Page 1

Flex-Net Phase II

Application Guide

Application Guide

LT-6045 Rev. 1

October 2012

Page 2

Page 3

1.0 Purpose 7

2.0 Ethernet Port Usage 8

2.1 Wiring/IP Settings .......................................................................................................... 8

3.0 Web Server 9

3.1 Web Browser Setup ....................................................................................................... 9

3.2 Using the Web Server .................................................................................................... 9

3.2.1 Queue Status ................................................................................................................. 10

3.2.2 Panel Info ....................................................................................................................... 10

3.2.3 CPU Status .................................................................................................................... 11

3.2.4 Alarm Logs ..................................................................................................................... 11

3.2.5 General Logs ................................................................................................................. 12

3.2.6 Live Trace ...................................................................................................................... 12

3.2.7 Network Status - TCP .................................................................................................... 13

3.2.8 Network Status - UDP .................................................................................................... 13

3.2.9 Network Status - ARP, Route and Devices .................................................................... 14

3.2.10 Current Level ................................................................................................................. 15

4.0 BACnet 16

4.1 Flex-Net Configuration for BACnet ................................................................................ 17

4.2 CAS BACnet Explorer .................................................................................................... 21

4.3 Visual Test Shell ............................................................................................................ 22

4.3.1 Configuring Device, Port and Name Settings ................................................................ 22

4.3.2 Setting up Filters ............................................................................................................ 23

4.3.3 Acknowledging Alarms ................................................................................................... 23

4.3.4 Monitoring Objects ......................................................................................................... 23

4.4 Wireshark ....................................................................................................................... 24

5.0 Job Details XML Report 25

5.1 Generating an XML Report ............................................................................................ 25

6.0 Mass Notification System Introduction 26

7.0 Boolean Equations for Mass Notification 28

7.1 Advanced Logic Editor ................................................................................................... 28

7.1.1 Device Status ................................................................................................................. 29

7.1.2 Eligible Input List ............................................................................................................ 29

7.1.3 Equation Dialog Box ...................................................................................................... 30

7.1.4 Comment Box ................................................................................................................ 30

7.2 Advanced Logic Example .............................................................................................. 30

7.2.1 Objective ........................................................................................................................ 30

7.2.2 Procedure ...................................................................................................................... 30

3

Page 4

8.0 Digital Messages 32

9.0 Relay Pulsing 34

9.1 Relay Pulsing Sequence ................................................................................................ 34

9.2 Producing a Relay Pulsing Sequence ............................................................................ 34

10.0 Zone Latching 36

10.1 Zone Latching Sequence ............................................................................................... 36

10.2 Producing a Zone Latching Sequence ........................................................................... 37

11.0 Autonomous Control Unit and Local Operating Consoles 38

11.1 Broadcast Priority ........................................................................................................... 38

11.2 ACU and LOC Configuration .......................................................................................... 38

11.3 ACU Operation ............................................................................................................... 40

11.4 LOC Operation ............................................................................................................... 40

12.0 Firmware Loading 41

12.1 Main Board Firmware ..................................................................................................... 41

12.2 Audio Card Firmware ..................................................................................................... 41

12.3 Quad-Loop Adder Firmware ........................................................................................... 42

12.4 RAXN-LCD and RAXN-LCDG Firmware ........................................................................ 42

13.0 Configuration Loading 43

14.0 Hardware Layouts 44

14.1 Display Modules ............................................................................................................. 44

14.2 Paging and Fire Fighter Telephone Modules ................................................................. 45

14.3 Adder Modules ............................................................................................................... 45

14.4 BBX-1024 Fire Node Backbox ....................................................................................... 46

14.5 BBX-1072 Fire Node Backbox ....................................................................................... 46

14.6 BB-5008 Fire Node Backbox .......................................................................................... 47

14.7 BB-5014 Fire Node Backbox .......................................................................................... 48

14.8 BBX-FXMNS Mass Notification Node Backbox ............................................................. 50

14.9 QBB-5000XT Audio Signaling Cabinet .......................................................................... 51

14.10 FX-LOC Local Operating Console ................................................................................. 52

Appendix A: Hardware Changes .................................................................................... 53

Appendix B: Using the Configurator ............................................................................... 56

4

Page 5

1.0 Purpose

The purpose of this document is to describe the major changes from the Flex-Net Phase I Fire

Alarm Control System to the Flex-Net Phase II Fire Alarm Control System. It is intended

primarily for application engineers who build and configure these fire alarm control systems.

Familiarity with the Flex-Net Phase I Fire Alarm Control System is assumed. The following

topics will be discussed:

• Ethernet Port Usage for Network Capability

• Setting up and using a Web Server

• BACnet implementation and functionality

• Mass Notification System implementation and functionality

• Use of Boolean Equations to operate Virtual Zones

• Voice Evacuation and Digital Message Preparation

• Relay Pulsing

• Zone Latching

• Autonomous Control Unit (ACU) and Local Operating Consoles (LOCs)

• Firmware Loading

• Configuration Loading

• Hardware Layouts

5

Page 6

2.0 Ethernet Port Usage

The Flex-Net FACP has built in network capability which can connect to larger networks via

Ethernet. This capability allows for further annunciation and control of the system through the

Open Graphical Network (OpenGN) software, the integrated web server and Building

Automation and Control Networks (BACnet) software. It is recommended that connections

only be made to secure networks.

2.1 Wiring/IP Settings

An Ethernet connection can be found in each node on the main board (MD-871A). The port is

labelled P7 and can be found in the bottom left corner of a mounted board. An Ethernet cable

can be connected from here directly to the required network through a router or switch.

Each node connected directly to the network requires its own Internet Protocol (IP) address to

identify it. The IP address must be unique to the node and it must not be used by any other

terminal or device on the network. This information is configured in the job file using the

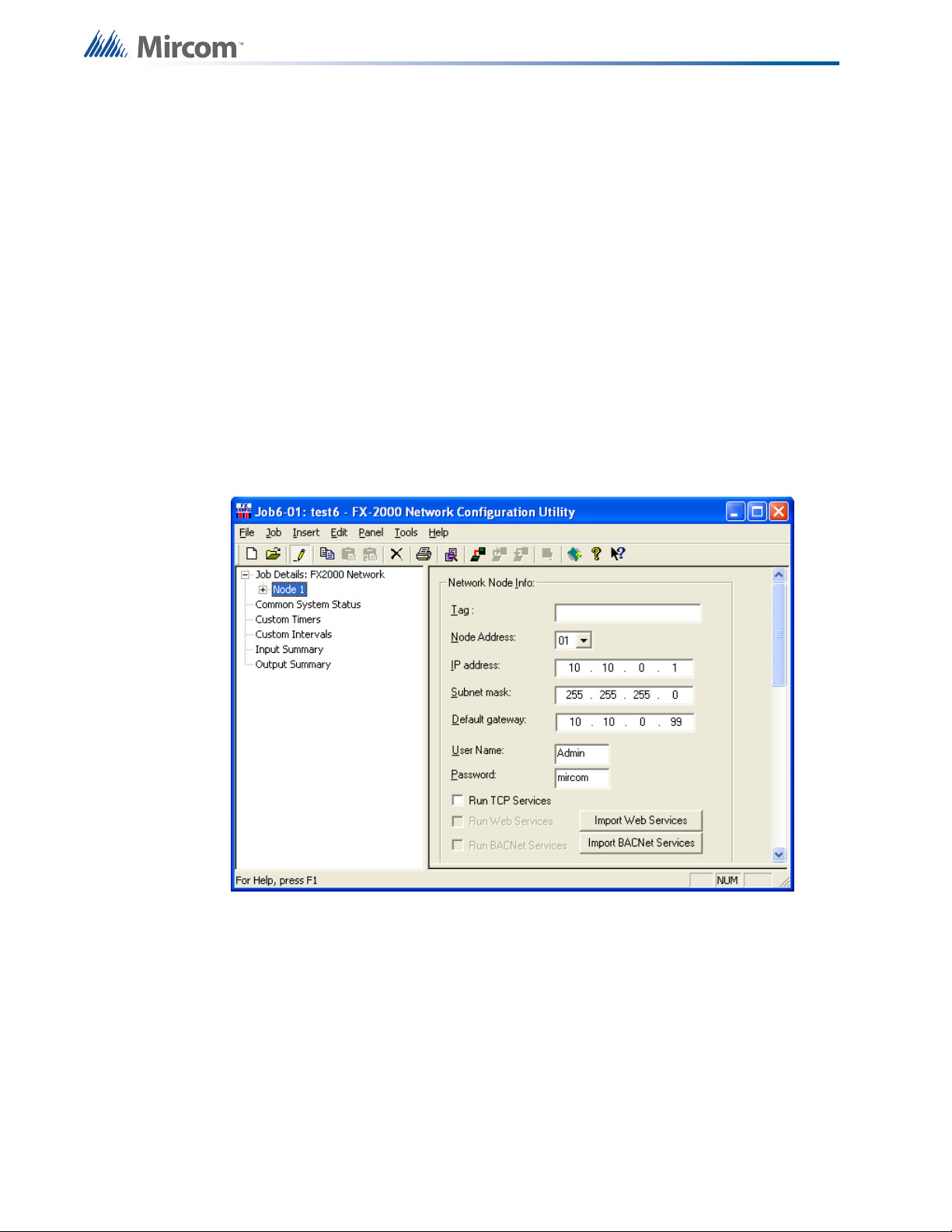

configurator. Refer to the figure below.

Ethernet Port Usage

In the configurator select the node from the Job Details tree on the left to display the Network

Node Info on the right. Each node requires a separate reserved static IP. Enter the IP address,

subnet mask and default gateway to complete the required networking information. The

subnet mask is a number that combined with the IP address identifies which network segment

the node resides on. The default gateway is the address of the router that the node connects

to. Contact your network administrator if you require assistance setting up a reserved static IP

or inputting correct values for the subnet mask and default gateway.

To allow an application, such as OpenGN or BACnet explorer, to connect and receive events

ensure that the check box "Run TCP Services" is selected.

To actively monitor the Ethernet connection for connectivity scroll down and select the

"Supervise Ethernet Connection" check box. This will create a trouble event if the node does

not detect an Ethernet connection.

6

Page 7

3.0 Web Server

The web server feature allows monitoring of the system remotely using any PC that resides on

the same network as the FACP. The web server displays much of the same information that

appears on any annunciator connected to the FACP.

3.1 Web Browser Setup

Before this feature can be accessed the job file must be configured to include the network

information described above in 2.1 Wiring/IP Settings and the "Run Web Services" check box

needs to be selected. If this box is greyed out then a CodeMeter key must be used to activate

a license using the Import Web Services button. A user name and password may also be set

in the configuration job file under the Network Node Info. If a user name and password are not

set the user name will be "admin" and the password will be "mircom" by default.

For optimal performance use the Internet Explorer browser version 6 or later, although other

web browsers are also supported. The web browser used to access the server must be set to

not cache web pages. Requiring the browser to request new information each time the server

page is accessed will ensure that the browser will not display old information that may be out

of date. To remove web site caching in Internet Explorer:

Web Server

1. Go to the browser's menu bar and select Tools, then select Internet Options at the

bottom of the drop down menu. The Internet Options dialogue box appears.

2. Under the General tab there is a section called Browsing History. From the Browsing

History section press the Settings button. A Temporary Internet Files and History

Settings dialogue box appears.

3. This dialogue box offers several options for when to check for newer versions of stored

pages. Select "Every time I visit the webpage" and press OK.

To access the webpage in an Internet Explorer web browser:

1. Enter the IP assigned to the specific panel followed by "/index.html" in the address bar.

For example if the IP address was “192.168.0.1” the full address would be “192.168.0.1/

index.html”.

2. Press enter and a prompt to enter the user name and password appears.

3. Enter the user name and password and press enter. The FACP can now be monitored

remotely.

3.2 Using the Web Server

The Web Server displays multiple pages that provide various types of information about the

function and operation of the Flex-Net system. In addition, there is information that is primarily

intended for network administrators. It allows them to access the Flex-Net system remotely for

monitoring or troubleshooting purposes. Each of these pages are described below with

accompanying screenshots.

7

Page 8

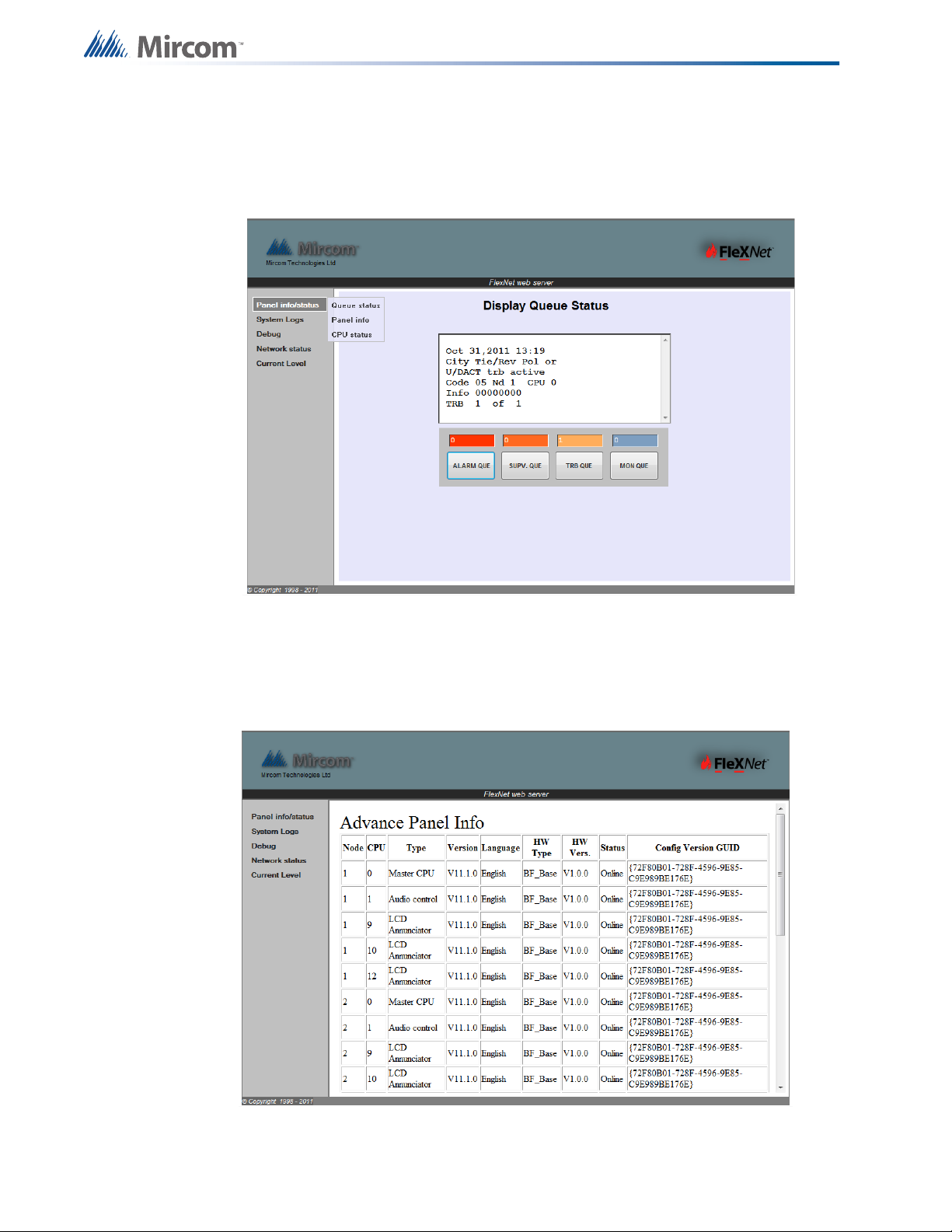

3.2.1 Queue Status

The Queue Status selection under Panel Info/Status displays the Display Queue Status page.

The Display Queue Status page shows the alarm, supervisory, trouble and monitor queues. To

browse through these queues press the corresponding button to display the list of events.

Web Server

3.2.2 Panel Info

The Panel Info selection under Panel Info/Status displays the Advanced Panel Info page. The

Advanced Panel Info page shows information about the CPUs connected to each node in the

system including firmware version and the current job via the GUID.

8

Page 9

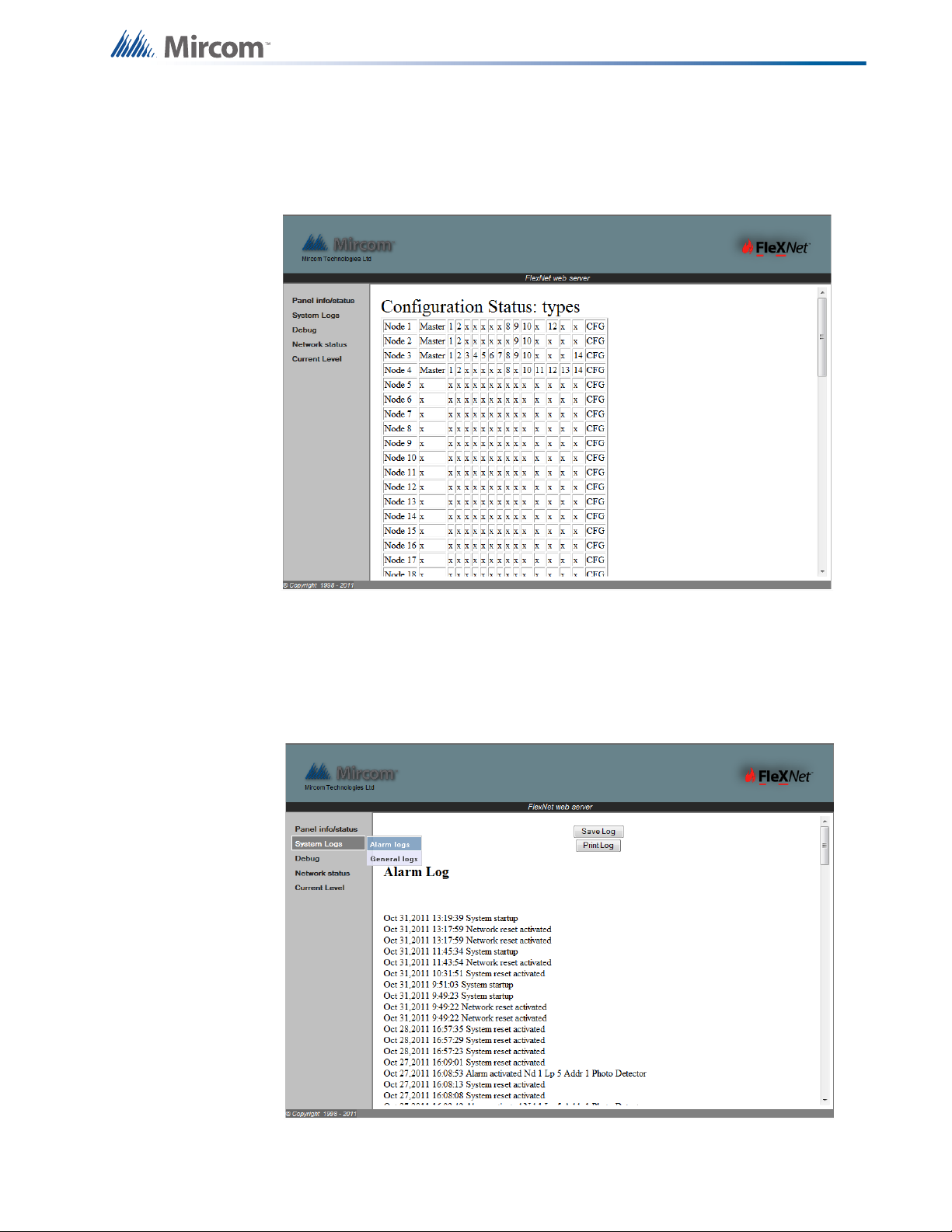

3.2.3 CPU Status

The CPU Status selection under Panel Info/Status displays the Configuration Status: Types

page. This page shows a list of the nodes that comprise the Flex-Net system. For each node

the CPUs that are in use are indicated by a CPU number beside their associated node.

Web Server

3.2.4 Alarm Logs

The Alarm Logs selection under System Logs displays the Alarm Log page. This page

displays the list of all Alarms that occur including network and system restarts. This log can be

saved to a file or printed using the appropriate buttons at the top of the page. Note that there is

a delay of a few minutes before the logs update, they are not updated in real time.

9

Page 10

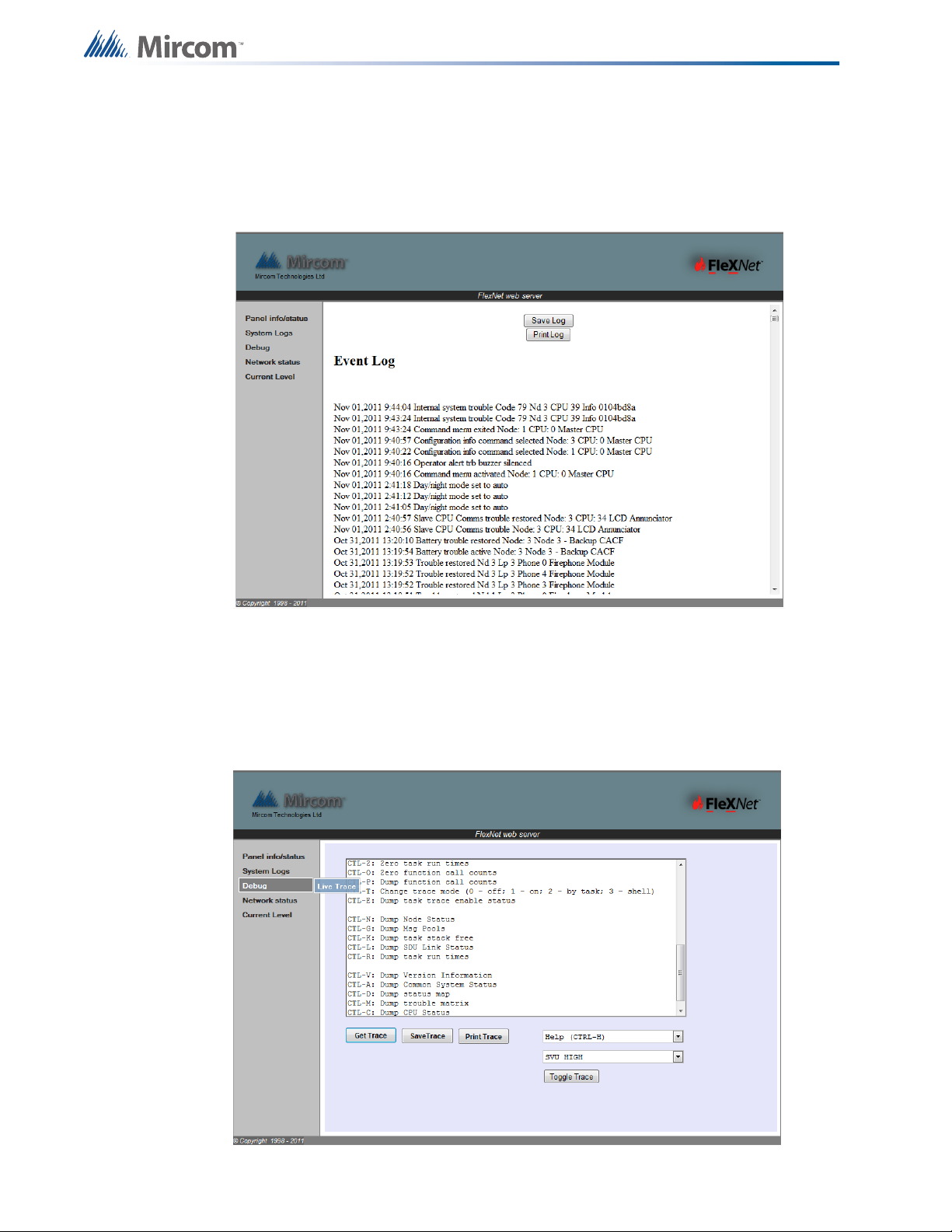

3.2.5 General Logs

The General Logs selection System Logs displays the Event Log page. This page displays a

list of all events that occur including troubles and alarms/ This log can be saved to a file or

printed using the appropriate buttons at the top of the page. Note that there is a delay of a few

minutes before the logs update, they are not updated in real time.

Web Server

3.2.6 Live Trace

The Live Trace selection under Debug displays a page that can be used by developers to

remotely monitor and debug the Flex-Net system. The type of trace can be selected from the

drop down menus and the level of the trace can be set by using the Toggle Trace button.

Press Get Trace to initiate the trace. The trace data can be saved or printed using the Save

Trace and Print Trace buttons respectively.

10

Page 11

3.2.7 Network Status - TCP

The TCP selection under Network Status displays the TCP Socket Table page. This page

displays a list containing all the connections currently being made to the web server from

remote locations. Each entry after the first represents a unique connection to the web server.

Web Server

3.2.8 Network Status - UDP

The UDP selection under Network Status displays the UDP Socket Table page. This page

displays a list containing all the BACnet applications currently connecting to the Flex-Net

system from remote locations. Each entry after the first represents a unique connection to the

web server.

11

Page 12

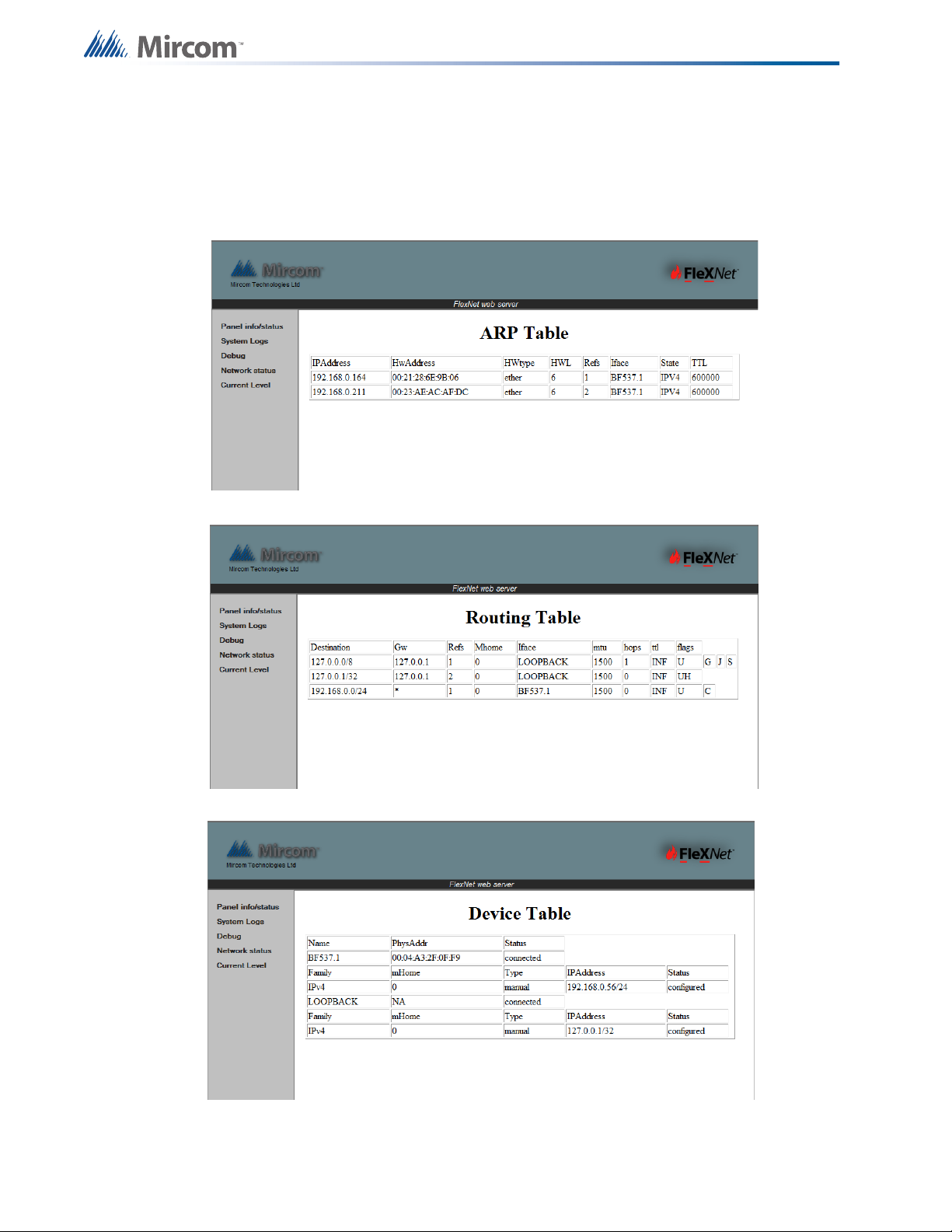

3.2.9 Network Status - ARP, Route and Devices

The ARP, Route and Devices selections under Network Status display the ARP Table,

Routing Table and Device Table pages respectively. Each of these pages contain information

intended to aid network administrators in remotely monitoring, troubleshooting and configuring

the network connection of the Flex-Net system.

Web Server

12

Page 13

3.2.10 Current Level

The Current Level selection displays a page that can monitor individual devices. To add a

device for current level monitoring:

1. Use the Display Line No. drop down to select the line for the device to be placed on.

2. Then enter the values for the node the device is on, the loop on that node it is on and the

device address in the fields labelled Node No, Loop No and Device Address

respectively.

3. Press Add and enter information for a second device or press Start to begin monitoring.

4. The Device Info window will update with current level readings and the percentage that

the current level is at before it reaches alarm level at or beyond 100%.

Web Server

13

Page 14

4.0 BACnet

BACnet stands for Building Automation and Control NETworks (http://www.bacnet.org). It is

an object-oriented communications protocol designed to consolidate different building

regulation systems to allow for collective monitoring and control through a single application.

Building regulation systems that can support the BACnet standard include heating, ventilation,

lighting control, access control as well as fire detection and alarm systems.

The Flex-Net system is capable of interfacing with other systems that communicate through

BACnet to provide centralized control and monitoring of a building’s regulation systems. The

BACnet protocol works by adapting different communication systems into a common

communication format.

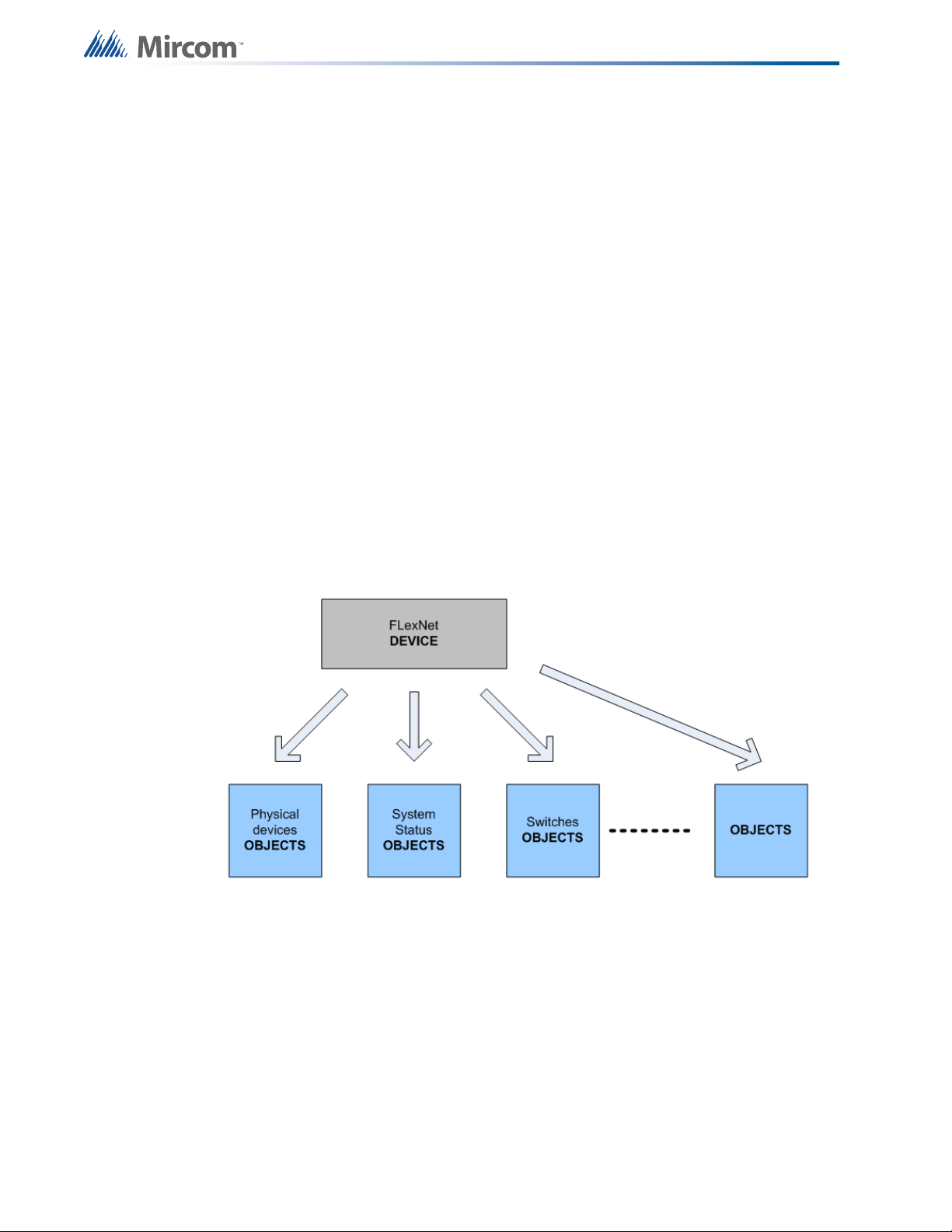

The consolidation of different communication systems is accomplished through the use of

“objects”. An object is defined as a collection of information related to a particular function that

can be uniquely identified and accessed over a network in a standardized way. The BACnet

protocol represents all information using these object data structures. Each object is defined

by a set of properties.

A confusion of terminology may arise when describing Flex-Net under the BACnet model.

Traditionally in the fire alarm industry the term “device” refers to things such as detectors,

strobes and alarms. For BACnet implementation, the entire Flex-Net system is modeled as a

“device” with many “objects”. The term “objects” refers to all the fire devices, system statuses

and switches connected to the Flex-Net system. This is illustrated in the figure below.

BACnet

14

Objects are all assigned properties that help define them and allow them to be monitored and

controlled. Objects can be classified into one of several different types. For example fire

devices can be subdivided into categories such as binary inputs, binary outputs, analog inputs

and analog outputs. In addition to an object type every object must be assigned an object

identifier and an object name. Depending on the type of BACnet device that the object is

associated with there will be more required properties that need to be assigned and others

that are optional.

BACnet uses a peer to peer architecture where any device can send service requests to any

other device. Protocol services include Who-Is, I-Am, Who-Has and I-Have for the purpose of

BACnet device and object discovery. These discovery service requests can be performed by

any BACnet device or object. BACnet services can provide event notifications such as

troubles or input activations. The services can also request current values from the Flex-Net

system.

Page 15

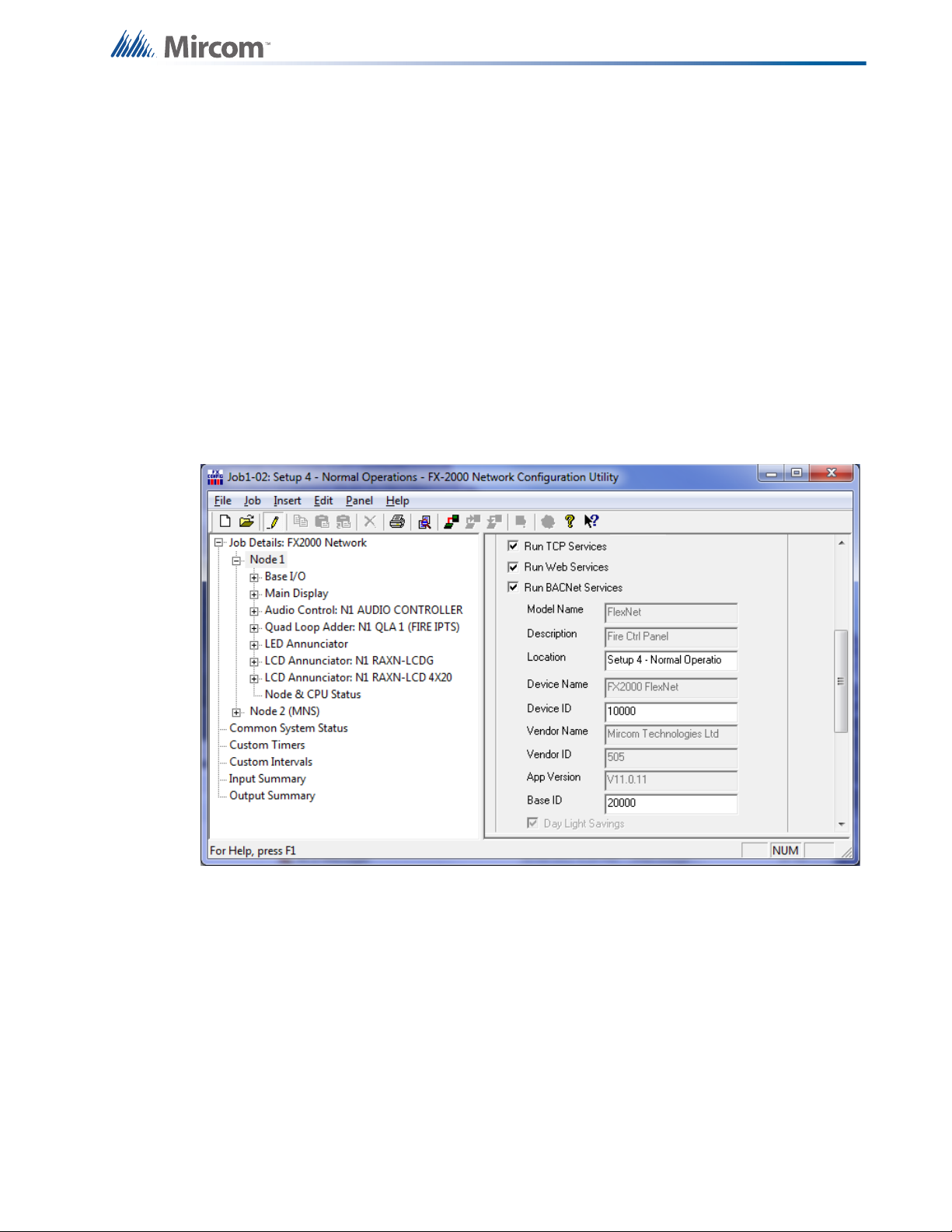

4.1 Flex-Net Configuration for BACnet

Note that the Flex-Net system is treated as a BACnet field panel and not a workstation. It does

not poll or query other BACnet field panels. Instead it replies to requests from workstations or

sends out notifications of new events.

Before BACnet services can be used with the Flex-Net system, the system must be configured

correctly. Network settings must first be set up as explained in 2.1 Wiring/IP Settings. The rest

of the configuration is performed using the configurator. In the configurator select the node

from the Job Details tree on the left to display the Network Node Info on the right.

From the Network Node Info window pane on the right select Run BACnet Services and Run

TCP Services to enable BACnet. If Run BACnet Services is greyed out then a CodeMeter key

must be used to activate a license using the Import BACnet Services button. Enter a Device ID

and a Base ID in the fields that become available. The value for the Base ID is where object ID

values will start from. To ensure that the value entered for the Device ID is outside the range of

possible object IDs enter a value lower than that of the Base ID. The Device ID defines the ID

of a BACnet device meaning the FACP. Refer to the figure below.

BACnet

As an example, the following points describe how addresses are assigned to addressable

devices by the configurator:

• The BACnet protocol specifies (2

22

- 1) or 4,194,303 available address IDs.

• Out of these, each FACP node reserves 24,000 IDs.

• Out of these 24,000 IDs, 13,000 are reserved for physical devices and 11,000 are for

statuses and switches.

• Node numbering starts from 0.

• Each node can support 7 CPUs (0-6) with 1,600 IDs available per CPU.

• Each CPU can support 4 loops (0-3) with 400 IDs available per loop.

• The method for identifying fire device address IDs is described by the following:

Base ID + (Node# x 24000) + (CPU# x 1600) + (Loop# x 400) + Fire Device ID

15

Page 16

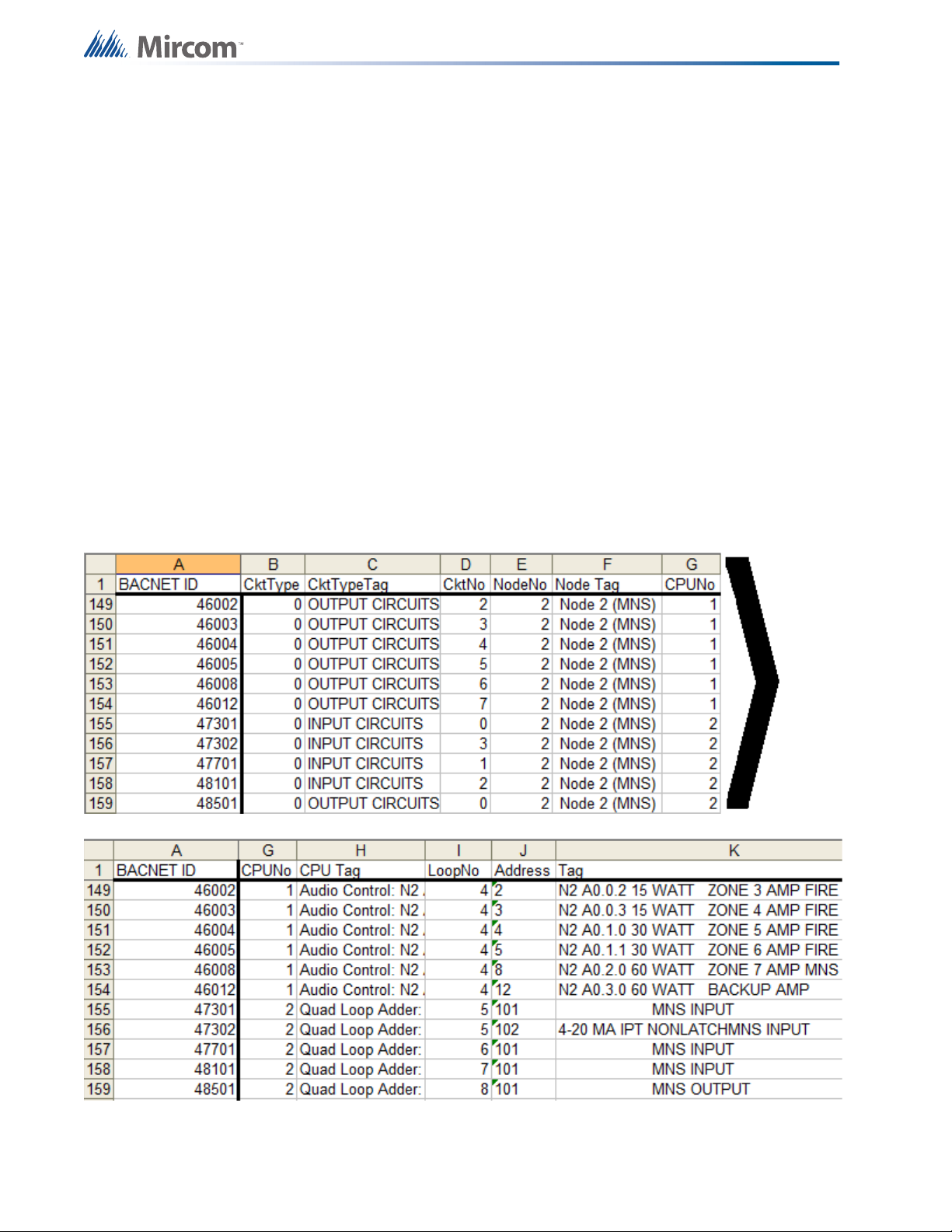

BACnet

This is for informational purposes only and is not intended to be used to identify objects or their

location. Instead the configurator can generate a BACnet XML report that includes the

address ID of each object as well as other identifying information such as node, CPU and loop

number. To generate an XML report:

1. Navigate to the configurator menu bar and select the Job drop down menu. From the

drop down menu select Export Job, the Export Current Job to a File window appears.

2. In this new window choose a location to save the file under the “Save in” drop down

menu.

3. Enter a name for the file under the “File name” drop down menu, and select “XML files

(*.xml)” under the “Save as type” drop down menu.

4. Press Save and a new window appears. In this new window select “BACnet Report Excel” and press OK.

The report will appear as shown below. The first column will list the BACnet ID of each object

in the Flex-Net system. Following this column other identifying information for the object will be

listed. The NodeNo, CPUNo and LoopNo columns describe which Node, CPU and Loop

each object exists on. The Node Tag and CPU Tag columns are descriptions of the Node and

CPU respectively. The Address column lists the fire device address and the Tag column

provides a description of the object. The CktType, CktTypeTag and CktNo columns contain

information that is used internally by the Flex-Net firmware to identify the object.

16

Page 17

BACnet

The object types that Flex-Net uses are binary input, analog input, multi-state input, life safety

point and binary output. The following table identifies which fire devices are classified under

which BACnet object types.

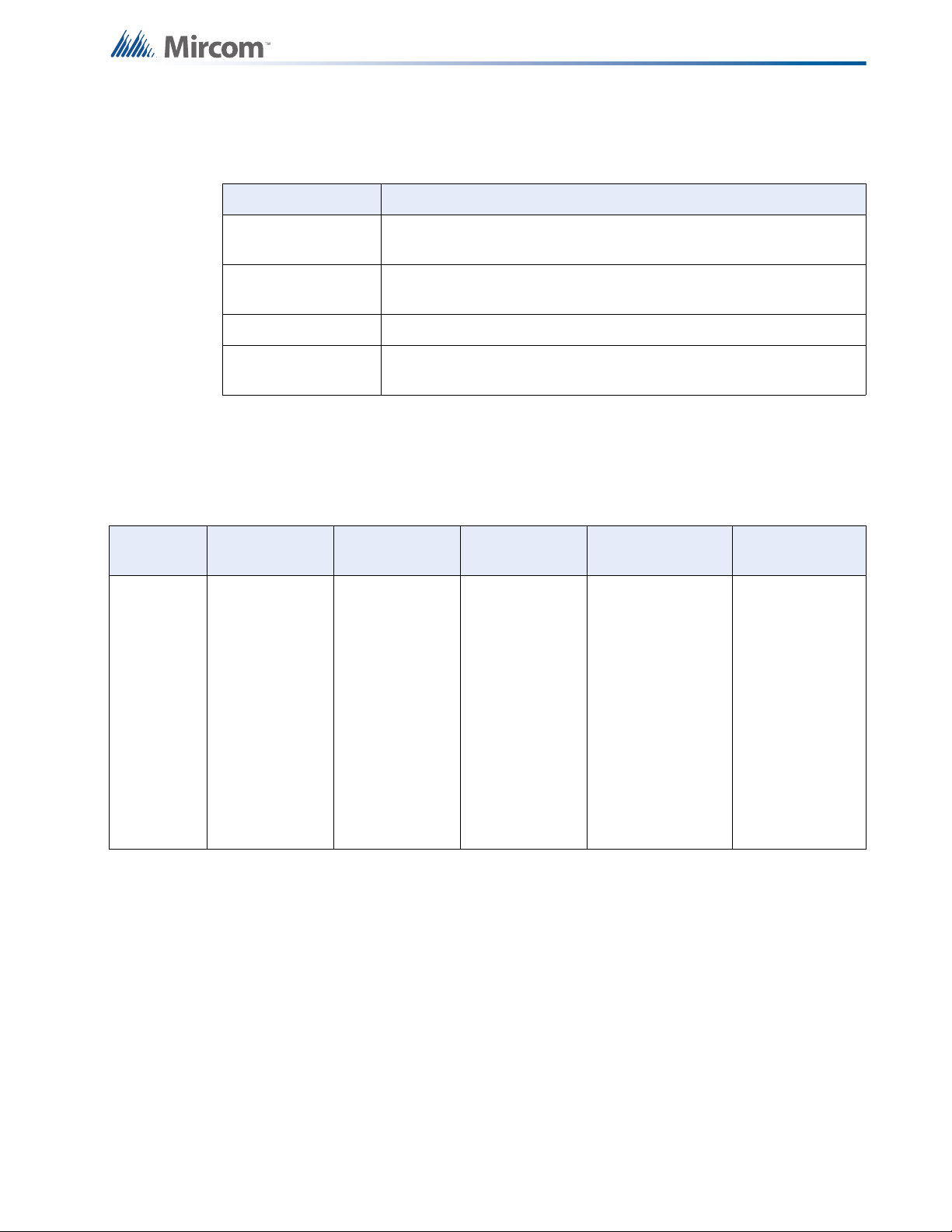

Object Type Fire Device Types

Binary Input Conventional Input, System Status, Page Select Switches, Manual

Control Switches, Miscellaneous Input Circuits

Object

Type

Object

Properties

Analog Input and

Multi-State Input

Ion Detector, Photo Detector, Heat Detector, Laser Detector,

COPTIR, 4-20mA Module, Acclimate Detector

Life Safety Point Fire Phone, Telephone Line, Generic Input

Binary Output Amplifier, Addressable Relay, Conventional Relay, Conventional

Signal, Control

Each of these object types have an associated set of properties. These properties identify the

object and the state it is in. The table below lists the properties associated with each BACnet

object that are used by the Flex-Net system. Some of the properties below are static, while

others are dynamic and are used to determine the state the object is in. The dynamic

properties in the table are bolded.

Binary Input Analog Input Multi-State

Life Safety Point Binary Output

Input

Object

Identifier

Object Name

Object Type

Present Value

Status Flags

Event State

Out of Service

Polarity

Description

Object

Identifier

Object Name

Object Type

Present Value

Status Flags

Event State

Out of Service

Units

Description

Object

Identifier

Object Name

Object Type

Present Value

Status Flags

Event State

Out of Service

Number of

States

Description

State Text

Object Identifier

Object Name

Object Type

Present Value

Status Flags

Event State

Out of Service

Reliability

Mode

Accepted Modes

Silenced

Operation

Expected

Description

Object Identifier

Object Name

Object Type

Present Value

Status Flags

Event State

Out of Service

Polarity

Priority Array

Relinquish

Default

Description

Active Text

Inactive Text

Each dynamic object property uses different types of information to describe the state of the

property. The type of information reported can also vary between different object types for the

same object property. The following discussion describes the different values each dynamic

object property can have for the different object types.

BINARY INPUTS: The Present Value property can be in one of two states: active or inactive.

For the Status Flags property a Boolean array [_,_,_,_] is displayed with each value in the

array representing the presence (1) or absence (0) of an Alarm, Fault, Override or Out of

Service respectively. For example a signal of 1,1,0,0 indicates the presence of an alarm and a

fault. Note that for Flex-Net override is never used. For the Event State property one of three

states is possible: normal, fault or off normal.

ANALOG INPUTS: The Present Value property is represented by a raw analog value in the

form of a pulse width PW4 signal. For the Status Flags property a Boolean array [_,_,_,_] is

displayed with each value in the array representing the presence (1) or absence (0) of an

17

Page 18

BACnet

Alarm, Fault, Override or Out of Service respectively. Note that for Flex-Net override is never

used. For the Event State property one of three states is possible: normal, fault or off normal.

MULTI-STATE INPUTS: The Present Value property ranges from 0-7 and each value

indicates one of the eight possible states. For the Status Flags property a Boolean array

[_,_,_,_] is displayed with each value in the array representing the presence (1) or absence (0)

of an Alarm, Fault, Override or Out of Service respectively. Note that for Flex-Net override is

never used. For the Event State property one of three states is possible: normal, fault or off

normal.

LIFE SAFETY POINTS: The Present Value property can be in one of three states: quiet, fault

or alarm. For the Status Flags property a Boolean array [_,_,_,_] is displayed with each value

in the array representing the presence (1) or absence (0) of an Alarm, Fault, Override or Out of

Service respectively. Note that for Flex-Net override is never used. For the Event State

property one of three states is possible: normal, fault or off normal.

BINARY OUTPUTS: The Present Value property can be in one of two states: active or

inactive. The Status Flags property a Boolean array [_,_,_,_] is displayed with each value in

the array representing the presence (1) or absence (0) of an Alarm, Fault, Override or Out of

Service respectively. Note that for Flex-Net override is never used. For the Event State

property one of three states is possible: normal, fault or off normal.

Now that BACnet has been enabled and configured in the job file to be sent to the panel other

software can be used to monitor and interact with the Flex-Net system using BACnet.

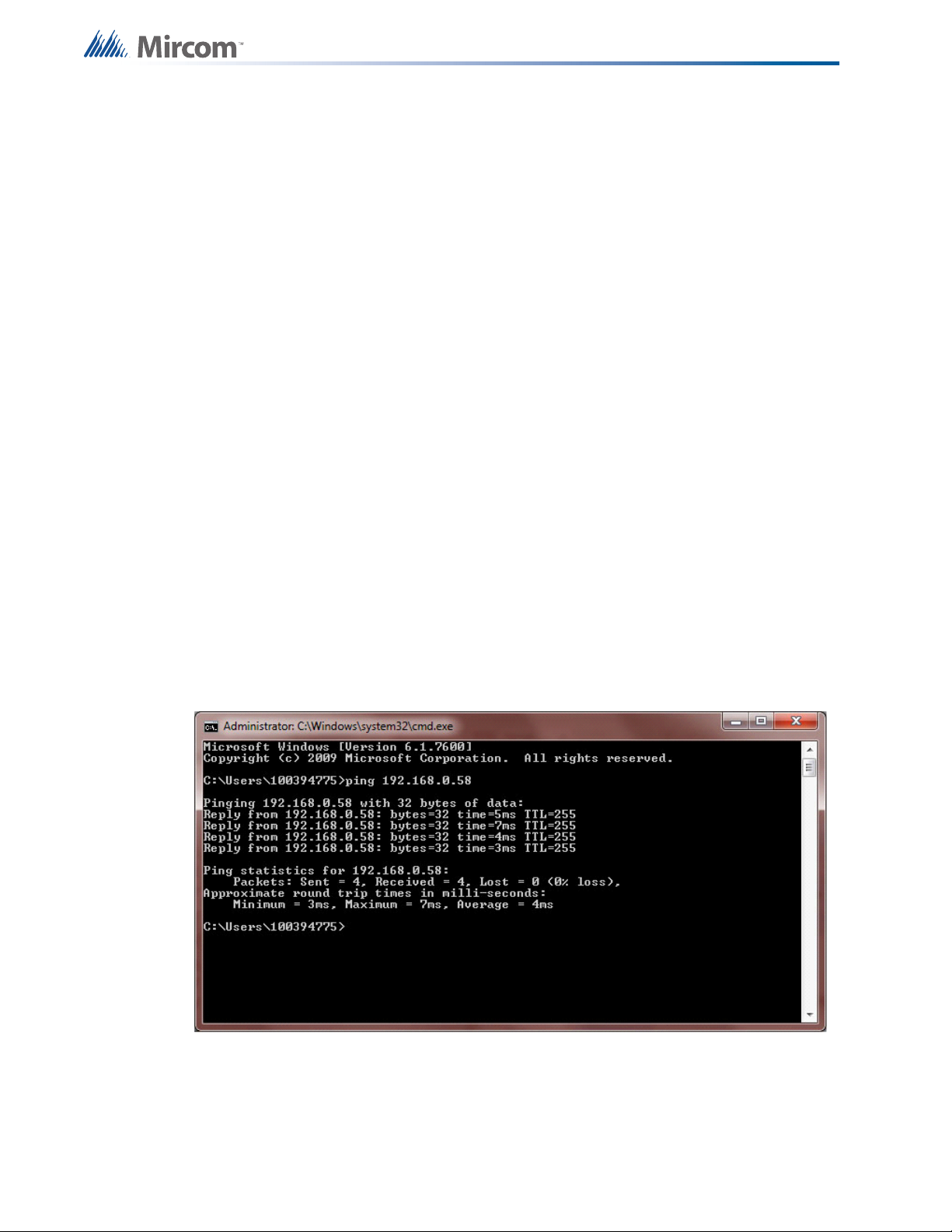

Before attempting to connect to the Flex-Net system using BACnet software ensure that there

is a network connection between the computer the software is located on and the FACP. To do

this open a command prompt window using your computer. Press Start, select Run, type

“cmd.exe” and press OK. In the command prompt window type “ping ” followed by the IP of the

FACP. If the destination host is unreachable check the network connection and make sure that

the computer and the FACP are on the same subnet with different IPs.

18

Page 19

4.2 CAS BACnet Explorer

There are many applications that can interface with BACnet devices. Three of these programs

will be described. The first program is called CAS BACnet Explorer. This program is useful for

testing, debugging and discovering BACnet networks and devices. The program can be

downloaded from the internet from: http://www.chipkin.com/cas-BACnet-explorer but it

requires a license to use. The license comes in the form of a USB key which must be plugged

into the computer the software is being used on. When installing the software the installer will

prompt for the installation of WinPcap. Allow this to install as it is part of the CAS BACnet

Explorer package.

BACnet

Once CAS BACnet Explorer is installed start the program. Some settings require

configuration:

1. Press the Settings button and a Settings dialogue box will appear.

2. In the Settings dialogue box press the Network tab on the left and check the BACnet IP

and the BACnet Ethernet check boxes.

3. Select the network card being used and then press OK.

The Discover function of the program identifies all objects associated with the Flex-Net

system. These objects include inputs, outputs, switches and system statuses. This function is

useful for confirming the presence and availability of all the objects associated with the FACP

and it must be performed before any FACP devices can be monitored.

1. Press the Discover button and a Discover dialogue box will appear.

2. Ensure that all check boxes on the left are selected. Select the All check box beside the

Network field.

3. In the Low Device Instance field enter the Device ID of the FACP that was set in the

configuration.

4. In the High Device Instance field enter a value one greater than the Device ID. Setting

this range ensures that only objects associated with the FACP will be discovered.

19

Page 20

BACnet

5. Press Send to begin the discovery process.

Note that sometimes the software will report errors while discovering, this will not affect the

outcome of the discovery. Once the discovery is complete the main window should display a

populated tree consisting of all the objects associated with the FACP. If the list does not

appear or is incomplete repeat the discovery process with all options selected.

The CAS BACnet explorer can also be used to monitor any changes in the properties of any of

the objects associated with the FACP. Once objects have been discovered the populated tree

can be expanded and individual objects can be selected. Each object can be expanded to

view its parameters and properties. To monitor an object right click on it and select “Add this

object to monitor list”. Repeat this for each object that needs to be monitored.

Objects will be monitored using default properties however the list of default properties may

not included all required properties. To set properties to be monitored click on the settings icon

and the Settings window appears. Use the Add and Remove buttons to select properties.

Press OK to confirm the settings.

Once objects and properties to be monitored are selected press the Monitor button in the main

window. All the objects to be monitored will be displayed in a new window titled Monitor List.

This window will display any changes in properties as they happen in real time.

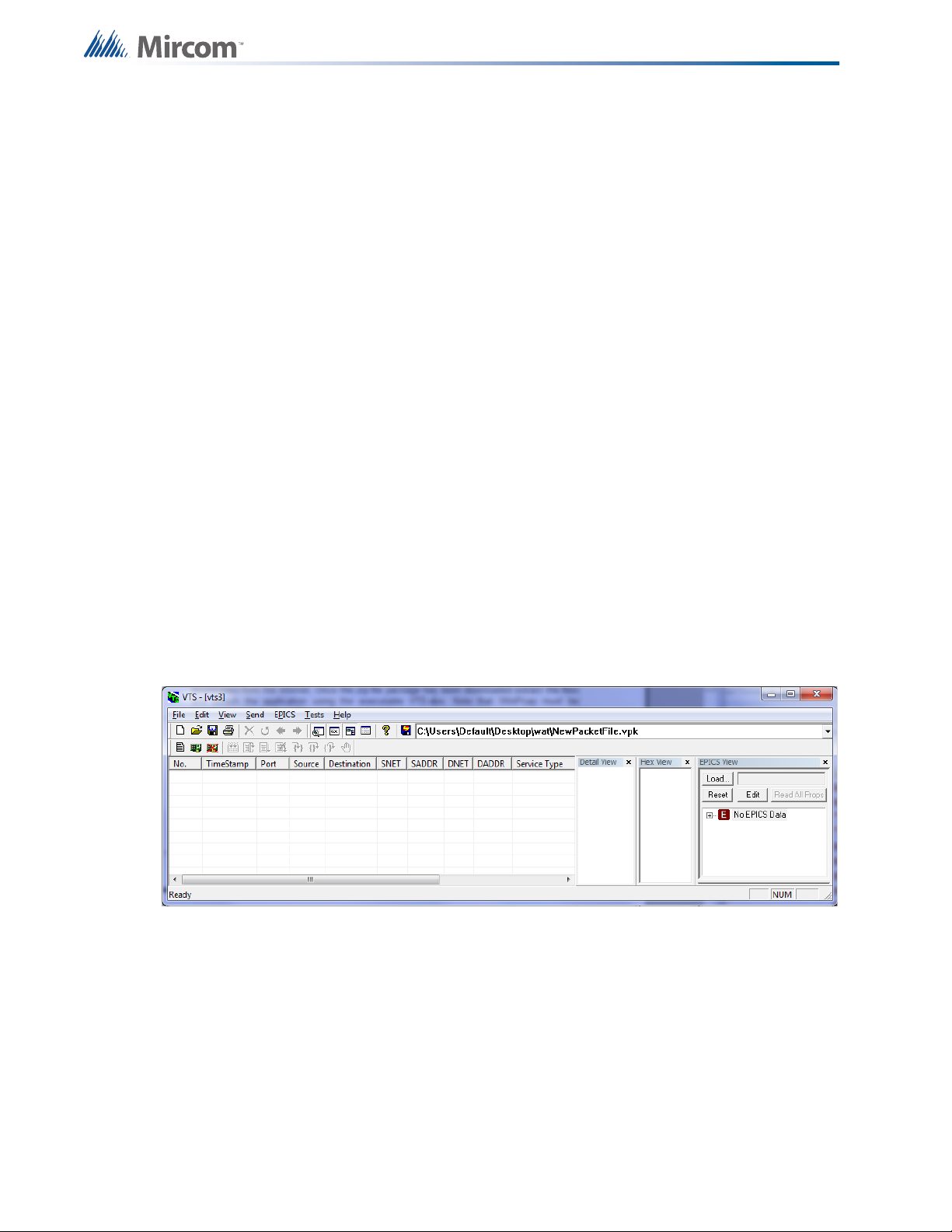

4.3 Visual Test Shell

The Visual Test Shell (VTS) is an application that is able to monitor BACnet objects and

communicate with BACnet devices to acknowledge alarms. It is freeware and can be

downloaded from: http://sourceforge.net/projects/vts/. Once the zip file package has been

downloaded extract the files and launch the application using the executable VTS.exe. Note

that WinPcap must be installed in order for the VTS application to launch.

4.3.1 Configuring Device, Port and Name Settings

1. From the taskbar select Edit then select Device. The Device Configuration window

appears.

20

2. Enter a name for the BACnet device in the Name field and its Device ID in the Instance

field.

3. Press OK to confirm your settings.

4. From the task bar select Edit then select Ports. The Port Configuration window appears.

5. Press the New button and in the Name field enter a name for the port.

6. Select the Enable check box and use the Network drop down box to select the device

that was configured in the Device Configuration window.

Page 21

7. Press the IP tab and ensure that the Interface drop down box displays the correct

network adapter.

8. Press OK to confirm your settings.

9. From the task bar select Edit then select Names. The Names window appears.

10. Press the New button and set the Address Type to Local Station if the FACP is on the

same subnet.

11. Use the Port drop down box to select the port created using the Ports menu. Enter a

name for the FACP. Enter the IP address assigned to the FACP in the configuration in

the Address field along with the port number.

12. Press OK to confirm your settings.

4.3.2 Setting up Filters

Navigate to the Edit menu and select either Capture Filter or Display Filter. The setup for each

filter type is the same, the difference being that the display filter changes what is displayed and

does not affect the log file while the capture filter directly affects what appears in the log file. To

create a new filter:

BACnet

1. Click the New button in the Filters window.

2. Select options for accepting or rejecting packets and set the Port, Address and Address

Type as before in 4.3.1 Configuring Device, Port and Name Settings.

3. Press OK to confirm your settings.

4.3.3 Acknowledging Alarms

1. Navigate to the menu bar and select Send. From the drop down menu navigate to Alarm

and Event then Acknowledge Alarm. The Acknowledge Alarm dialogue box will appear.

2. The majority of information to be filled in under the Acknowledge Alarm tab is only for log

file purposes and can be replaced with placeholder information. For the Acknowledging

Process Identifier, Event Object Identifier and Acknowledgement Source fields enter

placeholder text such as “1”.

3. Press both Time Stamp buttons and the Time Stamp window appears, enter placeholder

text such as “1” in the Time field for both windows and press OK.

4. For the Event State Acknowledged drop down select normal.

5. Select the IP tab in the Acknowledge Alarm window and select the destination FACP

using the Destination drop down menu.

6. Press Send to Acknowledge the alarm.

4.3.4 Monitoring Objects

Objects can be monitored by retrieving the current value of any property associated with an

object. This is accomplished by sending read property commands. To send a read property to

the FACP:

1. Navigate to the menu bar and select Send. From the drop down menu navigate to Object

Access then Read Property. The Read Property dialogue box will appear.

2. Under the Read Property tab press the ID button beside the Object ID field. The Object

ID dialogue box appears.

21

Page 22

3. In this dialogue box select the Object Type using the drop down menu and enter the

object’s BACnet ID under the Instance field. This is the ID described by the expression in

4.1 Flex-Net Configuration for BACnet.

4. Press OK and switch to the IP tab in the Read Property dialogue box.

5. Select the destination FACP using the Destination drop down menu.

6. Press Send to send the read property request. The request should be responded to by

the FACP with information about the object in the main VTS window.

4.4 Wireshark

Wireshark is an application that monitors and analyzes network packets. As streams of data

pass through a network the application captures the data and decodes the information

contained therein. This function can be used to troubleshoot and analyze network information.

The software is free and can be downloaded from http://www.wireshark.org/download.html.

Once the software is installed run the Wireshark application. From the menu bar select

Capture and from the drop down menu that appears select Interfaces. A new window will

appear where the network device being used can be selected. Select the appropriate network

card and press Start.

BACnet

All packets traveling through the network will now be monitored and displayed in the main

application window. To monitor BACnet packets only type “bacnet” into the filter field below the

menu bar and press Enter on your keyboard. Now only BACnet packets will be shown and all

other network traffic will be filtered out.

Select any packet to view details on its contents. The information in these packets can now be

used for troubleshooting or debugging purposes.

22

Page 23

5.0 Job Details XML Report

The job details XML is a representation of the job created in the configurator. It contains all the

CPUs and fire devices that make up the job as well as the correlations between them. The

XML format allows the job configuration to be read by a wider range of applications and

provides an alternative way to present the details of the configured job.

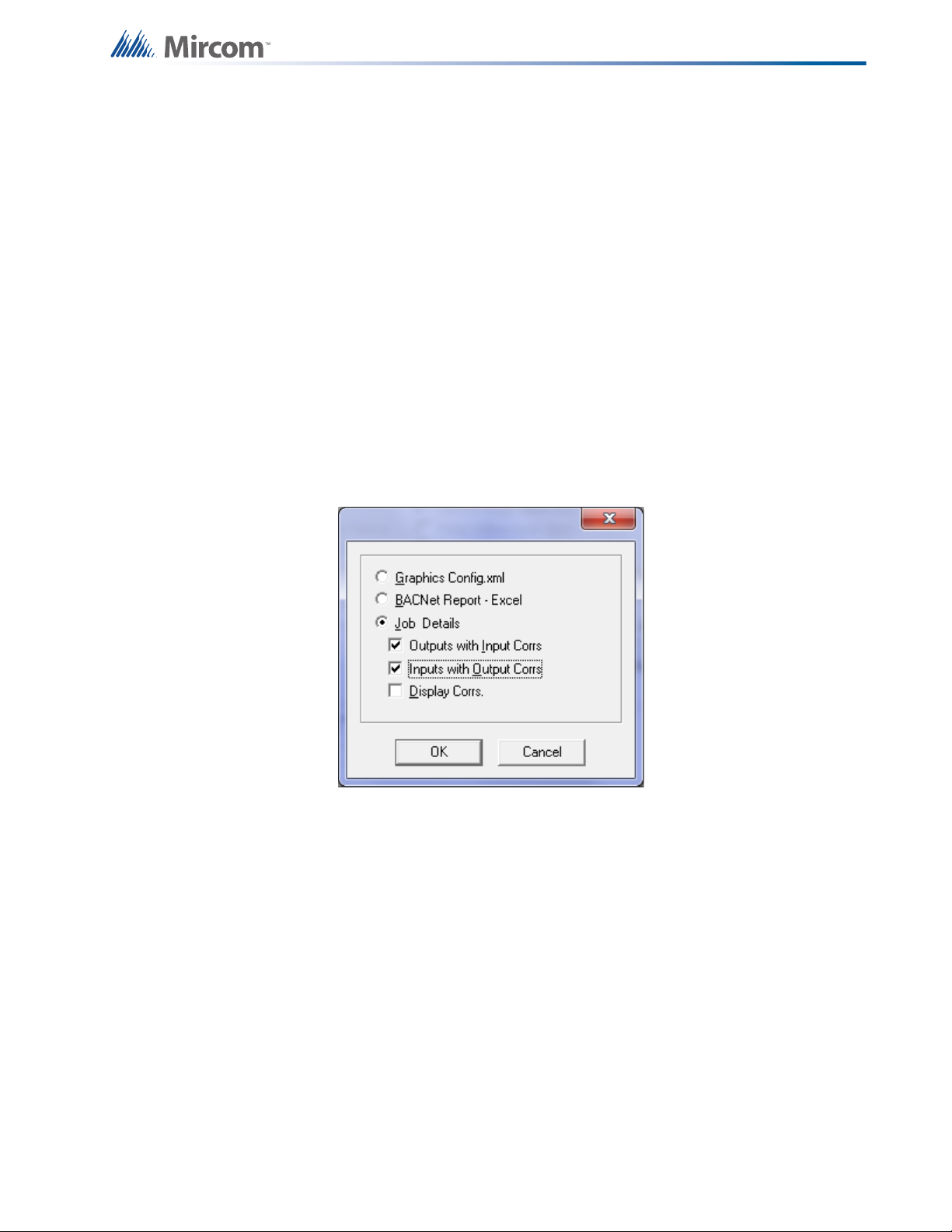

5.1 Generating an XML Report

1. Navigate to the configurator menu bar and select the Job drop down menu. From the

drop down menu select Export Job, the Export Current Job to a File window appears.

2. In this new window choose a location to save the file in under the “Save in” drop down

menu, enter a name for the file under the “File name” drop down menu, and select “XML

files (*.xml)” under the “Save as type” drop down menu.

3. Press Save and a new window appears. In this new window select “Job Details”. Select

the types of correlations to include in the job details XML by selecting from the check

boxes and press OK to generate and save the file.

Job Details XML Report

23

Page 24

Mass Notification System Introduction

6.0 Mass Notification System

Introduction

The Flex-Net Mass Notification System (MNS) allows announcements and notifications to be

made to the occupants of a facility. It is intended for notification outside of regular fire

evacuation messages and signals. The MNS is able to override the fire control system in case

there is a need to communicate higher priority information. Conversely, it is possible for the fire

control system to have communication priority over MNS.

The MNS comes integrated with the fire control and monitoring system. A single MNS panel

can display both MNS and fire events but each type of event will appear separately on different

annunciator displays. The modules on the MNS panel used for MNS and fire functionality are

arranged independently from each other and are accessed via two separate doors on the

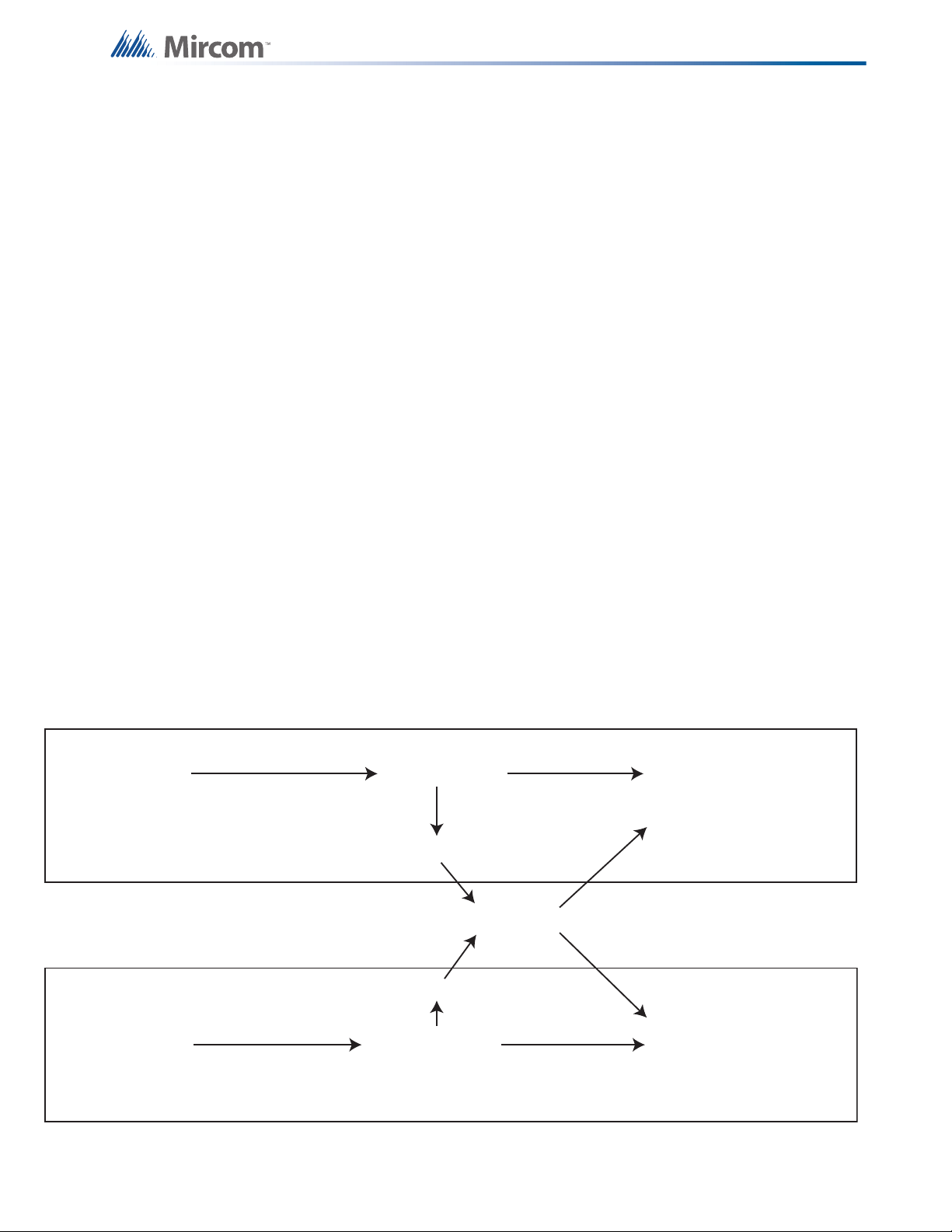

same panel. Refer to the figure below.

24

Even though the MNS panel has a fire monitoring component, fire devices cannot be

controlled by the MNS panel. Inputs for the MNS and the fire control system must reside on

loops connected to their respective nodes.

Page 25

Mass Notification System Introduction

Fire Input

- Manual Stations

- Switches

- Detectors

MNS Input

- Manual Stations

- Switches

- Other

Fire Zone

MNS Zone

Advanced Logic Equations

Fire Virtual Zone

MNS Virtual Zone

Output Hardware

- Speakers

- Horns

- Strobes

Output Hardware

- Speakers

- Horns

- Strobes

FIRE GROUP PRIORITY LEVEL 1

MNS GROUP PRIORITY LEVEL 2

MNS and the fire control and monitoring systems exist together on a single network, but it is

required that they be grouped separately on a software level. The input and output devices for

fire and MNS must be assigned to different zones and these zones must be in different groups.

Since input zones cannot activate outputs directly across a group, the MNS input zones will

not activate fire output signals and fire input zones will not activate MNS output signals.

To assign a group to a node select the node in the configurator using the Job Details tree on

the left. Create a new group or add it to an existing group by using the Network Node Info

window that appears on the right. Once the node has been assigned to a group membership,

common control switches such as system reset and total evacuation should be assigned to the

appropriate groups. This can be accomplished by selecting the node group that the switch has

been assigned to and selecting the appropriate group.

However, sometimes inputs from one group require the use of hardware present in a different

group. For example, the fire group may have inputs that require the use of amplifiers present

in the MNS panel. To communicate to the output zone across a group, virtual zones must be

used.

A virtual zone is a zone that is not correlated to any physical devices but is instead used to

communicate across groups through the use of advanced logic. Virtual zones are local to the

group that contains the outputs they intend to signal. They can monitor inputs across groups

and activate their associated outputs if the required conditions are met. The advanced logic

that drives these virtual zones consists of Boolean equations.

However, there may be situations where conflicts can occur. For example, two inputs may

attempt to activate the same output simultaneously. This is remedied by assigning priority to

either MNS or fire such that one will take precedence over the other. For example, if MNS has

a higher priority and a fire input is activated first then the fire output will remain active until an

MNS input is activated in which case the MNS output will take over and silence the fire output.

Fire output will resume to completion once the MNS output is cleared. Refer to the

supplementary diagram below.

25

Page 26

Boolean Equations for Mass Notification

7.0 Boolean Equations for Mass

Notification

Boolean equations are used to control the virtual zones that drive the activation of outputs

across groups. Using the Advanced Logic Editor dialog, an equation can be composed and

applied to an output circuit or a local input zone. This is done by specifying any number of local

and remote inputs zones and local input circuits (operands) and Boolean expressions

(operators).

When the result of the equation from an evaluation of the TRUE/FALSE state of all inputs is

TRUE the associated output will be energized. Note that applying an equation directly to an

output bypasses all of the regular input to output correlation processing.

Also note that the use of advanced logic does not modify the code at an executive level. These

equations are parsed and checked for syntax before being sent to the panel. The virtual input

is correlated to signals or other outputs as usual and the standard fire alarm processing is

performed by the executive control routine.

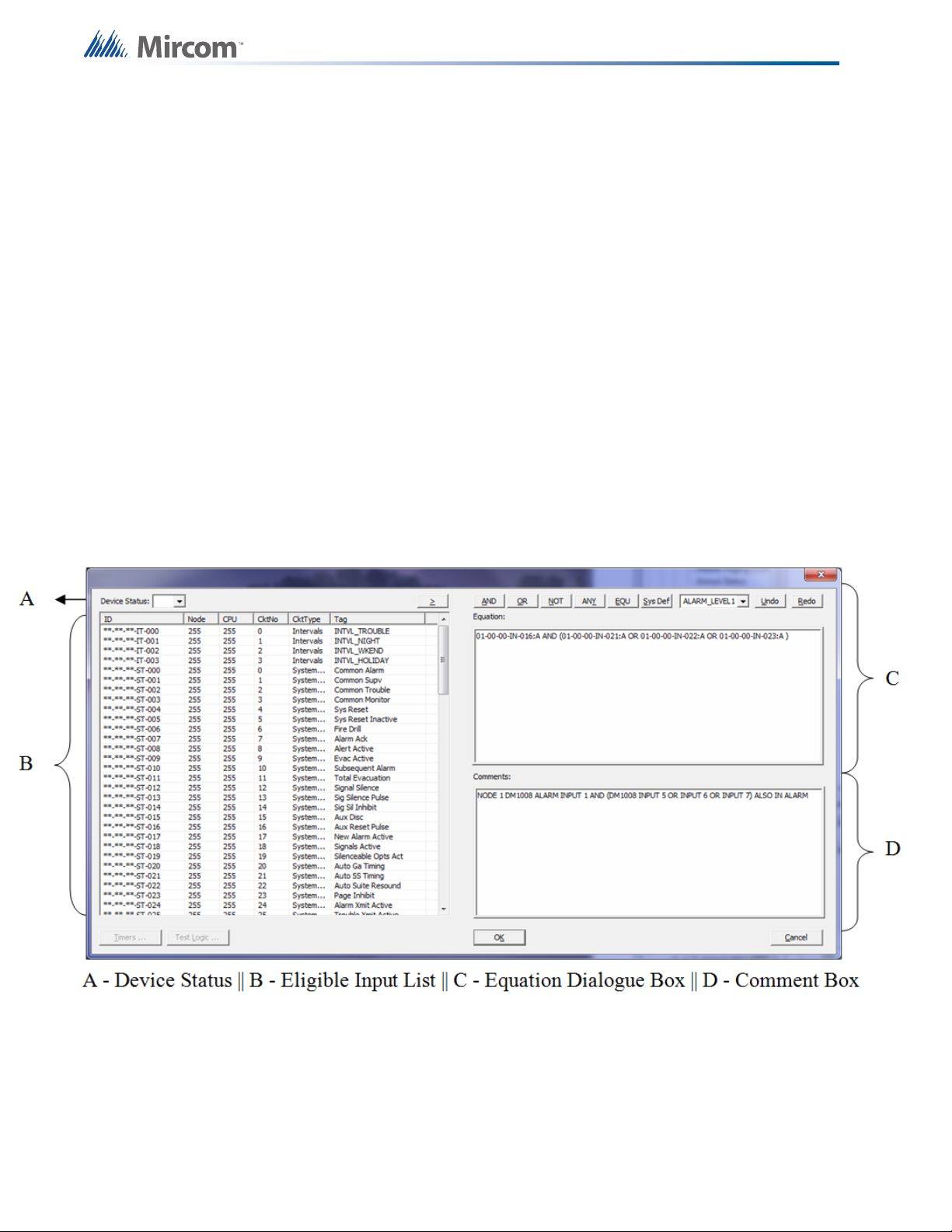

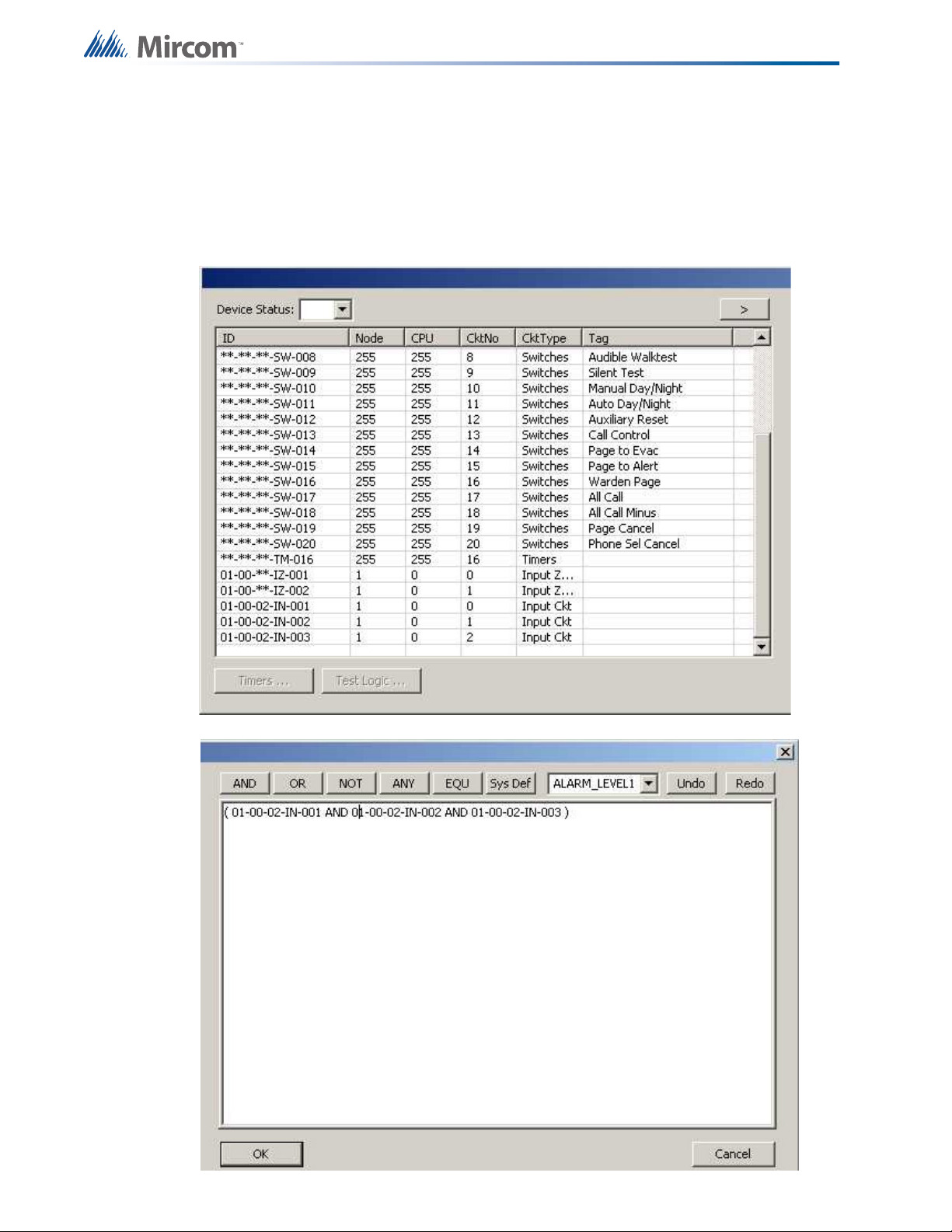

7.1 Advanced Logic Editor

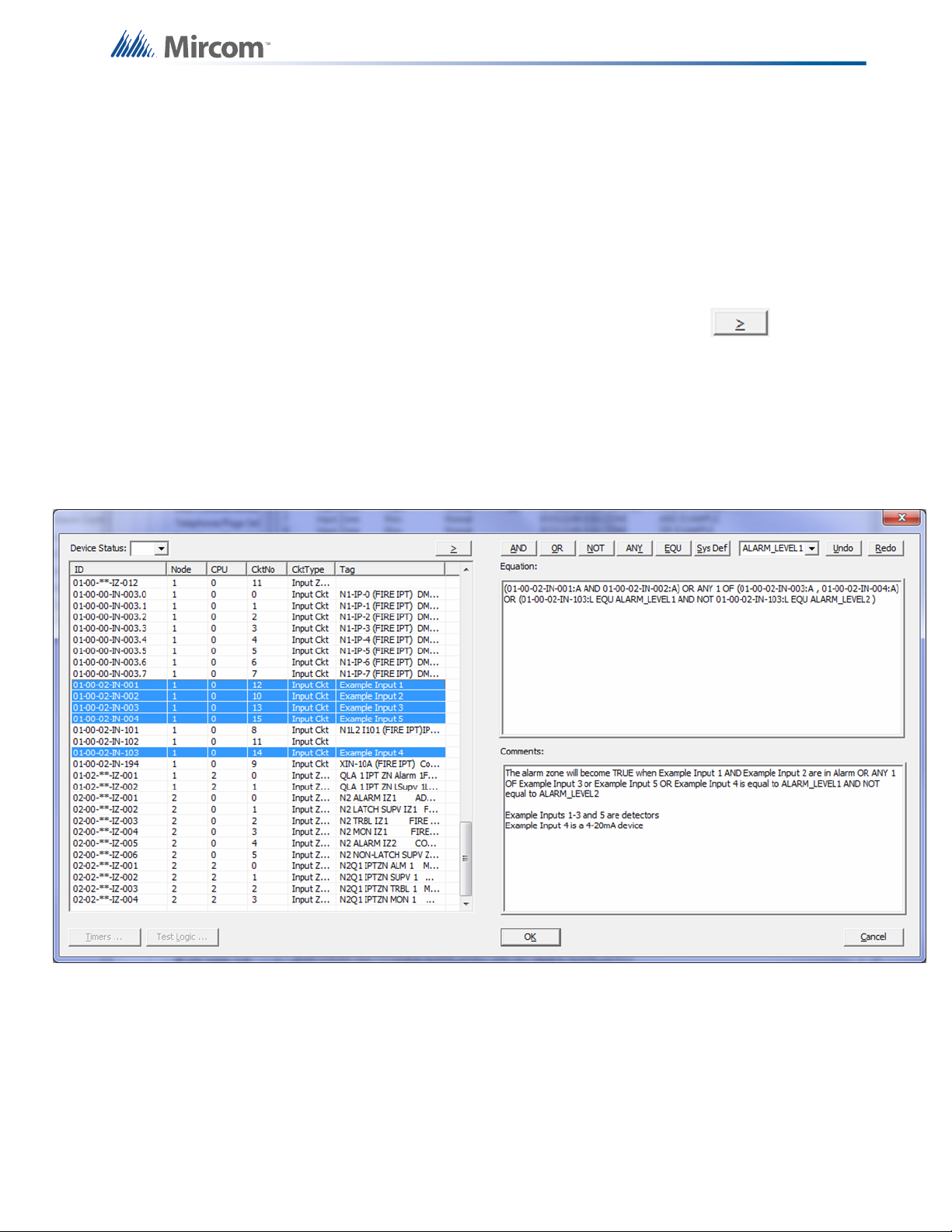

The following image is a screen capture of the Advanced Logic Editor dialogue.

26

To access the Advance Logic Editor select any zone or output such as a relay and click the

Advanced Logic tab in the bottom right window then press the Edit button. The Advanced

Logic Editor dialogue appears.

Page 27

7.1.1 Device Status

The Device Status allows a user to apply a mask to any device. Masks include:

“:A" – Alarm

“:B” – Bypass

“:F” – Fault

“:L” – Level

If a mask is applied to a device then the equation will only become TRUE when the specific

status changes. For Example “07-02-01-IZ-001:B”, this alarm zone will only become TRUE

when this zone is bypassed.

To apply a mask, use the drop down and select the desired mask before moving the input into

the Equation Dialog Box. If no mask is applied, any change in status will result in the equation

becoming TRUE.

7.1.2 Eligible Input List

Boolean Equations for Mass Notification

A list of all eligible inputs that can be referenced by equations. The list consists of local input

circuits and zones, remote zones, intervals, timers, and switches.

The ID column lists identification values for all eligible inputs. An ID is assigned to each input,

interval, timer, or switch to aid in identification when referenced in the equation dialog. The

address of each is used to structure the ID.

The ID is structured in the following manner:

Node No._CPU No._Loop No._CKt Type_CKt No.

Node No. – The numerical value assigned to the node.

CPU No. – The numerical value assigned to the CPU within the node

Loop No. – The numerical value assigned to the SLC where the device is physically

connected, if applicable

CKt Type – The circuit type. This is used to distinguish between an input circuit, zone, interval,

timer or status. The following are the abbreviations used for each circuit type:

IN – Input circuit

IZ – Input zone

SW – Switch

ST – System status

IT – Interval

TM – Timer

27

Page 28

CKt No. – The numerical value assigned to each status, switch, timer, interval, zone or input

by the Flex-Net Configurator

A double asterisk “**” is used if there is no applicable value for certain ID components such as

a Loop No. for a system status.

The Node and CPU columns list the numerical value of the node pertaining to each input

device or zone. A default value of 255 is applied to system statuses, control switches, timers,

and intervals as they are global inputs which apply to the entire network.

The Ckt No column consists of numerical values assigned by the Flex-Net Configurator to

each input.

The Ckt Type column identifies the type of input. Inputs can vary from system statuses,

switches, intervals, timers, input devices, and input zones.

The Tag column includes a general description of each input that helps identify it. This aids in

constructing an equation.

7.1.3 Equation Dialog Box

Boolean Equations for Mass Notification

The Equation Dialog Box is where the logic equations are structured. To insert an input, select

the input from the Eligible Input List and click the > button above the list.

To insert an operand, select the appropriate button above the Equation Dialog Box. To insert a

System Define, use the drop down to select the appropriate system define and then click the

Sys Def button. The Undo button removes the last change to the equation. The Redo button

reapplies the last removed change to the equation.

7.1.4 Comment Box

The comment box is used to attach comments to the advanced logic equation. Comments are

important for quickly explaining the intended function of an equation. This will allow for easier

troubleshooting and quicker review of the configuration later on.

7.2 Advanced Logic Example

7.2.1 Objective

To create an advanced logic equation using a combination of operators. The advanced logic

equation will be part of a virtual input zone. It will reference inputs that exist in a separate

group from the equation's virtual input zone. This virtual input zone will be referenced by an

output in its group that will activate when the equation that drives the zone becomes true.

28

7.2.2 Procedure

1. Create an alarm input zone in the same group as the outputs that are to be activated.

Tag the zone "Virtual Alarm Zone 1".

2. Create three input devices and tag them appropriately.

3. Select the alarm input zone and then select the Advanced Logic tab. Click the Edit

button and the Advanced Logic Dialog Box appears.

4. Select the Device Status mask ":A" for alarm.

Page 29

Boolean Equations for Mass Notification

5. Select the device tagged Example Input 1 and the device tagged Example Input 2 by

holding down the CTRL key and press the AND operator. Complete with brackets.

6. Press the OR operator

7. Select the devices tagged Example Input3 and Example Input 5 by holding down the

CTRL key followed by the ANY operator. The number in the ANY operator can be

modified to require more than 1 input state to become true. Change this value to 2.

8. Press the OR operator and insert an open bracket.

9. Select the Device Status mask ":L" for level.

10. Select the device tagged Example Input 4 and press the chevron button.

11. Press the EQU operator then select ALARM_LEVEL1 and press the Sys Def operator.

12. Press the AND operator and then press the NOT operator.

13. Select the device tagged Example Input 4 and press the chevron button.

14. Press the EQU operator then select ALARM_LEVEL2 and press the Sys Def operator.

15. Insert a close bracket.

16. Add a comment in the comment box and press OK.

The alarm zone will become TRUE when Example Input 1 AND Example Input 2 are in Alarm

OR ANY 1 OF Example Input 3 or Example Input 5 OR Example Input 4 is equal to

ALARM_LEVEL1 AND NOT equal to ALARM_LEVEL2. Example Inputs 1-3 and 5 are

detectors and example Input 4 is a 4-20mA device.

17. Select an output in the same group as the virtual zone, right click on it and Add

Correlations.

18. Select the virtual input zone and press Add. This output will now activate every time the

virtual input zone activates due to the equation being satisfied.

29

Page 30

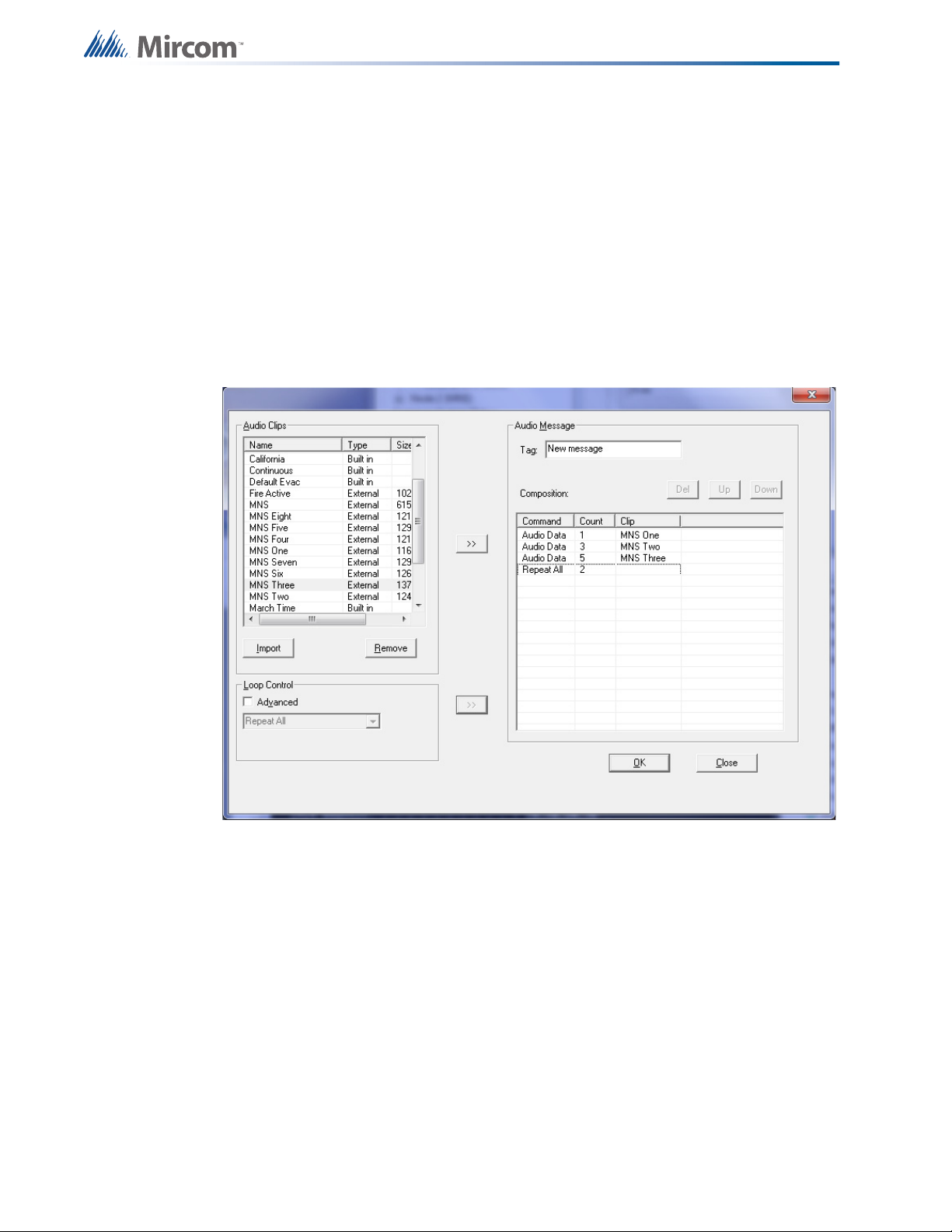

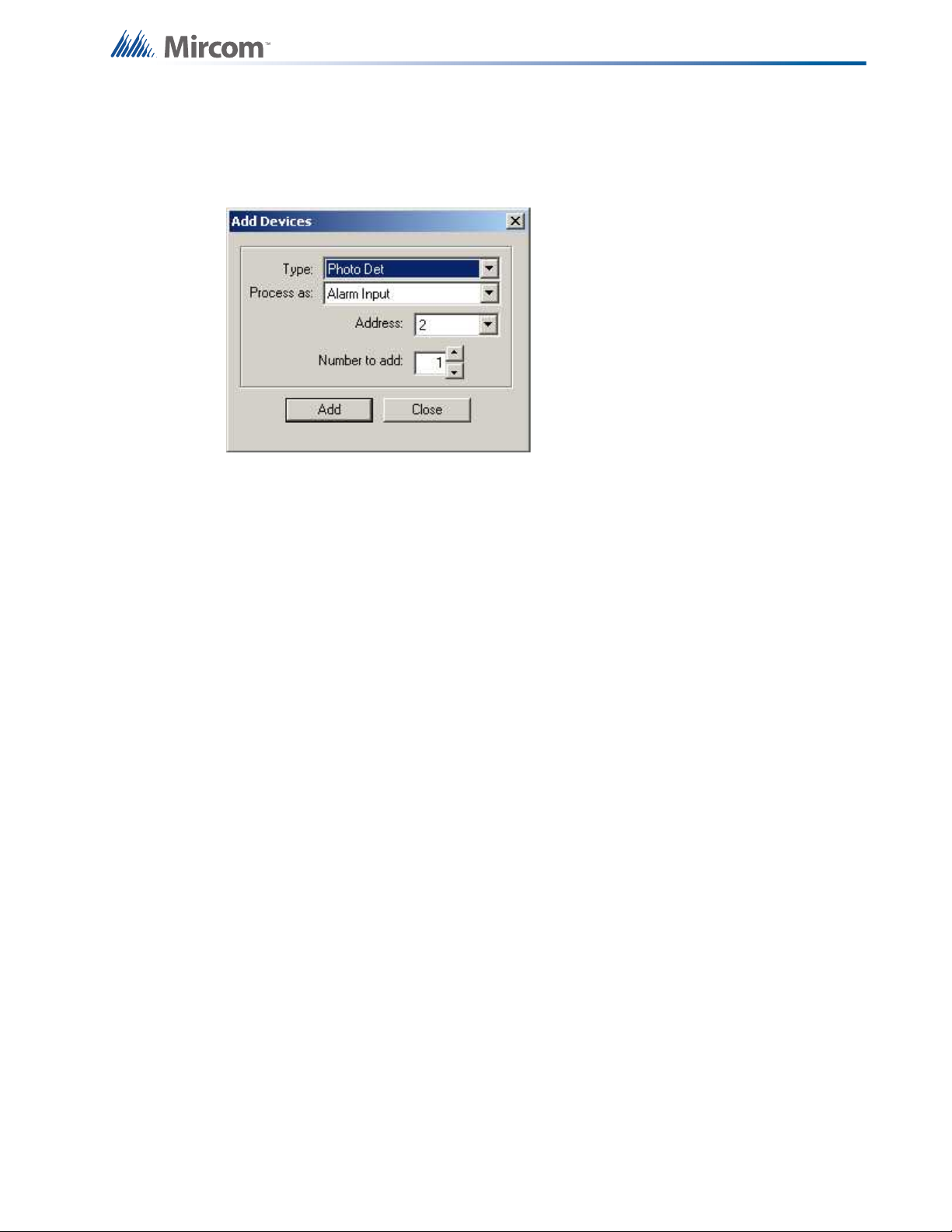

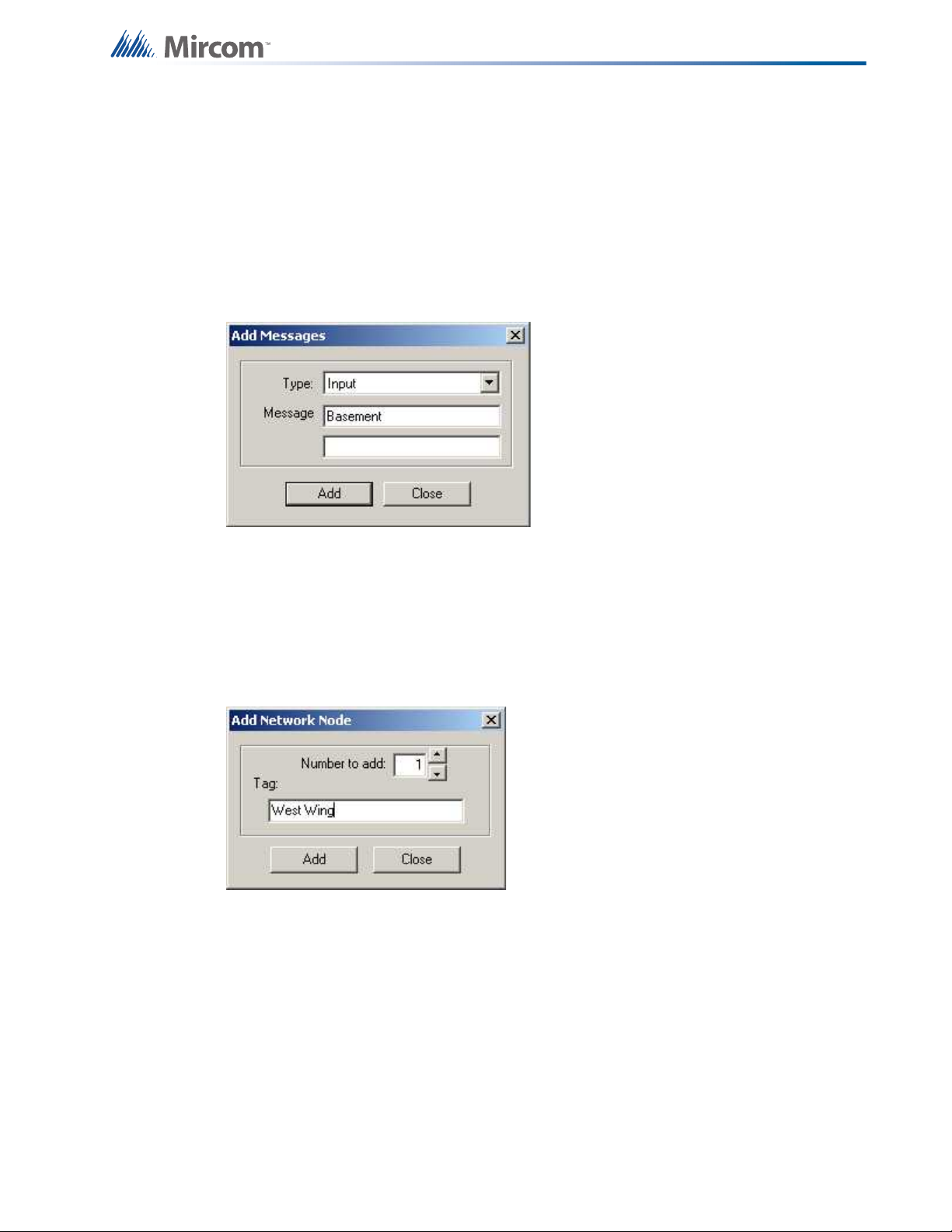

8.0 Digital Messages

Digital messages can be created in the Job Details section of the configurator. To create a

digital message go to the Audio section of the Job Details window and press the Set Up

button. The Audio Setup window appears. In this window press the Manage Messages button.

The Manage Messages menu lists each of the digital messages that can be used for the job

being configured. A new digital message can be created and added to the list using the Add

button. An existing digital message can be modified by selecting it and pressing the Edit

button. A digital message can be deleted from the list by pressing the remove button.

In the Manage Messages window press the Add button or select a message to edit then press

the Edit button. Refer to the figure below.

Digital Messages

30

In the new window either press the Import button and select an audio file to include in the

message or select an audio clip from the files already imported into the Audio Clips menu. All

audio files must be in .wav format. The .wav format must be sampled at 11.025 KHz, 16-bit

mono, ADPCM 4-bit. This format is suited for compressing voice. Alternatively, PCM (RAW) 16-

bit mono can be used for non-voice messages such as a whoop signal or sweep. A program

called Audacity is able to convert most audio file formats into the required .wav format. The

software is freeware and can be downloaded from http://audacity.sourceforge.net/.

Once an audio clip has been imported into the Audio Clips list it can be used to compose a

message. A message can be composed out of a single or out of multiple audio files. Select the

audio clip and move it over to the Composition list by pressing the dual chevron button beside

the Audio Clips list. The audio files in the Composition list can be reordered by selecting them

in the list and pressing the Up and Down buttons. The audio clips can be removed from the

Composition list by selecting them and pressing the Del button. An audio clip can also be set

to repeat a certain number of times, to do this double-click on the count column beside the

audio clip in the Composition list and enter the number of times to repeat it. The entire

Page 31

Digital Messages

composition can also be set to repeat by pressing the dual chevron button beside the Loop

Control menu.

More advanced methods of ordering audio files in a composition exist. Check the Advanced

option under Loop Control to enable it. With Advanced mode selected the Loop Control drop

down now has 4 loop levels that can be applied to audio clips in a nested loop format. The

Advanced mode also adds the Seq and Loop Base columns to the Composition window on the

right.

The inner most loop command is the highest loop level used in the composition. As audio clips

and loop commands are added to the composition they are given a sequence number in the

Seq column starting from 0. Loop commands are applied to audio clips above them starting

from the sequence number specified in the Loop Base column. Loop commands that are at an

outer level compared to the inner most used loop are applied to the entire composition above

that contains inner level loops. Loop levels and audio clips can be reorganized in the

composition window using the Up and Down buttons. They can be removed using the Del

button. Enter a name for the audio message in the Tag field and press OK to finalize the

composition, add it to the list of messages and to exit the menu. Refer to the figure below

where the entire composition is repeated once more.

31

Page 32

9.0 Relay Pulsing

Relay pulsing may be required for various setups where a relay will turn ON (close) and then

OFF (open) after a single switch press. An example of relay pulsing is to activate a prerecorded digital message using the first pulse and then to deactivate the message with the

second pulse, simulating a maintained switch.

9.1 Relay Pulsing Sequence

The sequence is initiated by either a switch or input circuit changing to an active state. The

changing of state from standby to active satisfies the first condition resulting in an input zone

tagged “Latch A” to become active and maintain its state. Maintaining the state or latching is

performed through advanced logic. See 10.0 Zone Latching.

Once “Latch A” is active, a timer called “Latch A Timer” is started. The timer is used to turn ON

the output relay once it starts running. Once the timer expires, the output relay will turn OFF.

Therefore, the timer is usually set for a short period of time in order to simulate a pulse such as

3 seconds.

Relay Pulsing

The second pulse is generated by the second press or the input circuit changing state to

inactive standby. This will satisfy the second condition and activate “Latch B”. “Latch B” will

start a second timer called “Latch B timer” in a similar manner as before. This will pulse the

relay for the second time.

9.2 Producing a Relay Pulsing Sequence

1. Create a monitor input zone. This zone will be activated based on the status of the

switch or input circuit. It will also be referenced in the advanced logic equations for both

latching zones. Tag the zone appropriately such as “Input Switch”

2. Create two (2) timers; Latch A timer and Latch B timer. Specify a time in seconds, for

example 3 seconds. Tag each timer appropriately

3. Create another monitor input zone. This zone will be “Latch A”. Highlight the zone and

select the advanced logic tab. Create an equation as shown:

01-00-**-IZ-007 OR (01-00-**-IZ-011 AND NOT **-**-**-TM-021 EQU TIMER_EXPIRED)

Where,

01-00-**-IZ-007 – Input Switch Zone

01-00-**-IZ-011 – Latch A Zone

**-**-**-TM-021 – Latch B Timer

Note – Latch B timer is referenced in the equation in order to un-latch the zone during

the second pulse

32

4. Create another monitor input zone. This zone will be “Latch A”. Highlight the zone and

select the advanced logic tab. Create an equation as shown:

**-**-**-TM-020 EQU TIMER_EXPIRED AND (NOT 01-00-**-IZ-007 OR 01-00-**-IZ-

012)

Where,

**-**-**-TM-020 – Latch A Timer

Page 33

Relay Pulsing

01-00-**-IZ-007 – Input Switch Zone

01-00-**-IZ-012 – Latch B Zone

5. Highlight Latch A Timer and click the edit button for Advanced Logic. Select the Latch A

Zone. This will start the timer once the Latch A Zone becomes active.

6. Highlight Latch B Timer and click the edit button for Advanced Logic. Select the Latch B

Zone. This will start the timer once the Latch B Zone becomes active.

7. Highlight the output relay and select the Advanced Logic tab. Create an equation that will

be true if either Latch A Timer or Latch B Timer is running.

**-**-**-TM-020 EQU TIMER_RUNNING OR **-**-**-TM-021 EQU TIMER_RUNNING

Where,

**-**-**-TM-020 – Latch A Timer

**-**-**-TM-021 – Latch B Timer

8. Correlate the input ckt or switch to the monitor zone “Input Switch”. If multiple switches

are to be used, an equation can be added to the monitor zone to reduce interference

between switches. Refer to the example below:

01-00-00-IN-008 AND NOT ANY 1 OF ( 01-00-**-IZ-007 , 01-00-**-IZ-009 , 01-00-**-IZ010 )

Where,

01-00-00-IN-008 – Input ckt 1

01-00-**-IZ-007 – Input Switch 2

01-00-**-IZ-009 – Input Switch 3

01-00-**-IZ-010 – Input Switch 4|

This equation is optional however this will reduce interference between switches. For

example, if the first switch is pressed generating the first pulse and then, while switch 1

is maintained, switch 2 is pressed. This could cause issues if the pulses were turning

ON/OFF digital messages as the first message would be overridden

33

Page 34

10.0 Zone Latching

Zone latching is a useful technique that can be applied to latch normally non-latching zones

such as monitor, trouble, and non-latching supervisory zones. Latching zones can be used to

maintain outputs or timers even if the original input is no longer active.

An example of when a latching zone is used would be to add a strobe delay for a period of

time after a page has occurred. The input being the page active status would initially activate a

zone. This zone is correlated to the output strobes that would activate with the activation of the

zone. However, the zone would need to remain active once the page active status is

deactivated therefore latching the zone is required. A timer can also be used to unlatch the

zone upon expiring.

10.1 Zone Latching Sequence

The basic sequence involves an initiating device, status, or zone and the zone used to latch

itself. The “latching zone” must have multiple methods of becoming active, either by the

activation of the initiating device/status/zone or by the “latching zone” itself. This is done

through advanced logic. Refer to the example below.

Zone Latching

The equation shown is specified in the advanced logic tab of the latching zone, 01-00-**-IZ011

01-00-00-IN-007 OR 01-00-**-IZ-011

01-00-00-IN-007 – Initiating device

01-00-**-IZ-011 – Latching Zone

Note: the latching zone is referenced in the advanced logic equation for the latching zone. This

allows the zone to latch itself.

Once the initiating device becomes active, the latching zone will become active as the

advanced logic equation would be satisfied. If the initiating device becomes de-active or is

restored, the latching zone will remain active as the equation would still be satisfied. Thus the

zone is latched. A system reset would be required to unlatch the zone similar to a normally

latching zone such as alarm.

By modifying the advanced logic equation with a timer, the latch can be set to unlatch upon the

expiration of the timer. For example,

01-00-00-IN-007 OR (01-00-**-IZ-011 AND NOT **-**-**-TM-021 EQU TIMER_EXPIRED)

The equation would remain satisfied as long as timer 21 does not expire. Upon expiration of

timer 21, and the initiating device is restored, the equation will no longer be satisfied and the

latching zone would be restored.

34

Page 35

10.2 Producing a Zone Latching Sequence

1. Create an initiating device. This can be a monitor zone, input circuit, or a status such as

All Call.

2. Create a non-latching zone such as a monitor zone. This will be used as the “Latching”

zone.

3. Highlight the “Latching” zone, and select the Advanced logic tab.

4. Create an equation that will activate the “Latching” zone by the initiating zone, input, or

status OR by the “Latching” zone itself.

Advanced Logic Equation shown for the “Latching” zone, 01-00-**-IZ-011

**-**-**-SW-017 OR 01-00-**-IZ-011

**-**-**-SW-017 – All Call Common switch

01-00-**-IZ-011 – Latching Zone

The Latching Zone, 01-00-**-IZ-011, will latch once the All Call switch is activated. If the

All Call is restored, the latch will remain latched until a system reset is initiated.

Zone Latching

35

Page 36

Autonomous Control Unit and Local Operating Consoles

11.0 Autonomous Control Unit and Local

Operating Consoles

The Flex-Net Mass Notification System (FX-MNS) interfaces with the user through the use of

the Autonomous Control Unit (ACU) or any one of multiple Flex-Net Local Operating Consoles

(FX-LOCs). Each FX-LOC is located remotely from the main FX-MNS panel allowing

messages to be sent from multiple locations in a building. The ACU and FX-LOCs are able to

monitor FX-MNS events and can broadcast announcements and pre-recorded digital

messages throughout a building.

Each FX-LOC contains switching and input module combination to broadcast pre-recorded

digital messages. The ACU contains a switch adder module to broadcast pre-recorded digital

messages. In addition to this each unit contains a paging module to broadcast

announcements and a display to monitor FX-MNS events.

11.1 Broadcast Priority

Broadcasting announcements or digital messages using an ACU overrides any broadcast

already in progress by an FX-LOC. Broadcasting announcements or digital messages using

an FX-LOC occurs on a first come first serve basis between the different FX-LOC terminals. If

one FX-LOC is being used to broadcast, another FX-LOC cannot be used until the first is no

longer in use. The following list identifies broadcast priorities from highest to lowest.

1. ACU announcement via paging microphone

2. ACU highest priority digital messages (priority is set on a software level)

3. ACU lowest priority digital messages (priority is set on a software level)

4. FX-LOC announcement via paging microphone

5. FX-LOC highest priority digital messages (priority is set on a software level)

6. FX-LOC lowest priority digital messages (priority is set on a software level)

11.2 ACU and LOC Configuration

The paging microphone for the ACU connects directly to the main board through a ribbon

cable connection and is given priority over the FX-LOC paging microphones and all digital

messages on a firmware level.

The ACU broadcasts digital messages using an IPS switch adder module. Each button on the

switch adder module can be configured as a zone switch in the configurator. For each zone

switch a priority level can be assigned and a digital message can be attached. The switch

adder module takes precedence over the switching and input module combination used by the

FX-LOC. For example, a priority of 10% assigned to a zone switch on the IPS switch adder

module used by the ACU will have a higher priority than a priority of 90% assigned to a zone

correlated to the input module used by the FX-LOC. Refer to the figure below.

36

Page 37

Autonomous Control Unit and Local Operating Consoles

The paging microphones used by the FX-LOCs are hardwired to the board belonging to the

ACU paging microphone. Their hierarchy is configured on a firmware level to have lower

priority than the IPS switch adder module messages used by the ACU but a higher priority

than the FDS switching module messages used by the FX-LOC.

The FX-LOC broadcasts digital messages using an FDS switching module. Each switch on

this switching module is hardwired to inputs on an input module that are correlated to input

zones in the configuration. Each input is correlated to its own input zone with a digital

message attached to each zone. Priority for FX-LOC digital messages is set between the input

zones. For example, an input zone with an assigned priority of 70% will over ride an input zone

with an assigned priority of 50%. Refer to the figure below.

37

Page 38

11.3 ACU Operation

To broadcast a pre-recorded digital message press a button on the selector with the

appropriate message. Buttons should be labelled to indicate the content of the message that

will play. The message will be broadcasted and loop continuously until the system is reset or a

higher priority operation is performed.

To broadcast an announcement remove the paging microphone from its receiver and key the

microphone to activate the amplifiers. Speak into the microphone to broadcast the

announcement. The Page Ready LED will be on to indicate it is in use as soon as the

microphone is keyed. The ACU paging microphone has the highest priority and will override all

other operations upon activation.

11.4 LOC Operation

To broadcast a pre-recorded digital message select a switch with the appropriate message

and move it to the ON position. Switches should be labelled to indicate the message that they

will play. The message will be broadcasted and loop continuously until the system is reset or a

higher priority operation is performed.

Autonomous Control Unit and Local Operating Consoles

To broadcast an announcement remove the paging microphone from its receiver and key the

microphone to activate the amplifiers. Speak into the microphone to broadcast the

announcement. Only one microphone can be used at a time.

If the Page Ready LED is on before the microphone is removed from the receiver then another

microphone is in use. If the LED is off then there isn’t a microphone in use indicating that they

are all available. If the LED turns on only after the paging microphone is removed then that

microphone is now active.

38

Page 39

12.0 Firmware Loading

The following items are required in order to load the firmware onto a panel:

• PC with a serial port

• Serial Cable

• QX-5000N RS-232 Debug Tool

•HyperTerminal

Before loading a new firmware onto the panel ensure that the PC being used has

HyperTerminal installed. Firmware needs to be individually loaded onto each board that

contains a CPU: the main board, the audio card, the quad-loop adder and the RAXN-LCD.

Refer to Appendix A: Hardware Changes for information about changes in component

positions from Flex-net Phase I.

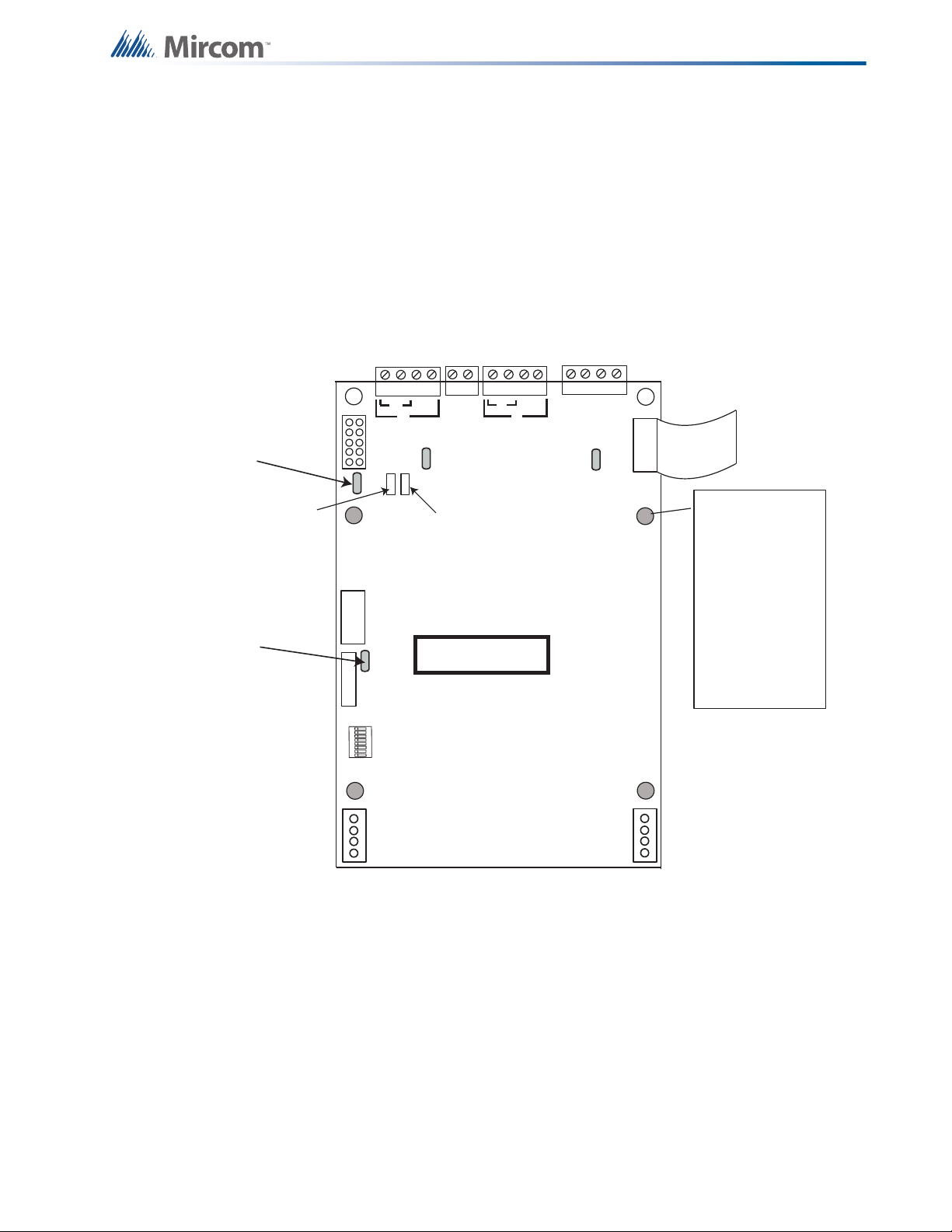

12.1 Main Board Firmware

1. Connect the serial cable from the PC directly to the main board.

Firmware Loading

2. Run the HyperTerminal software on the PC.

3. In the HyperTerminal start up prompt set the correct communications port and select a

baud rate of 115200.

4. Reset the processor on the main board by shorting the reset jumper. The jumper only

needs to be shorted momentarily, it should be normally open. During the reset process

press any key in HyperTerminal to enter the Flex-Net shell.

5. Input the following set of commands after the "flexnet>" prompt appears and press enter

after each one: "sf probe 1", "sf erase 0x200000 0x600000", and "run sflash".

6. Navigate to the HyperTerminal menu bar and select Transfer, then select Send File. A

Send File window appears.

7. Specify the location of the binary file that contains the new main board firmware by

entering the file path or by pressing the Browse button and searching for the file. Set the

Protocol to "Ymodem" and press Send.

8. When the "flexnet>" prompt reappears type in "reset" and press enter.

12.2 Audio Card Firmware

1. Connect the serial cable from the PC to the QX-5000N RS-232 Debug Tool and connect

the 8-pin head to the P4 RS-232 Debug port on the audio card. Ensure that the keyed

extrusion on the connector lines up with the one on the port.

2. Run the HyperTerminal software on the PC.

3. In the HyperTerminal start up prompt set the correct communications port and select a

baud rate of 115200.

4. Reset the processor on the audio card by shorting the reset jumper, JW4. The JW4

jumper is the closest one to the 8-pin port and only needs to be shorted momentarily, it

should be normally open. During the reset process press any key in HyperTerminal to

enter the Flex-Net shell.

5. Input the following set of commands after the "flexnet>" prompt appears and press enter

after each one: "sf probe 1", "sf erase 0x200000 0x600000", and "run sflash".

39

Page 40

6. Navigate to the HyperTerminal menu bar and select Transfer, then select Send File. A

Send File window appears.

7. Specify the location of the binary file that contains the new audio card firmware by

entering the file path or by pressing the Browse button and searching for the file. Set the

Protocol to "Ymodem" and press Send.

8. When the "flexnet>" prompt reappears type in "reset" and press enter.

12.3 Quad-Loop Adder Firmware

1. Connect the serial cable from the PC to the QX-5000N RS-232 Debug Tool and connect

the 8-pin head to the P5 RS-232 Debug port on the quad loop adder board. Ensure that

the keyed extrusion on the connecter lines up with the one on the port.

2. Run the HyperTerminal software on the PC.

3. In the HyperTerminal start up prompt set the correct communications port and select a

baud rate of 115200.

4. Reset the processor on the quad-loop adder by shorting the reset jumper JW1 on the

quad-loop adder main board. The jumper only needs to be shorted momentarily, it

should be normally open. During the reset process press any key in HyperTerminal to

enter the Flex-Net shell.

Firmware Loading

5. Input the following set of commands after the "flexnet>" prompt appears and press enter

after each one: "sf probe 1", "sf erase 0x200000 0x600000", and "run sflash".

6. Navigate to the HyperTerminal menu bar and select Transfer, then select Send File. A

Send File window appears.

7. Specify the location of the binary file that contains the new quad-loop adder firmware by

entering the file path or by pressing the Browse button and searching for the file. Set the

Protocol to "Ymodem" and press Send.

8. When the "flexnet>" prompt reappears type in "reset" and press enter.

12.4 RAXN-LCD and RAXN-LCDG Firmware

1. Connect the serial cable from the PC directly to the main board.

2. Run the HyperTerminal software on the PC.

3. In the HyperTerminal start up prompt set the correct communications port and select a

baud rate of 115200.

4. Reset the processor on the quad-loop adder by shorting the reset jumper JW1. The

jumper only needs to be shorted momentarily, it should be normally open. During the

reset process press any key in HyperTerminal to enter the Flex-Net shell.

5. Input the following set of commands after the "flexnet>" prompt appears and press enter

after each one: "sf probe 1", "sf erase 0x200000 0x600000", and "run sflash".

40

6. Navigate to the HyperTerminal menu bar and select Transfer, then select Send File. A

Send File window appears

7. Specify the location of the binary file that contains the new annunciator firmware by

entering the file path or by pressing the Browse button and searching for the file. Set the

Protocol to "Ymodem" and press Send.

8. When the "flexnet>" prompt reappears type in "reset" and press enter.

Page 41

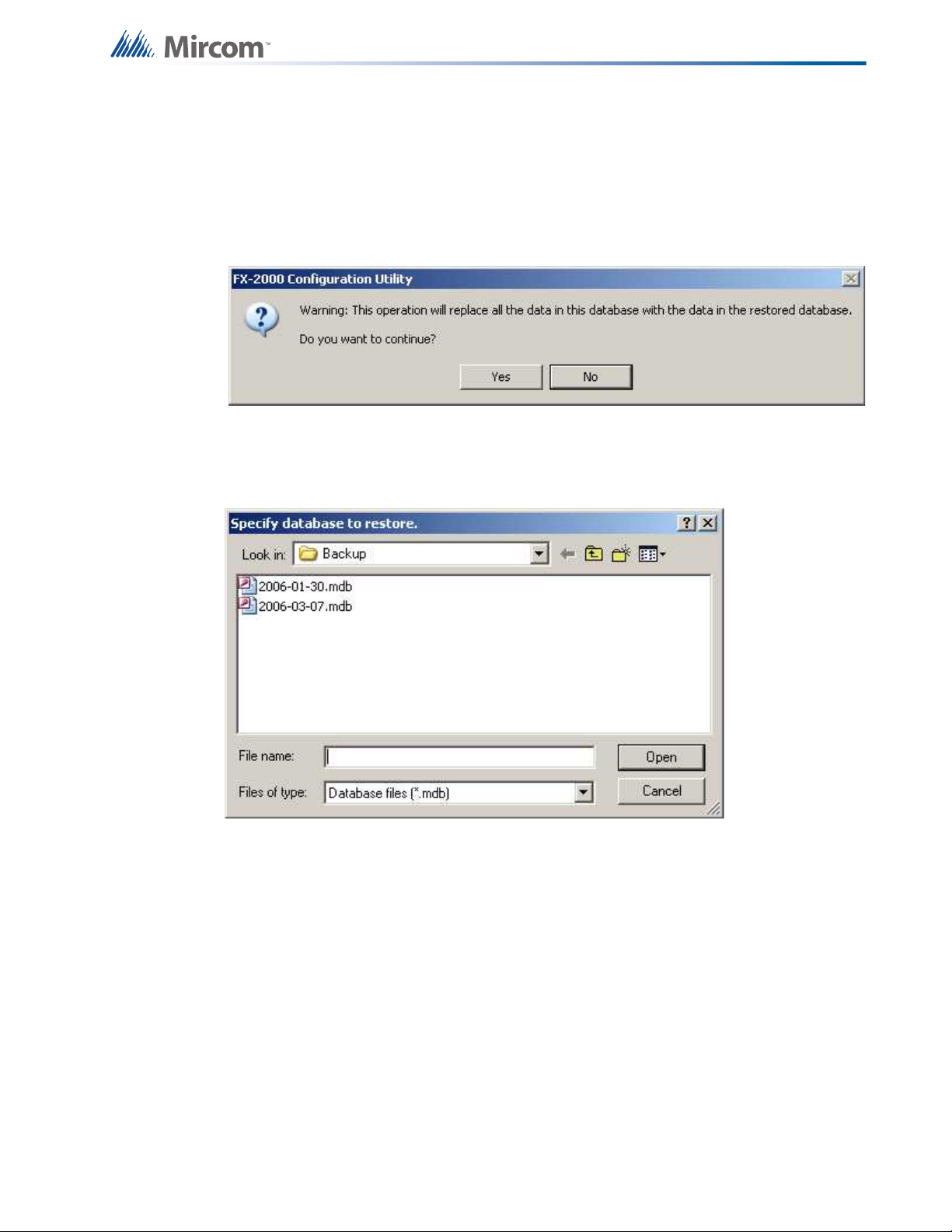

13.0 Configuration Loading

The following items are required in order to load a configuration onto a panel:

• PC with a serial or USB port

• Serial Cable or USB Cable

•UIMA Tool

• Registered CodeMeter Key

• FX-2000 Network Configuration Utility V11 or greater

Before loading a configuration job ensure that the PC being used has the FX-2000 Network

Configuration Utility software installed. Plug in the registered CodeMeter key to the PC and

start the Configuration Utility.

If an RS-232 cable is used in conjunction with a serial port to communicate between the panel

and the PC then the correct communications port needs to be set. To set the communications

port open the Network Configuration Utility and select File from the menu bar and select User

Preferences from the drop down menu. A new dialogue box appears. In the drop down box

labelled Serial Port select the port the RS-232 uses to connect to the PC. Press OK to confirm

the selection.

Configuration Loading

Connect the RS-232 cable or the USB cable to the UIMA then connect the 10-pin head of the

UIMA to the last CPU in the CPU chain that starts from the main board.

Establish a connection between the CPUs in the FACP and the PC. To do this press the

Connect icon in the task bar or navigate from the menu bar to Panel then select Connect from

the drop down menu. Once this connection has been established the configuration can be

loaded onto the panel. To load the active configuration onto the panel select the Send icon in

the task bar or navigate to the menu bar and select Panel then from the drop down menu

select Send Job. Specify which node to send the job to in the dialogue box that appears. Once

the job is verified and sent the software will prompt if you wish to make it the active job on the

panel. Each CPU on the panel can hold up to 3 jobs, if there are already 3 jobs on a CPU one

must first be removed to make room for the new one. To remove one of the 3 jobs stored on a

CPU use the configurator and select Panel from the menu bar. From the drop down menu

select Manage Jobs. Use the new dialogue box to delete one of the jobs.

If a job is not set as the active job from the configuration loading stage it can later be set to be

the active job using the interface on the FACP. To change the active job using the FACP

access the main display on any node or an annunciator for any node in the system. Press the

Menu button and scroll down using the arrow keys to the option titled "11 Choose Config".

Scroll through the available configurations using the arrow keys and confirm a selection by

pressing the Enter button. This will use change the configuration for all the nodes in the

system. To set configurations for individual nodes the Network Configuration Utility must be

used.

41

Page 42

14.0 Hardware Layouts

RAX-1048TZ

Programmable Zone

LED Annunciator Module

IPS-2424

Programmable Input

Switches Module

Display Modules

FDX-008

Fan Damper Module

Each of these Display Modules occupy one display

position and mount to the display cutouts on the

following chassis: