Page 1

Page 2

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

Safety Compliance Information

Safety Compliance

This equipment complies with:

- CSA C22.2 No. 60950-1-03 / Safety of Information Technology Equipment, Including Electrical Business Equipment.

- UL 60950-1 (1st Edition) / Safety of Information Technology Equipment, Including Electrical Business Equipment.

- IEC 60950-1 (1st Edition) Incorporating A1, A2, A3, A4, and A11/ Safety of Information Technology Equipment,

Including Electrical Business Equipment.

CAUTION

These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the operating instructions unless you are qualified to do so. Refer all

servicing to qualified service personnel. Servicing should be done in a static-free environment.

Electromagnetic Compatibility

- This equipment has been tested for verification of compliance with FCC Part 15, Subpart B, class A requirements for

Digital Devices.

- This equipment complies with the requirements of:

EN 55022 Class A, Electromagnetic Emissions,

EN 61000-3-2 & -3-3, Disturbance in Supply Systems

EN 61000-4-2, -3, -4, -5, -6, -8 & -11 Electromagnetic Immunity

CONTACT MIRANDA

For technical assistance, please contact the Miranda Technical support centre nearest you:

Americas

Telephone:

+1-800-224-7882

e-mail:

techsupp@miranda.com

Visit our web site at www.miranda.com

Asia

Telephone:

+81-3-5730-2987

e-mail:

asiatech@miranda.com

Europe, Middle East,

Africa, UK

Telephone:

+44 (0) 1491 820222

e-mail:

eurotech@miranda.com

France (only)

Telephone:

+33 (0) 1 55 86 87 88

e-mail:

francetech@miranda.com

i | UVP-101i

Page 3

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

Table of Contents

1 UVP-101i Universal Video Processor/Synchronizer...................................................1

1.1 Introduction...............................................................................................................................................1

1.2 Features ...................................................................................................................................................1

2 Installation .....................................................................................................................2

2.1 Unpacking.................................................................................................................................................2

2.2 UVP-101i Mechanical Installation.............................................................................................................2

2.2.1 Quartet-M Frame ...............................................................................................................................2

2.2.2 Symphonie Frame..............................................................................................................................2

2.2.3 Rear Panel Label...............................................................................................................................4

2.3 Signal Connections...................................................................................................................................5

2.3.1 Rear Panel Inputs and Outputs .........................................................................................................5

2.3.2 RJ-45 Connector................................................................................................................................6

2.3.3 Audio Bus Connector Layout.............................................................................................................6

2.4 Genlock ....................................................................................................................................................6

2.4.1 External Reference............................................................................................................................6

2.4.2 Analog Composite Video Input ..........................................................................................................7

2.4.3 Digital Video Input..............................................................................................................................7

2.5 Video Tracking Delay ...............................................................................................................................7

3 Operation .......................................................................................................................8

3.1 User Controls............................................................................................................................................8

3.1.1 LED Indicators ...................................................................................................................................8

3.1.2 Push Buttons ......................................................................................................................................9

3.1.3 Display ...............................................................................................................................................9

3.1.4 Parameter Adjustment using the Menu .............................................................................................9

3.1.5 Card Edge Menu Interface.................................................................................................................9

4 Description of Operating Functions ..........................................................................12

4.1 Video Input Selection [MENU: INP]......................................................................................................12

4.2 Composite Input Processing Functions [MENU: ICMP].......................................................................12

4.2.1 Input Format Detection [MENU: ICMP→FRMT]............................................................................12

4.2.2 Analog Video Source Types [MENU: ICMP→SRC] ......................................................................12

4.2.3 Composite Input Decoding Mode [MENU: ICMP→DECD]............................................................13

4.2.4 Composite Input Setup (NTSC only) [MENU: ICMP→SETP].........................................................13

4.3 Digital ProcAmp Functions [MENU: PROC]...........................................................................................13

4.3.1 Y Gain [MENU: PROC→Y]............................................................................................................13

4.3.2 Cb Gain [MENU: PROC→Cb].......................................................................................................13

4.3.3 Cr Gain [MENU: PROC→Cr].........................................................................................................13

4.3.4 Chroma Gain (saturation) [MENU: PROC→SAT]...........................................................................13

4.3.5 Overall Video Gain [MENU: PROC→ALL].....................................................................................13

4.3.6 Black Level [MENU: PROC→BLAK]..............................................................................................13

4.3.7 Hue Adjustments (NTSC/525 only) [MENU: PROC→HUE] ...........................................................14

4.3.8 Horizontal Position (COMP IN only) [MENU: PROC→HPOS] .......................................................14

4.4 Timing Adjustments [MENU: TIMG].....................................................................................................14

4.4.1 Timing mode [MENU: TIMG→MODE]............................................................................................14

4.4.2 Frame phasing [MENU: TIMG→FRAM] ........................................................................................14

4.4.3 Vertical phasing [MENU: TIMG→VERT] .......................................................................................14

4.4.4 Horizontal phasing [MENU: TIMG→HORZ]...................................................................................14

4.4.5 Horizontal Fine phasing [MENU: TIMG→FINE].............................................................................14

UVP-101i | ii

Page 4

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

4.5 Audio Processing Functions [MENU: ABUS→#1 and ABUS→#2].......................................................15

4.5.1 Audio De-Embedding [MENU: ABUS→#1 (or #2)→DMUX]..........................................................16

4.5.2 Audio Embedding [MENU: ABUS→#1 (or #2)→MUX]...................................................................16

4.5.3 VBIT Processing [MENU: ABUS→#1 (or #2)→VBIT].....................................................................16

4.6 Blanking Interval Processing [MENU: BLNK].......................................................................................16

4.6.1 Horizontal Interval Functions [MENU: BLNK→HANC] ..................................................................16

4.6.2 Vertical Interval Functions [MENU: BLNK→VANC].......................................................................16

4.7 Freeze Mode [MENU: FRZE] ...............................................................................................................16

4.7.1 Manual Freeze [MENU: FRZE→MAN] ..........................................................................................16

4.7.2 Automatic Freeze [MENU: FRZE→AUTO].....................................................................................17

4.8 Composite Video Outputs [MENU: COMP]..........................................................................................17

4.8.1 Setup Level [MENU: COMP→SETP] ............................................................................................17

4.8.2 Color Framing [MENU: COMP→CFRM]........................................................................................17

4.8.3 Horizontal Blanking/Edge Control [MENU: COMP→HBLK] ..........................................................18

4.8.4 Closed Captioning [MENU: COMP→CC] ......................................................................................18

4.8.5 Gain [MENU: COMP→GAIN].........................................................................................................18

4.9 Configurations [MENU: CONF] ............................................................................................................18

4.9.1 Load a Configuration [MENU: CONF→LOAD]..............................................................................18

4.9.2 Save a Configuration [MENU: CONF→SAVE]..............................................................................18

4.10 Factory Preset [MENU: FACT].............................................................................................................18

4.11 Other functions .......................................................................................................................................18

4.11.1 Test Patterns....................................................................................................................................18

4.11.2 EDH Detection and Reporting..........................................................................................................18

5 Specifications.............................................................................................................. 19

iii | UVP-101i

Page 5

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

1 UVP-101i Universal Video Processor/Synchronizer

1.1 Introduction

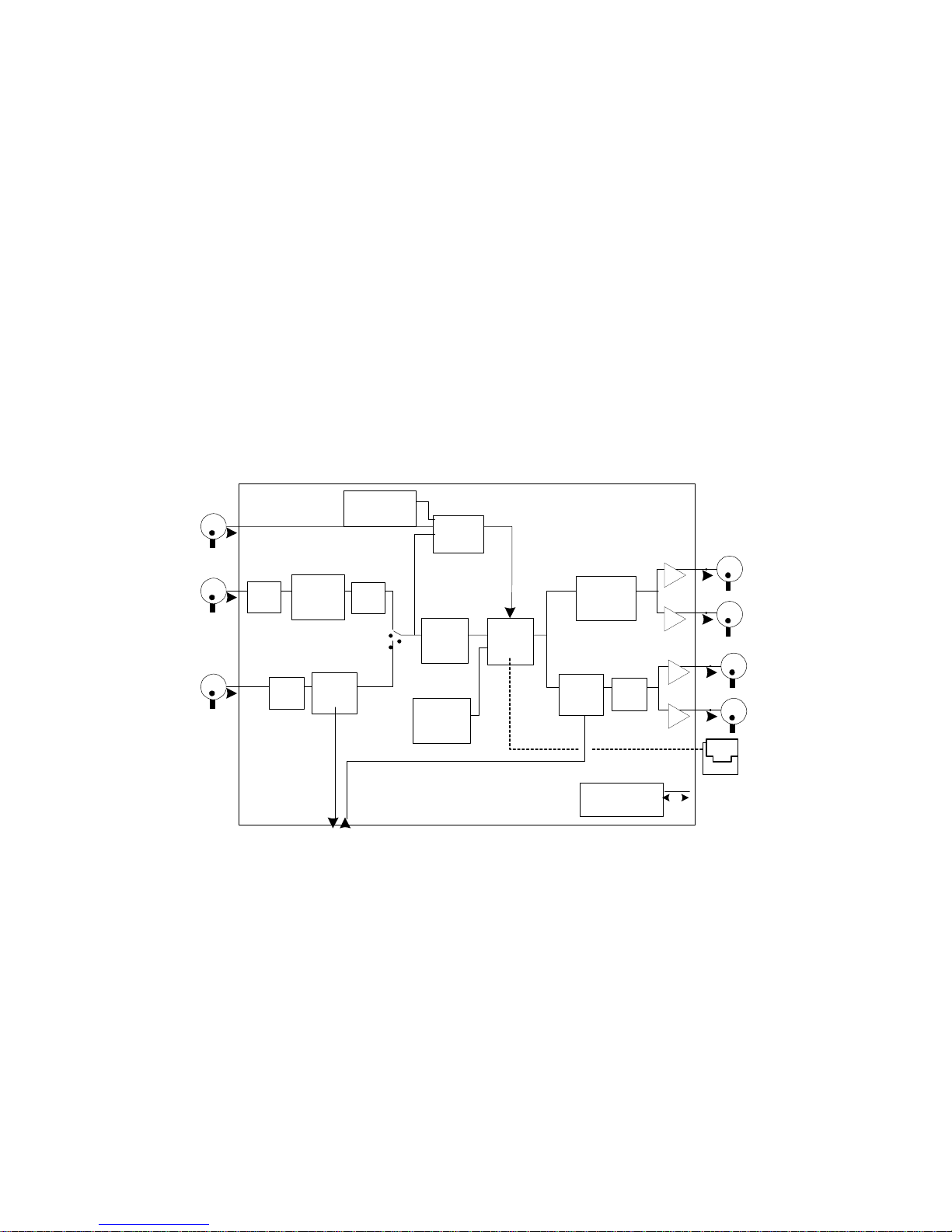

The UVP-101i is a universal video incoming feed processor supporting both digital and analog input

standards, 20-bit AES embedded audio handling and both digital and analog standards available at the

outputs. The analog input's adaptive decoder can handle a variety of decoding modes including Adaptive 2D,

Adaptive 3D and Super Adaptive. The built-in frame synchronizer can be used to lock remote feeds to a local

reference or to delay video signals by up to 4 frames. A built-in proc-amp provides a wide range of video

level and phase adjustments. The UVP-101i incorporates Automatic Gain Control (AGC) to handle the signal

amplitude instability typical of satellite sources, and Time Base Correction (TBC) to handle the timing

instability present on many feeds originating from video cassette (VCR). The UVP-101i is designed to work in

conjunction with the UAP-712i, the AAP-702i, or the DAP-712i audio processor. The UVP-101i can extract

embedded audio, pass it to the audio processor module for processing and re-embed the audio at the output.

A delay tracking output allows the audio processor to match the delay introduced by the UVP-101i. The

UVP-101i includes complete control of VANC allowing each line of the VANC to be passed, blanked or

processed. The UVP-101i’s flexible i/o and complete feature set make it ideal for in-studio and incoming feed

processing applications.

Digitally

Corrected

REF IN

Oscillator

Genlock

NTSC/PAL

IN

IN

AGC

3D

Adaptive

Decoder

Audio

EDH4:2:2

Demux

Digital Audio To/From

Audio Processor

TBC

Proc

Amp

Test

Generator

Frame

Sync

12Bit

Encoder

Audio

MUX

Microcontroller

Figure 1 UVP-101i Functional Block Diagram

1.2 Features

• 2D and 3D Adaptive decoder, including a Super Adaptive Decoding mode

• SDI and NTSC/PAL video input (selectable)

• SDI input can have up to 2 AES groups embedded

• Automatic 525/625 input format detection

• Reference input

• Built-in frame synchronizer

• Built-in TBC and AGC

• Digital proc-amp adjustments

• Flexible VANC/VBI processing

EDH

REMOTE

CONTROL

NTSC/PAL

OUT

4:2:2

OUT

Delay Out

GPI Out

UVP-101i | 1

Page 6

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

• 12-bit video signal processing and 20-bit audio embedding / de-embedding

• EDH monitoring and insertion

• SDI outputs with embedding of up to 2 AES groups (8 channels)

• Composite outputs

• True PAL decoding

2 Installation

2.1 Unpacking

Make sure the following items have been shipped with your UVP-101i. If any of the following items are

missing, contact your distributor or Miranda Technologies Inc.

• UVP-101i Universal Video Processor / Synchronizer

• Rear panel for frame

• Rear panel labels

• This manual

2.2 UVP-101i Mechanical Installation

The UVP-101i must be mounted within a Quartet-M or a Symphonie frame in order to provide power to the

module. The installation in a Symphonie frame also requires a Symphonie-R-M Rear Module. This section

describes how to install the UVP-101i in these frames. It is not necessary to switch off the power to these

frames when installing or removing the UVP-101i. Note: installation is also possible in Quartet, Quartet-C,

Solo, or Symphonie R-C frames, but the GPI / Delay connection will not be available in these cases. See

section 2.3.1 for more details.

2.2.1 Quartet-M Frame

To install this module into a Quartet-M frame follow these steps. For a closer look at module installation and

removal, refer to the Quartet Imaging Frame Guide to Installation and Operation.

1- Remove the frame’s front panel by rotating the thumb screws counter-clockwise. Pull on the handles.

2- Select an empty slot.

3- Carefully place the UVP-101i between a set of module guides and gently push the module towards the

rear of the frame until the module’s edge connector is secured to the backplane. Pull lightly on the

module, verifying that it does not move.

4- Replace the frame’s front panel. Make sure to rotate the thumb screws clockwise in order to secure it to

the chassis.

2.2.2 Symphonie Frame

Installing the Symphonie-R-M Rear Module

Before installing the UVP-101i module, you must first set and install the Symphonie-R-M Rear Module. To

install this module into the frame follow these steps. For a closer look at rear module installation and

removal, refer to the Symphonie Imaging Frame Guide to Installation and Operation.

2 | UVP-101i

Page 7

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

Rear module switch settings:

The switch locations on the Symphonie-R-M rear module are shown in Figure 2.1.

- The reference switch LK1 is used to select the reference source for the imaging module. Selecting local

(LK1 position 2-3) drives the reference signal, connected to the rear module, to the imaging module.

- The reference signal selected by LK1 must be terminated by selecting ON (switch LK2 to position 2-3).

Fig. 2.1 Symphonie-R-M Rear Module Switch Location

Rear module physical installation:

In order to maintain the inter-rear module spacing, make sure to remove and replace one rear module at a

time. That is, at all times, there must be at least 15 rear modules installed.

To install a module, follow these steps.

1. Locate an empty compartment.

2. Carefully place the rear module between the rear module guides and slowly push the module towards

the front until it rests against the rear panel. It may require a light pressure to compress the EMI gaskets

on both sides.

3. Using a flat-edge screwdriver, secure the top and bottom screws to the frame.

Installing the UVP-101i

To install this module into a Symphonie frame follow these steps. For a closer look at module installation

and removal, refer to the Symphonie imaging housing frame Guide to Installation and Operation.

1. Remove the front panel door by pulling on the door handles and gently lowering it.

2. Select the compartment corresponding to the previously installed Symphonie-R-M rear module.

3. Carefully place the module between the module guides and slowly push the module towards the rear of

the frame until the module’s edge connector is secured to the rear module. A light pressure to mate the

connectors may be required. Pull lightly on the module, verifying that it does not move.

4. Replace the front panel door.

UVP-101i | 3

Page 8

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

2.2.3 Rear Panel Label

Connector labels have been shipped with the UVP-101i. These labels are to be installed on the rear panel of

the Quartet-M or Symphonie frame in order to identify the module’s external connectors.

Quartet-M Frame

To install the label on a Quartet-M frame, follow these steps while referring to Figure 2.2.

Figure 2.2 Rear panel label installation on Quartet-M frame

1. On Quartet’s rear panel, locate the appropriate connectors and remove the screws.

2. Carefully apply the label to the connectors.

3. Replace the screws making sure not to damage the label.

Symphonie Frame

To install the label on a Symphonie frame, follow these steps while referring to Figure 2.3.

1. On Symphonie’s rear panel, locate the

appropriate connectors.

2. Remove the rear label mounting screws from the

rear module.

3. Carefully apply the label to the connectors

making sure the label’s text is read from top to

bottom (refer to the Module Label Orientation

sticker on each side of the rear module bay).

4. Replace the screws, making sure not to damage

the label.

Figure 2.3 Rear panel label

installation on a Symphonie frame

4 | UVP-101i

Page 9

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

REF IN

4:2:2 IN

COMP IN

REF IN

DELAY/GPI

4:2:2 IN

COMP IN

2.3 Signal Connections

2.3.1 Rear Panel Inputs and Outputs

The UVP-101i has eight connectors on the rear panel of the frame. Seven of these are common to all

installations. The other two differ according to the installation, as shown in the following figures and table.

UVP-101i UNIVERSAL VIDEO PROCESSOR / SYNCHRONIZER

Delay

GPI

4:2:2 IN

COMP IN

1

4:2:2 OUT

2

1

COMP OUT

Figure 2.4 (a) UVP-101i rear connectors (Symphonie R-M, Quartet-M)

UVP-101i Back (Symphonie-R-M, Quartet-M)

UVP-101i UNIVERSAL VIDEO PROCESSOR / SYNCHRONIZER

4:2:2 IN

COMP IN

1

4:2:2 OUT

2

COMP OUT

Figure 2.4 (b) UVP-101i rear connectors (Symphonie R-C, Quartet, Quartet-C, Solo))

UVP-101i Back (Symphonie-R-C, Quartet-C, Quartet, Solo)

Table 2.1 Rear panel connections

CONNECTOR CONFIG SIGNAL

REF IN All SMPTE 170M/PAL ITU 624-4 or

2 Vp-p/ 4 Vp-p Composite Sync

REF IN Note 1 Reference loop-through

COMP IN All Composite (NTSC or PAL) input

4:2:2 IN All 4:2:2 per SMPTE 259M-C (270 Mbps) input

2

1

2

4:2:2 OUT 1

All 4:2:2 per SMPTE 259M-C (270 Mbps) output

4:2:2 OUT 2

COMP OUT 1

All Composite (NTSC or PAL) output

COMP OUT 2

DELAY / GPI Note 2 Delay: Video tracking delay (see sect. 2.5)

Note 1: Quartet, Quartet C and Solo frames, and the Symphonie frame with the R-C rear module,

do not include an RJ-45 connector on the rear panel. Instead, they provide an eighth BNC

connector. That connector is used for a Reference loop-through when the UVP-101i is

installed. See figure 2.4 (b).

Note 2: The Quartet-M frame, and the Symphonie frame with the R-M rear module, provide 7 BNC

connectors and an RJ-45 connector on the rear panel. In this configuration, the RJ-45 is

used for Delay and GPI outputs, and there is no reference loop-through. See figure 2.4 (a).

(the same signal appears on both connectors)

(the same signal appears on both connectors)

GPI: A single GPI contact closure on pin 2, triggered by a

manual or automatic FREEZE (see section 4.7)

UVP-101i | 5

Page 10

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

2.3.2 RJ-45 Connector

The pinout of the RJ-45 connector on the rear panel is shown in figure 2.5.

Pin Signal Pin Signal

1 GND 6 Not connected (NC)

2 GPI Error 7 NC

3 GND 8 NC

4 Tracking delay (+) 9 NC

5 Tracking delay (-) 10 NC

Figure 2.5 RJ-45 connector pinout

2.3.3 Audio Bus Connector Layout

Figure 2-1

The UVP-101i incorporates two audio bus connectors, located on the front card edge (see figure 3.1). These

interconnect with outboard audio processors, which must be located in the same frame. The pin-out on the

HE-10 connectors is shown in table 2.2:

Table 2.2 Audio bus connector pin-out

Contact Signal

Type Description

1 GND - Ground

2 AES1 Output Audio signal (bi-phase mark)

3 AES2 Output Audio signal (bi-phase mark)

4 AUDIO DATA1 IN Input Audio data (not bi-phase mark)

5 AUDIO DATA2 IN Input Audio data (not bi-phase mark)

6 DATA clock Input Audio clock (3.072 MHz)

7 FRAME clock Input Frame clock at 48 KHz for L & R audio data

8 Tracking Output Video Processing Delay

9 27 MHz Output Output clock from UAP-101i to synchronize the audio

10 GND - Ground

2.4 Genlock

The UVP-101i can lock its output timing to one of four sources: the external reference, the analog composite

video input, the digital video input or an internal digitally-corrected oscillator. The source used to lock the

UVP-101i depends on the presence of a reference, the analog input, the digital input and the source type

(Satellite, Studio or VCR; see section 4.2.2).

2.4.1 External Reference

The external reference is usually a black burst composite signal or any composite video signal with burst

according to SMPTE-170M or ITU-624-4. It may also be any analog composite video signals (non-black

signal).

6 | UVP-101i

Page 11

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

The UVP-101i detects the line format of the reference. A valid analog composite reference signal will turn on

the REF indicator located on the module’s front end. The reference signal must be NTSC for 60 Hz sources

(NTSC, 525) and PAL for 50 Hz sources (PAL, 625). If there exists a line format mismatch between the

reference input and the composite input, the REF indicator flashes, but the output format is forced to black

and set according to the reference.

When the external reference is present, the digital or the analog input can be asynchronous and will be

frame synchronized with the reference.

2.4.2 Analog Composite Video Input

When the reference is not present and the analog video input is selected, the UVP-101i locks its timing

according to the analog composite video input. The input video can be any composite video signal (SMTPE170M or ITU-624-4) or a B&W composite sync (no burst).

2.4.3 Digital Video Input

When the reference is not present and the digital video input is selected, the UVP-101i locks its timing

according to the digital video input.

2.5 Video Tracking Delay

The video tracking delay is a signal that specifies the current processing delay of the card. It indicates to the

audio processor card the amount of delay that must be added in the audio path to compensate for the video

processing delay and frame sync function to avoid lip sync problems. The signal value is calculated by the

UVP-101i, and is not user-adjustable.

The video tracking delay signal is sent from the UVP-101i to external audio processors via the two ABUS

connectors. A differential signal using the RS-422A transport protocol is also available on the RJ-45

connector on the back of the frame (see sect. 2.3.2). Detailed specifications for this signal are available in

Miranda’s “Video Processing Delay Signal” document number 212-02S00-110.

UVP-101i | 7

Page 12

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

3 Operation

3.1 User Controls

Figure 3.1 below shows the card-edge user interface.

FRONT-TOP VIEW

Red

Green

Yellow

Black

ESC

Display

FREEZE

TEST

+

-

SELECT

1 3

2 4

AUDIO IN

DETECTED

ABUS #2

ABUS #1

525

625

REF

ERR

B&W

EDH

INPUT

UVP-101i UNIVERSAL VIDEO PROCESSOR/SYNCHRONIZER

UVP-101i

Figure 3.1 Card-edge user interface

3.1.1 LED Indicators

The 525/625 LEDs (green) indicate the line format of the selected input video. When the digital input is

selected, the display will indicate “525” or “625”. When the analog input is displayed, the LEDs still indicate

the line format, but the display also indicates the current composite format (NTSC or PAL).

The REF LED (green) turns on to indicate a valid composite signal has been detected on the REF IN BNC.

It will remain off if no reference signal is installed. If there is a line format mismatch between the reference

input and the selected video source, the REF LED flashes, but the output format follows the reference format

and is forced to black.

The input ERR (error) LED (red) will turn on if there is an error at the selected input or if the signal cannot be

locked. Also, if a standard is forced, for example, NTSC and the input signal detected is other than a NTSC

signal, the ERR LED will indicate an error. NOTE: in some cases, when the card is set to VCR mode (see

sect. 4.2.2) and forced standard, an incorrect input format will not be detected and the ERR LED will not

illuminate.

The EDH LED (red) turns on whenever an incoming EDH flag is detected.

The B&W LED (green) turns on when the analog video input is a monochrome signal (no subcarrier).

The TEST LED (yellow) will turn on whenever the internal test pattern is activated.

The FREEZE LED (yellow) will turn on whenever the manual freeze is enabled. It will also blink when the

card executes an automatic freeze in response to a loss of input or continuous input errors.

8 | UVP-101i

Page 13

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

3.1.2 Push Buttons

The following functions are accessible from the card-edge-mounted push buttons:

TEST Enables and Disables the internal test signal on both analog and digital outputs. Toggles

between 100% white bar and 75% Color Bars, black, and normal mode. When it is activated,

the EDH error codes (flags) are blanked as well as the HANC and VANC intervals on the

input side.

FREEZE Enables and Disables the manual freeze mode (see section 4.7.1).

The TEST and FREEZE LEDs will turn on when the indicated function is selected.

3.1.3 Display

The functionality of the four-character card-edge display is as follows:

• In Normal operating mode, it shows the currently-selected input format, and the display is dimmed.

• In Menu Adjustment mode, the display shows the current menu selection, and the display is at full

brightness.

3.1.4 Parameter Adjustment using the Menu

Most UVP-101i parameters are accessed and changed via an easy-to-use menu. The menu tree of figure 3.2

outlines the entire UVP-101i menu path. Each item in the menu is discussed in detail in sections 4.1 to 4.10.

Navigating Through the Menu

The front panel push-buttons are used to navigate the menu of Figure 3.2. The following describes the

function of each push-button when navigating through the menu.

To access the menu, the user must first press the SELECT push-button. Once in the menu, the four pushbuttons have the following functionality:

+: Press + to move down in the menu or to increase the parameter value. Holding down + during

an adjustment will increase the parameter value at a faster rate.

-: Press - to move up in the menu or to decrease the parameter value. Holding down - during an

adjustment will decrease the parameter value at a faster rate.

SELECT: Use SELECT to move to the right in the menu. Once you have moved to a parameter which

has a set of associated values, press SELECT to display the current value. After choosing a

new value using the + and – buttons, push SELECT. The new value is stored immediately in

non-volatile memory, and the display once again shows the parameter name.

ESC: Use ESC to move to the left in the menu. If ESC is pressed after making changes to a

parameter, the parameter is reset to the value it had prior to the change (but not if SELECT

was pressed). For example, after changing the brightness, press ESC. The menu is returned

to BRI and the previous brightness value is reloaded.

Automatic Exit From Menu After 1-Minute Interval

If the menu is currently being accessed and no push button has been pressed for 1 minute, the UVP-101i

automatically exits from the menu, and returns to normal mode. When this happens, changes made to the

current parameter will be stored.

3.1.5 Card Edge Menu Interface

The chart on the following two pages shows a detailed menu tree for the UVP-101i.

UVP-101i | 9

Page 14

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

Forced to 2 FLD when no REF IN

SEL SEL

SEL SEL SEL SEL

SEL

Figure 3.2 UVP-101i Menu Tree

DISPLAY VALUES NOTES

INP [ANA, SDI]

ICMP FRMT [AUTO, NTSC, PAL, B&W5, B&W6]

SRC [SAT, STUD, VCR]

(INP = ANA only)

DECD [SADP, A-3D, A-2D] (SRC = STUD or SAT only)

SEL

SETP [-10, ..., -0.1, 0, 0.1, .., 7.5, …, 10] IRE (NTSC only)

SEL

PROC Y [-800, …, -1, 0, 1, …, 800]

Cb [-800, …, -1, 0, 1, …, 800]

Cr [-800, …, -1, 0, 1, …, 800]

SAT [-800, …, -1, 0, 1, …, 800]

ALL [-800, …, -1, 0, 1, …, 800]

BLAK [-100, …, -1, 0, 1, …, 100]

HUE [-180, …, -1, 0, 1, …, 180] DEG (NTSC/525 only)

HPOS [-7, …, -0.5, 0, 0.5, …, 7] PIX (Analog input only)

SEL

SEL

SEL

TIMG MODE [4FLD, 2FLD]

FRAM [NOM, +1, +2, +3] FRM (with REF IN) (MODE = 2FLD only)

VERT [0, 1, …, 524] LINE (NTSC/525)

SEL

SEL

SEL

Analog NTSC input only

[0, 1, …, 624] LINE (PAL/625)

HORZ [0, 0.04, ..., 63.5] us (NTSC/525)

SEL

[0, 0.04, ..., 64.0] us (PAL/625)

FINE [-40, …, -1, 0, 1, …, +40] with REF IN only

SEL

ABUS #1 DMUX [OFF, GRP1, GRP2, GRP3, GRP4]

MUX [OFF, GRP1, GRP2, GRP3, GRP4]

VBIT [MUTE, PASS]

SEL

SEL

SEL

(1) (INP = SDI only)

#2 DMUX [OFF, GRP1, GRP2, GRP3, GRP4]

MUX [OFF, GRP1, GRP2, GRP3, GRP4]

VBIT [MUTE, PASS]

SEL

SEL

SEL

(1) (INP = SDI only)

BLNK HANC [PASS, BLNK]

VANC [PASS, BLNK, PROC, DECD, USER] (Analog input)

SEL

SEL

[PASS, BLNK, PROC, USER] (SDI input)

(continued)

10 | UVP-101i

Page 15

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

SEL SEL

SEL SEL SEL SEL SEL

DISPLAY VALUES NOTES

FRZE MAN [FLD1, FLD2, FRM]

AUTO [OFF, FLD, BLAK, BLK3] (not available with SRC = VCR or no REF IN)

COMP SETP [0, 7.5] IRE (NTSC/525 only)

(output)

SEL

CFRM [NEAR, +1] FRM (NTSC/525)

[NEAR, +1, +2, +3] FRM (PAL/625)

HBLK [NAR, WIDE]

CC [OFF, ON] (NTSC/525 only)

GAIN [-100,…,-1, 0, +1, …+100]]

CONF LOAD [USR1, USR2, USR3, USR4, USR5]

SAVE [USR1, USR2, USR3, USR4, USR5]

SEL

FACT [NO, YES]

SEL

(1): If the user does not use a UAP-712i or a DAP-712I, the audio mux and demux selection should be set to OFF for proper operation.

Underlined values are factory reset values. All parameters will be reset to these values when YES is selected

in the FACT menu.

UVP-101i | 11

Page 16

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

4 Description of Operating Functions

The operating functions of the UVP-101i are described in the following paragraphs. In all cases reference is

made to the location in the menu where the described function can be controlled. The functions are

presented in the order of their appearance in the menu tree.

4.1 Video Input Selection [MENU: INP]

The UVP-101i supports two types of video input: composite analog (ANA) and serial digital (SDI). Since both

types of video input can be present and valid at the same time, a manual selection (via the menu or remote

control) allows the user to select the desired input.

Format detection for the incoming SDI signal is automatic, and no user controls are provided. There are a

number of options available to the user for the analog input; these are found in the ICMP menu (section 4.2).

4.2 Composite Input Processing Functions [MENU: ICMP]

Several processing options are available for the composite analog input, as follows:

4.2.1 Input Format Detection [MENU: ICMP→FRMT]

The UVP-101i supports two modes of analog input format detection: automatic and forced. These modes can

be set at the card edge or by remote control.

Automatic Format Detection

The analog input module is able to automatically detect the input format (NTSC or PAL) and report it (card

edge LED and remote control). It also detects black and white signals (B&W) and configures the decoder

accordingly. When B&W signals are detected, the card-edge B&W LED will turn ON. Select AUTO to enable

the automatic format detection mode.

Forced Input Format Selection

This mode allows the user to select one of the supported input formats. The available options are NTSC,

PAL, B&W5 (525-line monochrome) and B&W6 (625-line monochrome). While in this mode of operation, the

UVP-101i remains configured for that format at all times regardless of the actual input signal’s format. If the

input signal’s format does not match the forced selection, the ERR LED will turn on. NOTE: in VCR mode, a

format mismatch is not always detected.

4.2.2 Analog Video Source Types [MENU: ICMP→SRC]

To simplify the controls for the users when the analog video input is used, the UVP-101i is pre-programmed

for 3 operational modes corresponding to the the most common source types. The STUDIO source type is

used for high quality sources, SATELLITE for satellite sources, and VCR for unstable sources.

Selecting a source type affects the Automatic Gain Control (AGC), the Time Base Correction (TBC) and the

output phasing adjustments, as follows:

Satellite

In this mode, the TBC is OFF and the AGC is ON. If there is a valid external reference, the output phasing

(V, H and fine H) is set with respect to the reference timing. If there is no reference, the output is free

running with respect to the input and there are no output phasing adjustments.

The automatic gain control accepts a –10 dB to +3 dB input level on the analog input based on 75%

modulation. The AGC is based on the sync level and affects the overall gain.

12 | UVP-101i

Page 17

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

Studio

In this mode, the TBC is OFF and the AGC is OFF. If there is a valid external reference, the output phasing

(V, H and fine H) is set with respect to the reference timing. If there is no reference, the output phasing is

set with respect to the analog video input (frame buffer mode).

VCR

In this mode, the TBC is ON and the AGC is OFF. If there is a valid external reference, the output phasing

(V, H and fine H) is set with respect to the reference timing. If there is no reference, the output is free

running with respect to the input and there is no output phasing adjustment. NOTE: in this mode,

mismatches between a forced input standard and the actual input are not always detected and flagged,

due to the TBC’s acceptance of a wide range of unstable sources.

4.2.3 Composite Input Decoding Mode [MENU: ICMP→DECD]

The UVP-101i offers the following decoding modes for the active picture:

• 2D adaptive (bandsplit/line based)

• 3D adaptive (bandsplit/field/frame based)

• Super Adaptive (smoothly adapts between all modes on a pixel by pixel basis)

4.2.4 Composite Input Setup (NTSC only) [MENU: ICMP→SETP]

The UVP-101i handles a wide range of setup levels on the composite input (from –10 IRE to +10 IRE). In the

user interface, the setup level is expressed in IRE for NTSC sources. PAL inputs are assumed to have 0 mV

input setup, and no selection is provided.

4.3 Digital ProcAmp Functions [MENU: PROC]

The functions described below apply to both the analog and digital video inputs.

4.3.1 Y Gain [MENU: PROC→Y]

Range from –800 to +800. Unity gain at 0. Multiply by 2 gain at +800. Zero gain at –800.

4.3.2 Cb Gain [MENU: PROC→Cb]

Range from –800 to +800. Unity gain at 0. Multiply by 2 gain at +800. Zero gain at –800.

4.3.3 Cr Gain [MENU: PROC→Cr]

Range from –800 to +800. Unity gain at 0. Multiply by 2 gain at +800. Zero gain at –800.

4.3.4 Chroma Gain (saturation) [MENU: PROC→SAT]

The chroma gain applies to the Cb and Cr gains at the same time. Range from –800 to +800. Unity gain at 0.

Multiply by 2 gain at +800. Zero gain at –800.

4.3.5 Overall Video Gain [MENU: PROC→ALL]

The overall gain applies to the Y, Cb and Cr gains at the same time. Range from –800 to +800. Unity gain at

0. Multiply by 2 gain at +800. Zero gain at –800.

4.3.6 Black Level [MENU: PROC→BLAK]

The black level (Y only) may be changed within a range of –100 to +100 in the digital domain.

UVP-101i | 13

Page 18

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

4.3.7 Hue Adjustments (NTSC/525 only) [MENU: PROC→HUE]

The hue can be adjusted from –180 to +180 degrees in steps of 1 degree in 525 and 1.4 degrees in NTSC.

The default value is zero.

4.3.8 Horizontal Position (COMP IN only) [MENU: PROC→HPOS]

Picture position may be adjusted by +/- 7 pixels (a total range of 518 ns) in steps of ½ pixel (37 ns).

4.4 Timing Adjustments [MENU: TIMG]

When a valid external reference is present, the video output is phased with respect to the reference input

(frame sync mode). Otherwise, it is phased according to the video input (frame buffer mode). In this section,

we will assume that the analog composite output and the digital video output are phased together. Hence,

the term “output” refers to both the digital and the analog outputs. However, the digital output is slightly in

advance (~ 3 us) compared to the analog output.

4.4.1 Timing mode [MENU: TIMG→MODE]

When the studio reference and the analog composite inputs are asynchronous, and in order to time the

output video with the reference, the built-in frame synchronizer continuously changes the processing delay of

the video input with respect to the outputs. Due to this inherent operation, aligning re-encoded video data

with the same color frame as the input video is not always guaranteed. Misalignment results in encoding

artifacts at the composite outputs.

In order to overcome this drawback, the UVP-101i provides a special timing mode to reduce the encoding

artifacts derived from a color frame mismatch between the composite outputs and the decoded composite

input during genlock mode. Setting the timing mode menu to 4FLD reduces encoding artifacts. This

parameter is only available when a studio reference is installed and an NTSC composite signal is detected.

Frame phasing is not possible in 4FLD mode.

4.4.2 Frame phasing [MENU: TIMG→FRAM]

Frame phasing allows a super coarse adjustment in frame increments. In the user interface, this adjustment

is from 0 to 3 in steps of 1 frame. When a reference is present (frame sync mode), the frame adjustment

allows additional frames to be added after the frame sync. Frame phasing is not possible in 4FLD mode.

4.4.3 Vertical phasing [MENU: TIMG→VERT]

The vertical phasing allows coarse adjustments in line increments. In the user interface, this adjustment is

from 0 to 524 (or 624) in steps of 1 line. When the V phasing is zero (0) and the H phasing is zero (0), it

means the output is vertically and horizontally phased with the reference. When the reference is not present

and the UVP-101i is locked to the input, the minimum processing delay of the card is 3 lines. NOTE: vertical

phasing is not possible when there is no reference input, and the UVP-101i is in Satellite or VCR mode.

4.4.4 Horizontal phasing [MENU: TIMG→HORZ]

The horizontal phasing allows a less coarse adjustment in 37 ns increments. In the user interface, this

adjustment is from 0 to 63.6us (or 64.0 us). When the V phasing is zero (0) and the H phasing is zero (0), it

means the output is vertically and horizontally phased with the reference. When the reference is not present

and the UVP-101i is locked to the input, the minimum processing delay of the card is 3 lines. NOTE:

horizontal phasing is not possible when there is no reference input, and the UVP-101i is in Satellite or VCR

mode.

4.4.5 Horizontal Fine phasing [MENU: TIMG→FINE]

The horizontal fine phasing allows a fine adjustment in steps of 0.5 ns. In the user interface, this adjustment

is from –40 to +40 in steps of one (1). When the V, H and fine phasing are set to zero (0), the output is

14 | UVP-101i

Page 19

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

phased with the reference or the input within less than +/- 18.5 ns. NOTE: fine phasing is only available when

a reference input is detected.

4.5 Audio Processing Functions [MENU: ABUS→#1 and ABUS→#2]

The UVP-101i does not possess on-board audio processing capability. However, it can disembed audio

carried in the SDI input signal, and pass it to an external processor (such as Miranda’s UAP-712i or DAP712i). It then re-embeds the processed audio into the SDI output. Up to two external processors are

supported. Communications with the external processors are handled through the audio bus via two 10-pin

connectors called “ABUS #1” and “ABUS #2” located on the card edge (see section 2.2). This interface

supports 20-bit audio processing. The source audio group (for disembedding at the input) and destination

audio group (for embedding at the output) are selectable through the menu for each bus.

Typical Applications with UAP-712i or DAP-712i: Only one audio group can be processed by these audio

cards. To mux/demux two groups, two outboard cards must be used. All other audio groups not processed

by the audio card are lost in frame sync mode. When used alone, the UVP-101i will pass the audio but a

couple of audio frames could be lost in frame sync mode. The audio is not affected in delay mode (or frame

buffer mode).

4:2:2 + AES

DEMUX

UVP-101i

Frame

Sync

Delay

Proc

Amp

Proc

Audio

Encoder

MUX

NTSC

4:2:2 + AES

AES

Analog

UAP-712i or DAP-712i

Audio

Case A: AES is extracted on UVP-101i, processed on UAP-712i or

DAP-712i, and re-inserted on UVP-101i

UVP-101i

Frame

NTSC

AES AES

Decoder

Sync

Delay

Proc

Amp

Audio

Proc

Encoder

MUX

NTSC

4:2:2 + AES

Analog

UAP-712i or DAP-712i

Audio

Case B: Audio from the UAP-712i or DAP-712i is inserted into the UVP-101i

4:2:2 + AES

DEMUX

UVP-101i

Frame

Sync

Proc

Amp

Encoder

MUX

NTSC

4:2:2 + AES

Case C: AES is extracted on the UVP-101i and processed

Figure 4.1 Typical applications of the UVP-101i with UAP-712i or DAP-712i audio processors

Proc

Delay

Audio

UAP-712i or DAP-712i

on the UAP-712i or DAP-712i

AES

Analog

Audio

UVP-101i | 15

Page 20

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

4.5.1 Audio De-Embedding [MENU: ABUS→#1 (or #2)→DMUX]

Audio De-Embedding from the digital input. Up to 2 Groups / 8 Channels are extracted and passed to a

companion audio delay/processor card via the header connectors on the front of the module.

4.5.2 Audio Embedding [MENU: ABUS→#1 (or #2)→MUX]

Audio embedding of up to 8 Channels (2 Groups) audio. Audio obtained from header connector linked to

companion audio card. When an audio group is inserted in the ancillary data, it overwrites only the previous

audio group (if present) that was present in the video. It does not affect any other ancillary data. This means

that if there are 4 groups of audio present in the video and we insert a new group 2, the previous group 2 is

replaced by the new one.

4.5.3 VBIT Processing [MENU: ABUS→#1 (or #2)→VBIT]

The user can choose to MUTE or PASS the VBIT in the selected audio bus.

4.6 Blanking Interval Processing [MENU: BLNK]

4.6.1 Horizontal Interval Functions [MENU: BLNK→HANC]

The user can select whether to PASS or BLANK the horizontal blanking interval for the digital video input.

When the HANC is blanked, the audio can still be de-embedded and re-embedded using the ABUS

connectors. The blanking function is performed between these two functions.

4.6.2 Vertical Interval Functions [MENU: BLNK→VANC]

Incoming vertical ancillary data can be manipulated on a block or line-by-line basis for the decoder setup and

proc-amp functions. This affects lines 10 to 23 for 525-line formats and line 6 to 23 for 625-line formats.

Block Basis :

PASS The line is unprocessed and buffered to the luminance channel only. Chroma data is set

to 0. Setup OFF, unity gain.

BLNK The line is blanked (black). Setup OFF.

PROC The line is processed by the Proc-Amp, adaptive decoding

DECD The interval is decoded (adaptive decoding, setup OFF, unity gain)

USER This setting allows the user to select the above settings on a line-by-line basis. This is

possible via iControl only.

4.7 Freeze Mode [MENU: FRZE]

The UVP-101i has a freeze mode that may be triggered manually or automatically. All the current Proc-Amp

functions are applied to the frozen image. When a freeze condition occurs (manual or automatic), the

horizontal (HANC) and vertical blanking interval (lines 1 to 9) are blanked. Only the active picture (including

lines 10 to 20) is displayed.

A GPI output is triggered when the freeze function is activated, provided that the freeze trigger has been

continuously present for more than one second.

4.7.1 Manual Freeze [MENU: FRZE→MAN]

A manual freeze may be triggered from from the card edge Freeze pushbutton or from a remote controller.

The image displayed when a manual freeze is triggered is shown in table 4.1.

16 | UVP-101i

Page 21

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

Table 4.1 Output when Manual Freeze is activated.

Menu Option Output Display

Field 1 (FLD1) Displays field 1 of the current frame.

Field 2 (FLD2) Displays field 2 of the current frame

Frame (FRM) Displays the current frame

4.7.2 Automatic Freeze [MENU: FRZE→AUTO]

The conditions which generate an automatic freeze are shown in table 4.2. The input error or loss of

lock/sync conditions enable the UVP-101i to handle a hot switch or temporary loss in the video. The

response of the UVP-101i to an Automatic Freeze trigger condition is shown in table 4.3.

Automatic Freeze is disabled if the source type selected at [ICMP→SRC] is VTR, or if there is no reference

input.

Table 4.2 Conditions which will trigger an Automatic Freeze

Freeze Conditions Description

Loss of input When the input module detects a loss of carrier on the analog or digital input.

Input error For a digital input, an input error condition is detected when there is a missing

or misplaced EAV/SAV code in the video. This error condition is also reported

by a LED on the card edge.

Loss of lock/sync For an analog input, an input error condition is detected by a loss of lock or a

misplaced sync pulse or too much noise in the video. This error condition is also

reported by a LED on the card edge.

.

Table 4.3 Output when Automatic Freeze is activated

Menu Option Output Display

OFF Disables Auto-Freeze

Field (FLD) Displays the last good field

Black (BLAK) Displays a black frame at the output.

Field then Black (BLK3) Displays the last good field for 3 seconds, then black.

4.8 Composite Video Outputs [MENU: COMP]

The following adjustments are available for the composite (NTSC or PAL) video output:

4.8.1 Setup Level [MENU: COMP→SETP]

The setup level for the composite output can be 0 IRE or 7.5 IRE in NTSC. There is no setup in PAL.

4.8.2 Color Framing [MENU: COMP→CFRM]

The color framing is adjusted according to the analog input reference or the composite video input (if there is

no reference). For digital video input when there is no reference input, the color framing is randomly

determined but can be adjusted by the user.

The color framing is adjustable on the composite output. In 525-line format, there are 2 possible color

framing choices (NEAR or +1). In 625-line, there are 4 possible choices (NEAR, +1, +2, +3).

UVP-101i | 17

Page 22

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

4.8.3 Horizontal Blanking/Edge Control [MENU: COMP→HBLK]

For the analog output only, the blanking interval can be NAR (narrow, as per SMPTE 259M : all pixels are

passed) or WIDE (as per SMPTE-170M).

4.8.4 Closed Captioning [MENU: COMP→CC]

The user can select whether closed captioning data from the incoming signal is inserted into the analog

output (NTSC only).

4.8.5 Gain [MENU: COMP→GAIN]

The overall level of the composite output signals can be adjusted.

4.9 Configurations [MENU: CONF]

There are five user configuration registers in on-board non-volatile memory. All card parameters are saved to

these registers, and may be recalled from them.

4.9.1 Load a Configuration [MENU: CONF→LOAD]

Select one of the five available user preset registers and load the UVP-101i with the parameter values stored

there.

4.9.2 Save a Configuration [MENU: CONF→SAVE]

Select one of the five available user preset registers and save the current parameter values of the UVP101i’s operating system into that configuration register..

4.10 Factory Preset [MENU: FACT]

Selecting YES loads the UVP-101i’s operating system with a factory-selected set of parameter values. The

values in this read-only factory set are underlined in the menu tree of figure 3.2.

The five user preset registers are not affected by this function.

4.11 Other functions

There are other aspects of UVP-101i operations which are not adjustable through the menu, but which are of

interest to the user. They are discussed in the following sections.

4.11.1 Test Patterns

There are two (2) test patterns available: color bars and black. They are accessed by the card-edge TEST

pushbutton. First push on this button activates COLOR BARS; second push activates BLACK; third push

turns the test pattern OFF.

The built-in test pattern is standard color bars with 75% color modulation and 100% white bar. It is enabled

by a direct access on the card edge.

The test pattern appears on both the digital and analog outputs. When it is activated, the EDH error codes

(flags) are blanked as well as the HANC and VANC intervals on the input side. Hence, no EDH errors can be

transmitted downstream when the test mode is enabled.

4.11.2 EDH Detection and Reporting

The input module supports error detection and handling (EDH) according to SMPTE RP-165. All error types

are reported (card edge LED or remote control).

All EDH error codes are inserted into the digital video output according to RP-165.

18 | UVP-101i

Page 23

PRELIMINARY GUIDE TO INSTALLATION AND OPERATION

5 Specifications

ANALOG INPUT

Signal: NTSC (525/60) SMPTE 170M

PAL (625/50) ITU-R BT.740-6

Return loss: > 35 dB up to 5.75 MHz

DIGITAL INPUT

Signal: 4:2:2 SMPTE 259M-C (270 Mbps)

Cable length: 250 m (850') Belden 8281

Return loss: > 15 dB up to 270 MHz

REFERENCE INPUT

External reference: SMPTE 170M/PAL ITU 624-4 or

2 Vp-p/ 4 Vp-p Composite Sync

Return loss: > 35 dB up to 5.75 MHz

DIGITAL OUTPUT

Signal (2): 4:2:2 SMPTE 259M-C (270 Mbps)

Return loss: > 15 dB up to 270 MHz

Jitter (wideband): < 0.2 UI (0.74ns) p-p

Delay tracking: Miranda video-audio tracking signal

Audio bus I/O (2): 10 pin connector to audio processor

COMPOSITE ANALOG OUTPUT

Signal (2): NTSC (525/60) SMPTE 170M

PAL (625/50) ITU 624-4

Return loss: > 35 dB up to 5.75 MHz

PROCESSING PERFORMANCE (DIGITAL)

Signal path: 10 bits (12-bit processing)

Processing delay: Minimum 3 lines, maximum 4 frames

Decode type: Adaptive 2D, Adaptive 3D, and Super Adaptive

Quantization: 12 bits

Sampling: 27 MHz (2X Oversampling)

Req response: +/- 0.1 dB to 5.5 MHz

Noise (unweighted): <-63 dB to 5.75 MHz

Differential gain: < 1%

Differential phase: < 1 degree

Linearity: < 1 %

UVP-101i | 19

Page 24

GUIDE TO INSTALLATION AND OPERATION PRELIMINARY

MISCELLANEOUS

Audio embedding: SMPTE 272M, ABD

Test signals: 75% color bars with 100% white bar;

black

Power: 12 W maximum

20 | UVP-101i

Loading...

Loading...