... 74

12.4 Mode 4: Agent Release, Dual Hazard, Not Cross-zoned, Split Release ....................... 75

12.4.1 Zone Configuration ........................................................................................................ 75

12.4.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 75

12.4.3 NAC Configuration ......................................................................................................... 75

12.4.4 How the Panel Works in Mode 4 .................................................................................... 76

12.5 Mode 5: Pre-action/Deluge, Single Hazard, Cross-zoned, Combined Release ............. 77

12.5.1 Zone Configuration ........................................................................................................ 77

12.5.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 77

12.5.3 NAC Configuration ......................................................................................................... 77

12.5.4 How the Panel Works in Mode 5 .................................................................................... 77

12.6 Mode 6: Pre-action/Deluge, Single Hazard, Not Cross-zoned, Combined Release ...... 79

12.6.1 Zone Configuration ........................................................................................................ 79

12.6.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 79

12.6.3 NAC Configuration ......................................................................................................... 79

12.6.4 How the Panel Works in Mode 6 .................................................................................... 79

12.7 Mode 7: Pre-action/Deluge, Dual Hazard, Cross-zoned, Split Release ......................... 80

12.7.1 Zone Configuration ........................................................................................................ 80

12.7.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 80

12.7.3 NAC Configuration ......................................................................................................... 80

12.7.4 How the Panel Works in Mode 7 .................................................................................... 81

12.8 Mode 8: Pre-action/Deluge, Dual Hazard, Not Cross-zoned, Split Release .................. 82

12.8.1 Zone Configuration ........................................................................................................ 82

12.8.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 82

12.8.3 NAC Configuration ......................................................................................................... 82

12.8.4 How the Panel Works in Mode 8 .................................................................................... 83

12.9 Mode 9: Agent Release, Single Hazard, Cross-zoned, NYC abort ................................ 84

12.9.1 Zone Configuration ........................................................................................................ 84

12.9.2 Hazard Configuration .......................................... ... ... .... ... ... ... ... .... ... ... ... .... .................... 84

12.9.3 NAC Configuration ......................................................................................................... 84

12.9.4 How the Panel Works in Mode 9 .................................................................................... 85

12.10 Mode 10: Agent Release, Single Hazard, Not Cross-zoned, Combined Release ......... 86

12.10.1 Zone Configuration ........................................................................................................ 86

12.10.2 Hazard Configuration ............................................. ... .... ... ... ... ... ..................................... 86

12.10.3 NAC Configuration ......................................................................................................... 86

12.10.4 How the Panel Works in Mode 10 .................................................................................. 87

12.11 Mode 11: Agent Release, Single Hazard, Cross-zoned, Combined Release ................ 88

12.11.1 Zone Configuration ........................................................................................................ 88

12.11.2 Hazard Configuration ............................................. ... .... ... ... ... ... ..................................... 88

12.11.3 NAC Configuration ......................................................................................................... 88

12.11.4 How the Panel Works in Mode 11 .................................................................................. 89

12.12 Mode 12: Pre-action/Deluge, Single Hazard, Cross Zoned, Combined Release .......... 90

12.12.1 Hazard Configuration ............................................. ... .... ... ... ... ... ..................................... 90

7

Page 8

Table of Contents

12.12.2 NAC Configuration ............. ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... ... ... ..... 90

12.12.3 How the Panel Works in Mode 12 .................................................................................. 91

12.13 Mode 13: Pre-action/deluge, Single Hazard, Not Cross Zoned, Combined Release ..... 92

12.13.1 Zone Configuration ....................... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ..... 92

12.13.2 Hazard Configuration ..................................................................................................... 92

12.13.3 NAC Configuration ............. ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... ... ... ..... 92

12.13.4 How the Panel Works in Mode 13 .................................................................................. 92

12.14 Mode 14: Pre-action/deluge, Single Hazard, Not Cross Zoned, Combined Release ..... 94

12.14.1 Zone Configuration ....................... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ..... 94

12.14.2 Hazard Configuration ..................................................................................................... 94

12.14.3 NAC Configuration ............. ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... ... ... ..... 94

12.14.4 How the Panel Works in Mode 14 .................................................................................. 95

13.0 Appendix A: Compatible Receivers 96

14.0 Appendix B: Reporting 97

14.1 Ademco Contact-ID ........................................................................................................ 97

14.1.1 FR-320 Event Codes .......................... ... .... ... ... ... .... ...................................... .... ... ... ... ... .. 97

14.2 Security Industries Association SIA-DCS ....................................................................... 98

14.2.1 FR-320 Event Codes .......................... ... .... ... ... ... .... ...................................... .... ... ... ... ... .. 98

15.0 Appendix C: Compatible Solenoids 99

16.0 Appendix D: Compatible Synchronized Modules and

Horn/Strobes (UL/ULC) 100

16.1 Compatible Bells ............. ... ....................................... ... ... .... ... ... ... ... ............................... 100

17.0 Appendix E: Specifications 101

18.0 Appendix F: Power Supply and Battery Calculations 104

19.0 Warranty and Warning Information 106

8

Page 9

List of Figures

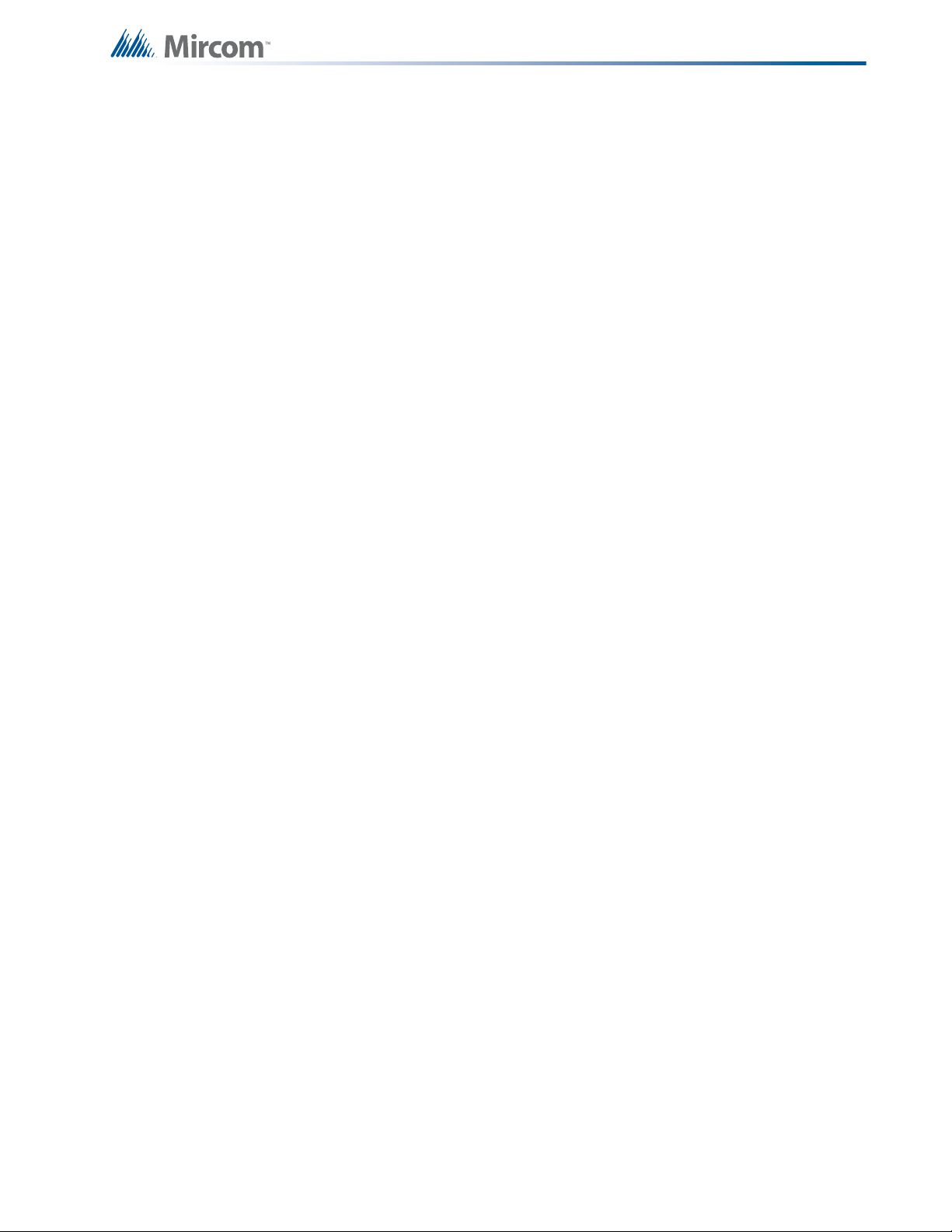

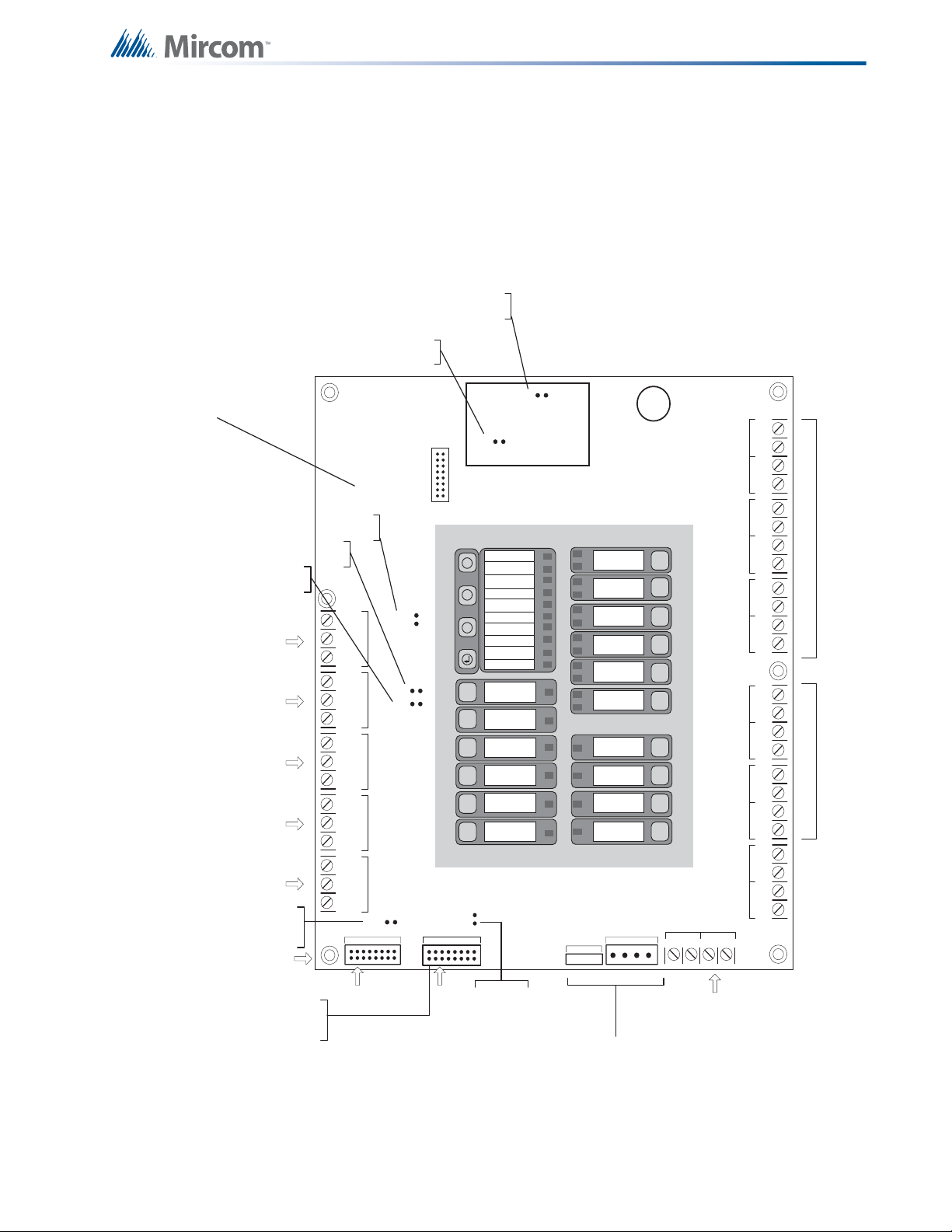

Figure 1 FR-320 Panel ..... .... ... ... ... .... ... ... ... .................................................................................. 16

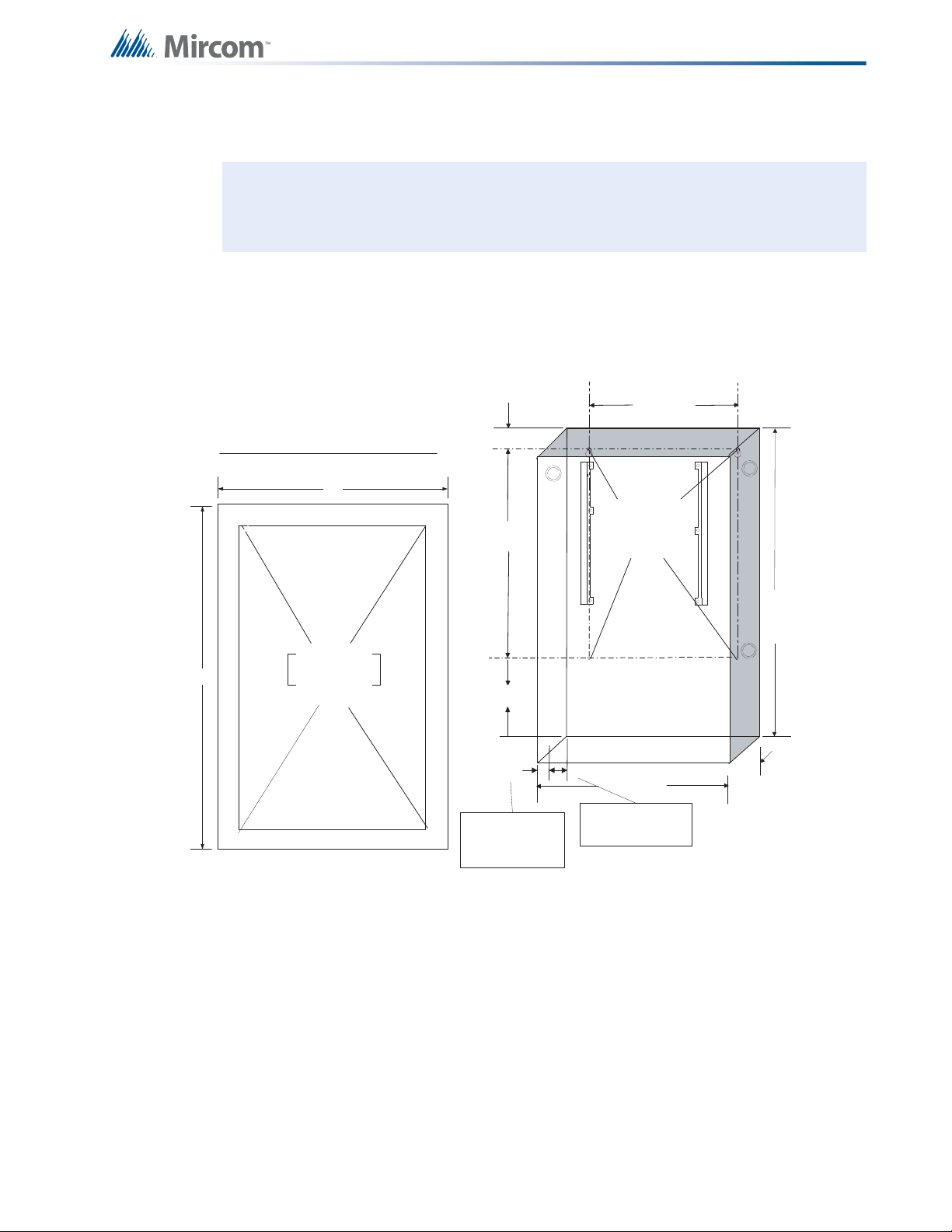

Figure 2 Box dimensions, semi-flush mounting and trim ring ...................................................... 19

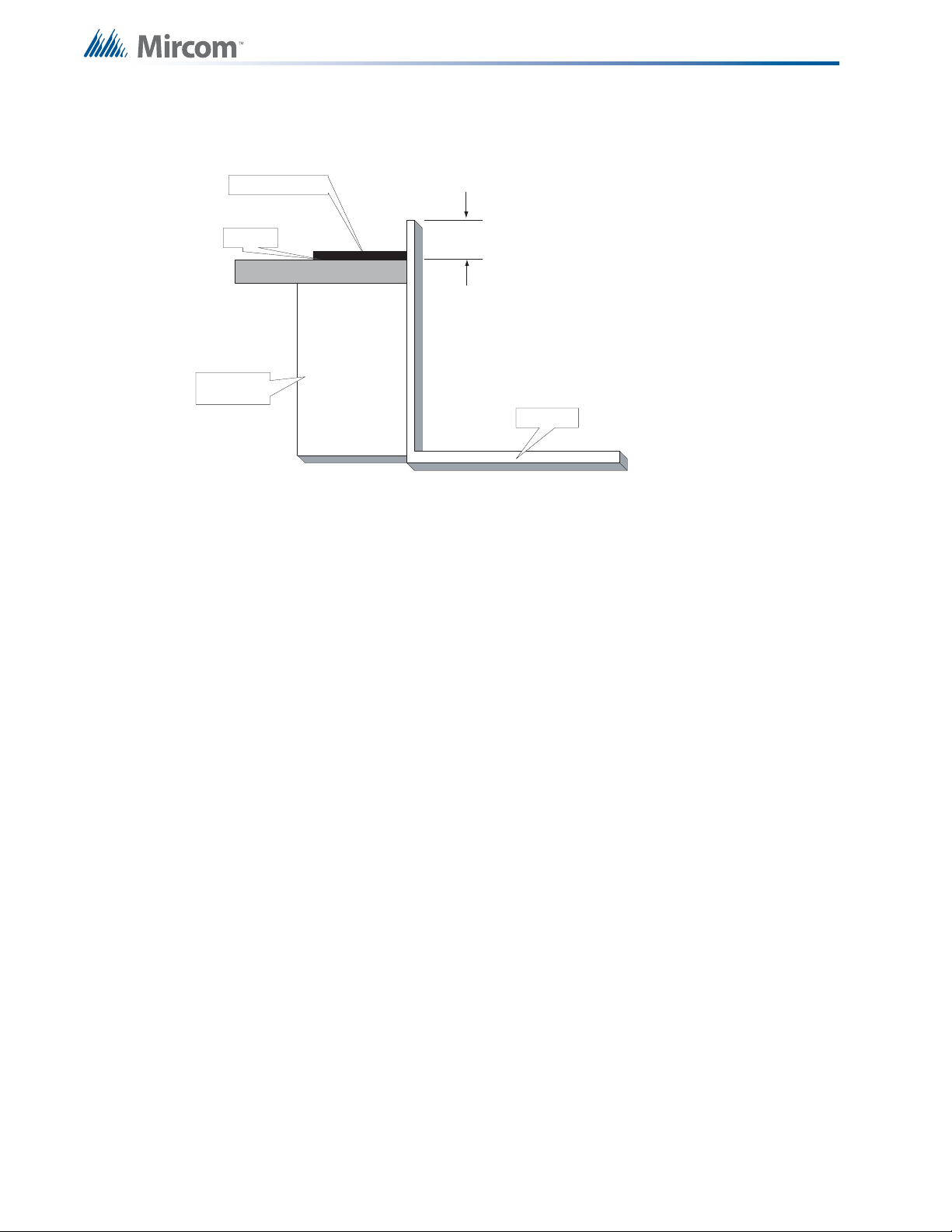

Figure 3 Flush Trim Detail ............................................................................................................ 20

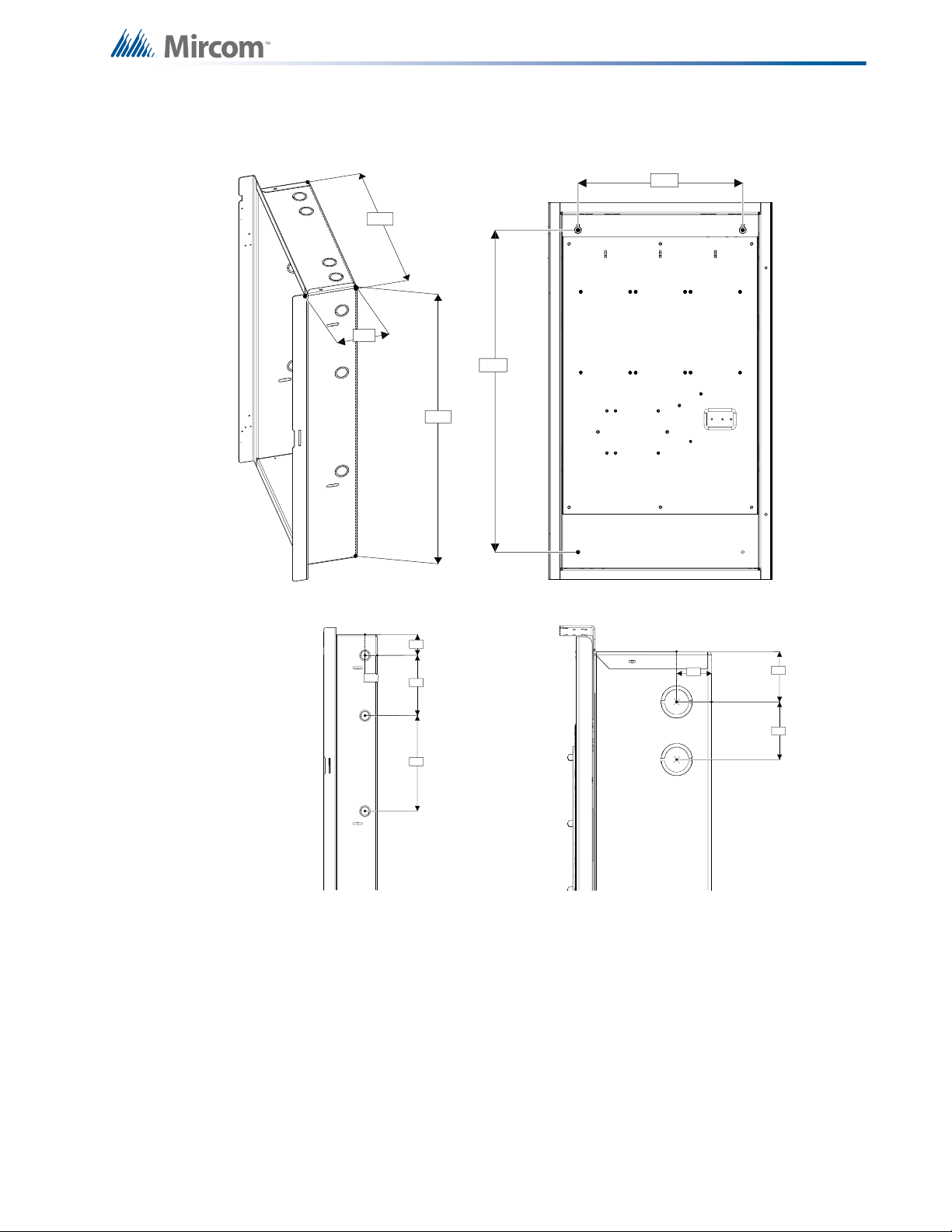

Figure 4 BBX-1024DS and BBX-1024DSR Installation Instructions and Dimensions ................. 21

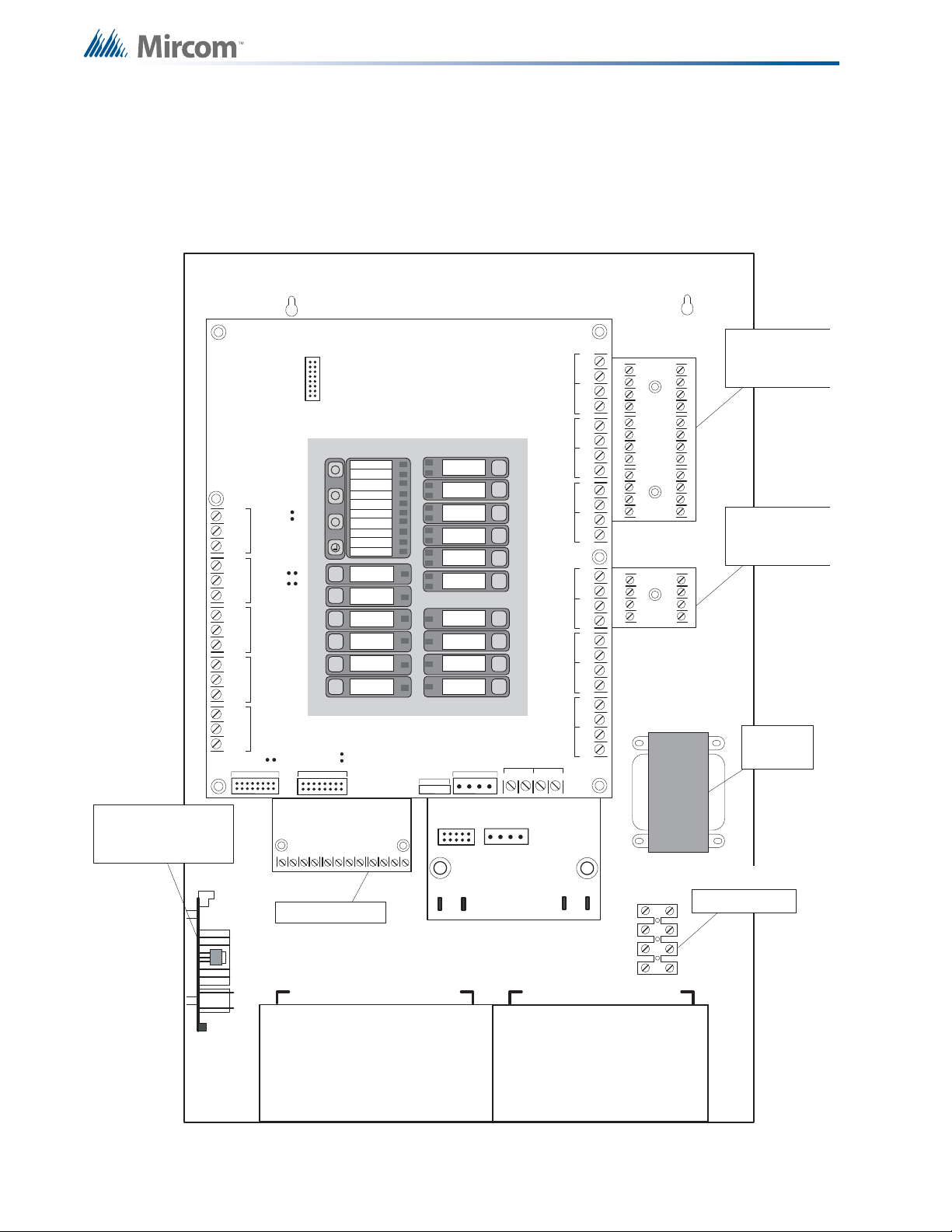

Figure 5 Installation of Adder Modules ......................................................................................... 22

Figure 6 Main Control Board cable connector and jumper settings ............................................. 23

Figure 7 ICAC-306 Input Class-A Converter Adder Module ................................ .... ... ... ... ... .... ... . 24

Figure 8 OCAC-302 Output Class-A Converter Adder Module .................................................... 25

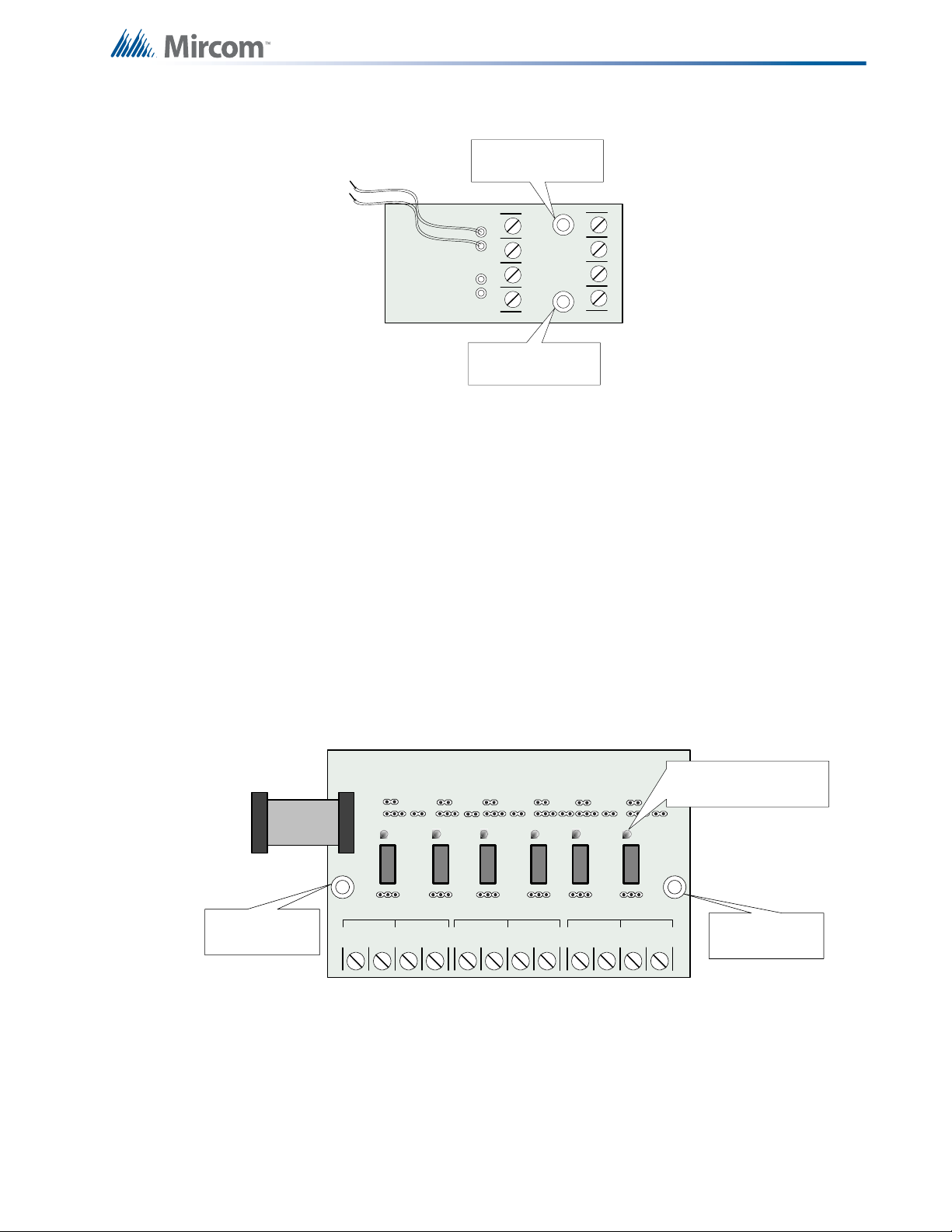

Figure 9 RM-306 six relay adder module ..................................................................................... 25

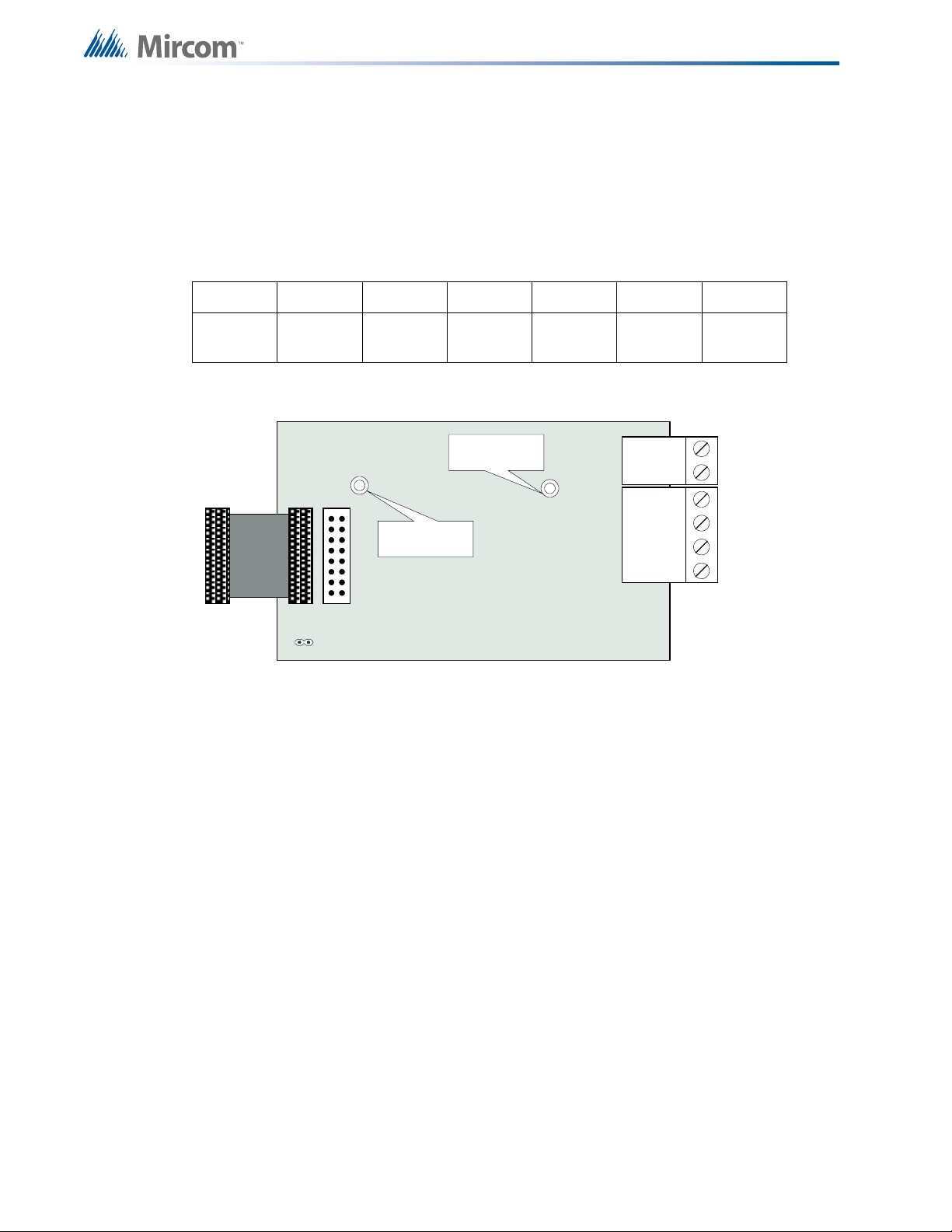

Figure 10 Polarity reversal and city tie module .............................................................................. 26

Figure 11 Initiating circuit – Class B or Style B Wiring .................. ................................................. 27

Figure 12 Initiating circuit– Class A or Style D Wiring .................................................................... 28

Figure 13 Abort and Manual Release Switch Class B or Style B Wiring ........................................ 28

Figure 14 Abort and Manual Release Switch Class A or Style D Wiring ....................................... 29

Figure 15 Indicating circuit – Class B or Style Y wiring .................... ...................................... .... ... . 30

Figure 16 Indicating circuit –Class A or Style Z wiring ................................................................... 30

Figure 17 Releasing Circuit Wiring ................................... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... ........ 31

Figure 18 Dialer Wiring ................................................ .... ... ... ... .... ... ... ... ... .... ... .............................. 31

Figure 19 Four-wire smoke detector wiring .................................................................................... 32

Figure 20 Relay per zone (RM-306) Terminal connection ............................................................. 32

Figure 21 Polarity reversal and city tie module terminal connection .............................................. 33

Figure 22 Power Supply Connection .............................................................................................. 34

Figure 23 LED indicators and control buttons ................................................................................ 39

Figure 24 Evacuation and Alert Codes .................................................. ... .... ... ... ... .... ... ... ... ........... 46

Figure 25 FR-320 Configuration ..................................................................................................... 48

Figure 26 Command Menu ................................................................................................. ... ........ 50

9

Page 10

List of Tables

Table 1 Settings permitted in CAN/ULCS527 ........ ... ... .......................................... ... .................. 27

Table 2 Power Supply Ratings .. .......................................... ... ... .......................................... ... ..... 34

Table 3 Initiating Circuit Wiring Distances ....................... .... ... .......................................... ... ... ..... 35

Table 4 Indicating Circuit Wiring Distances ................................................................................. 35

Table 5 Troubleshooting .............................................. ... ....................................... ... .... ... ... ........ 38

Table 6 Relay Types ................. ... ... ... .... ...................................... .... ... ... ... ... .... ... ... ..................... 44

Table 7 Settings permitted in CAN/ULCS527 ........ ... ... ... .......................................... .... ... ........... 47

Table 8 Settings permitted in UL864 ............................... .... ... ... ... .... ... ... ... ... .... ... ... ..................... 47

Table 9 Access Levels .......... .... ... ... ... .... ... ....................................... ... ... ... ... ............................... 49

Table 10 FR-320 Series Specifications ............................. .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ........... 101

Table 11 FR-320 System Modules and Annunciators ................................................................... 102

10

Page 11

1.0 FCC Notice

i

1.0.1 Notice for all FR-320 Series Built-in UDACTs Sold in the U.S.A.

Notes: The Ringer Equivalence Number (REN) assigned to each terminal device

provides an indication of the maximum number of terminals allowed to be

connected to a telephone interface. The termination on an interface may consist

of any combination of devices subject only to the requirement that the sum of the

Ringer Equivalence Numbers of all the devices does not exceed 5.

The REN for this product is part of the product identifier that has the format

US:AAAEQ##TXXXX. The digits represented by ## are the REN without a

decimal point (e.g., 03 is a REN of 0.3). For earlier products, the REN is

separately shown on the label.

Mircom's FR-320 SERIES BUILT-IN UDACT Digital Communicator de scribed in this manual

is listed by Underwriters Laboratories Inc. (ULI) for use in slave application in conjunction with

a listed Pre-action/Deluge and Agent Release Control Panel under Standard 864 (Control

Units for Fire Protective Signalling Systems). These Communicators comply with the National

Fire Protection Association (NFPA) performance requirements for DACTs and should be

installed in accordance with NFPA 72 Chapter 4 (Supervising Station Fire Alarm System).

These Communicators should be installed in accordance with this manual; the National

Electrical Code (NFPA 70); and/or the local Authority Having Jurisdiction (AHJ).

1.0.2 FCC Notice

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the

ACTA. On the telco transformer of this equipment is a label that contains, among other

information, a product identifier in the format US:AAAEQ##TXXXX. If requested, this number

must be provided to the telephone company. This equipment is capable of seizing the line.

This capability is provided in the hardware.

Type of Service: The Communicator is designed to be used on standard device telephone

lines. It connects to the telephone line by means of a standard jack called the USOC RJ-11C

(or USOC FJ45S). Connection to telephone company provided coin service (central office

implemented systems) is prohibited. Connection to p arty lines se rvice is subject to st ate t arif fs.

T ele phone Company Procedures: The goal of the telephone compa ny is to provide you with

the best service it can. In order to do this, it may occasionally be necessary for them to make

changes in their equipment, operations or procedures. If these changes might affect your

service or the operation of your equipment, the telephone company will give you notice, in

writing, to allow you to make any changes necessary to maintain uninterrupted service.

In certain circumstances, it may be necessary for the telephone company to request

information from you concerning the equipment which you have connected to your telephone

line. Upon request of the telephone company, provide the FCC registration number an d the

ringer equivalence number (REN ); both of th ese items are listed on the equipment label. The

sum of all of the REN’s on your telephone lines should be less than five in order to assure

proper service from the telephone company. In some cases, a sum of five may not be usable

on a given line.

If Problems Arise: If any of your telephone equipment is not operating properly, you should

immediately remove it from your telephone line, as it may cause harm to the telephone

network. If the telephone company notes a problem, they may temporarily discontinue service.

When practical, they will notify you in advance of this disconnection. If advance notice is not

feasible, you will be notified as soon as possible. When you are notified, you will be given the

opportunity to correct the problem and informed of your right to file a complaint with the FCC.

11

Page 12

FCC Notice

Contact your telephone company if you have any questions about your phone line. In the

event repairs are ever needed on the Communicator, they should be performed by Mircom

Technologies Ltd. or an authorized representative of Mircom Technologies Ltd. For information

contact Mircom Technologies Ltd. at the address and phone numbers shown on the back page

of this document.

12

Page 13

2.0 Introduction

Mircom’s FR-320 Series Pre-Action/Deluge and Agent Release Control Panel performs the

function of fire suppression in a wide variety of applications. It is capable of being used in an

agent release sprinkler system or in a pre-action or deluge sprinkler system. It can be used in

single-hazard or dual-hazard applications with or without cross-zoning. The pa nel includes

common alarm, supervisory, and trouble relays, and provides regulated and unregulated

auxiliary power along with four-wire smoke power. It supports auxiliary relays and a city tie

module. The auxiliary relays are based on a hazard area status. The FR-320 has six input

zones and four output zones, allowing for flexibility in most single and dual-hazard applications

for both deluge and agent releasing applications.

2.1 Panel Type

The panel can function as an agent release panel or as a pre-action/deluge panel, depending

on which of the available fixed configurations are chosen from the main programming menu.

2.1.1 Deluge sprinkler system

In deluge sprinkler system open-valve sprin kle r heads terminate to a water supply that is

controlled by a single valve. When the system detects fire, it automatically opens the valve via

a releasing circuit, allowing the water to flow through all the sprinkler heads. Deluge sprinkler

systems are useful for applications in which simultaneous discharge of water through every

sprinkler is required.

2.1.2 Pre- a ct ion sprinkler system

In a pre-action sprinkler system close-valve sprinkler heads are connected to pipes that are

supervised for air pressure. The pipes terminate directly to a water supply. Pre-action systems

are useful for applications in which the preven tion of an accidental discharge of water is

required.

2.1.3 Agent release system

In an agent release system, an extinguishing agent (such as Argon, dry chemical, CO2, Halon,

etc.) is automatically released upon fire detection. An abort function is added to prevent the

false release of the extinguishing agent.

2.2 Overall Features

• Basic unit has six Class B (Style B) initiating circuits, which may be configured as Class

A (Style D) using input Class A converter adde r modules. Each initiating circuit is preconfigured as Alarm, Supervisory (Latching or n on-latching), water-flow, Manual

Release Switch, or Abort Switch. There are two LEDs per circuit, one for Trouble

(amber), and one dual color (amber/red) LED for Supervisory (amber) and Alarm (red).

• Basic unit has 4 power limited class B (style Y) output circuits. Output circuits 1 & 2 are

indicating circuits while output circuits 3 & 4 are releasing circuits (circuit 4 can work as

an indicating circuit in some situations; check Pre-Programmed Modes on page 69 for

details). Each indicating circuit process type is pre-configured and can be silenceable.

The signal rates depend on the selected pre-programmed configuration.

• A pushbutton associated with each initiating, indicating and releasing circuit can

individually bypass the circuit.

• Configurable Signal Silence Inhibit and Auto Signal Silence Timers. For Canadian

installations, disable the Auto Signal Silence Timer.

13

Page 14

Introduction

• Subsequent Alarm, Supervisory, and Trouble operation.

• Four wire reset-able smoke power supply.

• Relay Contacts for Common Alarm, Common Supervisory, Common Trouble, and

Auxiliary Alarm Relay (disconnectable).

• RS-485 Interface for RA-1000 Series Remote Multiplex Annunciators and Smart relay

Module.

• Optional Modules for additional Relay Circuits, City Tie and Polarity Reversal Signaling.

• Extensive transie nt protection.

• Easy configuration of the panel using LCD service tool (CFG-300).

• Releasing circuit protection fro m false alarm by disconnecting the battery if the voltage

falls below 19V.

14

Page 15

3.0 Conventions

3.1 Circuits

Refers to an actual electrical interface for initiating (detection), indicating (signal), and

releasing.

3.2 Zone

Is a logical concept for a Fire Alarm Protected Area, and will consist of at least one Circuit.

Often the terms Zone and Circuit are used interch angeably, but in this Manual the term Circuit

is used.

3.3 Display Points

There is a display point associated with every initiating and indicating circuit of the FR-320

LED Series fire panel. For an initiating circuit there are two LEDs for every display point: one

single color (amber) and one dual color (r ed/am ber ). F or an ind ica tin g cir cuit th er e is o nly one

LED: one single color (amber), for every display point.

3.4 Wiring Styles

Initiating and indicating circuits are Class B (Style B and Y). Changing the initiating circuits to

Class A requires an ICAC-306 adder board which will convert SIX initiating zones from Class

B (Style B) circuits to Class A (Style D). This is done without penalizing the number of circuits,

which remains the same as in Class B (Style B). Changing the indicating circuits to Class A

requires an OCAC-302 adder board, which will convert TWO indicating zones from Class B

(Style Y) circuits to Class A (Style Z). Releasing circuits (Z) are Class B (Style B) only.

15

Page 16

4.0 System Components

4.1 Main Pre-Action/Deluge and Agent Release Control Panel

The following models are part of the FR-320 Series:

• FR-320

• FR-320-W

• FR-320-R

• FR-320-DW

• FR-320-DR

16

Figure 1 FR-320 Panel

All FR-320 Panels have the following features:

• Six Zone Pre-Action/Deluge and Agent Release Control Panel with LED display (red or

white door, black b ox.

• six Class B (Style B) initiating circuits, and four Class B (Style Y) output circuits

• Output circuits 1 & 2 are Class B (Style B) indicating circuits that can be converted to

Class A (Style Z) using an OCAC-302 Output Class A Converter adder module.

• Output circuits 3 & 4 are Class B (Style B) only releasing circuits.

• Each output circuit can draw 1.7A current, 5A tot al. A si x zone ICAC-306 Input Class A

Converter adder module may be used for Class A (Style D) wiring of Initiating circuits.

• The FR-320 contains Common Alarm, Common Supervisory & Common Trouble

Relays, auxiliary alarm relay (disconnectable), an RS-485 Interface for Remote

Annunciators and a Resettable Four Wire Smoke Detector Power Supply.

• Two batteries are required.

Additionally:

• FR-320-DW/R panels contain a dialer.

• FR-320 uses a BBX-1024DS or BBX-1024DSR enclosure.

Page 17

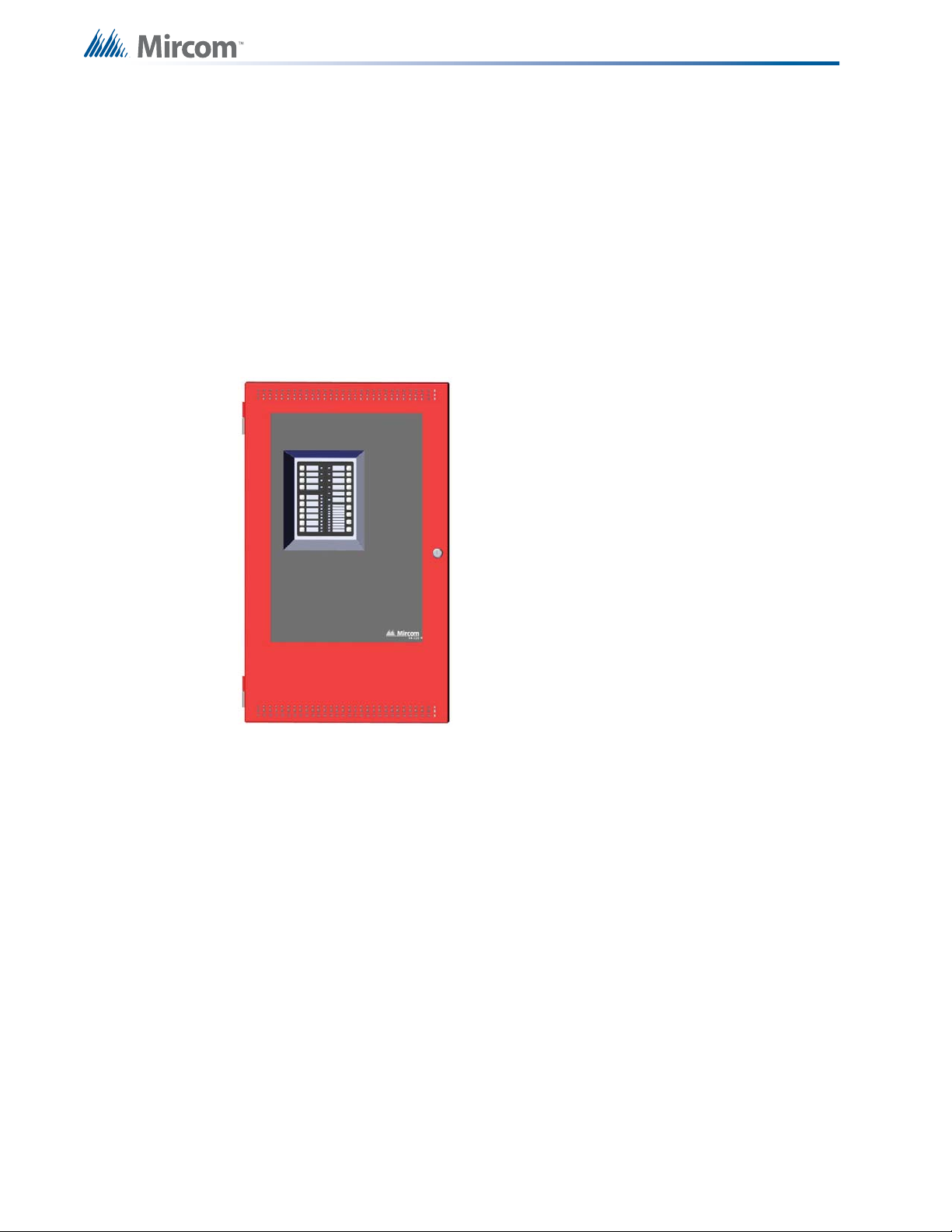

4.2 Relay Modules: Six Relays

NO/NC C

RELAY 1

NO/NC C

RELAY 2

NO/NC

C

RELAY 3

NO/NC C

RELAY 4CRELAY 5

NO/NC C

RELAY 6

NO/NC

POLARITY

REVERSAL

ALARM

POLARITY

REVERSAL

SUPV

CITY

TIE

+ | - + | - + | -

JW4

P1 P2

REMOTE RELAY

Advanced Life Safety Sol utions

FR-320 SERIES

BLK RED

BLK REDBLK REDBLK REDBLK REDBLK RED

- DET1 OUT+- DET2 OUT+- DET3 OUT+- DET4 OUT+- DET5 OUT+- DET6 OUT+

- DET1 RET+- DET2 RET+- DET3 RET+- DET4 RET+- DET5 RET+- DET6 RET+

Model Description

RM-306 Six-relay adder module

4.3 Polarity Reversal/City Tie

Model Description

PR-300 Polarity Reversal and/or City Tie Module

System Components

4.4 Smart Relay Module

Model Description

SRM-312W Smart Relay Module (12 relays) with white enclosure

SRM-312R Smart Relay Module (12 relays) with red enclosure

4.5 Input Class A Converter: Six Circuits

Model Description

Input Class A converter Module (six

ICAC-306

circuits). This module has built-in active

EOL resistors.

17

Page 18

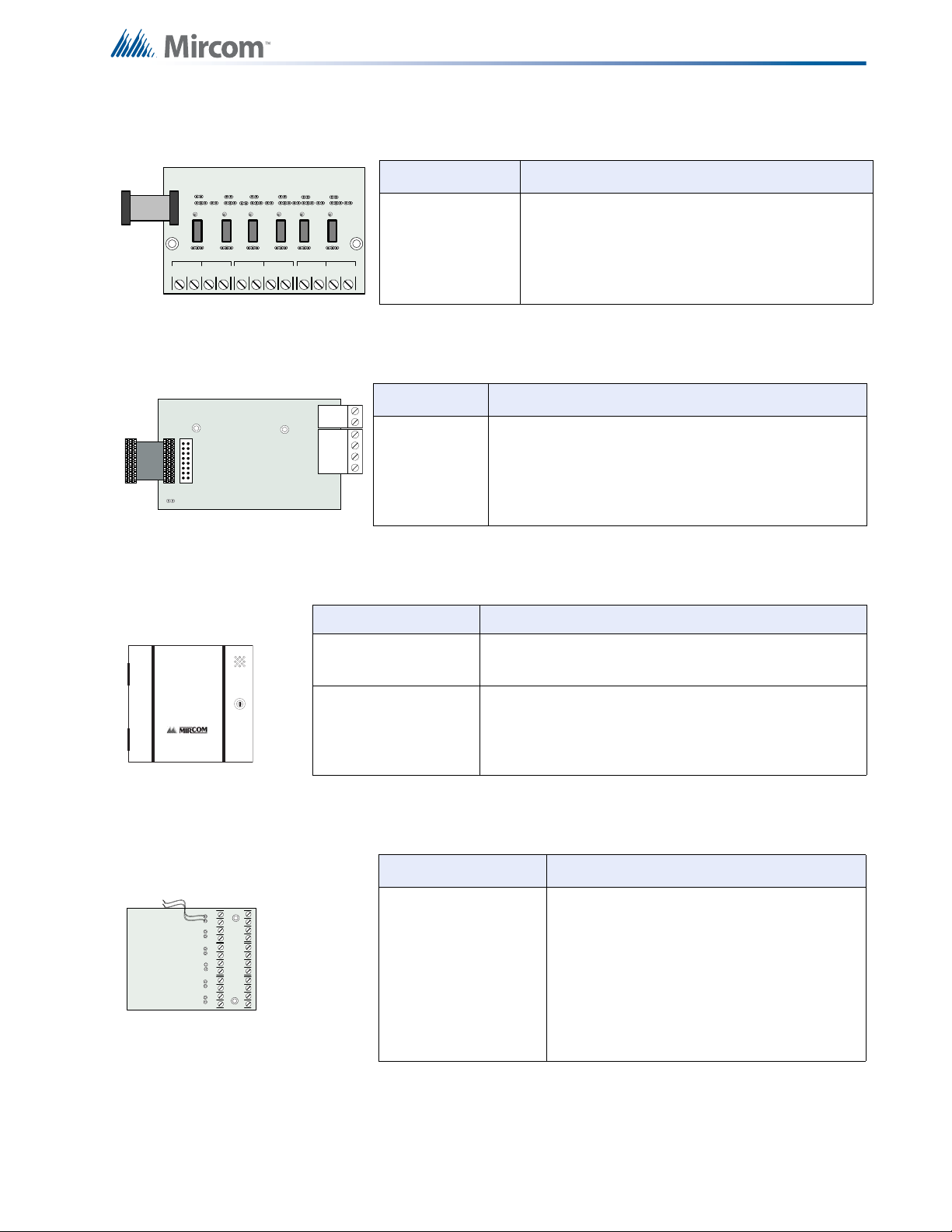

4.6 Output Class A Converter: Two Circuits

- SIG1 OUT+- SIG2 OUT+

- SIG1 RET+- SIG 2 RET+

BLK RED

BLK RED

A.C.ONCOMMON

TROUBLE

SIGNAL

SILEBCE

BUZZER

SILENCE

SIGNAL

SILENCE

LAMP

TEST

SYSTEM

RESET

SWITCH

ENABLE

FIRE ALARM

ANNUNCIATOR

BLACK

RED

Model Description

System Components

OCAC-302

4.7 RAM-216 Ancillary Annunciator

Model Description

RAM-216 16 Zone ancillary annunciator

4.8 Active end-of-line

The ELRX-300R(W) are power-saving End-of-Line resistors that eliminate the need for an

additional battery cabinet or larger batteries in order to meet the 60 hour standby requirement.

Model Description

ELRX-300 Active end-of-line resistor without plate

Output Class A converter module (two

circuits)

ELRX-300R Active end-of-line resistor with end-of-line red plate

4.9 Additional System Accessories

RAM-208 Eight Zone Remote Annunciator (ULC and ULI Approved)

RTI-1 Remote Trouble Indicator (ULC and ULI Approved)

RAM-1016/TZ Remote Annunciator (ULC and ULI Approved)

RAM-1016TZDS Remote Annunciator (ULC and ULI Approved)

MP-300 EOL resistor plate, 3.9KΩ (ULC and ULI Approved)

MP-300R EOL resistor plate, red (ULC and ULI Approved)

BC-160 External Battery Cabinet (ULC and ULI Approved)

MP-1500R/W Current Limiter (ULC and ULI Approved)

MP-320R/W Solenoid EOL Module (ULC and ULI Approved)

18

Page 19

5.0 Mechanical Inst allation

i

17"

22.5"

Adhere trim ring to

wall surfac e around

the FR-320 bac kbox.

PLACE FR-320 TRIM RI NG OVER BACKBOX

14.5"

4

.

5

"

11"

20.0"

1.5"

5.425"

14.5"

3.5"

1"

3.5" is the maximum depth

for semi -flus h mounting

using the fl ush trim ri ng

1" is the mini mum depth

above the wal l requi red

for semi -flush mounting

using the fl ush trim ri ng

4 Mounting

Holes for

Surf ace

Mounting

Note: Installation, use and maintenance should be in accord a nc e with the

manufacturer’s documents and the National Electrical Code, ANSI/NFPA 70, and

the National Fire Alarm Code ANSI/NFPA 72.

5.1 Installing the Enclosure

Install the FR-320 Series panel enclosure as shown below. Mount enclosure surface mount

using the four mounting holes with the provided screws.

Figure 2 Box dimensions, semi-flush mounting and trim ring

Remove the door (also disconnect the gr ound str ap), the de ad front an d se mi-flush mo unt th e

backbox into the wall. Peel the adhesive cover from the trim ring and stick to the wall surface

around the backbox, after wall is finished.

19

Page 20

Mechanical Installation

TRIM RING

MIN 1”

WALL

WOOD OR

METAL STUD

BACKBOX

Figure 3 shows a cross-section of the semi-flush mounted backbox and the trim ring. Make

sure to allow a minimum depth of 1” above the wall surface for proper door opening.

Figure 3 Flush Trim Detail

5.2 BBX-1024DS and BBX-1024DSR Mechanical Installation

The BBX-1024DS and BBX-1024DSR are suitable for flush or surface mounting, and have a

built-in trim ring.

Dimensions of Enclosure (minus built in trim ring) 14 1/2” x 4 1/4” x 26”

Distance between horizontal mounting screws 12”

Distance between vertical mounting screws 23 1/2”

Complete Dimensions of Enclosures 16 3/4” x 5 1/2” x 28”

20

Page 21

26.0 "

14.5 "

4.2 "

External Dimensions

23.5 "

1.3 "

1.7 "

2.0 "

Top View

2.1 "

1.3 "

6.0 "

9.5 "

Side View

Mechanical Installation

Mounting Dimensions

12.0 "

Figure 4 BBX-1024DS and BBX-1024DSR Installation Instructions and Dimensions

21

Page 22

5.3 Installing the Adder Modules

The FR-320 Series panel comes pre-assembled with all components and boards except for

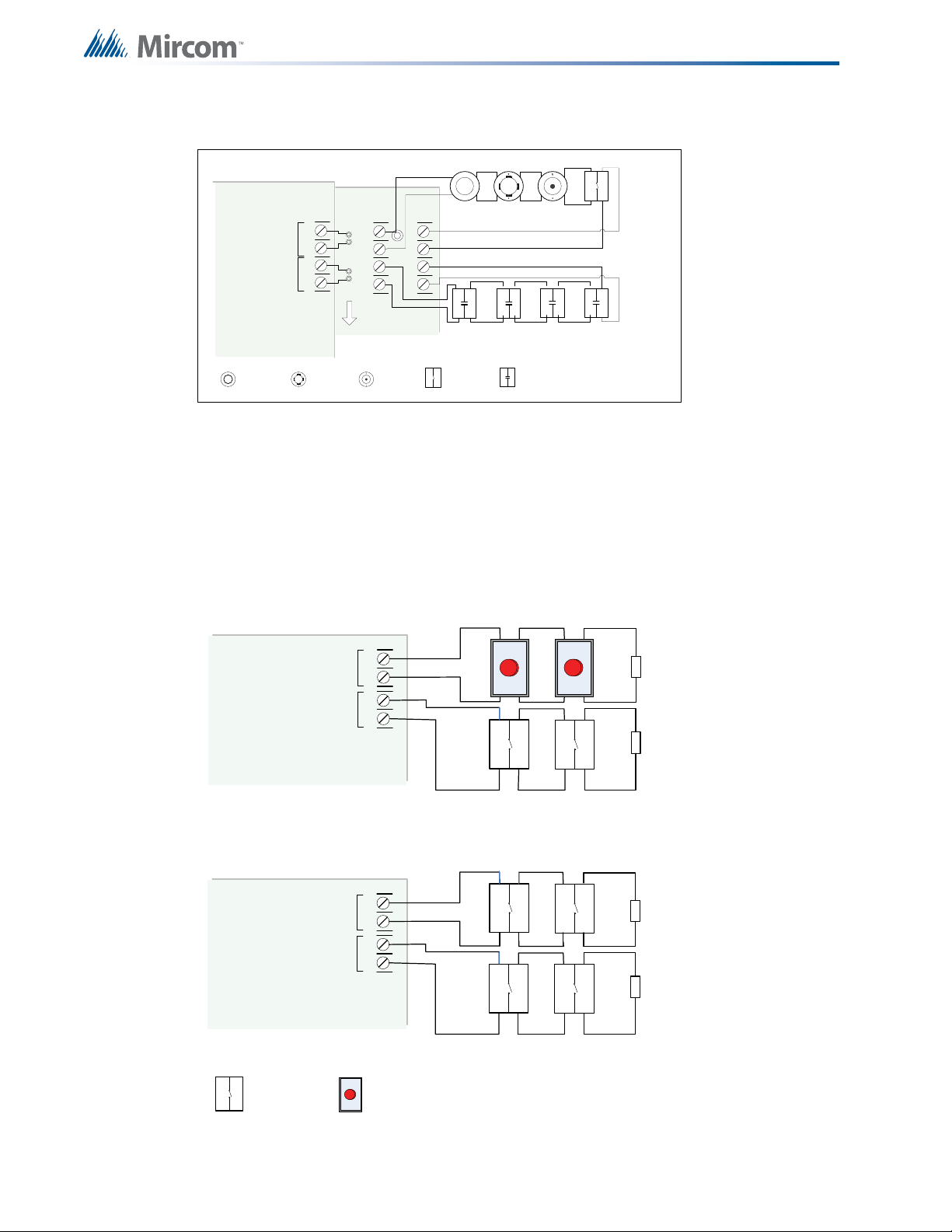

adder modules. Module installation locations are shown below. Refer to Figure 6 on the next

page for Jumper or DIP Switch settings and see 7.8 Wiring Tables and Information on page 35

for wiring specifications.

DET 1DET 2DET 3DET 4DET 5DET 6

-+-+-+-+-+-+

Mechanical Installation

CLASS-A con verter

board for detection

circuits ICAC-306 (6

circuits )

Reverse pola rity and city

tie module PR-300.

Mounted on hex spacer

with two screws provided

JW4

RS-4 85AUX. RELAYAL ARM RE LAY

S-+NC NOCNC NOCNC NOCNC NOC

JW7

JW5

JW6

RELAY

SUPERVISO RY

RELAY

TROU BL E

JW1

TO PR-30 0 MO DULE

Relay Module RM-306

X

M

?

JW2

TO RM-306 RELAY MOD ULE

AC ON

COMMON ALARM

COMMON SUPV

COMMON TROUBLE

BATTERY TROUBLE

REMOTE TROUBLE

GROUND FAULT

CPU FAIL

ABORT

RELEASED

SYSTEM

RESET

SIGNAL

SILENCE

AUXILIARY

DISCONNECT

LAMP

TEST

ALM/SUP/TBL/

BLDG AUDIBLE SIL

PRE

RELEASE

P6

(ZONE 1)

(ZONE 2)

(ZONE 3)

(ZONE 4)

POWER SUPPLY

SIGNAL

P6 P5

BAT TERY

+

P3

IAC1

(ZONE 1)

IAC2

(ZONE 2)

IAC3

(ZONE 3)

IAC4

(ZONE 4)

IAC5

(ZONE 5)

IAC6

(ZONE 1)

NAC1

NAC2

RAC1

RAC2

P4

POWER

-

RTI PORT

UNFLTD SPLY

COM- COM+TRB TRL

SEC TX

P1

SIG 1SIG 2SIG 3SIG 4

AUX

4-WIRE SPLY

-+-+-+-+-+-+

P2

CLASS-A con verter

board for indicating

circuits OC AC-302

(2 circuits)

Transformer

AC wiring terminal

22

BATTERY BATTERY

Figure 5 Installation of Adder Modules

Page 23

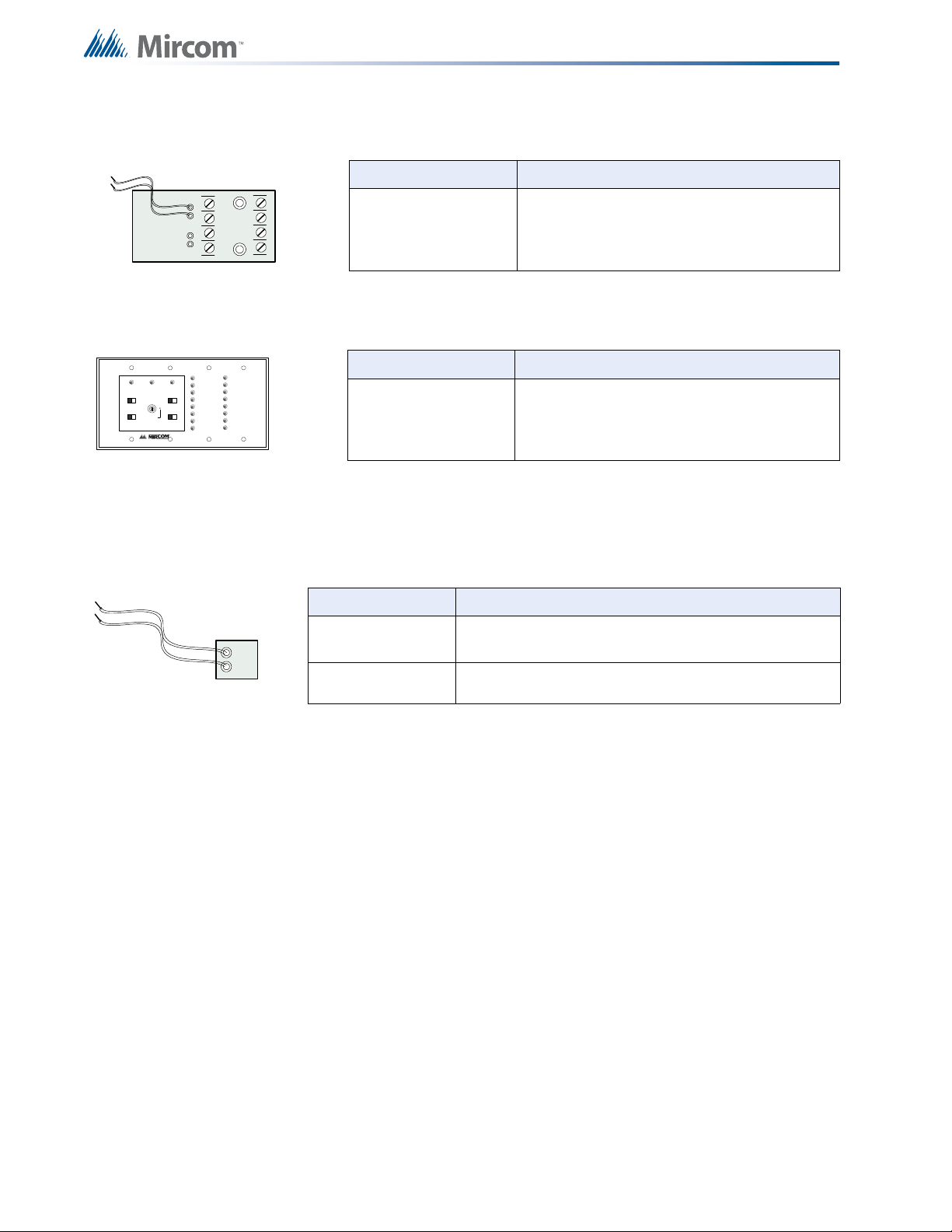

6.0 Cable and Jumper Connections for

Main Board, Core Board and Adder

Modules

6.1 Main Pre-Action/Deluge and Agent Release Control Board

JW4 -Factory Use Only

Always Short

JW5- Factory Use Only

Always Open

JW4

Main Board

JW6-Normally Open

RS-485 for

annunciators

Auxiliary Relay

Alarm Re lay

Supervisory

Relay

Trouble Relay

JW1 - ON- when

PR-300 not connected

Connect to PR-300

JW4 -Normally Short

5JW -Normally Open

Connect to

RM306 Relay

module

JW4

RS-4 85AUX. RELAYAL ARM RE LAY

S-+NC NOCNC NOCNC NOCNC NOC

JW7

JW5

JW6

RELAY

SUPERVISO RY

RELAY

TRO UB LE

JW1

TO PR-300 MODULE

P3 P4

TO RM-306 RELAY MODULE

Core Board

JW5

For front panel programming use CFG-300

configuration tool not UL-864 or ULC-S527

listed. Please refer to Document LT-922 for

details

AC ON

X

COMMON ALARM

COMMON SUPV

COMMON TROUBLE

M

BATTERY TROUBLE

REMOTE TROUBLE

?

GROUND FAULT

CPU FAIL

ABORT

RELEASE

SYSTEM

RESET

SIGNAL

SILENCE

AUXILIARY

DISCONNECT

LAMP

TEST

ALM/SUP/TBL/

BLDG AUDIBLE SIL

PRE

RELEASE

JW2

JW2 - ON- when

RM-306 not connected

control interface, including

AC power and battery supplies.

IAC1

(ZONE 1)

IAC2

(ZONE 2)

IAC3

(ZONE 3)

IAC4

(ZONE 4)

IAC5

(ZONE 5)

IAC6

(ZONE 1)

NAC1

(ZONE 1)

NAC2

(ZONE 2)

RAC1

(ZONE 3)

RAC2

(ZONE 4)

SIGNAL

POWER

Power supply and

UNFLTD SPLY

RTI PORT

COM- COM+TRB TRL

Unfiltered 24 V

supply

DET 1DET 2DET 3DET 4DET 5DET 6

-+-+-+-+-+-+

Initiating zones 1 to 6

SIG 1SIG 2SIG 3SIG 4

-+-+-+-+-+-+

AUX

4-WIRE SPLY

Indicating/Releasing zones 1 to 4

Figure 6 Main Control Board cable connector and jumper settings

23

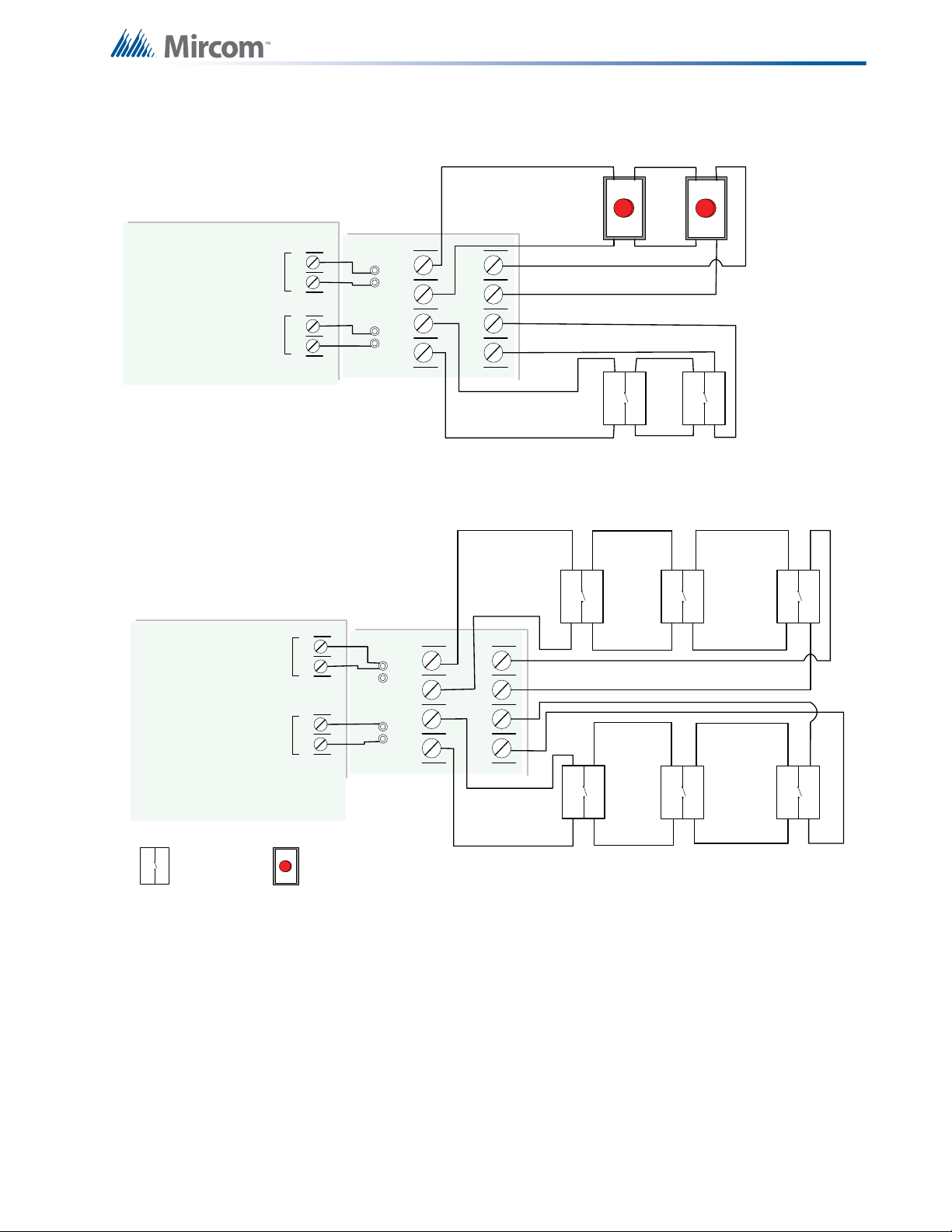

Page 24

Cable and Jumper Connections for Main Board, Core Board and Adder Modules

BLK RED

BLK REDBLK R E DBL K RE DBLK REDBLK RED

- DET1 OU T+- DET2 OUT+- DET3 OUT +- DET4 OUT+- DET5 OUT+- D ET6 OUT+

- DET1 RET+- DET2 RET+- DE T 3 RE T +- DET4 RET+- DET5 RET+- DET6 RET+

mounting hole for

#6-32 scr ews

All these pins comes with

red a nd black w i res w hi ch

are connected to the

detection circuit on the

main fire al arm boa rd . R e d

is p o s itive and black is

negati ve

ICAC-306

mounting ho l e for

#6-32 screws

6.1.1 Connectors and Jumpers on the Main Fire Alarm Board

JW1

Remove this jumper if PR-300 is connected.

P4 Cable from connector P1 of the RM-306 Relay Adder Module connects here.

Otherwise not used.

JW2

Remove this jumper if an RM-306 Relay Adder Module is used.

JW4 Shorted if there is no external unit on RS485. This jumper works as ‘end of line’

jumper. If one or more units are connected on RS485, only short on the last

connected unit. JW4 on all other units should be left open.

JW5 Normally open. To reset the password, place jumper here and power down the

panel (both AC power and batteries). Then power up the panel again, the

password is restored to the default after system startup. Once the system has

reset, REMOVE the jumper from the pins at JW5.

JW6 Normally open to BLOCK configuration via modem, PC with a UIMA converter

module or a CFG-300 Configuration Tool. Place jumper here to ALLOW any type

of configuration.

6.1.2 Connectors and Jumpers on the Core Board

JW4

JW5

Factory Use Only. Always Short.

Factory Use Only. Always Open.

6.2 ICAC-306 Input Class-A Converter Adder Module

Figure 7 ICAC-306 Input Class-A Converter Adder Module

There are no jumpers or cables to set on this module, just wiring from the converter (wires are

fixed here) to the Main Fire Alarm Board.

Initiating circuits must be wired from the ICAC-306 module to the Main Fire Alarm board. For

example, Initiating circuit 1 positive (red) and negative (black) wires are connected to the

positive and negative terminals (respectively) of Initiating circuit 1 on the Main Fire Alarm

Board. From the ICAC-306 converter Initiating circuits are wired out to the devices from the

positive and negative terminals marked DET OUT and the circuit return wires are brought back

to the converter module to positive and negative terminals marked DET RET.

24

Page 25

Cable and Jumper Connections for Main Board, Core Board and Adder Modules

- SIG1 OUT+- SIG2 OUT+

- SIG1 RET+- SIG2 RET+

BLK RED

BLK RED

mounting hol e for

#6-32 screws

OCAC-302

mounting hol e for

#6-32 screws

NO/NC C

RELAY 1

NO/ NC C

RELAY 2

NO/NC C

RELAY 3

NO/NC C

RELAY 4CRELAY 5

NO/NC C

RELAY 6

NO/NC

mounting hol e

for #6-32 screws

mounting hol e

for #6-32 scr ews

INDIVIDUAL GREEN

RELAY S T AT U S LED s

Connect to P6 on the

main fire alarm board

6

6.3 OCAC-302 Output Class-A Converter Adder Module

Figure 8 OCAC-302 Output Class-A Converter Adder Module

Indicating circuits must be wired from the OCAC-302 to the main Fire Alarm board. For

example indicating circuit 1 positive (red wire) and negative (black wire) is wired from the

Class A converter module to the positive and negative terminals of Indicating circuit 1 on the

Main Fire Alarm board.

The actual indicating zone is wired from the SIGNAL OUT positive and negative to the

signaling devices and then wired back to the SIGNAL RET positive and negative.

6.4 RM-306 Relay Adder Module

Cable from P1 of the RM-306 is connected to P4 on the Main Fire Alarm Board. The jumpers

located above each relay on the RM-306 are used to configure the relays. The jumpers

located below the relays are used to select either normally open contacts or normally closed

contacts.

Figure 9 RM-306 six relay adder module

25

Page 26

6.4.1 RM-306 Jumpers

POLARITY

REVERSAL

ALARM

POLARITY

REVERSAL

SUPV

CITY

TIE

+ | - + | - + | -

JW4

P1 P2

Mounting hole for

#6-32 screws

Mounting hole for

#6-32 screws

P1 Cable from RM-306 Relay Adder Module connects to P4 on Main Fire Alarm

Board.

6.4.2 RM-306 Correlations

The correlation of the relays are fixed and is as follows:

Relay1 Relay2 Relay3 Relay4 Relay5 Relay6

Cable and Jumper Connections for Main Board, Core Board and Adder Modules

Active

State

Hazard 1

Alert

Hazard 1

Alarm

Hazard 1

Release

Hazard 2

Alert

Hazard 2

Alarm

Hazard 2

Release

6.5 Polarity Reversal and City Tie Module (Model PR-300)

Figure 10 Polarity reversal and city tie module

The following hardware configuration must be performed before installing the PR-300.

6.5.1 PR-300 jumper settings

26

P1

P2 & JW4

The Alarm Transmit sign al to the PR-300 can be programmed to turn OFF when signal silence

is active. This allows the City Tie Box to be manually reset. On subsequent alarms the

silenceable signals will resound and the City Tie Box will be retriggered. See 8. Alarm Xmit-

Sil. on page 55 for more information.

The Trouble Transmit signal to the PR-300 can be programmed to delay AC power fail for 0, 1

or 3 hours if this is the only system trouble. See 9. Pwr Fail Tmr on page 55 for more

information.

Cable connects to P3 on the Main Board

Not used. Jumper JW4 remains on board.

Page 27

7.0 Field Wiring

!

+

-

STYLE B

WIRING

STYLE B

WIRING

INITIATING

CIRCUIT #1

INITIATING

CIRCUIT #2

INITIATING

CIRCUIT - 1

ALARM ZONE

INITIATING

CIRCUIT - 2

SUPERVISORY

ZONE

ION SMOKE

DETECTOR

PHOTO SMOKE

DETECTOR

HEAT

DETECTOR

PULL STATION

3.9K 1/2 WATT ELR

SUPERVISORY

FIRE ALARM MAIN BOARD

+

-

DET 1DET 2

NOTE: ACTIVE END OF LINE

RESISTORS MAY BE USED, BUT

THEY MUST BE USED ON ALL THE

INITIATING CIRCUITS.

Table 1 Settings permitted in CAN/ULCS527

NOTICE TO USERS, INSTALLERS, AUTHORITIES HAVING JURISDICTION, AND OTHER INVOLVED PARTIES

This product incorporates field-programmable software. In order for the product to comply with the

requirements in CAN/ULCS527, Standard for Control Units for Fire Alarm Systems, certain programming

features or options must be limited to specific values or not used at all as indicated below.

Program feature or

option

Permitted in CAN/

ULCS527? (Y/N)

System Reset and

Signal Silence on RAM-

N

208/216

7.1 Main Board Field Wiring

Wire devices to the terminals as shown in the figures that follow. Refer to 7.8 Wiring Tables

and Information on page 35 for wire gauges and 17.0 Appendix E: Specifications on page 101

for specifications.

Caution: Do not exceed power supply ratings.

Possible settings\methods

JW4 (Orange Wire) Intact =

Buzzer silence & Lamp Test

local function only. System

Reset & Signal Silence are

disabled.

Cut Jumper (Orange Wire) to

have all remote functions

operate.

Settings permitted in

CAN/ULCS527

Leave JW4 intact on

RAM-208/216

7.1.1 Initiating Circuit Wiring

Wiring diagrams for the initiating circuits are shown below. The panel supports Style B wiring

for the initiating circuits and Style D wiring for the indicating circuits. The initiating circuits are

supervised by a 3.9KΩ EOL resistor or an active EOL module.

Figure 11 Initiating circuit – Class B or Style B Wiring

27

Page 28

Figure 12 Initiating circuit– Class A or Style D Wiring

+

-

STYLE D

WIRING

STYLE D

WIRING

INITIATING

CIRCUIT #1

INITIATING

CIRCUIT #2

INITIATING

CIRCUIT - 1

ALARM

ZONE

INITIATING

CIRCUIT - 2

SUPERVISORY

ZONE

ION SMOKE

DETECTOR

PHOTO

SMOKE

DETECTOR

HEAT

DETECTOR

PULL STAT I O N

SUPERVISORY

4 MORE INITIATIN G

CIRCUITS NOT SHOWN

DCAC-306 CLASS A

CONVERTER MODULE

FIRE ALARM MAIN BOARD

BLK RED

BLK RED

- DET1

OUT+

- DET2

OUT+

- DET1 RET+- DET2 RET+

+

-

DET 1DET 2

ICAC-306

FIRE ALARM MAIN BOARD

+

-

+

-

DET 5DET 6

INITIATING

CIRCUIT #5

INITIATING

CIRCUIT #6

3.9K 1/2 WAT T EL R

OR ELRX-300/R

3.9K 1/2 WAT T EL R

OR ELRX-300/R

MANUAL RELEASE

SWIT CH

Use MS-403 ,404

USE ONLY NO

CONTACT

ABORT SWIT CH

CONNECT A UL /ULC LISTED ABORT STATION ACCEPTABLE TO

THE AHJ, COMPLYING WITH THE FOLLOWING SPECIFICATIONS:

MAXI MUM IMPEDANCE = 1.4K O HMS

RATED CURRENT = 45mA

RATED VOLTAGE= 24 V

Manual Release switches on separate circuits

Abort and Manual Release switches on separate circuits

FIRE ALARM MAIN BOARD

+

-

+

-

DET 5DET 6

INITIATING

CIRCUIT #5

INITIATING

CIRCUIT #6

3.9K 1/2 WAT T EL R

OR ELRX-300/R

3.9K 1/2 WAT T EL R

OR ELRX-300/R

7.2 Abort and Manual Release Switch Wiring

Field Wiring

Wiring for the abort and manual release switches is shown in Figure 13 and Figure 14. The

Abort and Manual release switches must be on different circuits. DET5 is used for the Abort

switch and DET6 is used for the manual release switch.

28

Figure 13 Abort and Manual Release Switch Class B or Style B Wiring

Page 29

FIRE ALARM MAIN BOARD

+

-

+

-

DET 5DET 6

INITIATING

CIRCUIT #5

INITIATING

CIRCUIT #6

FIRE ALARM MAIN BOARD

+

-

+

-

DET 5

DET 6

INITIATING

CIRCUIT #5

INITIATING

CIRCUIT #6

MANUAL RELEASE

SWIT CH

USE MS -403 ,404

USE ONLY NO

CONTACT

ABORT SWITCH

CONNECT A UL /ULC LISTED ABORT STATION

ACCEPTABLE TO THE AHJ, COMPLYING WITH THE

FOLLOWING SPECIFICATIO NS:

MAXI MUM IMPEDANCE = 1.4K O HMS

RATED CURRENT = 45mA

RATED VOLTAGE= 24V

Abort and Manual Release switches on separate circuits

.

BLK RED

BL K R ED

-DET5 OUT+-DET6 OUT+

-DET5 RET+-DET6 RET+

BLK RED

BL K R ED

-DET5 OUT+-DET6 OUT+

- DET5 RET+-DET6 RET+

ICAC-306

CLASS A

CONVERTER

MODULE

ICAC-306

CLASS A

CONVERTER

MODULE

Manual Release switches on separate circuits

Field Wiring

Figure 14 Abort and Manual Release Switch Class A or Style D Wiring

29

Page 30

7.3 Indicating Circuit Wiring

-SIG 1 +

STYLE Y

WIRING

STYLE Y

WIRING

INDICATING

CIRCUIT - 1

INDICATING

CIRCUIT - 2

BELL STROBE 3.9K 1/2 WATT ELR

INDICATING

CIRCUIT #1

INDICATING

CIRCUIT #2

HORN

FR-320 Panel

-SIG 2 +

BELL STROBE HORN

+

-

STYLE Y

WIRING

STYLE Y

WIRING

INDICATING

CIRCUIT #1

INDICATING

CIRCUIT #2

INDICATING

CIRCUIT 1

INDICATING

CIRCUIT 2

OCAC-302 CLASS A

CONVERTER MODUL E

FR-320 Panel

BL K R ED

BL K R ED

-SIG1 OUT+-SIG2 OUT+

-SIG1 RET+-SIG2 RET+

+

-

SIG 1SI G 2

The FR-320 Series Fire Alarm supports Class B or Style Y and Class A Style Z wiring for its

indicating circuits. Each circuit is supervised by a 3.9KΩ EOL resistor or active EOL module.

Each indicating circuit provides up to 1.7 A, 5 A maximum total if no auxiliaries are used.

Field Wiring

Figure 15 Indicating circuit – Class B or Style Y wiring

30

Figure 16 Indicating circuit –Class A or Style Z wiring

Page 31

7.3.1 Releasing Circuit Wiring

FIRE ALARM MAIN BOARD

+

-

+

-

SIG 3SIG 4

Re leasing

circuit #1

Re leasing

circuit #2

Solenoid EOL

module

MP-320R/ W

Solenoid EOL

module

MP-320R/ W

Solenoid Coil (See

the list ing for the

approved solenoids)

WARNING: EOL has to be close nipple

connected to the solenoid coil.

TIPTIP RINGRING

premise telephone

IF permitted

TIPTIP RINGRING

LINE-1

LINE-2

1

23

4

8

5

76

Public switch

Telephone company

wiring

TIP

RING

TIP

RING

RJ31X

GREY

BROWN

RED

GREEN

COCO RESRES

Line 2 is Wired as shown for Line 1

FIRE ALARM MAIN

BOARD

Wiring for the releasing circuit is shown in F i gur e 17 below. SIG3 and SIG4 output circuits are

reserved for the releasing circuits. Solenoid EOL module (MP-320R/W) is used to supervise

the solenoid coil. If the solenoid is already fitted with the directional diode then only the 3.9KΩ

EOL resistor is used. The supervisory current passes through the solenoid coil thus confirming

the integrity of the solenoid coil for open coil. The wiring is supervised for the open and short

conditions.

Field Wiring

7.4 Dialer Wiring (US only)

Figure 17 Releasing Circuit Wiring

If you have an FR-320D, there is a dialer on board and terminals marked Line 1 and Line 2

must be wired as shown in Figure 18 below.

Figure 18 Dialer Wiring

31

Page 32

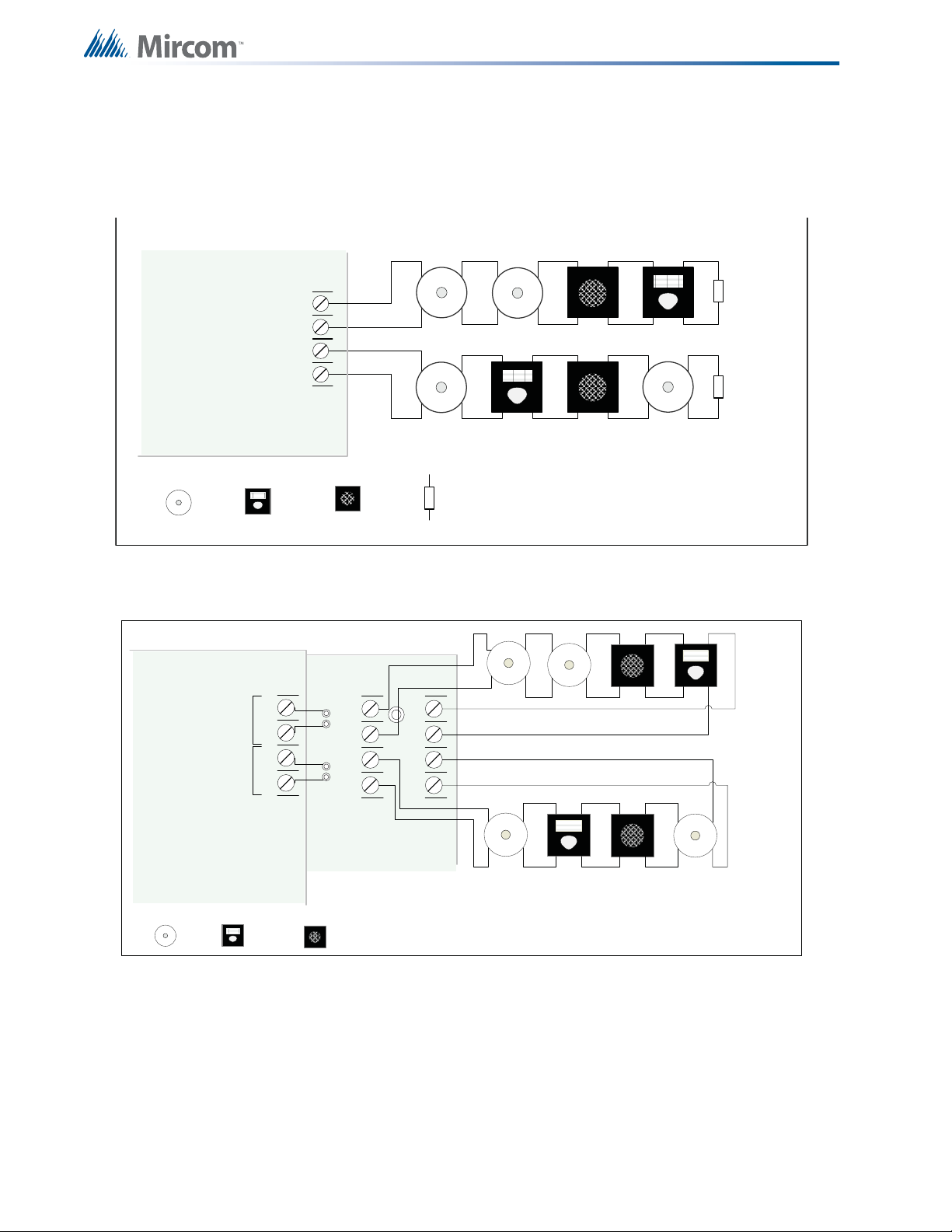

7.5 Four-Wire Smoke Detector Wiring

POWER

DETECTION

++

++

--

--

1

4

2

3

5

6

TO INITIATING

CIRCUIT

RESETTABLE 4-WIRE SMOKE

DETECTOR POWER SUPPLY

22VDC, 200mA

MAX. CURRENT - 300mA

MAX. RIPPLE VOL. 5mV

(POWER LIMITED)

4-WIRE DETECTION DEVICE

END OF LINE RELAY

LISTED S3403

MODEL A77-716B

MANUFACTURED BY

SYSTEM SENSOR

+

-

4-WIRE

SUPPLY

3.9K 1/2 WATT ELR

LEGEND

NOTES

ALL POWER LIMITED CIRCUITS

MUST USE TYPE FPL, FPLR,

OR FPLP POWER LIMITED

CABLE

FIRE ALARM M AIN BOARD

C

C

NO/NC

NO/NC

C

NO/NC

ALL RELAY CONTACTS

28V DC, 1 AMP

RESISTIVE LOAD

RM-306 6 RELAY ADDER MODULE

NORMALLY OPEN OR

NORMALLY CLOSED

CONNECTION IS

SELECTED BY JUMPER

ON RELAY BOARD.

NOTE: ALL RELAYS ARE POWER LIMIT ED

CIRCUITS AND MUST USE TYPE FPL, FPLR or

FPLP POWER LIMITED CABLE.

NORMALLY OPEN

CONNECTION

NORMALLY CLOSE

CONNECTION

RELAY

CIRCUIT #1

RELAY

CIRCUIT #2

RELAY

CIRCUIT #6

Field Wiring

7.6 Relay Adder Module Wiring

Figure 19 Four-wire smoke detector wiring

Wire relays on the relay adder module RM-306 as shown in Figure 20.

32

Figure 20 Relay per zone (RM-306) Terminal connection

Page 33

7.7 Polarity Reversal and City Tie Module (PR-300) Wiring

1

1

2

2

S

S

CITY TIE LOCAL ENERGY

RATED - 24VDC FILTERED

TRIP COIL - 14 Ohms, 250mA,

5mV RIPPLE

POLARITY REVERSAL ALARM

24VDC OPEN

12VDC AT 3.5mA

8mA MAX. SHORT

POLARITY REVERSAL SUPV.

24VDC OPEN

12VDC AT 3.5mA

8mA MAX. SHORT

PROTECTOR

1

1

2

2

S

S

1

1

2

2

S

S

PROCTECTOR

1

1

2

2

S

S

USE A SHORTING WIRE

WHEN THE CITY TIE IS

NOT USED

+

+

+

-

-

-

+

+

+

-

-

-

CONFIRMS TO NEMA STANDARD

SB3-1969 INTENDED FOR

CONNECTION TO POLARITY

REVERSAL CIRCUIT OF A REMOTE

STATION RECEIVING UNIT HAVING

COMPATIBLE RATINGS

DIN RAIL CONNECTION

TO EARTH GROUND

DIN RAIL CONNECTION

TO EARTH GROUND

POWER LIMITED

POWER LIMITED

POWER LIMITED

PR-300

PROCTECTEDPROCTECTED

UNPROCTECTEDUNPROCTECTED

POWER LIMITED CABLE TYPE

FPL, FPLR or FPLP MUST BE

USED FROM PR-300 TO

PROTECTORS.

Wire PR-300 Polarity Reversal and City Tie Mod ule (if used) as shown in Figure 21 below . See

17.0 Appendix E: Specifications on page 101 for module specifications. Power Limited cable

type FPL, FPLR or FPLP must be used.

For USA installation, the installer must use Atlantic Scientific (Tel: 407-725-8000), Model

#24544 Protective Device, or similar UL-Listed QVRG secondary protector, as shown.

For use in Canada, the Protective Device is not required but still recommended.

Field Wiring

Figure 21 Polarity reversal and city tie module terminal connection

33

Page 34

Field Wiring

!

BATTERY BATTERY

red

green

blk

yellow

P3

BAT TERY

P4

+

-

P1

P2

P6 P5

POWER SUPPLY

RAC2

(ZONE 4)

SPARE

RAC1

(ZONE 3)

P6

Deluge Panel Control Board

Power Supply Control Board

red

red

10A

slow blow

++

red

blk

NOTE: TO PREVENT SPARKING, CONNECT BATTERIES AFTER THE

SYSTEM MAIN A.C. POWER IS TURNED ON

240 VAC 50Hz

120 VAC 60Hz

N

GND

ALM/SUP/TBL/

BLDG AUDIBLE SIL

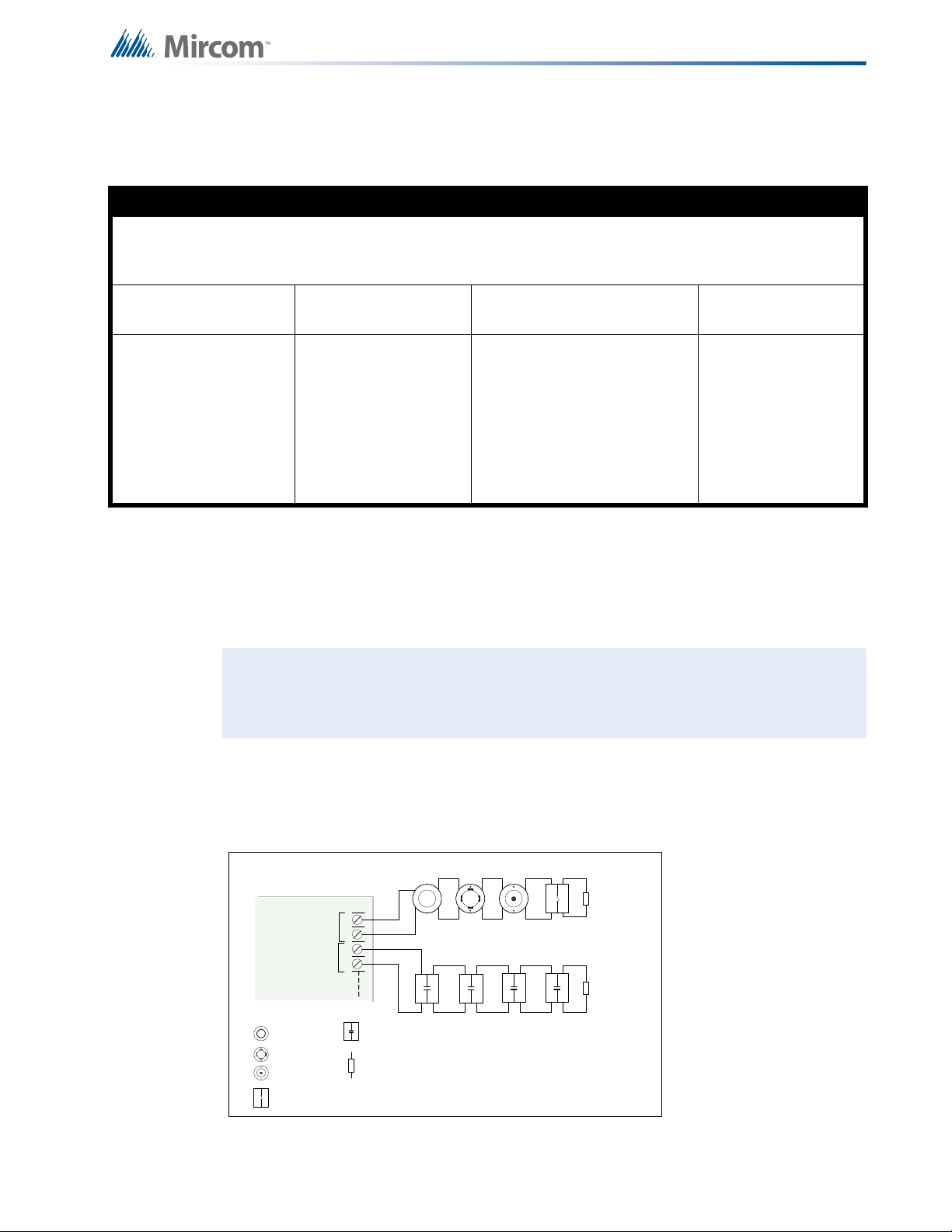

7.7.1 Power Supply Connection

The power supply is part of the Main Chassis. The ratings are:

Table 2 Power Supply Ratings

Type Rating

Electrical Input rating 120 VAC 60Hz 1.7A /240 VAC 50 Hz 0.85 A, 10A slow blow fuse on

secondary of transformer

Power supply total current

Battery fuse on Main module

Wire the power supply as shown below in Figure 22 using the proper wire gauge.

Caution: Do not exceed power supply ratings.

6.5A AC maximum @ secondary of transformer

10A, slow blow micro fuse

Figure 22 Power Supply Connection

34

Page 35

7.8 Wiring Tables and Information

i

i

Table 3 Initiating Circuit Wiring Distances

WIRE GAUGE MAXIMUM WIRING RUN TO LAST DEVICE

AWG FEET METERS

22 2990 910

20 4760 1450

18 7560 2300

16 12000 3600

14 19000 5800

12 30400 9200

Notes: For Class A the maximum wiring run to the last device is divided by two.

Maximum loop resistance should not exceed 100 ohms.

Maximum capacitance of 0.5uF total on each initiatin g circuit.

Field Wiring

Table 4 Indicating Circuit Wiring Distances

TOTAL

SIGNAL

LOAD

Amperes ftmftmftmftm Ohms

0.06 2350 716 3750 1143 6000 1829 9500 2895 30

0.12 1180 360 1850 567 3000 915 4720 1438 15

0.30 470 143 750 229 1200 366 1900 579 6

0.60 235 71 375 114 600 183 950 289 3

0.90 156 47 250 76 400 122 630 192 2

1.20 118 36 185 56 300 91 470 143 1.5

1.50 94 29 150 46 240 73 380 115 1.2

1.70 78 24 125 38 200 61 315 96 1.0

MAXIMUM WIRING RUN TO LAST DEVICE (ELR) MAX. LOOP

18AWG 16AWG 14AWG 12AWG

Notes: For Class A wiring the resistance in ohms is multiplied by two.

Maximum voltage drop should not exceed 1.8 volts.

RESISTANCE

7.9 Four-Wire Smoke Power (regulated)

Four-wire smoke power is provided for four-wire smoke detectors. This filtered supply is

supervised therefore a short will disconnect the power and the common trouble is active. The

power is reconnected after the 'RESET' key is pressed. See 17.0 Appendix E:

Specifications on page 101 for supply rating.

35

Page 36

7.10 Supervised Auxiliary Power (regulated)

Supervised auxiliary power is used to power the remote annunciators and smart relay

modules. This filtered circuit is supervised therefore a short will disconnect the power and the

common trouble is active. The power is reconnected after the 'RESET' key is pressed. See

17.0 Appendix E: Specifications on page 101 for supply rating.

7.11 Unfiltered Supply (full wave rectified)

This regulated supply is not supervised. If there is a short on this circuit, the auxiliary power

does not recover automatically when the short is removed. This power supply must be

disconnected, then reconnected and the panel reset to re-establish the auxiliary power supply.

See 17.0 Appendix E: Specifications on page 101 for supply rating.

Field Wiring

36

Page 37

8.0 System Checkout

i

8.1 Before turning the power “ON”

To prevent sparking, do not connect the batteries. Connect the batteries after powering the

system from the main AC supply.

1. C hec k that all modu les ar e installed in the proper location with the proper connections.

2. Check all field (external) wiring for opens, shorts, and ground.

3. Check that all interconnection cables are secure, and that all connectors are plugged in

properly.

4. Check all jumpers and switches for proper setting.

5. Check the AC power wiring for proper connection.

6. Check that the chassis is connected to EARTH GROUND (cold water pipe).

7. Make sure to close the front cover plate before powering the system from main AC

supply.

The best way to check out a panel first is to not connect any field wiring. Power up the panel

with an end of line. The panel should be free of trouble. Then connect one circuit at one time.

If a trouble occurs, correct the fault then continue the field wiring.

8.2 Power-up procedure

After completing the System Checkout procedures outlined above,

1. Power up the panel. The "AC ON" green LED and the “Common Trouble” LED shou ld

illuminate, and the buzzer should sound. Press the “System Reset” button. Since the

batteries are not connected, the trouble buzzer should sound intermittently and the

common trouble LED should flash.

2. Connect the batteries while observing correct polarity: the red wire is positive (+) and

black wire is negative (-). All indicators should be OFF except for normal power "AC ON"

green LED and green LED I4 (below the TROUBLE relay at left bottom of board).

Note: Green LED I4 is illuminated when the system is normal. This LED indicates that

the trouble relay is in normal standby condition.

3. Configure the Fire Alarm Control Panel as described in the Configuration section.

37

Page 38

8.3 Troubleshooting

Table 5 Troubleshooting

Symptoms Possible Cause

To correct the fault, check for open wiring on that particular circuit loop or if the Circuit

Circuit Trouble

Disconnect Button is active. Notes: (1) Bypassing a detection circuit or signal circuit will

cause a system trouble (off-normal status); (2) Bypassing a releasing circuit will cause a

supervisory signal.

System Checkout

Remote

Trouble

Ground Fault

Battery

Trouble

Common

Trouble

Remote Trouble will be indicated on the main panel display for any failure reported by,

or failure to communicate with a remote annunciator or other remote device.

This panel has a common ground fault detector. To correct the fault, check for any

external wiring touching the chassis or other Earth Ground connection.

Check for the presence of batteries and their conditions. Low voltage (below 20.4V) will

cause a battery trouble. If battery trouble condition persists, replace batteries as soon

as possible.

If only a common trouble is indicated on the main panel and none of the above

confirming trouble indicators are on, check the following for possible fault:

• Check for any missing interconnection wiring.

• Check for any Module missing that was part of the Configuration.

• Check for improperly secured cabling.

38

Page 39

9.0 Indicators, Controls and Operations

SYSTEM

RESET

AC ON

X

M

?

GROUND FAULT